Multi-grating structure-based semiconductor laser beam combination device and beam combination method

A grating structure and laser technology, which is applied to semiconductor laser devices, semiconductor lasers, laser devices, etc., can solve the problems of poor quality of semiconductor laser beam combining beams, and achieve a simple and not cumbersome structure, simple installation and adjustment, and high structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

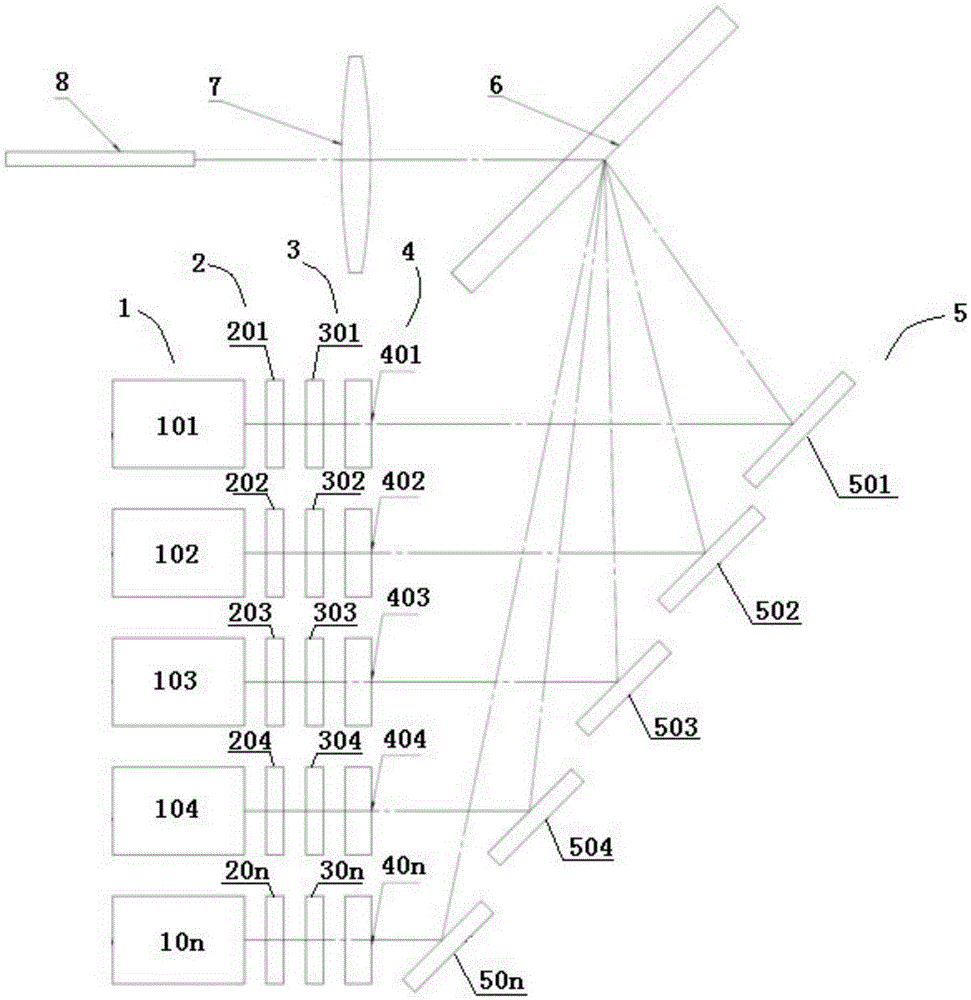

[0035] Such as figure 1 As shown, the semiconductor laser beam combining device based on the multi-grating structure of the present invention mainly includes a semiconductor laser group 1, a fast axis collimator mirror group 2, a slow axis collimator mirror group 3, a volume Bragg grating group 4, and a mirror group 5 , Diffraction grating 6, focusing mirror 7 and multimode fiber 8.

[0036] The semiconductor laser group 1 is composed of n semiconductor lasers 101-10n, the fast-axis collimating mirror group 2 is composed of n fast-axis collimating mirrors 201-20n, and the slow-axis collimating mirror group 3 is composed of n slow-axis collimating mirrors 301 ~30n, volume Bragg grating group 4 is composed of n individual Bragg gratings 401~40n, mirror group 5 is composed of n mirrors 501~50n, n is a positive integer and 2≤n≤1000.

[0037] Fast axis collimato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Reflection bandwidth | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com