Patents

Literature

37 results about "Billionth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

One billionth is the reciprocal of a billion, which means it has one of two definitions depending on whether the long scale or short scale definition is being used.

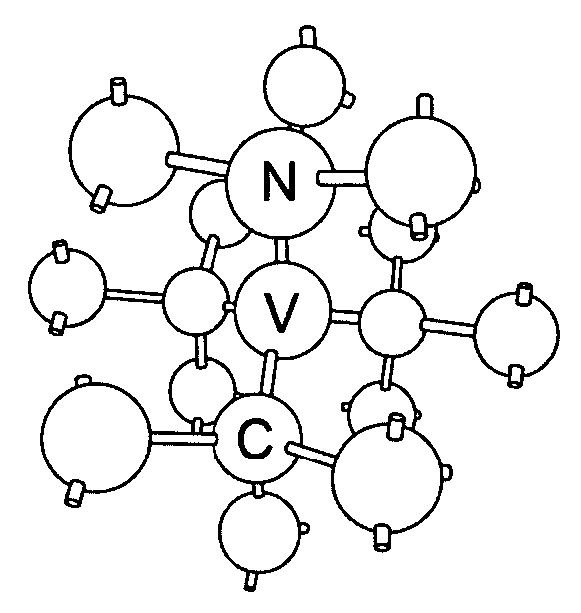

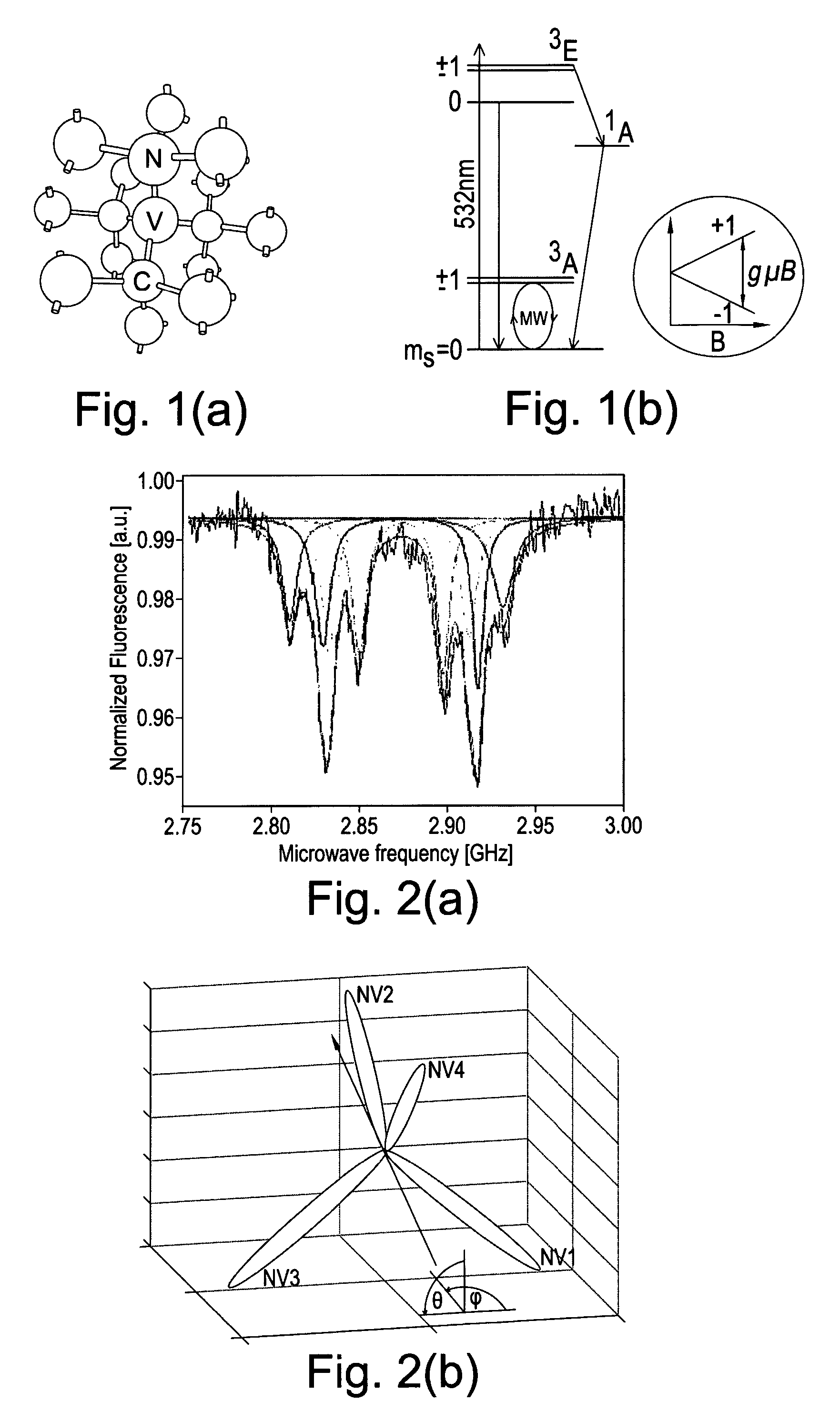

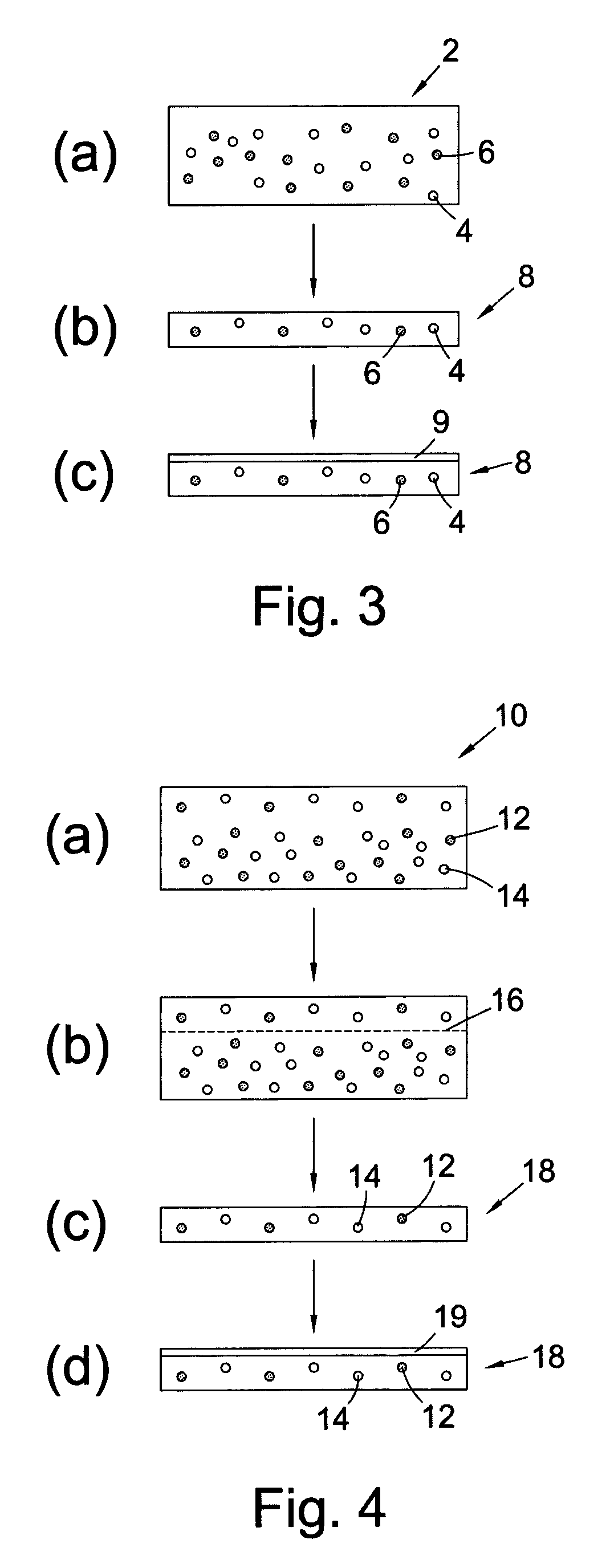

Diamond sensors, detectors, and quantum devices

ActiveUS8758509B2Improve excitation efficiencyIncrease the number ofUltra-high pressure processesNanoinformaticsBillionthSpins

A thin plate of synthetic single crystal diamond material, the thin plate of synthetic single crystal diamond material having: a thickness in a range 100 nm to 50 μιη; a concentration of quantum spin defects greater than 0.1 ppb (parts-per-billion); a concentration of point defects other than the quantum spin defects of below 200 ppm (parts-per-million); and wherein at least one major face of the thin plate of synthetic single crystal diamond material comprises surface termination species which have zero nuclear spin and / or zero electron spin.

Owner:ELEMENT SIX LTD

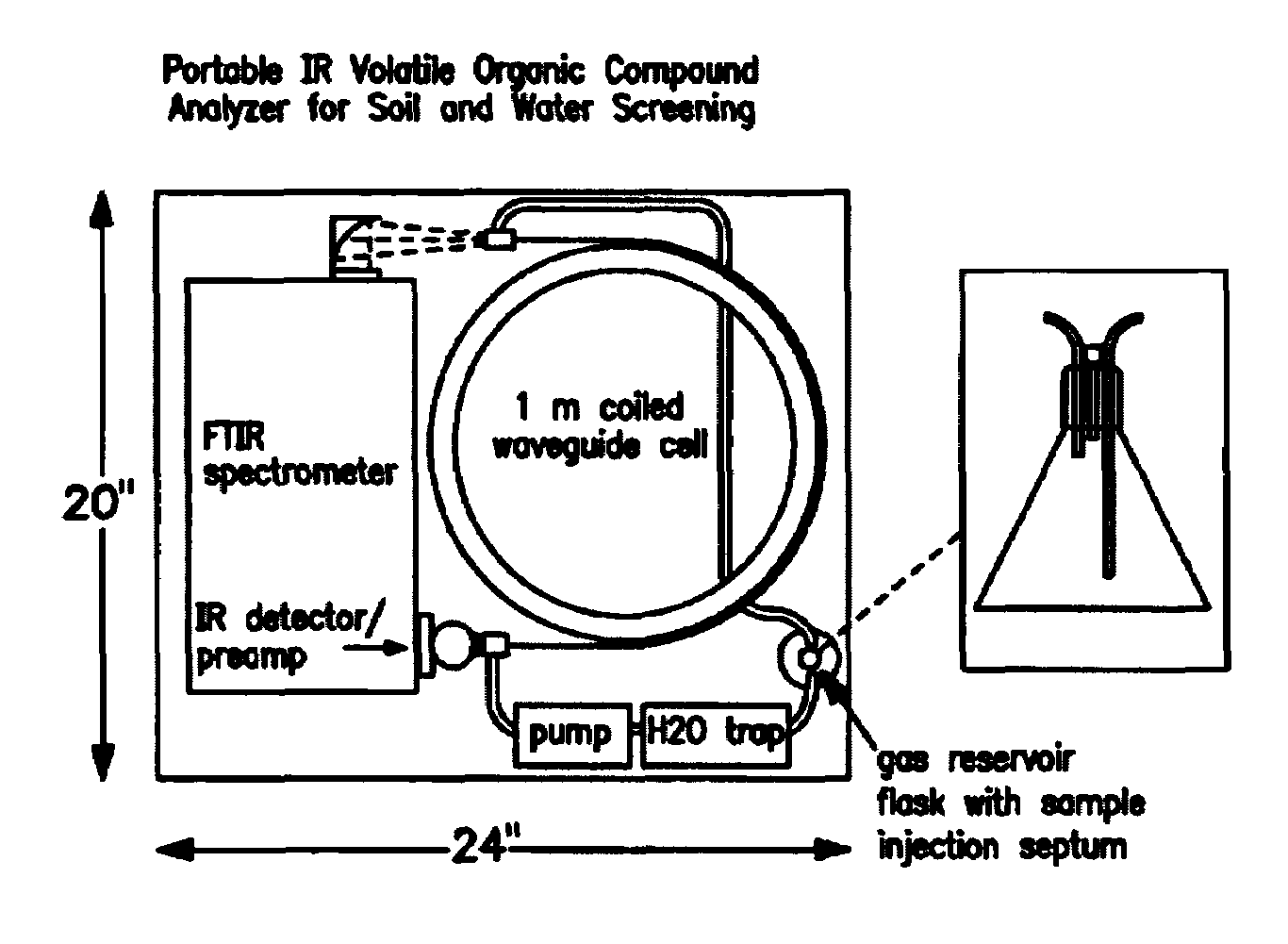

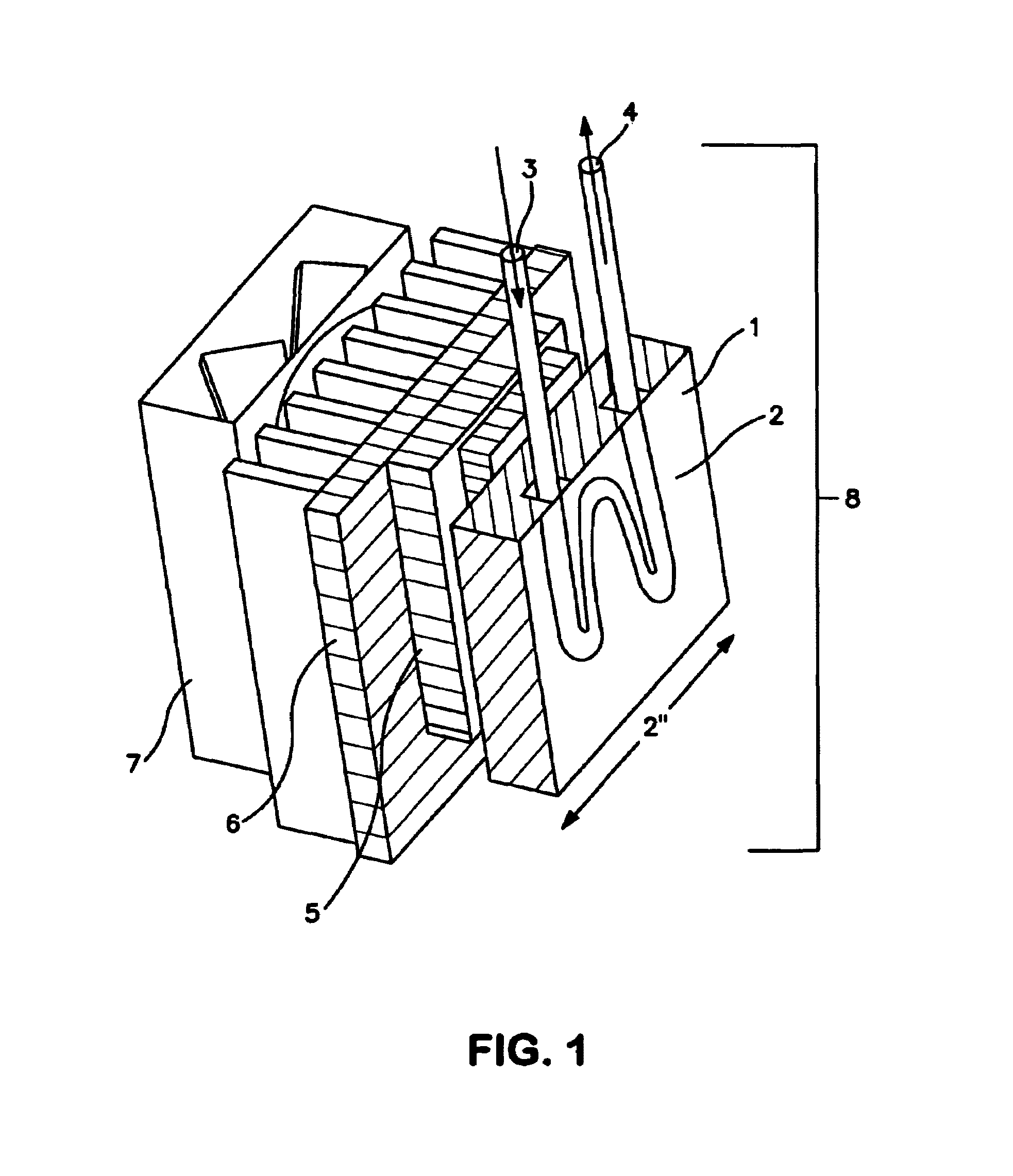

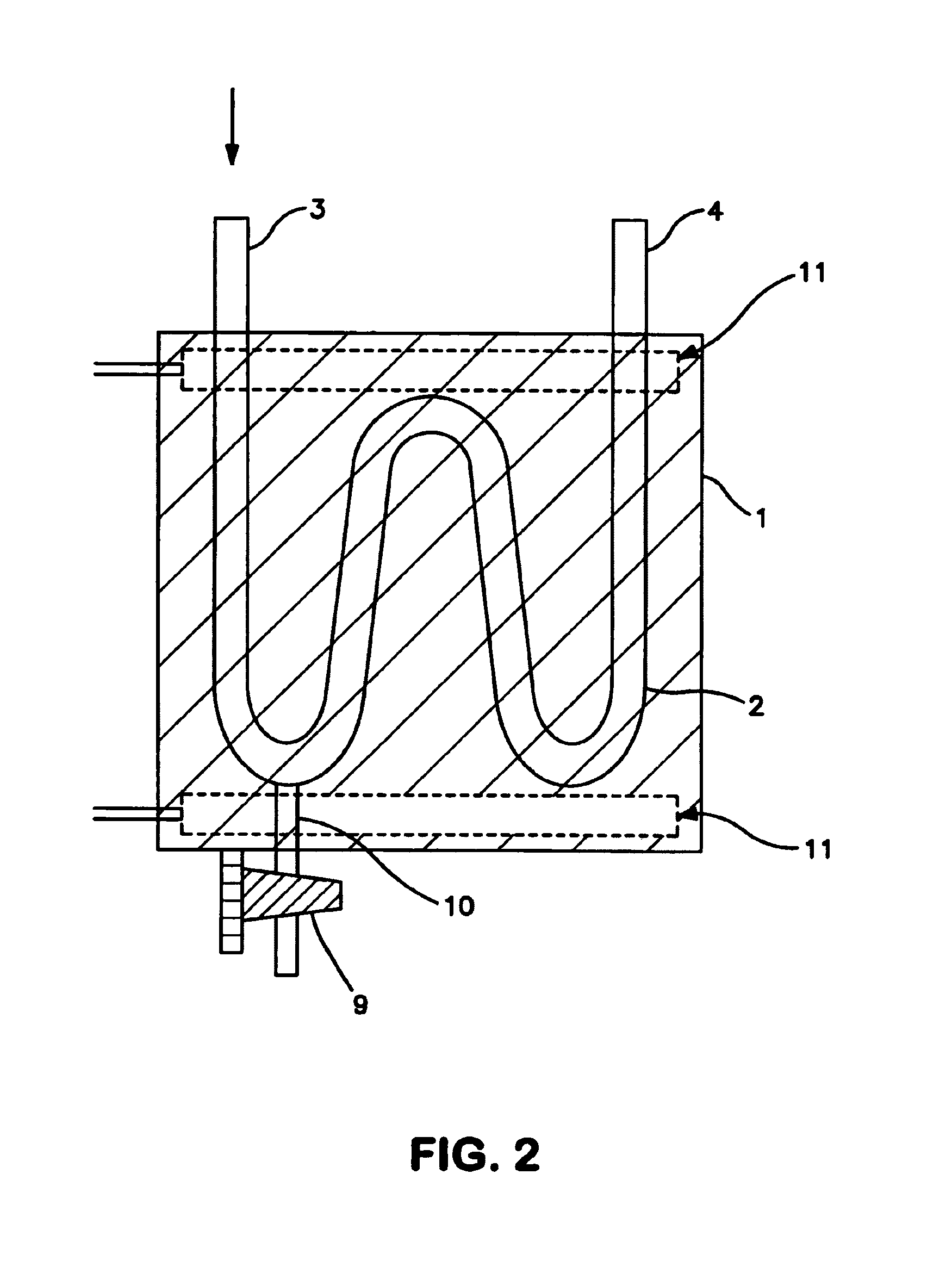

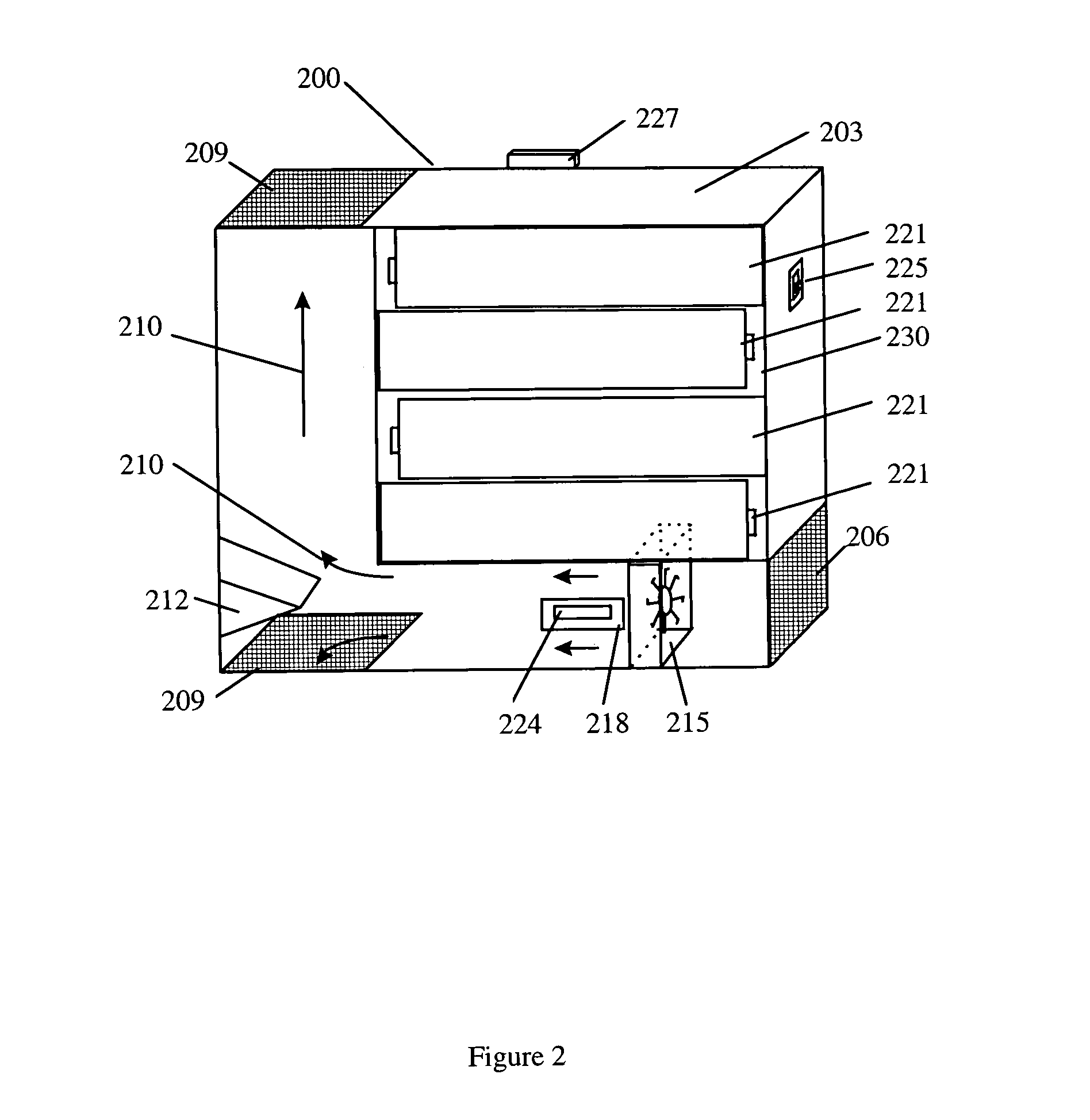

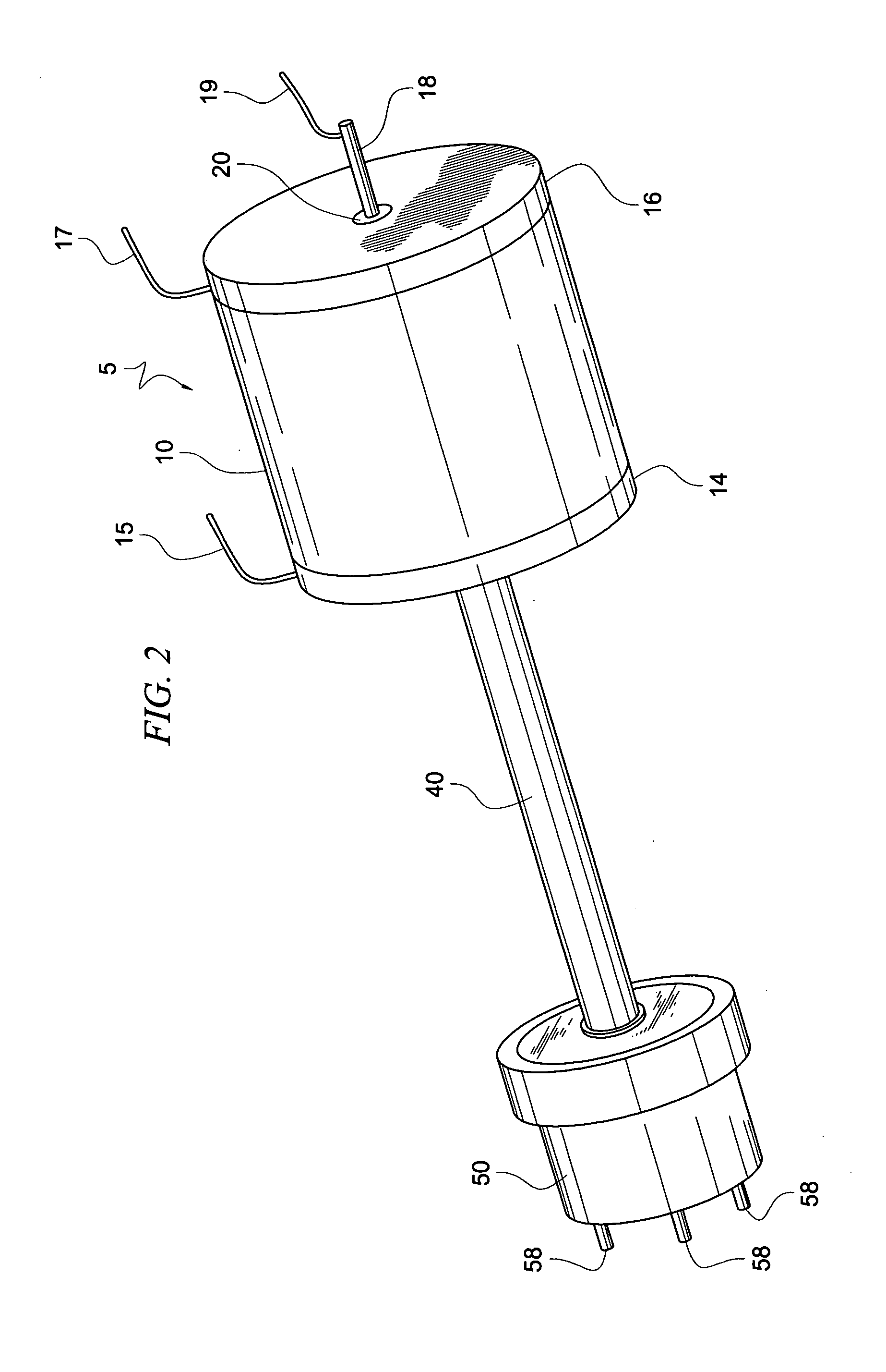

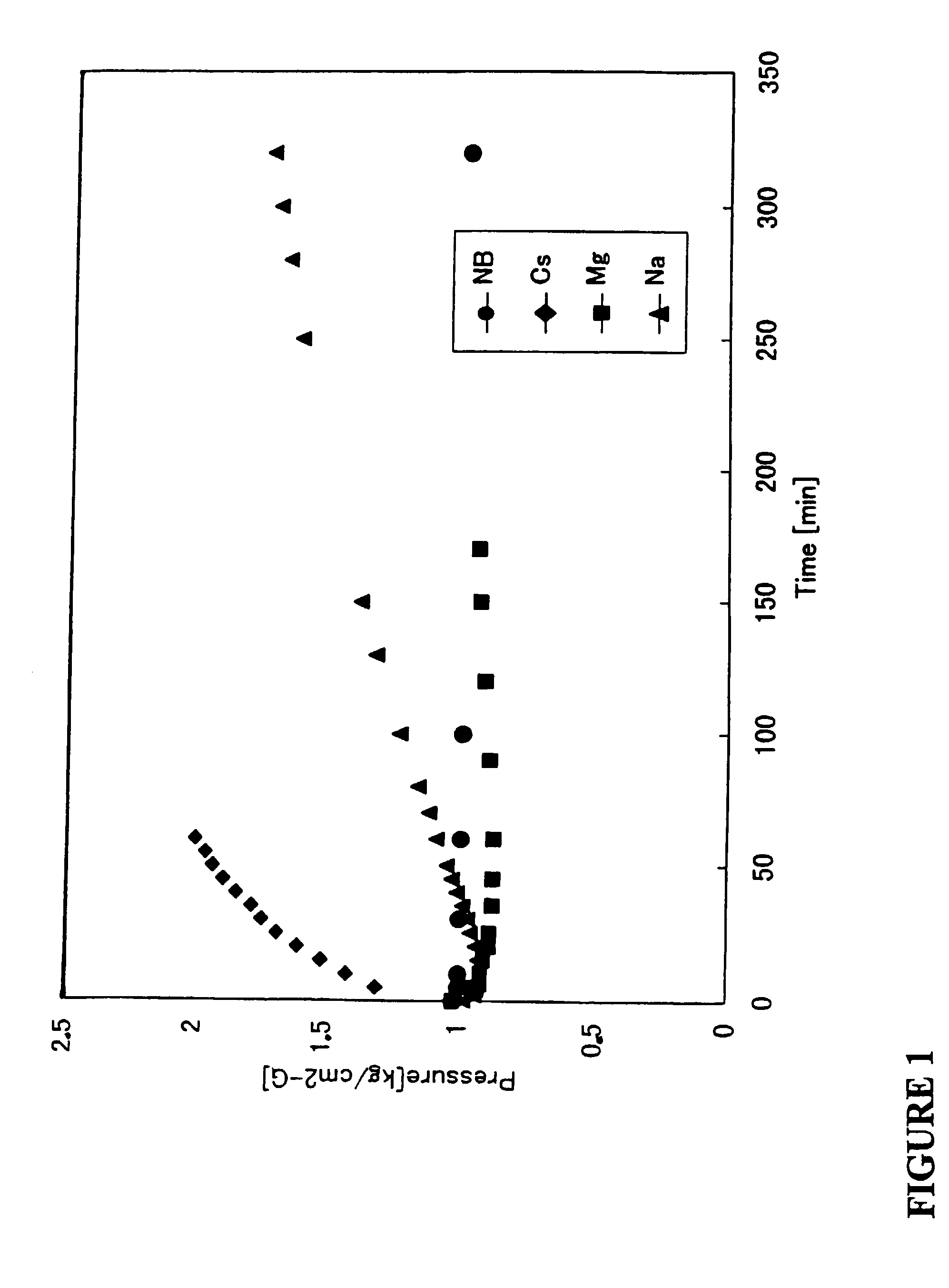

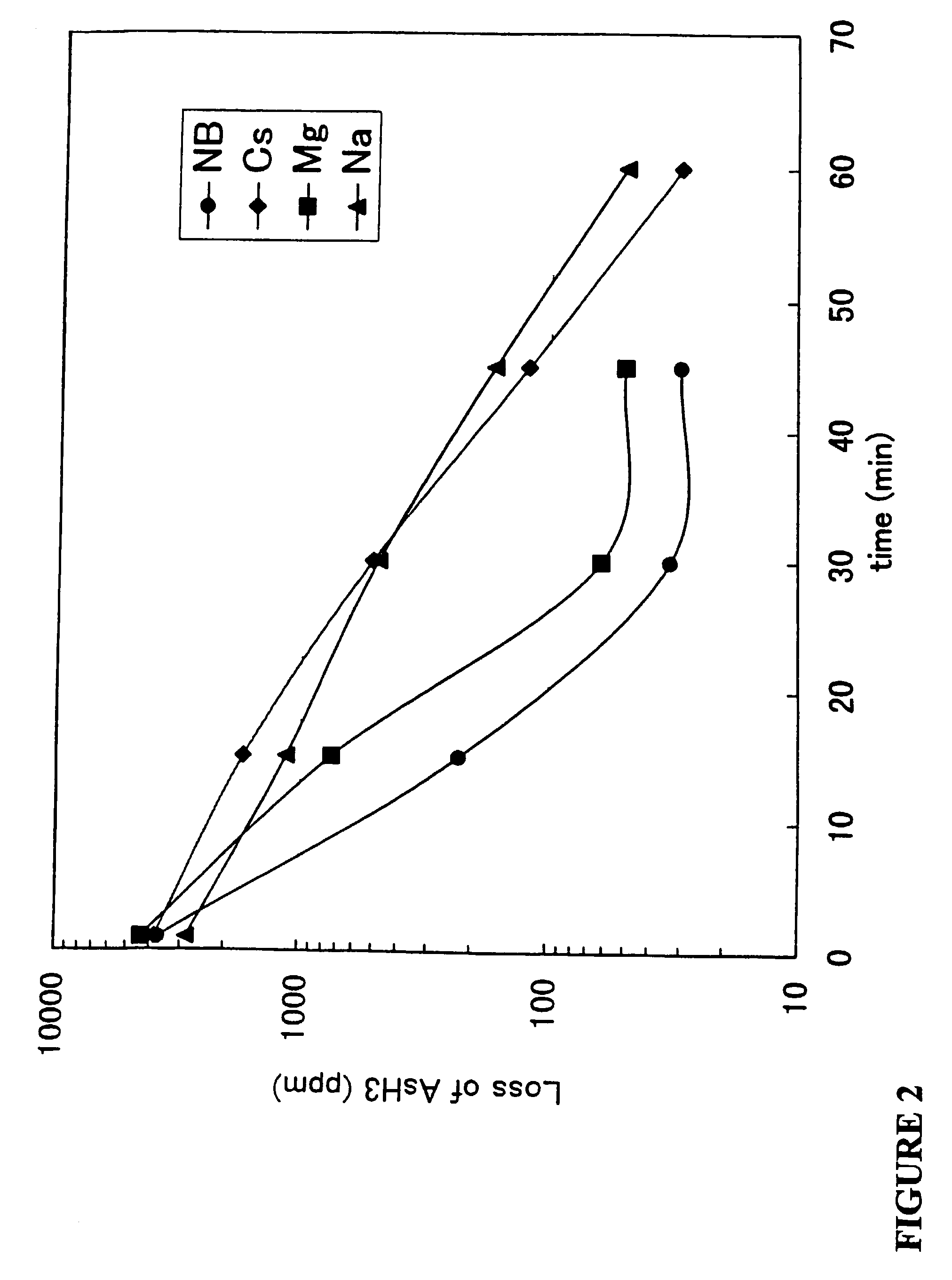

Thermoelectrically cooled water trap

InactiveUS7000490B1Low detection sensitivityEasy to removeWithdrawing sample devicesPreparing sample for investigationThermoelectric coolingWater vapor

A water trap system based on a thermoelectric cooling device is employed to remove a major fraction of the water from air samples, prior to analysis of these samples for chemical composition, by a variety of analytical techniques where water vapor interferes with the measurement process. These analytical techniques include infrared spectroscopy, mass spectrometry, ion mobility spectrometry and gas chromatography. The thermoelectric system for trapping water present in air samples can substantially improve detection sensitivity in these analytical techniques when it is necessary to measure trace analytes with concentrations in the ppm (parts per million) or ppb (parts per billion) partial pressure range. The thermoelectric trap design is compact and amenable to use in a portable gas monitoring instrumentation.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Methods and personal protection devices for repelling insects

InactiveUS7007861B2Low amountEliminate the problemBiocideLiquid surface applicatorsBillionthMosquito bite

Methods and devices for repelling insects are disclosed. The methods and devices provide personal protection from insect bites and insect landings, particularly mosquito bites. The methods and devices employ insect repellents such as pyrethroids at low (parts per billion) levels. The methods and devices effectively minimize the number of mosquitoes landing on a subject properly using the devices.

Owner:SC JOHNSON & SON INC

Method for treating reverse osmosis membranes with chlorine dioxide

InactiveUS20050061741A1Effective treatmentMinimize biofilm formationMembranesWater treatment parameter controlBillionthChlorine dioxide

Disclosed is a method for preventing osmotic membrane fouling comprising treating reverse osmotic feed water and membranes with chlorine dioxide at an extremely low concentration, e.g., as low as one part per billion in the feed water. The effective range may be in the range of 1-900 parts per billion. Also disclosed is a membrane separation system in which fouling is prevented using ultraviolet, pH acid adjustment or an electrochemical generator to produce the chlorine dioxide.

Owner:OCCIDENTAL CHEM CORP

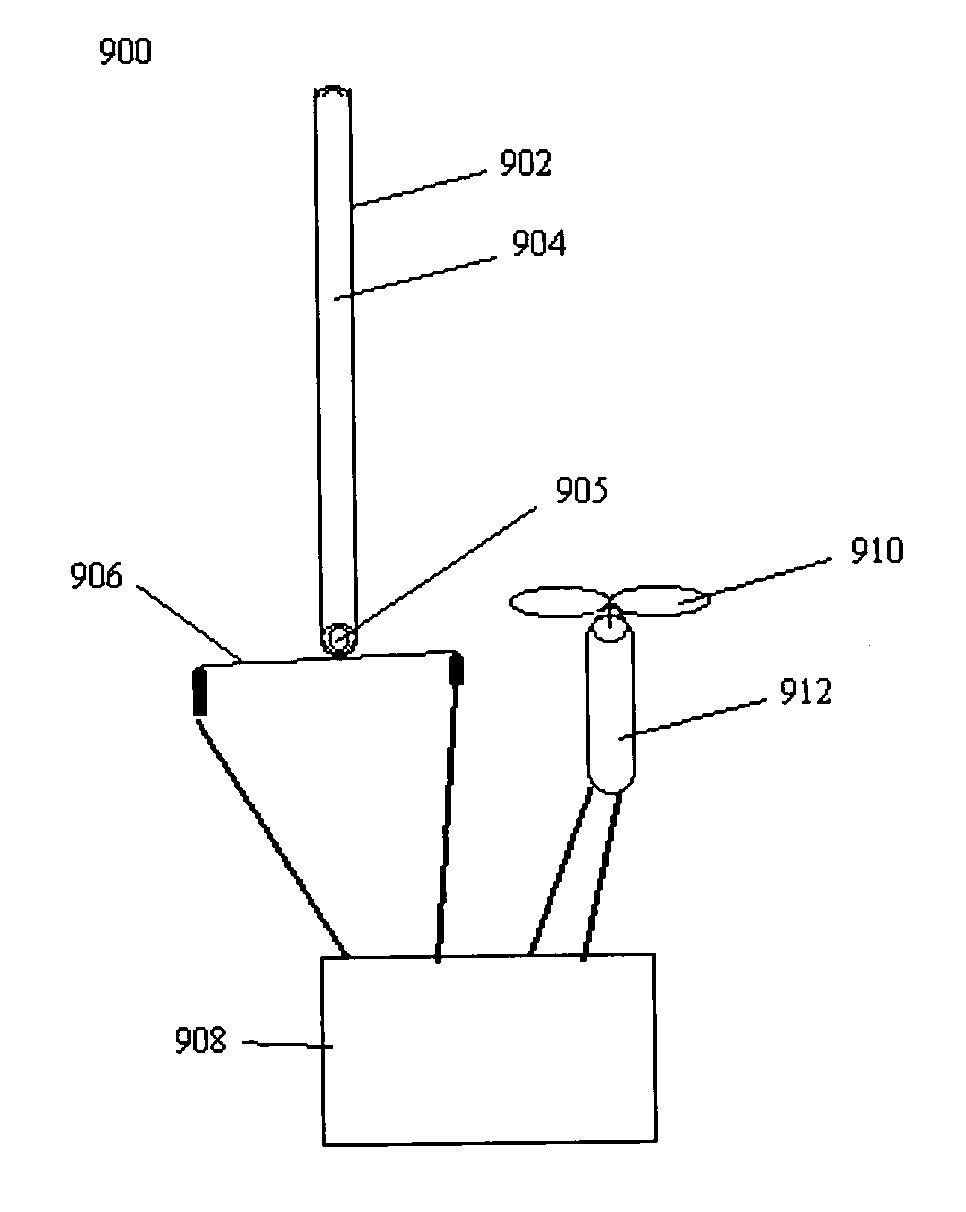

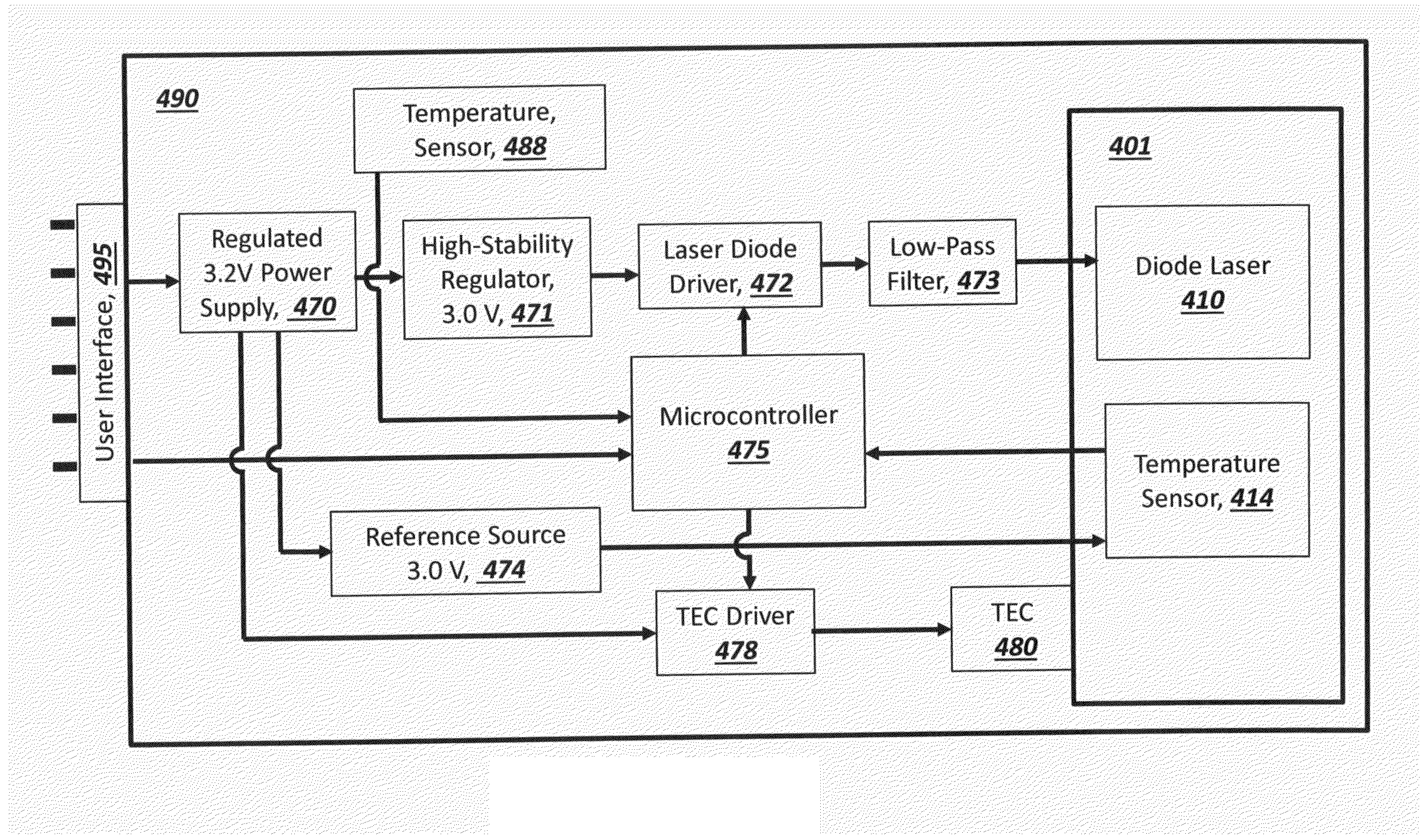

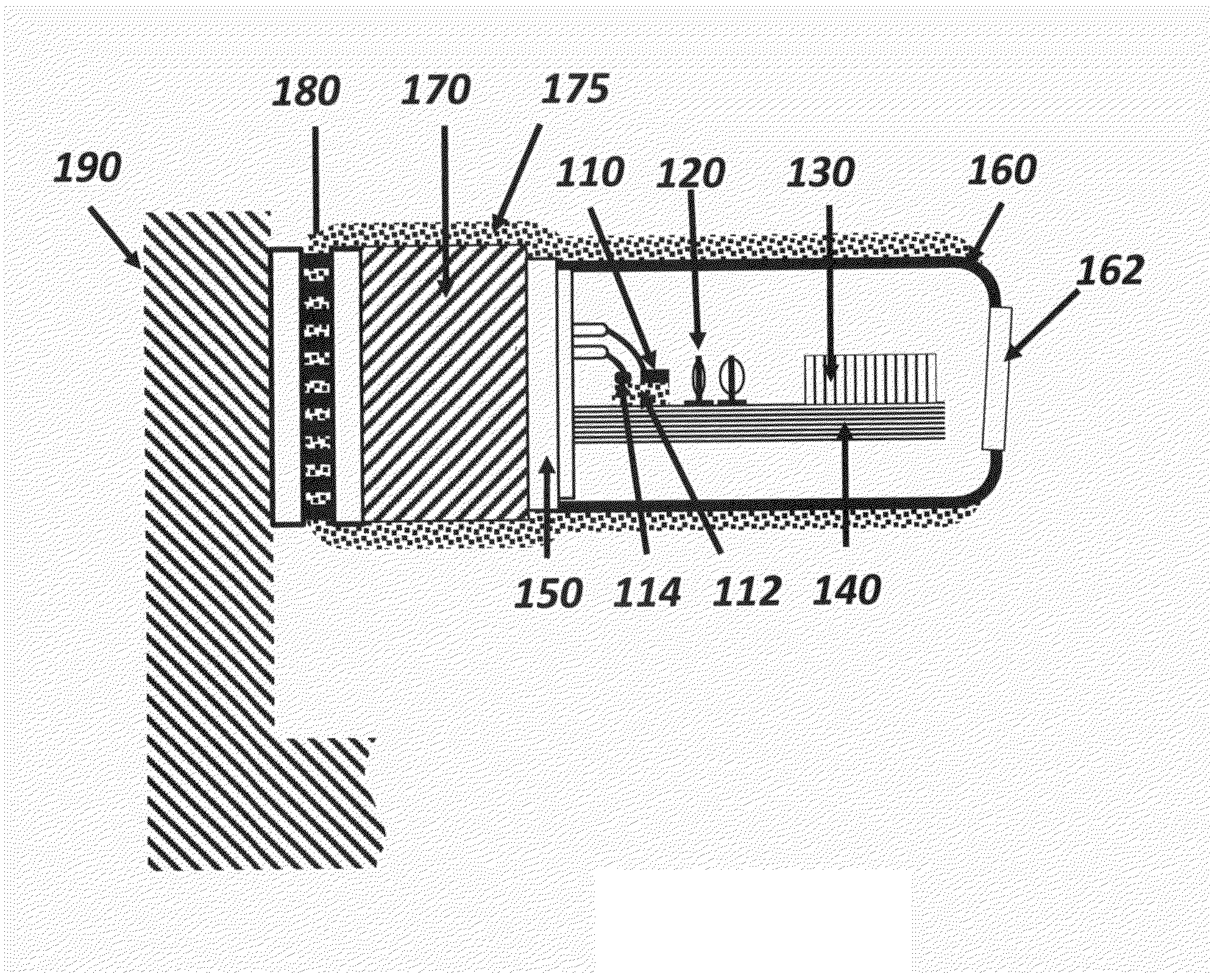

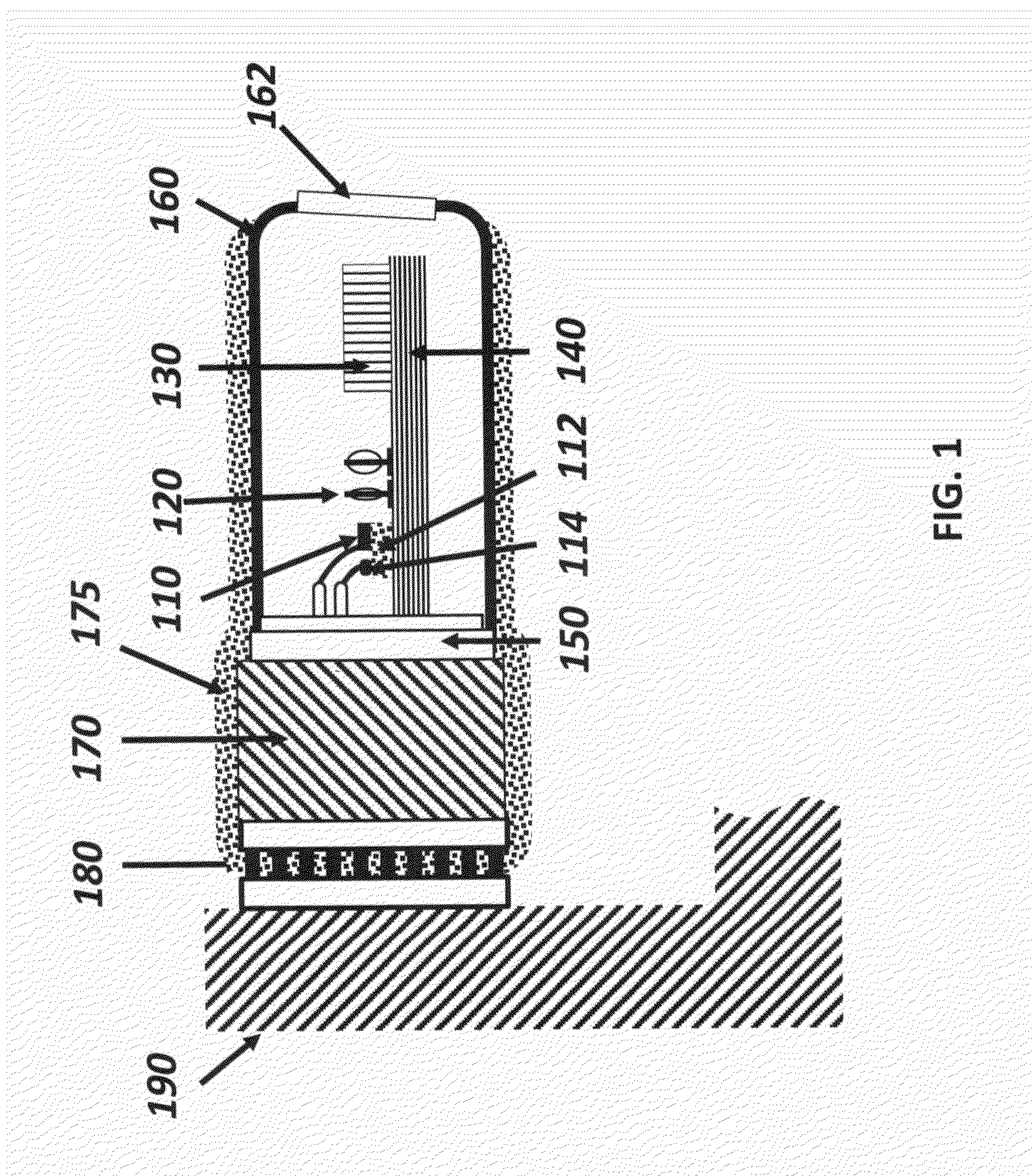

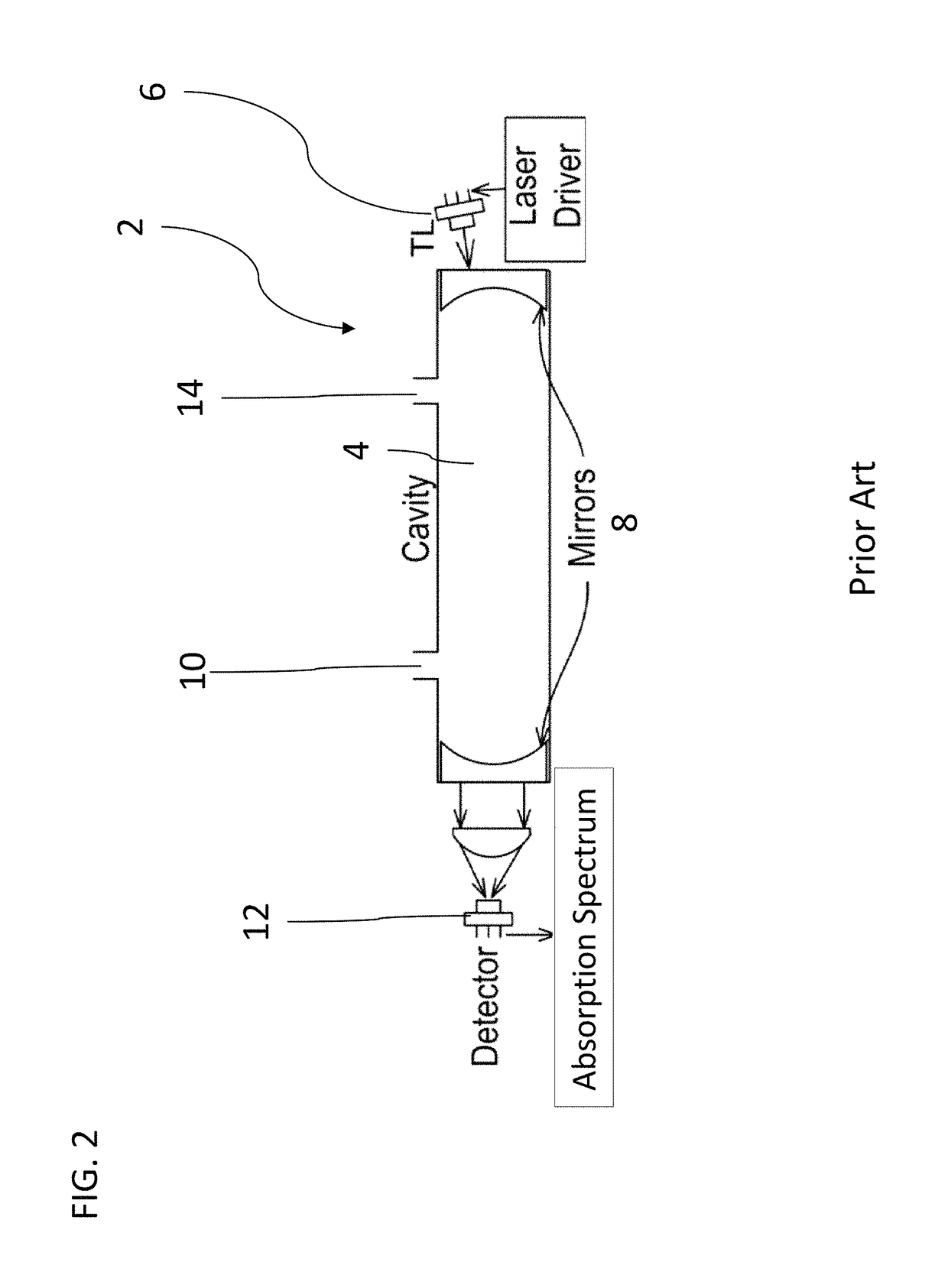

Wavelength-Stabilized Diode Laser

ActiveUS20140072004A1Improved wavelength stabilityReduced wavelength driftSemiconductor lasersLaser cooling arrangementsThermoelectric coolingBillionth

A hybrid external cavity laser (HECL) system comprises a diode laser, collection and collimation optics, and a volume Bragg grating, emits radiation at a single wavelength with a short-term wavelength stability in the order of at least one part in a billion The wavelength stability is achieved by use of a thermal management system, comprising inner and outer housings, each containing a temperature sensor, and electronic circuitry that monitors the temperatures and controls both the laser diode current and a thermoelectric cooler based on temperatures determined from said temperature sensors. The laser system is packaged in a compact enclosure that minimizes waste heat, facilitating use in applications that have heretofore employed stable, single-frequency lasers, including He—Ne lasers.

Owner:INNOVATIVE PHOTONIC SOLUTIONS INC

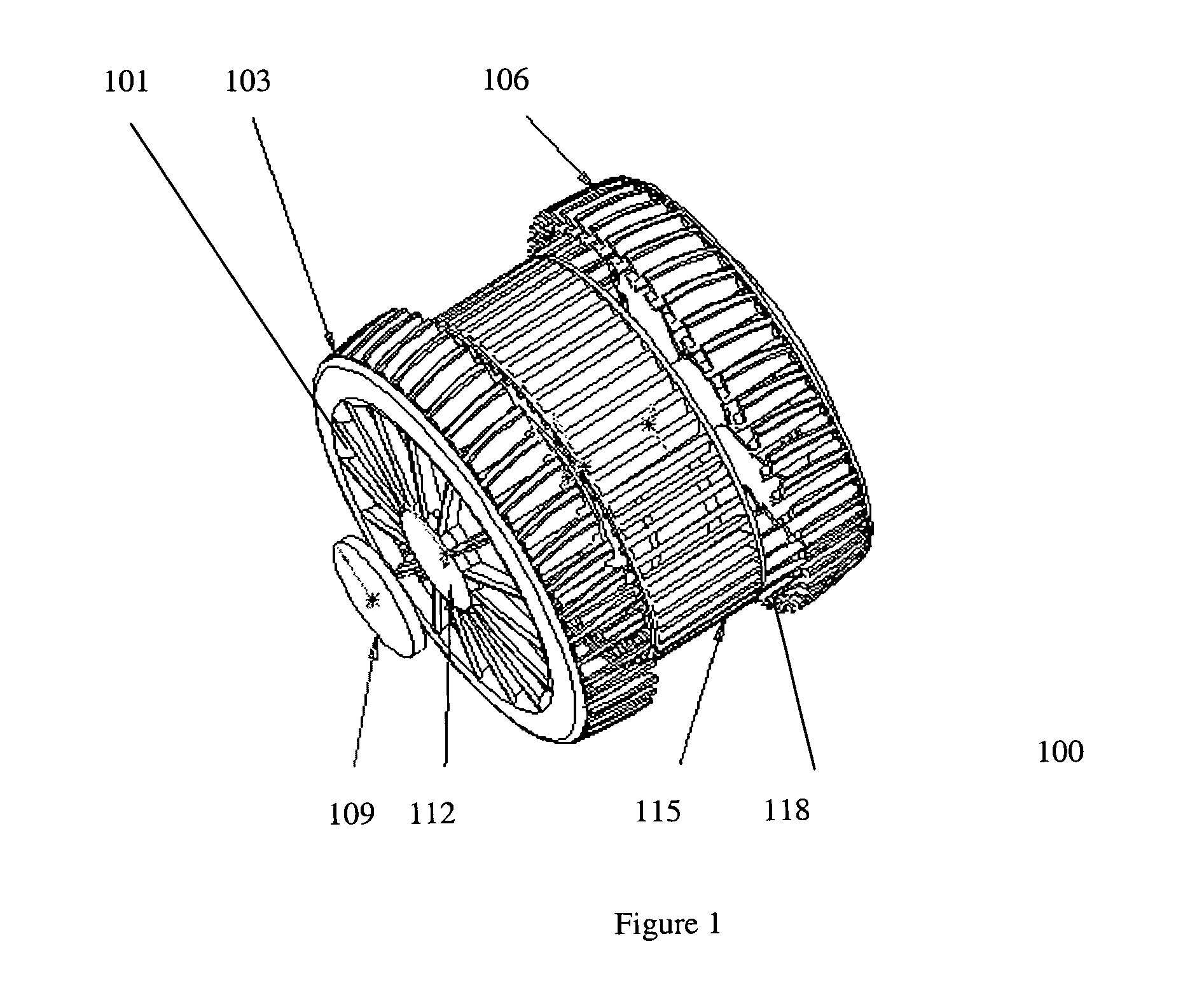

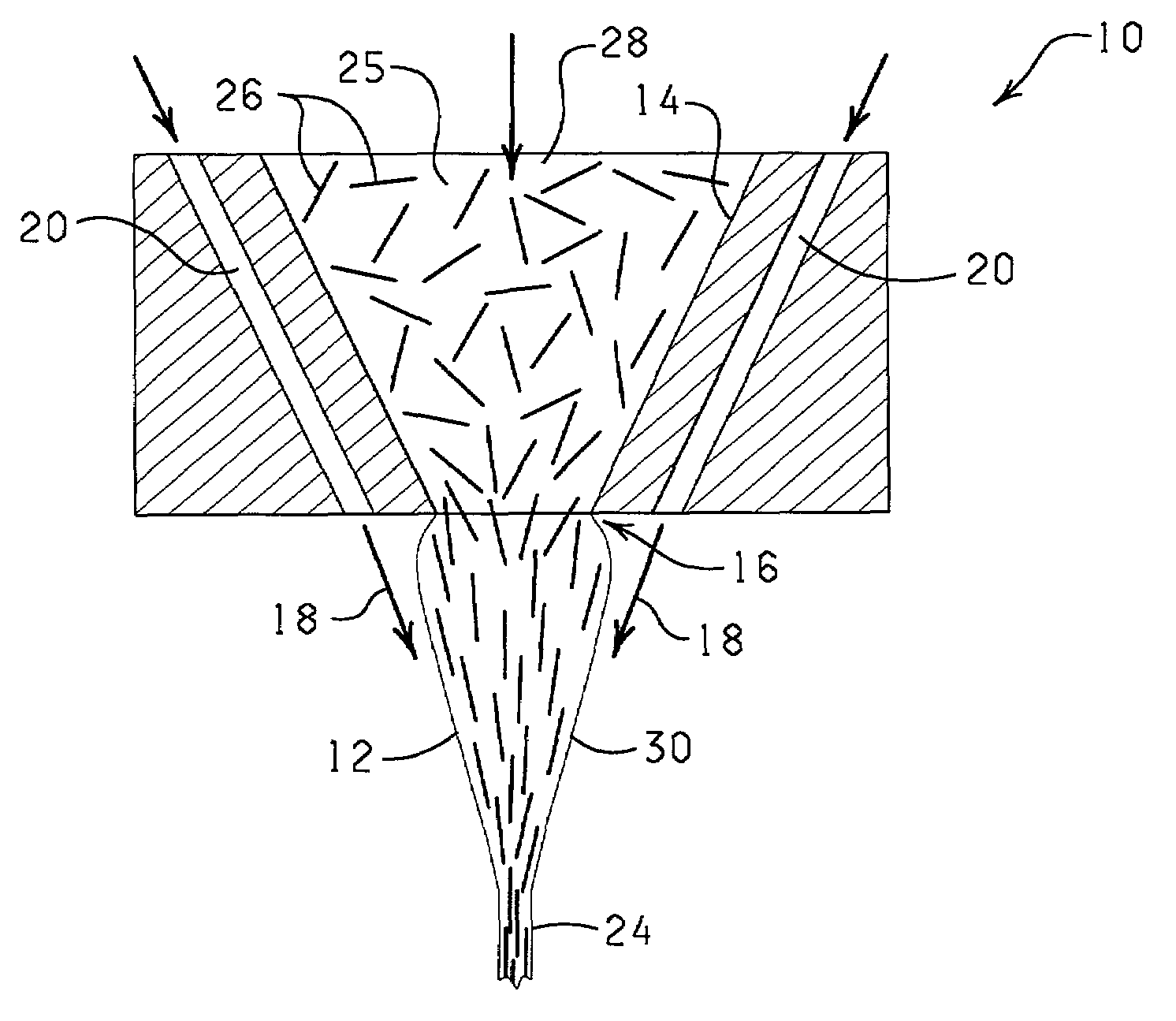

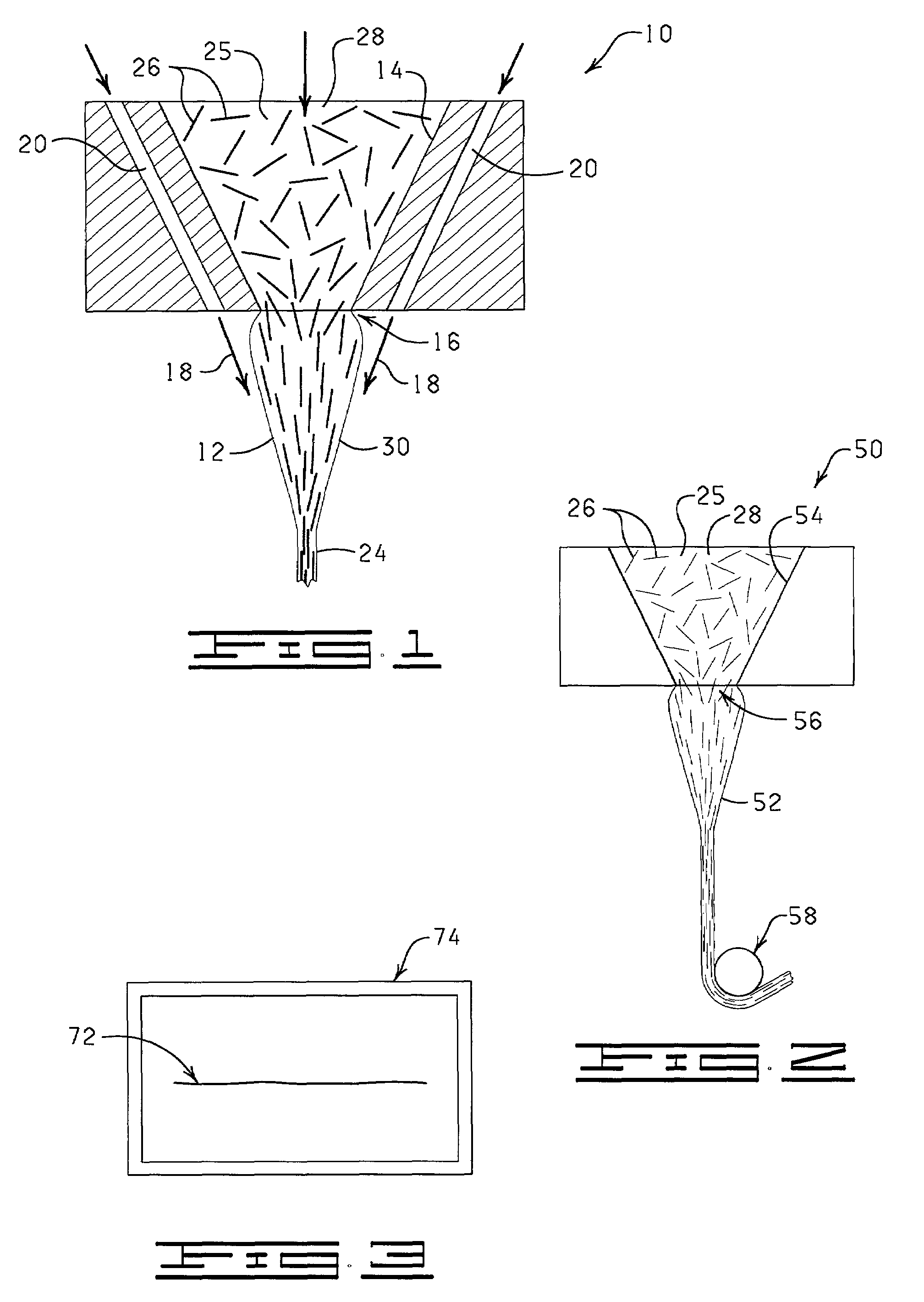

Method for forming a fibers/composite material having an anisotropic structure

InactiveUS7198745B2Enhanced orientation/alignmentGreat potentialMaterial nanotechnologyCeramic shaping apparatusFiberBillionth

A method for forming fibers / composite material having an anisotropic structure, comprising the steps of mixing an effective amount of fibers with a matrix material to form a deformable mixture containing less than about 96 weight percent of the fibers to about parts per billion of the fibers and wherein the fibers are randomly oriented in the deformable mixture. The deformable mixture can be extruded, stretched or otherwise deformed to form an extrudate. Pressure is applied about the extrudate to substantially compress the fibers in the extrudate to provide the fibers / composite material having an anisotropic structure.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

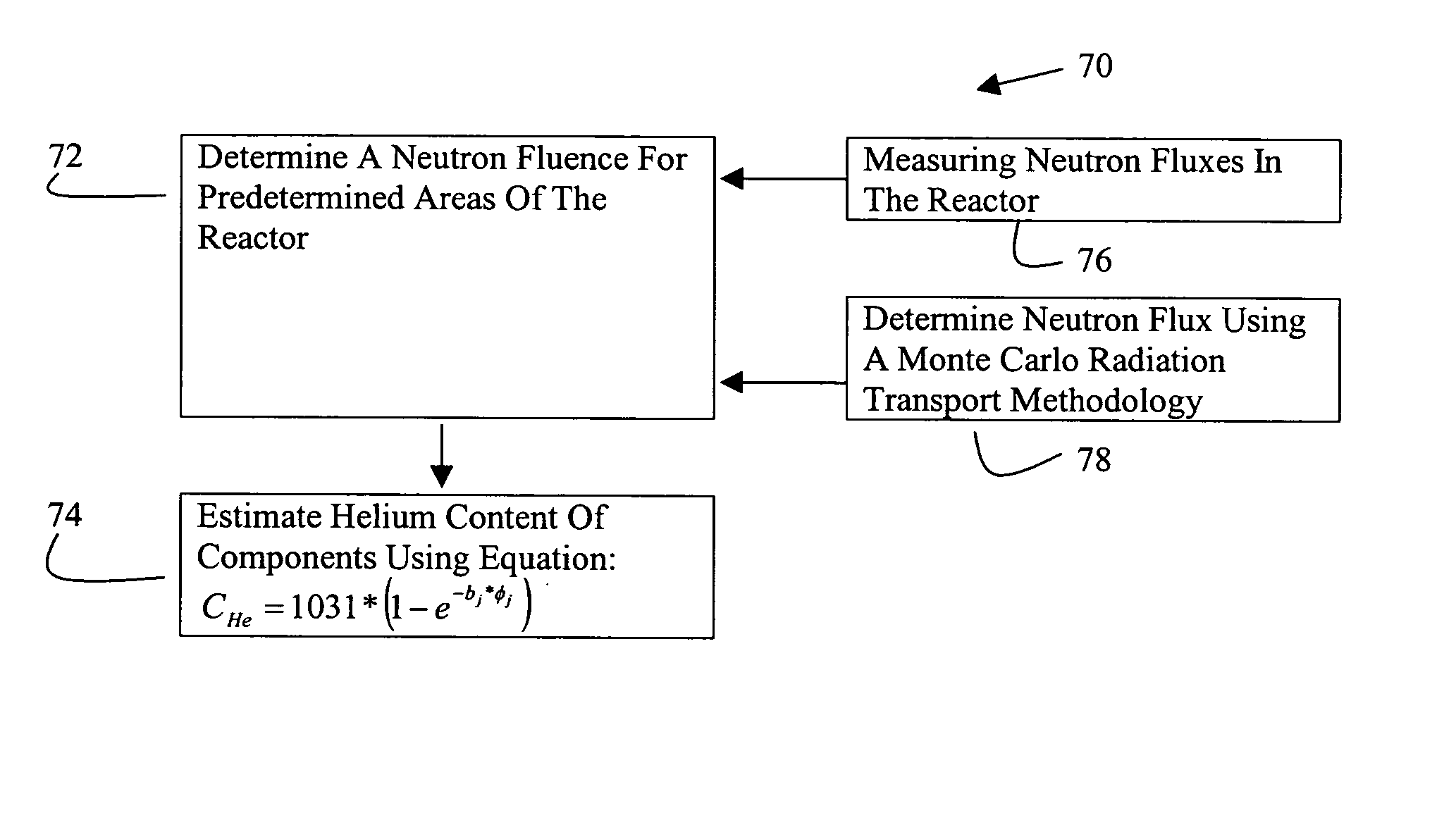

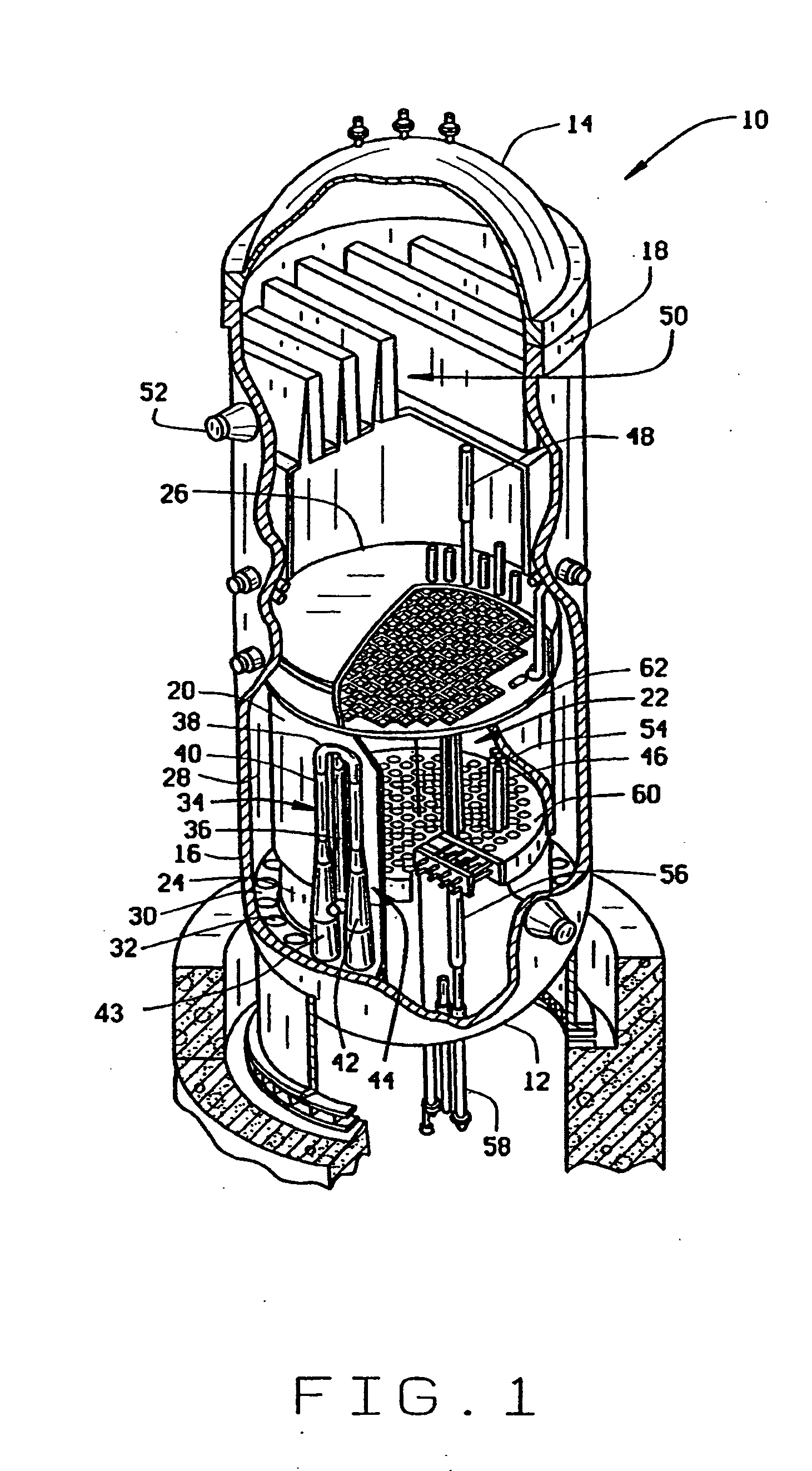

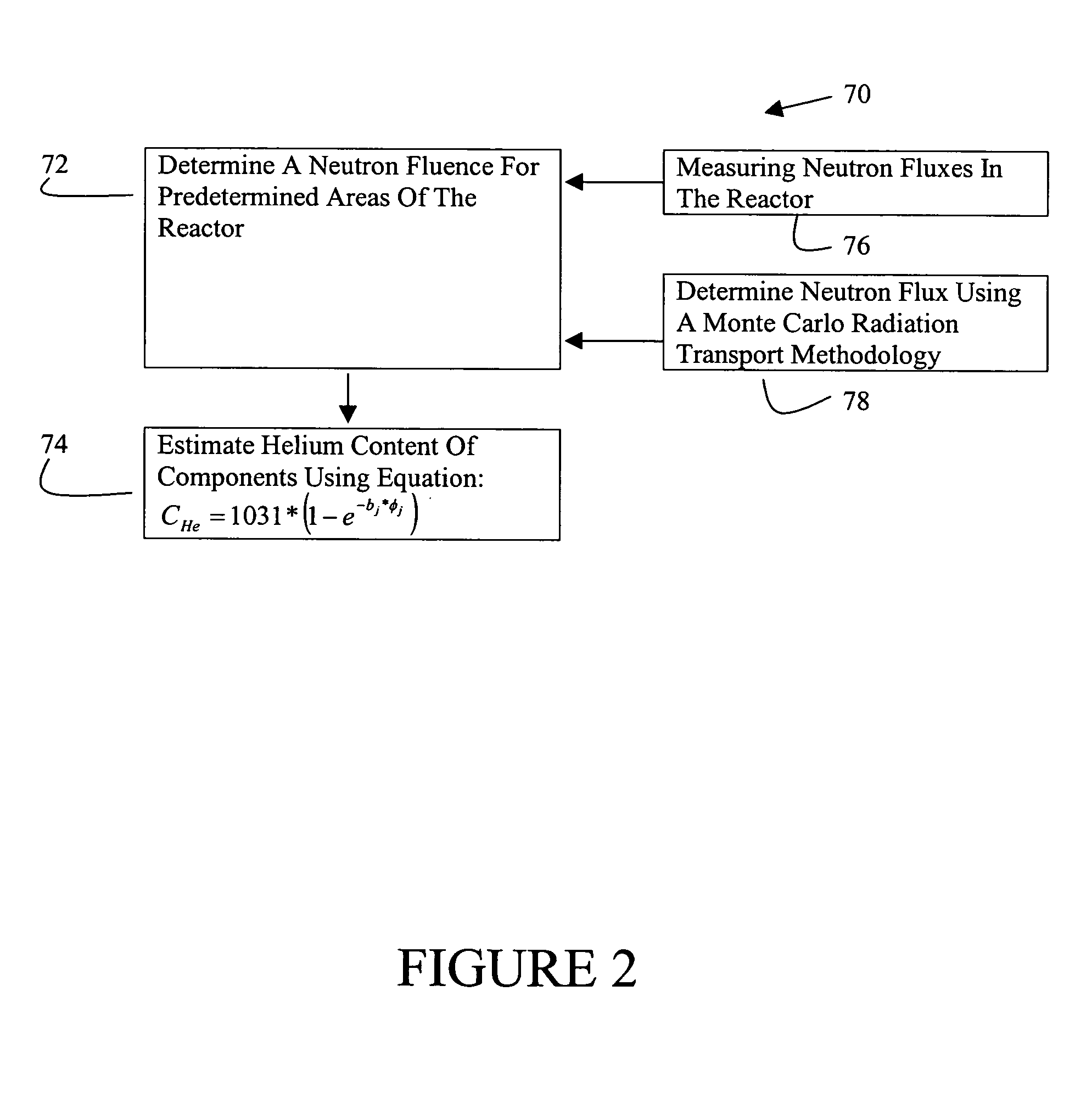

Systems and methods for estimating helium production in shrouds of nuclear reactors

A method for estimating a helium content of the stainless steel core shroud in a boiling water nuclear reactor includes, in an exemplary embodiment, determining a neutron fluence for predetermined areas of the reactor, and estimating a helium content of the stainless steel shroud at predetermined areas of the reactor using the following equation: CHe=1031*(1−e−b<sub2>j< / sub2>*φ<sub2>j< / sub2>), where CHe is the helium concentration as atomic parts per billion of helium in the stainless steel shroud per weight parts per million of boron in the stainless steel shroud, bj is a value between about 2.50 e−21 and about 5.00 e−21, φj is fluence expressed as neutrons per square centimeter, and subscript j denotes thermal fluence or fast fluence.

Owner:GENERAL ELECTRIC CO

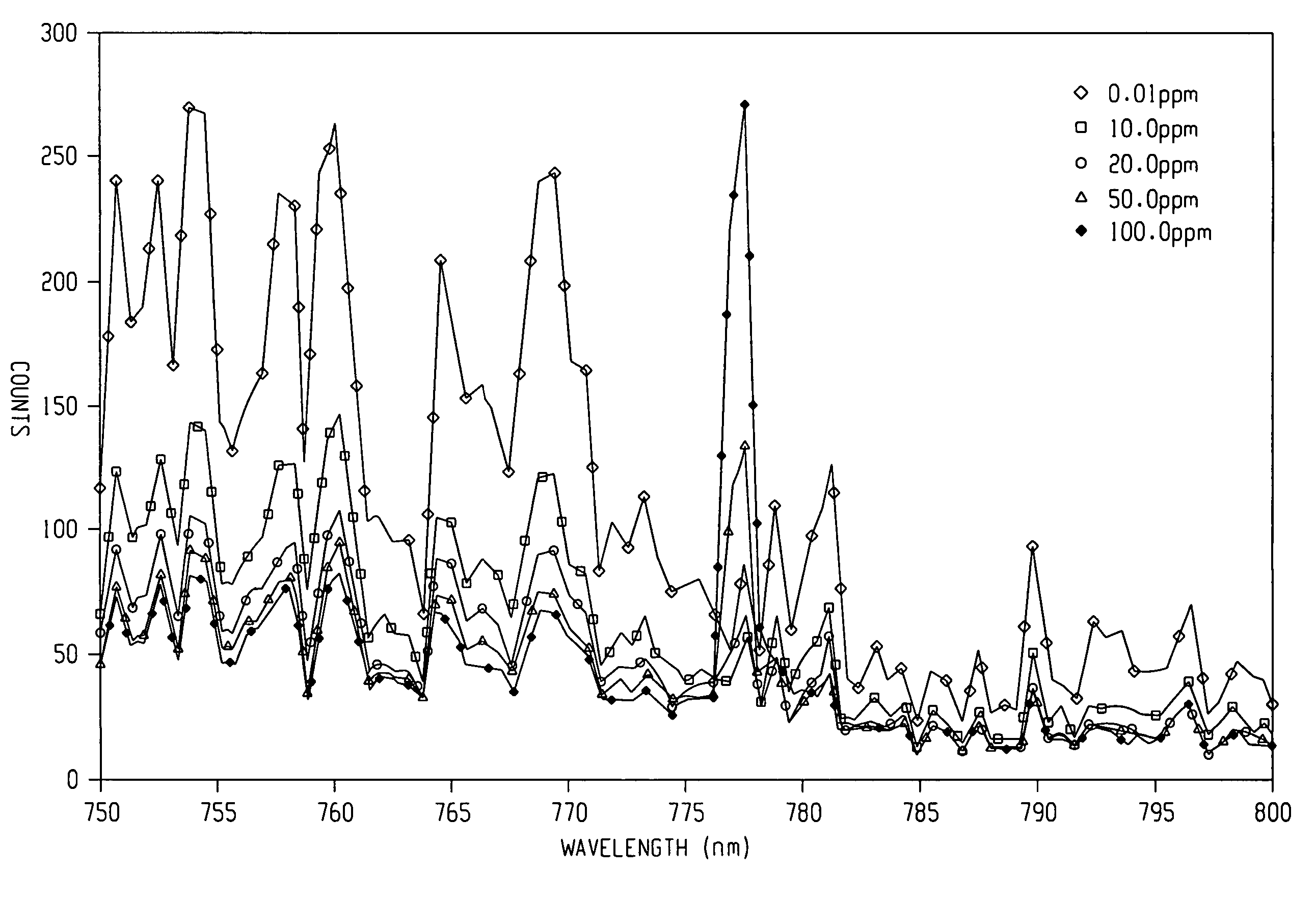

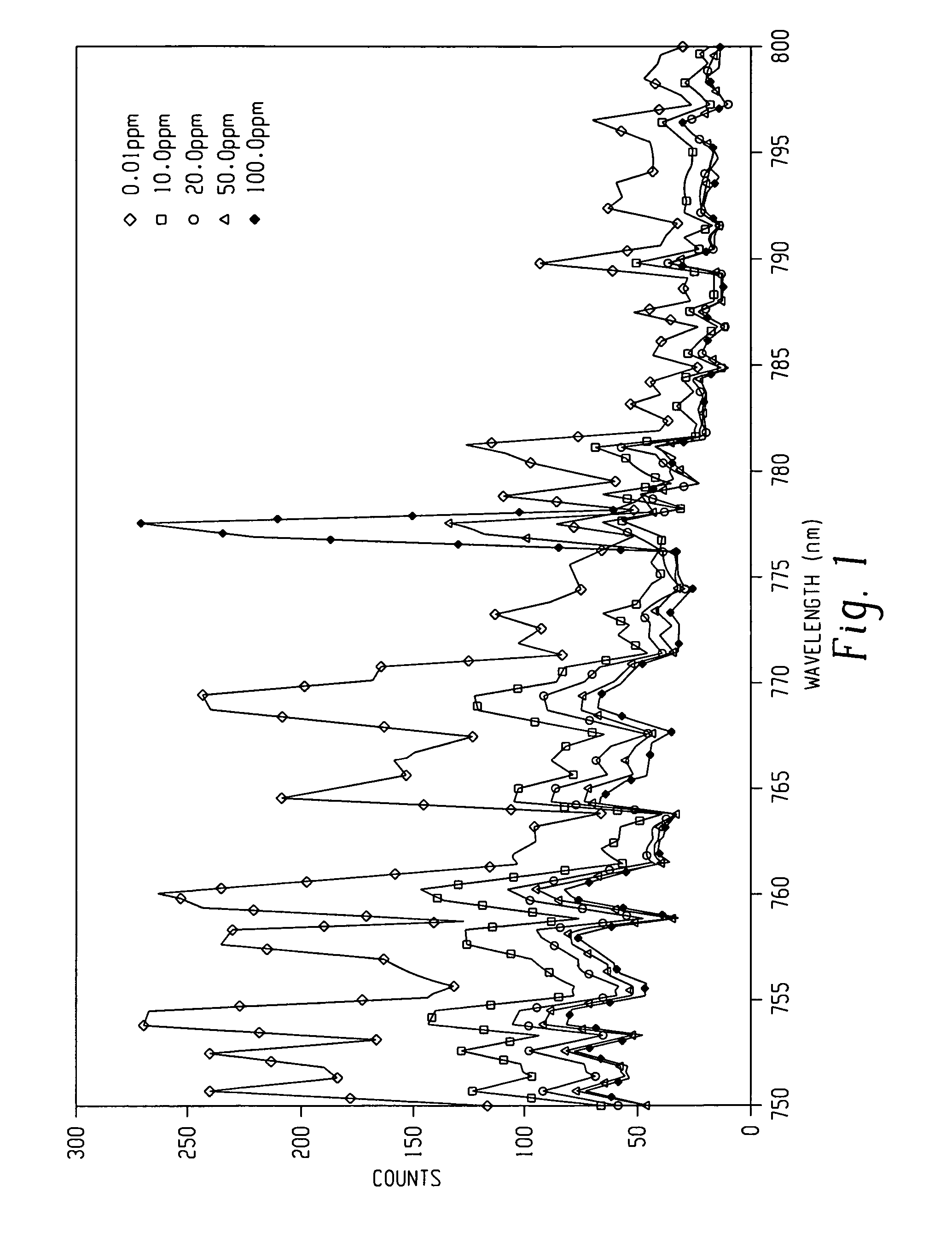

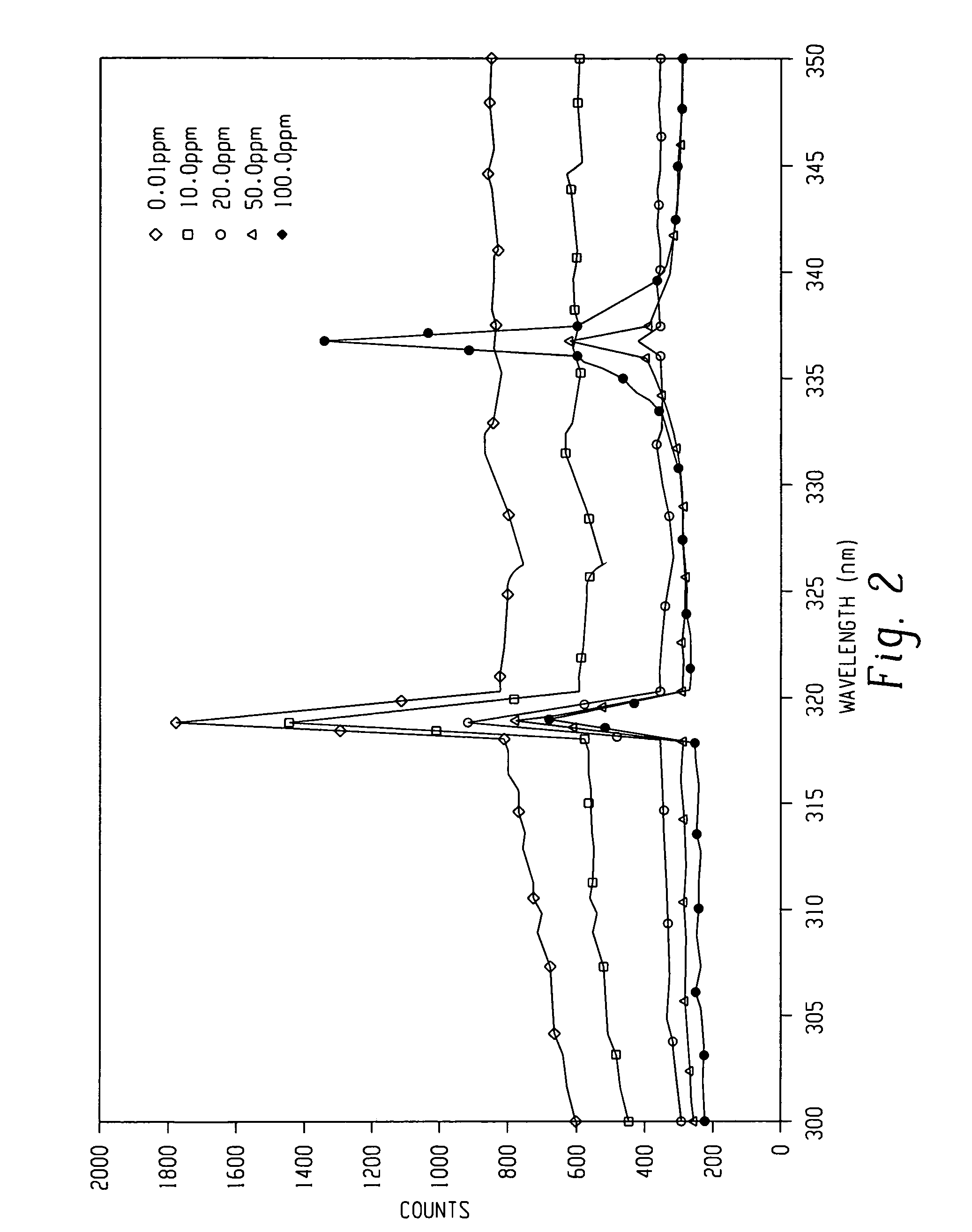

Processes for monitoring the levels of oxygen and/or nitrogen species in a substantially oxygen and nitrogen-free plasma ashing process

ActiveUS7381651B2Semiconductor/solid-state device testing/measurementElectric discharge tubesBillionthNitrogen

Processes for monitoring the levels of oxygen and / or nitrogen in a substantially oxygen and nitrogen-free plasma ashing process generally includes monitoring the plasma using optical emission. An effect produced by the low levels of oxygen and / or nitrogen species present on other species generally abundant in the plasma is monitored and correlated to amounts of oxygen and nitrogen present in the plasma. This so-called “effect detection” process monitors perturbations in the spectra specifically associated with species other than nitrogen and / or oxygen due to the presence of trace amounts of oxygen and / or nitrogen species and is used to quantitatively determine the amount of oxygen and / or nitrogen at a sensitivity on the order of 1 part per million and potentially 1 part per billion.

Owner:LAM RES CORP

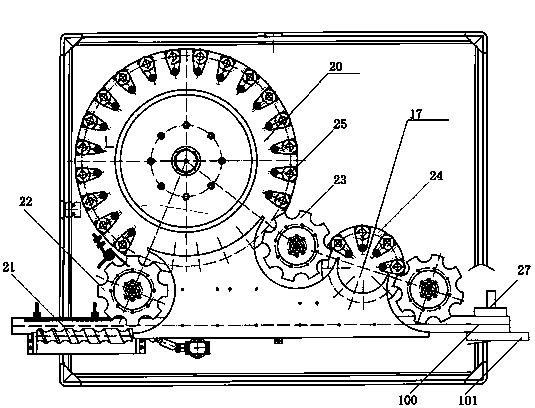

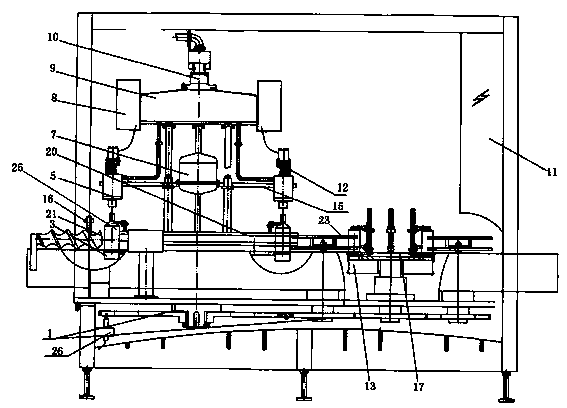

High-speed double-station-rechecking-type weighing quantifying filling machine

InactiveCN103466145AConsistent filling volumeRecheck high speedPackaging automatic controlBillionthEngineering

The invention relates to a high-speed double-station-rechecking-type weighing quantifying filling machine which comprises a machine frame, a transmission system, a rotation disc and a weighing filling station. A weighing sensor is arranged under the bottle position of the rotation disc to weigh the filling volume, and a weighing rechecking station is arranged behind the rotation disc. The weighing rechecking station comprises a rechecking rotation disc and weighing rechecking sensors arranged under the bottle position of the rechecking rotation disc, and a rejecting pushing device is arranged behind the weighing rechecking station. The filling machine has the advantages that filling quantity consistency is ensured due to the fact that a weighing sensor is arranged on a filling valve of the weighing filling station; the rechecking station is added behind the filling station, so that the filling volume of the front filling station can be rechecked, and products not meeting the filling volume can be effectively prevented from entering the next procedure. More importantly, the plurality of rechecking sensors installed at the weighing rechecking station work simultaneously to achieve the aim of high speed rechecking. By means of the filling machine, the probability that unqualified products flow into the next procedure is reduced from one fifty thousandth to one in hundreds of millions and one in billions.

Owner:四川宜宾岷江机械制造有限责任公司

Nanometer silver antimicrobial deodorizing silk stockings

InactiveCN101161136AIncrease dissolved oxygenImprove microcirculationFibre treatmentPanty-hoseBillionthFar infrared

The aim of the present invention is to provide a health silk stockings produced using nanometer silver antibiotic material. The solution of the present invention is that to obtain nanometer stage silver particle (1 nanometer is equal to billionth meter) combining electrical arc method and mechnical rubbing method, then to implement antioxidation and anticoagulation treatment to the particles, at last to prepare nanometer silver antibiotic solution. To dip in the silk stockings in the nanometer silver antibiotic solution which temperature is 80 to 95 DEG C for 24 to 48 hours, then to take out and airing as well as iron out, so that the health silk stockings of the present invention is made. The silk stockings of the present invention has strong antibiotic effect, moreover, it is ventilating and flexible which ensure feet to be dry, the antibiotic effect is durable, also it has the deodorization effect, as well as release anion and far infrared energy, so it is a health silk stockings with complete function.

Owner:SHENGHONG GRP CO LTD

Health-care silk stockings

InactiveCN102178354AIncrease dissolved oxygenImprove microcirculationPanty-hoseHosieryBillionthFar infrared

The invention aims to provide health-care silk stockings processed by utilizing a nanometer silver antibacterial material. In the technical scheme, a method for manufacturing the health-care silk stockings comprises the following steps of: obtaining nanometer silver granules of between 20 and 60 nanometers (1 nanometer is equal to one billionth meter) by combining an electric arc method and a mechanical lapping method, and performing the treatment of antioxidation and agglutinating resistance to prepare nanometer silver antibacterial solution finally; and immersing stockings weaved according to the requirement in the nanometer silver antibacterial solution at the temperature of 80 and 95 DEG C for 24 to 48 hours, taking the stockings out, airing, and ironing to obtain the health-care silk stockings. The nanometer silver antibacterial deodorizing health stockings manufactured by the method have ultrastrong sterilizing and antibacterial effects, are ventilated and soft in wearing, can often keep feet dry and comfortable, have a lasting antibacterial effect, are resistant to wash, can eliminate odor effectively and release negative ions and far infrared energy stably, and are health-care products which have complete and perfect functions.

Owner:薛金礼

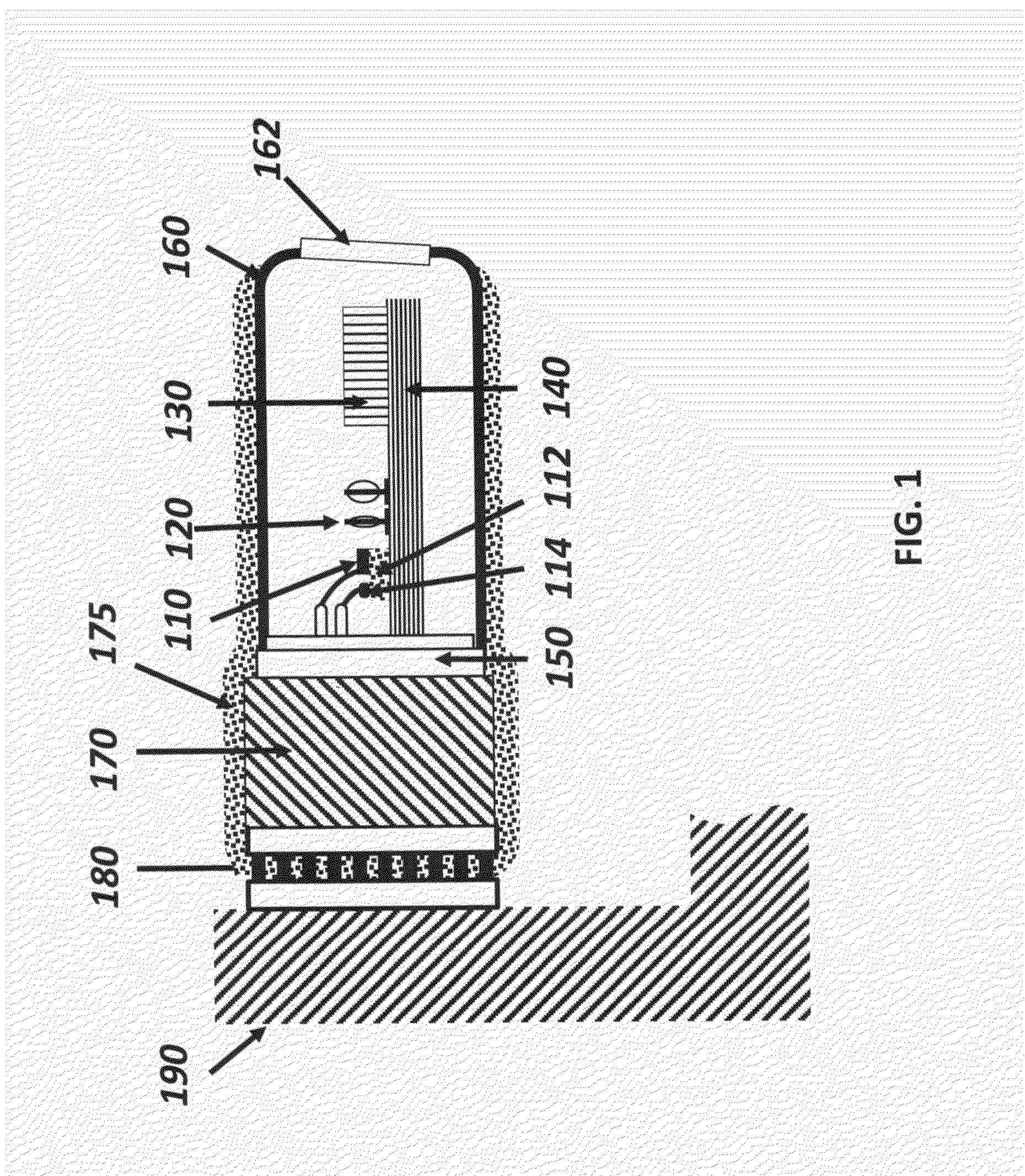

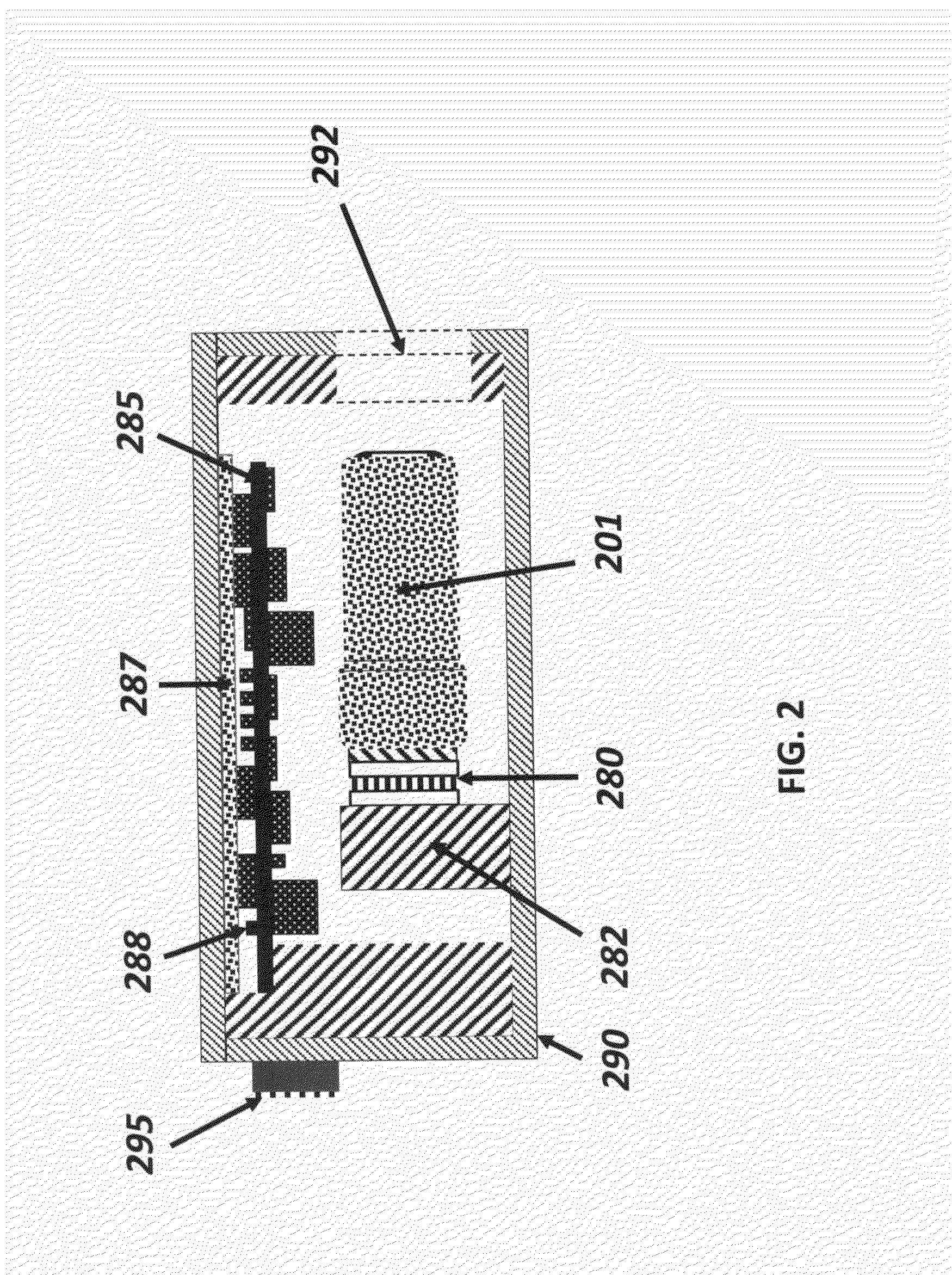

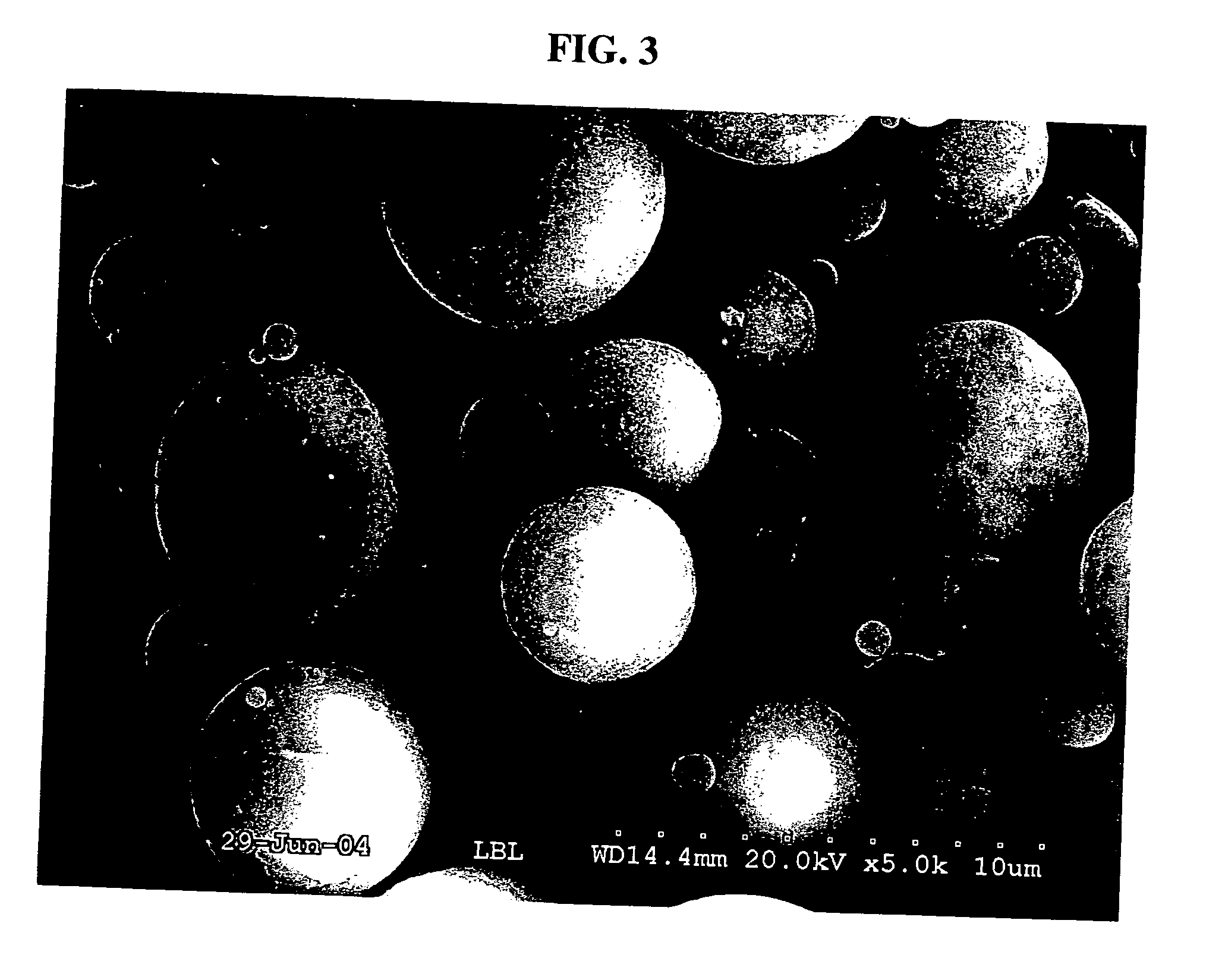

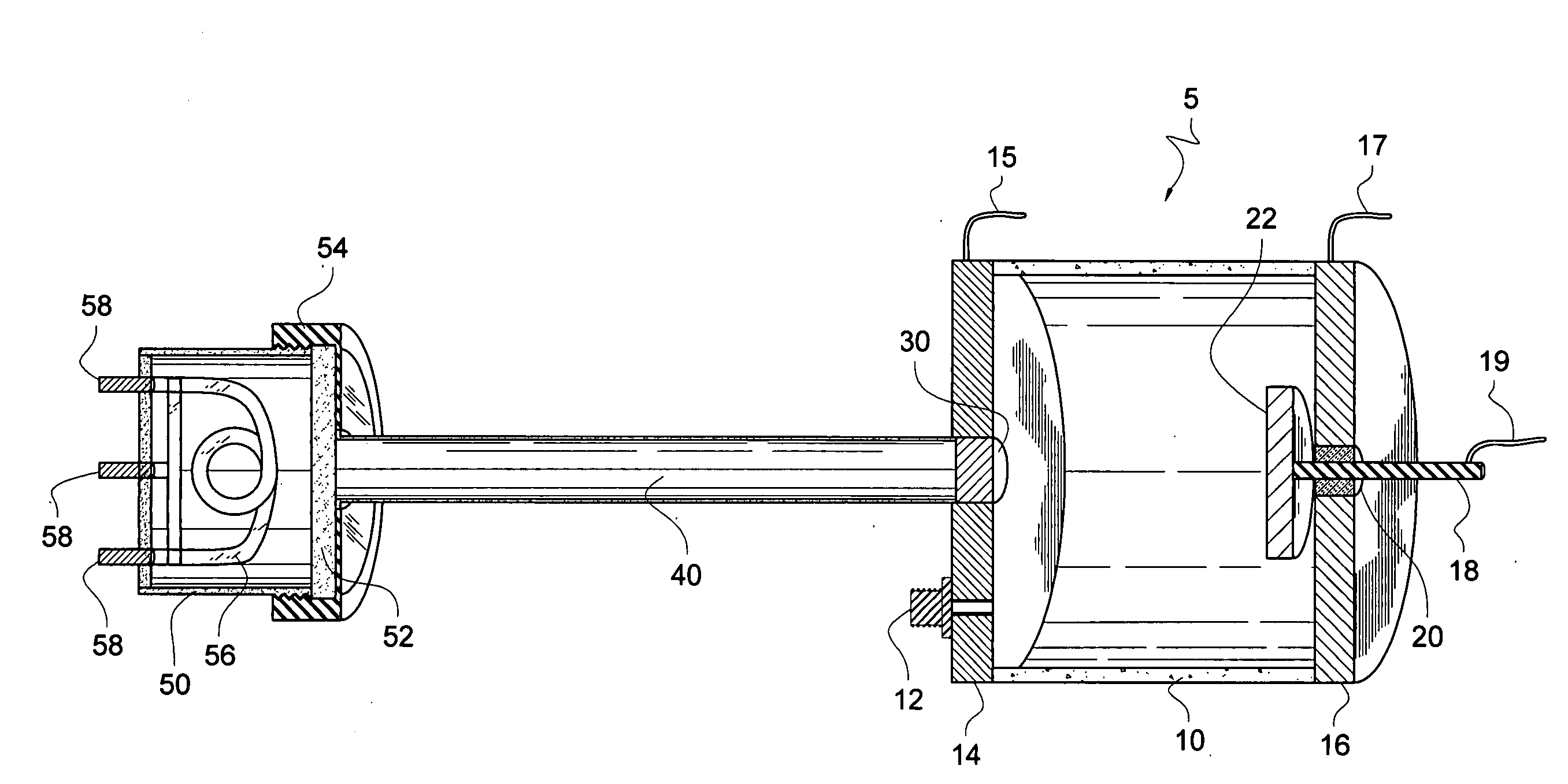

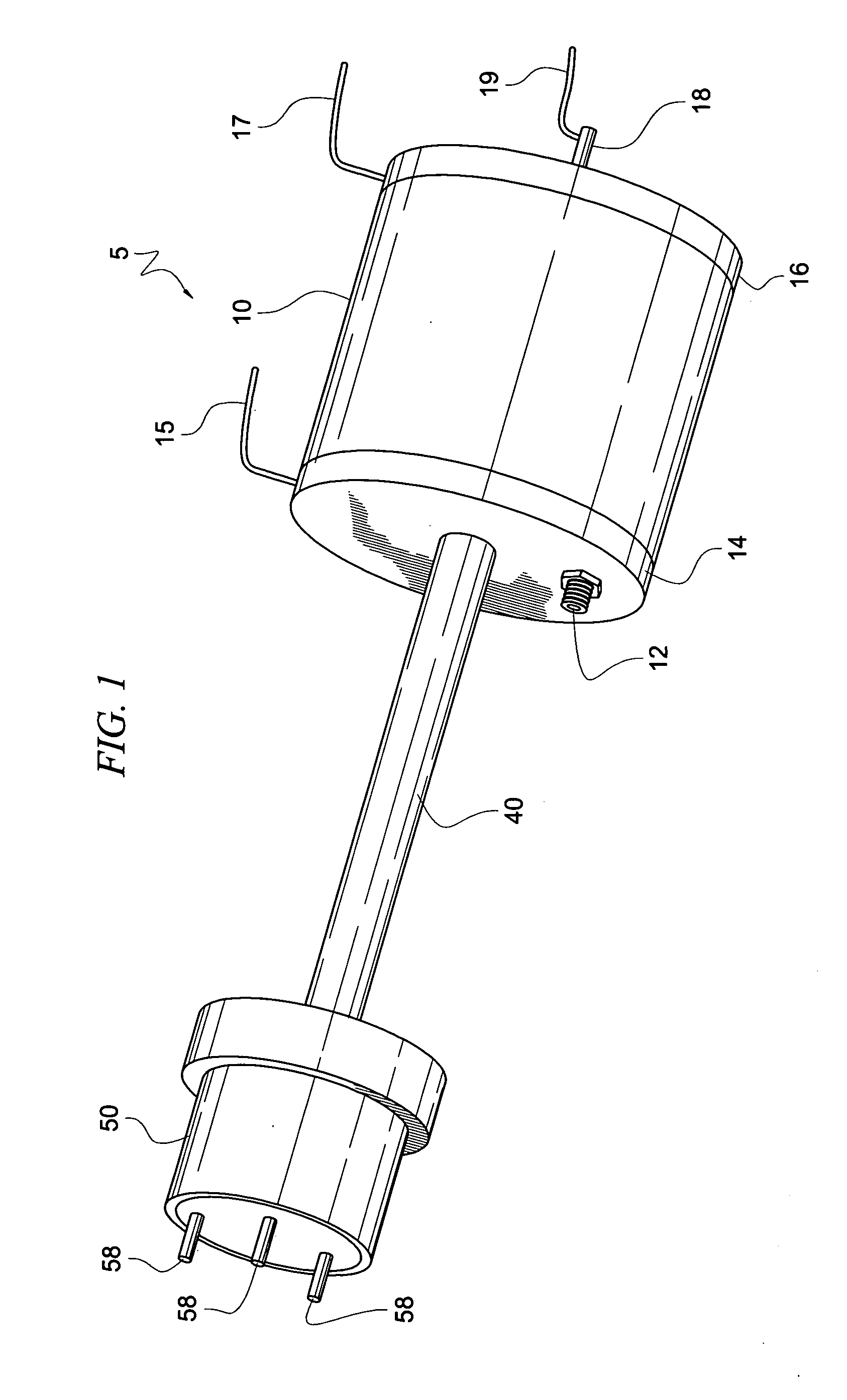

Wavelength-stabilized diode laser

ActiveUS9059555B2Improved wavelength stabilityReduced wavelength driftLaser optical resonator constructionLaser output parameters controlThermoelectric coolingBillionth

A hybrid external cavity laser (HECL) system comprises a diode laser, collection and collimation optics, and a volume Bragg grating, emits radiation at a single wavelength with a short-term wavelength stability in the order of at least one part in a billion The wavelength stability is achieved by use of a thermal management system, comprising inner and outer housings, each containing a temperature sensor, and electronic circuitry that monitors the temperatures and controls both the laser diode current and a thermoelectric cooler based on temperatures determined from said temperature sensors. The laser system is packaged in a compact enclosure that minimizes waste heat, facilitating use in applications that have heretofore employed stable, single-frequency lasers, including He—Ne lasers.

Owner:INNOVATIVE PHOTONIC SOLUTIONS INC

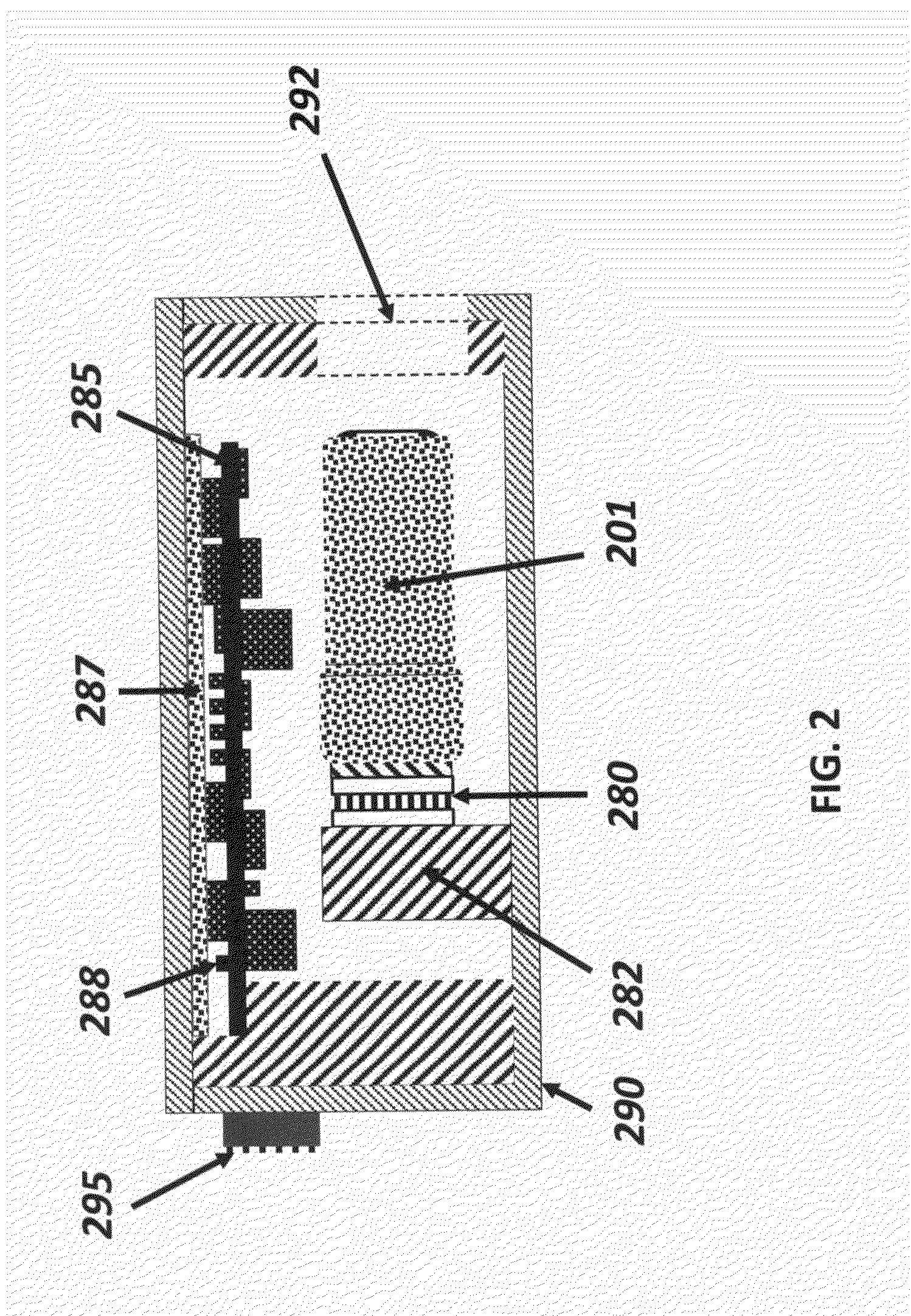

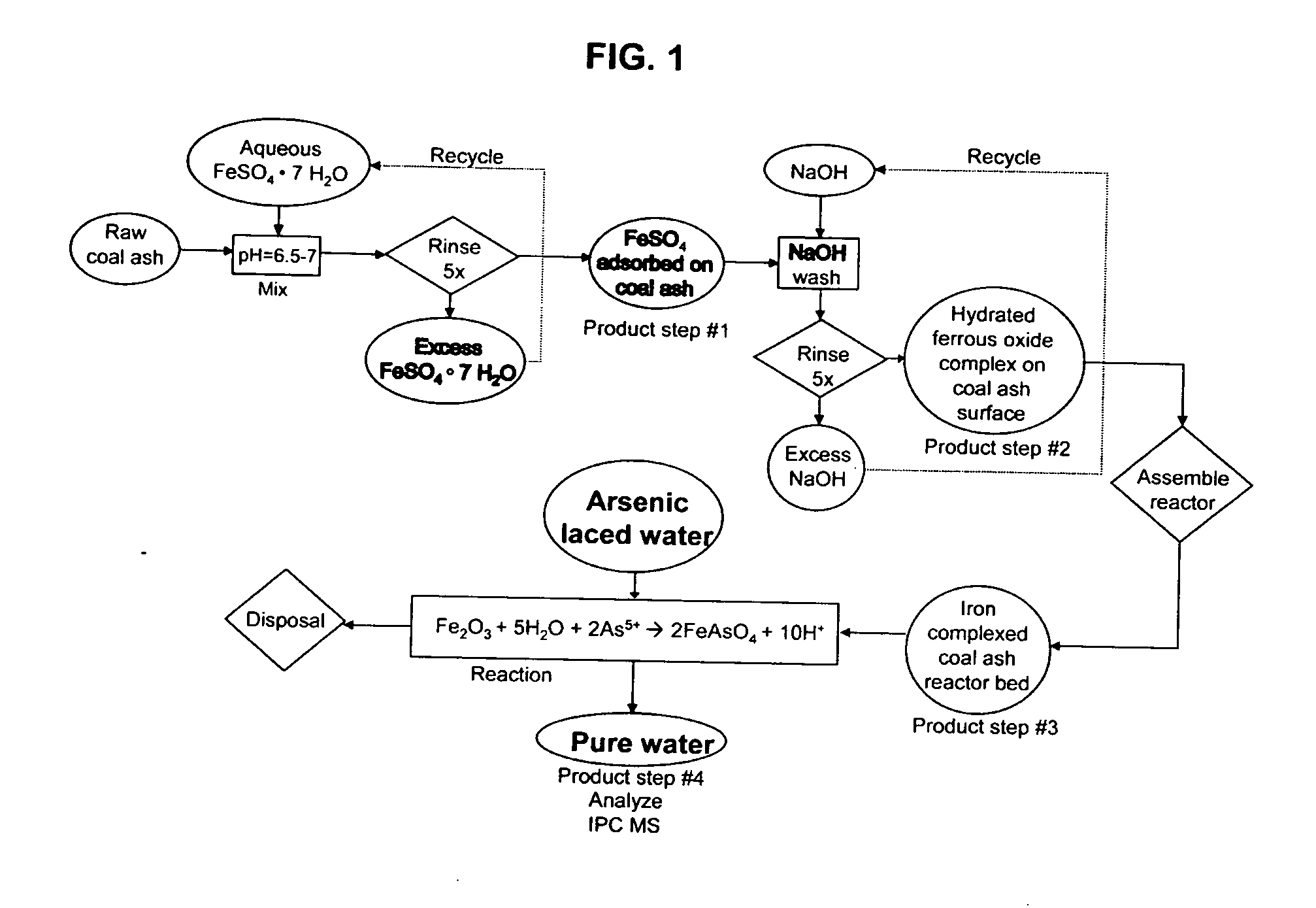

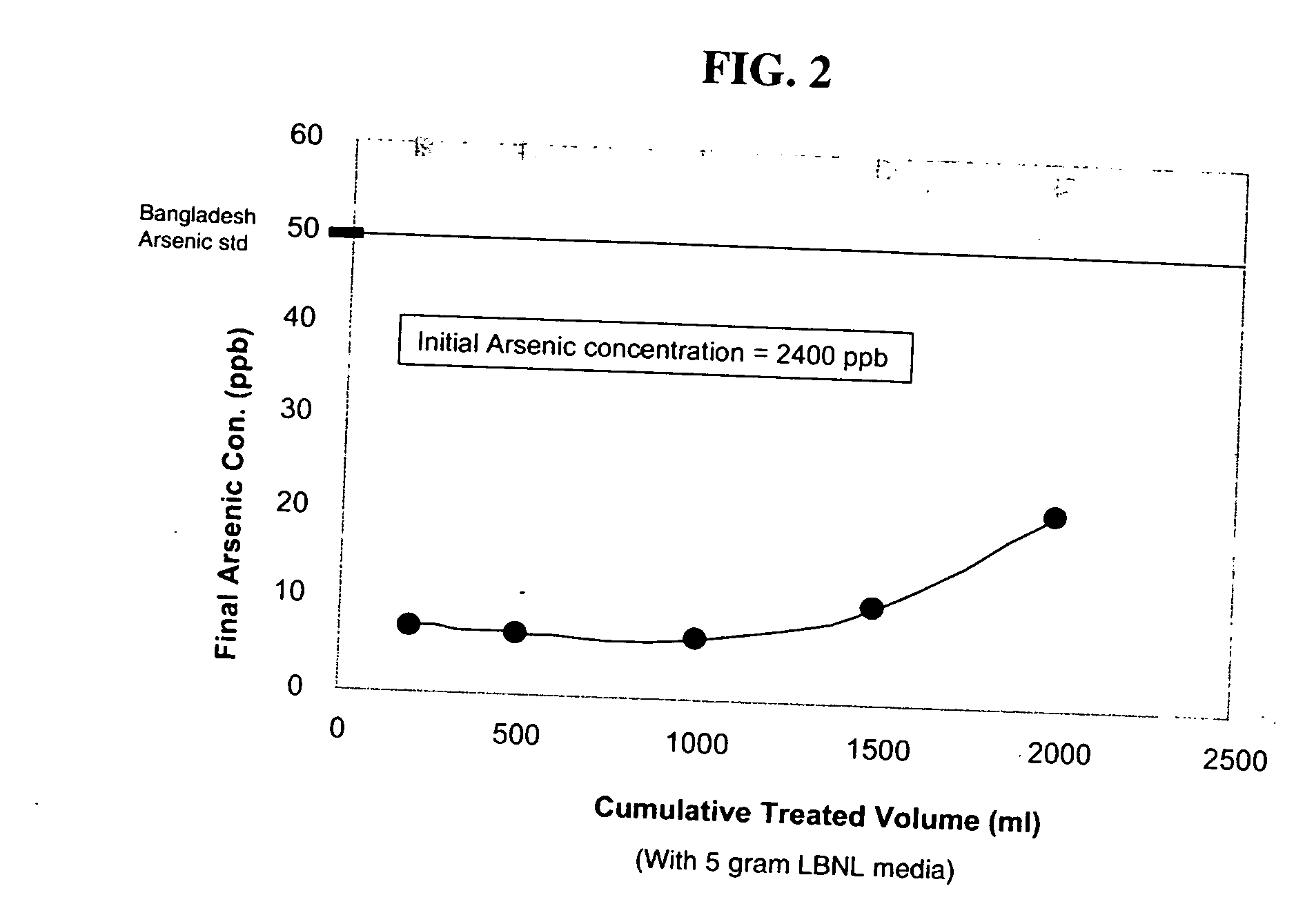

Treated bottom ash medium and method of arsenic removal from drinking water

InactiveUS20050250644A1Improve adsorption capacityIncrease investmentOther chemical processesSolid waste disposalWater useSorbent

A method for low-cost arsenic removal from drinking water using chemically prepared bottom ash pre-treated with ferrous sulfate and then sodium hydroxide. Deposits on the surface of particles of bottom ash form of activated iron adsorbent with a high affinity for arsenic. In laboratory tests, a miniscule 5 grams of pre-treated bottom ash was sufficient to remove the arsenic from 2 liters of 2400 ppb (parts per billion) arsenic-laden water to a level below 50 ppb (the present United States Environmental Protection Agency limit). By increasing the amount of pre-treated bottom ash, even lower levels of post-treatment arsenic are expected. It is further expected that this invention supplies a very low-cost solution to arsenic poisoning for large population segments.

Owner:RGT UNIV OF CALIFORNIA

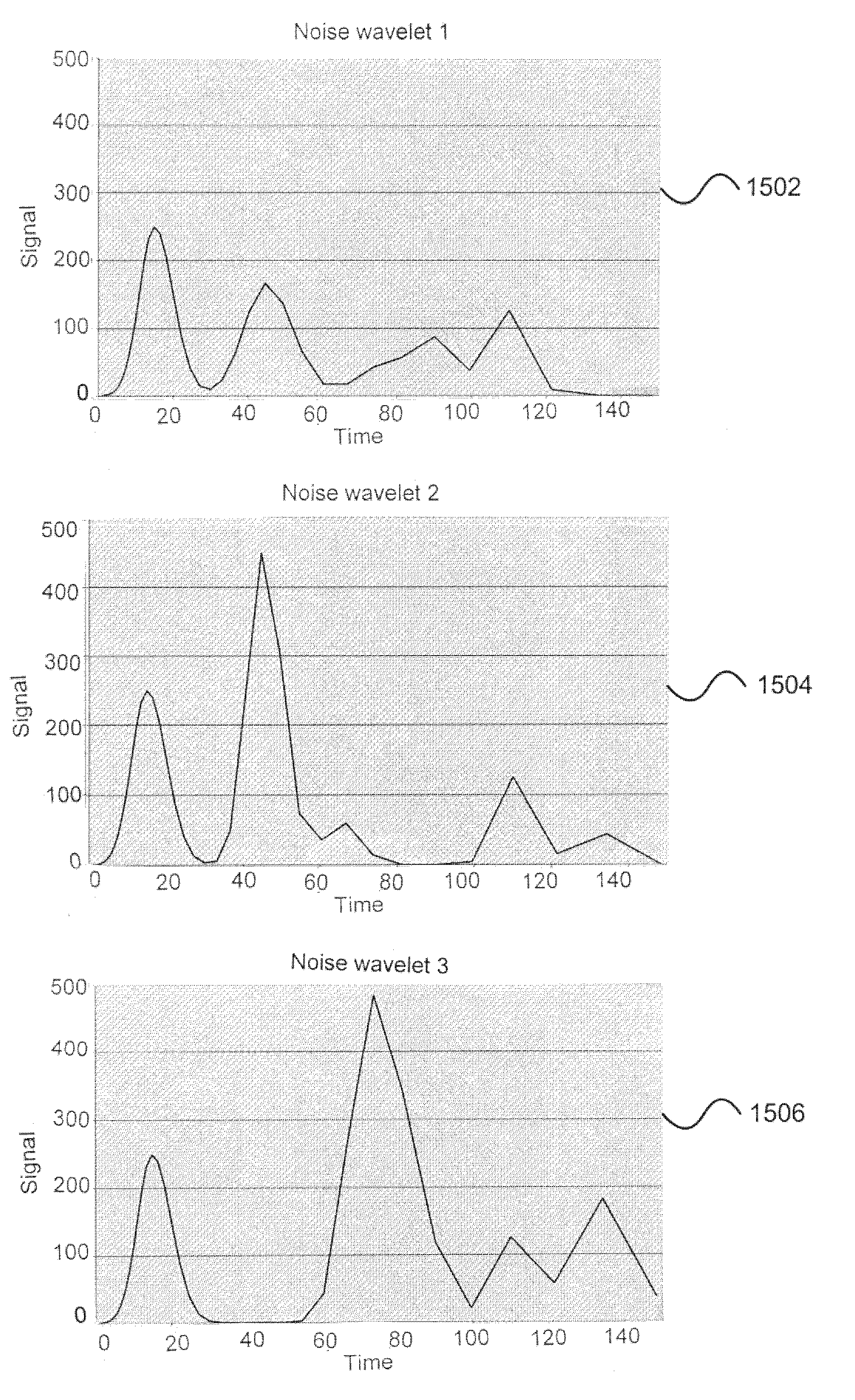

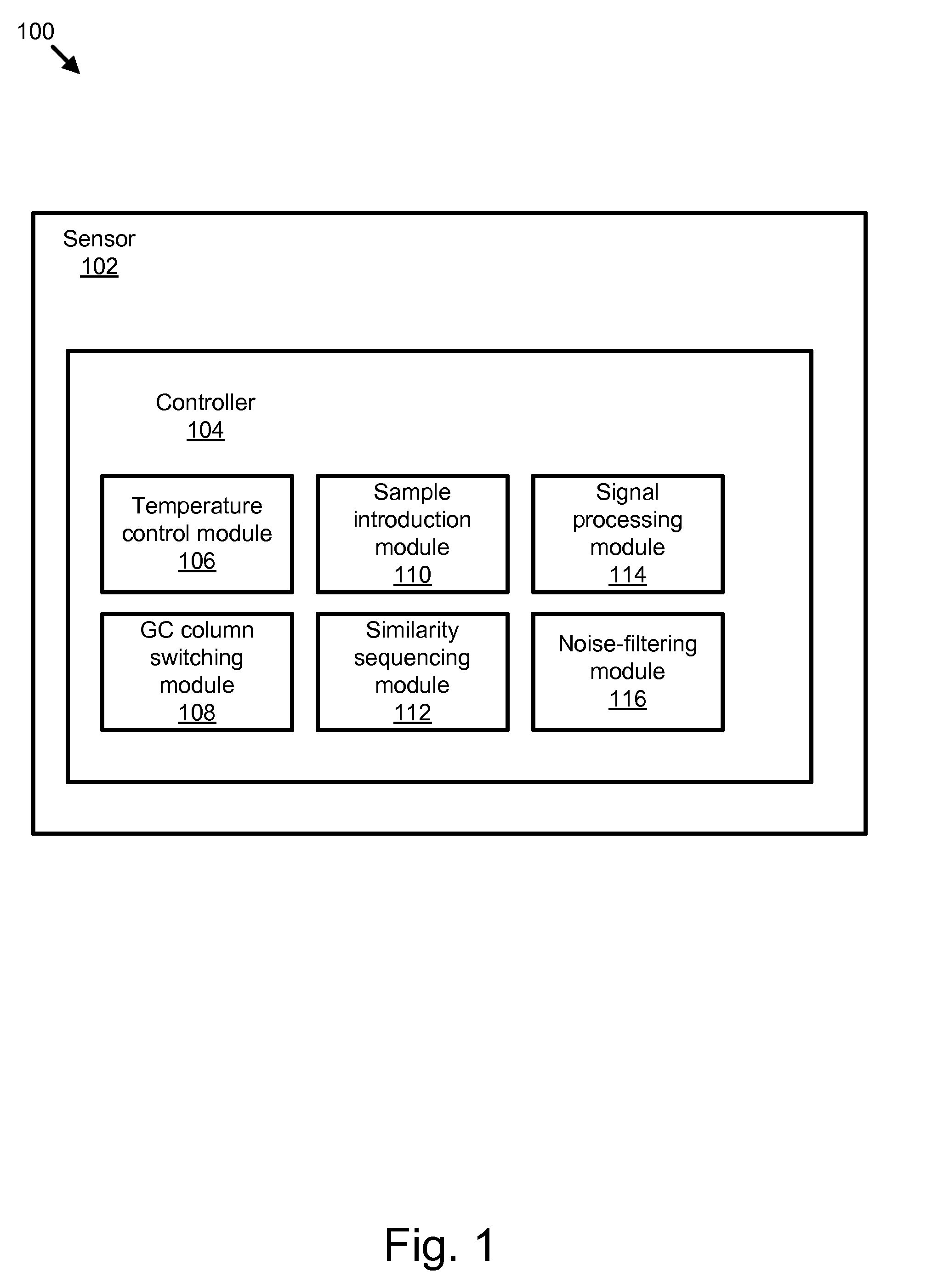

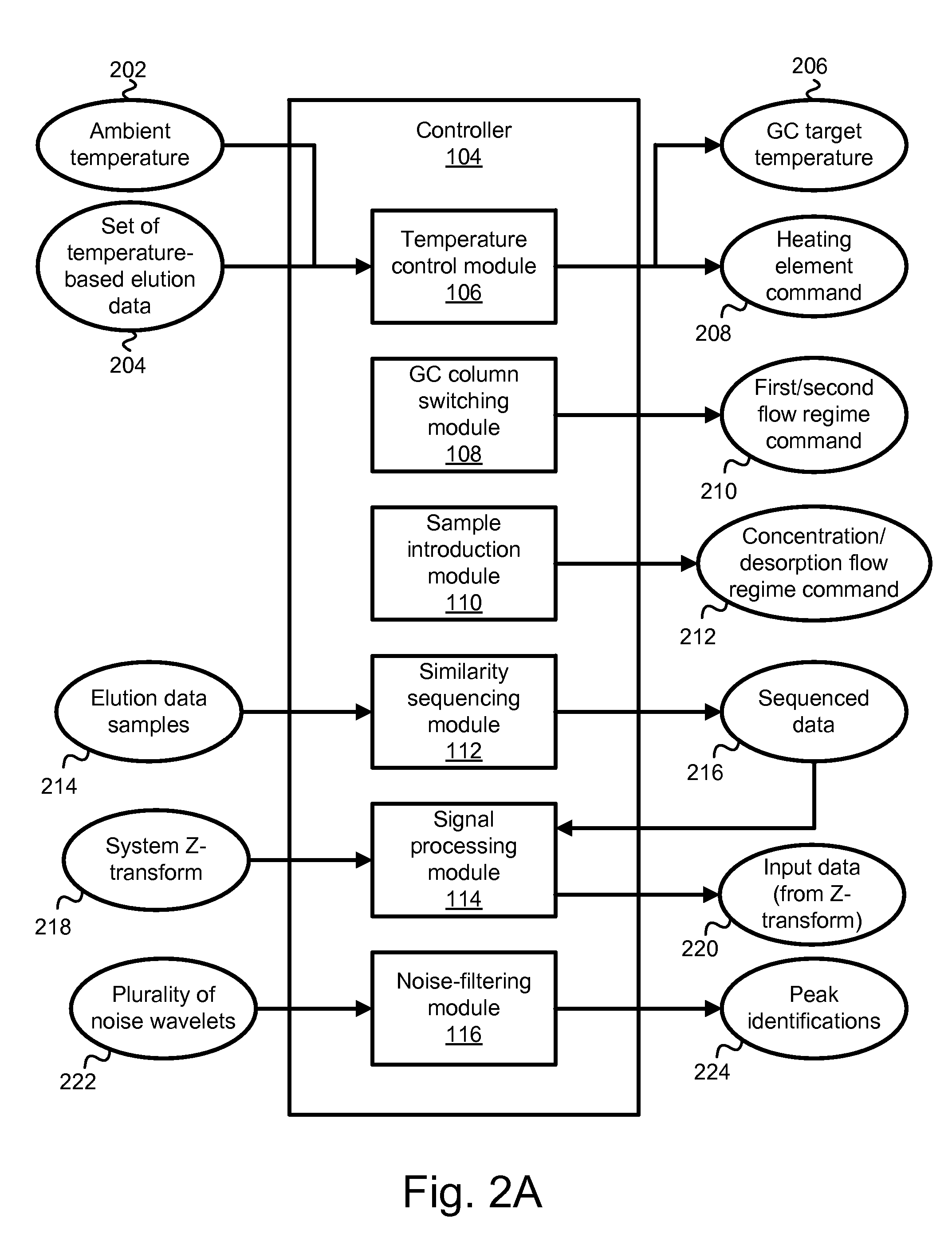

Apparatus, system, and method for low cost high resolution chemical detection

ActiveUS20080016943A1Low costSimple and inexpensive to manufactureComponent separationBillionthDetector circuits

An apparatus, system, and method are disclosed for low cost high resolution chemical detection. The apparatus includes two outer sealing bodies with flow channels etched into the bodies. Two gas chromatography (GC) columns are between the outer bodies, with a valve that switches flow regimes from series flow through the two GC columns to sample flowing directly to each GC column. The flow regimes are achieved with a single pump or dual pumps, and with one to three flow restrictions. The apparatus includes a preconcentration tube for concentrating chemicals of interest from the sample, and a sample switching valve and sampling pump to switch the sample flow from concentrating sample to delivering concentrated sample. The apparatus includes an engineered leak to equalize flow between a sample channel and a detector circuit. The sample channels may have impermeable inserts allowing the apparatus to measure chemicals in the parts-per-billion range.

Owner:WELCH EDWARD K II

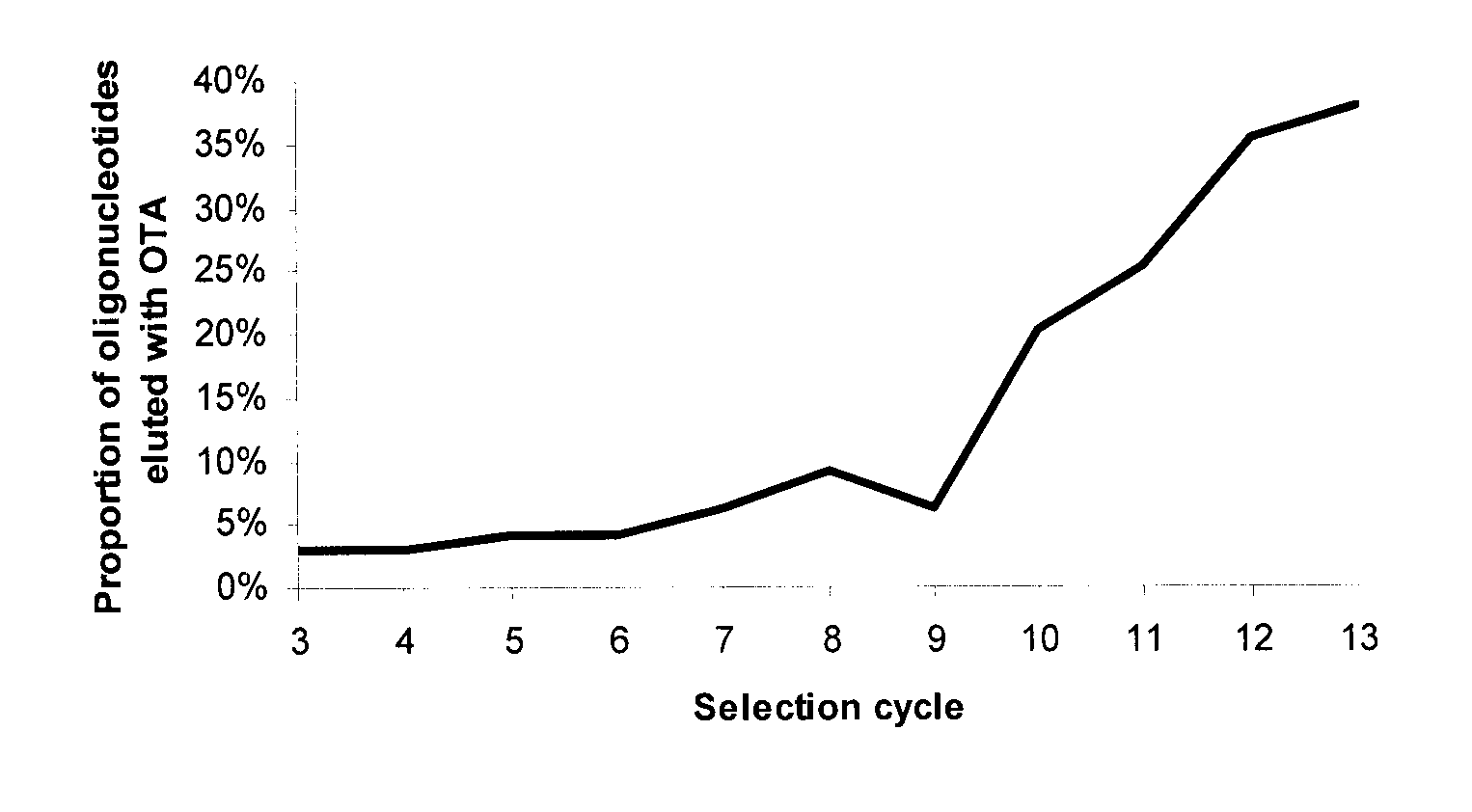

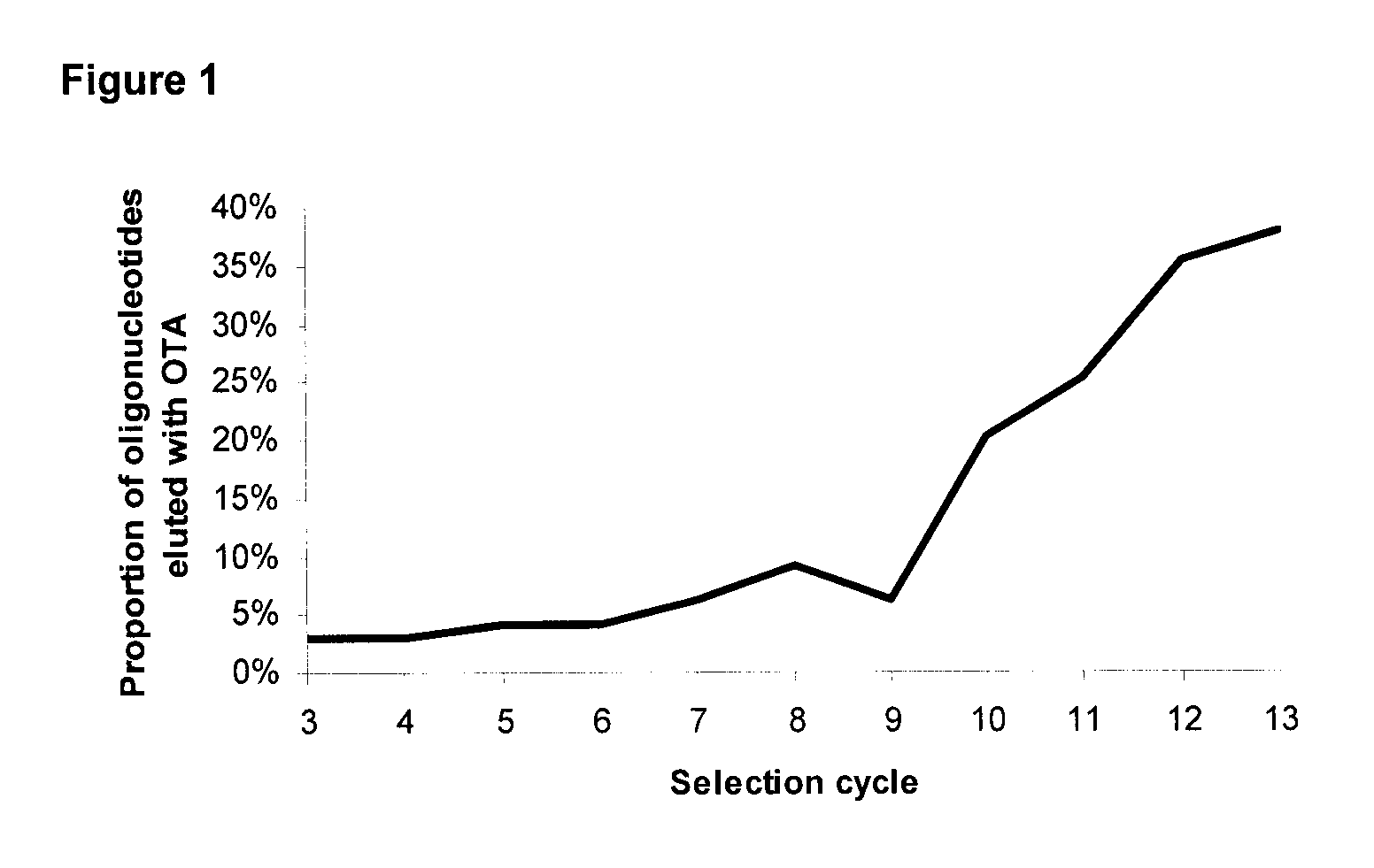

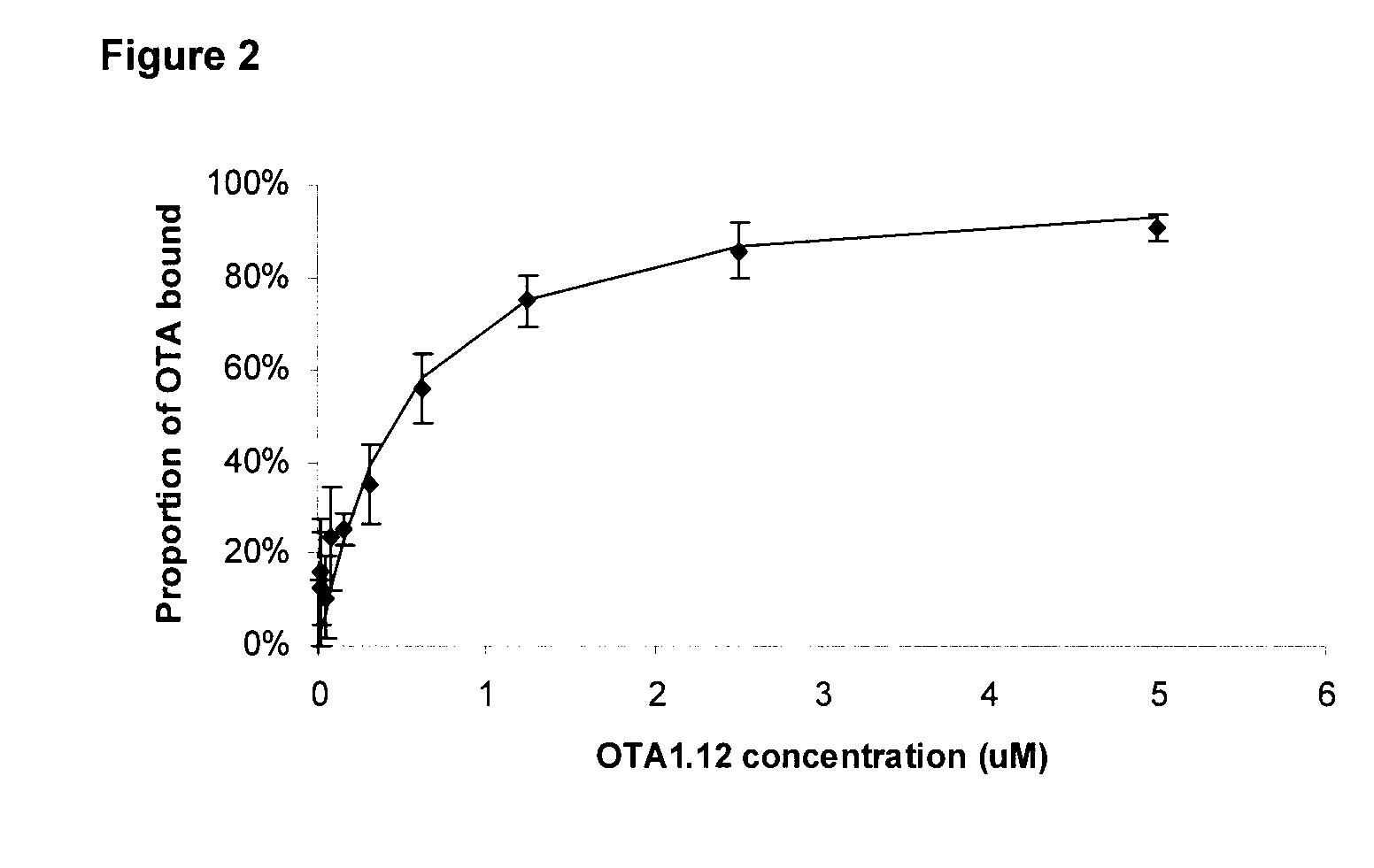

Method of Mycotoxin Detection

InactiveUS20110306508A1Strong fluorescenceImprove performanceComponent separationLibrary screeningBillionthQuantitative determination

The presence of mycotoxins in agricultural products necessitates large scale testing of a wide range of sample material to ensure the safety of food and feed. The mycotoxin ochratoxin A represents an enablement for all mycotoxins as the level of sensitivity necessary for regulatory requirements for this compound at the part per billion level are as low or lower than any other mycotoxin. This invention describes the identification of a set of DNA ligands with sufficiently high binding affinity and specificity for ochratoxin A to enable an improvement over existing methods for the separation, concentration and quantitative determination of ochratoxin A in sample material.

Owner:NEOVENTURES BIOTECH

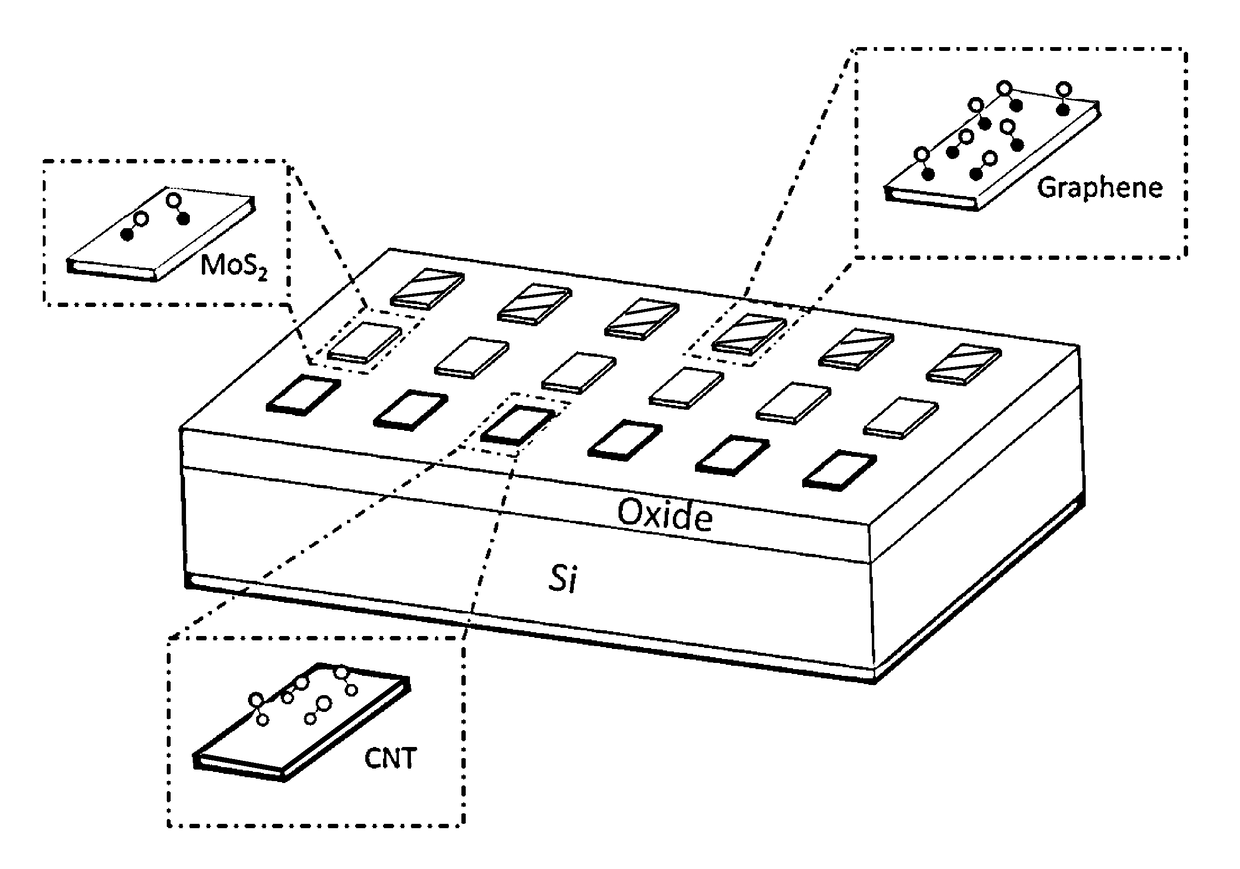

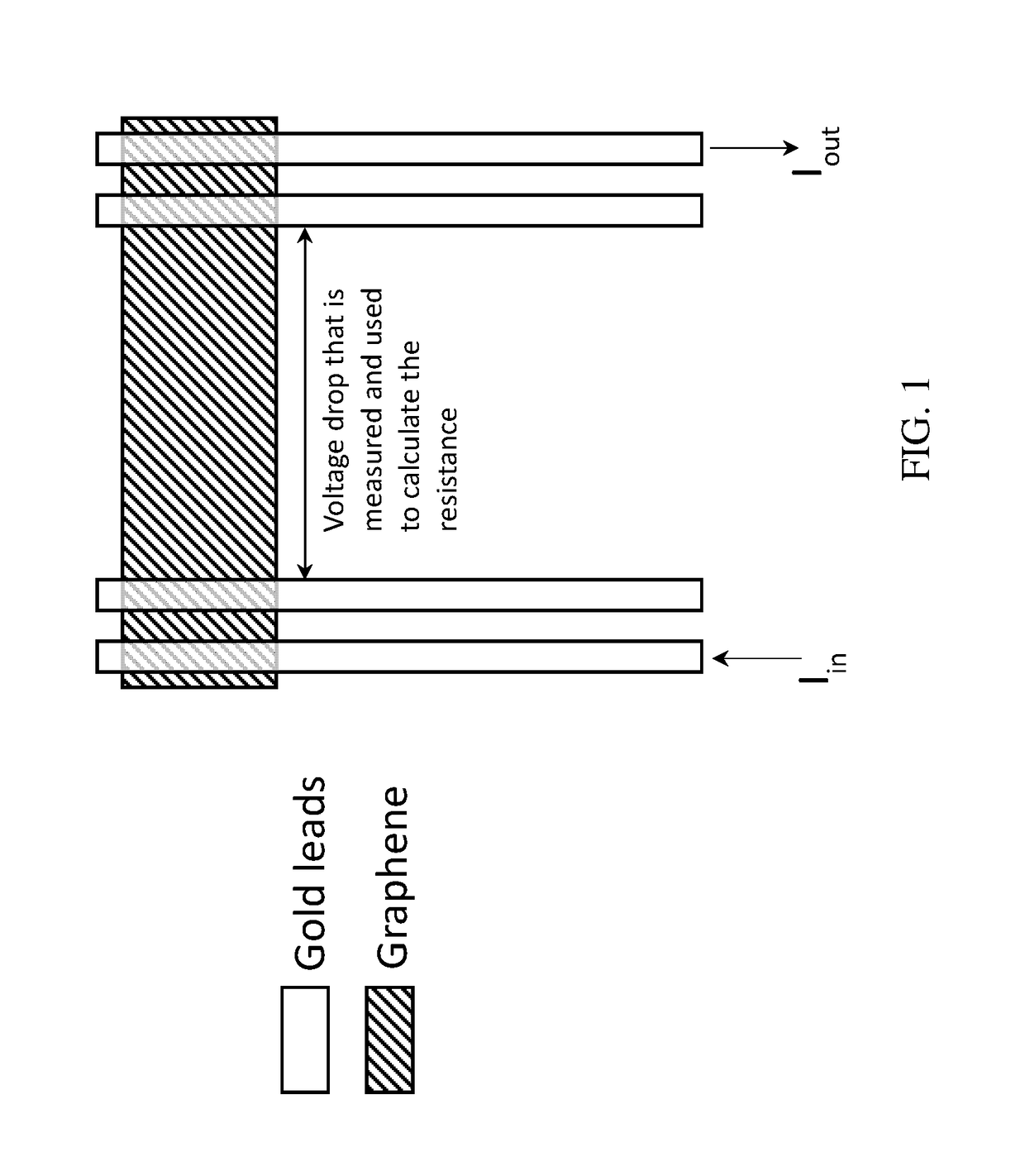

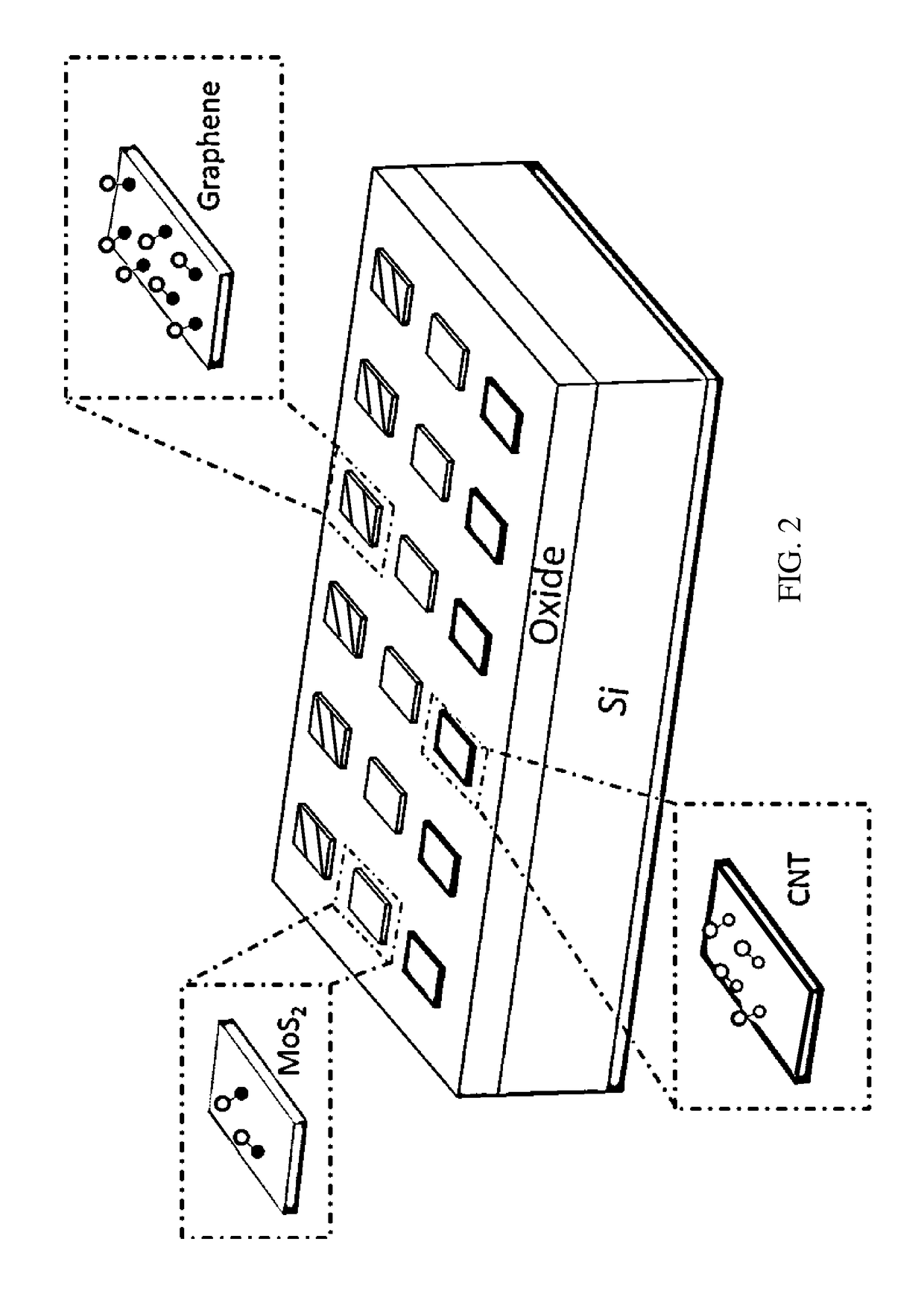

Enhancing sensitivity by directly printing nanosensors using advanced manufacturing techniques on a pre-amp board or a daughterboard

InactiveUS20180045698A1Improve conductivityReduce noiseInvestigating presence of gasesMaterial resistanceBillionthEngineering

The present invention provides a printable nanosensor and leads that can be manufactured using three-dimensional printing techniques and printing directly on a daughter board that can be connected to a self-contained pre-amplified printed circuit board. Although graphene is highly sensitive as a chemical sensor and can detect parts per million (ppm) concentrations of species, the integration of printed graphene and other two-dimensional sensing materials to form a sensor assembly can be used to increase the sensitivity even further, enabling detection of parts per billion (ppb) concentrations and even single molecule detection.

Owner:NASA

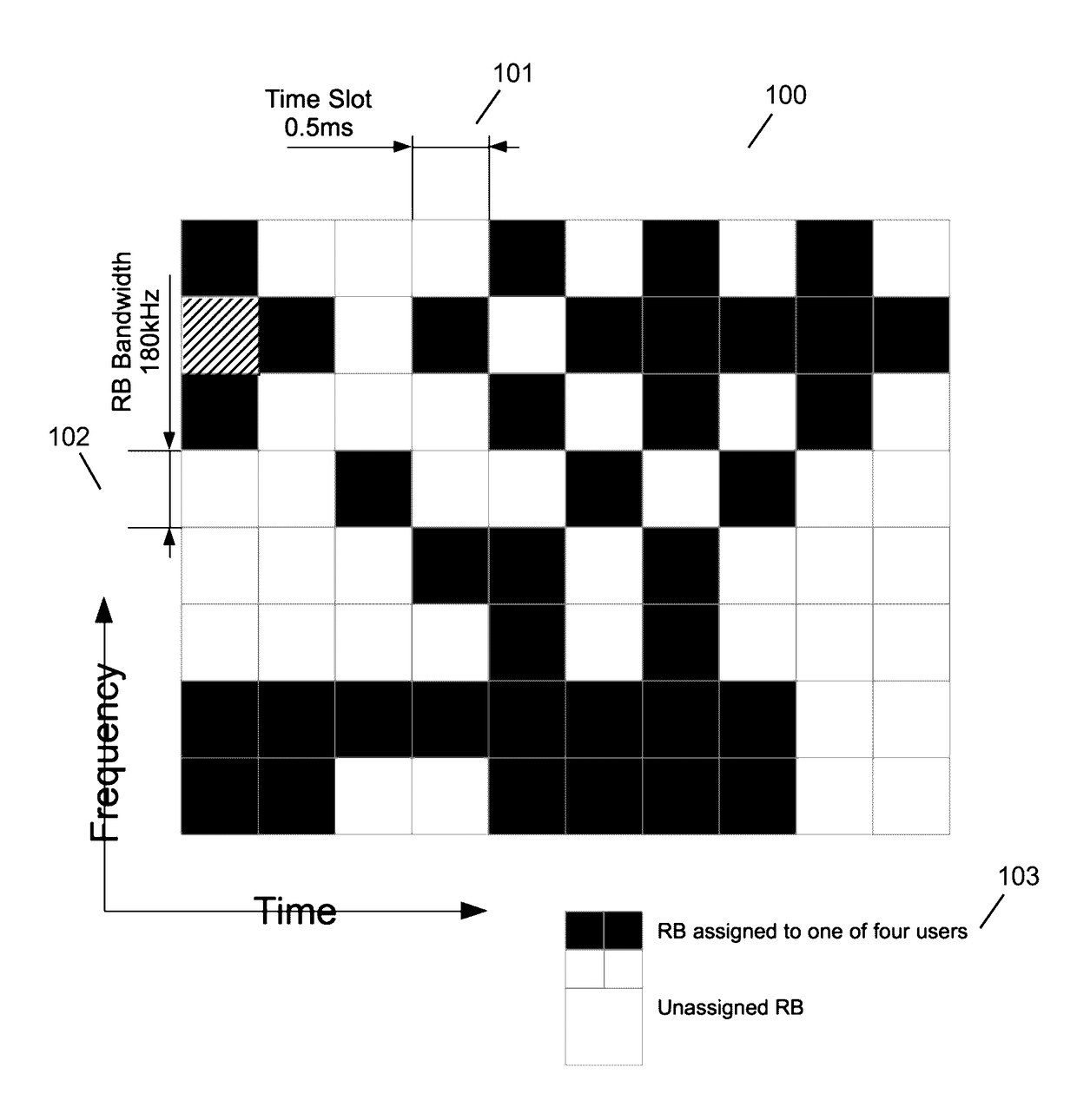

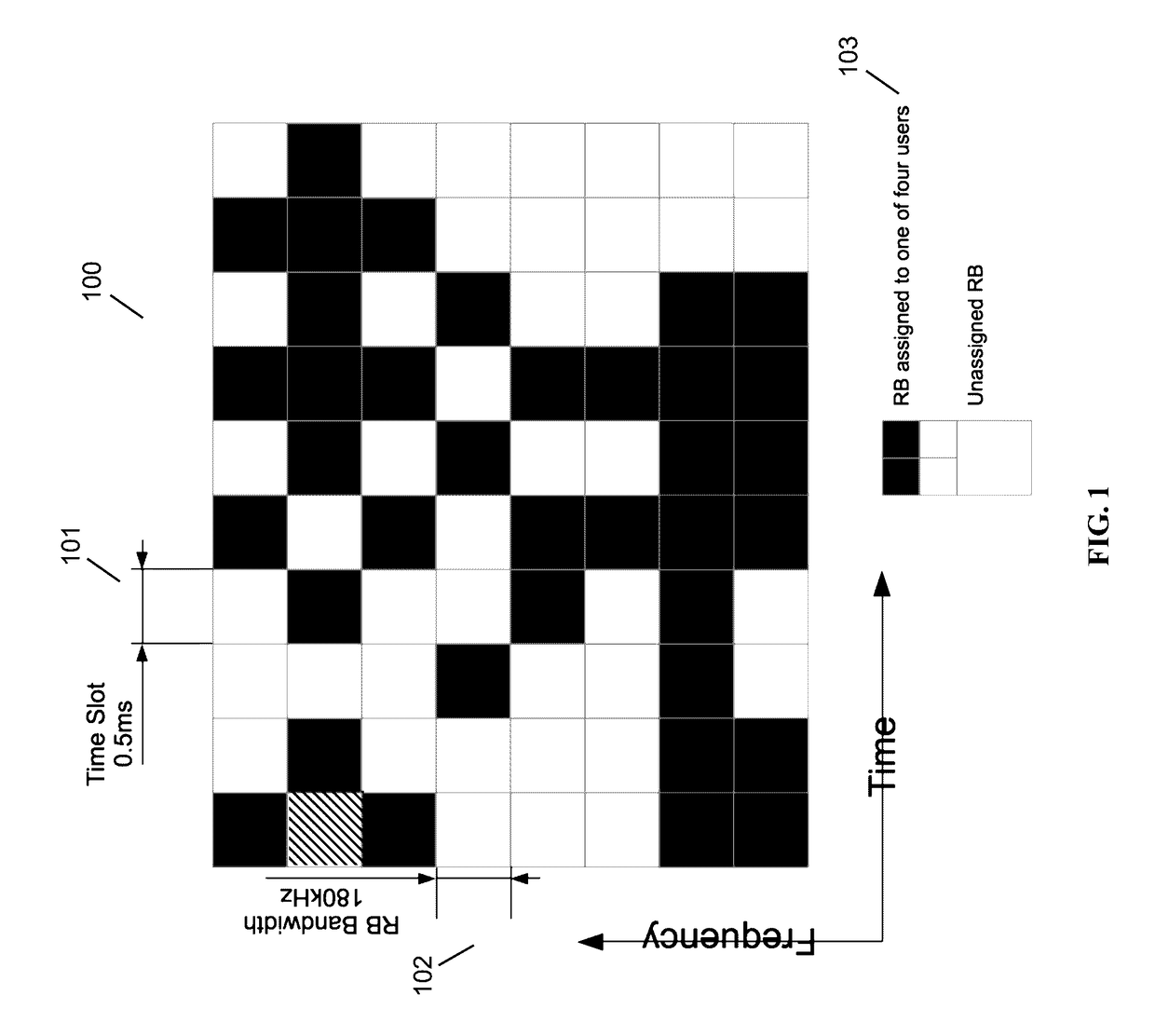

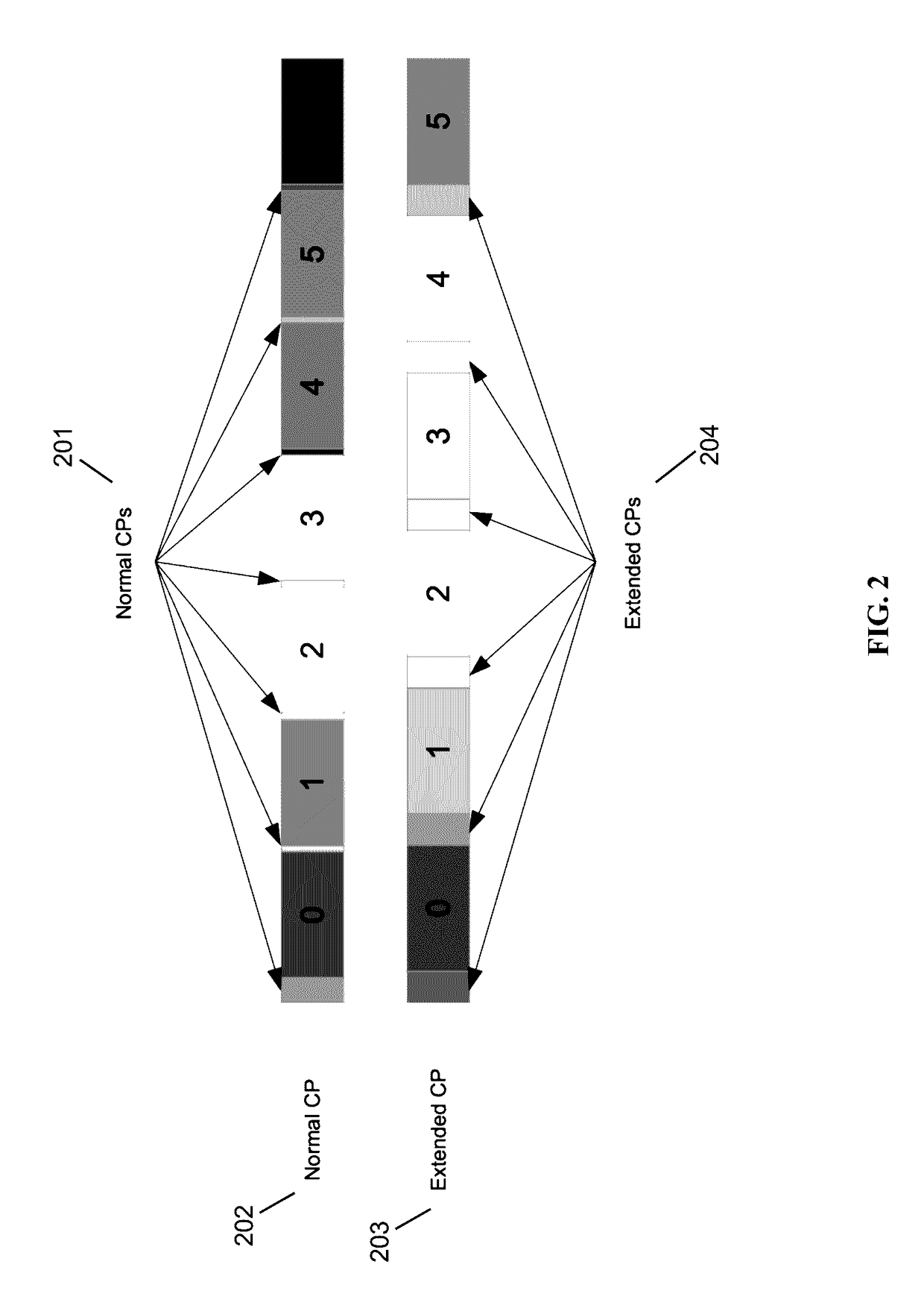

High-Precision Blind Carrier Synchronization Methods for LTE SC-FDMA Uplink

Methods and systems are described for frequency domain correction, time domain correction, and combinations thereof. Each Long Term Evolution (LTE) uplink residual frequency offset can be determined with less than 1 part per billion accuracy simultaneously and used for frequency offset correction. The disclosed method utilizes the same modulated signals for data and control as the 3GPP LTE wireless standard and can be embedded directly into the base station (downlink) PHY without additional hardware. The use of the disclosed methods provide multiple ways to simultaneously improve the uplink data throughput for every user in an LTE multiple access wireless system.

Owner:PHASORLAB

Long term-acting antibacterial healthy underpants

InactiveCN101224043AImprove antibacterial propertiesSoft and comfortable to wearFibre treatmentUndergarmentsBillionthAgglutination

The invention aims at providing a health care pants processed by a nano-silver antibacterial substance. The invention adopts the following technical proposal that using the combination of an electric arc method and a mechanical grinding method, nano silver particles of 20-60nm are obtained (1nanometer equals to 1divided by one billion meters), then the particles are processed by anti-oxidation and anti-agglutination to prepare a nano-silver antibacterial solution. The silk-stockings weaved according to requirements are dipped in the nano-silver antibacterial solution with the temperature of 80- 95 DEG C for 24-48 hours and then taken out for drying and ironing, thus obtaining the invention. The nano-silver antibacterial health care pants prepared by the method not only have super strong sterilization and antibacterial effect, but also have air permeability and soft quality. The pants have durable antibacterial effect and excellent resistance to water, and can effectively eliminate peculiar smell and discharge anion and far infrared energy stably, which is a complete health care product with complete functions.

Owner:SHENGHONG GRP CO LTD

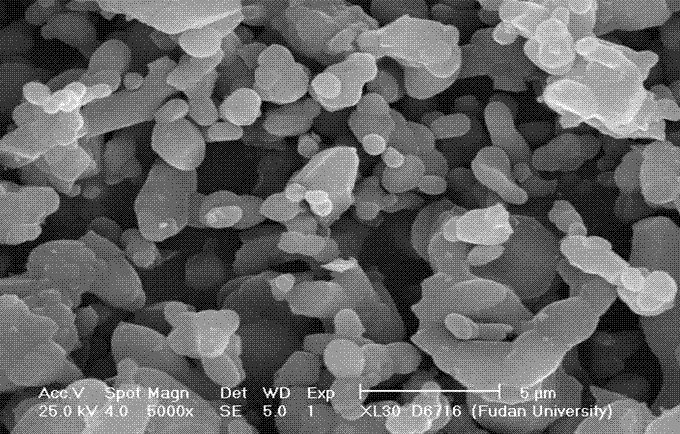

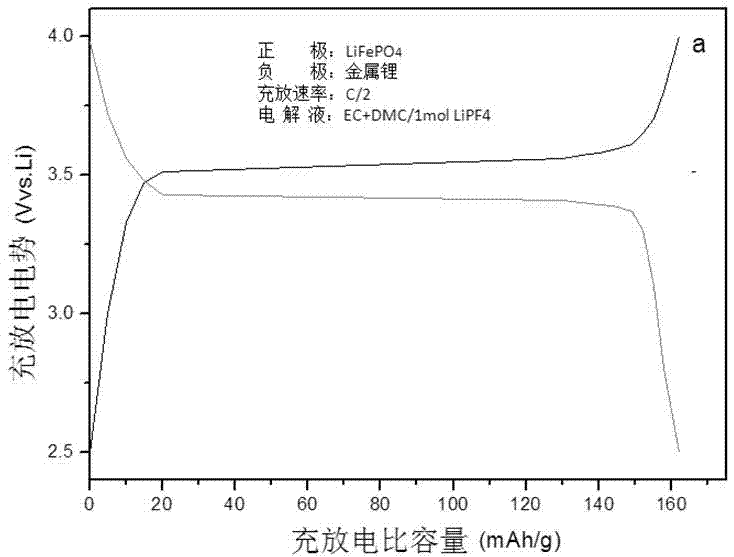

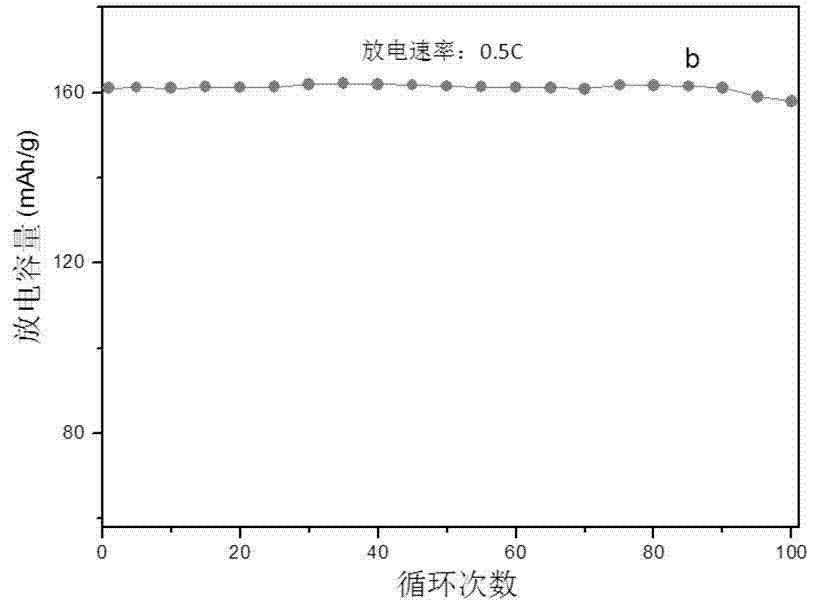

Method for improving conductivity of pure lithium iron phosphate anode material

InactiveCN103682336AImprove conductivitySimple processCell electrodesPhosphorus compoundsOxygenLithium-ion battery

The invention belongs to the technical field of electrochemistry, and in particular relates to a method for improving conductivity of a pure lithium iron phosphate anode material. According to the method, on the basis that the pure lithium iron phosphate anode material generally without conductivity is synthesized by using an ordinary method, a material with carbon-carbon and carbon-oxygen unsaturated bands is gasified by using a preset inert gas in a calcinator, subsequently the calcinator is cleaned at room temperature, and furthermore pure lithium iron phosphate is put into the calcinator to be subjected to inert gas calcination, so that the conductivity of the material is greatly improved. The conductivity of the material is increased to 1 / 10 siemens per centimeter from 1 ppb siemens per centimeter, or in other words, the resistance is reduced to be 10 Ohm from 1 billion Ohm. The residual carbon content of the lithium iron phosphate anode material treated by using the method is 0.3%, and the residual carbon content before the treatment is 0.2%. The method is used for preparing lithium ion batteries, a high capacity ratio can be obtained without adding conductive carbon, and the characteristics of excellent security property, long circulation period and the like can be achieved.

Owner:FUDAN UNIV

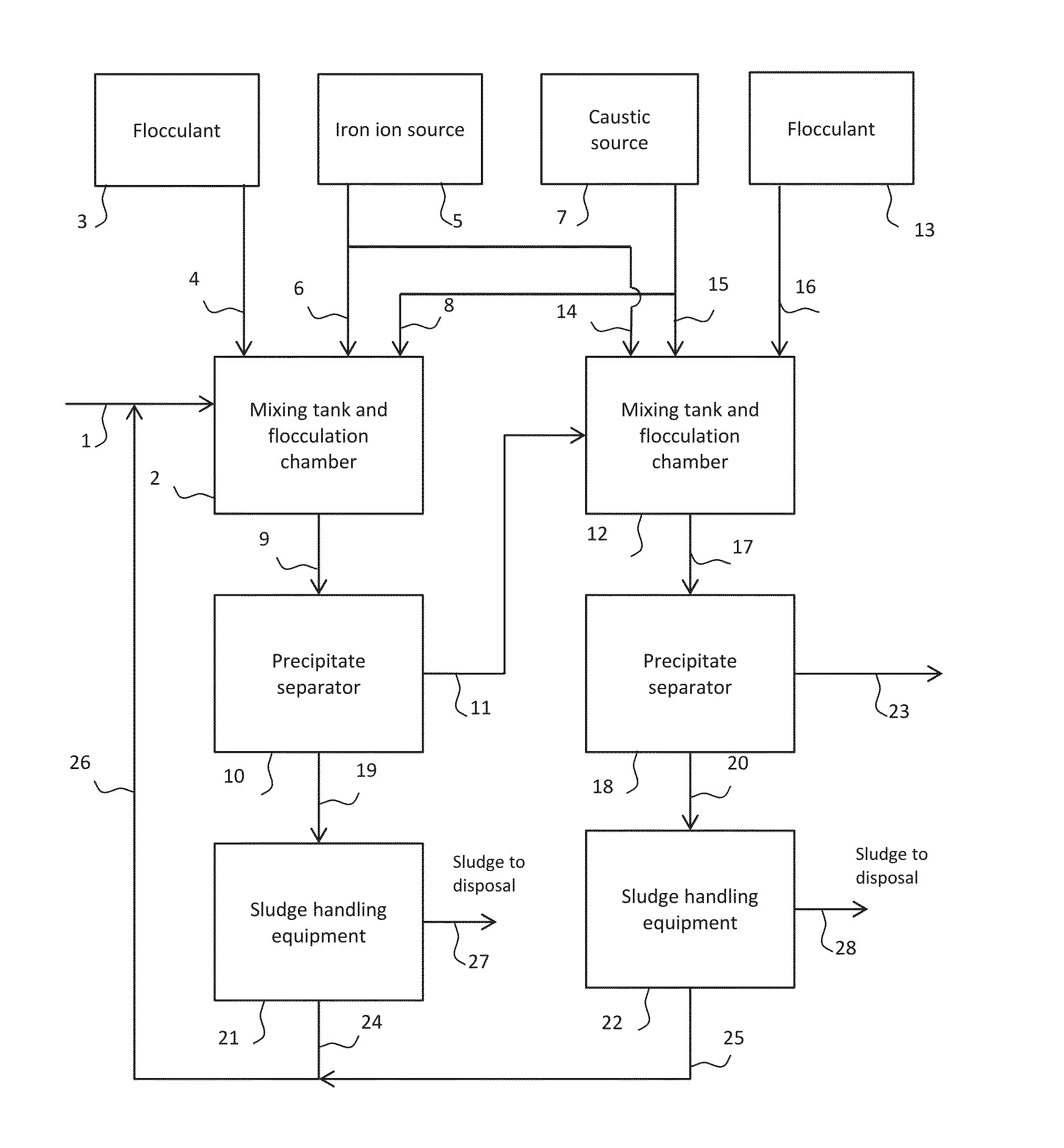

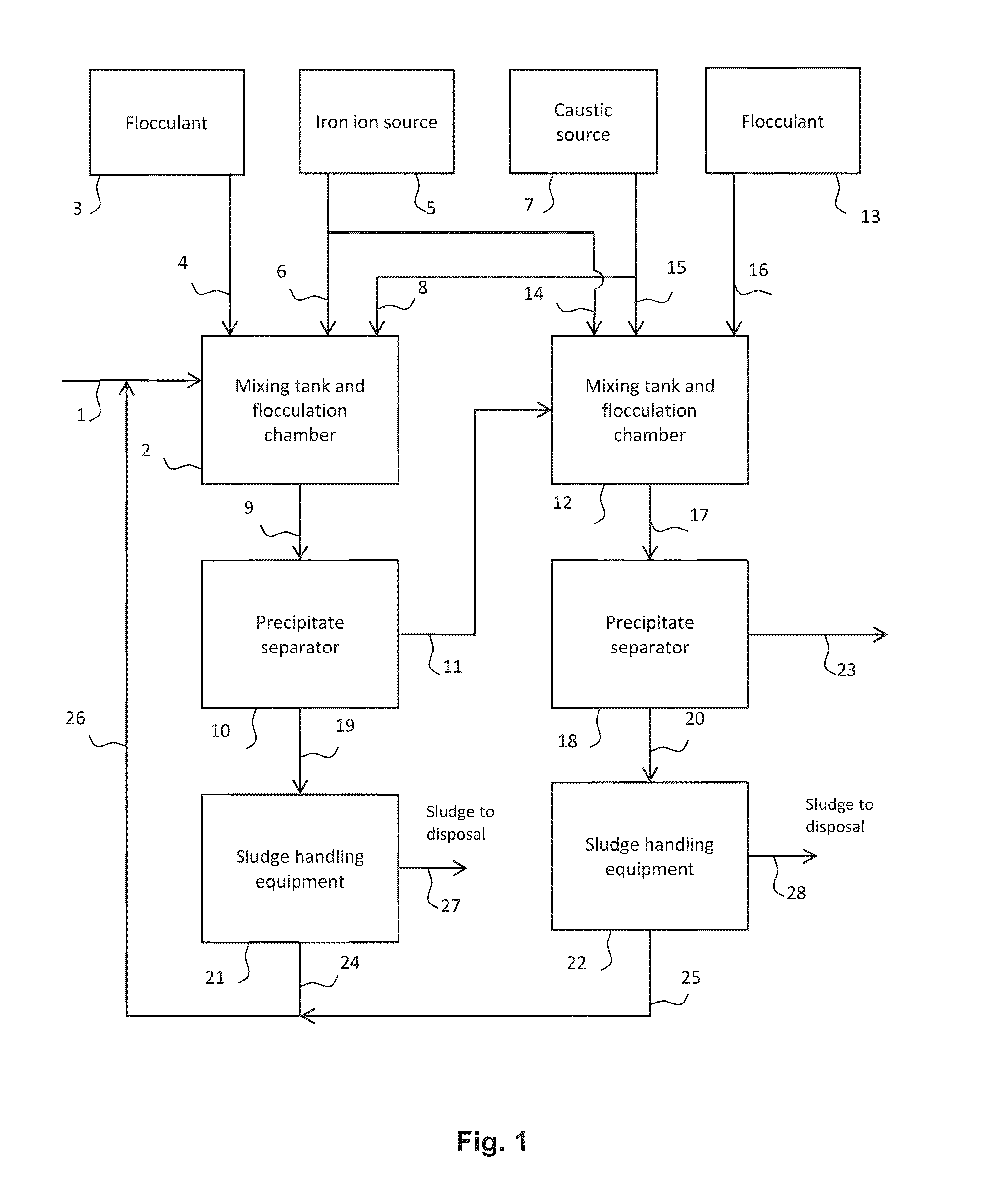

Removal of metals from wastewater

InactiveUS20160159669A1Reduce concentrationTreatment using aerobic processesWater contaminantsBillionthParticulates

A method for effecting a comprehensive removal of heavy metals from wastewater in a two stage process in which the wastewater is contacted in a first stage with a source of ferric ions under mildly acidic conditions (pH 5 to pH 8), preferably followed by the removal of the precipitated solids using a solid-liquid separation; a second stage follows in which the wastewater from the first step is contacted with a source of ferric ions under alkaline conditions (pH 8+) followed by the removal of the precipitated solids using a second solid-liquid separation. Used in conjunction with an initial oxidation step, the present method makes possible the removal of a whole suite of heavy metals present in both the anionic and cationic form in refinery wastewater. The treatment also removes metal compounds in the particulate phase. Metals concentrations can be significantly decreased from the mid to high ppb (parts per billion) range down to the low ppb range to meet the quality criteria for discharge.

Owner:EXXON RES & ENG CO

High-purity ammonia production device

ActiveCN104709925AWork lessAmmonia preparation/separationAmmonia productionActivated carbon filtration

The invention discloses a high-purity ammonia production device. The device is prepared by connecting the following components in sequence through pipelines: an ammonia raw material tank, a potassium-sodium alloy tank, a diaphragm compression pump, a condenser, a gas-liquid separation tank, and an ammonia finished product tank. An active carbon filter is arranged in the gas-liquid separation tank, the condenser and the gas-liquid separation tank are put in a refrigerating box, and the potassium-sodium alloy tank is the core component of the high-purity ammonia production device and is full of potassium-sodium alloy, which is prepared by melting high purity potassium and sodium together according to a certain ratio. The provided production device can be co-used with a distillation tower, a rectifying tower, and the like. When ammonia gas goes through the potassium-sodium alloy tank, gas containing the oxygen element such as oxygen gas, water, carbon dioxide, carbon monoxide, and the like is absorbed by the potassium-sodium alloy, the content of oxygen in the forms of oxygen gas, water, carbon dioxide, carbon monoxide, and the like is reduced to the ppb (part per billion) level, and the provided production device is suitable for producing high-purity ammonia gas.

Owner:HUNAN HIEND PRODUCTS CO LTD

Method and apparatus for measuring purity of noble gases

InactiveUS20070181818A1Accurately and quickly impurityQuickly and accurately measuringMaterial analysis using wave/particle radiationColor/spectral properties measurementsBillionthNoble gas

A device for detecting impurities in a noble gas includes a detection chamber and a source of pulsed ultraviolet light. The pulse of the ultraviolet light is transferred into the detection chamber and onto a photocathode, thereby emitting a cloud of free electrons into the noble gas within the detection chamber. The cloud of electrons is attracted to the opposite end of the detection chamber by a high positive voltage potential at that end and focused onto a sensing anode. If there are impurities in the noble gas, some or all of the electrons within the cloud will bond with the impurity molecules and not reach the sensing anode. Therefore, measuring a lower signal at the sensing anode indicates a higher level of impurities while sensing a higher signal indicates fewer impurities. Impurities in the range of one part per billion can be measured by this device.

Owner:CONSTELLATION TECH

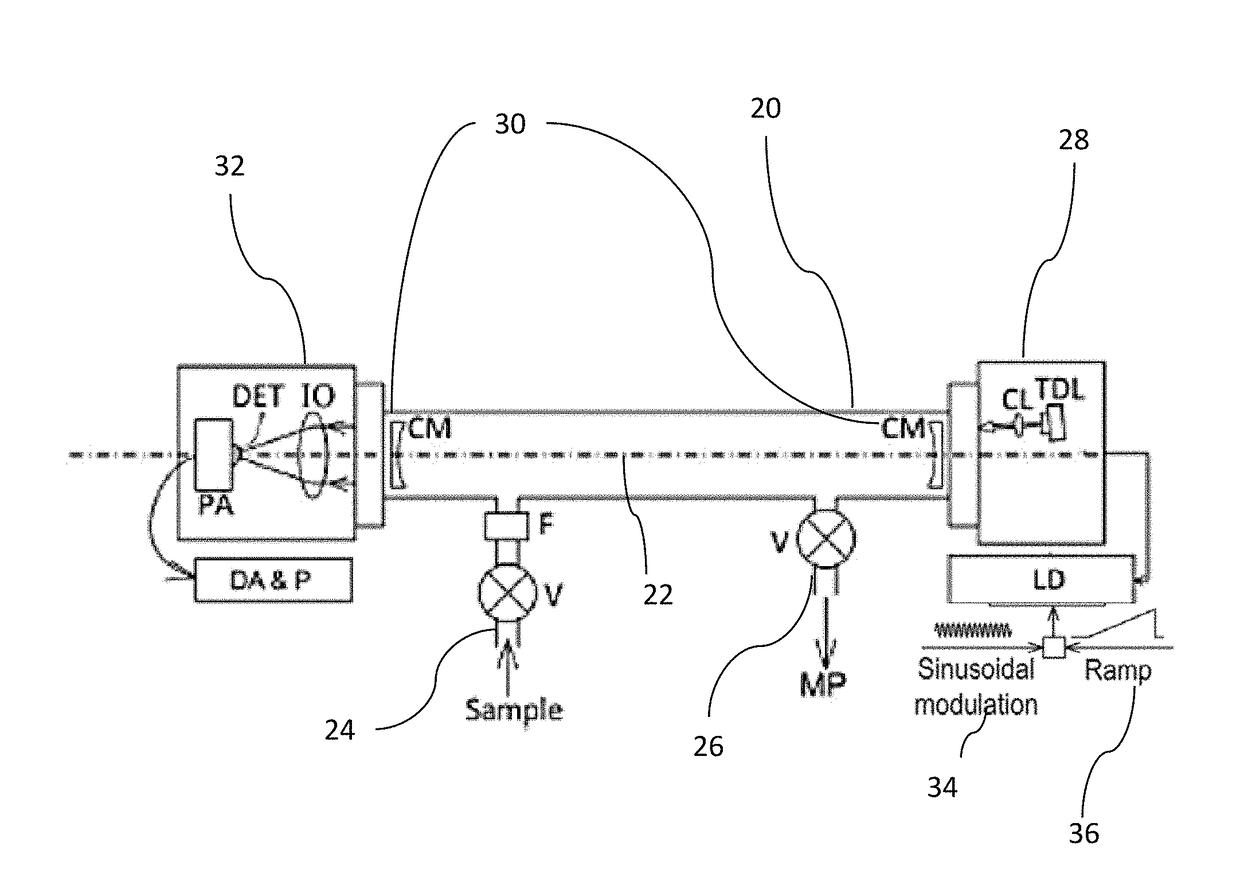

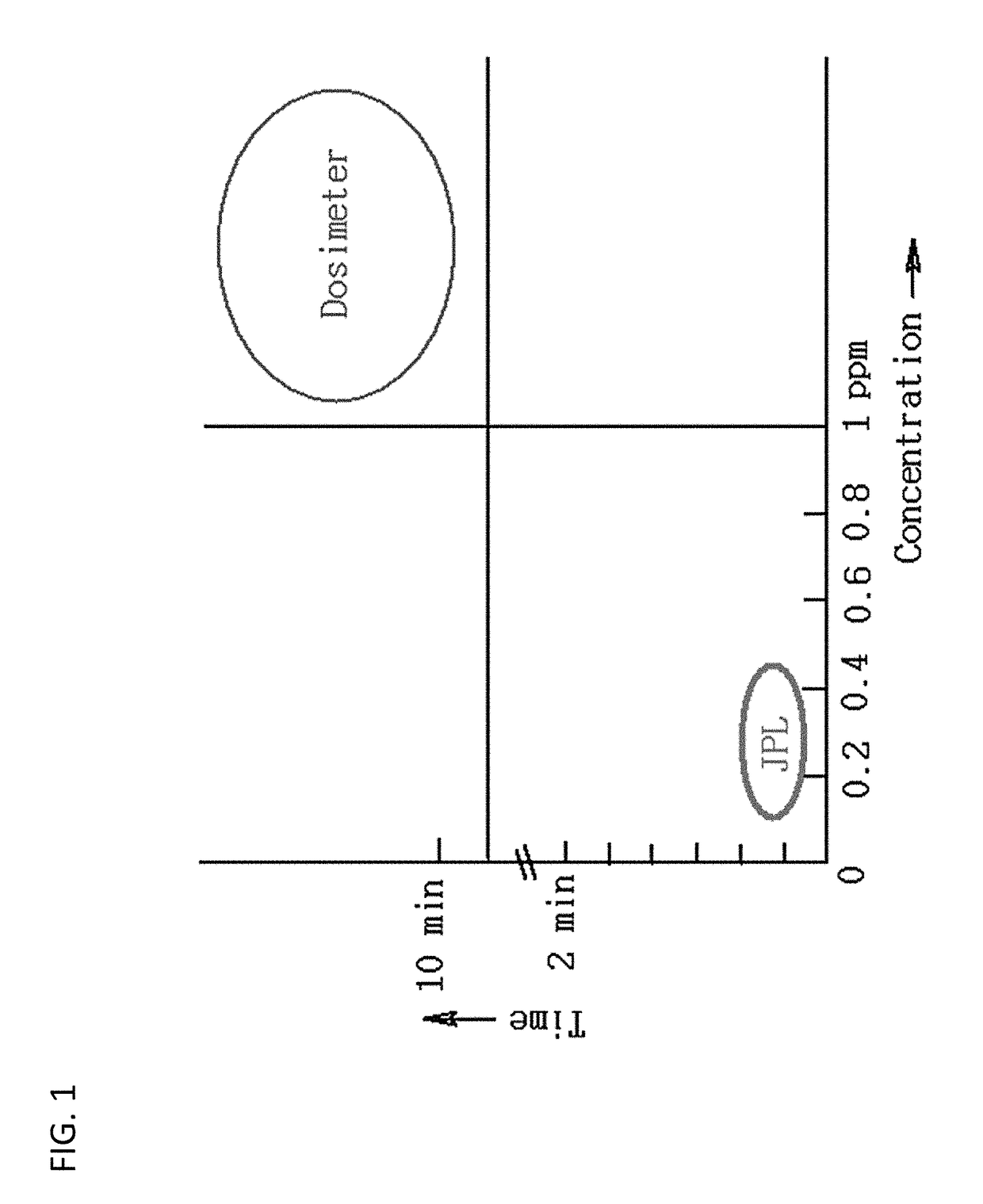

Method and Apparatus for the Spectroscopic Detection of Low Concentrations of Hydrogen Sulfide Gas

ActiveUS20180252641A1Maximize cumulative optical path lengthMaximizing optical-path lengthAbsorption/flicker/reflection spectroscopyColor/spectral properties measurementsPath lengthVolatiles

Spectroscopic apparatus and methods incorporating a gas sensor configured to detect low concentration gases, including gases that are hazardous volatiles are provided. Low concentration gases can comprise gases where detection of concentrations on the order of parts-per-million (ppm), and in many embodiments part-per-billion (ppb) is required. The gas may be a species, such as, for example hydrogen sulfide (H2S) that may be produced in drilling and / or volcanic eruptions. The spectroscopic apparatus and methods are configured to operate in particular atmospheres where gas detection can be challenging, such as in ambient air and / or in space where various contaminants may be present. The spectroscopic apparatus and methods may incorporate a long path length detector, such as, for example, a cavity-enhanced absorption spectrometer. The methods and apparatus further incorporate a wavelength modulation technique to improve the signal-to-noise ratio.

Owner:CALIFORNIA INST OF TECH

Method and materials for purifying hydride gases, inert gases, and non-reactive gases

InactiveUS7033418B2Selective and effective removalEfficient removalGas treatmentOther chemical processesBillionthReactive gas

A process for removing trace amounts of moisture and / or one or more impurities from contaminated hydride, inert and non-reactive gases, thus decreasing the concentration of the impurities to parts-per-billion (ppb) or parts-per-trillion (ppt) levels. The gas purifier materials of this invention include thermally activated aluminas, said aluminas including organic alumina materials, modified organic alumina materials, and modified inorganic aluminas. The thermally activated alumina materials of this invention are activated by heating the alumina material at a temperature between about 50° C.–1000° C. in an inert or non-inert atmosphere or in a vacuum and maintaining the activated material in the inert or non-inert atmosphere or in a vacuum atmosphere subsequent to said activation but prior to use.

Owner:MATHESON TRI GAS INC

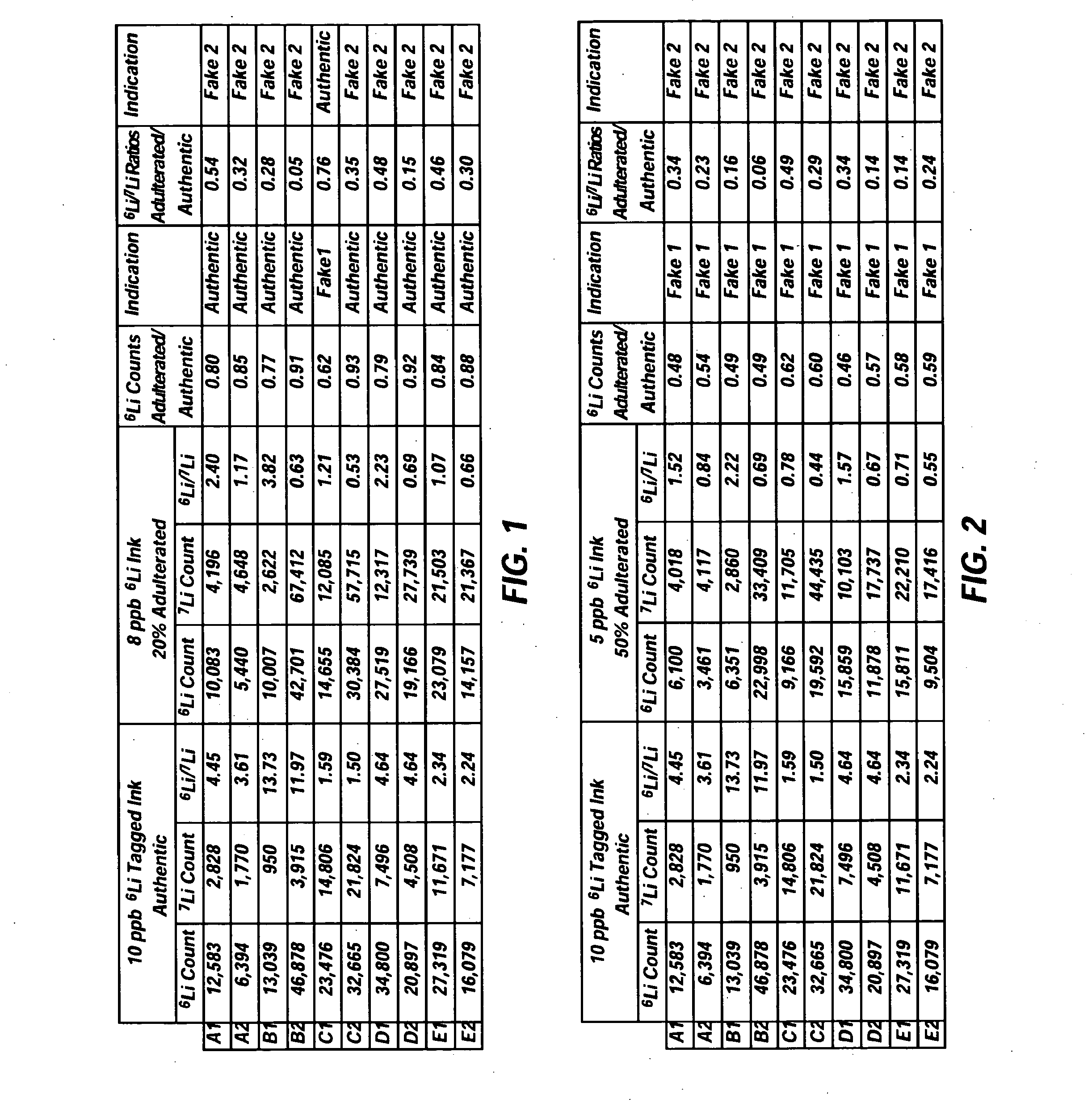

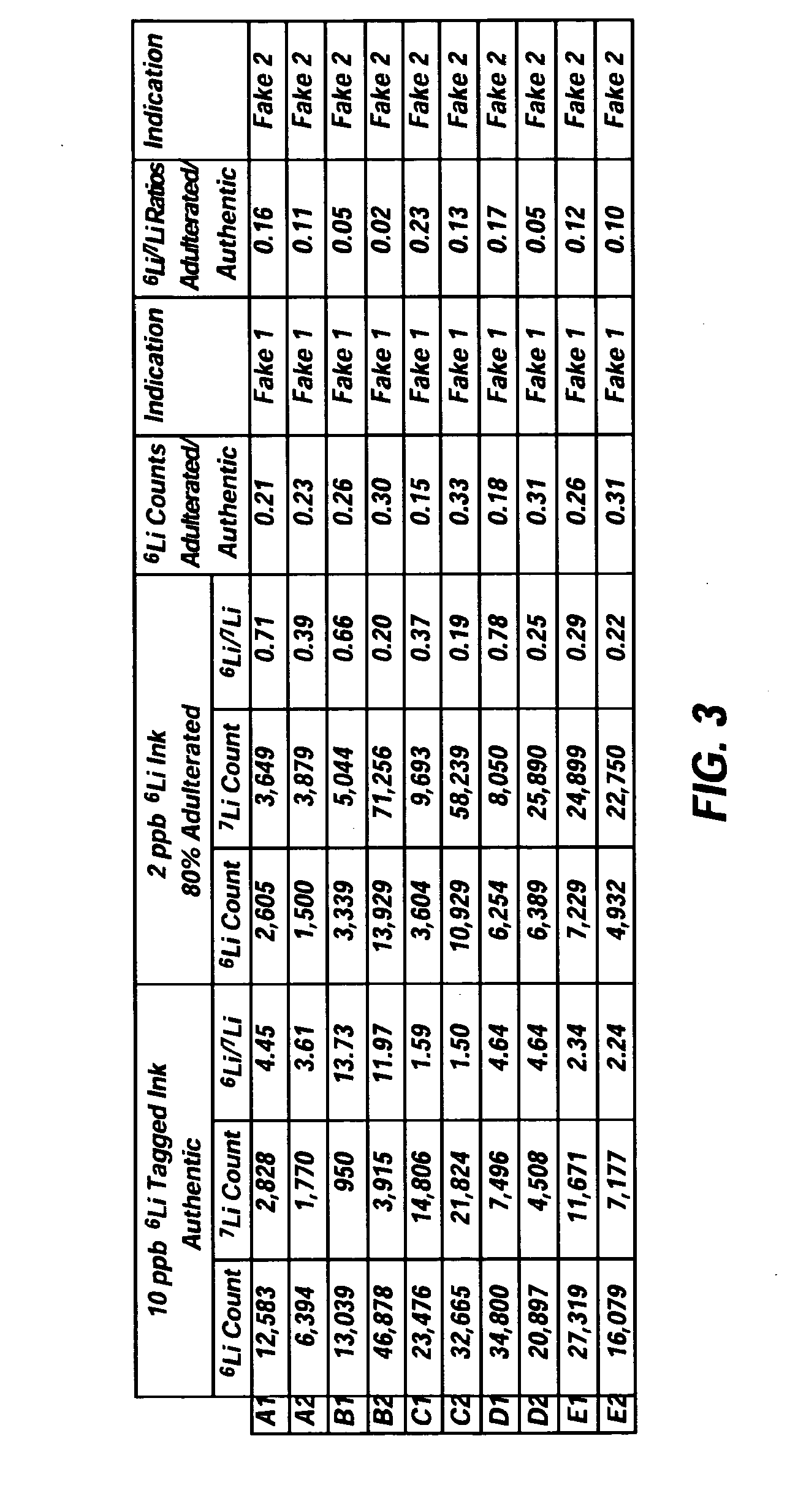

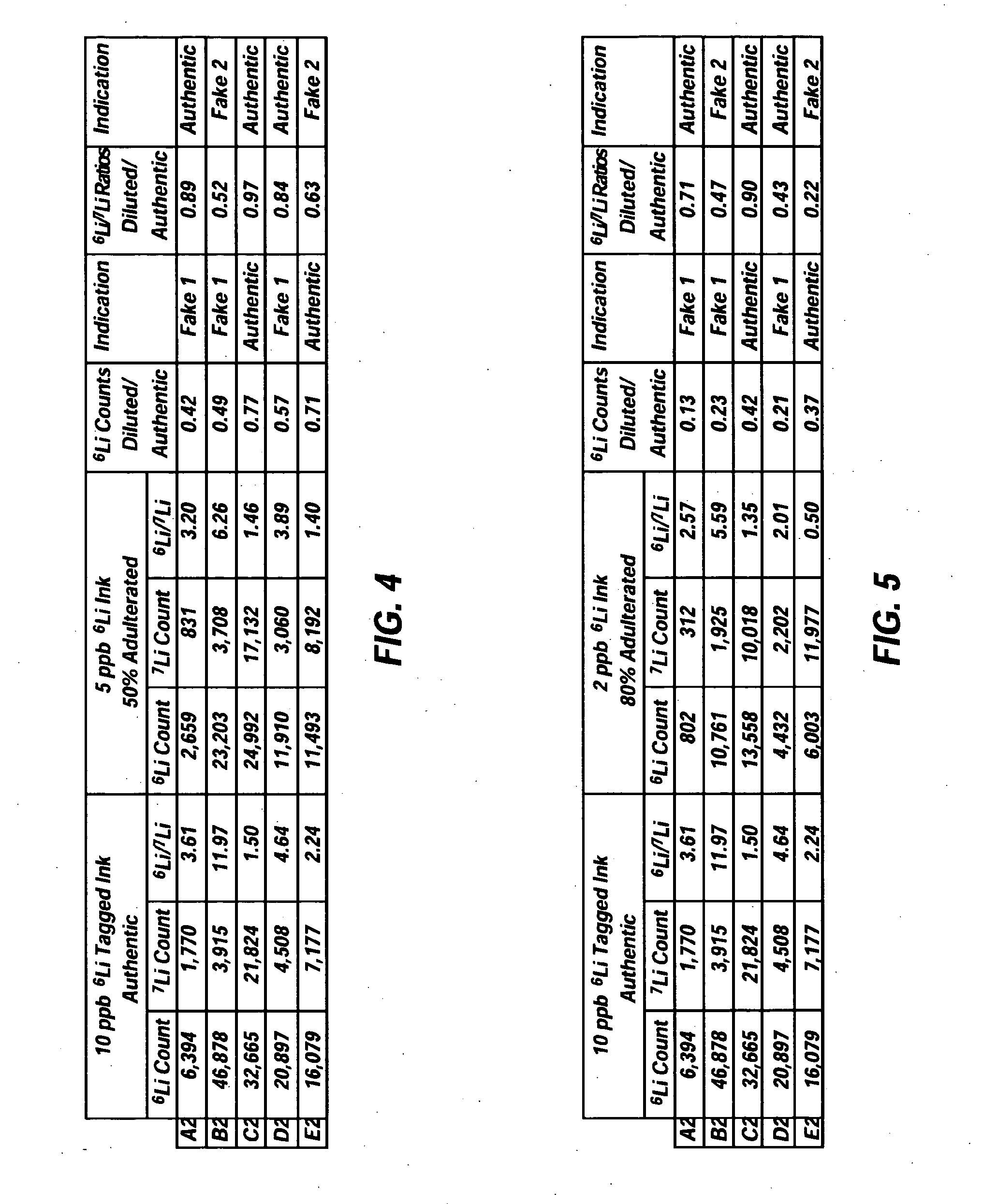

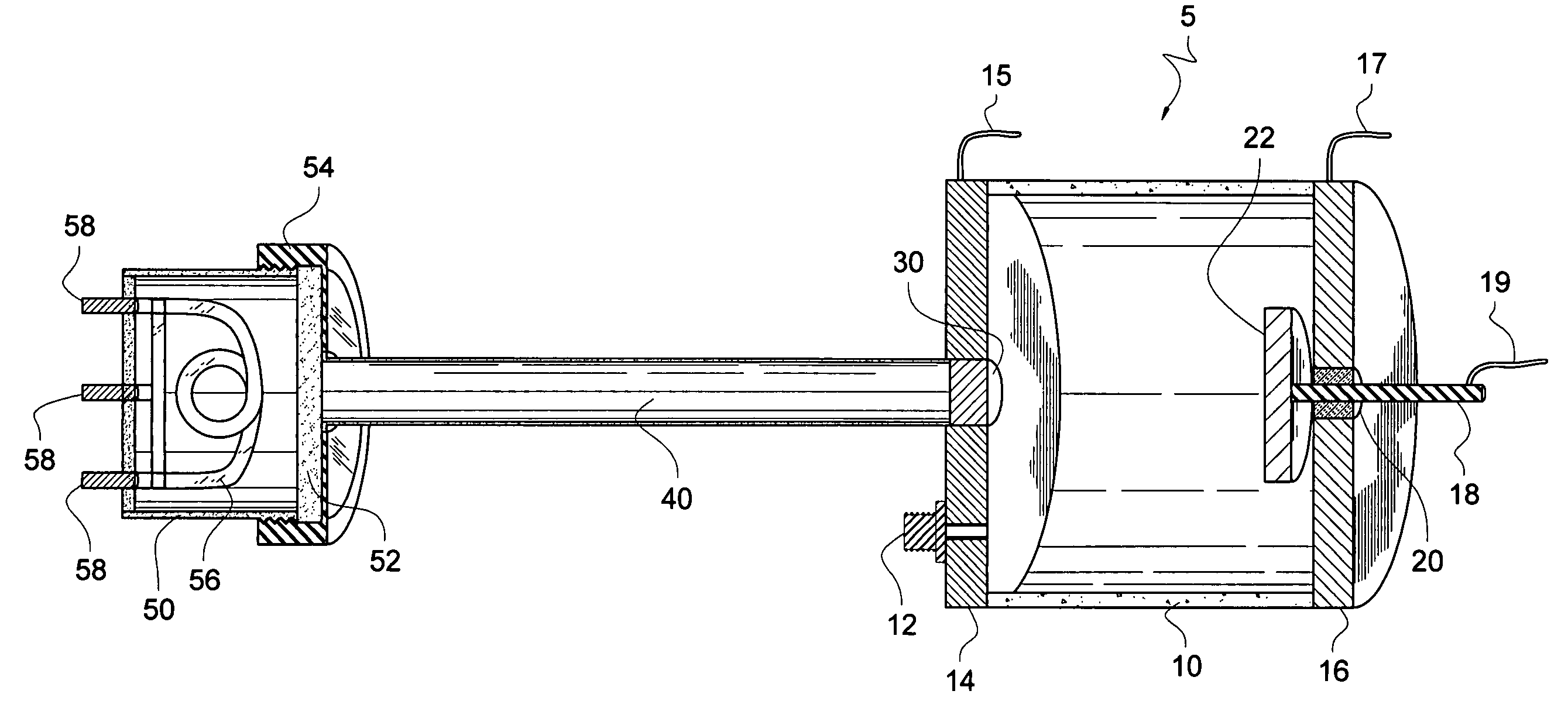

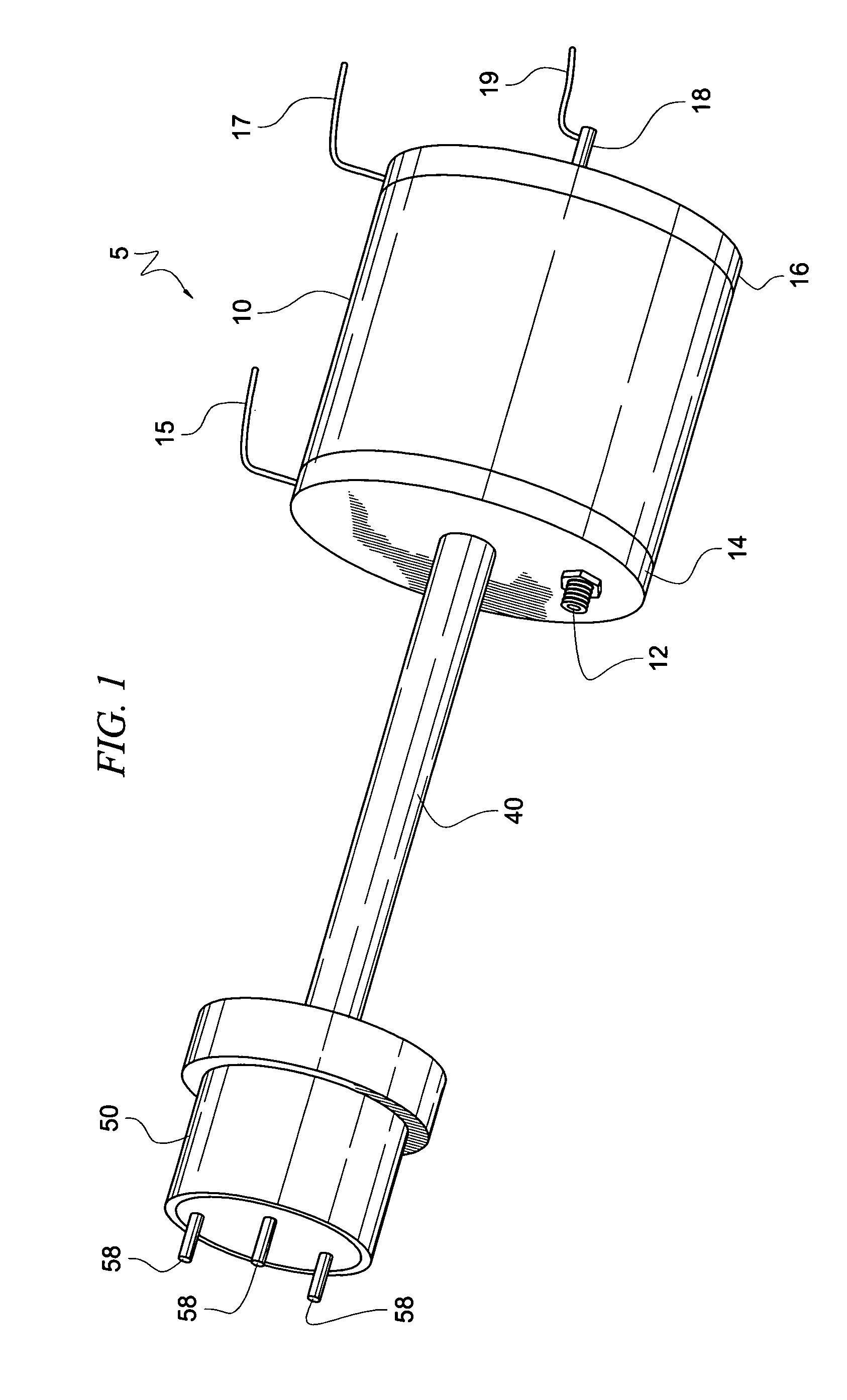

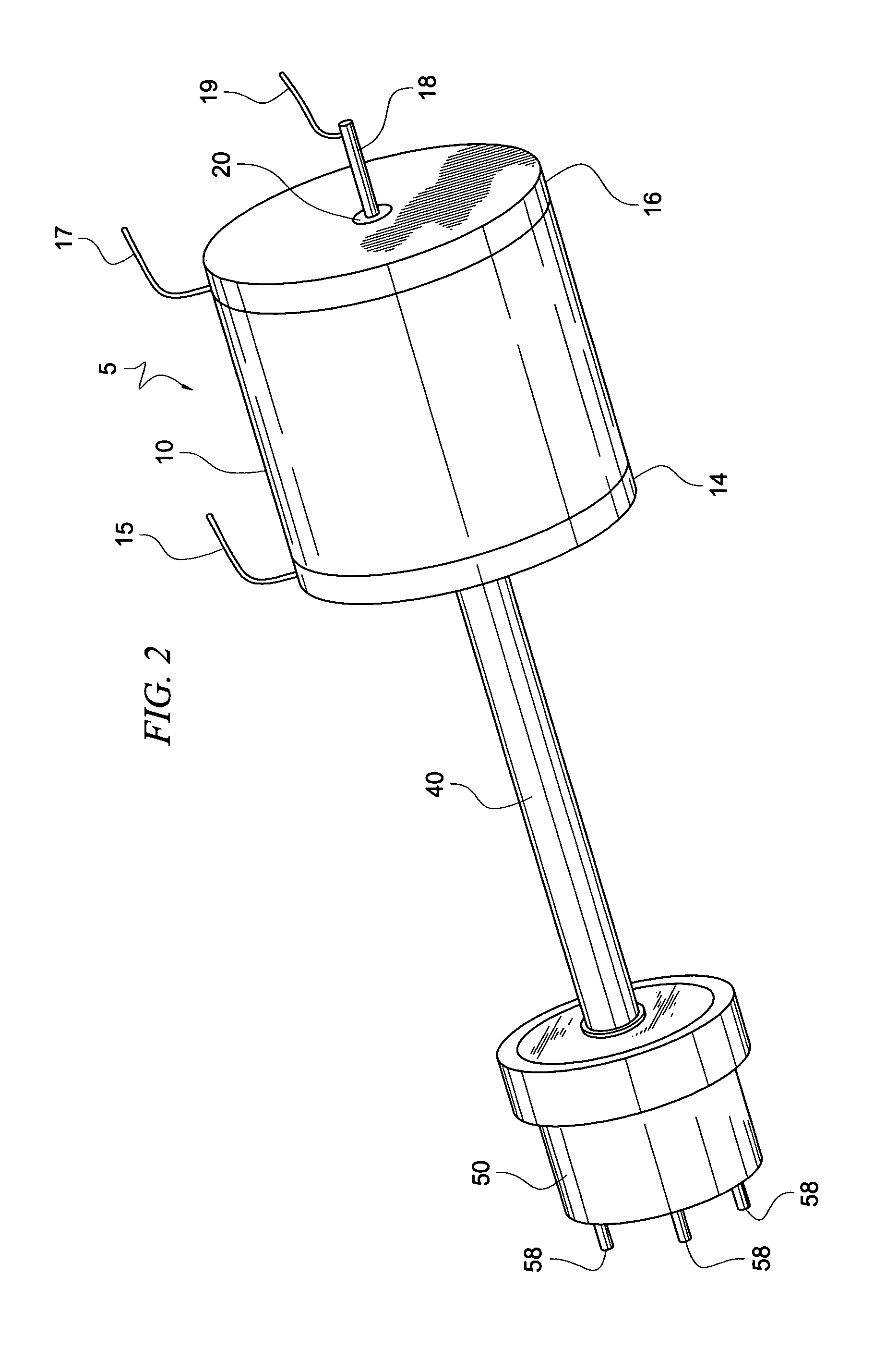

Methods and systems for identifying ink

ActiveUS20130221277A1Deterring the incidence of ink counterfeitingMaterial analysis by optical meansPattern printingBillionthIsotope

An ink composition includes a colorant visible under visible light and a tagging composition, including a carrier and a detectable marker dispersed or dissolved in the carrier. The detectable marker is an isotope of an element, the isotope being present in the ink composition in a concentration ranging from about 1 parts per billion (ppb) to about 1000 ppb.

Owner:HEWLETT PACKARD DEV CO LP

Method and apparatus for measuring purity of noble gases

InactiveUS7351981B2Accurately and quickly impurityQuickly and accurately measuringMaterial analysis using wave/particle radiationColor/spectral properties measurementsBillionthNoble gas

A device for detecting impurities in a noble gas includes a detection chamber and a source of pulsed ultraviolet light. The pulse of the ultraviolet light is transferred into the detection chamber and onto a photocathode, thereby emitting a cloud of free electrons into the noble gas within the detection chamber. The cloud of electrons is attracted to the opposite end of the detection chamber by a high positive voltage potential at that end and focused onto a sensing anode. If there are impurities in the noble gas, some or all of the electrons within the cloud will bond with the impurity molecules and not reach the sensing anode. Therefore, measuring a lower signal at the sensing anode indicates a higher level of impurities while sensing a higher signal indicates fewer impurities. Impurities in the range of one part per billion can be measured by this device.

Owner:CONSTELLATION TECH

Preparation of tobacco extract

A method for preparation of smoke extract from wood tar for flavouring and colouring of food products is disclosed. The smoke extract is with the present method produced by means of supercritical extraction of fractions of the wood tar. The extractions solvent, such as carbon dioxide, has very good properties of entraining and resolving the required fractions of the wood tar, and it is relatively simple to separate the resolved components in the retrieving process, as the different components have different solubility at different supercritical and subcritical conditions. Thus, a smoke extract containing less than 10 ppb (parts per billion) of benzo (a) pyrene and less than 20 ppb of benzo (a) athracene may be obtained. In one embodiment, the wood tar is subject to a separation process prior to the supercritical extraction to remove a substantial part of the unwanted components.

Owner:基姆·普拉施克

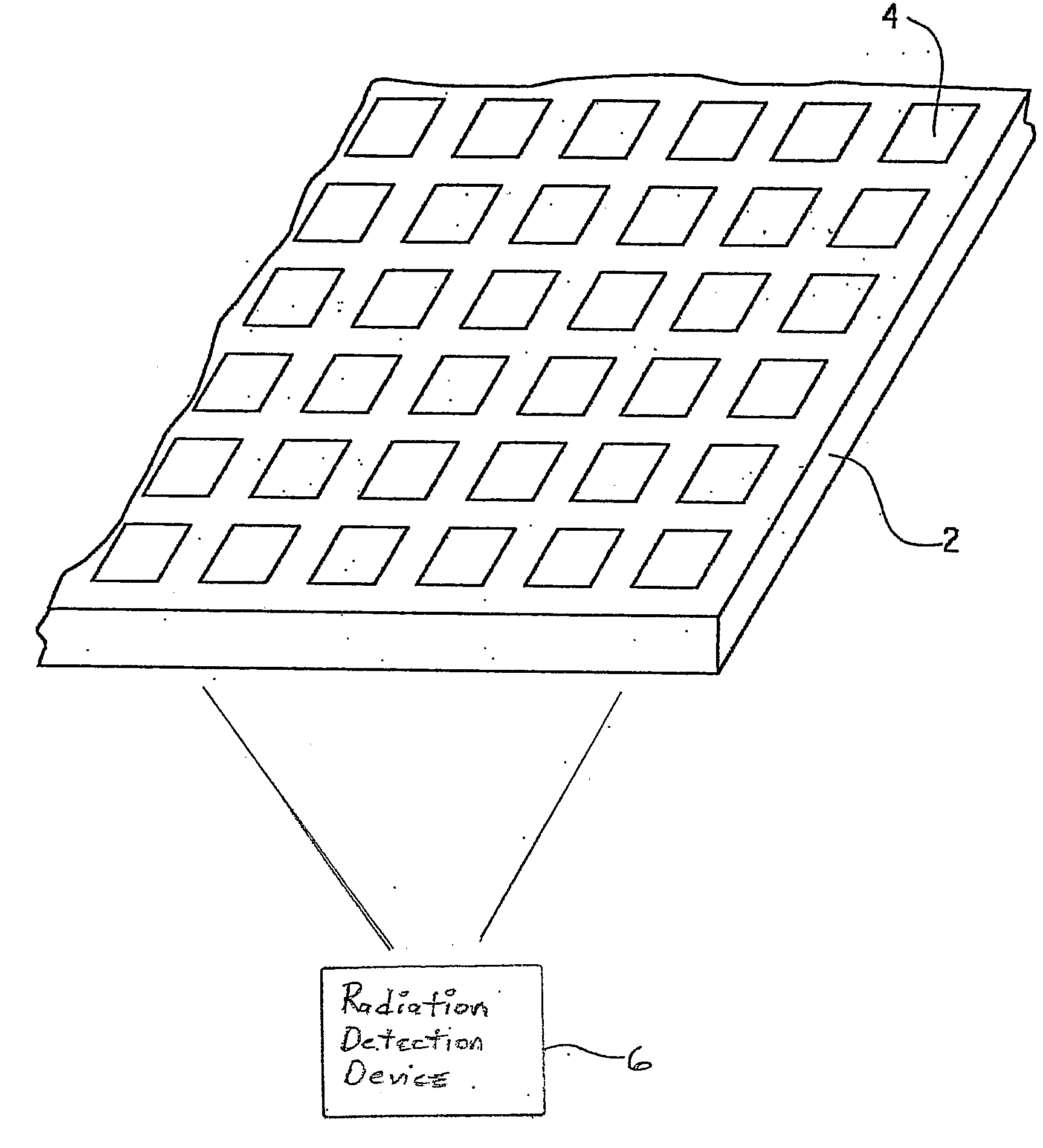

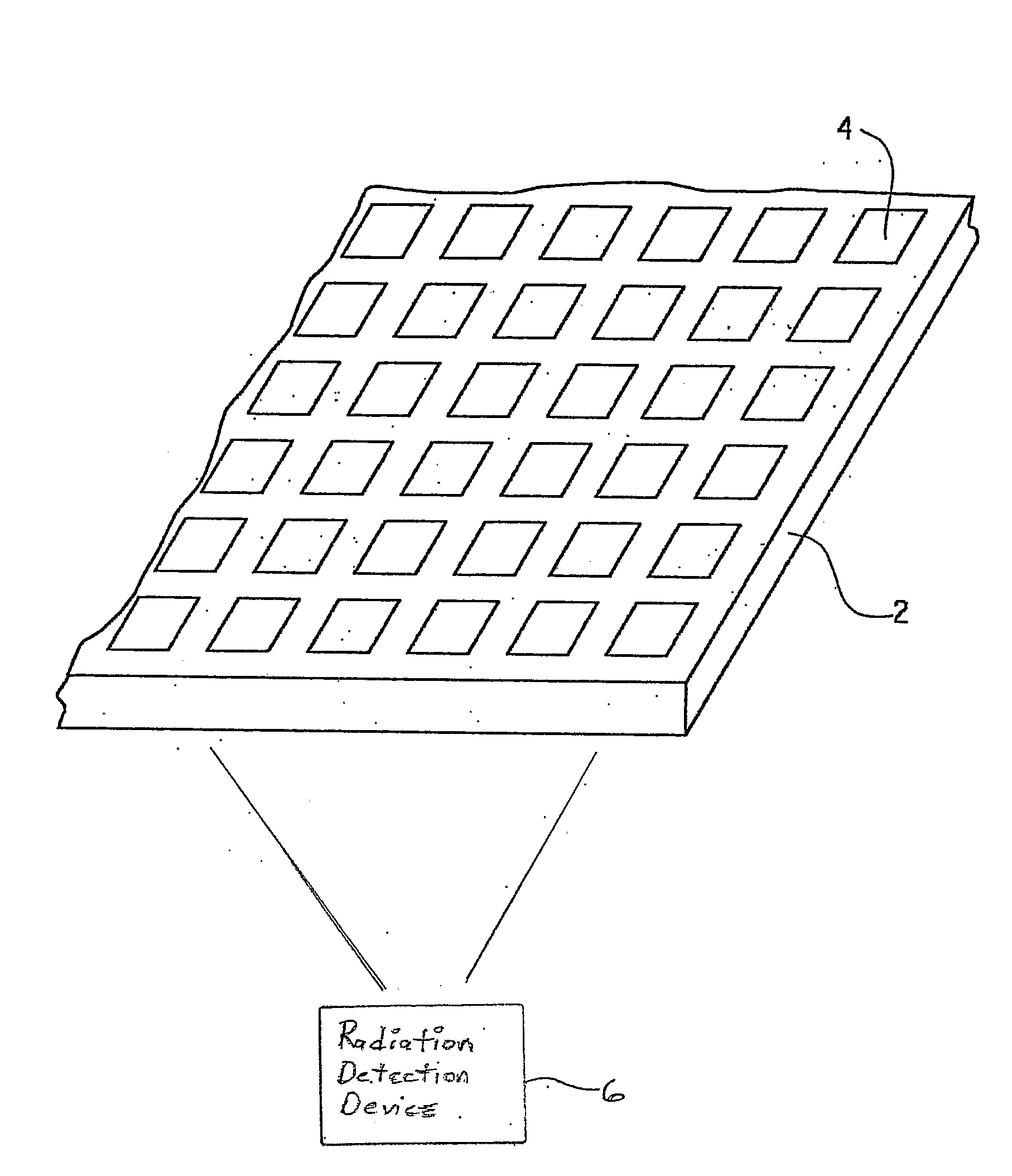

Radiation detector crystal and method of formation thereof

A radiation detector crystal is made from CdxZn1-xTe, where 0≦x≦1; an element from column III or column VII of the periodic table, desirably in a concentration of about 1 to 10,000 atomic parts per billion; and the element Ruthenium (Ru), the element Osmium (Os) or the combination of Ru and Os, desirably in a concentration of about 1 to 10,000 atomic parts per billion using a conventional crystal growth method, such as, for example, the Bridgman method, the gradient freeze method, the electro-dynamic gradient freeze method, the so-call traveling heater method or by the vapor phase transport method. The crystal can be used as the radiation detecting element of a radiation detection device configured to detect and process, without limitation, X-ray and Gamma ray radiation events.

Owner:PULLTAPS SL +1

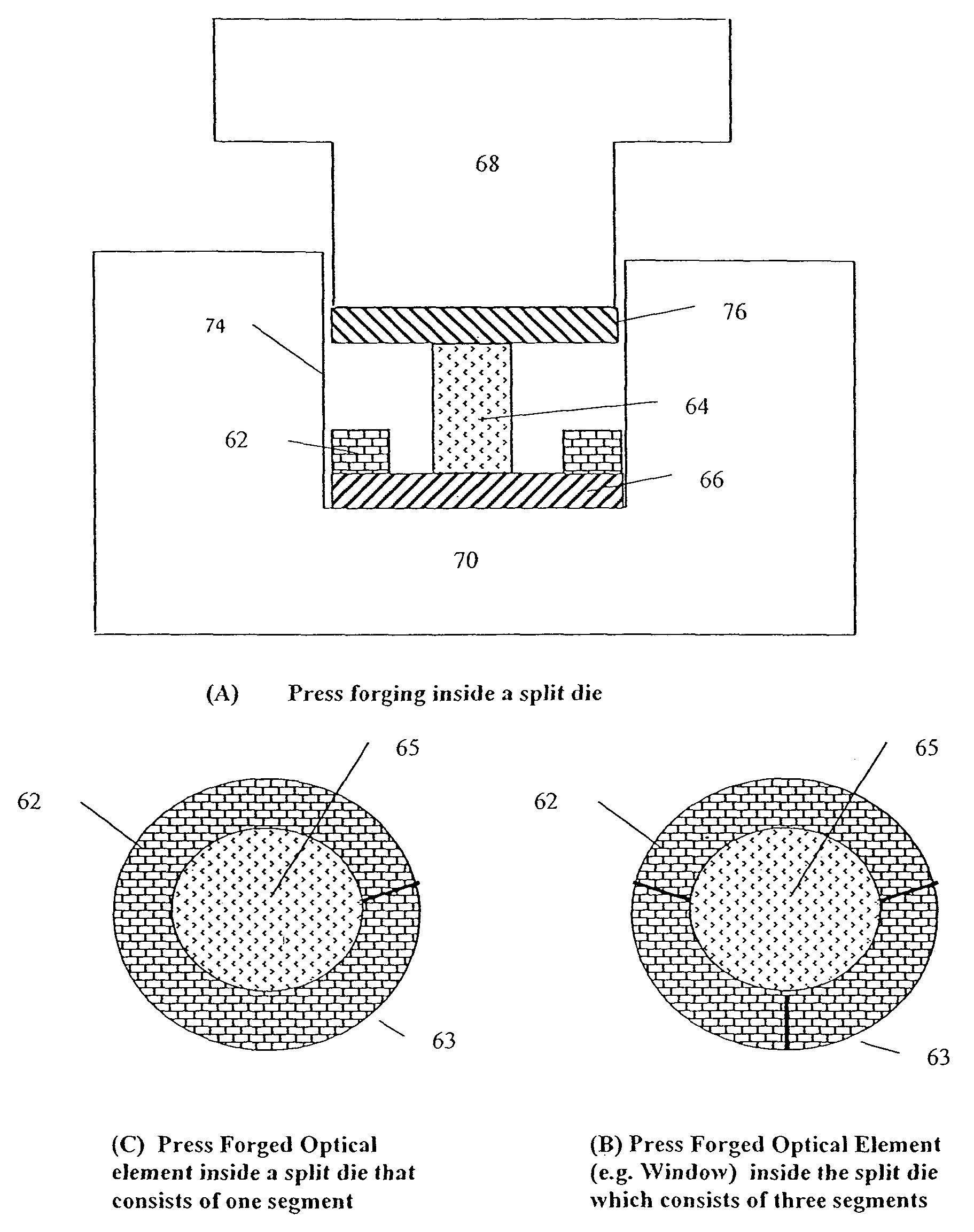

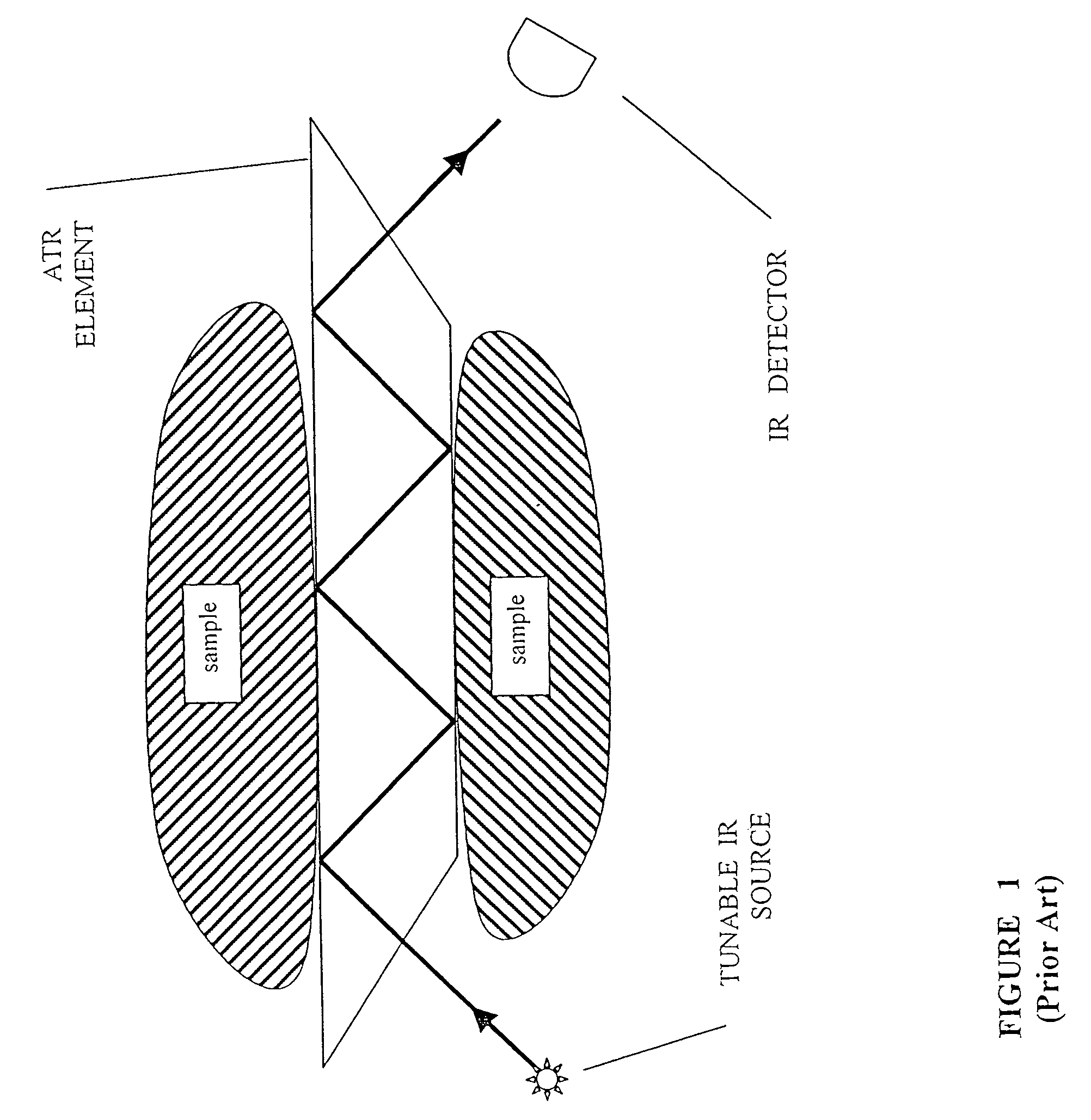

Forming transparent crystalline elements by cold working

InactiveUS7384581B2Easy to useChange hardnessScattering properties measurementsOptical articlesFiberRefractive index

An infrared optical element, and methods for its manufacture. The optical element is made by cold working an ingot of a soft crystalline ionic solid such as silver halide or a thallium halide inside a sacrificial split die. The solid preferably includes at most one part per million of metallic impurities and at most ten parts per million total impurities. Preferably, the Knoop hardness of the ionic solid is at most about 20, and the elongation ratio of the ionic solid is at least 10% at a temperature of 120-180° C. The optical element maybe a bulk element or a surface element. The optical element may be a refractive element, a diffractive element or a hybrid element. One such element is a flat sensor for attenuated total reflection spectroscopy. In one embodiment of the sensor, a thin layer of silver halide or thallium halide is formed by diffusion or deposition on the surface of a substrate having a lower index of refraction than the layer. The sensor also includes a mechanism for coupling infrared radiation in and out of the layer. The scope of the invention includes a cell for attenuated total reflection spectroscopy based on the sensor, and a spectrometer for attenuated total reflection spectroscopy based on the cell. It also includes an external sensor, which is connected to the spectrometer via two long infrared fibers, which enable measurements in remote locations.

Owner:KATZIR ABRAHAM

Preparation of Smoke Extract

A method for preparation of smoke extract from wood tar for flavouring and colouring of food products is disclosed. The smoke extract is with the present method produced by means of supercritical extraction of fractions of the wood tar. The extractions solvent, such as carbon dioxide, has very good properties of entraining and resolving the required fractions of the wood tar, and it is relatively simple to separate the resolved components in the retrieving process, as the different components have different solubility at different supercritical and subcritical conditions. Thus, a smoke extract containing less than 10 ppb (parts per billion) of benzo (a) pyrene and less than 20 ppb of benzo (a) athracene may be obtained. In one embodiment, the wood tar is subject to a separation process prior to the supercritical extraction to remove a substantial part of the unwanted components.

Owner:PLASCHKE KIM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com