Patents

Literature

693 results about "Mycotoxin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mycotoxin (from the Greek μύκης mykes, "fungus" and τοξικόν toxikon, "poison") is a toxic secondary metabolite produced by organisms of the fungus kingdom and is capable of causing disease and death in both humans and other animals. The term 'mycotoxin' is usually reserved for the toxic chemical products produced by fungi that readily colonize crops.

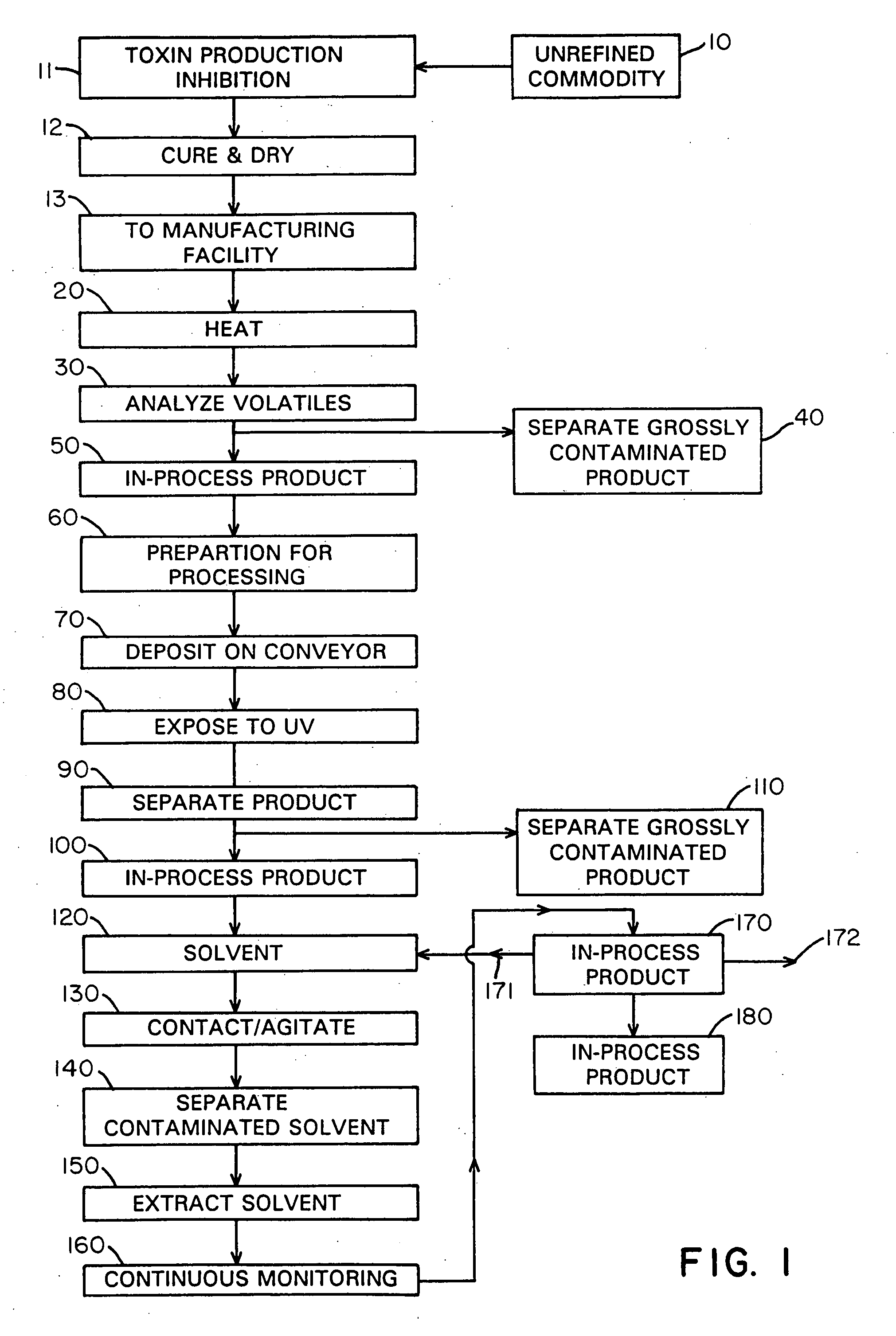

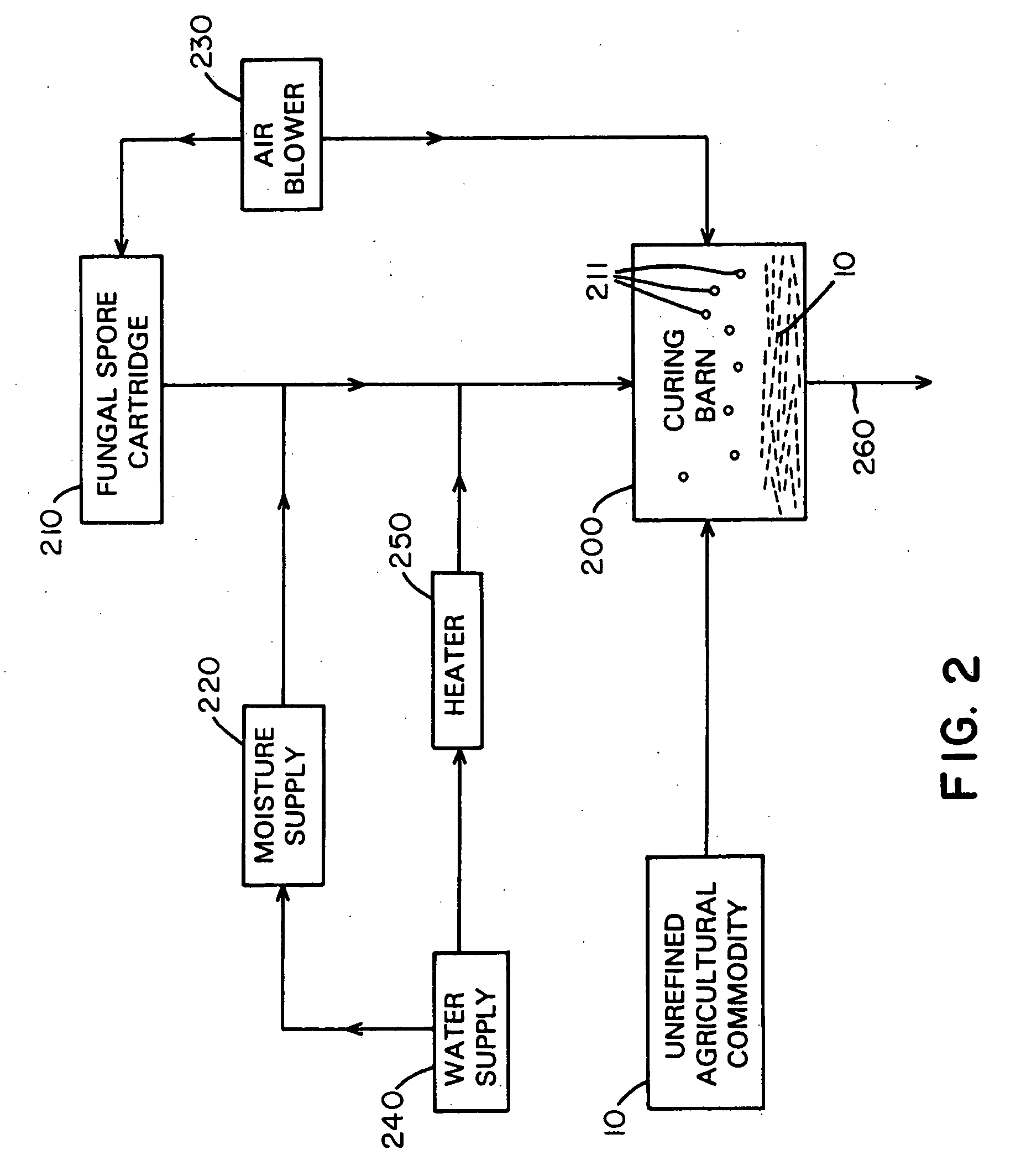

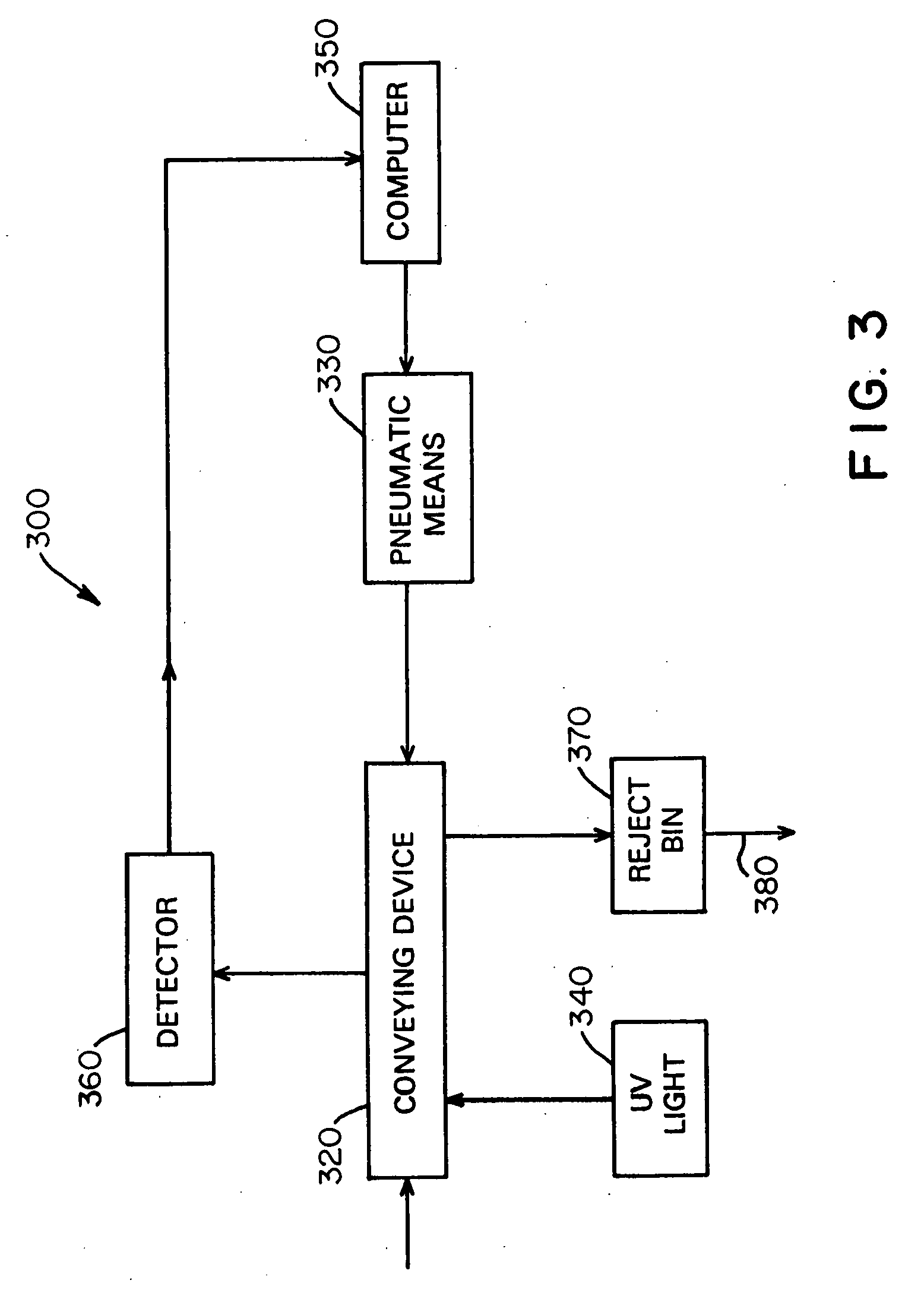

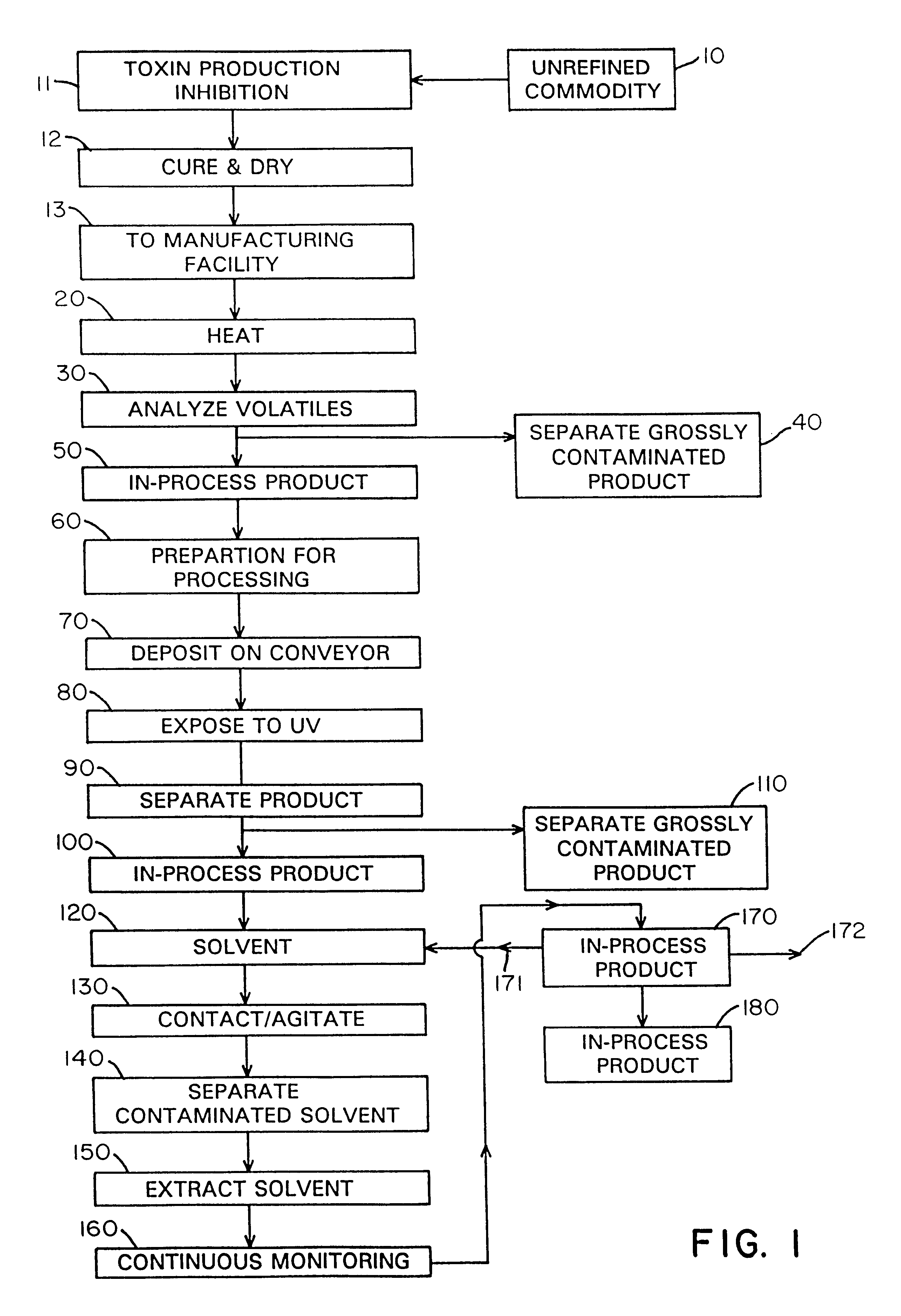

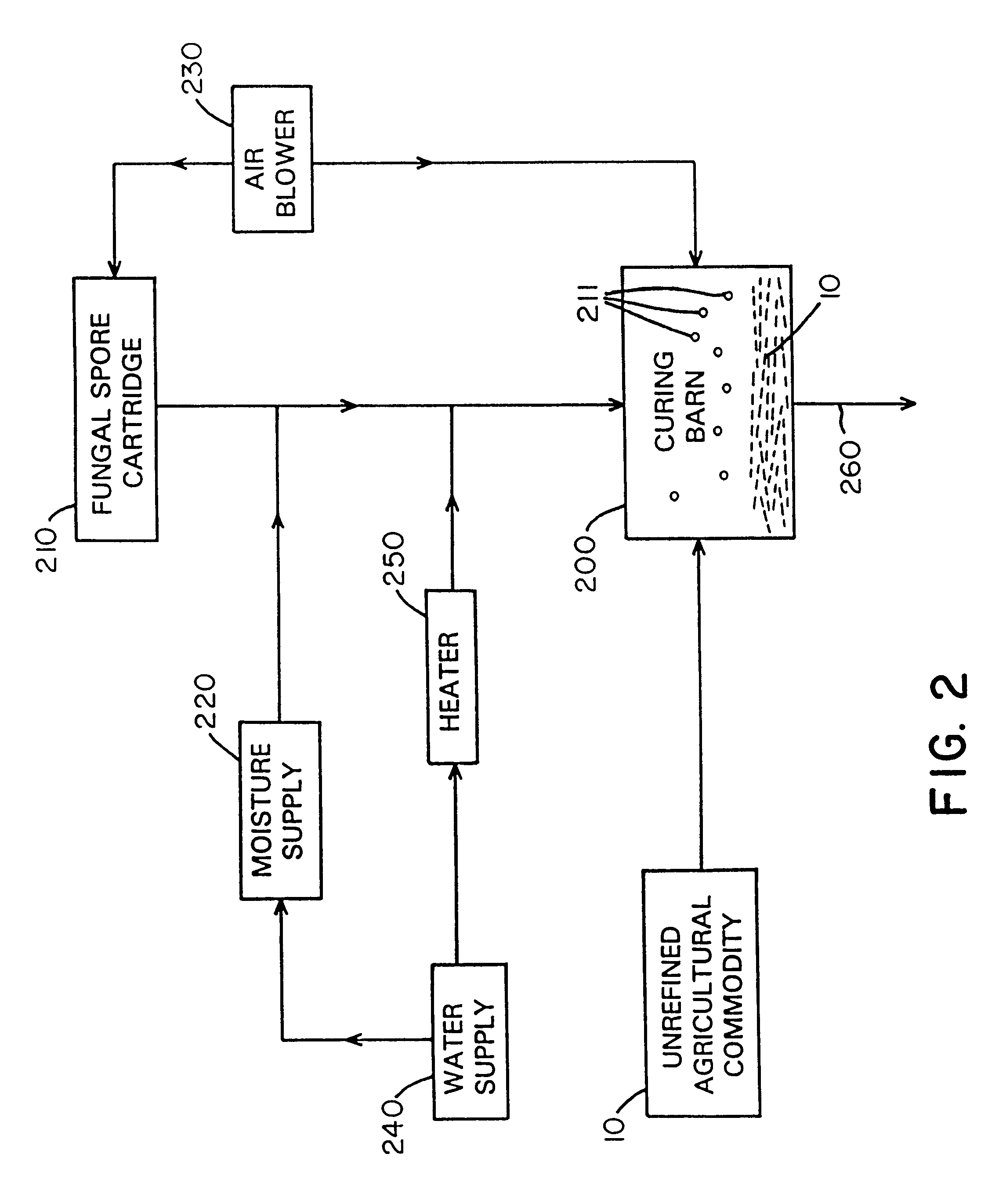

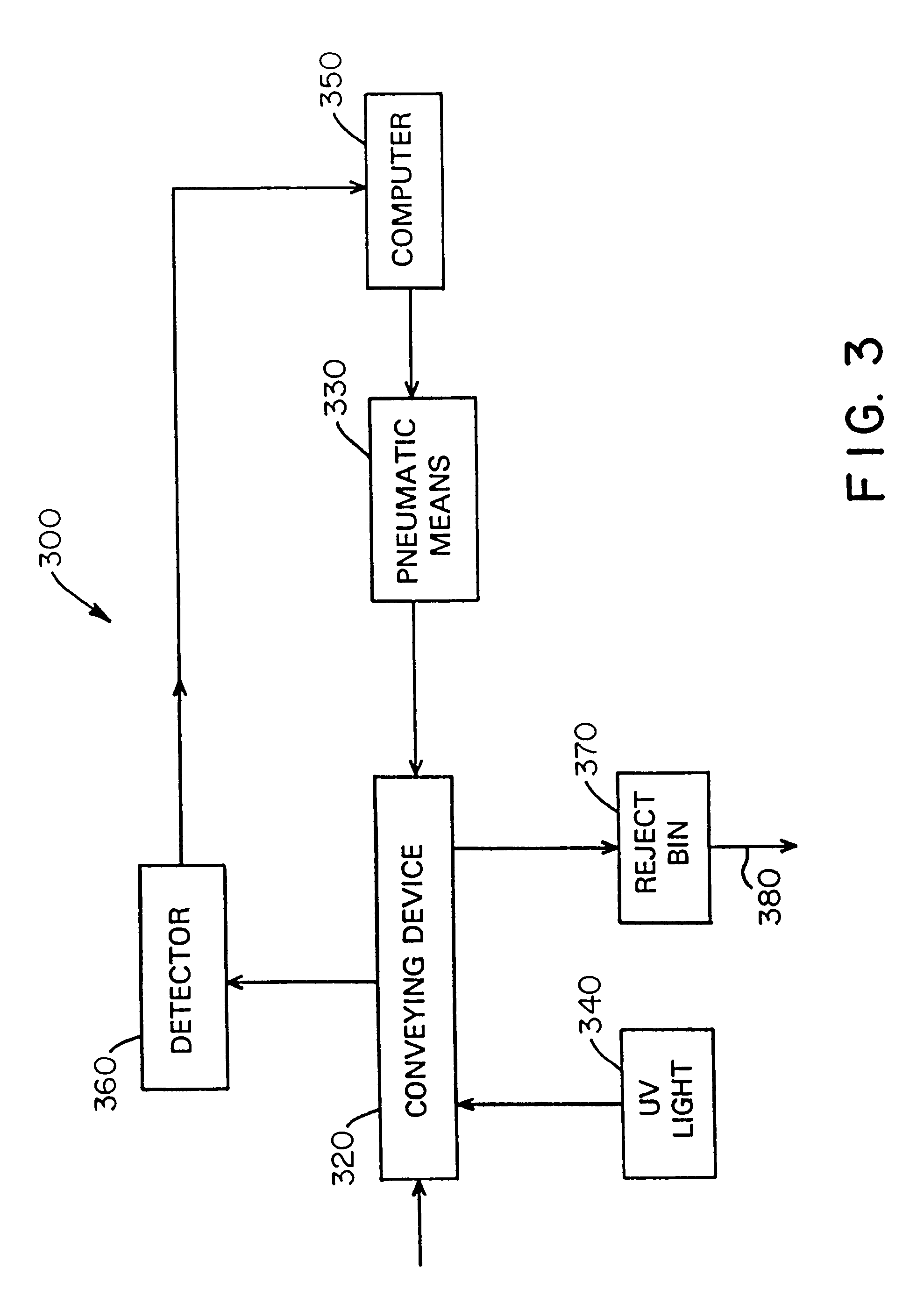

Method and system for continuous assay and removal of harmful toxins during processing of tobacco products

A process and system for continuous assay and removal of toxins from tobacco. Products such as tobacco contaminated with mycotoxins, particularly aflatoxins, and benzpyrene and its precursors, are subjected to treatment, generally in a solvent medium, to decontaminate the tobacco of the toxin. Continuous monitoring of all harmful toxins eluted from the cleaning solvent is performed by immunoantibody ultraviolet fluorescence, for example. A quality-control process ensures removal of harmful toxins from tobacco before further processing. Decontamination of extracted solvent streams and re-additives ensures safe reuse or disposal of the solvents and re-additives.

Owner:LANE KERRY SCOTT

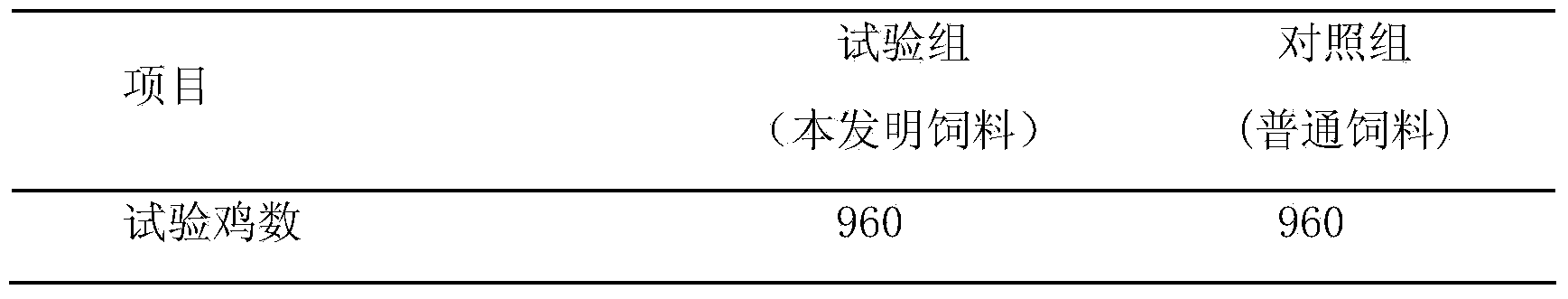

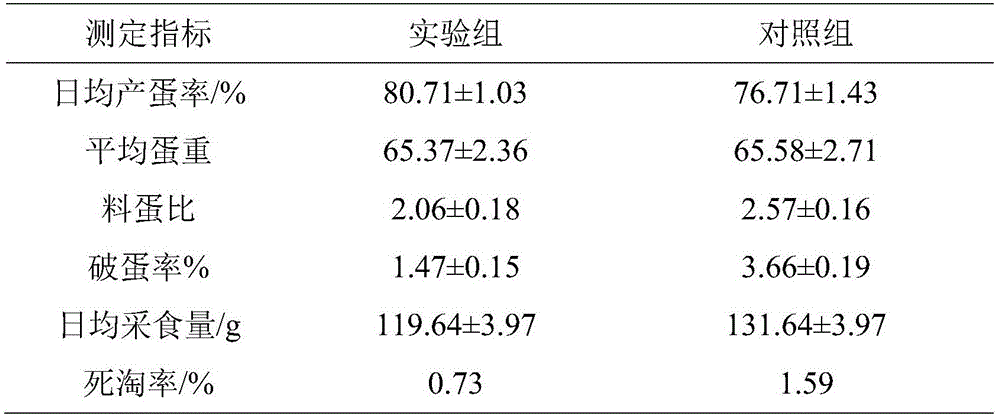

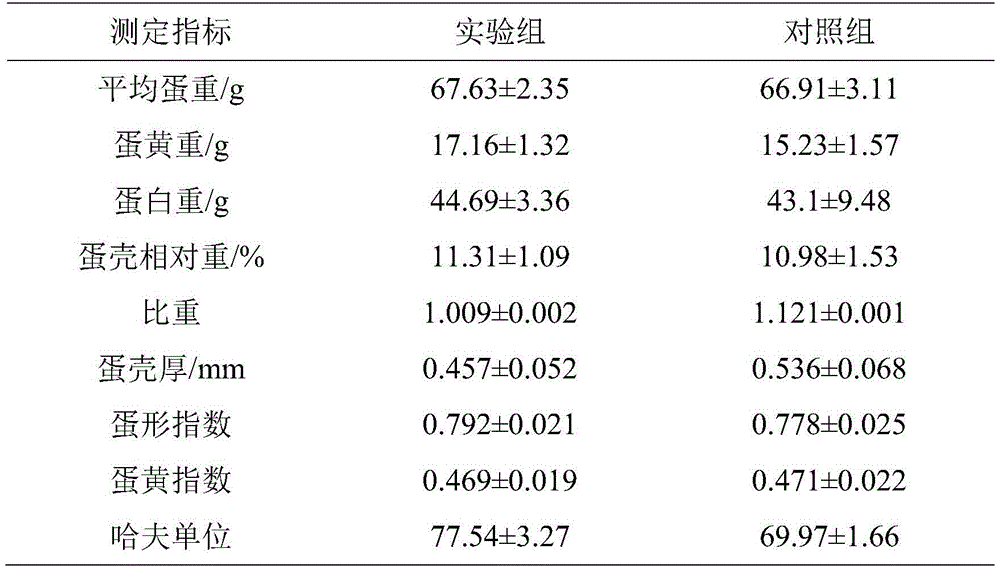

Laying hen composite premix

InactiveCN104106731AEffective pH adjustmentSoft textureFood processingAnimal feeding stuffFiberAnti nutrients

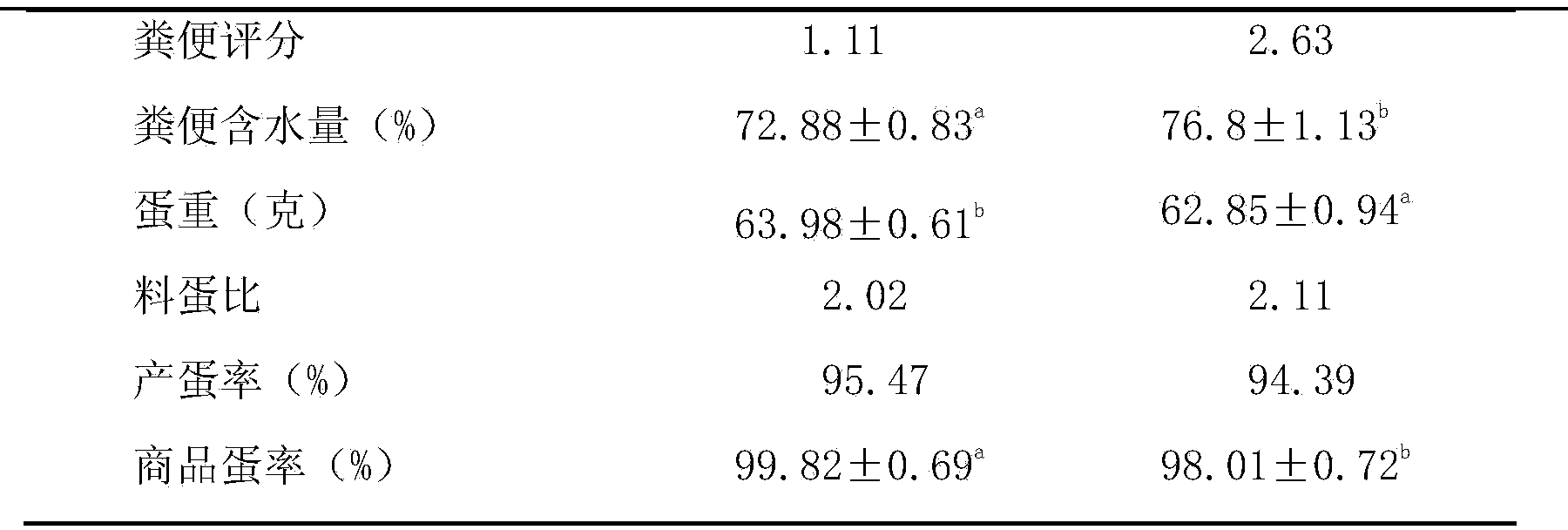

The invention discloses a laying hen composite premix, and belongs to the technical field of feed composition. A composite enzyme preparation containing beta-mannase, beta-glucanase, acidic proteinase, phytase, pectinase, and amylase is adopted to eliminate the anti-nutrient factors in soybean meal. Yeast cell wall type mycotoxin absorbent is used to effectively eliminate the hazardous factors that may affect the intestine health and are caused by using a large amount of corns. A stomach fortifying acid is used to effectively adjust the pH value of intestines. The used wood chips in the premix are soft and high in fiber content, do not hurt the intestines, do not pollute the environment, can effectively strengthen the digesting and absorbing abilities of laying hens, and have a stronger bearing and water-absorbing performance. The materials mentioned above are systematically and scientifically used to guarantee that the intestines of the laying hens be in the best state. The premix can improve the immunity and disease resistant performance of laying hens, and makes the laying hens exert the maximal laying ability. Moreover, the water content of manure is reduced, and the economic profit of farms that use the premix is prominently improved.

Owner:邵素英

Feedstuff for improving milking sow lactation amount

The invention relates to a foodstuff that can enhance the milk yield of lactation period sow, consisting of the following components in weight portion: 250 to 350 portions of calcium hydrogen phosphate, 250 to 350 portions of mountain meal, 100 to 130 portions of common salt, 30 to 40 portions t of choline, 45 to 55 portions of complex trace elements, 8 to 12 portions of complex vitamin, 30 to 50 portions of potassium chloride, 5 to 15 portions of methionine, 15 to 35 portions of lysine, 2 to 8 portions of valine, 50-150 portions of zeolite powder, 15 to 25 portions of medium and short chain fatty acids, 5 to 20 portions of feed attractant, 0.5 to 1 portions of lysozyme, 10 to 25 portions of mycotoxin absorbent, 5 to 7 portions of vitamin E, 2 to 5 portions of phytase, and 3 to 6 portions of chromium Picolinate. The invention adds nutritive additives and mycotoxin absorbent etc. into the foodstuff, thereby obviously intensifying the immunity of lactation period sow, dramatically enhancing the milk yield, bringing forward the oestrous period, and significantly increasing the ablactation weight of the piglet.

Owner:KUNMING HEMEIHUA FEED

Mycotoxin purification agent for feed and preparation method and application of agent

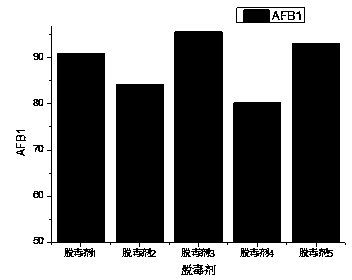

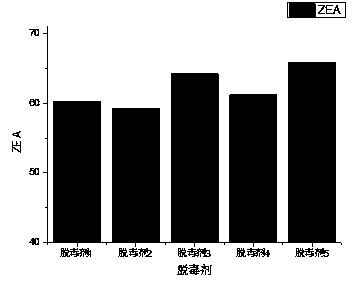

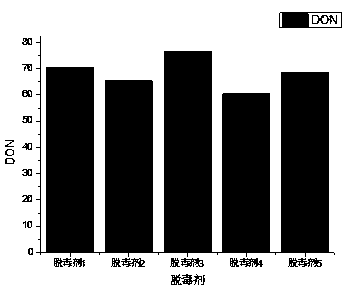

ActiveCN103859165AImprove performance in detoxifying toxinsGood application effectAnimal feeding stuffFood preparationDiseaseMycotoxin

The invention belongs to the technical field of additives, and particularly discloses a mycotoxin purification agent for feed, a preparation method and an application of the agent. The mycotoxin purification agent contains montmorillonite, bentonite, bacillus and fermentation concentrate thereof, inactivated compound lactobacilli and fermentation concentrate thereof, and yeast cell wall polysaccharides. When the mycotoxin purification agent for feed provided by the invention is adopted, mycotoxin can be adsorbed and degraded simultaneously, mycotoxin in the feed is effectively removed, damages of the mycotoxin to animals are reduced, and incidence rate of gastrointestinal diseases and other diseases is reduced. The mycotoxin purification agent has the characteristics of simple preparation method, wide material source, low price and great market application value in the field of feed additives.

Owner:重庆新威士生物科技有限公司

Pregnant sow high-efficiency feed and preparation method thereof

ActiveCN102326717AGuaranteed system performanceFortified vitamin nutritionFood processingAnimal feeding stuffSodium bicarbonateMycotoxin

The invention provides a pregnant sow high-efficiency feed and a preparation method thereof. Raw materials such as corn, maize, wheat bran, soybean, fish meal, feather meal, soybean phospholipids, powdered zeolite, L-lysine hydrochloride, DL-methionine, threonine, arginine, talc powder, calcium hydrogen phosphate, potassium chloride, sodium bicarbonate, sodium chloride, coating VC (vitamin C), monomer VE (vitamin E), vitamin premix, choline, a trace element premix, ethoxy quinoline, a physiological regulator, a hydrated aluminosilicate mycotoxin adsorbent and the like are adopted, and the pregnant sow high-efficiency feed is prepared by smashing and mixing the raw materials. The feed has the following advantages: especially the equilibrium of amino acid, a special function of the arginineto a pregnant sow, the nutrition effect of fiber source and level to the pregnant sow, the nutrition effect of energy source and level to the pregnant sow and the nutrition requirement difference of different parities are especially considered, so that the breeding potential of the pregnant sow can be greatly excavated, the survival rate of embryos is improved, nutrition requirements in each stage of good development of the embryos are guaranteed, and the normal physique and body weight increase of the sow in pregnancy duration are maintained.

Owner:JIEYANG TONGWEI FEED

Method for assay and removal of harmful toxins during processing of tobacco products

A process and system for continuous assay and removal of toxins from tobacco. Products such as tobacco contaminated with mycotoxins, particularly aflatoxins, and benzpyrene and its precursors, are subjected to treatment, generally in a solvent medium, to decontaminate the tobacco of the toxin. Continuous monitoring of all harmful toxins eluted from the cleaning solvent is performed by immunoantibody ultraviolet fluorescence, for example. A quality, control process ensures removal of harmful toxins from tobacco before further processing. Decontamination of extracted solvent streams and re-additives ensures safe reuse or disposal of the solvents and re-additives.

Owner:LANE KERRY SCOTT

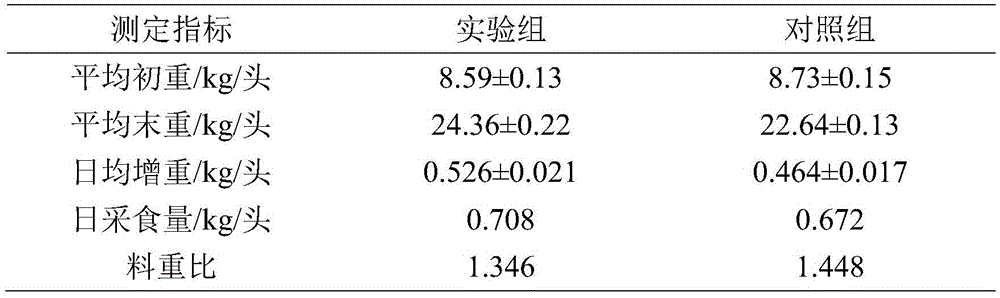

Feed for promoting nursery pig immunity

The present invention relates to a feed for improving immunity of nursing pig, which comprises the components as the weight of 220 to 280 shares of extruded soybean, 80 to 120 shares of fishmeal, 220 to 270 shares of soybean meal, 80 to 120 shares of whey powder, 80 to 120 shares of glucose, 30 to 70 shares of cheese protein, 20 to 45 shares of soybean oil, 20 to 45shares of dicalcium phosphate, 30 to 60 shares of calcium, 5 to 15 shares of lysine, 1 to 3 shares of methionine, 3 to 6 shares of threonine, 5 to 10 shares of trace elements in compound and 1 to 2 shares of compound vitamin. The present invention adds the nutritional additives and adsorbent mycotoxin into the feed, which significantly enhances the immunity and shortens the production cycle to the pig.

Owner:山东和美华农牧科技股份有限公司

Mildew-doffing agent feedstuff

ActiveCN101181008AImprove immunityAgainst infringementAnimal feeding stuffAccessory food factorsMycotoxinVitamin C

The invention relates to an antimold agent foodstuff, consisting of the following components in weight portion: 20 to 40 portions of Bacillus subtilis, 20 to 45 portions of astragalus polysaccharide, 200 to 350 portions of mycotoxins absobent, 20 to 50 portions of vitamin C, 20 to 50 Vitamin E, 5 to 15 portions of lysine, 5 to 15 portions of methionine, 200 to 250 portions of potassium chloride, and 180 to 520 portions of glucose. The invention adds nutritive additives and mycotoxins, etc. into the foodstuff, and can obviously intensify immunity of livestock and resist the attack of antibacterial enzyme to livestock.

Owner:荆州市和美华生物科技有限公司

Feed for lambs

InactiveCN102524550AMeet nutritional needsMeet energy supplyFood processingAnimal feeding stuffMycotoxinAnimal science

Owner:李健

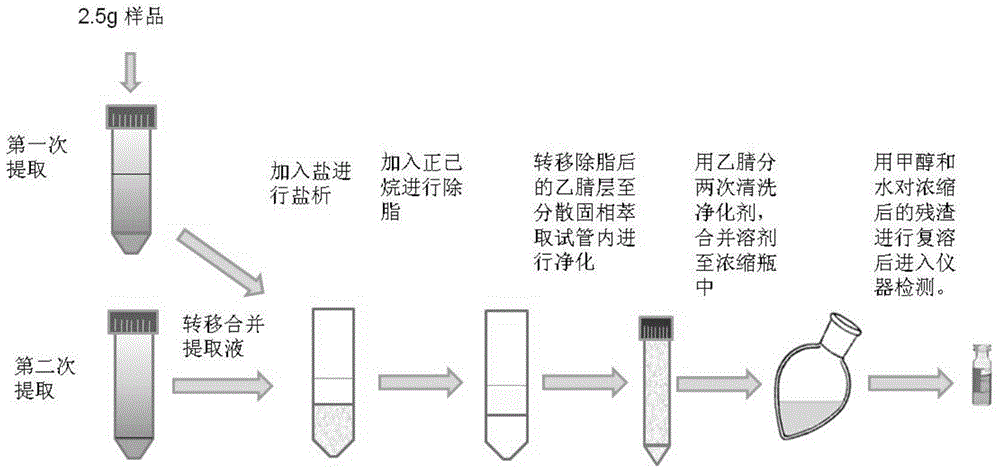

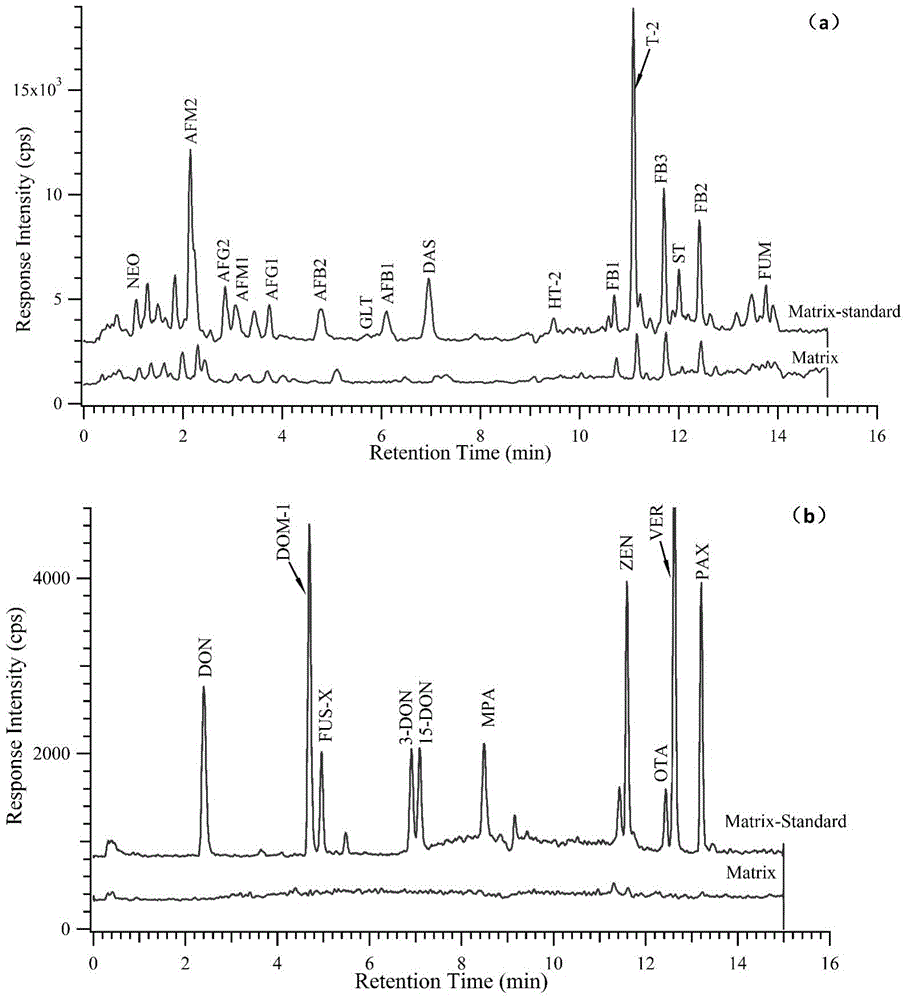

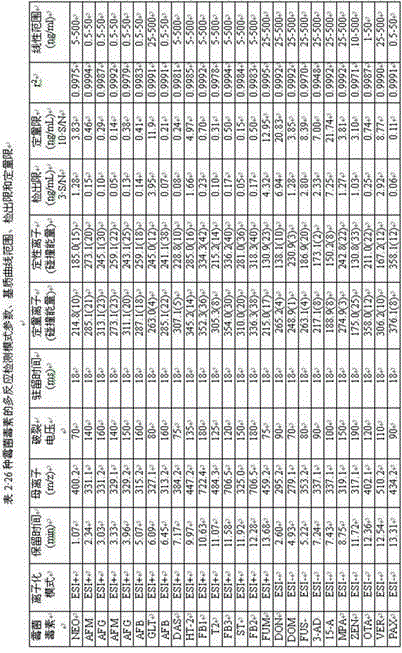

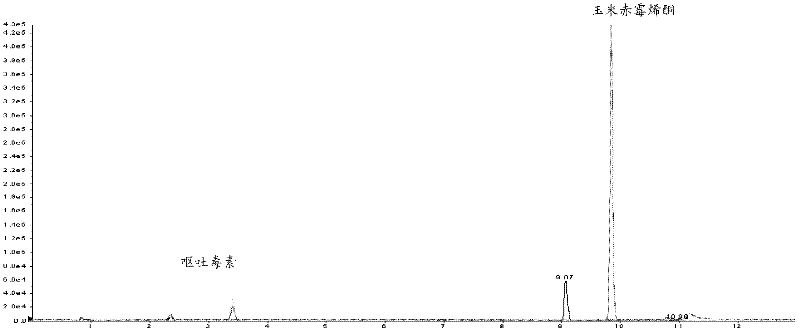

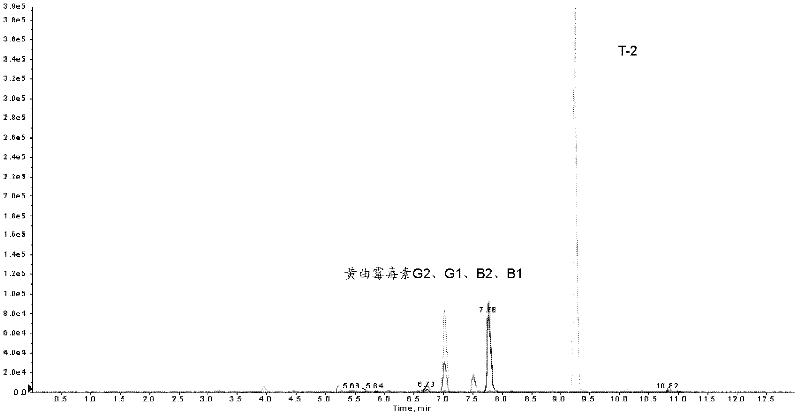

Method for simultaneously detecting a plurality of mycotoxins in sesame paste

The invention relates to a method for detecting a plurality of mycotoxins in a sesame paste, and particularly relates to a method which carries out pre-treatment by an optimized dispersive solid-phase extraction method (QuEChERS), and simultaneously detects 26 mycotoxins in sesame paste by ultra-high performance liquid chromatography-tandem mass spectrometry (UHPLC-MS / MS). The method particularly comprises: extracting a sample twice with acid-containing acetonitrile-aqueous solutions with different concentrations, adding magnesium sulfate and sodium chloride into the sample extract for salting out, performing centrifugation, adding n-hexane into the obtained supernatant, performing vortex oscillation and degreasing, purifying the product with C18 and magnesium sulfate, performing vacuum concentration, dissolving the residues again with methanol and water in order to obtain a sample analytic solution, and detecting the solution by a multi-reaction monitoring mode of ultra-high performance liquid chromatography-tandem mass spectrometry. The method improves the detection efficiency, saves detection cost, is high in sensitivity, high in repeatability, and high in adding standard recovery rate, and can be extended to detection of other samples with a high grease content.

Owner:PEOPLES REPUBLIC OF CHINA BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Composite micro-ecological feed additive and preparation method and premix thereof

ActiveCN102326677AImprove qualityImprove conversion rateAnimal feeding stuffAccessory food factorsFood additiveMycotoxin

The invention discloses a composite micro-ecological feed additive and a premix thereof, and belongs to the technical field of feed science and feed additive. The feed additive contains multiple probiotics, and has the functions of enhancing the immunity of livestock and poultry and improving the production performance of the livestock and poultry; and meanwhile, the feed additive can be used as a feed mildew-proof agent, has good adhesion identifying and removing capacity on feed mycotoxins, can effectively inhibit the growth of mycete in the feed and adsorb and degrade the mycotoxins, is a novel, safe, reliable and pollution-free pure fermented multifunctional micro-ecological preparation product, and has good application prospect.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

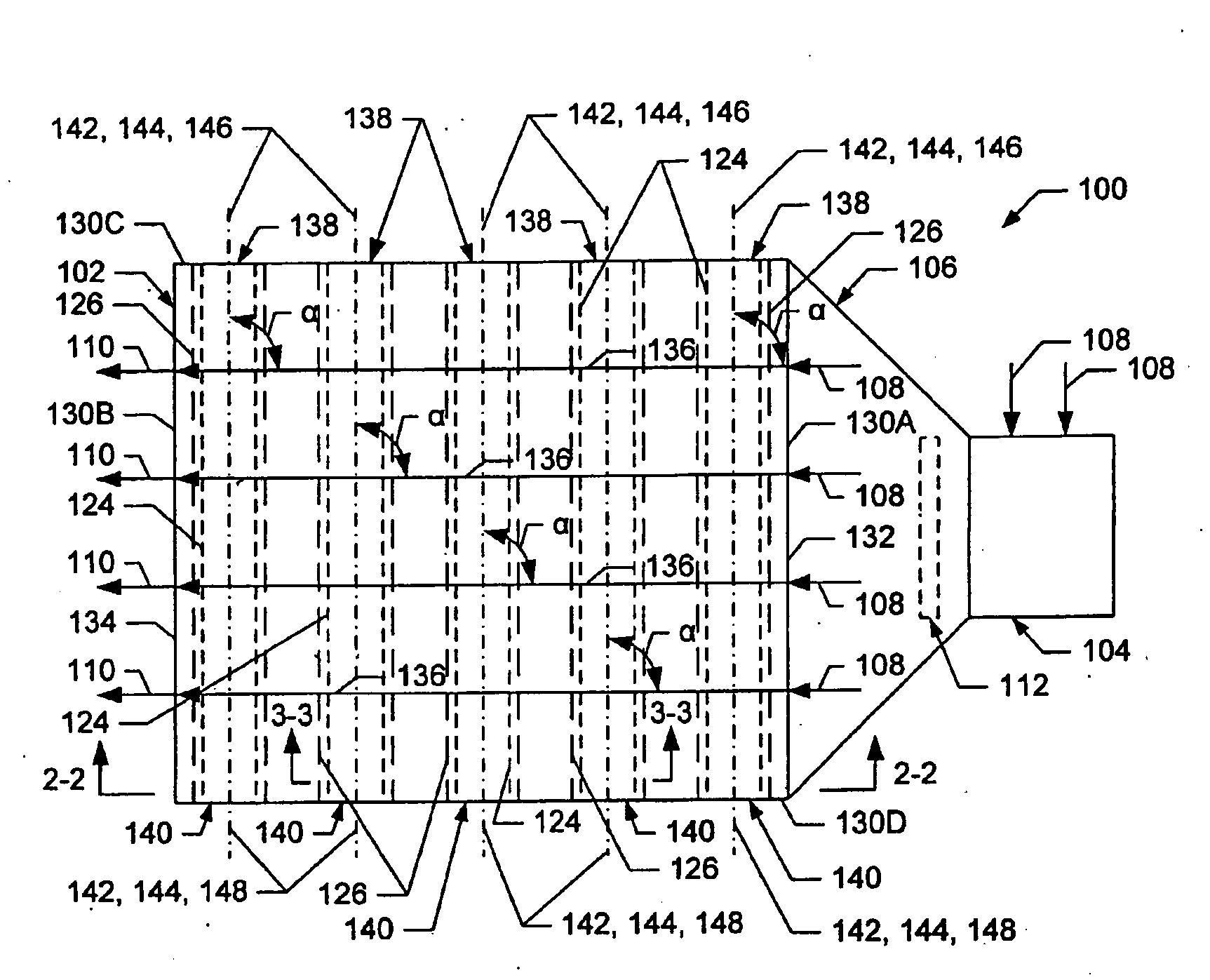

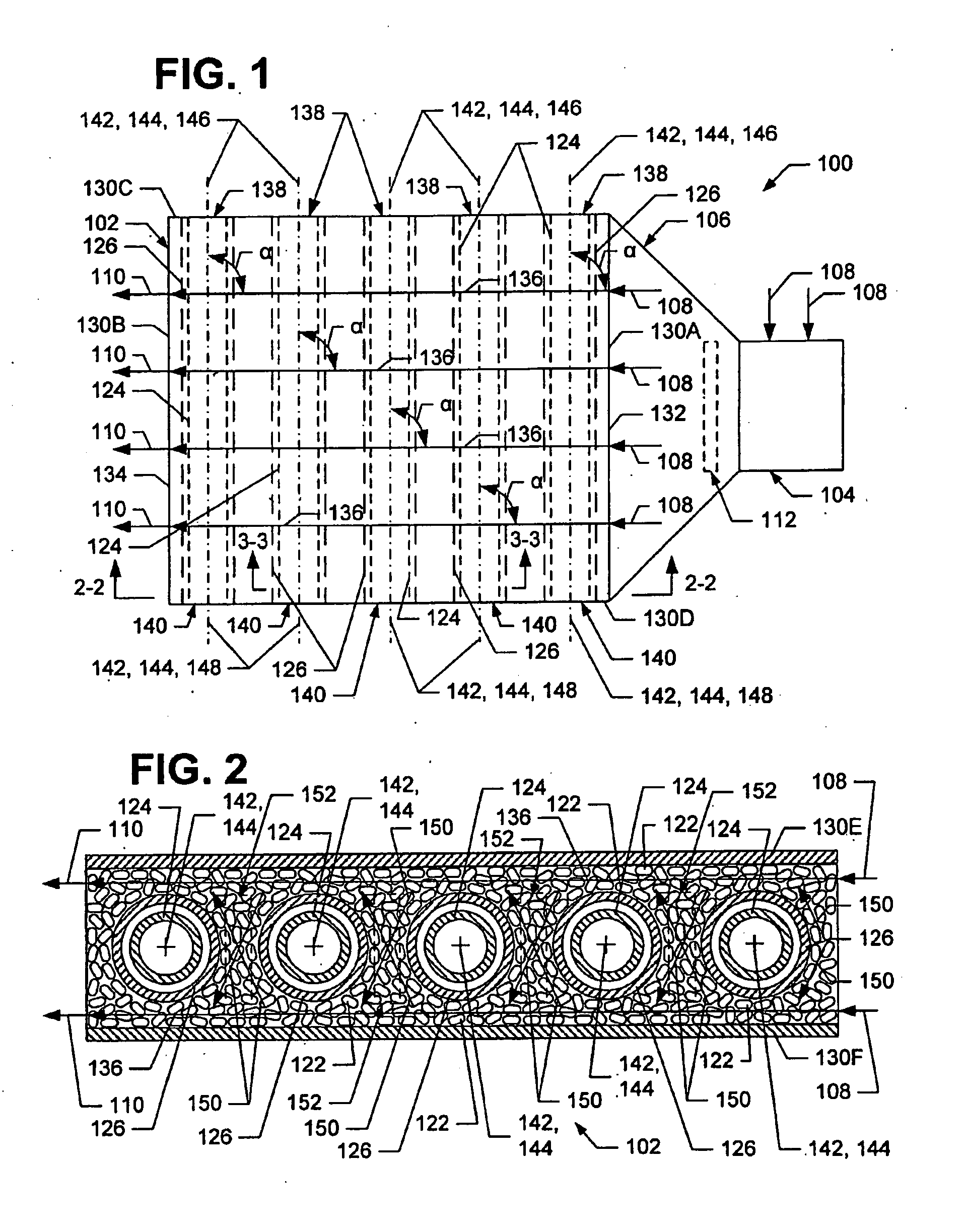

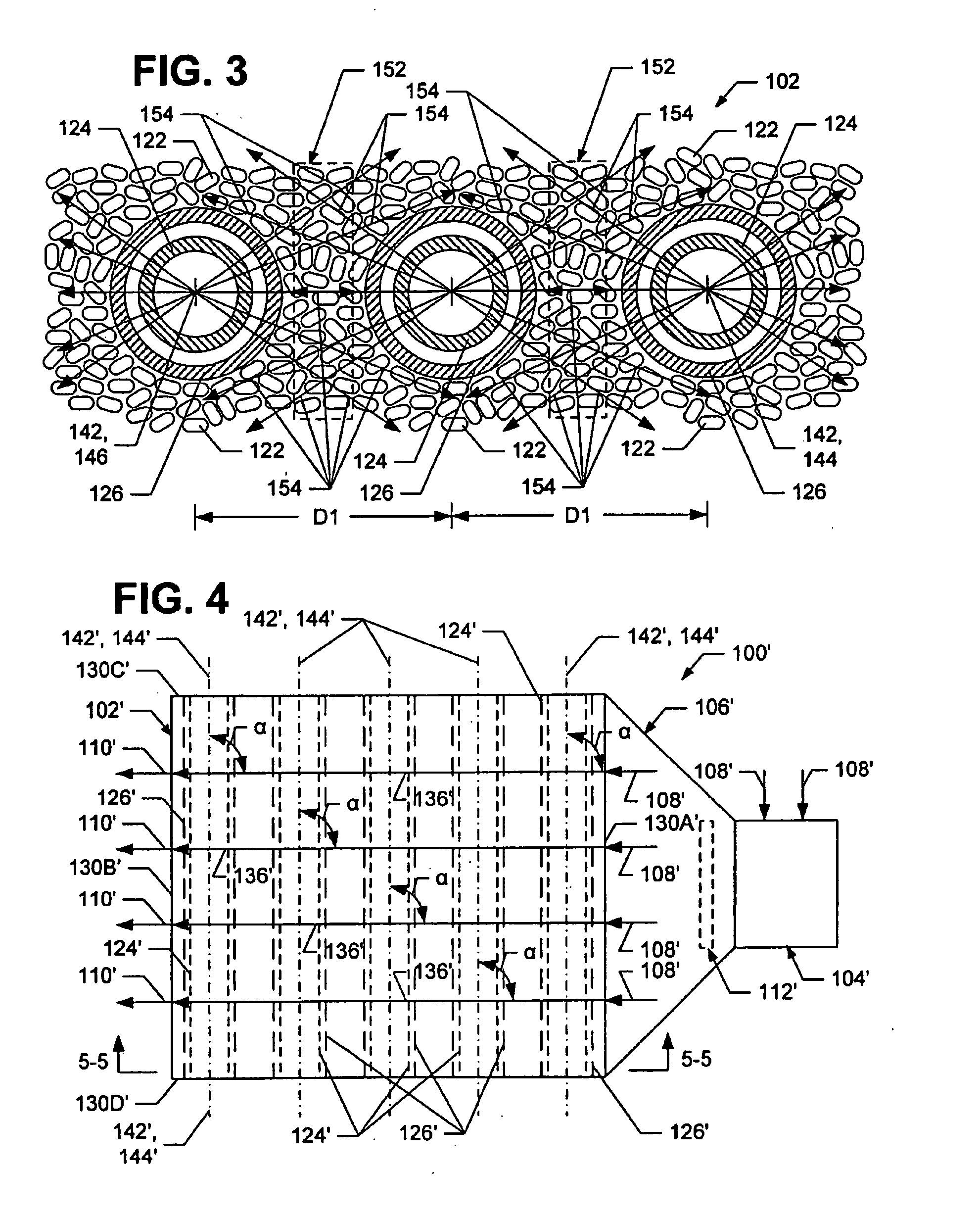

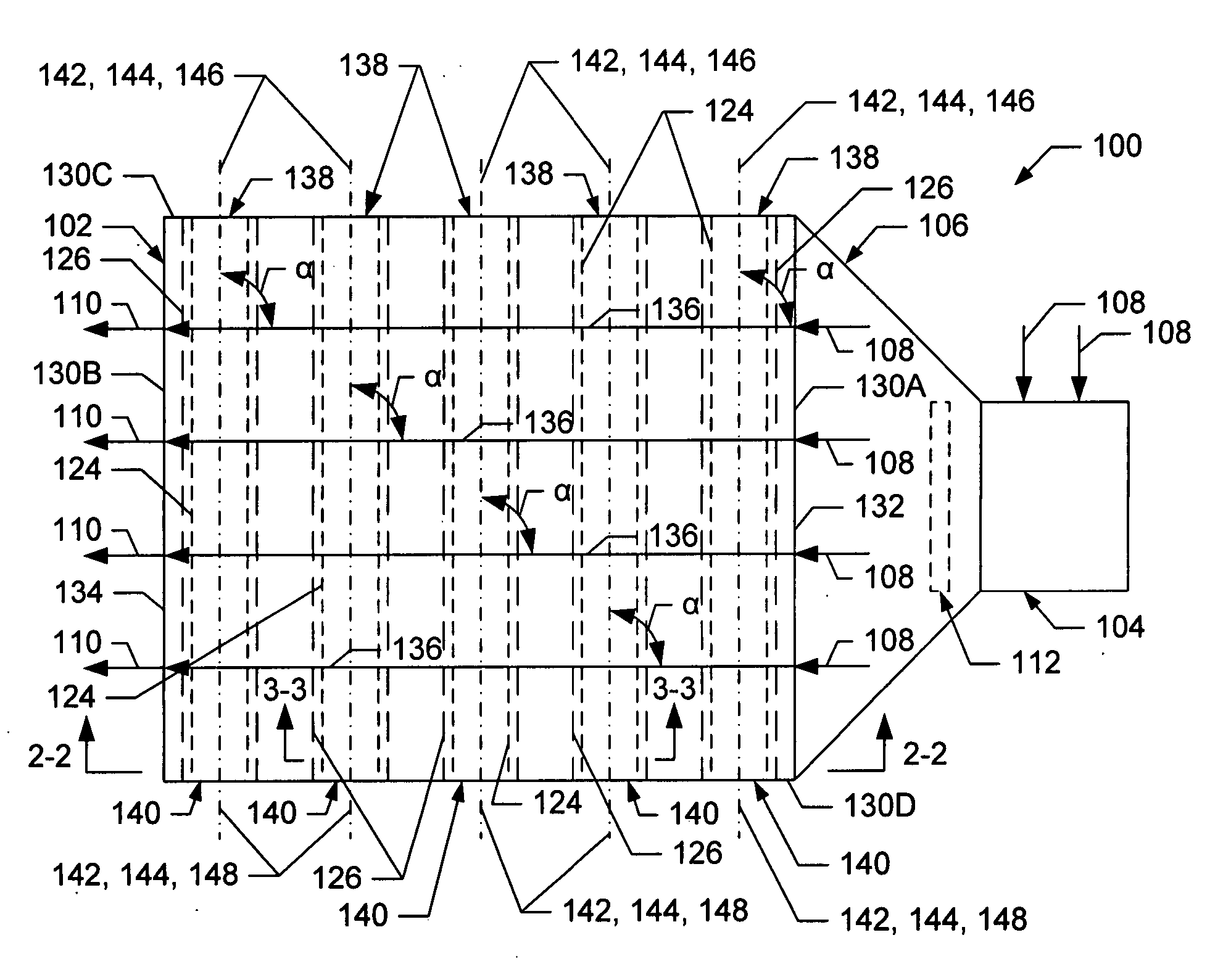

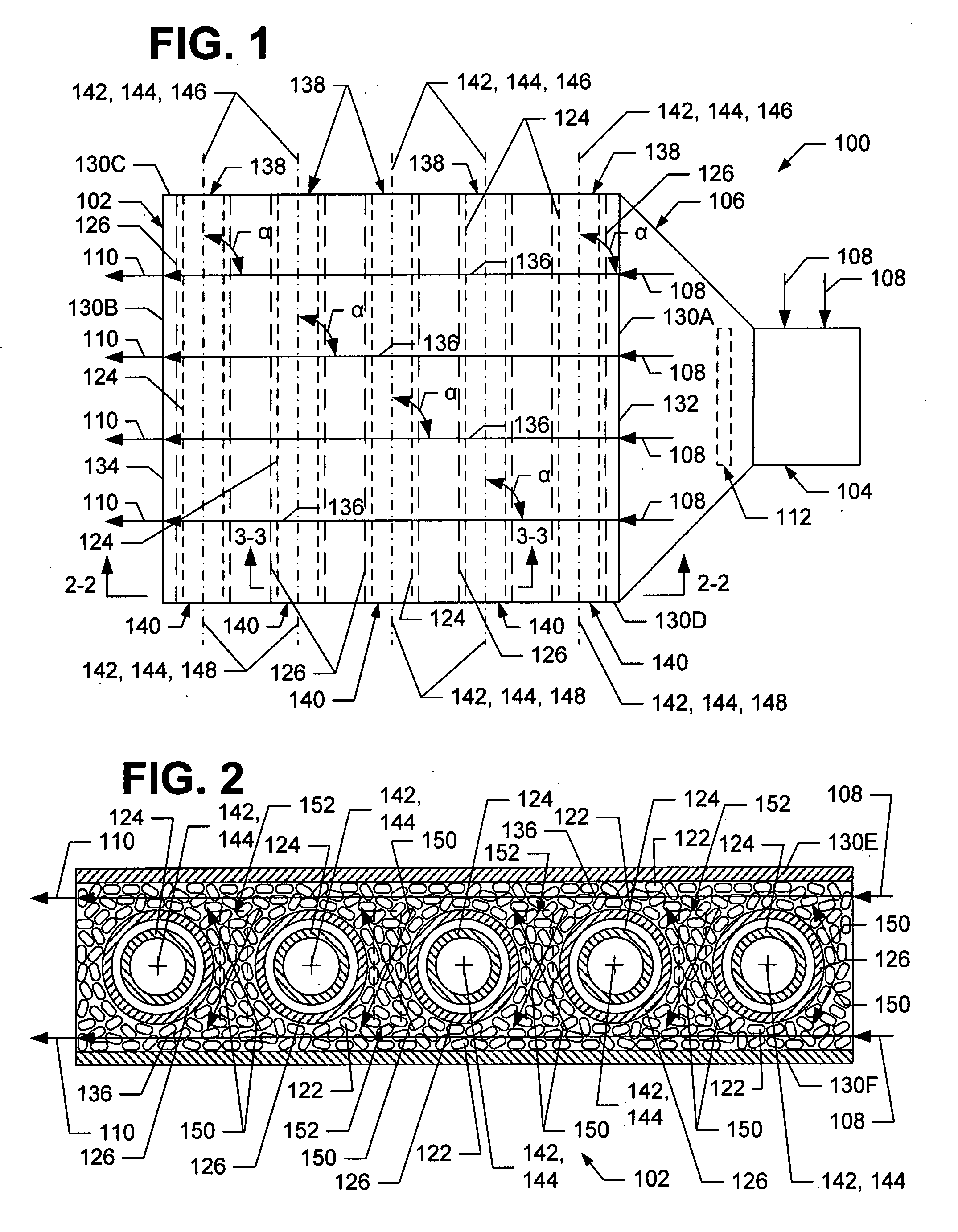

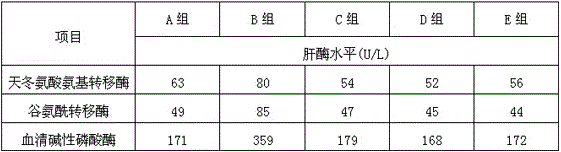

Photocatalytic air treatment system and method

InactiveUS20090280027A1Reduce humiditySpeed up photocatalytic oxidation reactionGas treatmentLighting and heating apparatusMycotoxinAir treatment

A photocatalytic air treatment system, including an apparatus and method, is provided for killing and / or mineralizing bacteria, viruses, mold, fungi, spores, mycotoxins, allergens, and other similar microorganisms and agents and similar organic matter, and for oxidizing volatile organic compounds. The system comprises one or more reactor beds configured in one or more stages with each reactor bed including a plurality of photocatalyst-coated media substantially surrounding a plurality of sheathed ultraviolet light sources. Adjacent ultraviolet light sources are positioned to create killing zones of photocatalyst coated media that are irradiated with ultraviolet light from the ultraviolet light sources and in which an increased number of hydroxyl radicals are present.

Owner:AKIDA HLDG

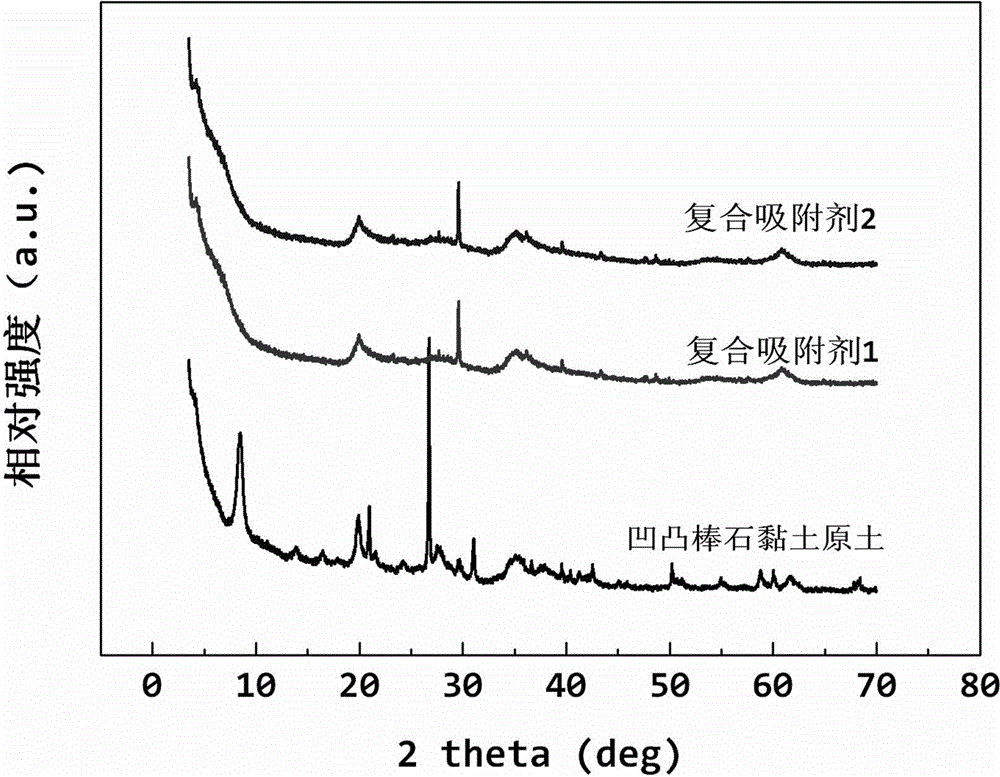

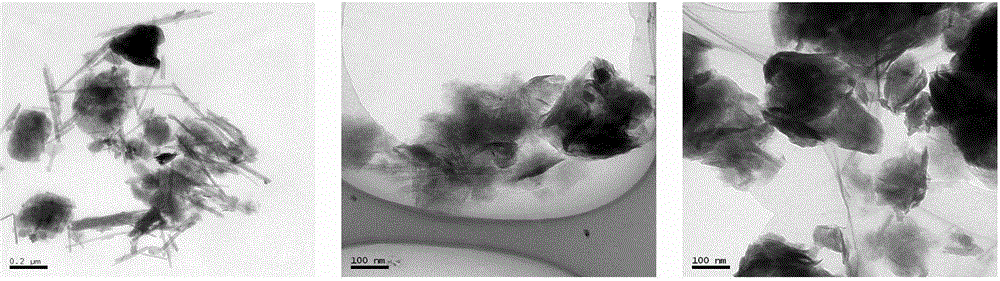

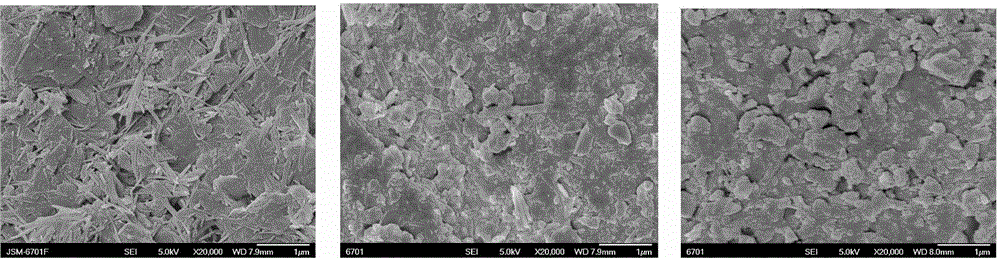

Method for preparing composite adsorbent by utilizing low-grade attapulgite clay

ActiveCN104383873ALarge specific surface areaNarrow pore size distributionOther chemical processesMycotoxinClay minerals

The invention discloses a method for preparing composite absorbent by utilizing low-grade attapulgite clay. The method comprises the steps of uniformly mixing attapulgite clay mineral powder containing quartz and dolomite with soluble silicate accounting for 20 to 600 percent of the weight of the attapulgite clay mineral powder and metal salt accounting for 10 to 500 percent of the weight of the attapulgite clay mineral powder or a solution containing the metal salt, then grinding the mixture, dispersing the mixture into water in a solid-liquid ratio of 1:100-1:10, adding an appropriate amount of additive, and aging for 1 to 4 hours; then transferring the mixture into a hydrothermal reaction kettle to react for 5 to 60 hours at the temperature of 120 to 300 DEG C, and then separating, washing, drying and crushing to obtain the adsorbent. According to the method, the quartz impurities and dolomite in the attapulgite clay mineral powder are converted into amorphous silicate with strong adsorption activity, and the prepared adsorbent is large in specific surface area and uniform in aperture distribution, is used for adsorbing and removing dye, heavy metal, organic molecules, radioactive elements, rare earth and mycotoxin and is wide in application prospect in the fields of biology, food, petrochemical industry, environment restoration, printing and dyeing waste water treatment and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Photocatalytic air treatment system and method

InactiveUS20070251812A1Increase the number ofImprove responseGas treatmentLighting and heating apparatusMycotoxinUltraviolet lights

A photocatalytic air treatment system, including apparatuses and methods, for killing and / or mineralizing bacteria, viruses, mold, fungi, spores, mycotoxins, allergens, and other similar microorganisms or agents, and for oxidizing volatile organic compounds (VOCs). The system comprises one or more reactor beds configured in one or more stages with each reactor bed including a plurality of photocatalyst coated media substantially surrounding a plurality of sheathed ultraviolet light sources that may be arranged in a plurality of configurations. Adjacent ultraviolet light sources are positioned so as to create killing zones of photocatalyst coated media therebetween that are irradiated with ultraviolet light from multiple sources and in which an increased number of hydroxyl radicals are present. The photocatalyst generally comprises titanium dioxide, but may include one or more enhancers. The media is formed from or is coated with a material that induces the photocatalyst to form a nano-particle structure.

Owner:AKIDA HLDG

Mildew-proof detoxication and detoxification mixed type feed additive

InactiveCN105594994AGrowth inhibitionEliminate the effects ofAnimal feeding stuffAccessory food factorsDiseaseSnow mold

The invention relates to a mildew-proof detoxication and detoxification mixed type feed additive, and belongs to the technical field of feed additives. The feed additive is prepared from the following raw materials in percentage by weight: 70 to 95 percent of modified montmorillonite, 0.4 to 0.8 percent of bacillus subtilis, 2 to 20 percent of yeast cell wall polysaccharide, 0.6 to 1 percent of glucose oxidase, 0.5 to 4 percent of methionine, 0.5 to 2 percent of alpha-mannatide and 0.5 to 4 percent of VC. The mildew-proof detoxication and detoxification mixed type feed additive has the advantages that the reasonable ingredient preparation is adopted; through reasonable use, mycotoxin can be adsorbed; the mildew growth is inhibited; the influence of mycotoxin on animal physiology is eliminated; the resistivity of animals on diseases is improved; the phenomenon of having loose bowels is reduced; the culture benefits are improved.

Owner:浙江大飞龙动物保健品股份有限公司

Methods and compositions for detecting fungi and mycotoxins

ActiveUS20080014582A1Effective treatmentIncreased susceptibilitySugar derivativesMicrobiological testing/measurementMycotoxinRegimen

The invention relates to a method of identifying a specific fungal species in patient tissue or body fluid. The method comprises the steps of extracting and recovering DNA of the fungal species from the patient tissue or body fluid, amplifying the DNA, hybridizing a probe to the DNA to specifically identify the fungal species, and specifically identifying the fungal species. The invention also relates to a method of identifying a mycotoxin in patient tissue or body fluid. The method comprises the steps of extracting and recovering the mycotoxin from the patient tissue or body fluid, contacting the mycotoxin with an antibody directed against the mycotoxin, and identifying the myocotoxin. Both of these methods can be used to determine if a patient is at risk for or has developed a disease state related to a fungal infection, and to develop an effective treatment regimen for the patient.

Owner:ADVATECT DIAGNOSTICS LLC

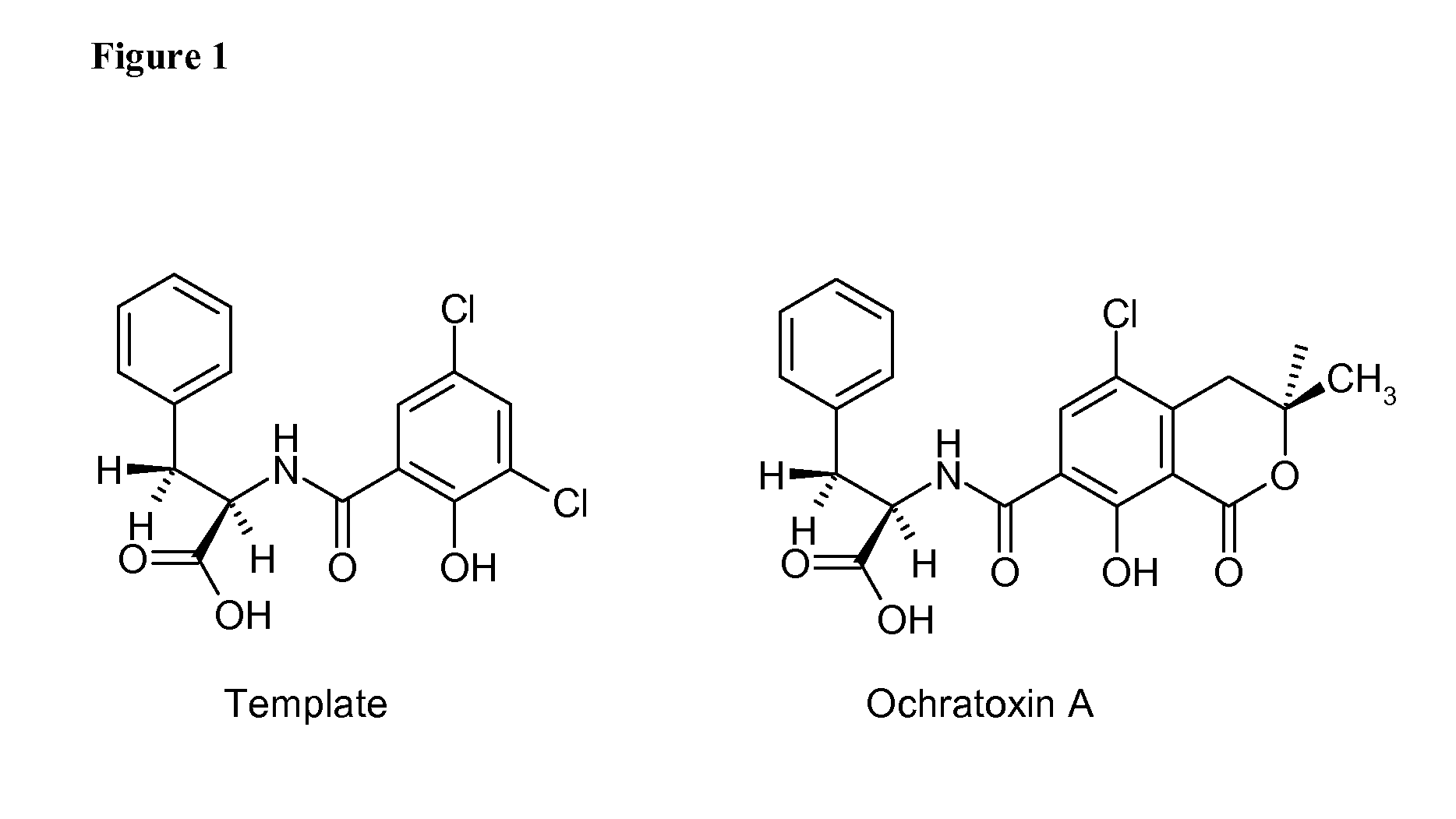

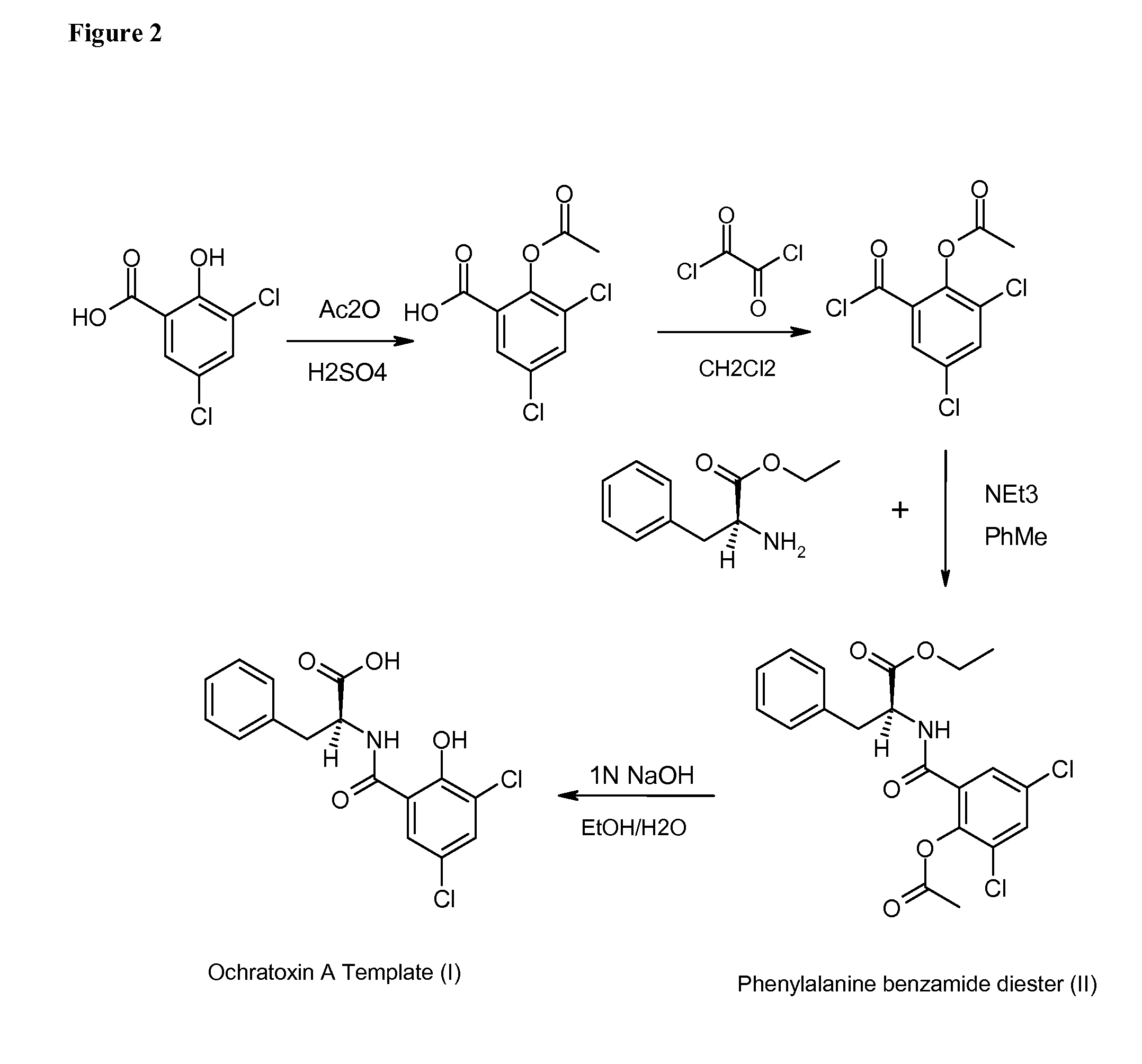

Synthetic mycotoxin adsorbents and methods of making and utilizing the same

The present invention relates generally to molecularly imprinted polymers (MIPs). In particular, the present invention relates to reusable, ecologically friendly MIPs that can be produced in relatively large quantities, methods of producing the same, and methods of utilizing the same (e.g., to sequester and / or adsorb target compounds (e.g., mycotoxins)). Compositions and methods of the invention find use in a variety of applications including dietary therapeutic, prophylactic, food and beverage processing and manufacture, as well as research, quality control and traceability applications.

Owner:ALLTECH CO LTD

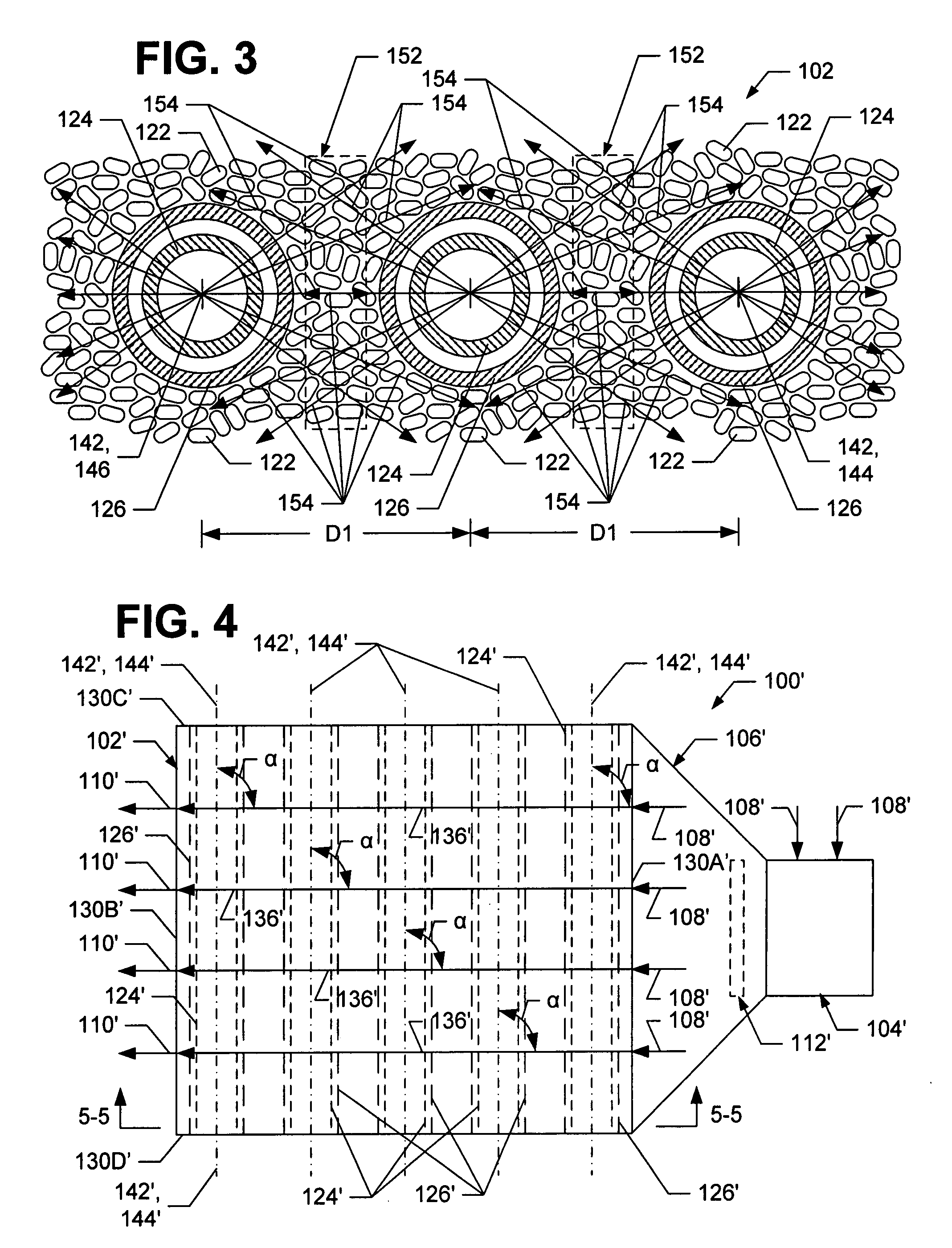

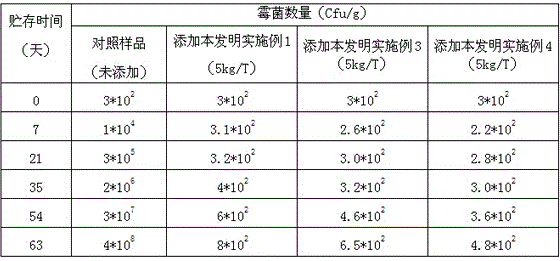

Bacillus amyloliquefaciens and application thereof

InactiveCN102191200AGood inhibitory effectHas subtractive effectBacteriaFood preservationMycotoxinToxin

The invention discloses Bacillus amyloliquefaciens and application thereof. The Bacillus amyloliquefaciens ASAG1 is a biocontrol bacterium, wherein the collection number is CGMCC No.3056. The invention also provides a microbial inoculum comprising the collected bacterial strain. The Bacillus amyloliquefaciens or the microbial inoculum has remarkable inhibition activity on stored grain fungi and extinction effect on stored grain mycotoxin.

Owner:ACAD OF STATE GRAIN ADMINISTRATION

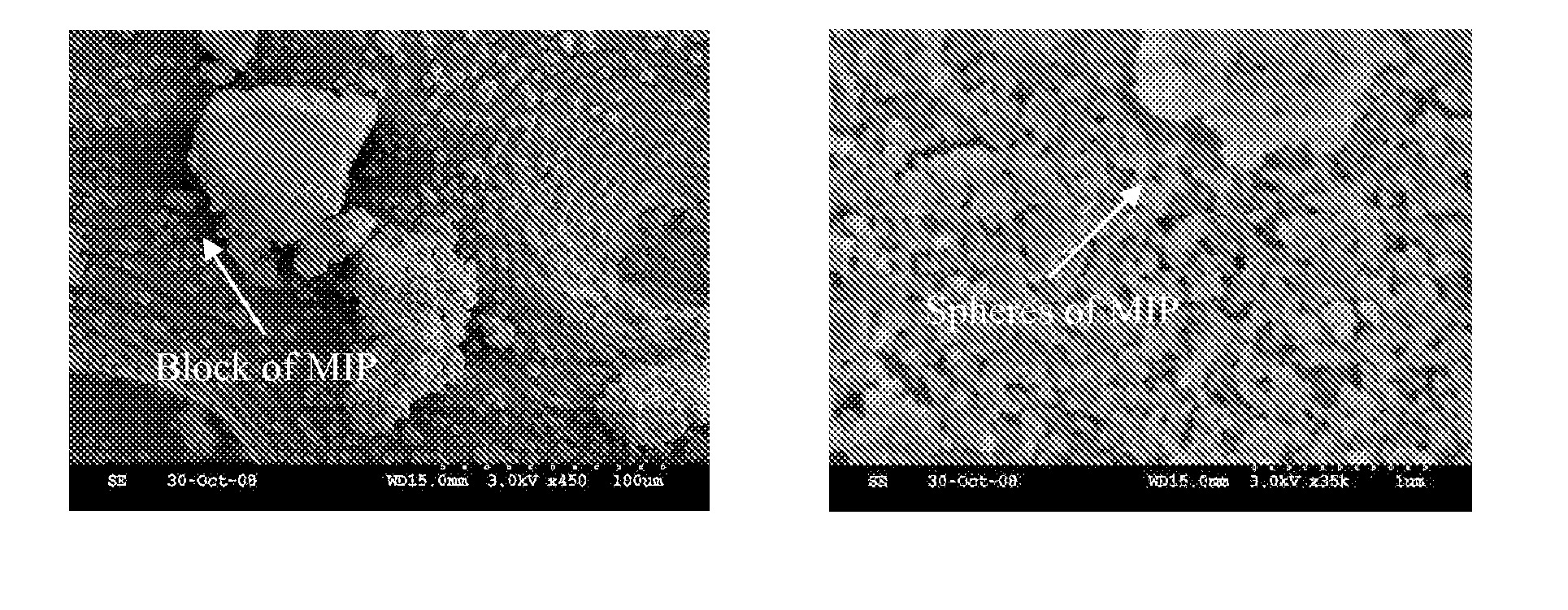

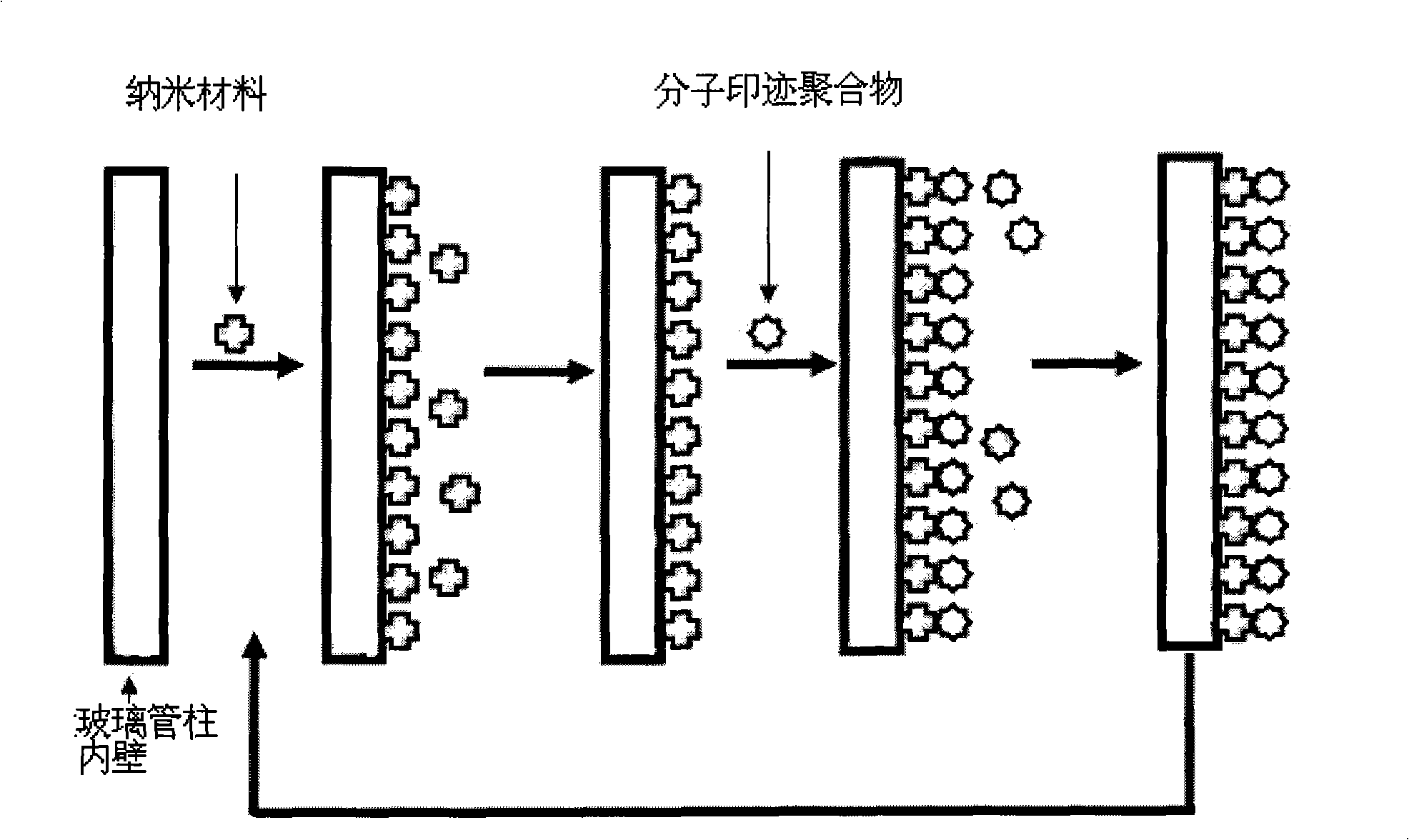

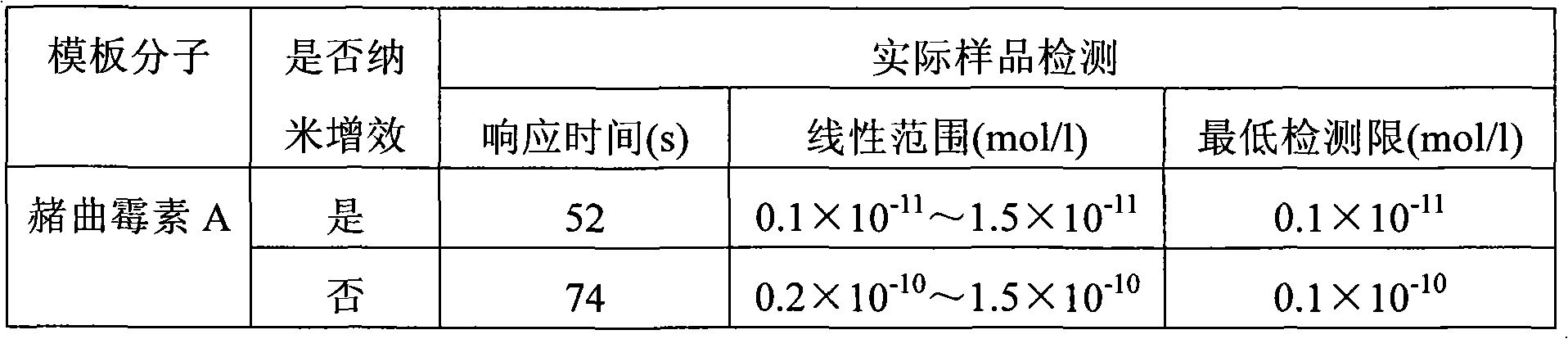

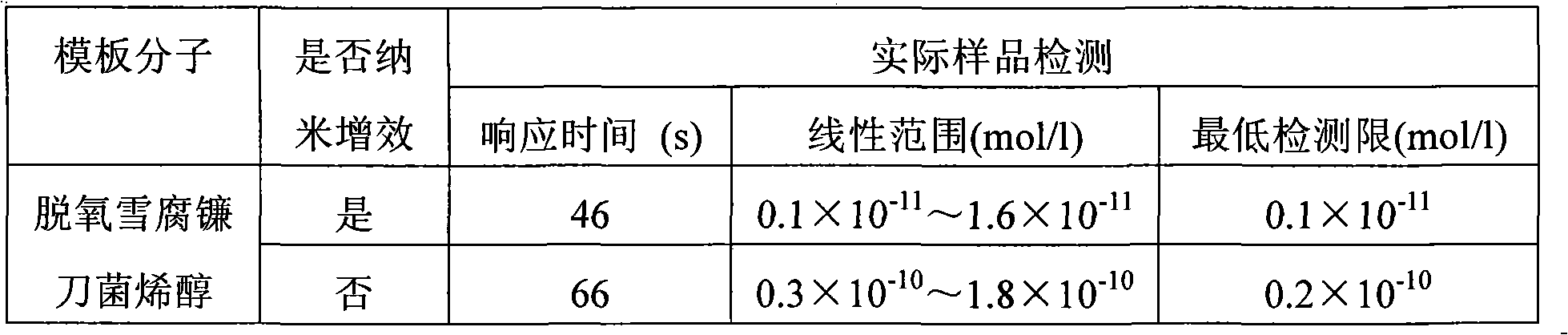

Trace amount mycotoxins molecular blotting column preparation method and application

InactiveCN101308066AIncreased sensitivityExpand the scope of detectionComponent separationChemiluminescene/bioluminescenceCross-linkFunctional monomer

The invention discloses a process for preparing a trace amount mycotoxin molecular imprinted column, which comprises the following steps of: selecting a functional monomer; evenly mixing a mycotoxin template molecule, the functional monomer, a cross-linking agent, a pore-forming agent, an initiator and an organic solvent by a certain molar ratio to prepare a molecular imprinting polymer solution; preparing a nano-solution; and dressing the nano-material and a molecular imprinting polymer on the internal surface of a glass pipe column. A method for detecting the trace amount mycotoxins includes: pumping a chemiluminescence system solution and a sample solution into a chemiluminescence analyzer respectively and detecting the mycotoxins in the sample. The molecular imprinted column of the invention has advantages of high sensitivity and accuracy. The nano-enhanced trace amount mycotoxin molecular imprinted column obtained in the invention is connected to the chemiluminescence analyzer for detecting mycotoxins, and purposes of high specificity, high sensitivity and fast detection to mycotoxins in the sample can be realized.

Owner:UNIV OF JINAN

Mycotoxin adsorbents

InactiveUS6827959B1Improve adsorption capacityOther chemical processesAluminium silicatesCation-exchange capacityMycotoxin

Owner:SUED CHEM IP GMBH & CO KG

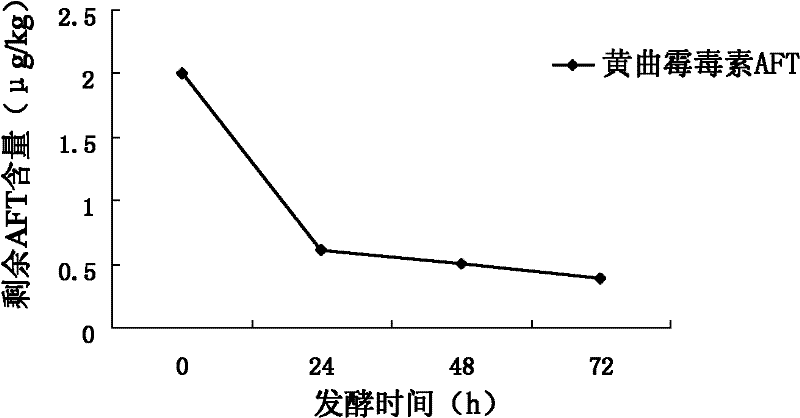

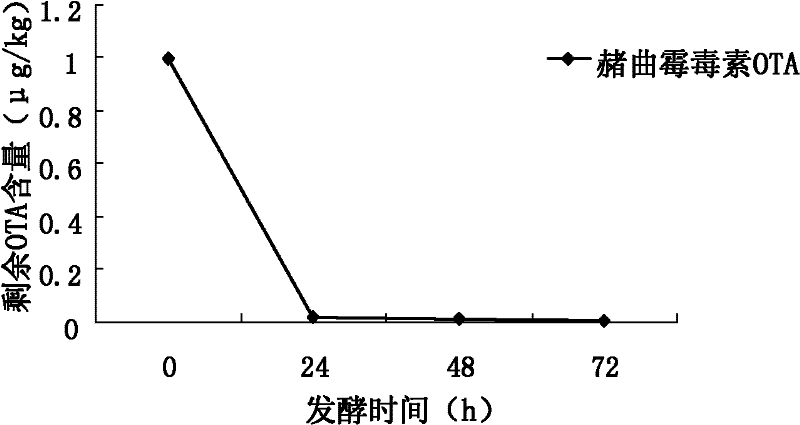

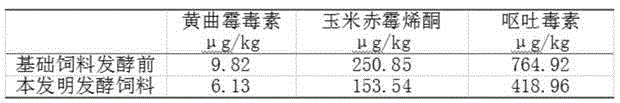

Microbial fermentation feed as well as production method and application thereof

ActiveCN105475624AGuaranteed functionalityGrowth inhibitionAnimal feeding stuffOrganic acidDry weight

The invention discloses microbial fermentation feed as well as a production method and an application thereof. The production method of the microbial fermentation feed comprises the following steps: (1) lactic acid bacteria, Clostridium butyricum Cb-2, yeast, Bacillus subtilis, a fermentation base-material and water are uniformly mixed, and a fermentation raw material is obtained; 2) aerobic fermentation and anaerobic fermentation are carried out in order for the fermentation raw material obtained in the step (1), and after fermentation, the feed is obtained. The microbial fermentation feed contains microecological viable organisms, and the total amount of beneficial bacteria is more than 5 x 10<9> cfu / g; the amount of mould and the content of mould toxin are lower than national limit standards; the feed is rich in organic acid, the content of lactic acid reaches 2.5%, and pH value is lower than 4.5; the titer of antibacterial peptide is higher than 1000 u / g, the titer of neutral protease is 150 u / g, the titer of alpha-amylase 300 u / g, dry weight for above, and the titer of total protease is higher than 600 u / g; the whole fermentation process is controlled in the range of 8-24 hours, the fermentation time is saved, and the dissipating energy is controlled below 3%.

Owner:SHANDONG BEE LAN BIOTECHNOLOGY CO LTD

Method for measuring content of mycotoxins in araliaceae plants by liquid chromatography-tandem mass spectrometry

The invention discloses a method for measuring the content of mycotoxins in araliaceae plants by liquid chromatography-tandem mass spectrometry, comprising the following steps of: (1) preprocessing an araliaceae plant sample to be measured by a solid-phase extraction column; and (2) measuring the content of one or more mycotoxins in the preprocessed araliaceae plant sample through the liquid chromatography-tandem mass spectrometry. The measurement method is high in sensitivity, good in specificity and good in accuracy, and applied to measurement of multiple component residuals of the mycotoxins in the araliaceae plants.

Owner:SHANGHAI INST FOR FOOD & DRUG CONTROL

Mycotoxin binding food and feed additives and processing aids, fungistatic and bacteriostatic plant protecting agents and methods of utilizing the same

InactiveUS20120070516A1Good removal effectGood for healthBiocideFood processingCelluloseProcedure Agents

Method is proposed useful to render harmless mycotoxins that contaminate food, animal feed and assist infection of plant hosts by microbial parasites, comprising binding mycotoxins by a novel adsorbent, consisting partially or in full of plant lignocellulosic biomass or isolated biomass components, e.g., acid hydrolysis lignin, enzymatic hydrolysis lignin, coniferous and deciduous wood, bark and needle particles, rice hulls, used coffee grounds, apricot stone shells, almond, walnut, sunflower hulls, cocoa and peanut shells. The materials may be further improved through genetic modification of plants and physicochemical treatment of lignocellulosic biomass, such as micronization. The resulting adsorbent can bind wide range of mycotoxins, including, mycotoxins difficult to bind (Ochratoxin, T-2, Deoxynivalenol, Nivalenol). Ability of porous materials containing lignin to thermally collapse at melting can be used to irreversibly entrap mycotoxins by adsorbing them in a wet system and then closing lignin pore structure under high-temperature treatment, such as drying.

Owner:CUBENA

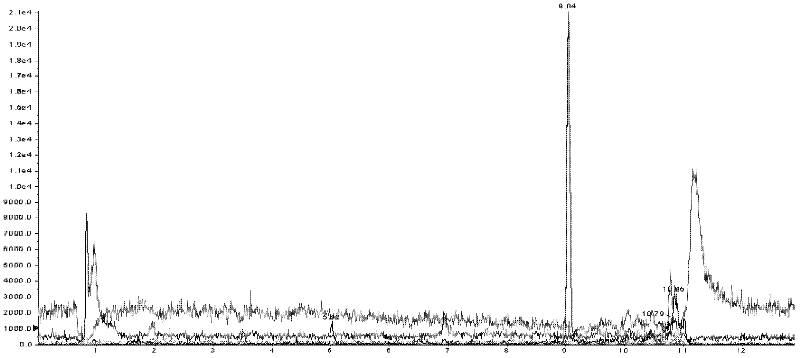

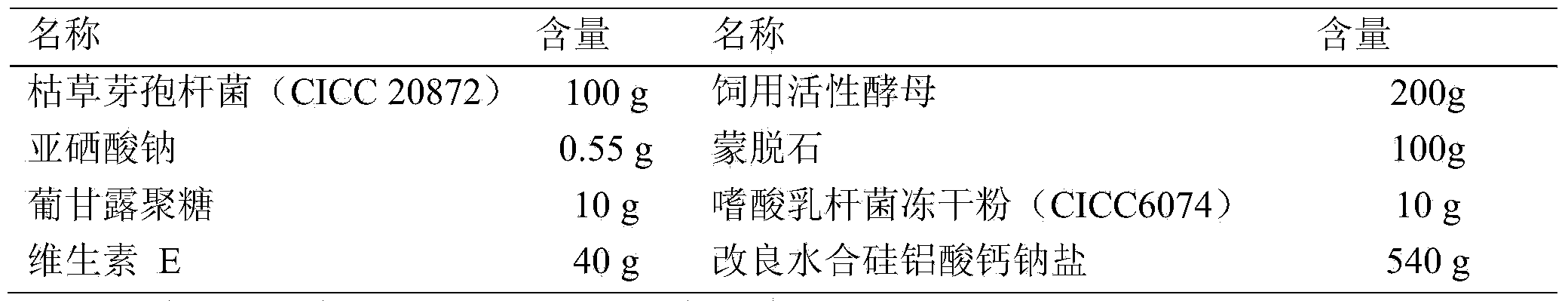

Mold removal agent for animal feed as well as preparation method and application of mold removal agent

ActiveCN103461677AImprove adsorption capacityGrowth inhibitionAnimal feeding stuffFood preparationMycotoxinFreeze-drying

The invention discloses a mold removal agent for animal feed as well as a preparation method and an application of a mold removal agent. The mold removal agent comprises the following components in parts by mass: 50-150 parts of bacillus subtilis, 5-15 parts of lactobacillus acidophilus freeze-dried powder, 0.1-1 part of sodium selenite, 25-55 parts of vitamin E, 100-300 parts of feed active dry yeast, 5-15 parts of glucomannan, 50-150 parts of montmorillonite and 350-700 parts of modified hydration aluminosilicate. The mold removal agent prepared by the method is environment-friendly and pollution-free, has extremely strong adsorption capacity for various common mycotoxin, forms a stable compound, is not absorbed by intestinal tracts and is excreted from a body along with faeces. The mold removal agent disclosed by the invention can be used for detoxicating, inhibiting the growth of mildews, improving the immunity of animals and promoting the growth of the animals.

Owner:南京日升昌生物技术有限公司

Additive of feed and preparing method thereof.

InactiveCN101366450AGrowth inhibitionImprove the immunityAnimal feeding stuffAccessory food factorsAnimal scienceMycotoxin

The invention relates to a feed additive for livestock and a method for preparing the same. The feed additive consists of modified montmorillonite, sodium diacetate, Chinese traditional medicine extract and glucose oxidase. If reasonably used, the feed additive can adsorb mycotoxin, inhibit the growth of molds, eliminate the influence of mycotoxin on physiology of animals, improve the capability of animals of resisting illnesses, obviously improve feed returns, improve the immunity effect of vaccine injection, improve the mating fertility rate and improve the number born.

Owner:GUANGDONG GALLOPER VETERINARY PHARMA

Feed mycotoxin removing agent

The invention relates to a feed mycotoxin removing agent. The feed mycotoxin removing agent comprises the following components in mass percentage: 20-30% of nano-sized montmorillonite, 20-30% of yeast cell wall polysaccharide, 5-10% of glucose oxidase, 3-5% of potassium chloride, 3-5% of vitamin E, 4-5% of vitamin C, 15-20% of glucose and 8-10% of compound Chinese herbal extract powder, wherein the compound Chinese herbal extract powder is compounded by Astragalus extract, rhubarb extract, licorice extract and Eucommia extract powder in a mass ratio of 1: 0.8-1.2: 0.8-1.2: 0.8-1.2. The feed mycotoxin removing agent can effectively avoid damage of mycotoxin to production performance and reproductive performance of animals and has a wide application prospect.

Owner:ZHENGZHOU FENGYUAN BIOLOGICAL TECH

Methods and Compositions for Identifying Mycotoxins and Fungal Species

InactiveUS20100075322A1Reliable and sensitive and specificEffective treatmentMicrobiological testing/measurementPreparing sample for investigationMycotoxinRegimen

The invention relates to a method of testing for a mycotoxin in patient tissue or body fluid and testing for a fungal species in the patient tissue or body fluid. The method can also be used to determine if a patient is at risk for or has developed a disease state related to a fungal infection, and to develop an effective treatment regimen for the patient.

Owner:MEDICAL SERVICE CONSULTATION INT

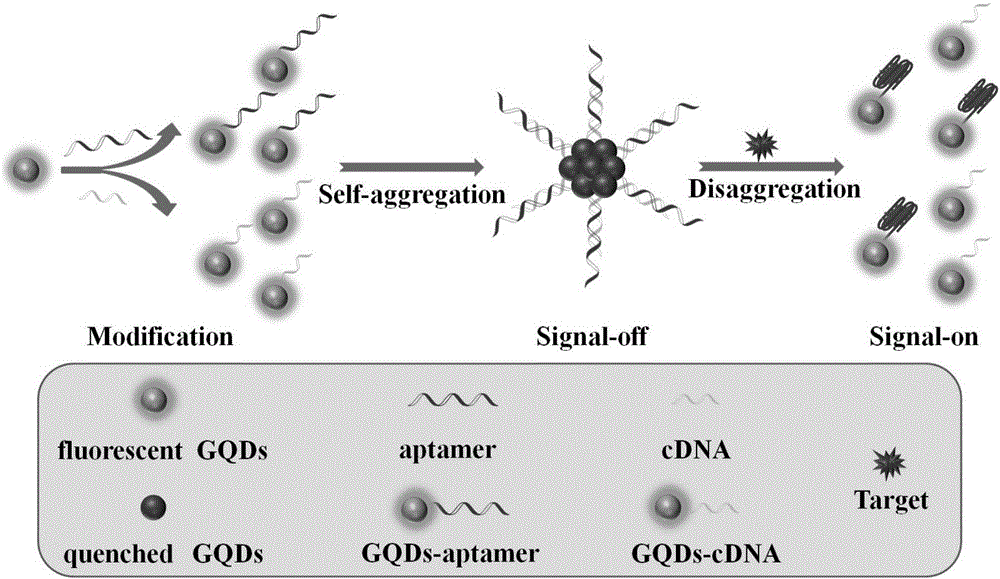

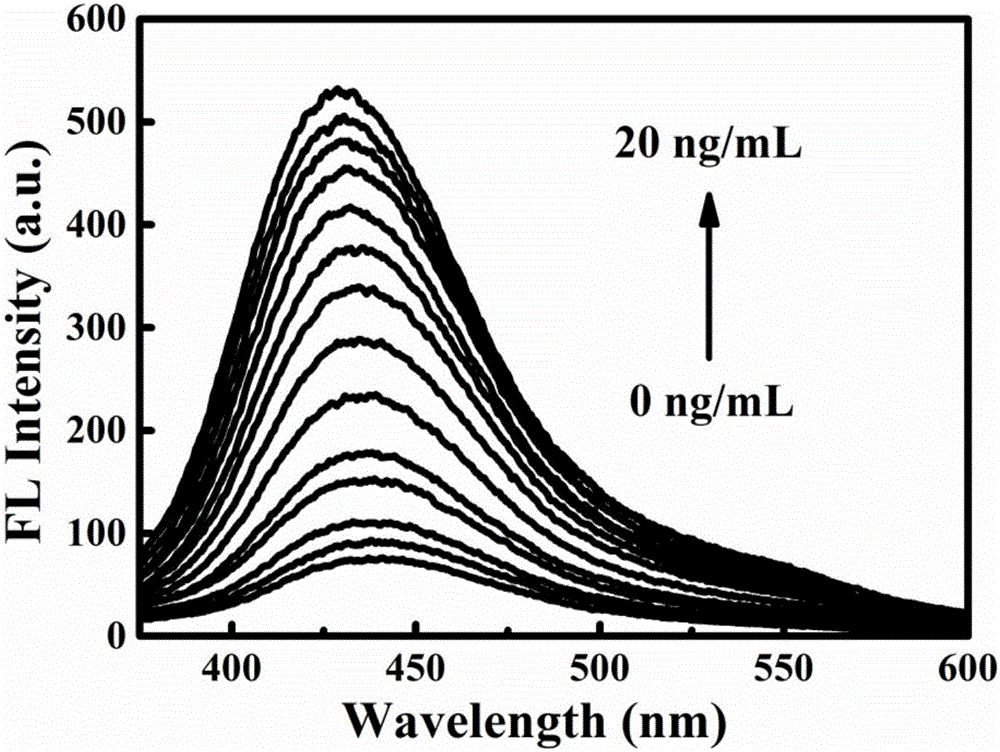

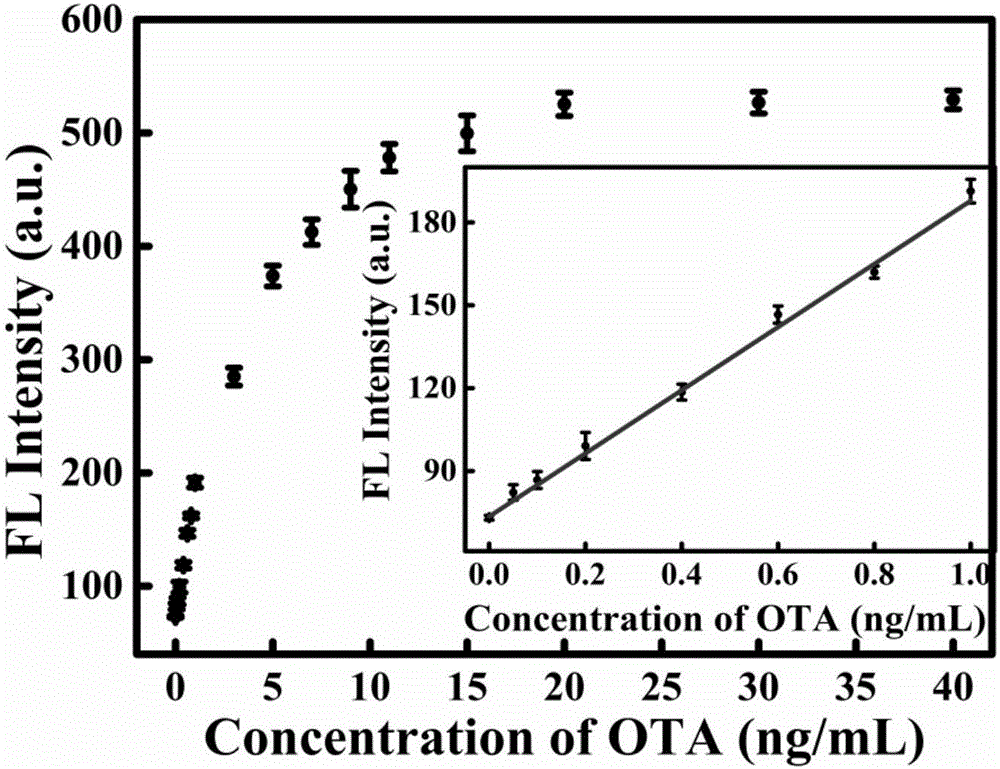

Fluorescent sensor for detecting mycotoxins and application method thereof

A fluorescent sensor for detecting mycotoxins and an application method thereof belong to the field of analytical chemistry. The surfaces of two groups of graphene quantum dots are modified respectively with aptamer DNA corresponding to mycotoxins or probe DNA complementary to the aptamer DNA, the graphene quantum dots are aggregated by DNA hybridization, exciton energy is transferred, and graphene quantum dot fluorescent signals are cancelled at last; mycotoxins are added then and engage in specific binding with the aptamer DNA, structural changes occur, the graphene quantum dot aggregation is disassembled and re-dispersed, and the system fluorescent strength is restored. The preparation method of the fluorescent sensor for detecting mycotoxins has a simple and feasible process, and the fluorescent sensor is green, low in cost, high in sensitivity and good in specificity and is successfully applied to standard added recovery of mycotoxins in actual wine samples.

Owner:BEIJING UNIV OF CHEM TECH

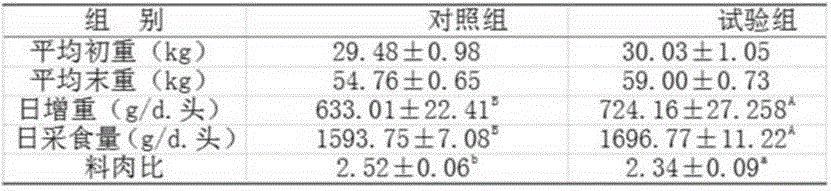

Pig complete fermented feed and preparation method thereof

InactiveCN105410410AEasy to operateReduce morbidityAnimal feeding stuffNutritive valuesAnimal science

The invention discloses a pig complete fermented feed preparation method and an application thereof. A pig complete fermented feed comprises the following main components: 60-70.5% of corn, 13-27% of soybean meal and the balance of wheat bran. The strain is composed of mixed lactic acid bacteria, saccharomyces and bacillus according to a ratio of (2-3):(1):(1). The fermented feed is prepared by performing solid state fermentation on a low-nutrition complete feed, molasses and multiple strains, can be used for feeding and nursing, pigs at multiple phases such as growth and pregnancy. The feed combines multi-phase physiological characteristics of pigs and aims at problems of component, nutrition and production of the pig feed at a current specific phase, the pig complete fermented feed can be prepared by using combination fermentation of the specific strains, nutrition value of the feed with low cost is increased, mycotoxin and antinutritional factors are reduced, usage of veterinary drug is reduced, culture cost is reduced, and animal health and production performance can be increased.

Owner:CHUYING AGRO PASTORAL GRP

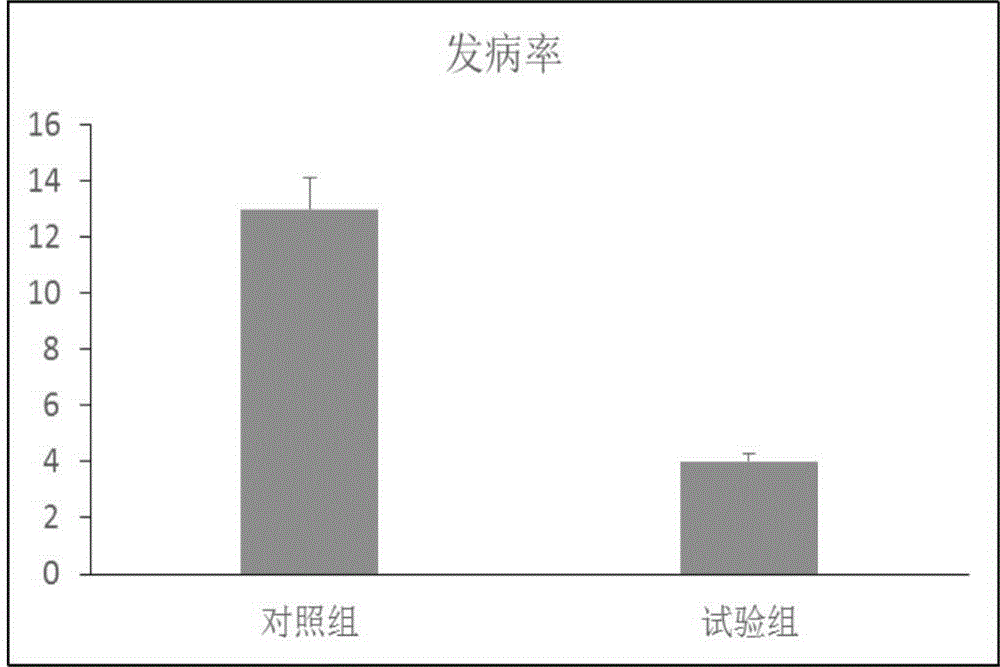

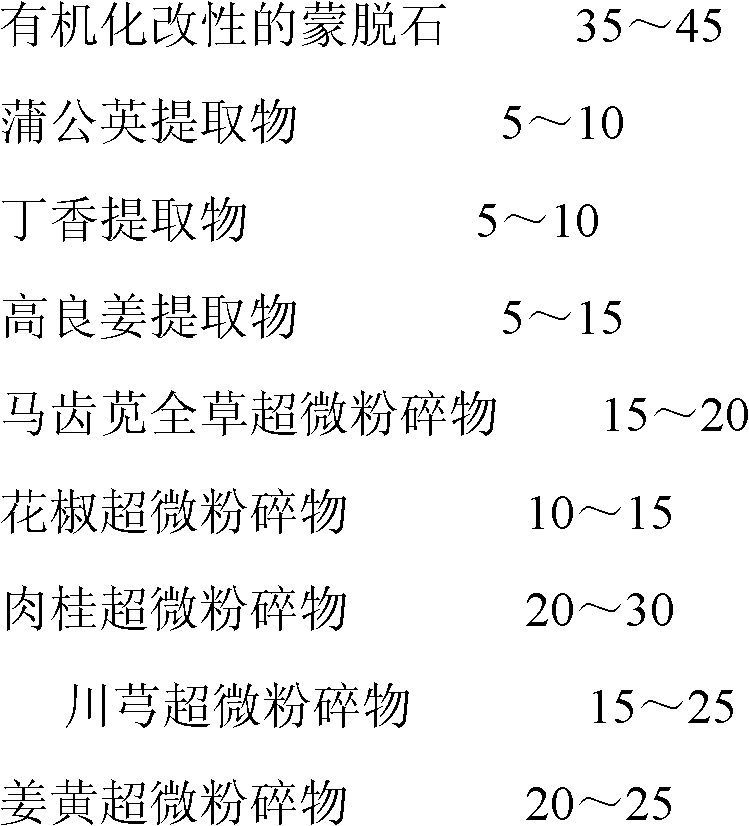

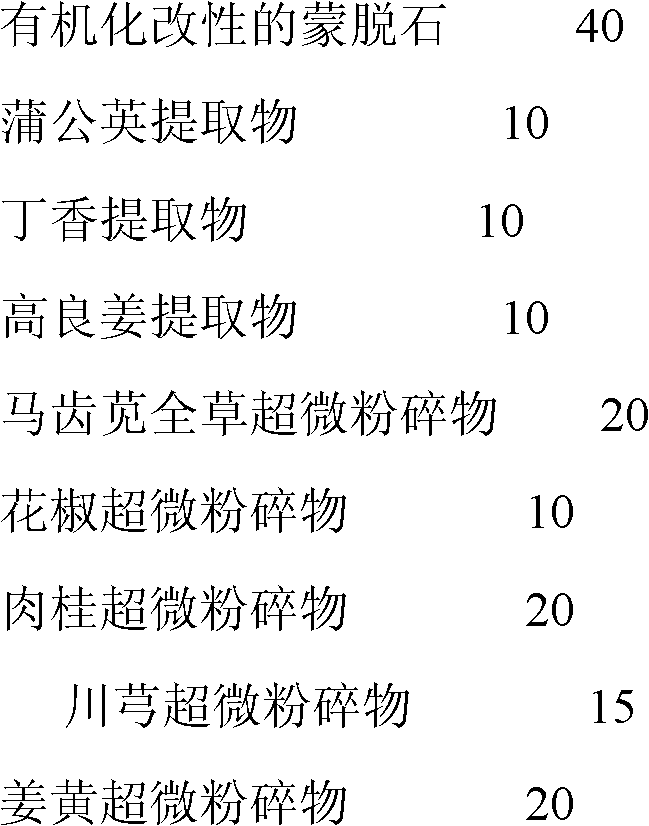

Mycotoxin detoxication agent for swine feed

ActiveCN103141685AImprove growth performanceIncrease production capacityAnimal feeding stuffMycotoxinSmoked Plum

The invention provides a compound mycotoxin detoxication agent for a swine feed, which is prepared by combining dandelion extract, clove extract, alpinia galangal extract, superfine ground purslane herb, superfine ground pepper, superfine ground cinnamon, fine ground smoked plum, superfine ground ligusticum wallichii, superfine ground rhizoma curcumae longae and organically modified montmorillonite. Raw materials of the compound mycotoxin detoxication agent are selected and obtained according to the plant species about homology of medicine and food of the National Ministry of Health, and thus the compound mycotoxin detoxication agent has the characteristics of wide source of the raw materials, high bioavailability and no toxicity and residue. The invention provides the compound mycotoxin detoxication agent which is capable of inhibiting propagation of mycetes and absorbing mycotoxin, and is also capable of effectively removing the damage of mycotoxin to the growth performance, the production performance and the health condition to animals.

Owner:唐山特驱饲料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com