Microbial fermentation feed as well as production method and application thereof

A technology of microbial fermentation and feed, applied in animal feed, animal feed, application, etc., can solve the problems of unsatisfactory application of microbial fermented feed, short maintenance time, and reduced conversion rate of fermented feed, so as to inhibit the growth of harmful bacteria, The effect of high content of functional ingredients and excellent fermentation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, the preparation of microbial fermented feed

[0060] 1) Mix the bran, brewer's grains, insect droppings and montmorillonite according to the same quality to obtain the fermentation base material;

[0061] Then mix the lactic acid bacteria, Clostridium butyricum Cb-2, Candida utilis, bacillus, the above-mentioned fermentation base material and water to obtain the fermentation raw material;

[0062] Wherein, the lactic acid bacteria are composed of Lactobacillus plantarum Lp and Pediococcus pentosaceae PP of equal mass;

[0063] Described spore is made up of equal mass spore B7348 and spore N9;

[0064] The number of viable bacteria in the described Lactobacillus plantarum Lp, Pediococcus pentosaceae PP, Clostridium butyricum Cb-2, Candida utilis, Bacillus B7348, and Bacillus N9 is 10 6 cfu / g;

[0065] The amount of lactic acid bacteria added is 50g of lactic acid bacteria per ton of fermentation base material;

[0066] The dosage of Clostridium butyricu...

Embodiment 2

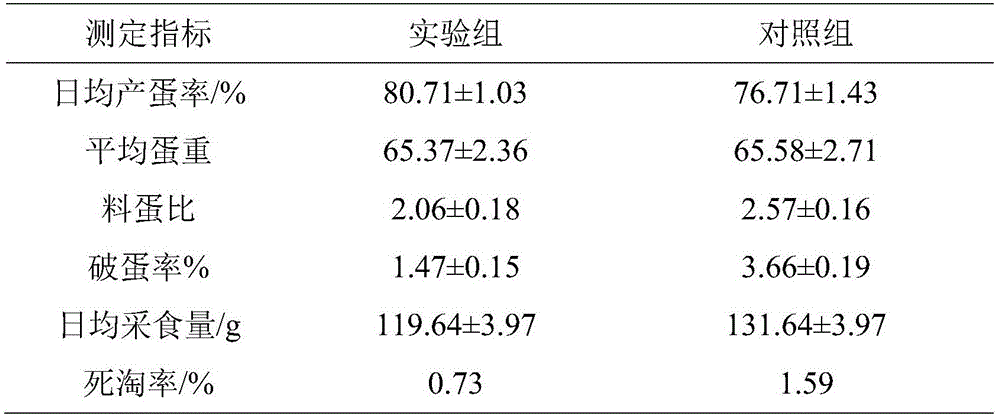

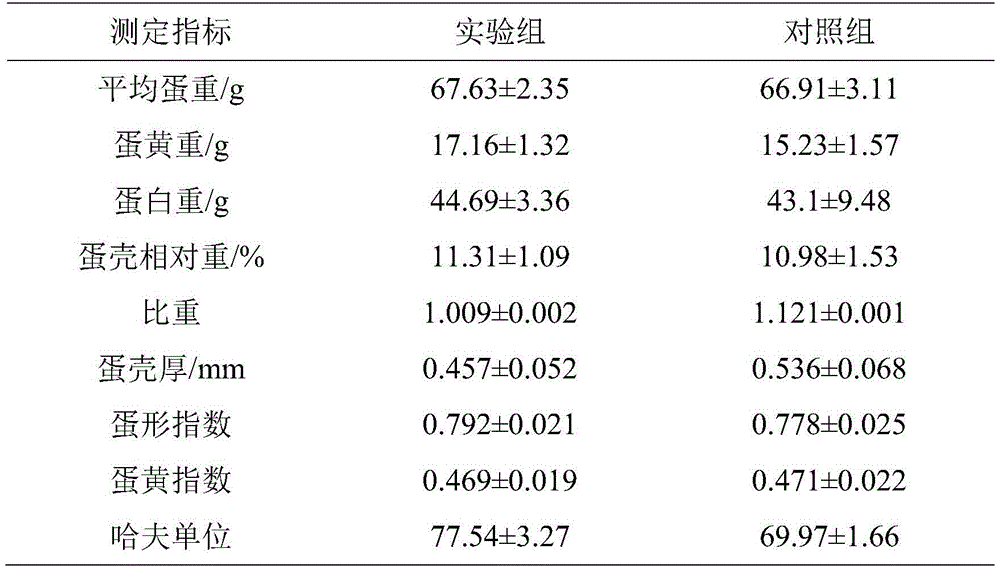

[0078] Embodiment 2, the application of microbial fermented feed in commercial laying hen breeding

[0079] 1.1.1 Experimental design

[0080] Select 300 healthy Hai-Line brown laying hens aged 375 days and divide them into two groups at random, namely the control group and the experimental group. Three parallel experiments were set up in each group, with 50 birds in each parallel. The experimental group was fed fermented feed in a fixed ratio (adding 4% of the obtained microbial fermented feed in Example 1 on the basis of the complete feed, that is, the mass ratio of the complete feed and the obtained microbial fermented feed in Example 1 was 100:4), Other conditions were exactly the same as the control group. The basal diets of the experimental group and the control group were exactly the same, and they had free access to food and water.

[0081] 1.1.2 Measuring indicators

[0082] Egg production performance: average daily egg production rate, broken egg rate, average egg...

Embodiment 3

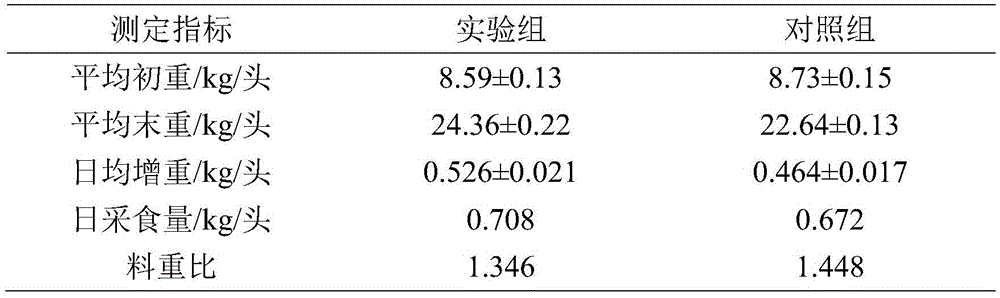

[0101] Embodiment 3, the application of microbial fermented feed in weaning piglet breeding

[0102] 2.1.1 Experimental design

[0103] 90 healthy 35-day-old Taishan black weaned piglets weighing about 8.5kg were selected for feeding experiment.

[0104] According to the principle of similar body weight and consistent sex ratio, they were randomly divided into two groups, namely the experimental group and the control group, and each group was set up in three parallels with 15 heads in each parallel. The experimental group was fed with basal diet and fermented feed (adding 2% of the microbial fermented feed obtained in Example 1 on the basis of the complete feed, that is, the mass ratio of the complete feed and the obtained microbial fermented feed in Example 1 was 100:2) , the control group was only fed the basal diet, and the test period was 30 days. The weaned piglets in the experimental group and the control group were fed with the same basal diet, and they were fed in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com