Mold removal agent for animal feed as well as preparation method and application of mold removal agent

A mold remover and technology for animals, which is applied in the field of animal feed mold remover and its preparation, can solve the problems of ignoring mold inhibition, saturation and incompleteness of the remover agent, treating the symptoms but not the root cause, etc., so as to promote animal growth and improve Animal immunity, the effect of inhibiting the growth of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

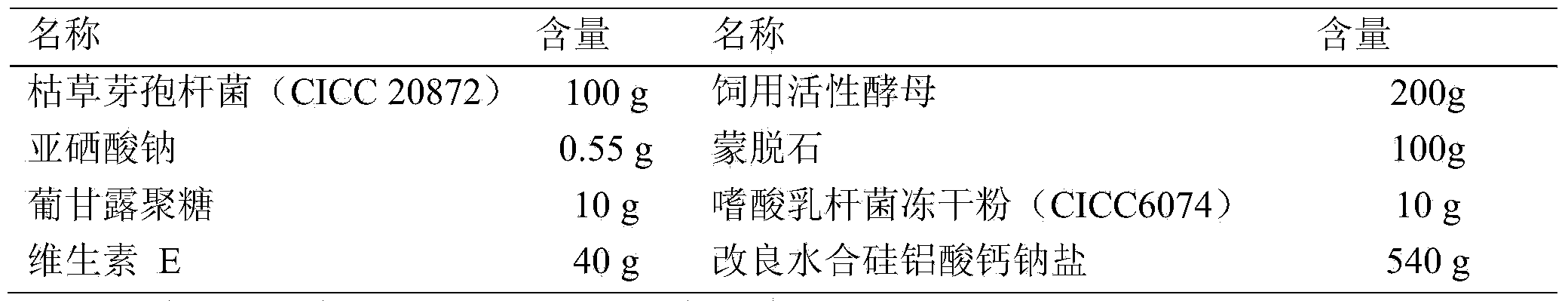

[0044] Example 1 Preparation of feed demolition agent for animals

[0045] Preparation of modified hydrated calcium aluminosilicate sodium salt: firstly, hydrated calcium aluminosilicate sodium salt mineral (purchased from American Milby Co., Ltd., with an effective content of more than 95%) is crushed by a fine crusher (Shanghai Vivo Power Jaw Crusher) PEW180×1300) and then sieved to obtain 3-10mm minerals, and then grind them on an agate ball mill (QM-4H ball mill produced by Nanjing Sangli Electronic Equipment Factory), with a volume ratio of 1:2, dry-wet The method of ball milling is dry ball milling (rotating speed of 200r / min) for the first 30 hours, and wet ball milling for the next 30 hours. The method is the same as the dry ball milling method, except that 12-15ml of absolute ethanol (per 50g mineral The amount added), the sample is dried after grinding. Observing the ground particles with a JEOL 2000F transmission microscope, it was found that the particles ≤100nm acco...

Embodiment 2

[0116] Weigh and mix each substance according to the following dosage: Bacillus subtilis (CICC20872) 70g (content is 1×10 10 cfu / g), Lactobacillus acidophilus freeze-dried powder (CICC6074) 7g (content 2×10 10 cfu / g), 0.2g sodium selenite, 30g vitamin E (500IU / g), 140g active dry yeast for feed (Ange Yeast Co., Ltd.), 7g glucomannan, 70g montmorillonite, according to Example 1 400 g of the modified hydrated calcium aluminosilicate sodium salt prepared by the steps described above.

Embodiment 3

[0118] Weigh and mix each substance according to the following amount: Bacillus subtilis (CICC20872) 130g (content is 1×10 10 cfu / g), Lactobacillus acidophilus freeze-dried powder (CICC6074) 13g (content 2×10 10 cfu / g), sodium selenite 0.8g, vitamin E50g (500IU / g), feed active dry yeast 260g (Angie Yeast Co., Ltd.), glucomannan 13g, montmorillonite 130g, according to Example 1 650 g of modified hydrated calcium aluminosilicate sodium salt prepared in the steps described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com