Patents

Literature

154results about How to "Change hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent-free polyaspartic acid ester polyurea elastic waterproof paint

ActiveCN103031045AGood elongation at breakEasy constructionPolyurea/polyurethane coatingsSolventIsocyanate

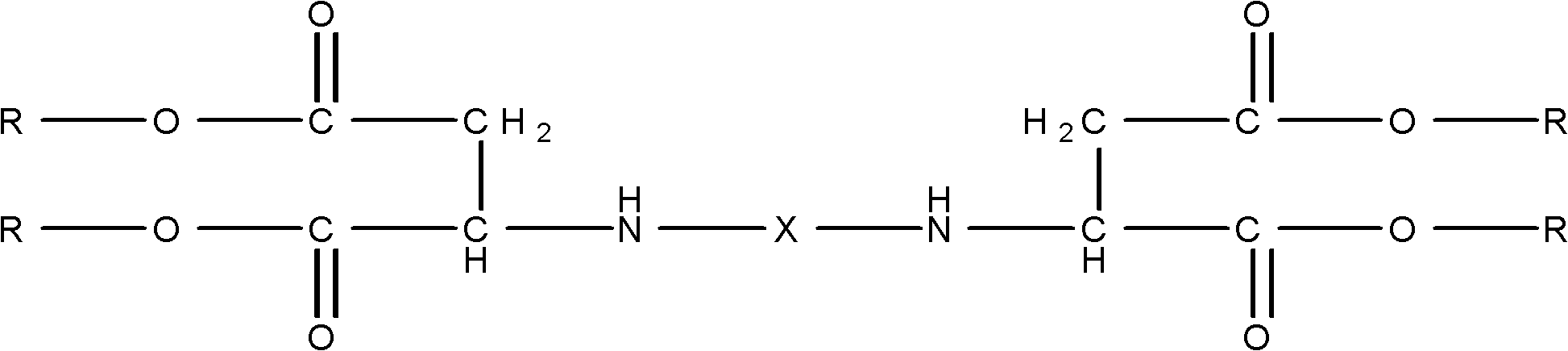

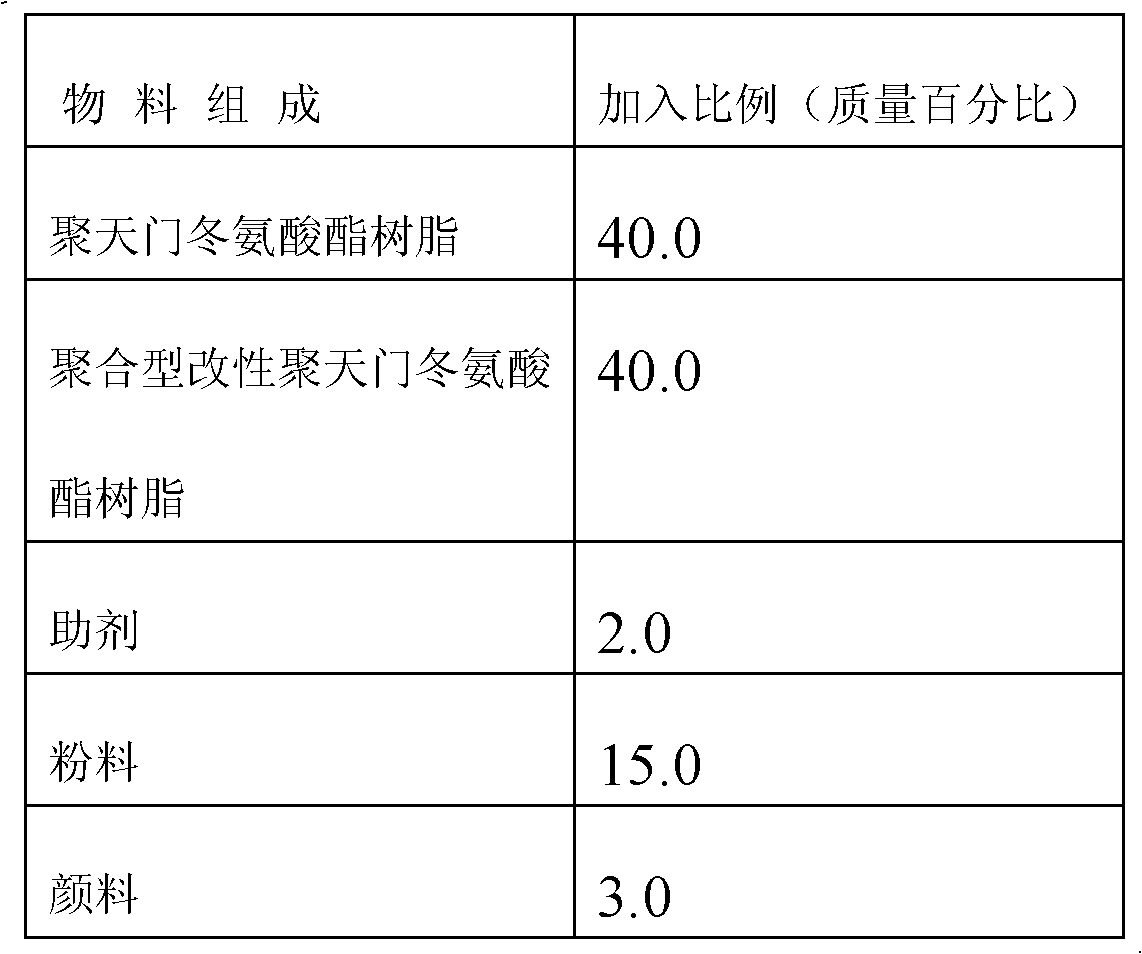

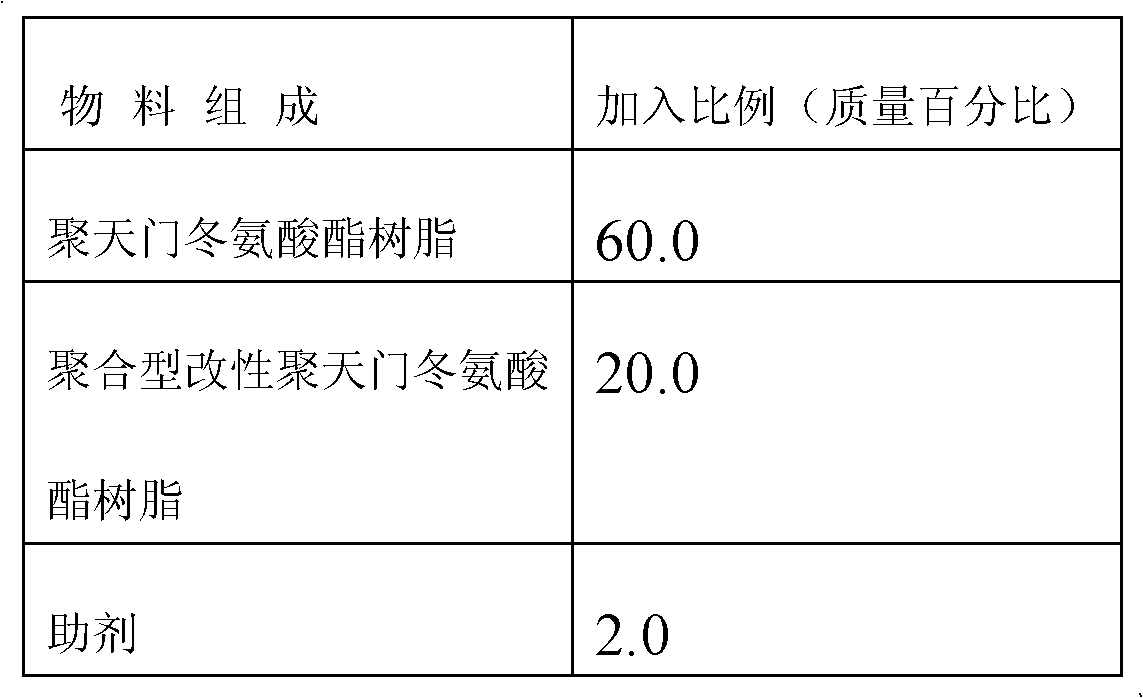

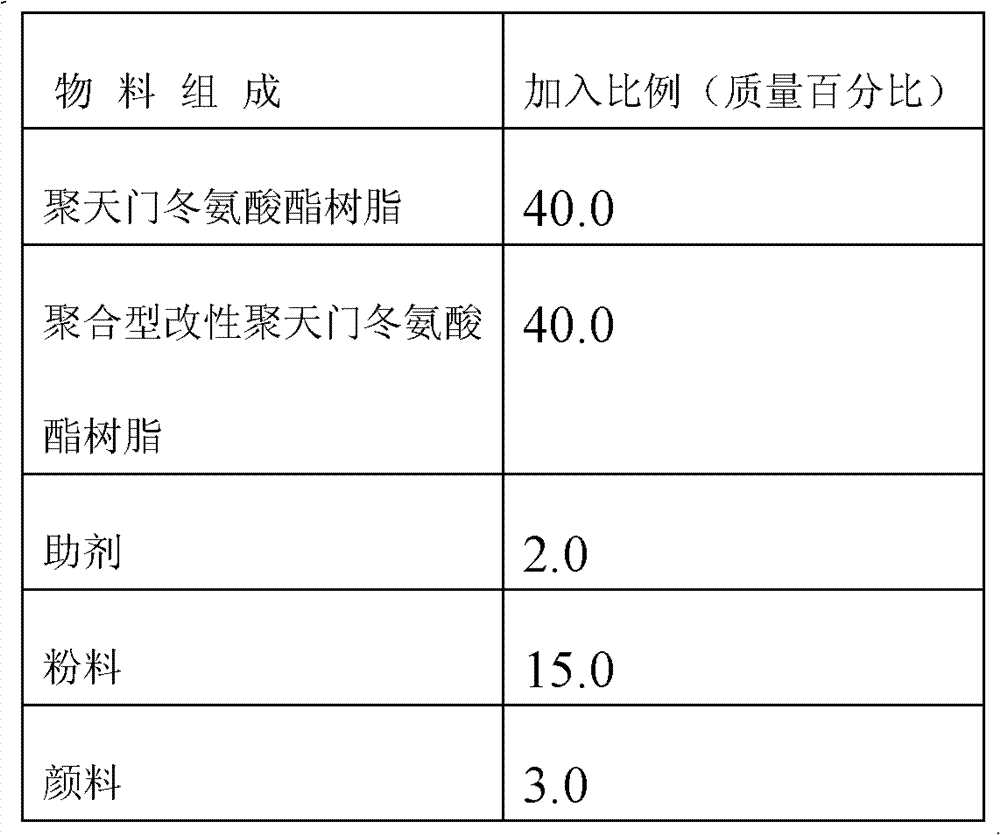

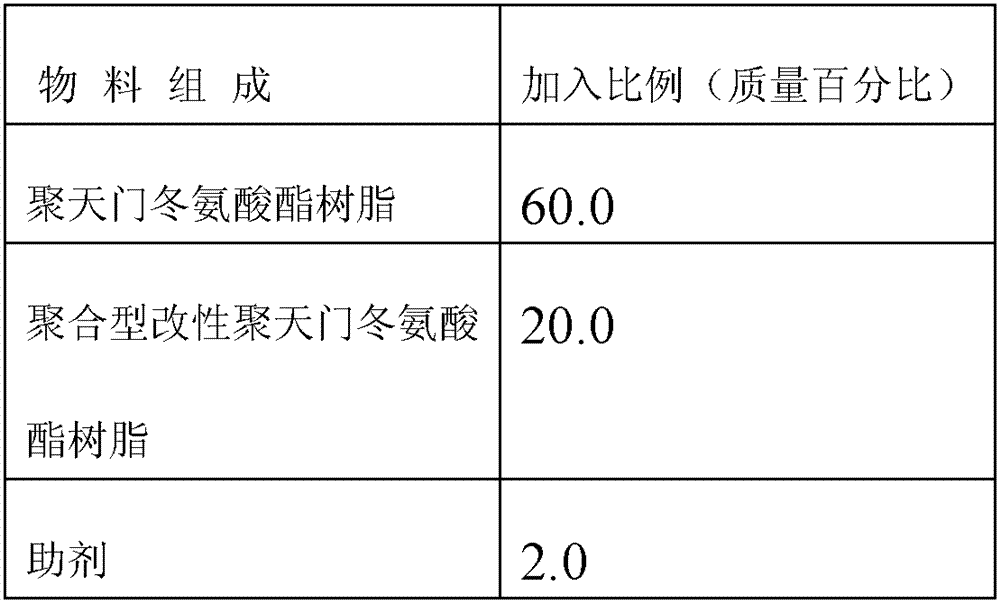

The invention relates to paint and a preparation method thereof and discloses solvent-free polyaspartic acid ester polyurea elastic waterproof paint. The solvent-free polyaspartic acid ester polyurea elastic waterproof paint is composed of a component A and a component, wherein the component A comprises 2%-35% of polyisocyanate and 65%-98% of end seal isocyanate prepolymer by weight percent; and the component B comprises 20%-60% of polyaspartic acid ester, 10%-40% of polymeric modified poly aspartic acid ester, 5%-30% of stuffing and a small amount of additives by weight percent. Compared with the polyurea paint processed by the polyaspartic acid ester, the solvent-free polyaspartic acid ester polyurea elastic waterproof paint processed by raw materials has the advantages that the construction is convenient, a special large-scale spraying device is not needed, the gelation time is prolonged, the surface drying time is shortened, the tensile strength is enhanced, the elongation at break is increased, and the elastic coating film hardness is increased, does not have a solvent, is environment-friendly and harmless to a human body.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

Timber softening fluid

InactiveCN103406961AFlame retardantChange hardnessWood treatment detailsWood impregnation detailsParaffin waxBoric acid

The invention discloses a timber softening fluid which is prepared from the following raw materials in parts by weight: 35 to 45 parts of semi-refined paraffin wax No.58, 15 to 25 parts of a softening agent containing multiple chemical components, 5 to 7 parts of boric acid and 35 to 45 parts of water.

Owner:安徽雪峰木业有限公司

Low-temperature conductive silver paste and preparation method thereof

ActiveCN102157222AGood shrinkage propertiesGood strengthConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialIsophoronePolyester

The invention discloses a low-temperature conductive silver paste and a preparation method thereof, relating to conductive silver paste materials and aiming at solving the problems of high cost and large resistance of conductive silver pastes used for a printing industry. The low-temperature conductive silver paste comprises the following components in percentage by weight: 45% of silver powder, 6% of additive bismuth oxide, 6.2% of macromolecule resin vinyl chloride-acetate, 6.2% of macromolecule resin polyester, 34% of solvent DBE and 2.6% of solvent isophorone. The preparation method comprises the following steps of: a, weighing and mixing the solvent DBE, the solvent isophorone and macromolecule resins according to weight percentage to obtain an organic carrier; b, weighing the silver powder and the additives according to the weight percentage, and then mixing with the organic carrier obtained from the step a in a stirring way to obtain a uniform paste; and c, grinding and rolling the paste obtained from the step b to obtain the low-temperature conductive silver paste.

Owner:CHENGDU BANKNOTE PRINTING

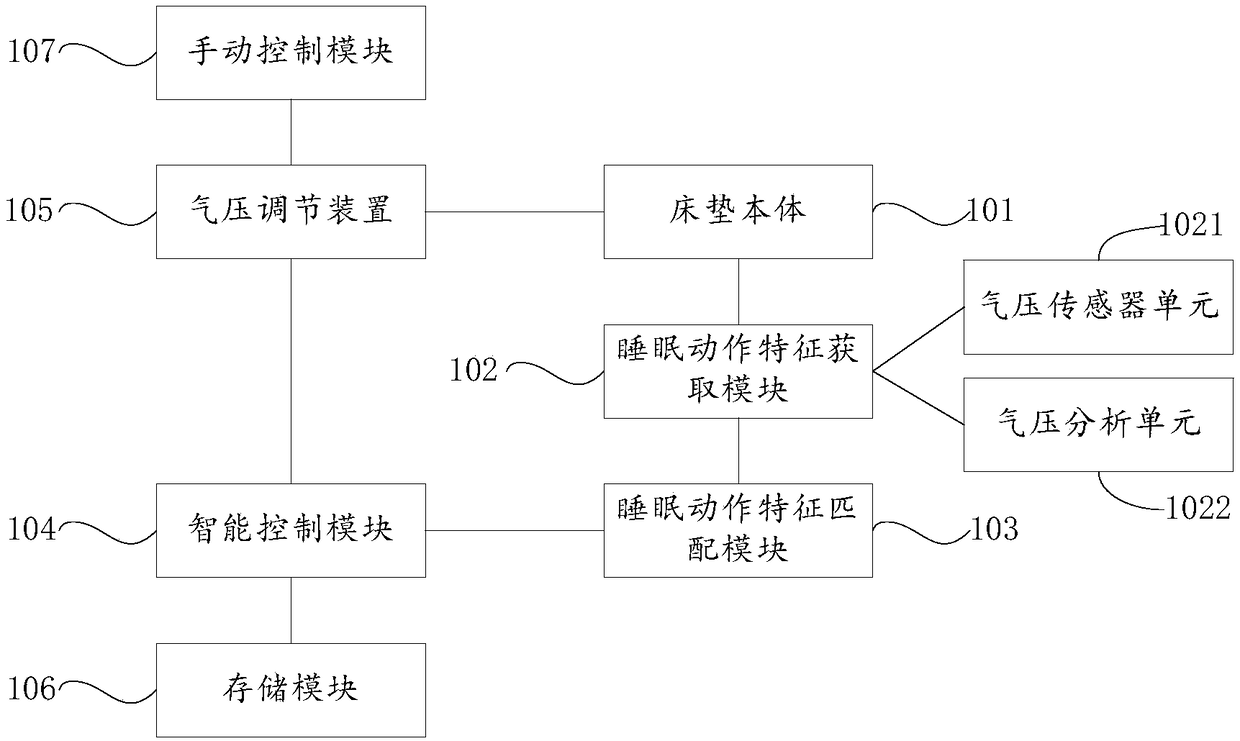

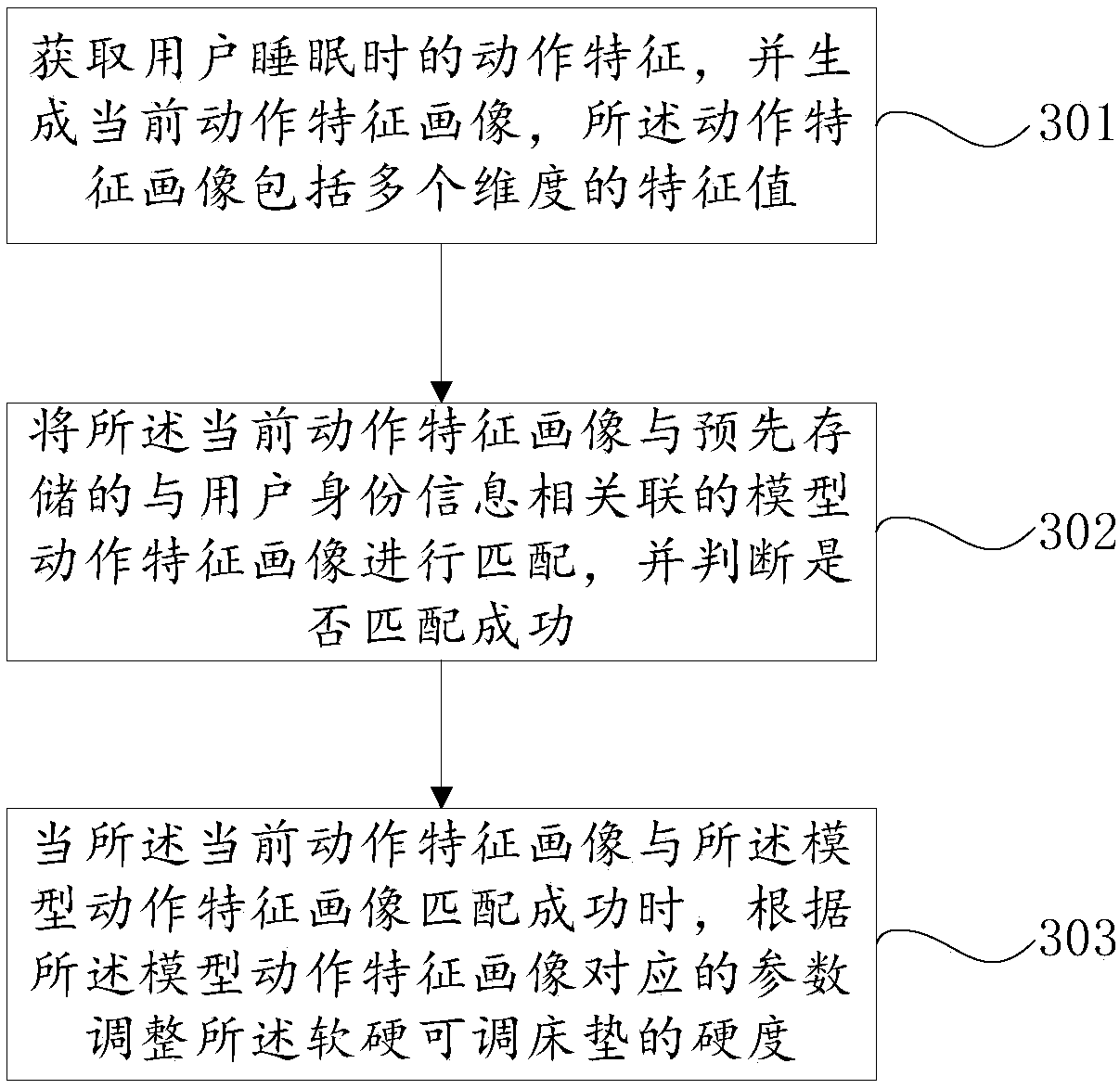

System and method for user sleep personalized service of intelligent soft and hard adjustable mattress

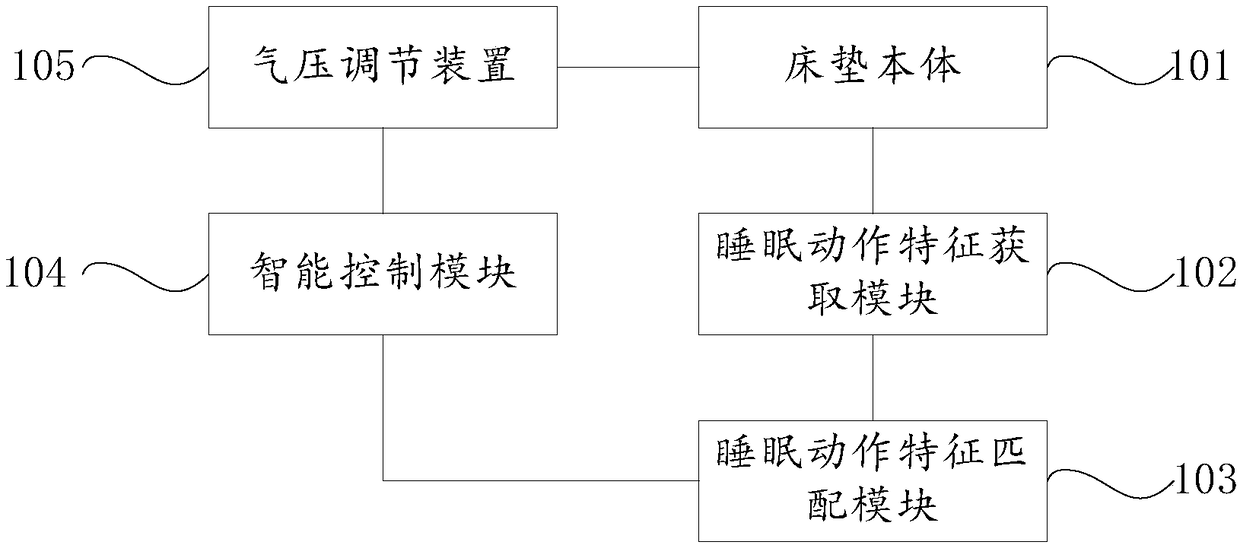

The embodiments of the application provide a system and a method for user sleep personalized service of an intelligent soft and hard adjustable mattress. The system comprises a mattress body, an air pressure adjustment device, a sleep action feature acquisition module, a sleep action feature matching module and an intelligent control module, wherein the mattress body is internally provided with anair bag; the air pressure adjustment device is connected with a vent hole of the air bag and is used for performing the softness and hardness adjustment and a deflating operation on the air bag; thesleep action feature acquisition module is used for acquiring the action features of a user during sleep and generating a current action feature portrait; the sleep action feature matching module is used for matching the current action feature portrait with a pre-stored model action feature portrait associated with the user identity information; the intelligent control module is used for adjustingthe hardness of the soft and hard adjustable mattress according to parameters corresponding to the model action feature portrait. The system and the method for the user sleep personalized service ofthe intelligent soft and hard adjustable mattress realize automatic adjustment of the mattress hardness according to the individual demands, thus being beneficial to user rest, sleep quality improvement as well as growth and development of juveniles.

Owner:浙江想能云软件股份有限公司

Improved thermoplastic elastomer material and its preparing method

The present invention belongs to the field high molecular material technology, and especially one improved thermoplastic elastomer material and its preparation. Into S.E.B.S body material PP, PE, PS,EVA and other plastic capable of being cross linked with the body material are added to improve the hardness, elongation strength, elongation are and other physical performance and to widen the application range.

Owner:余阿文

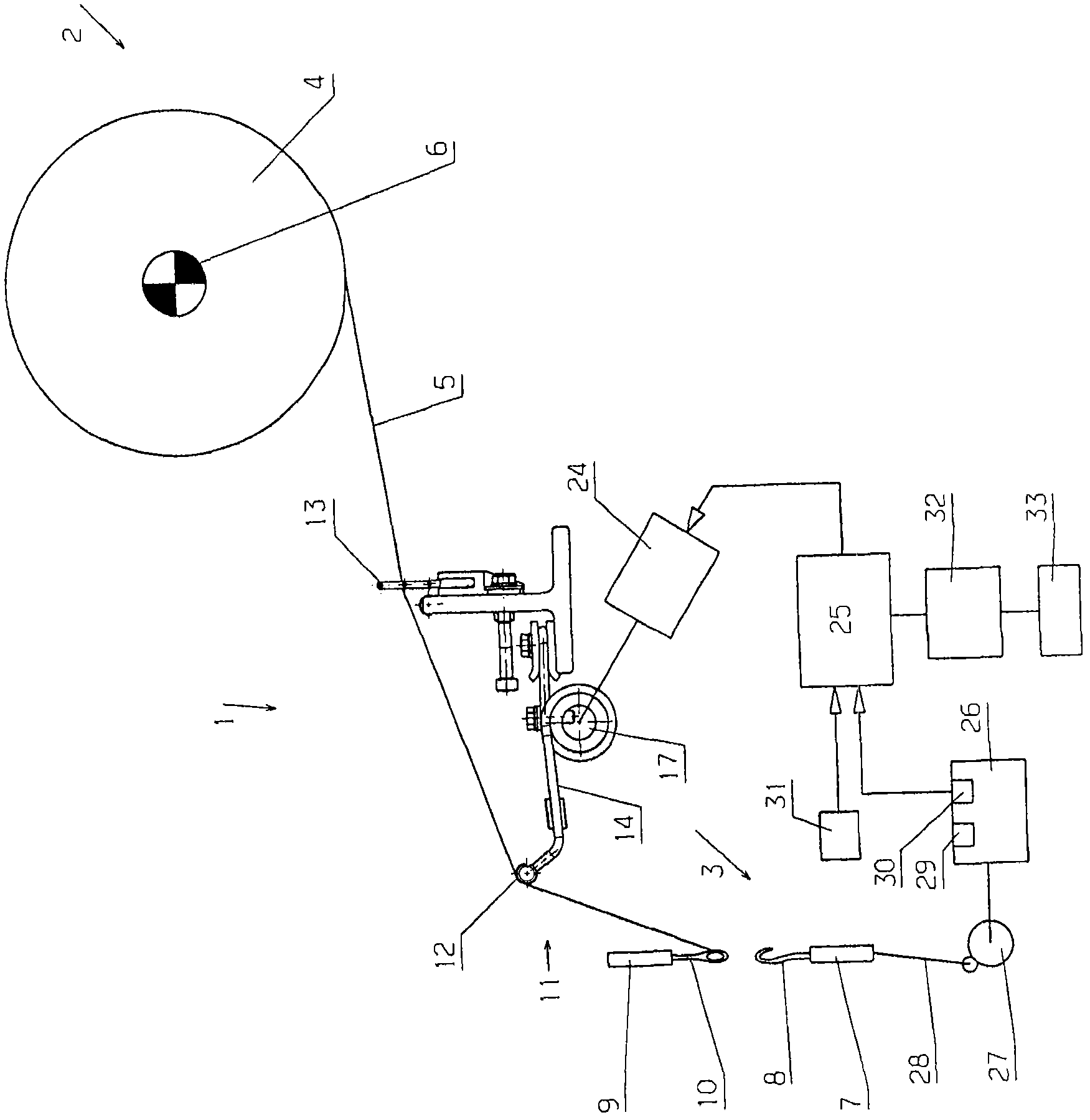

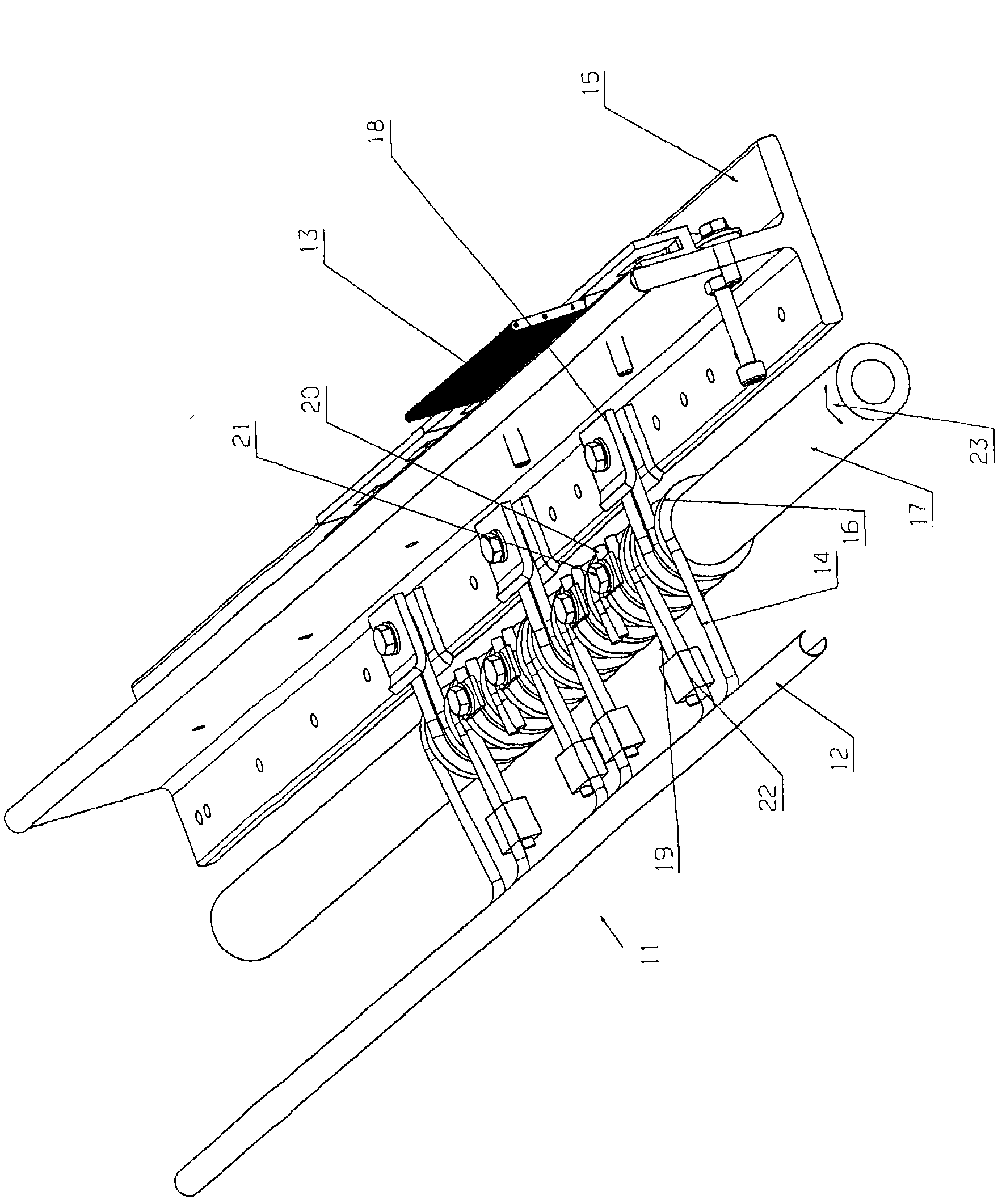

Warp knitting machine

ActiveCN102965835AChange natural frequencyChange hardnessWarp knittingWarp knittingMechanical engineering

The knitting machine (1) has a yarn feeding portion (2), an active region (3), and a thread tension compensating device (11) between the yarn feeding portion and the active region. The quality of knitted fabric is reduced to the minimum through a simple method. Therefore, the thread tension compensating device (11) can be actuated from the outside through a control device (17, 24) with which a natural frequency of the tension compensating device is varied.

Owner:KARL MAYER STOLL R&D GMBH

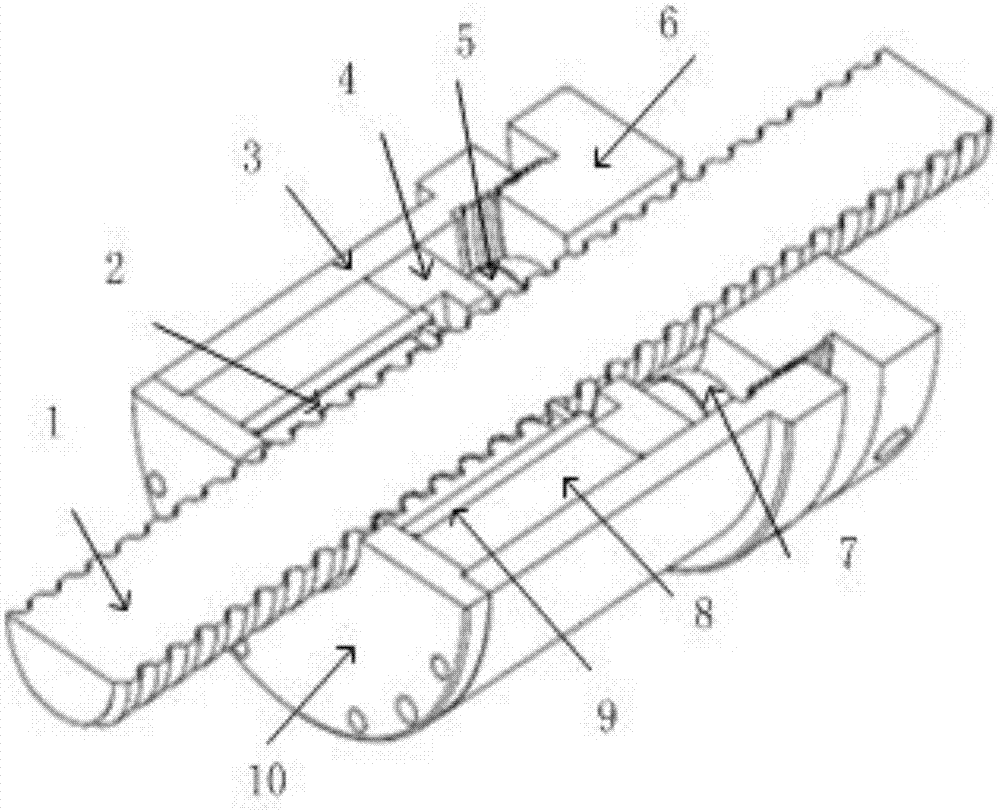

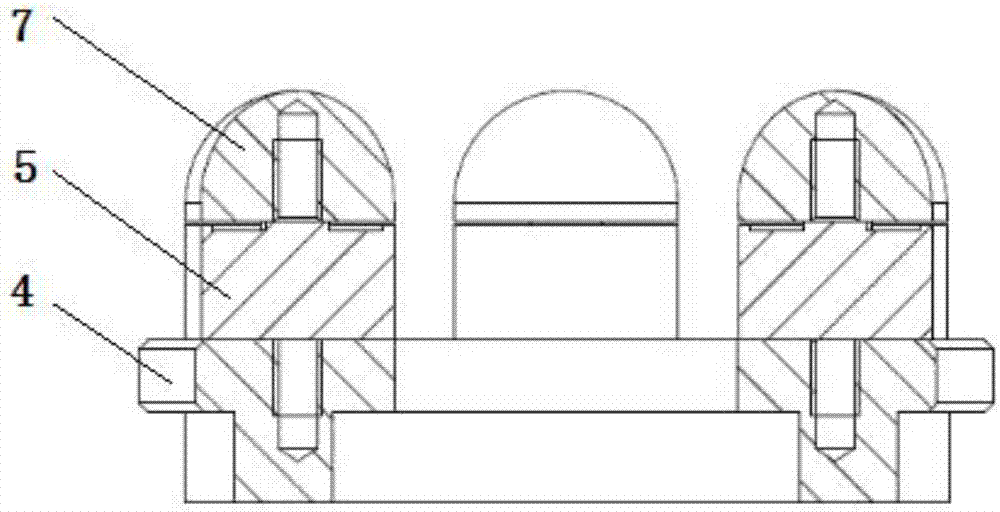

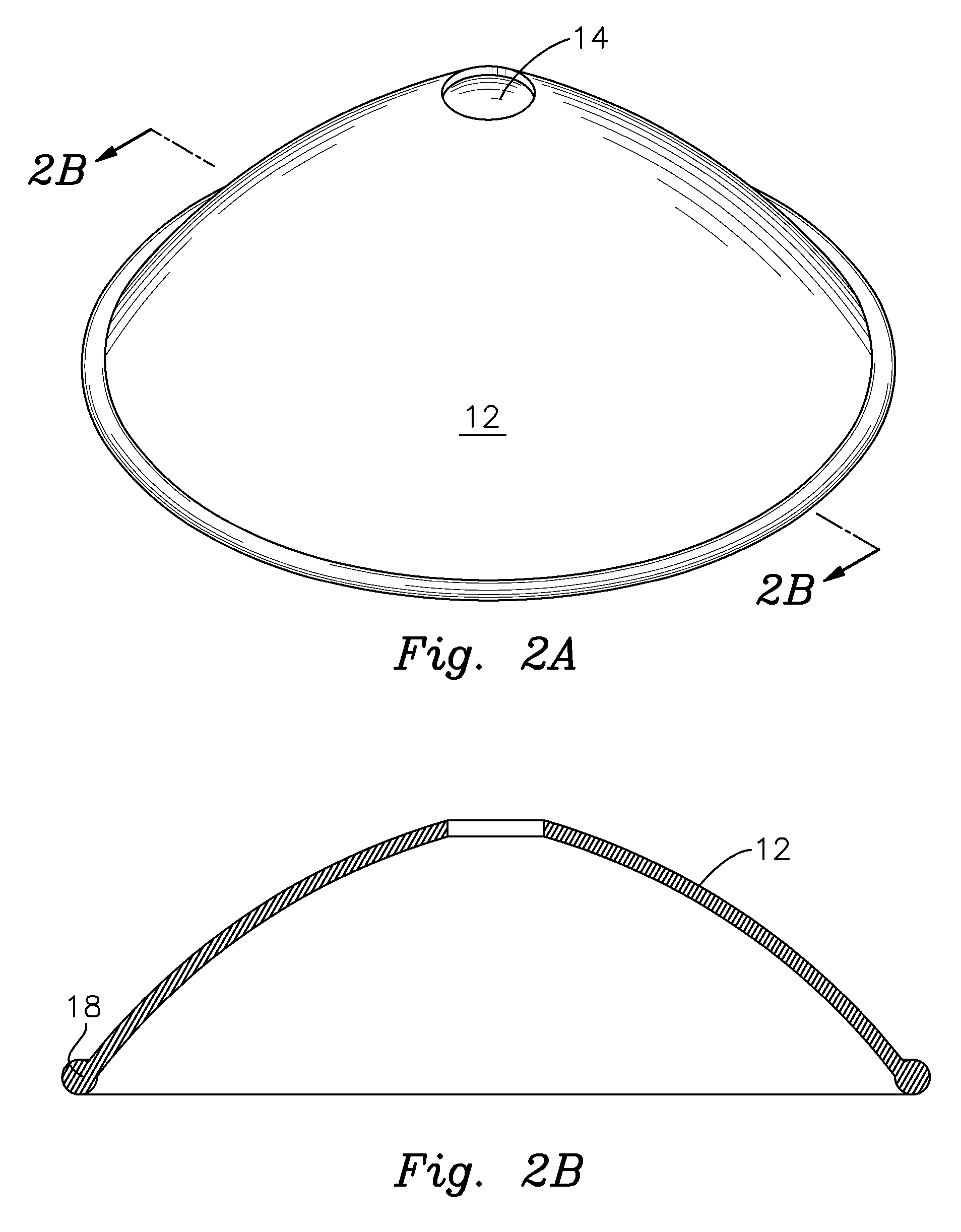

Tool for ball screw pair outer raceway grinding and grinding force loading

InactiveCN107322418AChange hardnessChange elasticityGrinding feed controlGrinding machinesPolyurethane elastomerAxial pressure

The invention provides a tool for ball screw pair outer raceway grinding and grinding force loading. The tool comprises a flexible nut, a grinding outer cover, a sensor assembly, a thread end cap, a polyurethane elastic body, a polyurethane buffering body and an outer cover base. The outer cover base is arranged at the front end of the grinding outer cover and forms a grinding cavity with the grinding outer cover, a first lead screw through hole is formed in the outer cover base, and the flexible nut is arranged in the grinding cavity and connected with a lead screw in a matched mode. The flexible nut is sleeved with the polyurethane buffering body, and the polyurethane buffering body is sleeved with the polyurethane elastic body. The inner wall of the polyurethane elastic body and the outer wall of the polyurethane buffering body are tightly matched, and the outer wall of the polyurethane elastic body and the inner wall of the grinding cavity are tightly matched. The thread end cap is provided with a second lead screw through hole and extends into the grinding cavity to be fixed from the rear end of the grinding outer cover, the sensor assembly is arranged between the thread end cap and the polyurethane elastic body and provided with tension and pressure sensors, and the pressure sensors measure the axial pressure of the thread end cap on the polyurethane elastic body.

Owner:NANJING UNIV OF SCI & TECH

Silica-gel-containing sponge mattress

ActiveCN103980694AChange hardnessGuaranteed constant temperatureStuffed mattressesSpring mattressesFoaming agentCold winter

The invention discloses a silica-gel-containing sponge mattress which comprises 75-90 parts of polyurethane, 15-20 parts of silica gel, 0.2-0.3 part of silicon oil, 0.1-0.2 part of crosslinking agent, 0.2-0.3 part of foaming agent, 0.1-0.15 part of catalyst, 0.05-0.2 part of foam stabilizer and 1.5-2.5 parts of water. The invention also discloses a preparation method of the silica-gel-containing sponge mattress, which comprises the following steps: weighing the raw material components, grinding the silica gel into granules with the granularity of lower than 100 meshes, evenly mixing all the components, putting into a foaming machine, foaming, cooling, and making the mattress according to the conventional method. By adding the silica gel into the raw materials and combining the advantages of the sponge and silica gel, the prepared sponge mattress feels warm in winter and cool in summer, has the effect of keeping the temperature constant, and is not too cold in cold winter or too hot in hot summer. According to the manufacturing method, the silica gel is ground into the granules with the granularity of lower than 100 meshes, and all the raw materials are mixed, foamed, cooled and prepared into the mattress according to the conventional mattress production method. The method is simple in operation sequence and suitable for large-scale production.

Owner:泉州玺堡家居科技有限公司

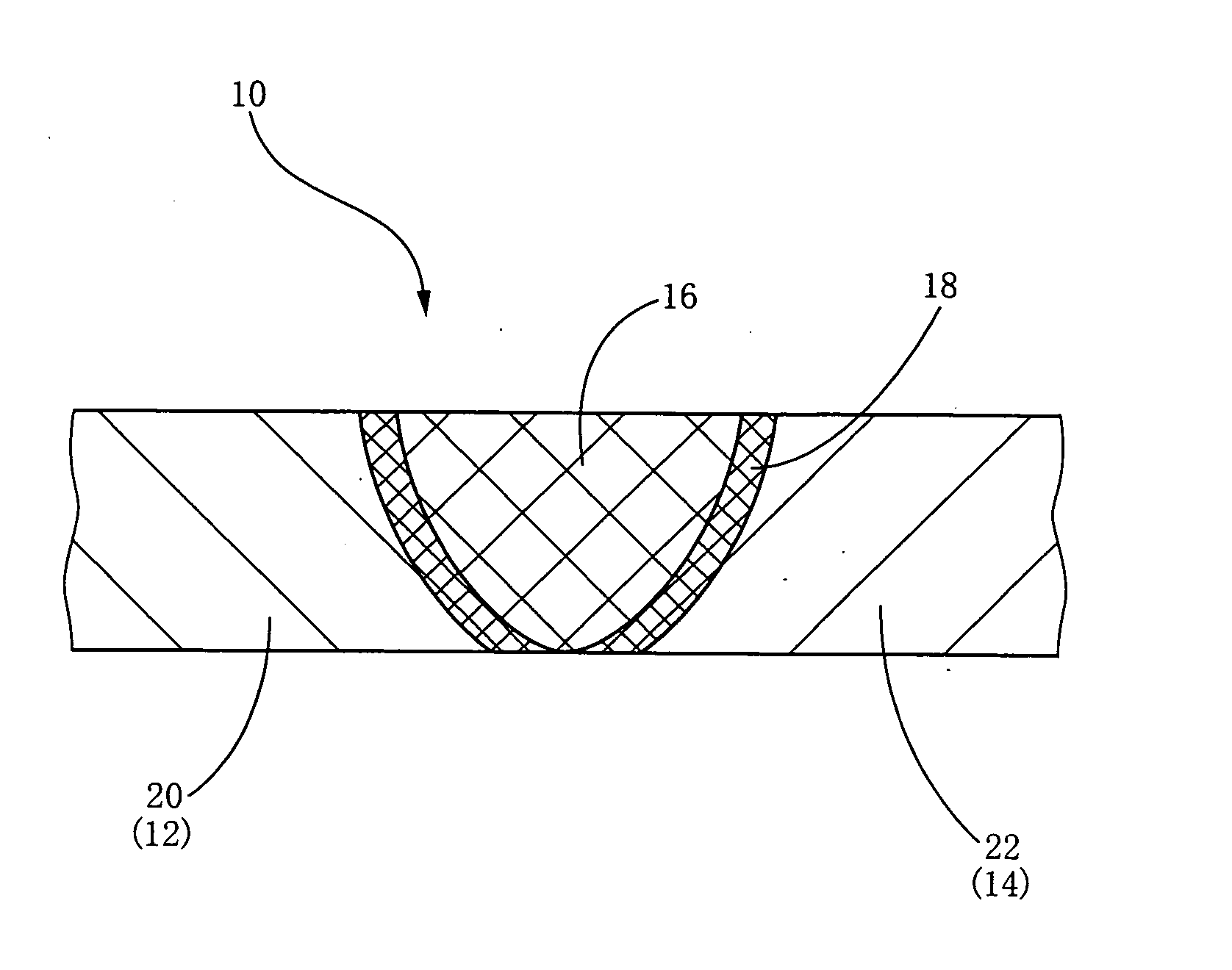

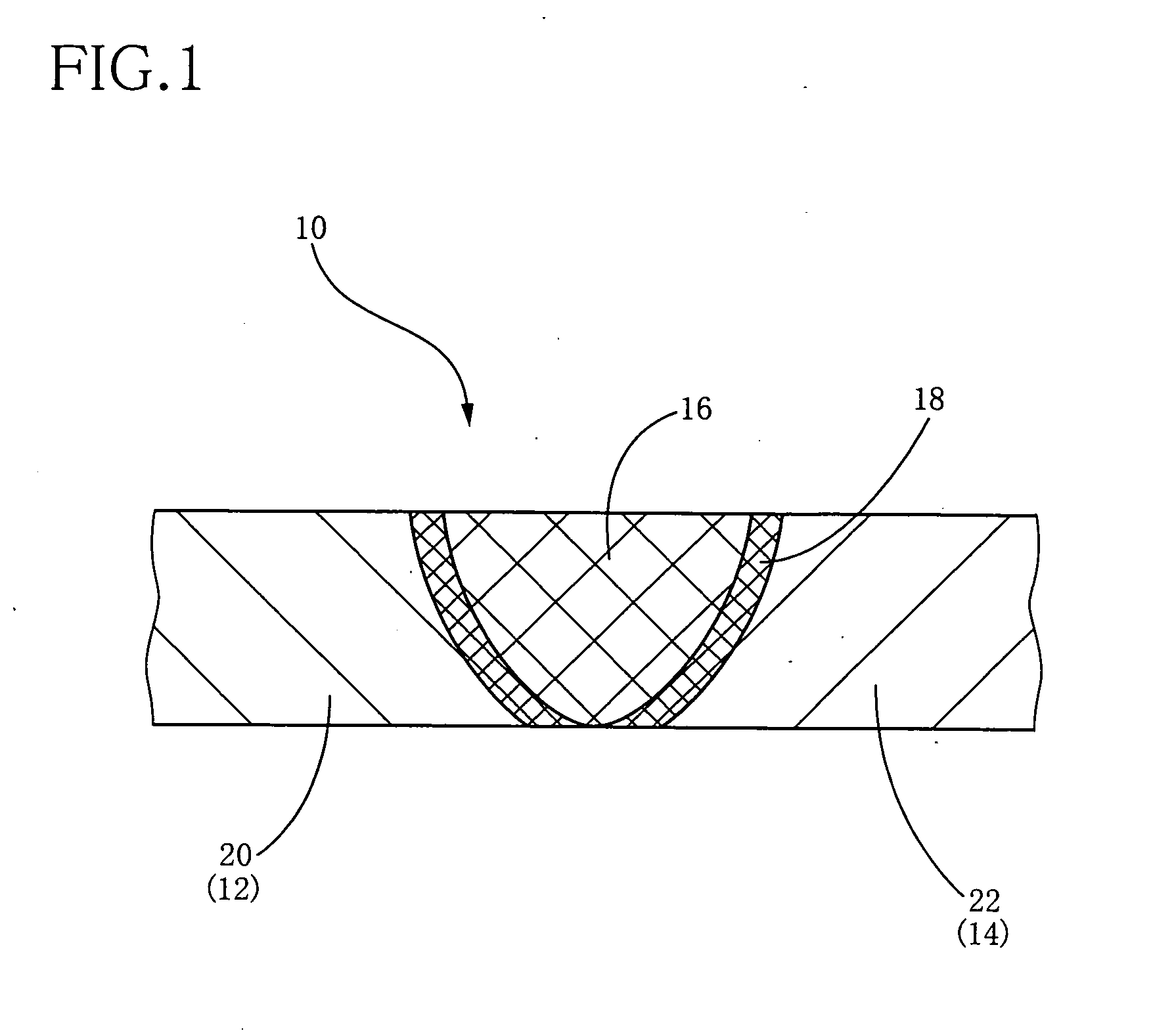

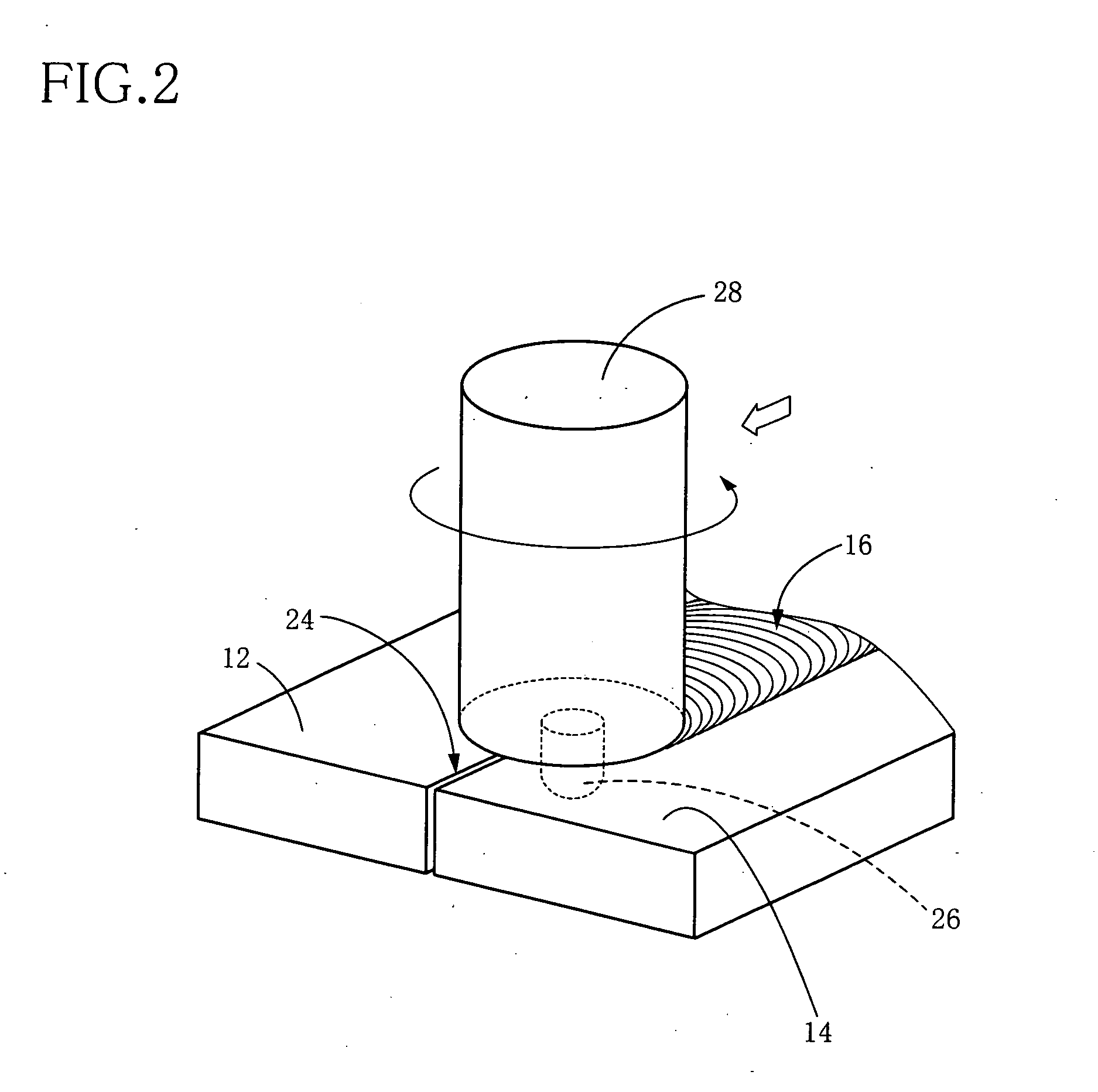

Method of joining aluminum alloy members and joined product used for press forming

InactiveUS20070138235A1Change hardnessGood effectWelding/cutting auxillary devicesAuxillary welding devicesHardnessFriction stir welding

A method of joining aluminum alloy members, including the steps of: obtaining a joined body including: (a) contacting aluminum alloy members each made of a 6000 series aluminum alloy with T4 temper; and (b) performing a friction stir welding operation on a contact portion of the aluminum alloy members at which they are held in contact with each other, so as to form a stir zone at the contact portion; and performing, on the obtained joined body, an underaging treatment which is an artificial aging treatment and which is completed before hardness of the stir zone reaches maximum hardness, the underaging treatment being performed before GP zones are formed at the stir zone of the joined body.

Owner:FURUKAWA SKY ALUMINUM CORP +1

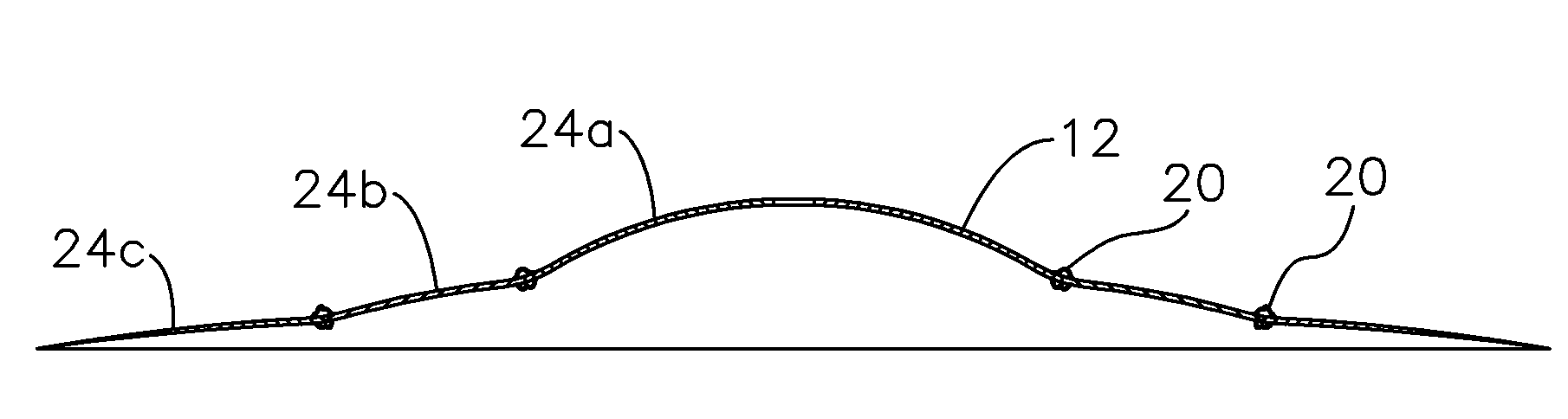

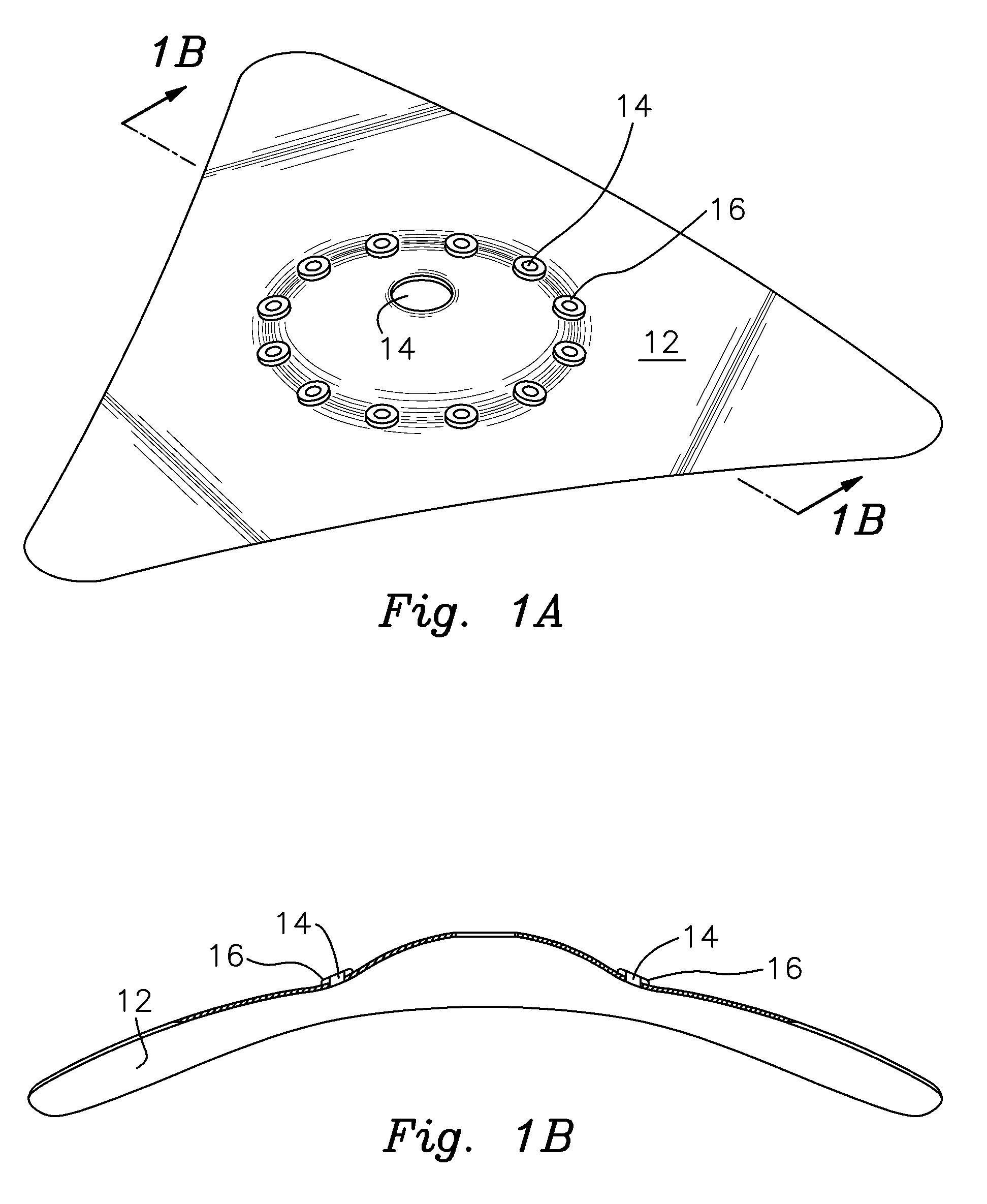

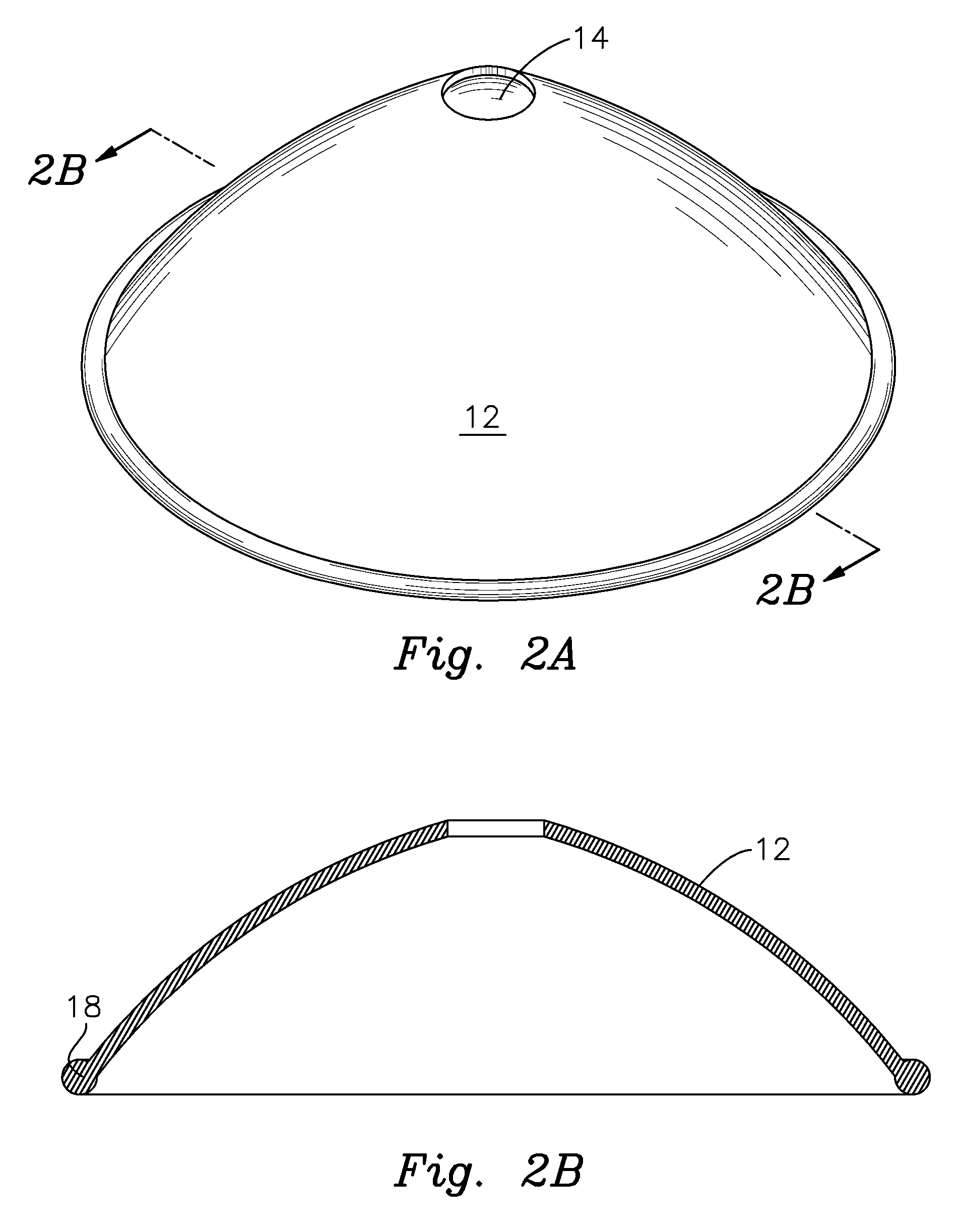

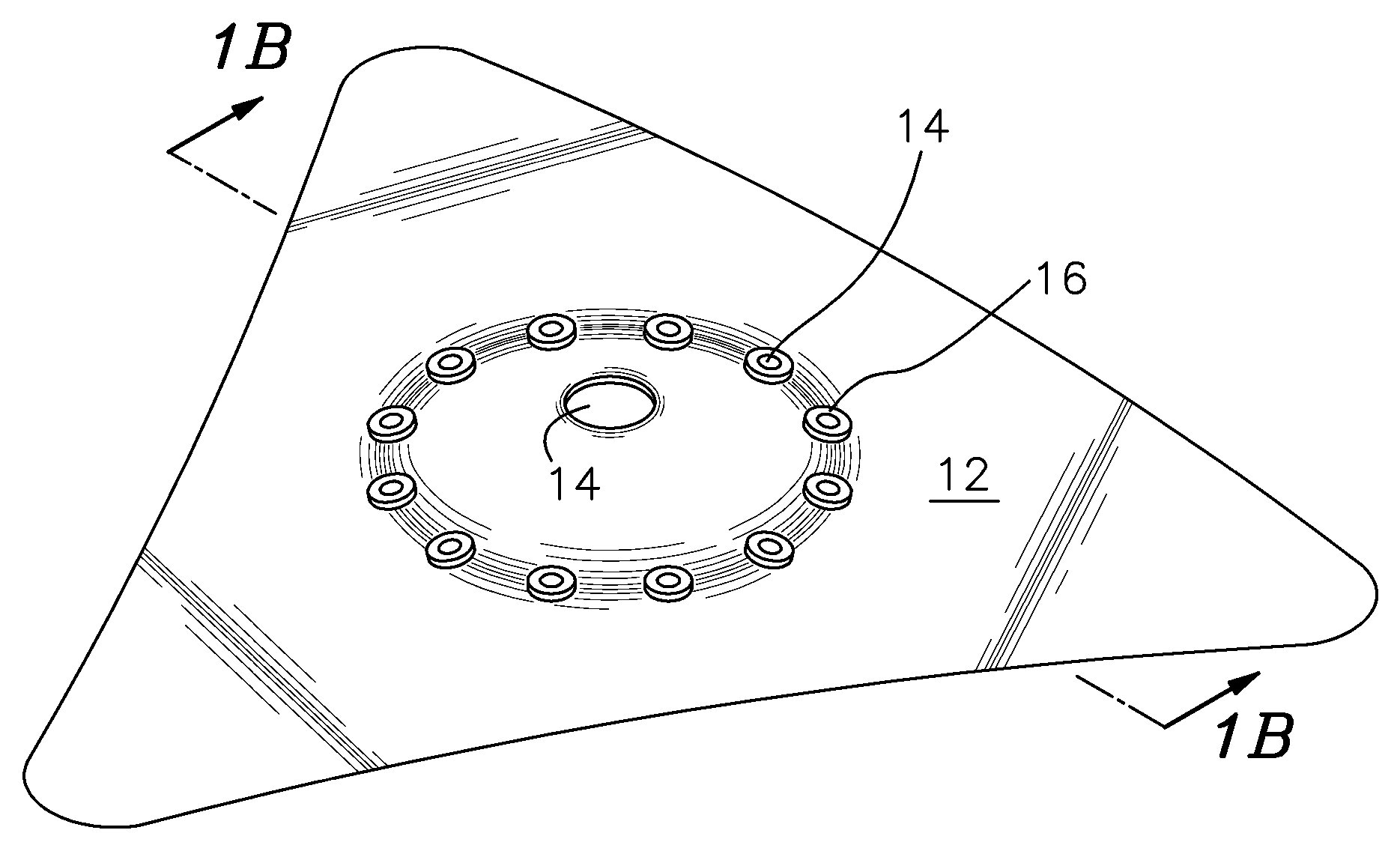

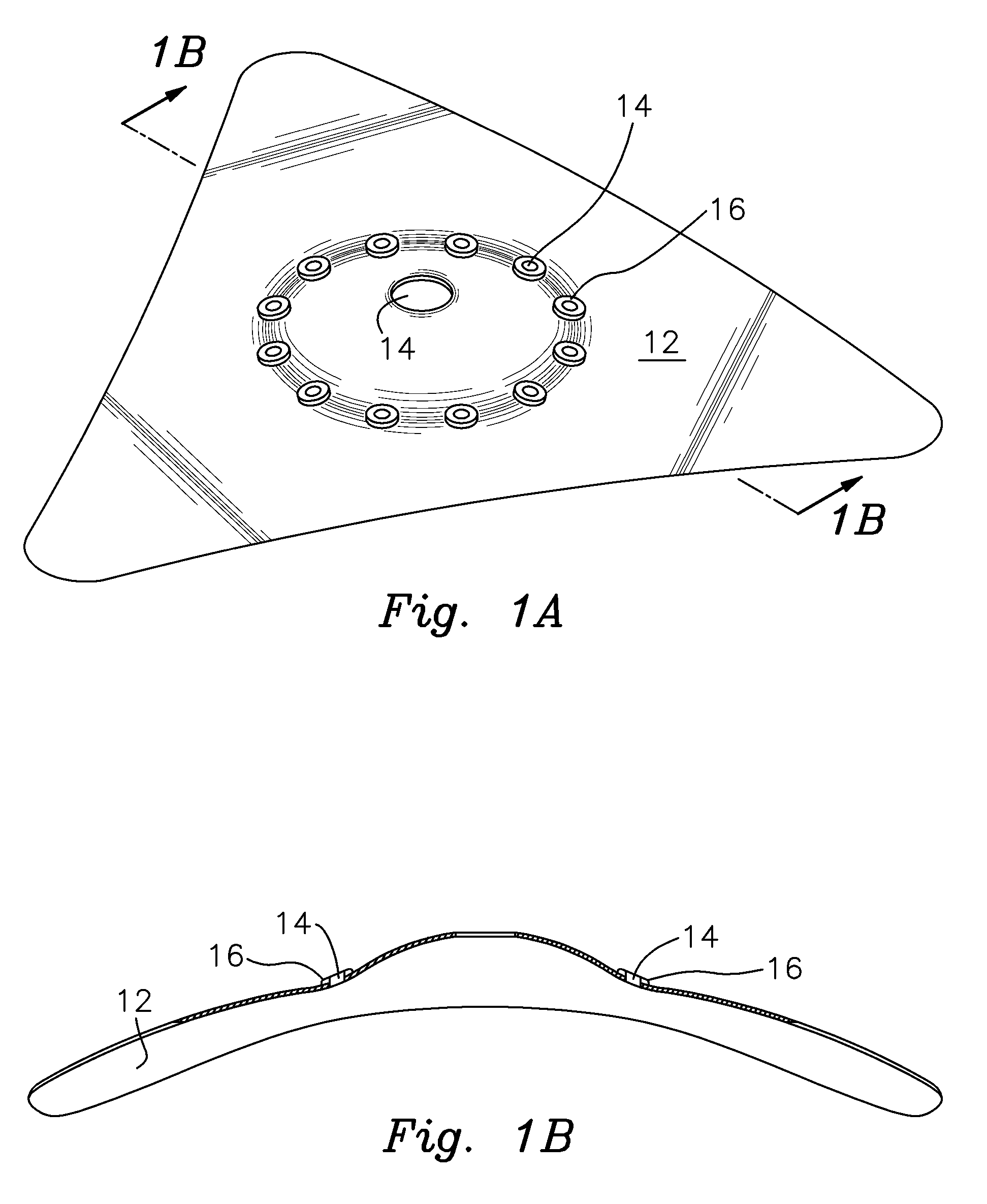

Percussion instruments using molten or plasticized metal

Cymbals and generally flat sheet instruments, as well as compound instruments, are formed using welding process and metal melting processes to form holes and edges with thickened edges from the melting processes, to join sections of metal, to add metal by creating beads at desired locations, to join sections with differing hardness and / or thickness, to create compound cymbals and compound flat sheet instruments by joint welding cymbals or sheet instruments together. The invention also includes cymbals and bells and various combinations and shapes thereof and the unique overtones attained thereby.

Owner:STANNARD JOHN

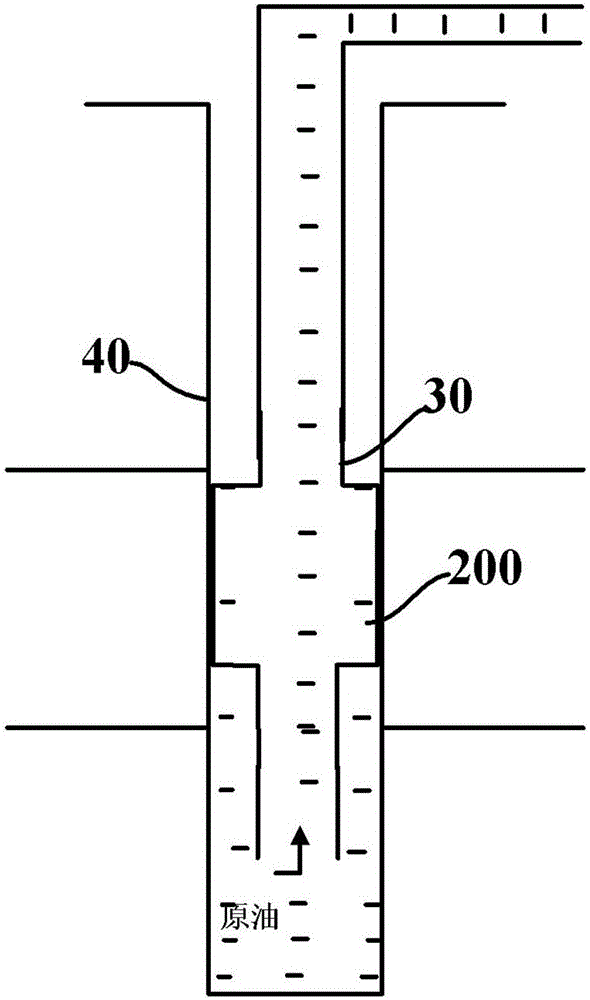

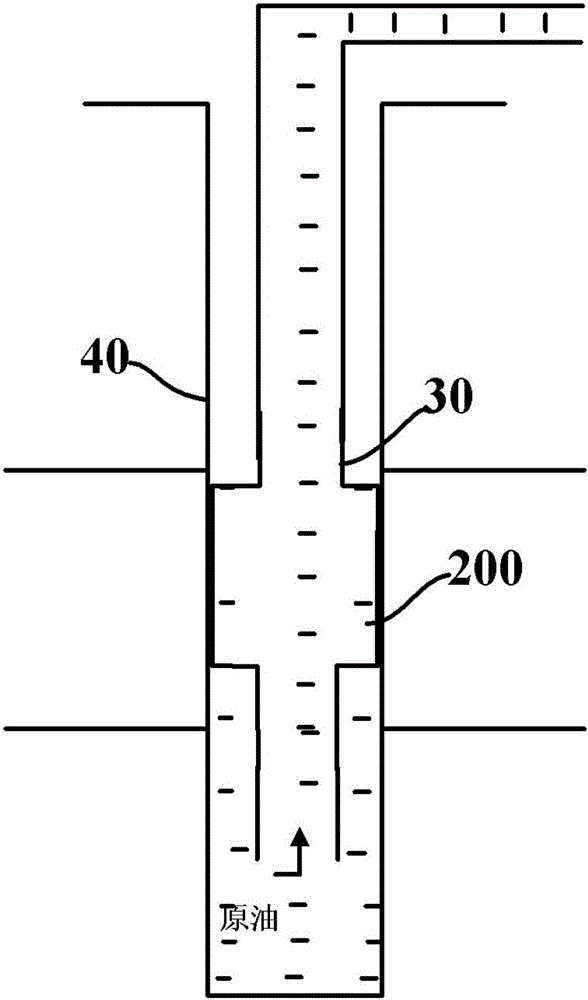

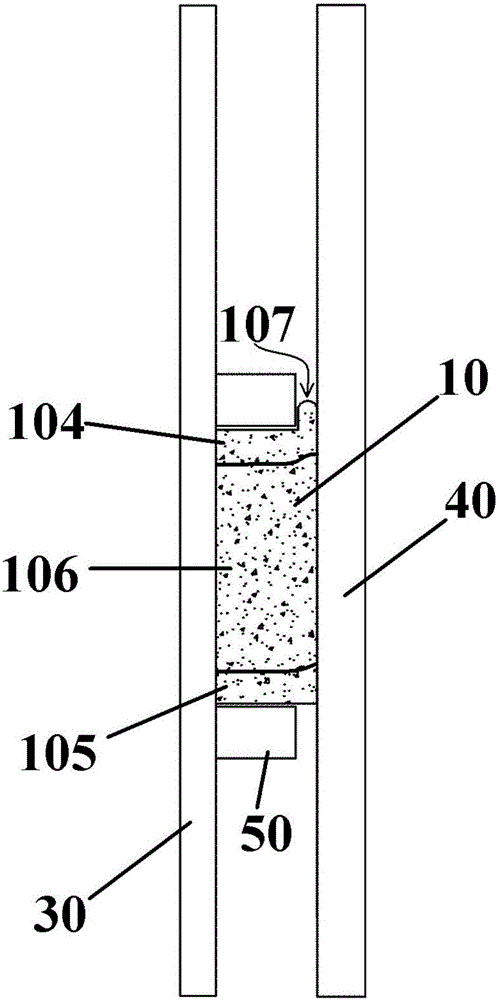

Rubber sleeve with lower end seal ring covered with opened copper sheet, packer and bridge plug

The invention relates to the field of sealing, in particular to a rubber sleeve with a lower end seal ring covered with an opened copper sheet, a packer and a bridge plug, wherein the rubber sleeve is used in the oil exploitation industry and can bearing high temperature and high pressure. The lower end seal ring of the rubber sleeve is covered with the first copper sheet, the first copper sheet covers the upper surface, the lower surface, the inner side face and the outer side face of the lower end seal ring, and the thickness of the first copper sheet is set in the mode that when the upper end bears first axial pressure, the lower end seal ring deforms in the radial direction so that the part, distributed on the inner surface of the lower end seal ring, of the first copper sheet can butt against a center tube and the part, distributed on the outer surface of the lower end seal ring, of the first copper sheet can butt against the sleeve; an annular opening is formed in the edge, located on the upper surface of the lower end seal ring, of the first copper sheet. The lower end seal ring is covered with the first copper sheet, the degradation function on the rubber sleeve by high-temperature and high-pressure steam micromolecules is reduced or prevented, and the sealing long-term effect of the rubber sleeve is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

Novel mud therapy product for emitting heat by being applied outside human body and application thereof

InactiveCN102743534AEnhance human immune functionVariation in hardness and adhesionHeavy metal active ingredientsAntipyreticMud therapySacroiliac joint

The invention discloses a novel mud therapy product for emitting heat by being applied outside human body, which is used for conditioning and relieving difficult and baffling joint pain symptoms such as cervical spondylosis, scapulohumeral periarthritis, prolapse of lumbar intervertebral disc, rheumatism, rheumatoid arthritis, hyperosteogeny and the like, and an application thereof. The mud therapy product consists of the following components in parts by weight: 10-80 parts of combined energy clay, 5-40 parts of a Chinese medicinal extract, 6-45 parts of a medical blender and 8-60 parts of beeswax. The mud therapy product disclosed by the invention has a rapid pain relieving effect on pain of neck, shoulders, waist, legs and joints and pain caused by various human body reasons; and compared with the conventional mud therapy product, the novel mud therapy product has the advantages: the service life is prolonged, and cost is saved.

Owner:北京东方创奇风湿骨病中医研究院 +1

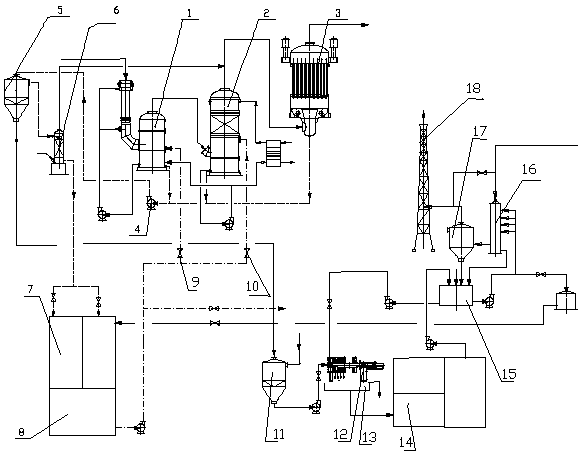

Treatment method for purifying sewage and tail gas from furnace gas in acid production from gypsum

InactiveCN102849814ASolve processing problemsAchieve recyclingDispersed particle separationMultistage water/sewage treatmentSewageSewage treatment

A treatment method for purifying sewage and tail gas from the furnace gas in the acid production from gypsum, belonging to the field of industrial sewage and waste gas treatment, is mainly divided into purification system acidic sewage circulation, sulfuric acid system acidic sewage treatment circulation and sulfuric acid system tail gas treatment circulation. The method uses the acidic sewage generated by the purification system acidic sewage circulation as the raw material of the sulfuric acid system acidic sewage treatment station, uses the solid generated by the sulfuric acid system acidic sewage treatment station as the raw material for the acid production from gypsum, and uses the alkaline sewage generated by the sulfuric acid system acidic sewage treatment circulation as the desulfurizer of the tail treatment step. The invention solves the treatment problem of the acidic sewage from the acid production from gypsum, realizes the cyclic utilization of the purification system washing acidic sewage, and reduces desulfurization cost through using the sewage after being subject to neutralizing treatment as the desulfurizer for the tail gas treatment.

Owner:葛洲坝石门特种水泥有限公司

Method for increasing the wet coefficient of friction of a thermoplastic elastomer and composition therefor

InactiveUS8779025B1Reduce tractionPrevent skinPaper coatingCoatingsMicrocrystalline waxThermoplastic elastomer

A method for increasing the wet coefficient of friction of a thermoplastic elastomer includes adding various ingredients to the thermoplastic elastomer. In one embodiment microcrystalline wax, amorphous polyalphaolefin ethylene copolymer, and a copolymer ethylene / propylene and olefins are added to the thermoplastic elastomer. And in another embodiment, microcrystalline wax and copolymer ethylene / propylene and olefins are added to the thermoplastic elastomer. The above compositions are formed into a sheet which can be used alone as a slip-resistant pad, or can be applied to a desired surface (such as that of a surfboard).

Owner:STONE DONALD DAVID

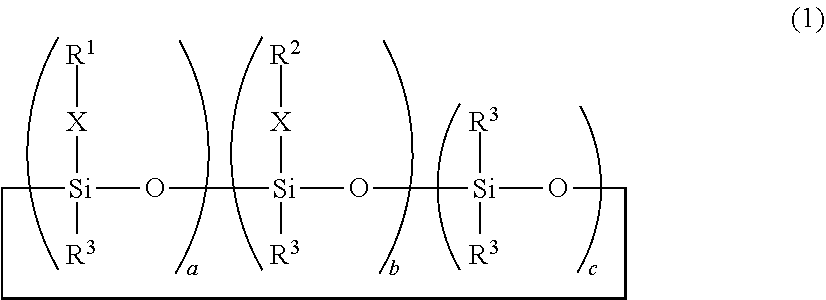

Thermally conductive polysiloxane composition

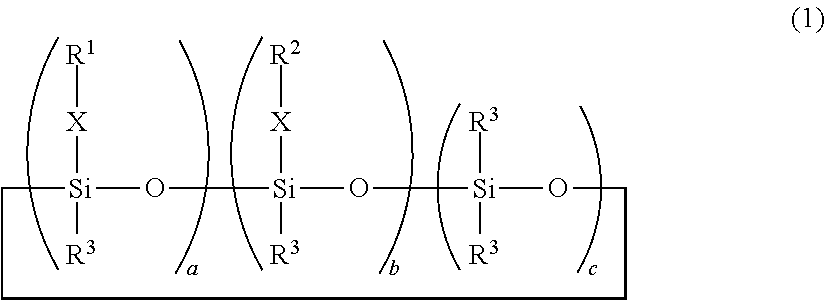

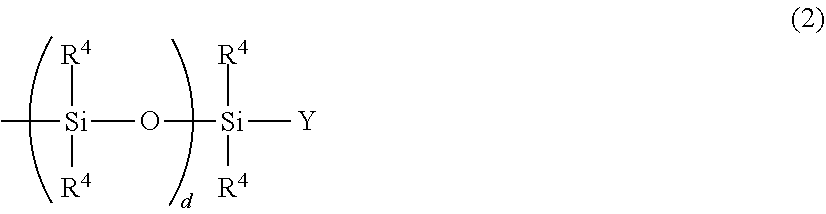

ActiveUS20200140736A1Low viscosityGood application effectHeat-exchange elementsModifications by conduction heat transferPlatinumPolymer science

The present invention relates to a thermally conductive polysiloxane composition comprising: (A) a thermally conductive filler, (B) a siloxane compound having a specified structure; (C) an alkoxysilane compound having a specified structure; (D) a polyorganosiloxane containing at least one aliphatic unsaturated group per molecule; (E) a polyorganohydrogensiloxane having two or more hydrogen atoms bonded to silicon atoms per molecule; and (F) a platinum-based catalyst.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

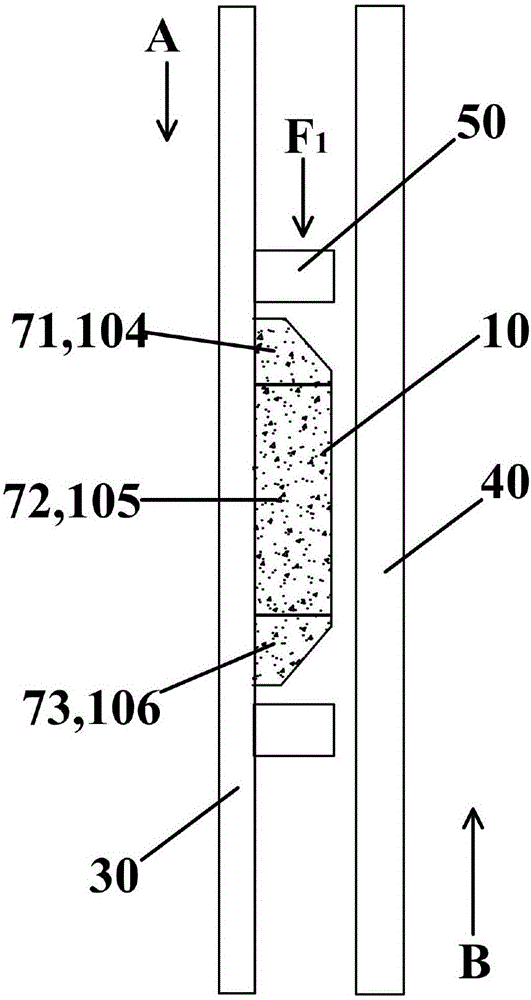

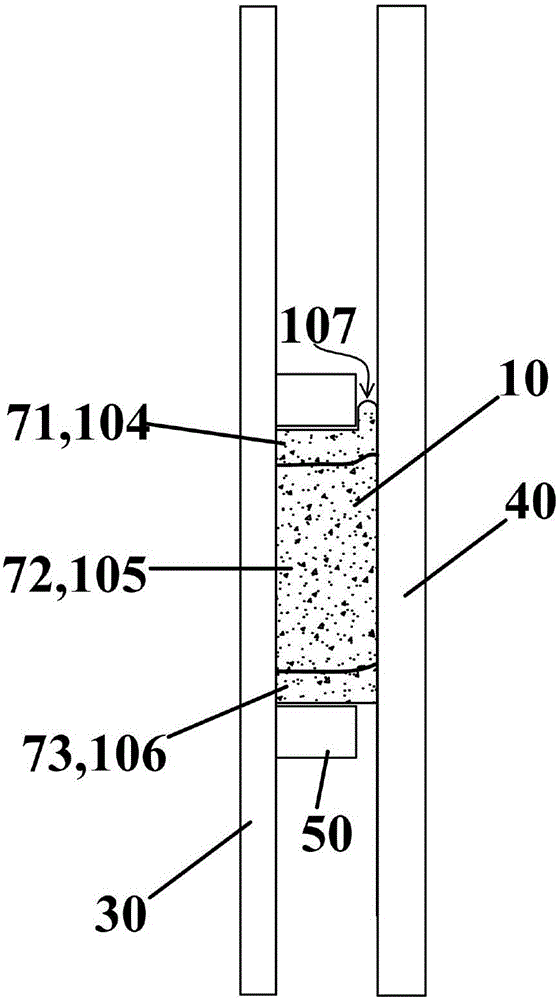

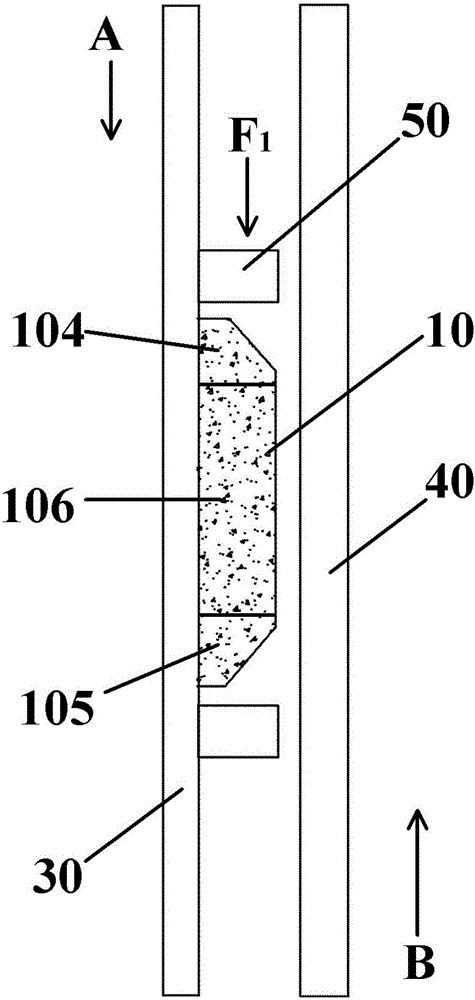

Rubber barrel with relatively hard upper and lower end parts, packer and bridge plug

The invention relates to the field of sealing and particularly relates to a rubber barrel with relatively hard upper and lower end parts, which is used in an oil exploitation process and can bear high temperature and high pressure, a packer and a bridge plug. According to one aspect of the invention, the rubber barrel is provided; and the hardness of the upper end part of the rubber barrel is greater than that of the middle part of the rubber barrel, so that the deformation of the middle part in the radial direction is greater than that of the upper end part in the radial direction when the upper end part bears first axial pressure. The hardness of the upper end part of the rubber barrel is greater than that of the middle part of the rubber barrel, so that the upper end part is almost used for transmitting the first axial pressure to the middle part and the lower end part, but not utilizes the first axial pressure to self radial deformation when the upper end part bears the first axial pressure. Therefore, the middle part and the lower end part have the radial deformation when the relatively small first axial pressure is used, and the sealing of the whole rubber barrel is realized.

Owner:TIANDING SEALING TECH BEIJING CO LTD

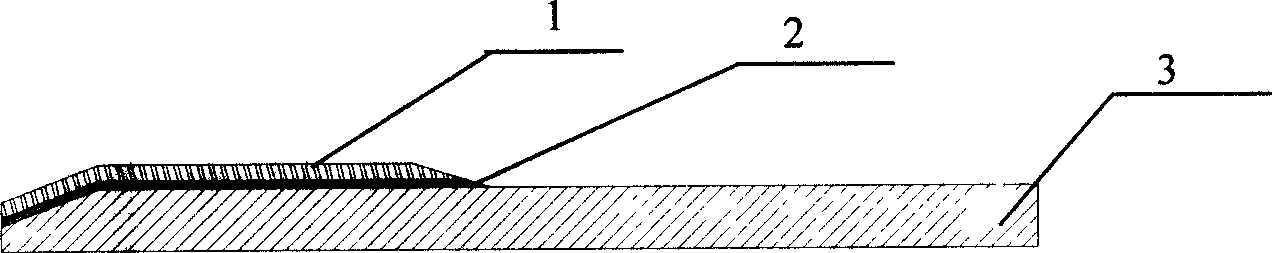

Wearable papermaking coating scraper

InactiveCN1834343AHigh bonding strengthNot easy to collapseDoctorsPulp material addition processesHardnessCeramic composite

A coating blade of wear proof type used in paper making process consists of steel blade body. It is featured as using a layer of alloy coat sprayed on surface of steel blade body as transition layer, using a layer of intermetallic compound / fine ceramics composite material sprayed on surface of alloy coat as operation layer to form three layer structure of coating blade with hardness of HRC 50-65.

Owner:SHANDONG UNIV OF SCI & TECH

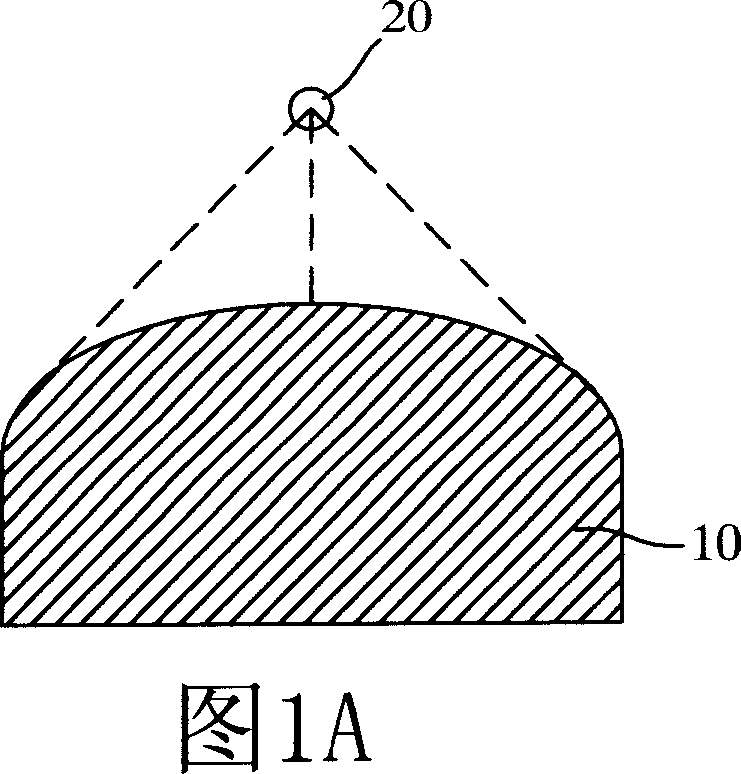

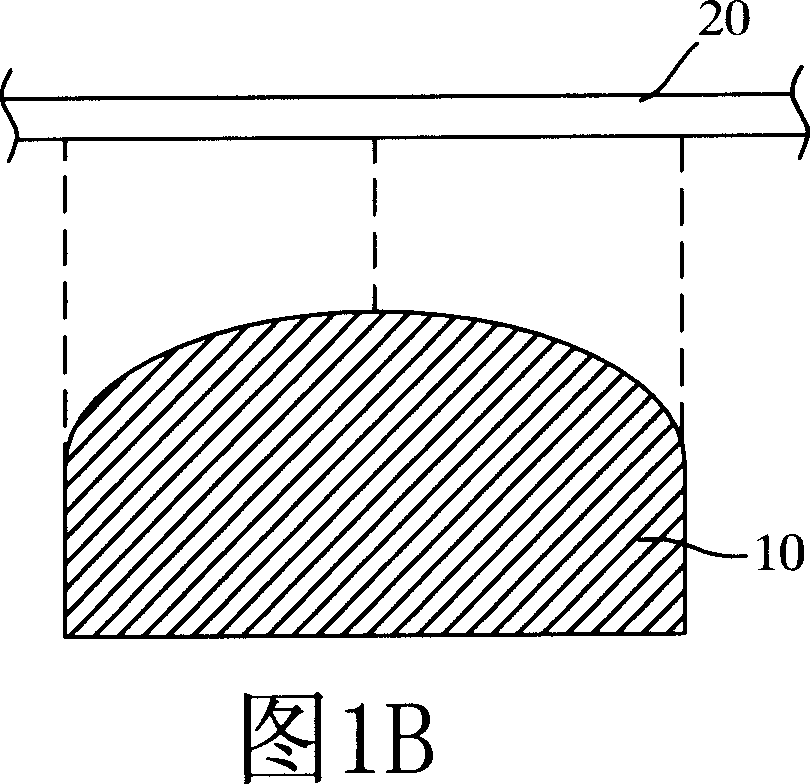

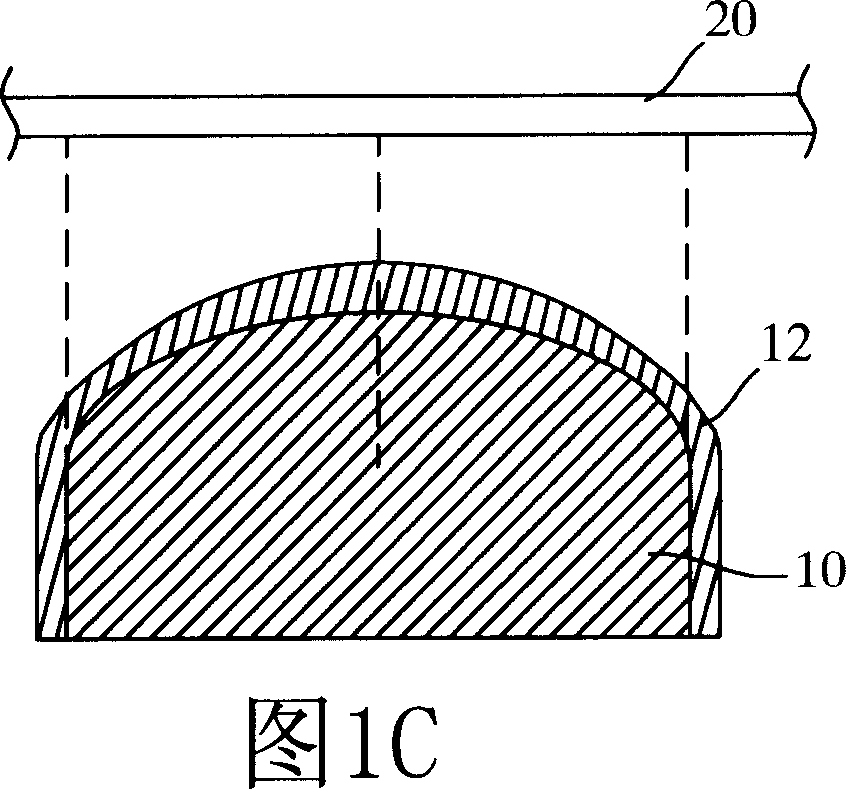

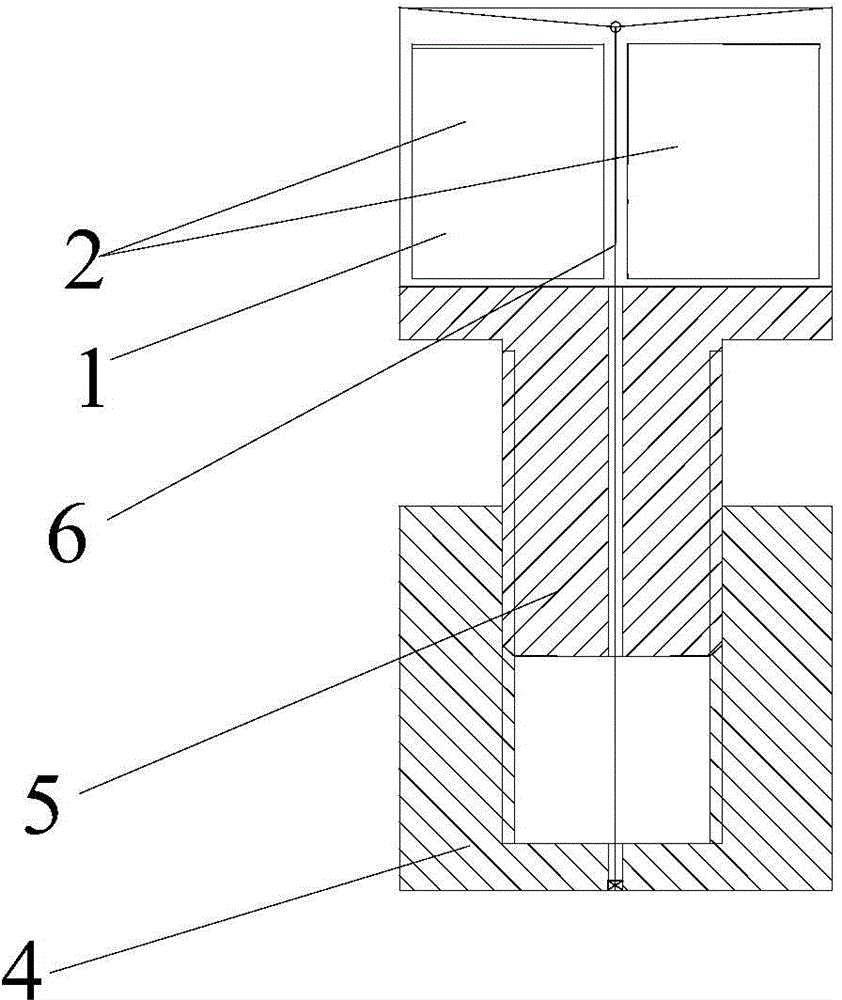

Diamond oscillating film

This invention relates to diamond vibration film and its process method, which comprises the following steps: forming different heating effect according to distance difference of non even energy of mode curved surface and isolation gas, such as resistance wires, electrical slurry and flares through one mode; filming the diamond materials onto mode surface to make diamond materials grow difference with non even vibration characteristics.

Owner:KINIK

Percussion instruments using molten or plasticized metal

Cymbals and generally flat sheet instruments, as well as compound instruments, are formed using welding process and metal melting processes to form holes and edges with thickened edges from the melting processes, to join sections of metal, to add metal by creating beads at desired locations, to join sections with differing hardness and / or thickness, to create compound cymbals and compound flat sheet instruments by joint welding cymbals or sheet instruments together. The invention also includes cymbals and bells and various combinations and shapes thereof and the unique overtones attained thereby.

Owner:STANNARD JOHN

Method of producing a polyurethane foam molded article

InactiveUS20060134398A1Change densityChange hardnessLayered productsThin material handlingPolyolHigh density

A method of producing a polyurethane molded article is provided, in which one molding machine which can provide distinctly polyisocyanate component(s) and two kinds of polyol components is used, and prior to completion of the feed of a first polyurethane mixture liquid containing a polyisocyanate and a polyol component without a blowing agent into a mold, a second polyurethane mixture liquid containing a polyisocyanate and a second polyol component with a blowing agent is fed into the mold. The method produces, in a single stage, a polyurethane foam molded article having the skin or high density portion selectively formed on portions of the molded article actually requiring them, where the proportions of the skin and the high density portion and the foamed core can be varied freely.

Owner:BAYER MATERIALSCIENCE AG

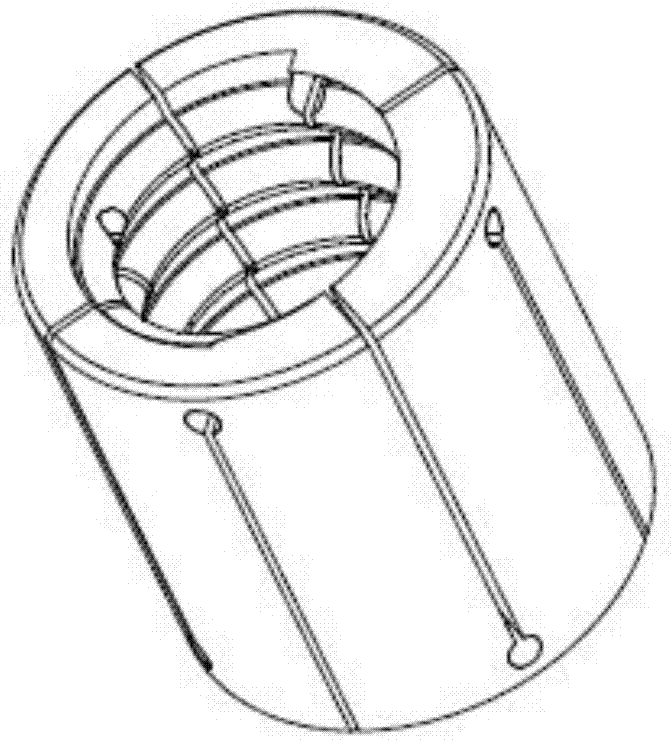

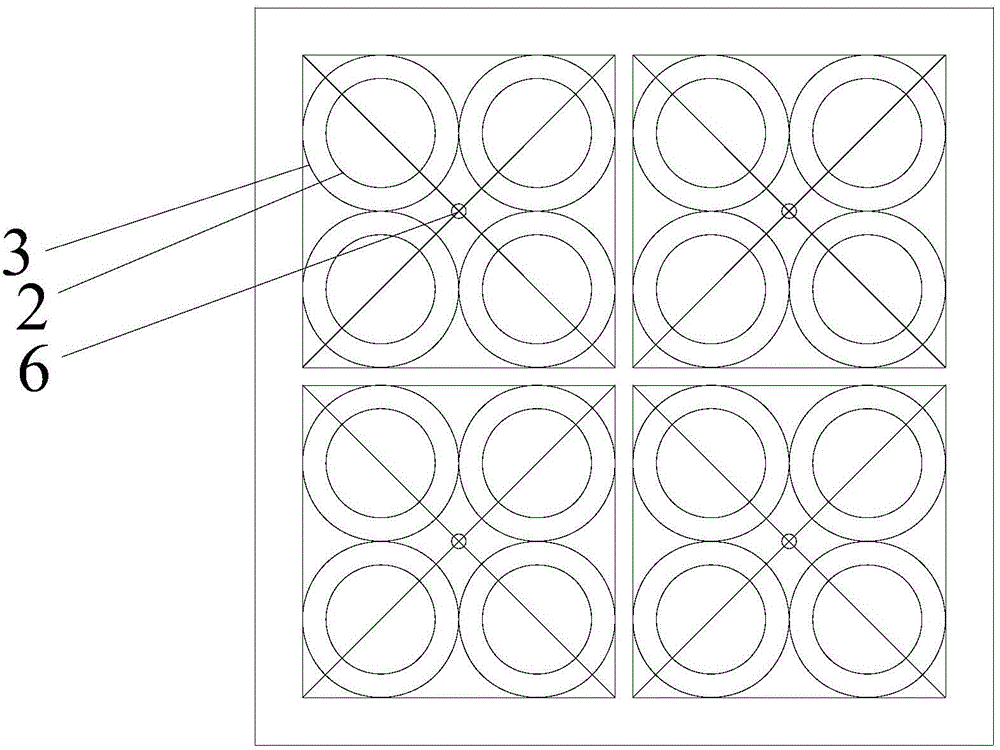

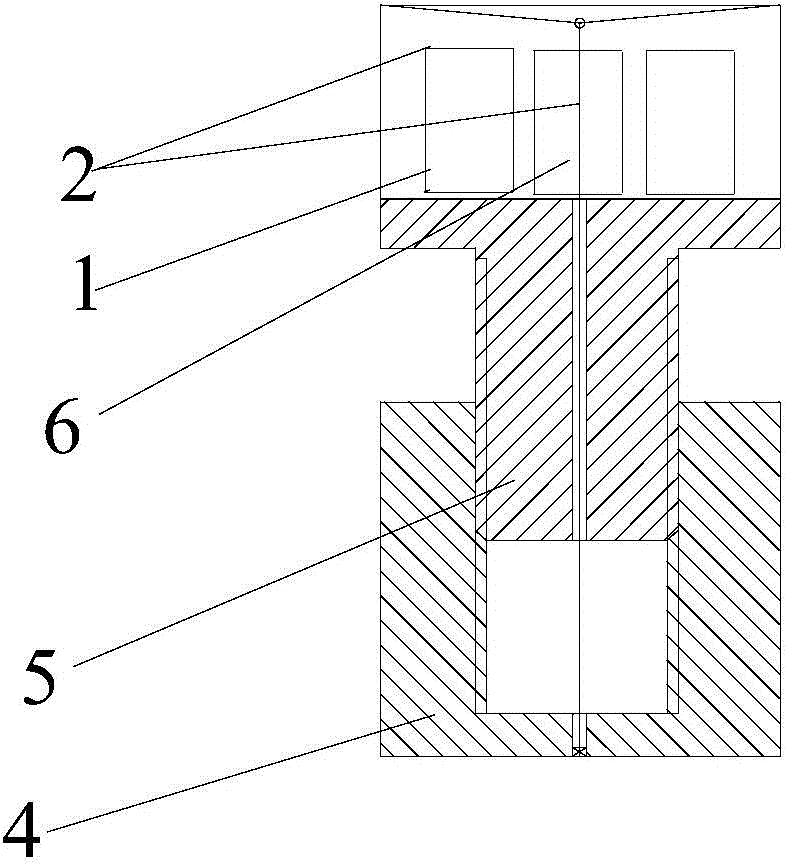

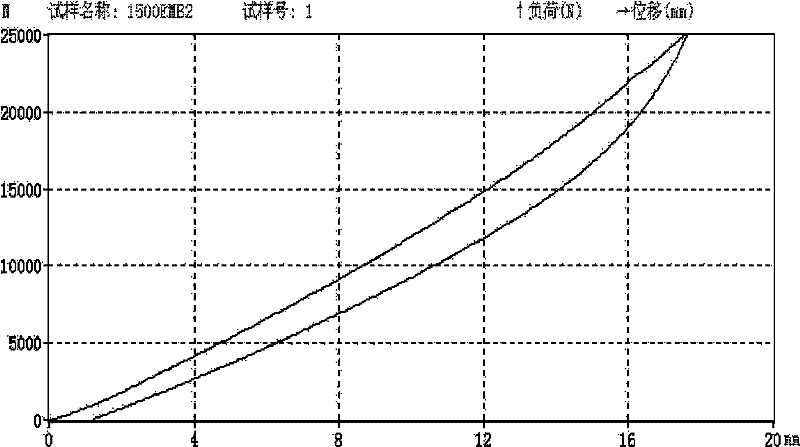

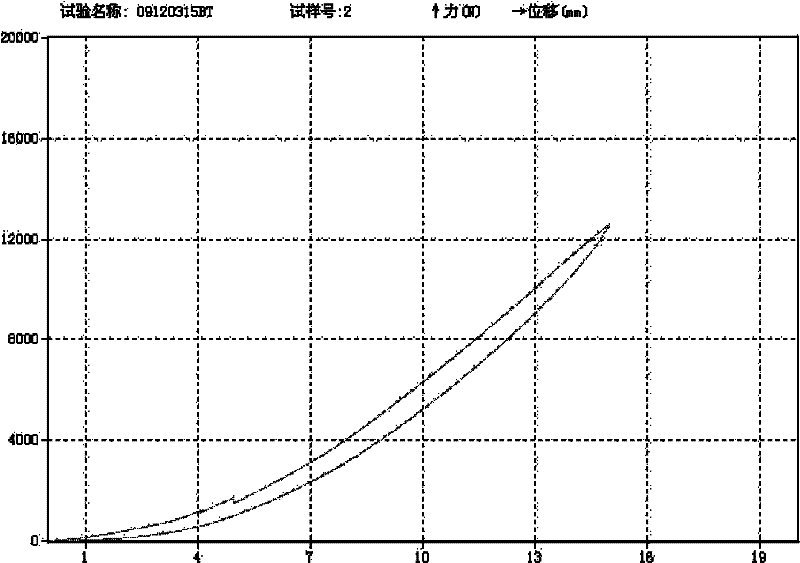

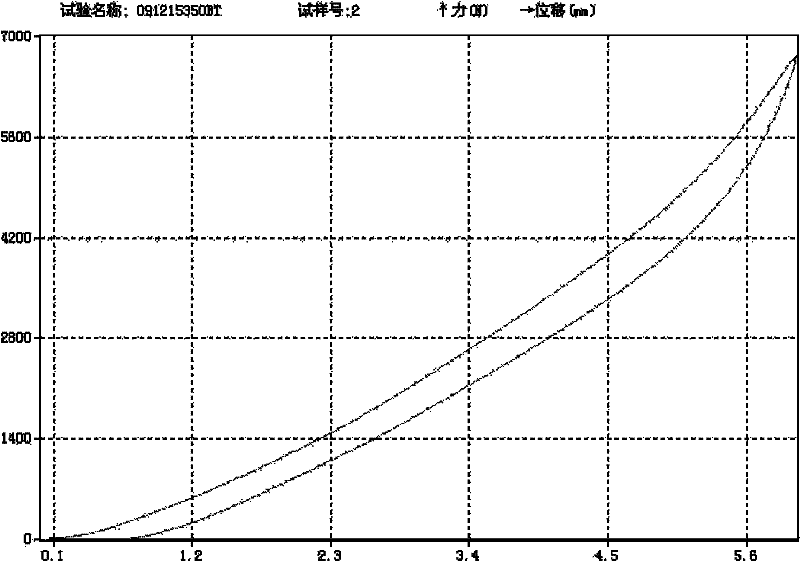

Elastic body with adjustable hardness and height and application thereof

InactiveCN104806672AChange hardnessRise steadilyMultiple spring combinationsSpring mattressesElastomerHardness

The invention relates to the technical field of elastic devices, in particular to an elastic body with adjustable hardness and height and an application thereof. The elastic body comprises an upper elastic body and a lower telescopic body, wherein the upper elastic body comprises at least one elastic unit; the elastic units are longitudinally and transversely arranged; each elastic unit sleeves a bag type structure, or a traction mechanism is directly arranged at the upper end of each elastic unit; the telescopic body consists of a base and a movable support, and the movable support is arranged on the base; the lower end of each elastic unit is fixedly arranged on the movable support; a pull rope is fixedly arranged on each bag type structure or each traction structure; multiple elastic units share one pull rope, or one elastic unit uses multiple pull ropes or one elastic unit uses one pull rope; each pull rope penetrates through the corresponding elastic unit along the axis of the corresponding elastic unit or penetrates through a gap between the elastic units, or multiple pull ropes penetrate through the interior or the surrounding of the elastic body, continue to penetrate through the movable support and are connected with the base; the movable support is moved up and down to drive the bottom part of each elastic unit to compress or loosen the corresponding elastic unit, so as to adjust the hardness and / or the height of the elastic body.

Owner:东莞丹蒂诗智能家居科技有限公司

Sound-insulating environment-friendly material used for decoration and production method of sound-insulating environment-friendly material used for decoration

ActiveCN110435259APrevent directional reflectionReduce resonanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesResonanceMedium frequency

The invention discloses a sound-insulating environment-friendly material used for decoration and a production method of the sound-insulating environment-friendly material used for decoration. The sound-insulating environment-friendly material comprises a hard sound-insulating layer, a sound-absorbing layer and a protective layer, wherein the sound-absorbing layer is arranged between the hard sound-insulating layer and the protective layer, the hard sound-insulating layer is arranged on the face opposite to an internal space, the protective layer is arranged on the face close to the internal space, and lamination bulges are arranged on the hard sound-insulating layer, so that effects on an external space are reduced, and the lamination bulges can reduce resonance between a wall and the hardsound-insulating layer; and the sound-absorbing layer comprises two layers of foamed polypropylene thin layers and a lamination fiber layer arranged between the two layers of foamed polypropylene thin layers, the protective layer is a foamed polypropylene sheet, and the lamination fiber layer is provided with winding small holes which communicate, thus a good effect of attenuating high-frequencynoise can be achieved, and closed hole structures of the foamed polypropylene sheet can insulate noise from low and medium frequency to medium and high frequency, so that broad-band noise is insulatedand absorbed.

Owner:深圳市集洁号环保科技有限公司

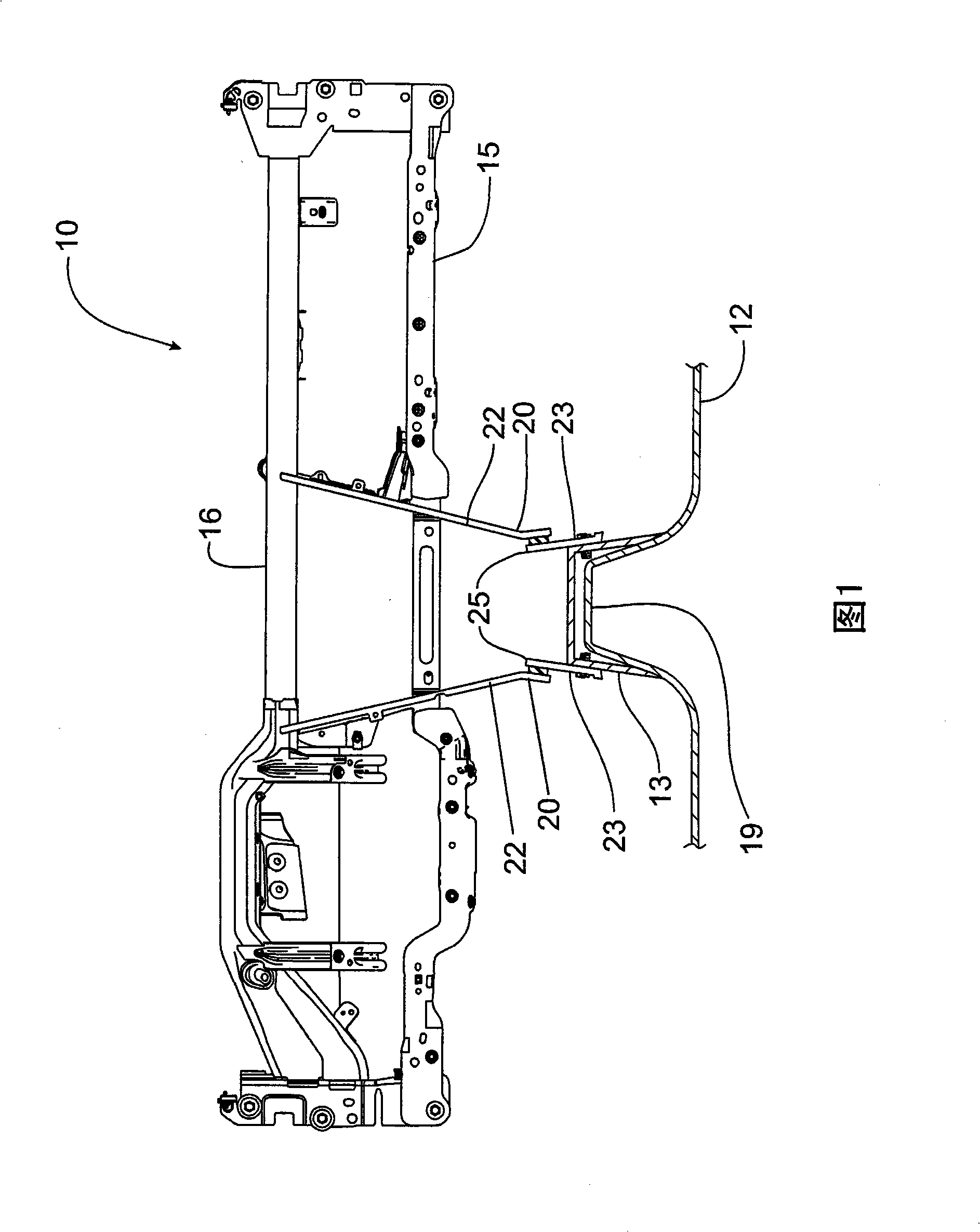

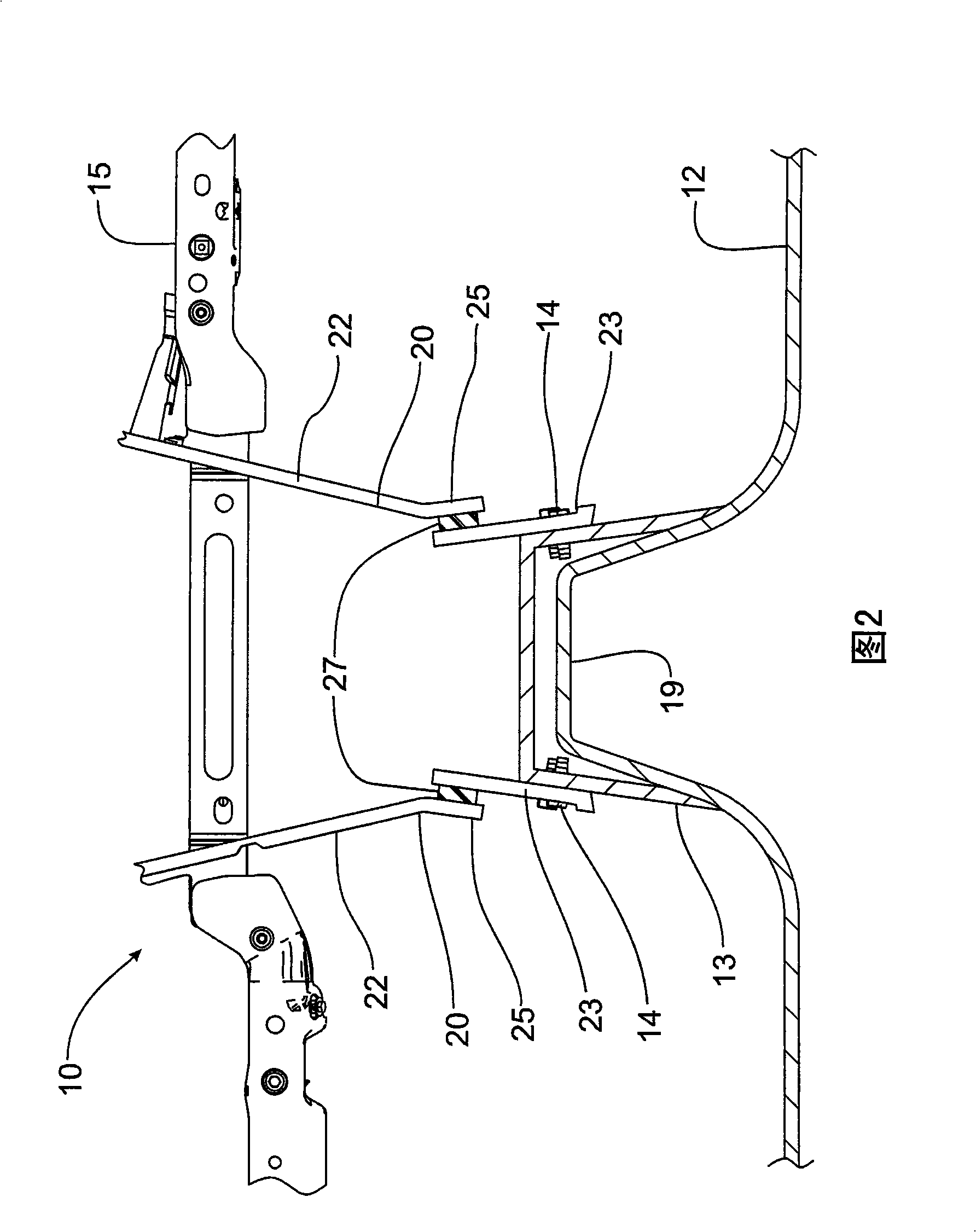

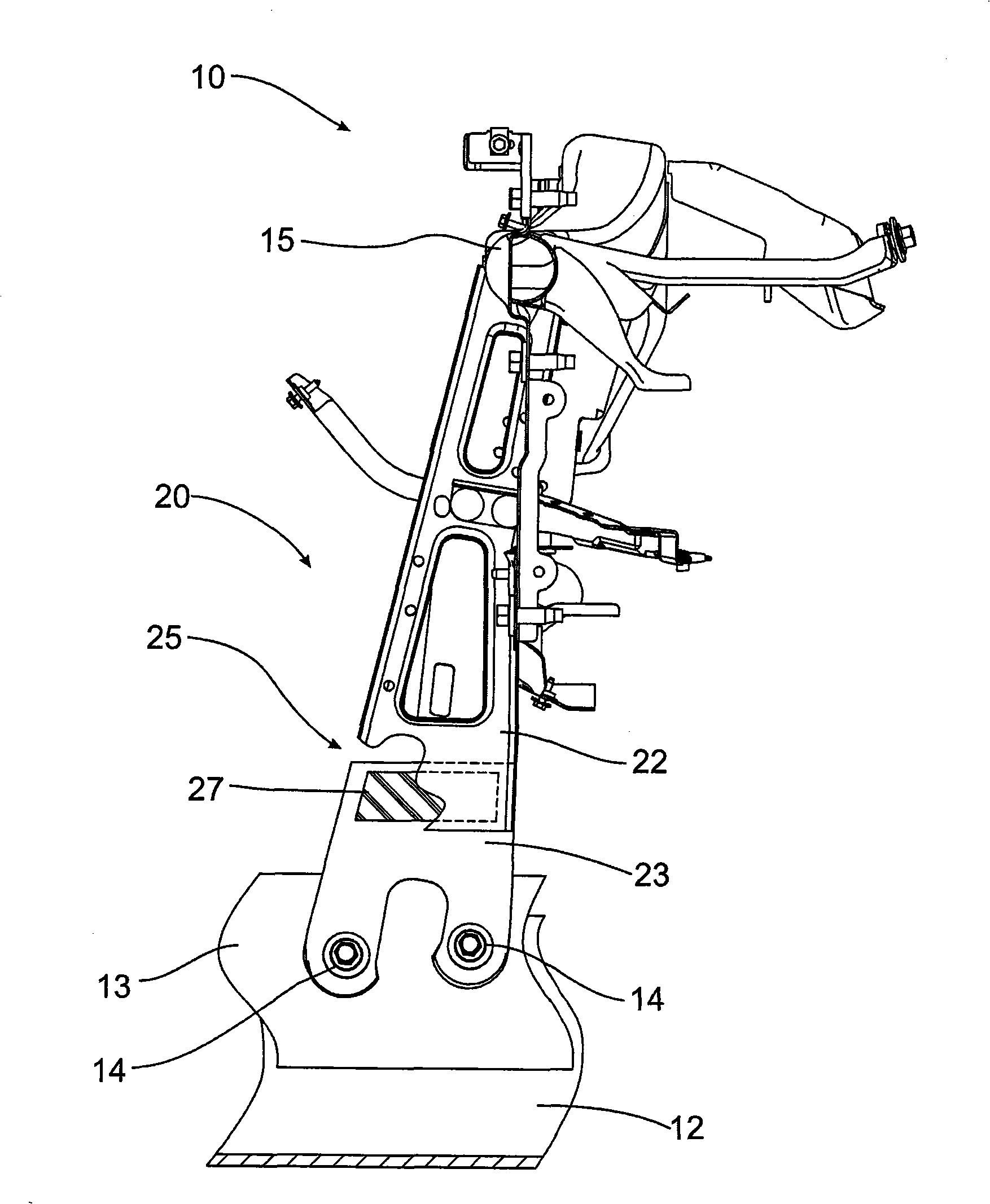

Vibration dampener for support braces in vehicles

A support frame for supporting an instrument panel above a floor pan of a motor vehicle includes a support brace that is formed in two pieces that have an overlap section between them forming a lap joint in which is located an elastomeric pad to dampen the transmission of low range vibrations through the support brace to the instrument panel. The overlap section is vertically spaced above the floor pan to position the elastomeric pad away from any heat generated by a vehicle exhaust system located beneath the floor pan. The elastomeric pad may be a single piece, or may be made from several separate elastomeric segments separated by vertical spaces.The support frame of the invention can prevent the transmission of low range vibrations to vehicle parts supported by the support frame and separates the vibration reducing materials away from the bottom plate for location without changing the present assembly process.

Owner:FORD GLOBAL TECH LLC

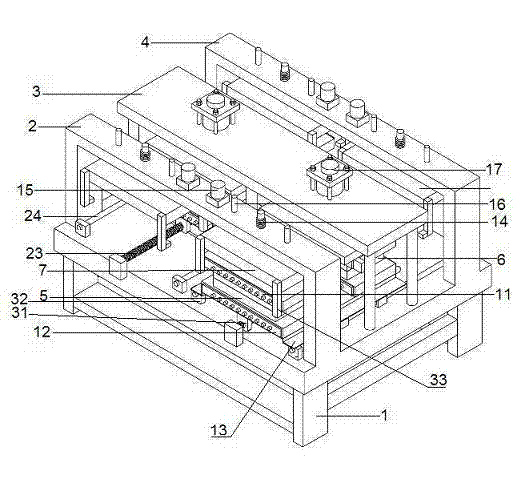

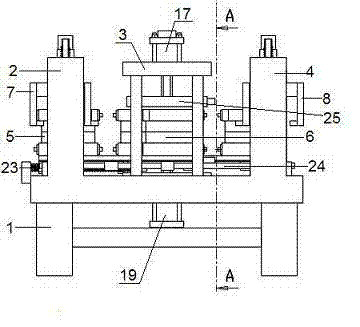

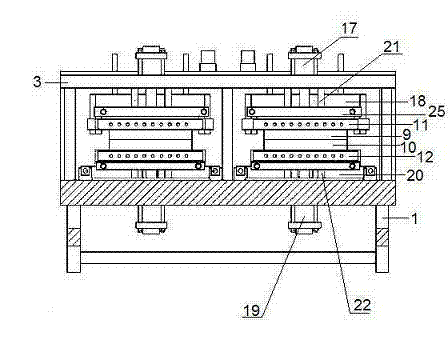

Molding machine for foam filling material

The invention discloses a molding machine for a foam filling material. The molding machine comprises a frame, a controller and a coldwater machine. The frame comprises a bottom bracing frame and a front support, a middle support and a rear support which are arranged on the bottom bracing frame. A cooling furnace, a first heating furnace, a second heating furnace, a first molding die, a second molding die, a front hook plate and a rear hook plate are disposed on the bottom bracing frame. An upper template and a lower template of the first molding die are positioned between an upper heating plate and a lower heating plate of the first heating furnace and are respectively connected with the upper heating plate and the lower heating plate. An upper template and a lower template of the second molding die are positioned between an upper heating plate and a lower heating plate of the second heating furnace and are respectively connected with the upper heating plate and the lower heating plate. After molding and processing, a molding sheet has an expected dimension so as to bring convenience for a subsequent cladding process of a composite material. In addition, strength, toughness and service life of the foam filling material are all effectively raised. And the product quality is significantly enhanced.

Owner:包爾曲棍球有限公司

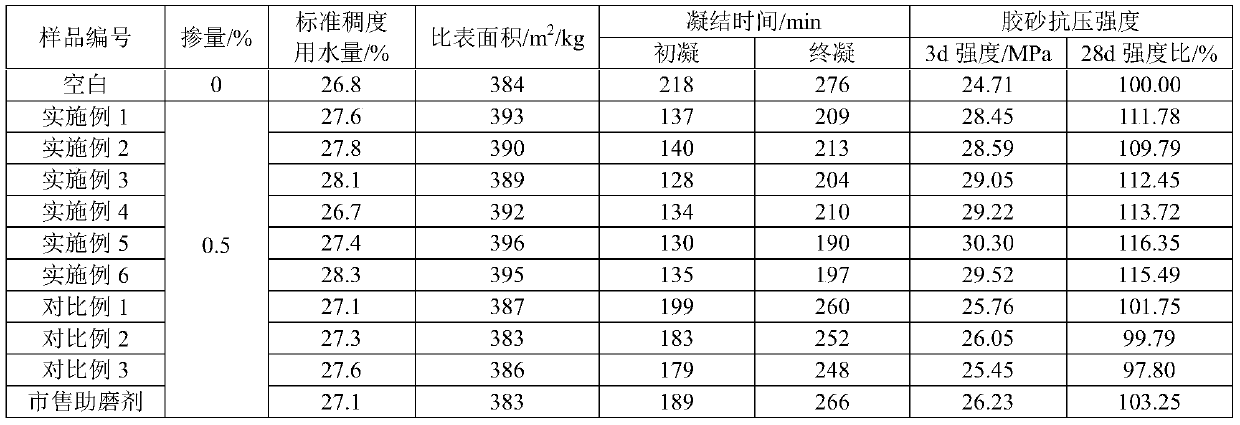

Liquid grinding aid capable of promoting coagulating, and preparation method thereof

The invention discloses a liquid grinding aid capable of promoting coagulating, and a preparation method thereof, and belongs to the technical field of cement additive. The liquid grinding aid capableof promoting coagulating is prepared from, by mass, aluminum sulfate of 5% to 15%, magnesium sulfate of 5% to 10%, modified alcohol amine small organic molecules of 40% to 50%, sodium lignosulfonateof 3% to 10%, calcium formate of 1.5% to 3%, and balance deionized water. According to the preparation method, aluminum sulfate and magnesium sulfate are mixed as a coagulating promoting main component, so that cement hydration process is accelerated; chemical imbalance caused by high content aluminium ions is capable of realizing dissolving of gypsum and C3A easily, promoting early stage generation of a large amount of ettringite, and realizing rapid coagulation; the modified alcohol amine small organic molecules are taken as a grinding aid enhancing component, and is high in stability; the preparation technology is simple; reaction is relatively mild; the liquid grinding aid is capable of promoting cement early stage rapid coagulation, and at the same time, early stage strength is ensured, later stage strength increasing is not influenced, and the adaptability on cement is excellent.

Owner:安徽海螺材料科技股份有限公司 +1

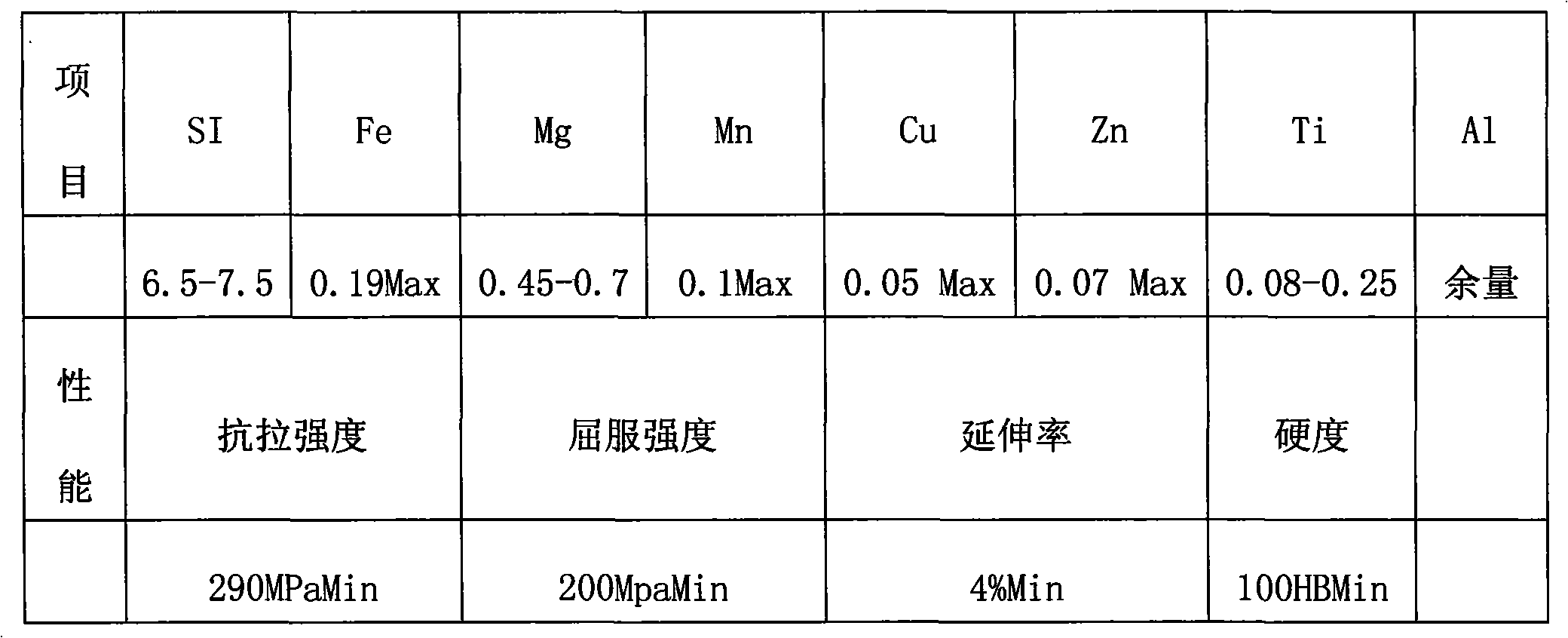

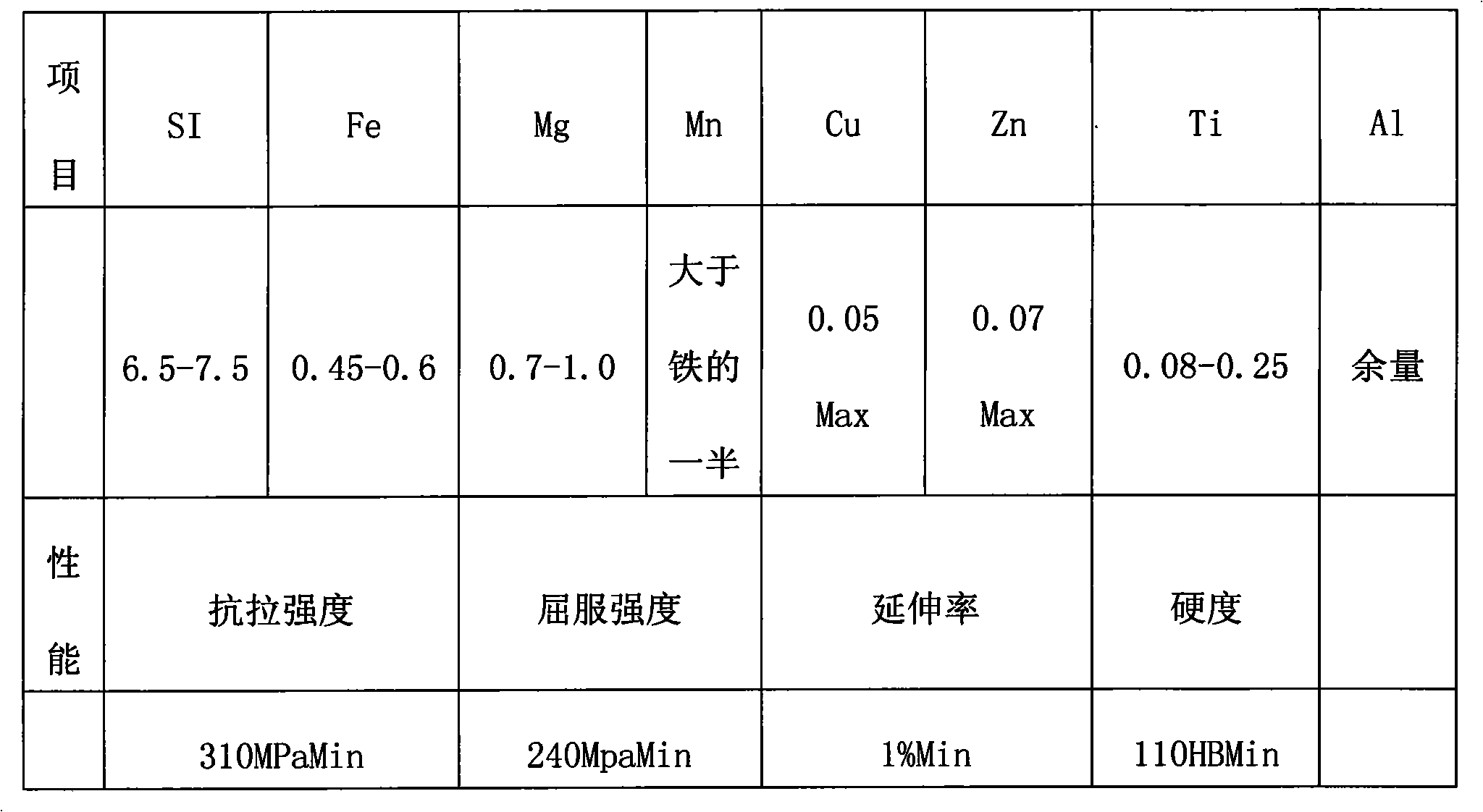

New material for changing processed broken chip

The invention relates to a new material for changing processed broken chip which comprises the chemical composition with the weight percentage: 6.5-7.5% of SI, 0.45-0.6% of Fe, 0.7-1.0% of Mg, Mn being more than half of Fe, 0.05% of Cu Max, 0.07% of Zn Max, 0.08-0.25% of Ti and the rest of Al. The chemical composition of the material is adjusted, so that the elongation and hardness value of cast parts are changed after heat treatment is carried out on the cast parts, thus achieving the effect of changing the difficulty of processing broken chip.

Owner:上海嘉朗实业有限公司

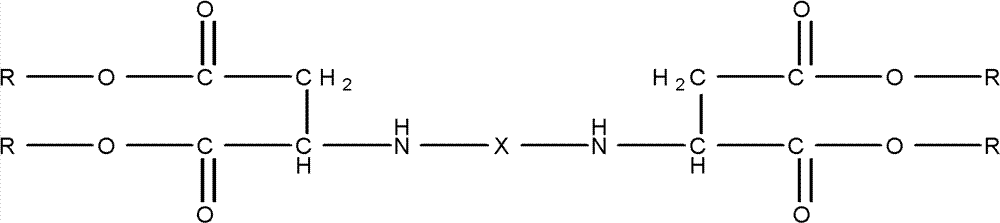

Solvent-free polyaspartate polyurea elastic waterproof coating

ActiveCN103031045BChange hardnessHigh tensile strengthPolyurea/polyurethane coatingsPolyaspartic acidSolvent free

The invention relates to paint and a preparation method thereof and discloses solvent-free polyaspartic acid ester polyurea elastic waterproof paint. The solvent-free polyaspartic acid ester polyurea elastic waterproof paint is composed of a component A and a component, wherein the component A comprises 2%-35% of polyisocyanate and 65%-98% of end seal isocyanate prepolymer by weight percent; and the component B comprises 20%-60% of polyaspartic acid ester, 10%-40% of polymeric modified poly aspartic acid ester, 5%-30% of stuffing and a small amount of additives by weight percent. Compared with the polyurea paint processed by the polyaspartic acid ester, the solvent-free polyaspartic acid ester polyurea elastic waterproof paint processed by raw materials has the advantages that the construction is convenient, a special large-scale spraying device is not needed, the gelation time is prolonged, the surface drying time is shortened, the tensile strength is enhanced, the elongation at break is increased, and the elastic coating film hardness is increased, does not have a solvent, is environment-friendly and harmless to a human body.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

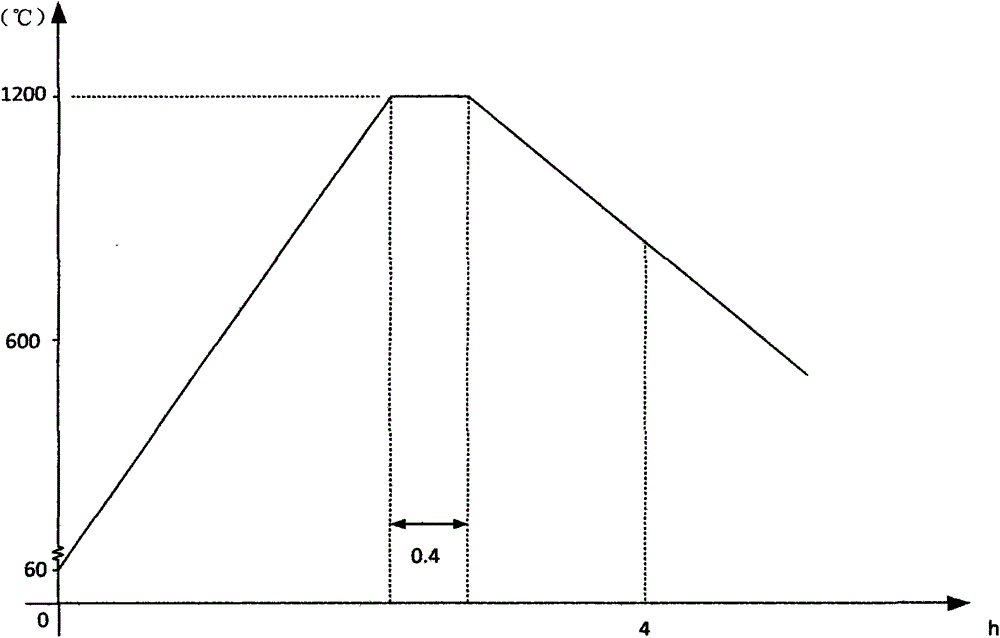

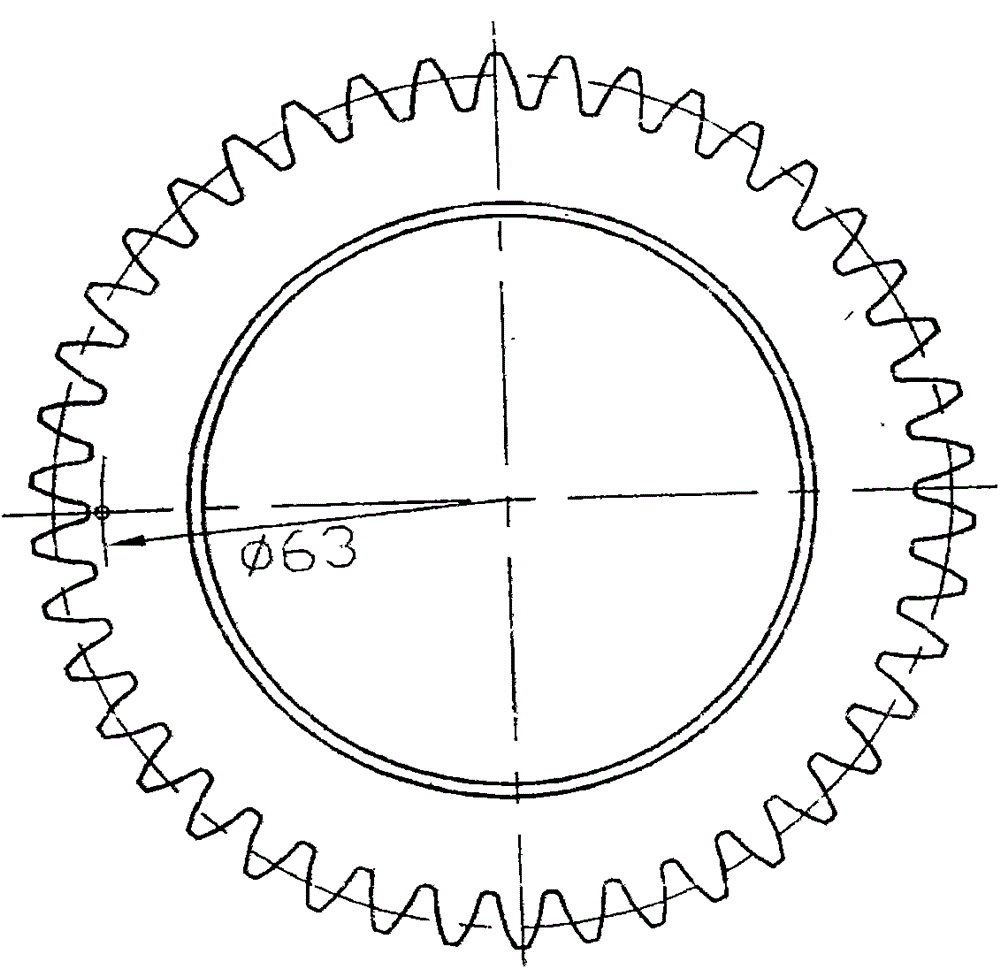

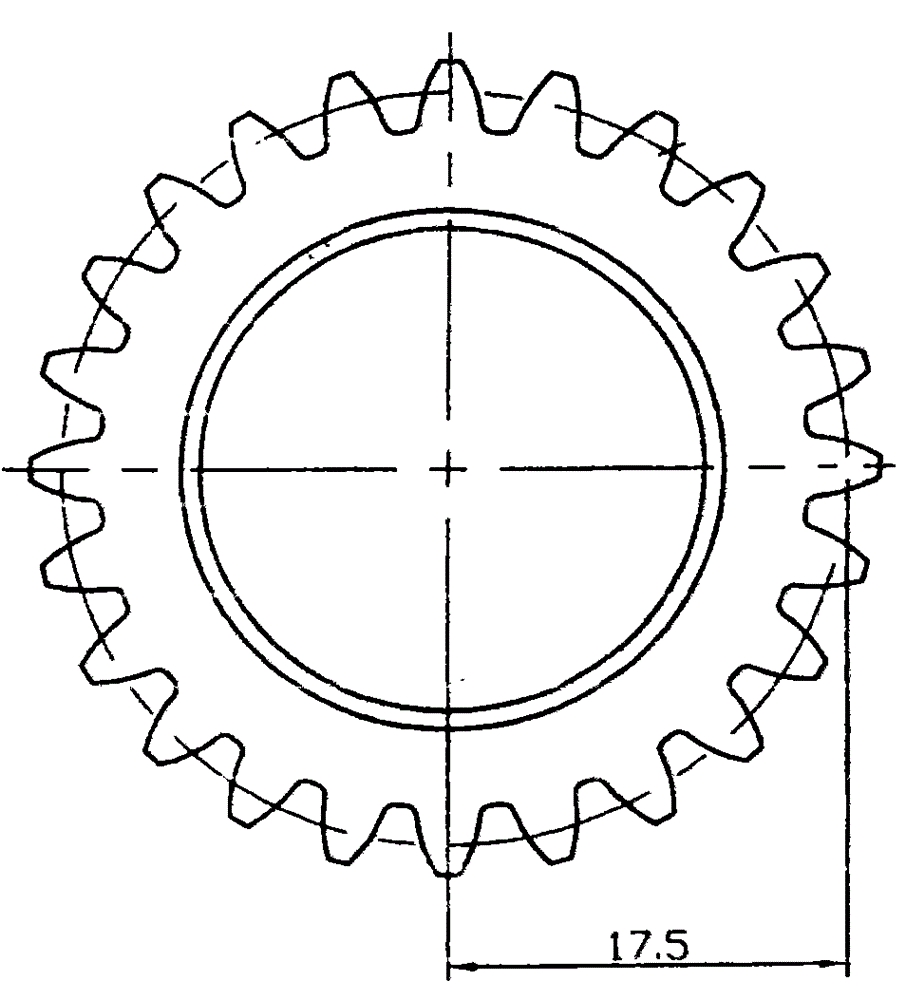

Powder metallurgy helical gear and manufacturing process thereof

InactiveCN105312553AChange hardnessChange resiliencePortable liftingGearing elementsManufacturing technologyIron powder

The invention discloses a powder metallurgy helical gear and a manufacturing process thereof. The gear is made of, by weight, powder raw materials including 0.7-1.0 parts of graphite, 0.5-3.0 parts of copper powder, 1.0-5.0 parts of nickel powder, 0.5-0.8 part of lubricating agents, iron powder and certain inevitable impurities; besides, the manufacturing process of the powder metallurgy helical gear includes the steps of raw material mixing, compressing, sintering, oil immersing and the like. The powder metallurgy helical gear and the manufacturing process thereof have the advantages that with respect to process, compared with a manufacturing process of an existing product, waste of raw materials is reduced, and the whole production energy consumption is saved by 1 / 4; besides, with respect to gear performance, the gear has the good performance that the torsion is over 120 N / M, and the hardness HRB is larger than 70, and the gear can well meet the requirement of a power device.

Owner:重庆道宇机电制造有限公司

60-degree natural rubber and production process thereof

The invention discloses a 60-degree natural rubber and a production process of the 60-degree natural rubber. The raw materials of the 60-degree natural rubber comprise 48%-65% of raw natural rubber, 1%-2.5% of vulcanizator, 5%-21% of high wear-resistant furnace black, 8%-28% of spraying carbon black, 5.5%-17% of active agent, 0.1%-0.6% of accelerator, 0.55%-3.2% of anti-aging agent and 0.5%-3% of plasticizer, and the natural rubber is produced by processes of plasifying and mixing. The 60-degree natural rubber has the advantages of good ageing resistance, good elongation at rupture, excellent wear resistance, good rebound value, good load compression amount and natural frequency; meanwhile, the rubber is low in production cost.

Owner:北京市长城机床附件有限责任公司

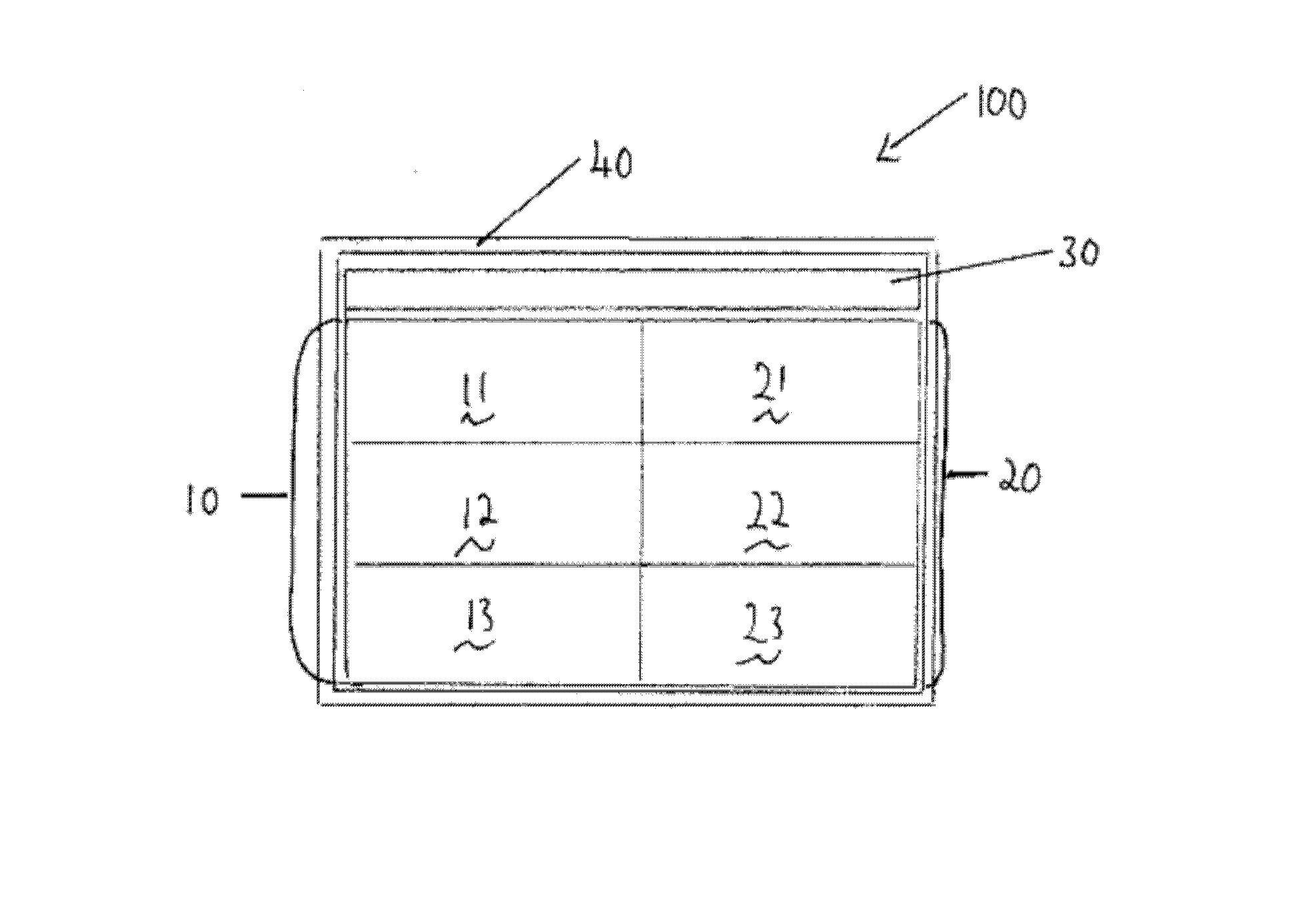

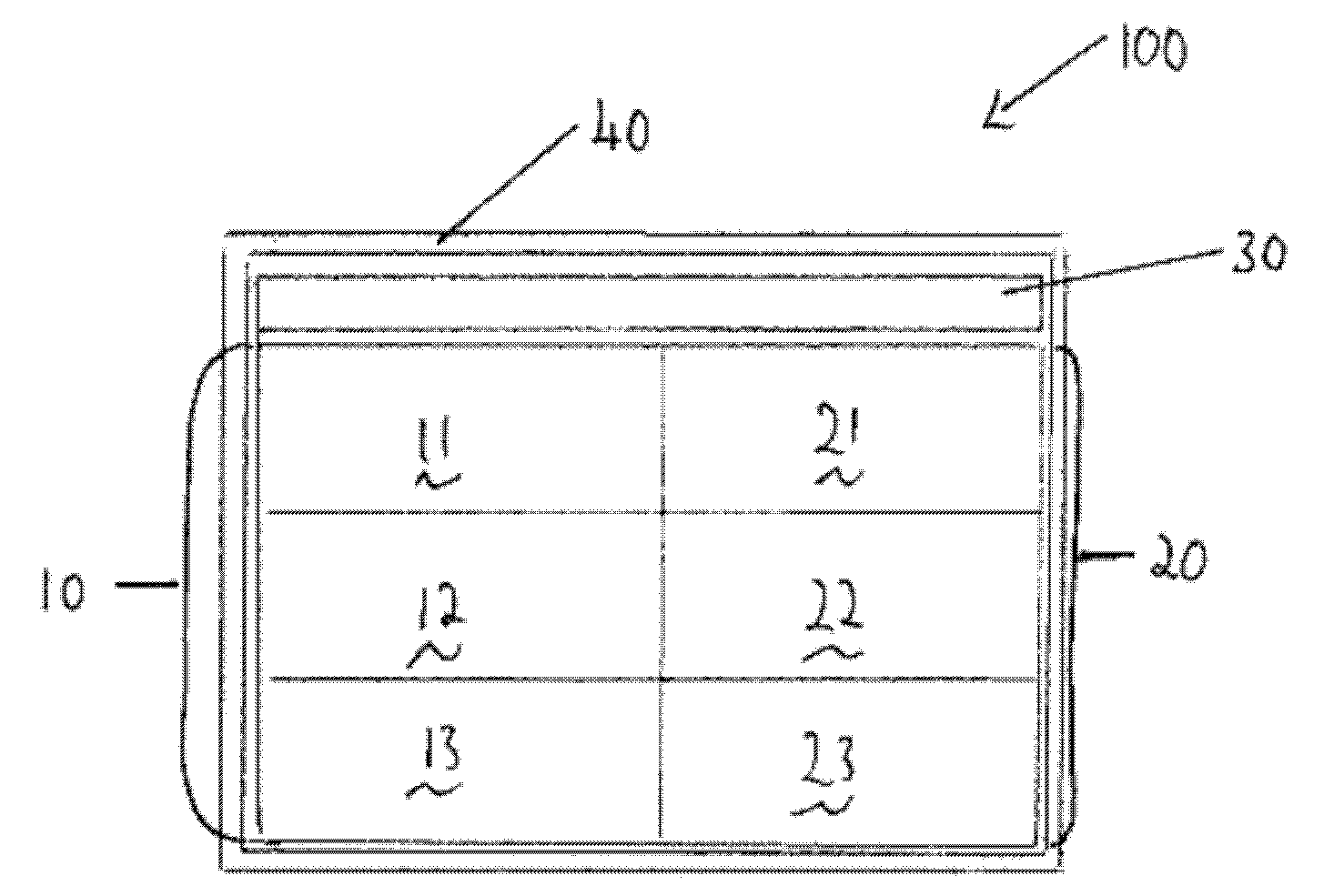

Packaged Mattress

InactiveCN102370366AMeet needsChange hardnessStuffed mattressesSpring mattressesBiomedical engineering

The invention discloses a mattress 10. The mattress includes a left assembly 10 and a right assembly 20 disposed side by side. The left assembly is composed of a plurality of piled mattress layers 11, 12, 13. The right assembly is composed of a plurality of piled mattress layers 21, 22, 23. An interlay layer covers an upper mattress layer 11 of the left assembly and an upper mattress layer 21 of the right assembly. A mattress sheath 40 warps the left assembly 10, the right assembly 20 and the interlay layer to form the mattress. The upper mattress layer 11 of the left assembly 10 has different rigidity with the neighboring lower mattress layer 12. The upper mattress layer 21 of the right assembly 20 has different rigidity with the neighboring lower mattress layer 22. And no elastic tool is adopted in the mattress 100.

Owner:COCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com