Liquid grinding aid capable of promoting coagulating, and preparation method thereof

A grinding aid and liquid technology, which is applied in the field of coagulation-accelerating liquid grinding aid and its preparation, can solve the problems of restricting the popularization and application of cement grinding aid, unstable quality of grinding aid, fluctuation of cement quality, etc., and achieve adaptability Good performance, reasonable proportion, change the effect of hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

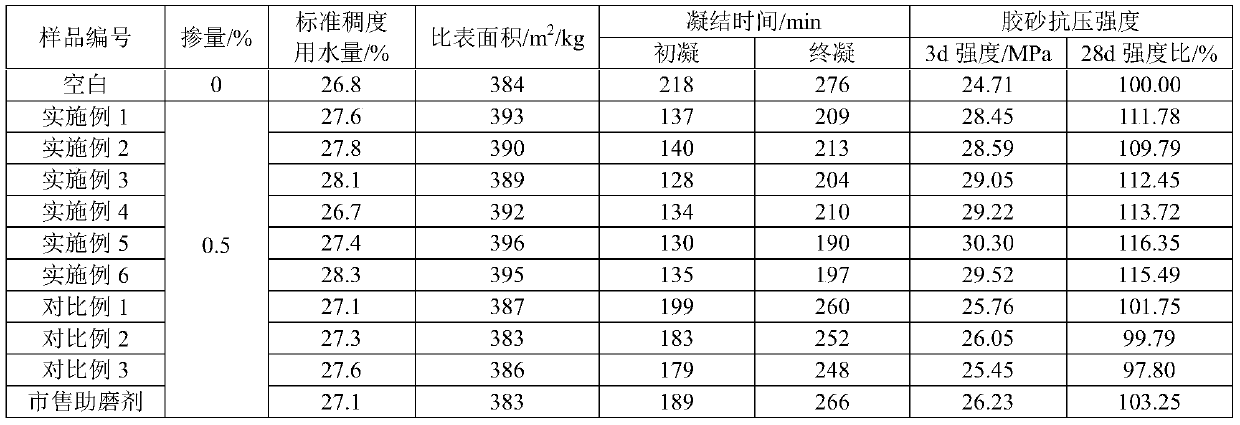

Examples

Embodiment 1

[0025] A coagulation-promoting liquid grinding aid, which is made of the following components and mass fractions of raw materials: 5% aluminum sulfate, 5% magnesium sulfate, 40% modified alcohol amine organic small molecules, 3% sodium lignosulfonate %, calcium formate 1.5%, the rest is deionized water;

[0026] The modified small organic molecules of alcohol amines are prepared by the following method: the polyamines and the small organic molecules of epoxy are placed in a reaction vessel, the temperature is raised to 30° C., and after reacting for 1 hour under the action of a catalyst, the obtained Then add an organic acid to the solution and react for 0.5h to obtain a modified alcohol amine organic small molecule; the molar ratio of the polyamine, epoxy organic small molecule, catalyst and organic acid is: 1:2:0.001:2 .

[0027] The polyamines are ethylenediamine.

[0028] The epoxy organic small molecule is ethylene oxide.

[0029] The catalyst is ferric chloride.

[0...

Embodiment 2

[0039] A coagulation-promoting liquid grinding aid, which is made of the following components and mass fractions of raw materials: 7% aluminum sulfate, 7% magnesium sulfate, 42% modified alcohol amine small organic molecules, 5% sodium lignosulfonate %, calcium formate 2%, the rest is deionized water;

[0040] The modified small organic molecules of alcohol amines are prepared by the following method: the polyamines and the small organic molecules of epoxy are placed in a reaction vessel, the temperature is raised to 35° C., and after reacting for 1.5 hours under the action of a catalyst, the Add an organic acid to the obtained solution and react for 1 hour to obtain a modified alcohol amine organic small molecule; the molar ratio of the polyamine, epoxy organic small molecule, catalyst and organic acid is: 1.5:3:0.0015:3 .

[0041] The polyamines are p-phenylenediamine.

[0042] The epoxy organic small molecule is propylene oxide.

[0043] The catalyst is aluminum chloride...

Embodiment 3

[0053] A coagulation-promoting liquid grinding aid, which is made of the following components and mass fractions of raw materials: 8% aluminum sulfate, 8% magnesium sulfate, 43% modified alcohol amine small organic molecules, 6% sodium lignosulfonate %, calcium formate 2%, the rest is deionized water;

[0054] The modified small organic molecules of alcohol amines are prepared by the following method: the polyamines and the small organic molecules of epoxy are placed in a reaction vessel, the temperature is raised to 45° C., and after reacting for 2 hours under the action of a catalyst, the obtained Then add an organic acid to the solution and react for 1.5h to obtain a modified alcohol amine organic small molecule; the molar ratio of the polyamine, epoxy organic small molecule, catalyst and organic acid is: 2:4:0.002:3 .

[0055] The polyamines are 1,4-butanediamine.

[0056] The epoxy organic small molecule is 1,2-epoxybutane.

[0057] The catalyst is tin chloride.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com