Patents

Literature

537results about How to "Prevent pulling out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

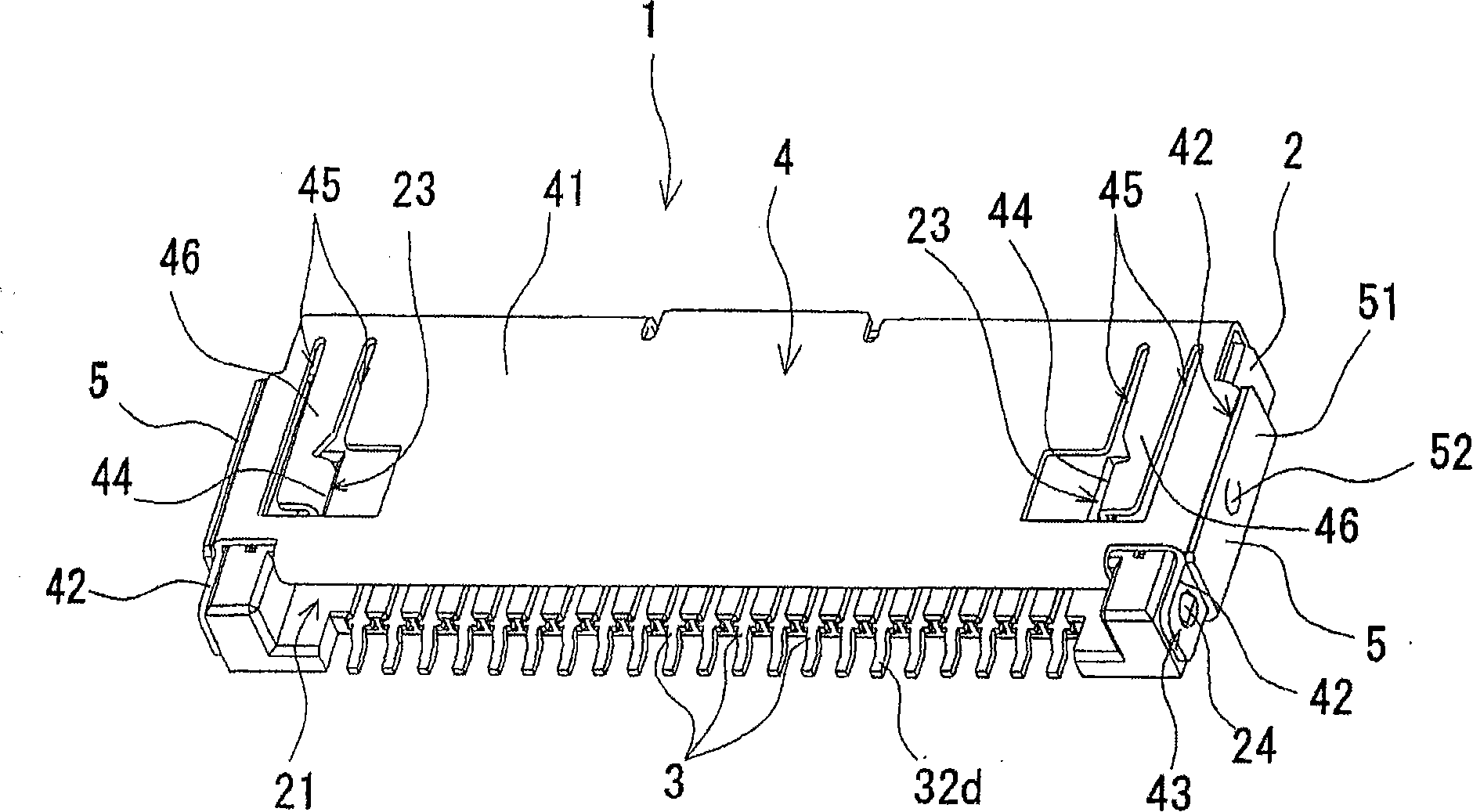

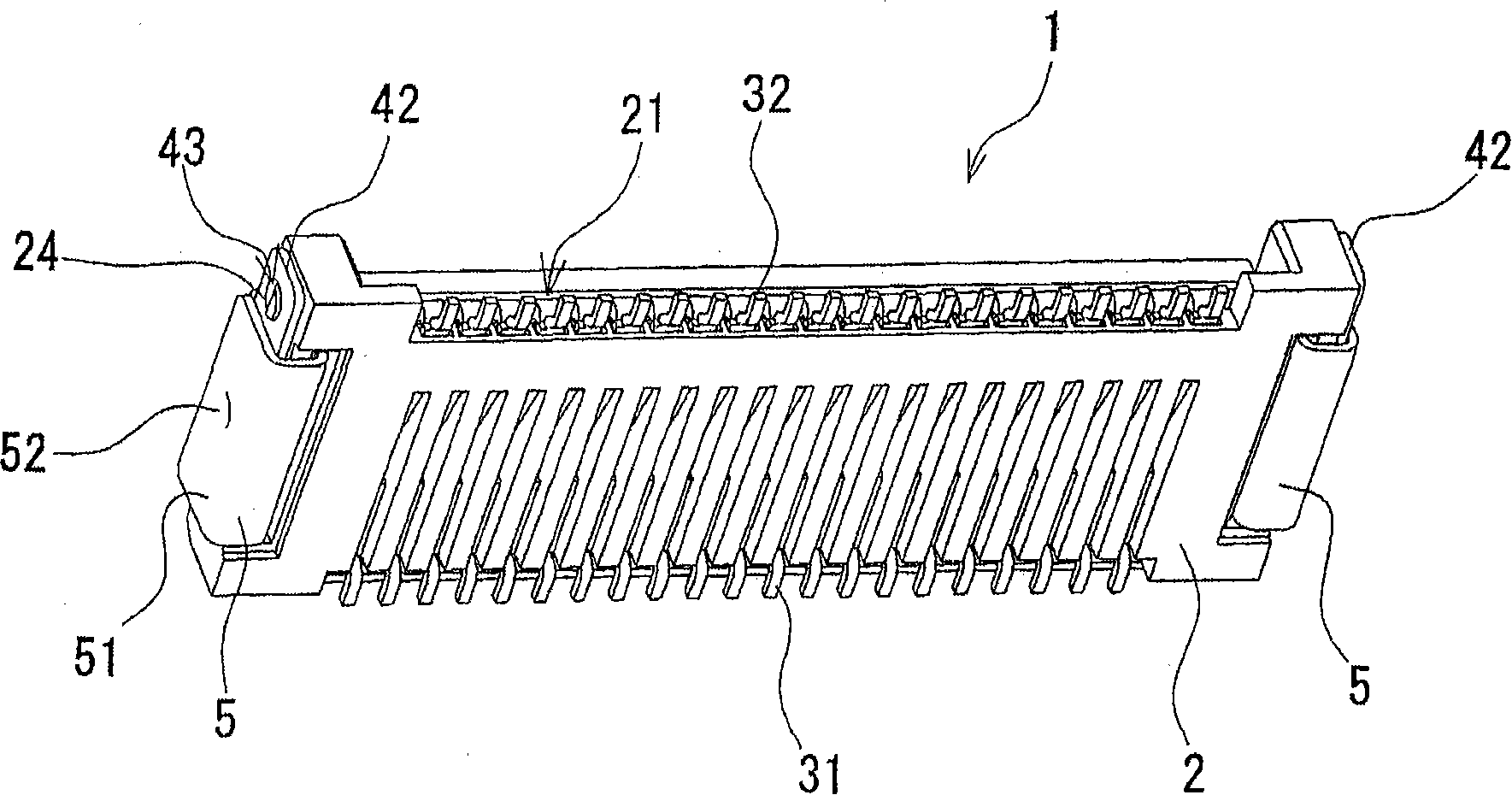

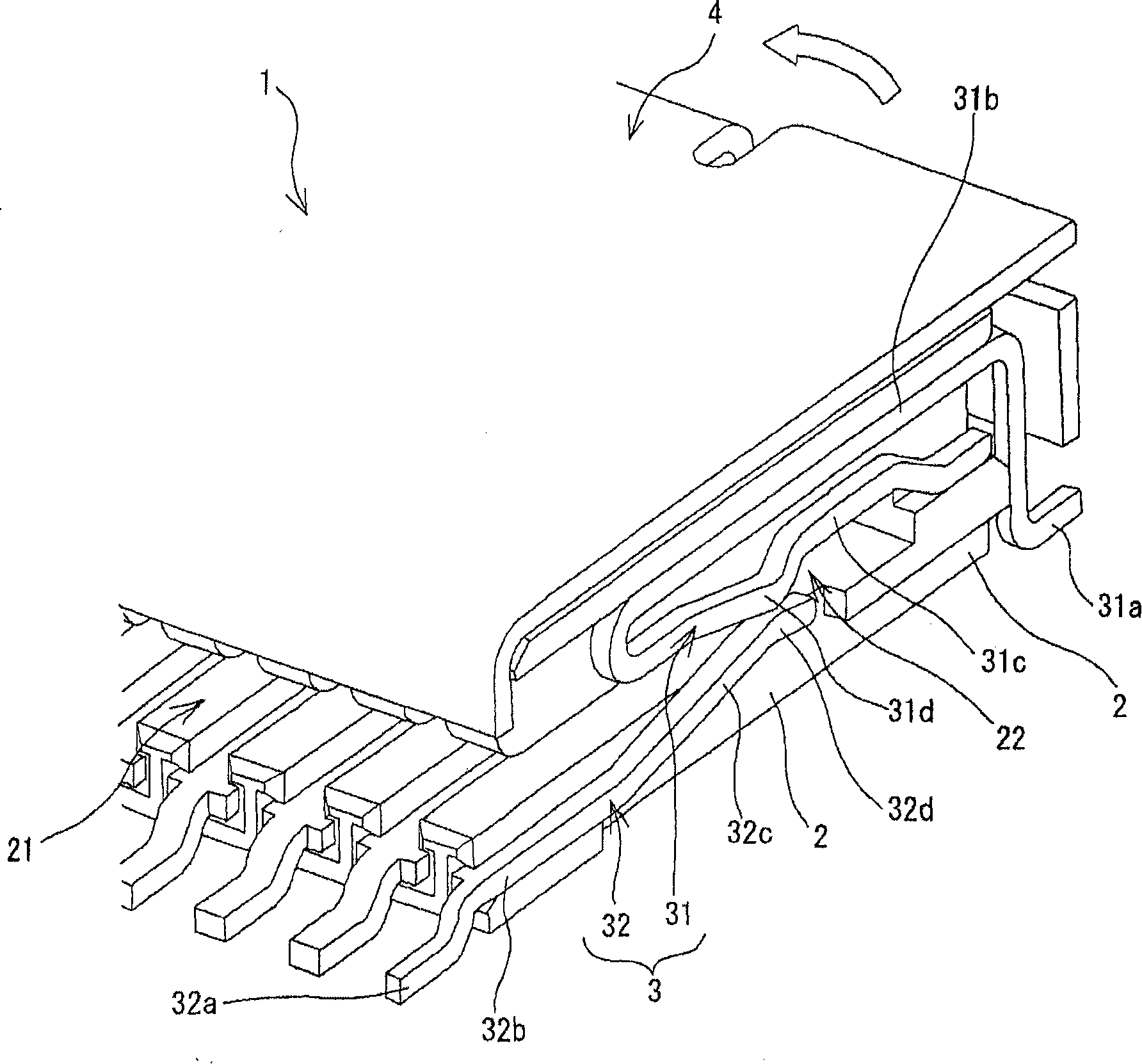

Connector

InactiveCN101242043AMaintain electrical connection reliabilityGuaranteed reliabilityCoupling device detailsEngineeringMental detachment

The present invention provides a connector, preventing FPC or FFC detachment and easy to assembly. Multiple contacts are serially arranged in an inserting space part having an inserting opening, an inserting via hole is penetrated from the surface to the inserting space one the connector main body of FPC or FFC, a cover mounted along the surface which penetrating with the inserting via hole and its basal end part rotatablely clipped in the connector main body, a clipped protruding is mounted on the cover, the clipped protruding inserts in the inserting via hole along the mounting position of the connector main body and protrudes towards the inserting space part, when the cover rotates, locating out of the inserting space part, and moving towards the outer direction of the inserting via hole by pressed. The clipped protruding is a protruding vertically mounted towards one side of the inner surface of the clipped space part, slantways forming on one side of the inserting port, having anelastic force moving towards the outer direction of the inserting port if one side of the inserting port is pressed.

Owner:SMK CO LTD

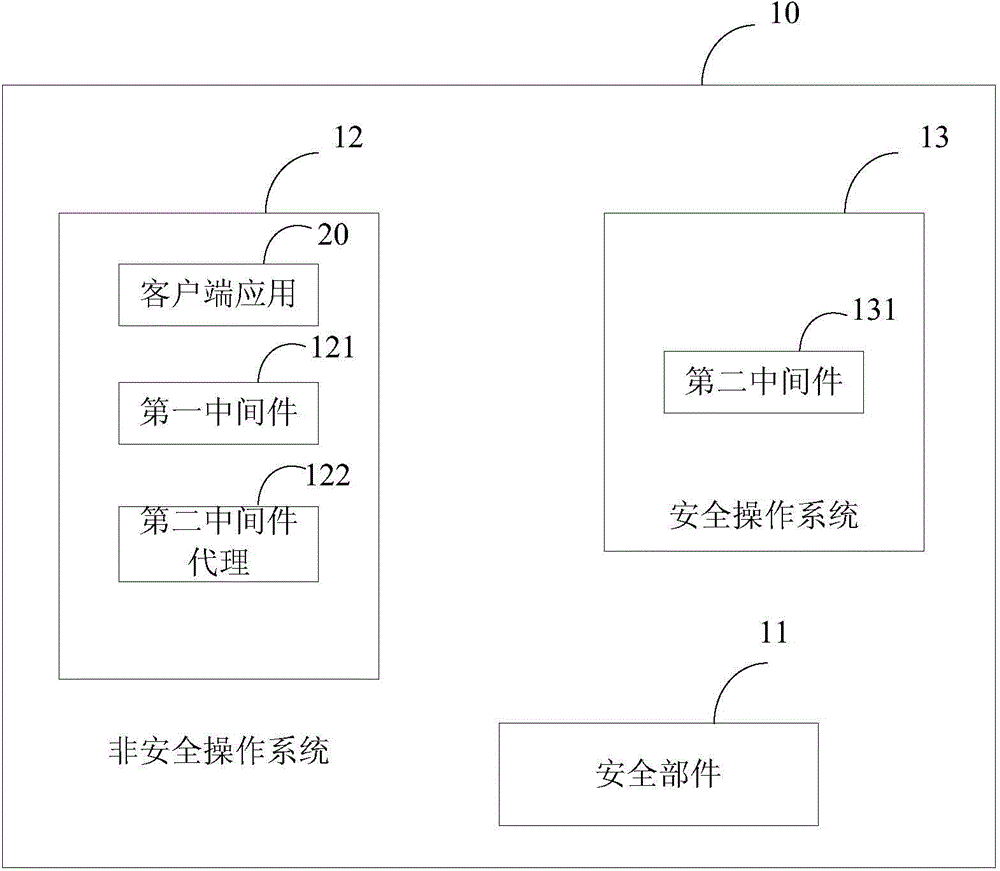

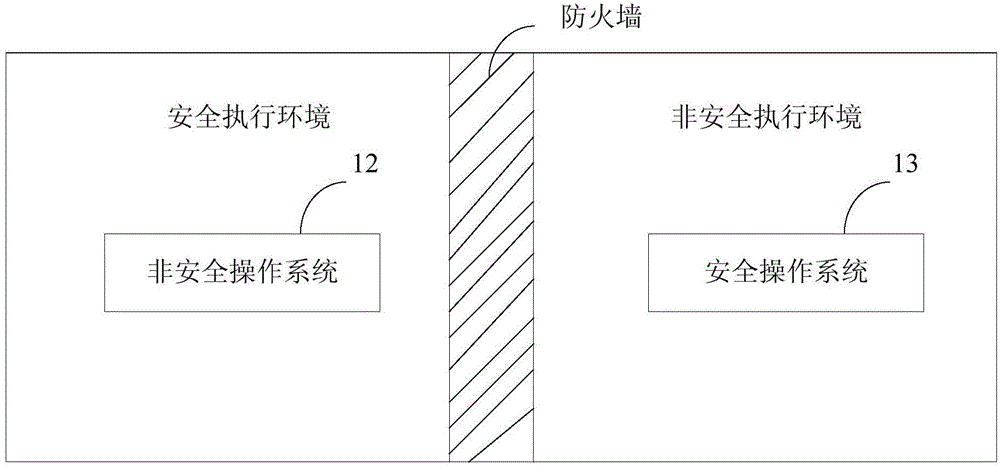

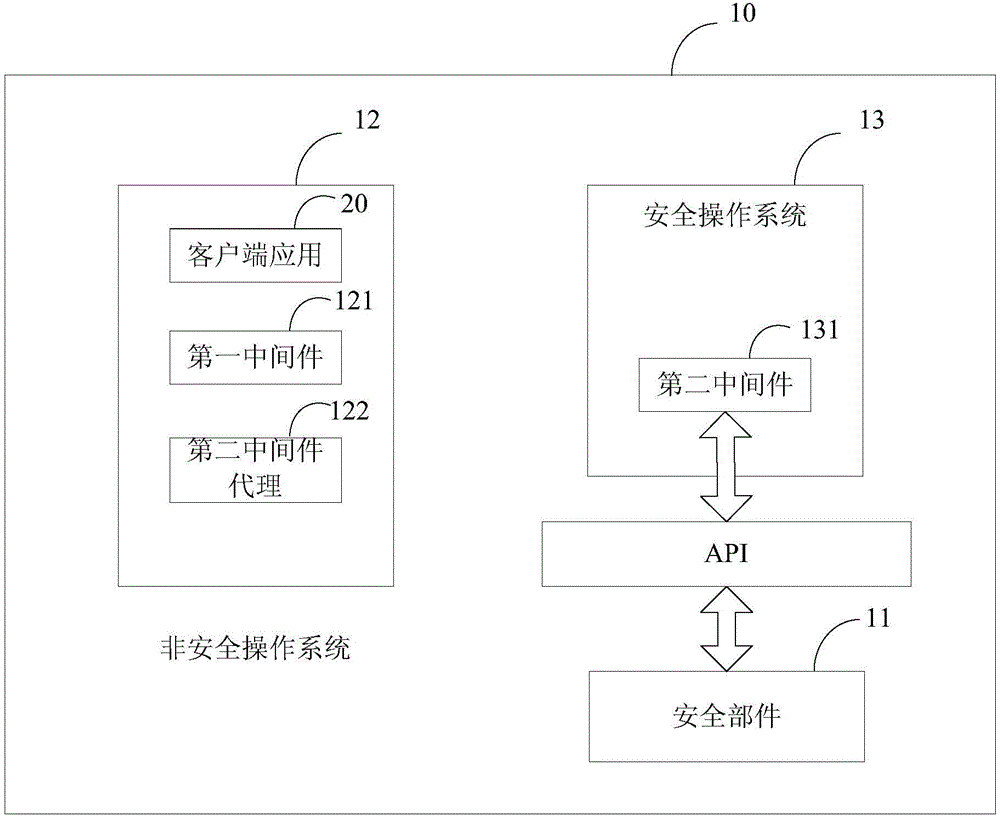

Device for safeguarding operational security of client side

InactiveCN104102876ALow costReduce complexityPlatform integrity maintainanceOperational systemClient-side

An embodiment of the invention discloses a device for safeguarding operational security of a client side. The device comprises a security part, an unsecure operating system, a secure operating system, a first middleware proxy, a second middleware proxy and second middleware, wherein the first middleware proxy and the second middleware proxy operate in the unsecure operating system, and the second middleware operates in the secure operating system. Client-side applications are installed on the unsecure operating system and directly call first middleware and call the second middleware through the second middleware proxy. Sensitive data in the client-side applications are stored in the security part, the first middleware is used for completing a part of service functions in the client-side applications in the unsecure operating system, and the second middleware is used for completing another part of service functions of the client-side applications by interacting with the security part in the unsecure operating system. According to the embodiment, potential security hazards of operations completed by the client side are reduced or even avoided.

Owner:WATCHDATA SYST

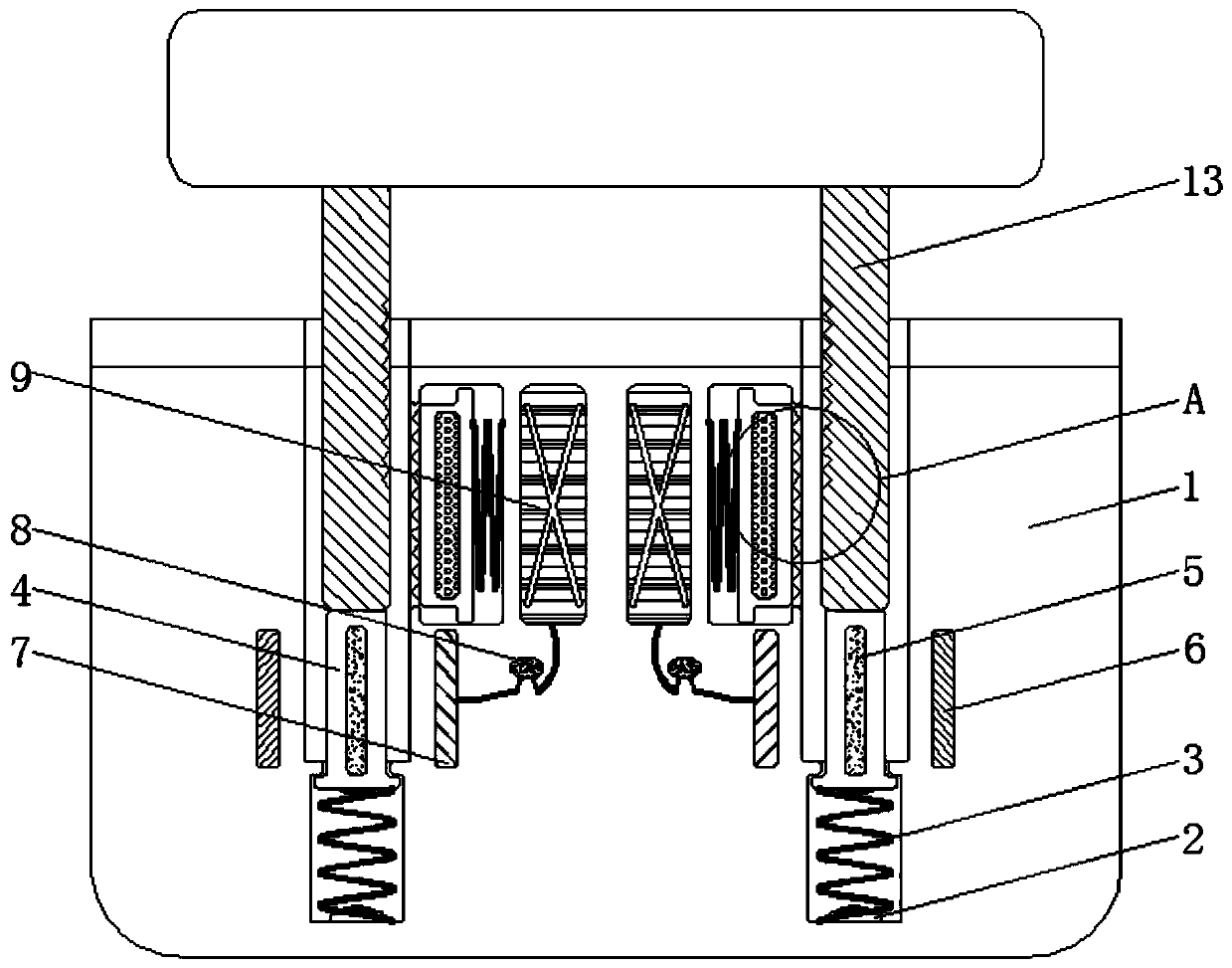

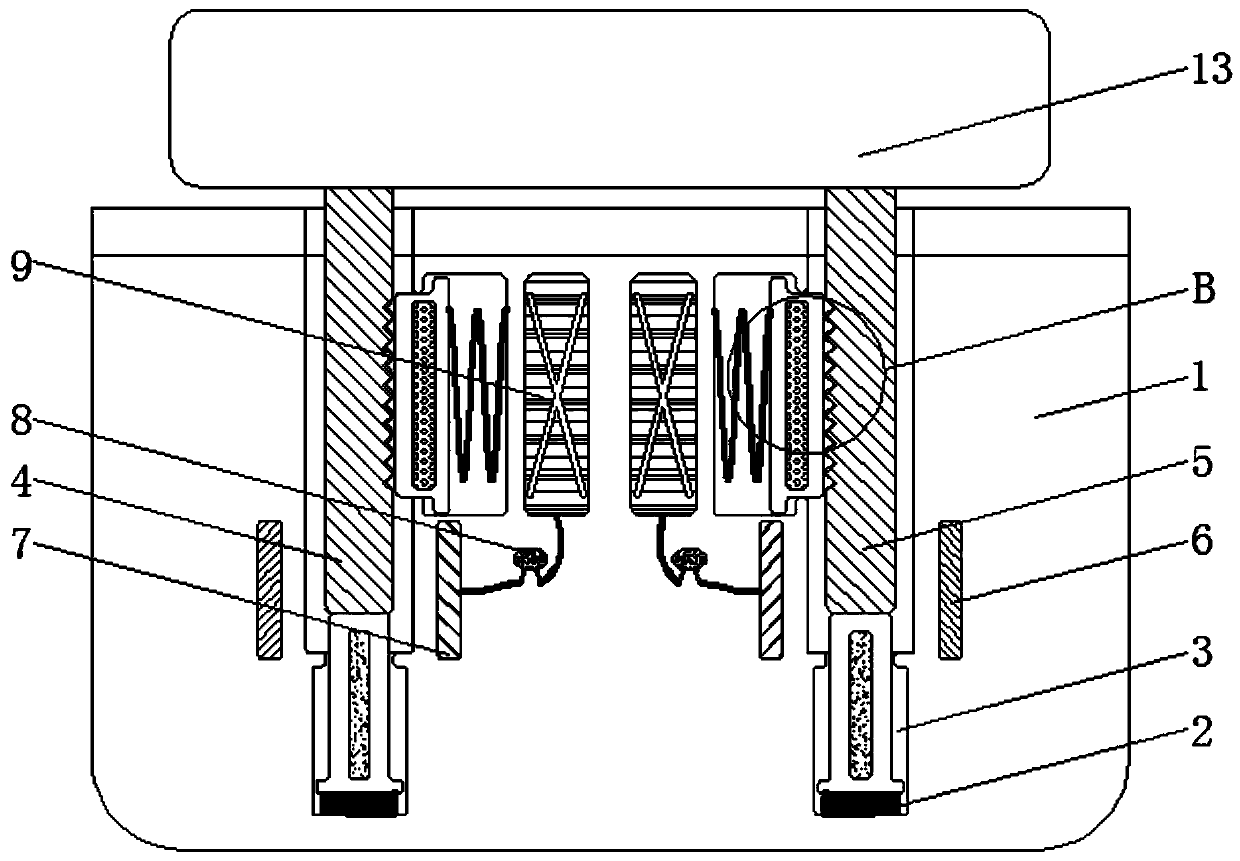

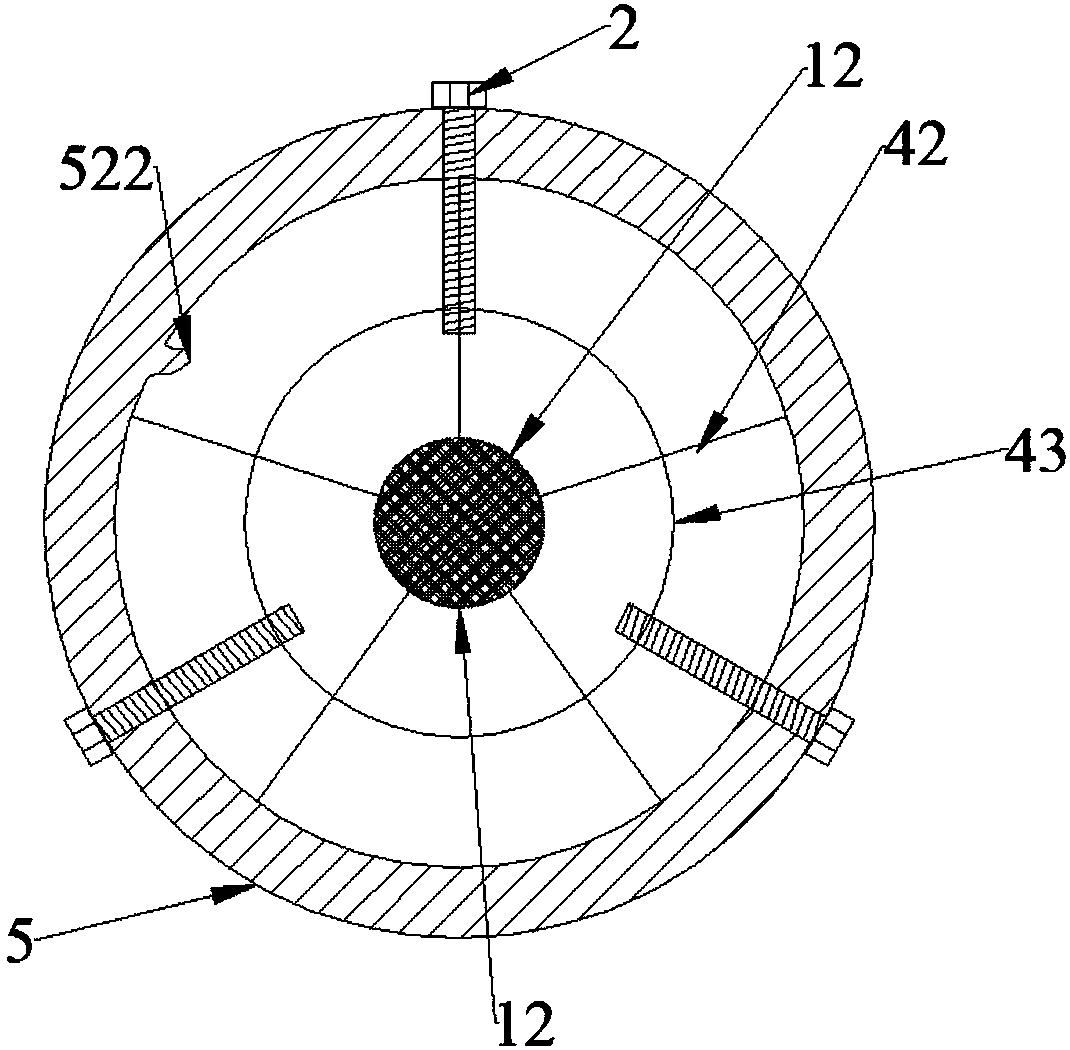

Self-locking socket and plug based on capacitance change

ActiveCN110994263APrevent pulling outTo achieve the effect of preventing accidental pullingEngagement/disengagement of coupling partsTwo-part coupling devicesDielectric plateHemt circuits

The invention discloses a self-locking socket and plug based on capacitance change, relates to the technical field of electric power and the self-locking socket and plug comprises a socket body, conductive columns are fixedly connected to the inner bottom walls of the two sides of the socket body, first springs are fixedly connected to the inner bottom walls of the two sides of the socket body, movable blocks movably connected with the inner wall of the socket body are fixedly connected to the tops of the first springs, and dielectric plates are fixedly connected to the middles of the movableblocks. The invention discloses a self-locking socket and plug based on capacitance change. The electromagnetic device is matched with the clamping block for use; when the plug is plugged with the socket, the plug extrudes the movable block to the bottom of the socket; the bottom of the movable block is contacted with the top of the conductive column; when the plug is pulled out by mistake, a circuit of the electromagnetic device is connected, at the moment, the clamping block moves outwards under the magnetic repulsion effect of the electromagnetic device, the clamping block is clamped with the clamping groove, movement of the plug is limited, and therefore the mistaken pulling prevention effect is achieved, the equipment plug is effectively prevented from being pulled out in the workingstate, stable work of equipment is guaranteed, and equipment burnout is effectively prevented.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER COMPANY +2

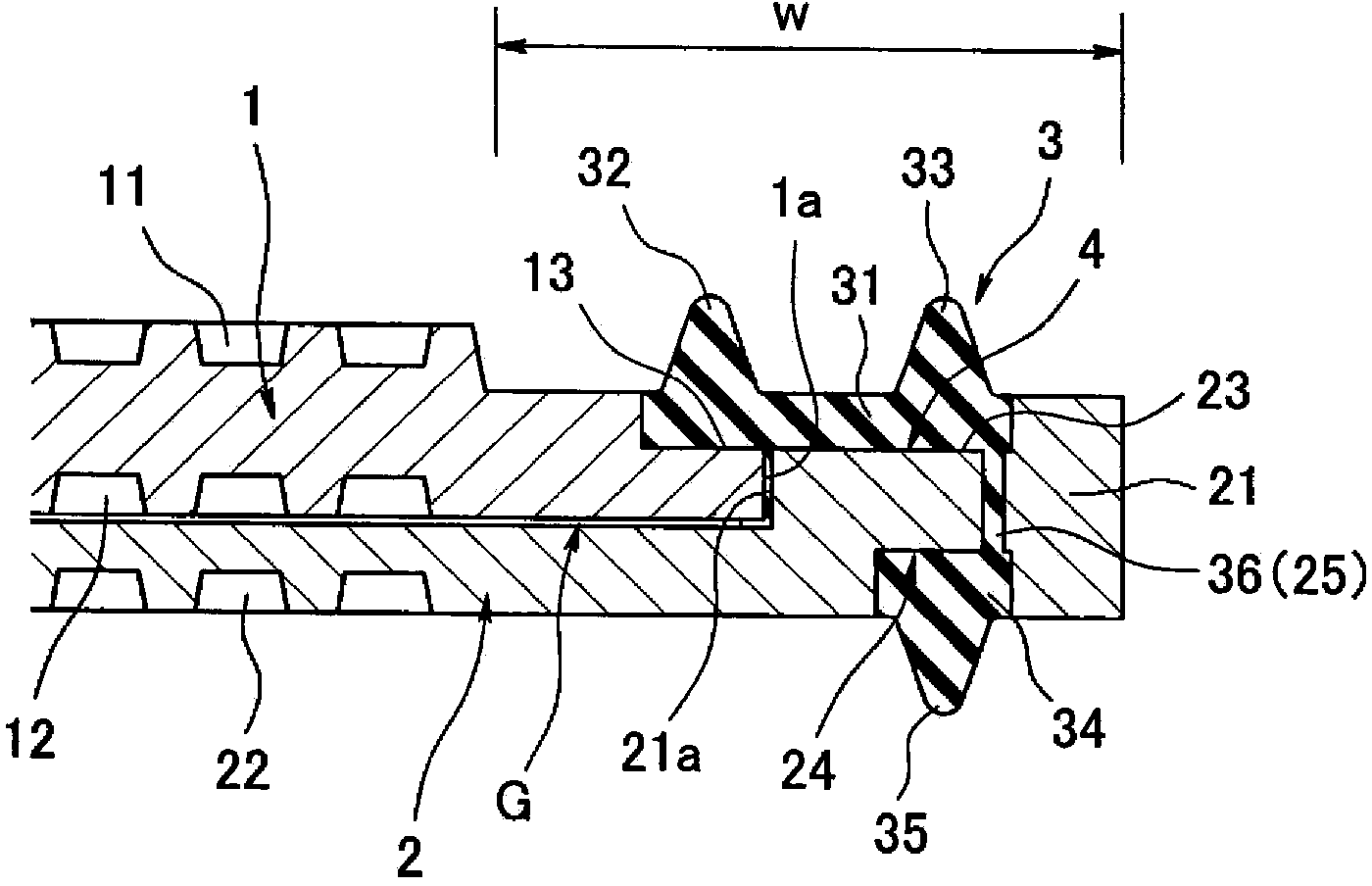

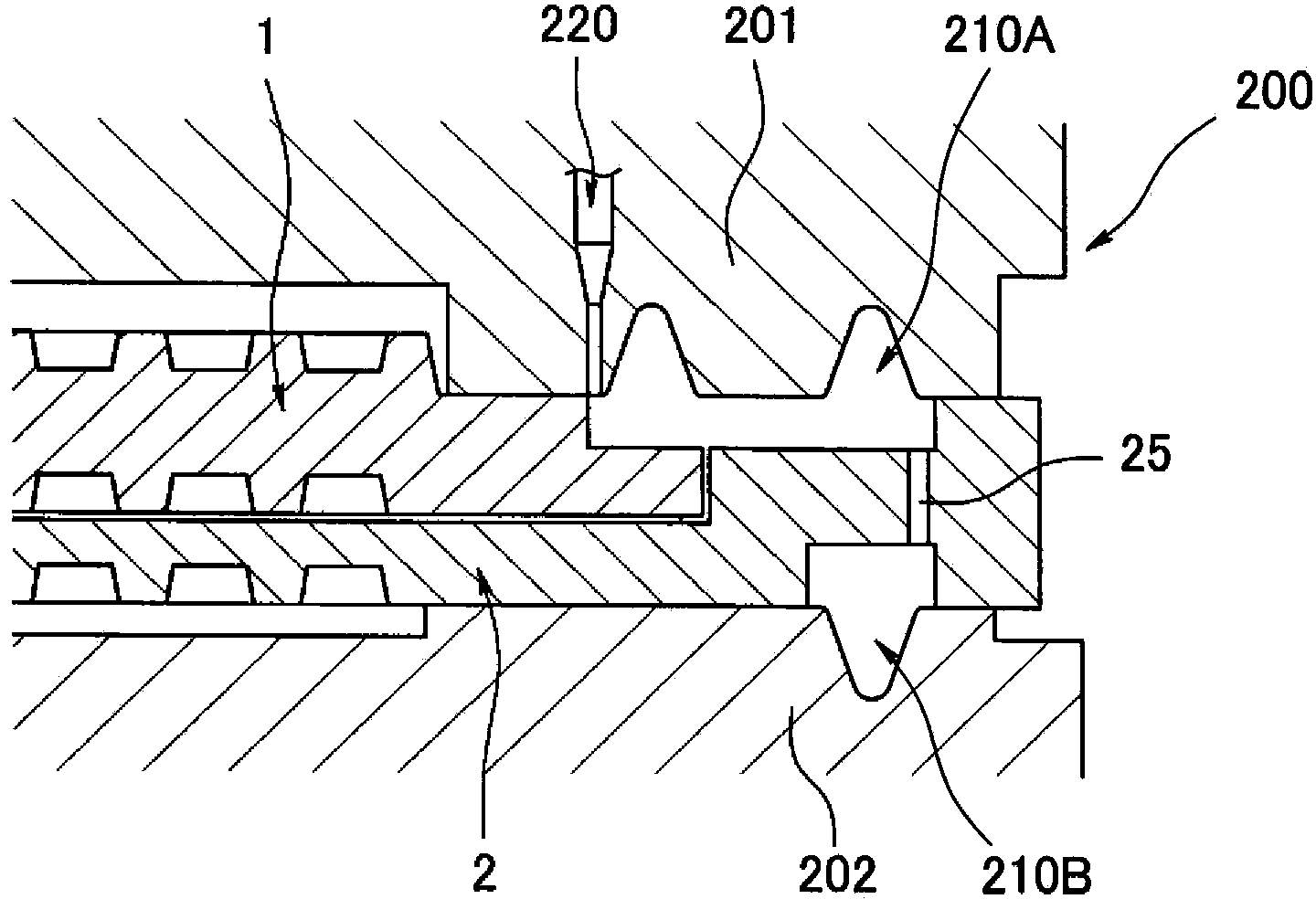

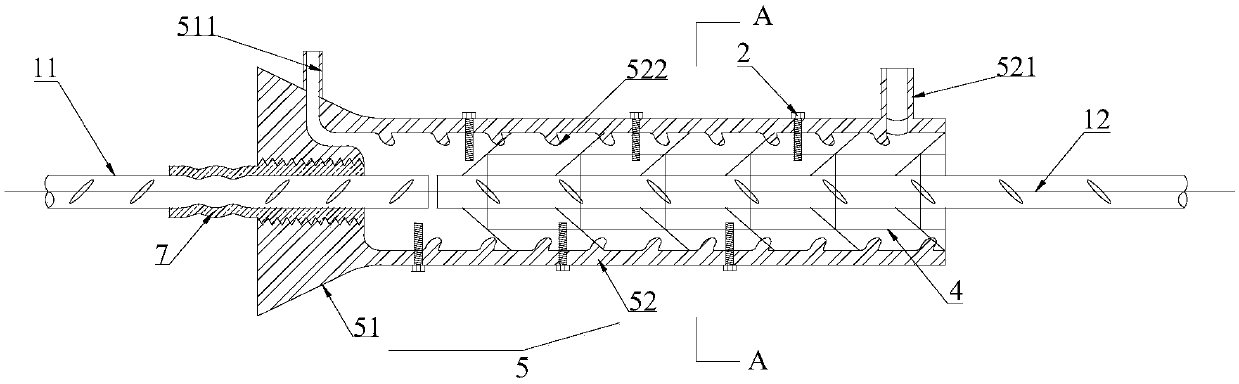

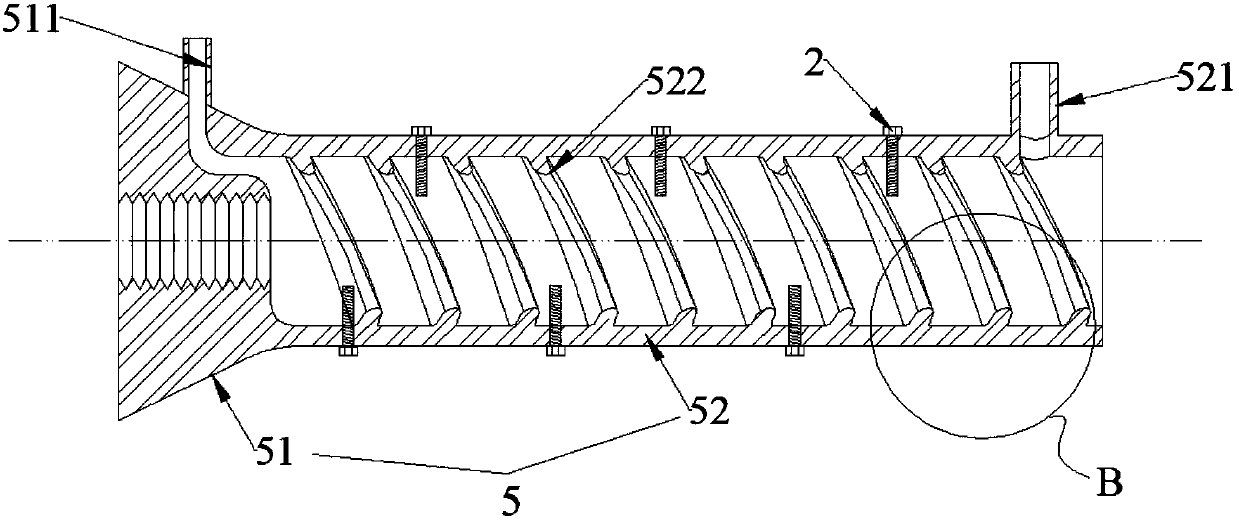

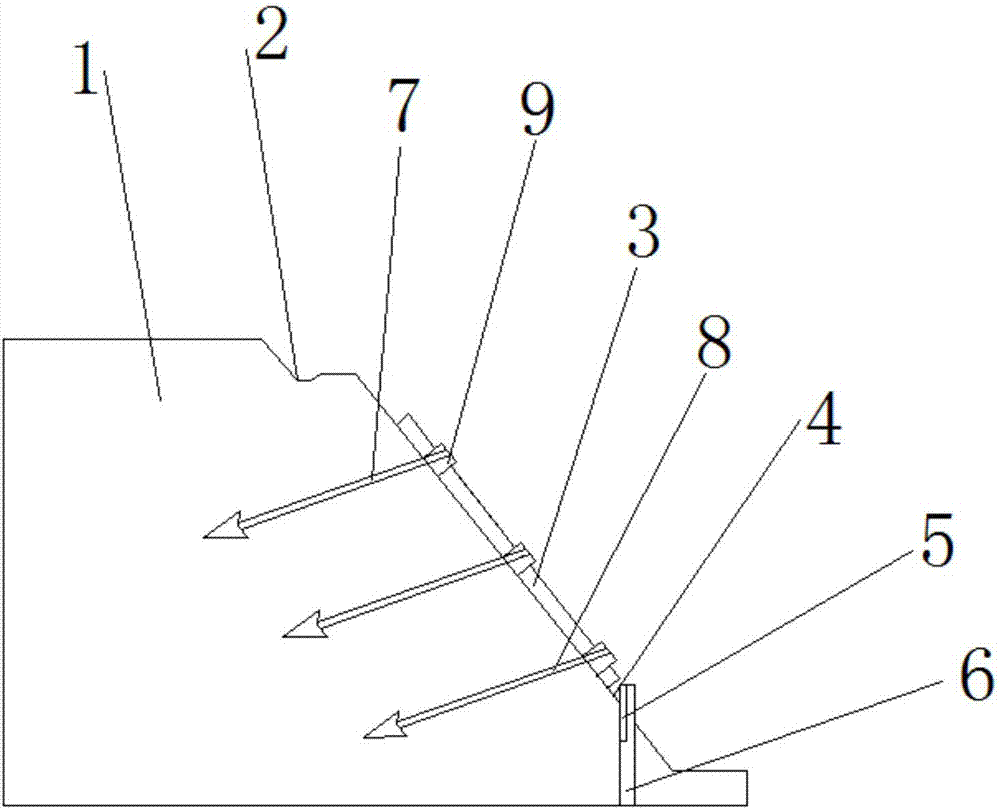

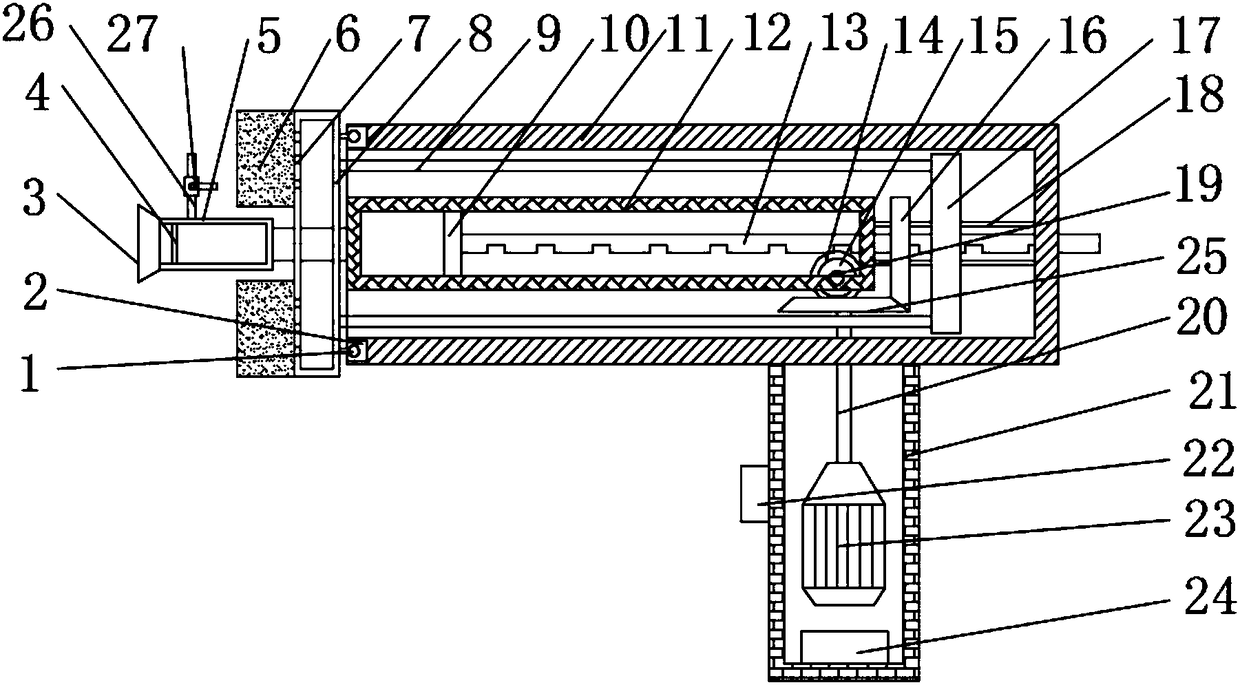

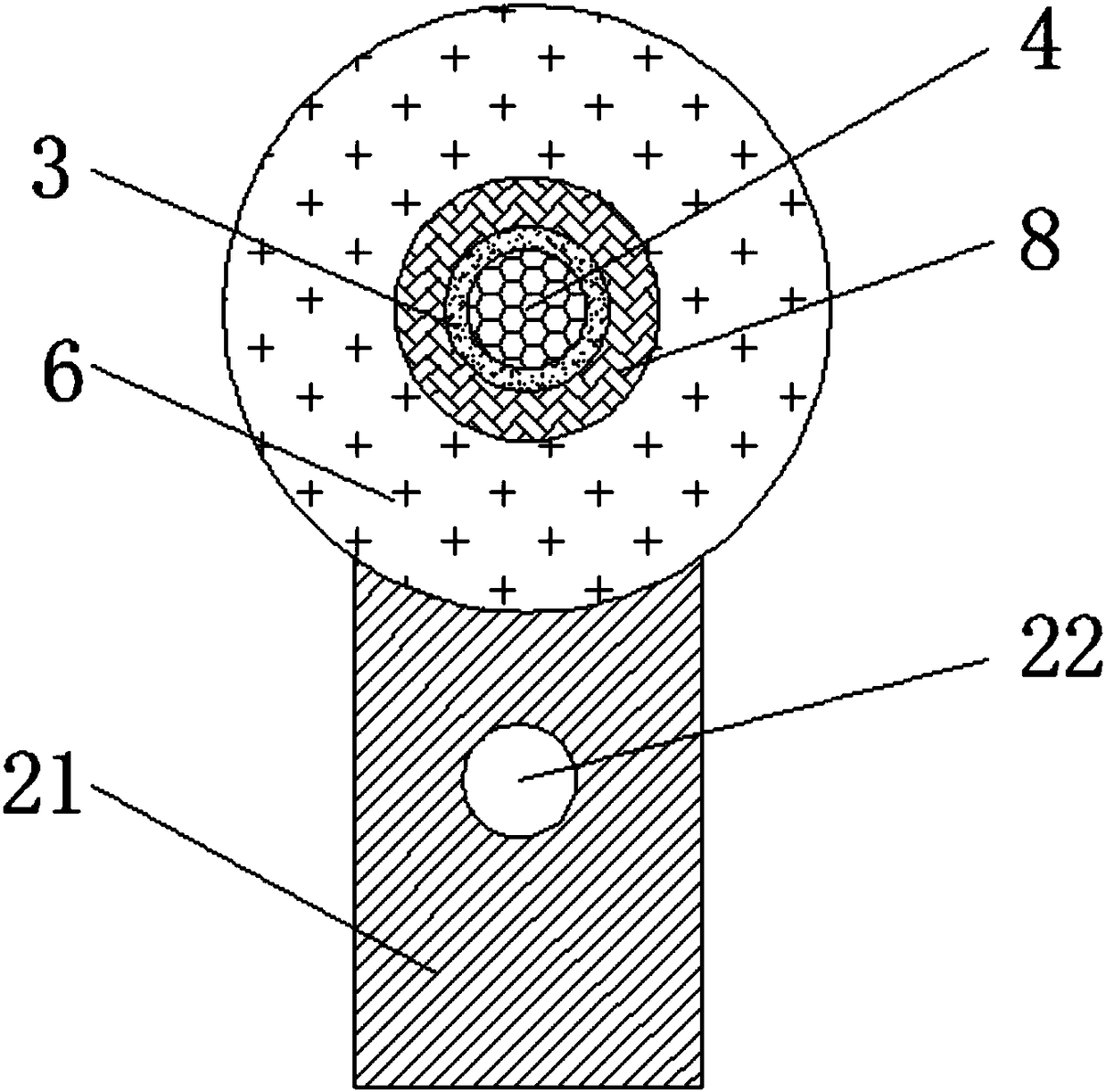

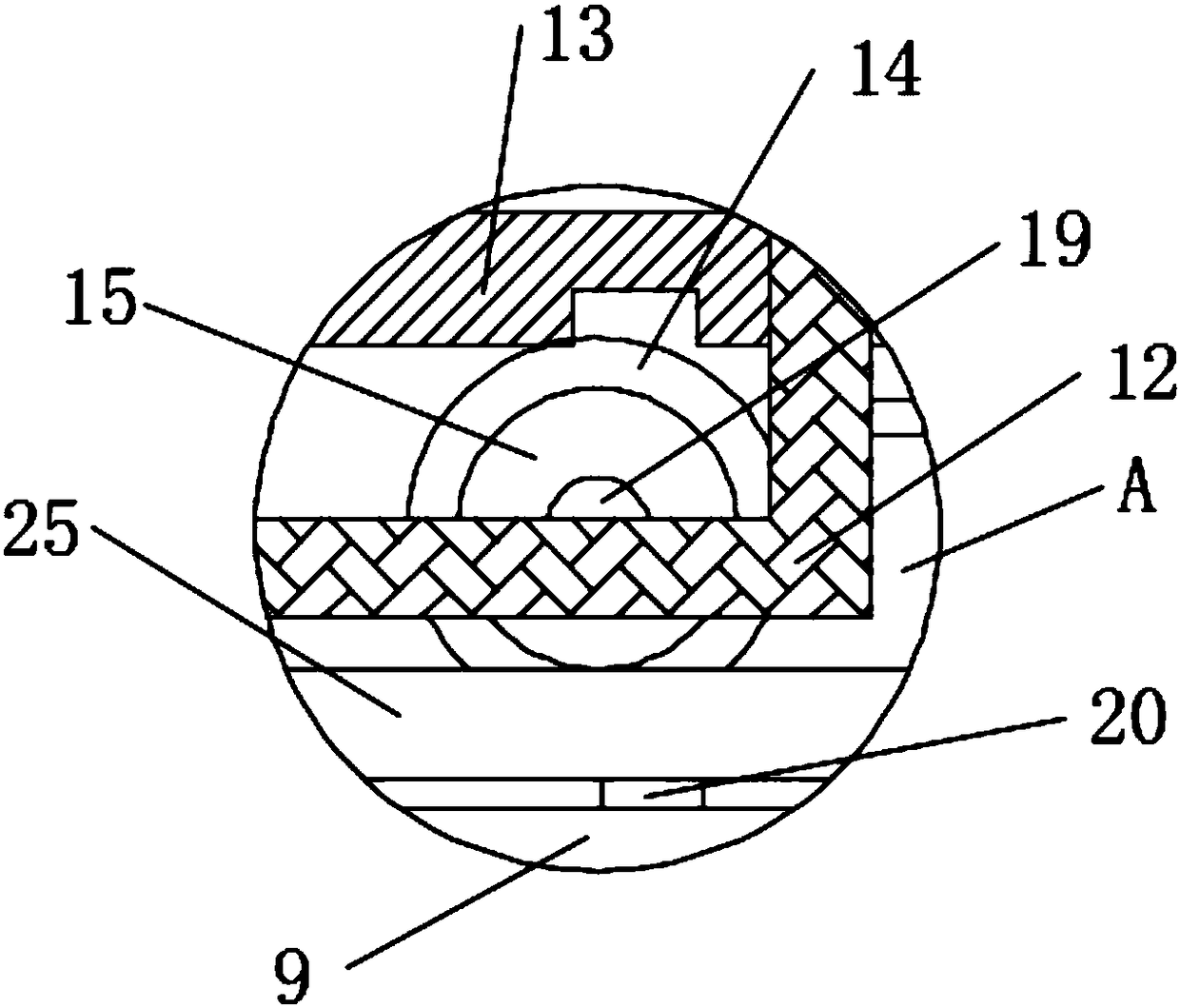

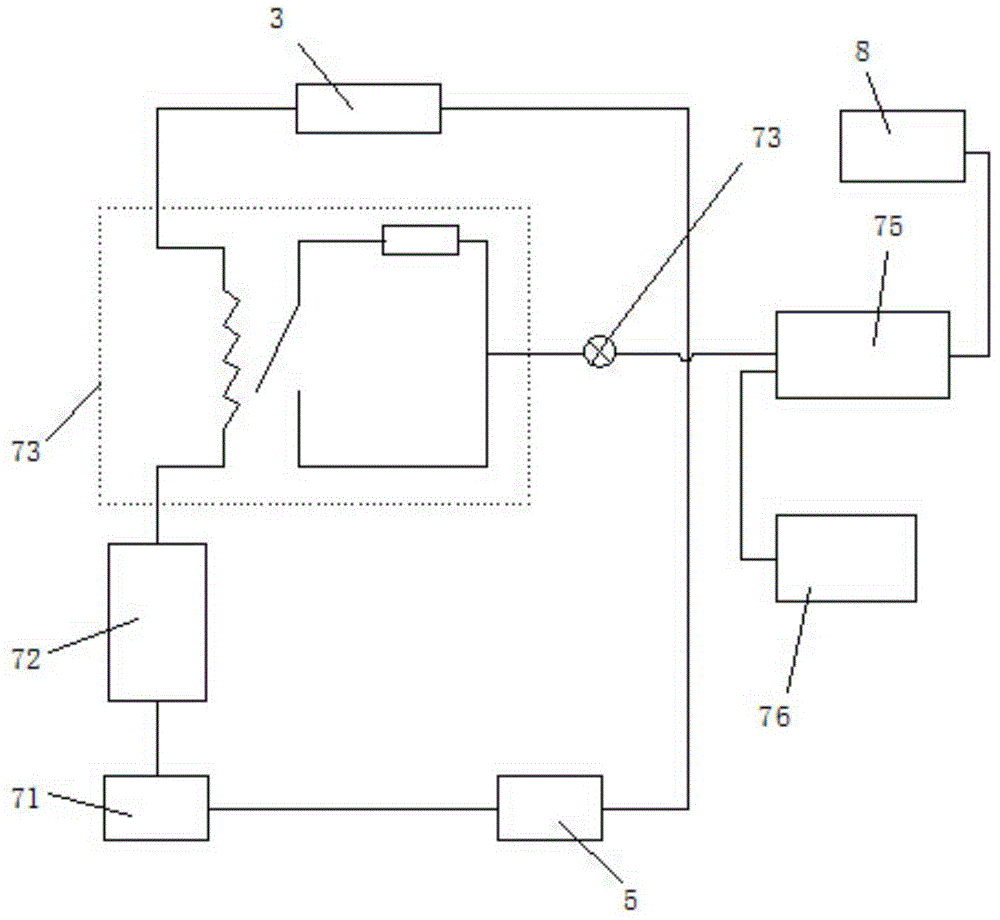

Oil and gas pipeline intelligent internal detection device based on multi-module combined location

ActiveCN103470959AReduce resistancePrevent pulling outPipeline systemsSpeed control systemElectromagnetic pulse

The invention discloses an oil and gas pipeline intelligent internal detection device based on multi-module combined location. The device comprises an internal detector arranged inside an oil and gas pipeline and a floor marker arranged outside the oil and gas pipeline. The internal detector comprises a driving system, a magnetic leakage detecting system, a speed control system, a distance measuring system and a low frequency emitting system, wherein the driving system, the magnetic leakage detection system, the speed control system, the distance measuring system and the low frequency emitting system are relatively fixedly connected together; the floor marker at least comprises a low frequency receiving system; the low frequency emitting system is used for sending detection results obtained by the magnetic leakage detection system out of the oil and gas pipeline; the low frequency receiving system is used for receiving low frequency electromagnetic pulse signals transmitted by the low frequency emitting system. The oil and gas pipeline intelligent internal detection device based on the multi-module combined location can timely obtain the detection data of the pipeline detector and analyze the detection data and accordingly rapidly determine the defect conditions of the pipeline.

Owner:BEIJING APC PETROCHEM TECH

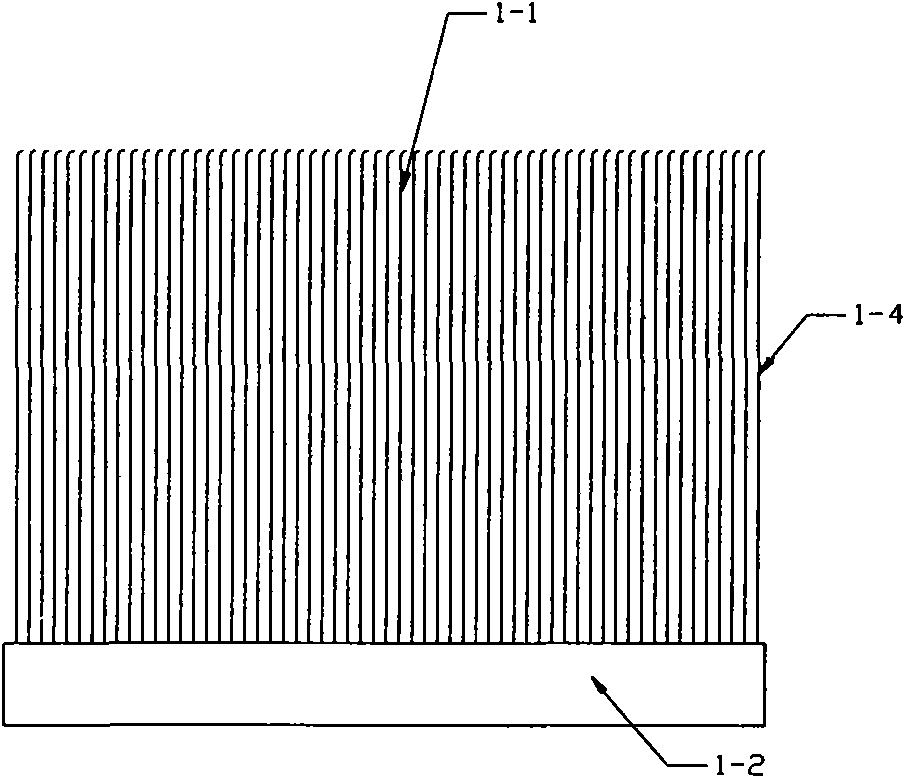

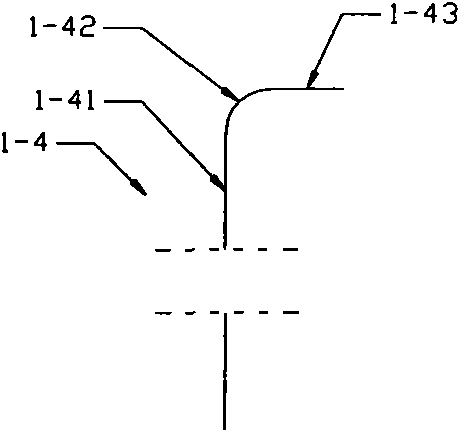

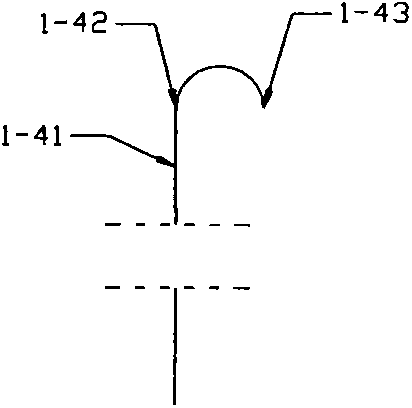

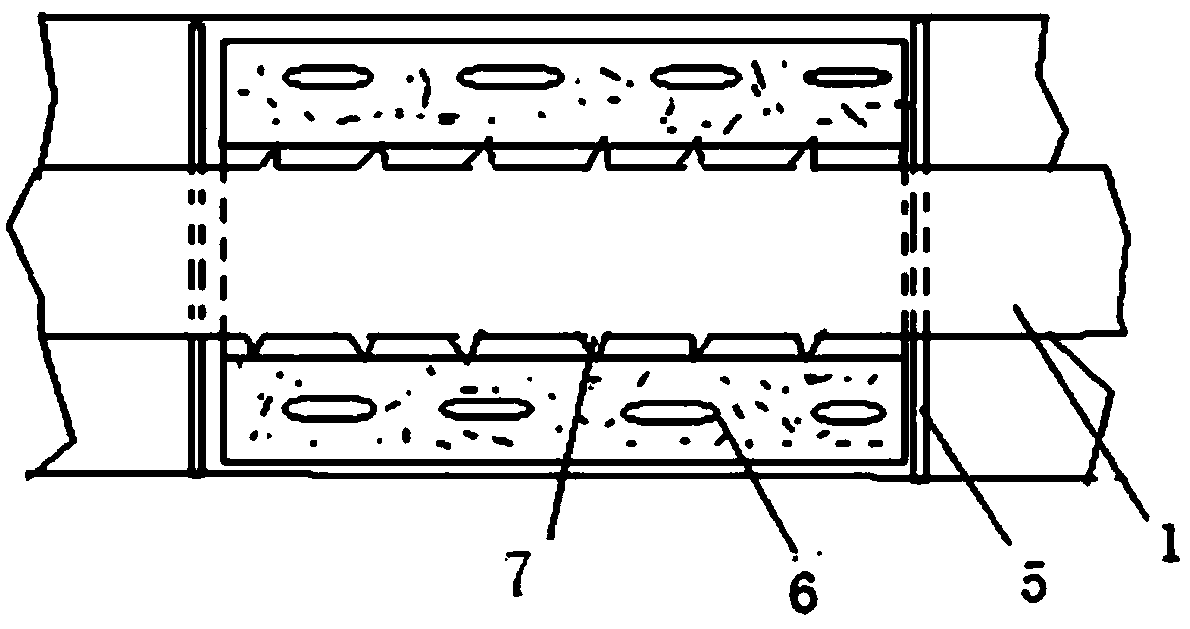

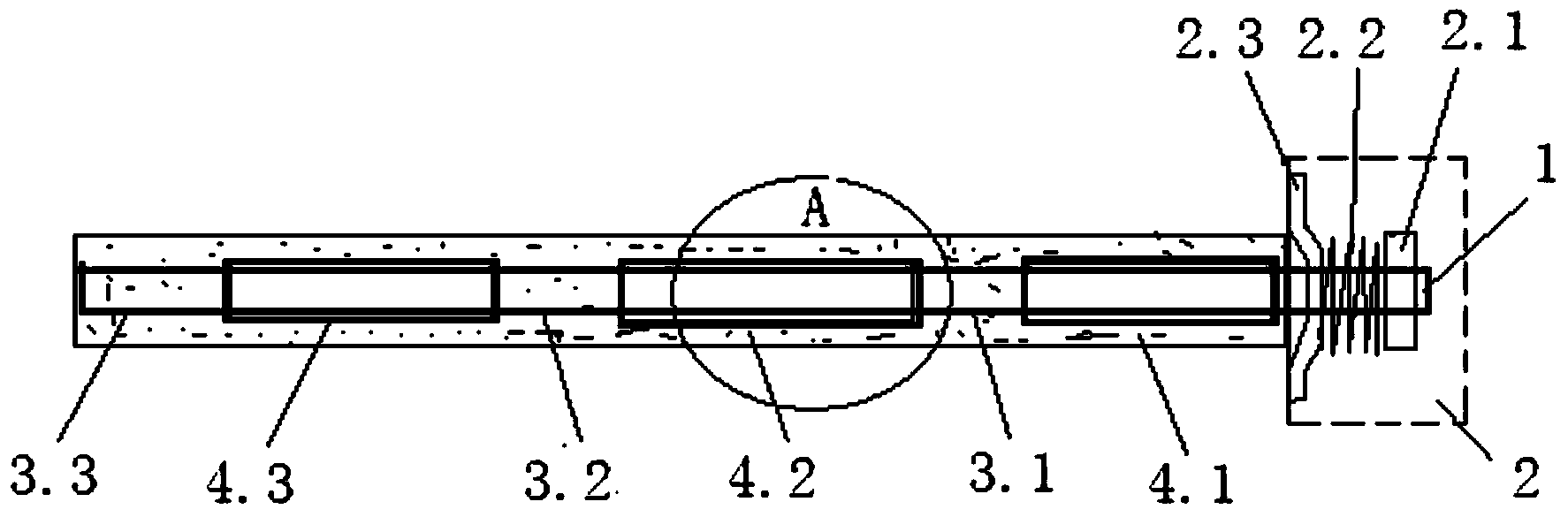

Multistage anchoring type resin anchor rod and anchoring method thereof

InactiveCN103758551AEliminate transfer stacking effectsAvoid failureAnchoring boltsStress concentrationAnnular cutter

The invention discloses a multistage anchoring type resin anchor rod and an anchoring method of the multistage anchoring type resin anchor rod. The multistage anchoring type resin anchor rod comprises an anchor rod body and an orifice pretensioner. Point anchoring sections are arranged on the anchor rod at intervals. Other sections are free sections. According to the point anchoring sections, tooth-shaped annular cutters are machined at the positions, provided with the point anchoring sections, of the anchor rod body. The tooth-shaped annular cutters are sleeved with two-component anchoring resin cartridges. The two ends of each two-component anchoring resin cartridge are sleeved with isolation gaskets. Accordingly, the anchor rod body is sequentially divided into the first free section, the first point anchoring section, the second free section, the second point anchoring section, the third free section and the third point anchoring section from an orifice, and it is required that the first free section is located in a surrounding rock loose area, the third point anchoring section is located in a surrounding rock elastic area, and other sections are located in a surrounding rod plastic area. The number of the point anchoring sections, the number of the free sections and the lengths of all the sections can be adjusted according to the surrounding rock pressure distribution characteristics, loads are dispersed, ultra-strong stress concentration is prevented from happening to the ends of the anchor rod, and the anchor rod body is prevented from breaking or being pulled out.

Owner:SHANDONG UNIV OF SCI & TECH

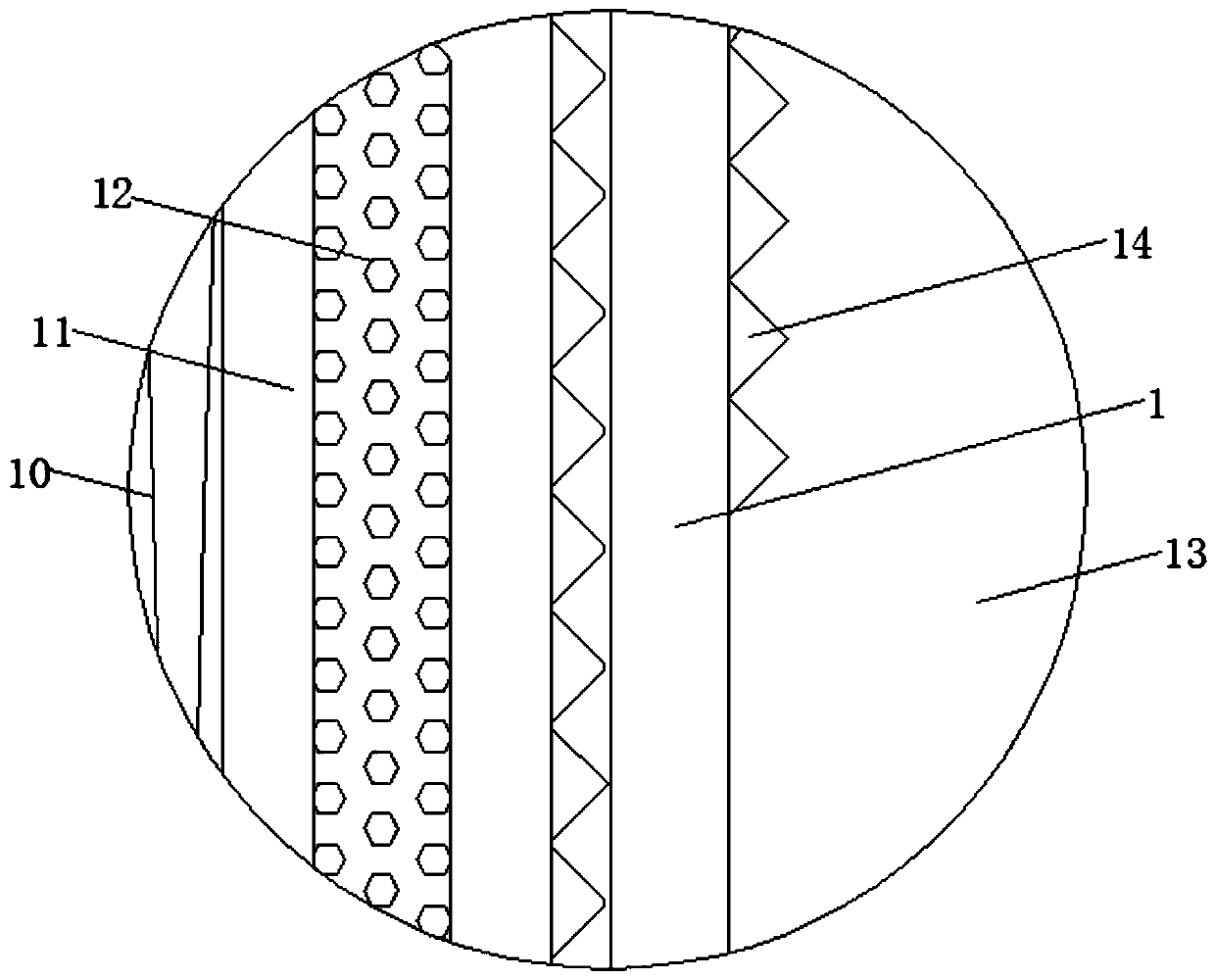

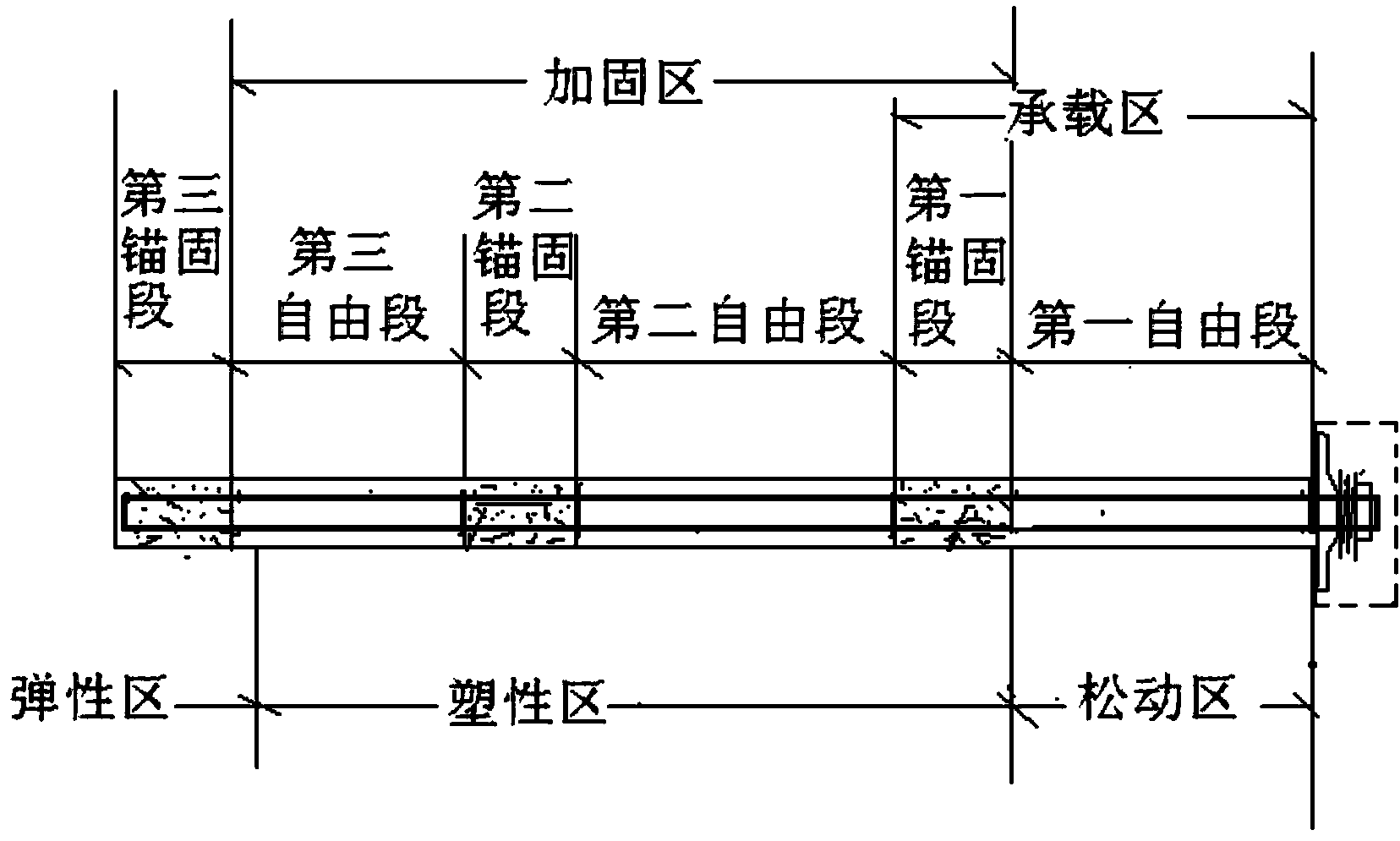

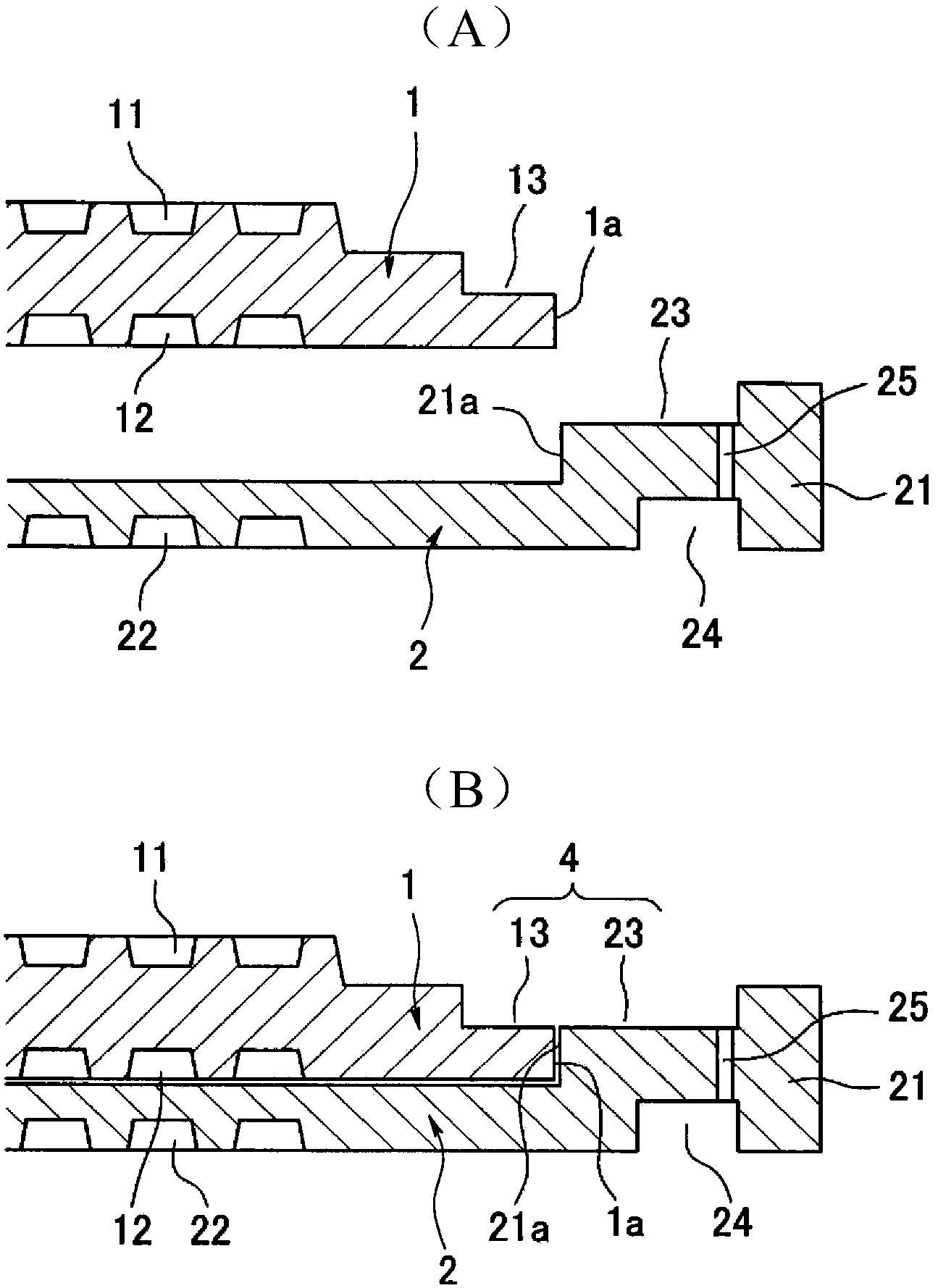

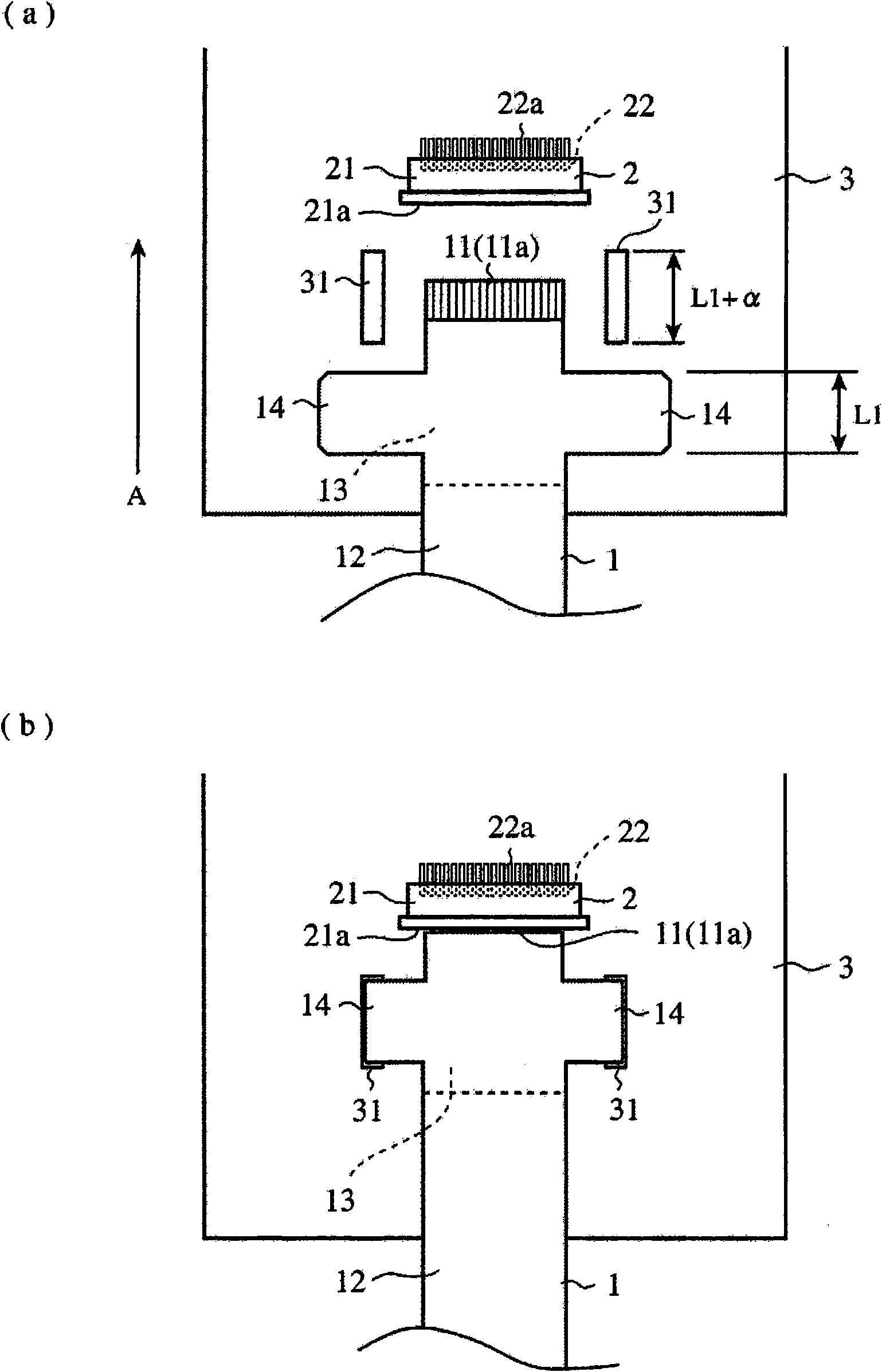

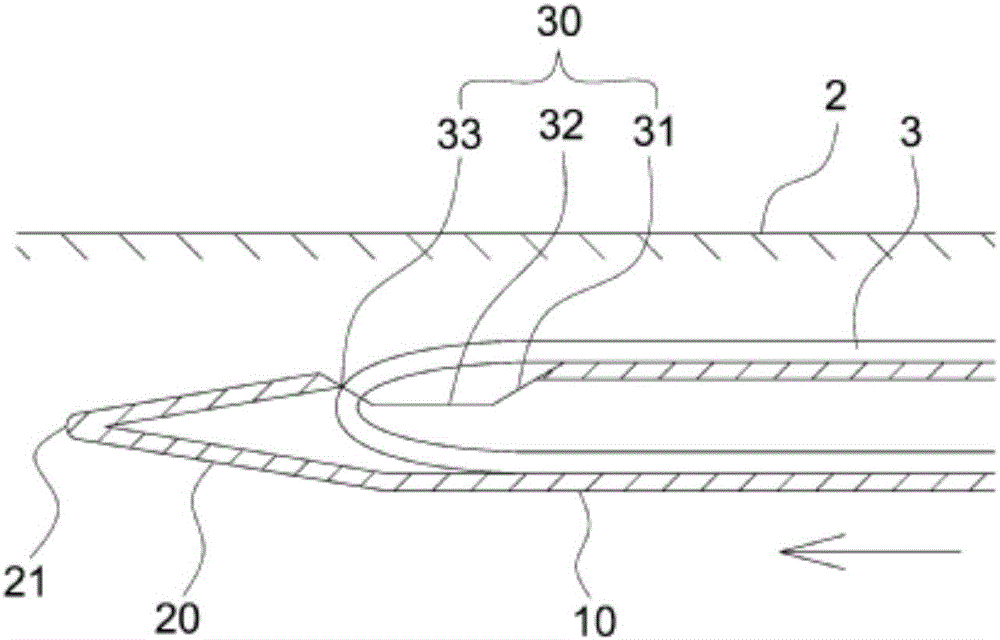

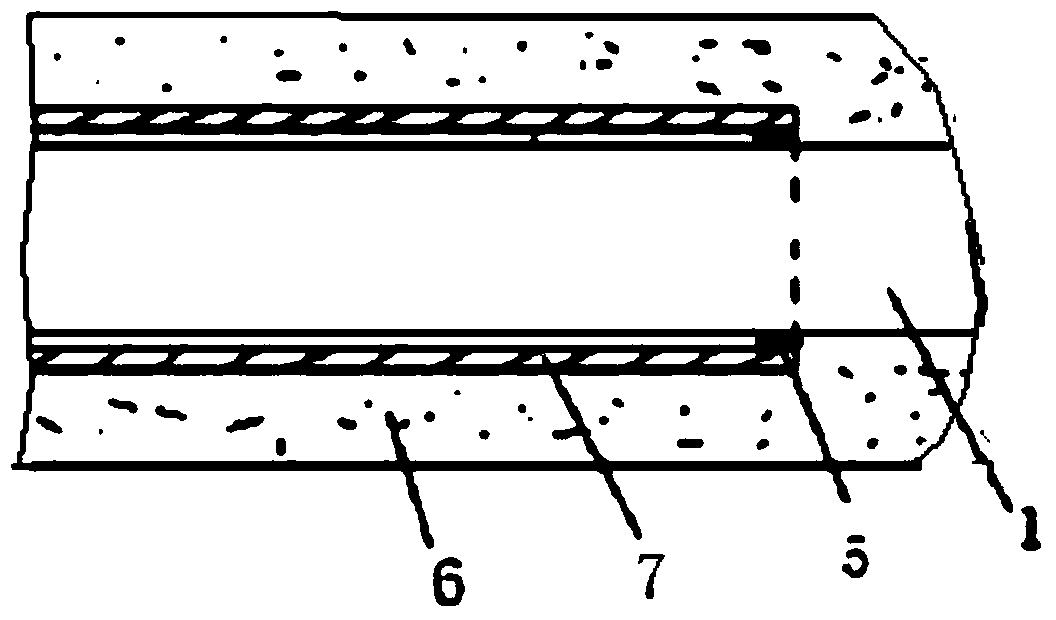

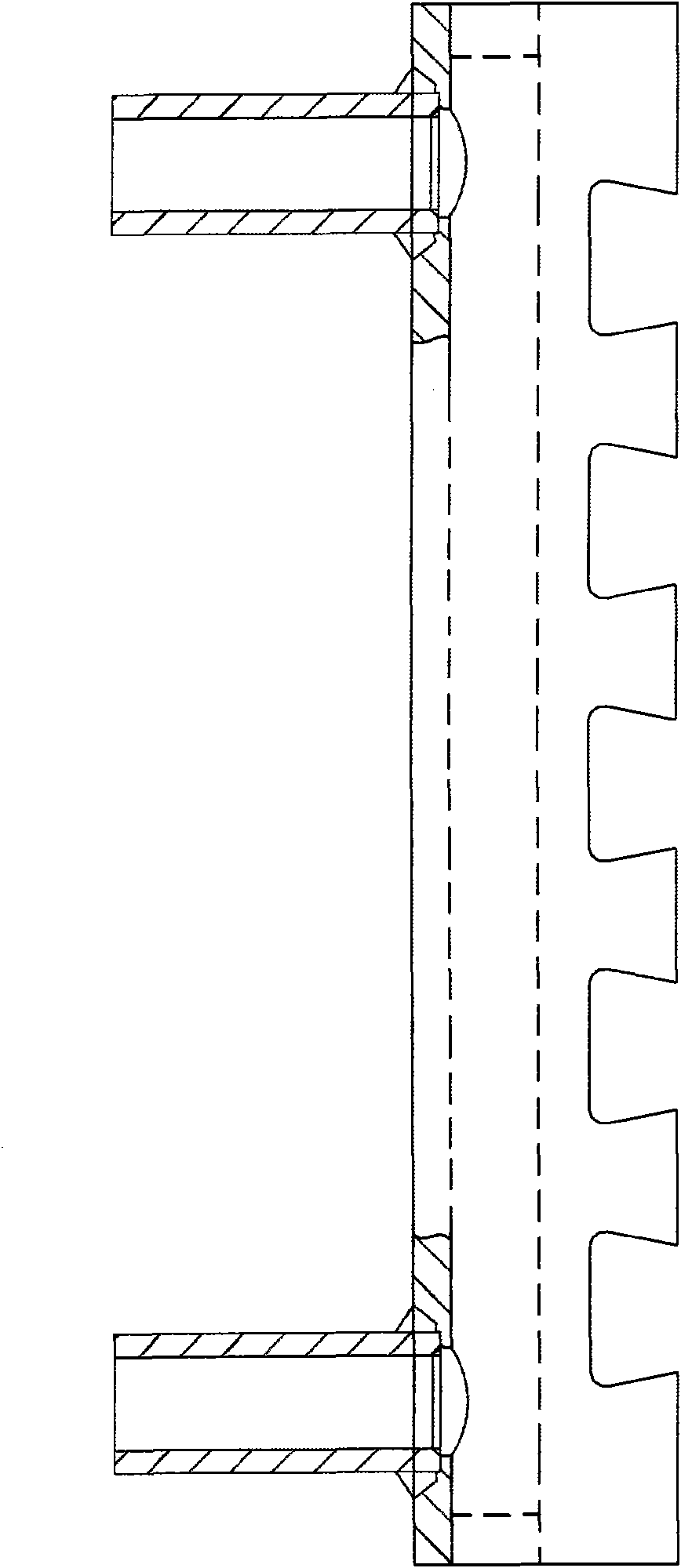

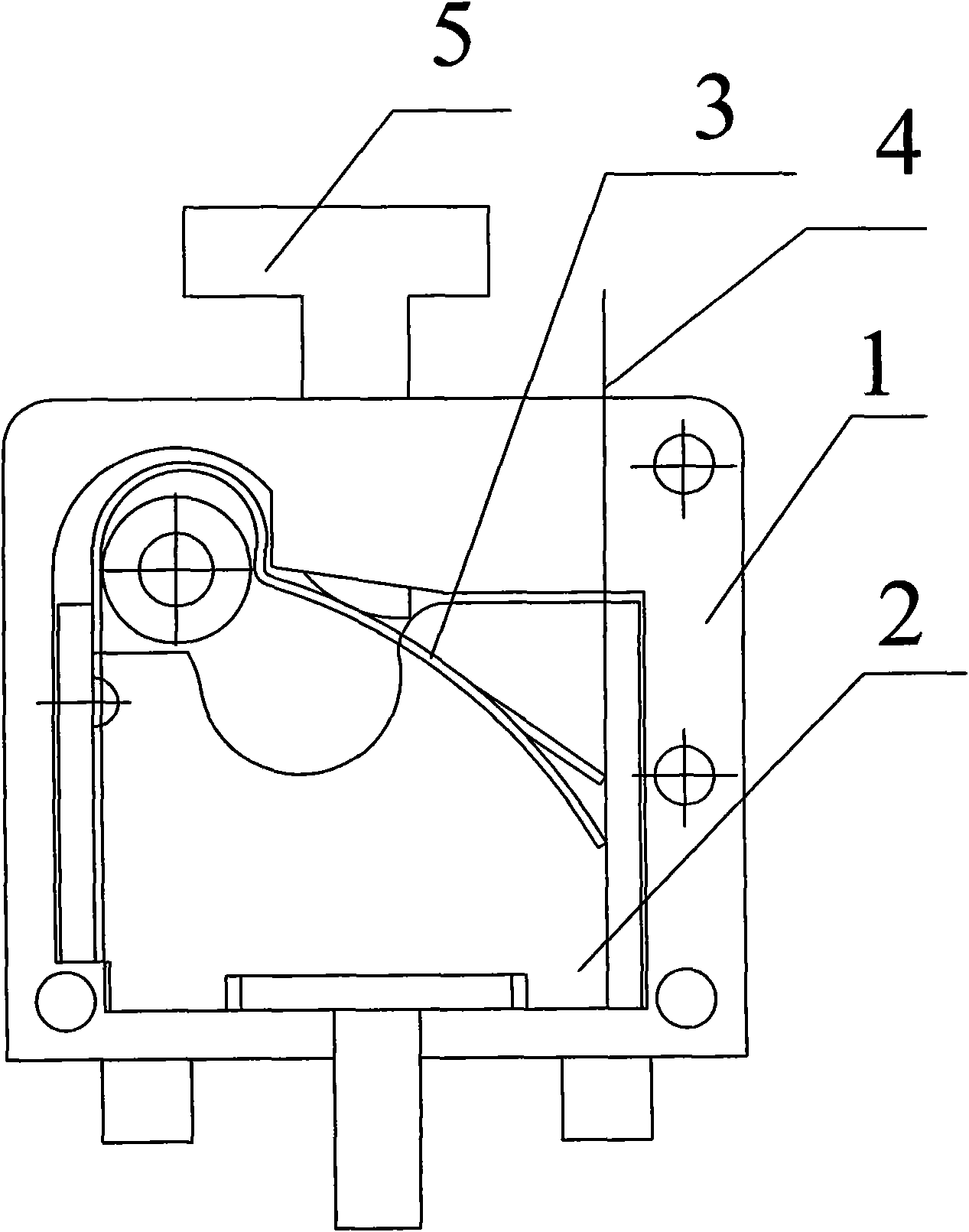

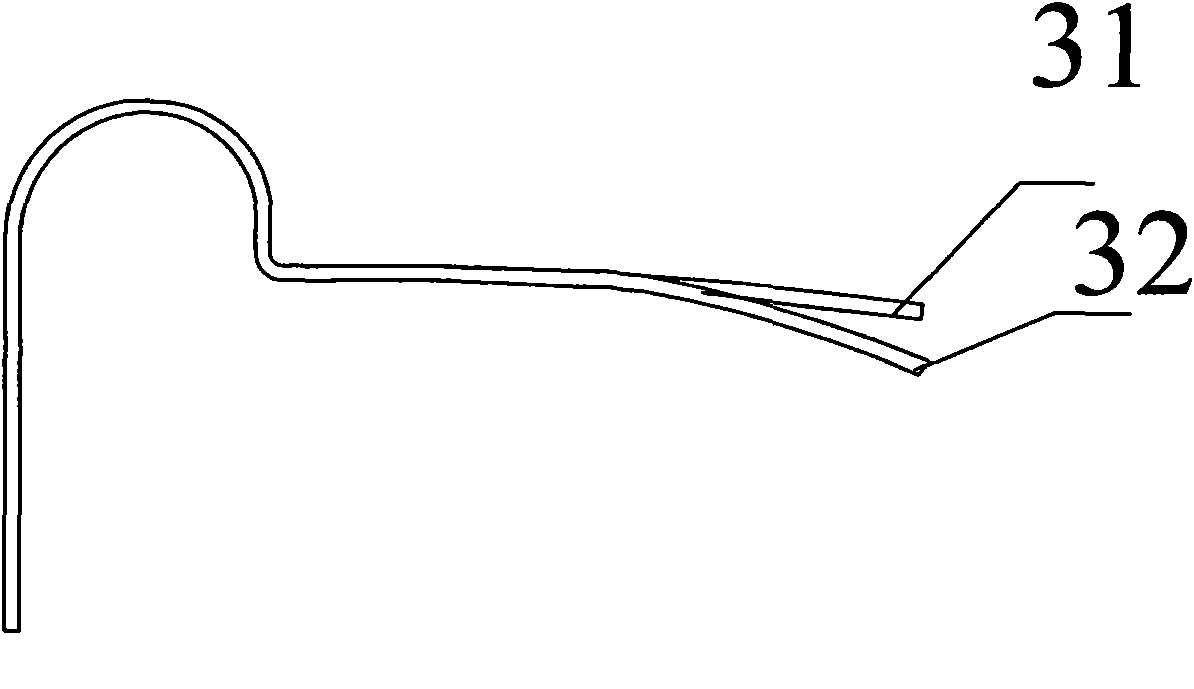

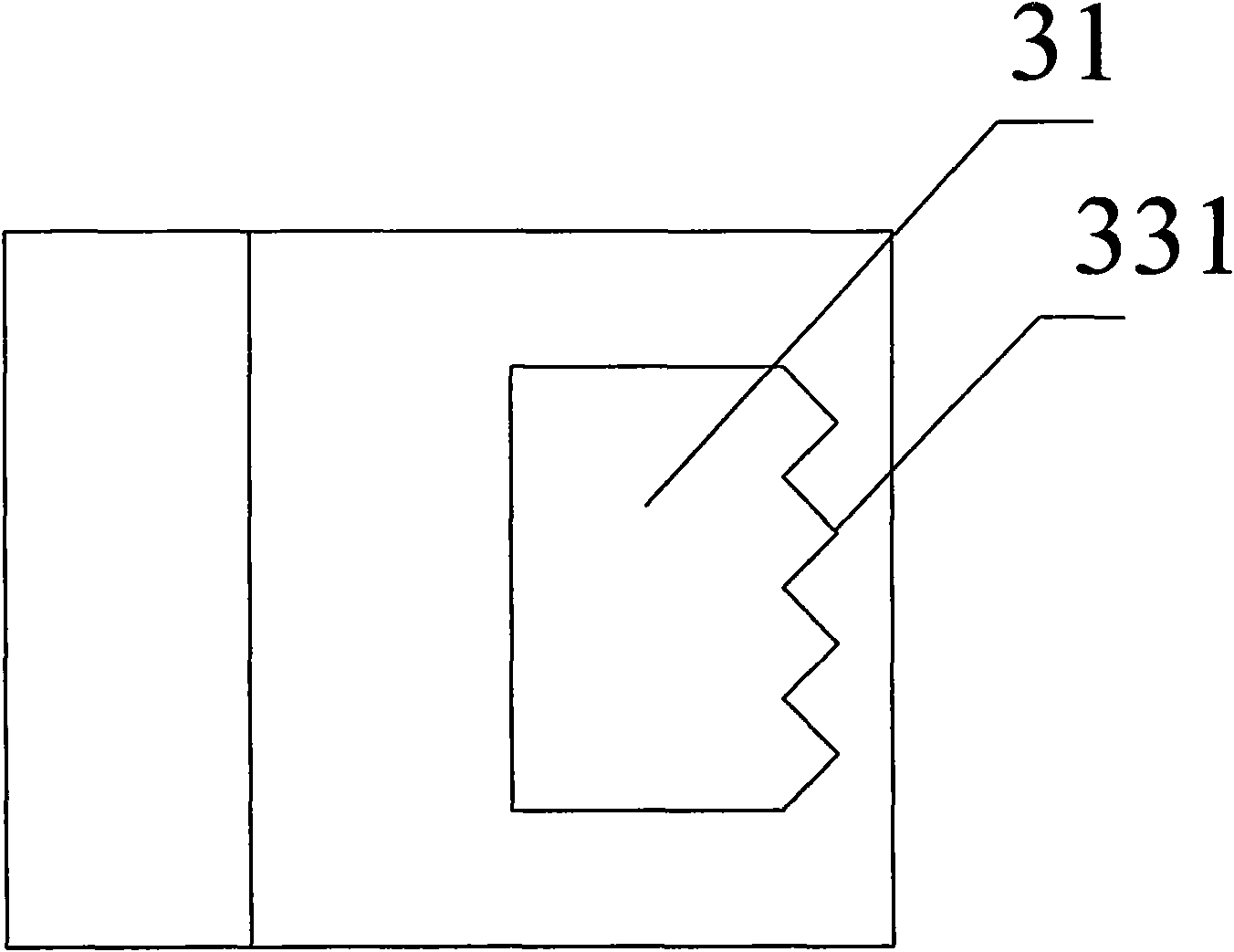

Plate-integrated gasket

ActiveCN103765058AReduce widthPrevent deviationEngine sealsFinal product manufactureEngineeringMechanical engineering

The purpose of the present invention is to provide a plate-integrated gasket configured so that a seal member (3), which is provided to plates (1, 2) laminated on each other, can be mounted within a reduced width and so that the gasket can be manufactured with increased productivity. In order to achieve the purpose, the plate-integrated gasket is configured so that one plate (1) and the other plate (2) are laminated on each other, the outer peripheral surface (1a) of the one plate (1) is fitted or loosely fitted in a stepped surface (21a) formed in the other plate (2), the seal member (3) consisting of an elastic material having rubber-like elasticity is integrally formed on the one plate (1) and the other plate (2) so as to straddle both the plates (1, 2), and the gasket has an affixed section (31) filled into a seal affixation groove (4) formed between the one plate (1) and the other plate (2).

Owner:NOK CORP

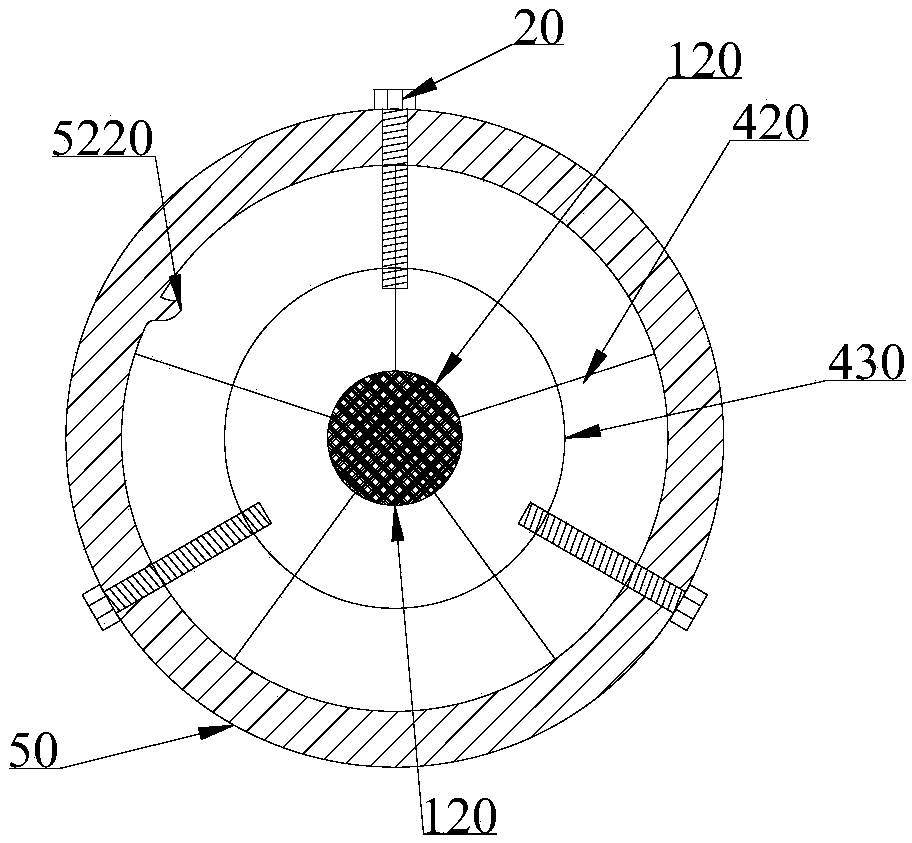

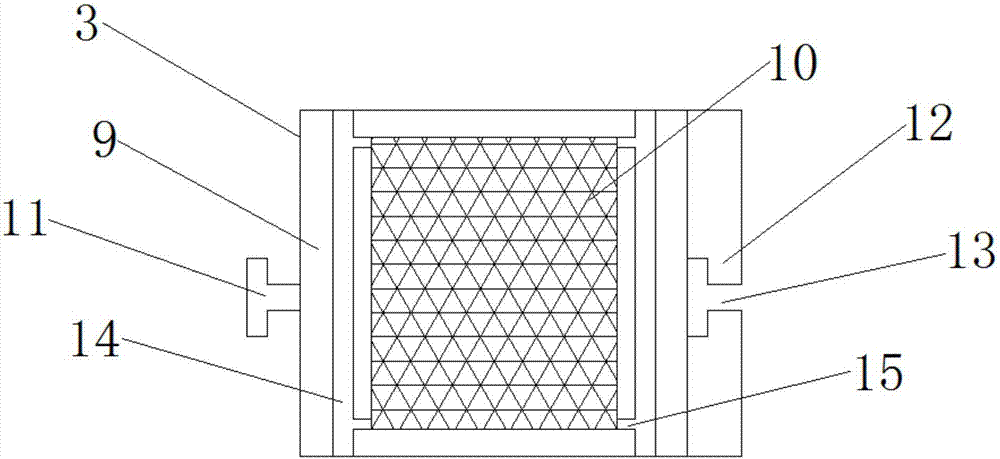

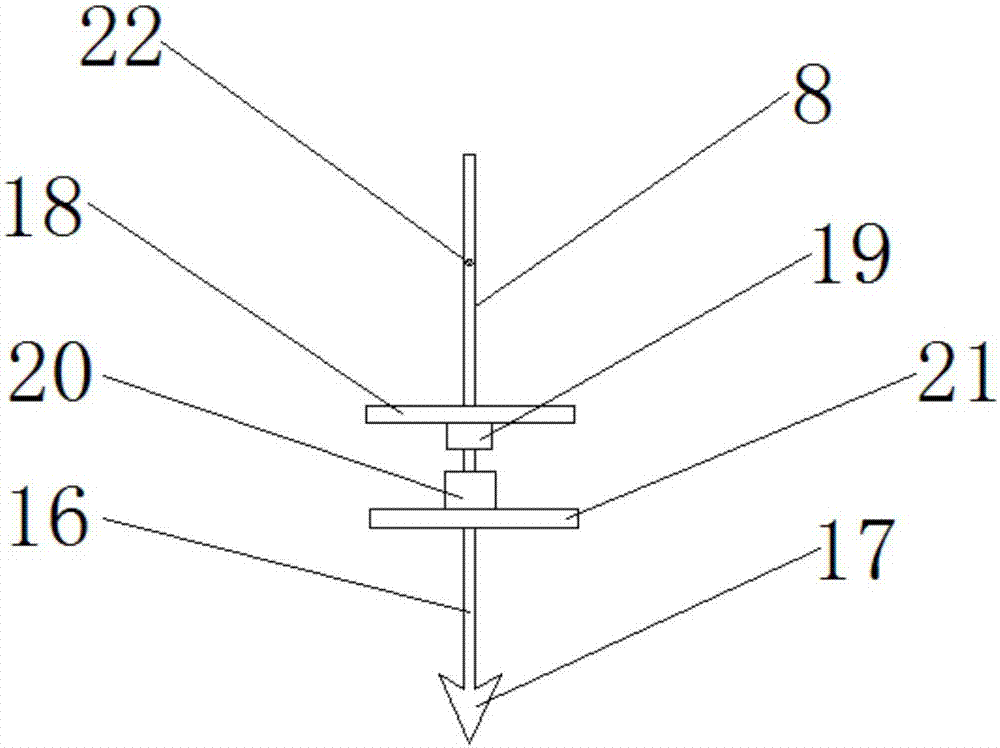

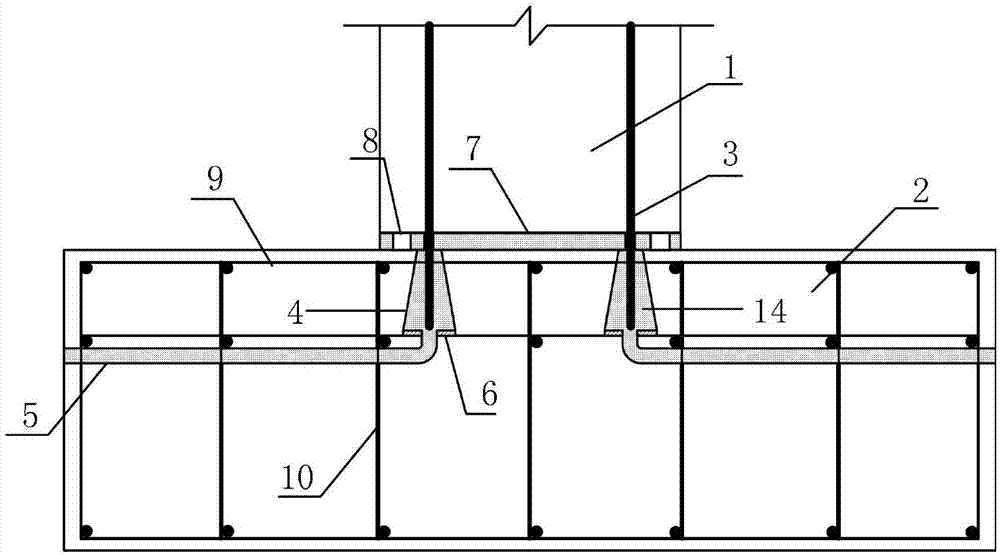

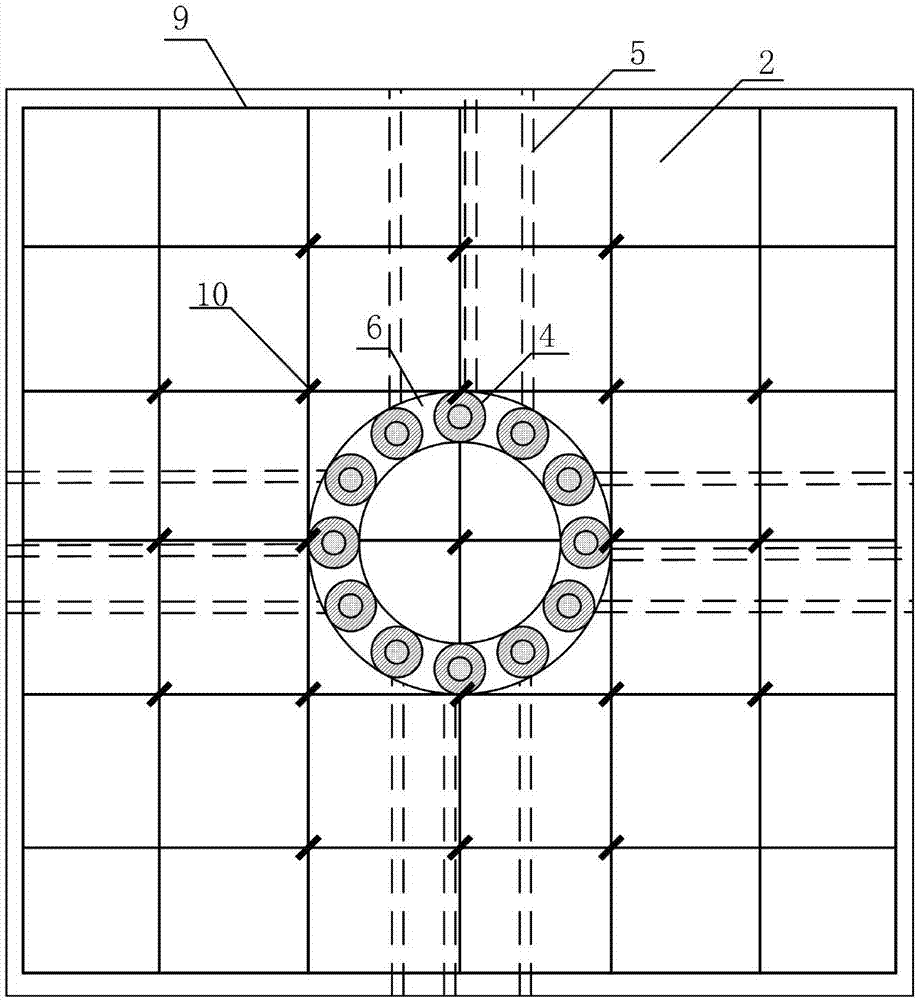

Assembly structure of assembly-type concrete member

The invention provides an assembly structure of an assembly-type concrete member. A sleeve comprises a non-grouting connection section and a grouting connection section. A steel skeleton comprises inner barbs and outer barbs, the diameter of a passage defined by the multiple inner barbs is smaller than that of a second to-be-connected steel bar, and the outline diameter defined by the outer barbsis larger than the diameter of an inner cavity of the grouting connection section. An alignment device comprises lower supports and upper supports which are both electromagnets, the same magnetic poles of the upper supports and the lower supports are opposite, and the upper supports and the lower supports are connected in the same circuit in series. All parts of the grouting sleeve are machined and manufactured correspondingly and then assembled, mass production is achieved, and the quality of all the parts is easy to control; connection of the grouting sleeve and a steel pipe transition section is operated by machines in a factory, the threaded connection quality is easy to control, the self-locking type steel skeleton is adopted, thus the purpose of pulling preventing is achieved, and shock resistance is improved; through the principle of magnetic levitation, fast and accurate centering of the steel bars of upper and lower concrete member bodies is achieved, so that the time and labor are saved; and through the series-connection circuit, the same magnetic forces of a plurality of supporting mechanisms can be achieved, and stable supporting is guaranteed.

Owner:HEFEI CONSTR ENG GRP

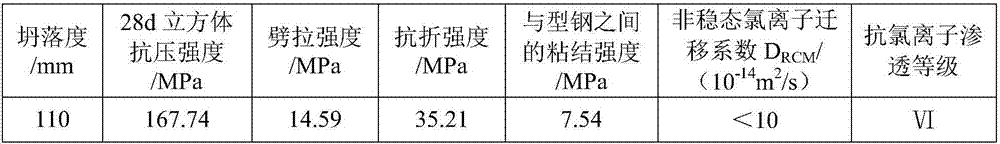

Ultrahigh strength high-performance fiber concrete at C160 strength grade and preparation method thereof

ActiveCN107382205APrevent pulling outImprove energy consumptionSolid waste managementModified carbonCarbon nanotube

The invention discloses an ultrahigh strength high-performance fiber concrete at C160 strength grade and a preparation method thereof. The concrete comprises the following components in parts by weight: 485 parts of cement, 82 parts of water, 1000 parts of macadam, 750 parts of fine aggregate, 70 parts of coal ash, 73 parts of rice hull ash, 102 parts of silica fume, 14.0 parts of water reducer, 9.5 parts of excitant, 1.6 parts of cellulosic fiber, 40 parts of hydroxy modified carbon nano tube dispersion liquid, 37 parts of graphene oxide dispersion liquid and 2.6 parts of de-foaming agent. The prepared concrete has higher toughness, durability, higher bonding strength with profile steel, compressive strength reaching up to 167.74MPa, breaking strength reaching up to 35.21MPa, splitting strength reaching up to 14.59MPa, bonding strength with profile steel reaching up to 7.54MPa and chloride penetration resistance grade at VI-grade. When the ultrahigh strength high-performance fiber concrete is applied to a profile steel concrete combined structure, the cooperative working property between the profile steel and the concrete is effectively exerted and the defects of poor bonding property of the profile steel and the concrete and incapability of fully utilizing the respective mechanical properties of the profile steel and the concrete can be overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

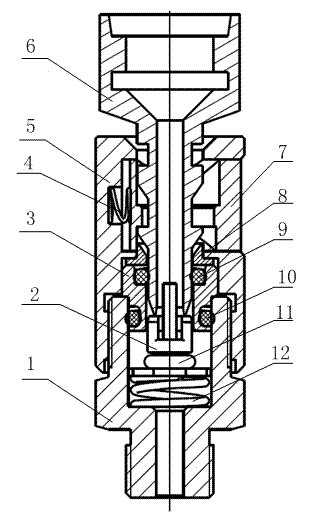

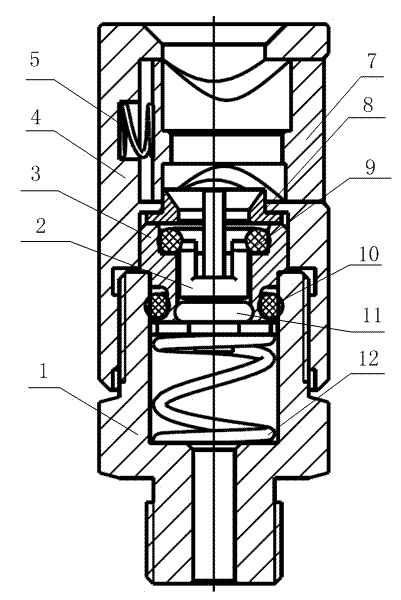

Quick connector

The invention discloses a quick connector. The quick connector comprises a fixed joint and a movable joint which is matched with the fixed joint in an insertion connection manner; a shutoff valve device is arranged in an insertion connection passage; the sidewall of the movable joint is provided with a step; the sidewall of the fixed joint is provided with a mounting hole which extends along the radial direction, and the tail end of the mounting hole sinks into the internal wall of the insertion connection passage; a button which slides along the extending direction of the mounting hole in a limiting manner is assembled in the mounting hole; a first elastic member which applies an acting force opposite to the bottom face of the mounting hole to the button is arranged between the button and the fixed joint; and the button is provided with a button passage which is used for passing through the insertion end of the movable joint, and a stopping block which is matched with the step of the movable joint in a stopping manner is arranged on the internal wall of the button passage. Due to the structure, the quick connector has the advantages that the quick connector can be automatically locked by directly inserting the movable joint into the fixed joint during locking and can be automatically unlocked by only pressing down the button during unlocking, the phenomenon of skidding can not occur, the operation is convenient, the locking and unlocking of the quick connector can be easily realized, and meanwhile, the sealing effect of the whole quick connector can also be guaranteed.

Owner:CAMA LUOYANG GAS SUPPLY

Push-button type test strip withdrawable glucometer

InactiveCN103698528APrevent pulling outReduce volumeBiological testingEngineeringPrinted circuit board

The invention discloses a push-button type test strip withdrawable glucometer, comprising a housing, an integrated circuit board on which a plurality of electrical elements are mounted, and a test strip withdrawing mechanism, wherein the integrated circuit board is mounted in the housing; the test strip withdrawing mechanism is partially mounted outside the housing so as to be operated conveniently, and partially mounted inside the housing so as to ensure that the test strip can be withdrawn conveniently after being used. The push-button type test strip withdrawable glucometer is small in size, simple in structure and convenient to operate; an operator does not need to touch the test strip while withdrawing the used test strip from the glucometer, and therefore, touch infection is effectively avoided.

Owner:NANJING YUYUE SOFTWARE TECH +3

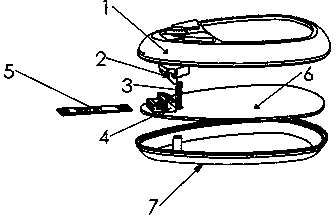

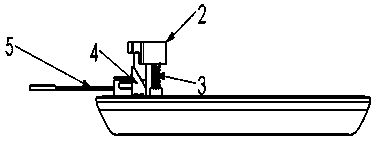

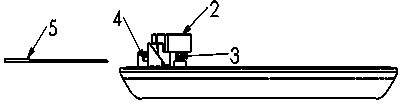

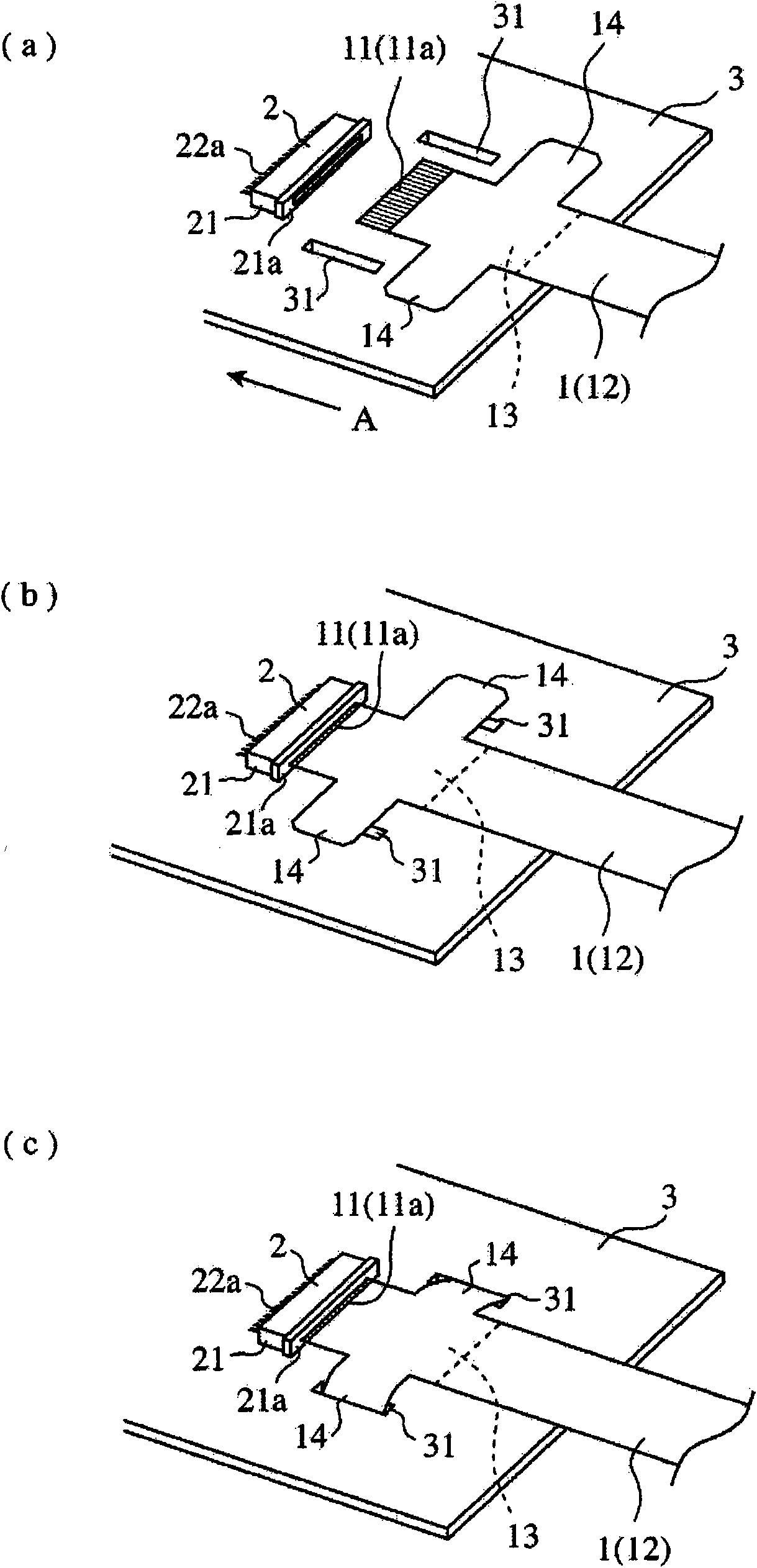

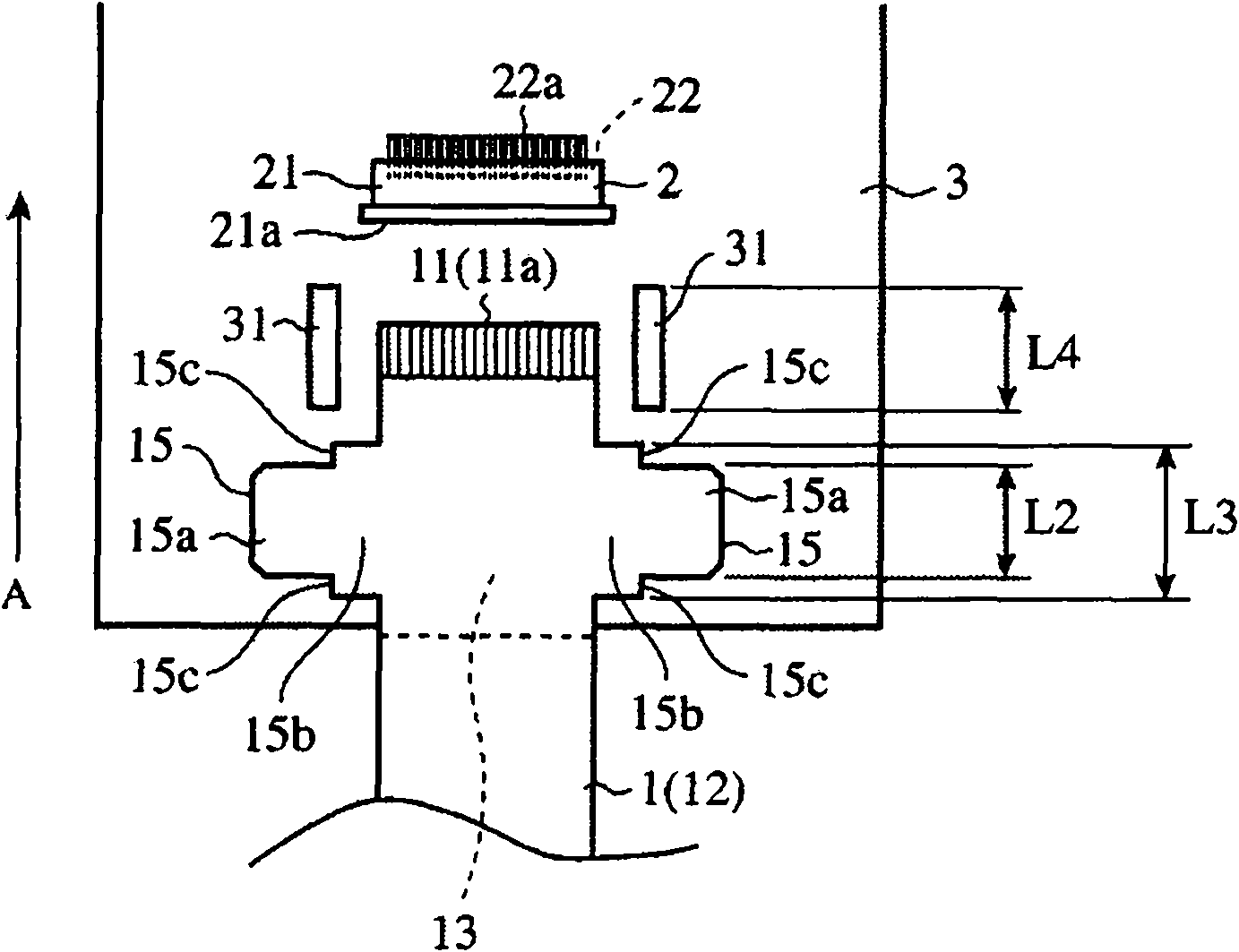

Structure for fixing flexible wiring board

InactiveCN101803475APrecise positioningPrevent insertionCircuit bendability/stretchabilityPrinted circuit aspectsElectrical conductorMechanical engineering

Owner:MITSUBISHI ELECTRIC CORP

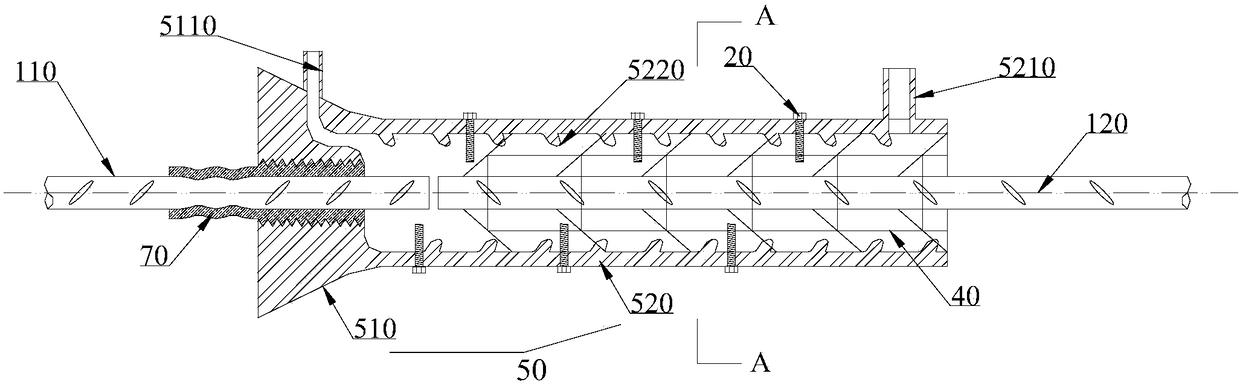

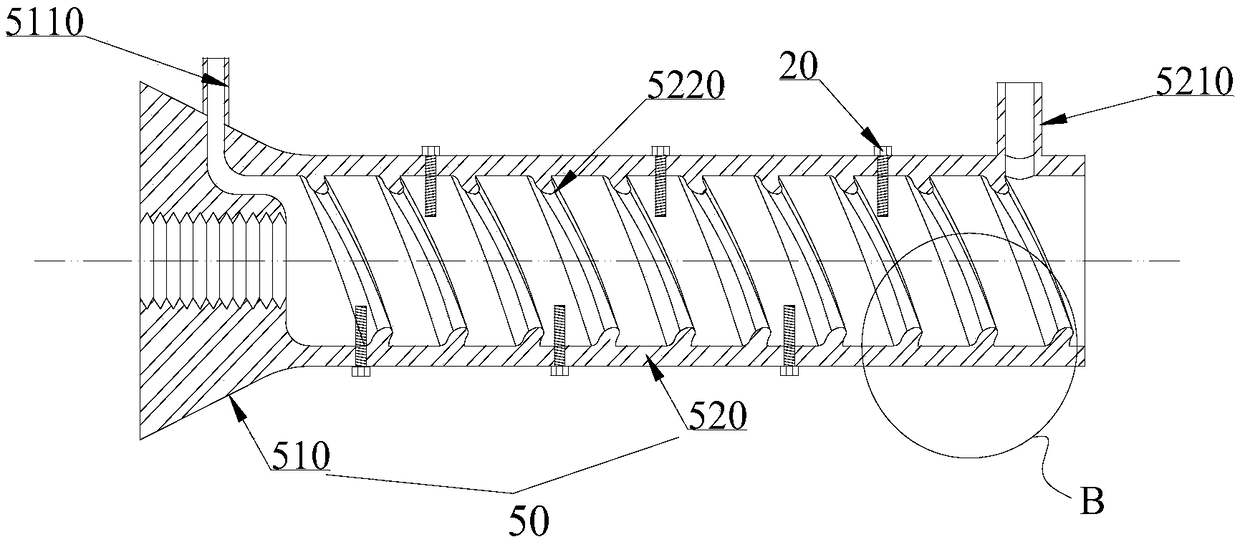

Anti-vibration assembly self-locking type semi-grouting sleeve

The invention provides an anti-vibration assembly self-locking type semi-grouting sleeve. The sleeve comprises a non-grouting connecting section and a grouting connecting section, wherein one tube body section of a steel tube transition section is fixedly arranged in the non-grouting connecting section; another tube body section extends to the outside of the non-grouting connecting section to forma rolling-pressing section which is in rolling-pressing connection with a first to-be-connected reinforcing steel bar; a steel framework comprises inner barbs and outer barbs; the inner barbs are enclosed to form a channel for allowing a second to-be-connected reinforcing steel bar to pass through, and the diameter of the channel is smaller than that of the second to-be-connected reinforcing steel bar; and the outline diameter enclosed by the outer bards is greater than the inner cavity diameter of the grouting connecting section. Each part of the grouting sleeve is separately processed and manufactured, re-assembled, and produced in batch, and easily controlled in quality; connection between the grouting sleeve and the steel tube transition section is operated in a plant through machinery, and threaded connecting quality is easily controlled; the first to-be-connected reinforcing steel bar and the steel tube transition section are directly connected in a rolling-pressing mode, so that processes are simple, and length, inserted into the sleeve, of reinforcing steel bars is easily controlled; and a self-locking type steel framework is adopted, so that the anti-pulling purpose is realized, and antiknock characteristic is improved.

Owner:HEFEI CONSTR ENG GRP

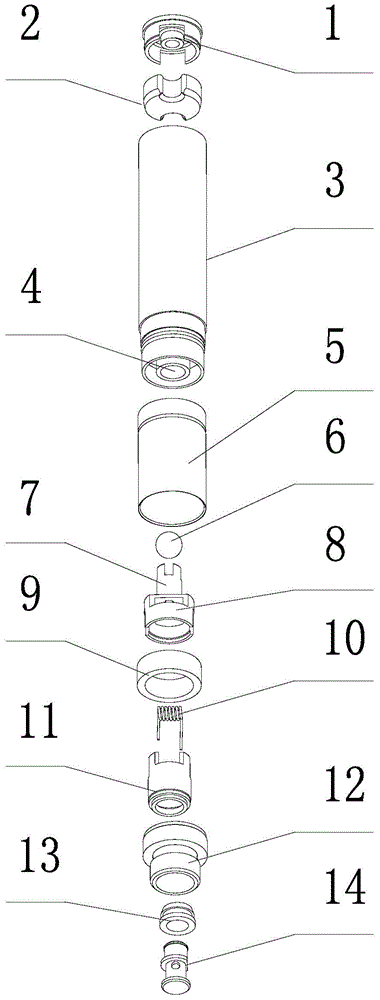

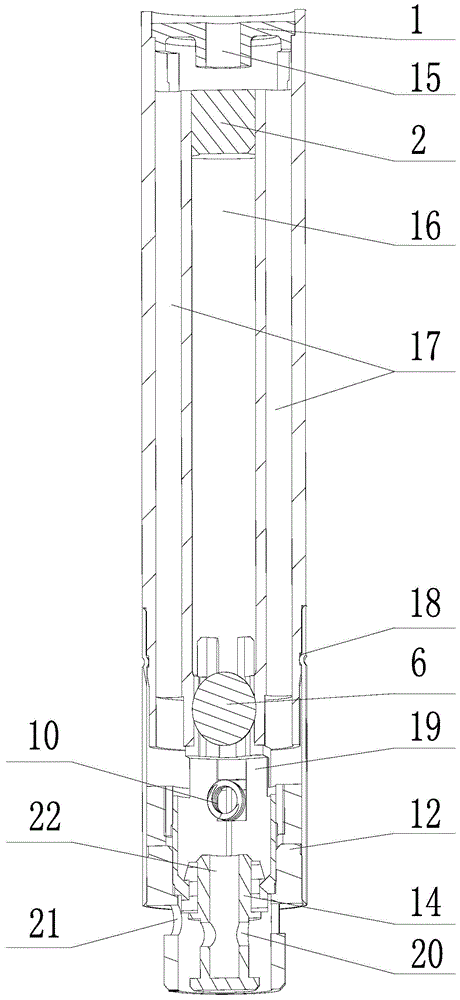

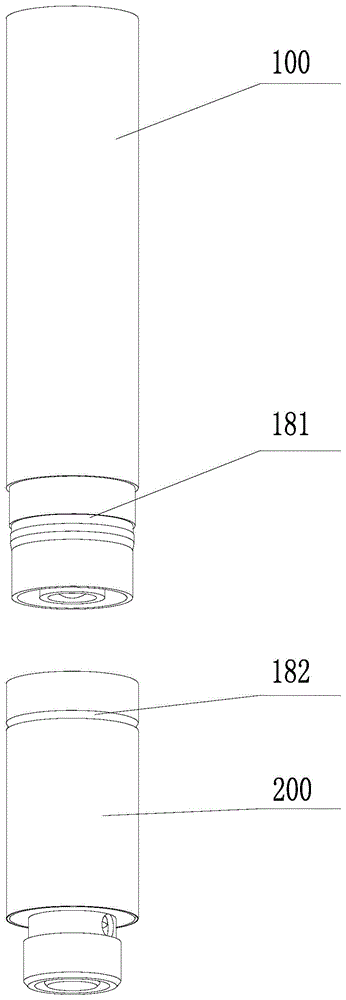

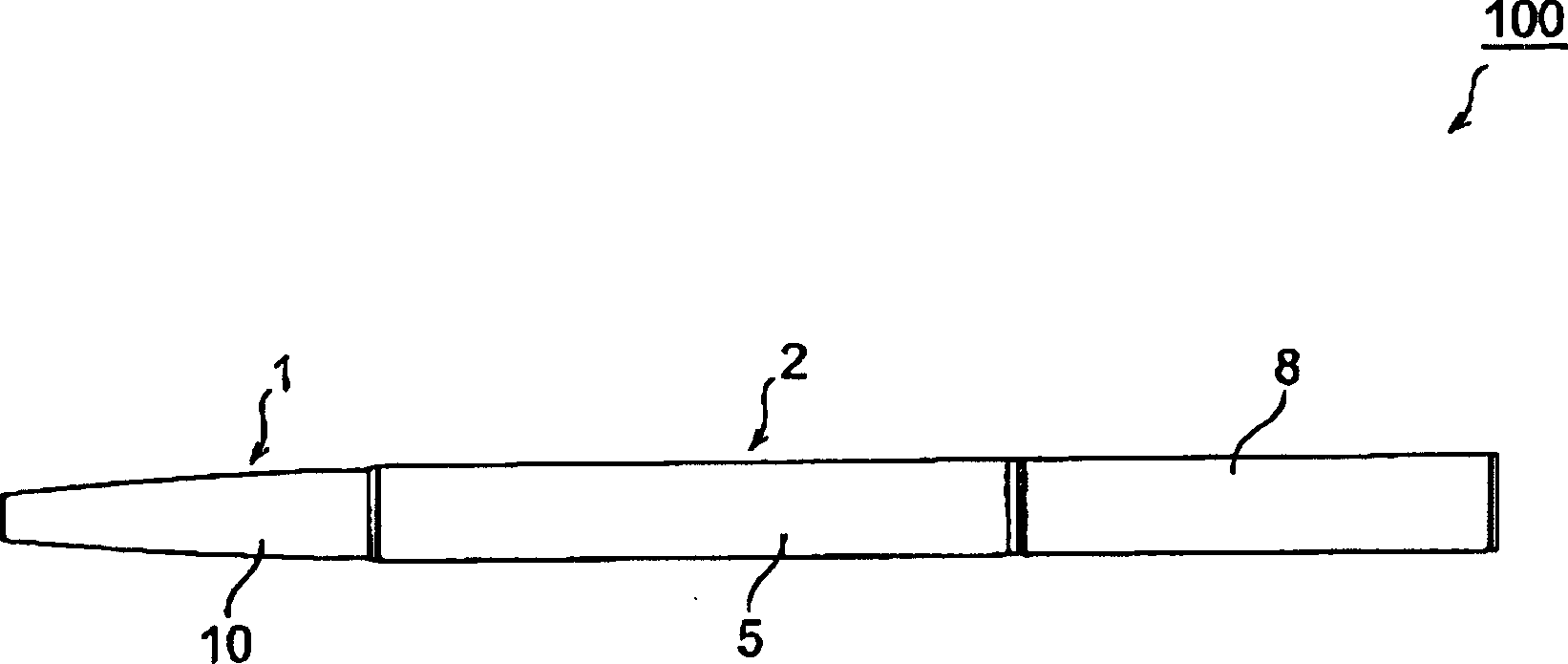

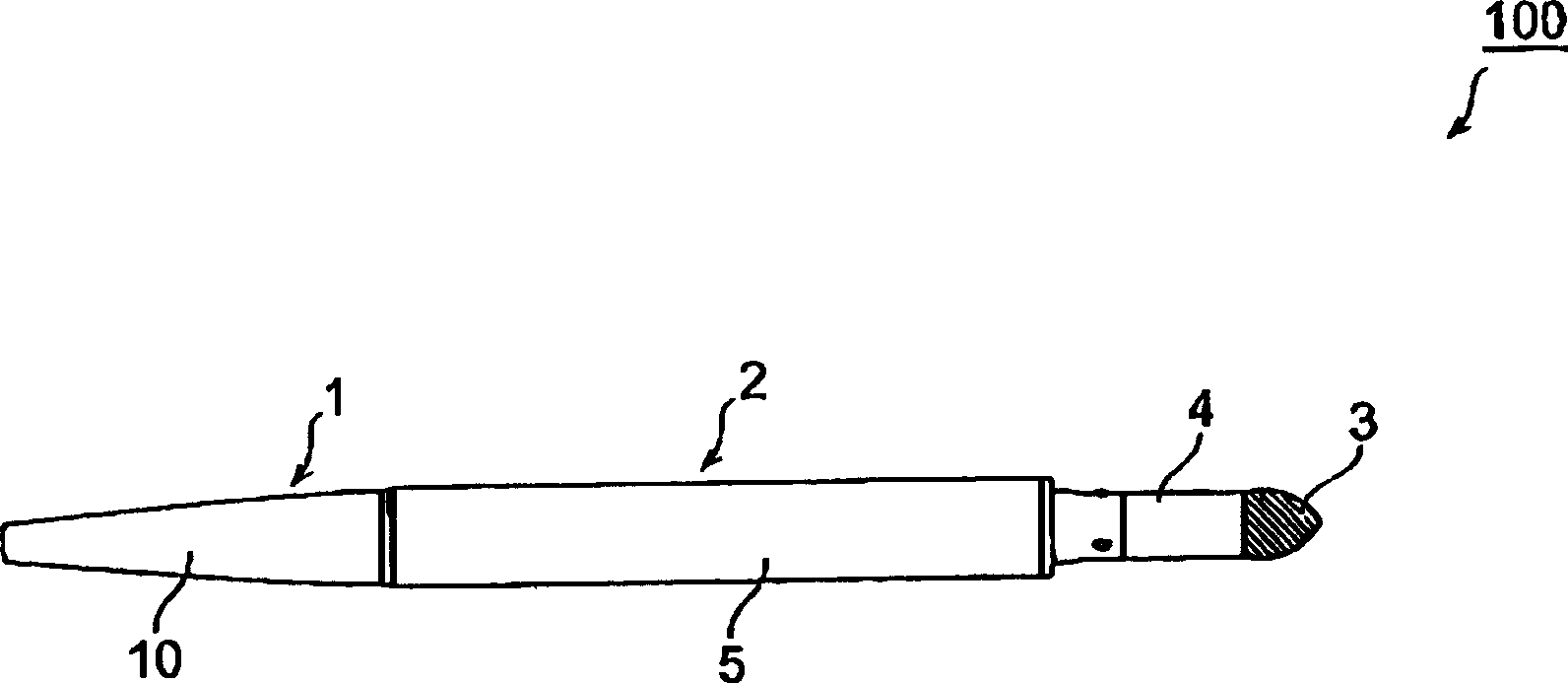

Locked leakage-proof electronic cigarette device

The invention discloses a locked leakage-proof electronic cigarette device. The locked leakage-proof electronic cigarette device includes a smoke cartridge unit and an atomization unit. The smoke cartridge unit includes a cylindrical smoke cartridge body with an axial extension partition plate; the axial extension partition plate divides the smoke cartridge unit into an axially extended tobacco tar holding chamber and a smoke channel; a tobacco bar lead-out hole is formed in the lower end of the tobacco tar holding chamber of the smoke cartridge body; and a tobacco tar stopper is arranged in the tobacco bar lead-out hole. The atomization unit includes an atomization core part, an atomization chamber, and a tobacco bar lead-in pipe; the tobacco bar lead-in pipe and the tobacco bar lead-out hole of the smoke cartridge body are in an inserting-pulling assembly; the tobacco bar lead-in pipe can push out the stopper in the tobacco bar lead-out hole; the atomization chamber is provided with a housing; the atomization chamber and an atomized smoke channel are arranged in the housing; and the housing of the atomization chamber is snapped onto and connected to the outer wall of the smoke cartridge unit. The electronic cigarette device can be used after being assembled, and has a locking and leakage-proof function.

Owner:INNOKIN TECH

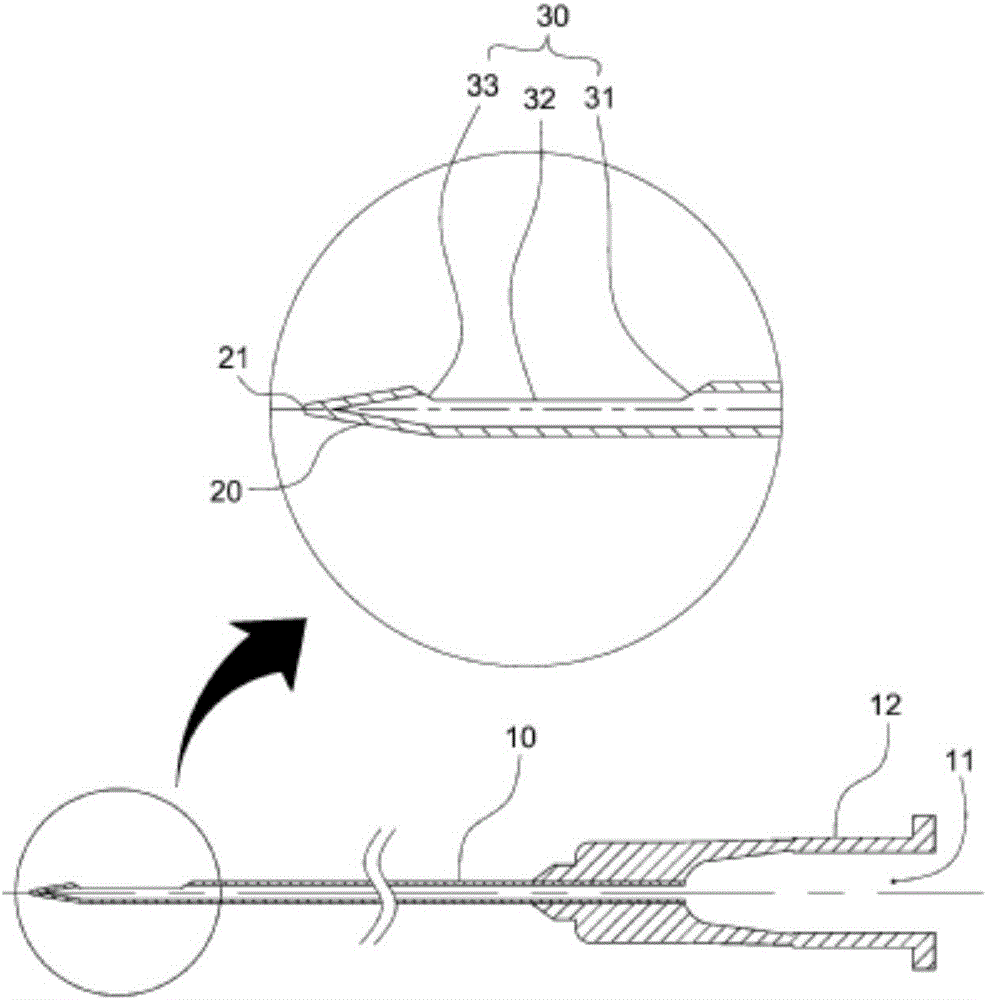

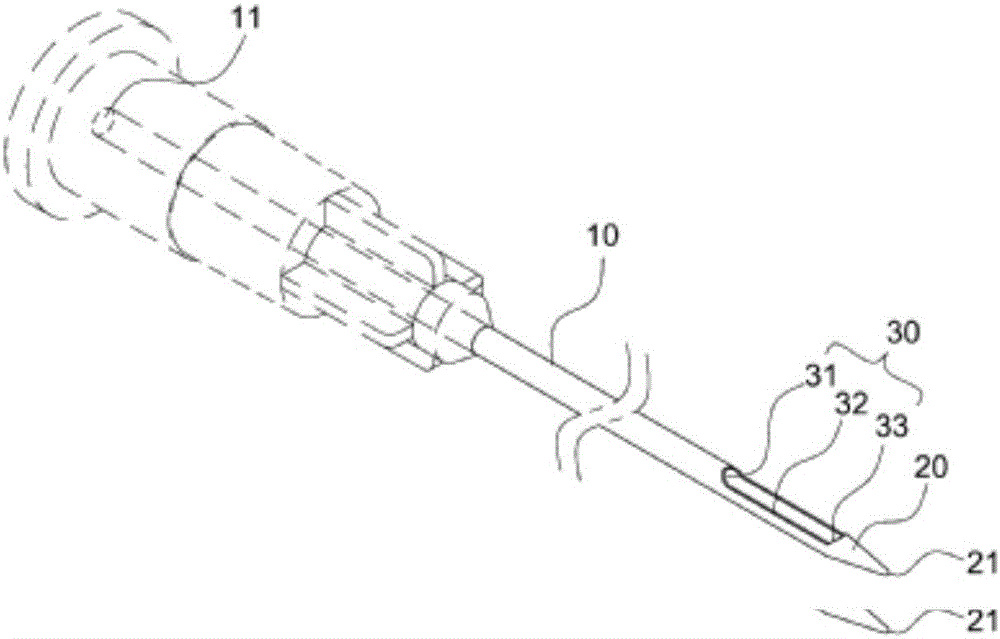

Thread implantation rod for preventing damage to subcutaneous tissue and blood vessels

ActiveCN106232158AAvoid damagePull out will notSuture equipmentsDiagnosticsSubcutaneous tissueBlood vessel

The present invention relates to a thread implantation rod and relates to a needle for thread-embedding therapy having a tubular shape for allowing a suture to be inserted and moved therein, wherein the end is rounded and blocked and also has a sharp shape so as to prevent the skin, muscle and blood vessels from being torn during an operation, thereby preventing damage to subcutaneous tissue.

Owner:金庚均

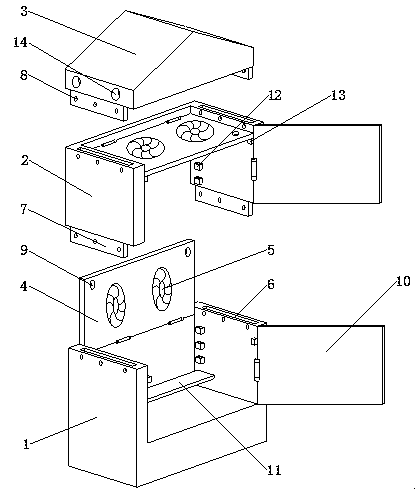

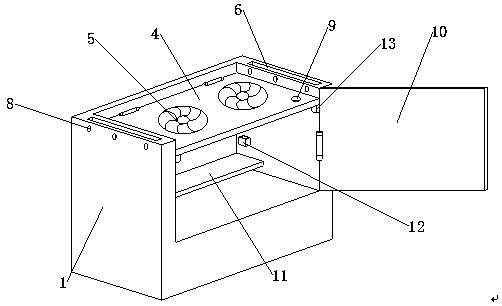

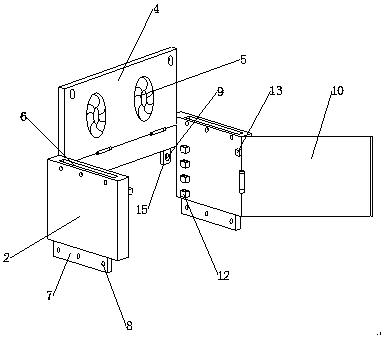

Spliced distribution cabinet with dumping resistance in vibration

ActiveCN109616902AImprove practicalityEasy to disassemble and repairSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringWater tanks

The invention provides a spliced distribution cabinet with dumping resistance in vibration, including a base cabinet, an expansion cabinet, a dust cover, a foundation, reinforced columns, plug-in holes, a water tank, and a water cavity. Receiving grooves are arranged on both sides of the upper ends of the base cabinet and the expansion cabinet, a receiving block is clamped inside the receiving groove. A movable plate is rotatably connected with the inner upper ends of the base cabinet and the expansion cabinet. At the bottom of the base cabinet, the water cavity is arranged, the water tank isfixedly arranged inside the water cavity, the bottom surface of the water tank is fixedly connected with a hollow column, the bottom of the hollow column is fixedly connected with a water absorbing block, the upper part of the water absorbing block is fixedly connected with a sliding block, the left and right sides of the sliding block are fixedly connected with metal hoses, the other end of the metal hose is fixedly connected with a cylindrical wedge, and the other end of the cylindrical wedge is inserted with a reinforcing column. Through the matching arrangement of the reinforcing column and the insertion hole, the reinforcing column can be automatically inserted with the insertion hole on the foundation when the power distribution cabinet meets strong vibration, and the power distribution cabinet can be rapidly reinforced on the foundation to avoid dumping.

Owner:浙江江山博奥电气有限公司

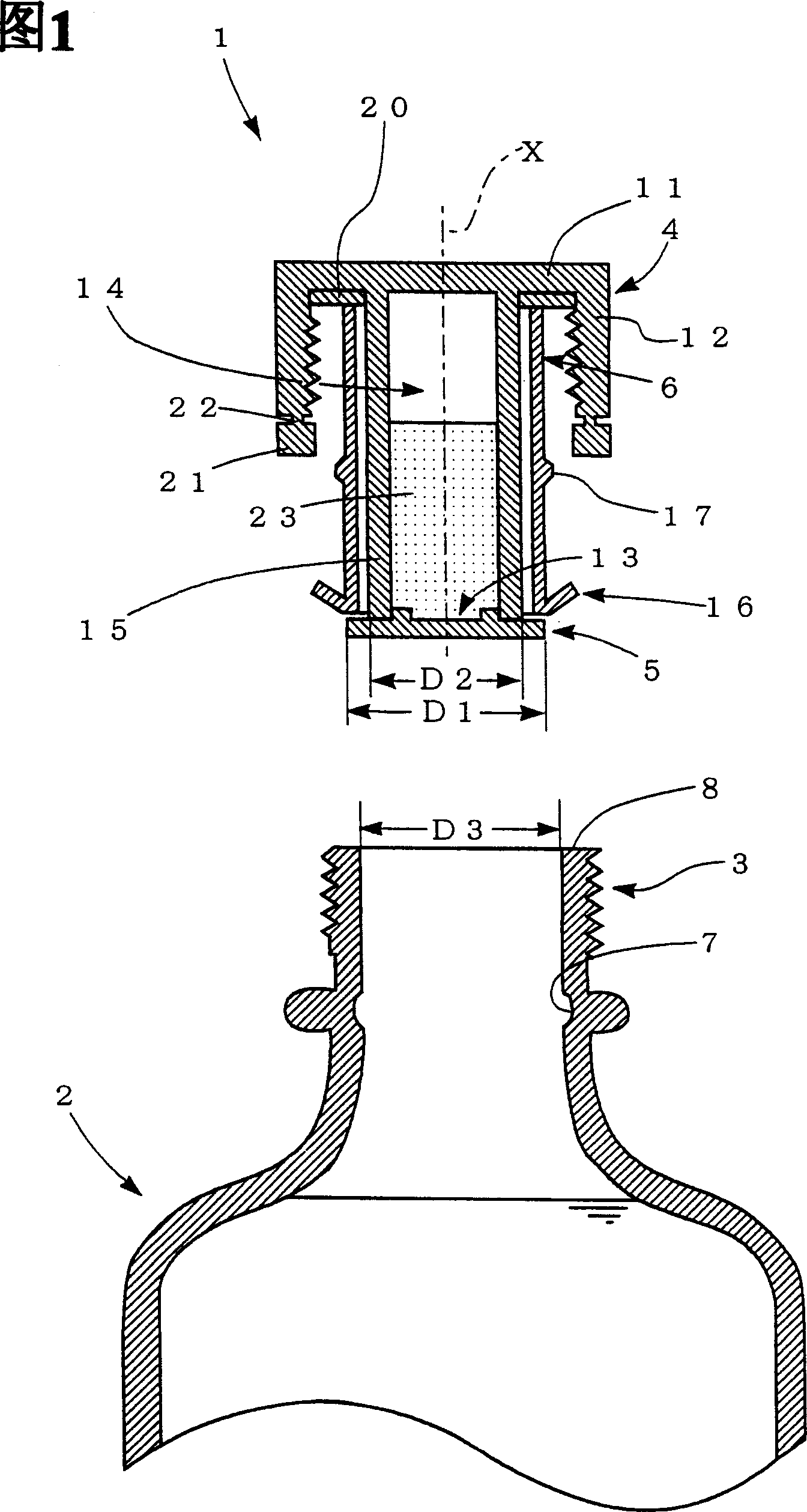

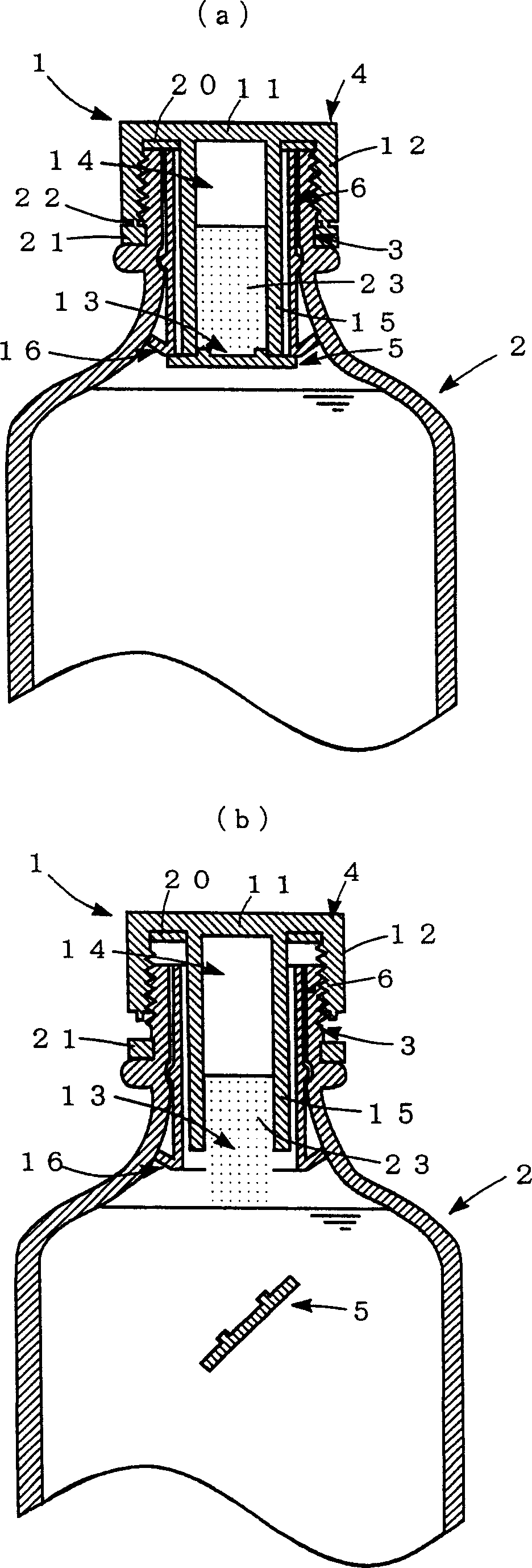

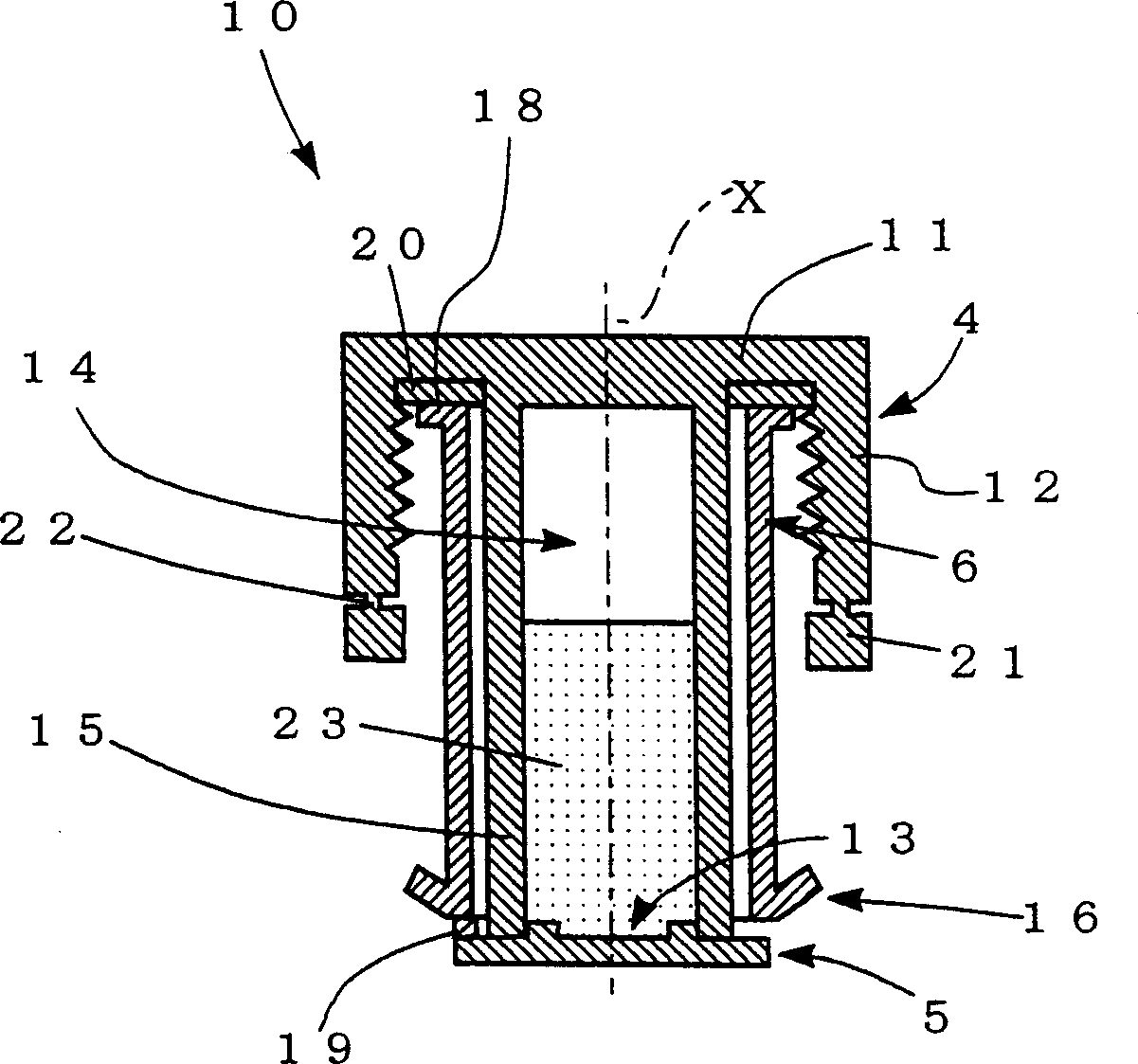

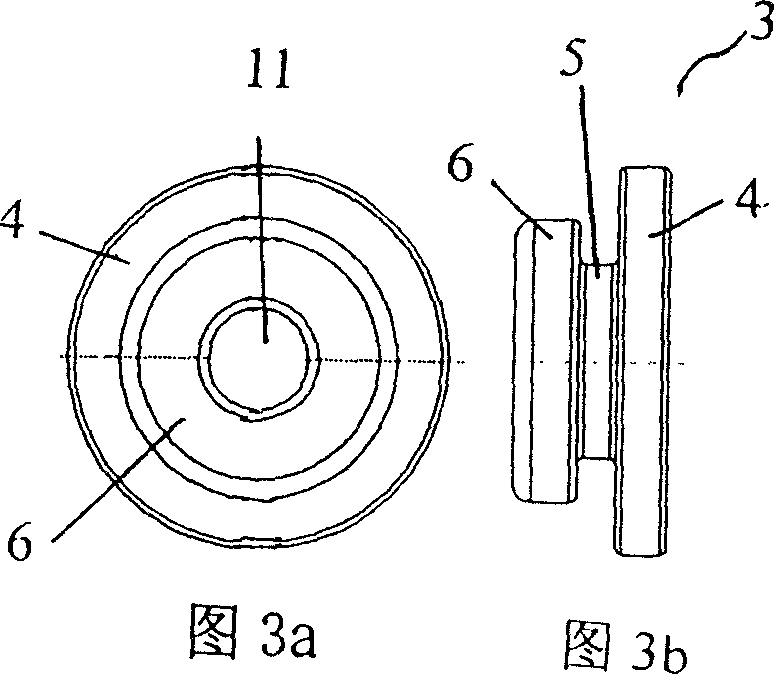

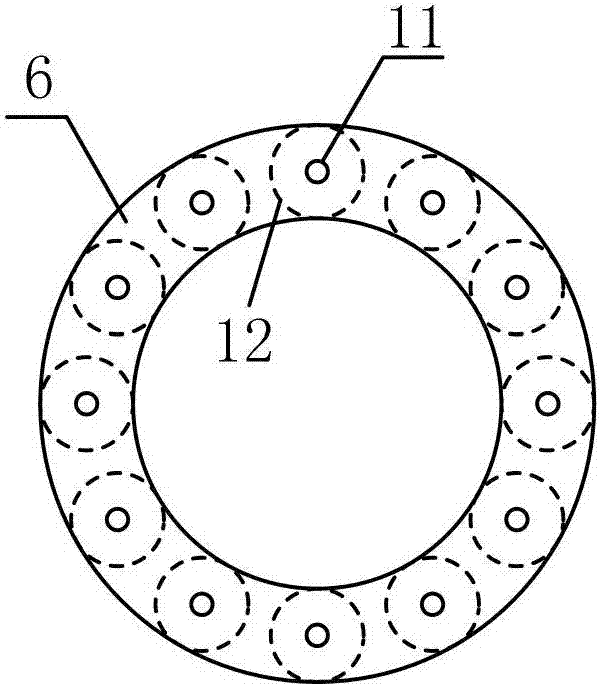

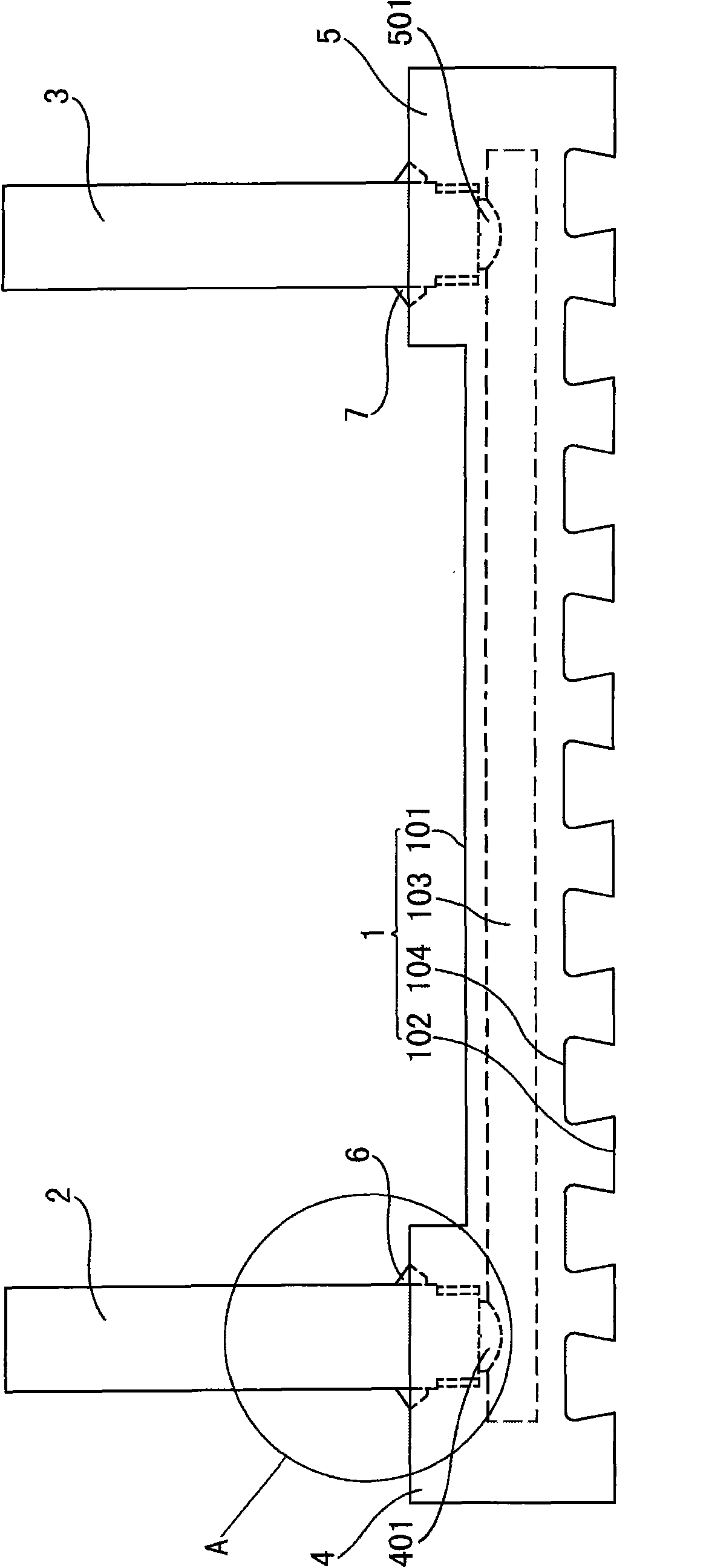

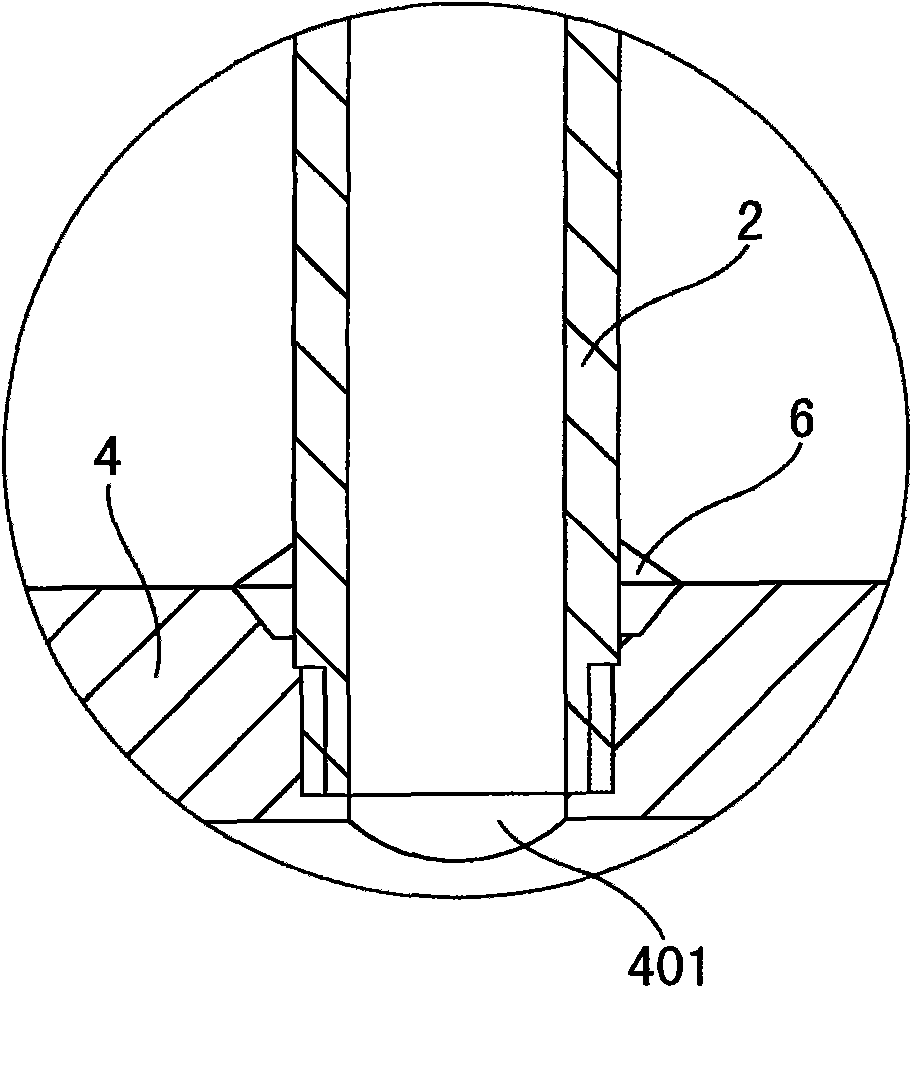

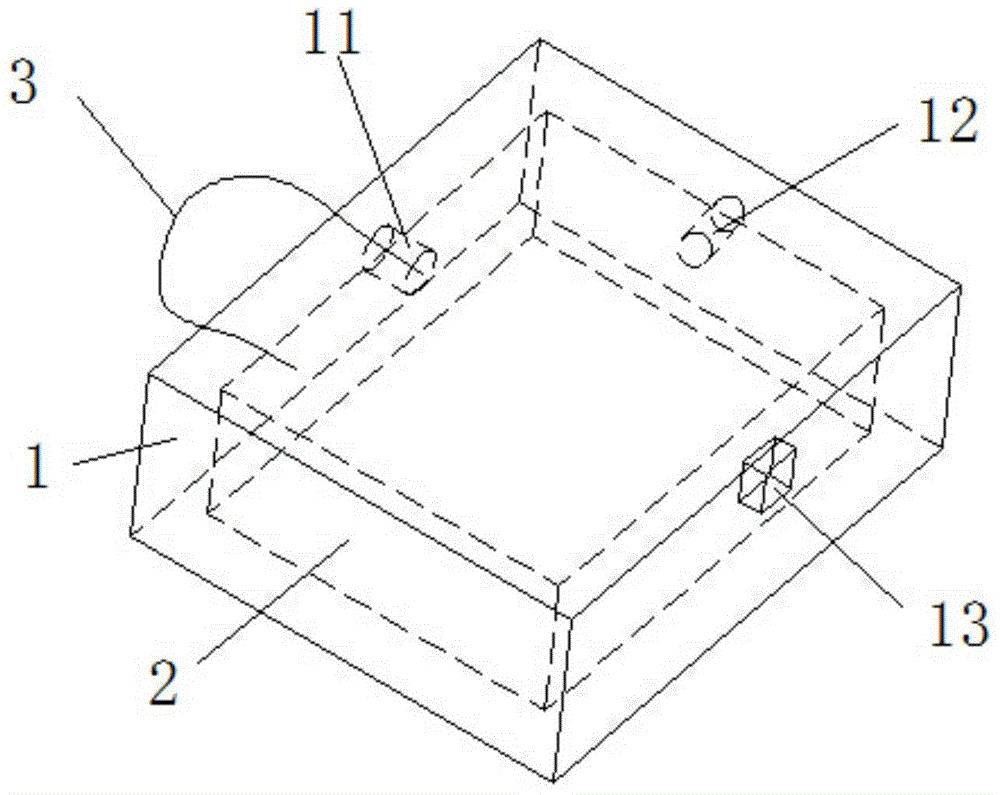

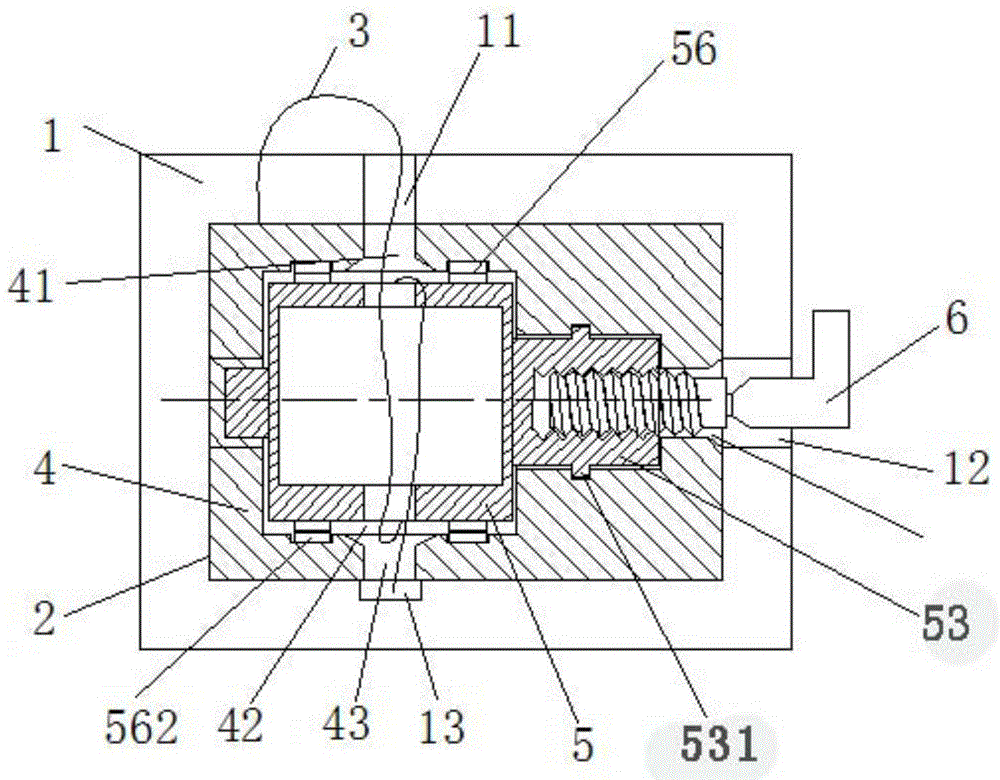

Container sealing structure and sealed lid for said structure

InactiveCN1477033APrevent pulling outEasy to insertCapsClosure capsEngineeringMechanical engineering

A cap (1) has a plug portion (4), a seal plug (5) and a sleeve (6). The plug portion (4) has a top board (11) to cover an opening portion (3) of a vessel (2), a side wall (12) projecting from the top board along its axis (X) which wall has an inner circumferential surface fits on an outer circumferential surface of the opening portion (3), and a cylindrical wall (15) forming a receiving chamber (14) having an opening mouth (13) at its under end face which wall projects from the top board at inner side of the side wall (12). The seal plug (5) has outer diameter (D1) which is larger than outer diameter (D2) of the cylindrical wall (15) and an seals the opening mouth (13). The sleeve (6) is loosely fitted on the cylindrical wall (15) and opens the opening mouth (13) by separating the seal plug (5) from the cylindrical wall (15) at relative movement of the cap (1) to the vessel toward direction where they separate from each other. A sepal portion (16) on the outer circumference of the sleeve (6) has outer diameter larger than inner diameter (D3) of the opening portion (3) and has flexibility to passe the inner diameter (D3) bending so as to avoid backward moving.

Owner:NIPPON TANSAN GAS

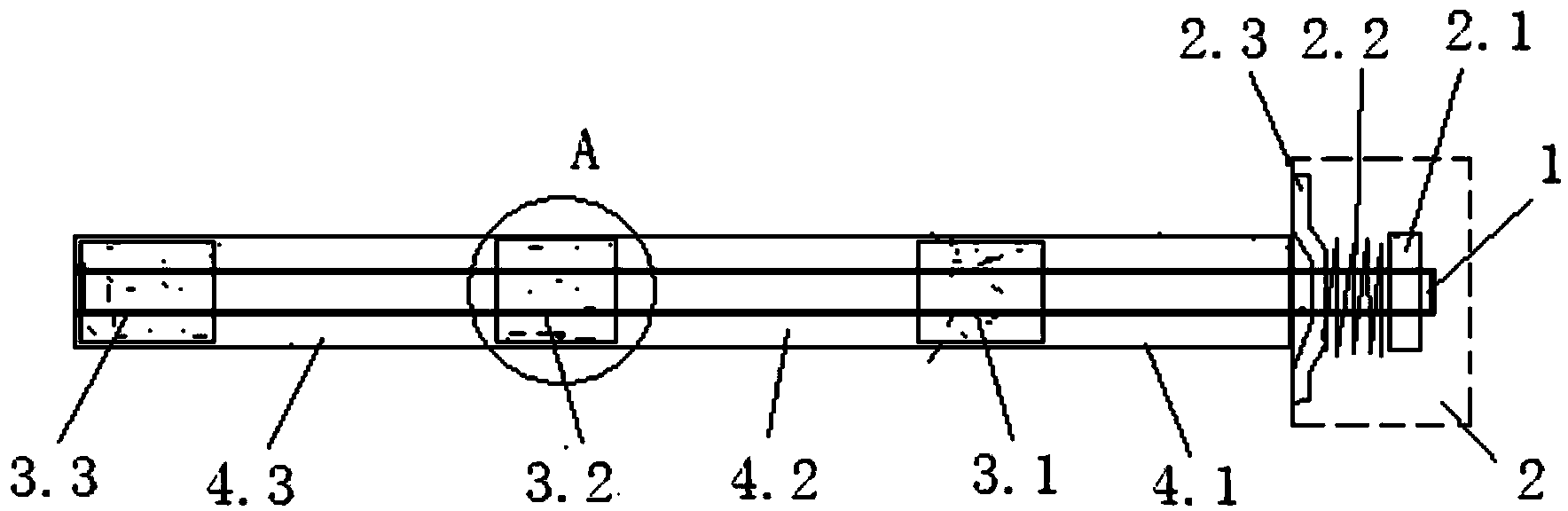

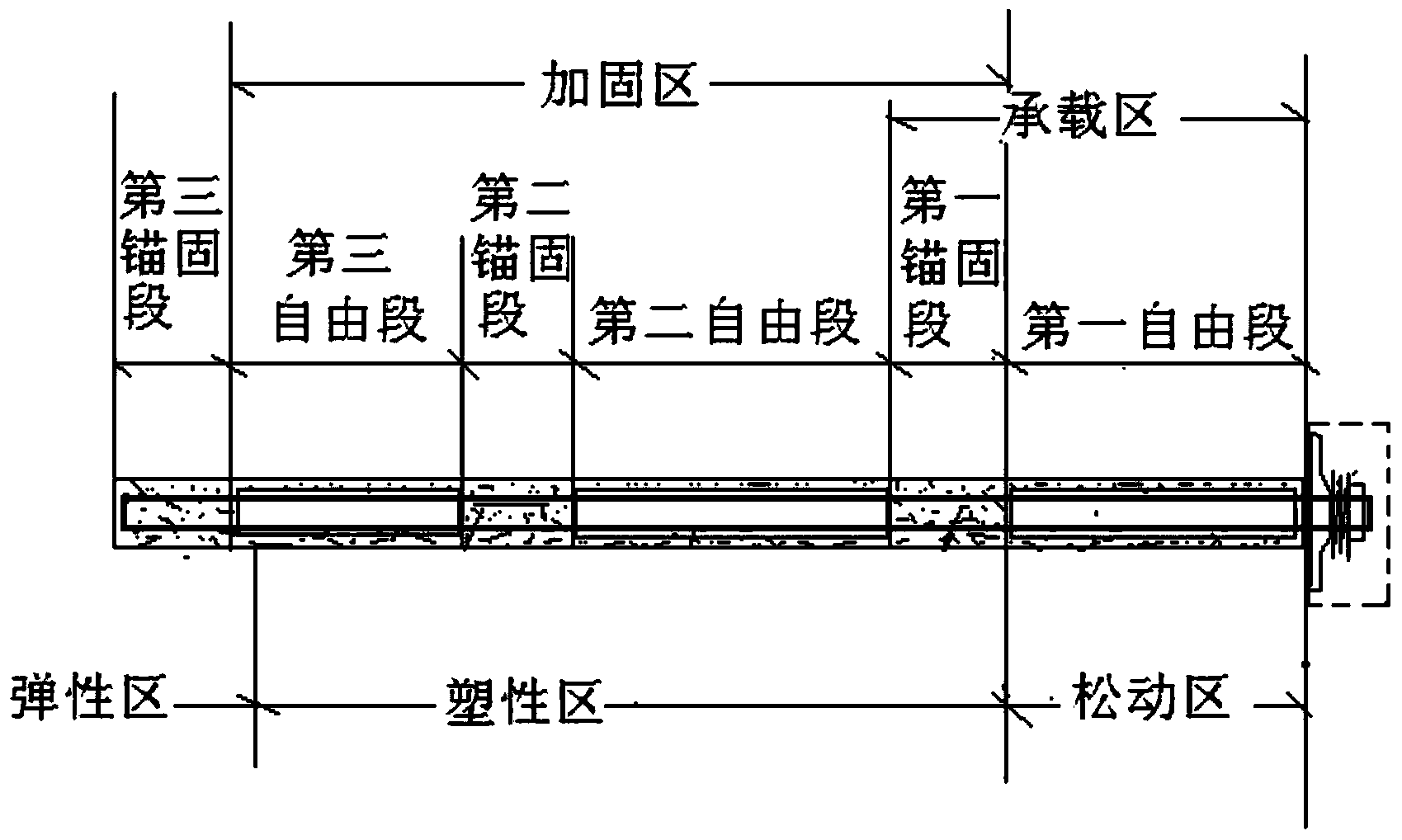

Multi-section anchoring type mortar anchor rod and anchoring method thereof

InactiveCN103850696AEliminate transfer stacking effectsAvoid failureBulkheads/pilesAnchoring boltsStress concentrationDistribution characteristic

The invention discloses a multi-section anchoring type mortar anchor rod and an anchoring method thereof. The multi-section anchoring type mortar anchor rod comprises anchor rod bodies and an orifice pre-tightening instrument, wherein free sections are arranged on the anchor rod at intervals; sections of plastic sleeves are sleeved on the anchor rod bodies, so as to form the free sections; the two ends of the plastic sleeves are plugged or tightened by using flexible gaskets; the anchor rod bodies sleeved with the plastic sleeves are arranged as the free sections and the rest anchor rod bodies are arranged as point anchoring sections, so that the anchor rod bodies are divided into a first free section, a first point anchoring section, a second free section, a second point anchoring section, a third free section and a third point anchoring section in turn from an orifice; the first free section is located in a loosening area of the surrounding rock; the third point anchoring section is located in an elastic area of the surrounding rock; the rest sections are located in a plastic area of the surrounding rock. The quantity and lengths of the point anchoring sections and the free sections can be adjusted according to the pressure distribution characteristics of the surrounding rock; the loads are scattered; ultra-strong stress concentration is prevented from generating on the end part of the anchor rod; the rod body is prevented from being broken or an anchored element is prevented from being taken out.

Owner:SHANDONG UNIV OF SCI & TECH

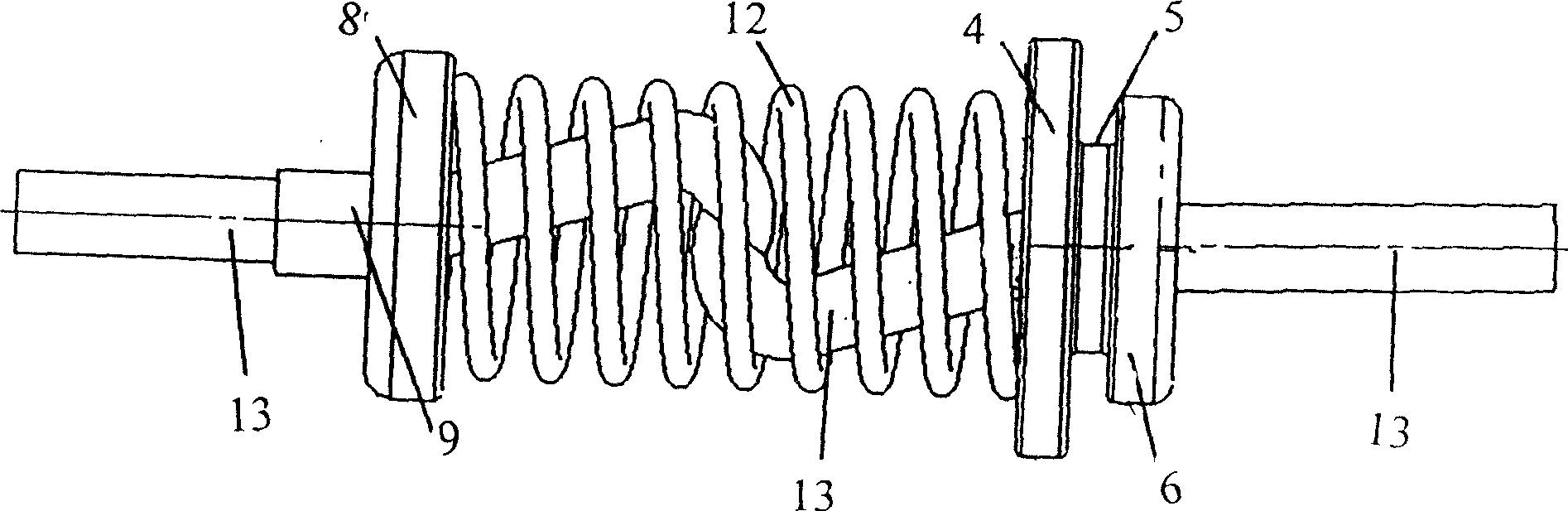

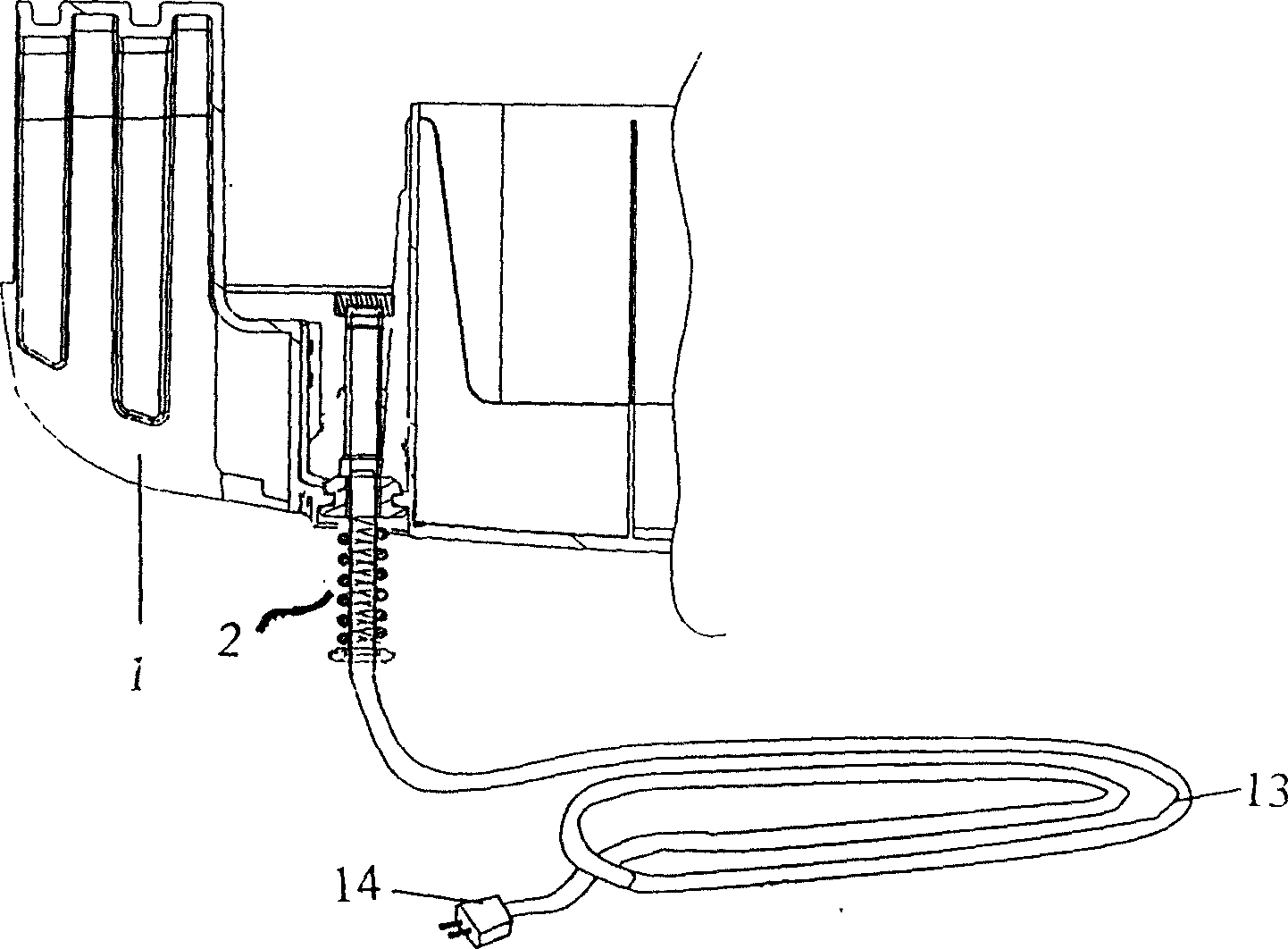

Power cord non-electricity protector

InactiveCN1767292APrevent pulling outCut down on time-consuming inspection processesCable arrangements between relatively-moving partsElectricityEngineering

The invention discloses a power wire electric-drop protector in the field of wire coiling device compound. It comprises a power wire and a wind spring, wherein the two ends of the wind spring are connected with the guide block end and the guide block head with the center hole; the power wire is coiled in the spring and separately integer inside the center hold of the guide block end and the guide block head; the guide block head is formed by a circular guide block head plate on one side, a concentric circular guide block plug on the other side and a card groove between them; the guide block end is formed by a circular guide block end plate and a concentric wire pipe.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Protective device for slope of water conservancy and hydroelectric project

InactiveCN107489128AImprove stabilityAvoid shockCoastlines protectionSewer pipelinesReinforced concreteArchitectural engineering

The invention discloses a protective device for a slope of a water conservancy and hydroelectric project. An intercepting channel is formed in the top of the slope; a protective mechanism is arranged at the bottom of the intercepting channel; a left connecting block is arranged on the left side of the protective mechanism, and a reinforced concrete beam is arranged on the right side of the left connecting block; a vertical draining groove is formed in the right side of the reinforced concrete beam, and transverse draining grooves are formed in the upper end and the lower end of the right side of the vertical draining groove; a protective net is arranged on the right sides of the transverse draining grooves; and a right connecting block is arranged on the right side of the protective net. A T-shaped groove is formed in the middle of the right connecting block; anchor rods and hollow anchor rods are arranged on one side of the protective mechanism; draining holes are formed in the surfaces of the hollow anchor rods; a draining channel is formed in the bottom of the protective mechanism; and slope protecting short walls and anti-slip piles are arranged at the bottom of the draining channel. The protective net is arranged on the right sides of the transverse draining grooves, a hole-shaped structure facilitates plant planting, the water and soil loss is reduced, and the stability of the slope is reinforced advantageously.

Owner:安徽诺鑫自动化设备有限公司

Conical pipe anchor bar connection structure for prefabricated assembly structure

ActiveCN107882051AImprove adhesionImprove binding abilityBridge structural detailsFoundation engineeringReinforced concreteEngineering

The invention discloses a conical pipe anchor bar connection structure for a prefabricated assembly structure, and belongs to the field of prefabricated assembly engineering. The connection structurecomprises a conical pipe, a grouting guide pipe and a fixing circular ring. The conical pipe is of a pre-embedded structure, the conical pipe can achieve a restraint effect on steel bars and groutingmaterials in the conical pipe, and meanwhile the tension capacity of the conical pipe in concrete can be improved. Frame vertical ribs and tie bars in a prefabricated bearing table also achieve a restraint effect on cracking of the bearing table or foundation concrete caused during pulling of the conical pipe. In prefabricated components, a conical pipe group is connected with the surrounding frame vertical ribs and the tie bars, and therefore the anchor performance of the conical pipe group can be improved. The steel bar anchorage length needed by the conical pipe anchor bar connection structure is small, the conical pipe anchor bar connection structure can be used for connection between a reinforced concrete structure prefabricated assembly component and a foundation or the bearing table, and rapid building of the prefabricated assembly reinforced concrete is achieved.

Owner:BEIJING UNIV OF TECH

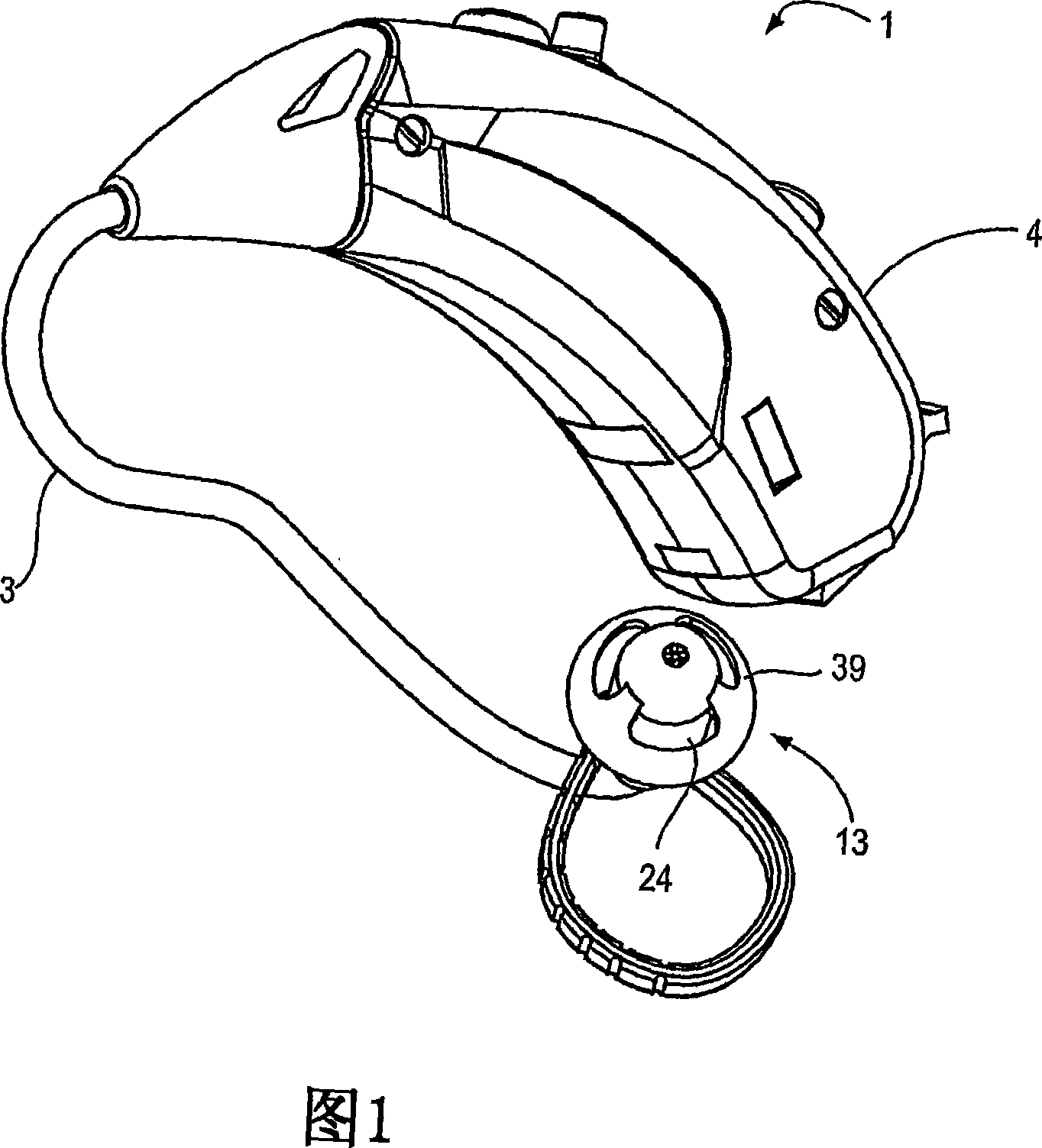

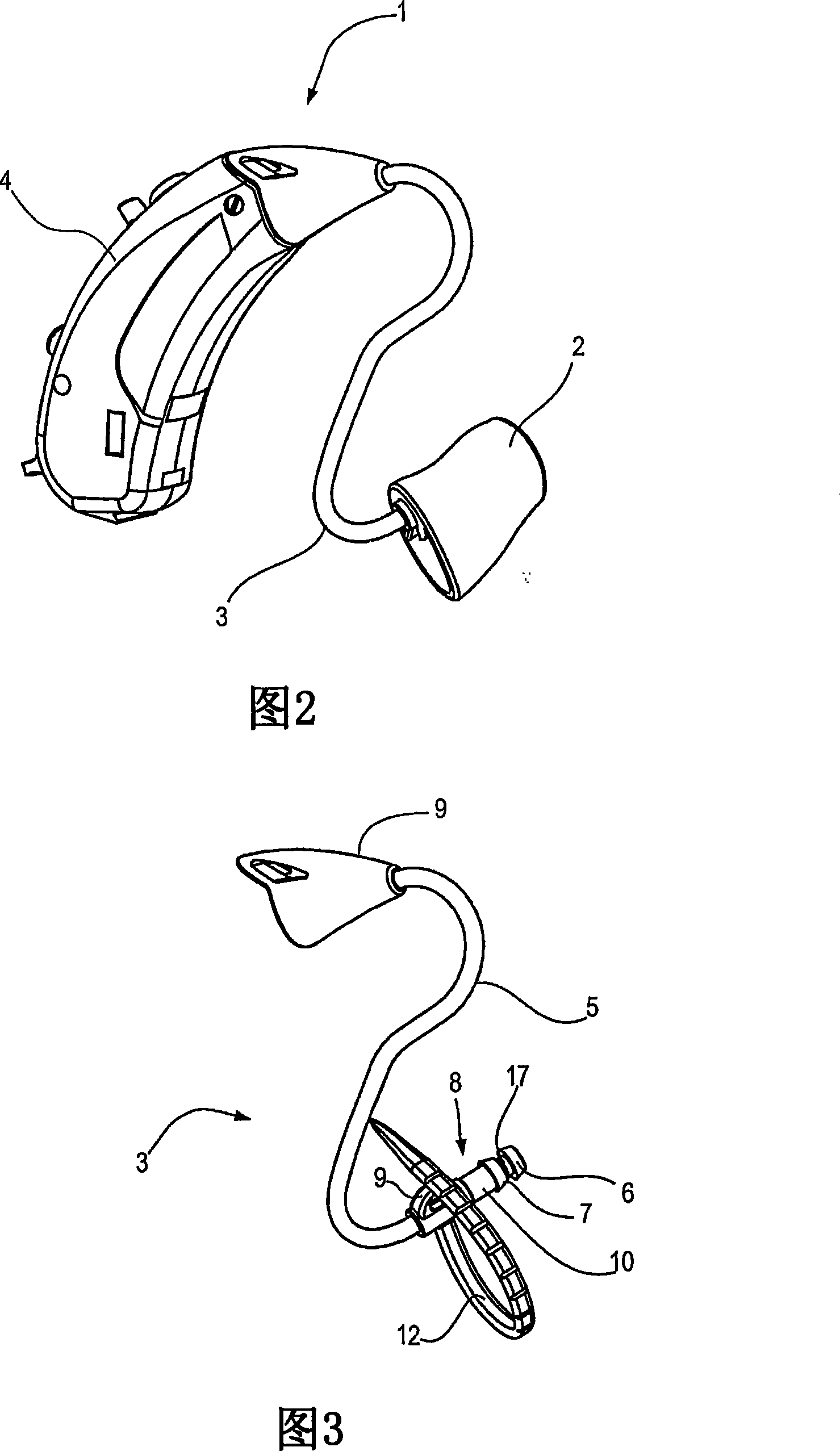

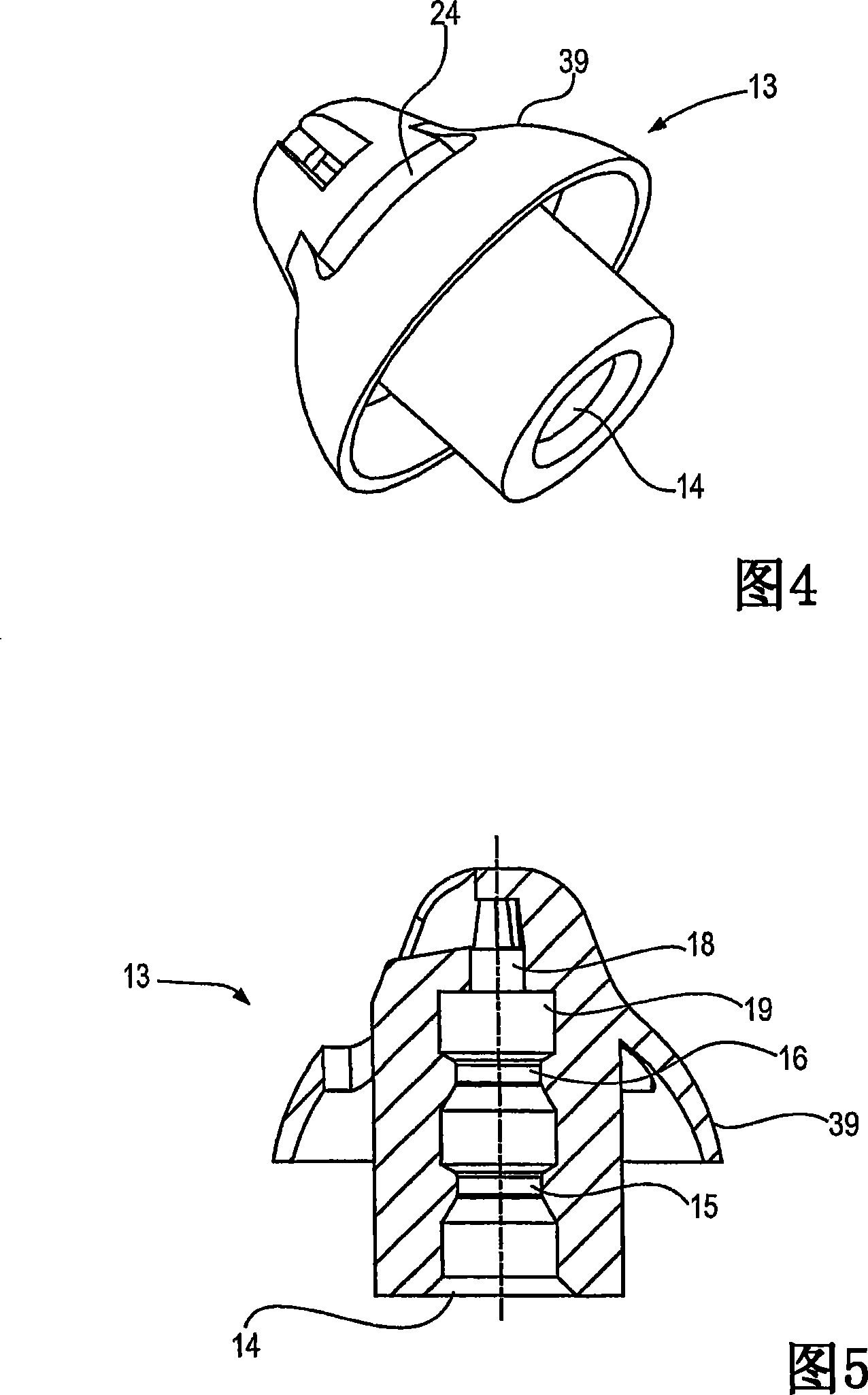

Hearing aid and an ear piece for a hearing aid

InactiveCN101218851APrevent pulling outFirmly connectedAdditive manufacturing apparatusEar supported setsHearing aidEngineering

A behind-the-ear hearing aid (1) comprises a housing (4), an ear piece (3) and a custom earplug (2), the custom earplug being adapted to fit the ear canal of an individual hearing aid user, the ear piece having a connector for connecting with the custom earplug, the connector and the earpiece having means for snap fitting engagement and means for defining the mutual rotational orientation. The invention further provides a custom earpiece for a hearing aid.

Owner:WIDEX AS

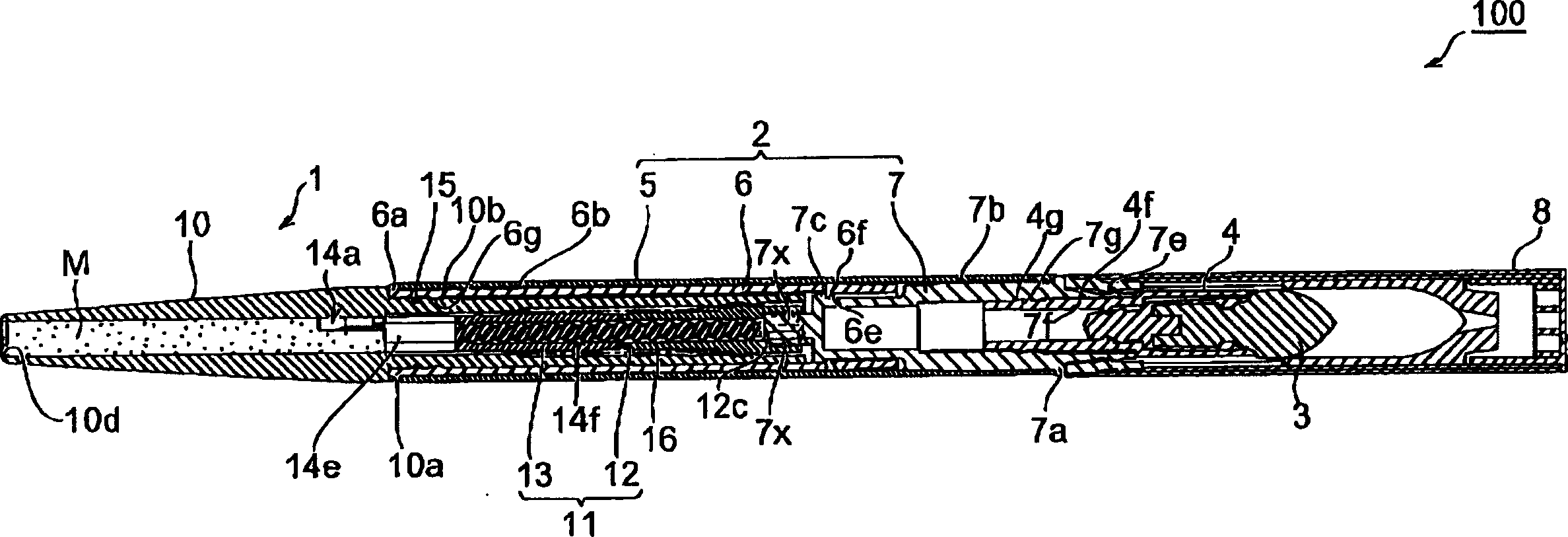

Stick-shaped cosmetic material cartridge

ActiveCN1765258APrevent pulling outAvoid breakingPropelling pencilsPackaging toiletriesScrew threadEngineering

In the rod-shaped cosmetic material box of the present invention, the rear inner cylinder (12) is accommodated in the outer cylinder (10) in a manner that can rotate but cannot move in the axial direction, and the front inner cylinder (13) can move in the axial direction but cannot rotate. It is connected with the rear inner cylinder (12) and applied force on the rear side by means of a force applying device (16) and is accommodated in the outer cylinder (10). The internal female thread (13x) of the front inner cylinder (13) is screwed with support A rod-shaped cosmetic material (M) and a male thread (14f) structure of a screw (14) having a male thread (14f) on the outside. Therefore, when a rotational force is given to the rear inner cylinder (12) from the rear side, the inner and outer cylinders will rotate relative to each other, and the screw (14) will advance and retreat smoothly so that the cosmetic material (M) is smoothly exported and introduced, and when the box ( 1) When the rod-shaped cosmetic material outlet container (100) has an impact action, the rear inner cylinder (12) can maintain a state of being stationary in the axial direction and reliably impart a rotational force from the rear side, and the front inner cylinder (13) leaves the rear inner cylinder (13). The inner cylinder (12) advances with the screw rod (14) against the force applying device (16), and utilizes the buffering effect of the force applying device (16) to absorb impact to prevent the cosmetic material (M) from being pulled out or broken. This improves quality without compromising export functionality.

Owner:TOKIWA CORP

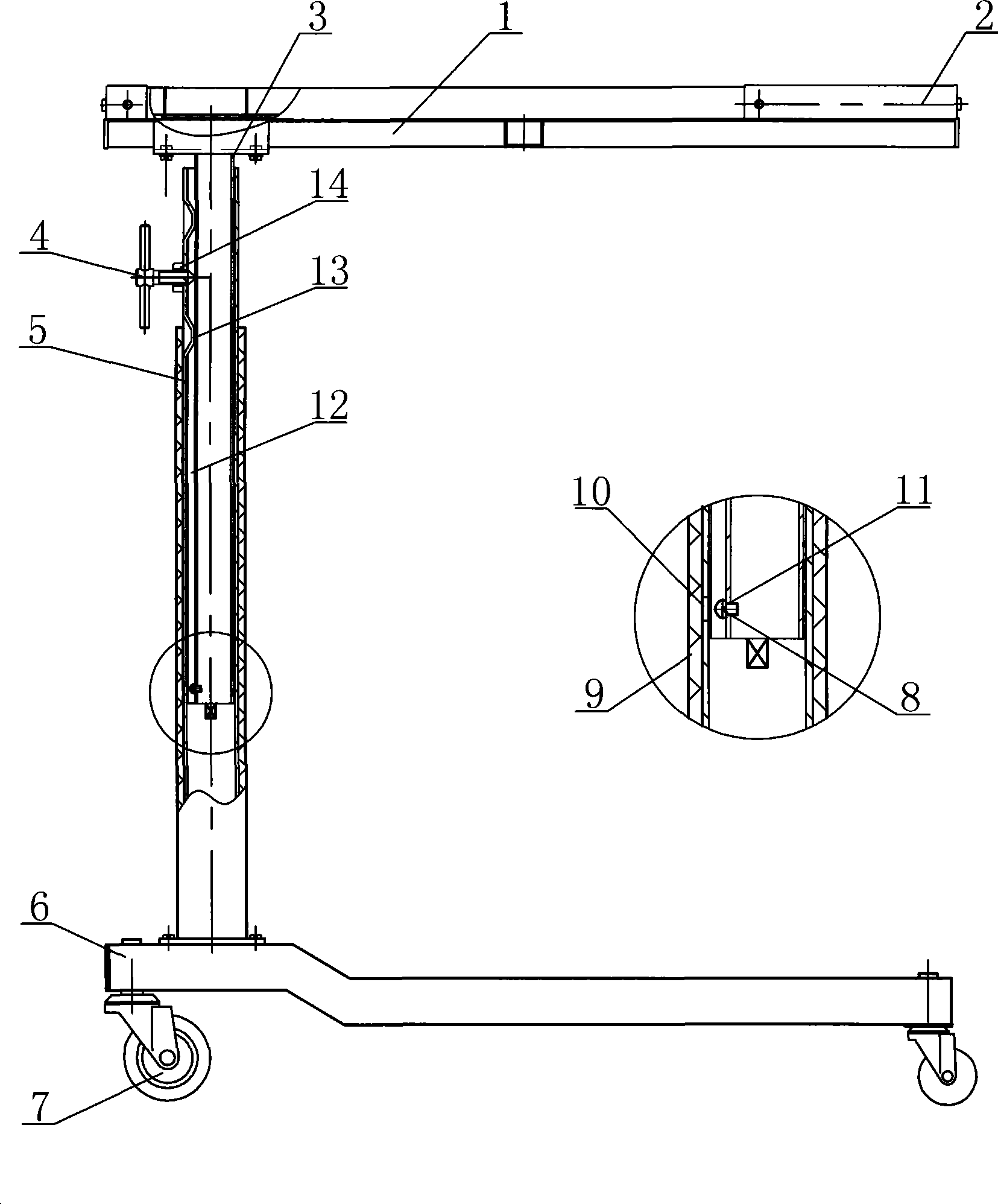

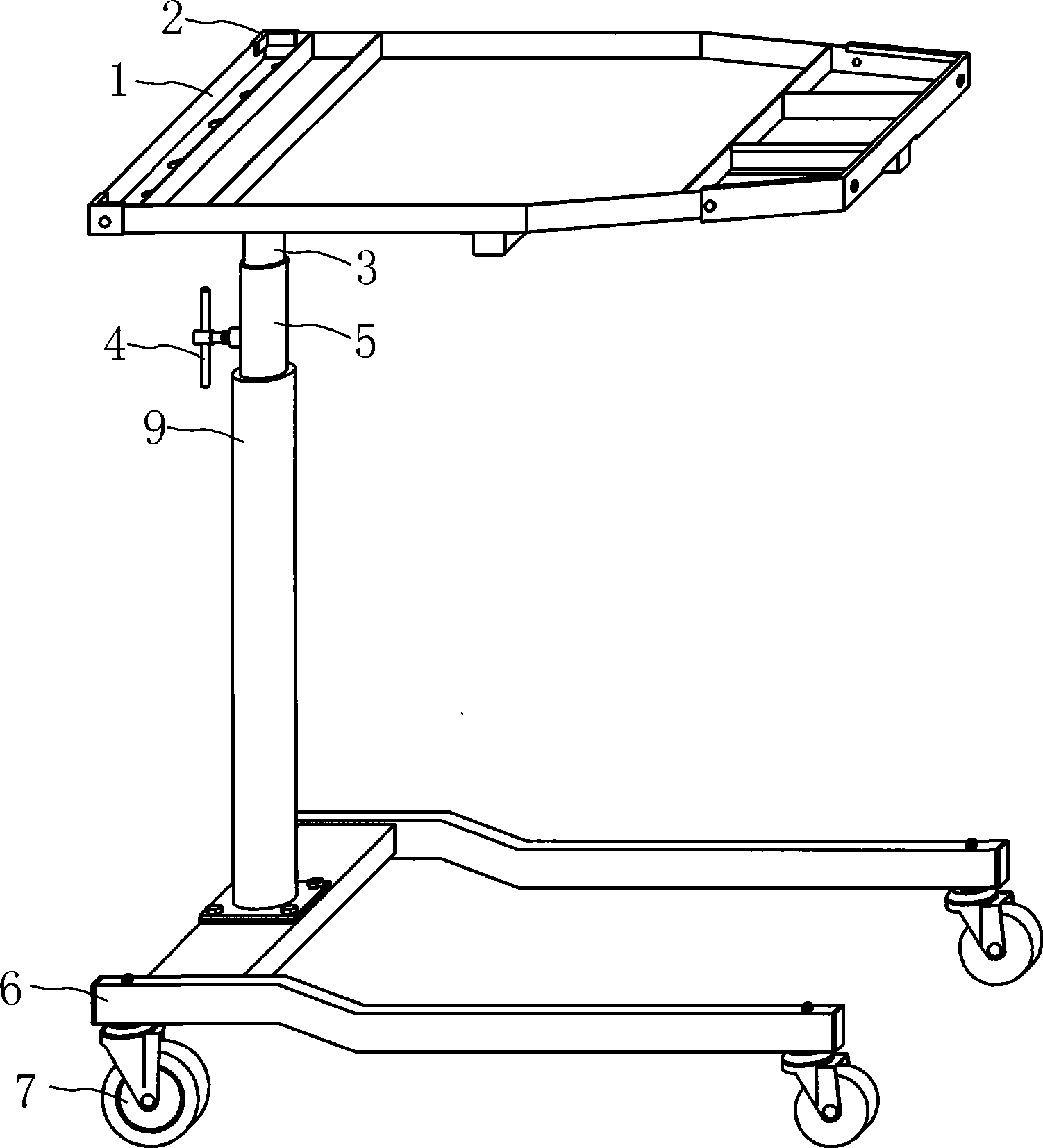

Elevated bench

The invention relates to a lifting working platform, comprising a working plate, a bottom frame, an upright post and a lifting tube; wherein, the lifting tube is arranged at the lower end of the working plate; the upright post is arranged on the bottom frame; the lifting tube is sleeved into the upright post; the bottom frame is provided with a universal wheel; two flutes are vertically positioned on the upper part of the outer wall of the upright post and a through hole is arranged at the lower part of the upright post; a guide groove is positioned on the outer wall of the lifting tube from top to bottom; a screw thread hole which is corresponding to the through hole is arranged at the lower part of the guide groove; and a stop nut goes through the through hole and is locked to the screw thread hole. The working table of the invention is safe and stable in sharp rising and falling, fixed and simple in operation, and convenient for the classification placement of tools, can be inserted deep into bottoms of cars and is suitable for a plurality of occasions.

Owner:谢翠斌

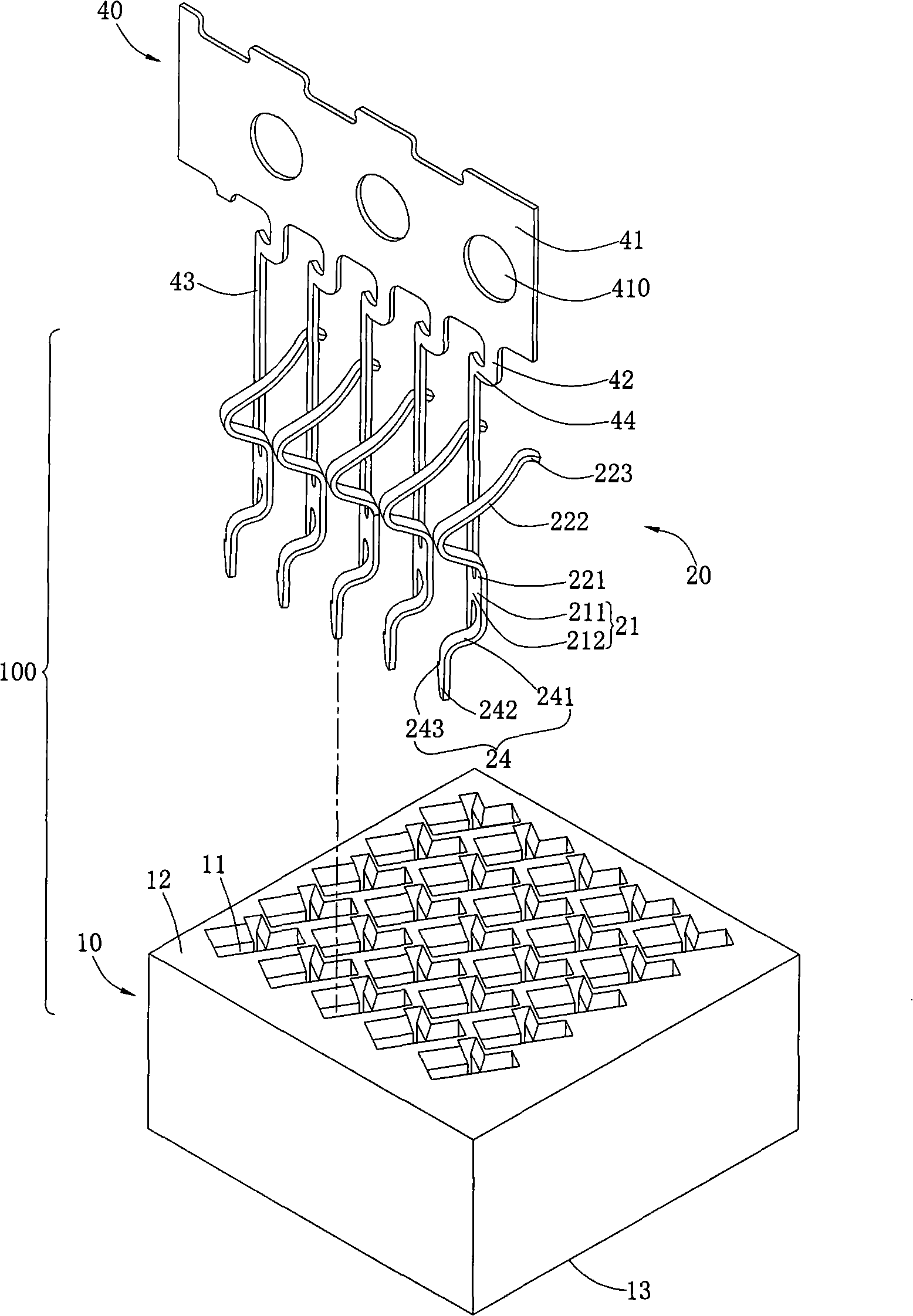

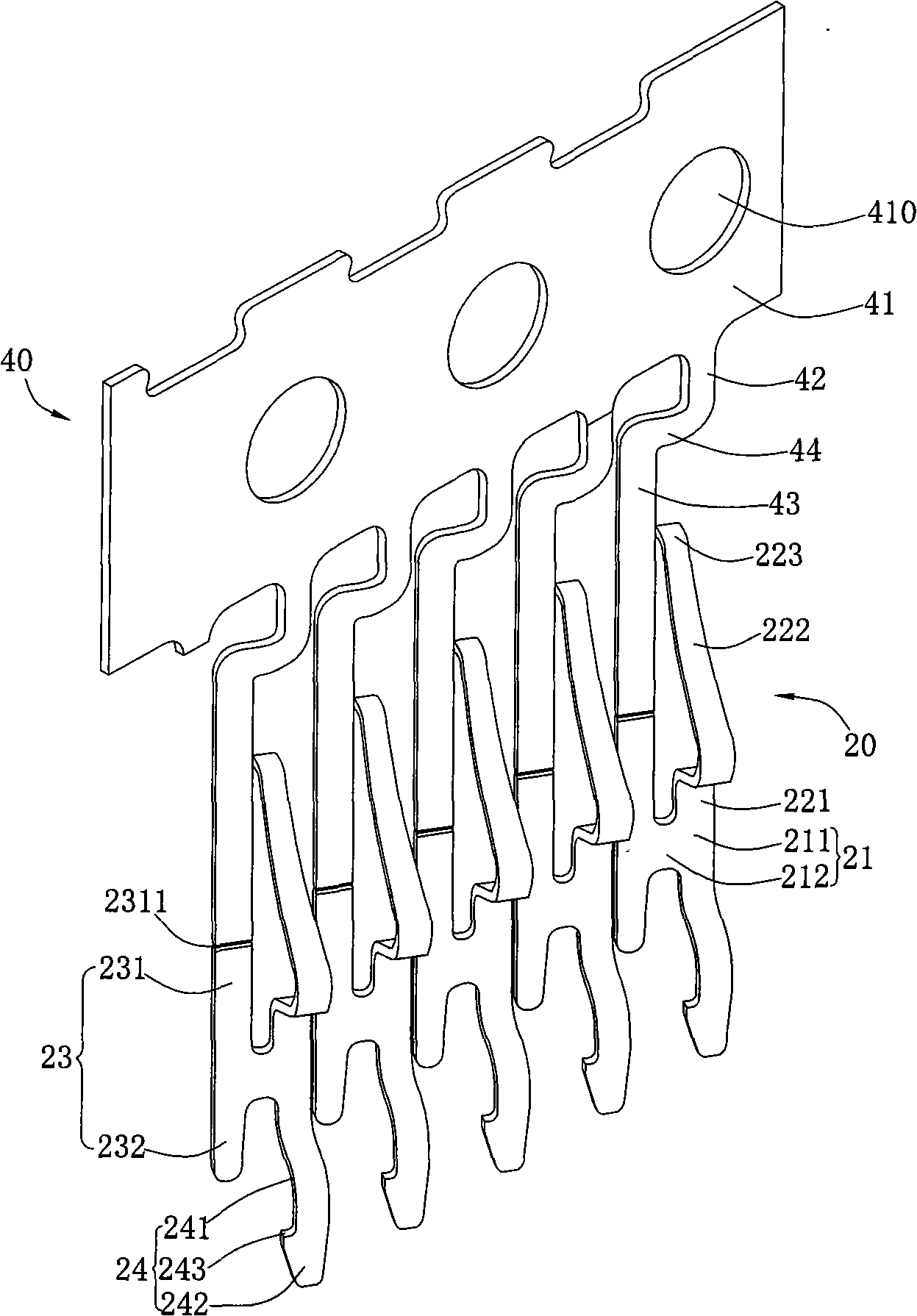

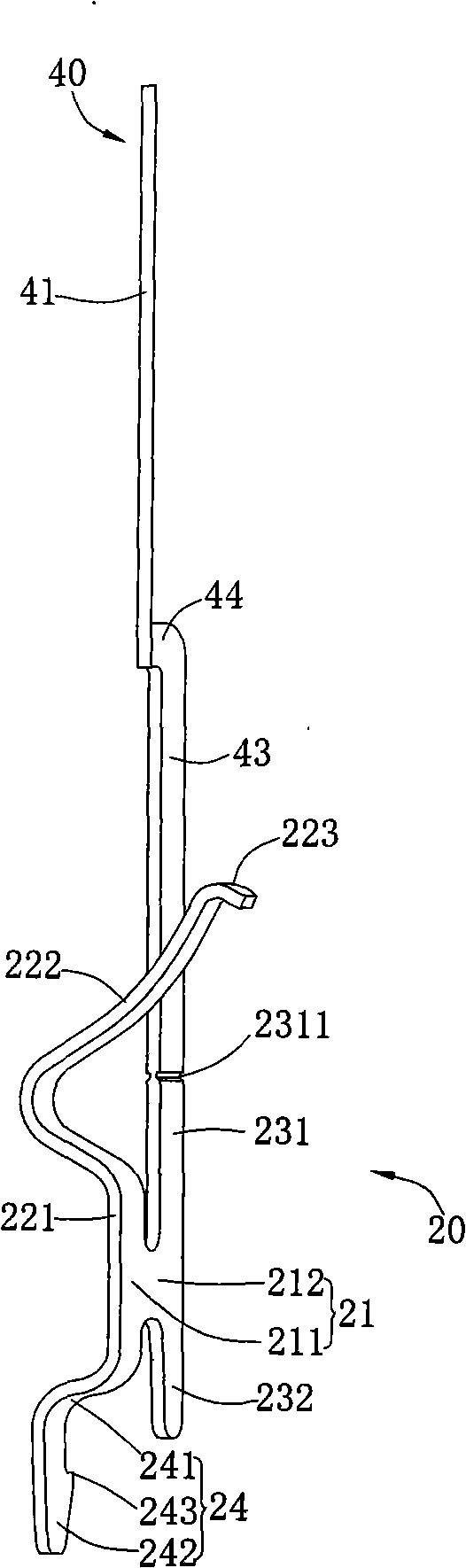

Terminal material strip structure and method for removing material strip of terminal material strip

ActiveCN101316023AReduce difficultyEasy to separateContact member manufacturingPull forceElectrical and Electronics engineering

The invention provides a terminal material band structure, comprising at least a material band and a plurality of conductive terminals which are connected on each material band; each material band is provided with a plate part; one end of the plate part is provided with a plurality of extension parts which use a common surface with the plate part; the end of each extension part is bent and extended to form a connecting plate; the end of the connecting plate is connected with a conductive terminal; each terminal is provided with a material band connecting part which is connected with the connecting plate; the material band connecting part is arranged on the extension surface of the connecting plate; furthermore, the connection position of the material band connecting part and the connecting plate is provided with a pre-cutting line; the pre-cutting line and the extension surface of the plate part form an angle. Compared with the prior art, the terminal material band structure of the invention leads the pre-cutting line and the extension surface of the plate part to form an angle, therefore, when the material band is broken, the material band applies an oblique pulling force on the conductive terminal so as to lead one end of the pre-cutting line to generate a tearing gap, lead the longitudinal connecting plate and the material band connecting part to be separated at the pre-cutting line position, and reduce the breaking difficulty of the material band.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

Copper cooling wall with reinforced piping structure

ActiveCN101935723AStressfulIncrease the stress pointCooling devicesManufacturing convertersStress conditionsWater channel

The invention provides a copper cooling wall with a reinforced piping structure. The copper cooling wall comprises a copper cooling wall body, at least one water inlet pipe and at least one water outlet pipe, wherein at least one cooling water channel is reserved in the copper cooling wall body; the water inlet pipe is welded on the cool surface of the copper cooling wall body, and is connected with the inlet of the cooling water channel; the water outlet pipe is welded on the cool surface of the copper cooling wall body, and is connected with the outlet of the cooling water channel; the water inlet pipe is inserted into the inlet of the cooling water channel, and is in threaded connection with the inner wall of the inlet of the cooling water channel; and the water outlet pipe is inserted into the outlet of the cooling water channel and is in threaded connection with the inner wall of the outlet of the cooling water channel. The copper cooling wall has the advantages of increasing stress points of the water pipe, and improving the stress condition of the water pipe to ensure that the stress of the water pipe is more uniform and a welding seam is hard to destroy; and because of lugs, the quality and the strength of the welding seam can be effectively improved, the consumption of copper can be greatly reduced, and the manufacturing cost of the copper cooling wall can be effectively controlled on the premise of ensuring the performance.

Owner:SHANTOU HUAXING METALLURGICAL EQUIP CO LTD

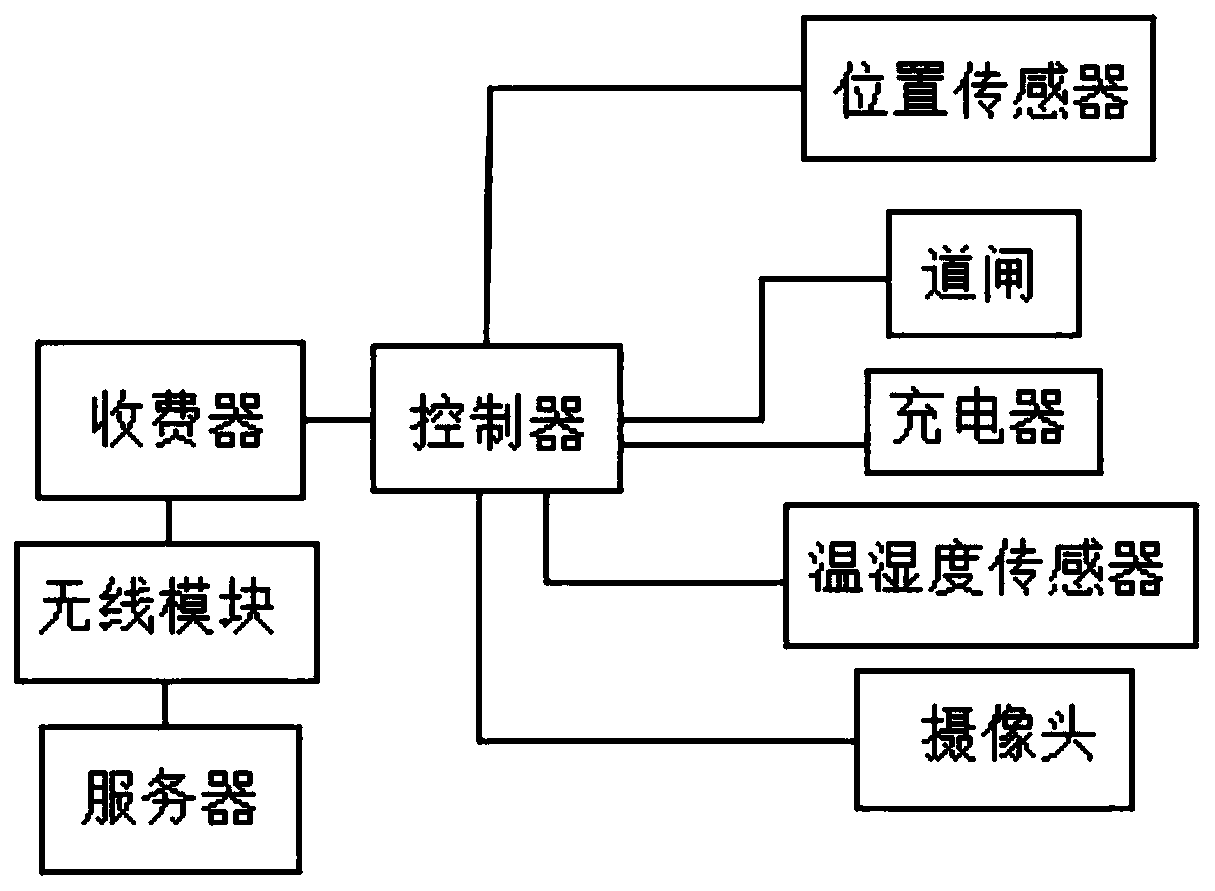

Intelligent charging station based on Internet parking

InactiveCN111063117AAvoid supply problemsProblems preventing private occupationApparatus for hiring articlesParking spaceThe Internet

The invention discloses an intelligent charging station based on Internet parking, which comprises a plurality of position sensors, a plurality of barrier gates, a plurality of chargers, a temperatureand humidity sensor, a camera, a controller, a toll collector, a wireless module and a server, wherein the plurality of position sensors are located at the corresponding parking spaces respectively and used for sensing vehicles in the area, the plurality of barrier gates are located at entrances of the parking spaces respectively and used for isolating the vehicles, and the plurality of chargersare located at the corresponding parking spaces respectively. The beneficial effects of the invention are that the use conditions of charging station parking spaces in each region can be integrated and compared, according to the method, the available charging parking space information is pushed to the customers in real time, the overtime vehicle is subjected to deduction punishment, the vehicle owner is forced to drive away the vehicle in time, the charging parking space supply problem is avoided, it can be guaranteed that the charging parking space is provided for the vehicle owner really needing charging, and the problem that the charging parking space is privately occupied by other vehicles is prevented.

Owner:JIESHOU XUNLIDA ELEVATOR CO LTD

Novel medical acne removing device

The invention discloses a novel medical acne removing device which comprises a roller, an annular sliding groove, a suction nozzle, a filtering screen, an exhaust tube, a cotton block, a through hole,an ethyl alcohol box, a connecting rod, a piston, a shell, an exhaust cylinder, a rack, a gear, a first bevel gear, a second bevel gear, a disk, a sleeve, a first shaft rod, a second shaft rod, a handle, a motor switch, a micro motor, a storage battery, a third bevel gear, an air discharging pipe and an air discharging valve. The device is simple in structure, convenient to operate, high in functionality and novel in design, the device is provided with the exhaust cylinder and the suction nozzle, an acne extractor is more rapidly drawn out after acne dirt is absorbed, time and labor are saved, pain of a user is relieved, the device is provided with the ethyl alcohol box and the cotton block, so that pores can be effectively disinfected, dirt cohered on skins can be effectively removed after the acne is absorbed, the infection of the pores caused by bacteria is avoided, and safety is improved.

Owner:杨铭

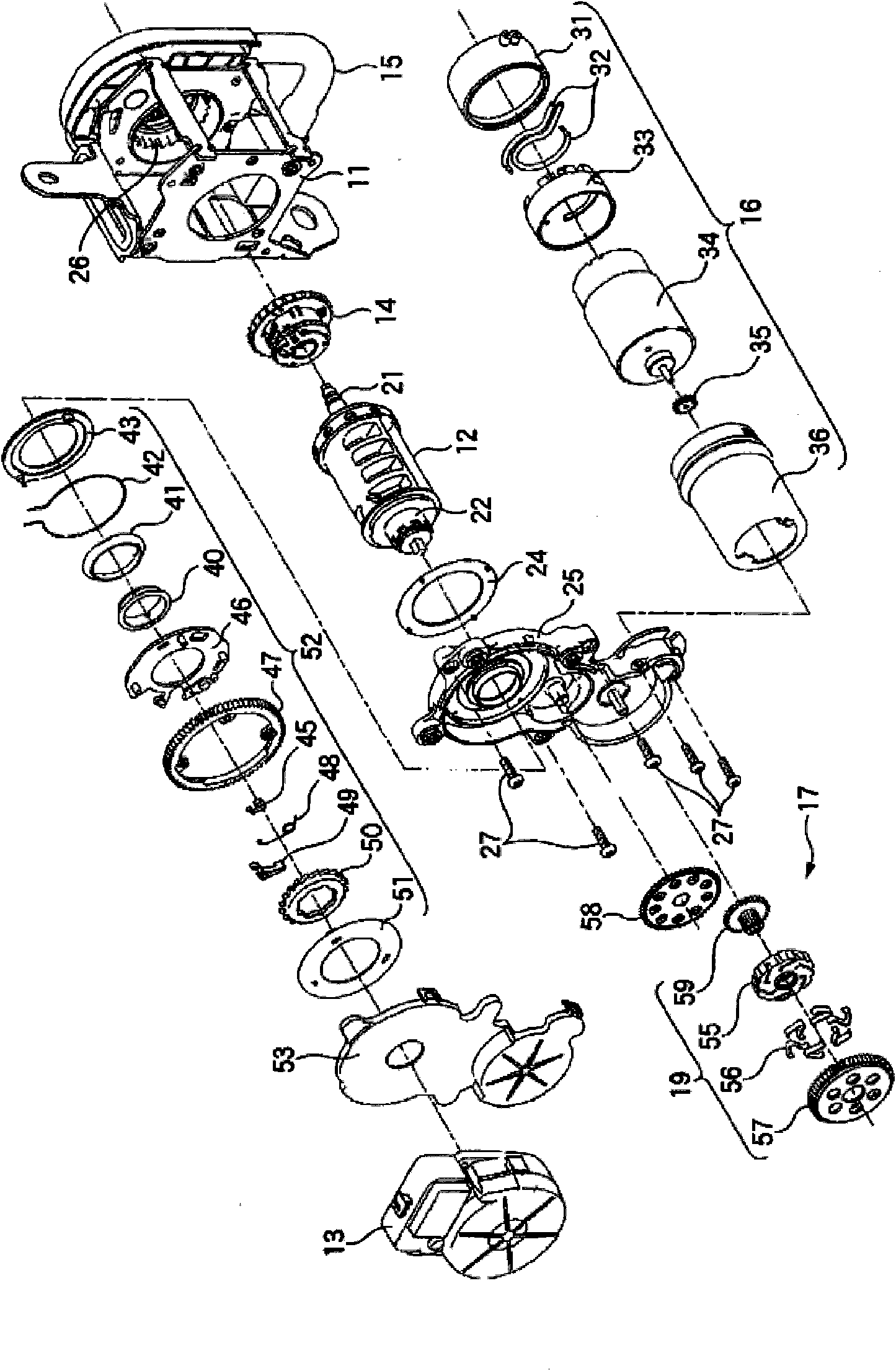

Seat belt device

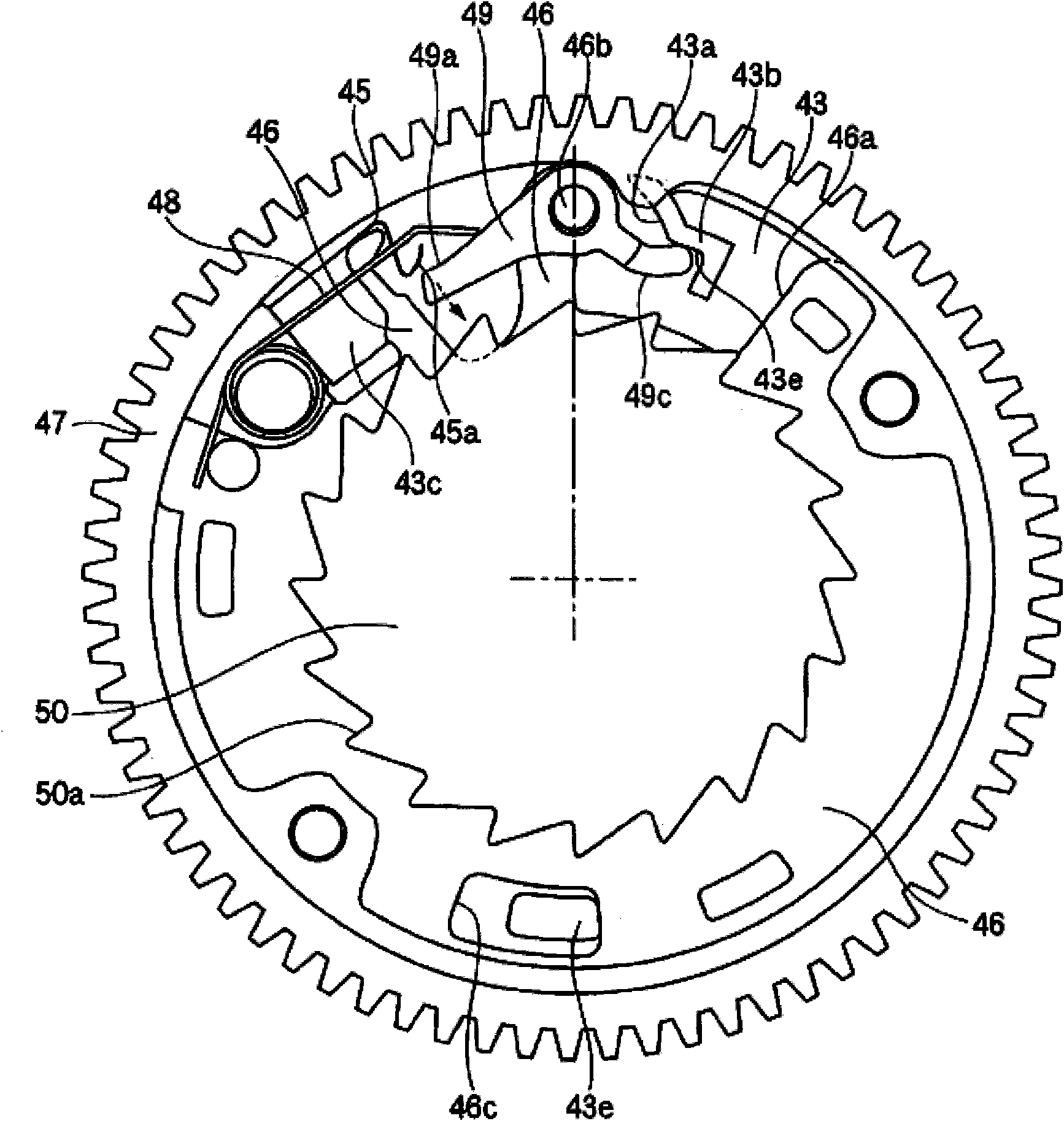

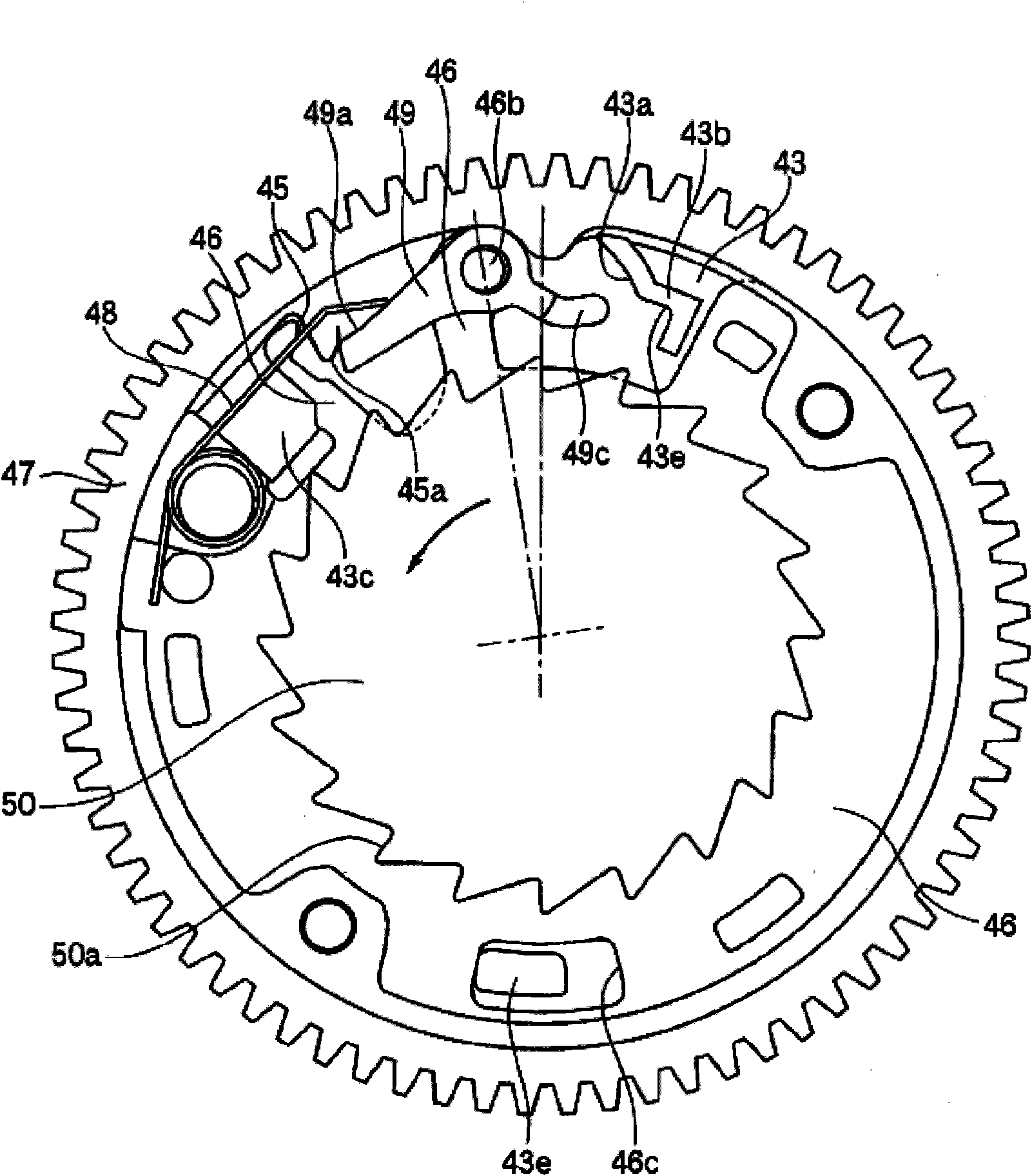

Provided is a seat belt device, which can cut the connection between a spindle for winding up a seat belt and an electric actuator reliably, when a pretentioner mechanism acts, thereby to constrain apassenger reliably at the pretentioner acting time. When a pretentioner mechanism (15) acts so that an engaging portion (49a) moves in the direction away from a first rotary member (50) while using the rotation of the first rotary member (50) by the pretentioner mechanism (15), a clutch (52) is elastically deformed by an engaging member (49) so that it regulates the movement of the engaging member(49), thereby to uncouple an electric actuator(34) and a spindle (12). The engaging member (49) rocks such that the engaging portion (49a) engages with an engaged portion (50a). A guide portion (43b)guides an extending portion (49c) extending to the opposite side of the engaging portion (49a) with respect to the hinge pin of the engaging member (49). The guide portion (43b) includes a radial guide portion (43a) for guiding the extending portion (49c) to move radially outward, as viewed from the center of the first rotary member (50). The radial guide portion (43a) has such a face to contactthe extending portion (49c) as has a center of curvature toward the extending portion.

Owner:AUTOLIV DEV AB

Tamper-resistant automatic warning seal device

InactiveCN105654843ADeter electricity theftRealize managementStampsVisible signalling systemsElectricityIntelligent management

Provided is a tamper-resistant automatic warning device, comprising a seal body and a seal wire. The periphery of the seal body is wrapped with a transparent plastic layer. The plastic layer is provided with an inlet used for the seal wire to pass through. One end of the seal wire is fixed with the seal body, and through plastic sealing by the plastic layer, the seal wire goes through the plastic layer, and then comes back to enter the seal body through the inlet. The seal body comprises a housing. The housing is internally provided with a storage cavity. The storage cavity is internally provided with a rotation device which rotates freely, and a driving rod used to drive the rotation device to rotate and make the rotation device and the housing fixedly lock. The housing is internally provided with a warning device. The device can effectively deter occurrence of user electricity stealing, and can perform real-time monitoring, sealing-off changing and other operations on a sealed meter, so as to realize digitized and intelligent management.

Owner:浙江四方格林系统工程有限公司

Wire connecting terminal special for photovoltaic wire connecting box circuit board

InactiveCN101673883AEasy connectionIncrease frictionClamped/spring connectionsEngineeringElectrical and Electronics engineering

The invention provides a wire connecting terminal special for a photovoltaic wire connecting box circuit board. The wire connecting terminal comprises a shell, an electric conductor arranged in the shell and a spring piece, wherein a wire inlet is arranged on the shell; the spring piece is arranged in the shell; one end of the spring piece is fixed on the inner surface of the shell, while the other end is abutted against the side edge of the electric conductor and in elastic contact with a lead inserted in the shell; the end of the spring piece in contact with the lead comprises a first elastic piece and a second elastic piece which are connected in a V shape; and the tail end of the first elastic piece is provided with a plurality of convex teeth. Because the tail end of the second elastic piece is provided with a plurality of convex teeth, when the spring piece is in the elastic contact with the lead, friction force between the spring piece and the lead is increased, thus the lead isnot easy to pull out after being inserted in the shell. The locking capacity of the wire connecting terminal is greatly improved and the connection between the lead and the electric conductor is morereliable.

Owner:江苏金苇电气科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com