Assembly structure of assembly-type concrete member

A technology for assembling structure and concrete, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of large reinforcement area, difficult control of quality standards, difficult operation, etc. Connection quality, the effect of improving the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

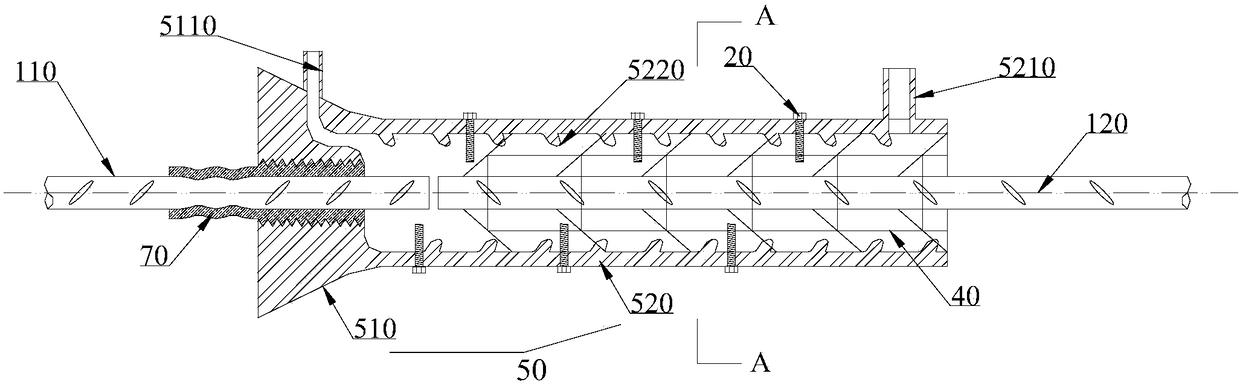

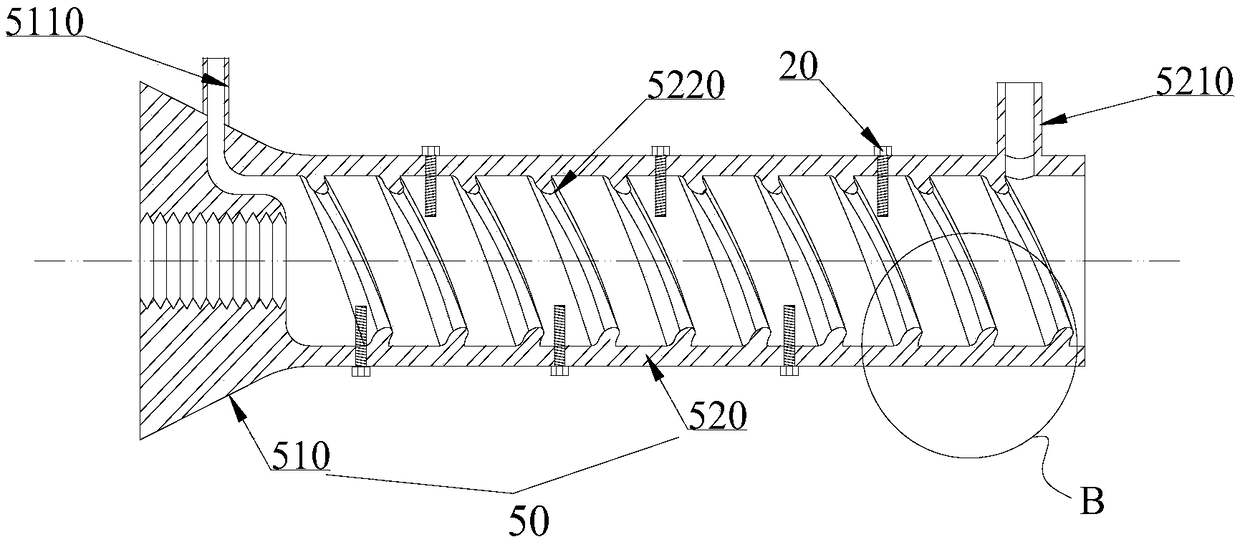

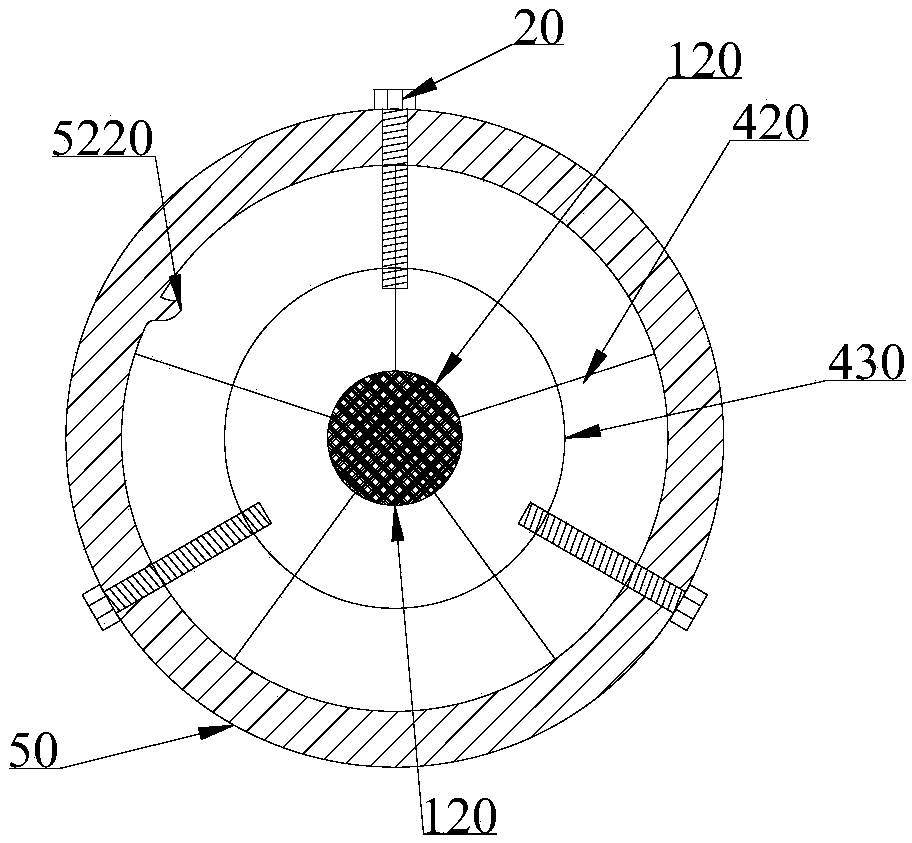

[0058] Such as figure 1 , figure 2 , image 3 As shown, an assembly structure of a prefabricated concrete member includes a sleeve 50, a steel pipe transition section 70, and a self-locking steel skeleton 40;

[0059] The sleeve 50 includes a non-grouting connection section 510 and a grouting connection section 520; the non-grouting connection section 510 is a conical cylindrical structure, and the grouting connection section 520 is a cylindrical structure; the small diameter end of the non-grouting connection section 510 and the grouting connection section 520 One end of the connection is connected, and the connection is rounded. A grouting hole 5210 is provided at the end of the grouting connection section 520 away from the non-grouting connection section 510, and a vent hole 5110 extends from the other end to the non-grouting connection section 510. The vent hole 5110 can be specifically: A first vertical and then horizontal air hole is set on the cone, and the air hole...

Embodiment 2

[0067] A method for processing an assembly structure of a prefabricated concrete component: comprising the following steps:

[0068] Step 1. Grouting sleeve 50 processing

[0069] The grouting sleeve 50 is processed by casting and integrally formed; one end is internally threaded, and multiple mounting holes are opened on the cylinder for standby;

[0070] Step 2. Steel pipe transition section 70 processing

[0071] Select a steel pipe with a suitable length and thickness as the steel pipe transition section 70; one end of the steel pipe transition section 70 is externally threaded for standby;

[0072] Step 3. Self-locking steel skeleton 40 processing

[0073] First, a plurality of longitudinal guiding steel bars 410 and a plurality of circumferential fixed steel rings 430 are welded into a cylindrical keel, and then a plurality of oblique steel branches 420 are radially and obliquely welded on multiple annular sections of the keel to form inner barbs 4210 and Outer barb 4...

Embodiment 3

[0077] A processing method for fabricated concrete components, comprising the following steps:

[0078] Step 1. Binding of reinforced skeleton of prefabricated concrete members

[0079] One end of the first to-be-connected steel bar 110 is bound and fixed with other steel bars to form a reinforced skeleton of a prefabricated concrete member. The other end of the first to-be-connected steel bar is inserted into the rolling section 710 of the steel pipe transition section 70, and the steel pipe transition section 70 is realized by rolling machinery. The connection with the first steel bar 110 to be connected, so that the self-locking semi-grouting sleeve 50 is pre-installed in the reinforced skeleton of the prefabricated concrete member;

[0080] Step 2. Pouring of prefabricated concrete elements

[0081]Connect the plastic pipe 80 to the grouting hole 5210 and vent hole 5110 on the side wall of the sleeve 50 and lead it out of the component formwork, then the concrete placing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com