Multistage anchoring type resin anchor rod and anchoring method thereof

An anchoring and bolting technology, which is used in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of tensile failure and inability to adapt to the deformation and displacement of the surrounding rock, so as to prevent the failure from being pulled, and eliminate the transmission superposition. Effects, Effects of Spreading Loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

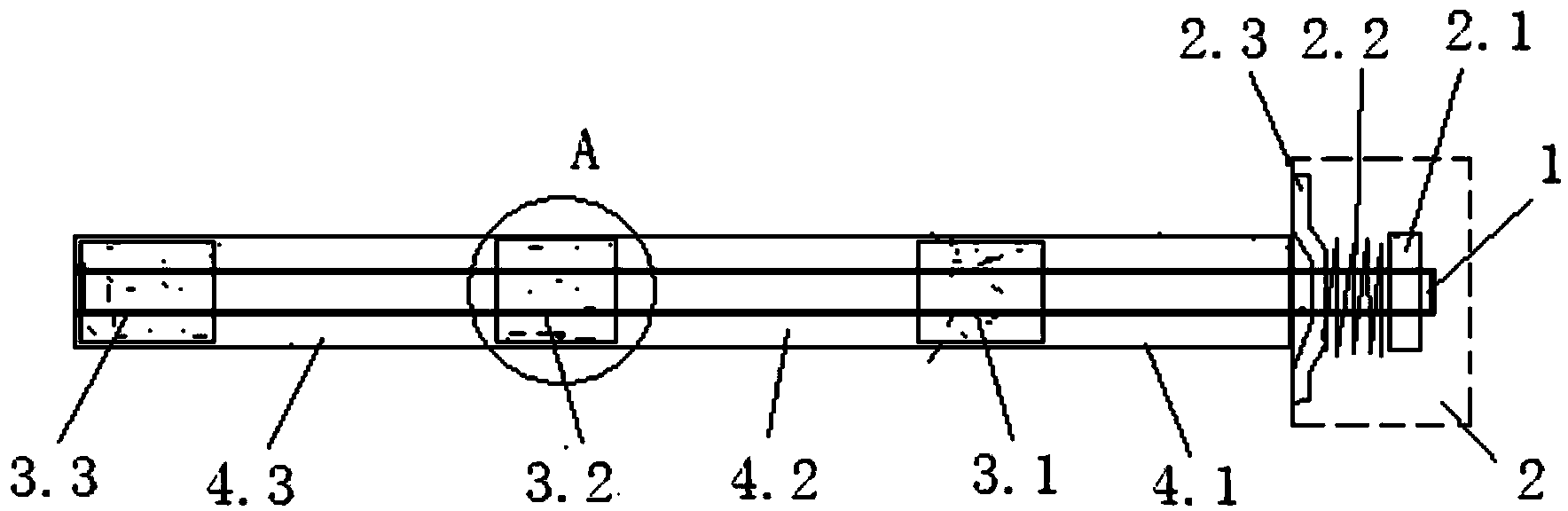

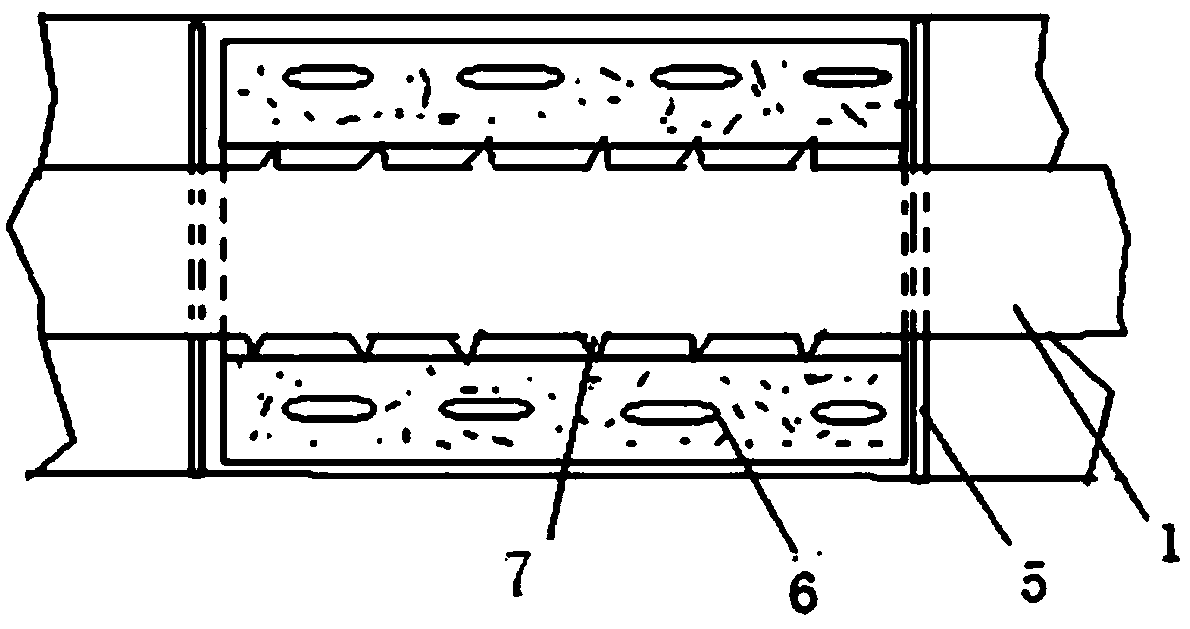

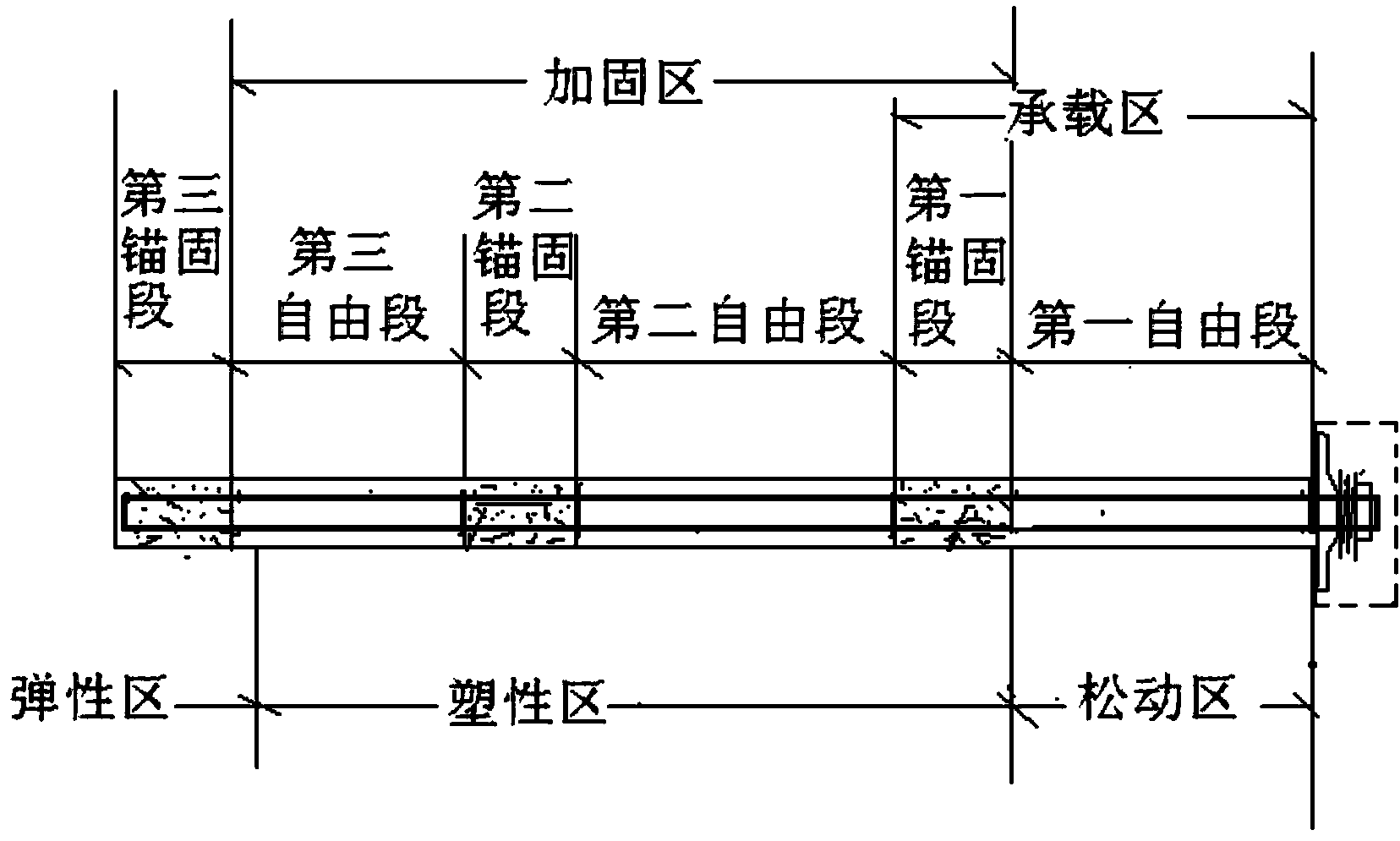

[0020] Such as figure 1 , figure 2 The multi-segment anchoring resin anchor shown in the figure includes an anchor body 1 and an orifice pretensioner 2. The orifice pretensioner 2 is composed of a nut 2.1, a pressure spring 2.2 and a tray 2.3, and is arranged on the anchor body 1 at intervals. There is a point anchoring section, and the remaining sections are free sections; the point anchoring section is processed with a toothed ring knife 7 on the anchor body 1 of the section, and the toothed ring knife 7 is covered with a two-component resin anchoring drug roll 6, The two-component resin anchoring cartridge 6 is covered with isolation washers 5 at both ends; thus, the anchor rod body 1 is sequentially divided into the first free section 4.1, the first point anchoring section 3.1, the second free section 4.2, and the second Point anchoring section 3.2, third free section 4.3, third point anchoring section, the length of each point anchoring section and free section should e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com