Terminal material strip structure and method for removing material strip of terminal material strip

A strip and terminal technology, which is applied in the field of terminal strip structure and strip removal, can solve the problems of increased production man-hours and difficulty in folding materials, and achieve the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

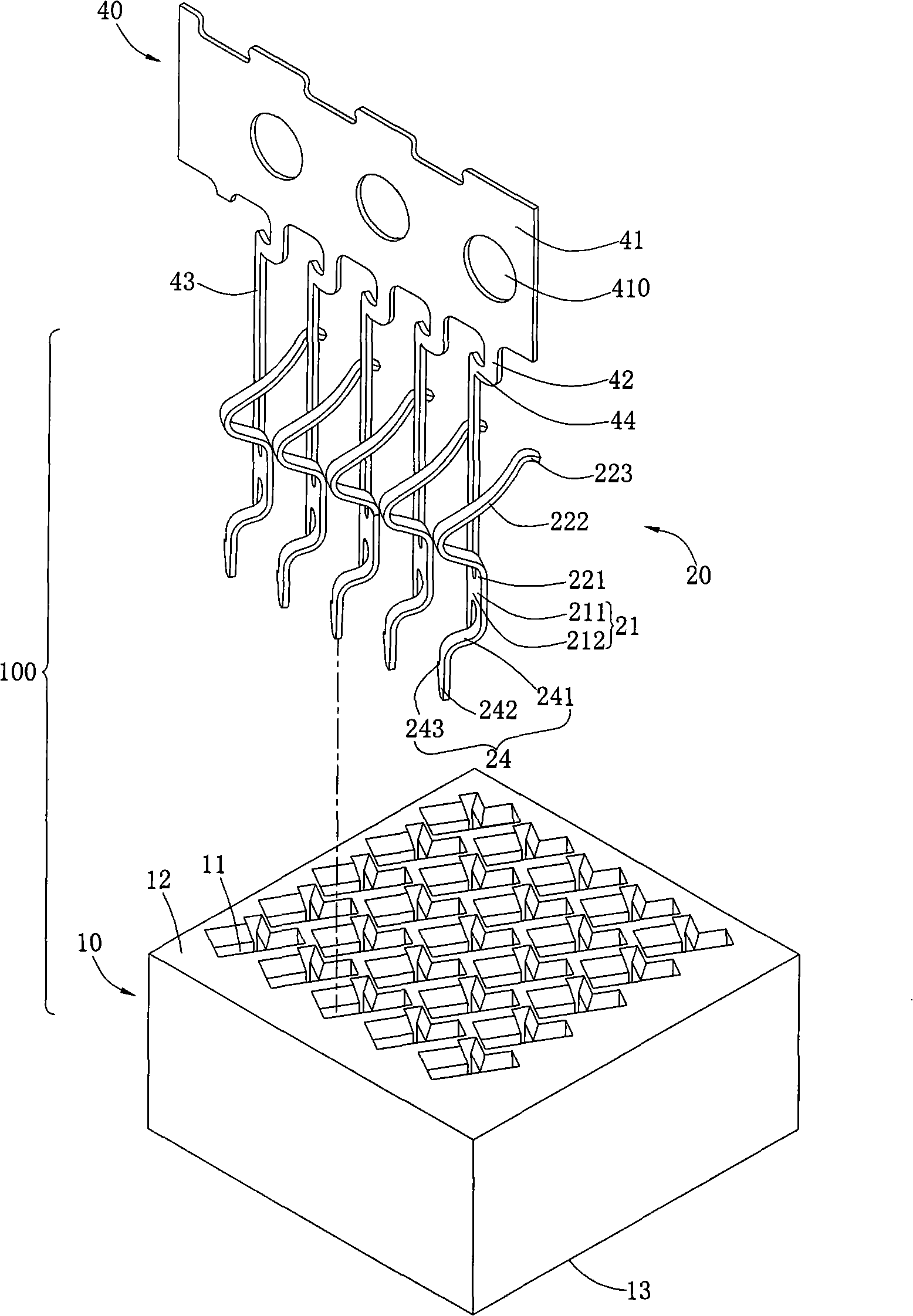

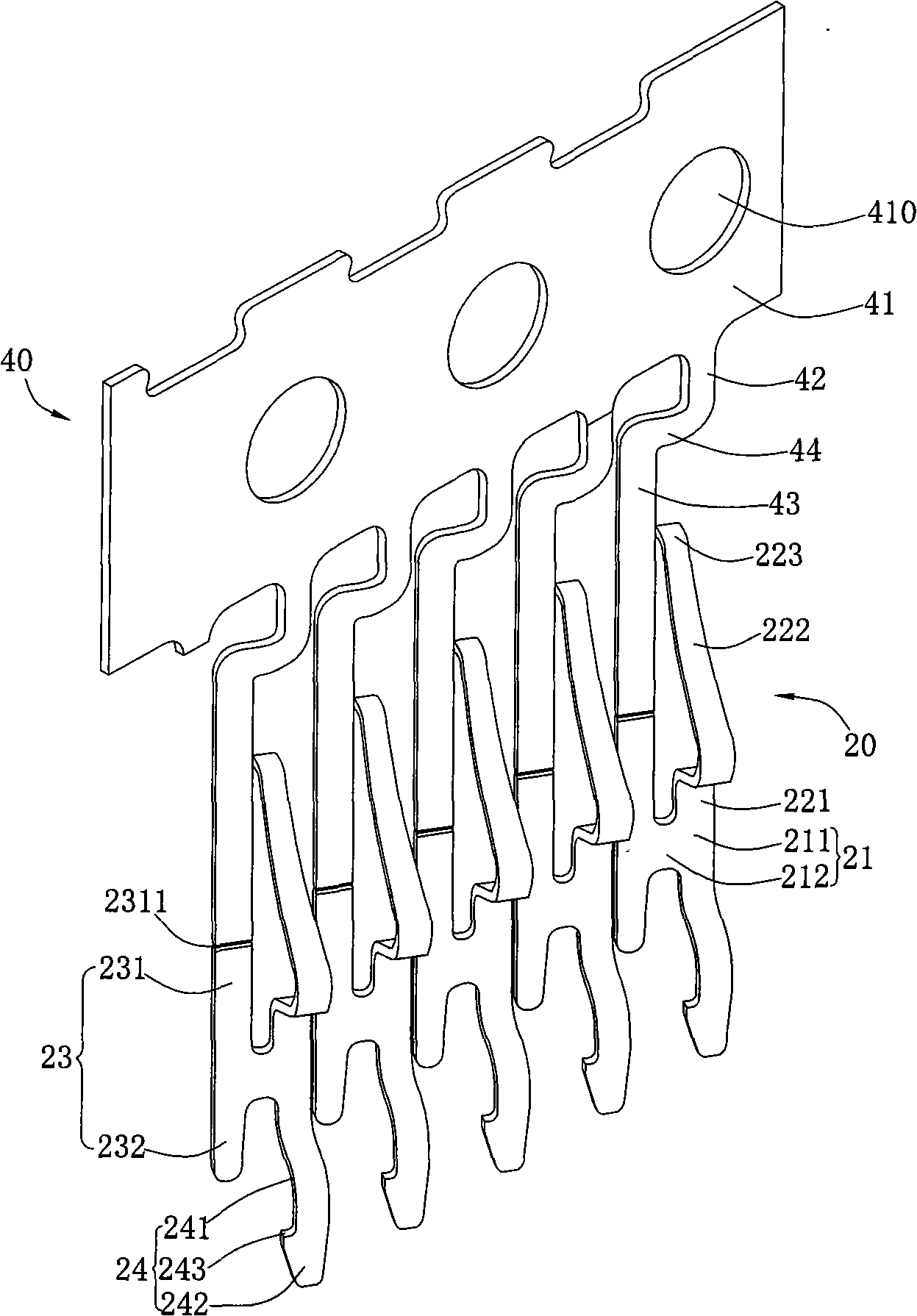

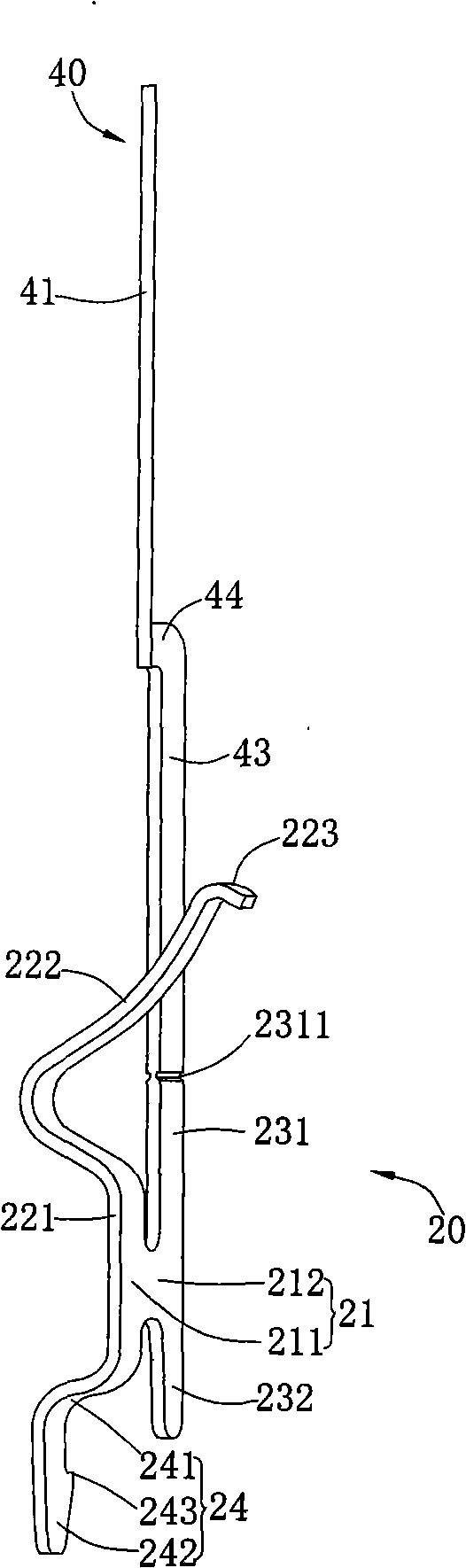

[0023] Please refer to figure 1 and Figure 5 , the present invention relates to an electrical connector 100, which is used to electrically connect a chip module (not shown) to a circuit board (not shown), which includes: an insulating body 10, multiple rows of terminals 20 and terminals 20 corresponds to 30 solder balls (such as Figure 5 ), wherein the insulating body 10 is provided with multiple rows of terminal accommodating grooves 11, and the terminals 20 are correspondingly accommodated therein; the solder balls 30 are installed in the terminal accommodating grooves 11 and abut with the corresponding terminals 20 (eg, Figure 5 ).

[0024] Please refer to figure 1 , Figure 5 and Image 6 , the insulating body 10 is roughly in the shape of a rectangular parallelepiped, which has a first surface 12 and a second surface 13 opposite to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com