Plate-integrated gasket

An integrated, plate technology, applied in the direction of fuel cells, electrochemical generators, electrical components, etc., can solve the problems of consistent compressibility characteristics, increase in fuel cell size, complex structure of the mold 200, etc., to improve productivity and prevent deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

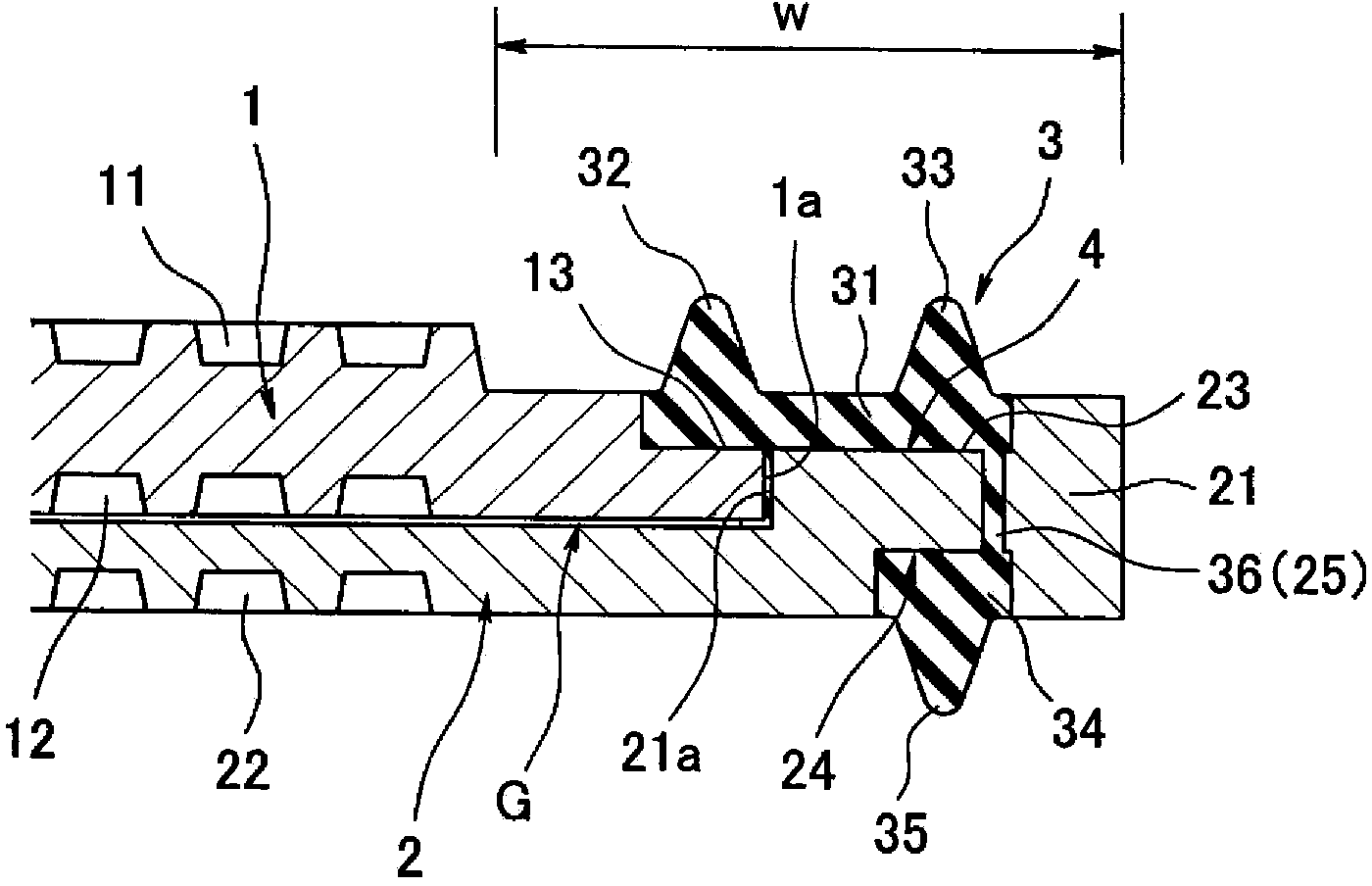

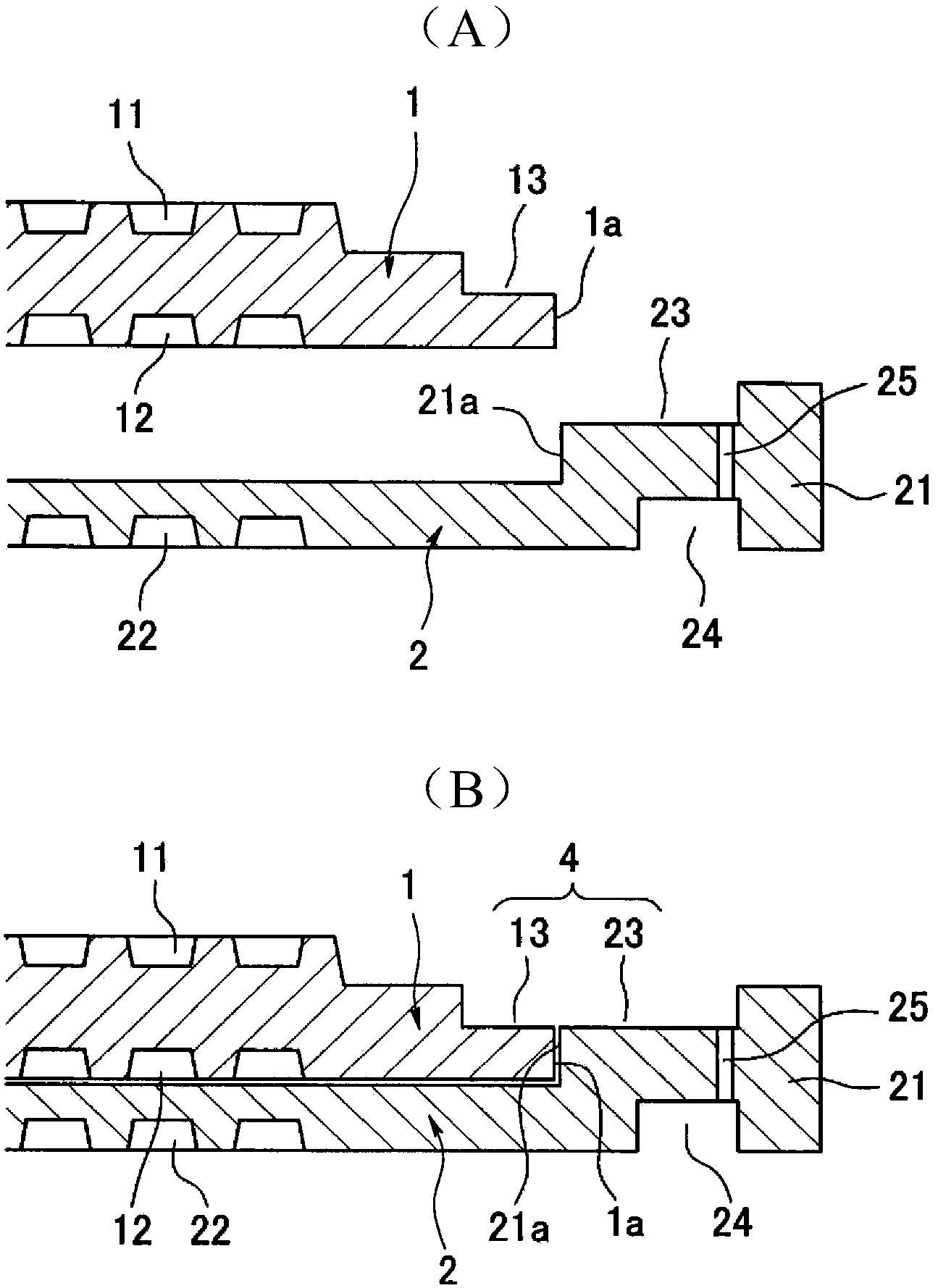

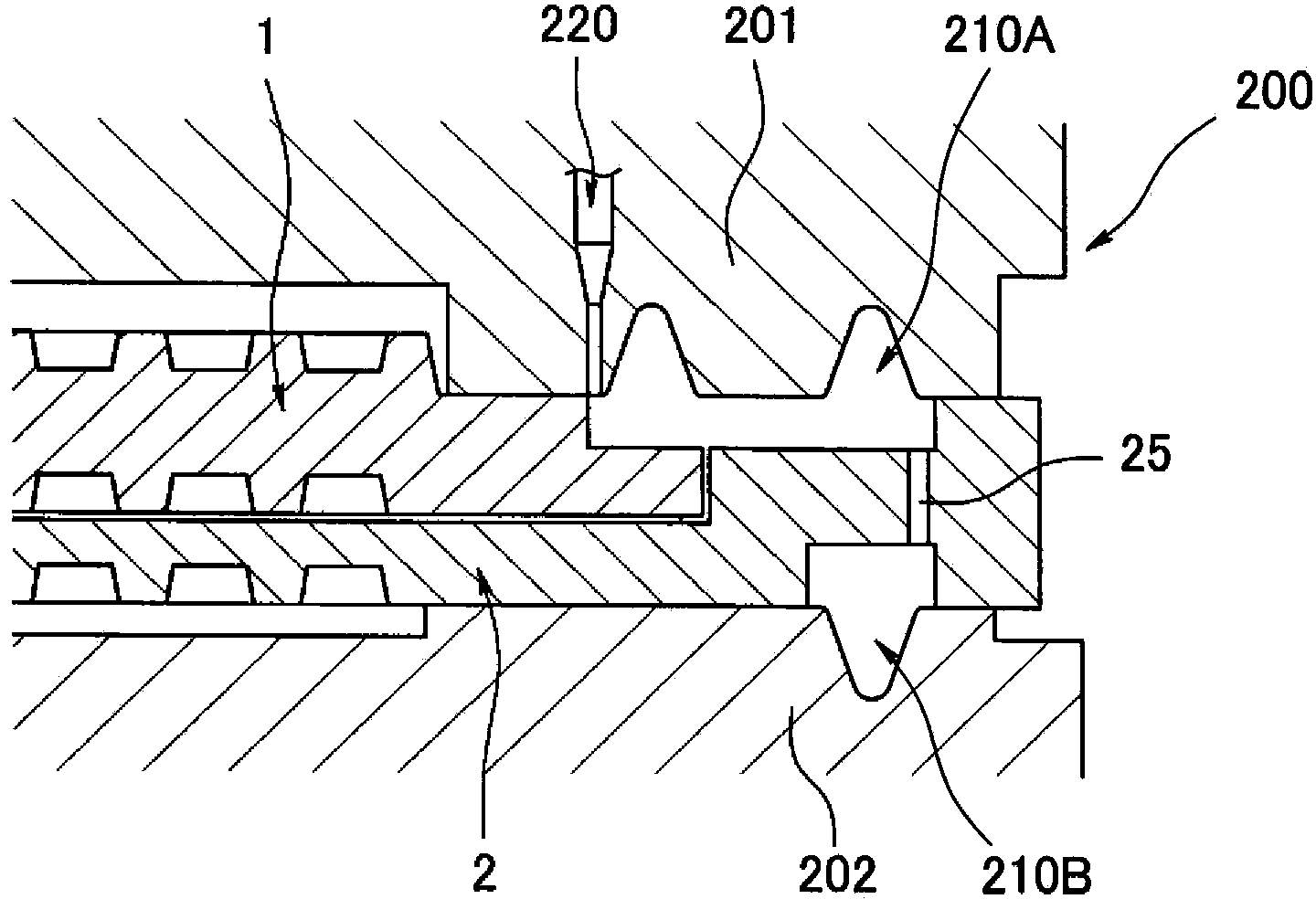

[0078] Hereinafter, preferred embodiments in which the plate-integrated gasket according to the present invention is applied to a fuel cell gasket will be described in detail with reference to the drawings.

[0079] first, figure 1 It is a view showing a double-sided lip gasket for a fuel cell as a first embodiment. In this sealed structure, reference numerals 1 and 2 are respectively plate-shaped separators made of a conductive material such as carbon, and correspond to the plate material described in claim 1 . The separators 1 and 2 are stacked on top of each other, and at the same time, the outer peripheral surface 1a of the upper first separator 1 in the figure fits into the stepped surface formed along the outer peripheral portion 21 of the lower second separator 2 toward the inner peripheral side. 21a.

[0080] The first flow path groove 11 is formed on the upper surface of the first separator 1 , and the second flow path groove 12 is formed on the opposite surface, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com