Copper cooling wall with reinforced piping structure

A technology to strengthen the structure and stave, applied in the direction of cooling device, furnace cooling device, furnace cooling, etc., can solve the problems of reducing the overall strength of the copper stave, the depth of the welding groove is not deep enough, and cracks are easy to occur, so as to control the manufacturing cost , Improve the stress situation and avoid the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

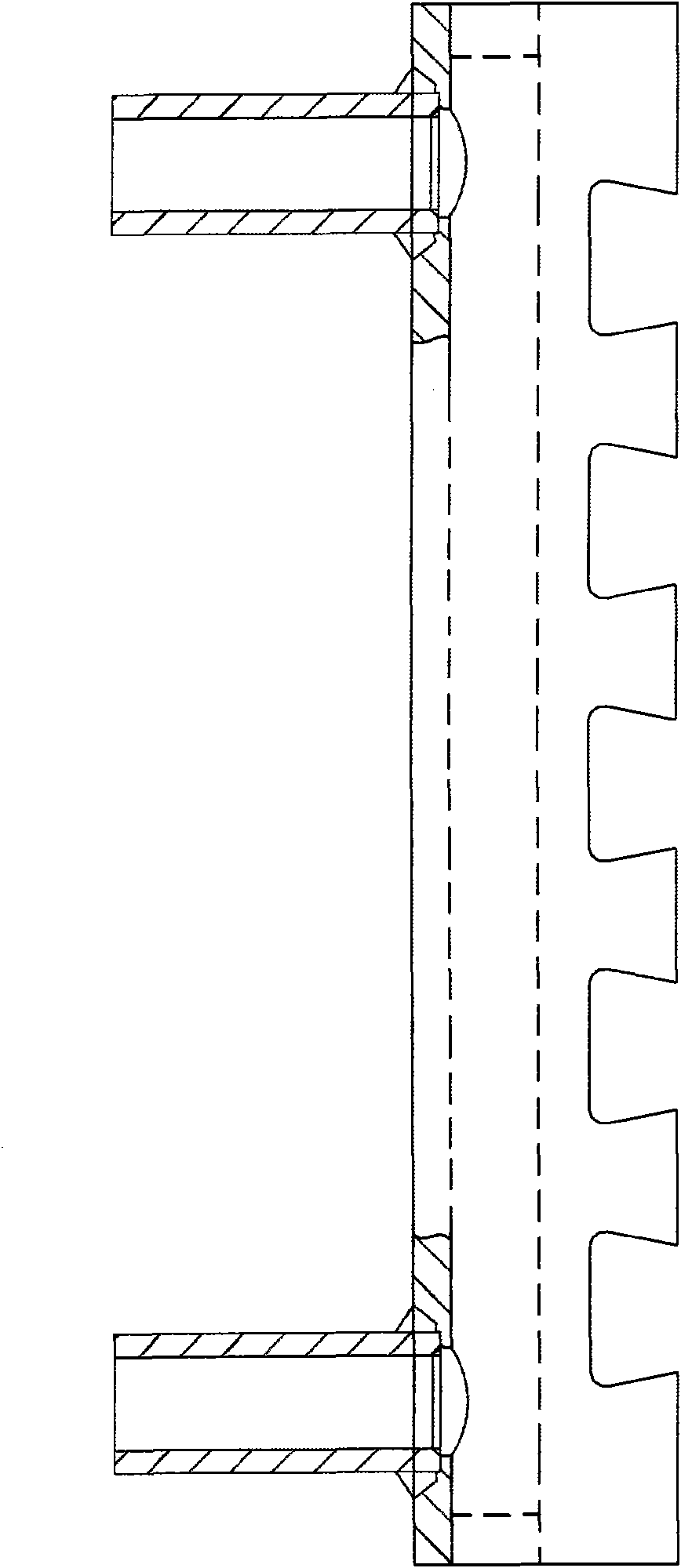

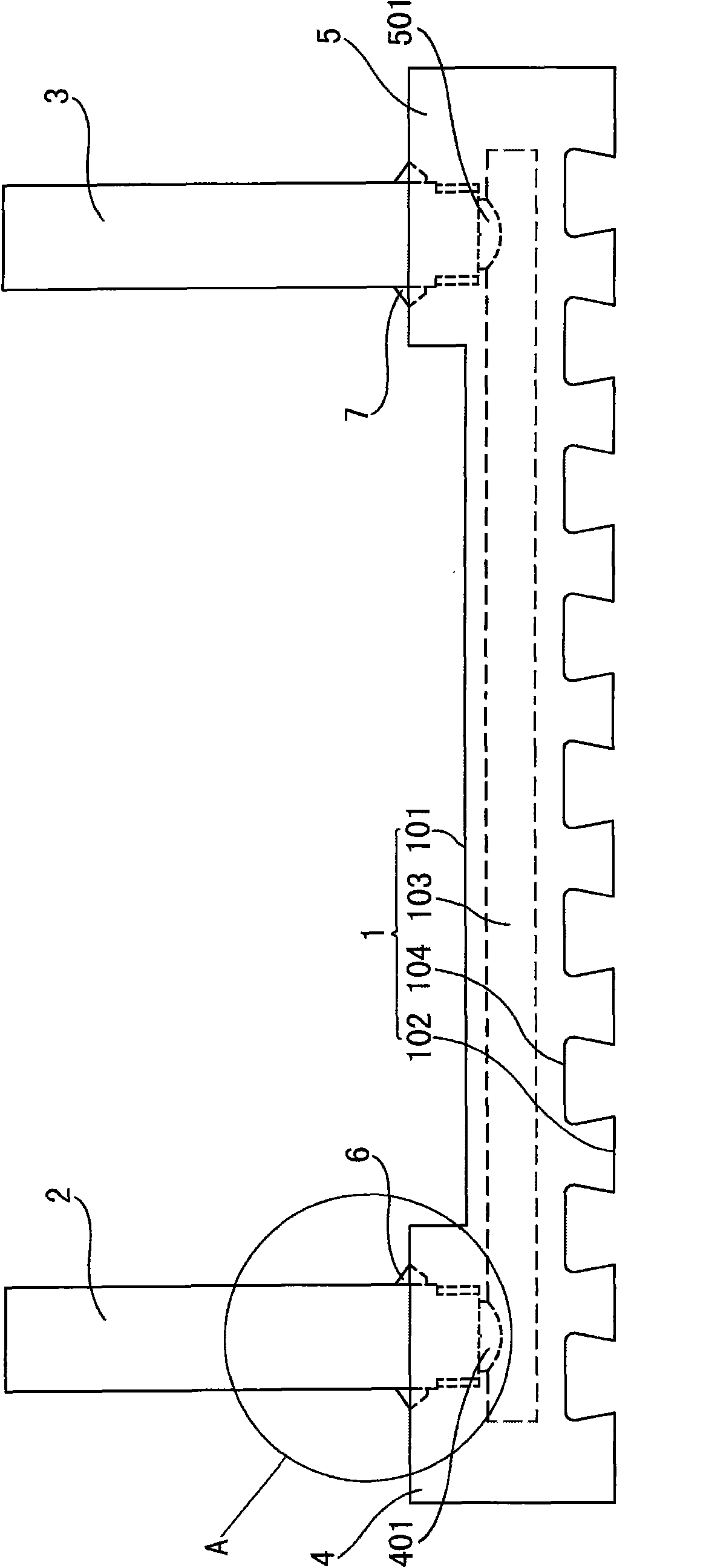

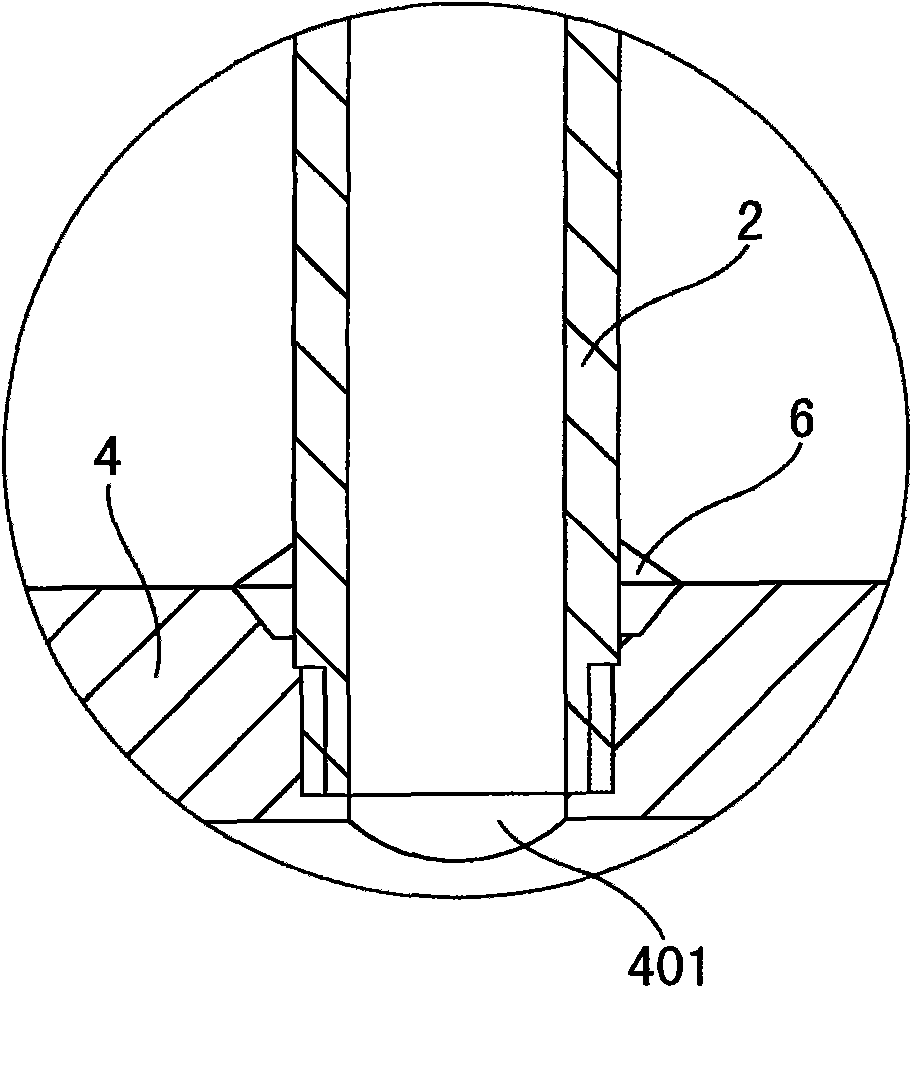

[0026] Such as Figure 2-4 As shown, a copper stave with pipe strengthening structure in this embodiment includes a copper stave body 1, three water inlet pipes 2 and three water outlet pipes 3, and three cooling water passages 103 are opened in the copper stave body 1 to feed Water pipe 2 connects the inlet of corresponding cooling water channel 103 on the cold surface 101 of copper stave body 1, and water outlet pipe 3 connects the corresponding cooling water channel 103 outlet on the cold surface 101 of copper stave body 1, and the heat of copper stave body 1 The surface 102 is provided with at least two dovetail grooves 104 parallel to each other for hanging slag, and also includes protrusions. The bumps include a first bump 4 and a second bump 5, the first bump 4 is arranged on the cold surface 101 of the copper stave body 1, and the first bump 4 is located above the inlet of the cooling water channel 103, The first bump 4 is provided with a first connecting hole 401 tha...

Embodiment 2

[0034] Such as Figure 5 As shown, the difference between the copper stave of a kind of pipe reinforcement structure in this embodiment and embodiment 1 is:

[0035] The distance from the cold surface 101 of the copper stave body 1 to the cooling water channel 103 is 15 mm.

[0036] The first protruding block and the second protruding block are integrated to form a complete protruding block without a groove. There is also no dovetail on the hot side. The disadvantage of this solution is that it consumes more copper, so the cost is higher.

Embodiment 3

[0038] The difference between the copper stave of a pipe strengthening structure in the present embodiment and the embodiment 1 is:

[0039] The first bump 4 and the second bump 5 are respectively connected to the copper stave body 1 by screws.

[0040] The distance from the cold surface 101 of the copper stave body 1 to the cooling water channel 103 is 25 mm.

[0041] The strength of the weld seam of this scheme is increased, but when the outside of the water inlet pipe 2 and the water outlet pipe 3 are subjected to external forces, due to the long-term stress between the first bump 4, the second bump 5 and the copper stave body 1, it is easy to If it is too large, gaps will appear, resulting in water leakage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com