Patents

Literature

67results about How to "Increase feed area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for breeding procambarus clarkii spring seedlings in pond

InactiveCN104206329AIncreased burrow areaIncrease feed areaClimate change adaptationPisciculture and aquariaStrawProcambarus clarkii

The invention provides a method for breeding procambarus clarkii spring seedlings in a pond. A pot bottom-shaped pond structure is replaced by a structure formed by a circular groove and a shallow, so that the enlargement of a burrowing breeding area of crawfish, the complete freezing-drying of the pond, the enlargement of a feeding area and the like are facilitated; a step-by-step precipitation method is used for guiding the burrowing overwintering and reproduction of the crawfish, and straws are used for preserving heat and protection against cold; aquatic plants are arranged in two stages, corrugated clay tile shelters are arranged among the aquatic plants, so that the perching area of the crawfish is enlarged, and fresh and tender green feeds are provided; fertilizers are applied to cultivate sufficient natural bait organisms in three stages to ensure the fertility of water in the pond, so that the rapid growth of the aquatic plants is facilitated, and sufficient high-quality natural biologic baits are cultivated for feeding the crawfish; the above measures have the advantages of strengthening the physique of the crawfish, increasing the overwintering survival rate of the crawfish, reducing the probability of cannibalization of the seedlings, increasing the proportion of the spring seedlings, improving the specification uniformity of the seedlings and the like, and are significant for improving the unit breeding yield and economic benefits of the pond.

Owner:MINGGUANG YONGYAN AQUATIC GROUP CORP

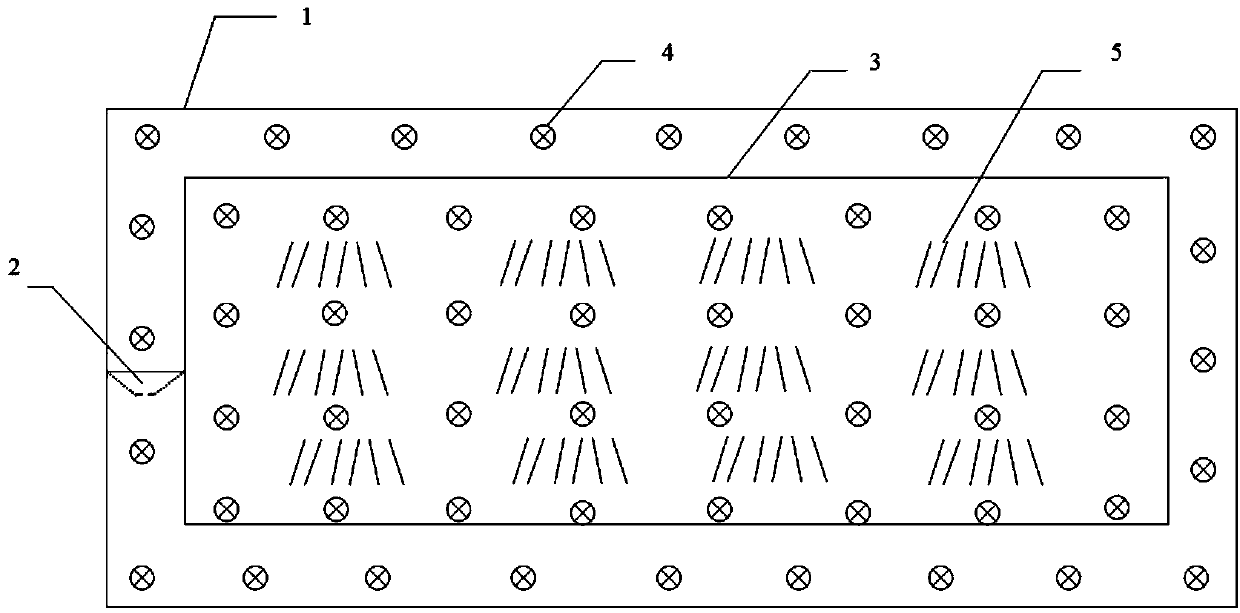

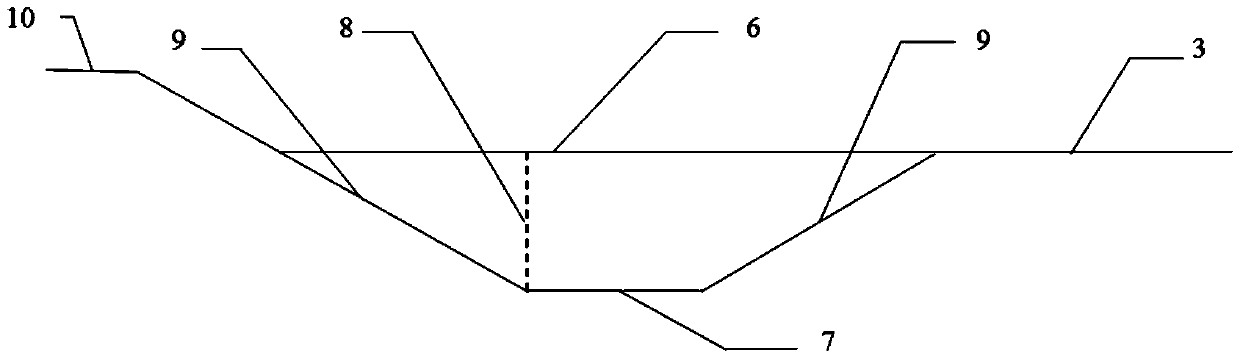

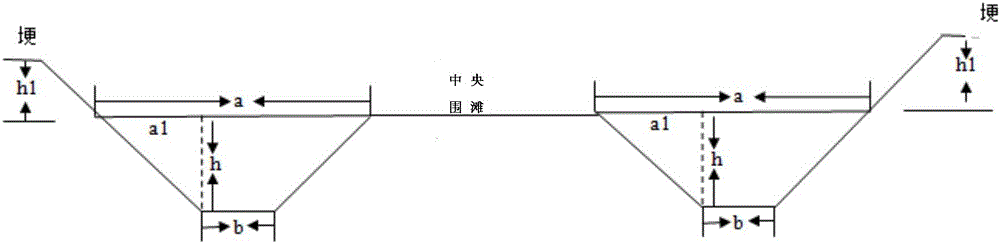

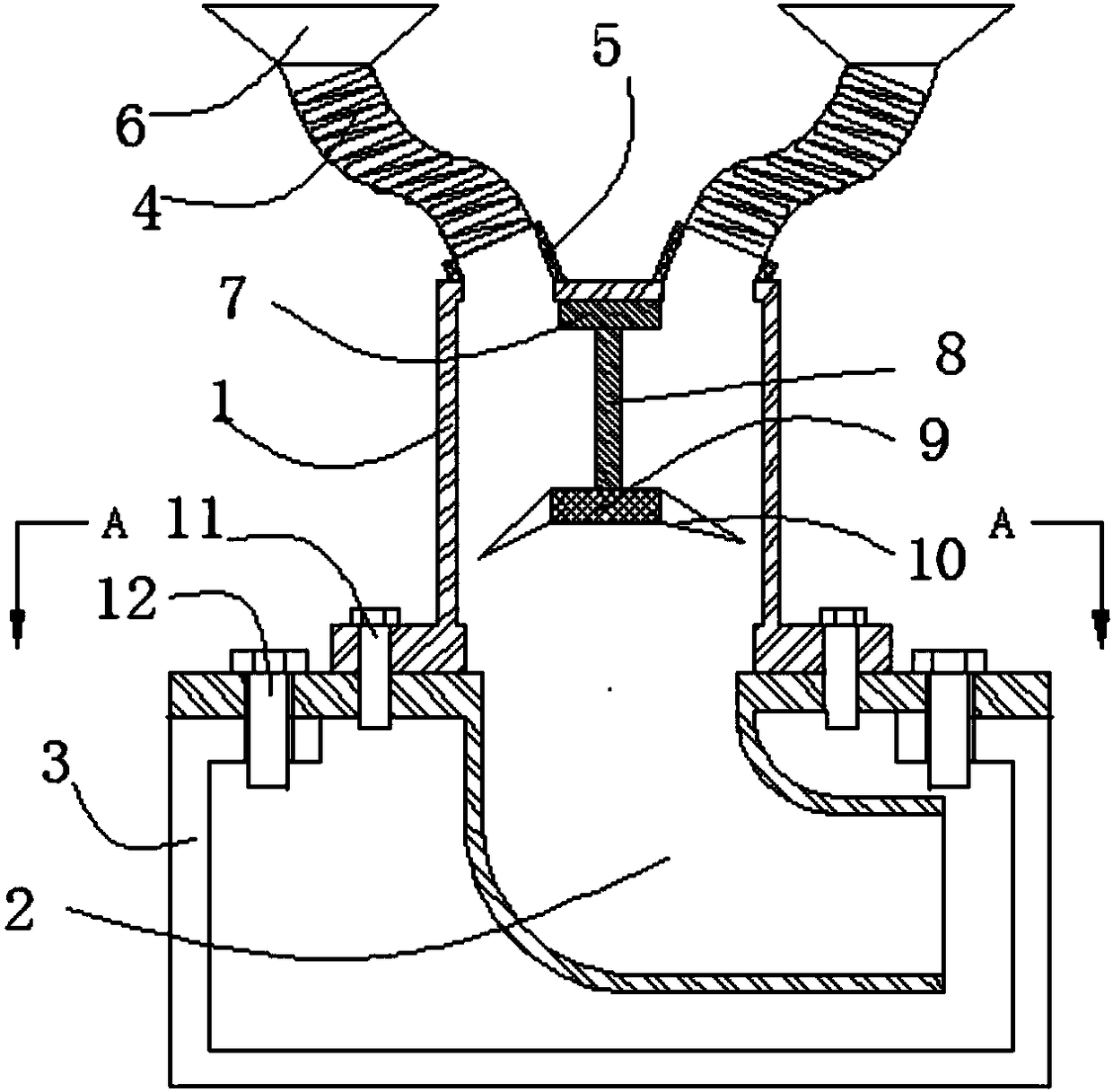

Breeding method and pond for improving commercial specification and yield of procambarus clarkii in pond

ActiveCN105994027AEasy plantingIncrease coverageClimate change adaptationPisciculture and aquariaShrimpProcambarus clarkii

The invention provides a breeding method and a pond for improving the commercial specification and the yield of procambarus clarkii in the pond. The breeding method comprises the following steps: drying the pond under the sun; putting young procambarus clarkii into the pond for the first time; performing catch rotation on commercial procambarus clarkii for the first time; putting young procambarus clarkii into the pond for the second time; performing catch rotation on commercial procambarus clarkii for the second time; and thoroughly draining water of the pond, and catching all commercial procambarus clarkii. The pond comprises a circular groove which is digged along the periphery of the pond, wherein the circular groove has an upper bottom width of 6 to 10 meters, a lower bottom width of 1 to 5 meters, a depth of 0.8 to 1 meter, a ridge height of 0.8 to 1 meter and a slope ratio of 1: 3; the area of the circular groove accounts for 20 to 30% of the total area of the pond; the a region, located at the inner side of the circular groove, of the pond is piled with a central enclosed beach; and the distance between the water level of the pond and the central enclosed beach is in a range of 10 to 70 cm. The invention has the following beneficial technical effects: by adopting the method provided by the invention, 200 to 250 kg of commercial procambarus clarkii can be harvested in two seasons, wherein the proportion of the commercial procambarus clarkii with a specification of 40 g or more reaches 60 to 70%.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

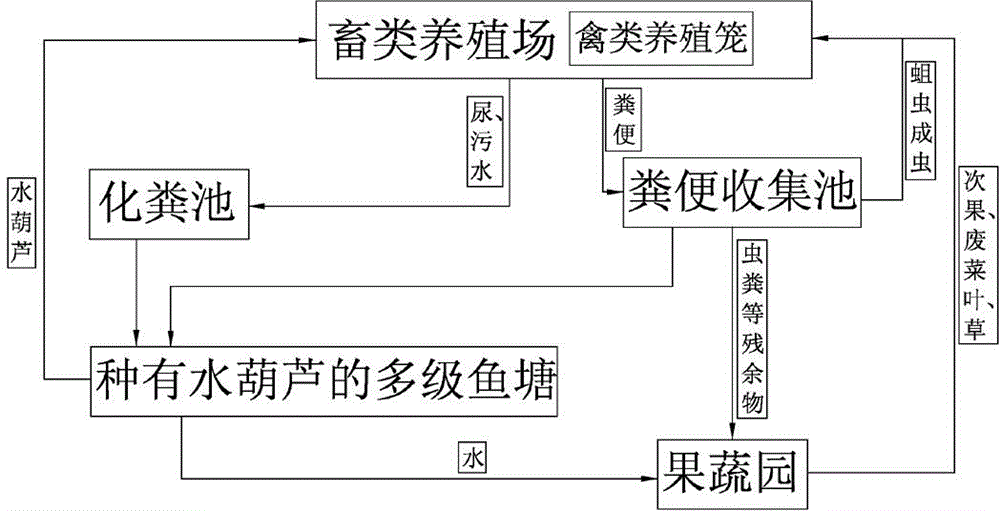

Poultry and livestock ecological cycle raising system and raising method

InactiveCN104396825AAchieve recyclingIncrease the feeding areaClimate change adaptationAnimal feeding stuffAnimal scienceOperation mode

The invention provides a poultry and livestock ecological cycle raising system, which comprises a poultry and livestock raising farm and an excrement collecting pool, wherein flyblows or hatched fly maggot larvas are inoculated in the excrement collecting pool, the fly maggot larvas are used as food of the poultry and livestock, frass is used as fertilizers of fruit and vegetable gardens, cull fruits, waste vegetables and the like of the fruit and vegetable gardens are used as food of the poultry and livestock, a septic tank is arranged under the tail end of a sewage discharging opening in the poultry and livestock raising farm, an outlet of the septic tank is communicated with a multiage fishpond, hydrophilous purification plants are planted in the multiage fishpond and are used as the food of the poultry and livestock, and water in the multiage fishpond is used for irrigating the fruit and vegetable gardens. Meanwhile, the raising system is adopted for carrying out a poultry and livestock ecological cycle raising method. The poultry and livestock ecological cycle raising system has the advantages that nutrient substances can be cyclically utilized between animals and plants, meanwhile, the self-sufficiency of the whole farm raising is realized, zero pollution and zero discharging are realized, in addition, the operation mode is simple, and the circulation speed is high.

Owner:建瓯市天牧泉养殖科技发展有限公司

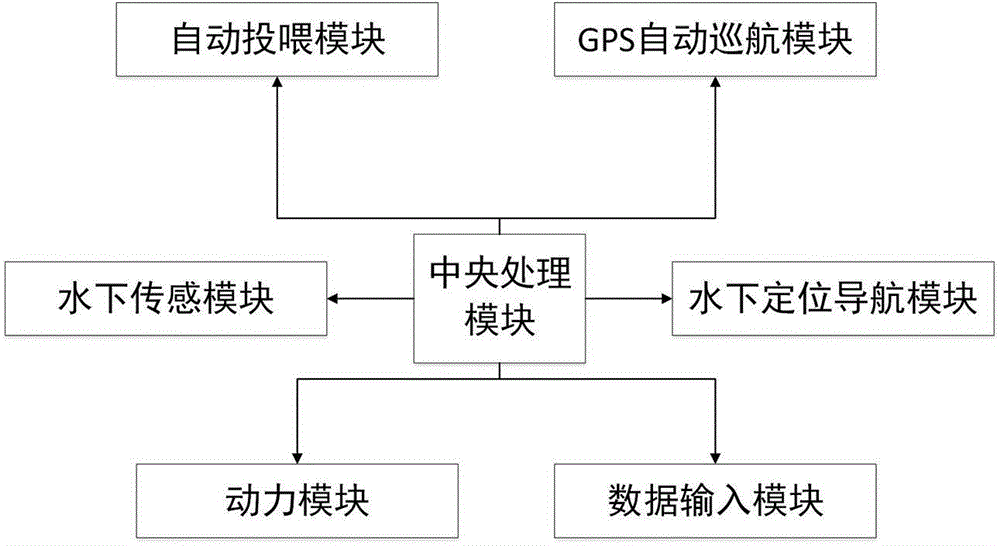

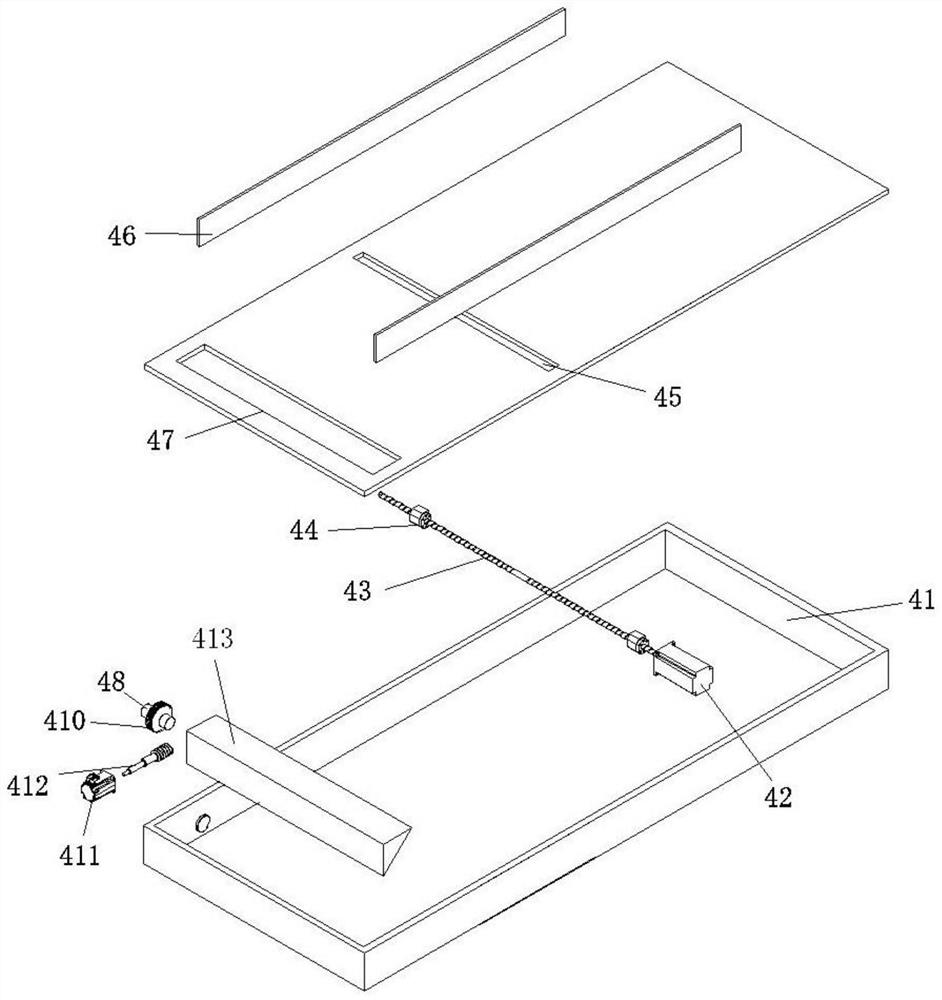

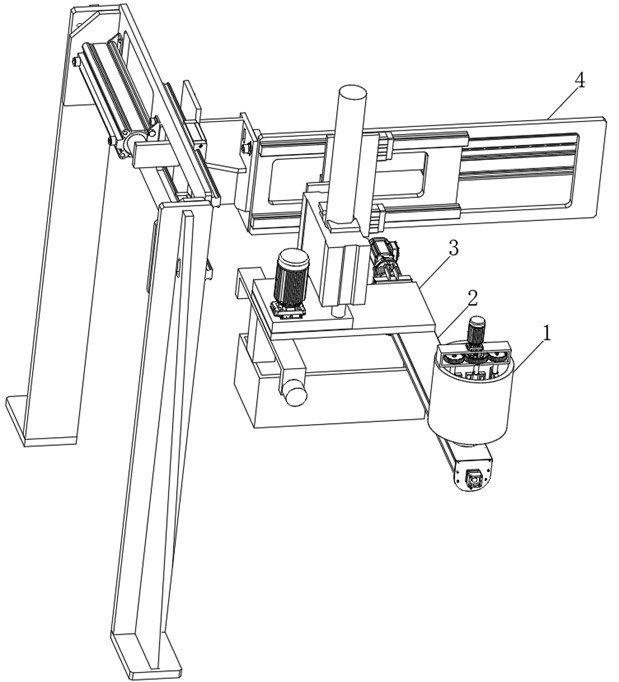

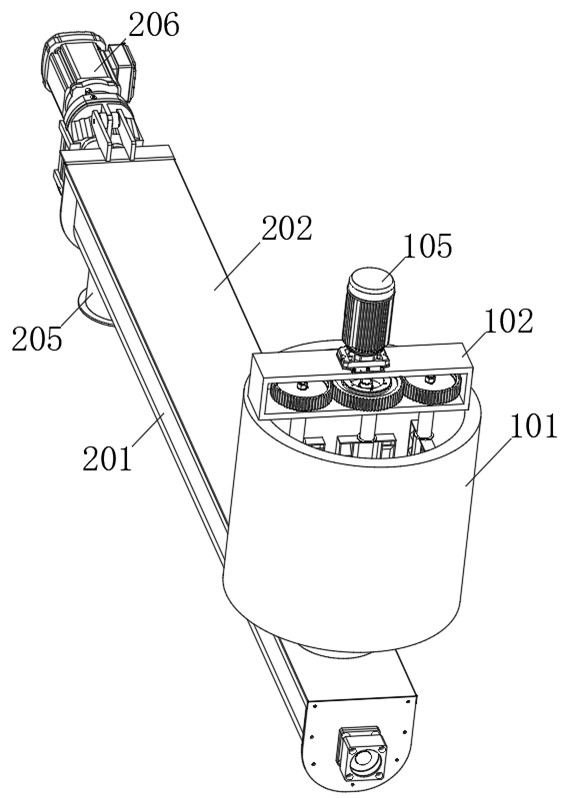

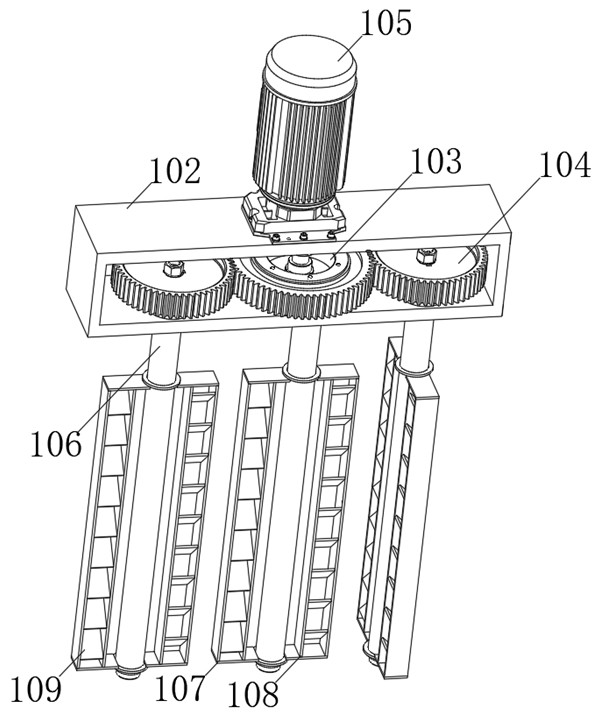

Novel automatic feeding system for aquaculture and implementation method thereof

InactiveCN105284694ASolve artificial feedingSolve the problems existing in the feeding of the bait feederPisciculture and aquariaComputer moduleEngineering

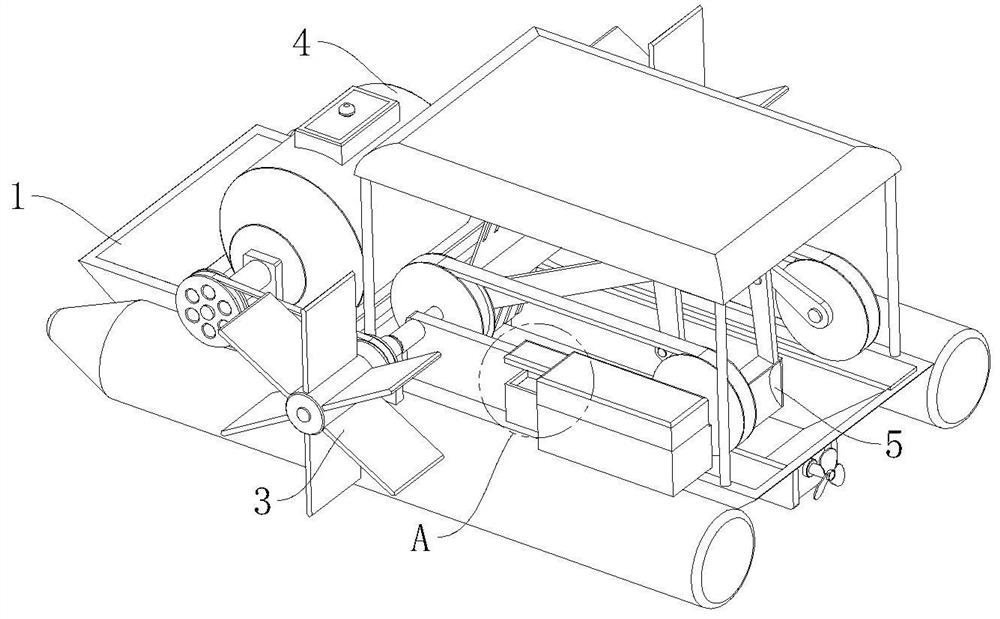

The invention relates to a novel automatic feeding system for aquaculture and an implementation method thereof. The novel automatic feeding system for the aquaculture comprises a feeding boat, a central processing module arranged on a boat body of the feeding boat, an automatic feeding module, a GPS automatic cruise module, an underwater positioning and navigating system, an underwater sensing module, a power module and a data input module, and the automatic feeding module, the GPS automatic cruise module, the underwater positioning and navigating system, the underwater sensing module, the power module and the data input module are connected with the central processing module. By means of the novel automatic feeding system for the aquaculture and the implementation method thereof, the purposes of being complete in bait, uniform in feeding, large in bait feeding area, suitable for various ponds and cultured objects can be achieved.

Owner:FUJIAN YUJIAAO CULTURE TECH CO LTD

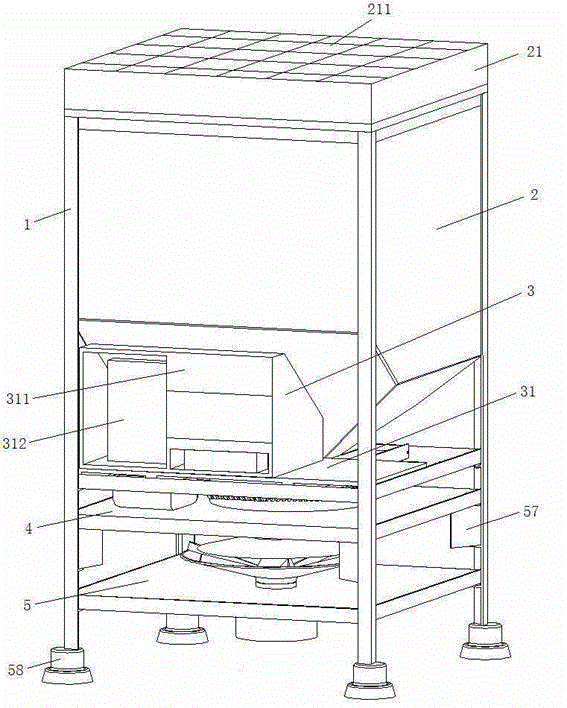

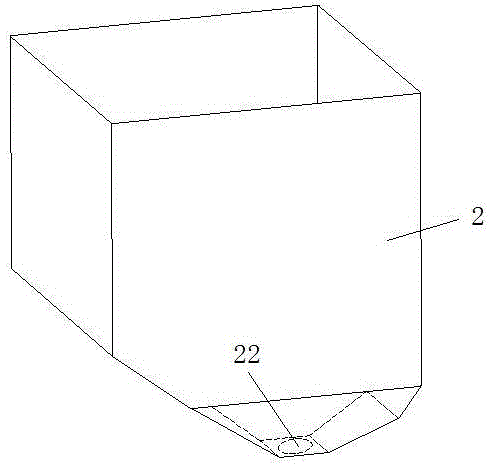

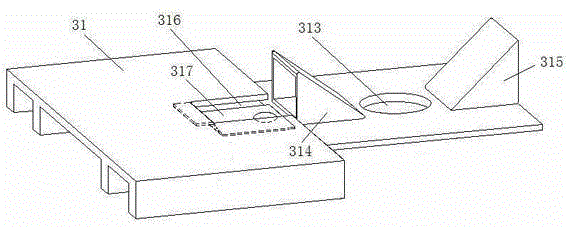

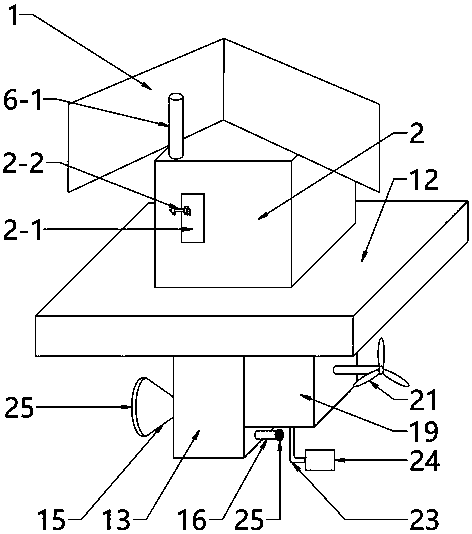

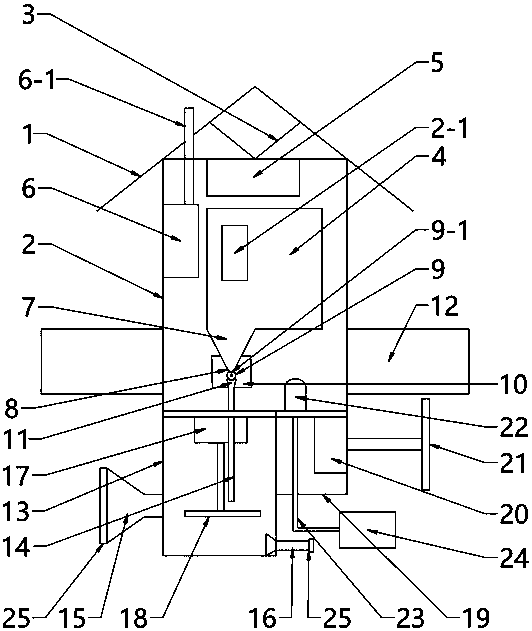

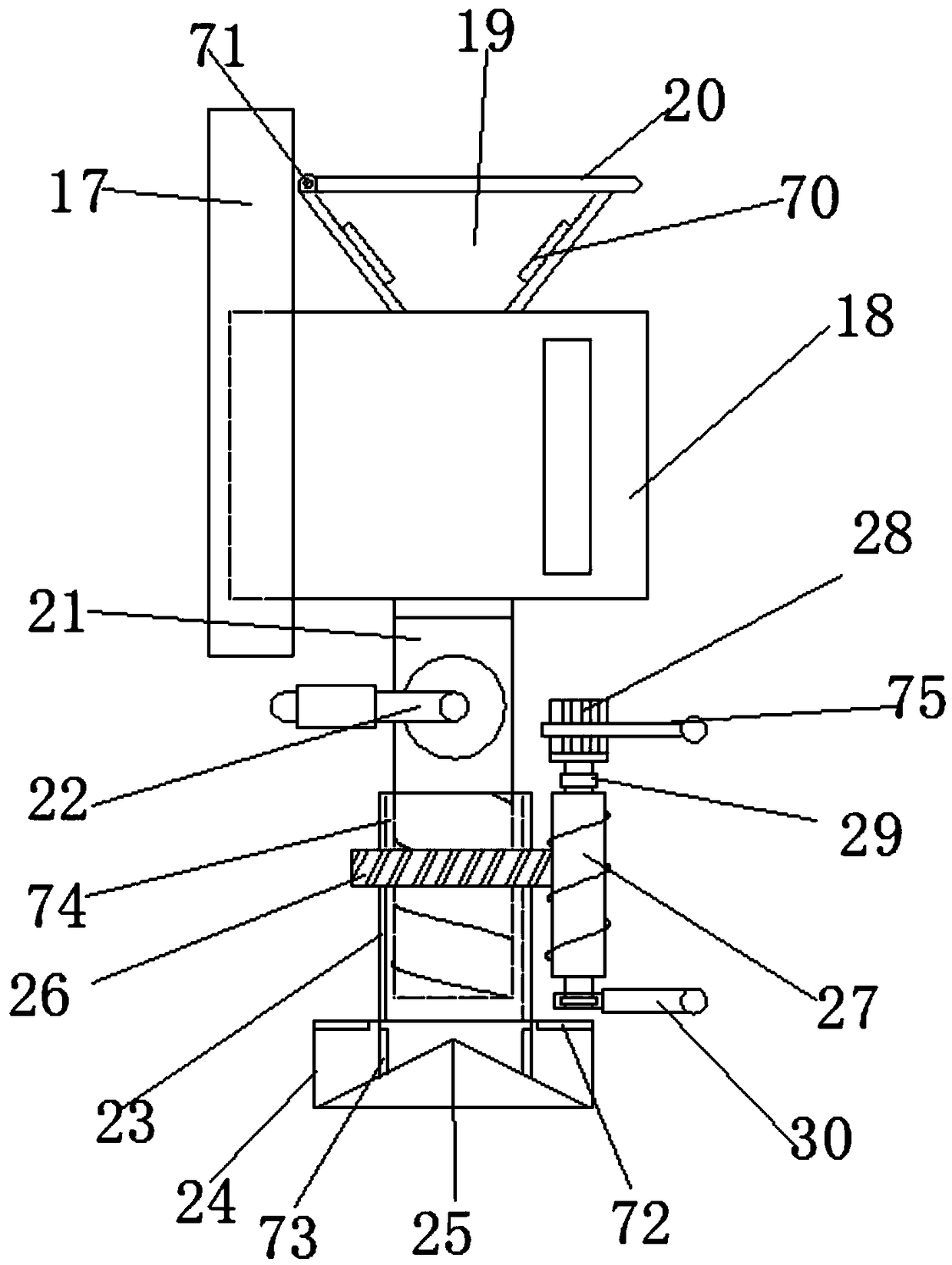

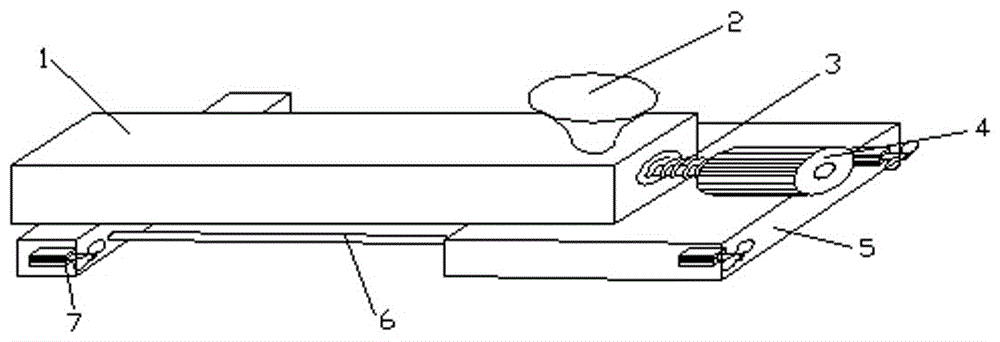

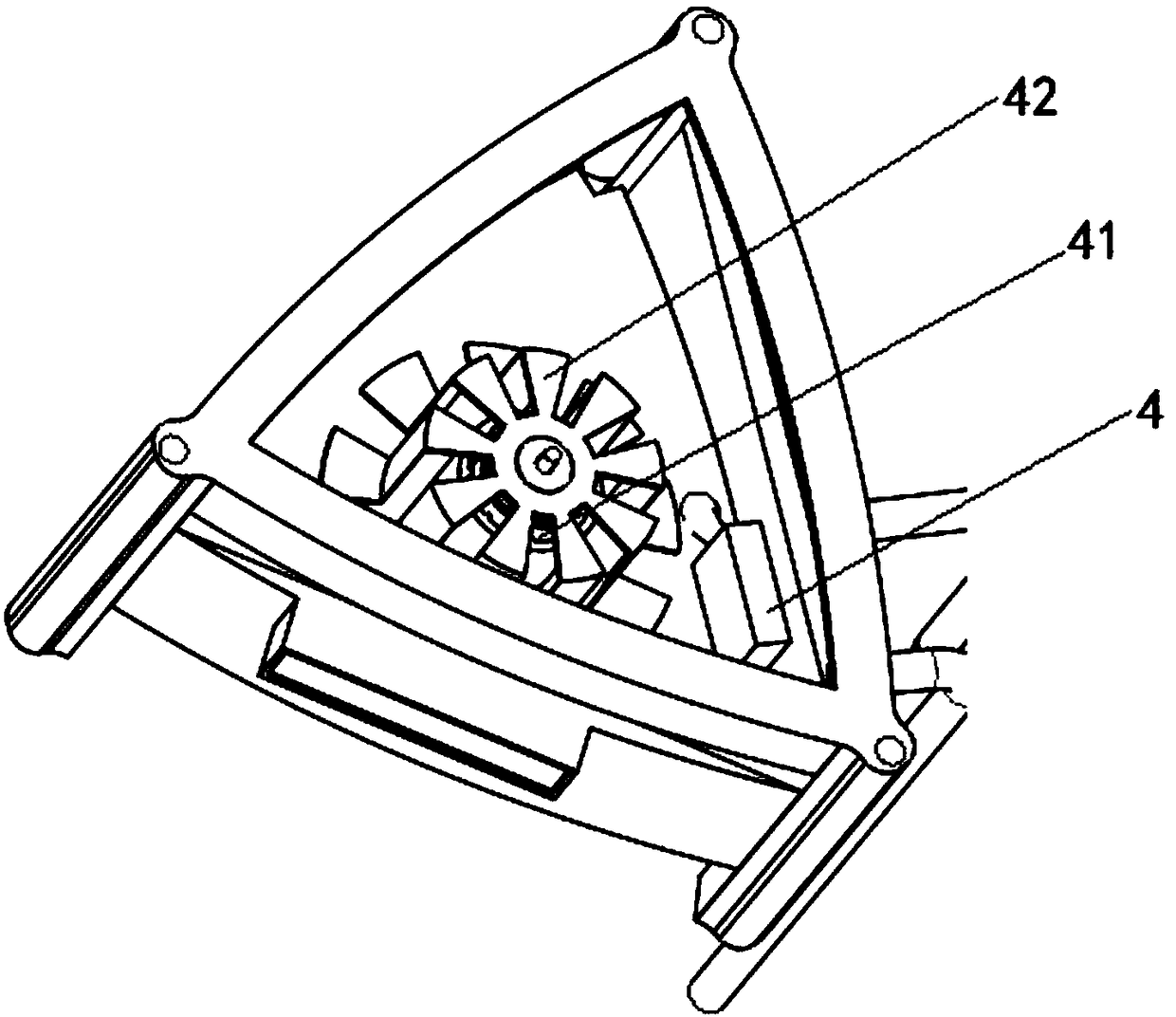

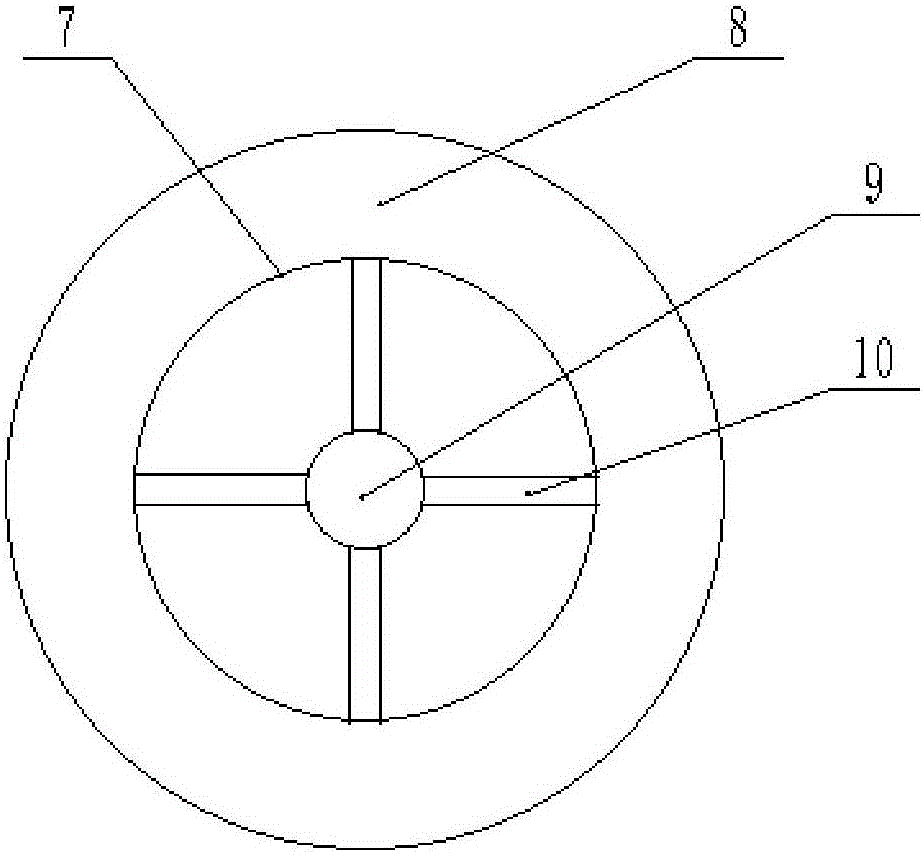

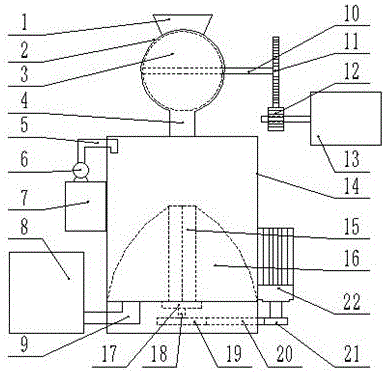

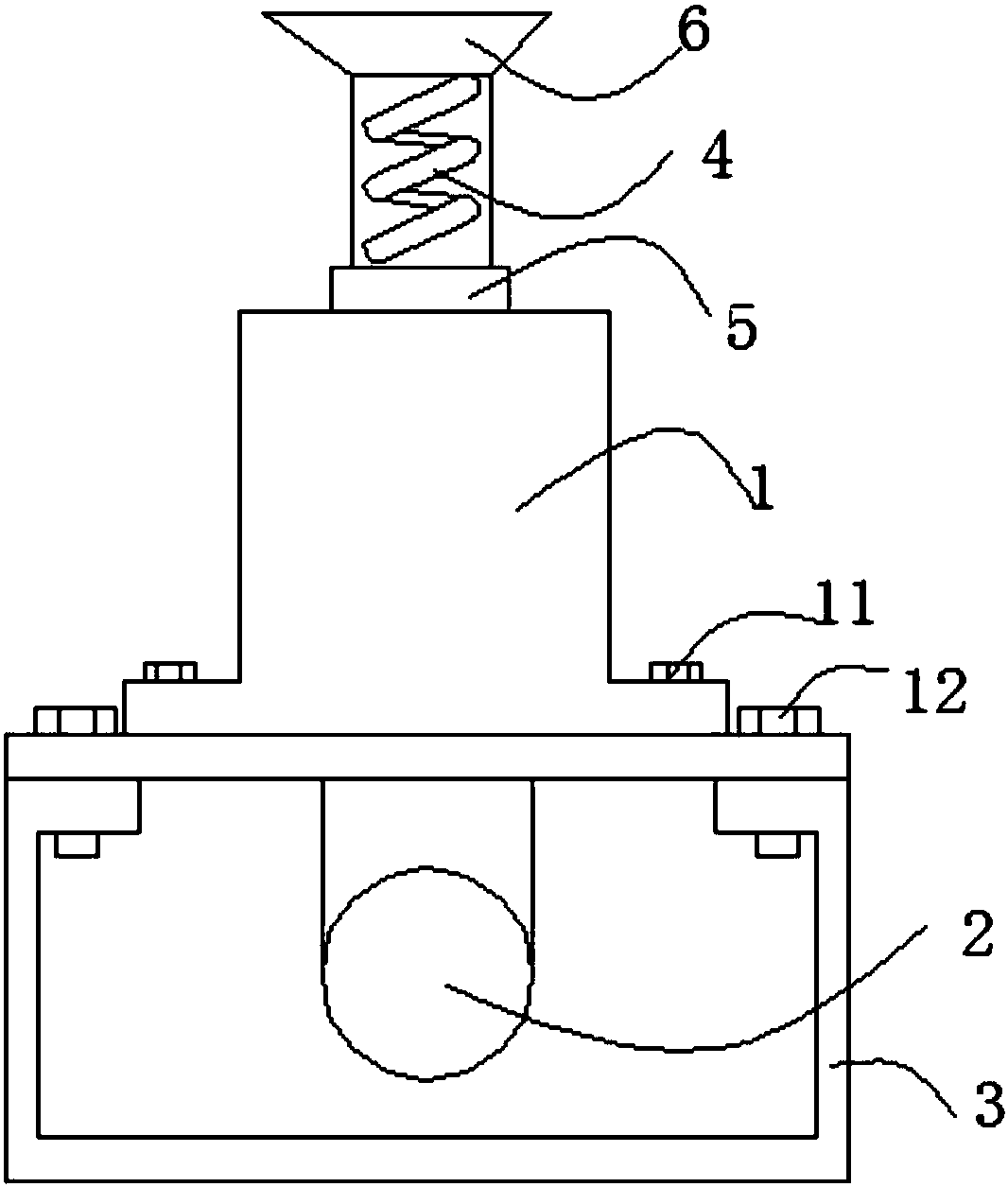

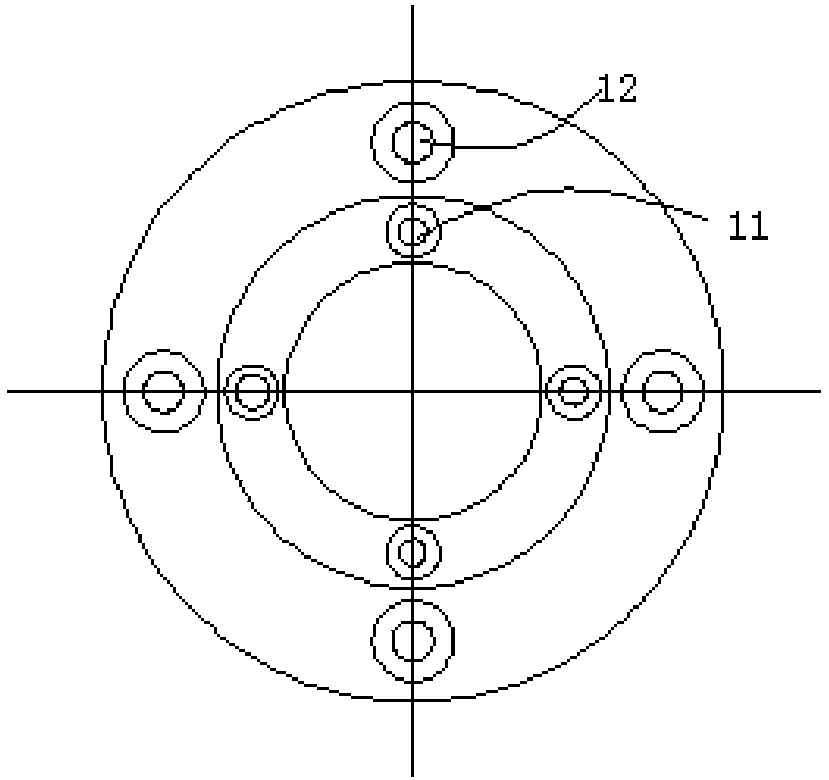

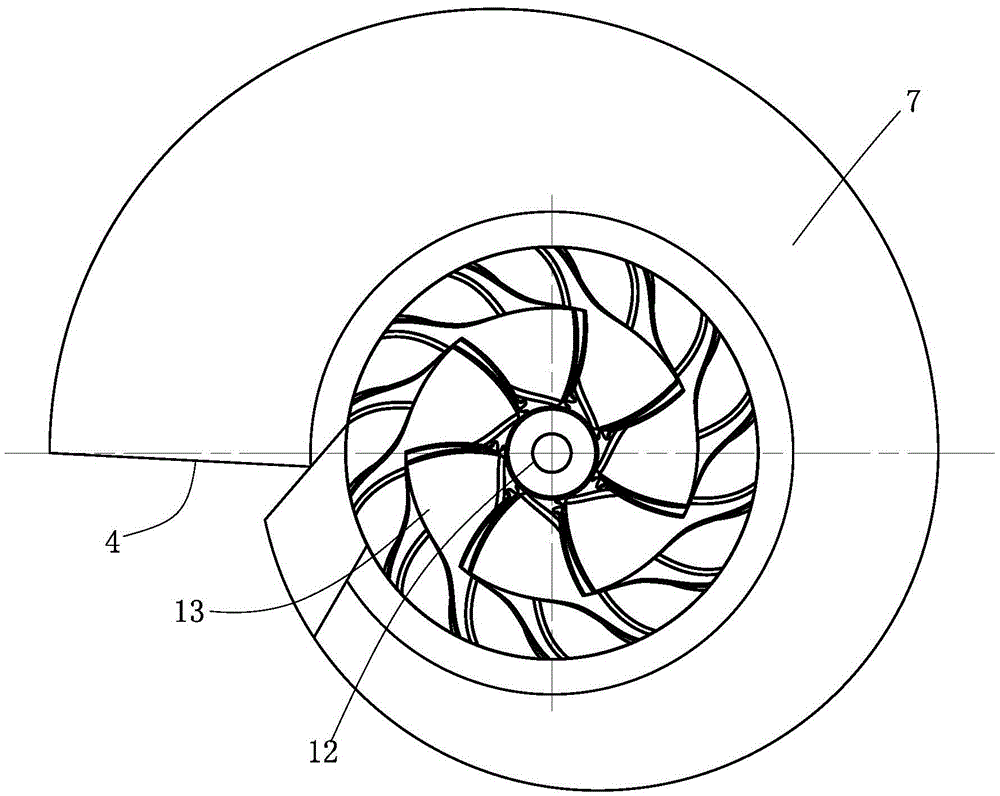

Feeding machine capable of throwing bait for 360 degrees

ActiveCN104782551AIncrease centrifugal forceIncrease feed areaClimate change adaptationAgricultural fishingEngineeringSolar cell

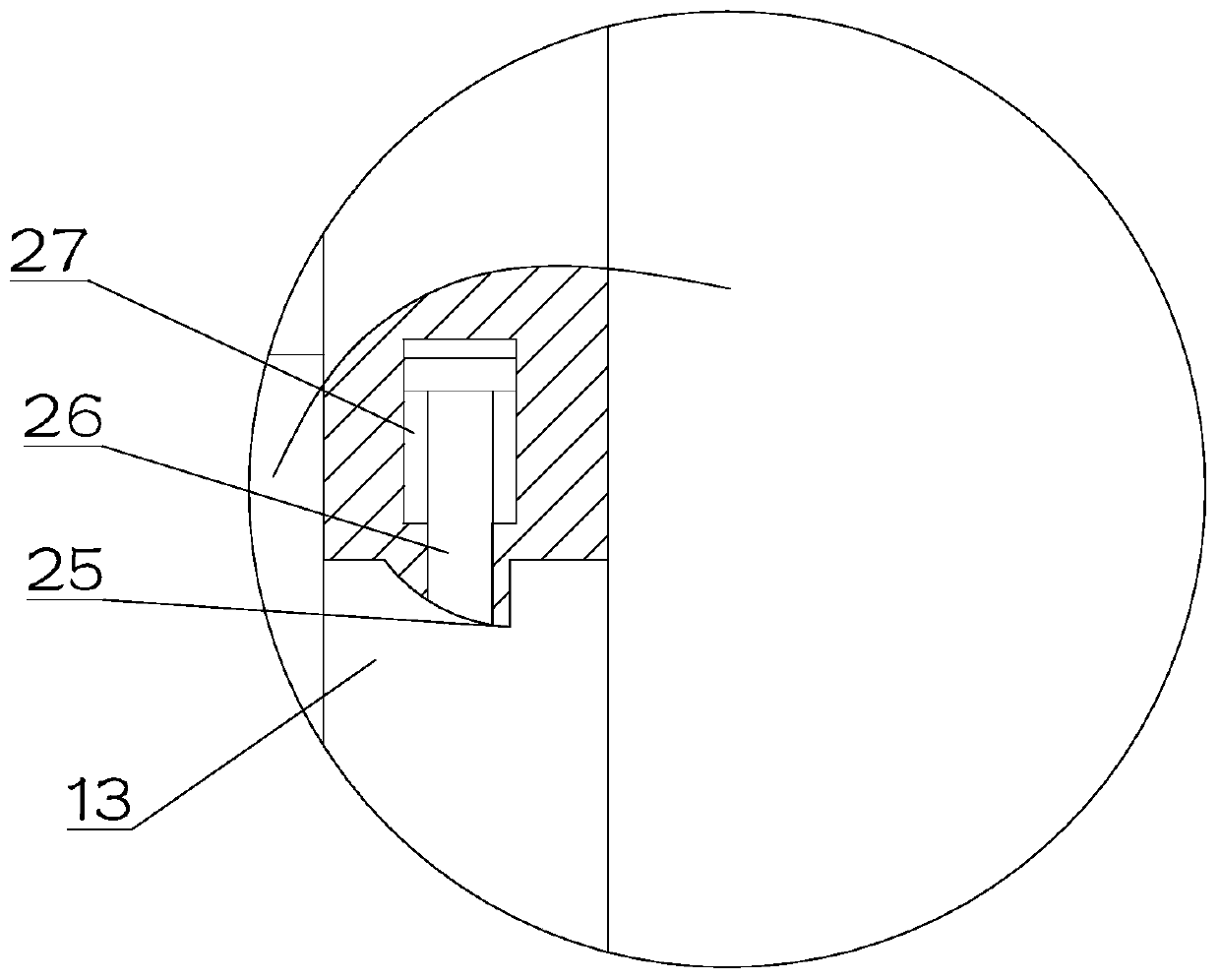

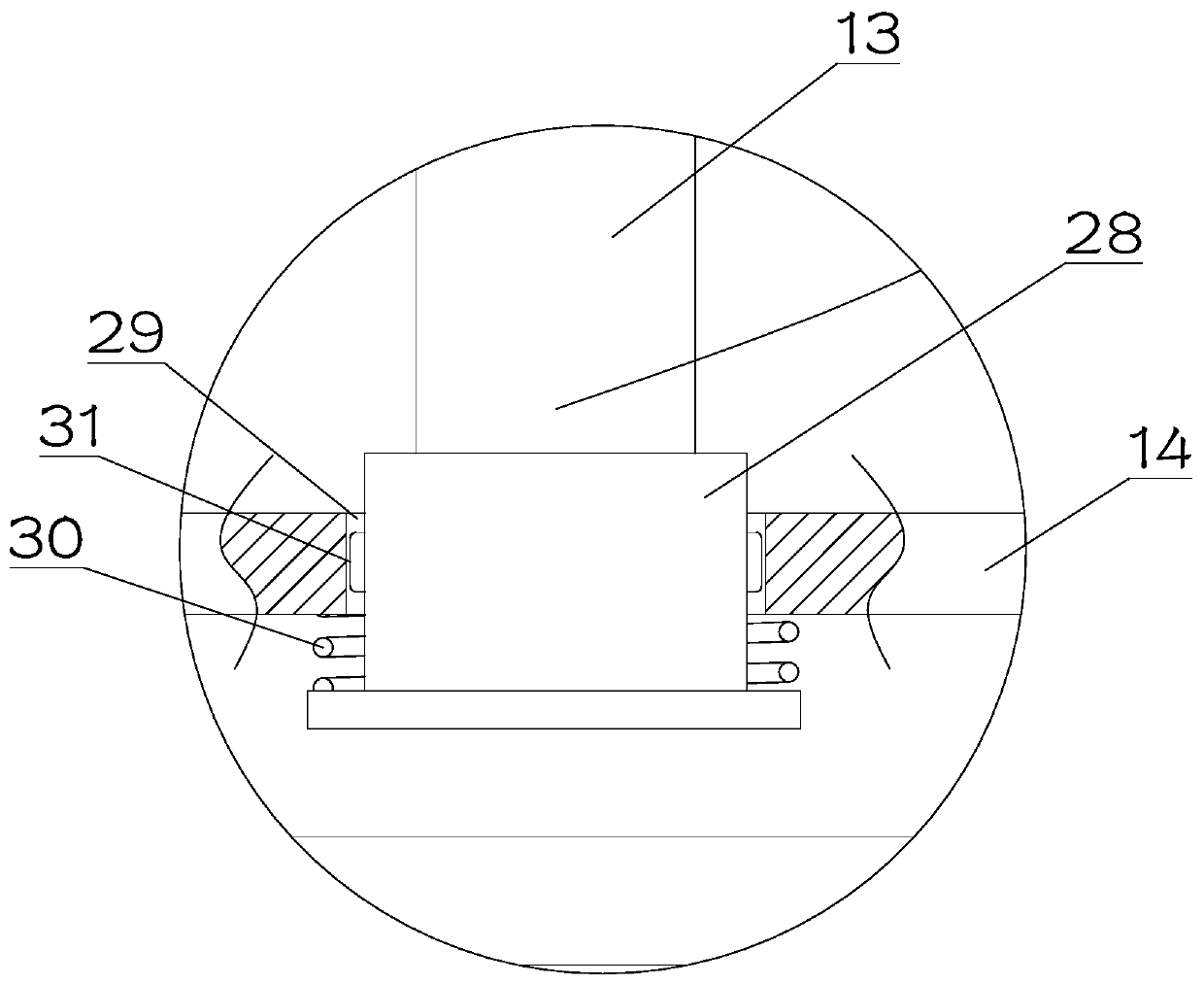

A feeding machine capable of throwing bait for 360 degrees comprises a rack. A bait box, a control box, a feeding box and a bait throwing layer are arranged in the rack in sequence from top to bottom, one side of the upper port of the bait box is hinged to an upper cover with a solar cell panel, the lower end of the bait box is a hopper shaped like an inverted trapezoid, a discharge port is formed in the bottom of the bait box, a base plate of the control box is shaped like a ladder, a control box body and a storage battery are arranged on the high-end of the base plate of the control box, the low-end of the base plate of the control box is provided with an upper discharging hole, a left bait box supporting seat and a right bait box supporting seat, a mounting hole with a bait pressing spring piece is formed in the high-end, a circular groove is formed in the upper end face of a feeding box base plate of the feeding box, the inner bottom face of the groove is provided with a center hole with an inner thread, a lower discharging hole and a feeding plate, the upper end face of the feeding box base plate is further provided with a feeding plate electric motor, an output shaft of the feeding plate electric motor is provided with a worm, a lower discharging pipe and a bait throwing plate cover are arranged on the portion which is distributed with inner thread holes in the lower end face near the lower discharging hole, an assembly hole is formed in the upper end face of a bait throwing layer base plate of the bait throwing layer, the lower end face of the bait throwing layer base plate is provided with a bait throwing plate electric motor, and an output shaft of the bait throwing plate electric motor is provided with a bearing and a bait throwing plate in series. The feeding machine capable of throwing the bait for 360 degrees is suitable for throwing the bait in large areas of water.

Owner:SHANGHAI OCEAN UNIV

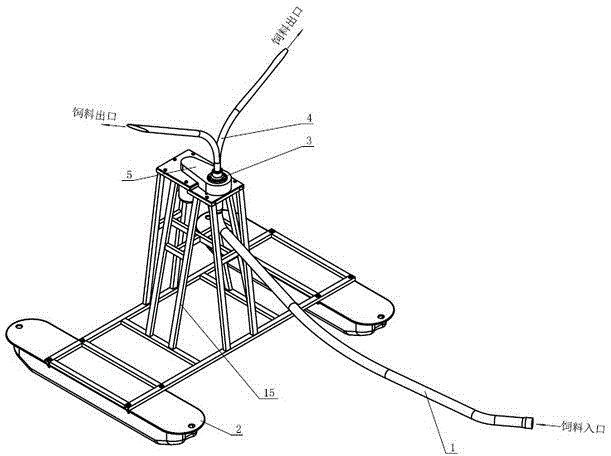

Pontoon-type powered rotary feed spreader

ActiveCN103548748ARealize long-distance transmissionNo damagePisciculture and aquariaWind drivenAquatic product

The invention relates to the field of aquatic feed feeding equipment, in particular to a pontoon-type powered rotary feed spreader, which comprises pontoons which are arranged at the bottom and a powered rotary feed spreading component which is fixedly arranged on the pontoons through a support. The powered rotary feed spreading component comprises a feed supply pipe, a powered rotary feed spreading device and a feed spreading pipe. The feed supply pipe is communicated with the feed spreading pipe through the powered rotary feed spreading device. The powered rotary feed spreading device drives the feed spreading pipe to rotate. The feed supply pipe supplies feed to the powered rotary feed spreading device and the feed spreading pipe through a wind-driven supply system. The powered rotary feed spreading device drives the feed spreading pipe to rotate to spread out the feed. The pontoon-type powered rotary feed spreader has the advantages that the pontoon-type powered rotary feed spreader floats on water for operation, the feeding position can be changed anytime, the spreader is not influenced by natural wind, the normal feeding operation can be ensured anytime, the effect of remote feed conveying is realized, the spreader can adapt to feeding of fish ponds with different sizes, the feed is spread uniformly and the feeding area is larger; the spreader is not required to be fixed through piling, the fishing operation is not influenced, the overall structure is simple and the effect is good.

Owner:CHENGDU TONGWEI AUTOMATION EQUIP

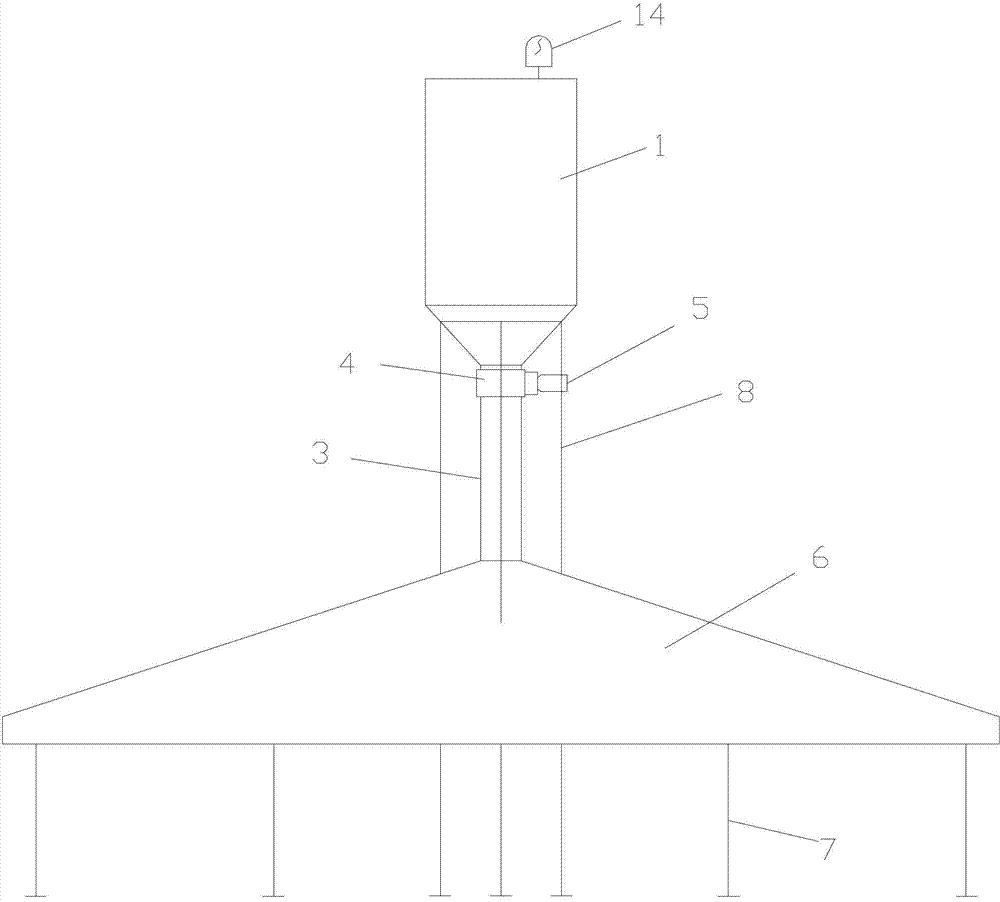

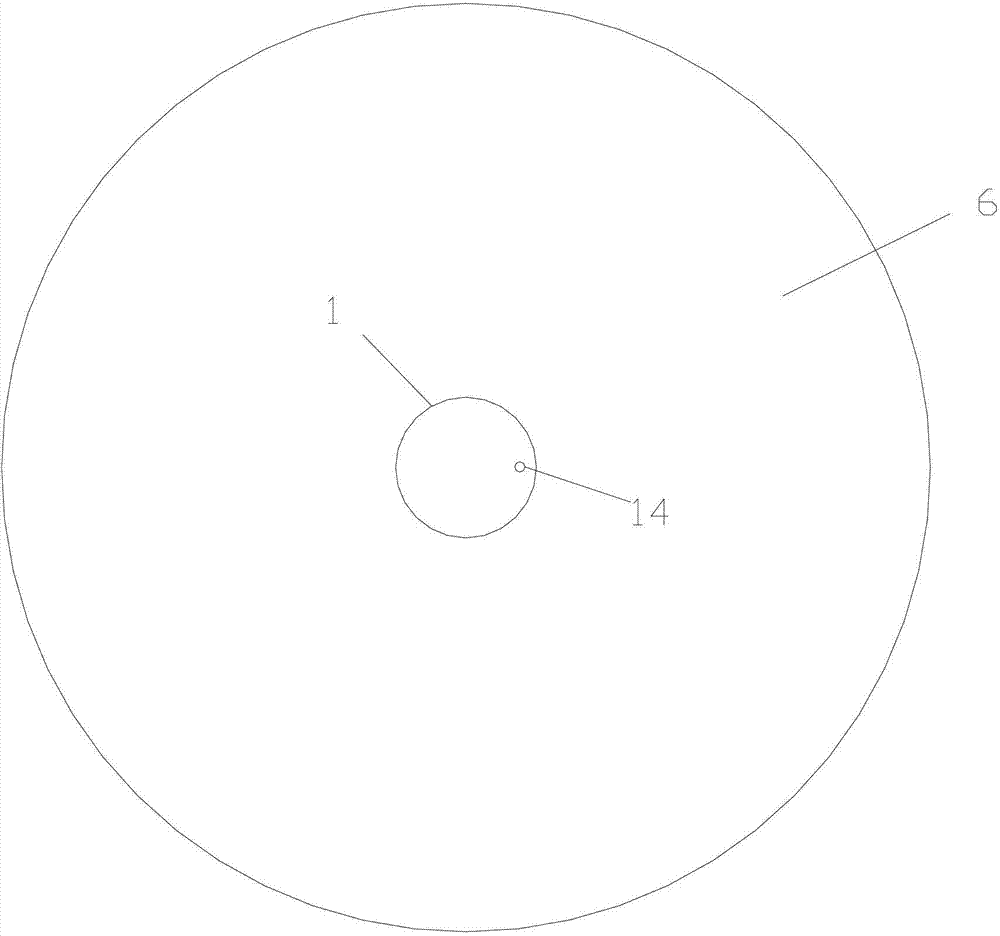

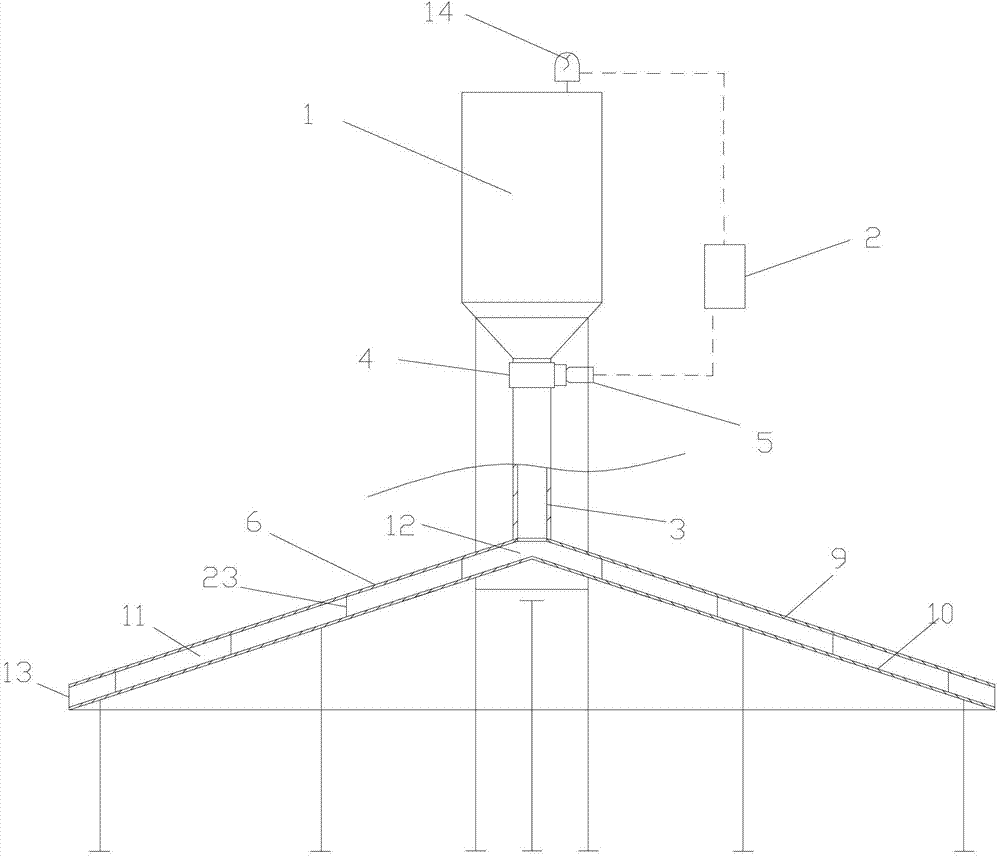

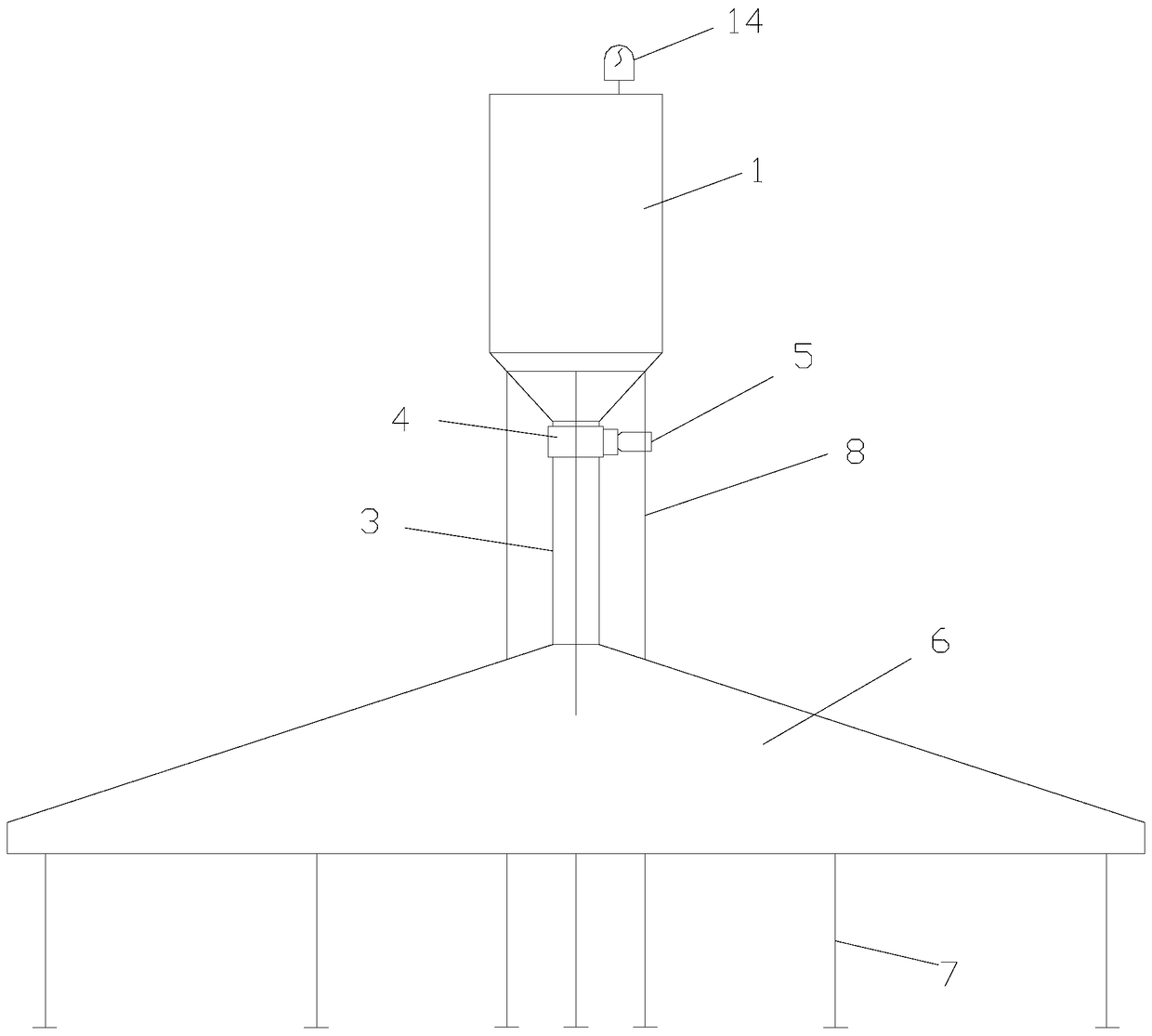

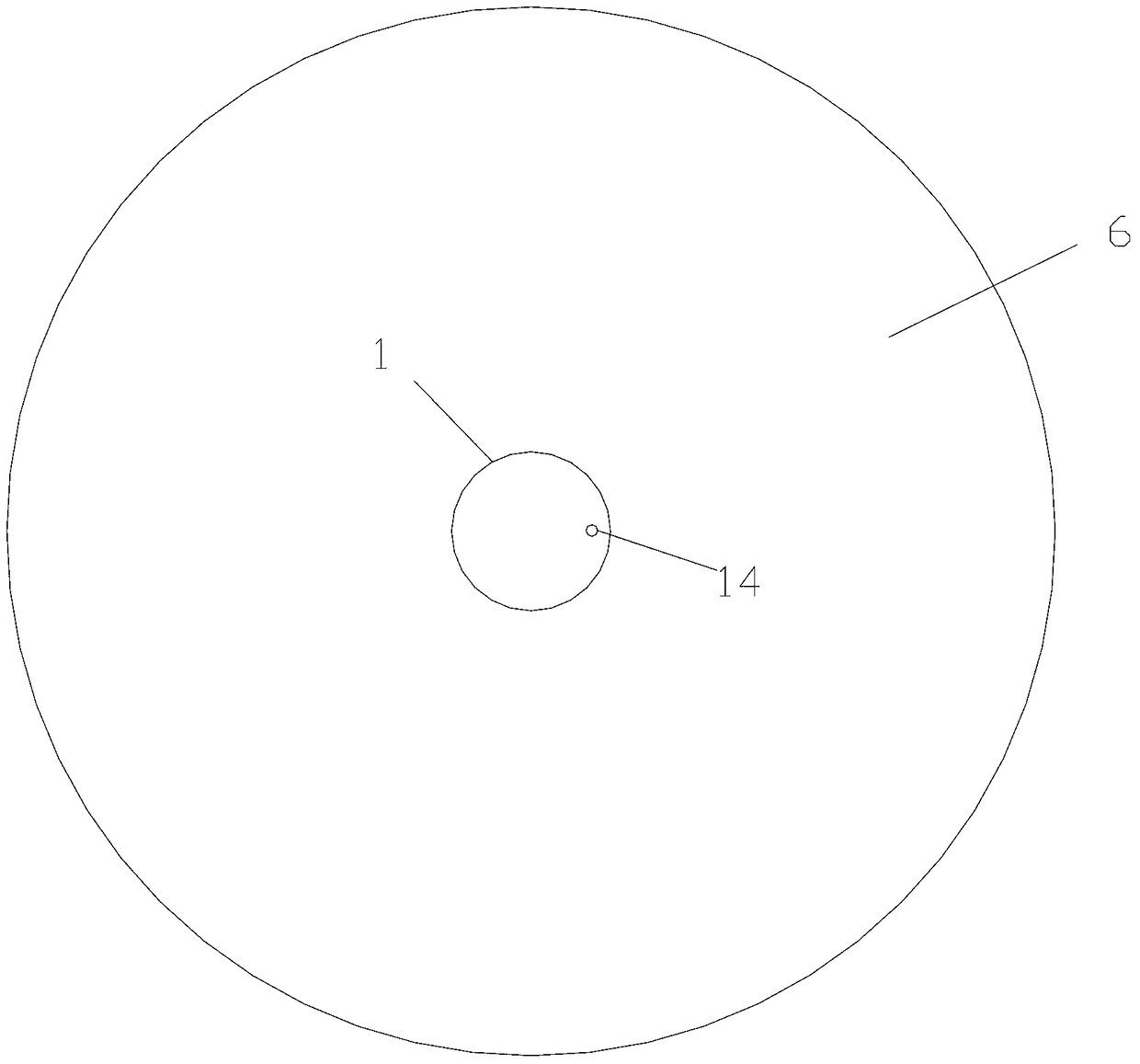

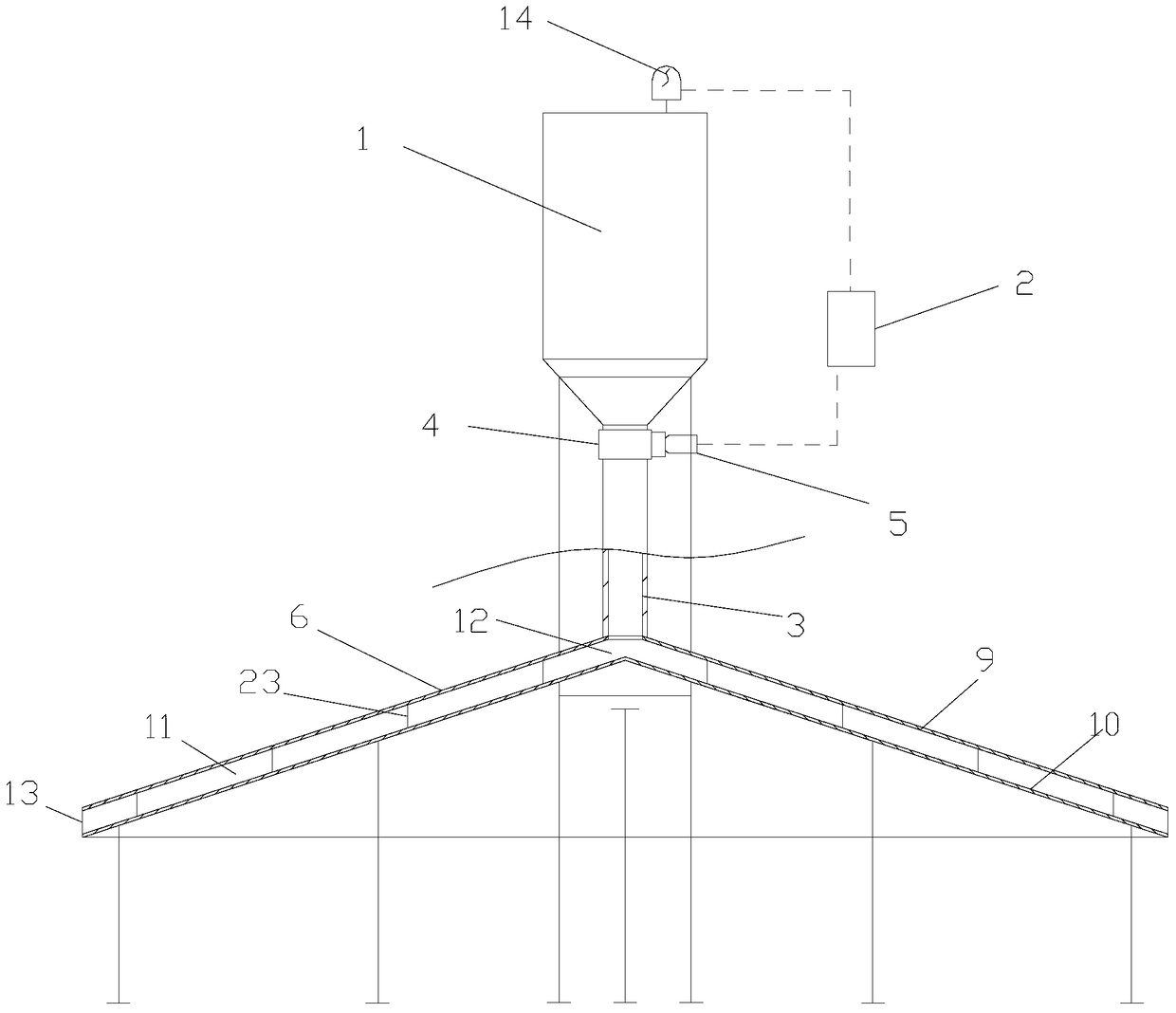

Automatic free-range chicken feeding device

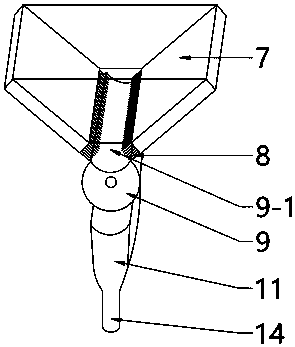

The invention discloses an automatic free-range chicken feeding device which comprises a feed bin and a controller. A feeding tube is arranged on the lower portion of the feed bin, the feeding tube is provided with a rotary feeding valve, and the rotary feeding valve is in transmission connection with a feeding motor. A conical top is arranged on the bottom of the feeding tube, supporting bars are arranged on the lower portion of the conical top, and the feed bin is fixed on a support which penetrates through the conical top. The conical top is composed of an upper conical face and a lower conical face which are parallel to each other and are distributed up and down, connecting ribs are arranged between the upper conical face and the lower conical face, and a feeding gap is formed in the area between the upper conical face and the lower conical face. A feed port of the feeding gap is communicated with the feeding tube, and a discharge port of the feeding gap is placed on the edge of the conical top. The controller controls the feeding motor, and the controller is further connected with an acousto-optical alarm controlled by the controller. The automatic free-range chicken feeding device can achieve automatic feeding, the feeding range is wide, meanwhile, the function that chickens can take shelter from rain is also achieved, and the automatic free-range chicken feeding device is particularly suitable for feeding free-range chickens.

Owner:新沂市港发商贸有限公司

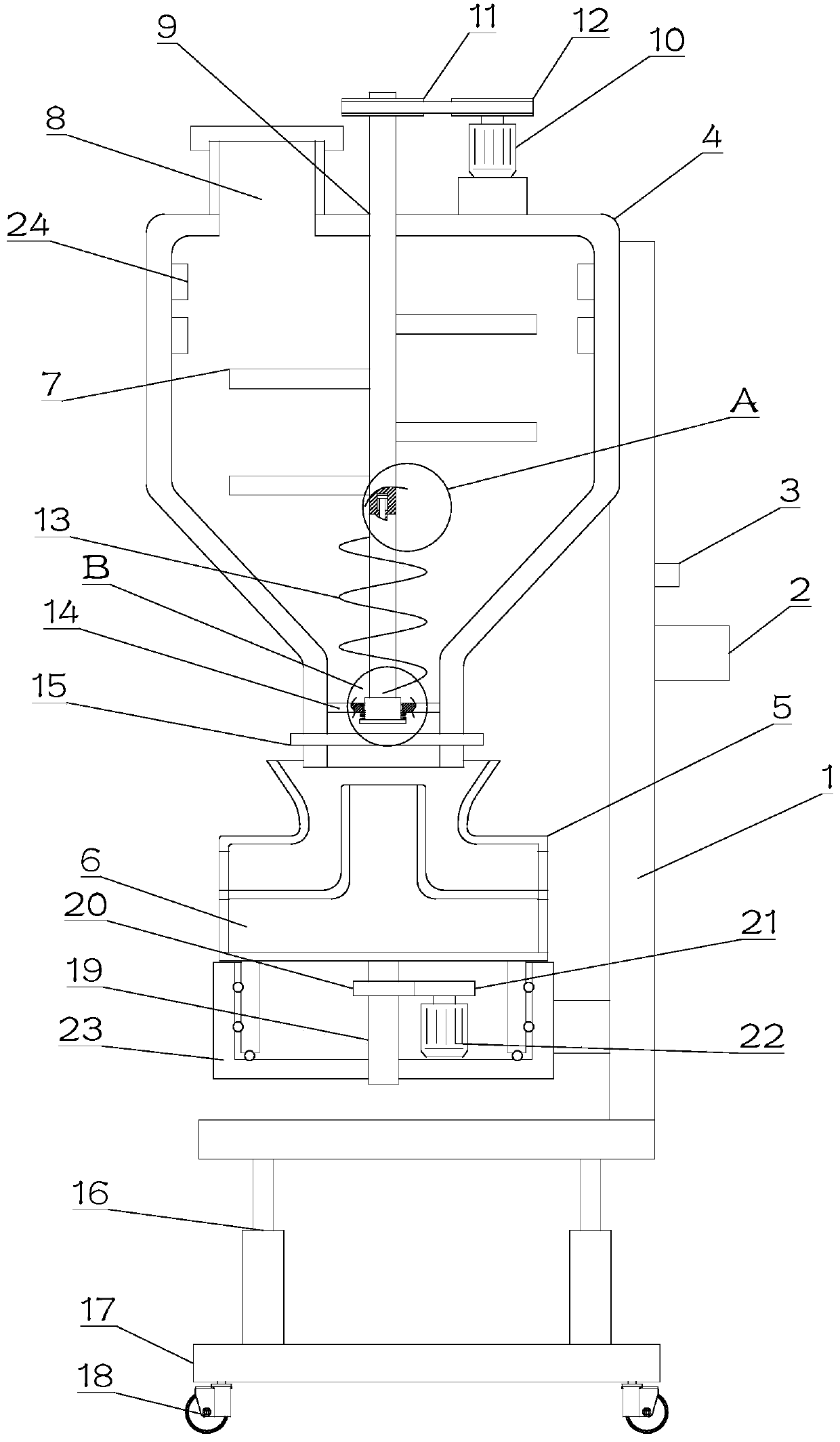

Artificial-intelligence-based feed putting device

ActiveCN110537497APrevent compactionAvoid cloggingClimate change adaptationAnimal feeding devicesSmart technologyVALVE PORT

The invention discloses an artificial-intelligence-based feed putting device, and relates to the technical field of artificial intelligence. The artificial-intelligence-based feed putting device comprises a support, the support is provided with a storage box and a scattering box from top to bottom in sequence, a first rotary shaft penetrates through the top of the storage box, a driving mechanismis arranged at the top of the first rotary shaft, stirring rods are further fixed to the first rotary shaft, and a conveying auger is installed at the bottom of the first rotary shaft; a discharging port is formed in the bottom of the storage box, the conveying auger is arranged inside the discharging port, an opening-closing valve is arranged in the discharging port, and a rotary mechanism is arranged on the scattering box; the scattering box comprises a conveying box A and a conveying box B arranged at the bottom of the conveying box A, a feed inlet of the conveying box A is formed in the outer side of the conveying box B, and the side faces of the conveying box A and the conveying box B are both provided with a feed outlet. By means of the artificial-intelligence-based feed putting device, materials are prevented from being hardened, the feed putting area is increased, energy is saved, and movement is facilitated; timing feed putting is achieved, the intelligentization is improved,and the labor intensity is reduced.

Owner:XUZHOU BODAO TECH PROMOTION SERVICE

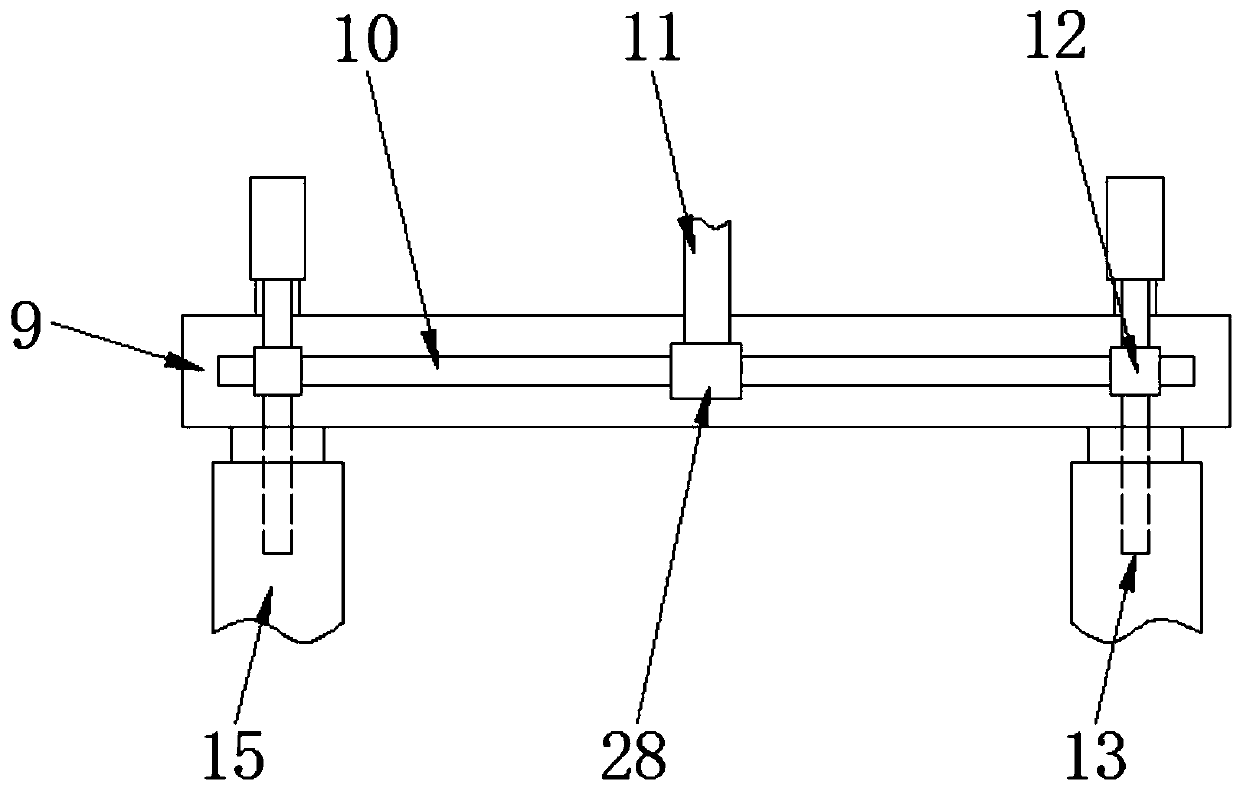

Working method of feed putting equipment for aquaculture

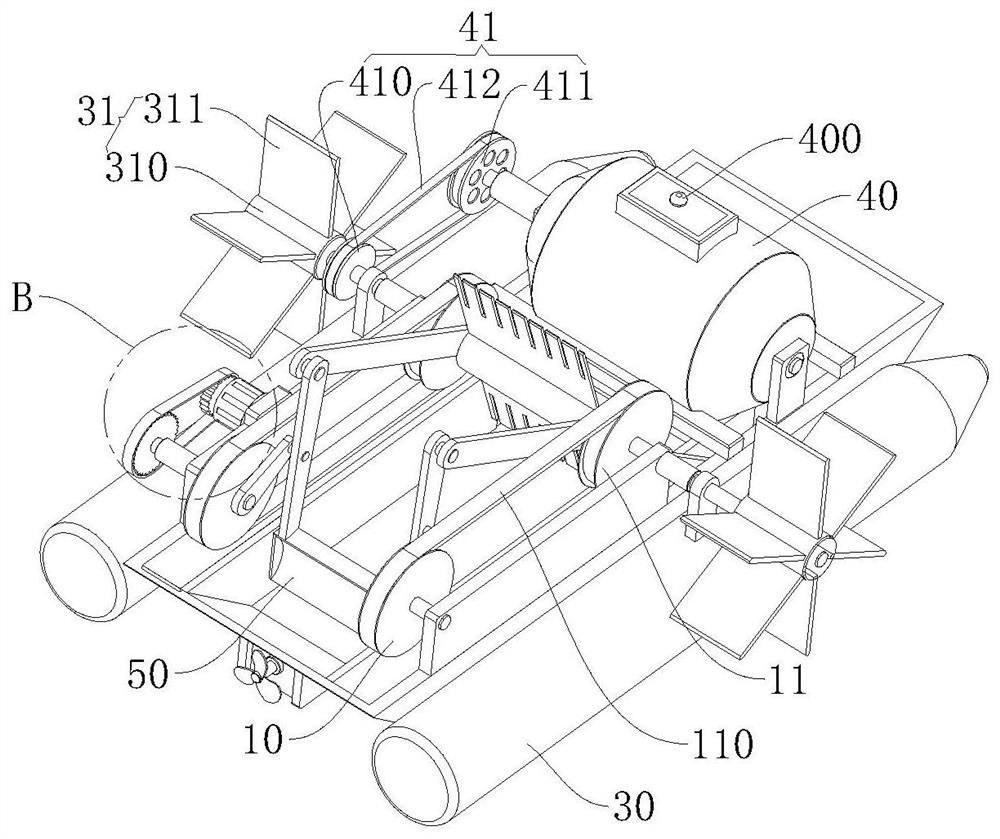

InactiveCN112335590AReduce resistanceImprove driving efficiencyWaterborne vesselsRotary stirring mixersEngineeringShovel

The invention relates to the technical field of aquaculture feed throwing, in particular to a working method of feed putting equipment for aquaculture. The equipment comprises a ship body, and furthercomprises a controller, traveling mechanisms, a uniform stirring mechanism and a spreading mechanism, and the traveling mechanisms are arranged at the two sides of the ship body to support travelingof the ship body; and each traveling mechanism comprises two supporting air bags and two rotating assemblies, the uniform stirring mechanism comprises a feeding kettle, a transmission assembly and twostirring assemblies, the spreading mechanism is arranged in the ship body and used for throwing feed, the spreading mechanism comprises a throwing shovel, a driving assembly and connecting rod assemblies, and the driving assembly is electrically connected with a controller. According to the method of the feed throwing equipment for aquaculture, feed can be prevented from falling on the water surface in a centralized manner, the feed can be thrown dispersedly, the feeding area is increased, meanwhile, the process is simple, the throwing efficiency is high, and the feeding cost can be reduced.

Owner:ANHUI HUATENG AGRI TECH CO LTD

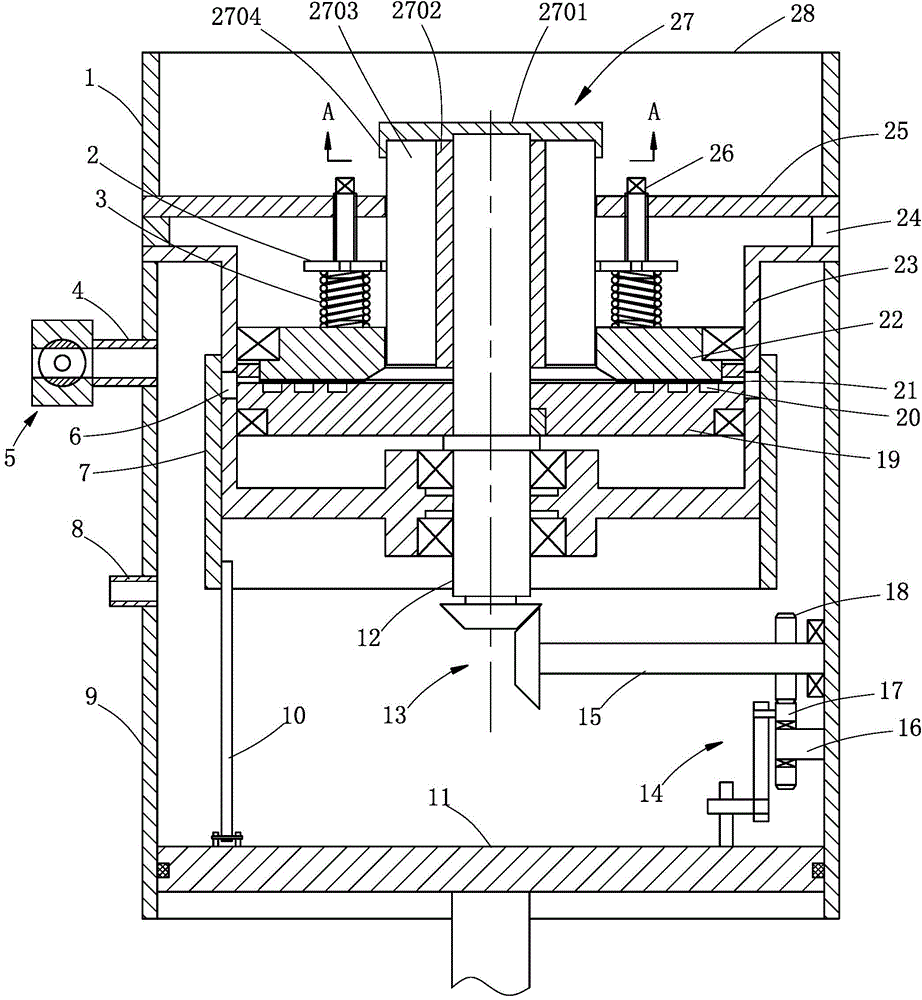

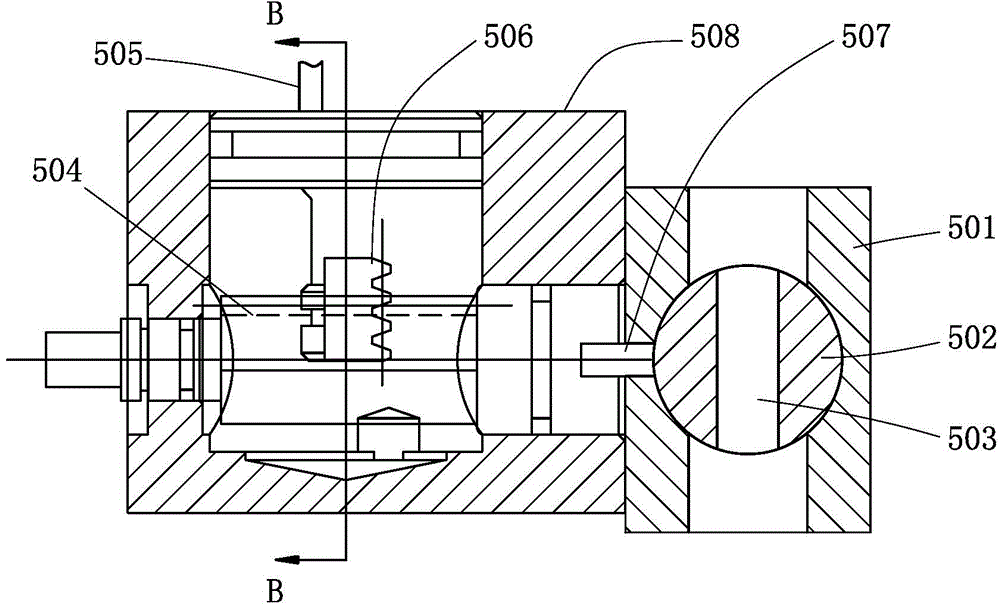

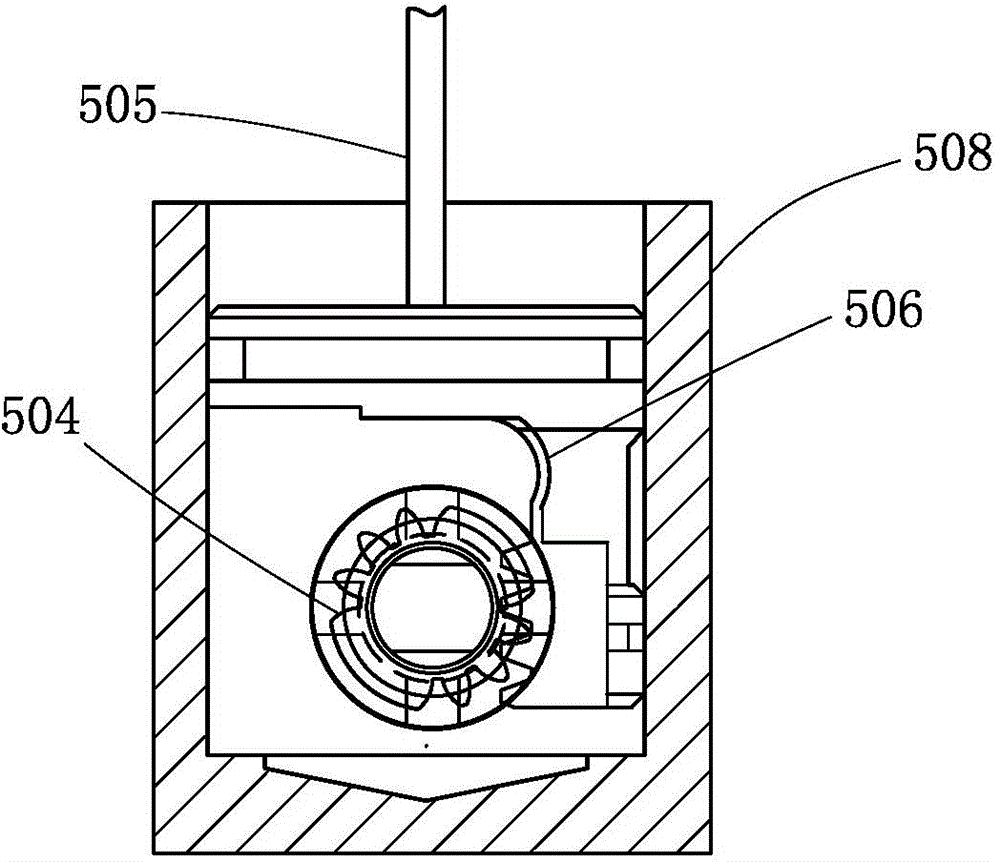

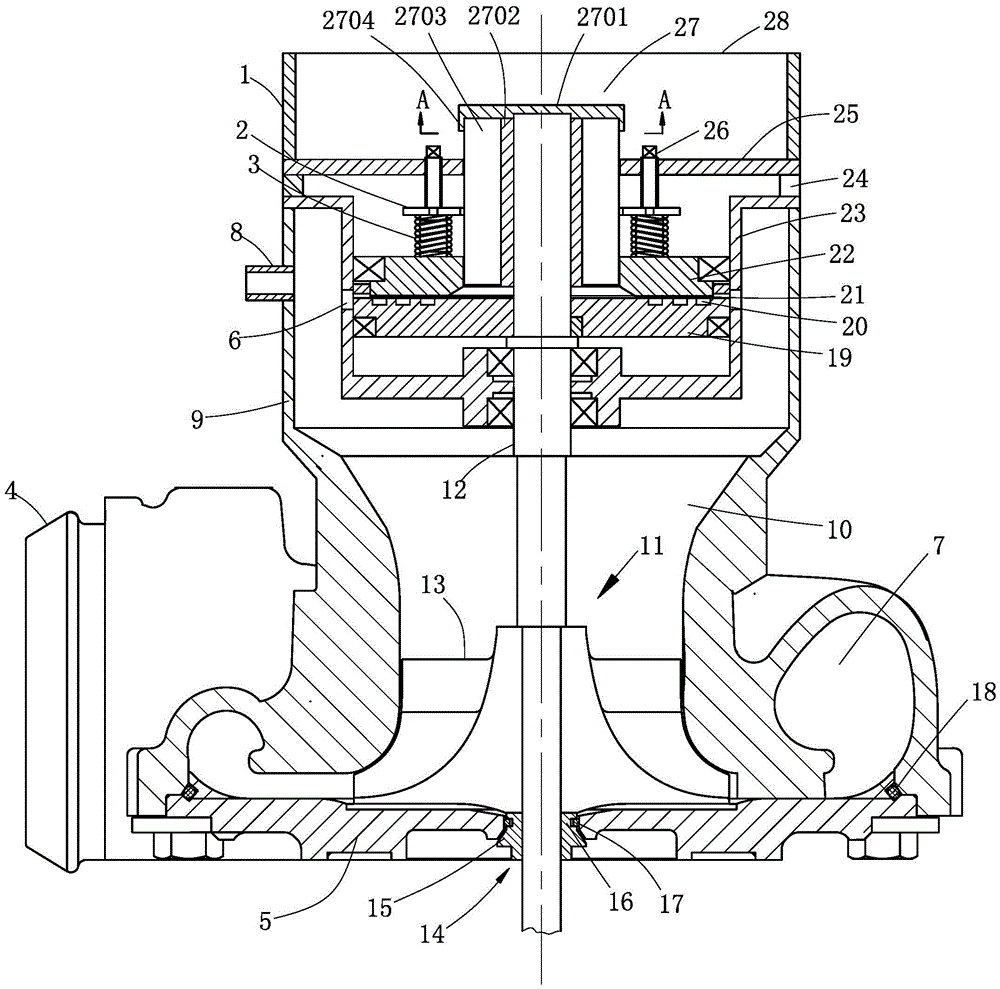

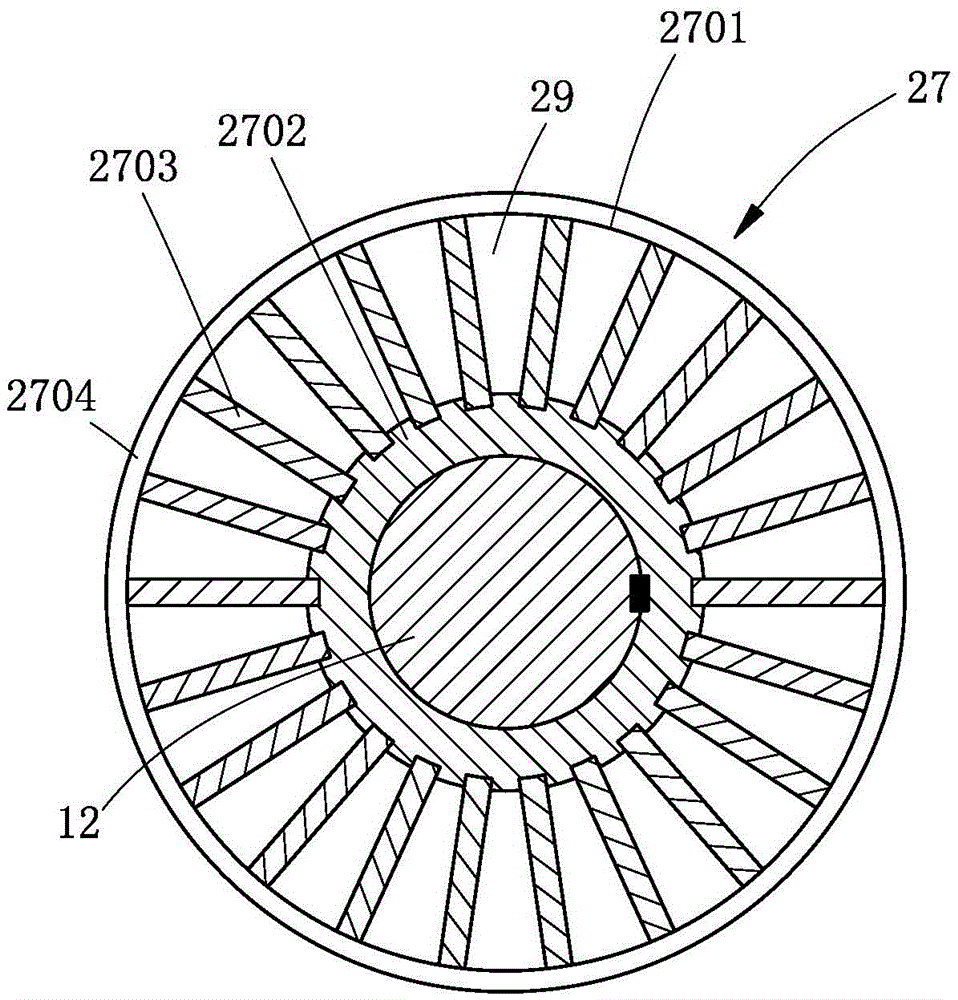

Plunger pump

ActiveCN104481834AGood effectIncrease inhalationPositive displacement pump componentsPumpsImpellerDrive shaft

The invention discloses a plunger pump and belongs to the technical field of fluid pumps. The plunger pump comprises a pump body, wherein a partition wall is arranged in the pump body close to a material inlet, a mounting barrel is arranged in the pump body between the partition wall and a plunger, and a transmission shaft is rotatably arranged on the mounting barrel. A turntable is fixedly arranged on the transmission shaft in a cavity, a floating plate is arranged between the partition wall and the turntable, an impeller is fixedly arranged on the transmission shaft, and feeding channels are formed between every two adjacent blades. Circulation gaps are formed between the floating plate and the turntable, and a plurality of through holes corresponding to the circulation gaps at positions are formed in the mounting barrel. The transmission shaft penetrates out from one end of the mounting barrel to be connected with the plunger. A sleeve is slidably arranged on the outer surface of the mounting barrel and is connected with the plunger through a connection rod. A material outlet is arranged on the pump body and connected with a ball valve which is controlled by the plunger. The plunger pump solves the technical problems of the existing plunger pump of insufficient suction volume and excessive leakage amount, and is widely applied to continuous fluid transportation.

Owner:NINGBO LIS IND

Silkworm breeding method

The invention discloses a silkworm breeding method, and relates to the technical field of silkworm breeding. The silkworm breeding method comprises the steps that a breeding room is selected, guide rails are paved at the opposite two sides of the floor in the breeding room, and a pulley across the floor is arranged on the guide rails; thorough disinfection and cleaning are conducted on all the facilities in the breeding room; a breeder stands on the pulley to pave thin films, place mulberry leaves and place five instar silkworms, the mulberry leaves are given three times to the silkworms every day, the indoor air is circulated, the light is even, and indoor temperature and indoor humidity are controlled; after the silkworms are placed for 5-8 days, the breeder stands on the pulley to spray chemicals on the silkworms, when the silkworms enter the cocoon production period, laying out cocooning frame mounting tools which are placed on the pulley in advance on the floor is conducted to make matured silkworms mount cocooning frames to cocooning, and the indoor temperature and the indoor humidity are controlled; cocooning tools are collected, and cocoons are harvested. Compared with the prior art, by means of the silkworm breeding method, the problems that the use ratio of an existing silkworm breeding field is low, the labor intensity is high, the silkworm cocoon yield is low, the quality is poor, and the working efficiency is low can be solved.

Owner:鹿寨县科技工贸和信息化局

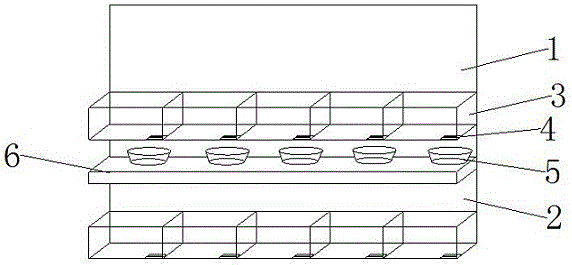

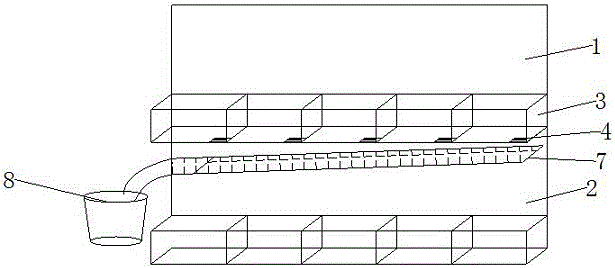

Dual-layer bamboo rat rearing device

The invention discloses a dual-layer bamboo rat rearing device, and belongs to the technical field of animal feeding devices. The dual-layer bamboo rat rearing device is defined by four walls and a roof and comprises an upper-layer device and a lower-layer device. The upper-layer device is supported by a support. The support is supported by a supporting column. The upper end of the supporting column is connected with the support. The lower end of the supporting column is arranged on the lower-layer device. The upper-layer device and the lower-layer device are peach divided into a plurality of rat rings. Excrement leakage grooves are formed inside the rat rings. A device for collecting excrement is arranged below the excrement leakage grooves. Due to the dual-layer rearing device, the bamboo rat rearing area can be increased, the rat ring occupied space is reduced, and the number of reared rats is increased remarkably. The rearing device is simple in structure, reasonable in design, convenient to manufacture, low in cost and suitable for large-scale rearing and application, and time and labor are saved during excrement removal.

Owner:南宁市浩特竹鼠养殖场(微型企业)

Intelligent bait feeding device based on solar energy

InactiveCN108077145AReasonable structural designGuaranteed spreading pathClimate change adaptationAgricultural fishingEngineeringSolar cell

The invention relates to the technical field of aquaculture, in particular to an intelligent bait feeding device based on solar energy. The intelligent bait feeding device based on the solar energy comprises a solar cell panel, a supporting box, a floating block and a mixing box, wherein the solar cell panel is fixed above the supporting box; a bait box, a storage battery and a controller are arranged in the supporting box; a discharging hopper is arranged below the bait box; a discharging roller is arranged below the discharging hopper; a notch is formed in the discharging roller; the floating block is fixed on the lower layer of the outer wall of the supporting box; the mixing box is provided with a water inlet and a water outlet; a stirring motor is fixedly arranged on the inner wall ofthe upper portion of the mixing box; and a propelling device is arranged below the supporting box. The intelligent bait feeding device based on the solar energy is reasonable in structural design, power is supplied by the solar energy, discharging can be controlled by the discharging roller with the notch, bait enters the mixing box, can be stirred and can be completely mixed with water, in a traveling process of the device, water can naturally flow into the mixing box and can flow out from the water outlet, therefore, the bait which is mixed with the water is taken away, and the bait can befed in a dispersed manner favorably.

Owner:于海阔

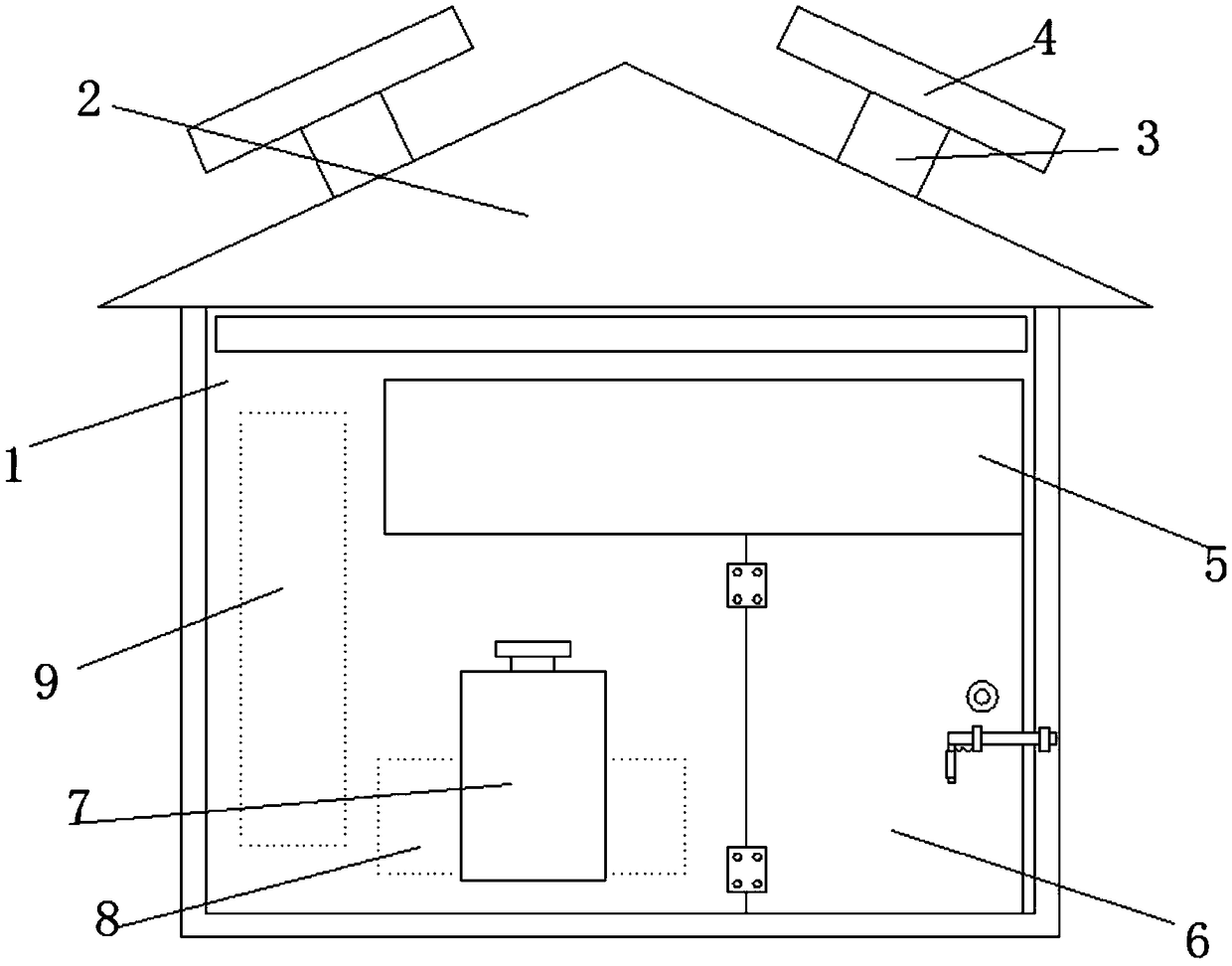

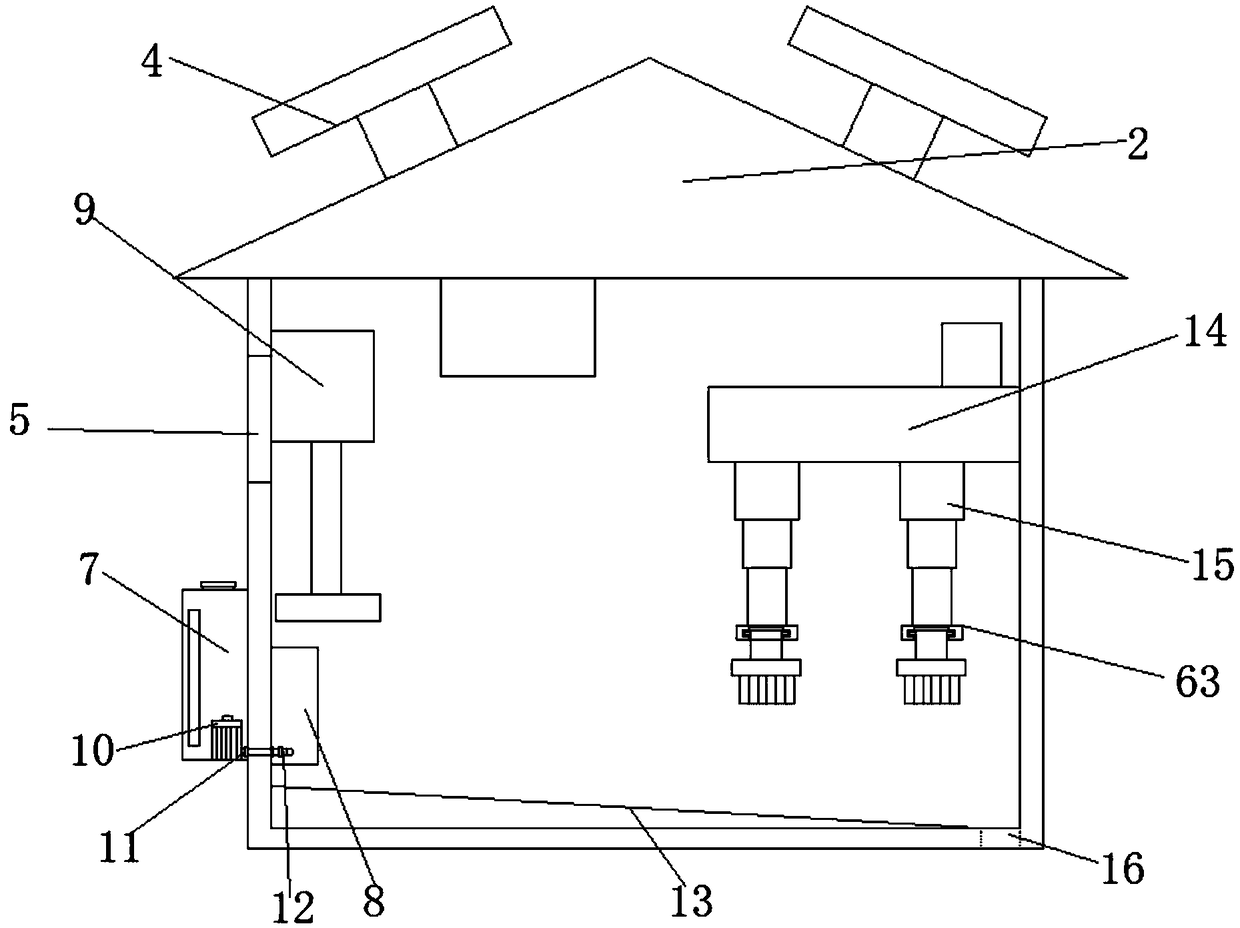

Raising house for poultry raising

The invention discloses a raising house for poultry raising. The raising house comprises a raising house body. A roof is arranged at the top end of the raising house body. Photovoltaic plates are symmetrically arranged on the two sides of the top end of the roof. The photovoltaic plates are connected with the roof through supporting columns. One side of the raising house body is provided with an observing hole and a house door located on the lower side of the observing hole. One side of the raising house body is provided with a water tank located on one side of the house door. The side, closeto a water tank, in the raising house body is provided with a spraying mechanism and a feeding mechanism located on one side of the spraying mechanism. A water pump is arranged in the water tank. Theoutput end of the water pump is provided with a water conveying pipe which sequentially penetrates through the side wall of the water tank and the side wall of the raising house body and extends intothe raising house body. One end of the water conveying pipe is provided with a hose. The raising house has the advantages that a movement mechanism drives a sweeping mechanism to move horizontally, the sweeping mechanism continuously rubs manure, the manure is effectively and more rapidly cleaned away, the raising house is simple and reasonable in design and high in practicability, the environmentcleanliness of the raising house is ensured, and the cleaning residence is provided for poultry.

Owner:嘉善铂汉塑胶五金有限公司

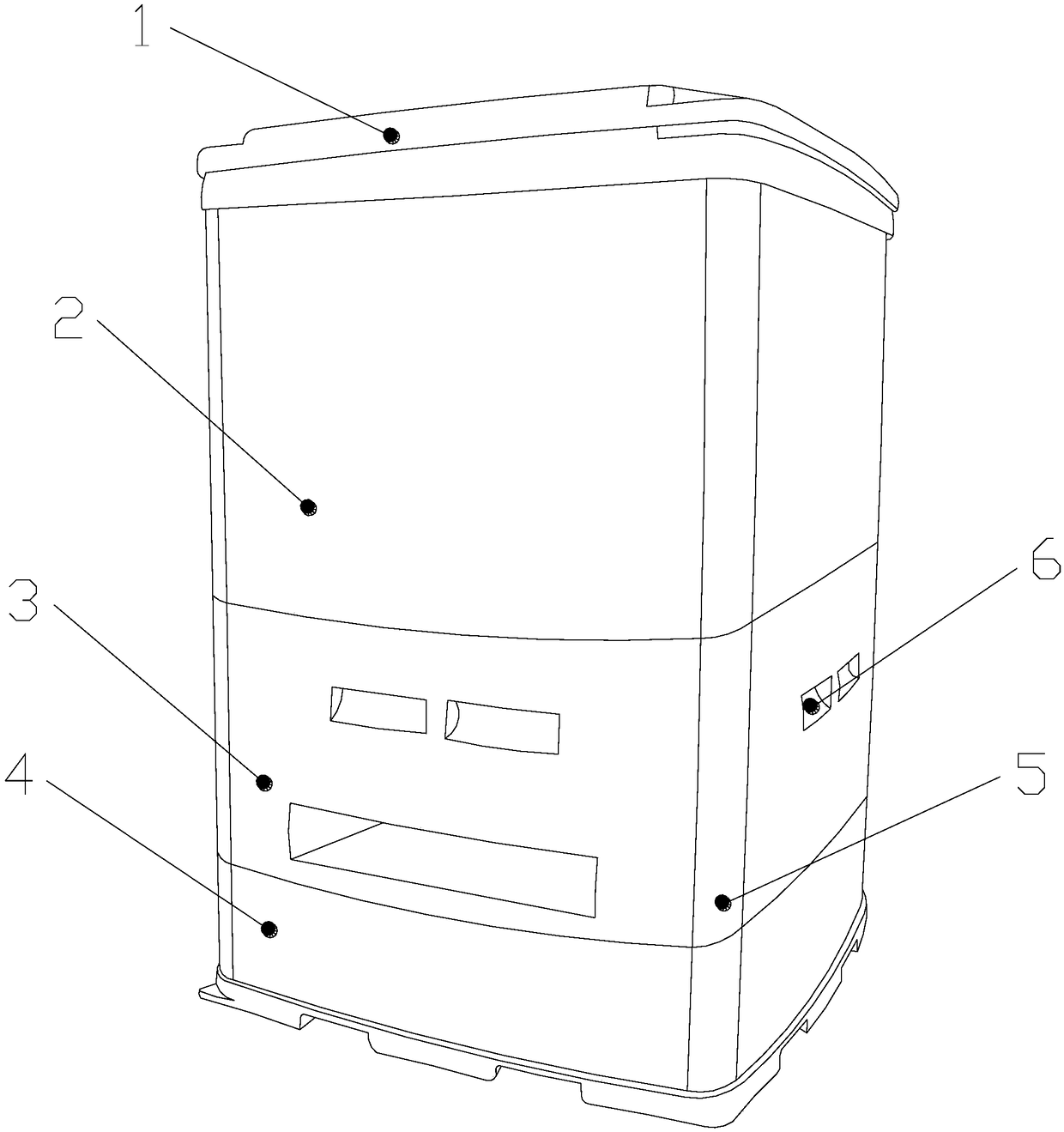

Bait putting machine used for aquaculture

InactiveCN108401961AAvoid sinking situationsIncrease feed areaClimate change adaptationPisciculture and aquariaEngineeringHigh pressure

The invention discloses a bait putting machine used for aquaculture. The bait putting machine structurally includes a sealing upper cover, a material storage box, a bait putting box, a dampproof base,artistical lines and a convenient-type handle groove; the dampproof base is of a rectangular structure, the upper end of the dampproof base is in engagement with the bottom of the bait putting box, and a groove for buckling the material storage box is formed in the upper end of the bait putting box. The bait putting machine has the advantages that the provided bait putting box is connected with the material storage box through a feeding port, and baits drive a pulling mechanism to move after the material storage box discharges the baits at fixed time, and then fall into a discharging groove in sequence; additionally, the pulling mechanism is in linkage with a linkage mechanism through a first transmission mechanism and drives a second transmission mechanism to control a starting device topower on and start a vacuum machine, high pressure is generated by the vacuum machine to blow air, and the baits in the discharging groove are blown out of the bait putting box fast for sprinkling. The material putting area is effectively increased, the material putting range is wide, fishes in a long distance can eat the baits, and the situation that the baits are soaked for a long time and sinkto the bottom is avoided.

Owner:黄裕年

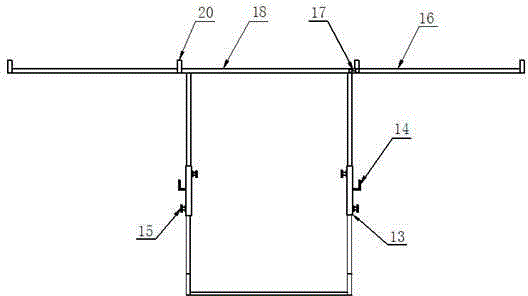

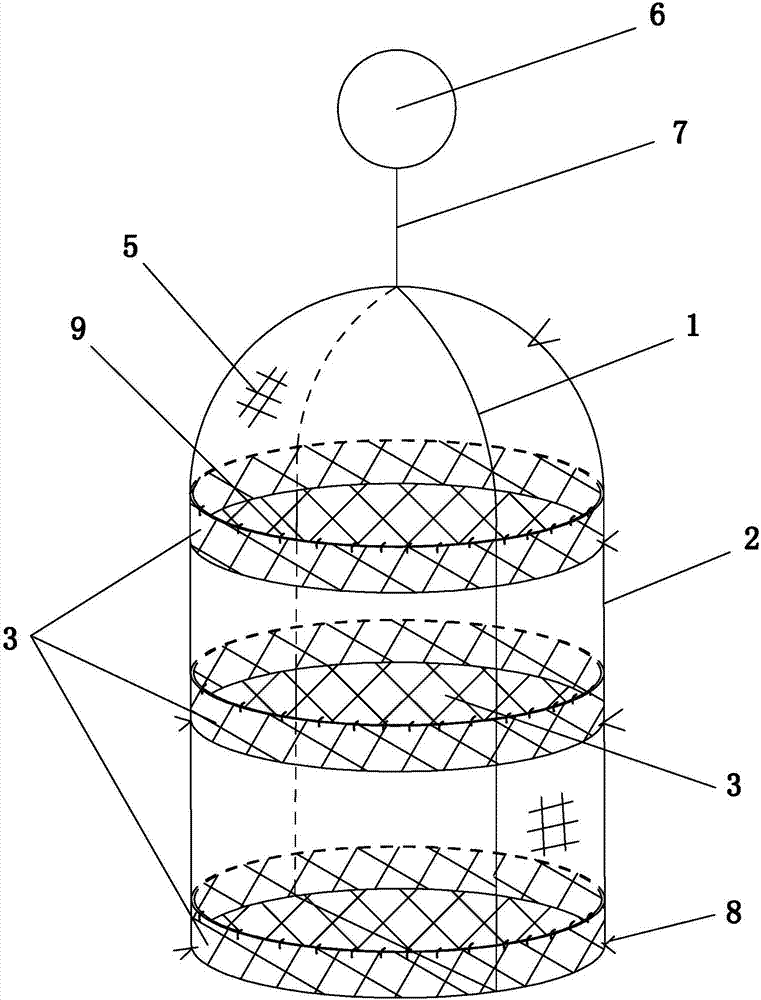

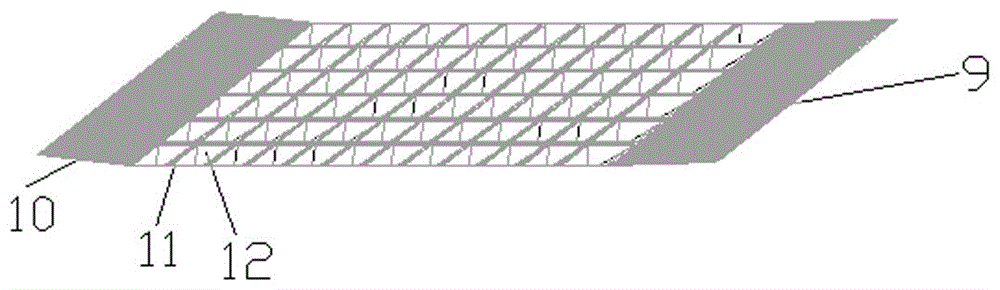

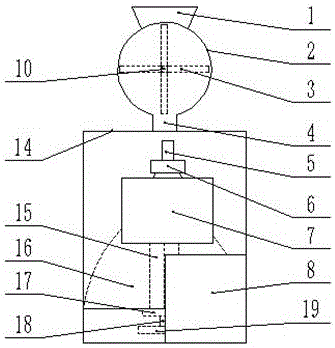

Feeding table for mixed cultivation of fish and shrimp

InactiveCN106937618AIncrease the number ofIncrease feed areaClimate change adaptationPisciculture and aquariaShrimpOedogonium

The invention provides a feeding table for mixed cultivation of fish and shrimp. The feeding table mainly comprises an oblique support arranged on the top, and a main support connected with the bottom of the oblique support, wherein the top end of the oblique support is connected with a floating ball; at least two circular net racks which are arranged at intervals along the vertical direction are fixed in a space defined by the main support, and the bottom side of the circular net rack arranged at the lowermost side is flush with the bottom end of the main support; the bottoms and the side faces of the circular net racks are wrapped with bottom net pieces; a feeding table main body is defined by the oblique support and the main support, and the side faces and the top of the feeding table main body are wrapped with purse net pieces. According to the feeding table, the number of the circular net racks can be increased according to the depth of water in a pond and the total stocking number of fish and shrimp, so that the aims of enlarging the feeding area and increasing feeding efficiency can be achieved; the apertures of the purse net pieces vary according to the individual sizes of the fish and the shrimp, and the bred shrimp can freely enter a purse net to eat feed, but the fish bred by means of mixed cultivation cannot enter the feeding table for robbing the shrimp feed, so that the aim of separated feeding in a fish and shrimp mixed cultivation pond is achieved.

Owner:QINZHOU UNIV

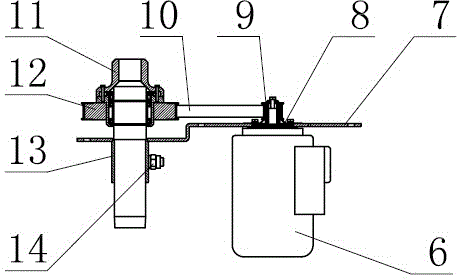

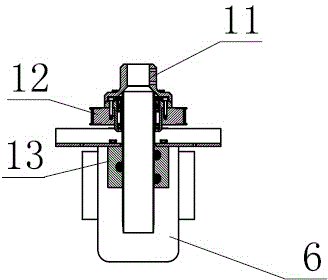

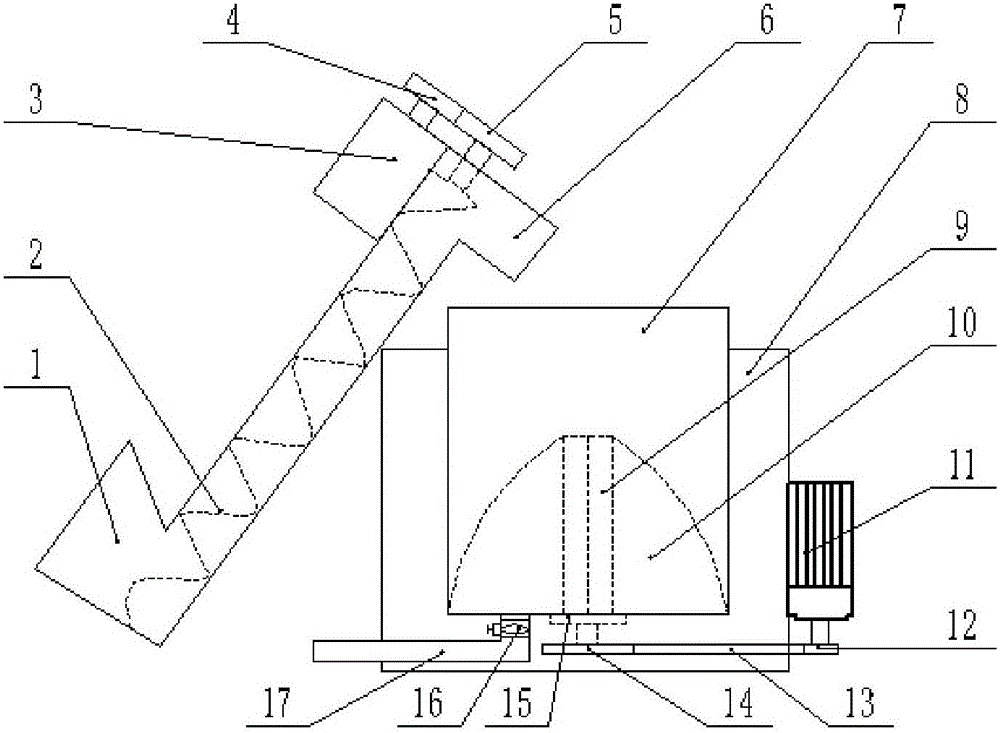

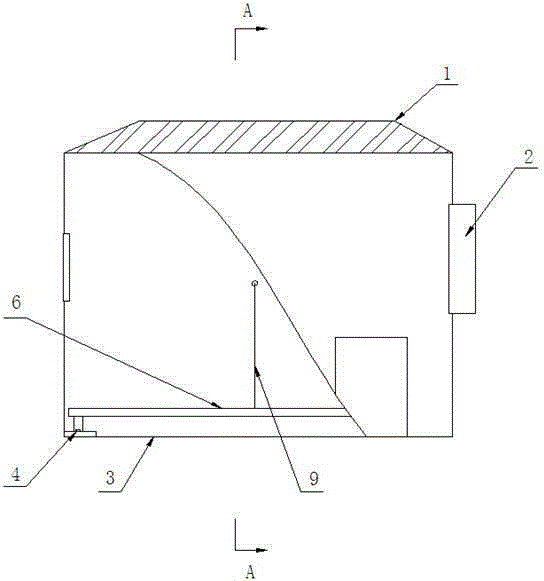

Automatic feeding machine for shrimp pond

InactiveCN106359232AFully baitedLess residue at the bottom of the boxClimate change adaptationPisciculture and aquariaMotor shaftShrimp

The invention relates to an automatic feeding machine for a shrimp pond and belongs to the technical field of aquaculture. The automatic feeding machine comprises a machine frame. The machine frame is composed of a feeding box, a feeding hopper, an auger, a motor and a floating body. The feeding box and the motor are installed on the floating body, the feeding box is provided with the feeding hopper, the auger is installed in the feeding box, one end of the auger is connected to a motor shaft, and a driving device is installed on the floating body. According to the automatic feeding machine for the shrimp pond, material transmission and a fishing boat principle are combined; by improving the structure of the feeding box, the feeding area is large, the feeding uniformity is high, and shrimp feed feeding efficiency is effectively improved.

Owner:NANNING HAOFA TECH

Automatic feeding device for free-range chickens

The invention discloses an automatic feeding device for free-range chickens, which comprises a feed bin and a controller. A feeding pipe is arranged at the lower part of the feeding bin, a rotary feeding valve is arranged on the feeding pipe, and the rotating feeding valve is driven by a feeding motor. connected, a conical top is provided at the bottom of the feeding pipe, and a pole is provided below the conical top, and the feed bin is fixed on a bracket passing through the conical top; the conical tops are parallel to each other And it is composed of an upper cone surface and a lower cone surface distributed up and down, and a connecting rib is provided between the upper cone surface and the lower cone surface. The area between the upper cone surface and the lower cone surface is a blanking gap. The feed inlet of the material gap communicates with the feed pipe, and the feed outlet is located at the edge of the conical top; the controller controls the feed motor and is also connected to a sound and light alarm controlled by it. connect. The automatic feeding device can realize automatic feeding, has a wide range of feeding, and at the same time has the function of keeping chickens from rain, and is especially suitable for breeding free-range chickens.

Owner:新沂市港发商贸有限公司

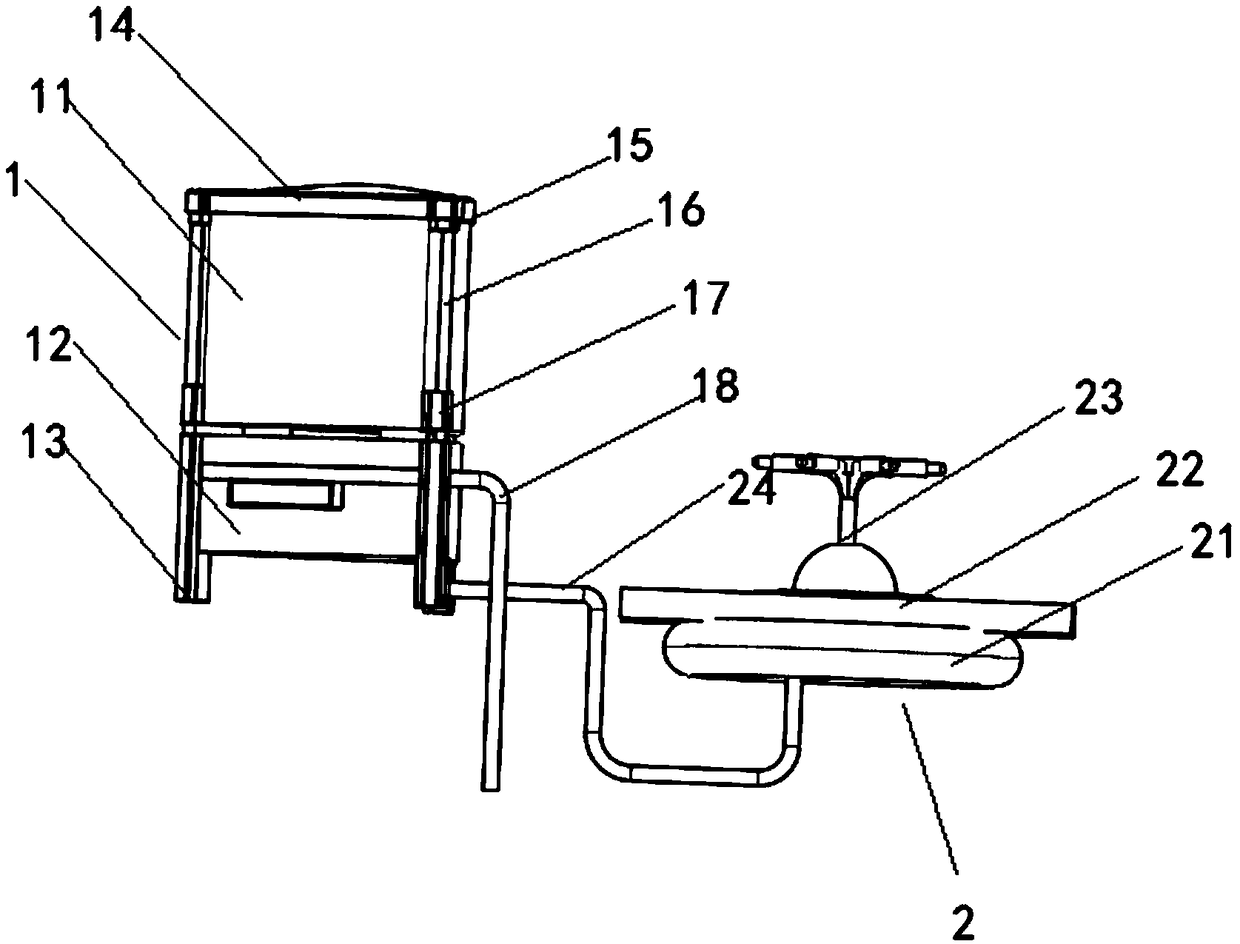

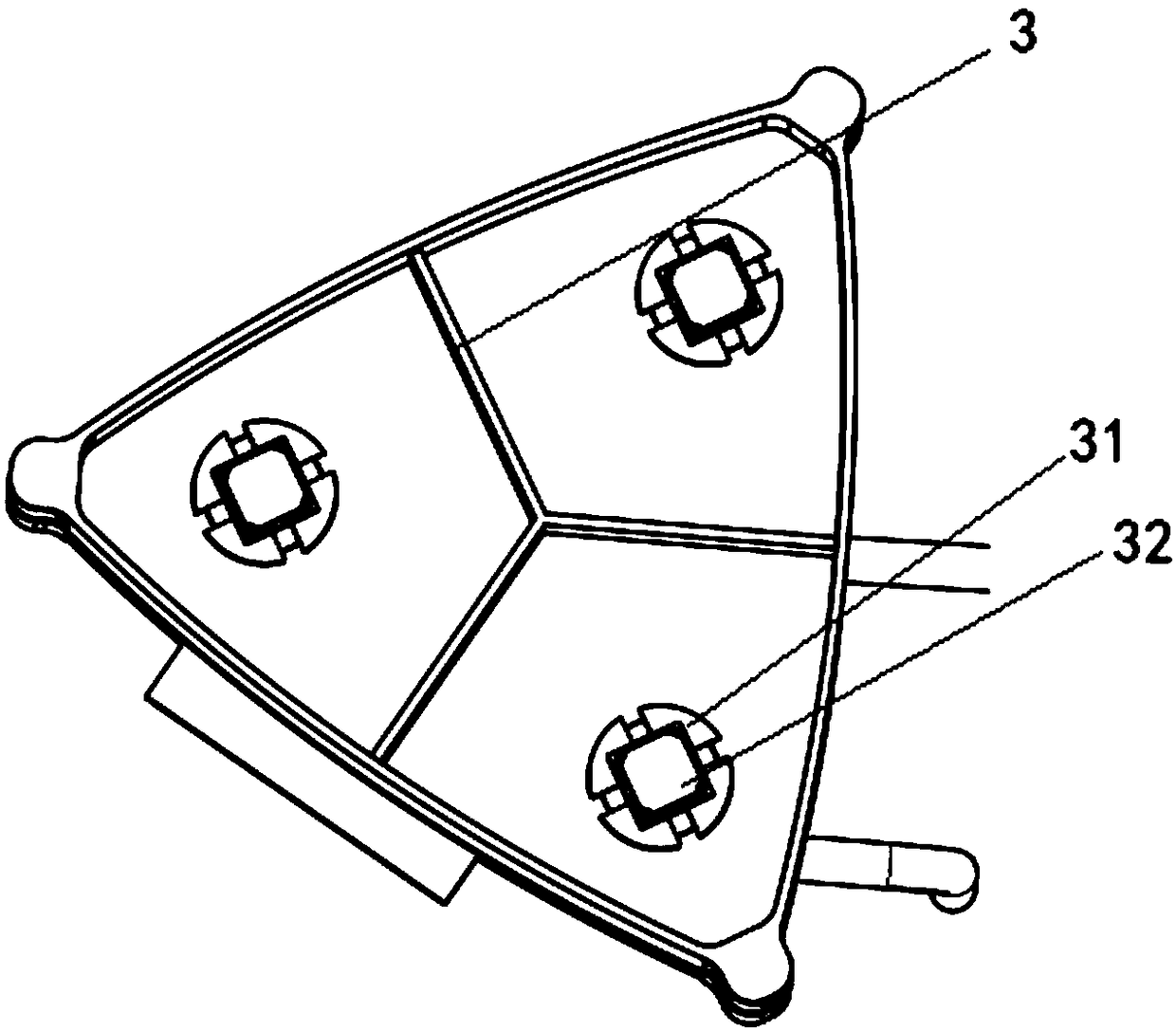

Fish feeding device of pond

ActiveCN108575854ALarge feeding areaIncrease feed areaClimate change adaptationPisciculture and aquariaEngineeringAquaculture

The invention relates to the technical field of aquaculture, in particular to a fish feeding device of a pond. The device comprises a material control box, the material control box is a regular triangle cylindrical shape and characterized by comprising a distribution box and a mixing box, and a spraying mechanism is further connected with the mixing box. By means of the device, all-direction scattering can be conducted to increase feeding area.

Owner:嘉善县陶庄小学

Fiber raw material stirring device for spinning

InactiveCN105771787AIncrease the mixing areaImprove stirring efficiencyRotary stirring mixersTransportation and packagingFiberRotational axis

The invention relates to the field of spinning and in particular relates to a fiber raw material stirring device for spinning. The device is capable of fully stirring fiber raw materials, so that the subsequent processing or treatment is facilitated. The device structurally comprises a box body, wherein a stirring cylinder is arranged inside the box body; a rotating shaft is arranged inside the stirring cylinder; a stirring blade is arranged on the rotating shaft; a seal ring is arranged at the lower end of the rotating shaft; a large belt wheel is arranged at the lower end of the seal ring; the large belt wheel is connected with a small belt wheel via a belt; the small belt wheel is connected to a stirring motor; the stirring motor is mounted at the right end of the box body; a feeding opening is formed in the left end of the box body; a conveying belt is arranged inside the feeding opening; a feeding motor is arranged at the upper end of the conveying belt; a pinion is arranged on the motor and is meshed with a large gear mounted on a spiral conveying belt; a discharging opening is formed in the lower right part of the large gear and is located at the upper part of the stirring cylinder. The fiber raw material stirring device for spinning implements the fiber raw material stirring function, is simple in structure and convenient to use, and is applicable to a variety of places.

Owner:SUZHOU HUACE TEXTILE SCI & TECH

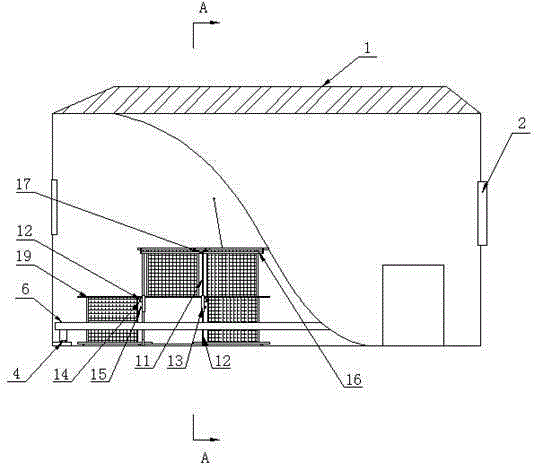

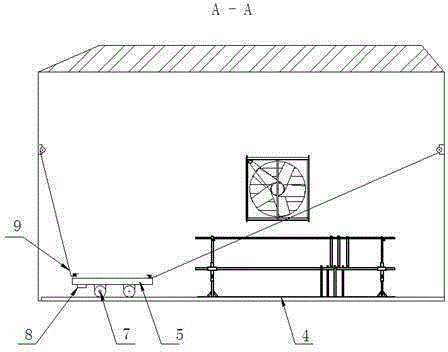

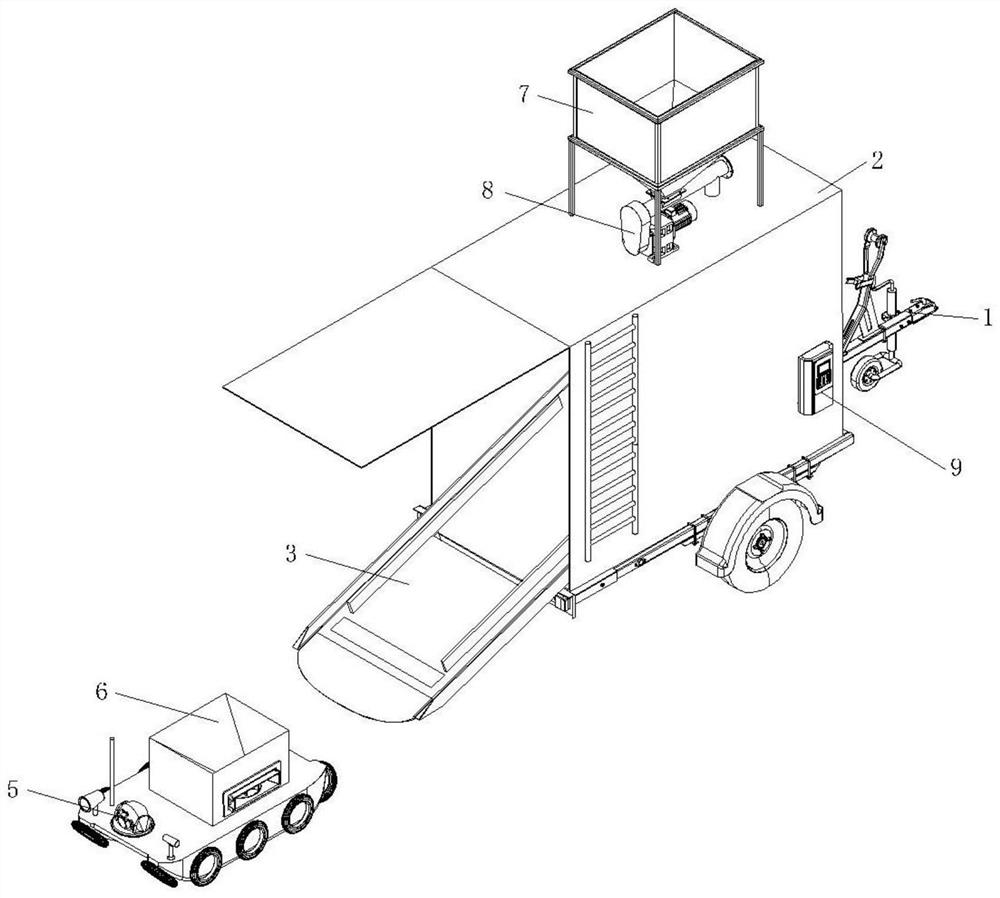

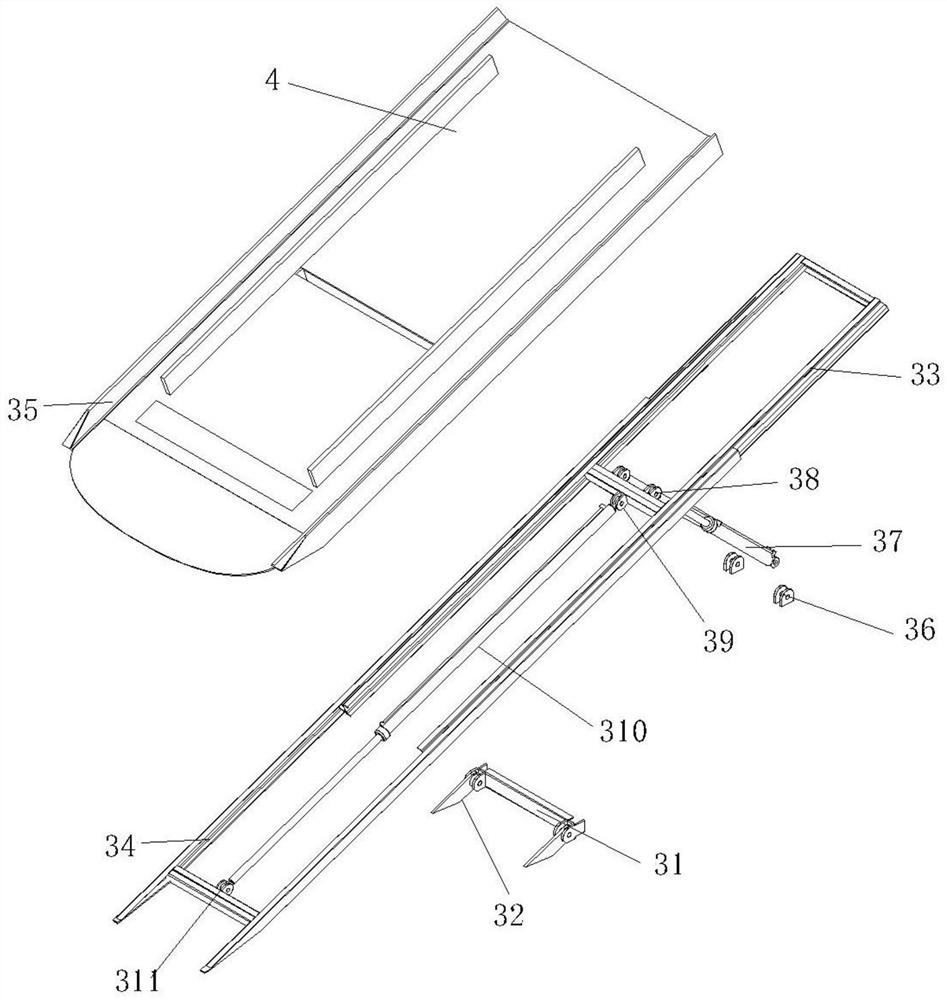

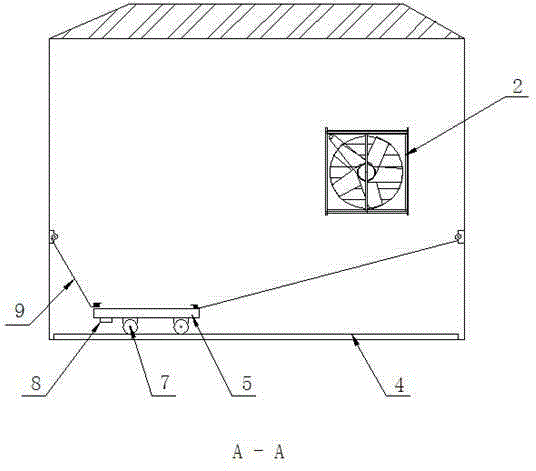

Pond feeding device for aquaculture

InactiveCN112293330AIncrease feed areaAuxiliary fixationClimate change adaptationPisciculture and aquariaEngineeringZoology

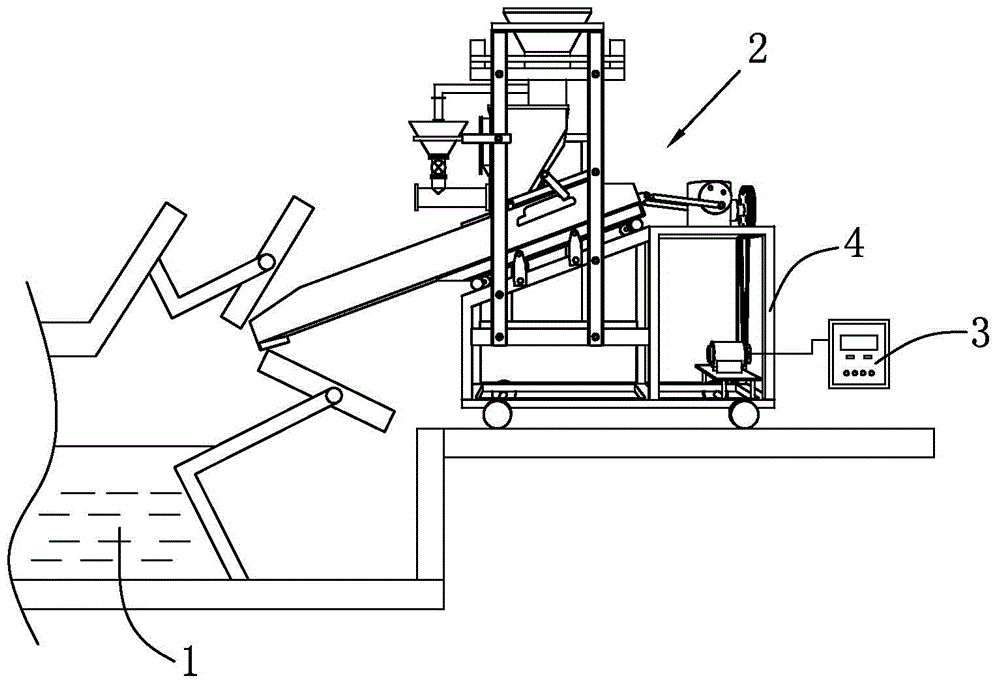

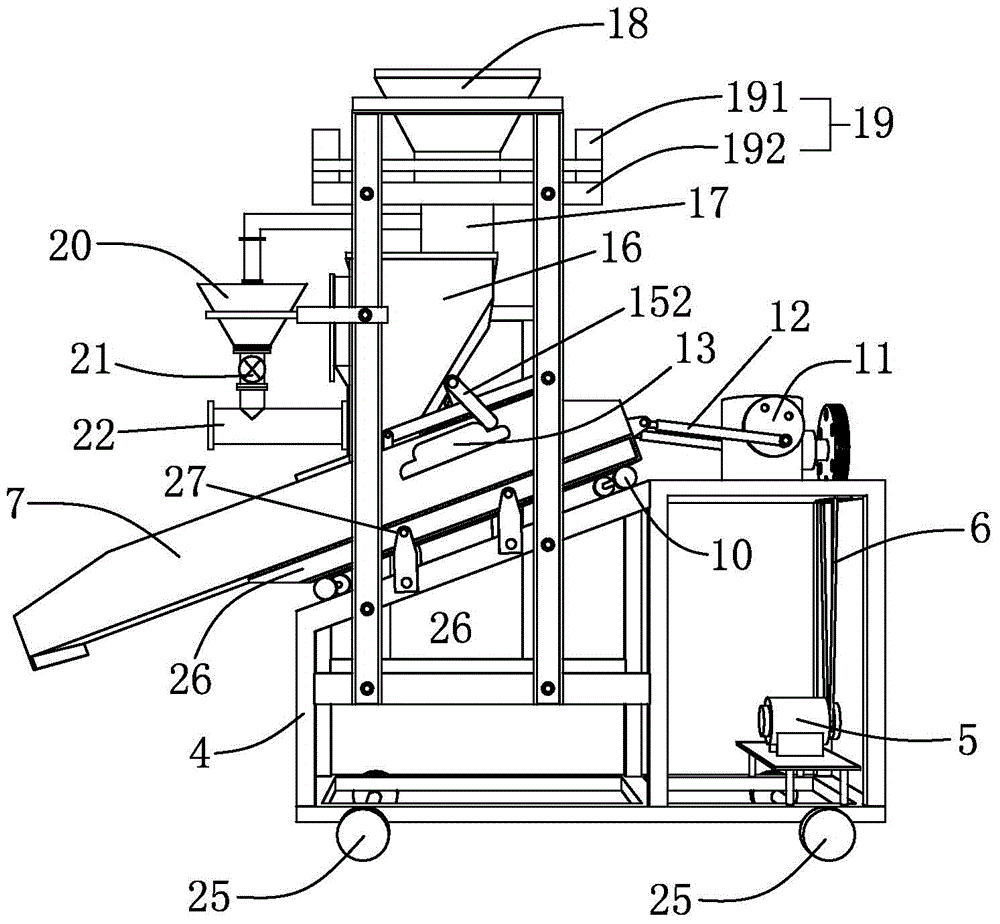

The invention discloses a pond feeding device for aquaculture. The pond feeding device comprises a traction trailer, a box body, a parking mechanism, a remote control ship, a feeding mechanism, a storage hopper, a spiral conveying device and a controller; the box body is arranged at the top end of the traction trailer; the parking mechanism is arranged at the bottom end of an inner cavity of the box body in the front-back direction. the remote control ship is arranged on the outer side of the box body and can be stored to the inner side of the parking mechanism; the feeding mechanism is arranged at the top end of the remote control ship; the storage hopper is arranged on the rear side of the top end of the box body; and the spiral conveying device is arranged at a discharging port in the bottom end of the storage hopper, and a discharging port of the spiral conveying device extends into the top end of the inner cavity of the box body. According to the pond feeding device for aquaculture, automatic ashore loading and unloading of the remote control ship can be achieved, workers do not need to manually carry the remote control ship into the water surface of a pond, feed supplementing, storage and transportation of the remote control ship are facilitated, operation is easy and practical, the feed throwing range of the remote control ship is widened, and the feeding efficiency is improved.

Owner:梁文俊

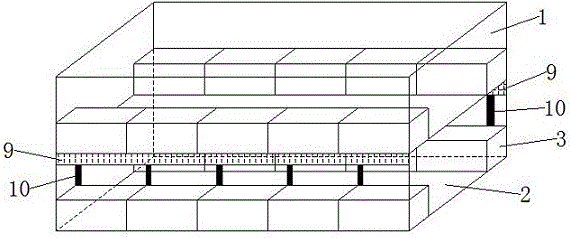

Silkworm breeding room

InactiveCN104621055AIncrease the areaIncrease feed areaAnimal husbandryEngineeringUltimate tensile strength

The invention discloses a silkworm breeding room, and relates to the technical field of silkworm breeding. The silkworm breeding room comprises a room body which is provided with a window, a door and a ceiling. A water screen air conditioner is arranged on the wall of the room body, the floor of the room body is a cement floor, and a drainage groove is formed in the floor; guide rails are arranged on the opposite two sides of the floor, and a pulley across the floor is arranged on the guide rails. Compared with the prior art, the silkworm breeding room has the advantages that the structure is simple, the manufacturing cost is low, the area use ratio is high, the working efficiency can be improved significantly, and the labor intensity is reduced.

Owner:LUZHAI COUNTY SCI & TECH BUREAU

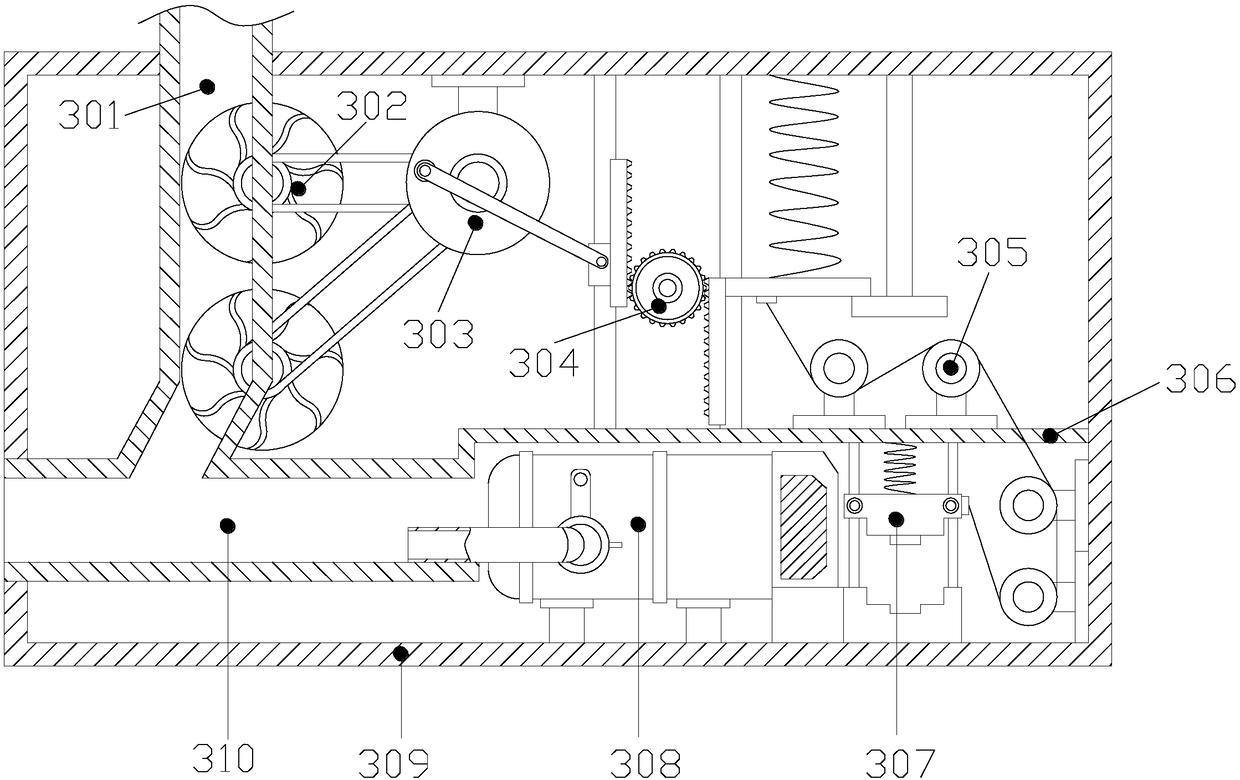

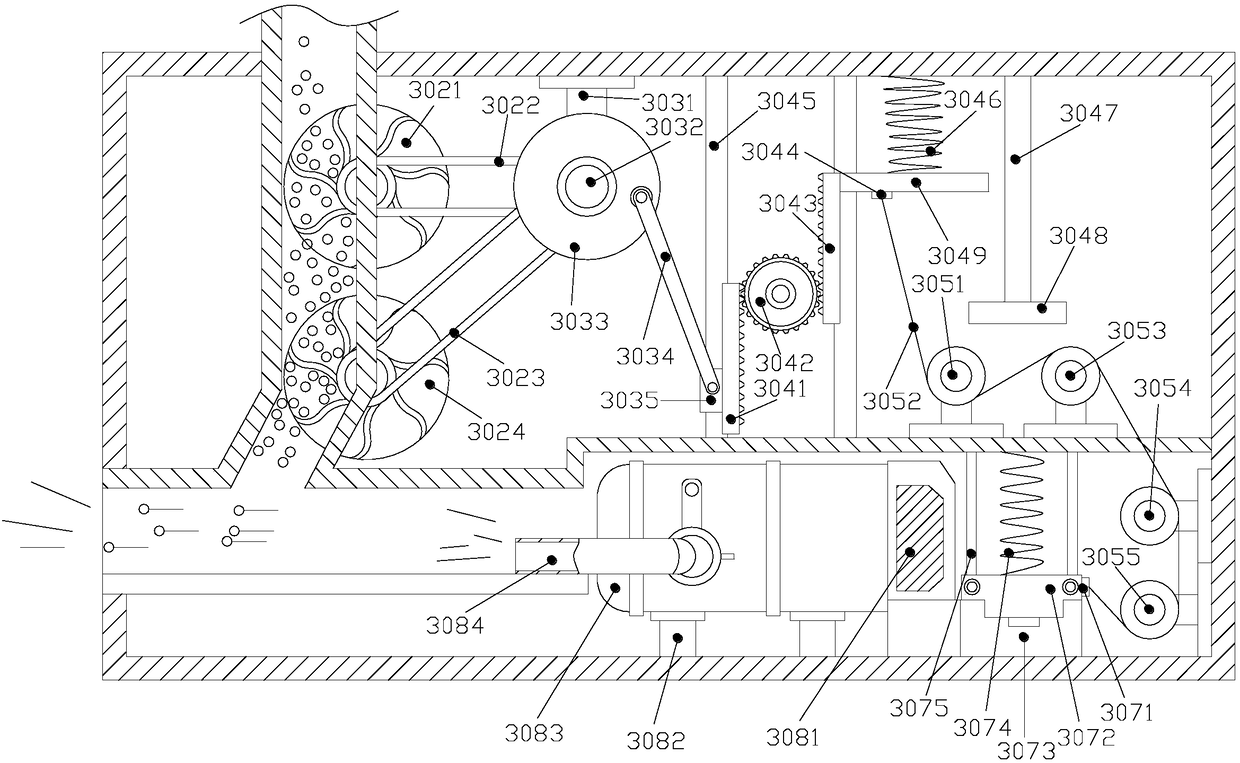

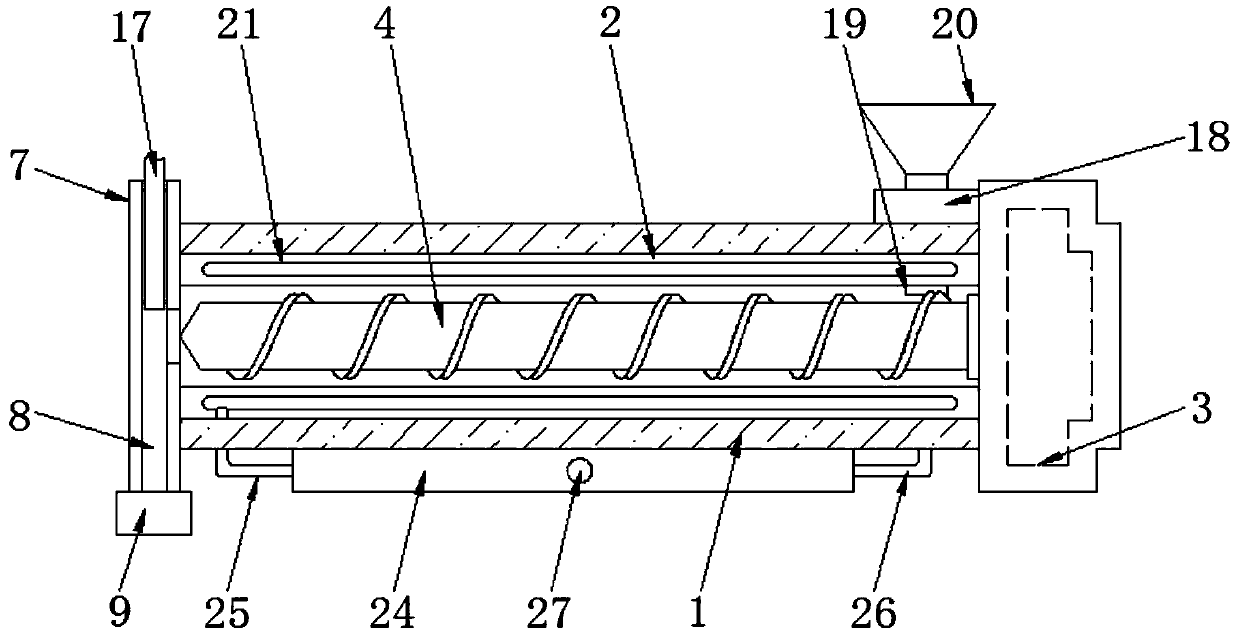

Material supply device for producing glass

The invention discloses a material supply device for producing glass. A material supply machine comprises a machine frame, a motor and a transmission system, wherein a support roller is arranged on the machine frame; a circular disc crank mechanism is arranged on the transmission mechanism; a connecting rod is arranged on the circular disc crank mechanism; the outer side of a material conveying frame is provided with a projected part; a material blocking plate is arranged in the material conveying frame; a jacking mechanism is arranged on the material blocking plate and is arranged on the projected part; a material collecting cabin is arranged on the material conveying frame; a feeding passage is arranged on the material collecting cabin and is connected with a material storage cabin; a weighing device is arranged on the machine frame; the weighing device is connected with a control system; the other end of the feeding passage is connected with an emergency material supply cabin; the bottom of the emergency material supply cabin is provided with a discharging valve; a support frame is arranged on a glass pool cellar; a combining plate is rotationally connected onto the support frame and is arranged at one side of the material supply machine. The material supply device has the advantages that the content of raw materials in the material storage cabin is controlled; meanwhile, the content of raw materials in the material conveying frame is controlled to be not less than the content of standard supplied materials; the continuous and uniform material supply of the material supply machine in the glass pool cellar is ensured; the material supply area is large.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

Screw barrel component for injection molding machine

The invention discloses a screw barrel component for an injection molding machine. The screw barrel component comprises a barrel, and the inner wall of the barrel is fixedly connected with a barrel bushing; and the inner right side of the barrel is fixedly connected with a driving device, and the barrel bushing is internally provided with an outer screw rod. The invention relates to the technicalfield of injection molding machines. According to the screw barrel component for the injection molding machine, through arrangement an inner screw rod in the outer screw rod, the inner screw rod absorbs heat for providing heat energy to the outer screw rod and improving the rotating force of the outer screw rod, so that tremendous internal friction heat generated by interface shear, of polymers atthe clearance position between the barrel bushing and the outer screw rod is increased; quick and efficient fusion of the polymers is achieved, and then one side of a feed chute communicates with oneside of a fine groove through rotation of a cylindrical rod in a cylindrical pipe; since a material separation mechanism is arranged, the waiting time of the injection molding machine can be shortened effectively; and the working efficiency of the injection molding machine can be improved greatly, and the energy consumption is reduced.

Owner:ZHEJIANG OCEAN UNIV DONGHAI SCI & TECH COLLEGE

Fur pulp recovery device for spinning

InactiveCN106400361AAvoid cloggingRealize shuntTransportation and packagingRotary stirring mixersResource utilizationPulp and paper industry

The invention relates to the field of spinning and especially relates to a fur pulp recovery device for spinning. The recovery device can continue stirring collected fur pulp and adding water, so that recycling and reusing are achieved, and a resource use rate is increased. The structure of the device comprises a feeding hole, wherein a feeding box is disposed under the feeding hole, feeding blades are disposed in the feeding box, the feeding blades are connected to a transmission rod, a large gear is connected to the tail end of the transmission rod, the large gear is meshed with a small gear which is connected to a feeding motor, and a feeding pipe is disposed on the lower end of the feeding box; a stirring box is disposed on the lower end of the feeding pipe, a rotation shaft is disposed on the lower end of the stirring box, stirring blades are connected to the rotation shaft, a sealing ring is disposed on the lower end of the rotation shaft, a connecting rod is connected to the lower end of the sealing ring, a large belt wheel is disposed on the lower end of the connecting rod, the large belt wheel is connected to a small belt wheel by a belt, and the small belt wheel is connected to a stirring motor. The fur pulp recovery device for the spinning provided by the invention has the advantages that the structure is simple; use is convenient; and the device is applicable to various occasions.

Owner:东群织造(苏州)有限公司

Grain breaking apparatus with spring hose inlets

InactiveCN109107705AHigh strengthGood shaping effectFeeding-stuffGrain treatmentsEngineeringDischarger

The invention discloses a grain breaking apparatus with spring hose inlets. The grain breaking apparatus comprises a shell, material feeders, a material discharger, a rack and a crushing component, wherein the shell is provided with the two material feeders, the material feeder comprises a spring hose, a joint and a material inlet, the lower end of the spring hose is connected to the joint, the upper end of the spring hose is connected to the material inlet, the joint is connected to the shell, the material discharger is installed at the lower end of the shell, and the material discharger is fixed in the middle of the rack. According to the present invention, the grain breaking apparatus has the novel structure, is suitable for the agricultural field, overcomes the disadvantage that the material inlet of the conventional shredder cannot move, can move the material feeder according to the different positions of the material, and can be conveniently used by farmers.

Owner:丁加艳

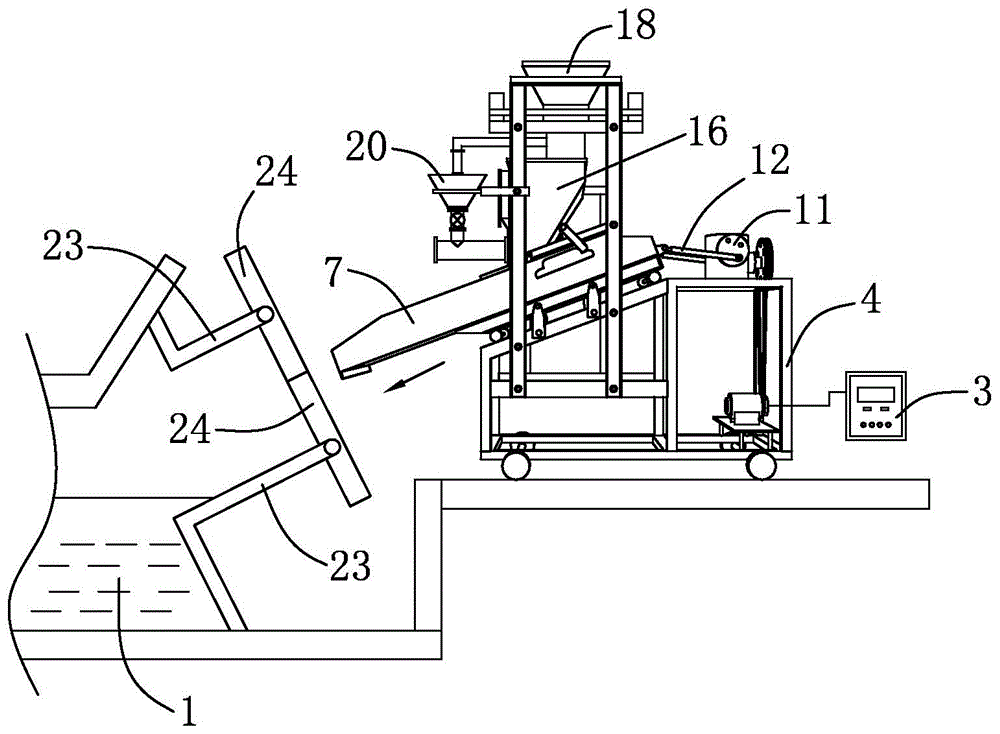

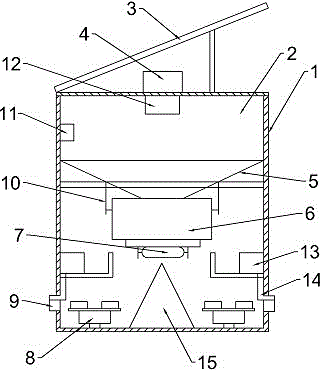

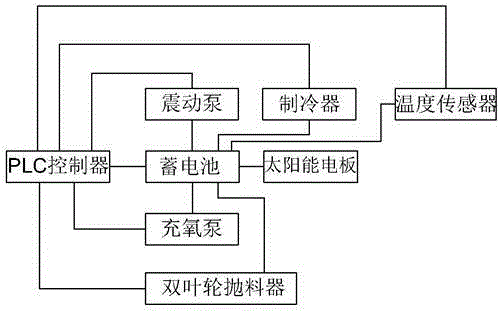

Multifunctional bait casting machine for Chinese mitten crab

InactiveCN106605622ASmooth castingQuality assuranceClimate change adaptationAgricultural fishingImpellerOxygen

The invention discloses a multifunctional bait casting machine for Chinese mitten crabs. The machine comprises a housing. A bunker is arranged on the top inside the housing. The lower end of the bunker is connected with a discharging hopper. A vibration discharging device is arranged under the discharging hopper. A vibration bump is arranged under the vibration discharging device. A control device is arranged on the front surface of the housing. A solar panel and a storage battery are arranged on top of the housing. A temperature sensor and a refrigerator are arranged in the bunker. A distributor fixed on the bottom of the housing is arranged right below the vibration pump. Two double-impeller throwers are arranged on the left side and the right side of the distributor respectively. The left sidewall and the right sidewall of the housing, close to the bottom end of the housing, are equipped with two throwing openings that correspond to the double-impeller throwers in position. An oxygen charging pump, on the inner wall of the housing, is arranged over each throwing opening. Each oxygen charging pump is connected with an oxygen charging pipe. One end of each oxygen charging pipe is arranged near the corresponding throwing opening. The multifunctional bait casting machine has a simple structure, is convenient to operate, covers a wide bait casting area, and is high in work efficiency. Moreover, bait is sent to the bottom of a pond after passing through the throwing openings to be oxygenated, so the oxygenation effect is great and the bait can be evenly cast.

Owner:CHONGQING ZEZUO AGRI CO LTD

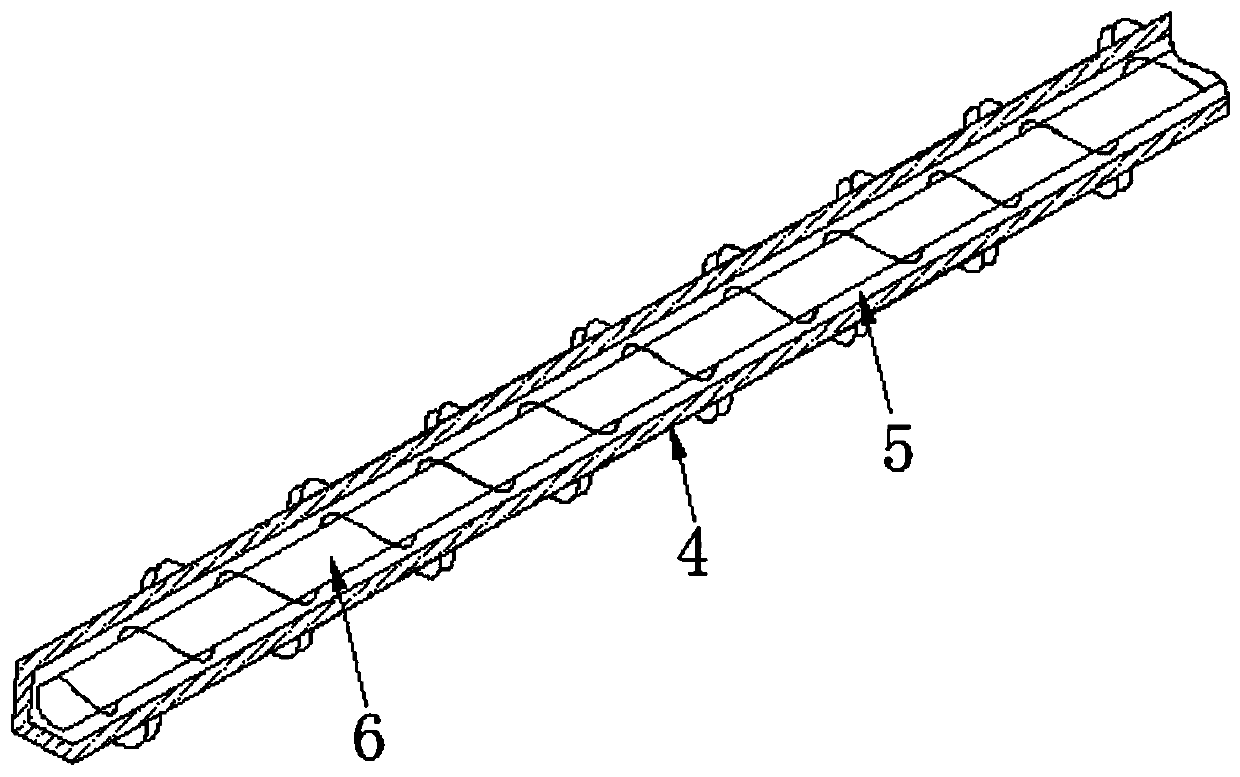

Feeding equipment for wheat flour blending treatment and working method thereof

ActiveCN114570276AMix evenly and comprehensivelyQuick mixTransportation and packagingMixer accessoriesPolymer scienceEngineering

The invention relates to the technical field of wheat flour blending treatment, in particular to material adding equipment for wheat flour blending treatment and a working method thereof.The material adding equipment comprises a material mixing assembly, a conveying assembly, a material adding assembly and a displacement assembly, the material mixing assembly is installed above one end of the conveying assembly, the conveying assembly is installed in the material adding assembly, and the displacement assembly is installed above the other end of the conveying assembly; the material adding assembly is installed below the displacement assembly, the material mixing assembly comprises a material mixing barrel, a first installation frame and three stirring frames, a plurality of inclined plates are obliquely fixed to the two ends of the interior of each stirring frame at equal intervals, a rotating connecting column drives the stirring frames to rotate, the three stirring frames rotate at the same time, and different positions in the material mixing barrel are stirred; the inclined plates are arranged in an inclined manner, so that the inclined plates can be in full contact with blended powder in the mixing barrel, the blended powder can leak out from a gap between the two inclined plates when the blended powder is stirred by the inclined plates, the stirring speed of the blended powder is increased, different blended powder can be mixed more comprehensively and uniformly, the mixing efficiency is higher, and time and labor are saved.

Owner:ANHUI WANXUE FOOD

a paint pump

ActiveCN104454552BIncrease inhalationImprove output efficiencySpecific fluid pumpsPump componentsImpellerDrive shaft

The invention discloses a coating pump, and belongs to the technical field of fluid pumps. The coating pump comprises a pump body, a feeding port is formed in one end of the pump body, and a vortex-shaped vortex channel is formed in the other end of the pump body. A partition wall is arranged at the position, close to the feeding port, inside the pump body, and an installing tube is arranged at the position, between the partition wall and a plunger piston, inside the pump body. A transmission shaft is installed on the installing tube in a rotating mode and penetrates through an installing cavity, and a rotating disc is fixedly installed at the position, inside the installing cavity, of the transmission shaft. A floating disc is arranged inside the installing cavity, a first impeller is fixedly installed on the transmission shaft, a circulation gap is formed between the floating disc and the rotating disc, and multiple through holes corresponding to the circulation gap are formed in the installing tube. The area of the section of the vortex channel is gradually increased outwards from the center of a vortex, a second impeller is fixedly installed on the transmission shaft and used for guiding fluid into the vortex channel, and a discharging port is formed in the tail end of the vortex channel. The technical problems that an existing coating pump is insufficient in suction volume and low in output efficiency are solved, and the coating pump is widely applied to continuously conveying the fluid.

Owner:NINGBO LIS IND

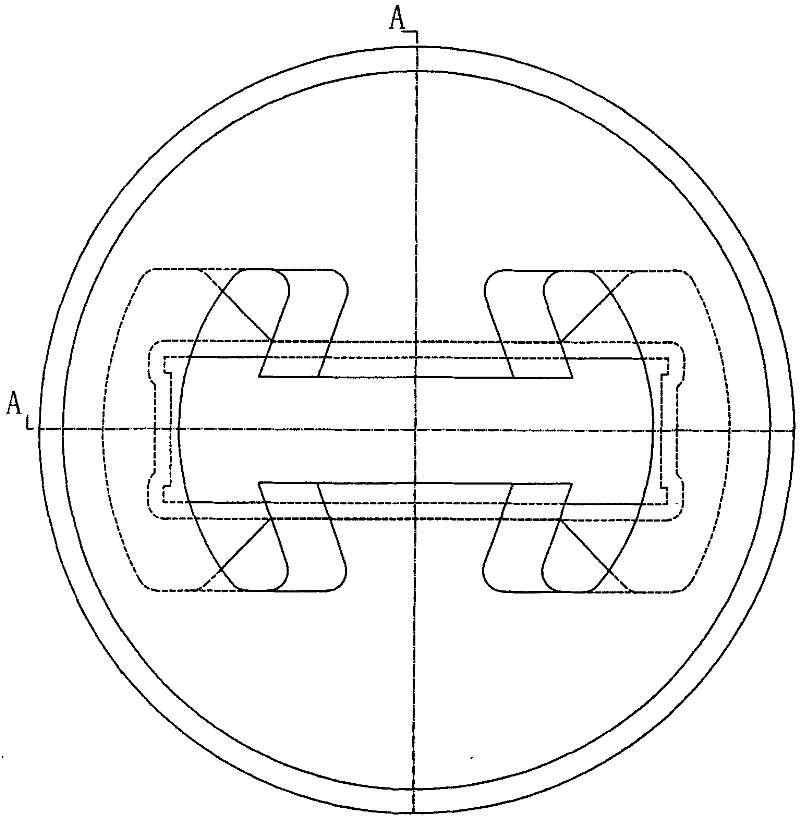

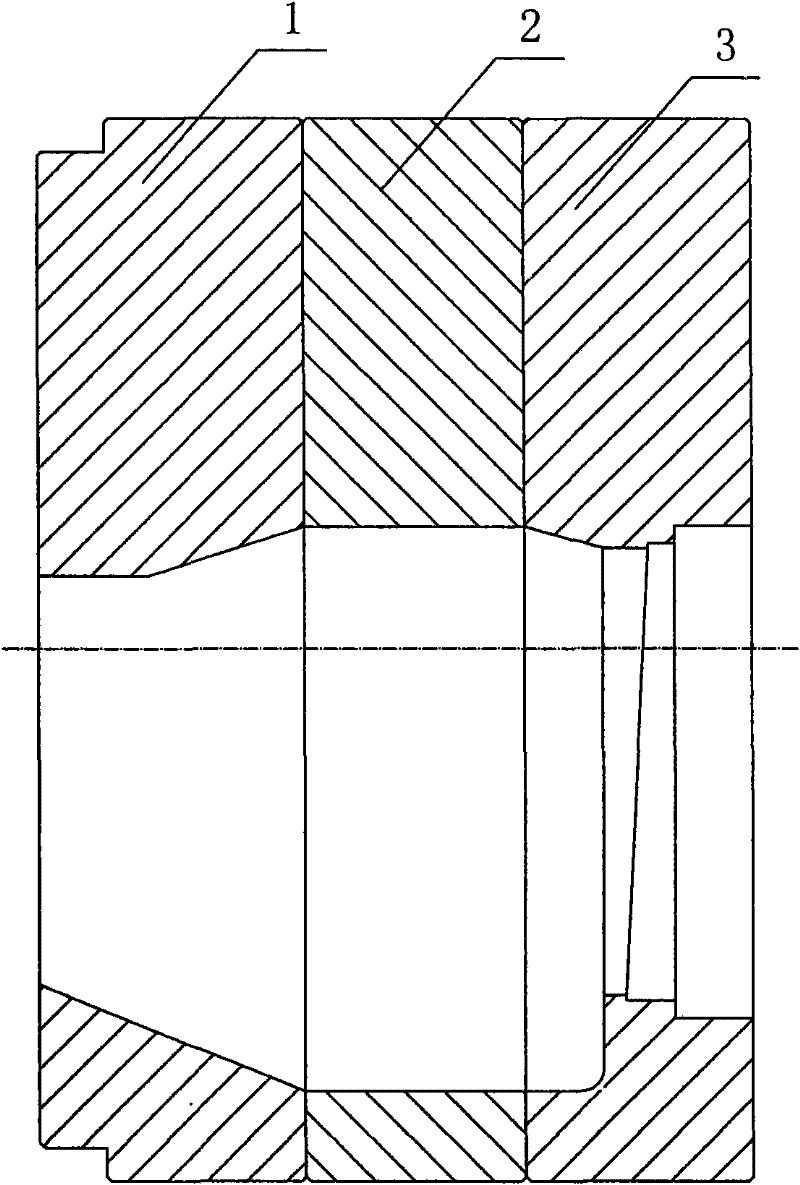

Large-scale solid profile hot extrusion mould of medium extruder

InactiveCN101658878BEnhanced feedingIncrease flow rateExtrusion diesVolumetric Mass DensityEngineering

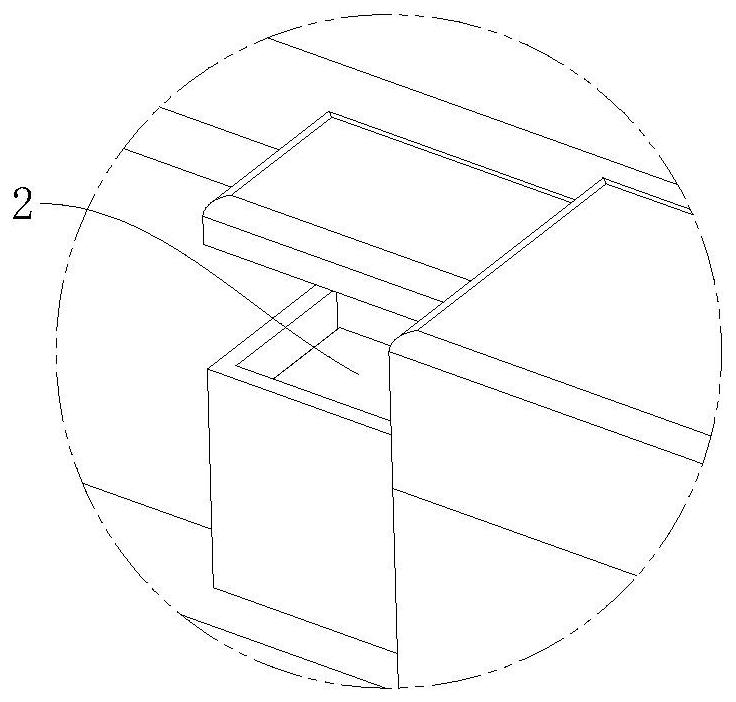

The invention relates to a large-scale solid profile hot extrusion mould of a medium extruder, formed by orderly laying up a front guide plate (1), a secondary guide plate (2) and a mould surface (3) from front to back. The front guide plate (1) comprises a first center material inlet hole (11), and the upper hole wall and the lower hole wall of the first center material inlet hole (11) consist of a front straight hole wall (111) and a back inclined hole wall (112), the back inclined hole wall (112) is gradually extended from front to back, the left hole wall (113) and the right hole wall (113) form an inclined hole wall shape, and the inclined hole wall is gradually extended. The secondary guide plate (2) comprises a second center material inlet hole (21), and the second center material inlet hole (21) is in a dumbbell shape. The center part of the second center material inlet hole (2) is adjacent to a mould cavity of the mould surface, and the left end and the right end are extended. The mould surface (3) comprises a guide pit (31) and the mould cavity (32), the upper pit wall (311) and the lower pit wall (311) form an inclined surface shape, and the inclined surface is tapered.The invention can guarantee the sufficient material supply of large-scale solid profile angle positions, can effectively increase extruding force, and guarantee the density and the strength of profiles.

Owner:JIANGYIN GIANSUN MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com