Patents

Literature

119results about How to "Smooth casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly floating agrochemistic formulations for rice field and method of producing the same

The invention discloses the composite of an environment-friendly rice flotable agricultural chemical preparation and a novel manufacture process thereof, which belongs to the field of farm chemical. The preparation is formed by compounding 0.1 to 50 percent of a weed killer, an insecticide, a fungicide or plant growth regulator active ingredients, 0.1 to 30 percent of a micropore sustained release agent, and 99.8 to 20 percent of a floatble carrier according to mass percentage. The preparation can effectively save the active ingredients by more than 70 percent, and can be directly applied on the surface of rice paddy field. The preparation has the characteristics of low cost, high efficacy, lasting drug action, safety, convenient use and so on, and is an environment-friendly agricultural chemical preparation.

Owner:湖南大方农化股份有限公司

Isothermal extrusion production method of refractory metal rotating target material

ActiveCN104846341ASimple processHigh densityExtrusion diesVacuum evaporation coatingAlloyVolumetric Mass Density

The invention relates to an isothermal extrusion production method of a refractory metal rotating target material. During the preparation of the refractory metal rotating target material by adopting an isothermal extrusion process, a target material tube target blank needs to be pressed firstly by adopting CIP (Cold Isostatic Pressing), then a refractory metal or refractory metal alloy target blank with density of 60-80 percent is obtained through sintering, then the pre-sintered target tube blank is contained in an isothermal extrusion die, the high-density low-oxygen-content refractory metal rotating target material is obtained by adopting a relatively simpler isothermal extrusion production flow, the method is not limited by materials, the geometric size, surface quality, internal organization, physical property and the like of the entire target material can be enabled to be optimal, the production efficiency is greatly improved, the production cost is reduced, and the method is particularly suitable for producing refractory metal alloy rotating target materials which are difficult to produce by adopting other processes. The casting uniformity is high and the crystal gains are fine and tiny; the compactness is high and the density reaches more than 99 percent; the process is simple and the production cost is low.

Owner:GEMCH MATERIAL TECH SUZHOU

Al-Mg-Ca-Fe alloy contg. micro-carbon, low silicon, low phosphorous, low-sulphur used for steelmaking

The invention relates to a micro low carbon, low silicon, low phosphor, and low sulfur Al-Mg-Ca-Fe alloy used in steel-making. It uses as deoxidizer and contains 20-85wt% Al, 5-20wt% Mg, 1-15wt% Ca, C less than 0.02wt%, Si less than 1.0wt%, P less than 0.02wt%, S less than 0.02wt%, the rest is Fe. It is smelted from line frequency furnace. The invention has the advantage of easy to use, stable, and could improve the recovery factor of the metal element. The molten steel treated by the deoxidizer has good fluidity, high work rates, high benefits, etc. The deoxidizer could discharge the impurity, and it has good mechanical behavior, good quality, long useful life and good social benefit.

Owner:本溪冶炼集团有限公司

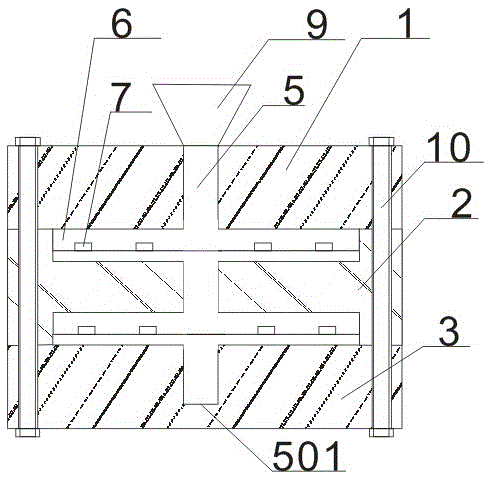

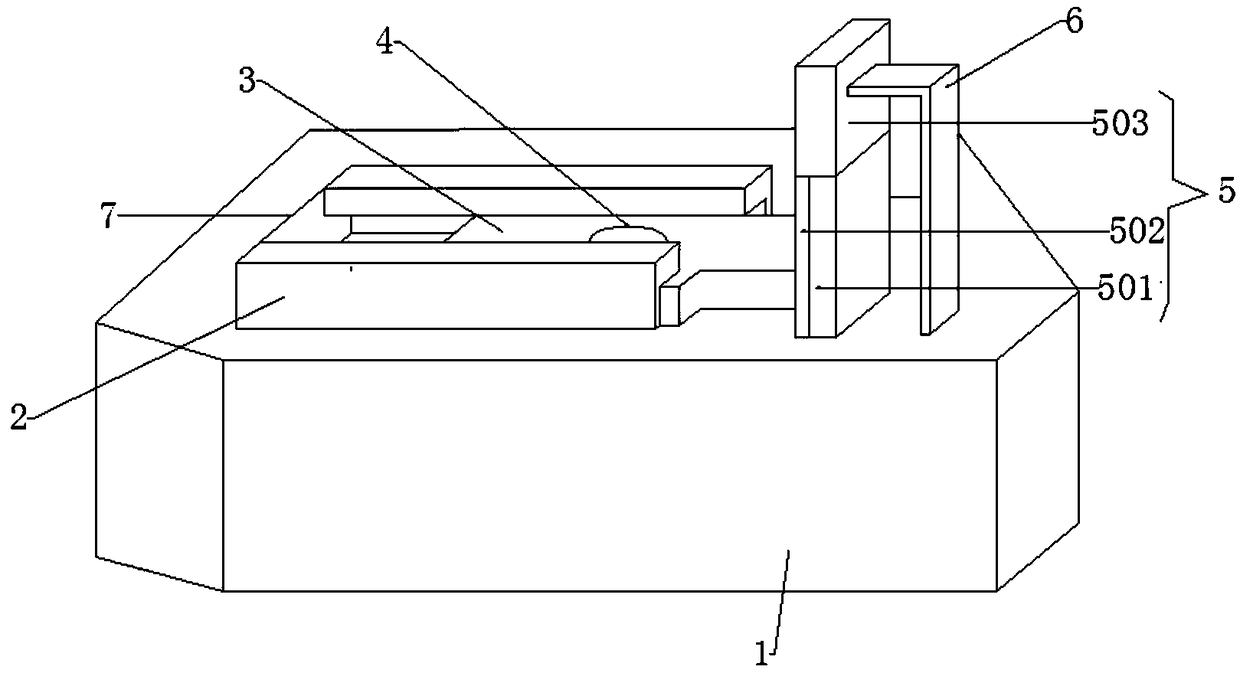

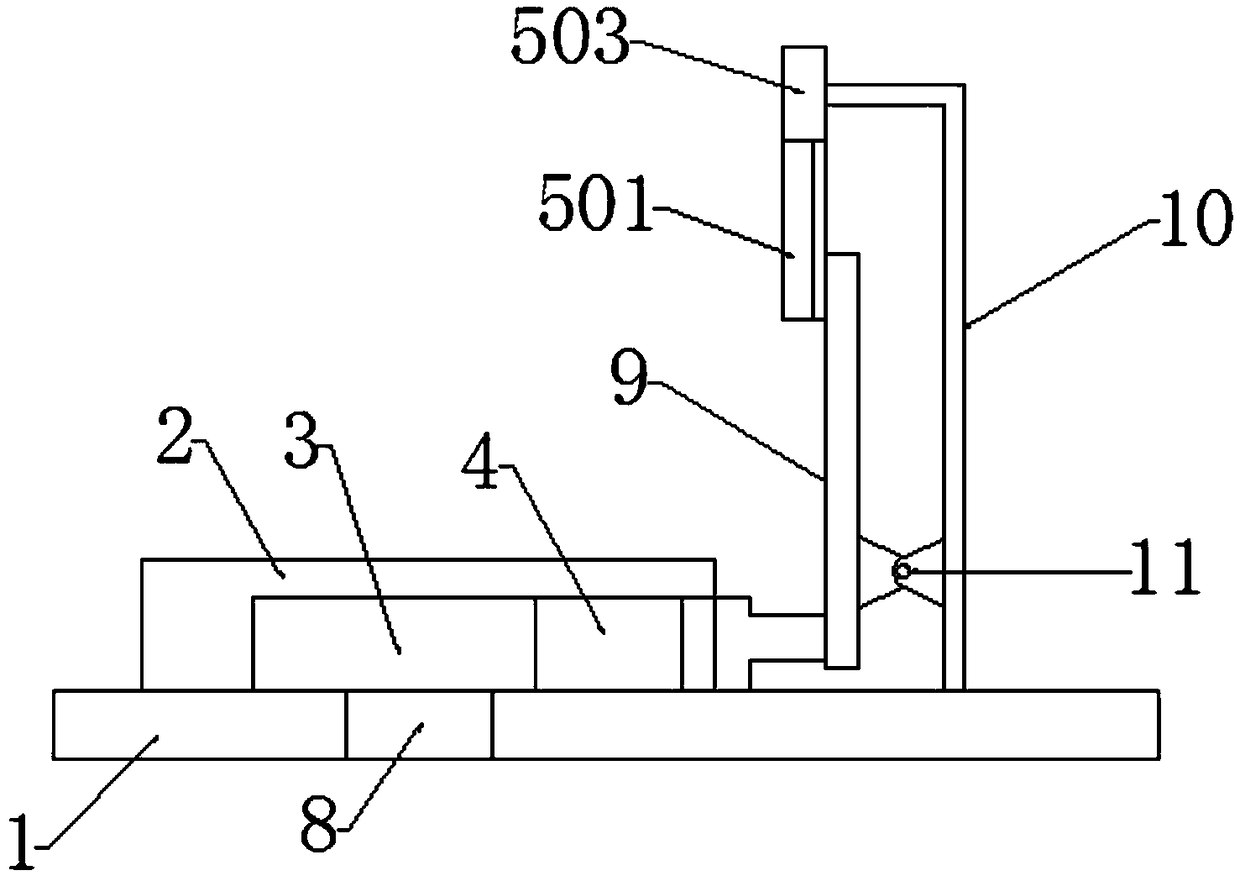

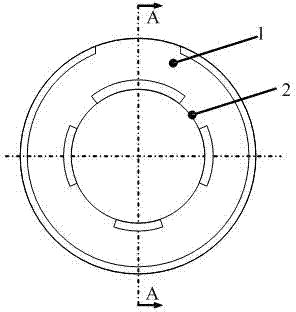

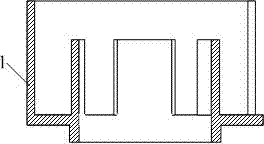

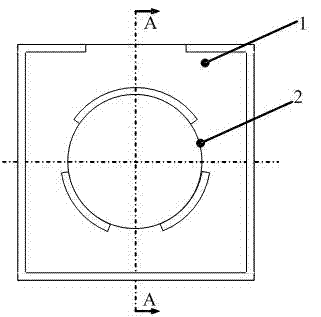

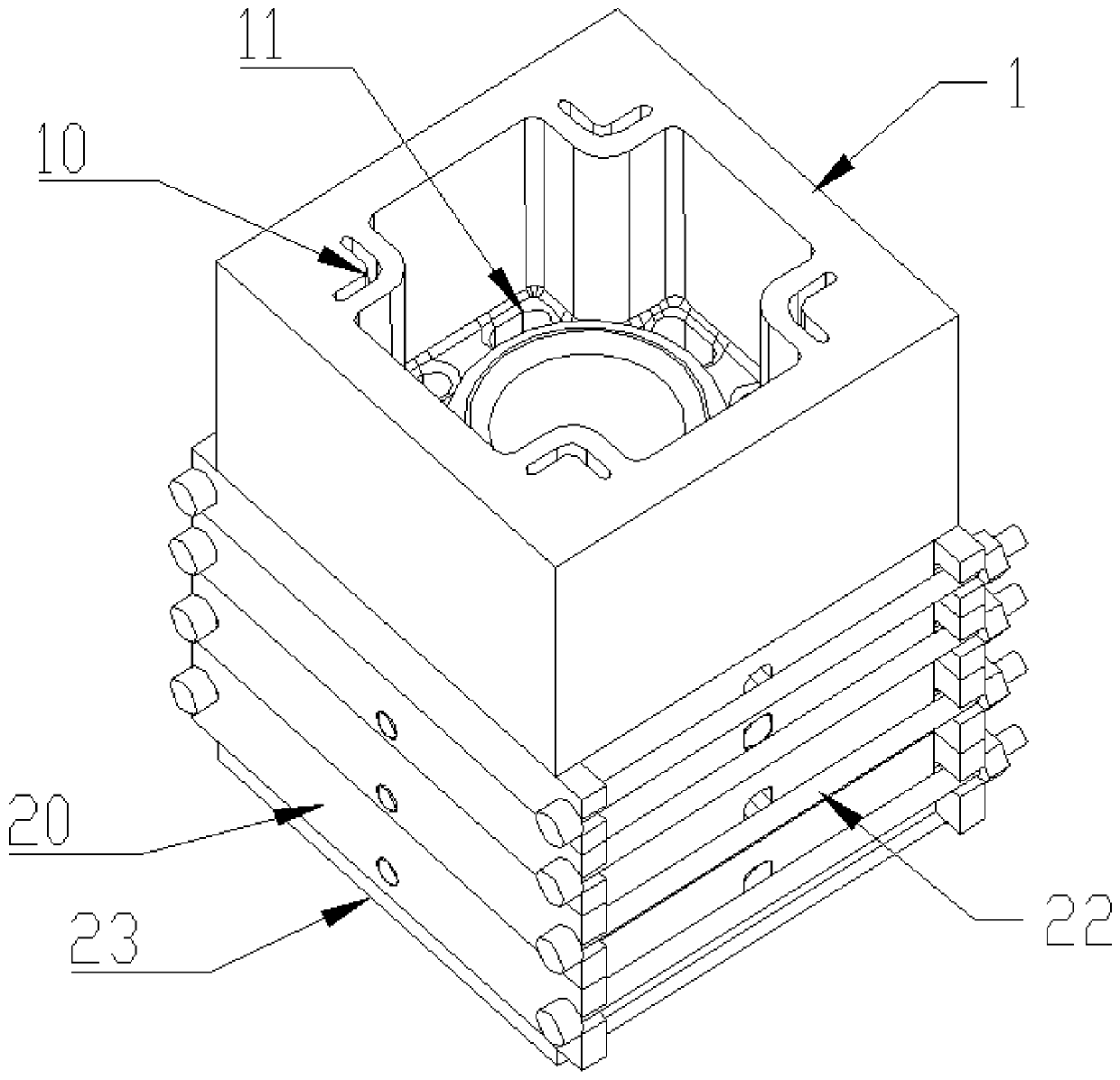

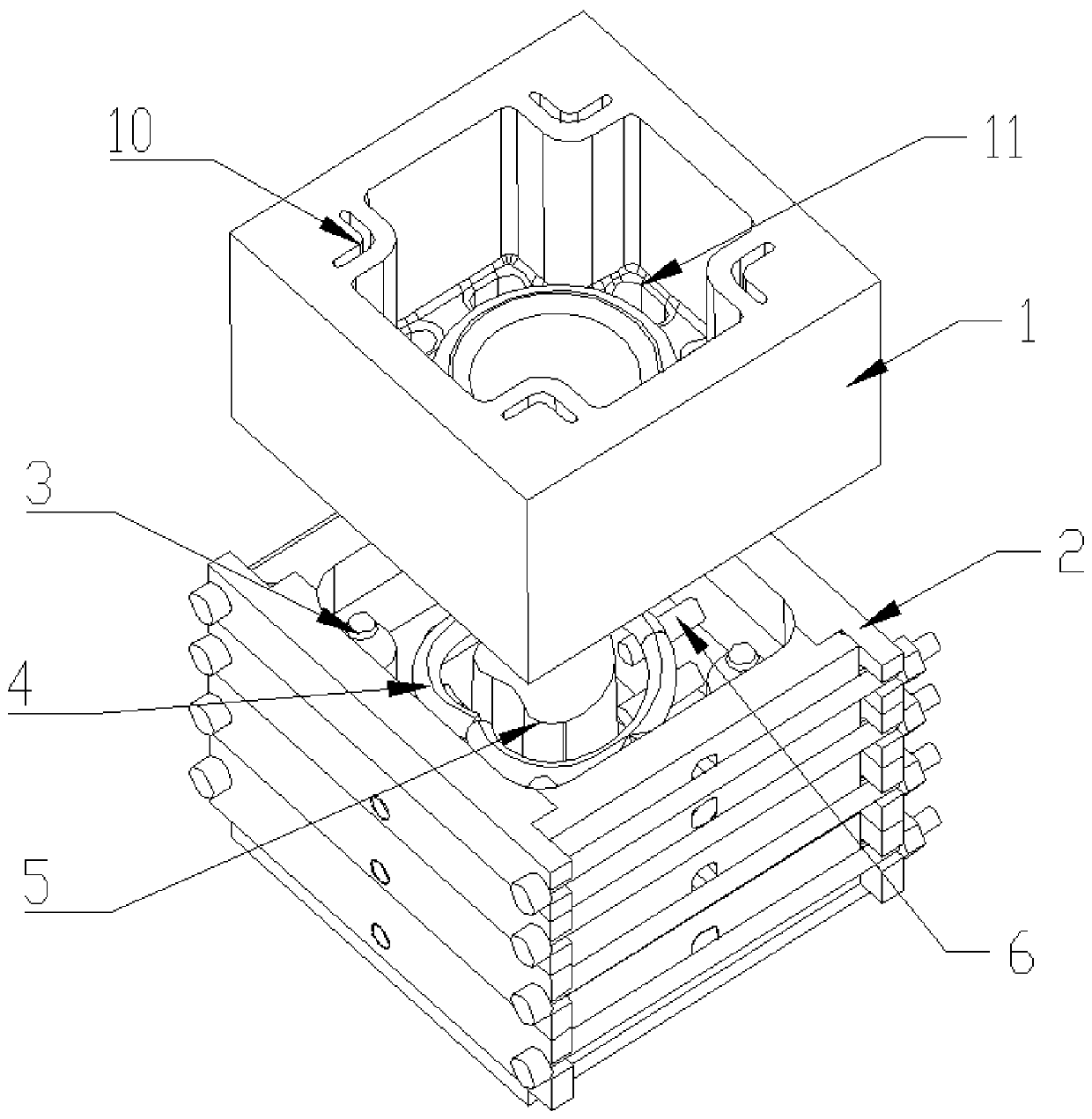

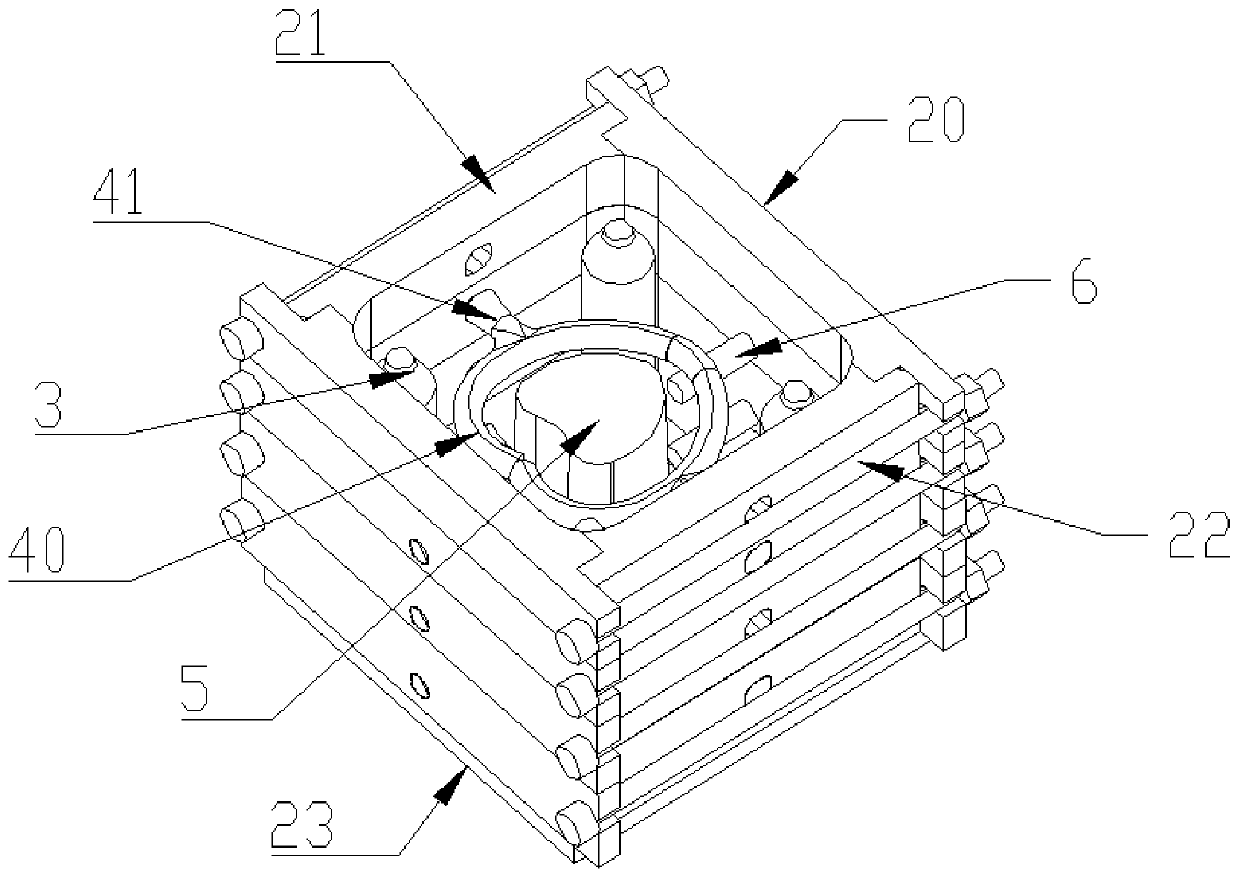

Casting mold for cylindrical housing part and casting method by using the mold

InactiveCN103143685AShorten speedThe casting process is stableFoundry mouldsFoundry coresComposite materialManufacturing engineering

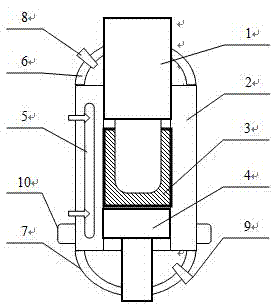

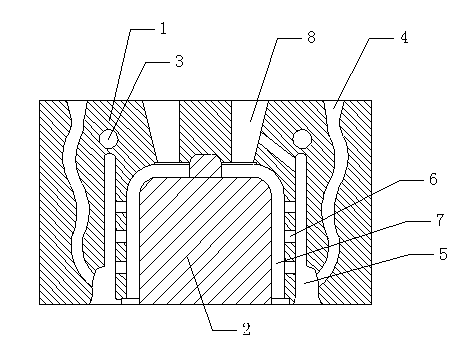

The invention discloses a casting mold for a cylindrical housing part comprising an outer mold (1), an inner mold (2), runners (4), a molding cavity (7) and risers (8). The outer mould (1) is composed of two half-mold bodies, the cylindrical inner mold (2) is located at the center of the outer mold (1); two runners (4) are arranges at both sides of the cavity (7), each runner (4) is connected to a buffer channel (5), each buffer channel (5) is connected with the molding cavity (7) through connecting channels (6), and both sides of the top of the molding cavity (7) are provided with a riser (4) each. The invention also discloses a casting method by using the mold. In the invention, molten aluminum is fully filled in the molding cavity, and the molten aluminum pressures of various parts of the molding cavity is balanced, so no crack is produced after the molten aluminum is cooled, the yield is high, the casting process is continuous and fast, and the efficiency is improved.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Method for producing 23MnB steel by adopting vacuum process

ActiveCN102409133AImprove hardenabilitySmooth castingManufacturing convertersFerrous metallurgyAluminium

The invention discloses a method for producing 23MnB steel by adopting a vacuum process and belongs to the field of ferrous metallurgy. The invention aims at solving the technical problem of providing a method for producing 23MnB steel by smooth casting with a large-size continuous casting machine. The method comprises the following steps of: a, smelting in a converter; b, when steel tapping, adding calcium carbide in molten steel and then adding aluminum, so that the weight percentage content of acid-soluble aluminum in the molten steel is between 0.014% and 0.019%; c, refining in an LF (ladle furnace); d, after refining, carrying out vacuum circulation treatment, wherein in the treatment, aluminum is added into the molten steel so that the content of acid-soluble aluminum is 0.025-0.055%, titanium is added so that the content of titanium is 0.02-0.06%, and boron is added so that the content of boron is 0.0005-0.003%; and e, continuously casting. According to the invention, the content of acid-soluble aluminum is strictly controlled from various steps, the yield of boron is high, the hardenability of the 23MnB steel is good, and the water gap of the large-size continuous casting machine is prevented from being dwindled.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Method for controlling nitrogen content of 20CrMnTi series gear steel with high scrap ratio produced by electric furnace process

ActiveCN112553527AReasonable designIncrease tapping temperatureMelt-holding vesselsProcess efficiency improvementSlagTundish

The invention discloses a method for controlling the nitrogen content of 20CrMnTi series gear steel with a high scrap ratio produced by an electric furnace process. The steel comprises the componentsin percentage by weight: 0.17%-0.23% of C, 0.17%-0.37% of Si, 0.80%-1.10% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 1.00%-1.30% of Cr, 0.010%-0.040% of Al, 0.04%-0.10% of Ti and the balance Fe and inevitable impurities. By reasonably controlling tapping carbon and tapping temperature of an electric furnace, selecting a reasonable technology route and key parameters, optimizing the addition amount of tapping aluminum blocks and slag charge, optimizing a refining operation technology and adopting argon sealing and an overall tundish for continuous casting, thetechnical indexes such as purity, hardenability and oxygen content of the steel for a gear are guaranteed while the nitrogen content is effectively reduced, and various technical requirements of usersfor high-grade gear steel are completely met.

Owner:ZENITH STEEL GROUP CORP +1

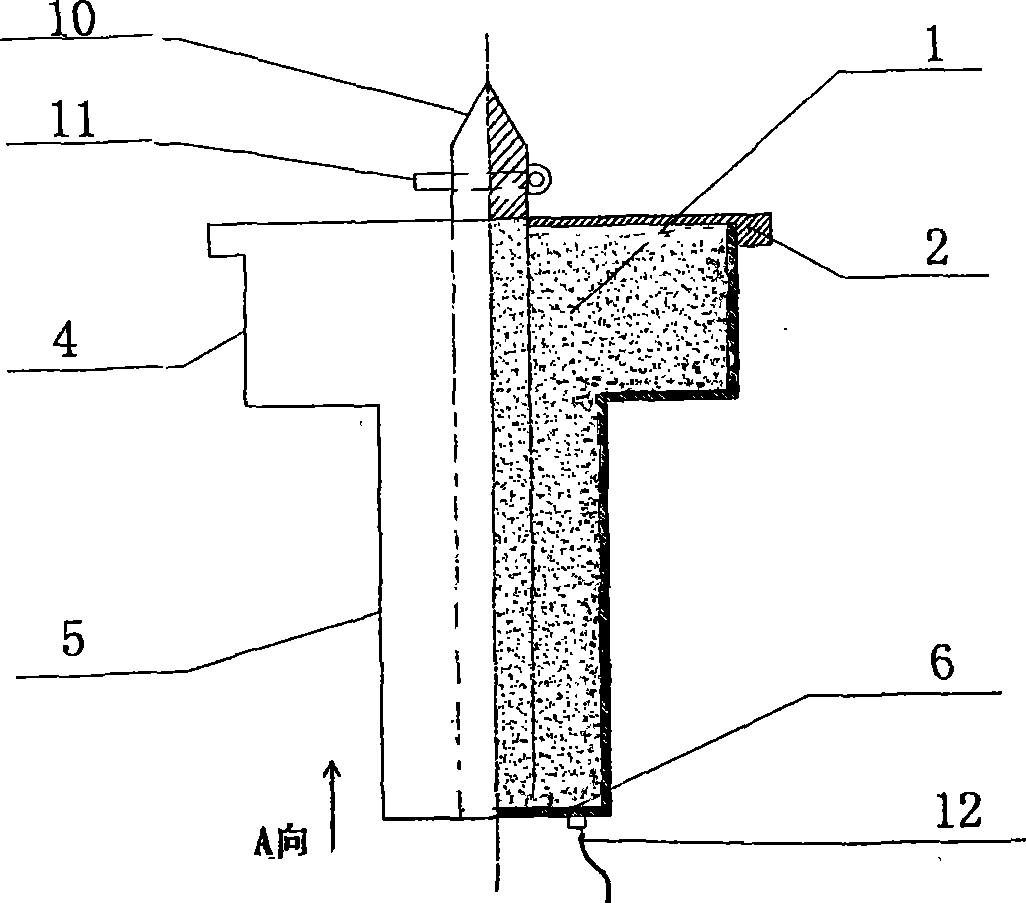

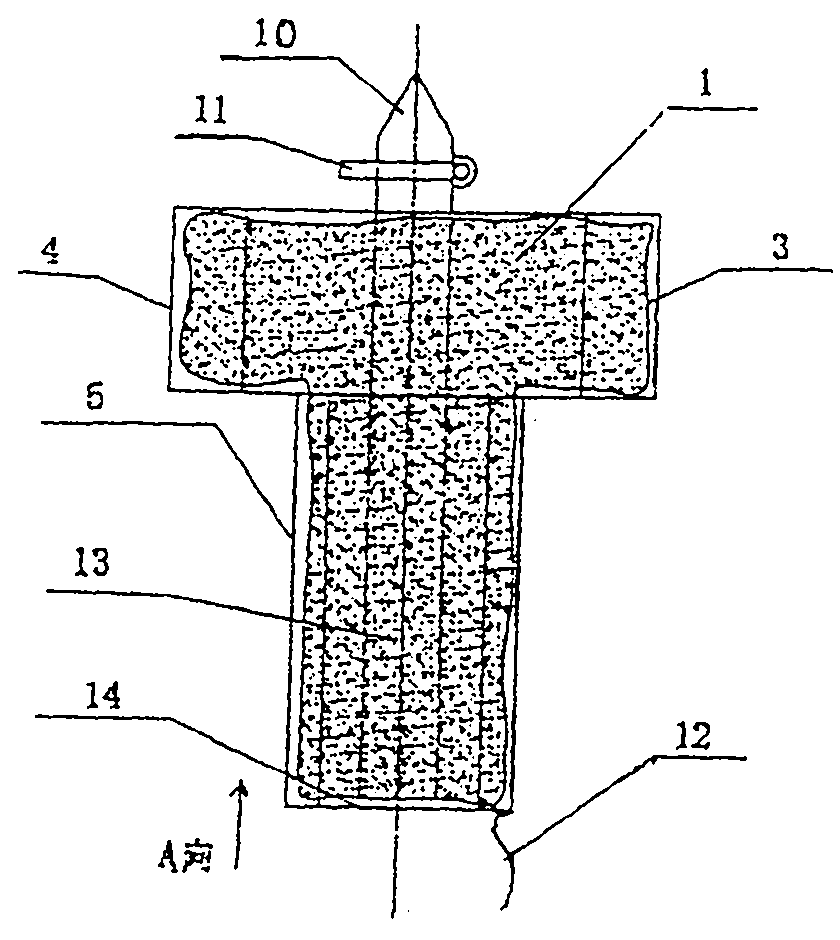

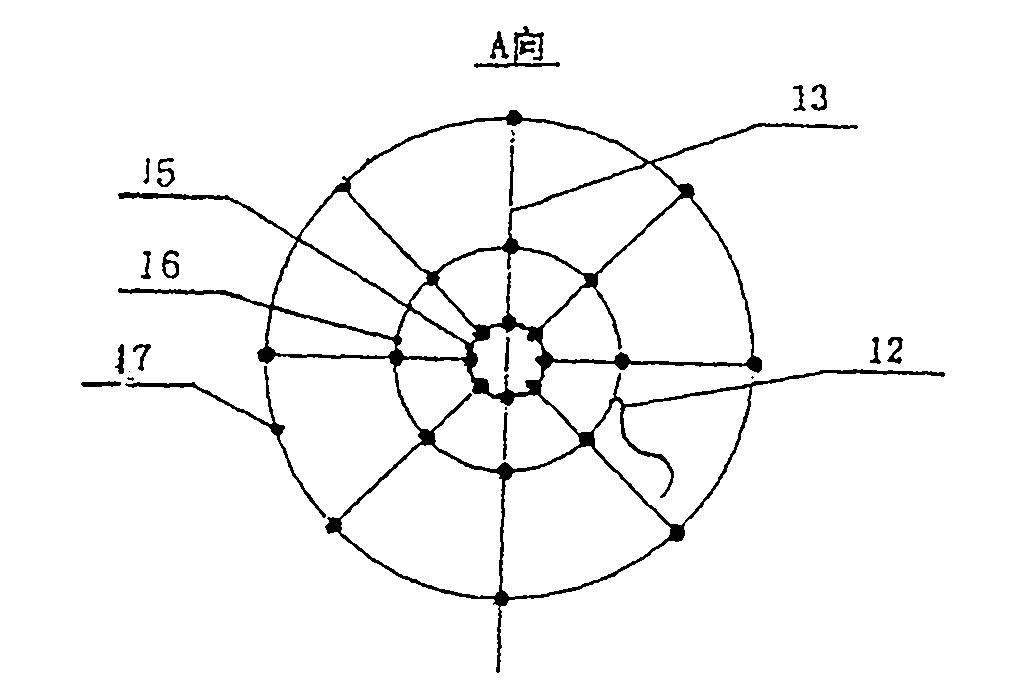

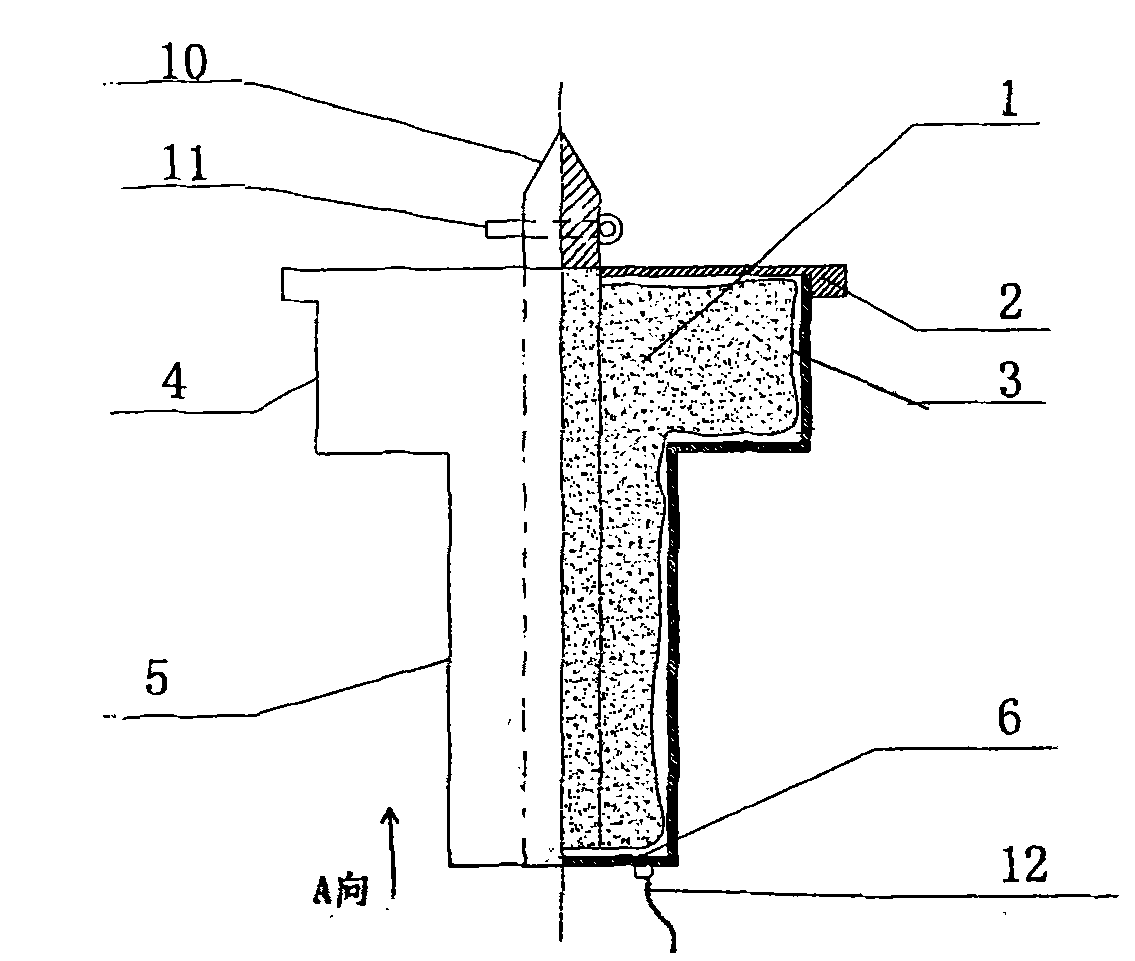

Ladle nozzle casting conduction plug and use method thereof

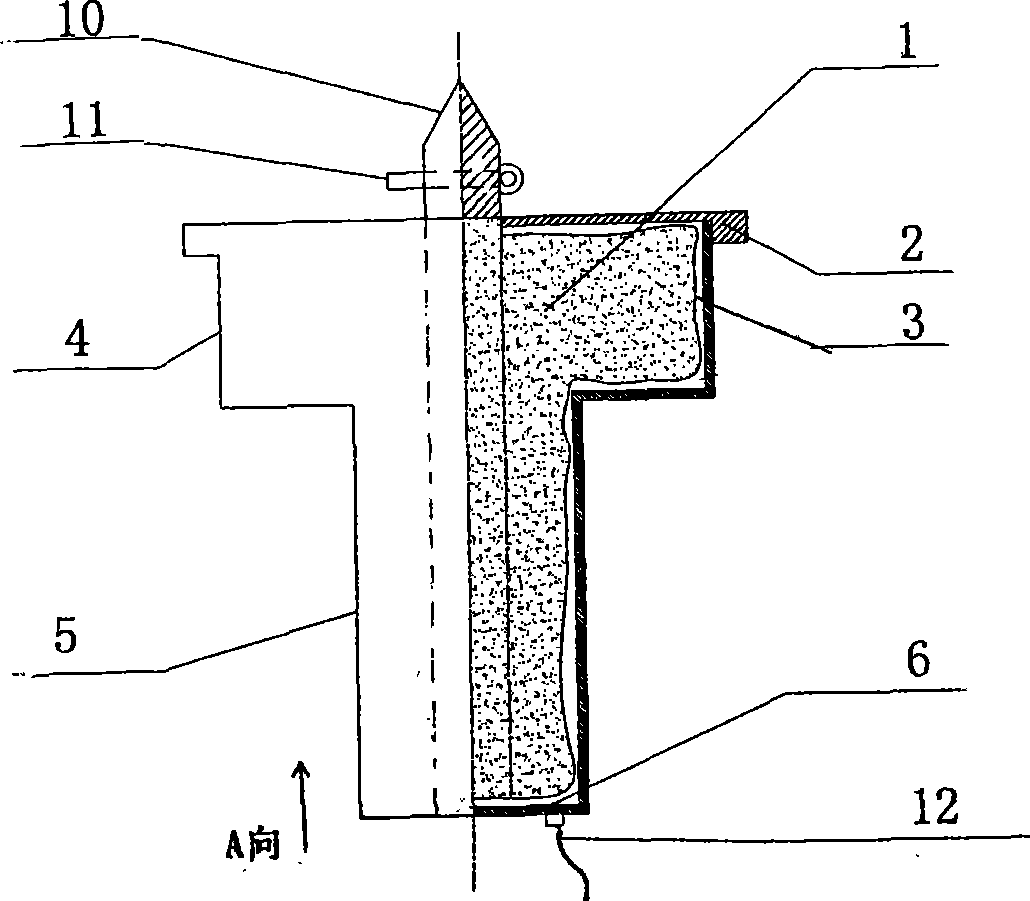

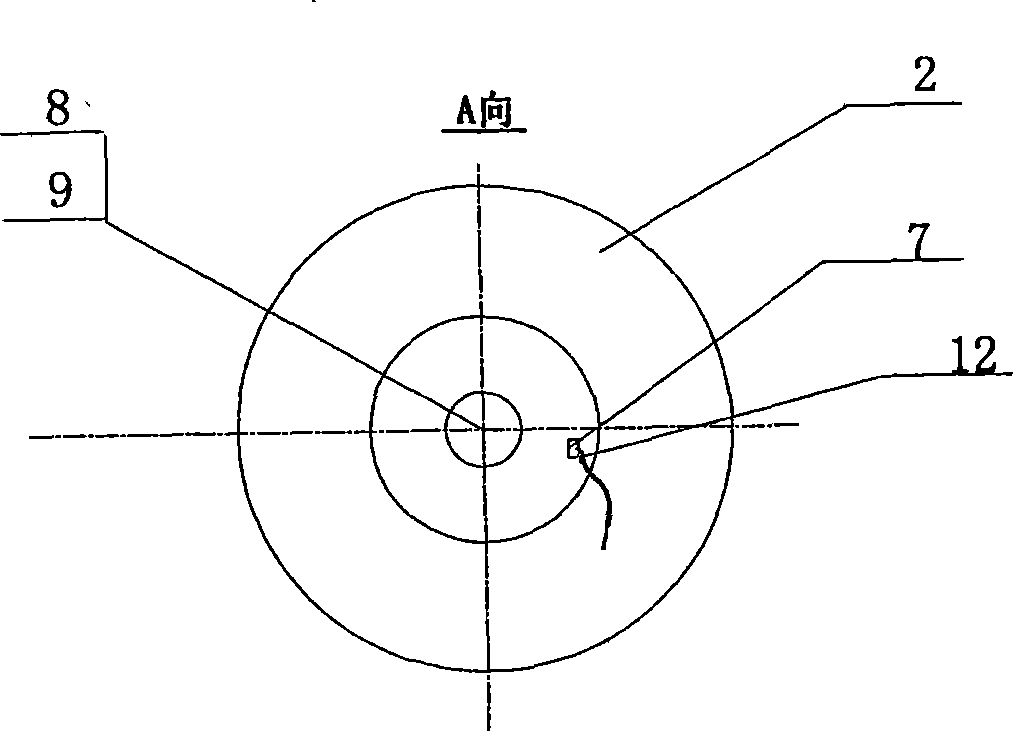

InactiveCN101380675AChange the setting methodAppropriate dosageMelt-holding vesselsBrickHigh intensity

The invention discloses a ladle nozzle casting drainage plug and a using method thereof. The invention belongs to an attachment device of the ladle for starting the casting operation, in particular to a drainage device used for casting molten steel by a brick cup nozzle at the bottom part of the ladle as well as a using method thereof. The drainage device includes a drainage agent and is characterized in that a plug cap and a plug post are connected into a cylinder with variable diameters; a plug cover is arranged on the plug cap; a bottom plate in a mushroom shape is arranged below the plug post; the drainage agent is packaged / or directly connected into the cylinder composed of the plug cap, the plug post, the plug cover and the bottom plate by a soft bag; the plug cap and the plug post are arranged in a guide rod in a sliding way; a haulage rope is hung on the bottom plate. When in use, the plug post is inserted and fixed into the brick cup nozzle; the plug cap is covered above the brick cup. During casting, the drainage agent drains under the effects of the heat and the gravity of the hot molten steel. The invention has the advantages of simple structure and easy manufacturing; being convenient for arranging the drainage plug for a short time; proper dosage of the drainage agent, high intensity, accurate position, large covering area, stable, safe and reliable mounting, avoiding residues from plugging the nozzle, saving the cost for treating the plugging of the nozzle and being beneficial to production.

Owner:安徽中实冶金材料工程技术研究有限公司

Composite alloy of Al - Mg - Ca - Fe with lower carbon, silicon, phosphor, and sulfur in use for final steelmaking deoxidizer

This invention relates to a final deoxidizer for steelmaking, which is low-C, low-Si, low-P and low-S Al-Mn-Mg-Ca-F alloy. The alloy can be used as the final deoxidizer for steelmaking with good effect, and does not need further refinery of steel. The alloy comprises: C less than or equal to 0.2 wt.%, Si less than or equal to 1.0 wt.%, P less than or equal to 0.02 wt.%, S less than or equal to 0.02 wt.%, Al 40-50 wt.%, Mn 1.0-10 wt.%, Mg 0.1-10 wt.%, Ca 0.1-10 wt.%, and Fe as balance. This invention adopts main frequency induction furnace smelting to produce the final deoxidizer. The final deoxidizer has such advantages as high specific gravity, low melting point, no pulverization, good deoxidation and desulphurization effects, high yield, high fluidity of deoxidized molten steel, no nodulation, easy suspension of deoxidized product, low inclusion total content, high molten steel purity, good steel quality, fine grains, good mechanical properties, and long service life.

Owner:李兴有

Method for producing high-alloy high-strength peritectic steel with compact strip production (CSP) sheet continuous casting machine

The invention discloses a method for producing a high-alloy high-strength peritectic steel with a compact strip production (CSP) sheet continuous casting machine. The method comprises the following steps that preliminary desulphurization of molten iron is conducted; decarburization, dephosphorization and transition of furnace are conducted; refining treatment outside a ladle furnace(LF) is conducted, and qualified molten steel is obtained; tundish protective casting of an air curtain retraining wall is mounted; first cooling of a funnel type sheet continuous casting machine is conducted; recooling with automatic water distribution is conducted; push bending and straightening are conducted; shearing of a mechanical swinging shear is conducted; and high-alloy high-strength peritectic steel casting blanks are obtained. According to the method for producing the high-alloy high-strength peritectic steel with the CSP sheet continuous casting machine, cooperation of water volume and water temperature is achieved through adoption of high crystallization rate casting powder and a crystallizer, and low cooling is achieved; generation of surface indentation and cracks of blank shell in the crystallizer because peritectic characteristic line contracts too much is effectively controlled; the problem that surface vibration is deep is effectively solved through high-frequency and small-amplitude technology; smooth casting and stable control over quality of the high-alloy high-strength peritectic steel under the CSP sheet continuous casting high pulling speed are achieved; compared with the prior art, surface defect rate of the casting blanks is controlled below 0.5%; and international advanced level is reached.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

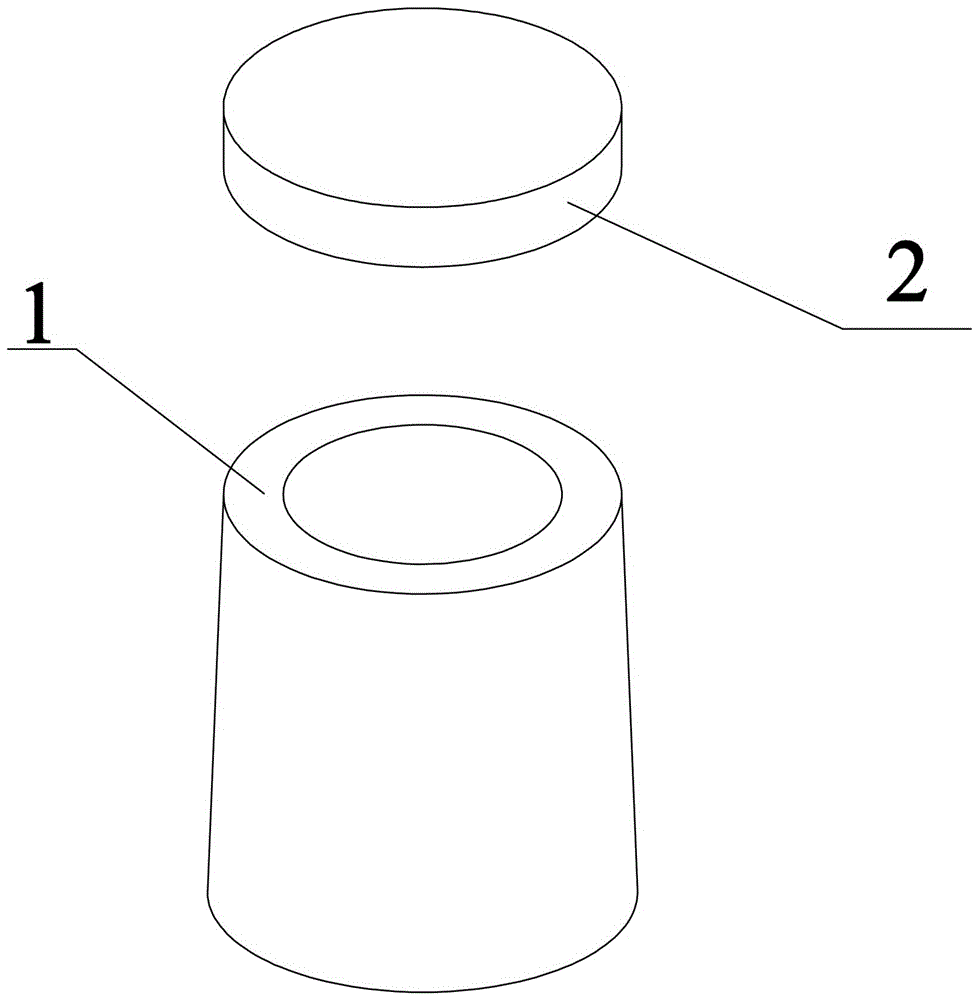

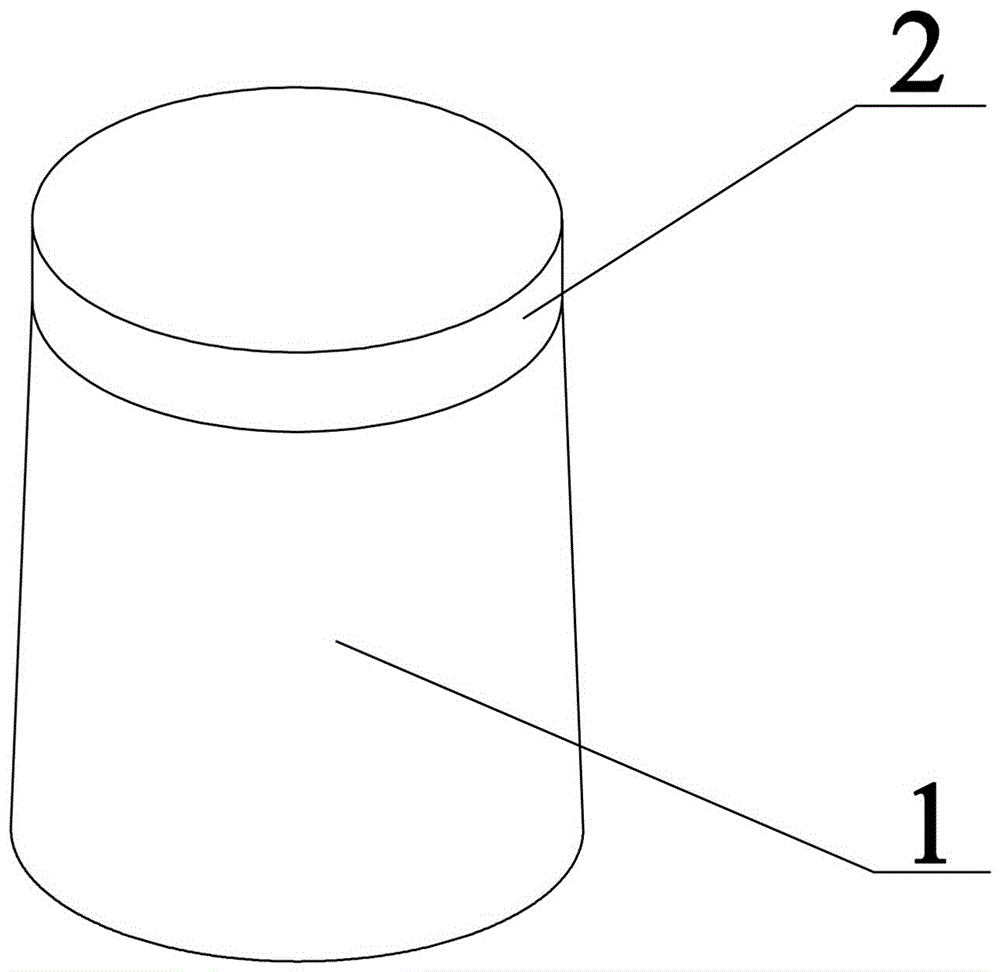

Cast steel exothermic riser sleeve

The invention relates to a casting riser sleeve, in particular to a cast steel exothermic riser sleeve. The two ends of the exothermic riser sleeve are opened. A top cover is arranged at the top end of the exothermic riser sleeve. The top cover is made of precoated sand. The exothermic riser sleeve is adopted for replacing a sand mold overflow riser in the prior art, the setting time is prolonged, heat supply is uniform, and the interior of an exothermic riser is free of defects, deformation and expansion; and the surface of a casting is bright and clean, the appearance is tidy, the technology yield is increased by 4.6%, and the production cost is reduced.

Owner:西峡飞龙特种铸造有限公司

Method for producing 23MnB steel in converter process

ActiveCN102424894AImprove hardenabilityFree oxygen removalProcess efficiency improvementTitaniumMolten steel

The invention discloses a method for producing 23MnB steel in a converter process, belonging to the field of ferrous metallurgy, and aiming to solve the technical problem of providing a method for producing the 23MnB steel through smooth casting of a large-scale continuous casting machine while the hardenability of boron-containing steel is guaranteed. The method comprises the following steps: a,smelting in a converter; b, adding calcium carbide and aluminum into molten steel when the steel is discharged, so that the weight percentage of acid-soluble aluminum in the molten steel is 0.014-0.019 percent; c, stopping heating when the temperature of the molten steel is 1570-1585 DEG C during refining, adding the aluminum into the molten steel so that the content of the acid-soluble aluminum is 0.025-0.055 percent, adding titanium so that the titanium content is 0.02-0.06 percent, and adding boron so that the boron content is 0.0005-0.003 percent; and d, casting continuously. The content of the acid-soluble aluminum is controlled in each step, the hardenability of the boron-containing steel is good, and the water port of the large-scale continuous casting machine can be prevented frombecoming smaller.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

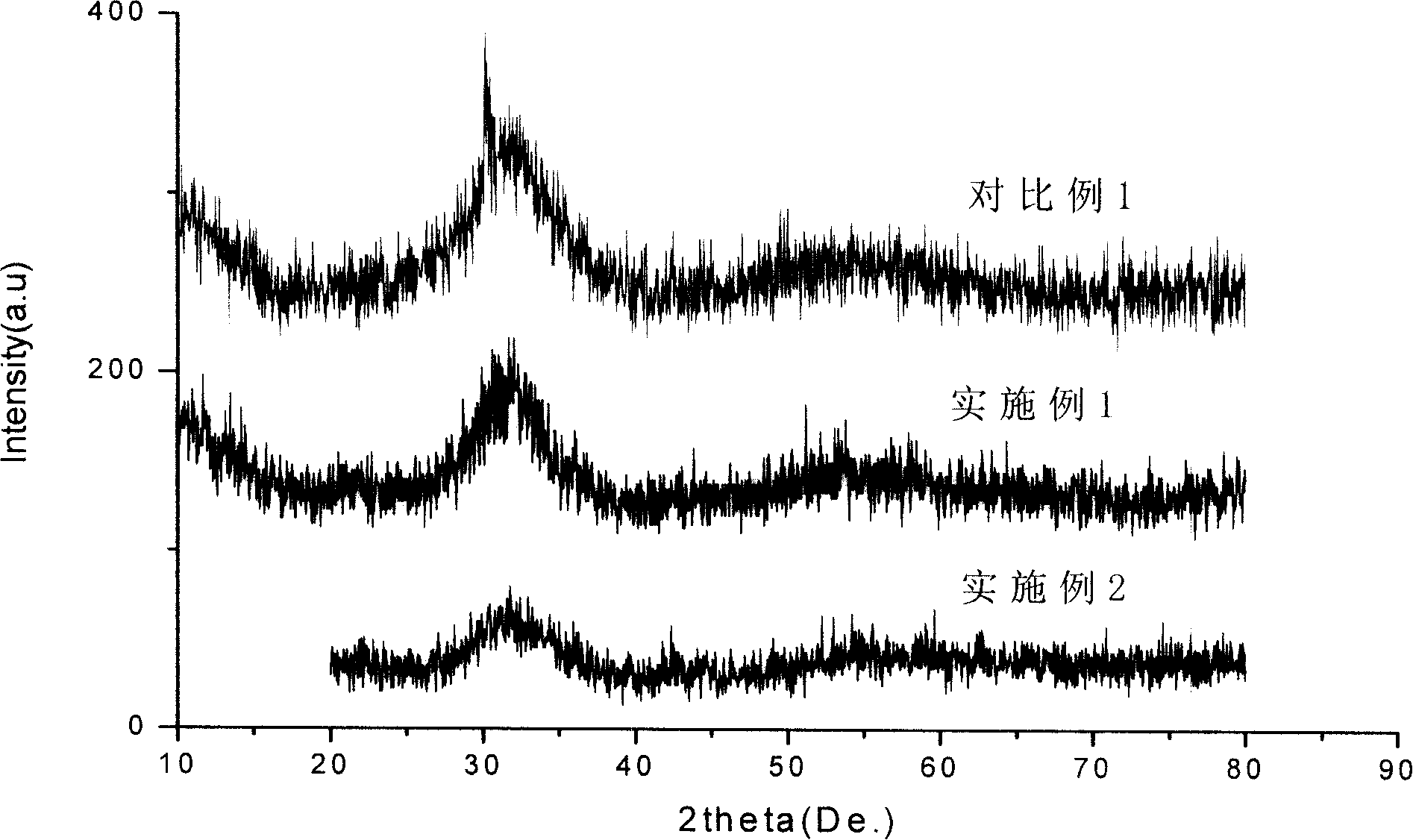

Method for improving amorphous alloy forming ability

InactiveCN101195874AImprove mechanical propertiesLower requirements for environmental protectionRare earthAmorphous metal

The invention discloses a preparation method of amorphous alloy, which comprises the following steps: under the gaseous protection, an element is added in one of Zr radical, Ti radical, Mg radical, Cu radical, La radical and Fe radical amorphous alloys, the amorphous alloys are melted in the reaction furnace according to the metric ratio and rapidly cooled to coagulate, and the added element is a lanthanon element. The lanthanon element occupies 0.1 percent to 10 percent of the entire atom percent content of the amorphous alloy. By adopting the method of the invention to prepare amorphous alloy, the requirement to the raw material and the foreign impurity gas content of the reacting container can be reduced, and simultaneously, the amorphous forming capability and performance of the amorphous alloy is enhanced.

Owner:BYD CO LTD

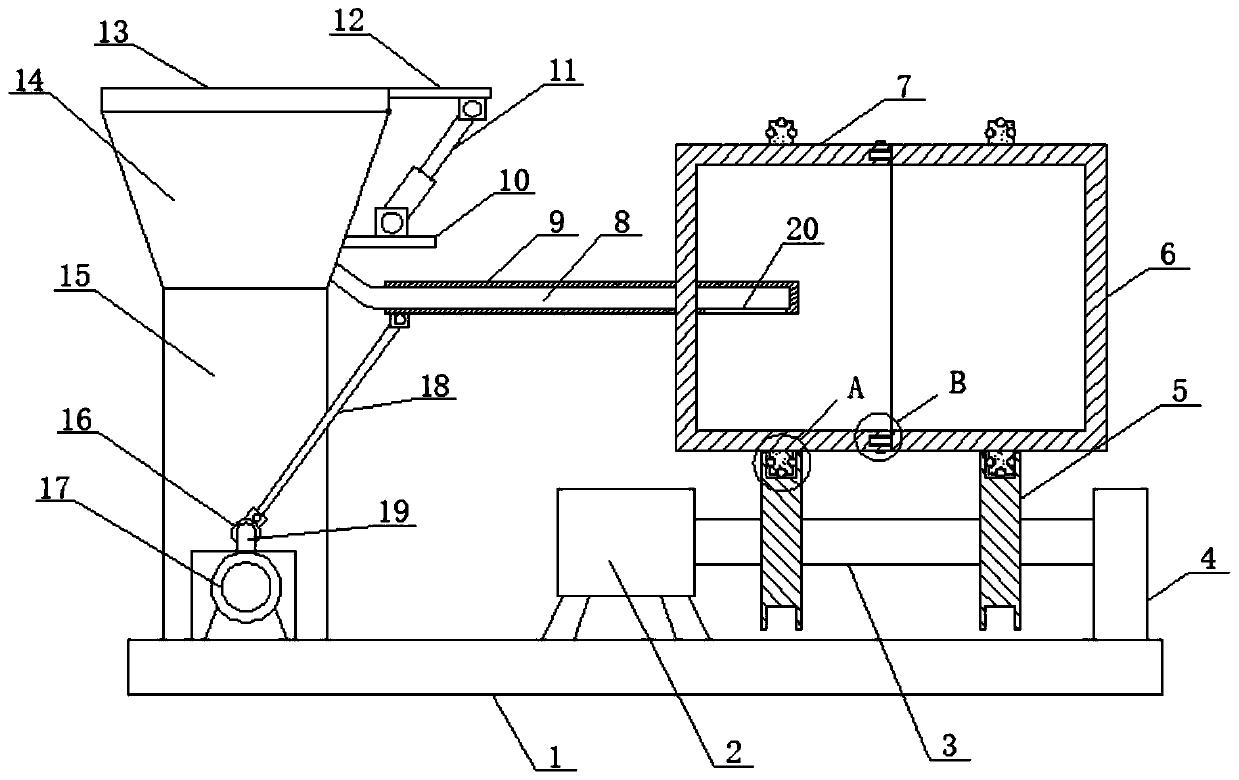

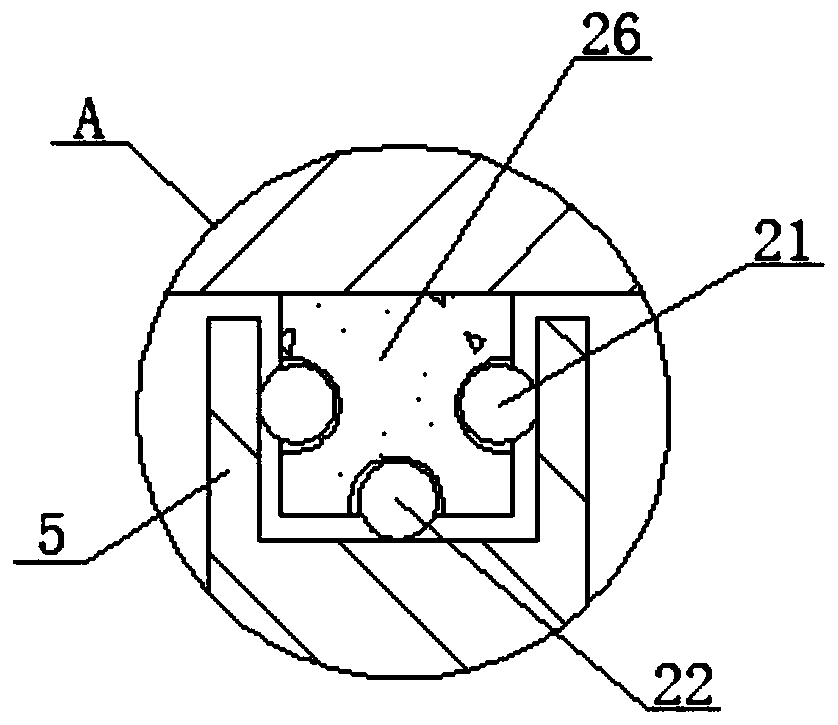

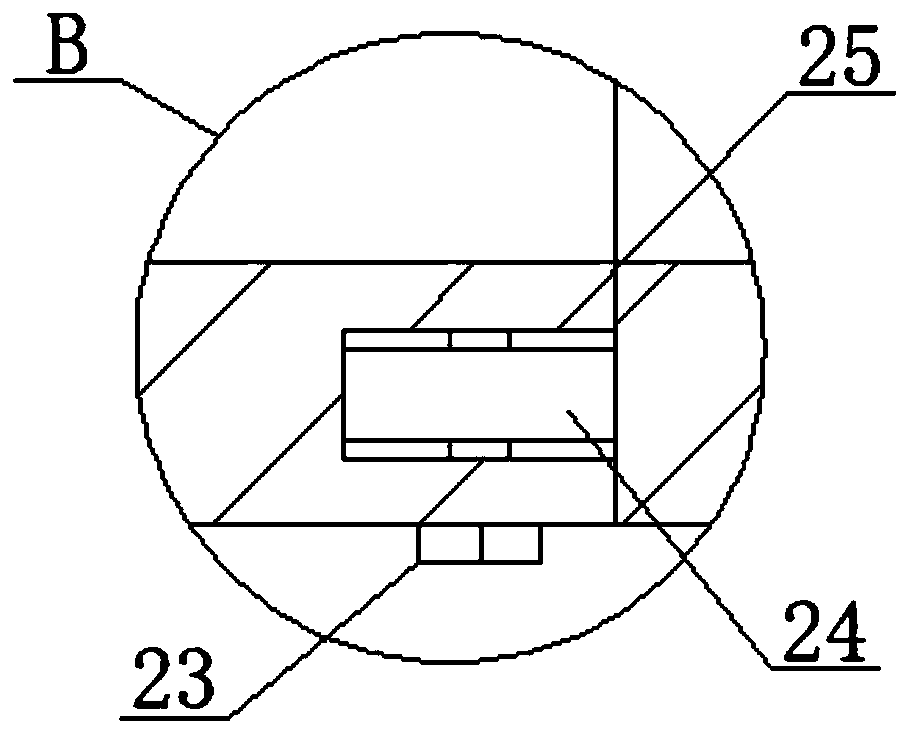

Centrifugal casting device and method for alloy steel casting and forging

The invention discloses a centrifugal casting device and method for alloy steel casting and forging. The centrifugal casting device comprises a bottom plate, a second centrifugal casting cylinder is arranged in a fixing ring on the left side, a first centrifugal casting cylinder corresponding to the second centrifugal casting cylinder is arranged in a fixing ring on the right side, an output shaftof a second motor is provided with a crankshaft connected with a mounting frame, a sleeve is arranged on the outer side of the crankshaft, an injection hopper is arranged at the top of the mounting frame, a second casting pipe penetrating through the second centrifugal casting cylinder is arranged on the outer side of a first casting pipe, a casting port is arranged on the outer side of a secondcasting pipe, and a connecting rod is arranged between the second casting pipe and the sleeve. The second motor and the crankshaft are arranged, the crankshaft is driven to rotate by starting the second motor, the sleeve on the outer side drives the second casting pipe which is connected with the sleeve through the connecting rod to move leftwards and rightwards, the effect that the casting position is not fixed is achieved, casting is uniform, and casting quality is high.

Owner:南通聚星铸锻有限公司

Production method of steel containing boron

The invention relates to the field of steel metallurgy technology, in particular to a production method of steel containing boron. When casting on a continuous caster, the steel containing boron produced by the method will not generate a lot of Al2O3 to obstruct a mold gap of the continuous caster. The production method of the steel containing boron comprises the following steps: primary smeltingof a steel liquid by a converter, steel tapping, ladle refining in a LF furnace, and casting. a, carrying out pre-deoxidation during the steel tapping process: pouring calcium carbide into the steel ladle to make the oxygen activity of the steel liquid to be less than 0.0025%; b, further deoxidizing when refining: adding 3.5-4.5kg of calcium carbide per ton of steel before refining and heating, and adding 0.15-0.45kg of metal aluminum pills per ton of steel during the heating process; c, firstly adding aluminium into the steel liquid after refining to make the content of aluminium in the steel liquid to reach 0.005-0.010%, then adding ferrotitanium to control titanium of the steel liquid within 0.020-0.035%, finally adding ferroboron to control boron within 0.0005-0.0035%. By the adoptionof the method, even a small dimension continuous caster of 200*200mm can also be used to smoothly cast the steel containing boron. In addition, the method provided by the invention is suitable for the casting of the steel containing boron by the use of continuous casters of all cross-sectional dimensions.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Micro-carbon, low-silicon, low-phosphor and low-sulphur aluminum-magnesium-calcium-iron alloy used for smelting steel and deoxidizing

The invention discloses an aluminum magnesium calcium ferroalloy with micro-carbon, low silicon, low phosphorus and low sulfur used in steelmaking deoxidization, which is characterized in that the weight percent of the invention is 10 to 98 Al, 0.1 to 5 Mg and 0.5 to 65 Ca; C is no more than 0.02; Si is no more than1.0; P is no more than 0.02; S is less than 0.02 and the rest is Fe. The invention is to provide the aluminum magnesium calcium in ferro with micro-carbon, low silicon, low phosphorus and low sulfur used in steelmaking deoxidization to solve the problem existing in prior art that white smoke bursts during the process of steelmaking deoxidization, which affects observation of liquid steel and lowers the steel quality.

Owner:本溪冶炼集团有限公司

Precoated sand mold for casting stainless steel thin-walled workpiece

InactiveCN105665650AGood high temperature collapsibilityImprove compromiseFoundry mouldsFoundry coresSteel castingThin walled

The invention discloses a precoated sand mold for casting a stainless steel thin-walled workpiece. The precoated sand mold comprises a cover mold, at least one intermediate mold and a bottom mold, which are arranged in order from top to bottom, wherein casting cavities are formed between the adjacent molds; a communicated vertical runner is formed in the cover mold, the intermediate mold and the lower mold; one end of the vertical runner is arranged on a pouring gate on the cover mold, and the other end blocks the bottom mold; the vertical runner is communicated with a transverse runner; the transverse runner is communicated with the casting cavities through auxiliary runners; the casting runners are communicated with exhaust vents. With adoption of the precoated sand mold disclosed by the invention, the stainless steel casting with the thickness of 2-3 mm can be casted; the casting is not liable to crack; the finished product yield is high.

Owner:张建

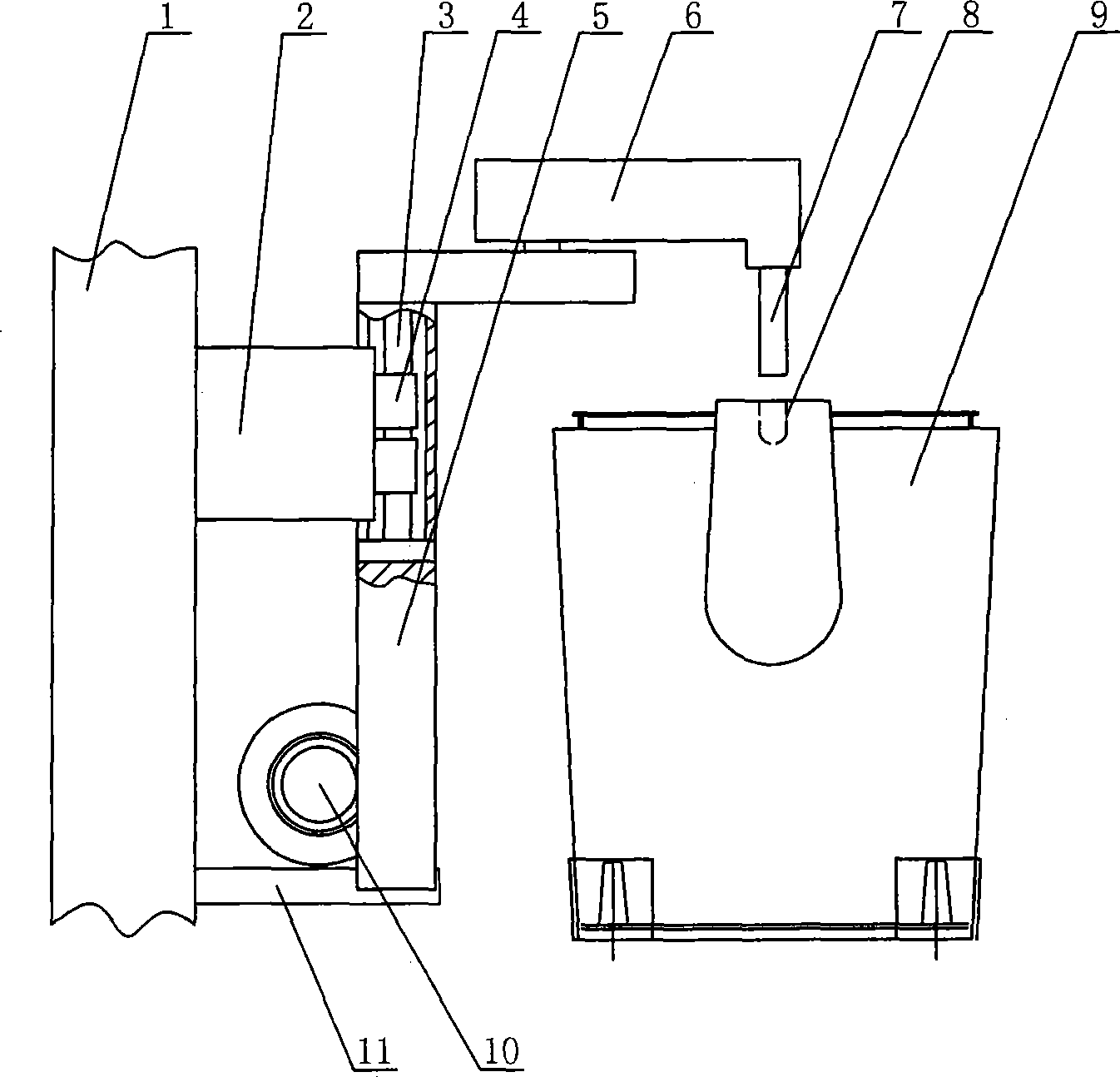

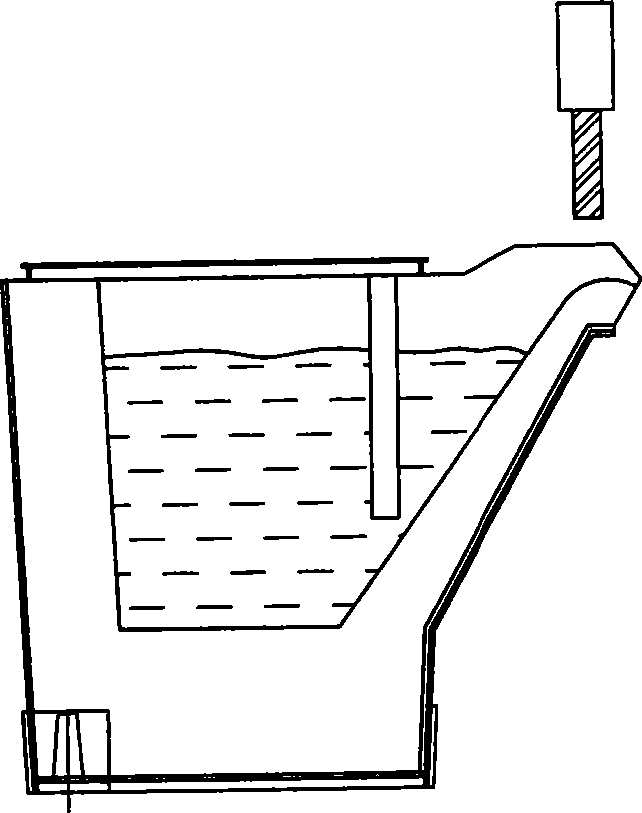

Pouring ladle with controlling mechanism of iron water flow

InactiveCN101433957AHigh degree of automationWith guided smoothingMelt-holding vesselsMotor driveControl signal

The invention relates to a casting ladle with a molten iron flow control mechanism. The casting ladle consists of a ladle frame and a ladle, wherein the ladle is provided with a ladle spout. The ladle frame is provided with a vertical beam vertically and glidingly. A horizontal beam is arranged on the upper end part of the vertical beam. The horizontal beam is vertically provided with a check block on one end corresponding to the ladle spout. A motor driving the vertical beam to do vertical movement is arranged on the ladle frame at a position corresponding to the bottom of the vertical beam. The casting ladle adopts a central control system to send a signal to a servo motor using gears and racks to realize the vertical movement of the vertical beam according to digital revolution given by a controller, realizes precise multi-point positioning displacement control with a digital control signal, and can cast stably and precisely compared with the prior pouring mode of casting ladle. The casting ladle is suitable to be used for casting castings which are complex in shape and light in mass and volume and is suitable for adjusting iron flow during mass product casting.

Owner:ZHIHENG TIANJIN IND

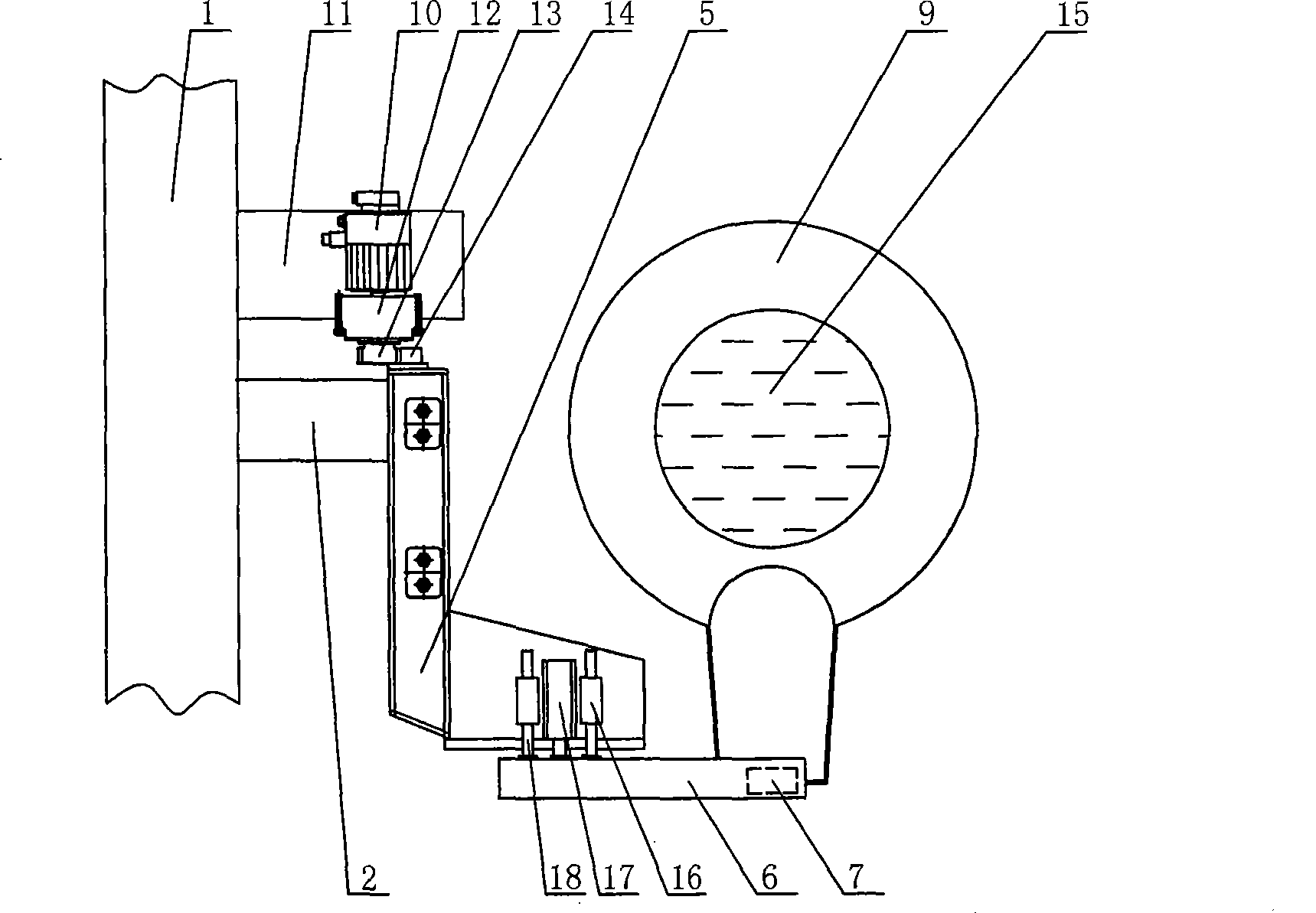

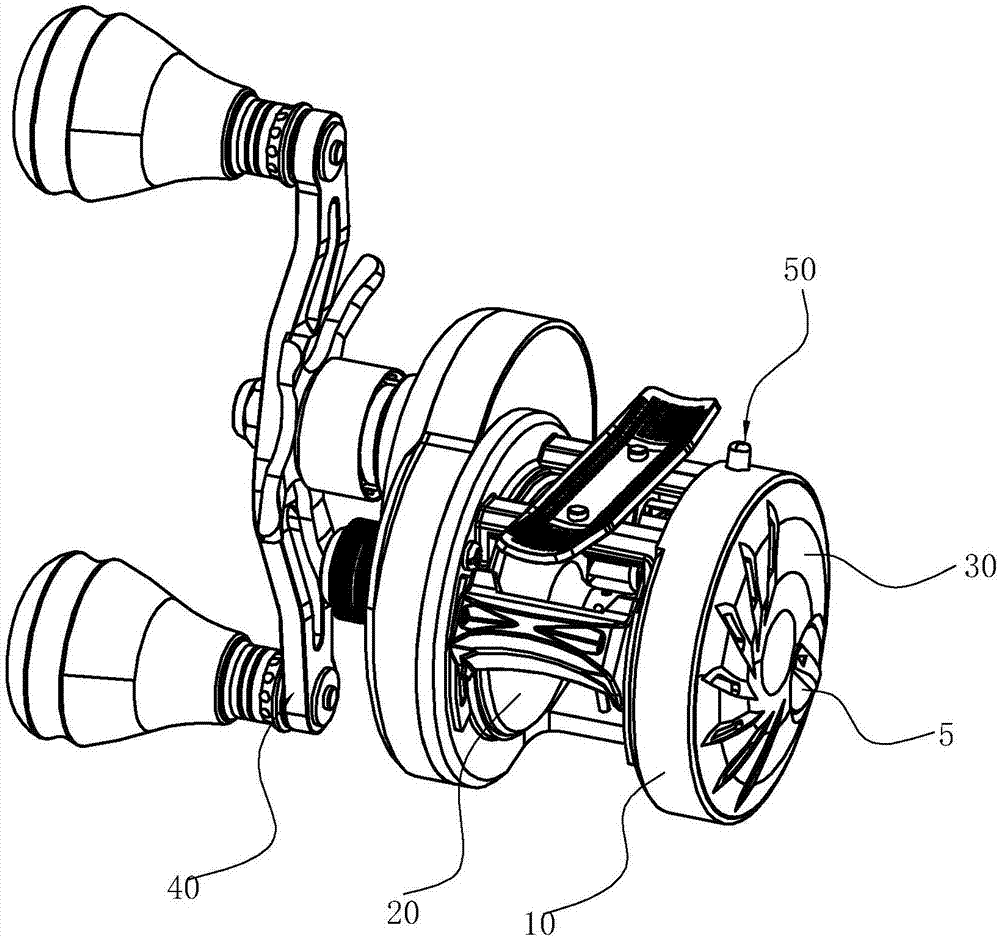

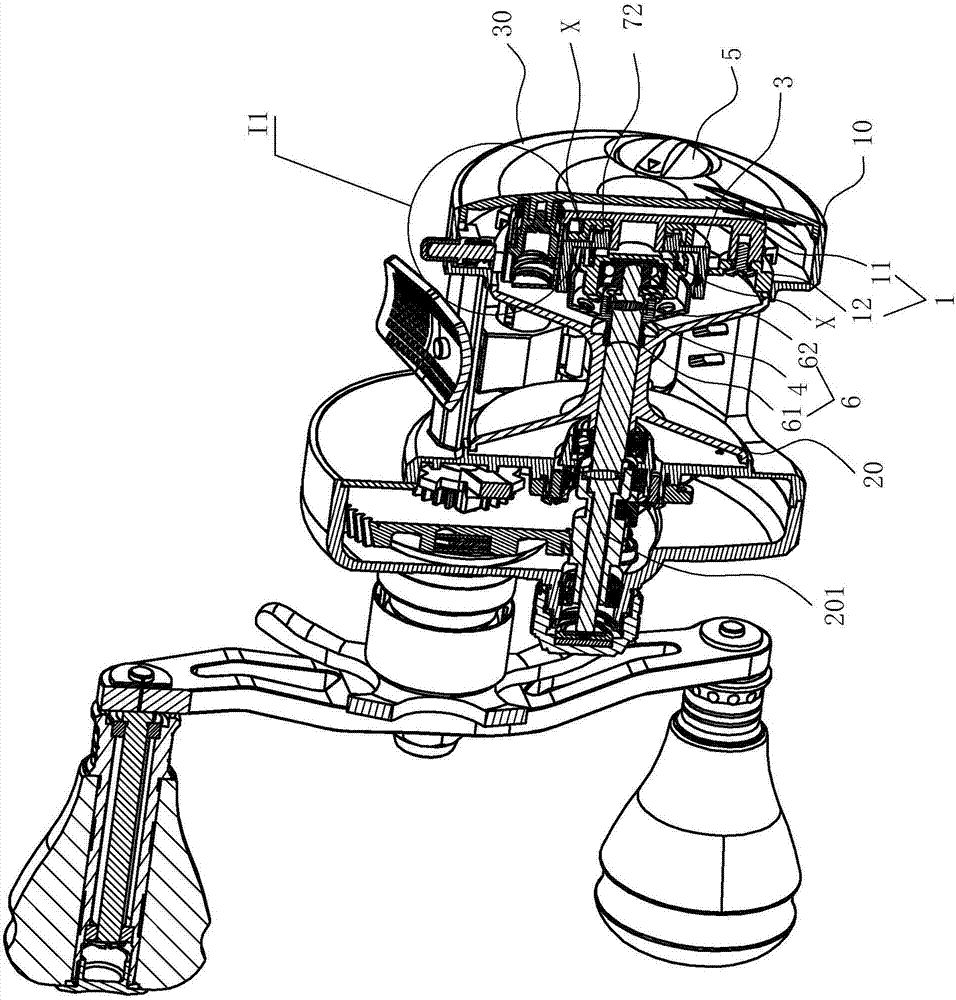

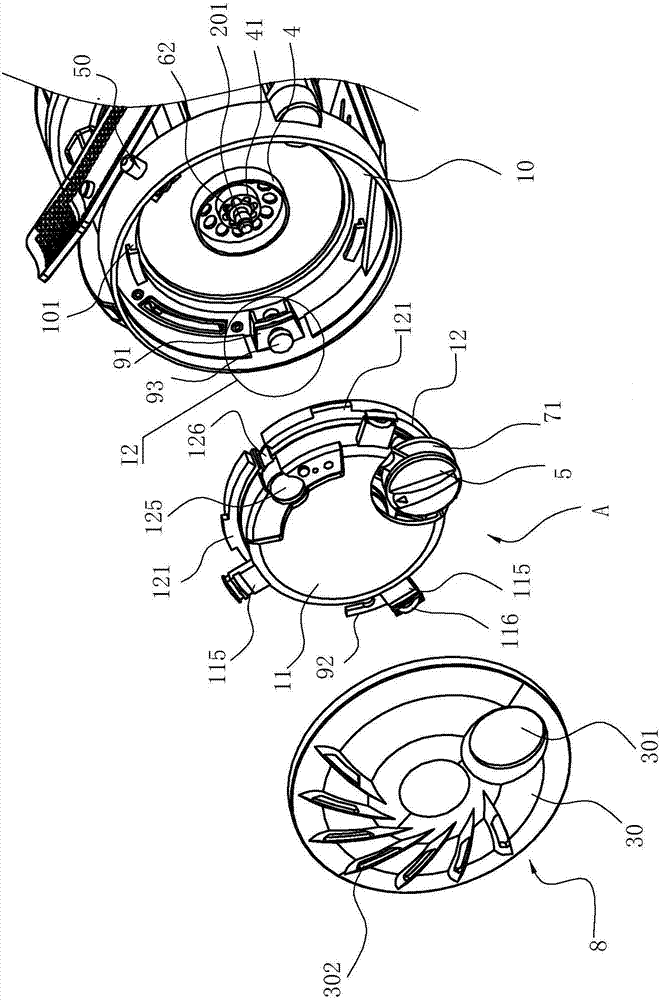

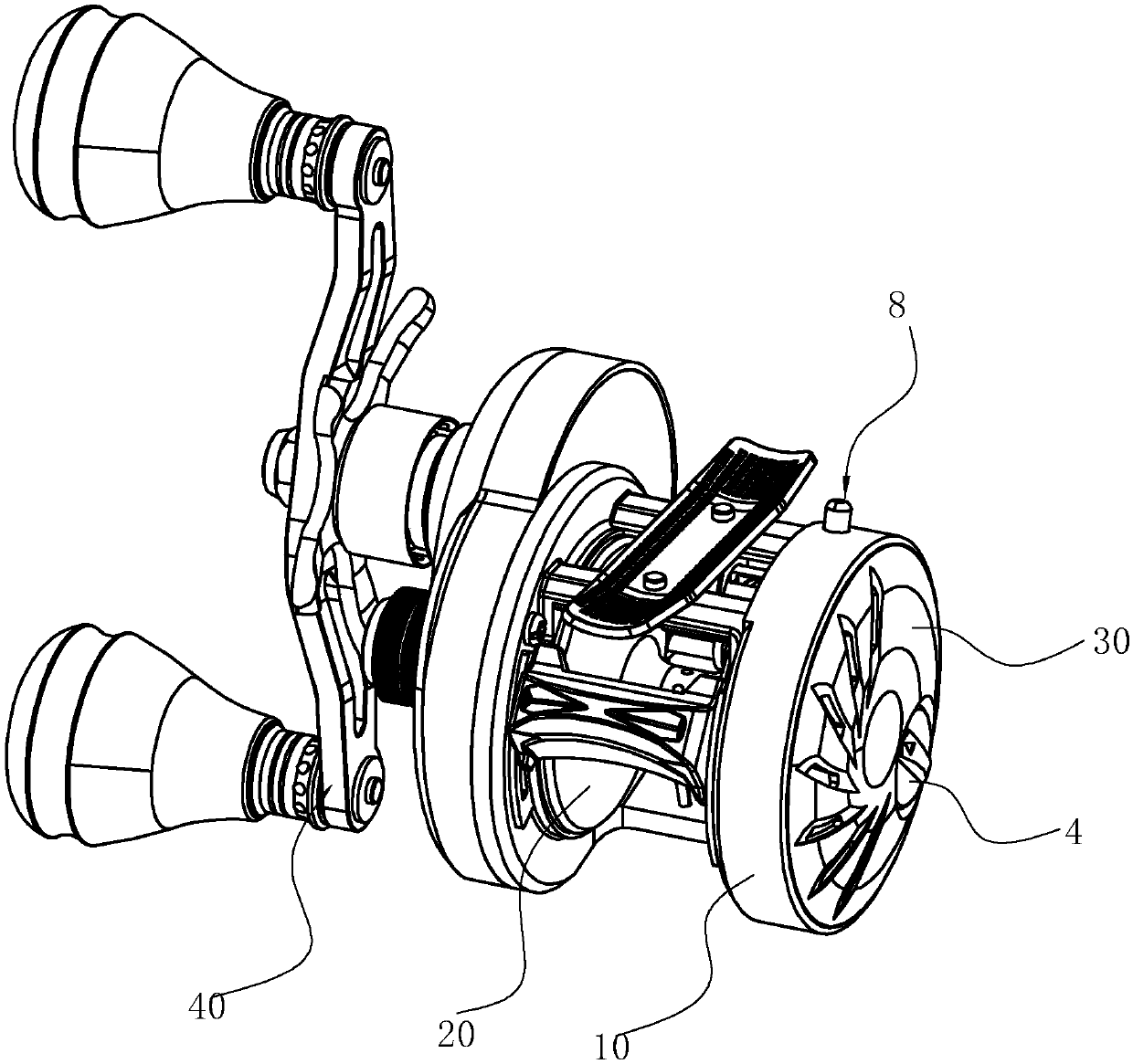

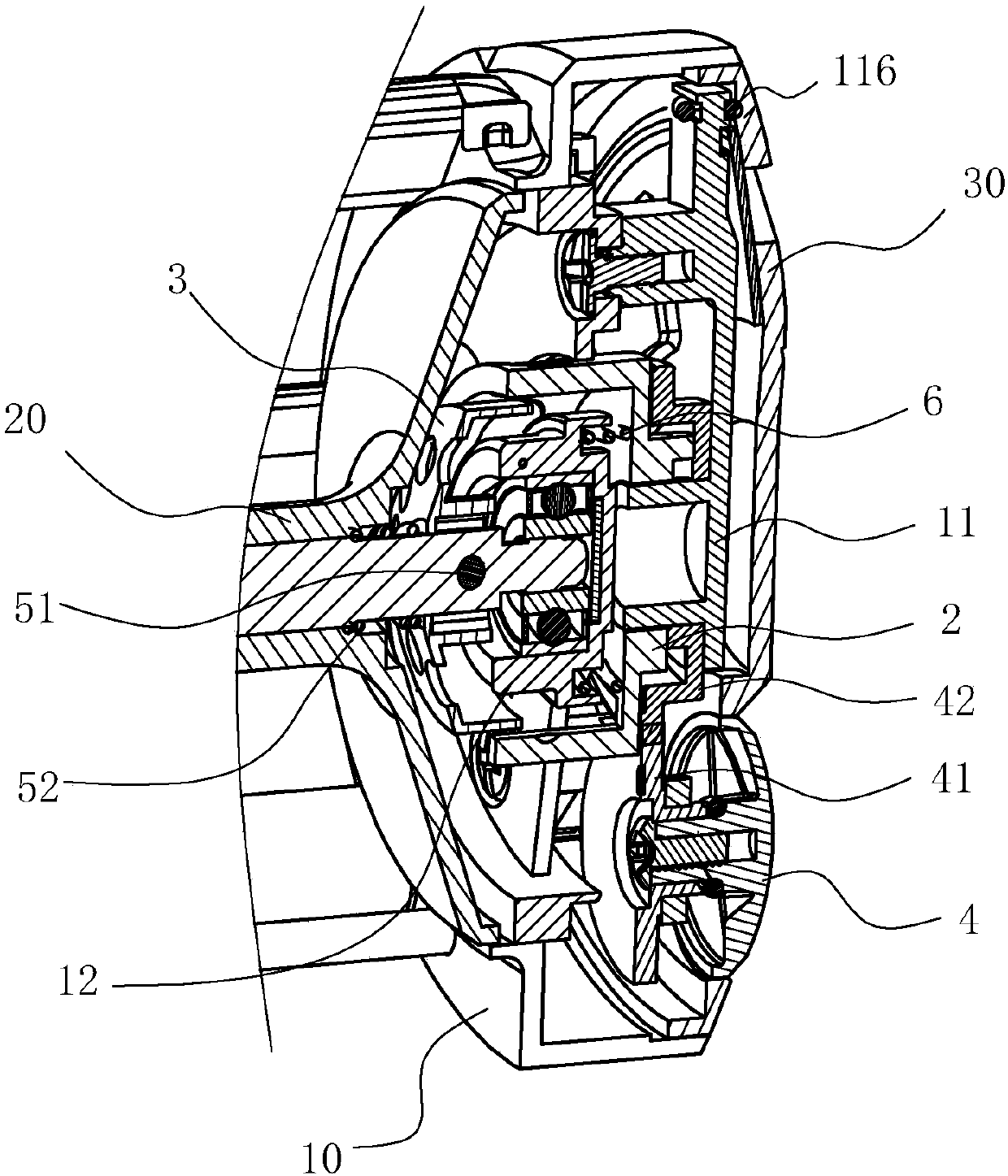

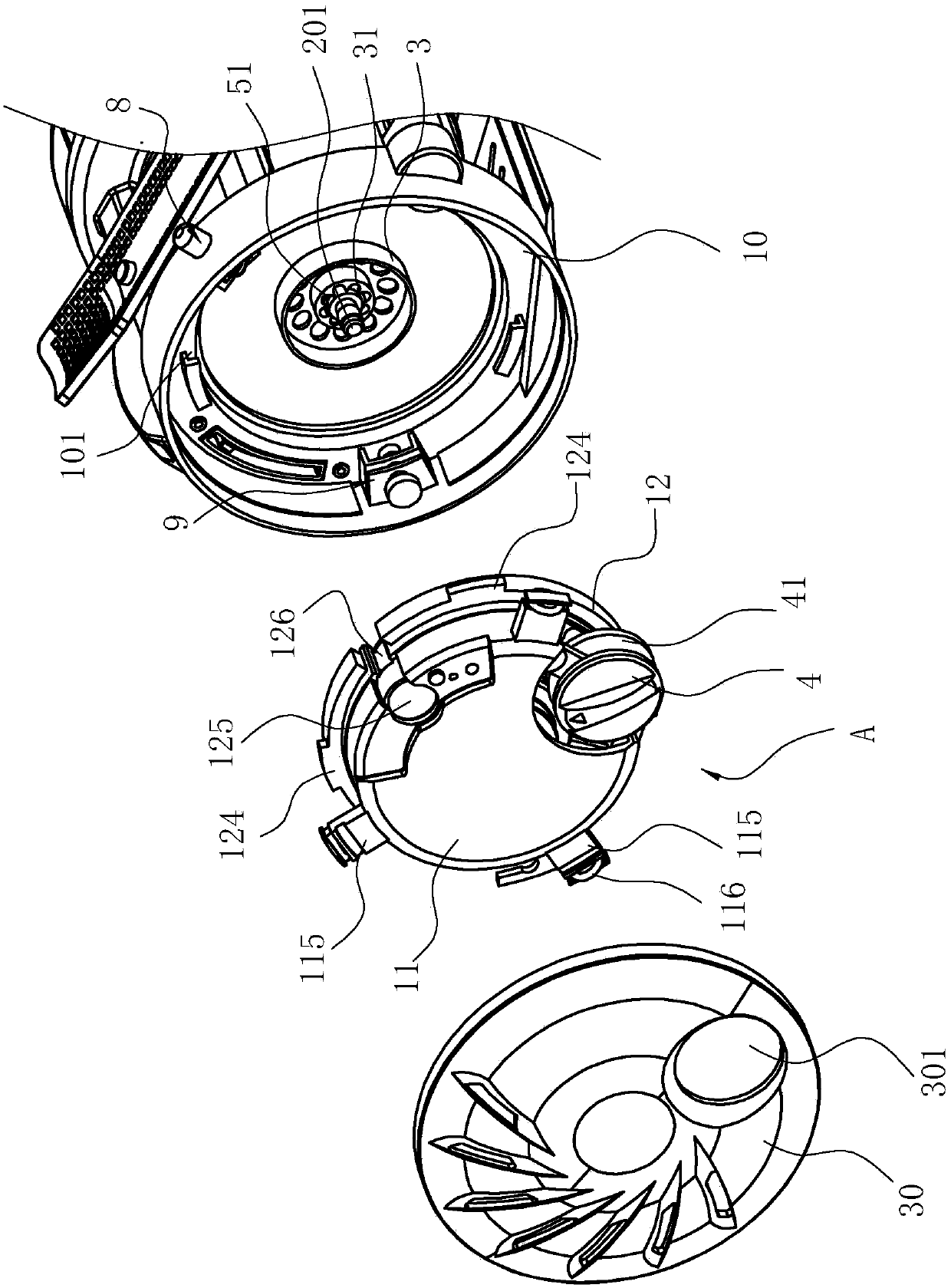

Drum with function of quickly opening side cover

The invention relates to a drum with a function of quickly opening a side cover. The drum comprises a body, the side cover and a damping structure. The damping structure further comprises a damping seat, a seat with magnetic blocks, a damping disc and an adjusting button, the damping disc is matched with the magnetic blocks. The drum is characterized by further comprising a resistance fine adjustment assembly and a rough adjustment assembly, the seat is supported on the damping seat, the fine adjustment assembly and the adjusting button are mounted on the damping seat, and the damping seat isclamped on the inner wall of the body; a mounting hole is formed in the side cover, the adjusting button can penetrate the mounting hole, an elastic clamp leg which axially extends is mounted on the inner wall of the side cover, a clamp seat is arranged on the damping seat, a bayonet which is clamped with the elastic clamp leg is arranged on the clamp seat, a button which is butted to a first spring is radially mounted on the body and corresponds to the bayonet, the tail of the button corresponds to the elastic clamp leg, and the elastic clamp leg can be driven to be separated from the bayonetalong with internal compression actions on the button. The drum has the advantages that the side cover can be quickly opened by means of operation by people with bare hands, and the drum is simple inintegral structure and convenient to operate.

Owner:NINGBO HAIBO GRP CO LTD

Novel damper structure of wire wheel of shaking wheel

The invention relates to a novel damper structure of a wire wheel of a shaking wheel. The novel damper structure is arranged on one side of the wire wheel and comprises a damper seat, a cylinder bodywith a magnet block, a damper plate matched with the magnet block and an adjustment button exposed on a side cover of the shaking wheel. The novel damper structure is characterized in that the cylinder body is supported on the damper seat and can move in the axis direction; the damper plate sleeves a wire wheel shaft and can rotate together with the wire wheel shaft, a plurality of grooves of different depths are formed in one end surface of the damper plate, a pin shaft fixed on the wire wheel shaft can insert into any one of the grooves, and a first spring which abuts against the other end surface of the damper plate sleeves the wire wheel shaft, so that the damper plate can move along the wire wheel shaft in the axis direction and then abuts against the pin shaft; meanwhile, a driving part matched with the adjustment button to drive the cylinder body to move in the axis direction is arranged to make the magnet block get away from or get close to the damper plate. The novel damper structure has functions of rough adjustment and fine adjustment, so that throwing braking force of a fish wire wheel is matched with throwing speed of baits to meet the using requirements of users better.

Owner:NINGBO HAIBO GRP CO LTD

Fire sprinkler head used for dust collector

The invention discloses a fire sprinkler head used for a dust collector, which comprises a nozzle frame and a splash tray, wherein the lower end of the nozzle frame is provided with a base, and the base is internally provided with a first through hole, the splash plate comprises a disk and a splash groove uniformly distributed around the disk, and the disk is fixedly connected with the upper end of the nozzle frame, the base is provided with an insertion slot, and the open end of the first through hole is provided with an insertion board which is matched with the insertion slot, and the insertion board is provided with a second through hole matched with the first through hole; the top surface of the base is provided with a bimetal member in contact with the insertion board, and the bimetalmember is arranged at one end of the insertion board and is in contact with the insertion board to push the insertion board, so that the second through hole is aligned to the insertion board. The self-resetting bimetal member is used as a heat-receiving component, so that the fire sprinkler head is resistant to falling, is not easily damaged, the fire temperature is reduced, the bimetal member isreset, the insertion board plate slides manually, the through holes are sealed again, and the fire sprinkler head can be reused without replacement.

Owner:JIANGSU RENHE ENVIRONMENTAL EQUIP

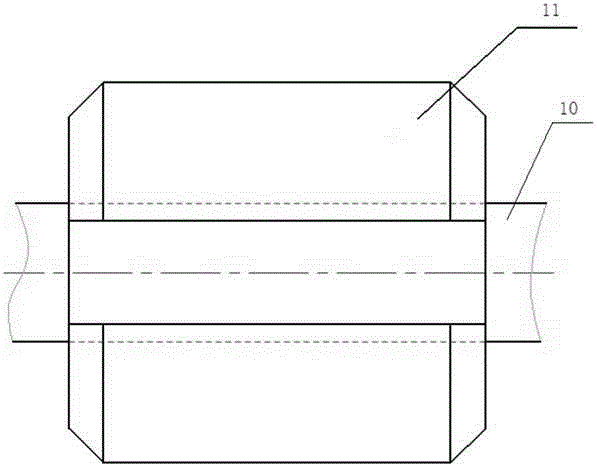

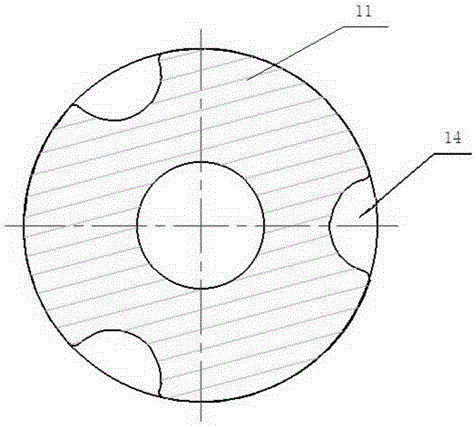

Split plate for casting aluminum alloy composite round ingot blank

The invention provides a split plate for casting an aluminum alloy composite round ingot blank. The split plate comprises a split plate body and at least three split openings formed in the split plate body, wherein the split plate body is round or square and is made of fire-resistant heat insulating materials. The split plate is matched with a round ingot crystallizer and has a hot top effect simultaneously, so that the heat gradient of aluminum liquid in the crystallizer in all directions can be distributed consistently, and the aluminum alloy composite round ingot blank is ensured to be cast smoothly.

Owner:苏州有色金属研究院有限公司

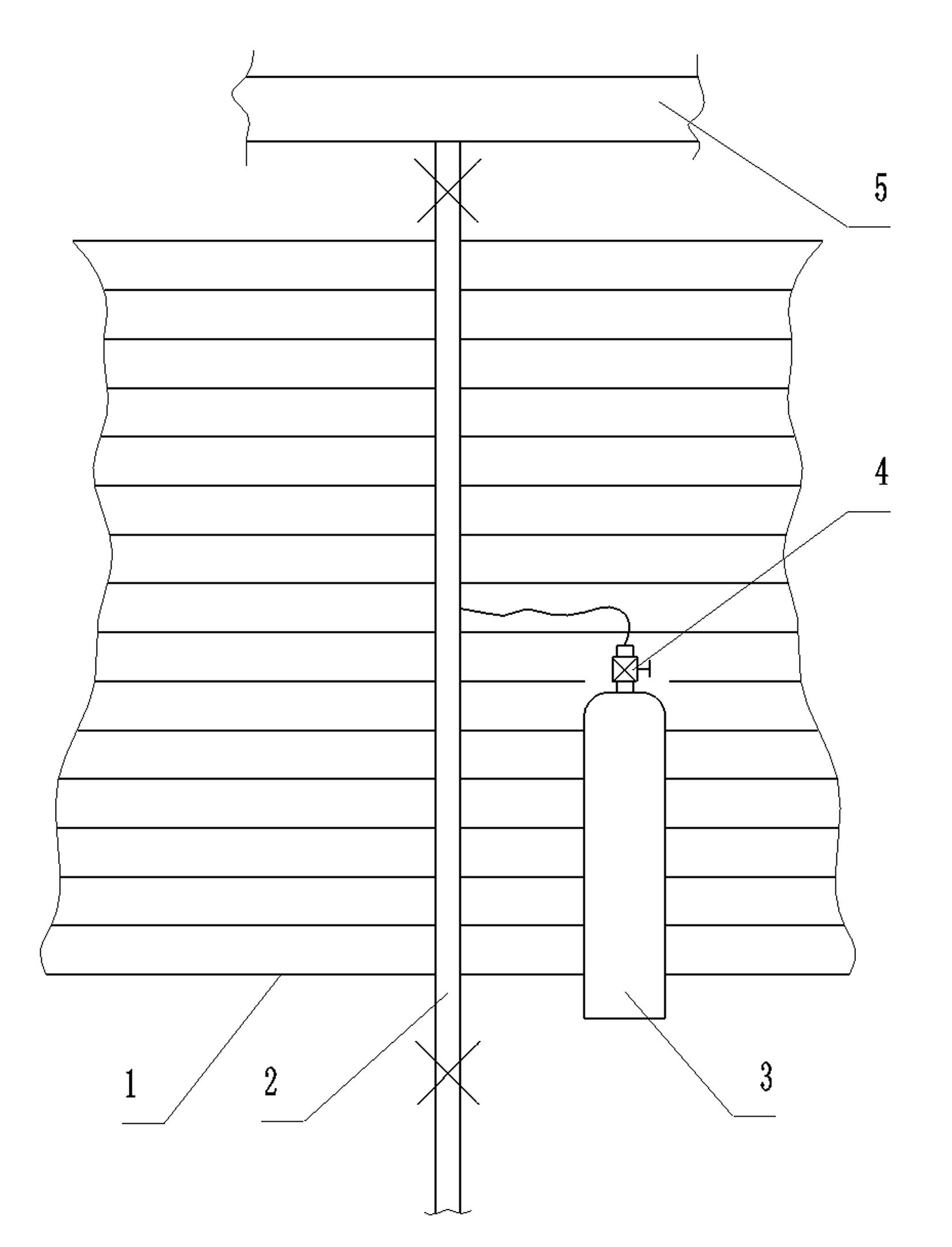

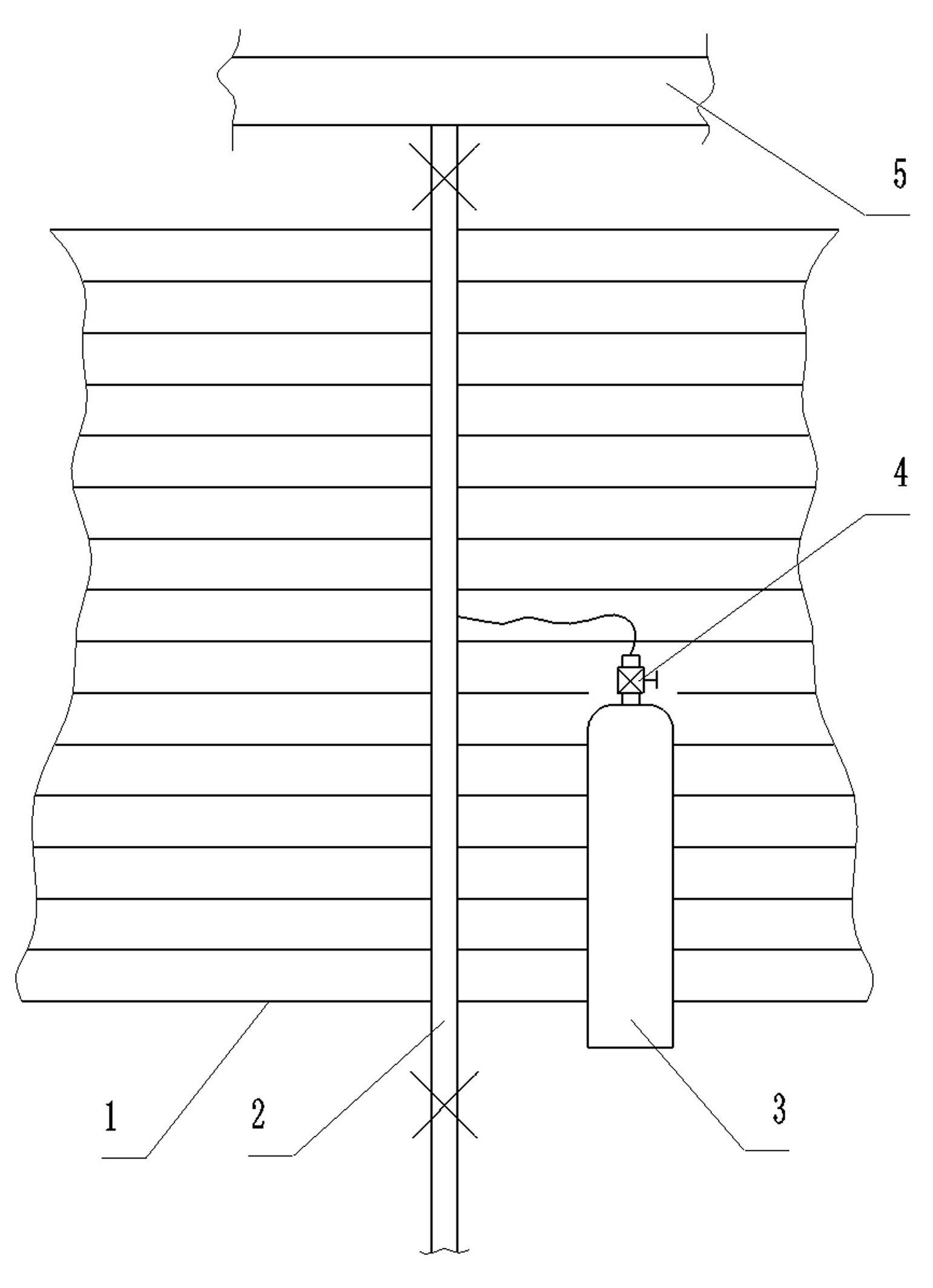

Method for applying carbon dioxide by use of farmland micro-irrigation system

InactiveCN102138448ASmooth castingDosage controllableFertilising methodsHorticulture methodsDrip irrigationProcess engineering

The invention discloses a fertilizer applying technology which specifically applies the carbon dioxide gas fertilizer on the field crops by use of a micro-irrigation system of the current water-waving agriculture. The micro-irrigation system at least comprises a branch pipe and a capillary pipe of a pipeline system; a container filled with the carbon dioxide gas is connected to the joint of the branch pipe, and a valve of the container is opened so that the carbon dioxide gas enters the capillary pipe through the branch pipe and is discharged from a water outlet of the capillary pipe and applied to a plant canopy layer, wherein the daily applying time is 2-3 hours, and the daily applying quantity is 300-400 liters per mu. Tests indicate that the crop yield can be increased by 8-13% by applying the carbon dioxide gas fertilizer on crops such as carbon dioxide gas to the drip irrigation cotton, sauce tomato, wheat and the like, and the mature period is 3-5 days earlier. According to the invention, the micro-irrigation system is used as a conveying channel to apply the carbon dioxide gas to the field, and the carbon dioxide gas is used as a gas source; and the method is simple and feasible, easy to control dosage, safe, reliable and chip, and realizes uniform application.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

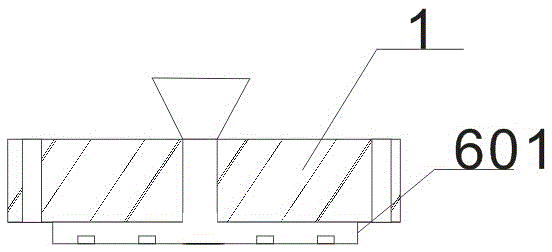

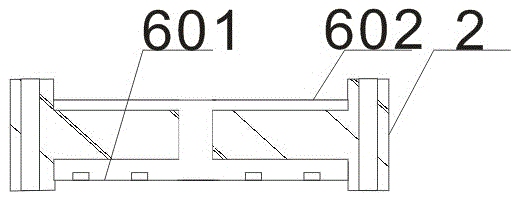

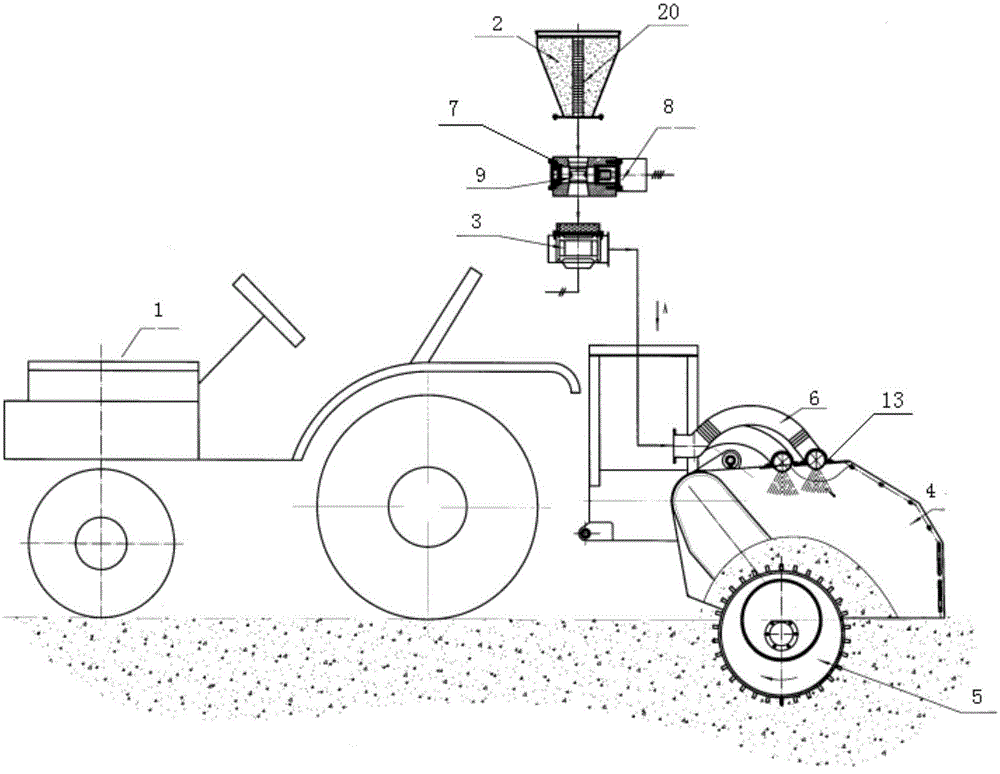

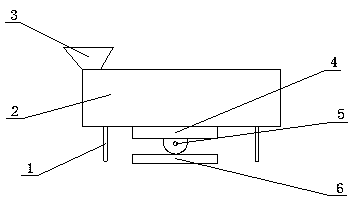

Closed sprayed pesticide mixer

ActiveCN104823956ANo diffusionSmooth castingInsect catchers and killersAgricultural engineeringTillage

The invention discloses a closed sprayed pesticide mixer. The mixer comprises an agricultural machine and a pesticide feeding mechanism, wherein the pesticide feeding mechanism comprises a pesticide bucket, a blower and a sealing hood; the blower is arranged below the pesticide bucket, the discharge opening of the pesticide bucket faces the air inlet of the blower, the sealing hood is opened in the lower part and is a shell-type hollow cavity matched with the ground, a rotary tillage roller is arranged in the internal lower part of the sealing hood and partially extends out of the sealing hood, the rotary tillage roller is arranged in the rear part of the agricultural machine, the pesticide feeding mechanism is fixedly connected with the agricultural machine, and the rotating speeds of the rotary tillage roller and the agricultural machine are synchronous; the sealing hood is connected with the air outlet of the blower through a corrugated pipe; the agricultural machine is used for supplying power and a power supply. The closed sprayed pesticide mixer adopts the rotary tillage roller to perform rotary tillage and enables soil to be fined, turned up, mixed with a pesticide flow in the sealing hood and then restored to the ground; since all operations are performed in the hood, the pesticide is impossible to spread. The closed sprayed pesticide mixer is uniform in discharge of the pesticide, safe, reliable, simple in structure, small in maintenance amount and low in cost.

Owner:安徽春晖生态环境科技有限公司

Ladle nozzle casting conduction plug and use method thereof

The invention discloses a ladle nozzle casting drainage plug and a using method thereof. The invention belongs to an attachment device of the ladle for starting the casting operation, in particular to a drainage device used for casting molten steel by a brick cup nozzle at the bottom part of the ladle as well as a using method thereof. The drainage device includes a drainage agent and is characterized in that a plug cap and a plug post are connected into a cylinder with variable diameters; a plug cover is arranged on the plug cap; a bottom plate in a mushroom shape is arranged below the plug post; the drainage agent is packaged / or directly connected into the cylinder composed of the plug cap, the plug post, the plug cover and the bottom plate by a soft bag; the plug cap and the plug post are arranged in a guide rod in a sliding way; a haulage rope is hung on the bottom plate. When in use, the plug post is inserted and fixed into the brick cup nozzle; the plug cap is covered above the brick cup. During casting, the drainage agent drains under the effects of the heat and the gravity of the hot molten steel. The invention has the advantages of simple structure and easy manufacturing;being convenient for arranging the drainage plug for a short time; proper dosage of the drainage agent, high intensity, accurate position, large covering area, stable, safe and reliable mounting, avoiding residues from plugging the nozzle, saving the cost for treating the plugging of the nozzle and being beneficial to production.

Owner:安徽中实冶金材料工程技术研究有限公司

Method for billet continuous casting machine to manufacture stainless steel billet with titanium ferrite

ActiveCN109554517AShorten the time of precipitationGuaranteed surface qualityProcess efficiency improvementAlkalinitySlag

The invention discloses a method for a billet continuous casting machine to manufacture a stainless steel billet with titanium ferrite. The method comprises the steps that quenching and tempering of AOD final slag are conducted, TiO2 refined slug is prepared by an LF furnace with high alkalinity, titanium is prepared by the LF furnace, and the continuous casting processes are conducted to the billet caster are achieved. According to the method for the billet continuous casting machine to manufacture the stainless steel billet with the titanium ferrite, the quenching and tempering of the AOD final slag are adopted to lay a great foundation for the LF furnace to refine the slag, the TiO2 refined slag is prepared by the LF furnace with the high alkalinity so that titanium inclusions can be separated out, technology of the LF furnace to prepare the titanium is improved so that saturated solvent degree of titanium nitride and stability of a titanium component can be improved, covering agenttechnology in the high alkalinity is adopted by the continuous casting of the billet continuous casting machine so that TiN can be separated, thus problems of flocculent flowing and casting blank included slag of the continuous casting machine are avoided, so that the billet continuous casting machine can successfully cast the stainless steel billet with the titanium ferrite. According to the stainless steel billet with titanium ferrite, the pass rate is greater than or equal to 97%, and the surface quality of wire milling is ensured.

Owner:XINGTAI IRON & STEEL

Outer mold forming mold of special-shaped conformal cooling water channel mold and used for casting

PendingCN110883312AUniform heat dissipation and coolingSmooth castingFoundry mouldsFoundry coresMechanical engineeringCasting

The invention discloses an outer mold forming mold for a special-shaped conformal cooling water channel mold and used for casting. The outer die forming mold comprises an upper sand mold and a combined molding frame, the upper sand mold is covered at the top of the combined molding frame, a sand cavity is formed in the top of the upper sand mold, and a mold forming cavity is formed in the top of the combined molding frame; an inner cavity sand mold is arranged at the center of the mold forming cavity, and a plurality of layers of independent conformal water channel sand cores are arranged in the vertical direction of the peripheric side walls of the inner cavity sand mold; and the upper sand mold is internally provided with a casting opening formed along the periphery of the top of the mold forming cavity in a rain-pouring mode. The rapid cooling forming of the outer mold is facilitated, and a plurality of layers of independent annular conformal cooling water channels are built in theformed outer mold, so that rapid and uniform heat dissipation and cooling is facilitated when the outer mold forms a product; the rain-type casting opening enables uniform casting to be convenient, and the feeding efficiency is improved; and heat dissipation and disassembly of the combined molding frame of an overall metal material are convenient.

Owner:佛山市顺德精密模具研究院有限公司

Instrumentation platform system

ActiveCN106365015AInsure property damageReduce accident liability risk valueElevatorsBuilding liftsSupporting systemRemote control

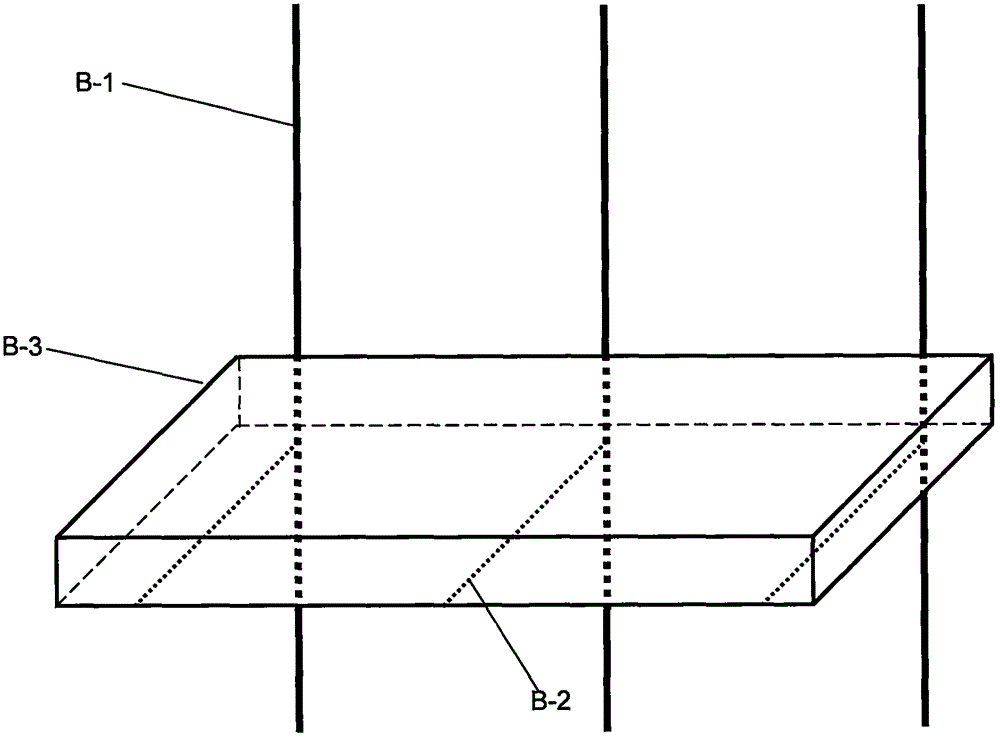

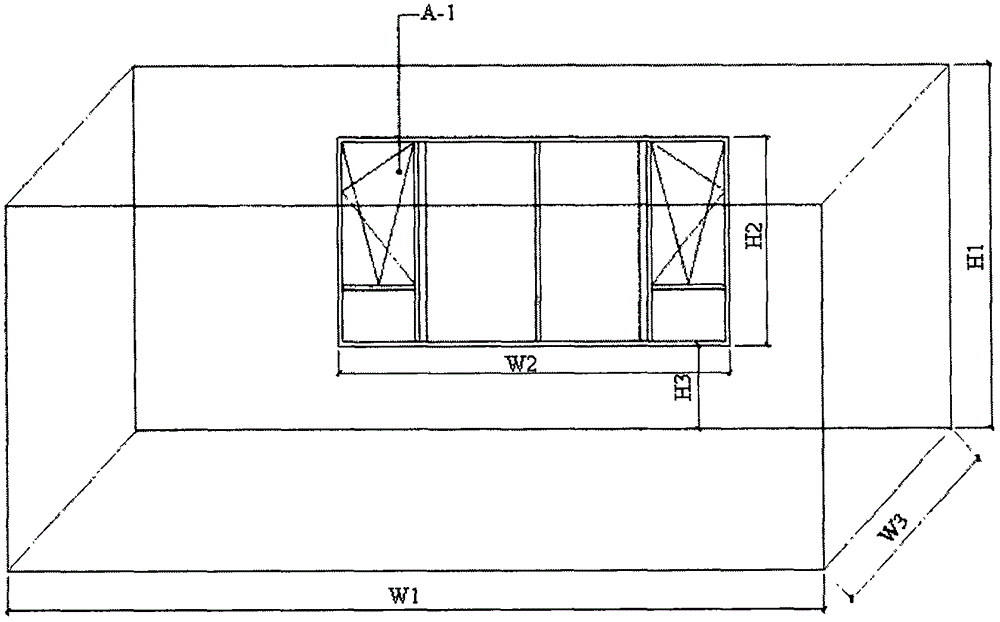

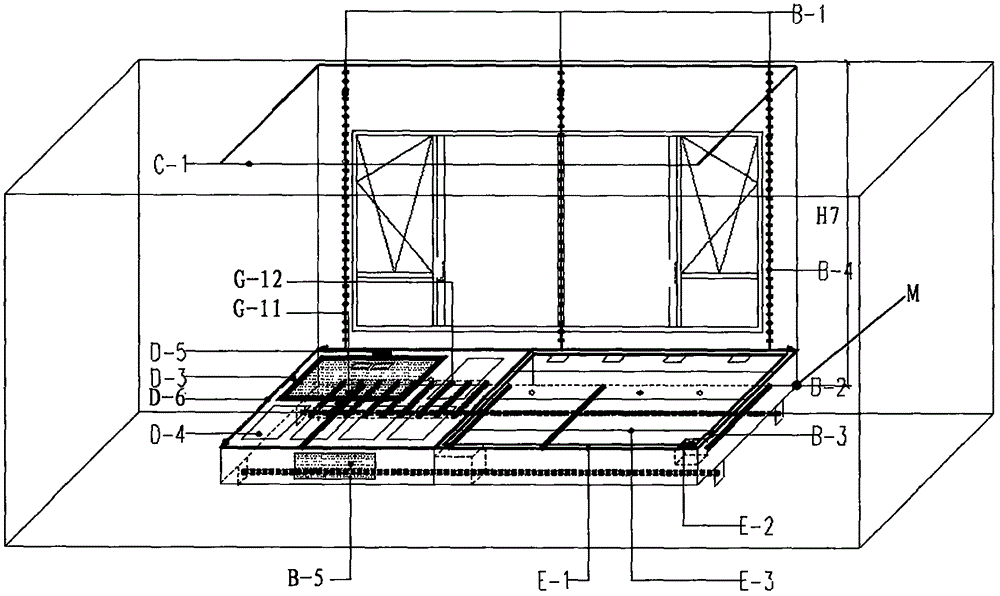

The invention relates to movable balconies, in particular to an instrumentation platform system. The instrumentation platform system aims to solve the problem that a user cannot receive express deliveries conveniently when being away from home and further improve the room environment scientifically. The platform system comprises a main platform system B-3 and a vertical rail system B-1. A platform fixing triangular bracket supporting system B-2 is arranged under the main platform system B-3. The main platform system B-3 and the platform fixing triangular bracket supporting system B-2 are installed on the vertical rail system B-1 and can move up and down along the vertical rail system B-1 and be fixed in positions at different heights. By the adoption of the instrumentation platform system provided by the invention, the ordered express deliveries can be received quite conveniently in a remote control mode, and the room environment can be improved conveniently and scientifically.

Owner:HUINIAO TECH DEV BEIJING CO LTD

Production method of low-sulfur peritectic steel continuous casting round billet

InactiveCN111519081AReduce oxidationGuaranteed purityElectric furnaceProcess efficiency improvementCarbide siliconElectric arc furnace

The invention discloses a production method of a low-sulfur peritectic steel continuous casting round billet. The production method comprises the following steps that by using scrap steel and molten iron hot charging as a raw material, a raw material is sent into an electric arc furnace to smelt into molten steel, aluminum shots are added into the molten steel to perform primary deoxidation duringtapping, and lime and fluorite are added to perform slagging; during refining, a silicon carbide deoxidizing agent is added into the molten steel for slag surface diffusion deoxidization, white slagis produced during refining, the content of S and Al in the obtained molten steel is controlled, then the molten steel enters a refining furnace for vacuum degassing treatment, and after vacuum degassing treatment, the chemical components of the molten steel are adjusted to be controlled within a preset range; and finally, continuously casting the molten steel into a round billet. The molten steelis effectively desulfurized, the oxidability of the molten steel is reduced, the purity of the molten steel is ensured, the fluidity of the molten steel is improved, smooth casting in the continuouscasting process is ensured, smooth production is ensured, the working efficiency is improved, and meanwhile the surface quality of round billets is effectively ensured.

Owner:NANJING IRON & STEEL CO LTD

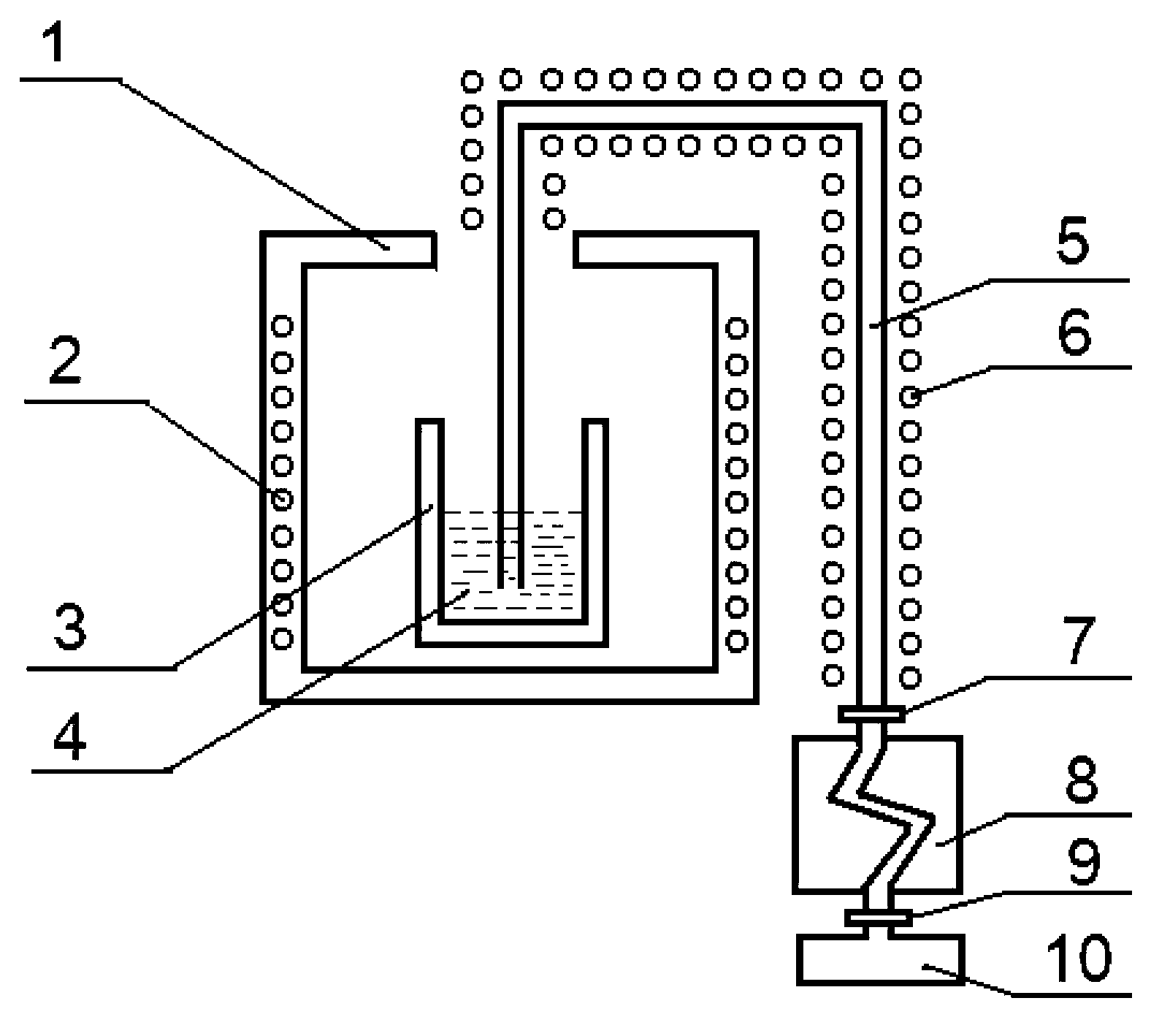

Aluminium alloy casting device

The invention provides an aluminium alloy casting device. High-temperature atmospheric furnace heating electric resistance wires surround a high-temperature atmospheric furnace body; a crucible is arranged in the high-temperature atmospheric furnace body with the opening upward; aluminum or aluminium alloy is arranged in the crucible; one end of a stalk is introduced into the bottom of the crucible from the opening of the high-temperature atmospheric furnace body; the other end of the stalk is in air-tight seamless connection with the upper end of a cavity via a valve; stalk heating resistance wires surround the part of the stalk, which is out of the high-temperature atmospheric furnace body; the lower end of the cavity is in air-tight seamless connection with a vacuum pump via a second valve; and a first valve and the second valve are both lower than the bottom of the crucible. According to the aluminium alloy casting device disclosed by the invention, the stable casting of aluminium alloy melting liquid is realized, and temperature and pressure do not need to be strictly controlled. In addition, the casting device has the advantages of simple structure and convenient working process and operation technology. Due to the fact that the aluminium alloy casting device is free from a furnace pressure control and regulation device, the low cost and quick casting of the aluminium alloy can be realized without carrying out complex pressure regulation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com