Isothermal extrusion production method of refractory metal rotating target material

A technology of isothermal extrusion and refractory metal, which is applied in the field of warm extrusion production, can solve the problems of long cycle time, high cost and quality defects of refractory metal targets, and achieve fine grain size, low production cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

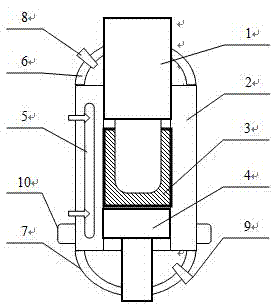

Image

Examples

Embodiment 1

[0038] Example 1: The rotating metal molybdenum-niobium alloy target is produced by an isothermal extrusion process. After mixing 90at% molybdenum powder and 10at% niobium powder through a three-dimensional mixer, they are installed in a rubber mold with a diameter of 170mm. Carry out cold isostatic pressing at a pressure of 180Mpa, take out the cold-pressed ingot, and sinter in a vacuum hot-pressing sintering furnace at a temperature of 1300°C for 4 hours, and the density after pre-sintering is 75%. After processing the outer diameter of the alloy ingot, put it into the isothermal extrusion die, the extrusion temperature is 1700°C, the size of the extruded tube blank is 130mm in inner diameter, 160mm in outer diameter, and the density is 99.1%. The extruded tube blank is combined with the stainless steel liner through the bonding process to obtain a molybdenum-niobium alloy rotating target.

[0039] Example 2: The isothermal extrusion process is used to produce rotating metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com