Split plate for casting aluminum alloy composite round ingot blank

A technology for casting aluminum alloy and shunt plate, which is applied in the field of aluminum alloy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

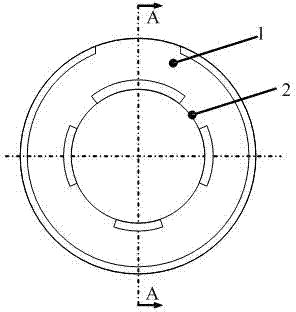

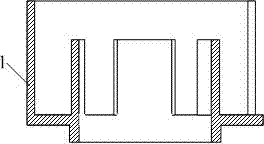

[0017] Such as figure 1 , figure 2 As shown, the splitter plate for casting an aluminum alloy composite round ingot includes a splitter body 1 and a splitter opening 2 provided thereon. The splitter body 1 is circular in shape, and there are four splitter ports 2 .

Embodiment 2

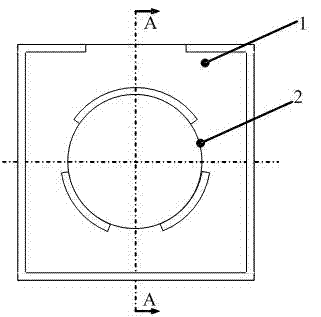

[0019] Such as image 3 , Figure 4 As shown, the diverter plate for casting aluminum alloy composite round ingots includes a diverter plate body 1 and diverter ports 2 arranged thereon. The shape of the diverter disc body 1 is square, and there are three diverter ports 2 .

[0020] The main body of the diverter plate is made of refractory and thermal insulation material, which can reduce heat loss and is easy to clean; it has no less than three diverter ports, which can ensure uniform flow and consistent distribution of the thermal gradient of the aluminum liquid, and also have the function of a hot top. The shape of the diverter plate body can be made into circular, square or other shapes according to different occasions.

[0021] In specific application, the diverter plate of the present invention is used in conjunction with the round ingot crystallizer, and at the same time has the function of a hot top, which can make the thermal gradient distribution of the aluminum liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com