Casting mold for cylindrical housing part and casting method by using the mold

A casting mold and cylindrical technology, which is applied in the field of mold casting, can solve the problems of low yield and achieve the effects of stable casting process, continuous and fast casting process and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

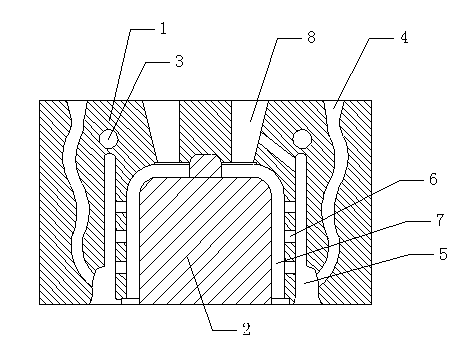

[0023] Embodiment: a casting mold for a cylindrical shell part, the outer mold 1 is composed of two halves of the mold body, positioning pins 4 are arranged on the mating surface, and the cylindrical inner mold 2 is located in the middle of the outer mold 1; two S Shaped runners 4 are located on both sides of the cavity 7, each runner 4 is connected to the buffer channel 5, the buffer channel 5 is connected to the cavity 7 through the connecting channel 6, and a riser is provided on both sides of the top of the cavity 7 4; The bottom end of one buffer channel 5 is connected to the cavity 7 and the top of the other buffer channel 5 is connected to the riser 8 .

[0024] The casting method includes the following steps:

[0025] Step 1: Preparation before casting, melting aluminum alloy, and heating the mold;

[0026] Step 2: Fix the inner mold on the casting table, apply paint on the mold, fix half of the outer mold body on the casting table through the clamp, and then move the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com