Method for billet continuous casting machine to manufacture stainless steel billet with titanium ferrite

A billet continuous casting and stainless steel technology, applied in the field of metallurgy, can solve the problems of short treatment time of inclusions, difficult casting, high water viscosity, shorten the precipitation time of TiN, ensure the surface quality, and stabilize the absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

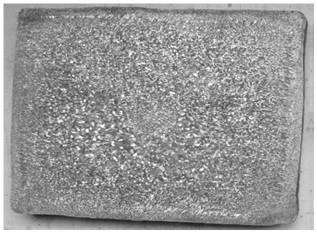

Image

Examples

Embodiment 1

[0039] The chemical composition and mass percentage of the titanium-containing ferritic stainless steel billet in this example are: C: 0.055%, Mn: 0.20%, Si: 0.60%, P: 0.023%, S: 0.001%, Cr: 17.1%, Ni: 0.10%, Al: 0.02%, N: 0.0138%, Ti: 0.17%, and the rest are iron and unavoidable impurities.

[0040] The method for producing titanium-containing ferritic stainless steel billets by billet continuous casting machine in this embodiment includes AOD final slag quenching and tempering, LF furnace high alkalinity and TiO 2 Refining slag, LF furnace with titanium, billet continuous casting machine continuous casting process, the specific process steps are as follows:

[0041] (1) AOD final slag quenching and tempering: the dephosphorized hot metal is smelted by AOD, the reduction slag is removed after AOD reduction, and the weight of the remaining slag is controlled at 17kg / t steel. Steel, at the same time add lime 4kg / t steel, make the final slag binary alkalinity CaO / SiO 2 : 2.6; ...

Embodiment 2

[0050] The chemical composition and mass percentage of the titanium-containing ferritic stainless steel billet in this example are: C: 0.05%, Mn: 0.9%, Si: 0.42%, P: 0.020%, S: 0.001%, Cr: 17.28%, Ni: 0.23%, Al: 0.03%, N: 0.012%, Ti: 0.19%, and the rest are iron and unavoidable impurities.

[0051] The method for producing titanium-containing ferritic stainless steel billets by billet continuous casting machine in this embodiment includes AOD final slag quenching and tempering, LF furnace high alkalinity and TiO 2 Refining slag, LF furnace with titanium, billet continuous casting machine continuous casting process, the specific process steps are as follows:

[0052] (1) AOD final slag quenching and tempering: the dephosphorized hot metal is smelted by AOD, the reduction slag is removed after AOD reduction, and the weight of the remaining slag is controlled at 20kg / t steel. Steel, at the same time add lime 5kg / t steel to make the final slag binary alkalinity CaO / SiO 2 : 2.97;...

Embodiment 3

[0058] The chemical composition and mass percentage of the titanium-containing ferritic stainless steel billet in this example are: C: 0.03%, Mn: 0.45%, Si: 0.35%, P: 0.017%, S: 0.004%, Cr: 17.10%, Ni: 0.10%, Al: 0.025%, N: 0.017%, Ti: 0.14%, and the rest are iron and unavoidable impurities.

[0059] The method for producing titanium-containing ferritic stainless steel billets by billet continuous casting machine in this embodiment includes AOD final slag quenching and tempering, LF furnace high alkalinity and TiO 2 Refining slag, LF furnace with titanium, billet continuous casting machine continuous casting process, the specific process steps are as follows:

[0060] (1) AOD final slag quenching and tempering: the dephosphorized hot metal is smelted by AOD, the reduction slag is removed after AOD reduction, and the weight of the remaining slag is controlled at 17kg / t of steel. Steel, at the same time add lime 4kg / t steel, make the final slag binary alkalinity CaO / SiO 2 : 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com