Method for extracting and concentrating gutta-percha and recycling organic solvent

A technology of organic solvent and eucommia gum, which is applied in the field of extraction and separation of natural products, can solve the problems of inapplicability to industrial production, low purity of eucommia gum, unfavorable industrial production, etc., to achieve low production cost, reduce energy consumption, and increase economic efficiency The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

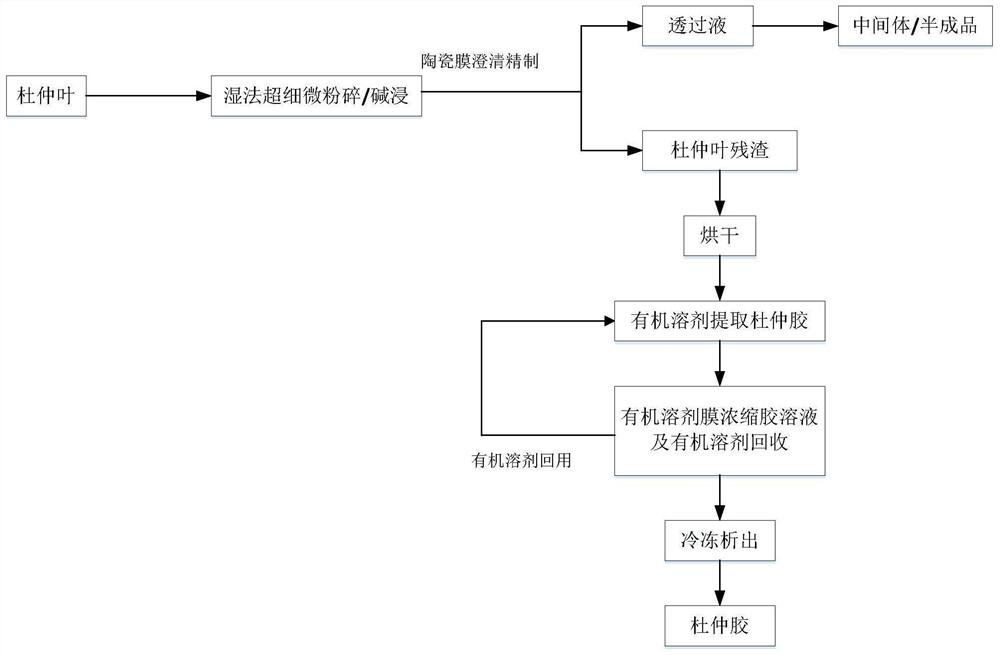

Method used

Image

Examples

Embodiment 1

[0040] The method for extracting, separating and purifying Eucommia gum from leaves of Eucommia provided in this embodiment is as follows:

[0041] Step (1): Wash the raw material of eucommia leaves, dry them, grind them mechanically, and set them aside.

[0042] Step (2): Soak the material in a small amount of 4.5% dilute alkali solution for 2 hours, and then add the raw material of Eucommia ulmoides leaves to the dilute alkali solution at a material-to-liquid ratio of 1:15 into a wet-process ultrafine pulverizer. The power of the wet ultrafine pulverizer is 2kw, and the particle size after pulverization is 2-40μm.

[0043] Step (3): The feed liquid obtained by pulverizing in the step (2) is separated by a ceramic membrane with a membrane pore size of 0.2 μm to obtain the Eucommia leaf filter residue and permeate. Rinse and filter the Eucommia leaf filter residue with clean water until it is basically colorless, and control the liquid pH value of the cleaned filter residue a...

Embodiment 2

[0047] The method for extracting, separating and purifying Eucommia gum from leaves of Eucommia provided in this embodiment is as follows:

[0048] Step (1): Wash the raw material of eucommia leaves, dry them, grind them mechanically, and set them aside.

[0049]Step (2): Soak the material in a small amount of 6% dilute alkali solution for 0.5 h, and then add the raw material of Eucommia ulmoides leaves to the dilute alkali solution at a material-to-liquid ratio of 1:10 into a wet-process ultrafine pulverizer. The power of the wet ultrafine pulverizer is 10kw, and the particle size after pulverization is 2-40 μm. The temperature was controlled at room temperature.

[0050] Step (3): The feed liquid obtained by pulverizing in step (2) is separated by a ceramic membrane with a membrane pore size of 0.2 μm to obtain the waste residue of Eucommia leaves and the permeate. Rinse and filter the eucommia leaf waste residue with clear water until it is basically colorless, and contro...

Embodiment 3

[0054] The method for extracting, separating and purifying Eucommia gum from leaves of Eucommia provided in this example, the specific operations are as follows

[0055] Step (1): Wash the raw material of eucommia leaves, dry them, grind them mechanically, and set them aside.

[0056] Step (2): Soak the material in a small amount of 5.5% dilute alkali solution for 0.25h, and then add it into a wet-process ultrafine pulverizer according to the material-liquid ratio of Eucommia leaf raw material and dilute alkali solution: 1:5. The power of the wet ultrafine pulverizer is 12kw, and the particle size after pulverization is 2-40μm. The temperature was controlled at room temperature.

[0057] Step (3): The feed liquid obtained by pulverizing in step (2) is separated by a ceramic membrane to obtain Eucommia leaf waste residue and permeate. The membrane pore size is 0.2 μm. Rinse and filter the eucommia leaf waste residue with clean water until it is basically colorless, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com