A treatment method and system for high-concentration phosphating wastewater

A treatment method and high-concentration technology, which is applied in the treatment method and system field of high-concentration phosphating wastewater, can solve the problems that do not meet the actual use requirements, slow floc sedimentation speed, poor use effect, etc., and achieve the improvement of large dosage , short residence time, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

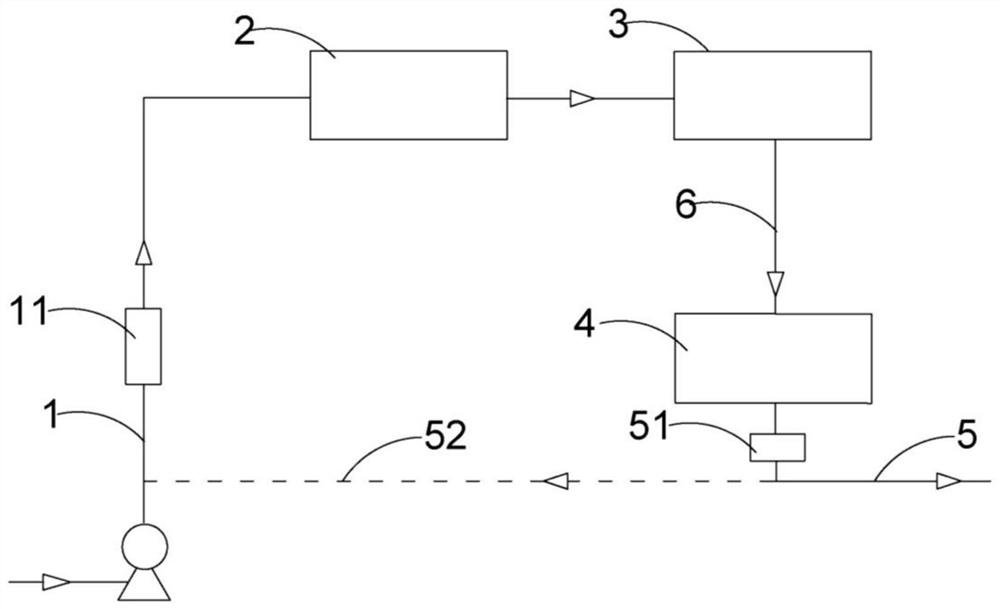

[0036] see figure 1 , a treatment system for high-concentration phosphating wastewater; including a water inlet pipe 1, a primary mixing pool 2, a secondary mixing pool 3, an air flotation pool 4 and an outlet pipe 5, the primary mixing pool 2, the secondary mixing pool 3 and the air flotation tank 4 are connected through the delivery pipeline 6 in turn, and the waste water is connected to the first-level mixing tank 2 from the water inlet pipe 1, and in the first-level mixing tank 2, it is forced to stir with the coagulant PAC and magnetic powder to form a first-level mixing tank system. The primary mixing system flows into the secondary mixing tank 3 through the delivery pipeline 6, and is forced to stir with the coagulant PAM in the secondary mixing tank 3 to form a secondary mixing system. The secondary mixing system flows into the air flotation tank 4 through the delivery pipeline 6, and the secondary mixing The system air flotation tank is separated into scum and effluen...

Embodiment 2

[0041] A treatment method for high-concentration phosphating wastewater,

[0042]The average COD of the sewage to be treated is 251.637 mg / L, the average total phosphorus concentration is 267.851 mg / L, and the average total nickel content is 14.332 mg / L. The sewage is treated according to the following steps:

[0043] (1) Adjust pH: The pH value of phosphating wastewater is stabilized in the neutral range of 6~7 through online real-time regulation;

[0044] (2) Level 1 mixing: the phosphating wastewater is pumped into the flocculation reaction tank through the lift pump, and 50mg / L PAC coagulant and 10mg / L magnetic powder are added, and stirred and mixed for 25 minutes to form a first-level mixing system;

[0045] (3) Two-level mixing: the first-level mixing system enters the coagulation aid reaction tank, and 20mg / L PAM coagulant aid is added, and the mixing reaction is stirred for 25 minutes to form a second-level mixing system;

[0046] (4) Air flotation separation: The se...

Embodiment 3

[0050] A treatment method for high-concentration phosphating wastewater,

[0051] The average COD of the sewage to be treated is 370.311 mg / L, the average total phosphorus concentration is 273.862 mg / L, and the average total nickel content is 16.663mg / L. The sewage is treated according to the following steps:

[0052] (1) Adjust pH: The pH value of phosphating wastewater is stabilized in the neutral range of 6~7 through online real-time regulation;

[0053] (2) Level 1 mixing: Phosphating wastewater is pumped into the flocculation reaction tank through a lift pump, 75mg / L PAC coagulant and 15mg / L magnetic powder are added, and the mixing reaction is stirred for 30 minutes to form a first-level mixing system;

[0054] (3) Two-stage mixing: and the mixed system enters the coagulation aid reaction tank, and 30mg / L PAM coagulant aid is added, and the mixing reaction is stirred for 30 minutes to form a two-stage mixing system;

[0055] (4) Air flotation separation: the secondary m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com