Vacuum generator and construction method and application thereof

A technology of vacuum generators and construction methods, which is applied in infrastructure engineering, machines/engines, waterway systems, etc., and can solve problems such as piping, leaking from pressurized water layers, difficulty in achieving expected results, and complicated equipment assembly to achieve accelerated Large precipitation capacity, automatic well-washing infiltration path, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

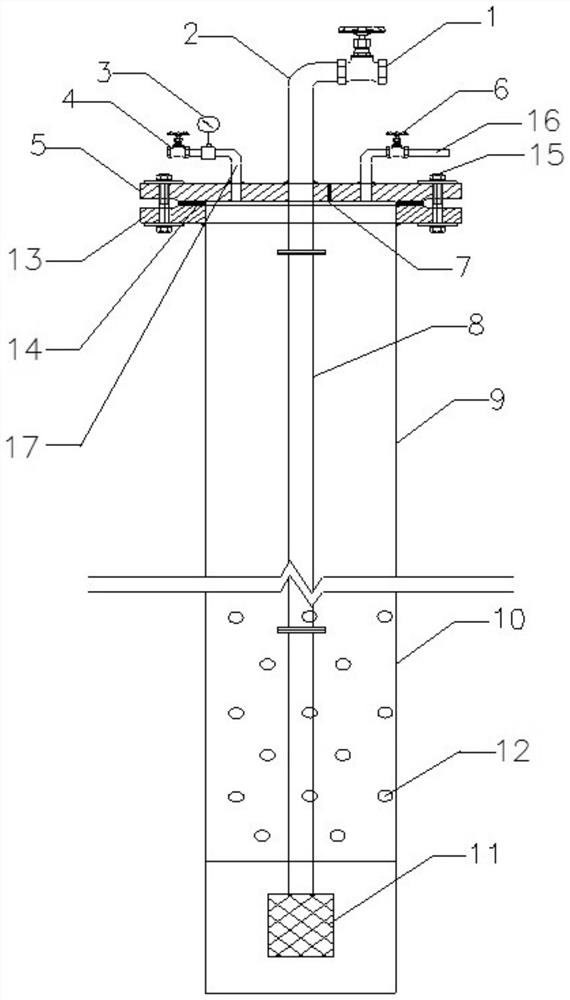

[0035] like figure 1 As shown, this embodiment provides a vacuum generator, which includes a tube well, a submersible electric pump 11 , an outlet pump pipe 8 , a drain pipe 2 , a water inlet pipe 16 and an exhaust pipe 17 .

[0036] The tube well is made of steel pipe with a diameter of 273mm and a wall thickness of 6mm. One end of the tube well is welded and closed with a 6mm steel plate, and the other end is open and sealed with a flange cover plate 5 . The tube well includes a connected tube well solid tube part 9 and a tube well flower tube part 10 , and the tube well flower tube part 10 is provided with a number of water inlet holes 12 . The length of the tube well flower tube part 10 is determined according to the depth and soil layer required for precipitation. The outside of the tube well flower tube part 10 is provided with a filter screen.

[0037] The submersible electric pump 11 is arranged at the closed end of the tube well. The submersible electric pump 11 is c...

Embodiment 2

[0040] This embodiment provides a construction method of the vacuum generator described in Embodiment 1, comprising the steps of:

[0041] (1) Leveling the site and removing underground obstacles;

[0042] (2) Measuring and releasing well location;

[0043] (3) The drilling rig is in place;

[0044] (4) Start drilling;

[0045] (5) Hole-forming inspection, since the precipitation capacity of the vacuum generator is stronger than that of ordinary tube wells, the recommended hole-forming diameter is 800mm;

[0046] (6) The tube well is placed, and the height of the tube well exposed to the ground is 0.5~1m;

[0047](7) Backfill filter material, in order to ensure the water output of the well and prevent the influx of fine sand into the well, take 3.5~4.5m from the top of the tube well as the dividing point, and the diameter between the tube well and the borehole wall below the dividing point is 1.5 m. ~3mm gravel and coarse sand backfill, the backfill should be uniform, and ...

Embodiment 3

[0054] This embodiment provides an application of the vacuum generator described in Embodiments 1 and 2 in hydraulic engineering, comprising the following steps:

[0055] (1) Close the exhaust valve 4 on the exhaust pipe 17 and the water inlet valve 6 on the water inlet pipe 16, turn on the submersible electric pump 11, and the water in the pipe wells (9, 10) is discharged along the water outlet pipe 8 and the drain pipe 2 At the same time, negative pressure is formed in the closed space in the tube well, and the groundwater enters the tube well under the action of negative pressure and is continuously discharged;

[0056] (2) Observe the negative pressure in the tube well through the positive and negative pressure gauge 3. When air enters the tube well to reduce the negative pressure, turn off the submersible electric pump 11, open the exhaust valve 4 and the water inlet valve 6, and pass the water inlet pipe 16. Inject water into the tube well until the exhaust pipe 17 overf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com