A method of improving intermetallic compounds in cast alloys

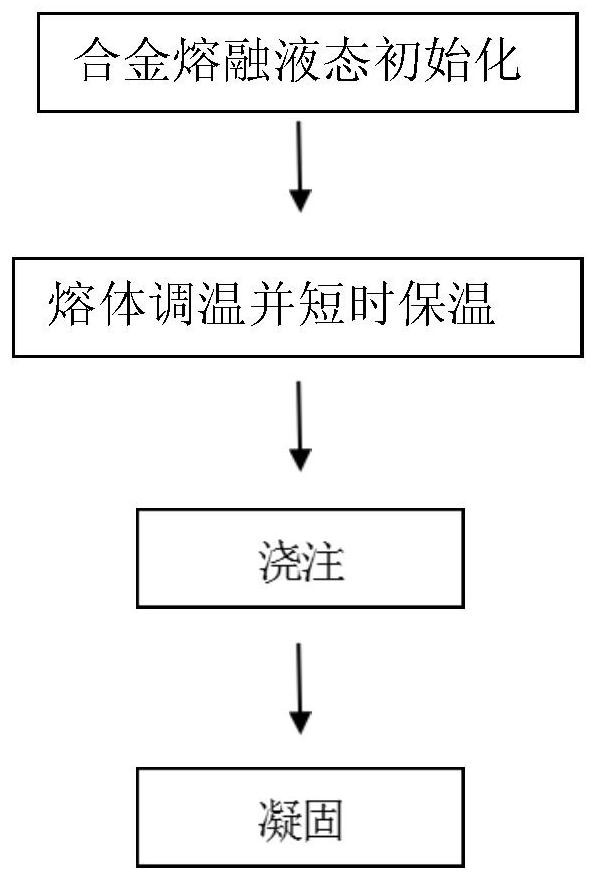

A technology for intermetallic compounds and casting alloys, which is applied in the field of improving intermetallic compounds in casting alloys, can solve problems such as material brittle fracture, and achieve the effects of reducing scrap rate, quantity, and formation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

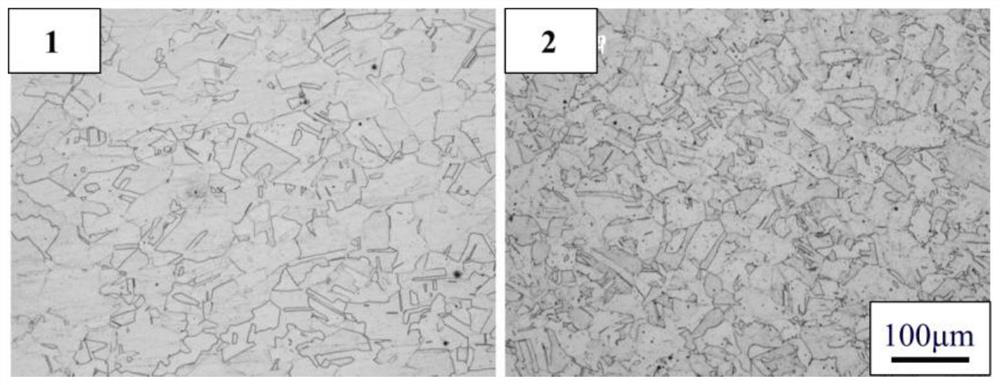

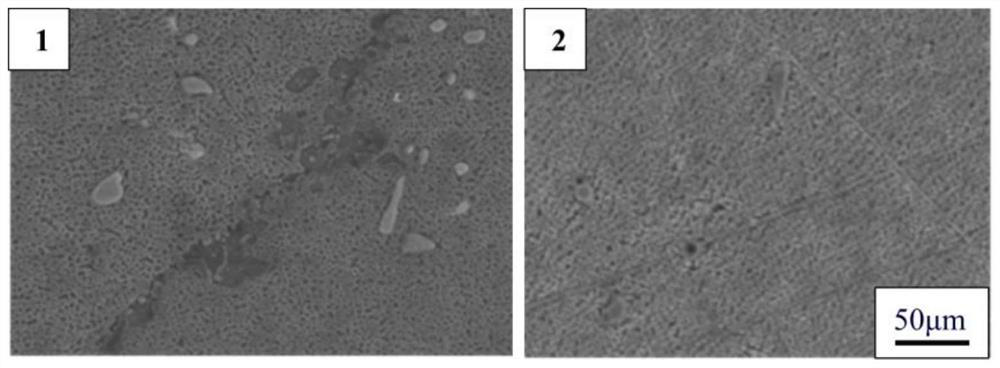

[0069] The GH4169 alloy has a large tolerance of material expansion and contraction recovery run-out, so that the material is scrapped when it exceeds the limit value before the fatigue life of the material expires due to the large tolerance of the material cycle deformation recovery fluctuation. It has become a hot spot in the industry to solve the microstructure stability of the intermediate metal compound of the material and then reduce the expansion and contraction rebound value during the use of the material. Under this process, the expansion and contraction recovery run-out tolerance of the material has been significantly changed.

[0070] Table 1 Main chemical composition of GH4169 alloy

[0071] C Cr Ni co Mo ≤0.08 17.0-21.0 50-55.0 0.02-1.0 2.80-3.30 Al Ti Nb Si Fe 0.30-0.70 0.75-1.15 4.85-5.40 ≤0.2 Remain

[0072] The main intermetallic compounds in GH4169 alloy are shown in Table 2.

[0073] The melting point (°C) o...

Embodiment 2

[0119] The yield of iron-based alloy M42 is only 45% due to material brittleness in the process of rolling thin plates (thickness below 1.5mm), and the service life of thin plate materials is not optimistic. Through the process of the invention, the finished product rate of the alloy M42 thin plate is increased to 80%, and the service life is increased to 3 times of the original one. This is because the present invention changes the material macro effect brought about by the microstructure of the alloy intermetallic compound.

[0120] Table 4 Main chemical composition of iron-based alloy M42

[0121]

[0122]

[0123] The main intermetallic compounds in the iron-based alloy M42 are shown in Table 5.

[0124] Table 5 Melting point of compounds in M42 alloy (°C)

[0125] Simple substance melting point compound melting point compound melting point V 1919 VC 2830 TiC 3160 Mo 2617 Mo 2 C

2690 W 2 C

2730 C 3727 MoC 2...

Embodiment 3

[0170] The high-end copper-based alloy ZrCrCu needs to meet both mechanical properties and electrical conductivity, but the mechanical properties and electrical conductivity are contradictory, and improving one of them will weaken the other. The material of the invention is simultaneously improved in terms of mechanical properties and electrical conductivity.

[0171] Table 7 Main chemical composition of copper-based alloy ZrCrCu

[0172] C Cr Zr Fe max0.05 0.8-1.1 0.13-0.2 max0.03 Cu Mg Si mn margin 0.0005-0.008 max0.01 max0.01

[0173] The specific smelting method is as follows:

[0174] Step 1. Copper-based alloy ZrCrCu alloy liquid initialization

[0175] (1) First put the cast alloy raw materials copper, copper chromium and copper zirconium into a quartz crucible, and put the quartz crucible into a vacuum induction melting furnace with magnetic stirring function, then vacuumize, and when the vacuum degree reaches below 9Pa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com