Patents

Literature

244 results about "Gutta-percha" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

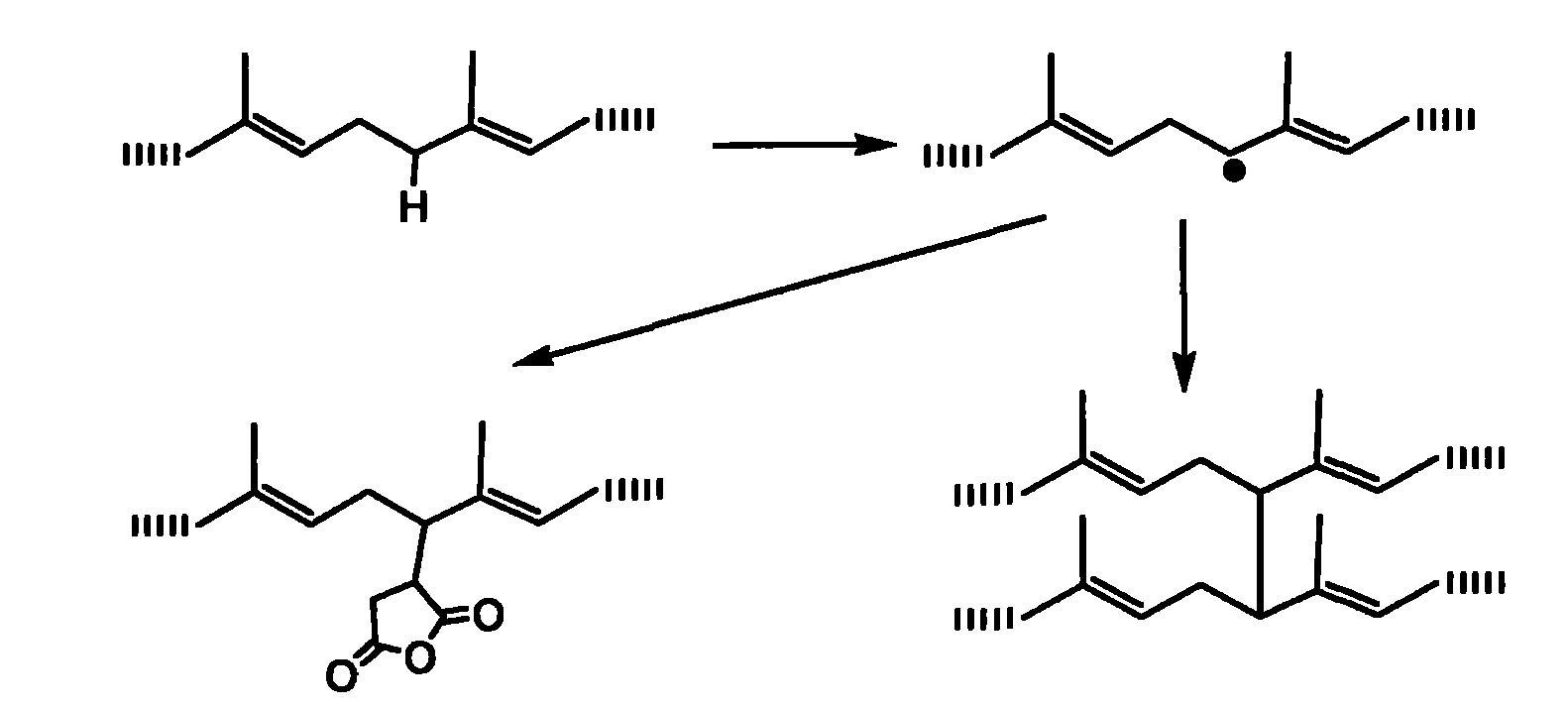

Gutta-percha refers both to trees of the genus Palaquium in the family Sapotaceae and the rigid, naturally biologically inert, resilient, electrically nonconductive, thermoplastic latex produced from the sap of these trees, particularly from Palaquium gutta.

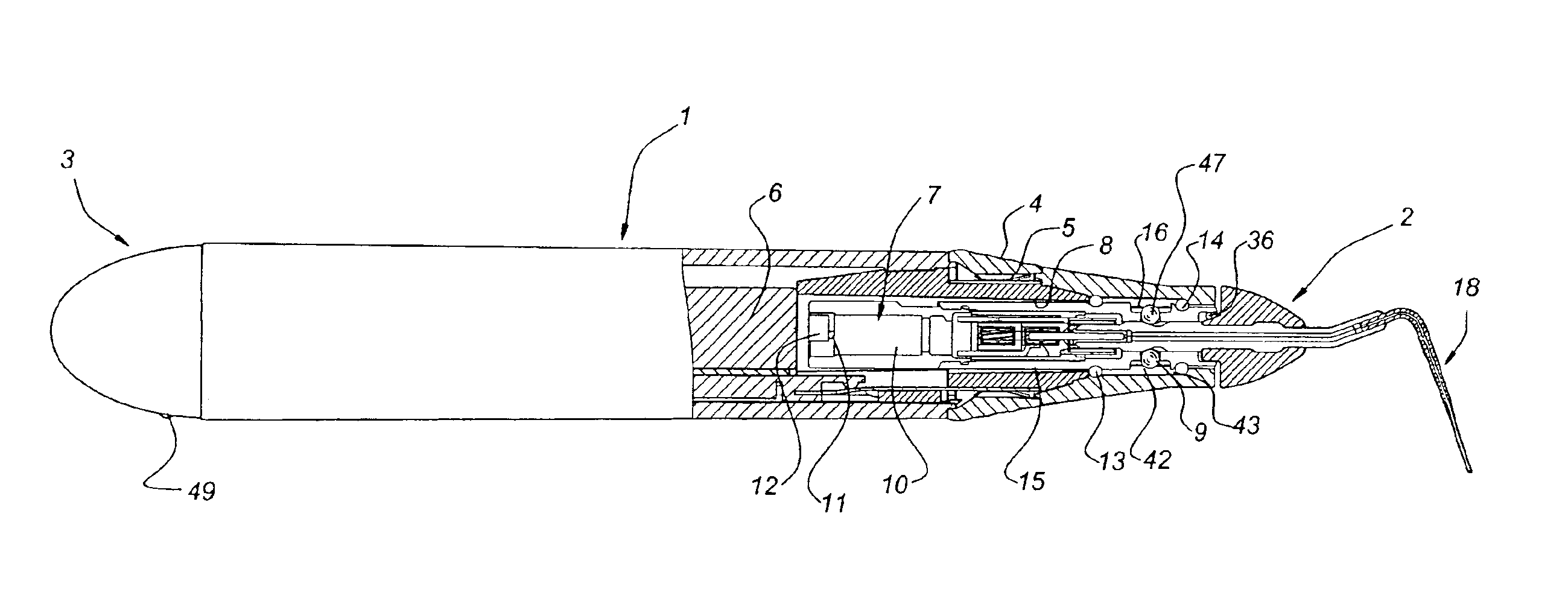

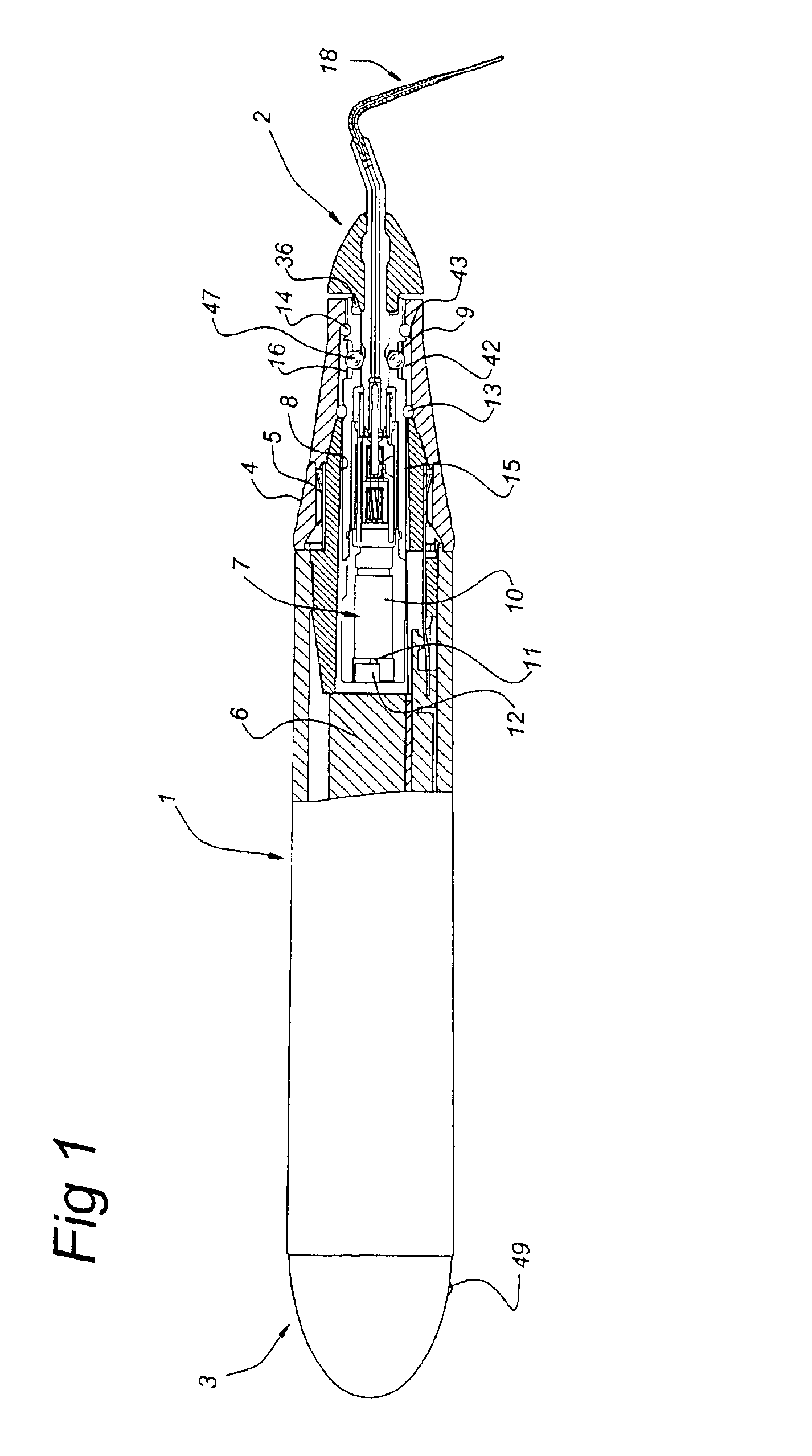

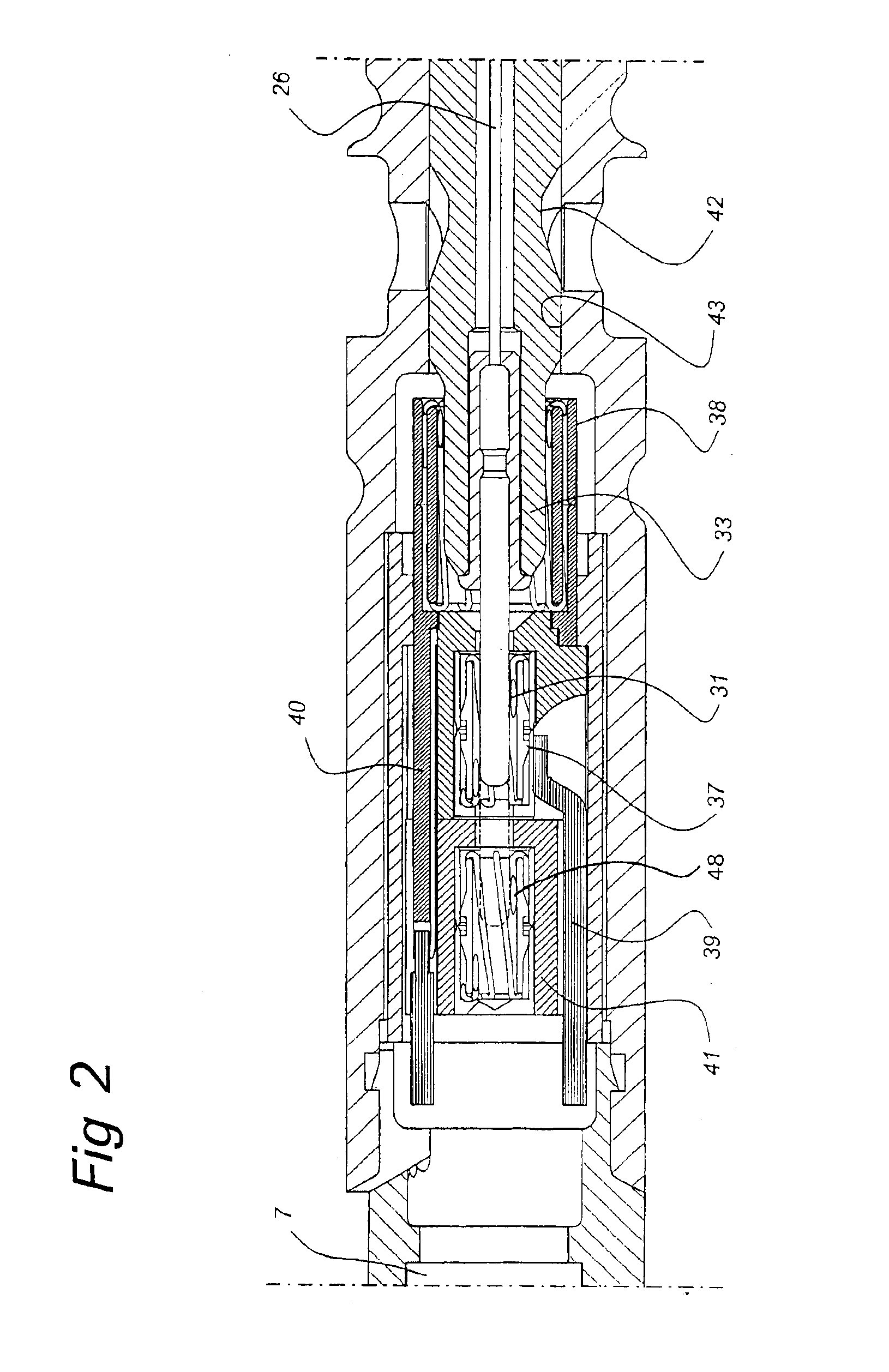

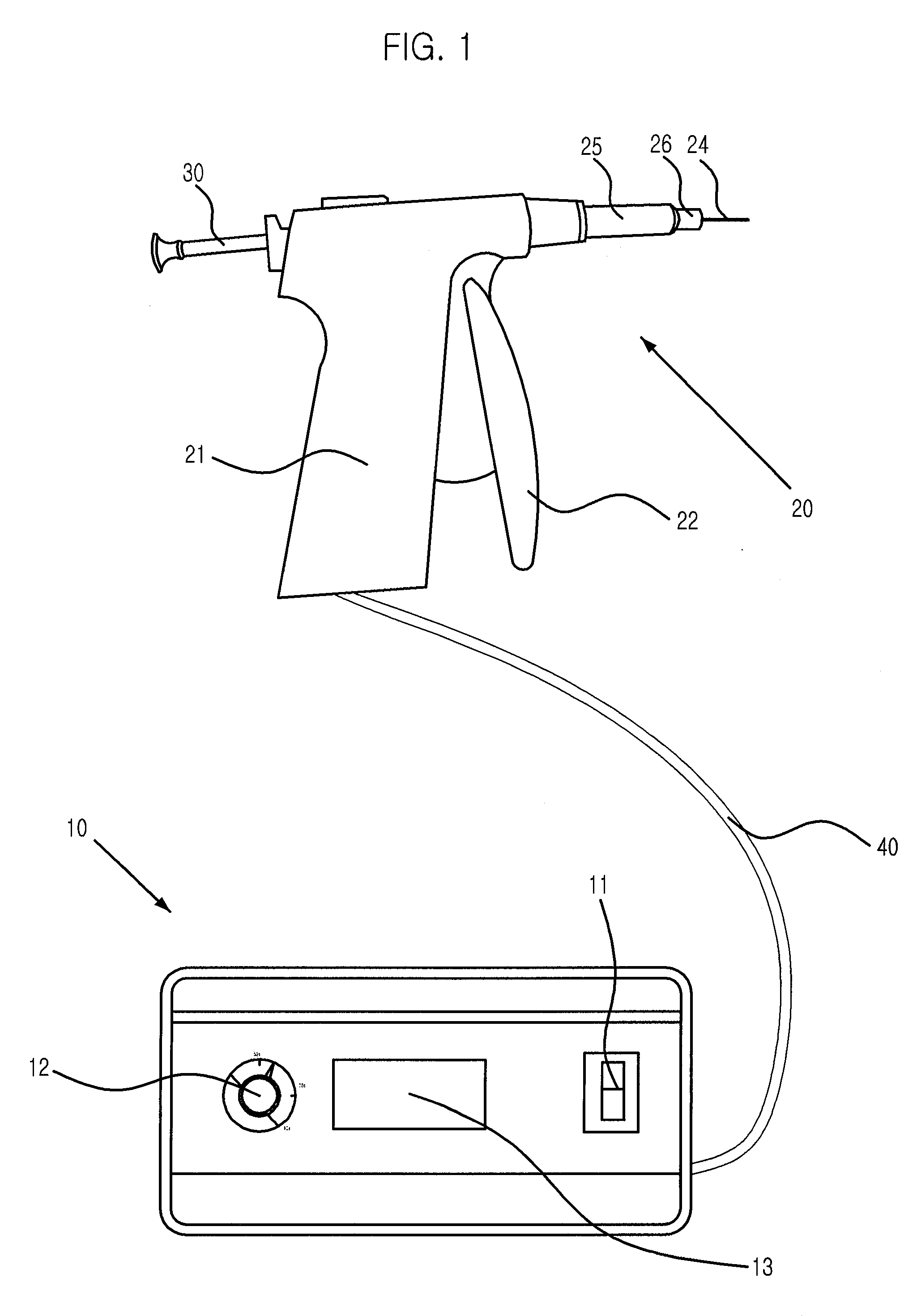

Device for performing an endodontic treatment

InactiveUS6910887B2Solve excessive vibrationGood effectTooth pluggers/hammersTeeth fillingEndodontic therapyGutta-percha

A device for use in an endodontic treatment, for example for filling a root canal of a tooth that is empty as a consequence of the removal of the nerve, with a thermoplastic product such as gutta percha, which product is distributed in the root canal by means of heating and pressing. The device includes a housing that can be grasped by hand, a treatment element provided at one end of the housing, and a device for making the treatment element vibrate.

Owner:MEGADENT ENDO PRODS

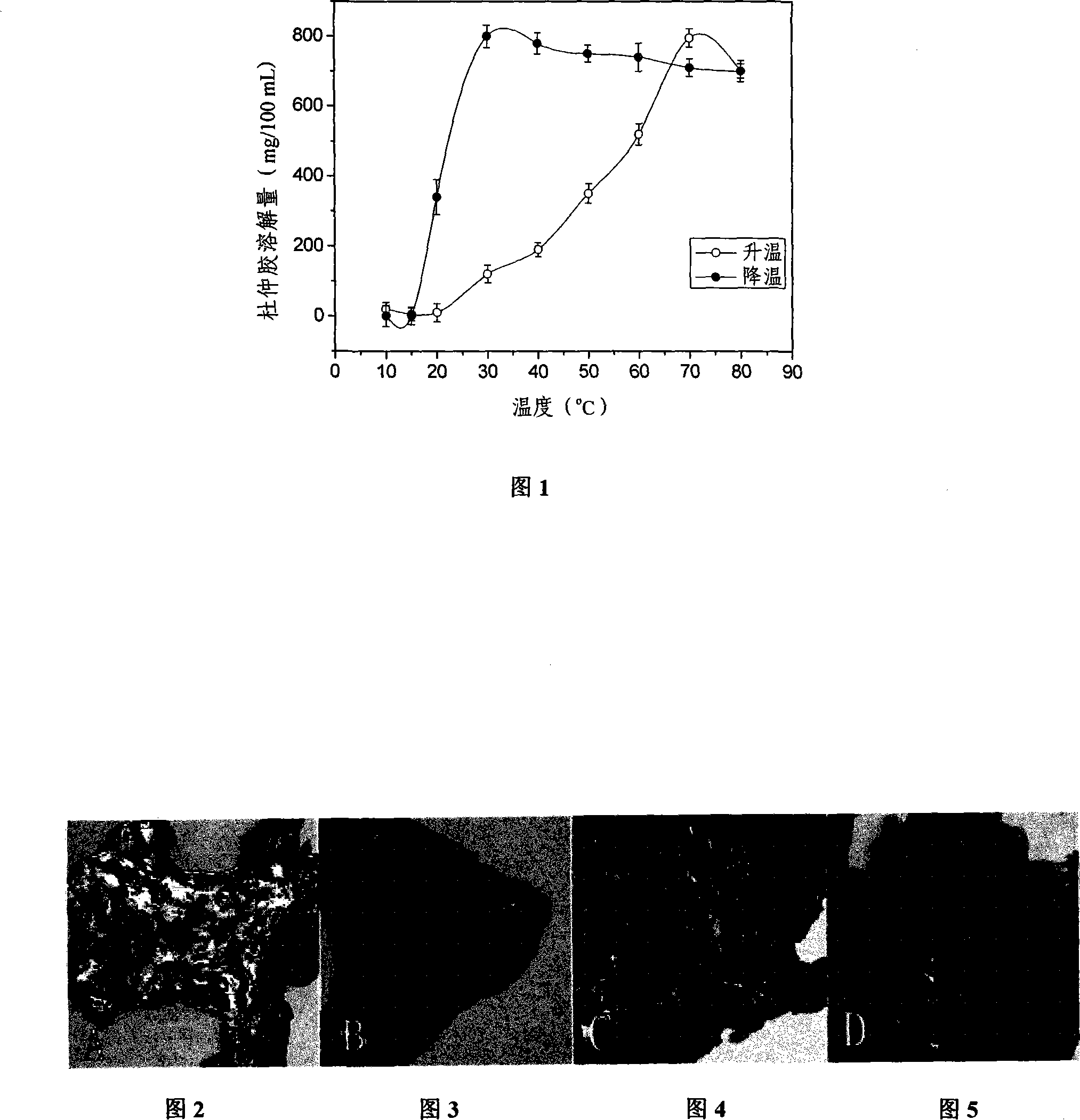

Method for extracting filament gutta-percha from eucommia leaf and skin

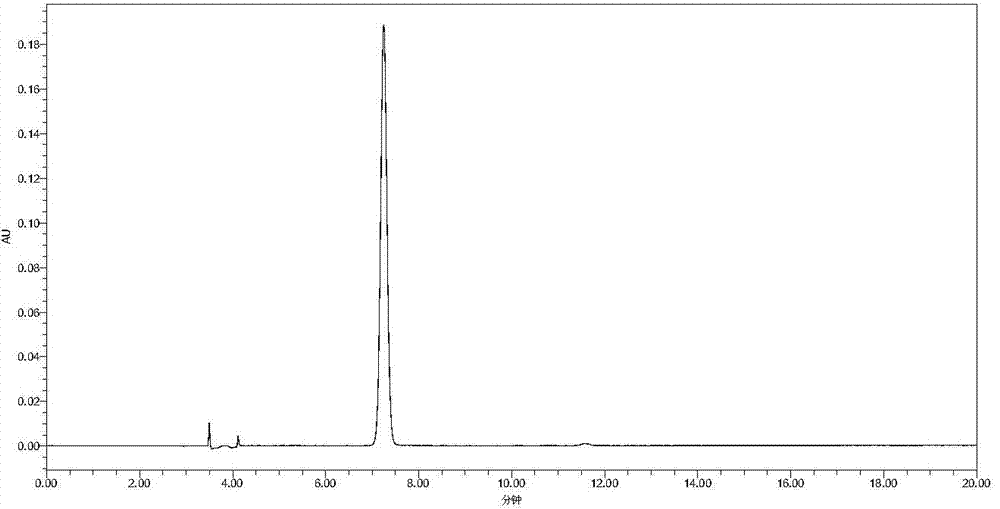

InactiveCN101157827AHigh yieldImprove qualityNatural resin processFermentationGutta-perchaPolymer science

The invention discloses an extraction method of filament eucommia rubber from eucommia leaves and peel; the method uses petrol ether as solvent to extract the eucommia rubber and has the steps: first, the eucommia leaves or the peel is made into small pieces and added with NaOH solution to dissolve cuticle; then cellulase is added to hydrolyze cell wall; the petroleum ether solvent at 60 DEG C to 90 DEG C of boiling range is added; then the obtained solution is extracted through recirculation at the temperature of 85 DEG C and filtrated when being hot, then cooled and frozen; the filament eucommia rubber is produced after filtration. Concentration of the NaOH solution is 0.5 percent to 1.5 percent and the dissolution time is 6 hours; pH value of the cellulase used for hydrolyzing the cell wall is 4 at temperature of 50 DEG C; enzymatic hydrolysis time is 1 hour to 2 hours and the time for reflux extraction is 2 hours; the frozen time is 30 minutes to 60 minutes at temperature of minus 20 DEG C to 0 DEG C. The method can effectively and completely extract the eucommia rubber to make original eucommia rubber and keep the original biological characteristics and physical properties and status and the original molecular structure and polymerization of the eucommia rubber; the method uses the cellulose to extract pretreated eucommia leaves raw materials, and gets the eucommia rubber of high quality when getting high yield.

Owner:GUIZHOU UNIV

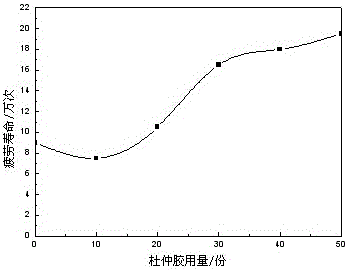

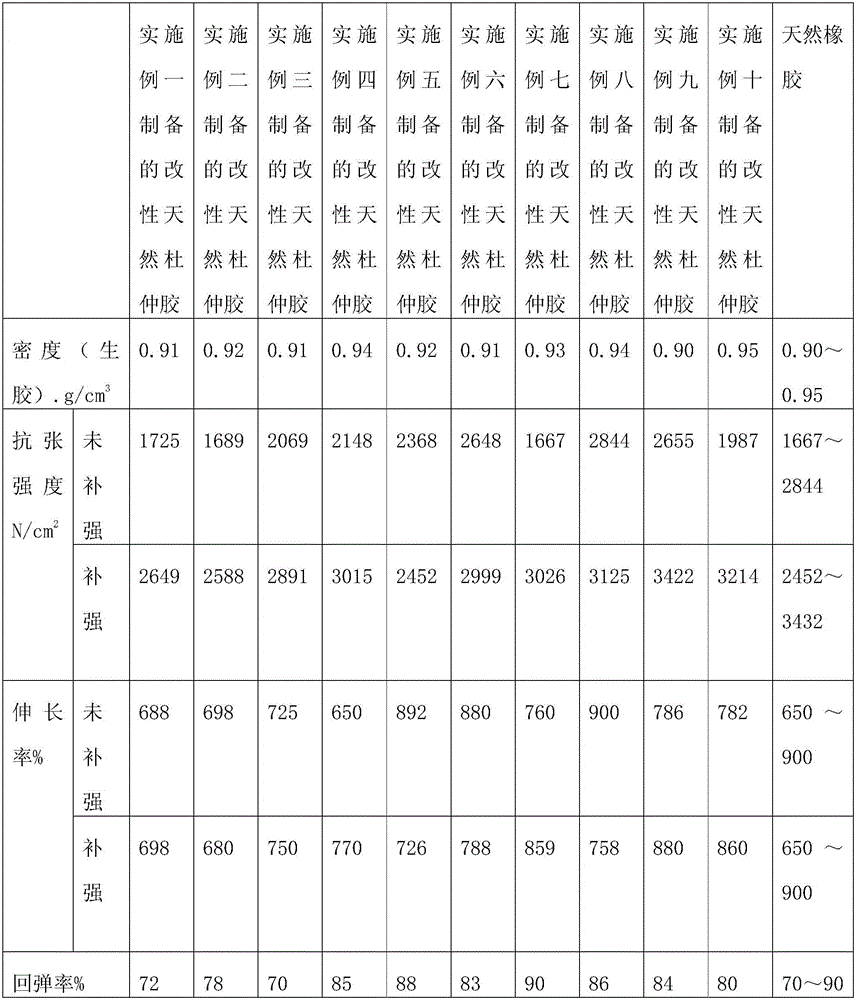

Natural and fatigue-resistant gutta-percha vulcanized rubber and preparation method thereof

InactiveCN105801925AThe ingredients of the formula are reasonableImprove fatigue resistanceRubber materialPolymer science

The invention provides natural and fatigue-resistant gutta-percha vulcanized rubber and a preparation method thereof and relates to rubber and a preparation method thereof. The natural and fatigue-resistant gutta-percha vulcanized rubber is prepared from components in parts by weight as follows: 10-100 / 0-90 parts of the gutta-percha / blend rubber, 4-8 parts of an active agent, 1-4 parts of an anti-aging agent, 30-80 parts of reinforcing filler, 1-6 parts of a vulcanizing agent, 1-4 parts of a vulcanization accelerator, 0-10 parts of a softening agent and other auxiliaries. The preparation method of the fatigue-resistant gutta-percha / blend rubber vulcanized rubber comprises the following technological steps: A, plastication and mixing; B, remilling and vulcanization. The fatigue-resistant gutta-percha / blend rubber vulcanized rubber has reasonable components in the formula and higher anti-fatigue performance. The vulcanized rubber material prepared with the method has good anti-fatigue performance and long service life, can be widely applied to tires, triangular belts, synchronous belts, conveying belts and shock-reducing rubber products and has higher popularization and application value.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

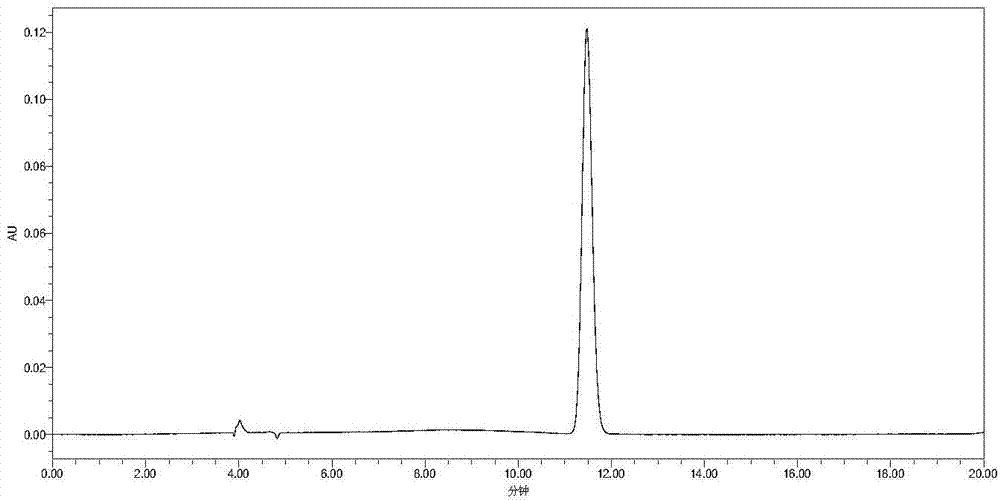

Method of extracting gutta-percha through enzymolysis

Provided is a method of extracting gutta-percha through enzymolysis. One of natural eucommia skin or eucommia leaves or eucommia wing skin is placed in clean water to be cleaned and dried, and moisture content of the eucommia skin, the eucommia leaves, or the eucommia wing skin is enabled to be less than 5%. A compound enzyme which comprises, by mass, 0.27% of cellulose, 0.01% of pectinase, and 0.02% of protease is added, enzymolysis undergoes 1-3 days under stirring at a speed of 500 r / min under 50 DEG C. Mixture after the enzymolysis is filtered, dregs of the filtered mixture are sent to an ultrasonic extraction tank for ultrasound extraction, and glue mixed liquor is produced. The glue mixed liquor is filtered in a grading mode, impurities are eliminated, and the glue mixed liquor with the impurities eliminated is sent to a separation tank. Eventually the gutta-percha is extracted through the method that gutta-percha crystals are precipitated at a low temperature. The method is simple in process, little in pollution, high in yield rate, low in cost, and ideal in effect; the extraction rate reaches more than 95%, and the gutta-percha content reaches 99.9%; and the produced gutta-percha is long in gelatin silk, high in tensile and tearing-proofing physical strength, and capable of being applied to wide fields.

Owner:HENAN HENGRUIYUAN IND

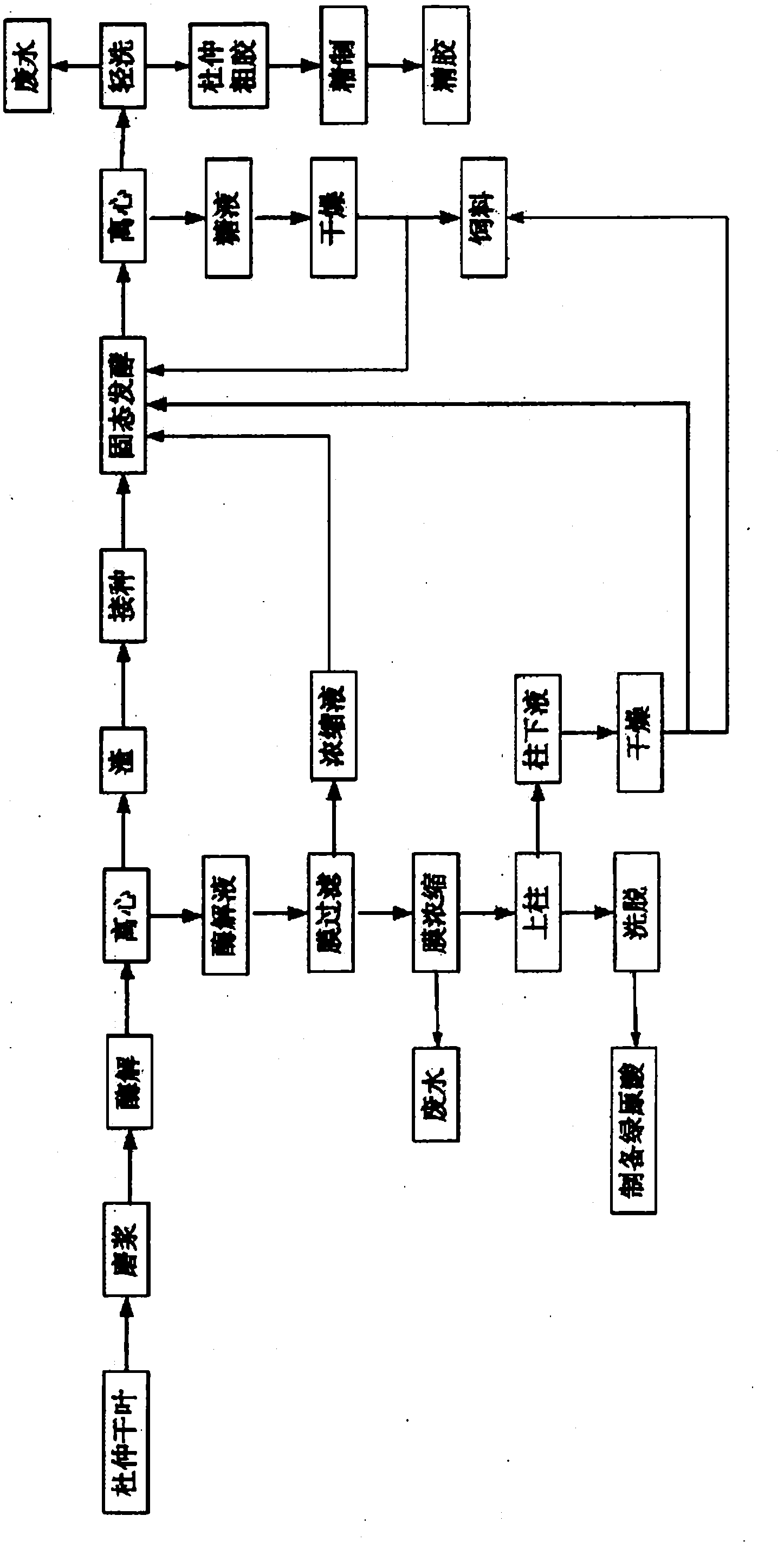

A method for extracting eucommia gum from eucommia leaves

The invention relates to a method for extracting natural products, in particular to a method for extracting eucommia gum from eucommia leaves by using a biological method. The following process steps are included: the first step is pretreatment of eucommia leaves, including pulping and enzymatic hydrolysis. The second step is the preparation of the nitrogen source, including membrane filtration, membrane concentration and resin adsorption, and drying the membrane filtration concentrate and the subcolumn liquid as the nitrogen source for later use. The third step: extraction of eucommia gum, including inoculation of Eucommia ulmoides-16 for solid-state fermentation, separation of solid and liquid from the fermentation product, drying of the liquid as a carbon source for future use, and light washing and refining of the crude gum to obtain fine gum. This method has high production efficiency, low production cost, and can co-produce chlorogenic acid to increase income.

Owner:武汉普赛特膜技术循环利用有限公司

Shape memory functional material with gutta percha and method for preparing same

The invention relates to a shape memory functional material containing gutta-percha and a method for making the same. The functional material is technically characterized in that the compositions in mass portion are: 10 to 50 portions of gutta-percha, 10 to 60 portions of rubber, 10 to 30 portions of polyethylene, 0.5 to 3 portions of accelerating agent containing sulfur, 1 to 3 portions of antideteriorant, 1 to 5 portions of zinc oxide, 0 to 2 portions of magnesia, 1 to 5 portions of sulfur, 1 to 3 percent of dicumyl peroxide, 10 to 70 portions of siliceous reinforcing agent and 1 to 10 portions of stearine. The invention provides the shape memory functional material containing gutta-percha and the method for making the same and can be applied to produce the products such as an orthopedic external fixation material, a prosthetic limb sleeve, a sports protection tool and a health beauty appliance. A medical gutta-percha plate replaces plaster to serve as the orthopedic external fixation material because the gutta-percha plate is sanitary, light and convenient and radiotransparent X, has convenient and simple operation, high quality and low price, and is more popular compared with other imported macromolecule materials for replacing plaster; the shape memory functional material can be made into a film stuck with the metal perfectly because the material has good radar wave-transparent performance, thereby synthesizing a radar wave-transparent material for sealing a pore radar waveguide antenna and contributing to the development of the war industry.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Gutta-percha compositions for obturating dental root canals

Improved compositions comprising a mixture of gutta-percha and a hydraulic material containing calcium silicate, calcium aluminate, calcium phosphate, and calcium sulfate compounds are provided. Preferably, the composition includes hydroxylapatite mineral. The composition is particularly suitable for obturating and sealing dental root canals. The composition should provide a stable barrier to bacterial and fluid leakage in the root canal system of a tooth. In addition, the composition should help promote the growth of new bone and tissue surrounding the root tip area.

Owner:DENTSPLY SIRONA INC

Grafted gutta percha asphalt modifier

InactiveCN102093518AImprove performanceBreak dependenciesBuilding insulationsPolymer scienceGutta-percha

The invention discloses a grafted gutta percha asphalt modifier which relates to modification of asphalt serving as a building material in the technical field of transportation. The conventional asphalt modifier is mainly selected from byproducts of the petrochemical industry, such as SBS (Styrene Butadiene Styrene), SBR (Styrene Butadiene Rubber) and the like. The materials are nonrenewable and have high dependence on high-quality crude oil. The invention provides natural renewable high polymer gutta percha for asphalt modification, which is used for lowering the dependence of the conventional asphalt modifier on petroleum serving as a nonrenewable resource. The gutta percha is trans-form-polyisoprene which is easy for ordered agglomeration and crystallization and cannot be directly applied to asphalt modification. In the grafted gutta percha asphalt modifier, small molecules are grafted on the long chain of a gutta percha molecule to partially damage the crystallization of the gutta percha. Although the elasticity of the gutta percha is not as high as that of gutta percha treated by vulcanization, a part of plasticity is kept and the gutta percha becomes a rubber-plastic dual thermoplastic elastic material. High and low temperature performance of asphalt can be improved, and technical requirements of national and ministerial standards are met.

Owner:李志刚 +2

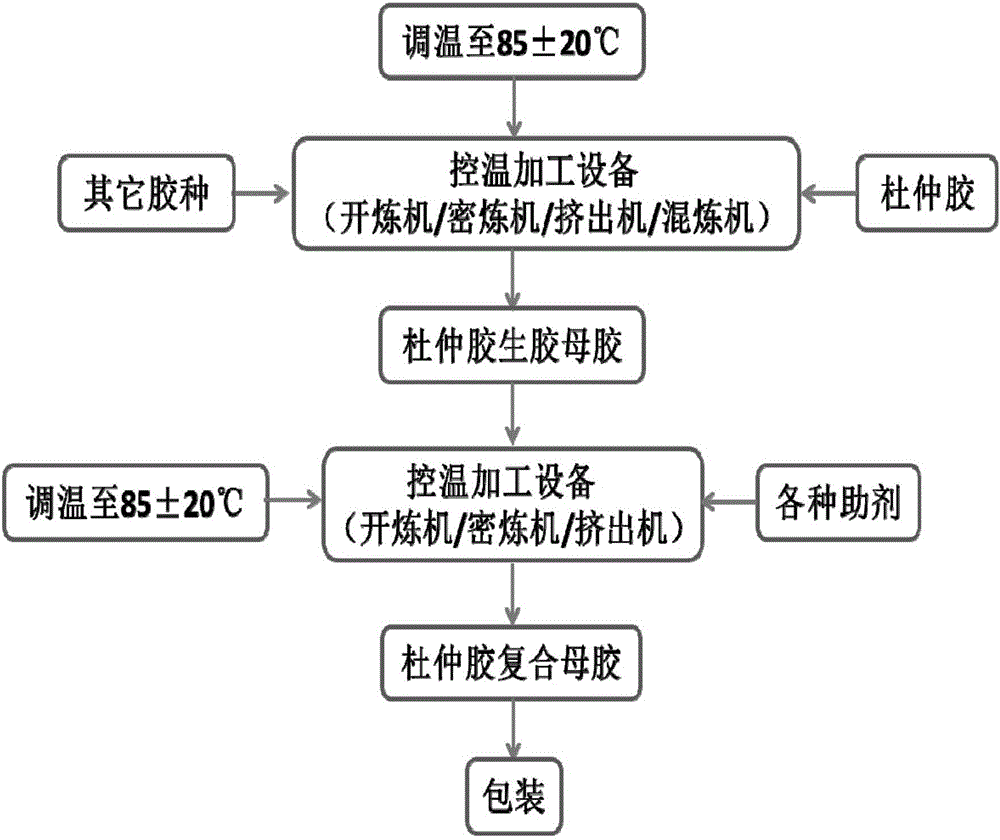

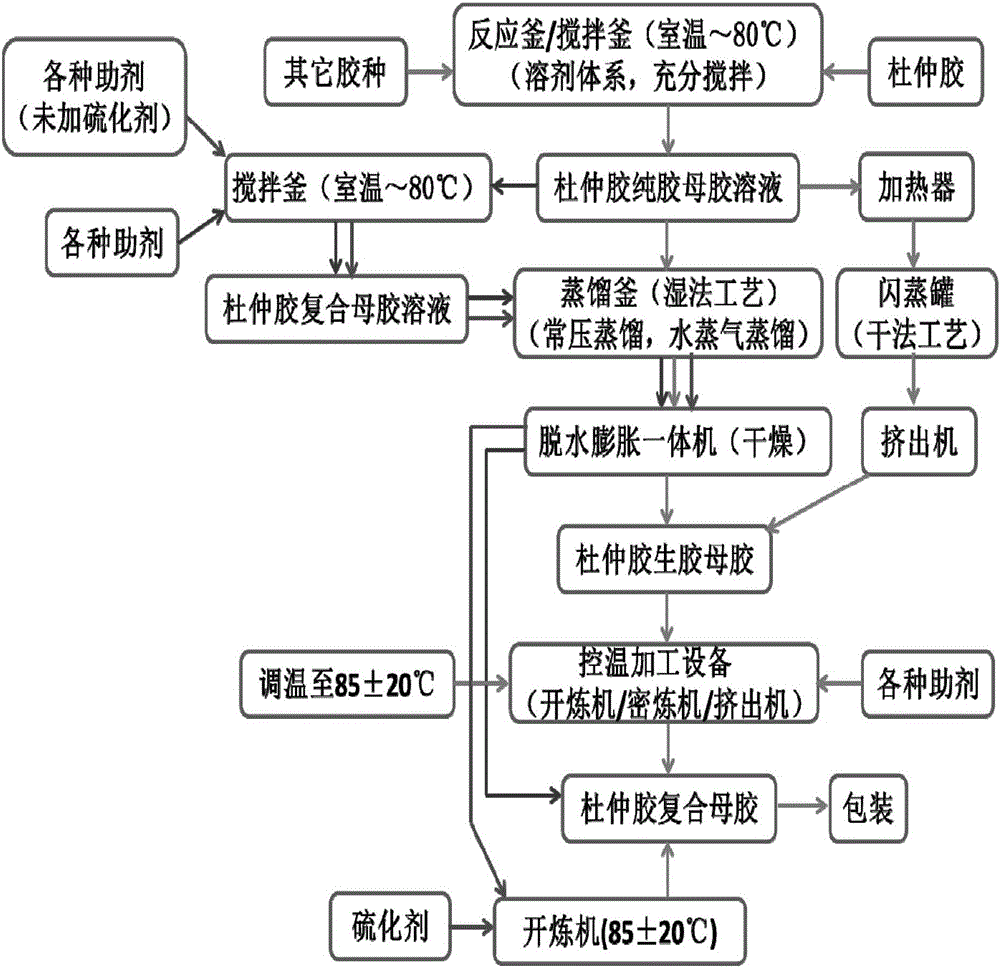

Gutta-percha masterbatch co-blended material capable of being directly used as traditional rubber material

The invention relates to a gutta-percha masterbatch co-blended material capable of being directly used as a traditional rubber material. Gutta-percha is hard rubber at room temperature, cannot be directly used as a rubber material, thereby hindering large-scale application of the gutta-percha in rubber industries. The gutta-percha is specially co-blended with other rubber types to prepare a gutta-percha masterbatch. The preparation method can be divided into a dry process and a wet process, wherein the dry process comprises that through a temperature controllable open mill, an internal mixer, an extruder, a mixing machine and other processing devices, the gutta-percha is evenly mixed in other rubber types according to a certain proportion to prepare the co-blended new material; the wet process comprises that through a reaction kettle, a stirring kettle and other devices, the gutta-percha and other rubber types are dissolved in a good solvent according to a proportion and fully stirred to prepare the co-blended new material through solvent recovery and other processes. According to the processes, the gutta-percha raw masterbatch can be prepared; other auxiliary agents are added to prepare the gutta-percha composite masterbatch, and the barrier is cleared up for large-scale market application of the gutta-percha.

Owner:BEIJING UNIV OF CHEM TECH

Gutta percha shape memory polymer composite material and preparation method thereof

The invention discloses a gutta percha shape memory polymer composite material and a preparation method thereof. The composite material is compounded from the following raw materials in parts by weight: 33-54 parts of polyethylene, 27-48 parts of gutta percha, 9-23 parts of an inorganic reinforcing material, 1.5-4.5 parts of a cross-linking agent and 0.5-1.5 parts of an antioxidant. When in preparation, all the raw materials are weighed according to the mixture ratio and uniformly mixed and stirred, then a mixture is subjected to mixing in an open mill at 135-165 DEG C for 10-15min, then hot-press forming is performed in a pressure forming machine, the temperature is controlled at 145-175 DEG C, and cooling is finally performed for preparation. The obtained composite material has the advantages of good resistance to high temperature, relatively great deformation and relatively easy figuration, and the field of use is expanded.

Owner:湖北格霖威新材料科技有限公司

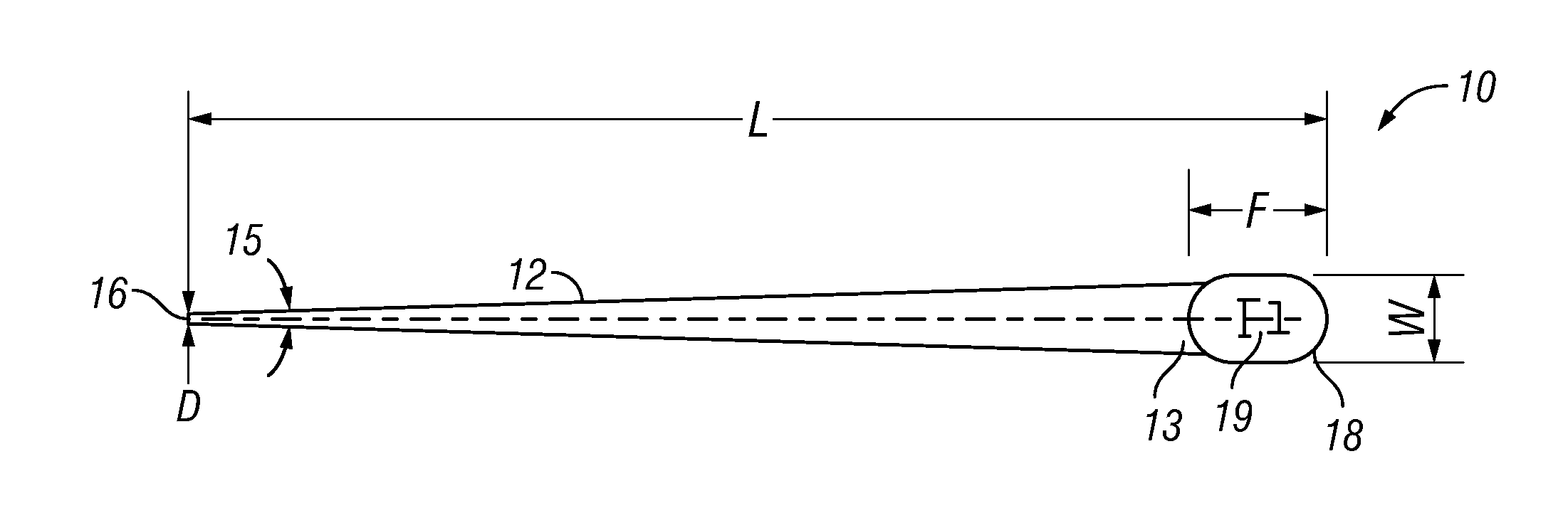

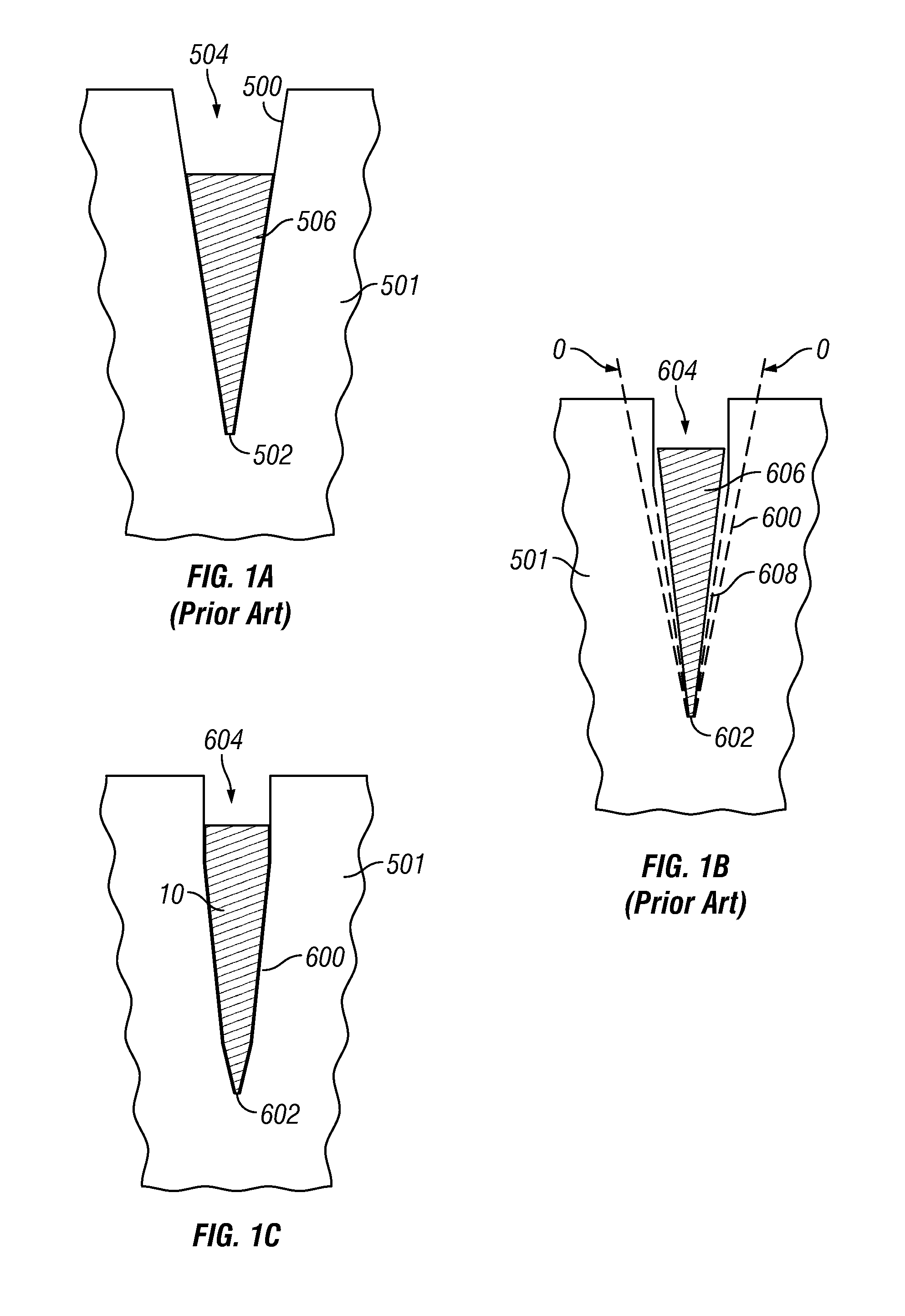

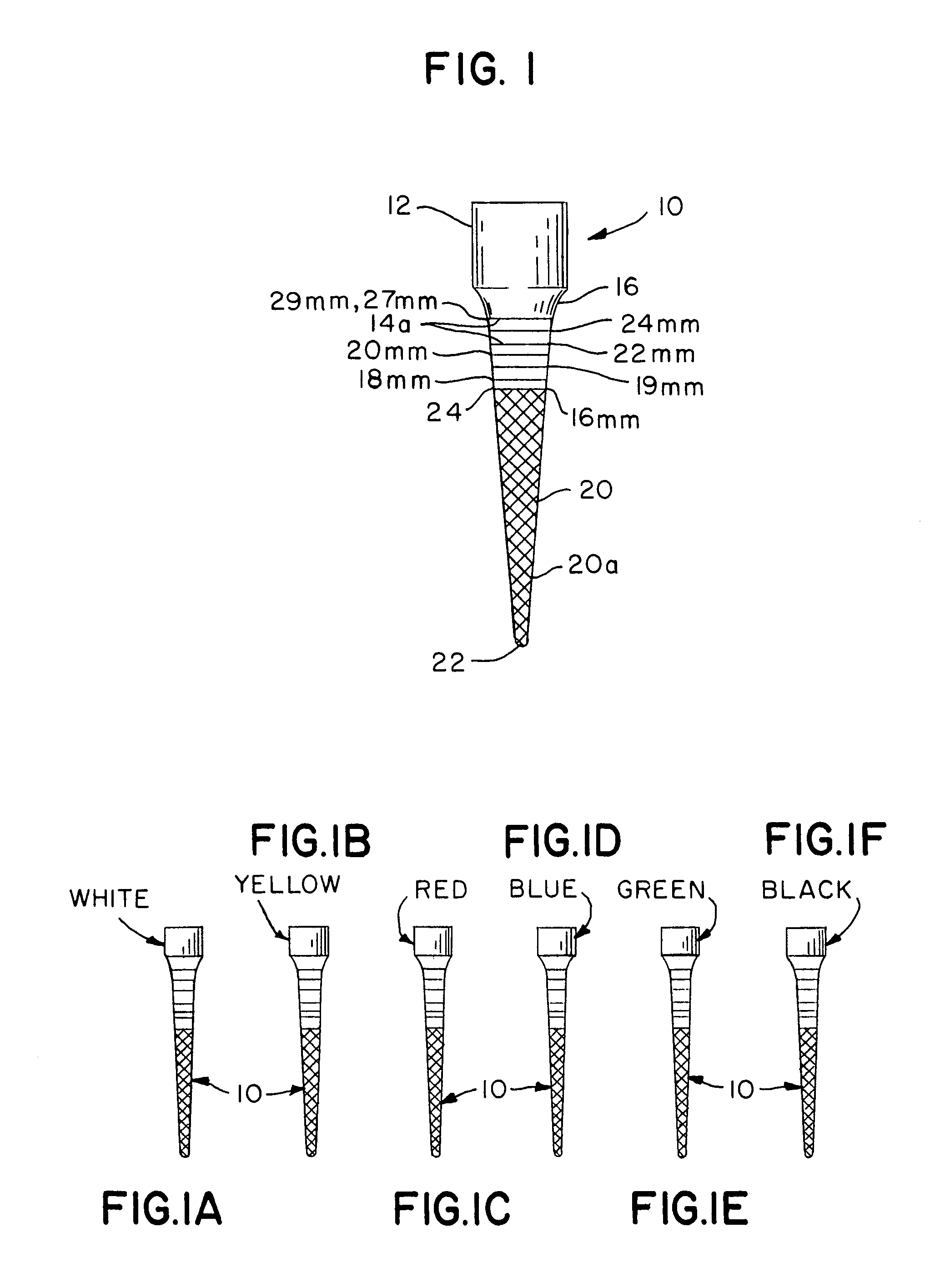

Multi-taper dental root canal filling points/cones and process of making same

InactiveUS20140272802A1Improve airtightnessLess micro-leakageTeeth fillingTeeth cappingGutta-perchaStructure of the Earth

The present invention provides an improved root canal filling point / cone having a structure that can be manufactured precisely to result in better obturation with less micro-leakage. One aspect of the present invention is directed to a molded root canal filling point having progressively decreasing tapers from the smaller tip end to the larger end. Another aspect of the present invention is directed to a thermo-pressure molding process for manufacturing root canal filling appliances (e.g., Gutta Percha points). A further aspect of the present invention is directed to the structure of the mold for undertaking thermo-injection molding.

Owner:TULSA DENTAL PROD LLC

Method for increasing gutta-percha content in eucommia leaves

The invention discloses a method for increasing the gutta-percha content in eucommia leaves by spraying chemicals on the leaves. The method comprises the steps of preparing water solution with the concentration of salicylic acid being 10-200ppm and the mass fraction of magnesium sulfate being 0.01-0.08 percent, spraying the prepared solution to the leaves of growing eucommia trees on the rainless days before sunrise or after sunset and carrying out spraying for 1-4 times every two months, wherein the spraying interval is not shorter than 15 days. By adopting the method for carrying out foliage spray, the eucommia leaves can be harvested from October to November, and the gutta-percha content in the eucommia leaves is higher than the gutta-percha content in the eucommia leaves growing on the same condition without foliage spray by 20-50 percent. The method can be implemented in an industrialized, large-scale and standardized mode, and is good in economic benefit and wide in market application prospect.

Owner:JISHOU UNIVERSITY

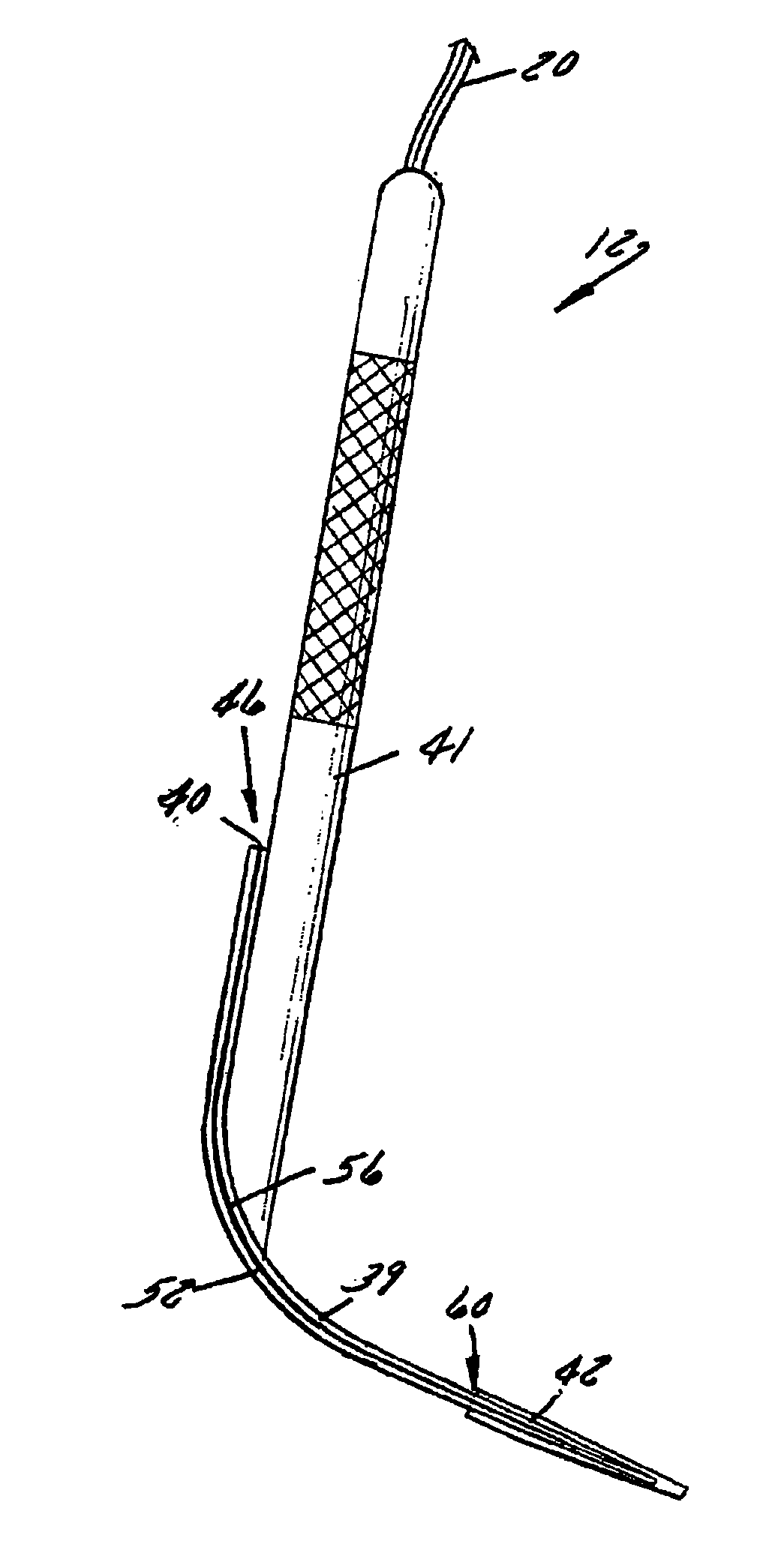

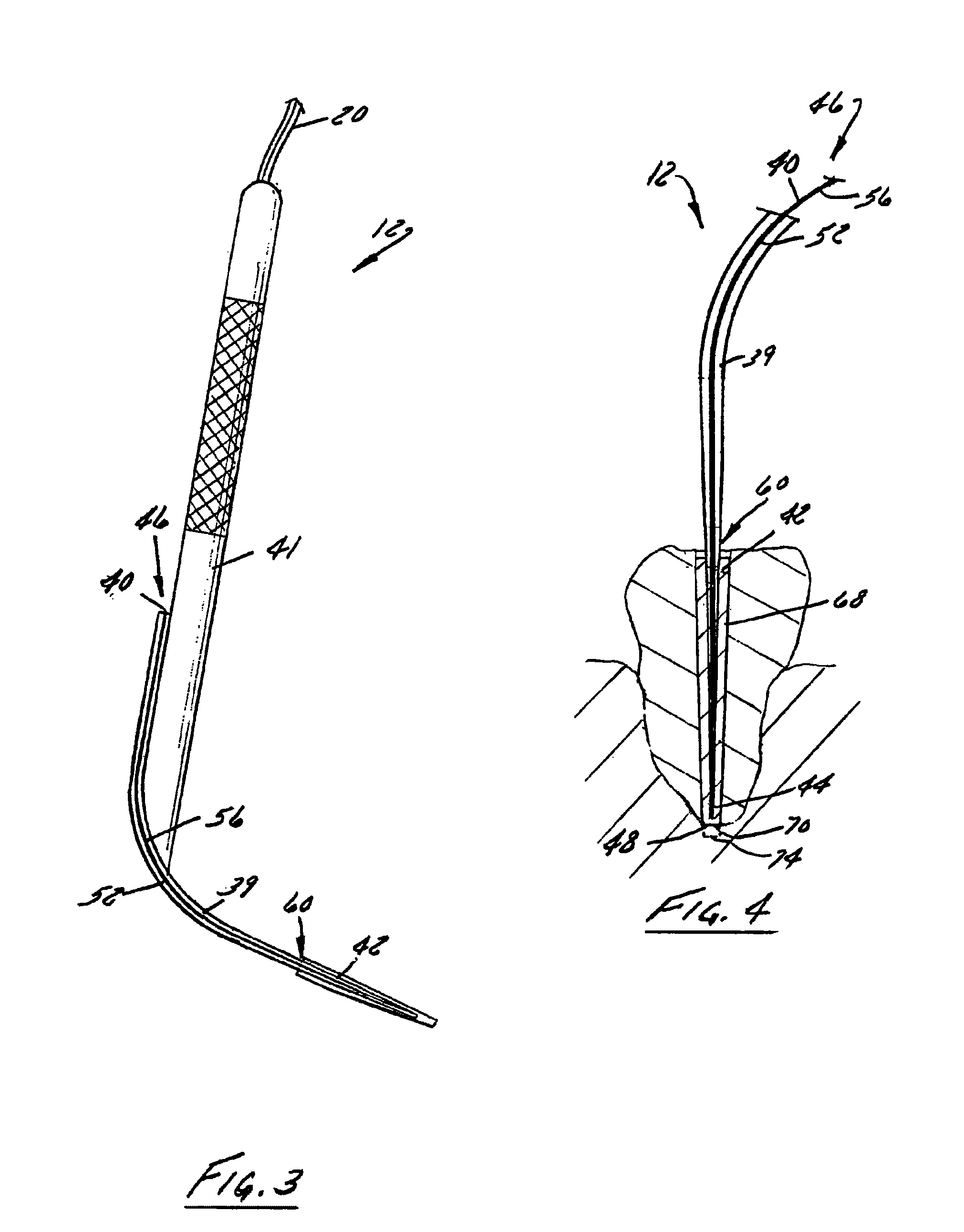

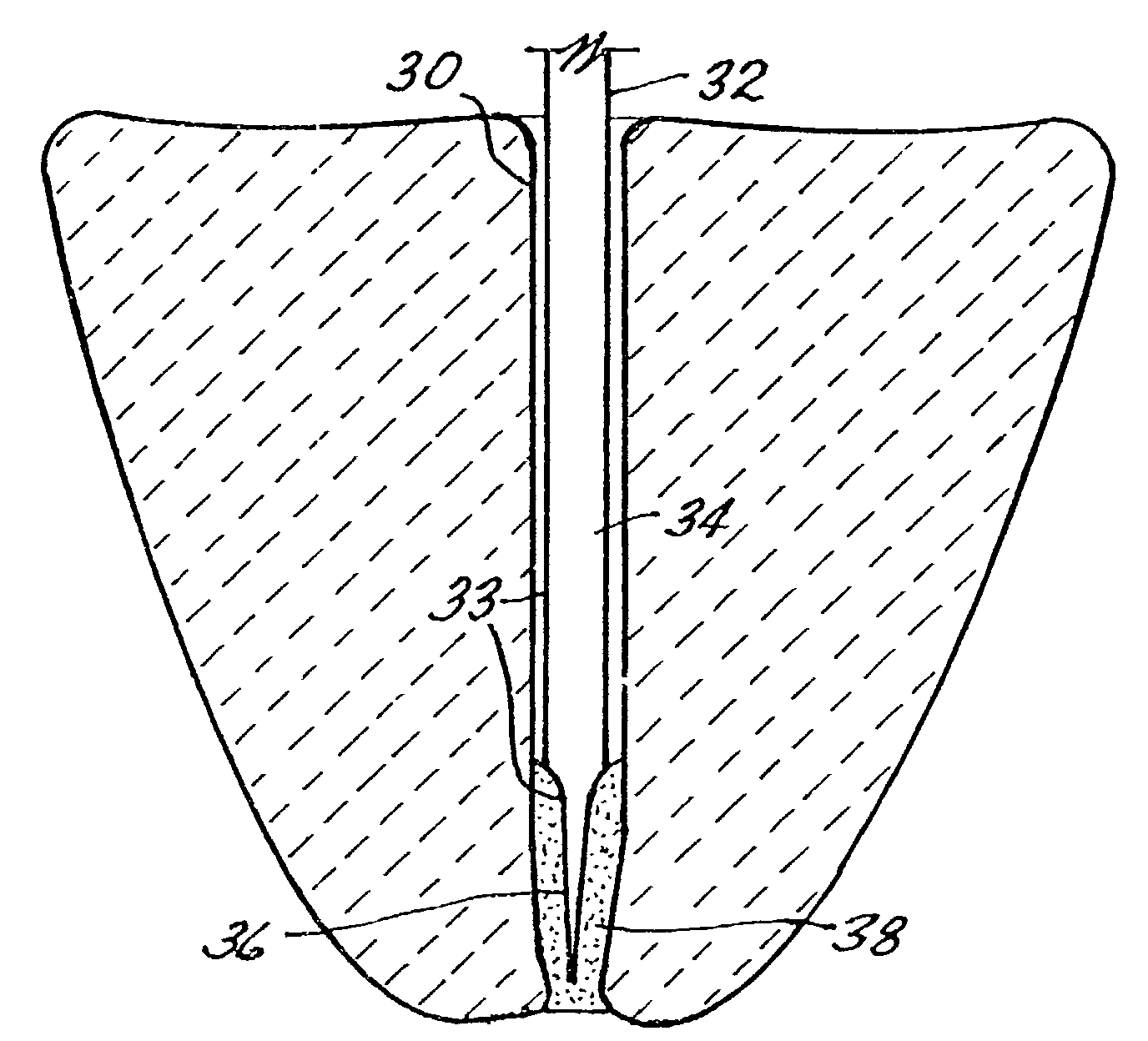

Device and method for in canal gutta-percha heating and condensation

InactiveUS20100124728A1Improve abilitiesImproving canal obturationTeeth fillingWheelchairs/patient conveyanceGutta-perchaMedicine

A device and method of forming a gutta-percha tooth canal obturation. The device includes an amount of gutta-percha that is supported by a thermally conductive core. The core and the gutta-percha are both positioned within a root canal. In canal heating of the core heats the gutta-percha proximate an application point thereby improving the ability to compact the gutta-percha to the shape of the root canal and achieve three dimensional obturation preventing reinfection of the canal.

Owner:WALIA HARMEET

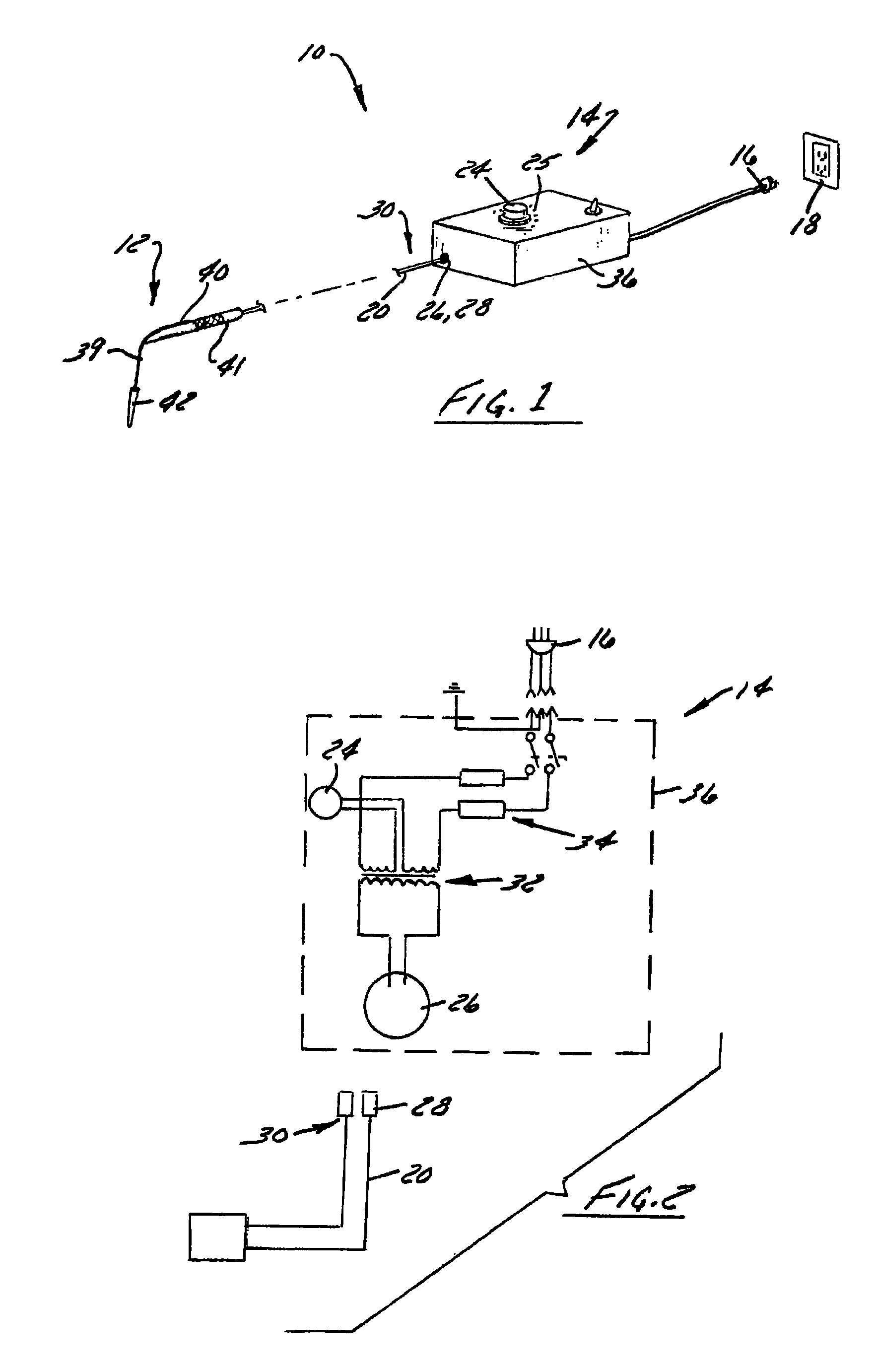

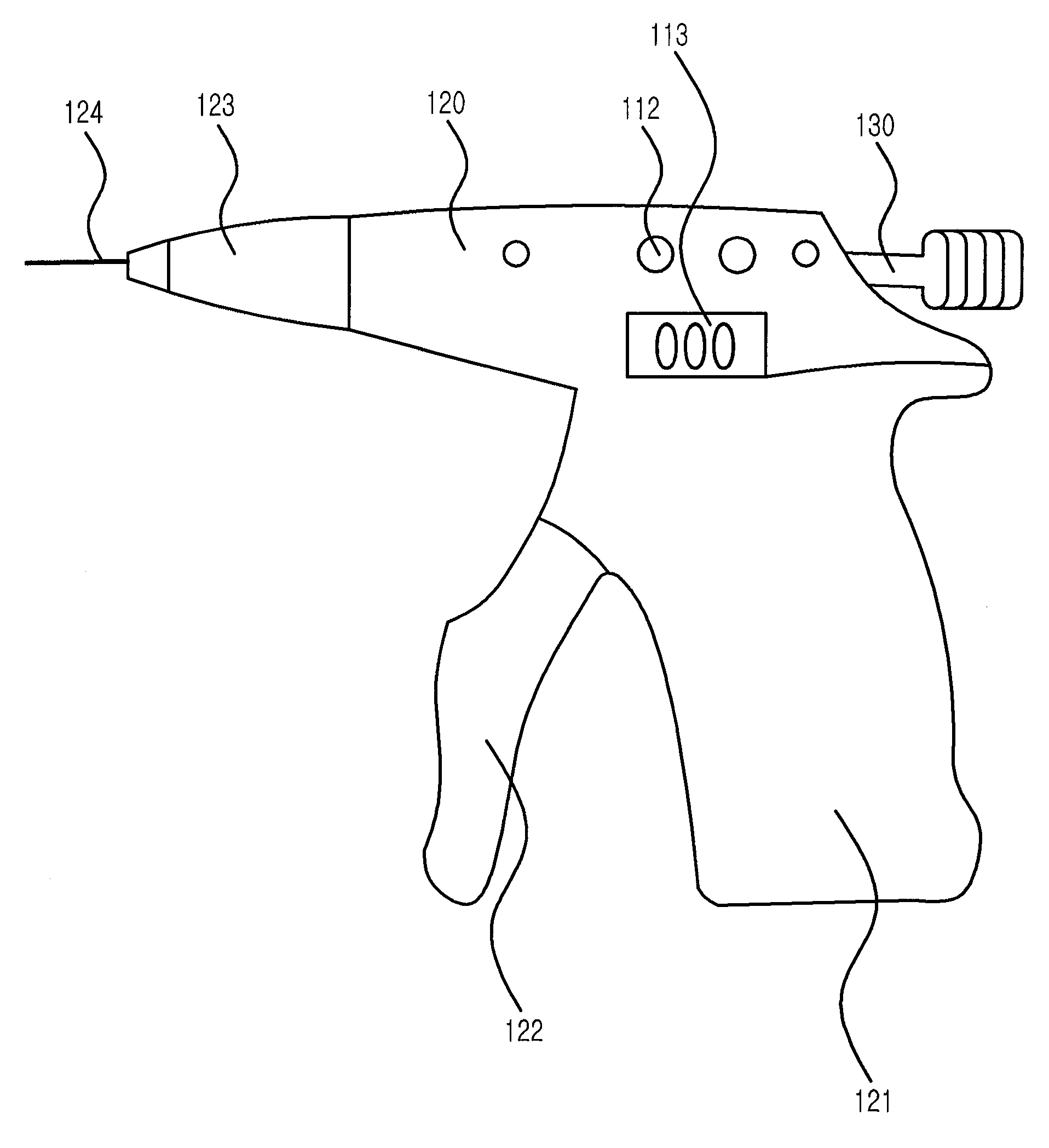

Wireless Recharger of Complete Melting Type For Encoding Treatment

ActiveUS20080187883A1Effective at generating heatMaximize convenienceTeeth fillingWheelchairs/patient conveyanceGutta-perchaControl circuit

A complete melting type cordless filling instrument for endodontic treatment is disclosed which uses a switching circuit, to be operable using a miniature dry battery for supplying DC power. The filling instrument includes a body with a battery for supplying DC power, a heater at a front end of the body to heat and melt gutta-percha, an injector mounted to the body in front of the heater to discharge the melted gutta-percha, a charging part provided at the body to charge the gutta-percha in the body, a feeding member which feeds the gutta-percha charged in the body, a filling switch which turns on the heater, and a control circuit installed in the body, to control a temperature of the heating core and an operation of the heating core. The control circuit includes the filling switch, and a switching circuit adapted to efficiently maintain electrical energy supplied from the battery.

Owner:BNL BIOTECH

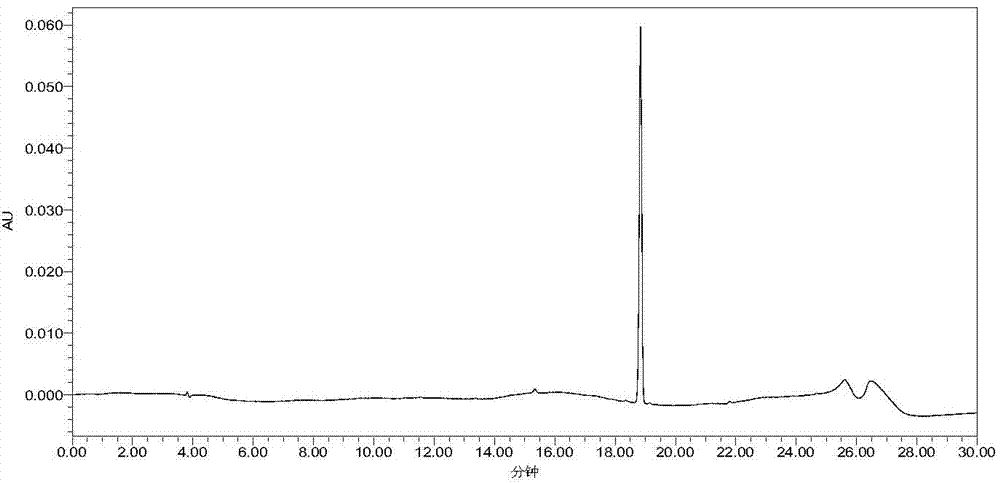

Method for extraction and separation of chlorogenic acid, pinoresinol diglucoside, aucubin and gutta-percha from eucommia ulmodies oliv raw material

ActiveCN104496816ARealize comprehensive utilizationEasy to operateSugar derivativesCarboxylic acid esters separation/purificationChlorogenic acidOrganic solvent

The invention discloses a method for extraction and separation of chlorogenic acid, pinoresinol diglucoside, aucubin and gutta-percha from a eucommia ulmodies oliv raw material. The method comprises the steps: extracting from the eucommia ulmodies oliv raw material by an organic solvent, concentrating, successively carrying out hot water dissolving, cold precipitation and centrifugal separation on the concentrate to obtain a centrifugal liquid, carrying out enrichment, elution and concentration on the centrifugal liquid, to obtain an eucommia ulmodies oliv extract, separating and purifying the eucommia ulmodies oliv extract, and thus respectively obtaining the pinoresinol diglucoside, chlorogenic acid and aucubin; and carrying out hydrolysis and organic solvent extraction on the extract residue, to obtain the gutta-percha. The method extracts and separates the high-purity chlorogenic acid, pinoresinol diglucoside, aucubin and gutta-percha from the eucommia ulmodies oliv with relatively high yield simultaneously, has the advantages of simple operation and low cost, realizes the comprehensive utilization of natural resources, and meets industrialized production.

Owner:MICOLTA BIORESOURCE INC LTD

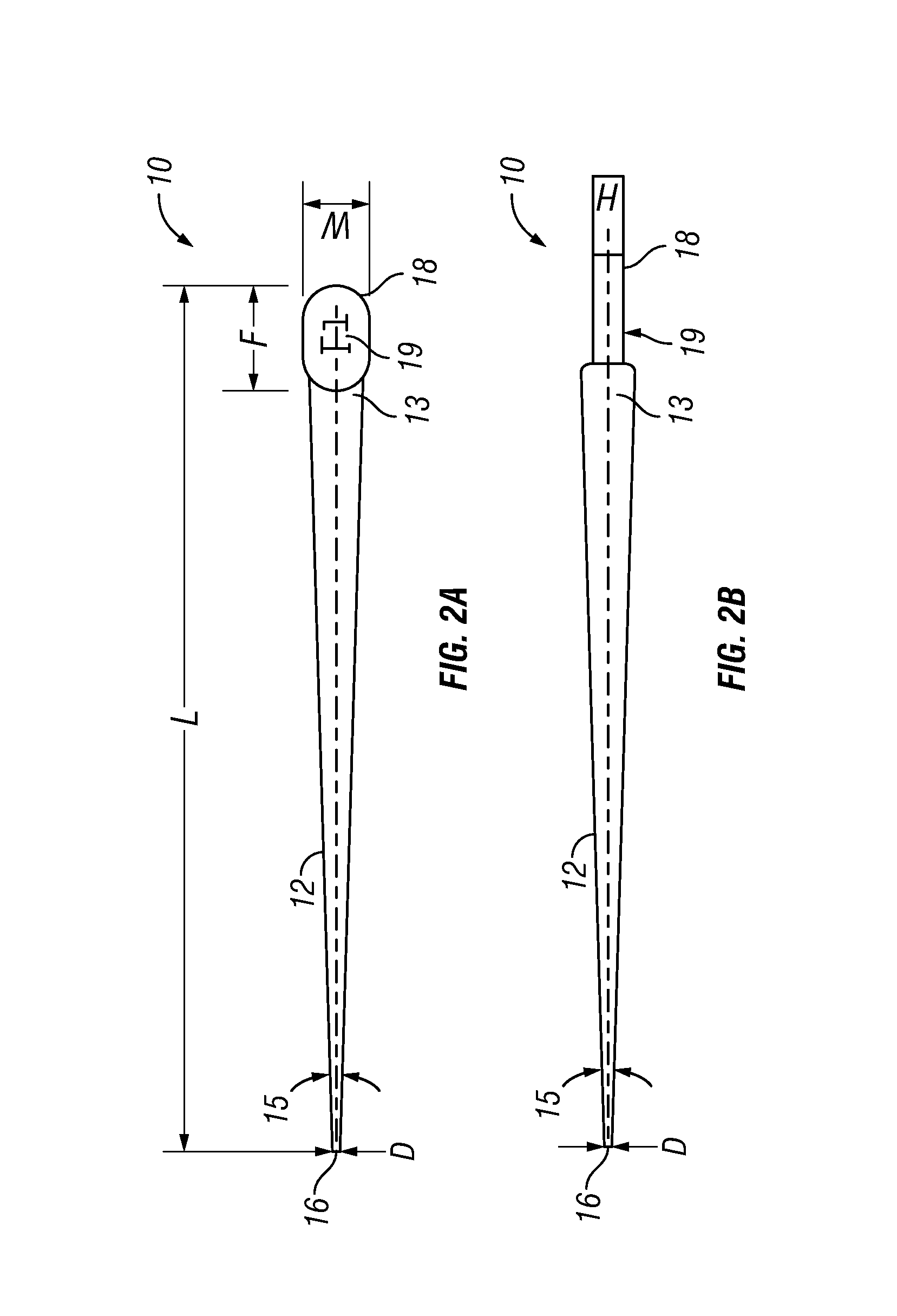

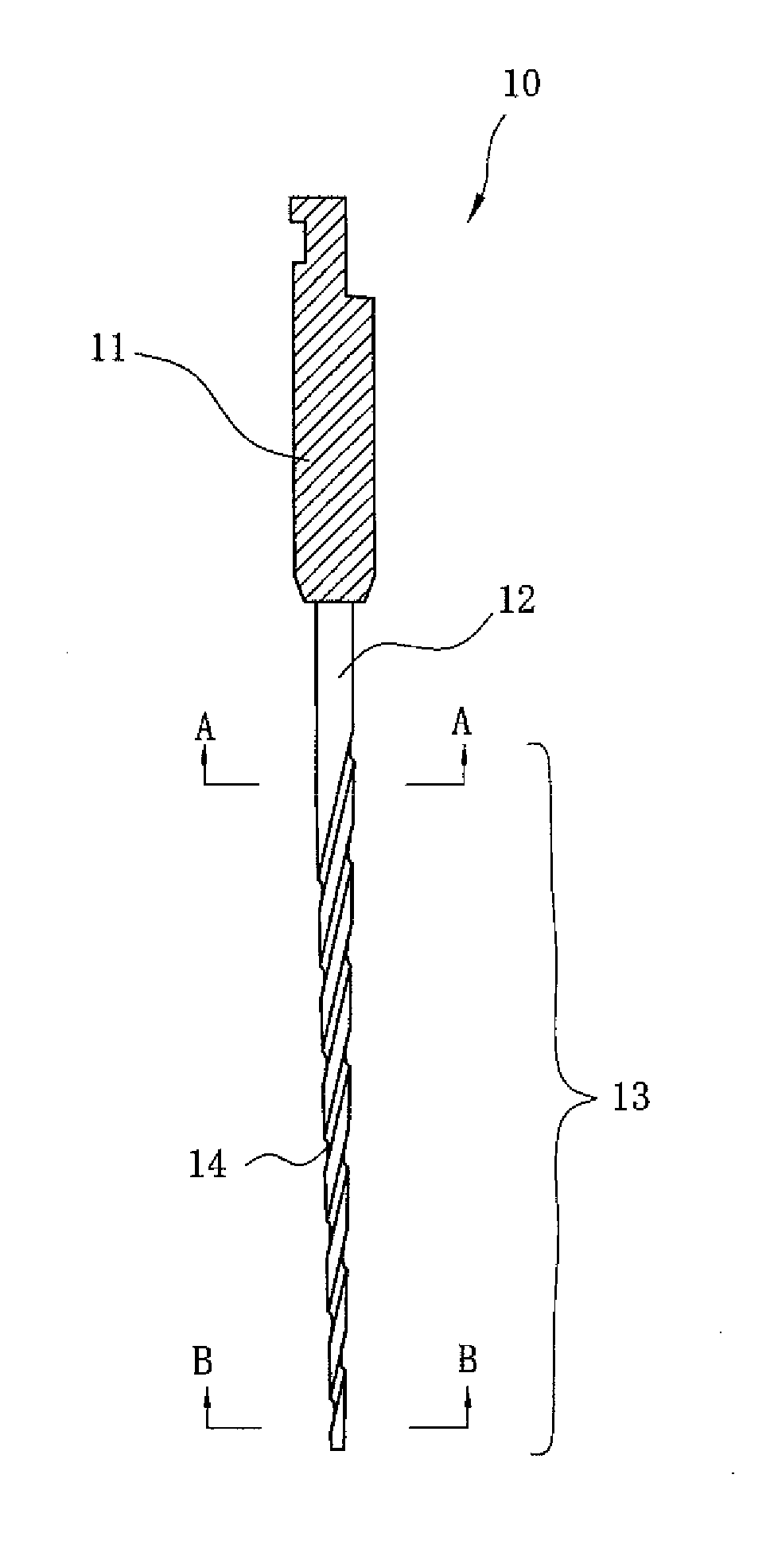

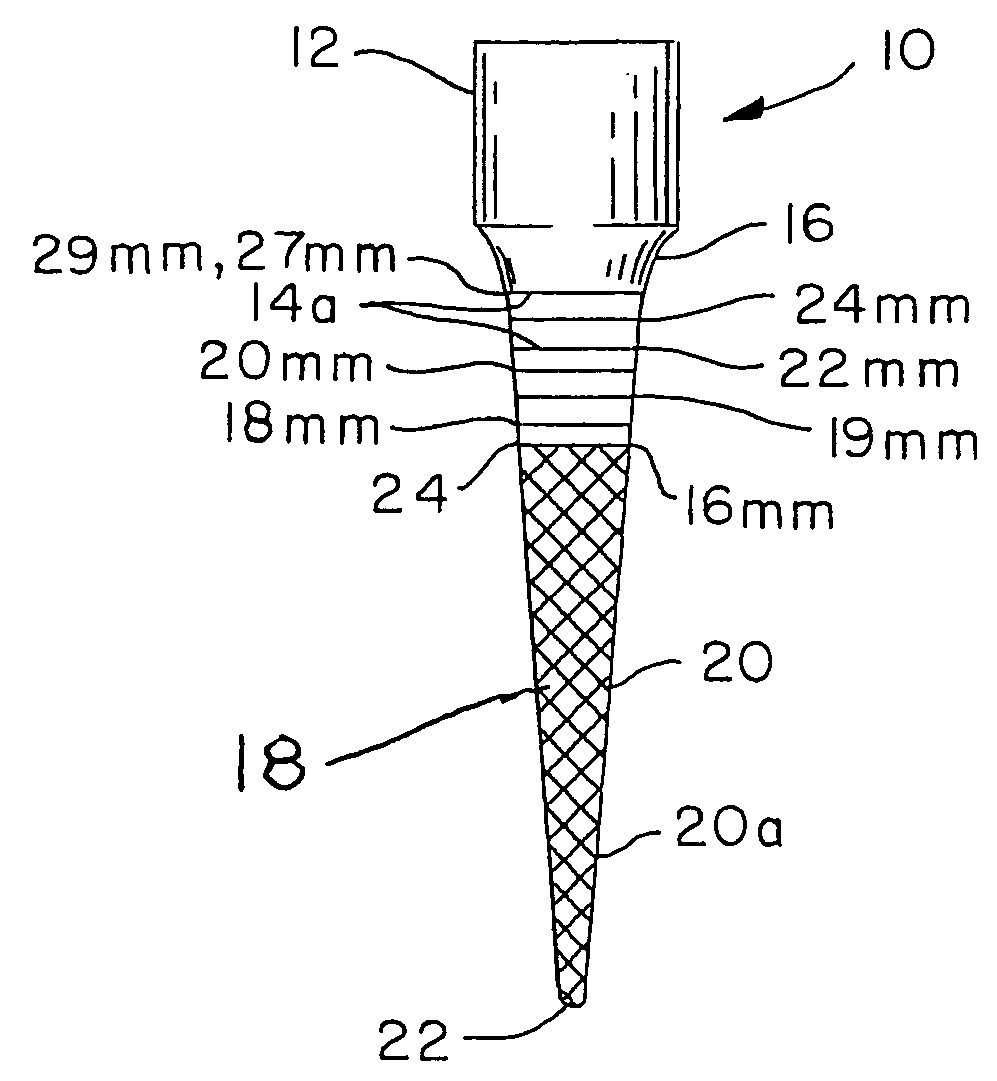

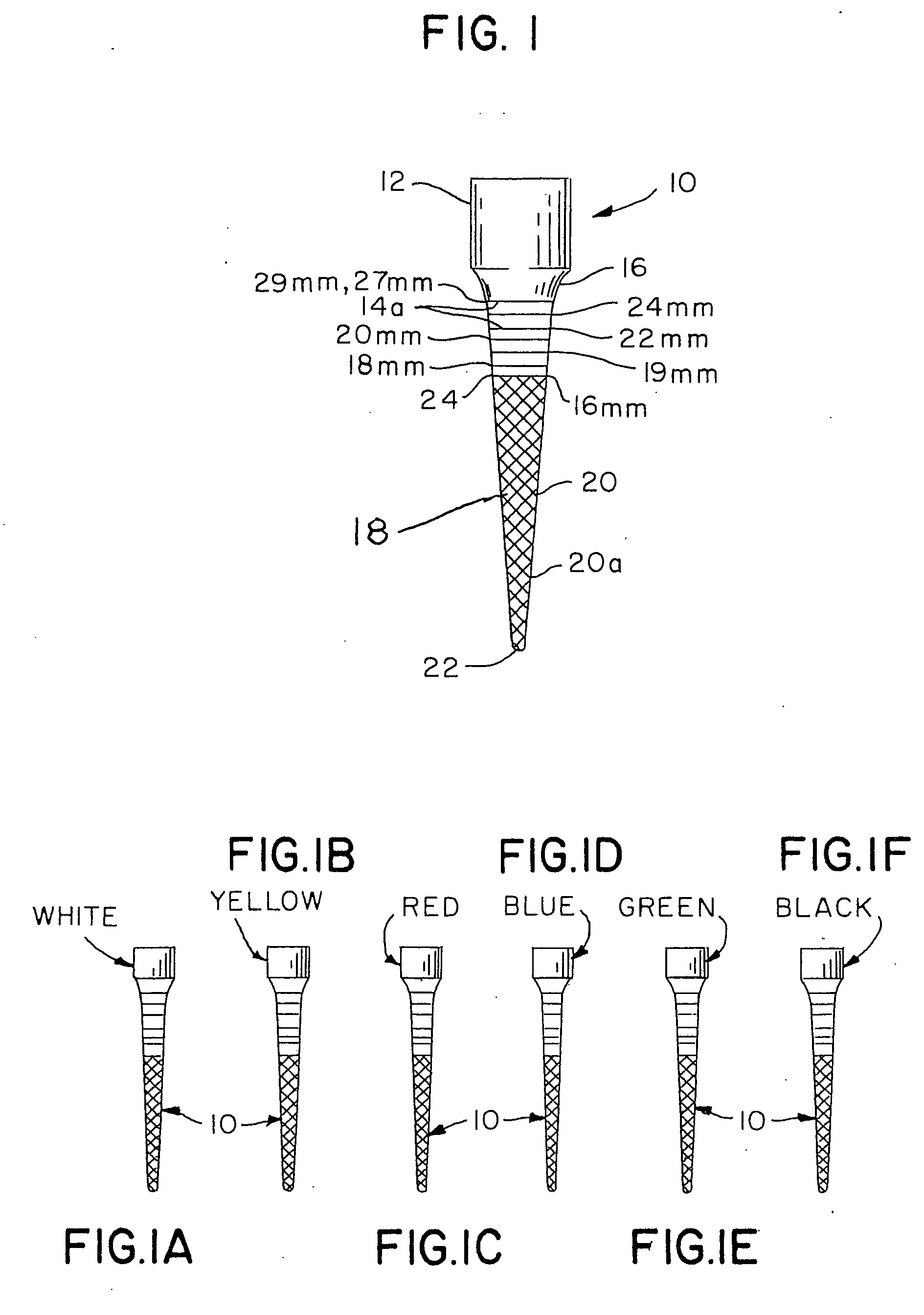

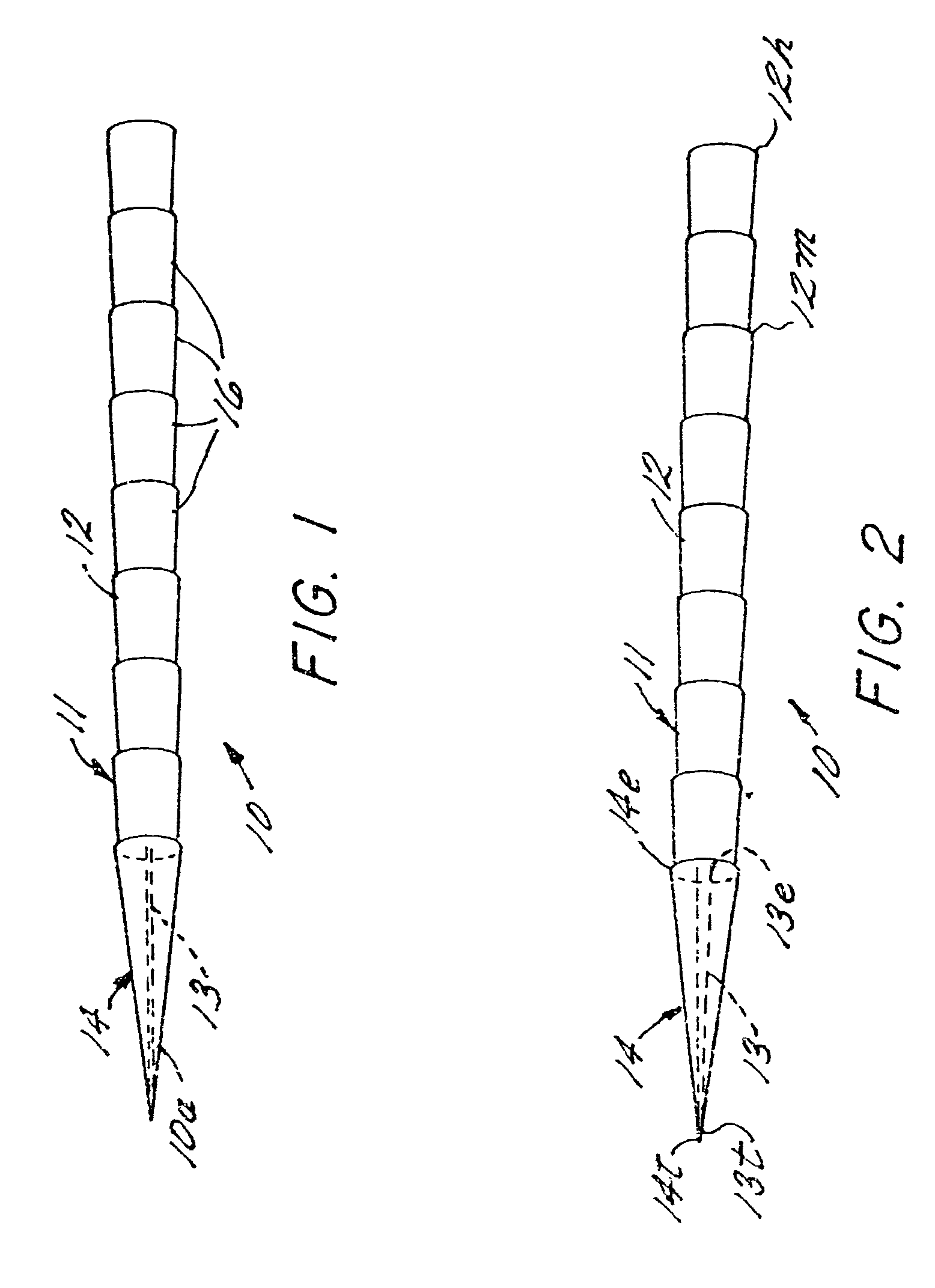

Gutta-percha remover

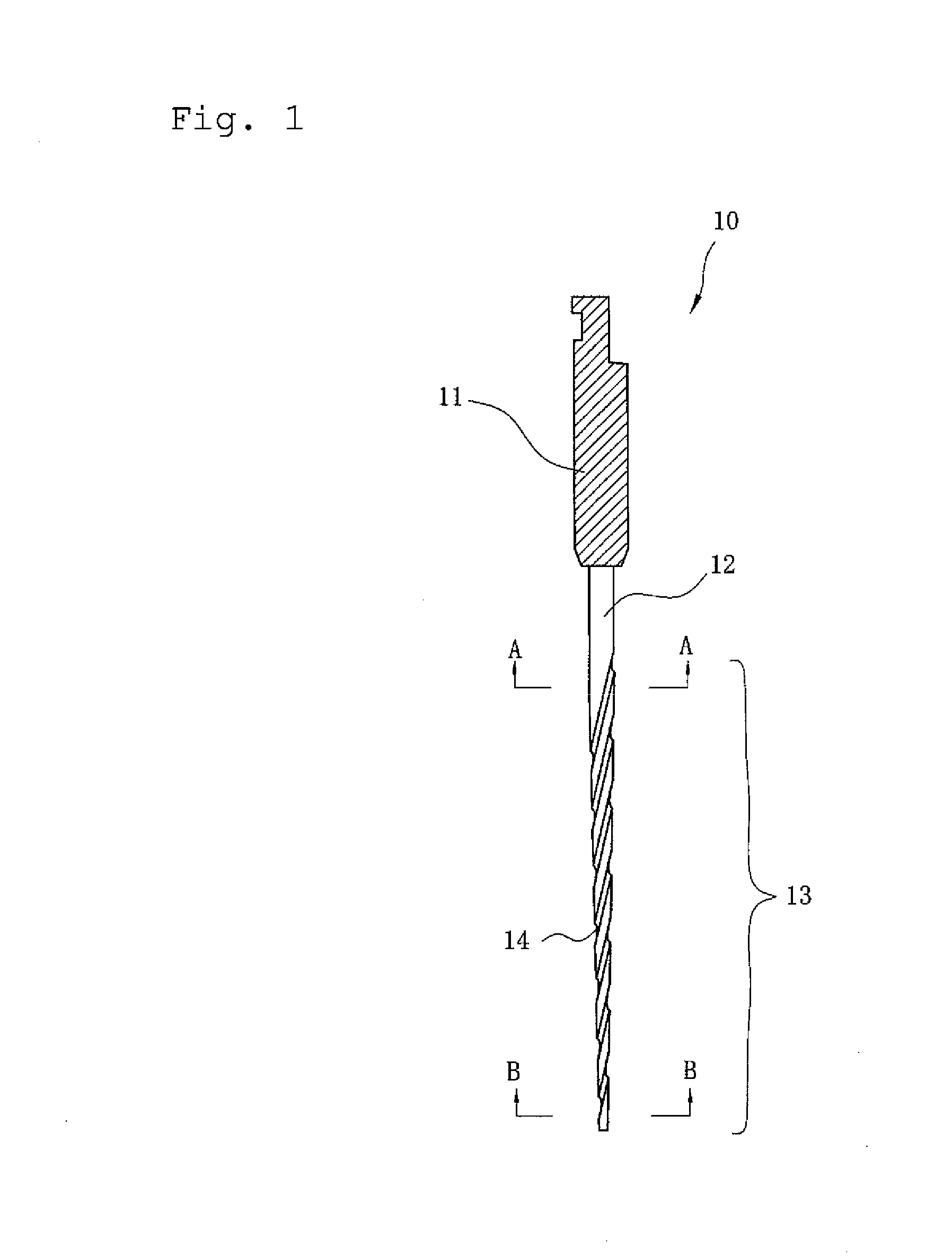

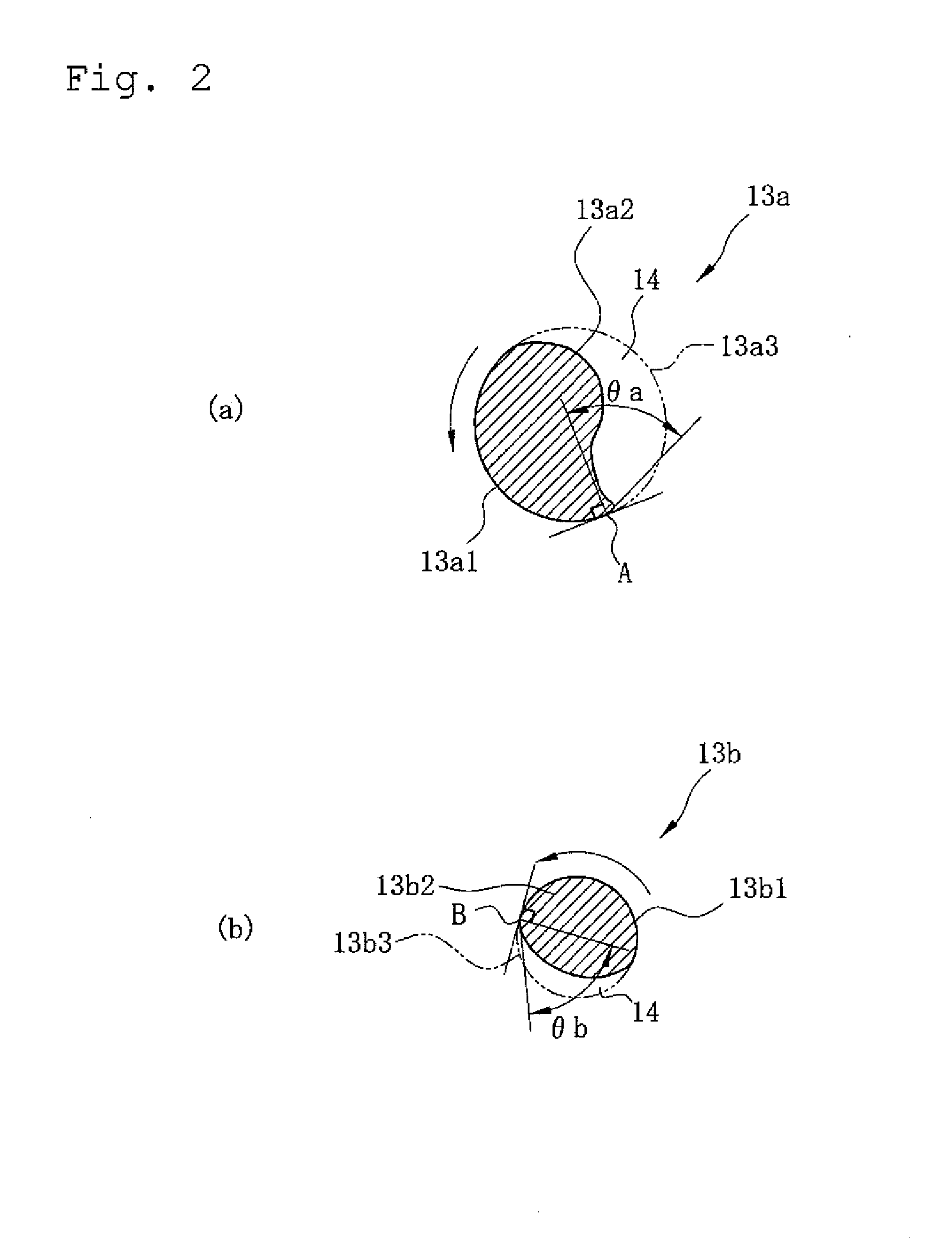

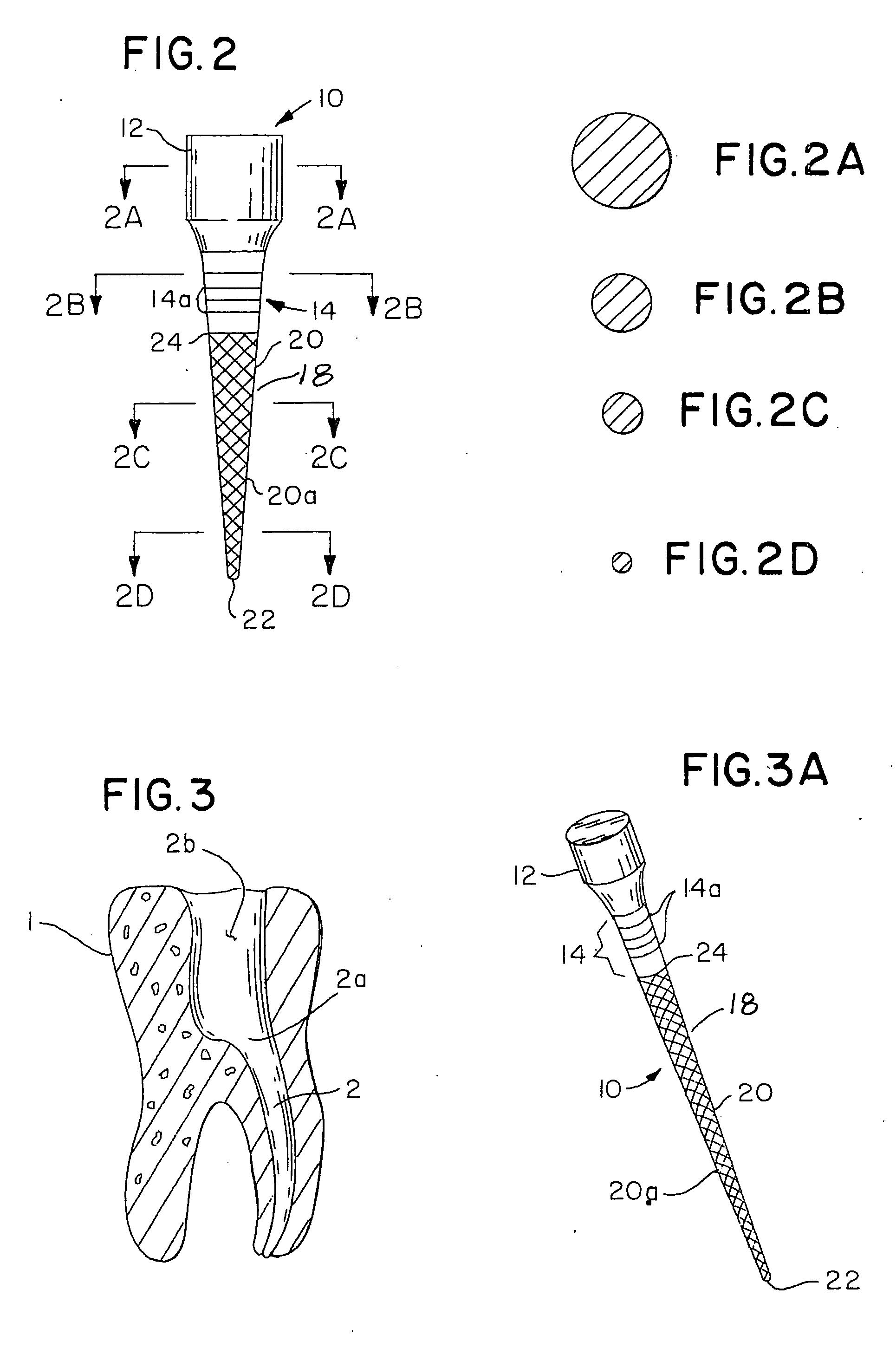

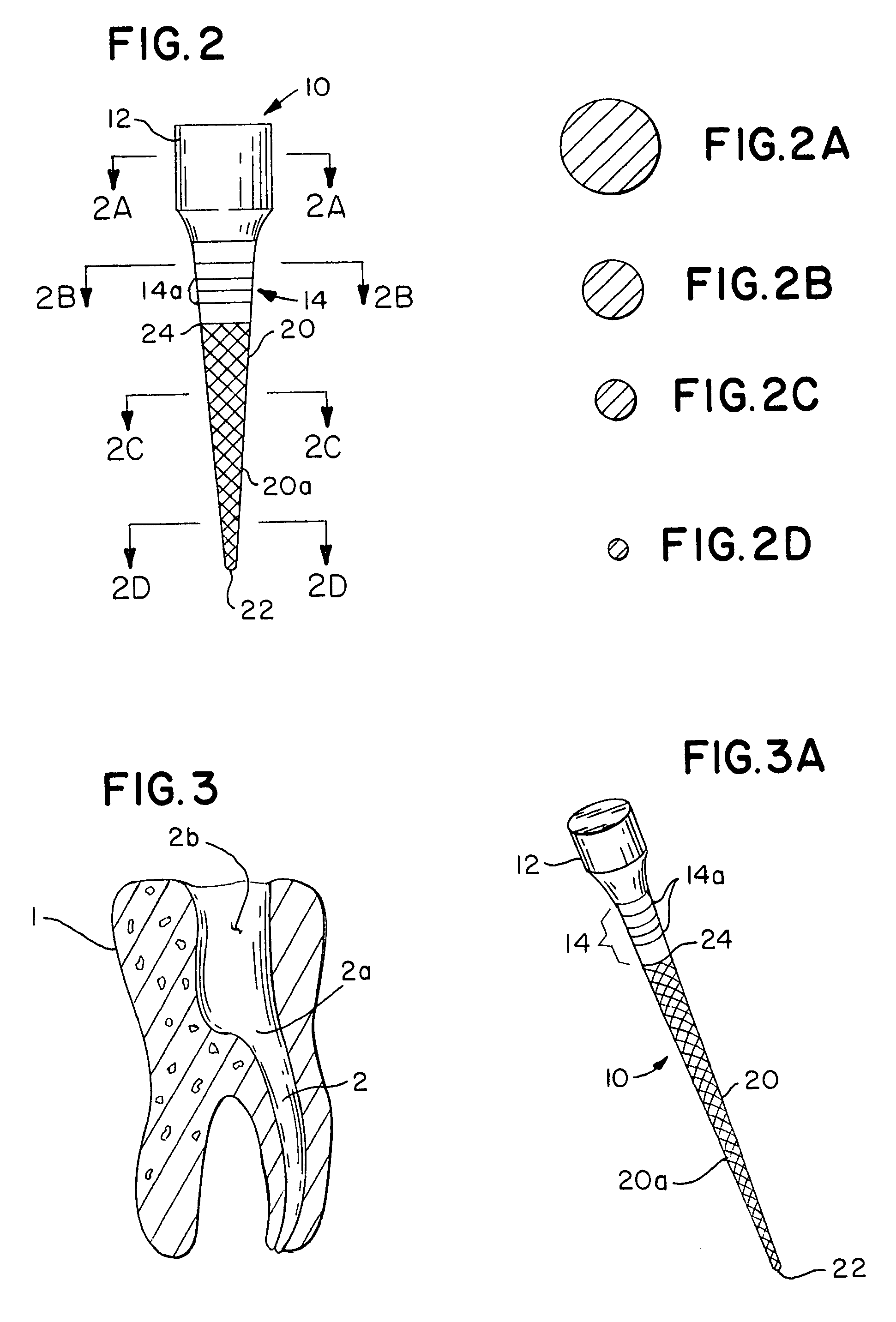

ActiveUS20120021376A1Increase the areaEasy to disassembleNerve needlesTeeth cappingGutta-perchaEngineering

A gutta-percha remover suitable for removing gutta-percha and having flexibility with good compliancy to curvature of a root canal and superior removing capability for forming a sufficient gap between the gutta-percha and the root canal wall is provided.A gutta-percha remover (10) includes a shaft (12), a tapered working portion (13) connected to the shaft (12), and one, two, or more screw-shaped grooves (14) formed in the working portion, wherein as to cross sections (13a, 13b) of a base end and a tip of the working portion, the tip of the working portion (13) is greater in rate of the area of each cross-section to corresponding circle (13a3, 13b3) circumscribing said each cross section.

Owner:MATSUTANI SEISAKUSHO CO LTD

Preparation method of root canal filling material

InactiveCN101416923AGood adhesionImprove stabilityImpression capsDentistry preparationsGutta-perchaFilling materials

The invention discloses a preparation method of root canal filling materials, which comprises the steps that: (1) the mixture composed of thermoplastic copolymerization-modified polymer or / and grafted modified polymer and inorganic filler treated with surface modification as well as compounds which have resisting function to X-ray is evenly blended by adopting a kneader; and (2) the mixture is mixed for 5 minutes to 40 minutes in melting state with the temperature of 140 DEG C to 250 DEG C, then the root canal filling materials of the invention are prepared; the root canal filling materials prepared by the method has the advantage of not only excellent stability of gutta-percha filling materials, but also excellent cohesiveness of Resilon resin filling materials; the defects of poor adhesive bonding performance of the gutta-percha filling materials and easy degradation of the Resilon resin filling materials which are used in current clinics can be overcome; and compared with the gutta-percha filling materials and the Resilon resin filling materials, the stability and the cohesiveness are greatly improved.

Owner:HOSPITAL OF STOMATOLOGY SUN YAT SEN UNIV +1

Method for extracting high-purity gutta-percha from cortex eucommiae key fruit

The invention discloses a method for extracting high-purity gutta-percha from cortex eucommiae key fruit. The method comprises the steps of: 1, processing the cortex eucommiae key fruit, particularly separating kernel from the cortex eucommiae key fruit mechanically; 2, carrying out enzymolysis, adding 3-10 times of enzymatic hydrolysate in the processed enzymolysis and carrying out enzymolysis for 3-10h at a temperature of 35-55 DEG C; and 3, extracting the high-purity gutta-percha, drying the cortex eucommiae key fruit subjected to the enzymolysis until the water content is 3-10 percent, extracting with petroleum ether as a solvent through adopting a soxhlet extraction method, adding alcohol to precipitate the gutta-percha after extracting, and filtering to obtain the high-purity gutta-percha. According to the invention, complex enzyme preparation enzymolysis, soxhlet extraction and ultrasonic assistance are applied to the field of extraction of the gutta-percha. Compared with the prior art, the method has the characteristics of mild reaction conditions, low requirement on equipment, no pollution, and high yield and purity of the gutta-percha, and is wide in application prospect.

Owner:JISHOU UNIVERSITY

Gutta-percha tip composite and DLP printing application thereof

ActiveCN109846718AGood biocompatibilityHigh precisionImpression capsAdditive manufacturing apparatusFailure rateGutta-percha

Owner:SOUTH CHINA AGRI UNIV

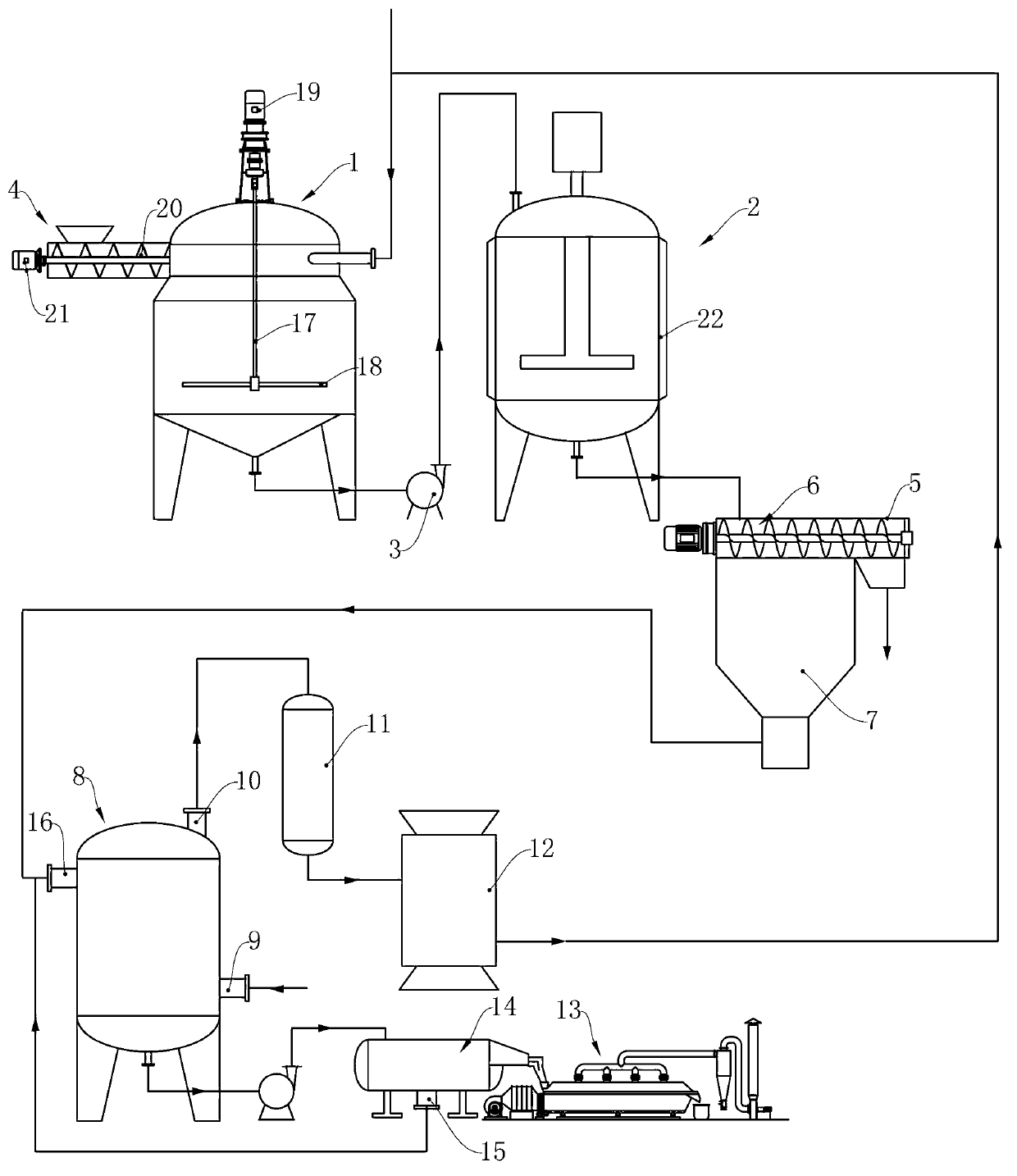

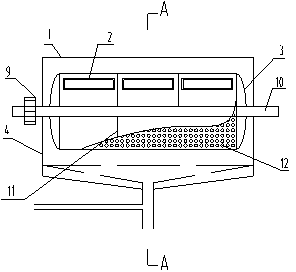

Gutta-percha refining system

Owner:山东贝隆杜仲生物工程有限公司

Gutta-percha bead filler for tire and preparation method thereof

The invention provides a gutta-percha bead filler for a tire and a preparation method thereof and relates to a bead filler for a tire and a preparation method thereof. Gutta-percha is synthesized (TPI) or natural gutta-percha (EUG), the number-average molecular weight is 150,000-500,000 and the molecular weight distribution index PI is 1.8-3.5. The natural gutta-percha is derived from a gutta-percha extract contained in leaves, peels and shells in eucommia ulmoides plants. The invention adjusts a production technology for preparing the gutta-percha bead filler for a tire with higher hardness and strength. According to the invention, after the gutta-percha is combined with the others, various mechanical properties of the sizing material, such as, overall hardness, ageing resistance, fatigue resistance, shearing resistance and dynamic temperature rise, are improved, wherein the improvement of permanent deformation under compression and dynamic heat dissipating is especially obvious; after the bead filler is prepared, the shape of a tire ring can be excellently kept; the operation stability of a tire can be increased, the rolling resistance can be reduced and the fatigue resistance can be enhanced; the gutta-percha bead filler is suitable for the manufacturing of various tire products.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

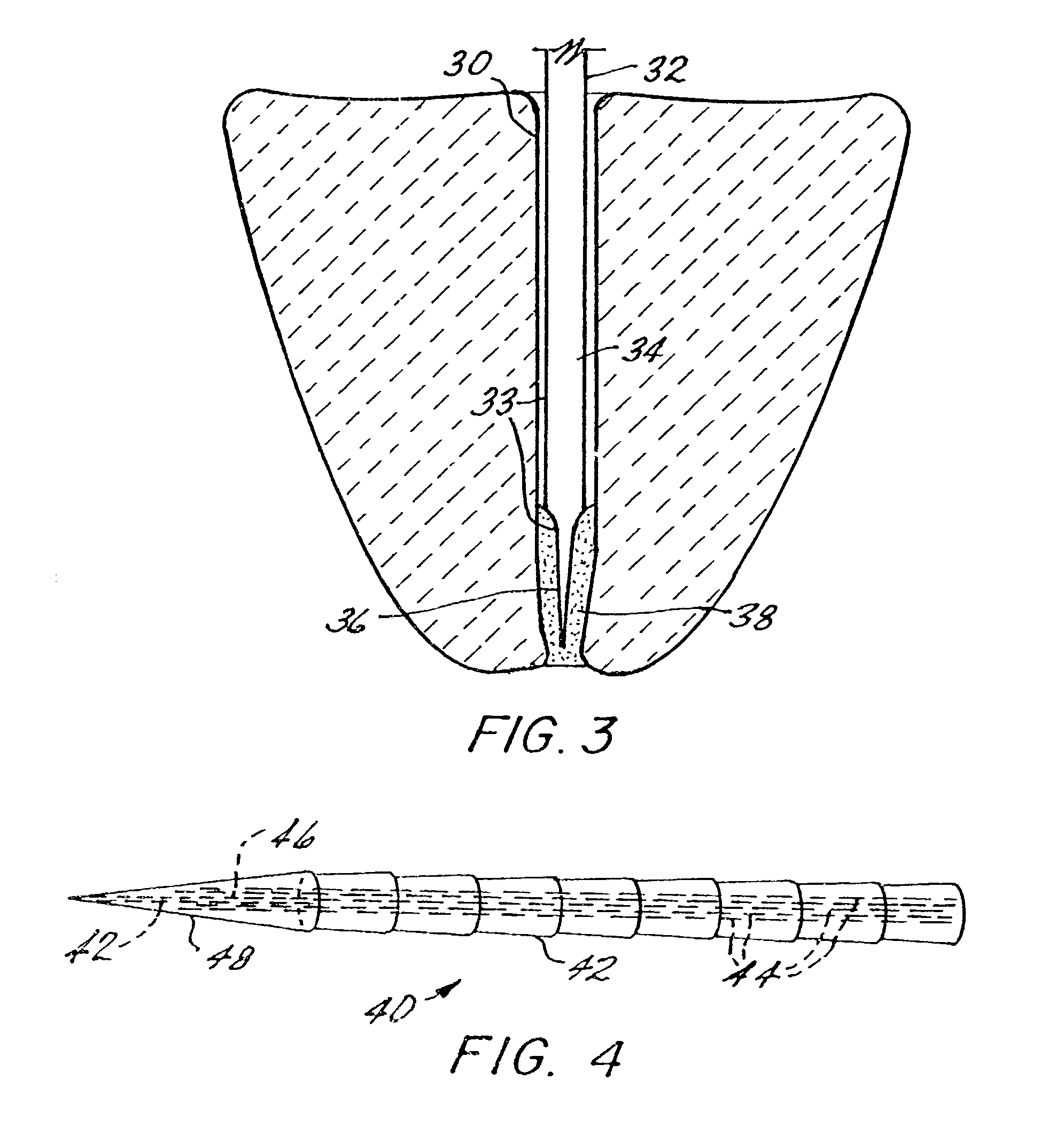

Integral gutta percha technique

InactiveUS20060154212A1Reduce leakageEasy to useTeeth fillingTeeth cappingGlass ionomersGutta-percha

An integral, one-piece silanated particle impregnated gutta percha core / cone technique employs a thin layer of a luting agent, such as glass ionomer cement with a machined gutta percha core / cone, precisely matches the preparation, thereby reducing leakage and achieving a hermetic seal. The hermetic seal is further enhanced by a mono-block bond that occurs between the silanated particles in the gutta percha and the appropriate chemical sealant. Optional cryogenic treatment of the gutta percha material changes its molecular weight, making it stiffer and conducive to forming an integral, one piece core / cone, without the need for a separate carrier core to install the tapered gutta percha core / cone within the root canal. Additionally, the tapered body of the core / cone may be reticulated in a slightly three dimensional texturized framework to increase surface area and therefore increase retention. Optional line demarcation indicia are also placed on the core / cone. Additionally, the head of the core / cone can be gripped by a delivery vehicle clasp.

Owner:KOCH KENNETH +2

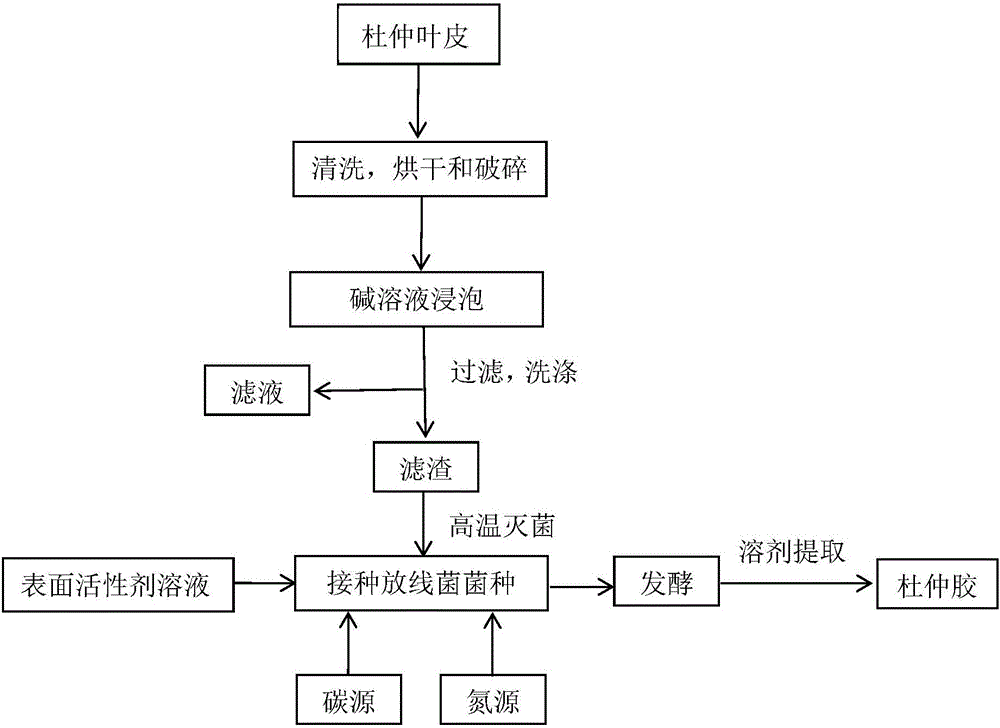

Method for extracting gutta-percha from leaves and bark of eucommia ulmoides

The invention discloses a method for extracting gutta-percha from the leaves and bark of eucommia ulmoides. The method comprises the steps that the leaves and bark of the eucommia ulmoides are washed, dried and mechanically crushed, soaking is carried out with aqueous alkali at normal temperature, filtering is carried out, and filter residues are subjected to high temperature sterilization; an aqueous surfactant solution is added to adjust the moisture content of the filter residues, then the filter residues are inoculated with actinomycetes strains, a carbon source and a nitrogen source are added, and fermentation is carried out to damage cellulose in the leaves and bark of the eucommia ulmoides; then the gutta-percha is extracted through a conventional solvent method. Through aqueous alkali pretreatment on the gutta-percha, the leaves and bark of the eucommia ulmoides are fermented through actinomycetes in an alkali environment to degrade lignin, meanwhile, and the aqueous surfactant solution is added to improve the degradation efficiency of the actinomycetes on the cellulose in the leaves and bark of the eucommia ulmoides. According to the method, the gutta-percha yield is increased, and meanwhile the efficiency of extracting the gutta-percha through a biodegradation method is improved.

Owner:广州存正生物科技有限公司

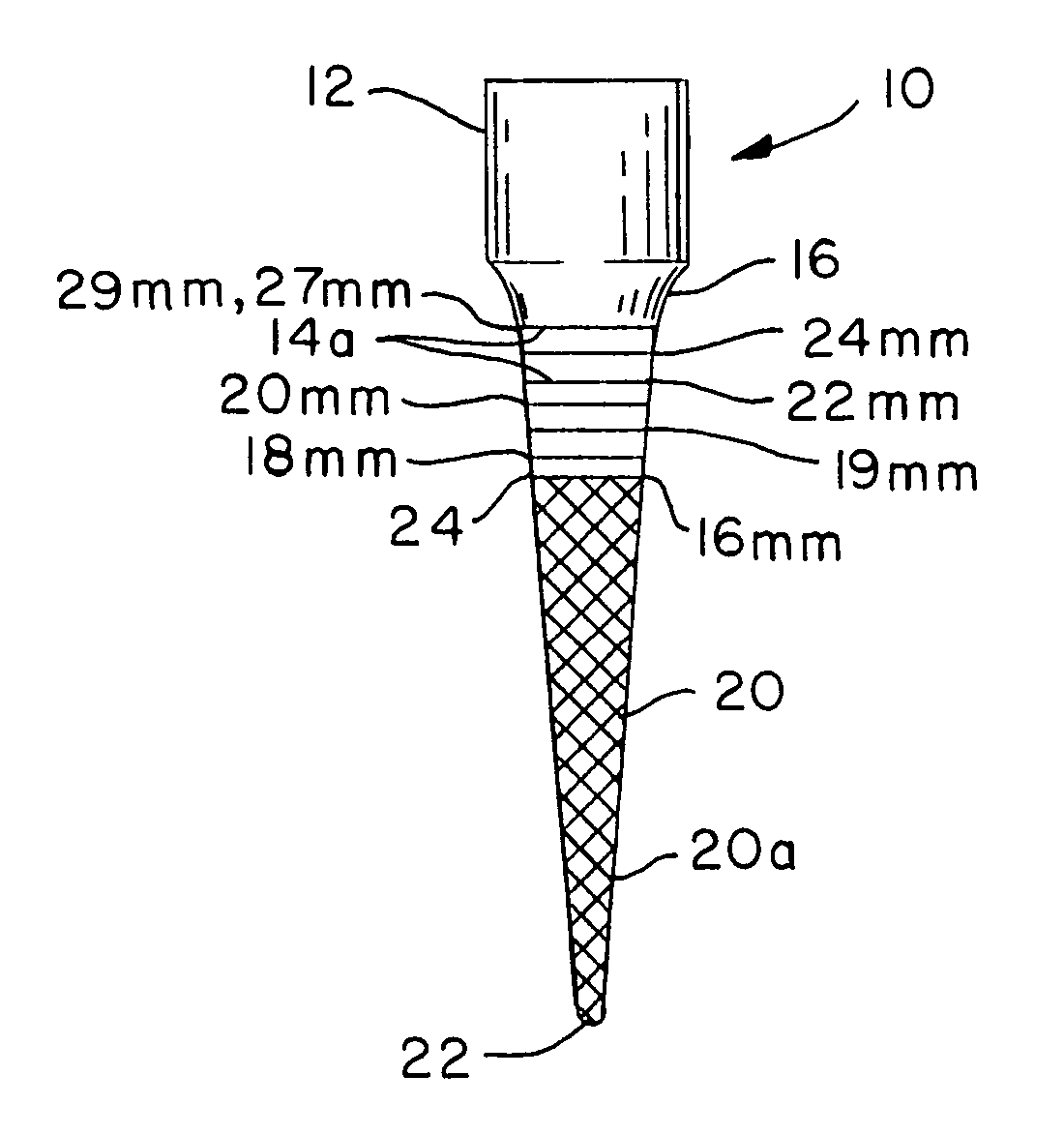

Integral gutta percha technique

ActiveUS7097455B2Reduce leakageEasy to useImpression capsWheelchairs/patient conveyanceGlass ionomersGutta-percha

An integral, one-piece silanated particle impregnated gutta percha core / cone technique employs a thin layer of a luting agent, such as glass ionomer cement with a machined gutta percha core / cone, precisely matches the preparation, thereby reducing leakage and achieving a hermetic seal. The hermetic seal is further enhanced by a mono-block bond that occurs between the silanated particles in the gutta percha and the appropriate chemical sealant. Optional cryogenic treatment of the gutta percha material changes its molecular weight, making it stiffer and conducive to forming an integral, one piece core / cone, without the need for a separate carrier core to install the tapered gutta percha core / cone within the root canal. Additionally, the tapered body of the core / cone may be reticulated in a slightly three dimensional texturized framework to increase surface area and therefore increase retention. Optional line demarcation indicia are also placed on the core / cone. Additionally, the head of the core / cone can be gripped by a delivery vehicle clasp.

Owner:BATCHING SYST +2

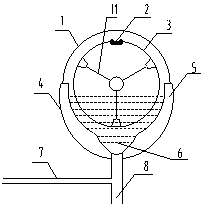

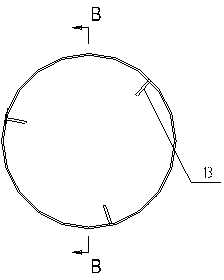

Method for extracting gutta-percha through enzymolysis

The invention discloses a method for extracting gutta-percha through enzymolysis. The method comprises the following steps: eucommia barks using as raw materials are burst and crushed, protease is used for decomposing protein components in the eucommia barks, pectinase is used for decomposing cell walls and intercellular layers in the eucommia barks, cellulase is used for improving the decomposition of cellulose and hemicellulose so as to decompose non-gutta-percha substances in the eucommia barks into components which can be completely separated from gutta-percha, and target substances are separated from waste components by adopting a method of rotating a separation tube in an enzymolysis device in a water tank, wherein rectangular stirring blades are arranged on the inner wall of the separation tube, and form inclination angles of 10 to 15 degrees with a support shaft, so that the separation completeness of the target substances and the waste components is ensured. The method is clean, safe, environment-friendly, low in cost, high in efficiency and suitable for industrial production, and the purity of the extracted gutta-percha is high, and can reach over 92 percent.

Owner:HENAN HENGRUIYUAN IND

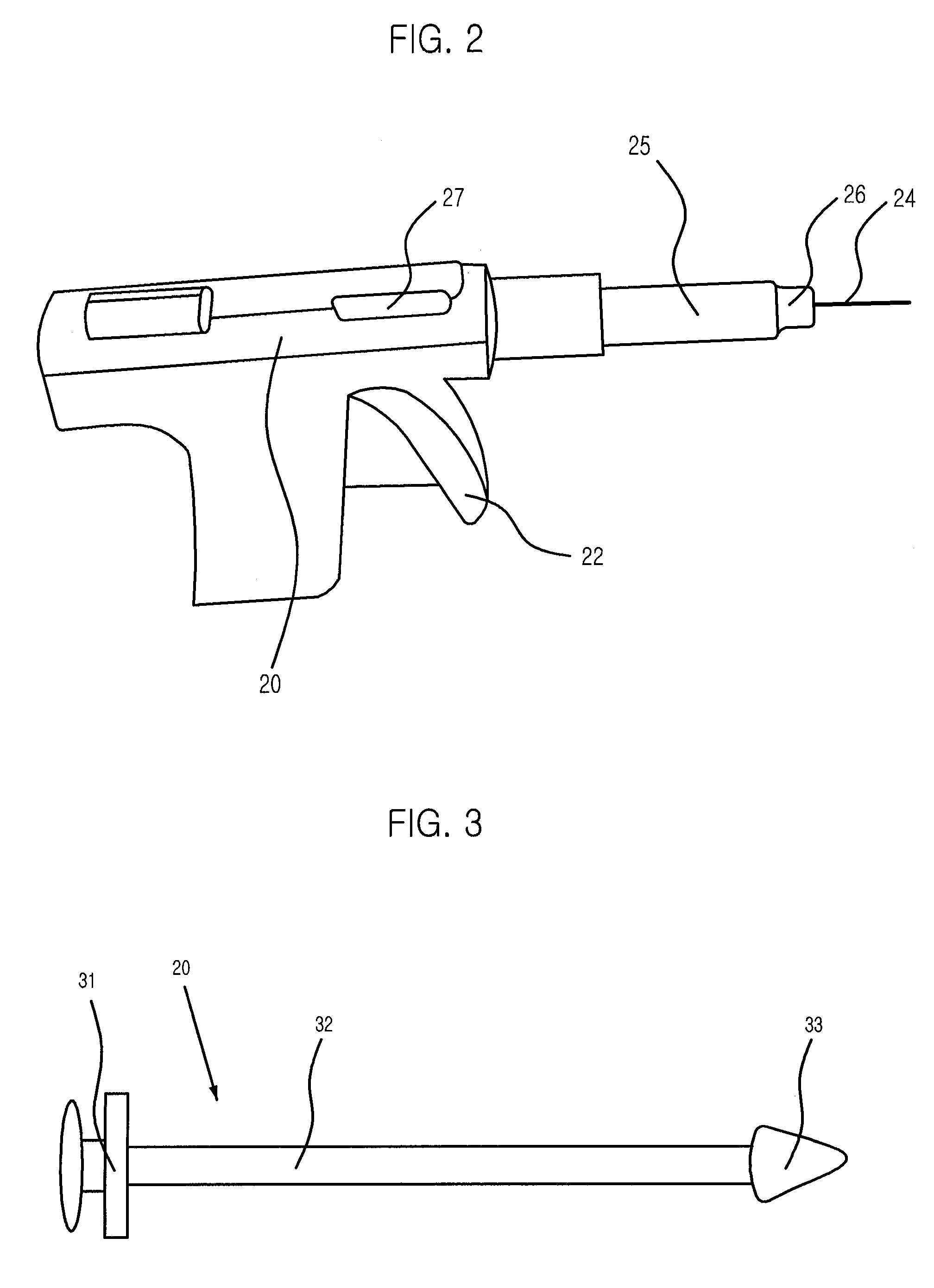

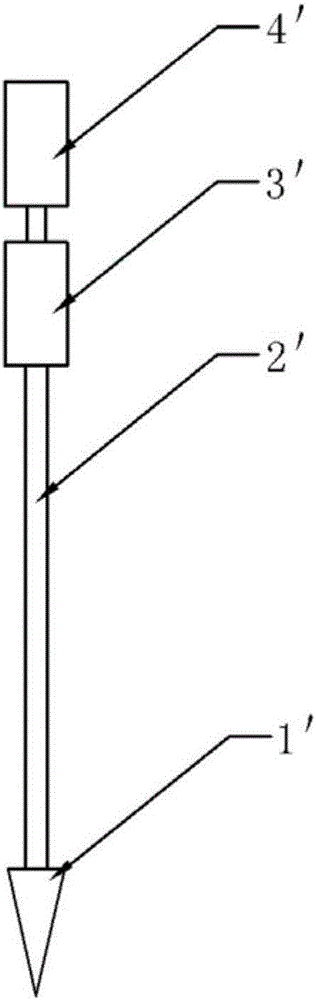

Endodontic post system

InactiveUS7086864B2Strengthen toothPrevent subsequent root fracturesTeeth fillingFastening prosthesisGutta-perchaEndodontic files

An endodontic post comprising a combined endodontic post and filling material tip in a single unit. To use the post unit, the device is placed in an oven or heater to heat and soften the thermoplastic material. The device will then be placed in a root canal that has been opened to a predetermined dimension by use of endodontic files, to seal the apical end. If necessary, the gutta percha can be compacted toward the apex, while it is still in the softened state, to ensure the apex is adequately sealed. The post is then cemented into place by lining the canal walls with a bonding agent and filling the interface between the post and the walls of the canal with a dual cure resin cement. This will result in a coronal seal of the canal via resin restorative material and an apical seal of the canal by means of gutta percha and sealant. The remaining portion of the post, extending supra-gingivally, will be used to build a core around it. Any excess will be cut off. One length of the device will be longer to accommodate the longer roots in anterior teeth. Another length will be shorter to accommodate smaller roots in the molar region.

Owner:PENTRON CLINICAL TECH

Preparation method of modified natural gutta-percha with improved elasticity

The invention discloses a preparation method of modified natural gutta-percha with improved elasticity.The method comprises the steps that gutta-percha is dissolved in an organic solvent A to be prepared into a gutta-percha solution, then, the gutta-percha solution is added into a reaction kettle, a conjugated diene monomer and a catalyst are added, then a reaction is performed at the constant temperature, then the reactant is precipitated and washed with an organic solvent B and finally dried in a low-temperature vacuum drying box to obtain constant weight, and therefore the modified natural gutta-percha is obtained.The preparation method has the advantages that the original degree of crystallinity of the gutta-percha is lowered, elasticity of the gutta-percha is increased, and the characteristic of the gutta-percha can reach using standard character of natural rubber, so that the gutta-percha can be widely applied in rubber industry, the condition of lack of natural rubber resources in China is relieved, gutta-percha which is endemic to china, wide in planting area and easy to popularize is efficiently utilized and popularized, the problem that the gutta-percha cannot be widely applied in rubber industry is solved, preparation technology is simple, the using effect is good, and popularization is promoted.

Owner:ZHEJIANG XUYUAN DUZHONG BIOLOGICAL TECH CO LTD

Novel oil-resistant gutta-percha elastomer and preparation method thereof

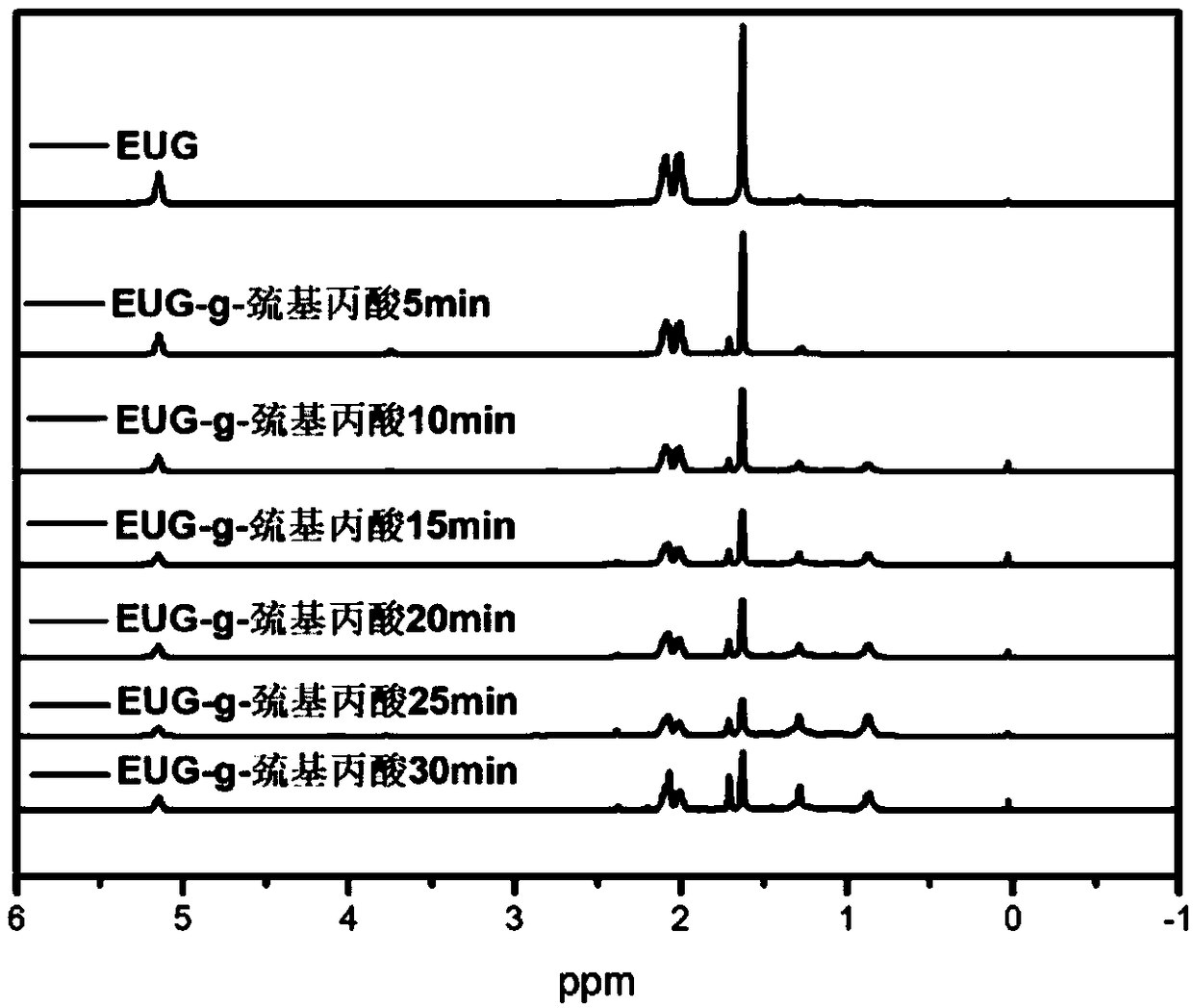

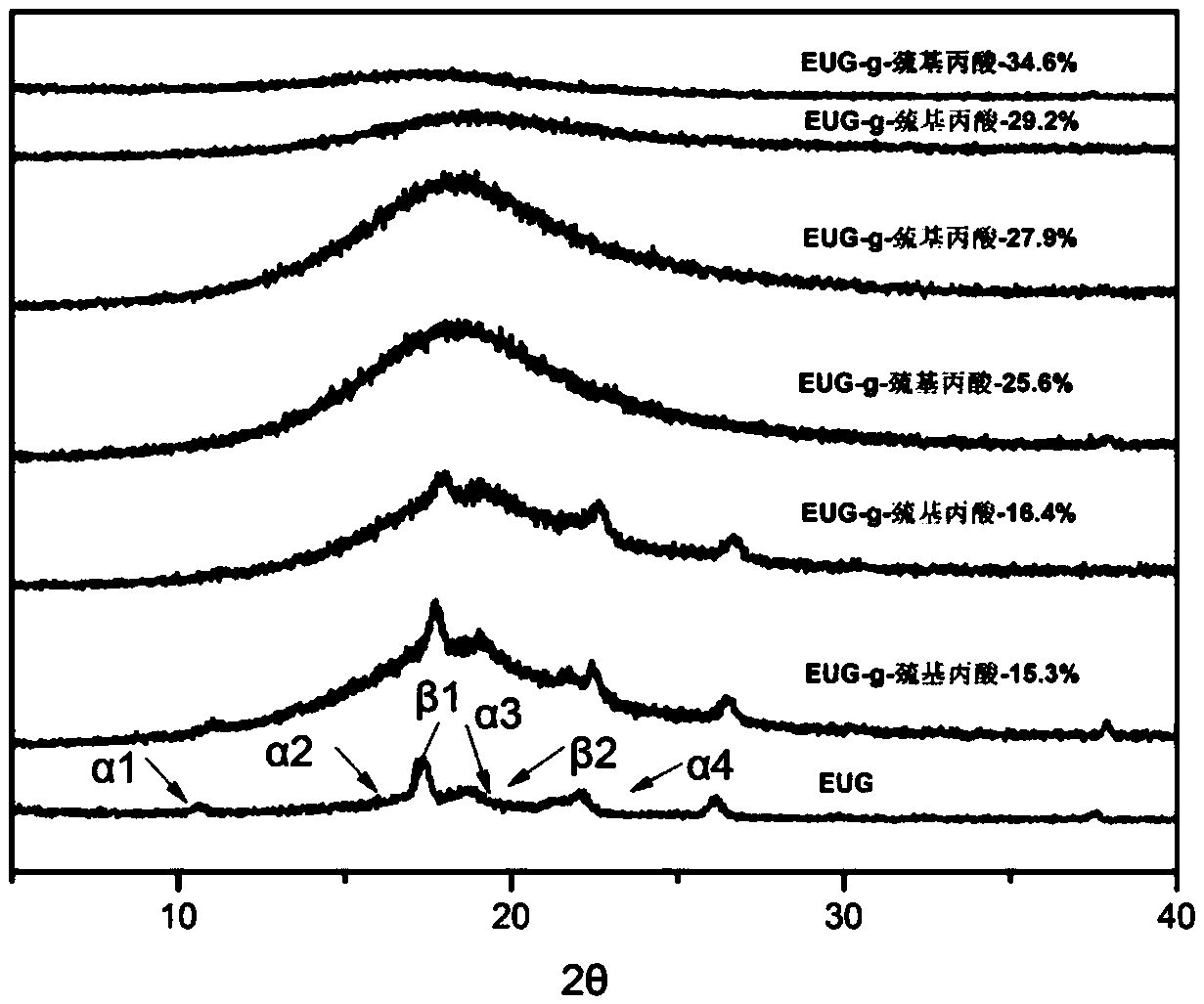

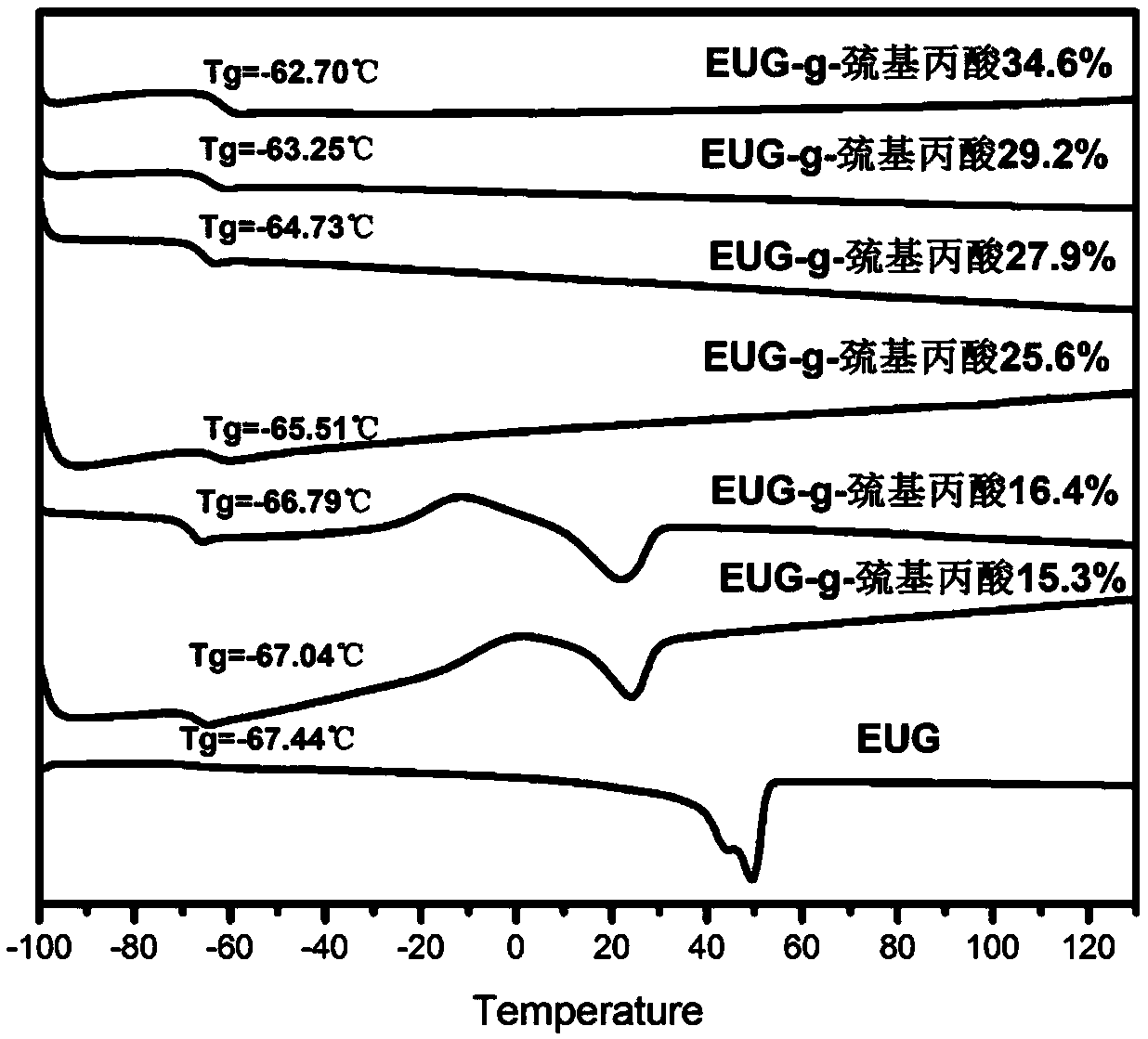

The invention relates to the field of rubber materials, in particular to a novel oil-resistant gutta-percha elastomer and a preparation method thereof. According to the preparation method, gutta-percha serves as a raw material, and mercaptan serves as a graft micromolecule and is grafted onto original double bonds of the gutta-percha by using a click chemical method so as to obtain the novel oil-resistant gutta-percha elastomer. According to the novel oil-resistant gutta-percha elastomer and the preparation method thereof, a regular structure of trans-isoprene in a molecular chain of the gutta-percha is destroyed, so that the gutta-percha is in an elastomer form under the normal temperature condition, and the application field of the gutta-percha is expanded; and the grafting yield can becontrolled through the reaction time, when the grafting rate exceeds a critical value, a crystalline structure in the gutta-percha molecule can be destroyed, meanwhile, functional groups with different polarities are introduced, so that the physical properties of the gutta-percha are changed, and the gutta-percha is endowed with new chemical performance. Different from graft modification a traditional free radical method, the novel oil-resistant gutta-percha elastomer and the preparation method thereof have the advantages that the click chemical method is not liable to cause side reactions, inaddition, the reaction period is short, reaction products are controllable, and a process is simple.

Owner:BEIJING UNIV OF CHEM TECH

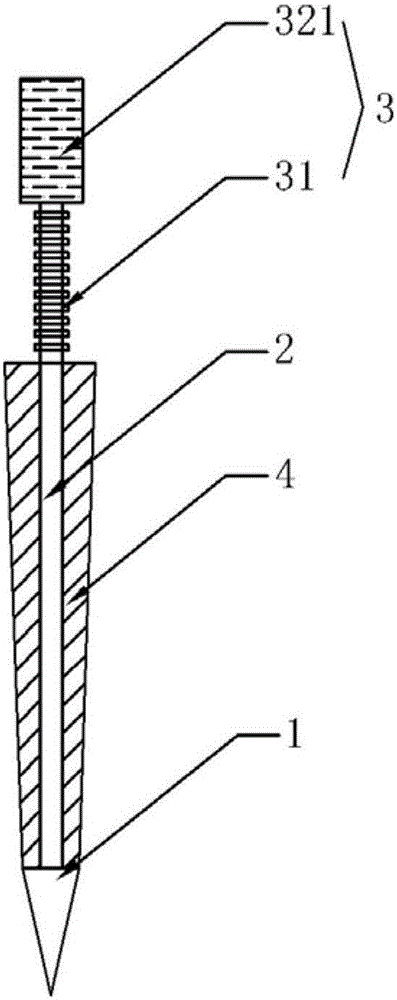

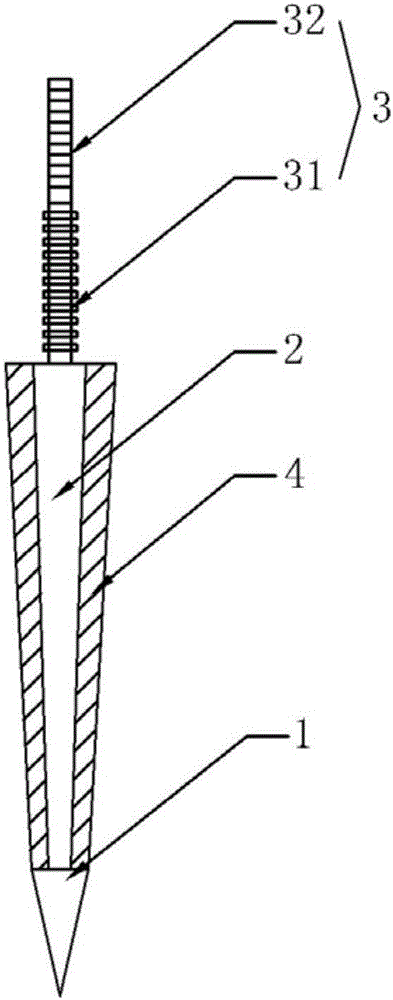

Manufacturing method of root canal filling tip

ActiveCN106377434AGood biocompatibilityEasy to useImpression capsDentistry preparationsGutta-perchaBiocompatibility Testing

The invention provides a manufacturing method of a root canal filling tip, and belongs to the field of medical equipment. The manufacturing method of the root canal filling tip comprises the following steps: step 1, selecting a medical vanadium-free nickel-free titanium alloy wire as a raw material; step 2, processing a first end of the vanadium-free nickel-free titanium alloy wire into a cone to form a closed section; step 3, processing a filling section from a thick end of the closed section on the vanadium-free nickel-free titanium alloy wire; step 4, cutting into a plurality of scale lines from one end of the filling section on the vanadium-free nickel-free titanium alloy wire to form a depth measuring section; and step 5, manufacturing a mould with a mould cavity, putting the filling section in the center of the mould cavity of the mould, and injecting heated gutta-percha into the mould cavity to enable the gutta-percha to uniformly wrap the periphery of the filling section. The root canal filling tip manufactured by the manufacturing method provided by the invention adopts the vanadium-free nickel-free titanium alloy wire as the raw material, has high biocompatibility and is safe to use; and the root canal filling tip adopts an integrally formed structure, avoids welding and prevents harmful substances in a welding flux from permeating a human body.

Owner:莫总鸣

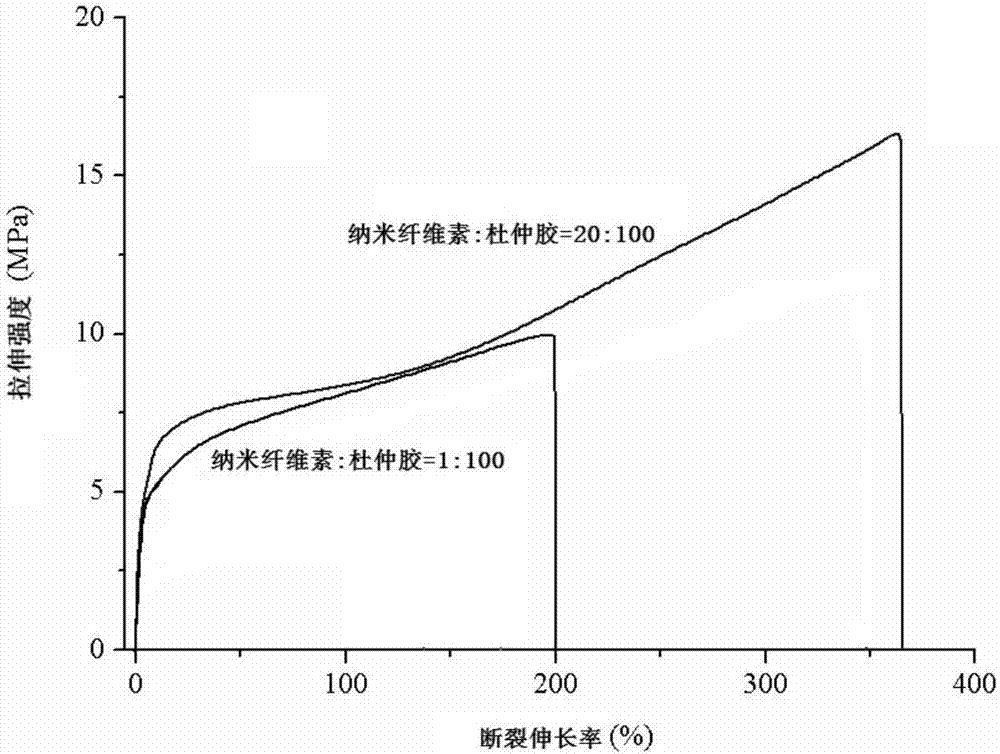

Gutta-percha and nanocellulose composite film and preparation method thereof

The invention discloses a gutta-percha and nanocellulose composite film and a preparation method thereof, and relates to the technical field of composite films. The preparation method comprises the following steps: dissolving gutta-percha into an organic solvent to obtain a gutta-percha solution; adding nanocellulose to the gutta-percha solution; stirring to obtain a mixed solution; pouring the mixed solution into a flat plate or a die of which the bottom is flat; ventilating and drying under a room temperature to obtain the gutta-percha and nanocellulose composite film. According to the method, gutta-percha and nanocellulose are composited to form a macromolecular film for the first time; the elongation at break is 200-365%; the gutta-percha and nanocellulose composite film is degradable, green, environmentally friendly, and renewable; the preparation method is simple, efficient, and free from any additive.

Owner:NORTHWEST A & F UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com