Patents

Literature

148 results about "Anterior teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In dentistry, the term anterior teeth usually refers as a group to the incisors and canine teeth as distinguished from the posterior teeth, which are the premolars and molars. The distinction is one of anterior (front of the body) versus posterior (rear of the body). The distinction holds in both the upper jaw (maxilla) and lower jaw (mandible). As a rough guide, it can be said that the anterior teeth are tailored to biting (breaking the food into chewable chunks) whereas the posterior teeth are tailored to chewing (comminuting the food into swallowable particles).

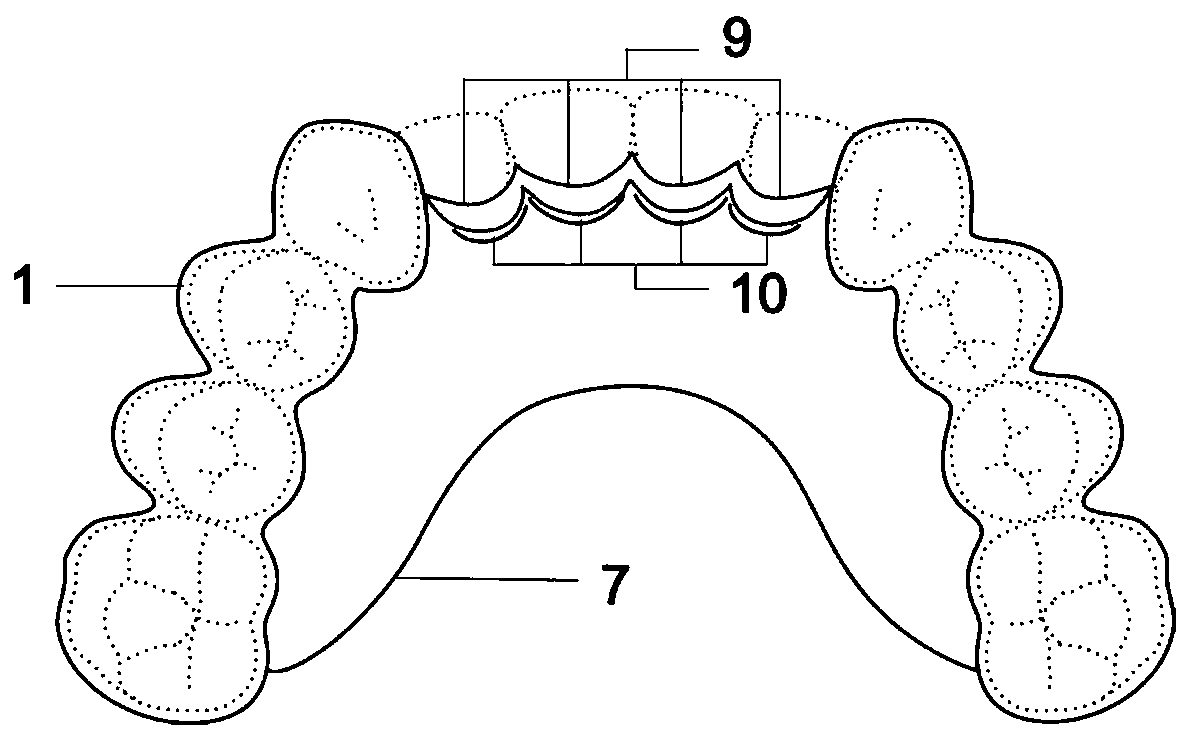

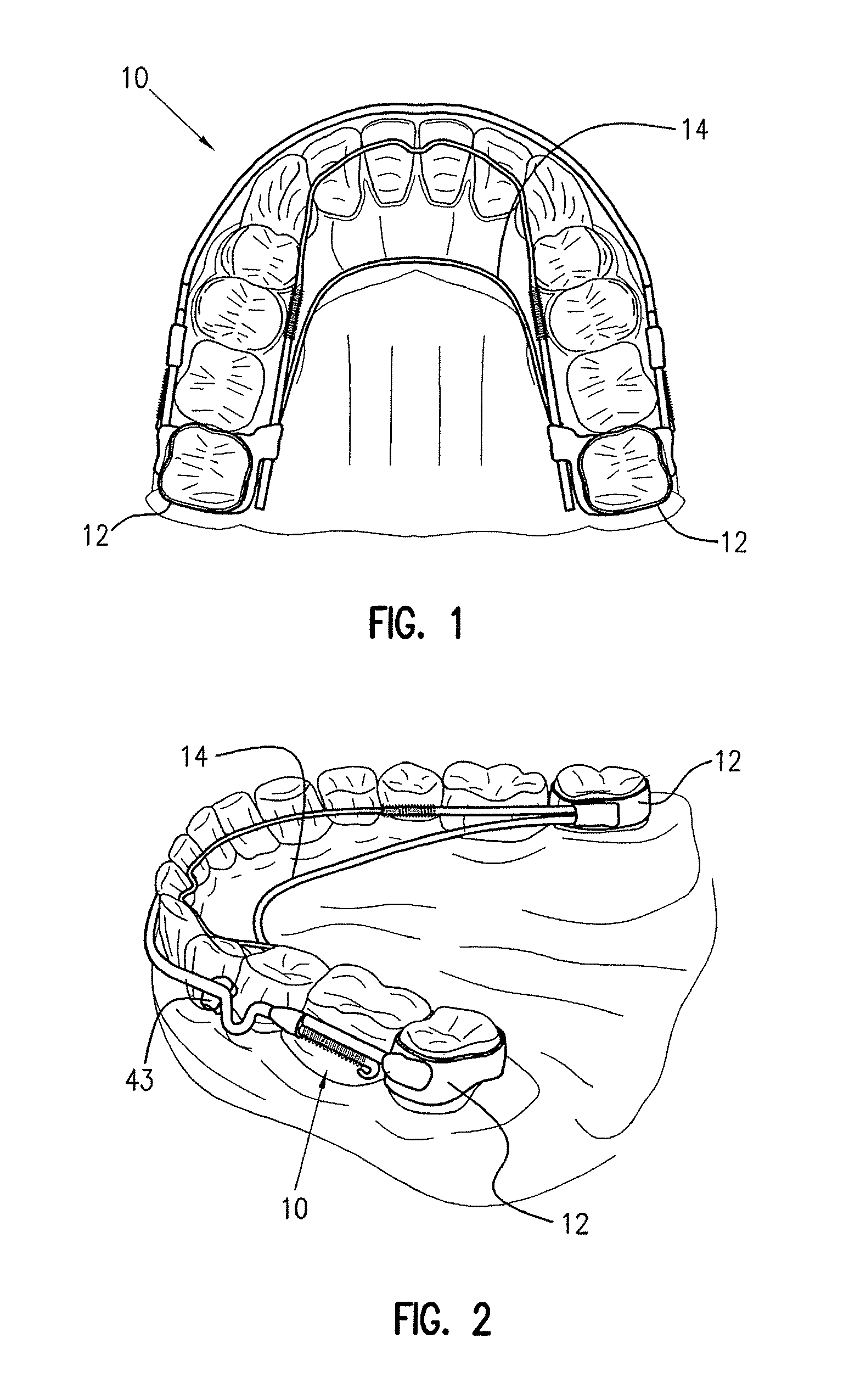

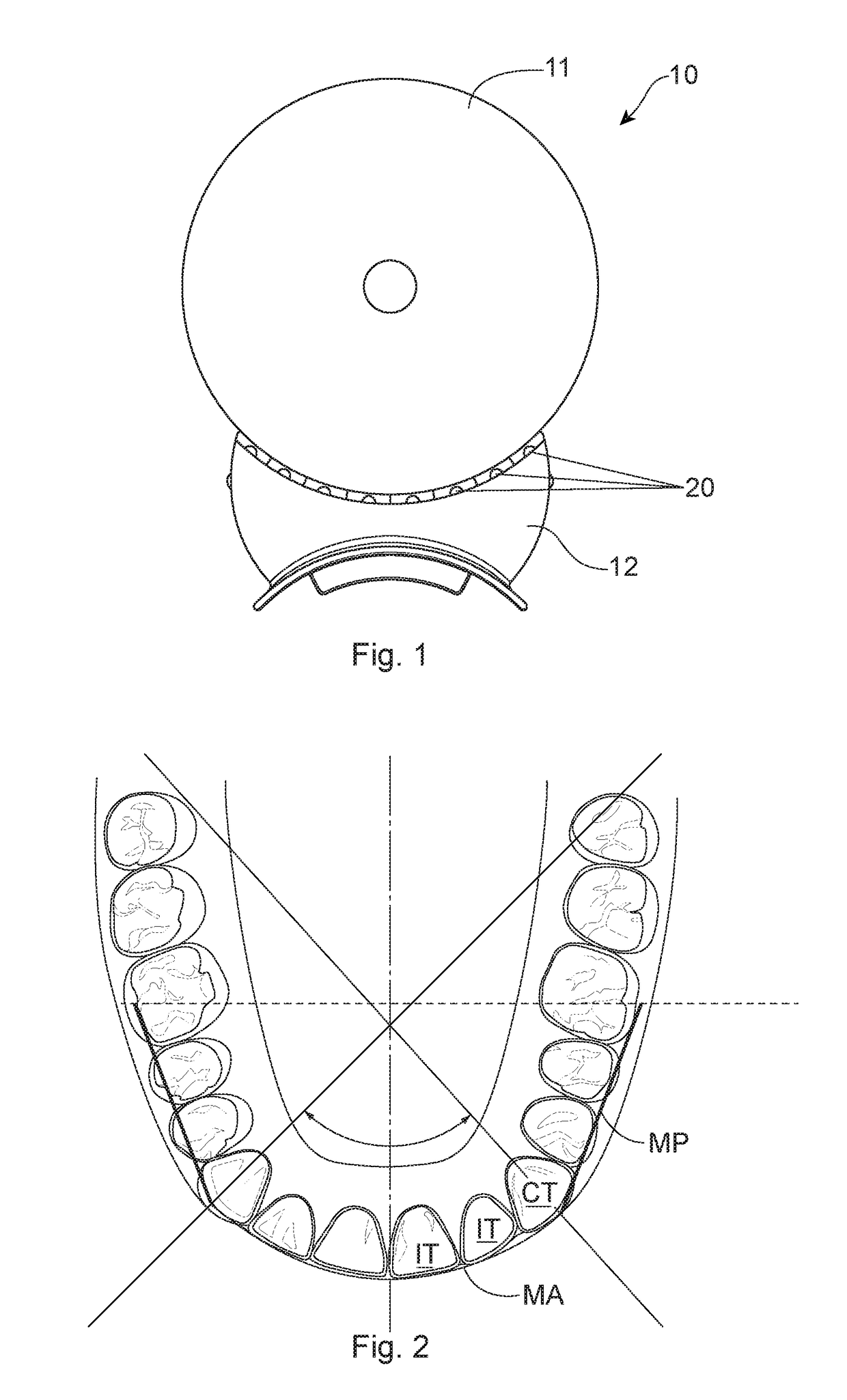

Orthodontic teeth positioning appliances

InactiveUS20120129117A1Efficient use ofEasy to useOthrodonticsDental toolsTooth positionAnterior teeth

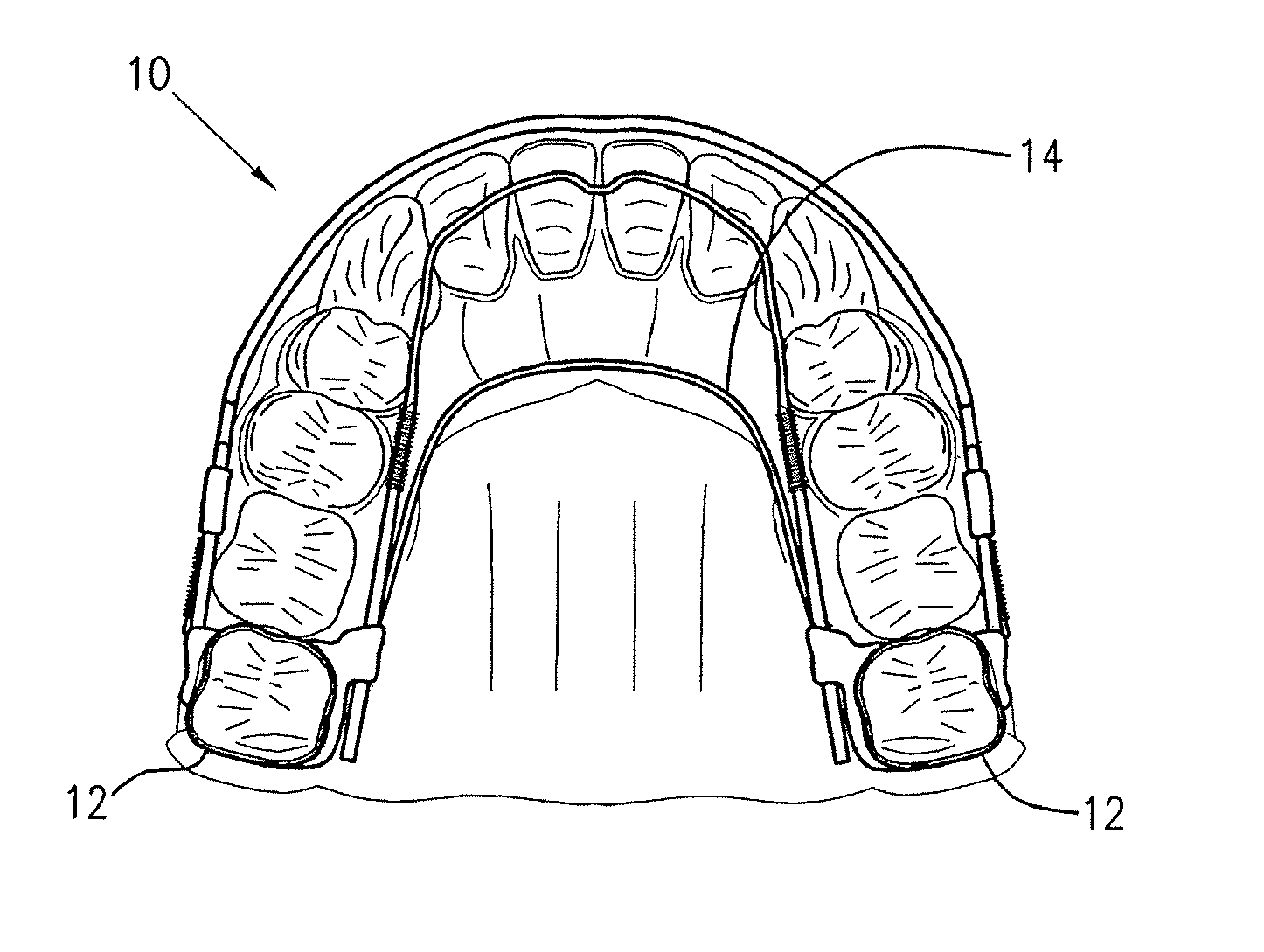

An Orthodontic teeth positioning appliance comprising an anterior positioning component, a posterior component and a resilient means connecting the anterior and posterior components. The anterior positioning component is configured to be in contact with, in order to push against, the lingual faces of a plurality of anterior teeth, when worn by the user and the posterior component is configured to be anchored to at least one posterior tooth, when worn by the user in order that the resilient means urges apart the anterior positioning component from the posterior component. The appliance is preferably removable by the user.

Owner:ORTHO PRO TEKNICA

Invisible spring aligner

An orthodontic appliance for positioning one or more anterior teeth in a jaw of a patient comprising a clear labial component which extends over the labial surfaces of the patient's teeth and which has an anterior portion and a pair of posterior portions on opposite sides of the dental arch. The anterior and posterior portions of the labial component are in direct contact with the exterior surfaces of the teeth so that no other components of the appliance are located between the anterior and posterior portions of the labial component and those exterior surfaces of the teeth. A lingual component is located within the patient's dental arch for supporting the appliance and for applying force to the patient's anterior teeth, the lingual component operating to move the anterior teeth against the anterior portion of the labial component which serves as a reference against which the teeth are positioned.

Owner:GREAT LAKES ORTHODONTICS

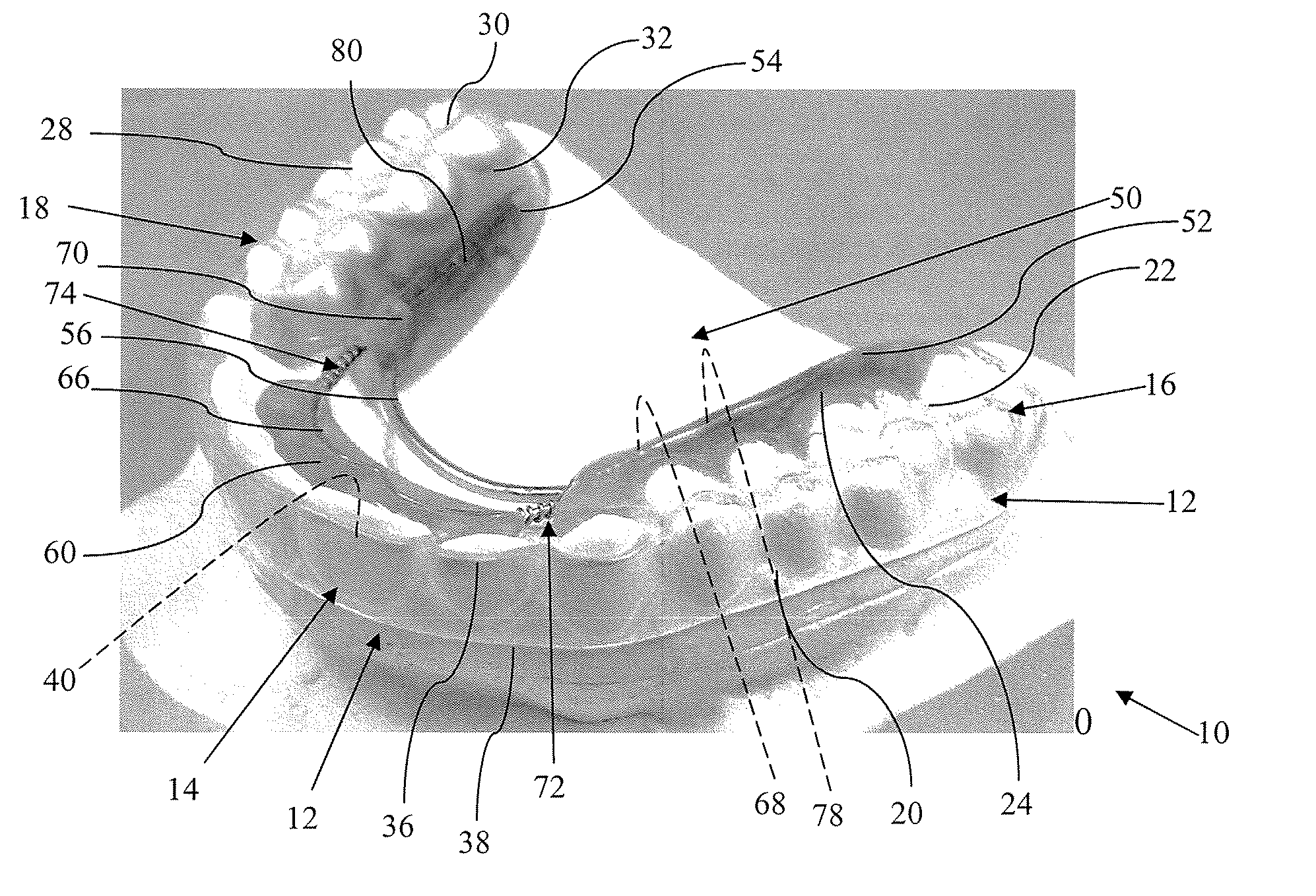

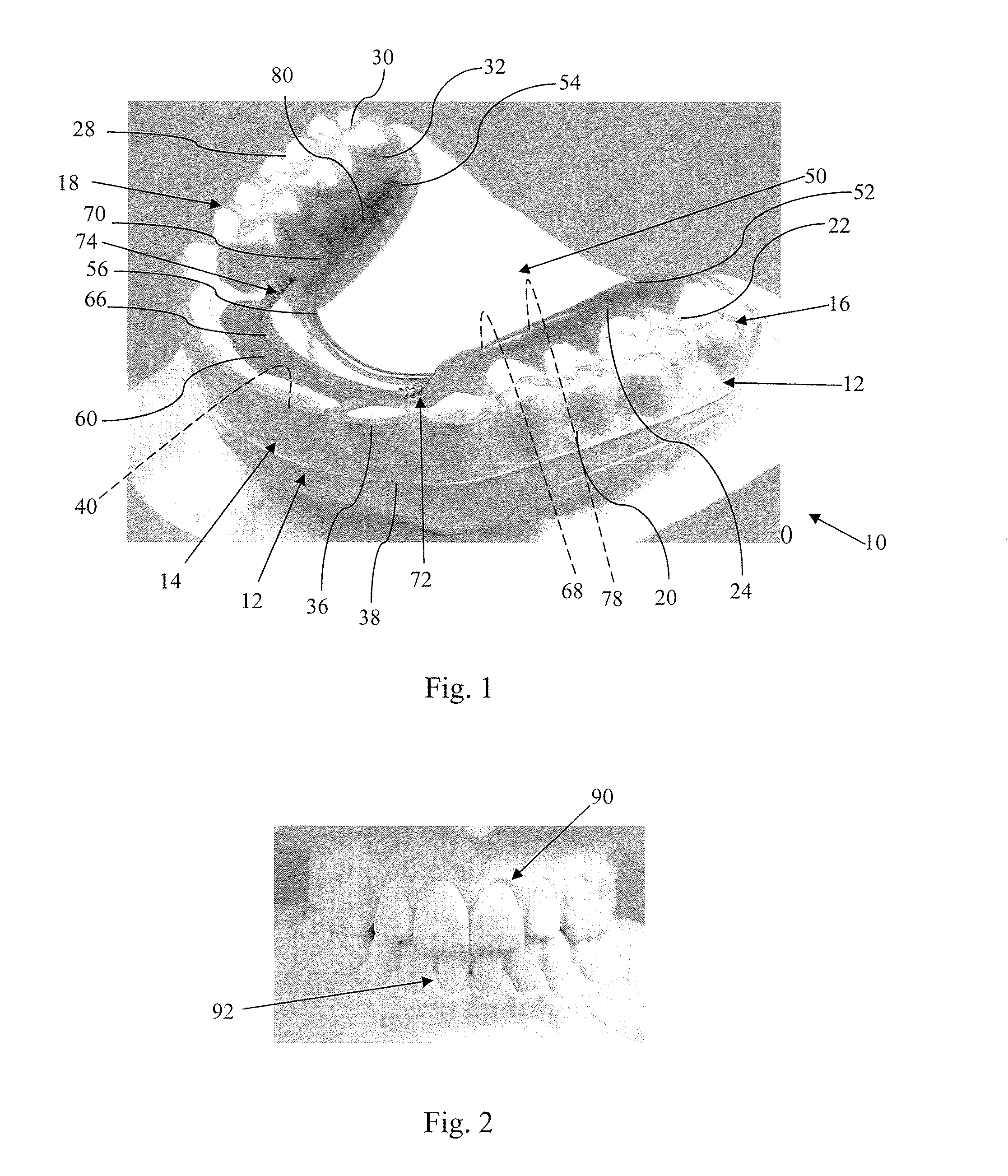

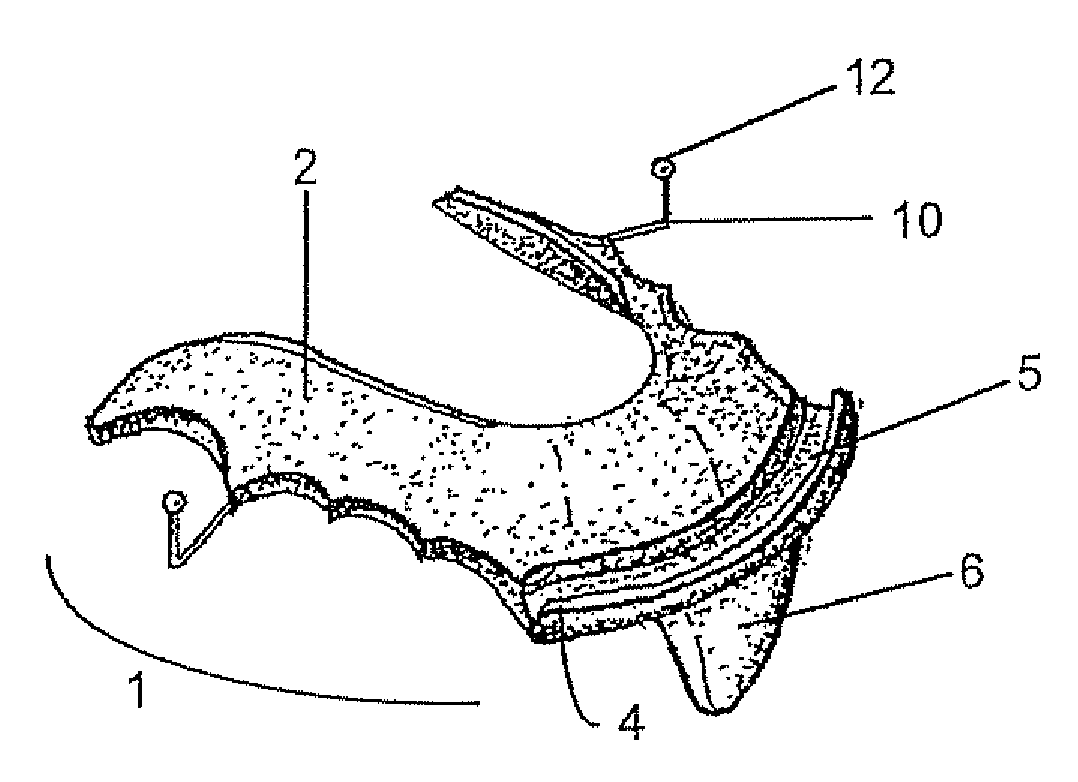

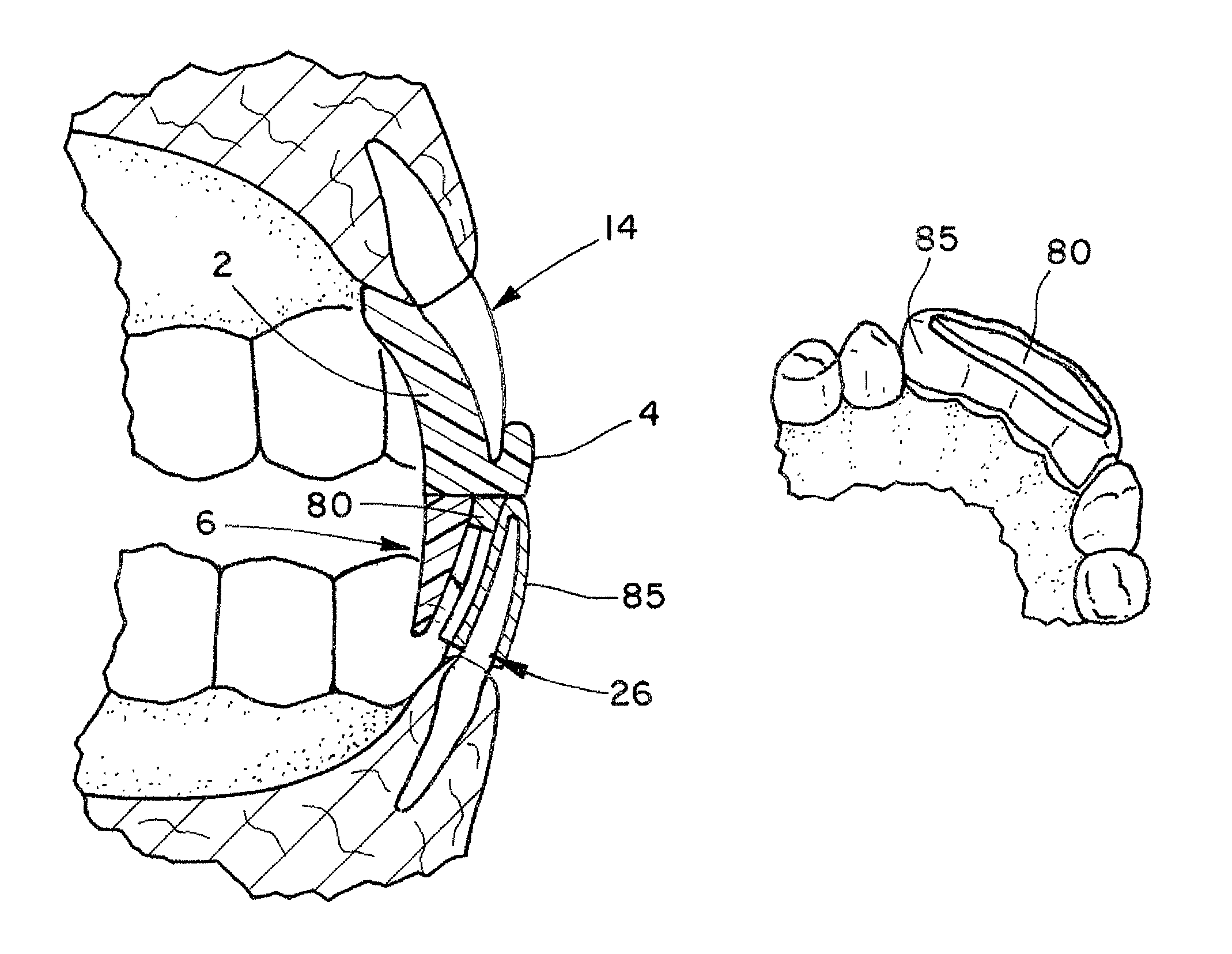

Oral Sleep Apnea Device

An oral sleep apnea device is a dental appliance designed to advance the lower jaw of a user suffering from sleep apnea while reducing lingual discomfort and the risk of harmful tooth movement and rotation during use. The present invention accomplishes this through the use of a maxillary and a mandibular dental plate coupled to the upper and lower jaw, respectively, without direct contact with the incisal or labial surfaces of the anterior teeth. Both appliances comprise a lingual surface mount. The maxillary dental plate comprises an advancement mechanism. The advancement mechanism being operatively engaged to the mandibular dental plate repositions the mandibular plate to a forward location relative to the maxillary dental plate. During the repositioning of the mandibular dental plate the mandibular lingual surface mount distributes pressure evenly to the lingual surfaces on the lower jaw, reducing localized pressure points which can cause tooth movement.

Owner:STEIN IVAN F

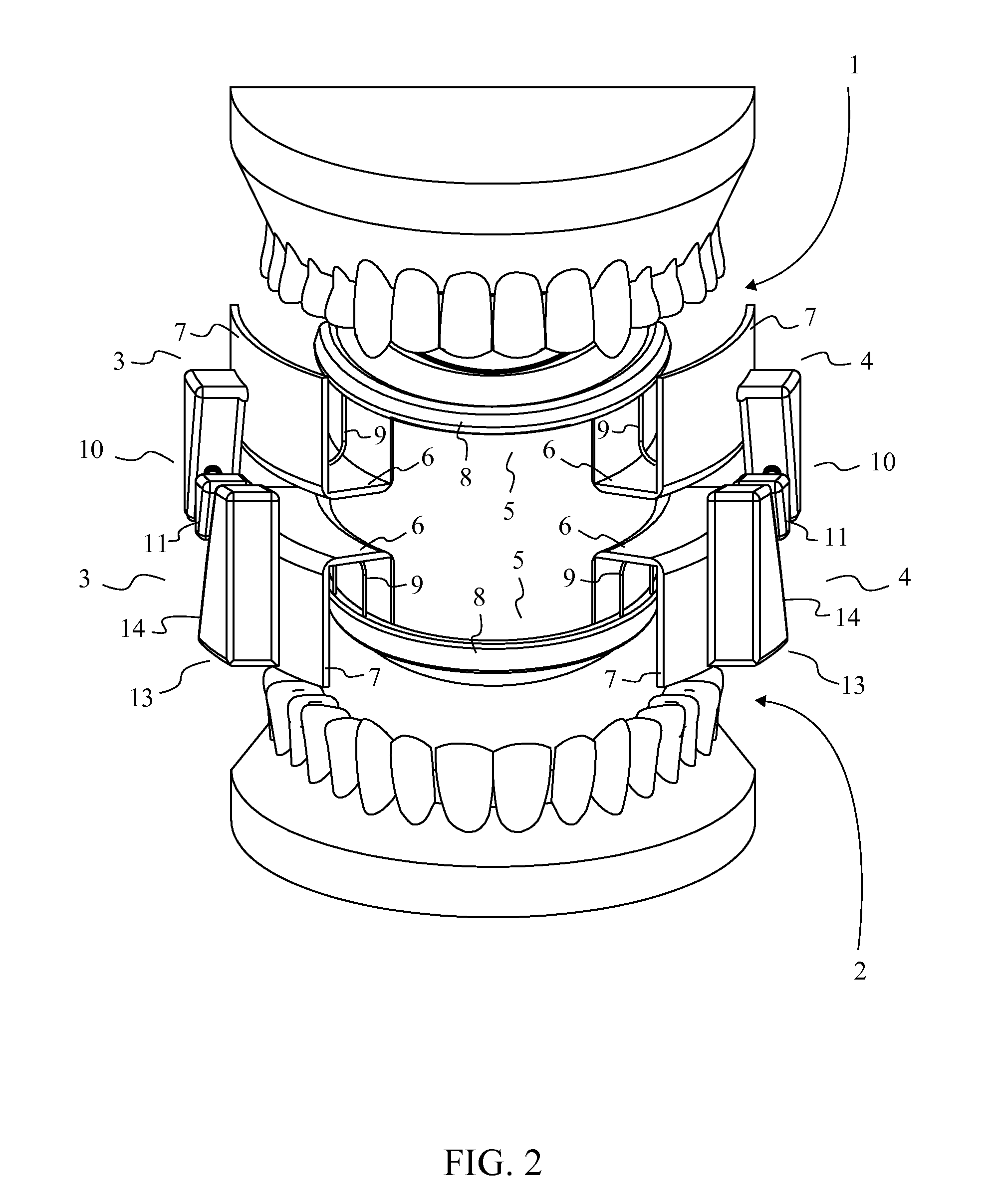

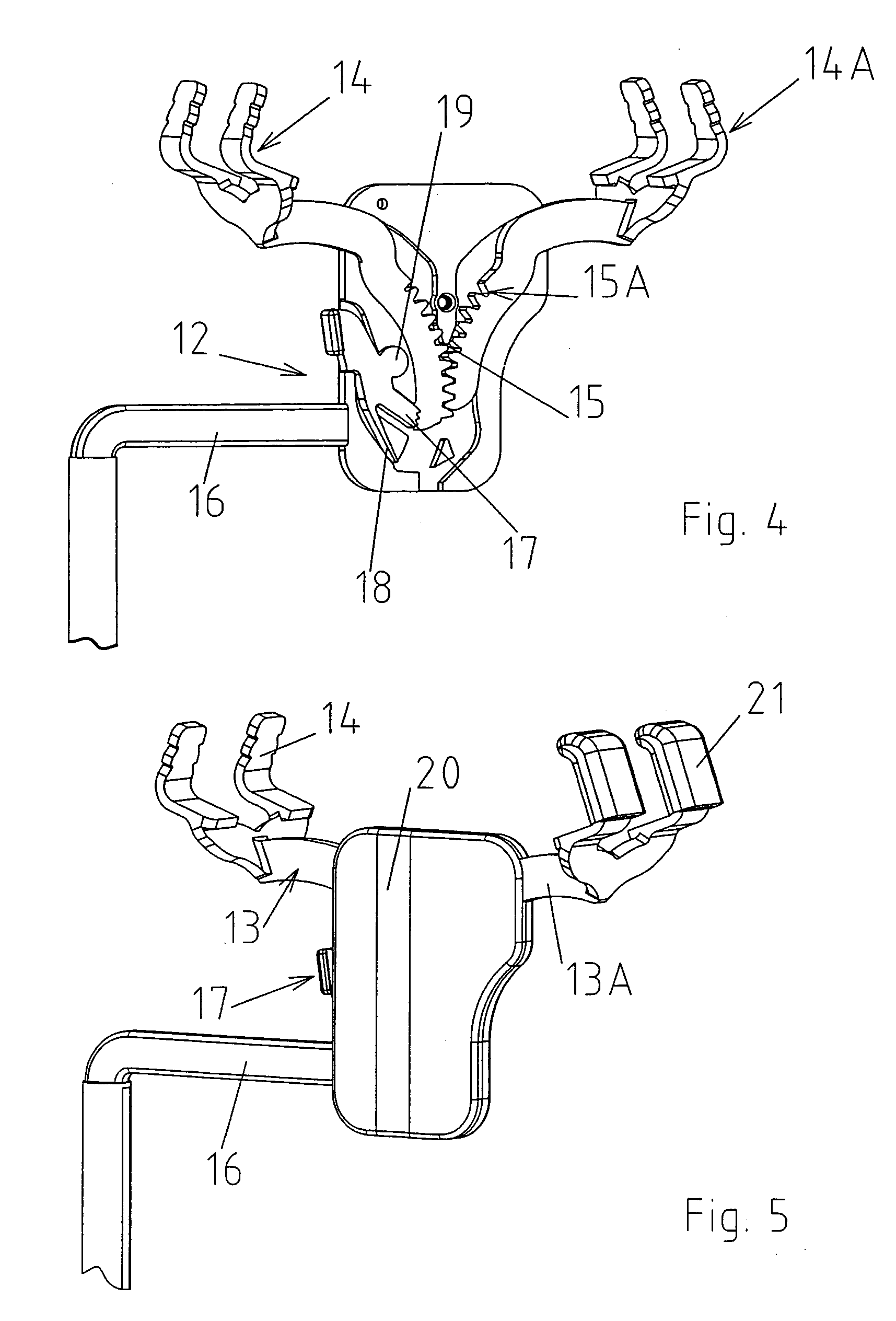

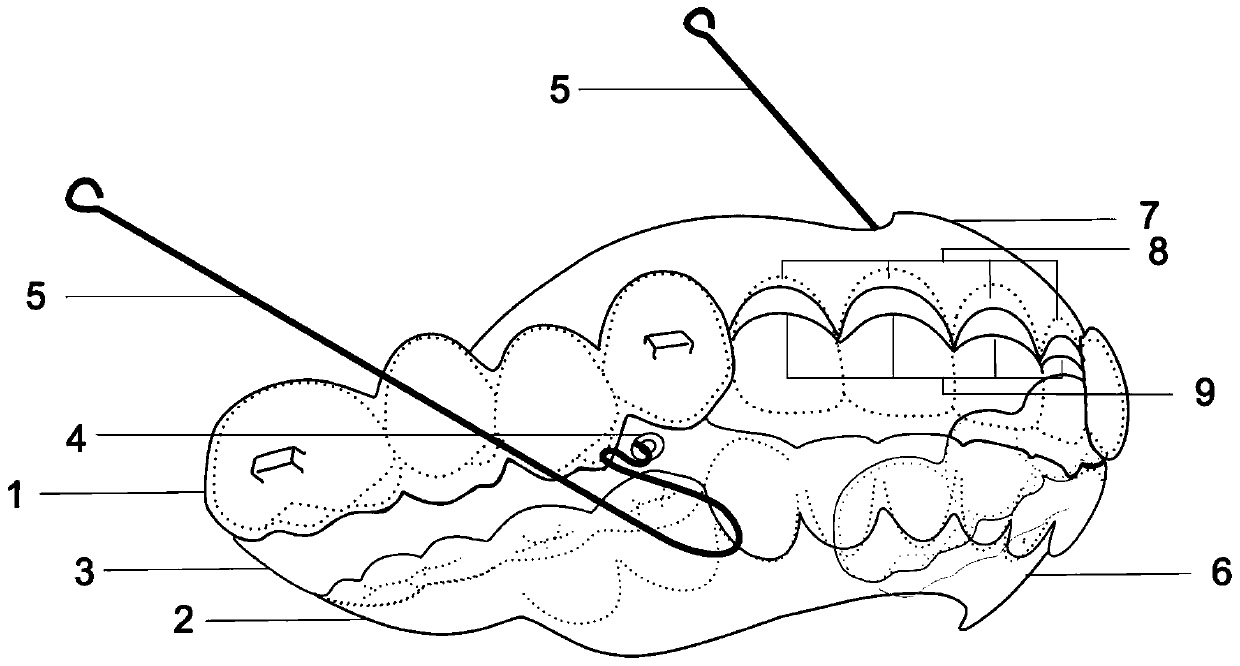

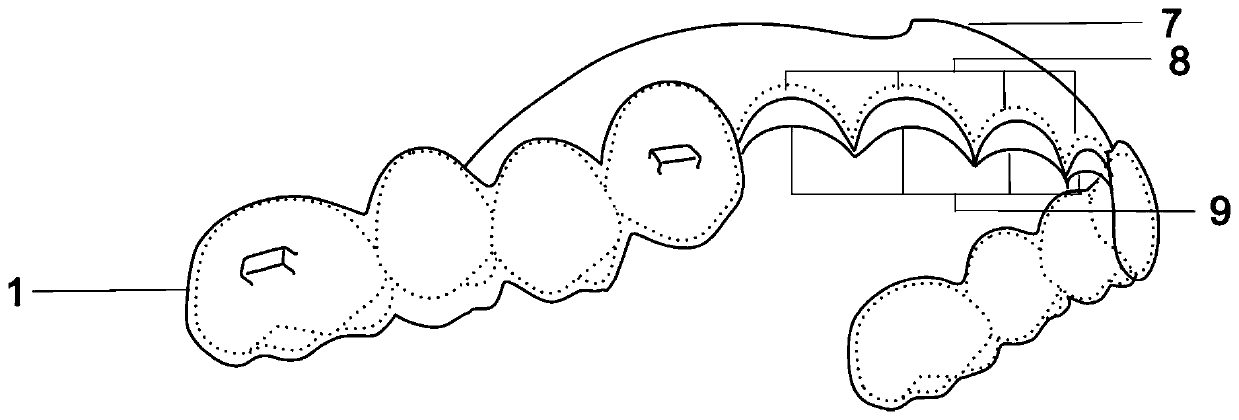

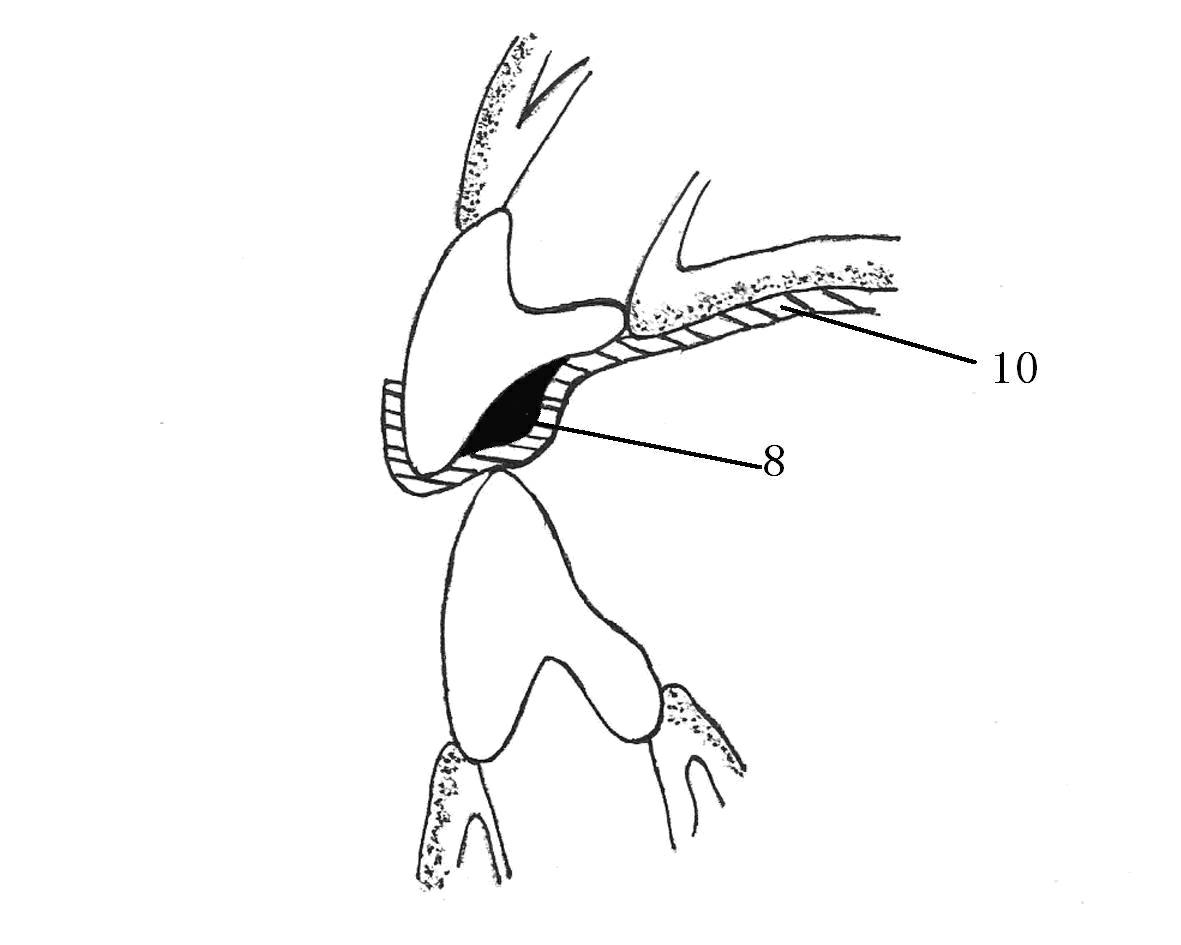

Intraoral mandibular advancement device for treatment of sleep disorders

ActiveUS20080099029A1Eliminates and reduces disadvantageSnoring preventionDental toolsTreatment sleepAnterior teeth

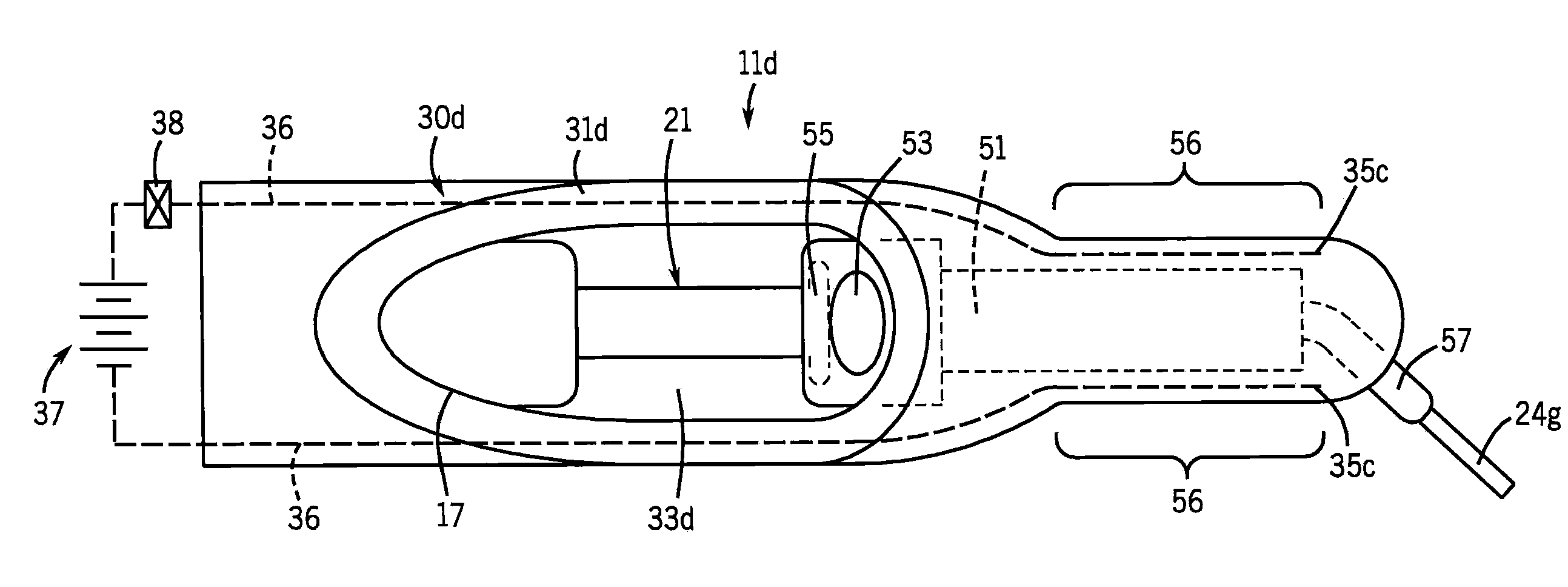

An intraoral mandibular advancement device to treat sleep disorders in a user having an obstructed airway includes a maxillary appliance with a main body for removable attachment to the maxillary teeth; a protrusive element distending from the central portion of the main body; and retention means extending from the main body for retention of the device on the maxillary teeth during sleep. A mandibular appliance removably attaches to the mandibular anterior teeth and includes a lingual spacer that extends posteriorly from the mandibular anterior teeth. The anterior aspect of the protrusive element of the maxillary appliance contacts the posterior edge of the lingual space and thereby causes mandibular advancement.

Owner:LAMBERG STEVEN B

Orthodontic retainers

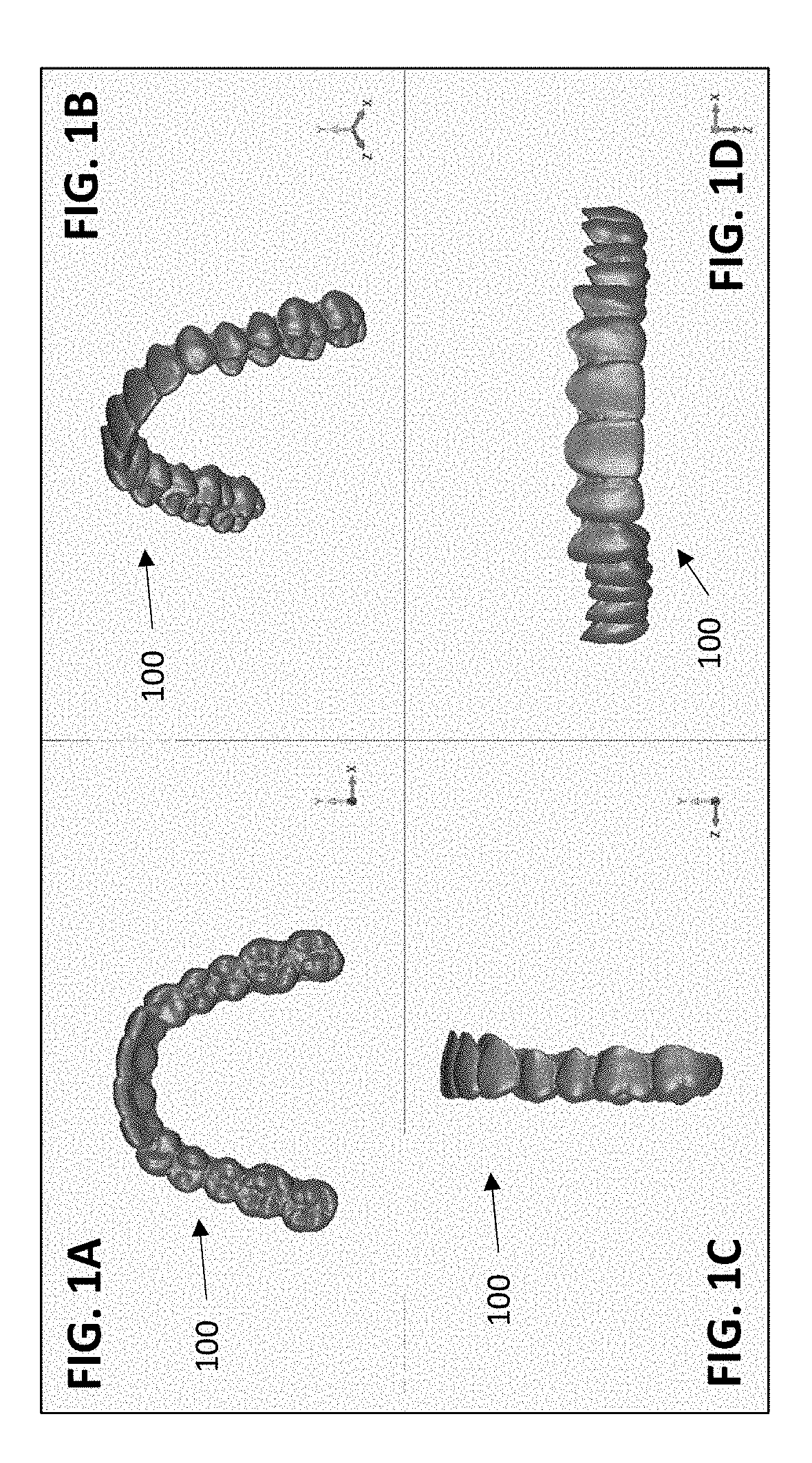

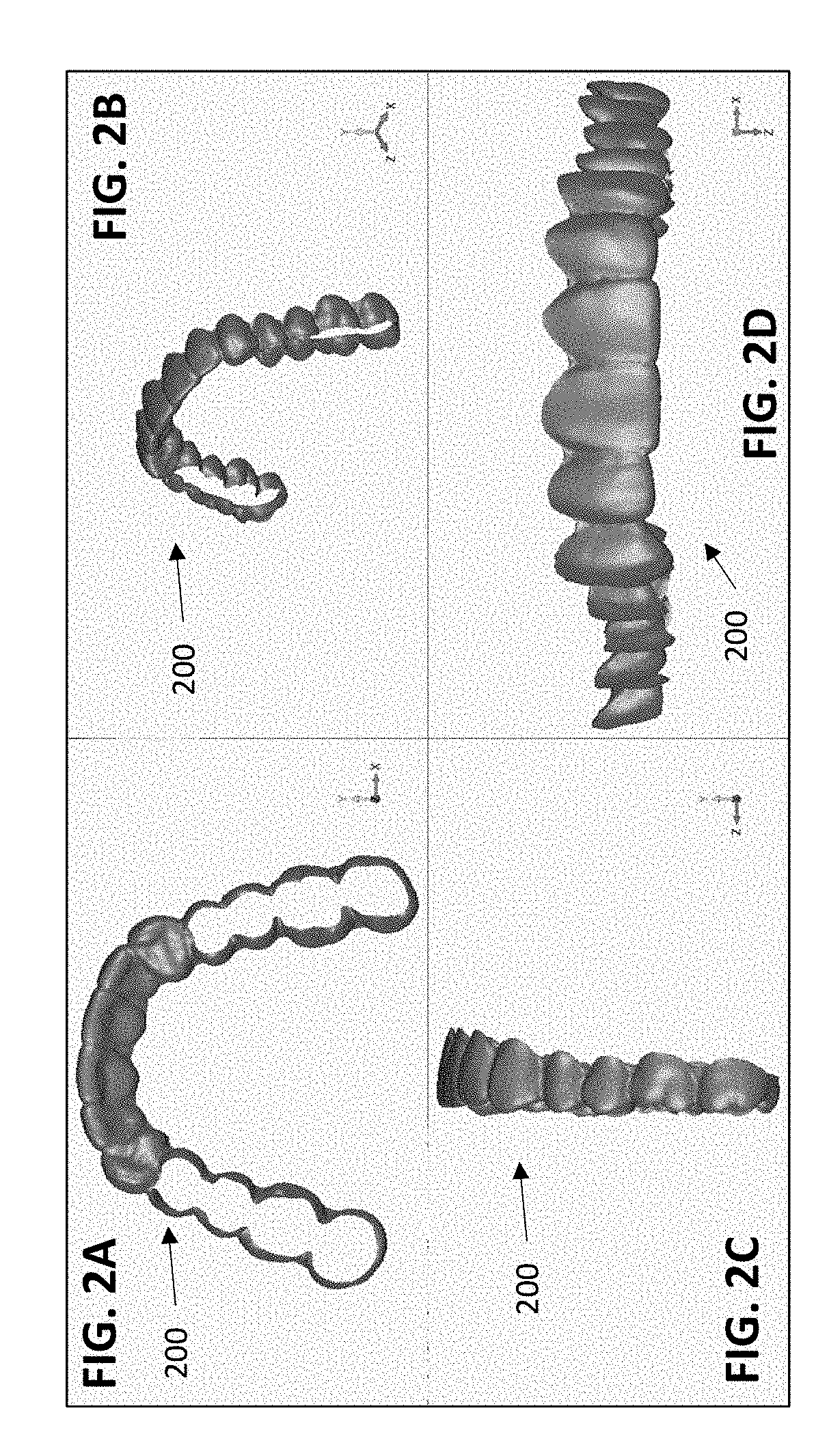

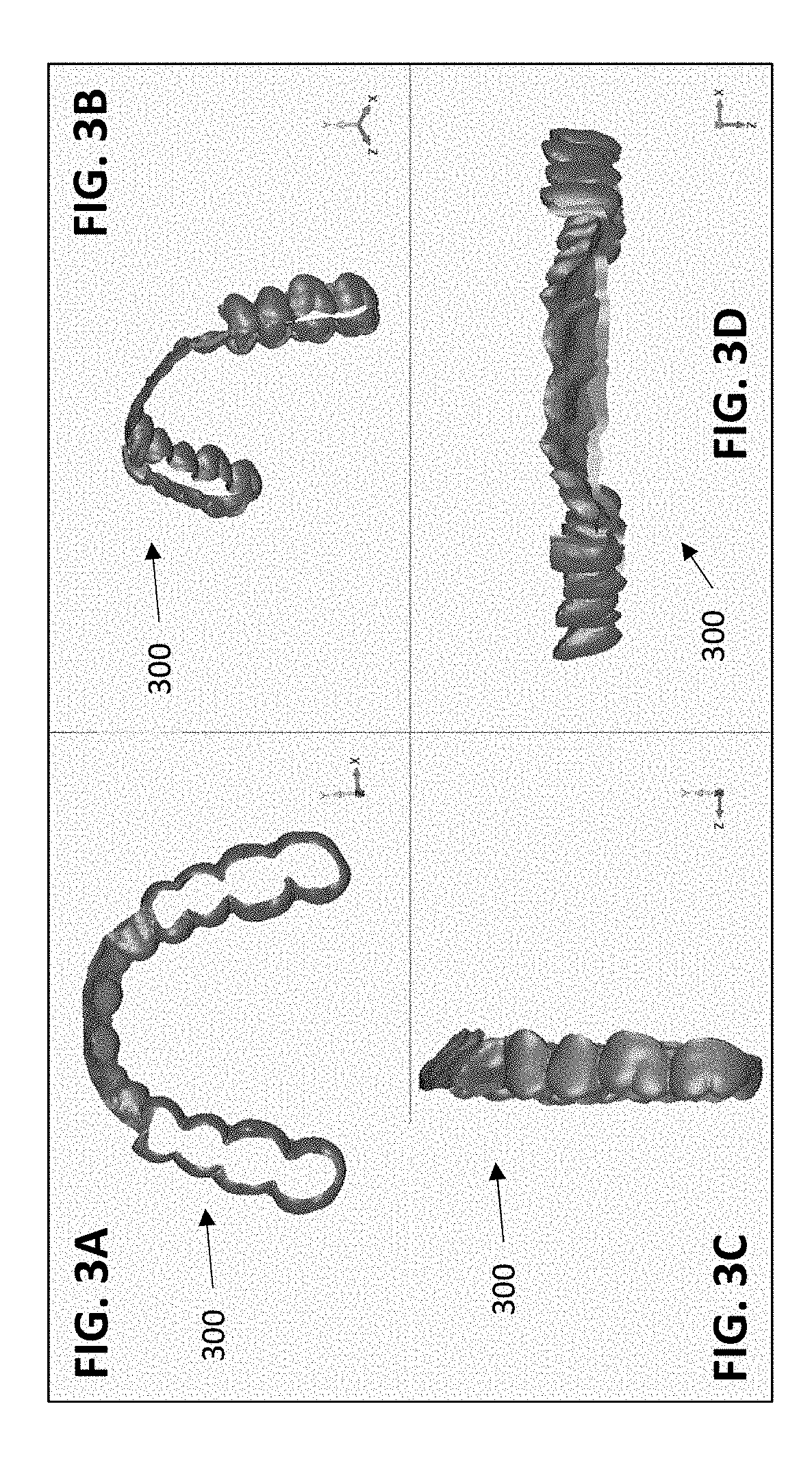

ActiveUS20190152152A1Low profileAvoids tendencyImpression capsAdditive manufacturing apparatusOrthodontic retainerAdditive layer manufacturing

Dental retainer devices are provided. The dental retainer devices can be customized based on patient specific dental anatomy and dental treatment plans. Methods of making the dental retainer devices are also provided. The methods can included additive manufacturing. Methods are also provided for customization of a dental retainer device based on the patient specific anatomy. The methods for customization can include providing a dentist with different options for anterior teeth coverage, posterior teeth coverage, and palatal configurations for the dental retainer devices.

Owner:ALIGN TECH

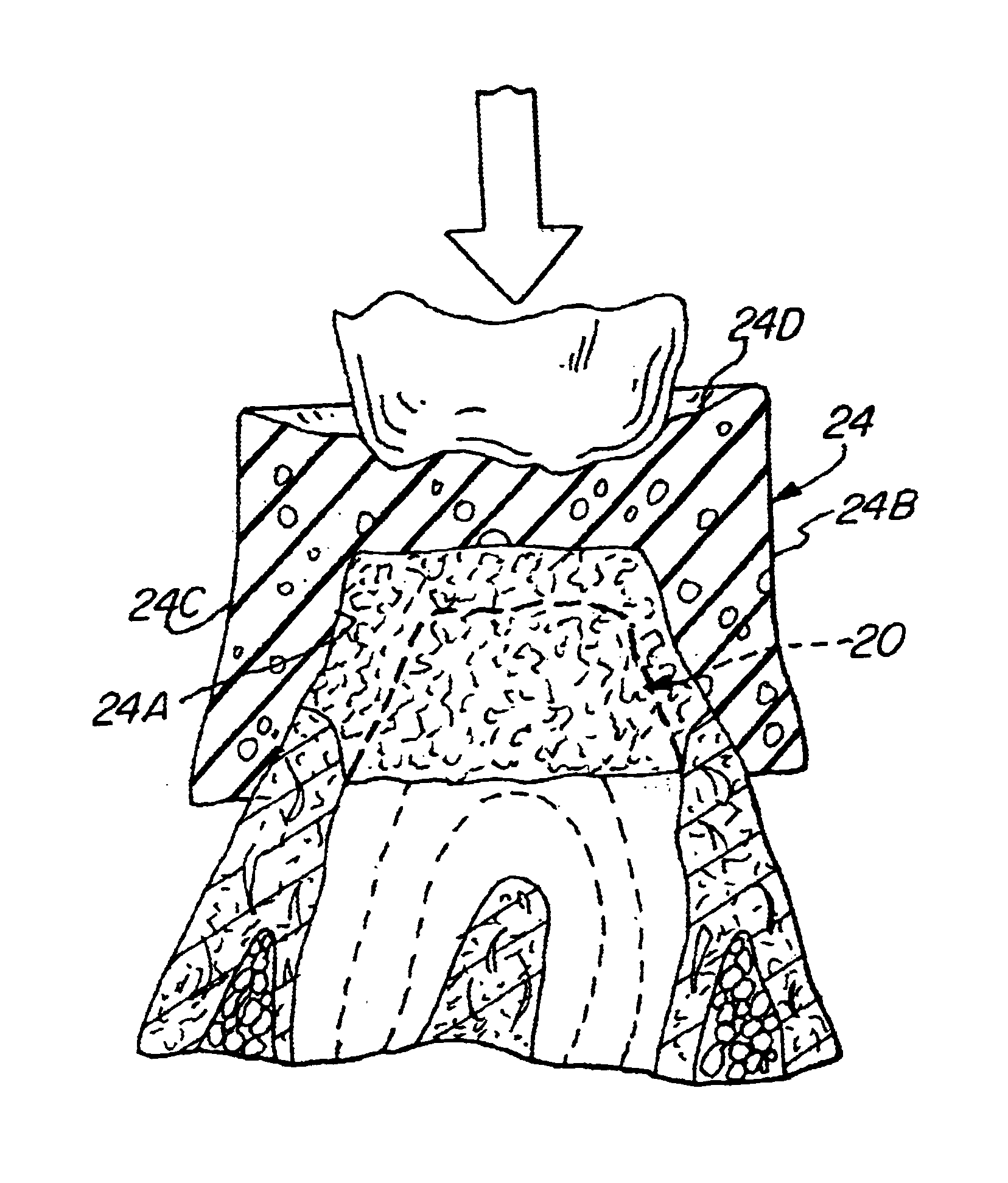

Method and device for the retraction and hemostasis of tissue during crown and bridge procedures

InactiveUS6890177B2Positive in operationEasy to operateImpression capsDental aidsBite force quotientGingival space

A method and a device for effecting the cordless retraction of the gingival sulcus tissue prior to the taking of an impression of a tooth for making a crown or bridge which is attained by controlling any bleeding in the gingival sulcus area, and utilizing a dental dam preferably formed of a sponge or foam like material to contain an astringent fortified silicone impression material embedded about the prepared tooth, and using the patient's biting force to apply the necessary pressure onto the dam until the silicone impression material sets and adheres to the dam to enhance easy removal of the set impression material from the tooth. The dam is formed to accommodate either the posterior teeth or the anterior teeth.

Owner:CENTRIX

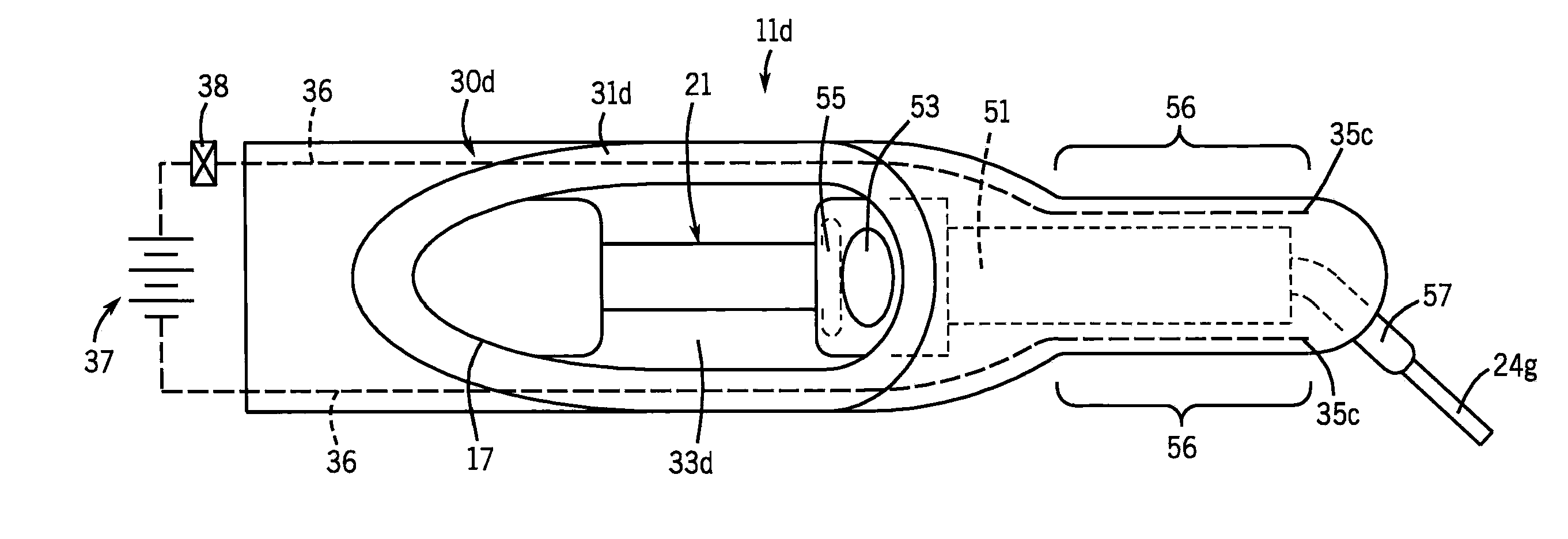

Intraoral mandibular advancement device for treatment of sleep disorders

ActiveUS7730891B2Eliminates and reduces disadvantageSnoring preventionDental toolsAnterior teethMaxillary tooth

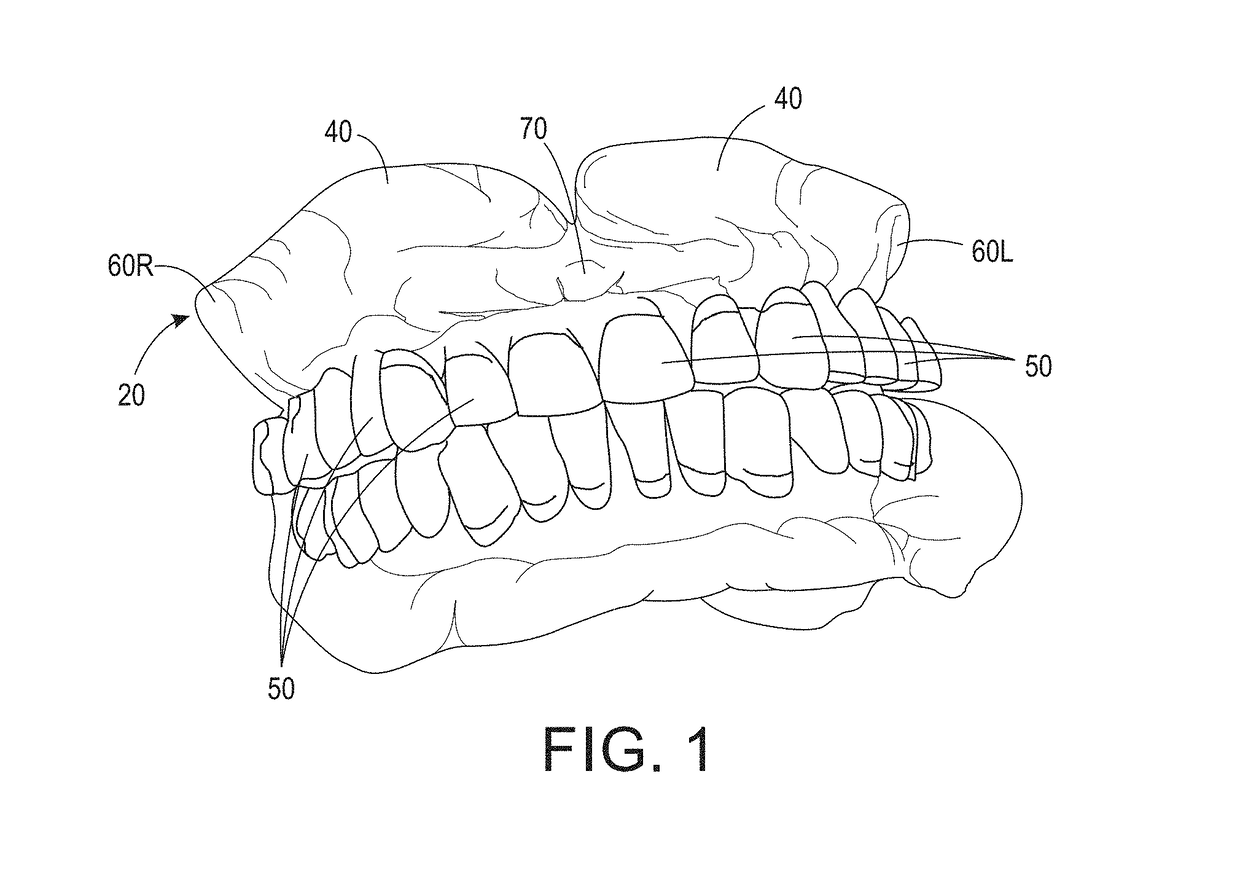

An intraoral mandibular advancement device to treat sleep disorders in a user having an obstructed airway includes a maxillary appliance with a main body for removable attachment to the maxillary teeth; a protrusive element distending from the central portion of the main body; and retention means extending from the main body for retention of the device on the maxillary teeth during sleep. A mandibular appliance removably attaches to the mandibular anterior teeth and includes a lingual spacer that extends posteriorly from the mandibular anterior teeth. The anterior aspect of the protrusive element of the maxillary appliance contacts the posterior edge of the lingual space and thereby causes mandibular advancement.

Owner:LAMBERG STEVEN B

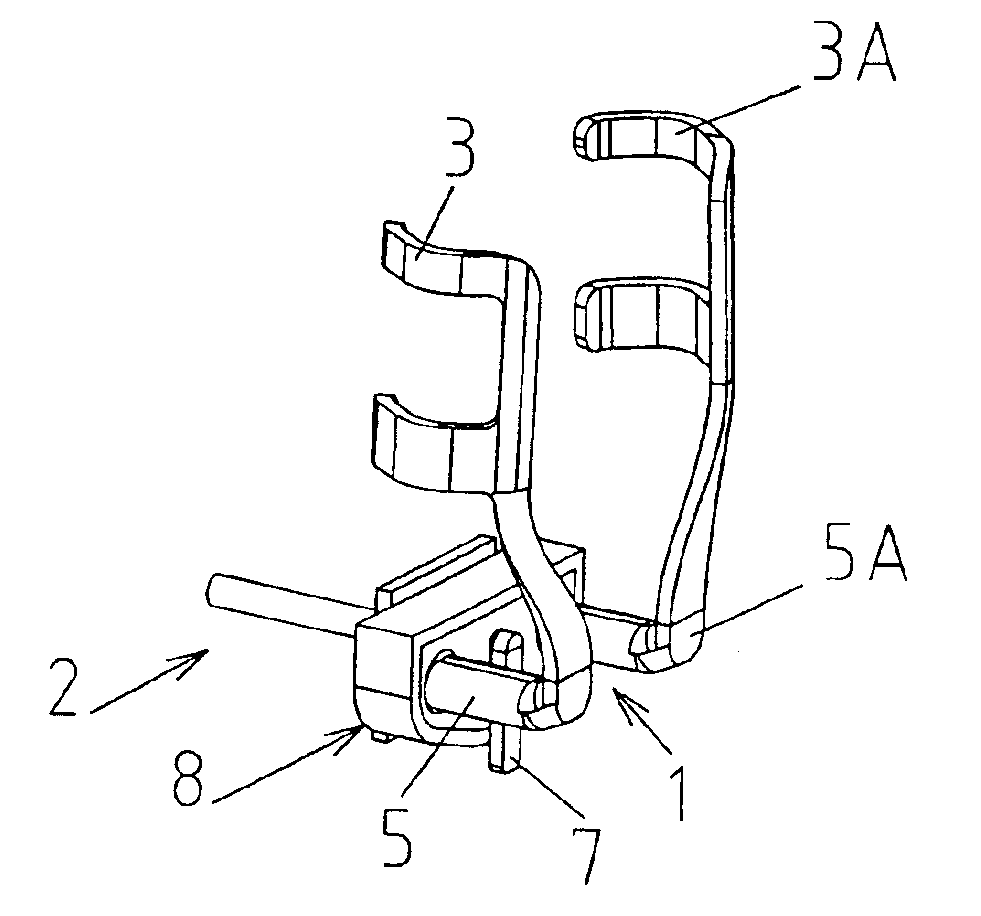

Holder for digital sensors for dentistry

InactiveUS6905244B2Maximum comfortPrecise positioningX-ray/infra-red processesRadiation diagnostics for dentistryEngineeringAnterior teeth

In the holder set for digital sensors for dentistry, the holders for each kind of radiograph such as periapical radiographs of front teeth (anterior teeth) and lateral teeth (posterior teeth), on one hand, and bitewing radiographs, on the other hand, can be used for all sensor formats, the sensors being seized in the respective holders in a self-centered manner by two arms independently of their format.

Owner:KERRHAWE

Interocclusal appliance and method

ActiveUS7658193B2Color be alteredHardness be alteredImpression capsOthrodonticsInterocclusal appliancePermlastic

An interocclusal appliance is formed from a single polymer material composition as one unitary piece or from multiple polymer material compositions as a two-piece preform. The two-piece preform includes a base material and an impression material that has a softening point lower than the base material. Teeth are received into the heat-softened impression material, so as to contour the impression material. A portion of the impression material also may contour to a portion of the user's palate. In certain embodiments, substantially no polymeric material contacts the front surfaces of the front teeth, leading to greater comfort and better air flow between front teeth. In still another embodiment, the appliance fits over front teeth only and no polymeric material contacts the maxillary molars.

Owner:HAYLOFT ENTERPRISES INC

Dental insert and method of tooth restoration

InactiveUS20050255428A1Overcome deficienciesEasy to handleDam holdersTooth clampsDental insertRestorative material

A device for creating interproximal contacts of restorations placed between posterior and anterior teeth comprising a single or plurality of dental inserts which is sized and dimensioned and can be inserted into unset restorative material and compacted so as to exert lateral forces in the interproximal areas of tooth preparations thereby creating tight anatomical and functional interproximal contacts. A method of use of said dental inserts is also described.

Owner:COOPERSMITH ALLAN

Holder for digital sensors for dentistry

ActiveUS20040096040A1Maximum comfortPrecise positioningX-ray/infra-red processesImage-conversion/image-amplification tubesEngineeringAnterior teeth

In the holder set for digital sensors for dentistry, the holders for each kind of radiograph such as periapical radiographs of front teeth (anterior teeth) and lateral teeth (posterior teeth), on one hand, and bitewing radiographs, on the other hand, can be used for all sensor formats, the sensors being seized in the respective holders in a self-centered manner by two arms independently of their format.

Owner:KERRHAWE

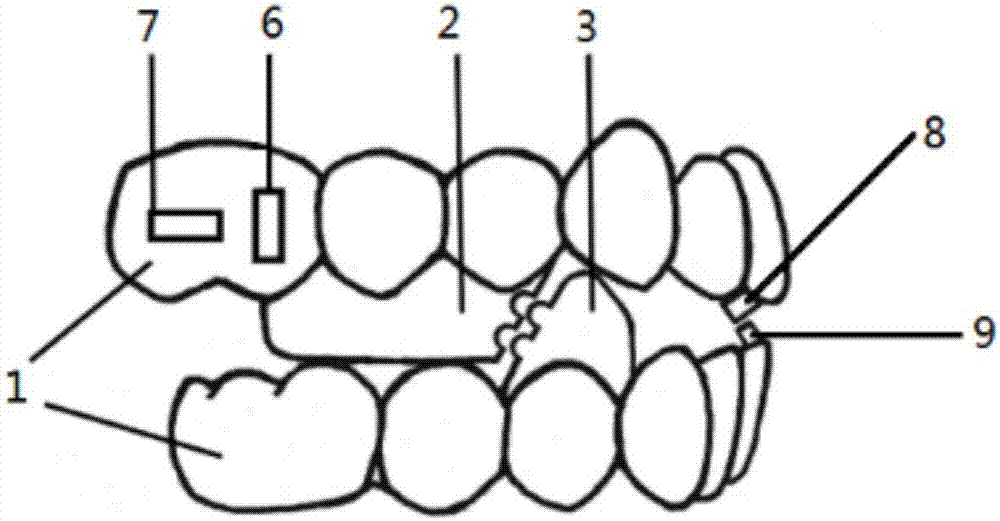

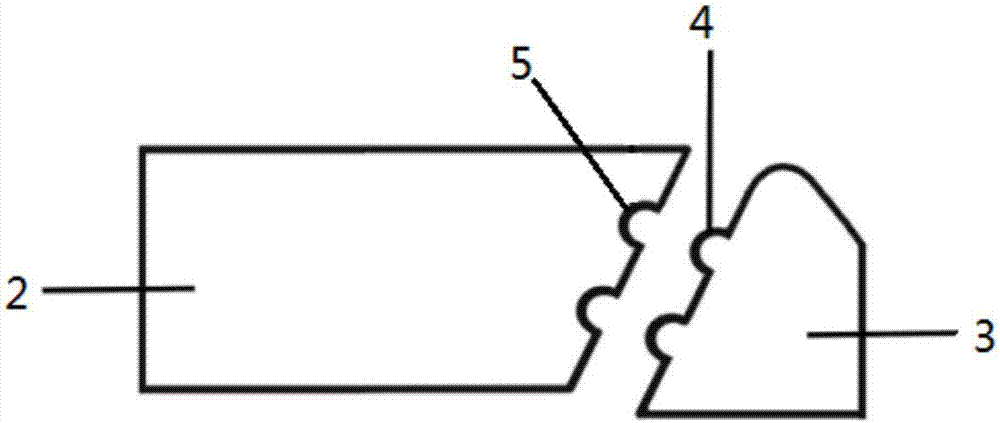

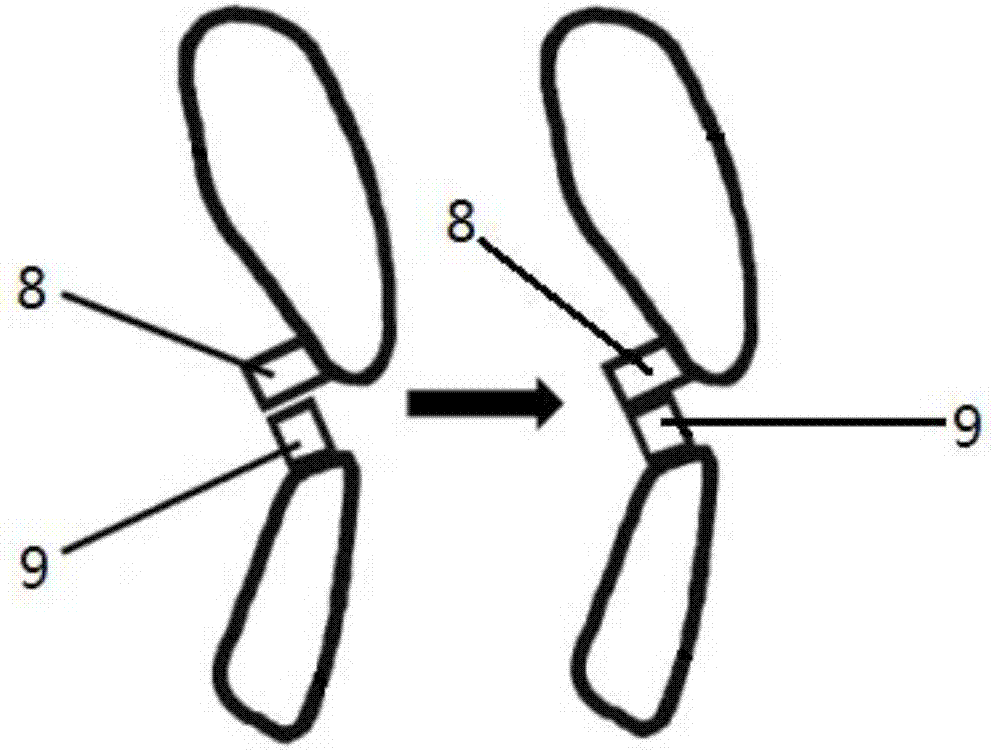

Invisible mandibular advancement orthotic method and invisible orthotic apparatus based on same

Theinvention discloses an invisible mandibular advancement orthotic method and an invisible orthotic apparatus based on same. The invisible mandibular advancement orthotic method comprise the following steps of acquiring related conditions of to-be-treated teeth; determining a target advancement position of a maxilla and a target advancement position of a mandible; according to a target distance of mandibular advancement relative to maxilla advancement, advancing the mandible from an initial position of the mandible to the target position of the mandible through a plurality of steps; according to tooth arrangement conditions, adjusting and controlling each tooth in an tooth arch in a three-dimensional direction including a horizontal direction, a vertical direction and a sagittal direction; determining a target position to which a first molar of the maxilla moves to according to a target distance of mandible advancement; and moving the first molar of the maxilla from an initial position to the target position. The invisible orthotic apparatus comprises an invisible orthotic three-dimensional dental brace, a mandibular advancement slant tooth fit pad, and an anterior tooth press down auxiliary guide board. The invisible mandibular advancement orthotic method and the invisible orthotic apparatus based on the method can advance the mandible and push distal molar movement simultaneously, and improves the orthotic efficiency of angle class II malocclusion cases.

Owner:HOSPITAL OF STOMATOLOGY SUN YAT SEN UNIV

Formed denture and method of making same

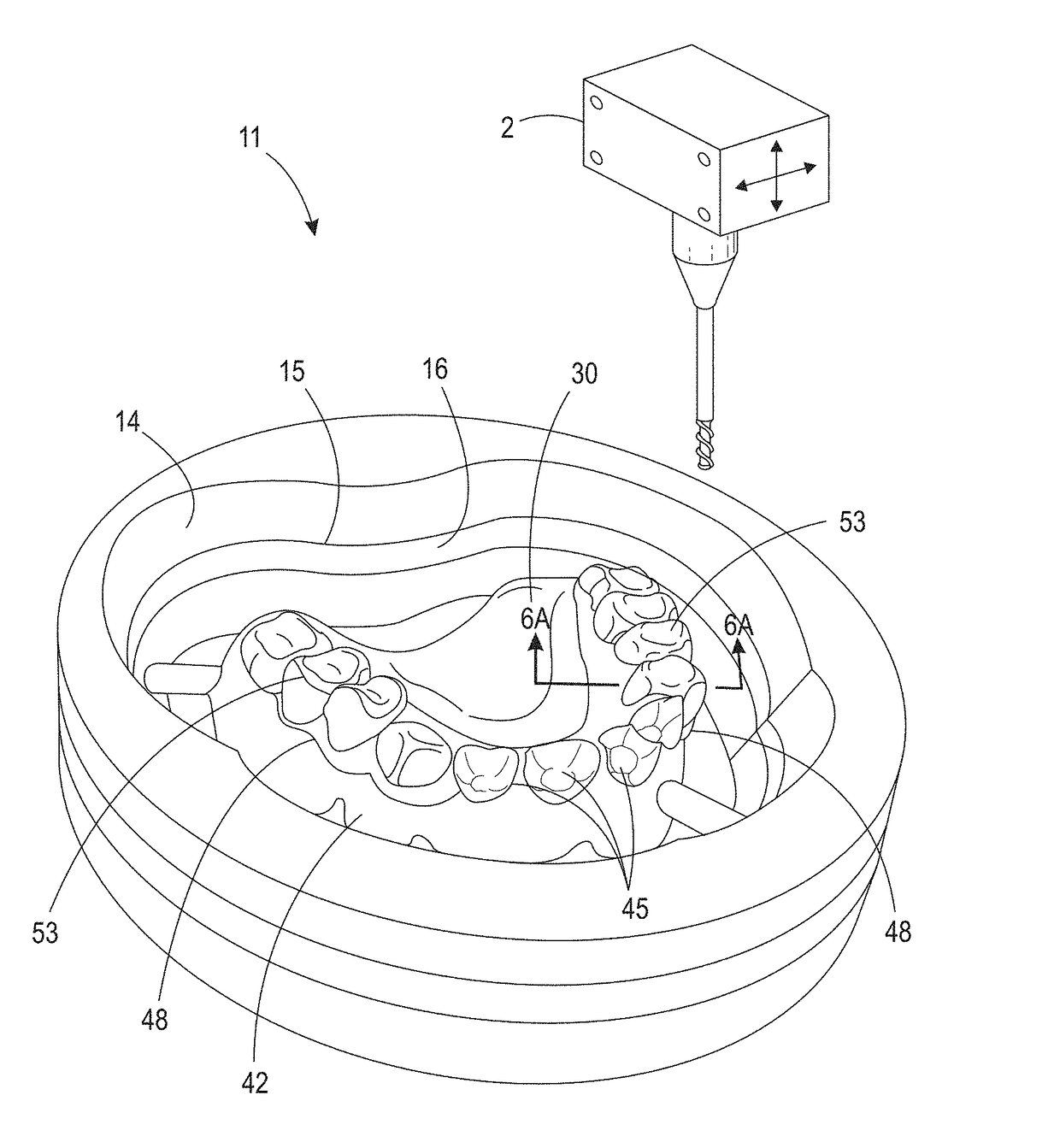

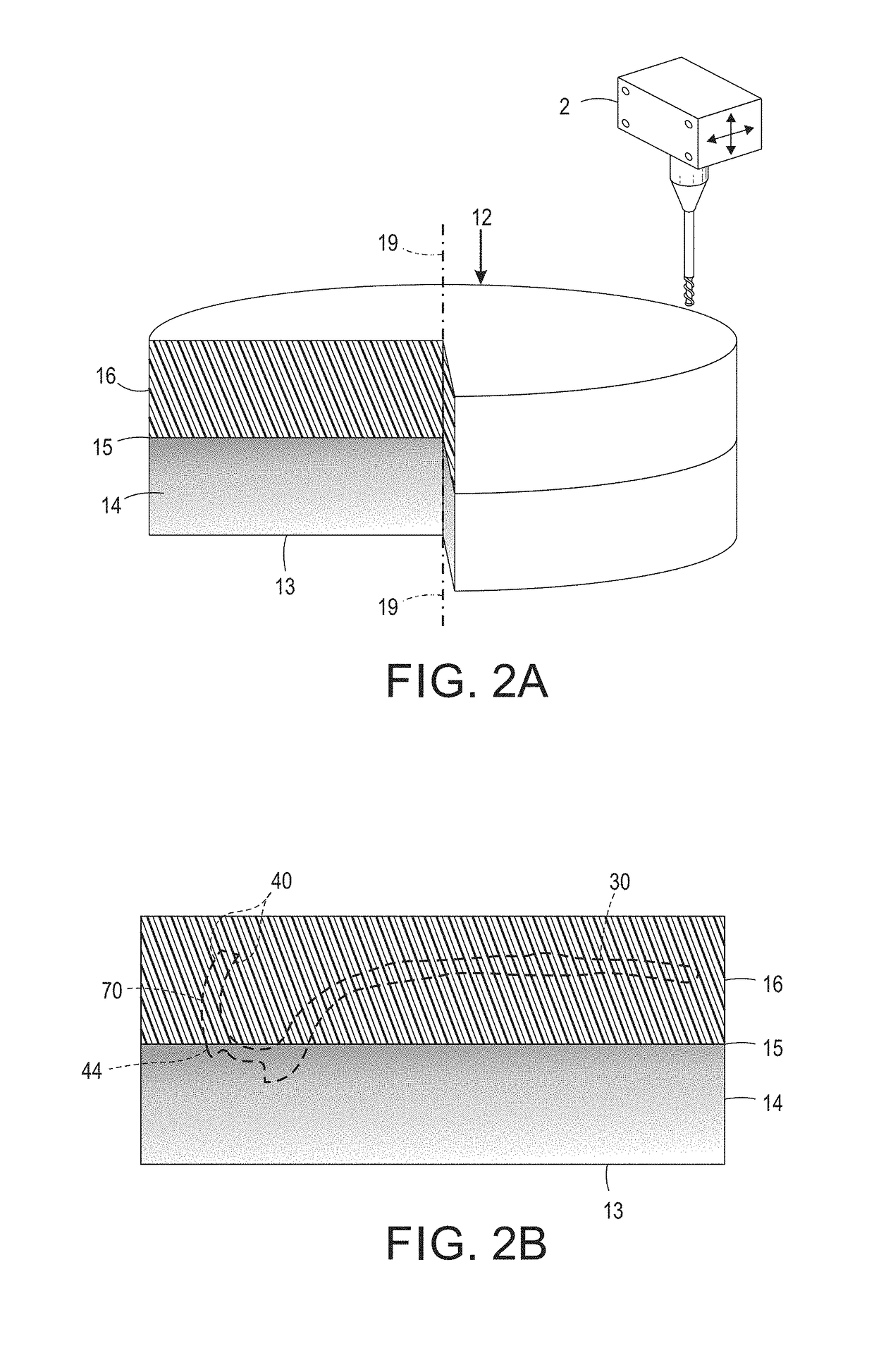

ActiveUS20180042705A1Efficient and accurateImprove fitArtificial teeth3D printingDenturesDenture base

A method of fabricating a denture, comprising milling a preliminary try-in denture from denture material comprising a layer of denture base material contiguous with a layer of denture tooth material. Denture base material is removed from the block to form a first part of the, labial, buccal, gingival, and flange regions of the denture base to form a preliminary denture. A preliminary mold is created from this preliminary denture. The preliminary denture is then further modified with deformable waxes in gingival and anterior tooth recesses to form a preliminary try-in denture, which is fitted to a patient and adjusted to optimal dimensions. The adjusted try-in denture is then reproduced by further molding methods, producing the final denture.

Owner:GLOBAL DENTAL SCI

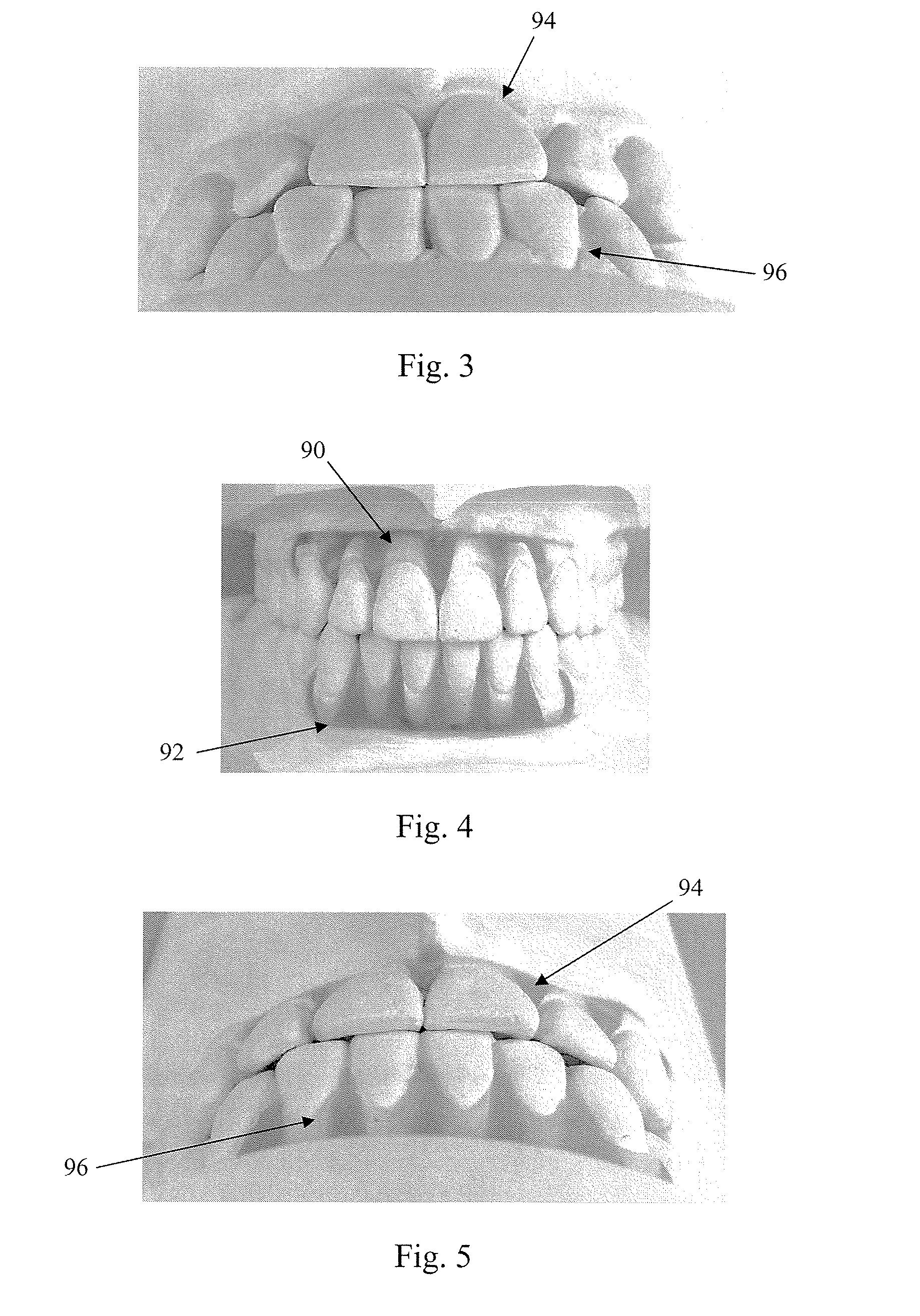

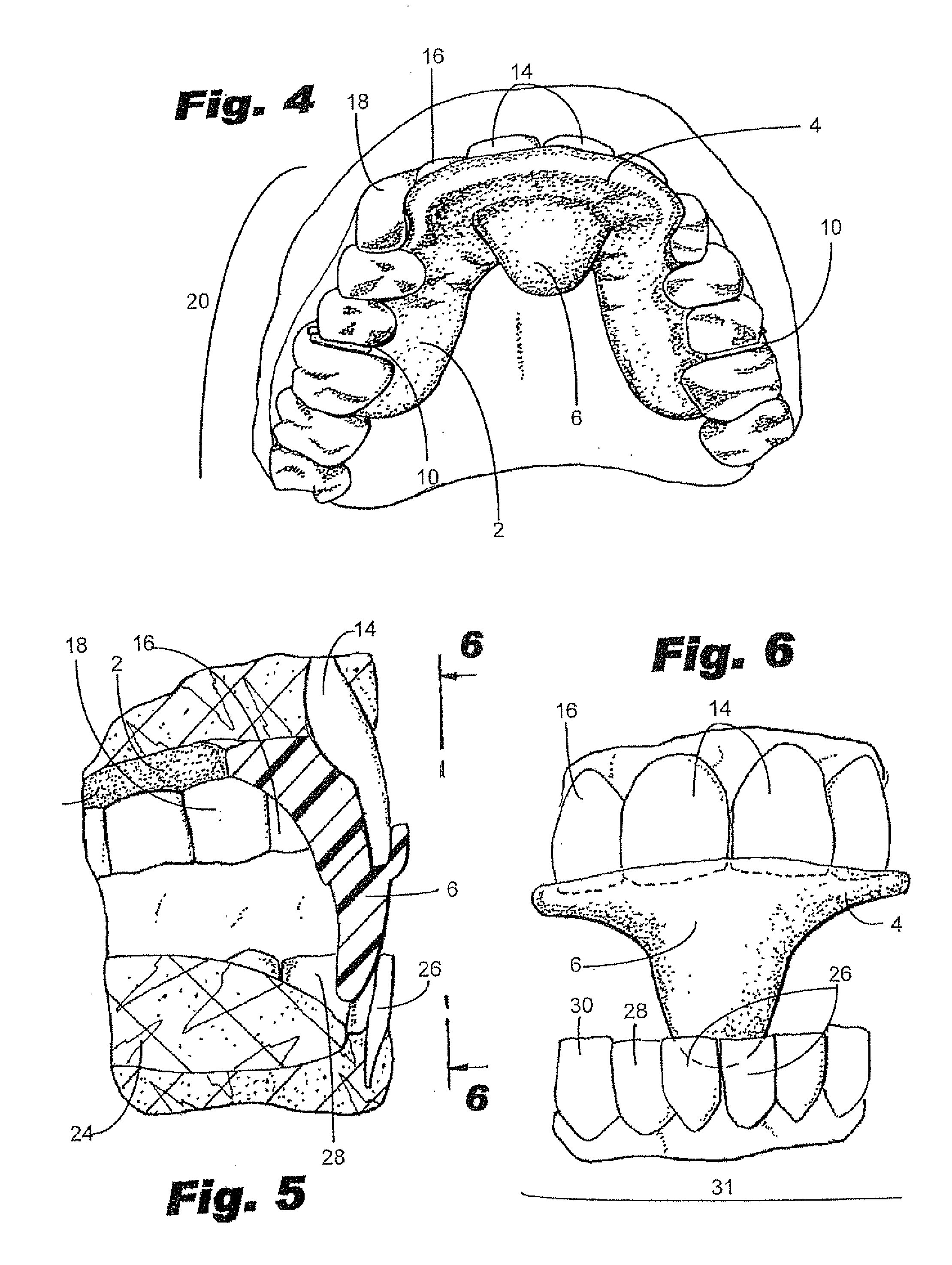

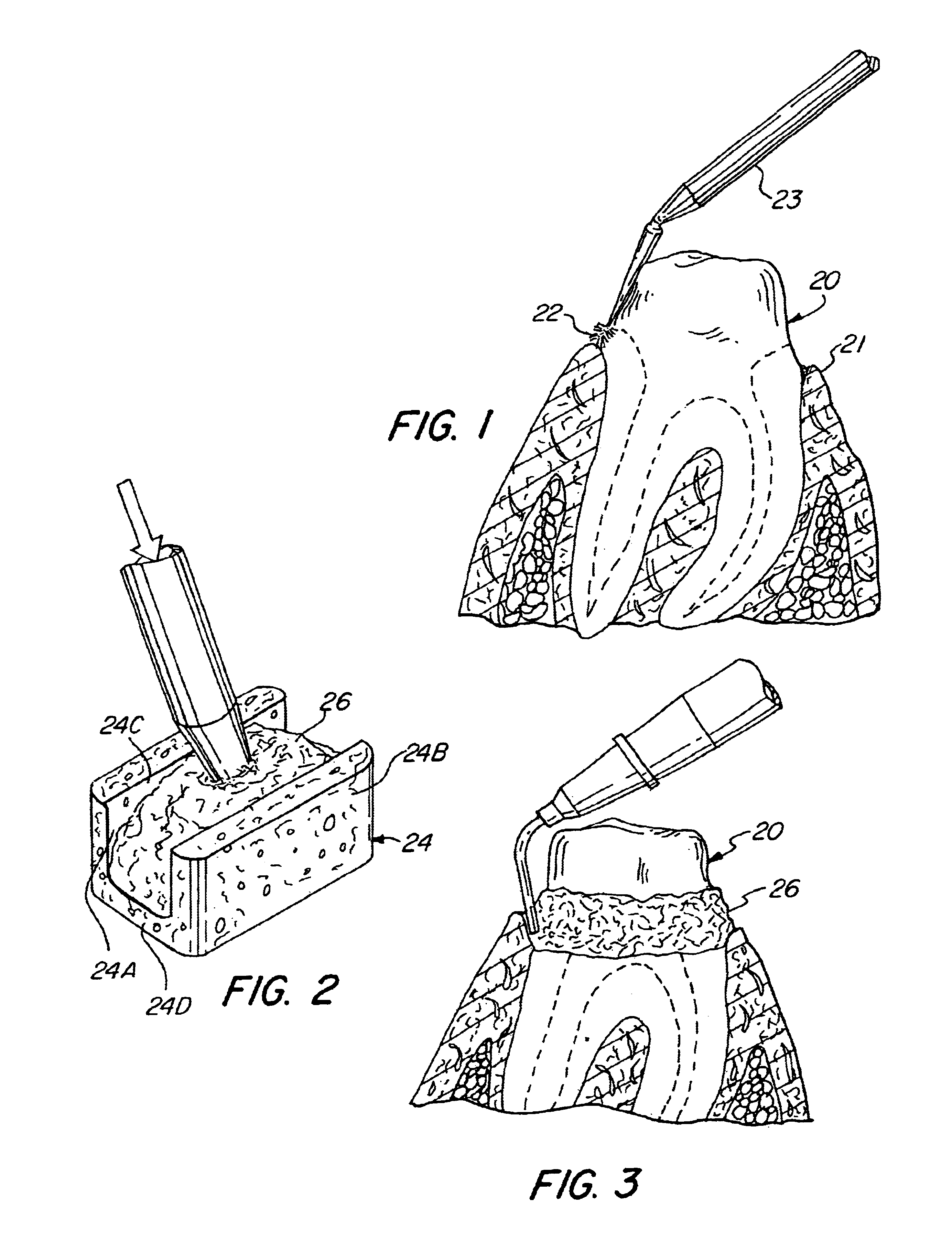

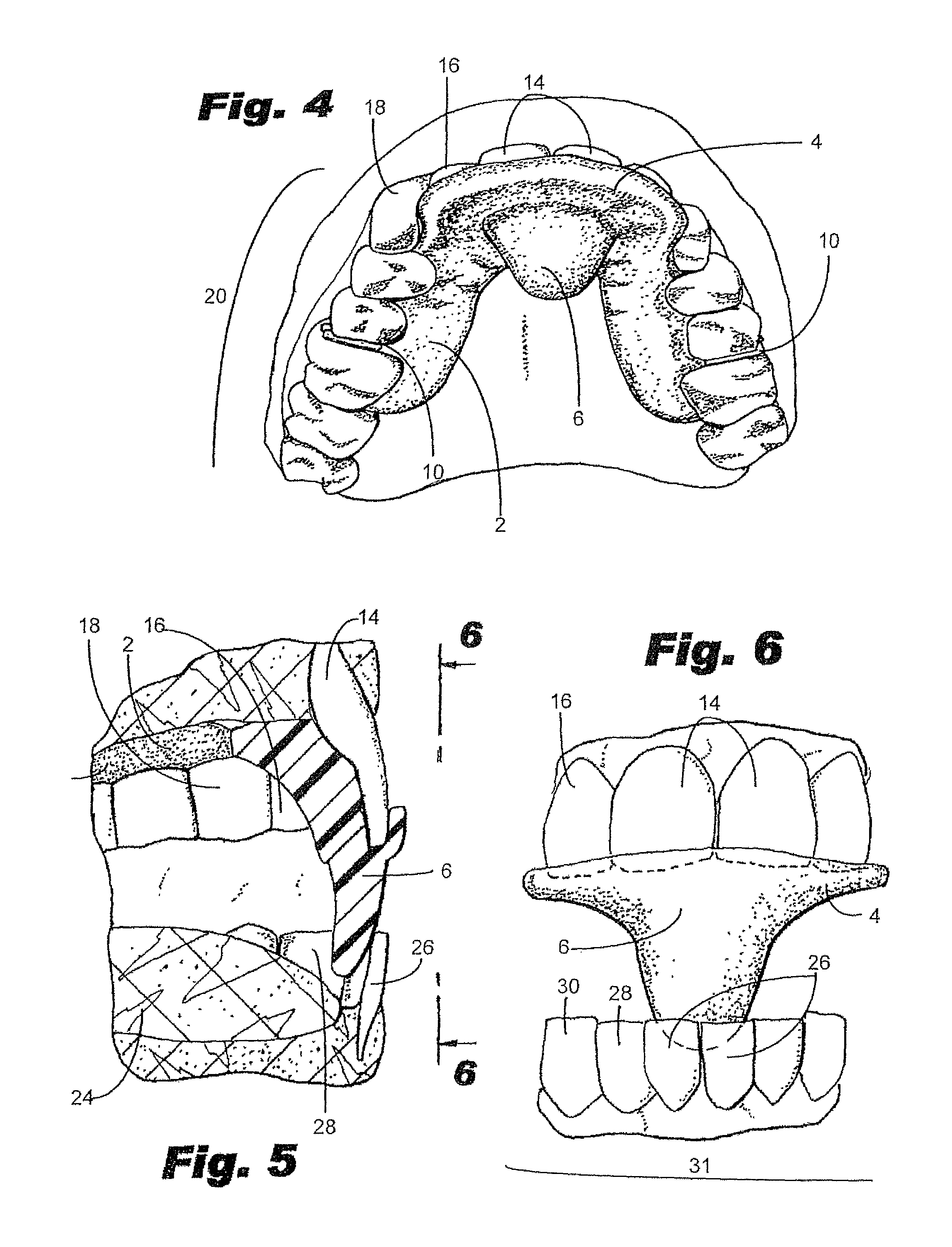

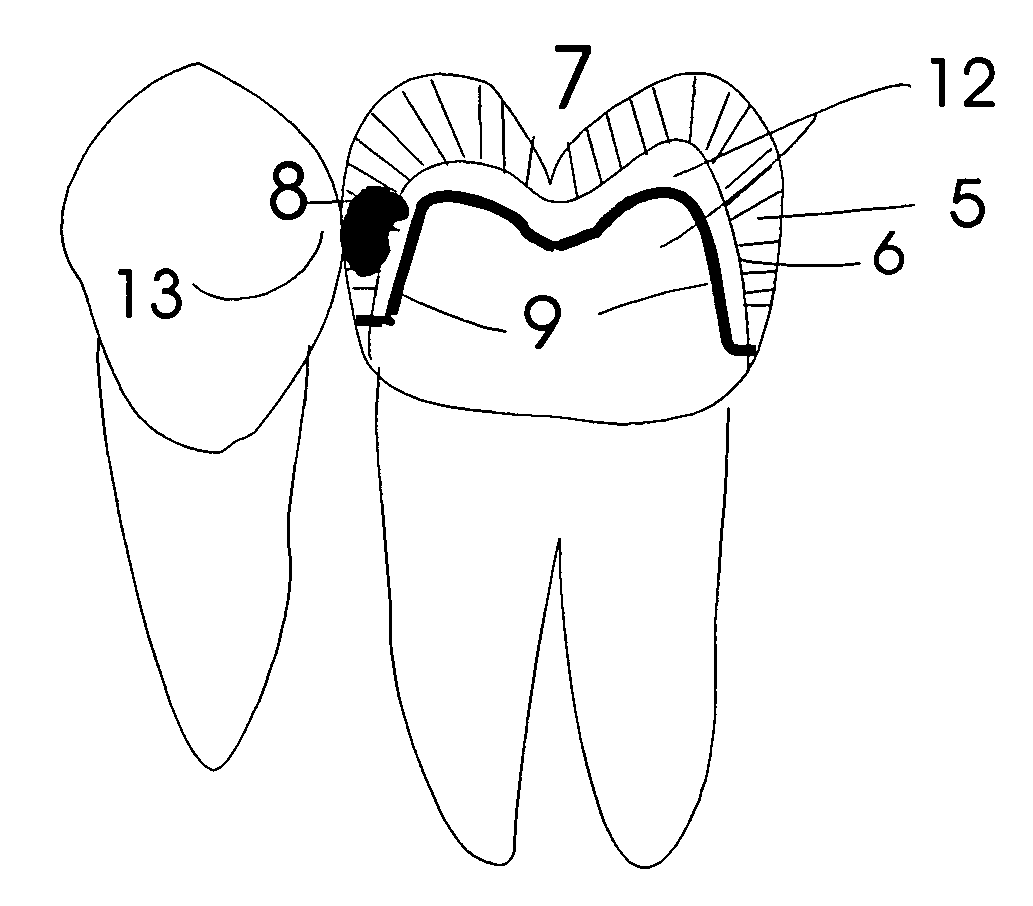

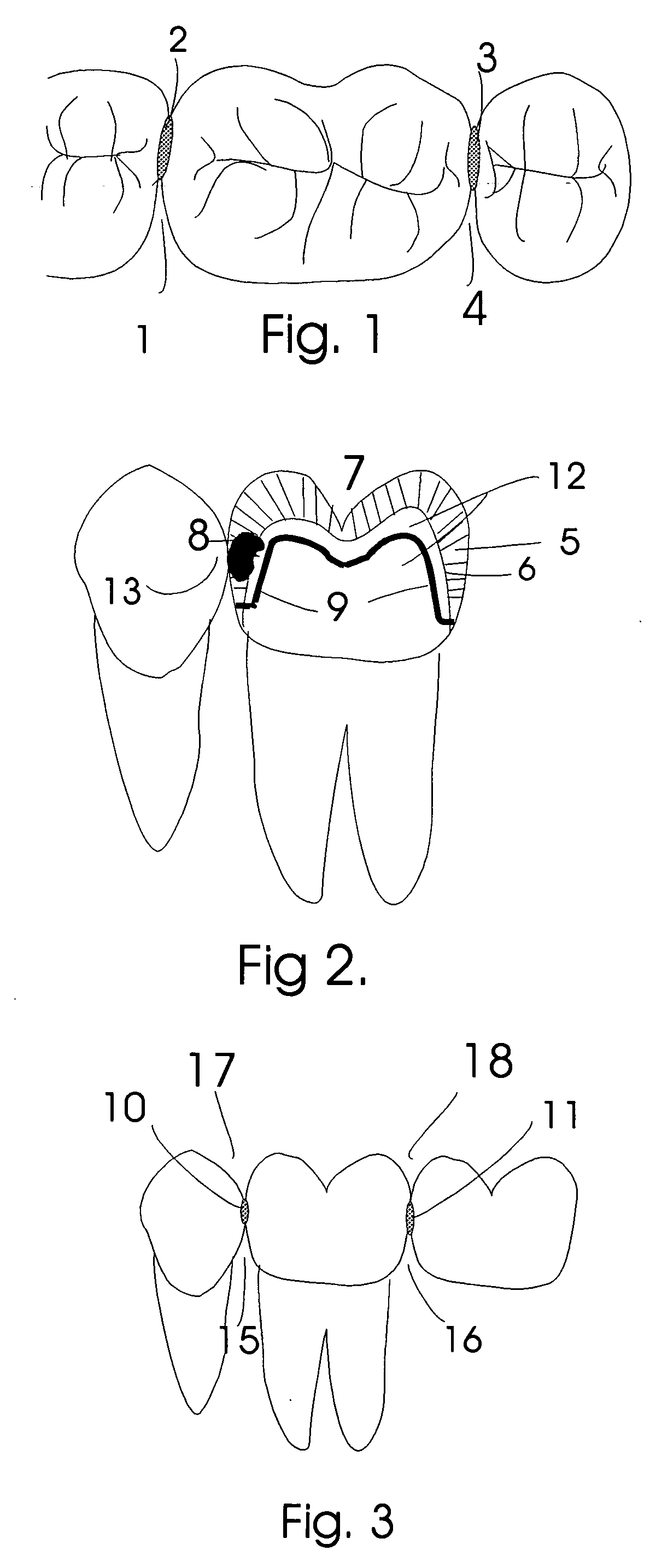

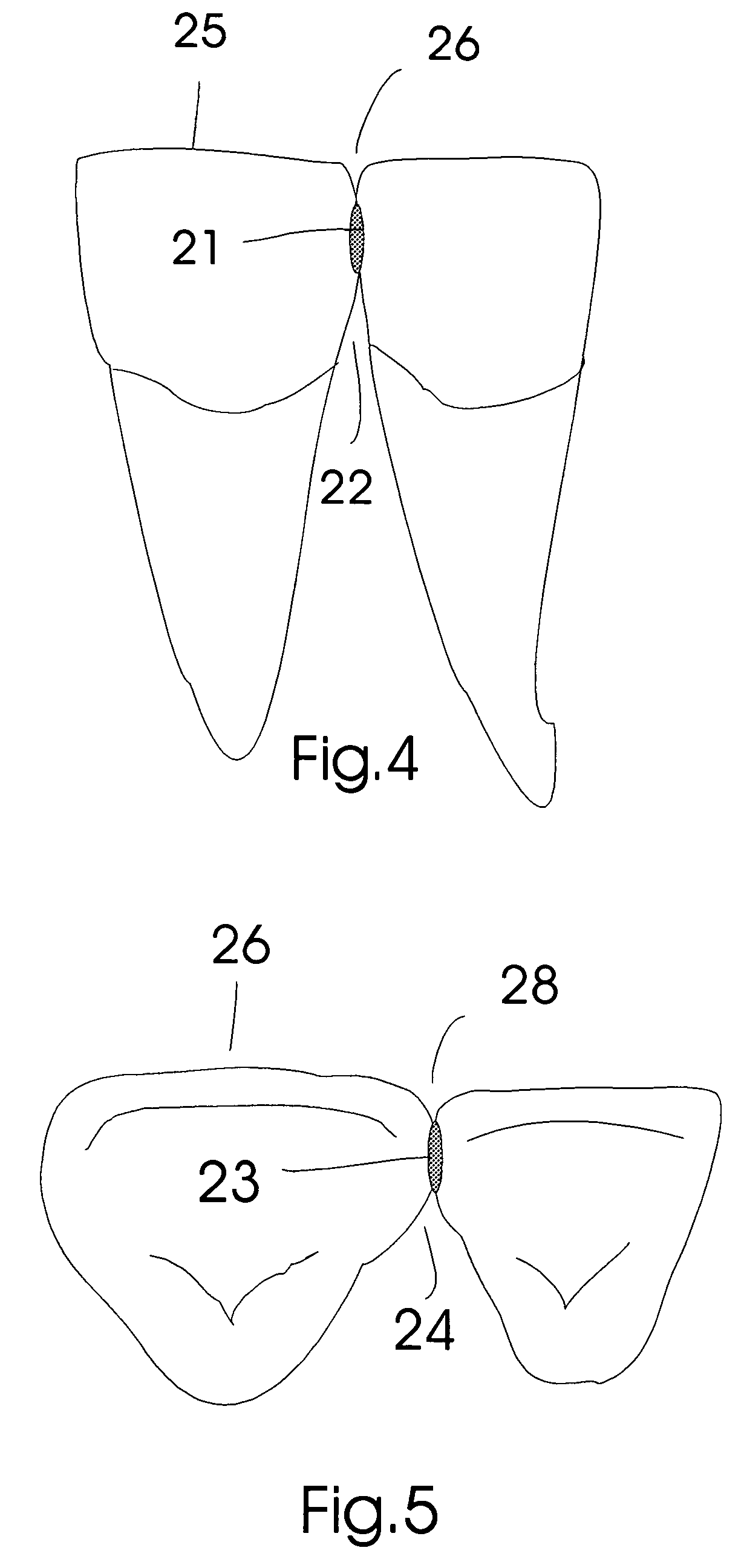

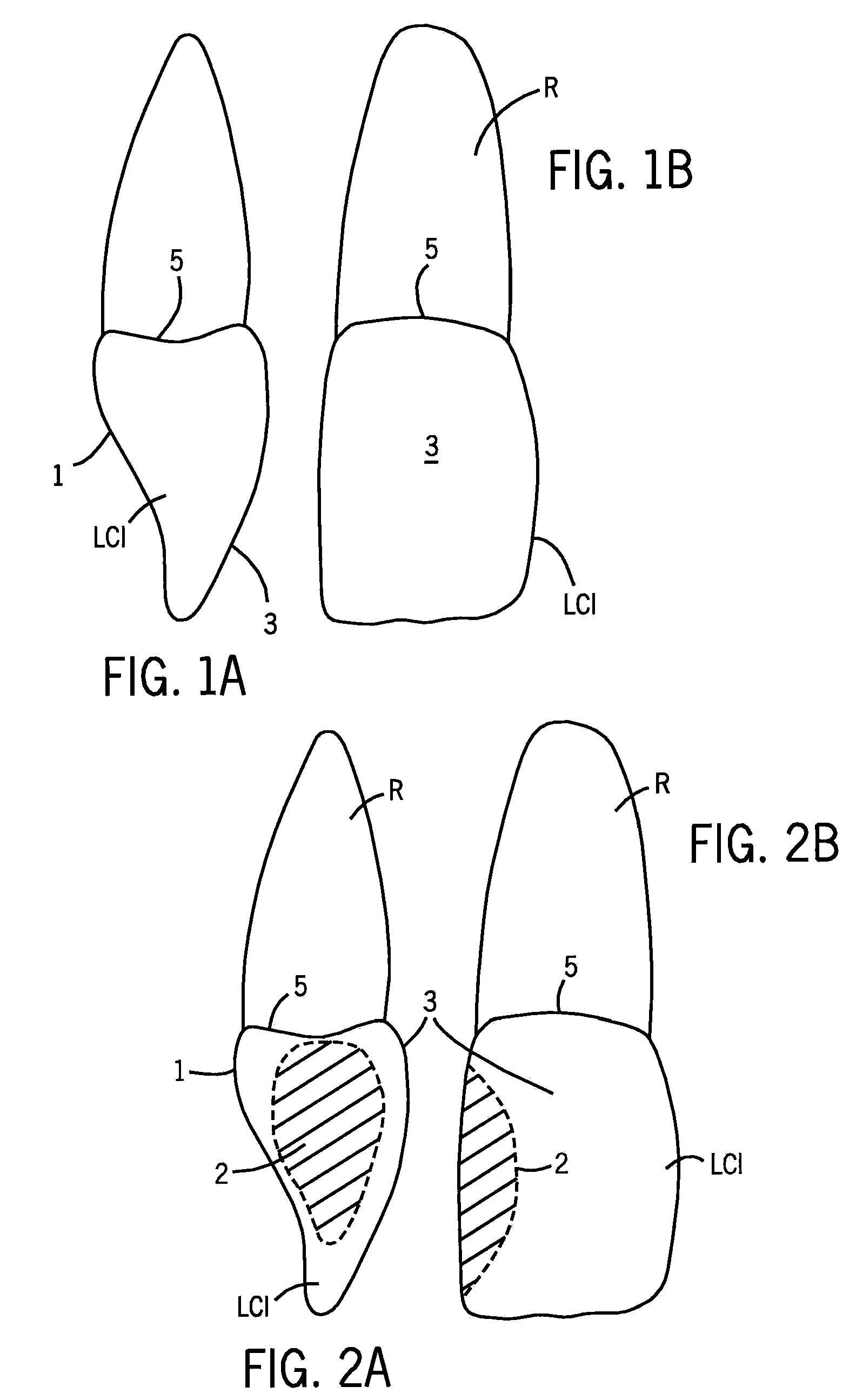

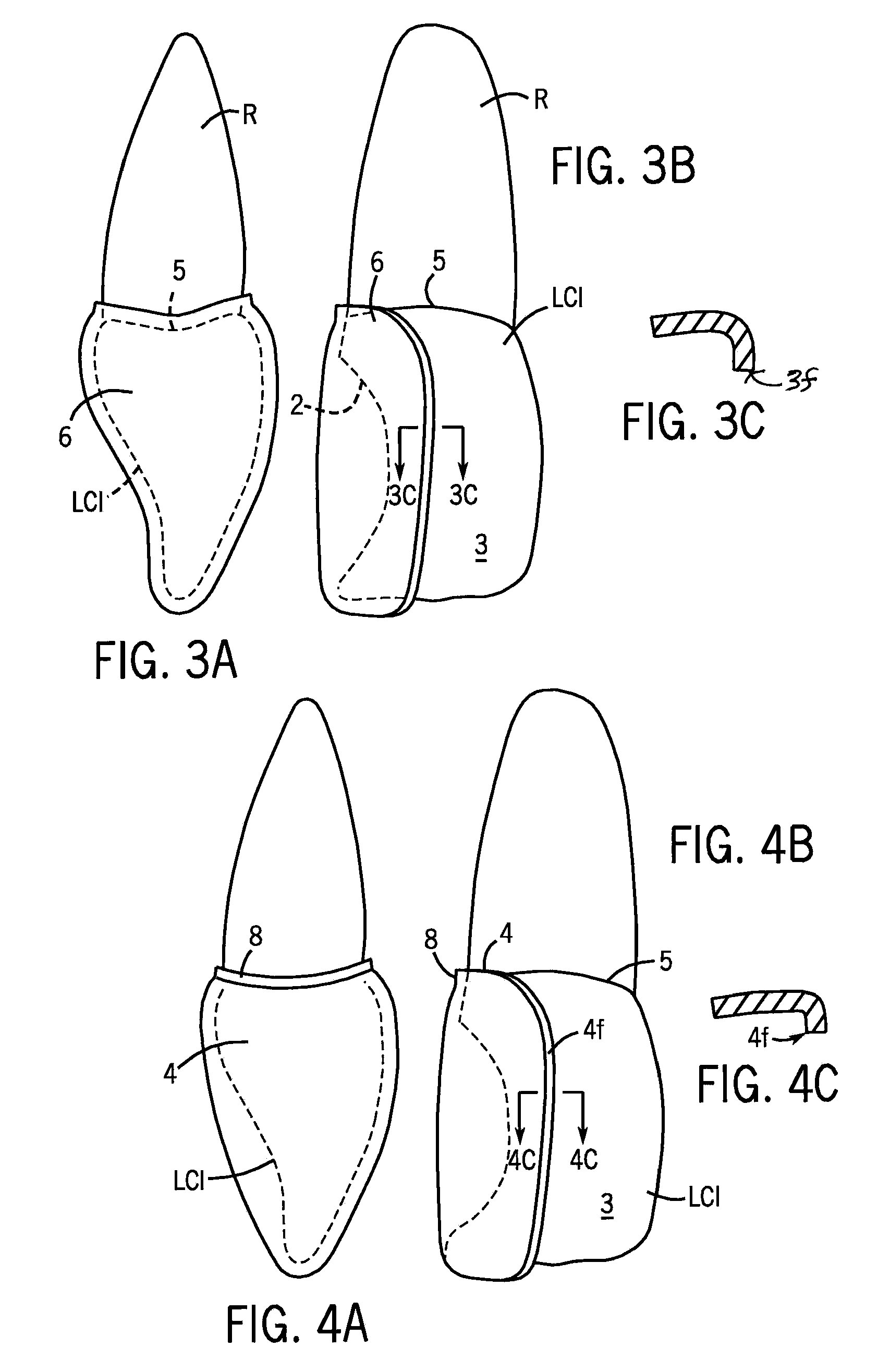

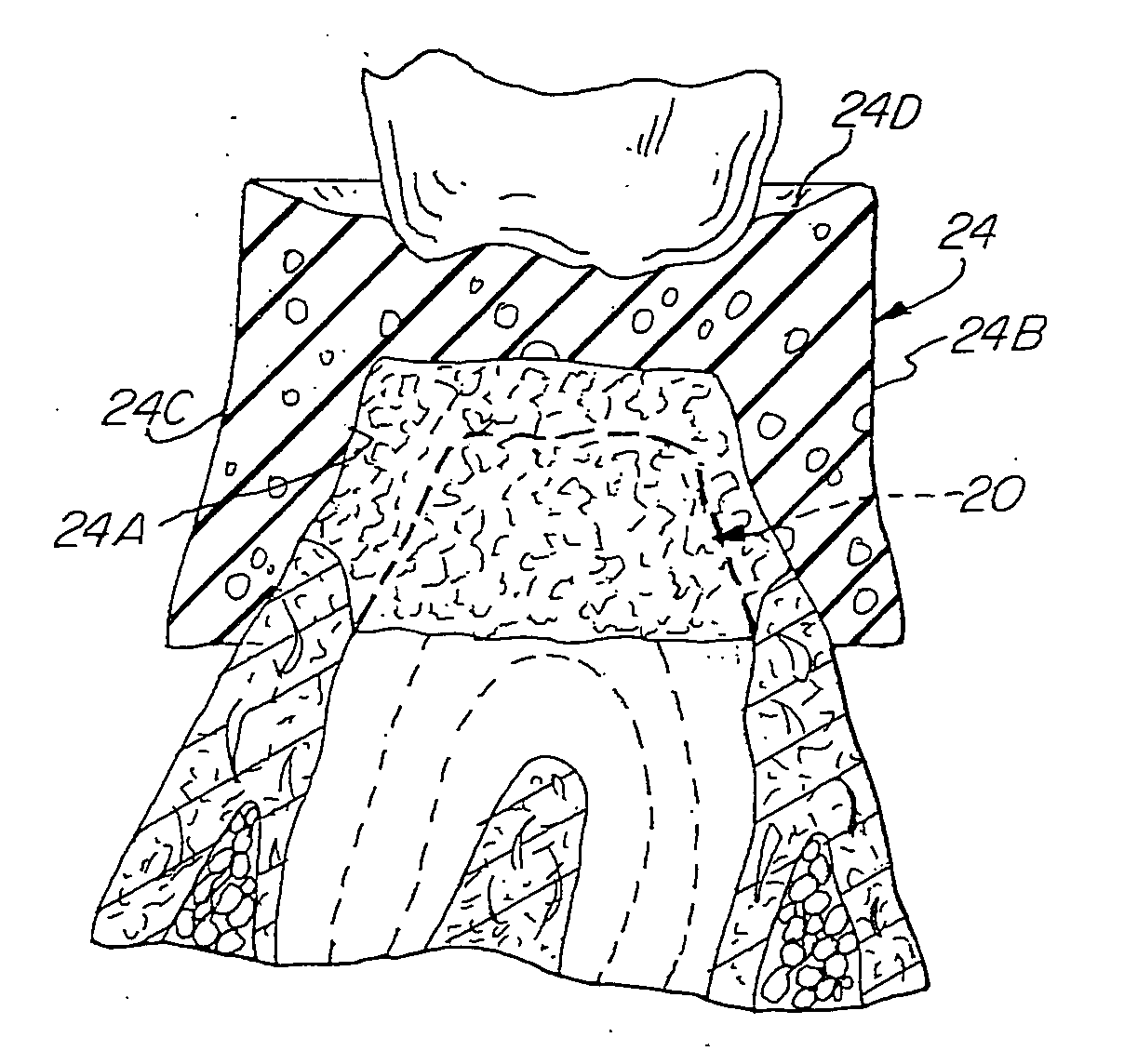

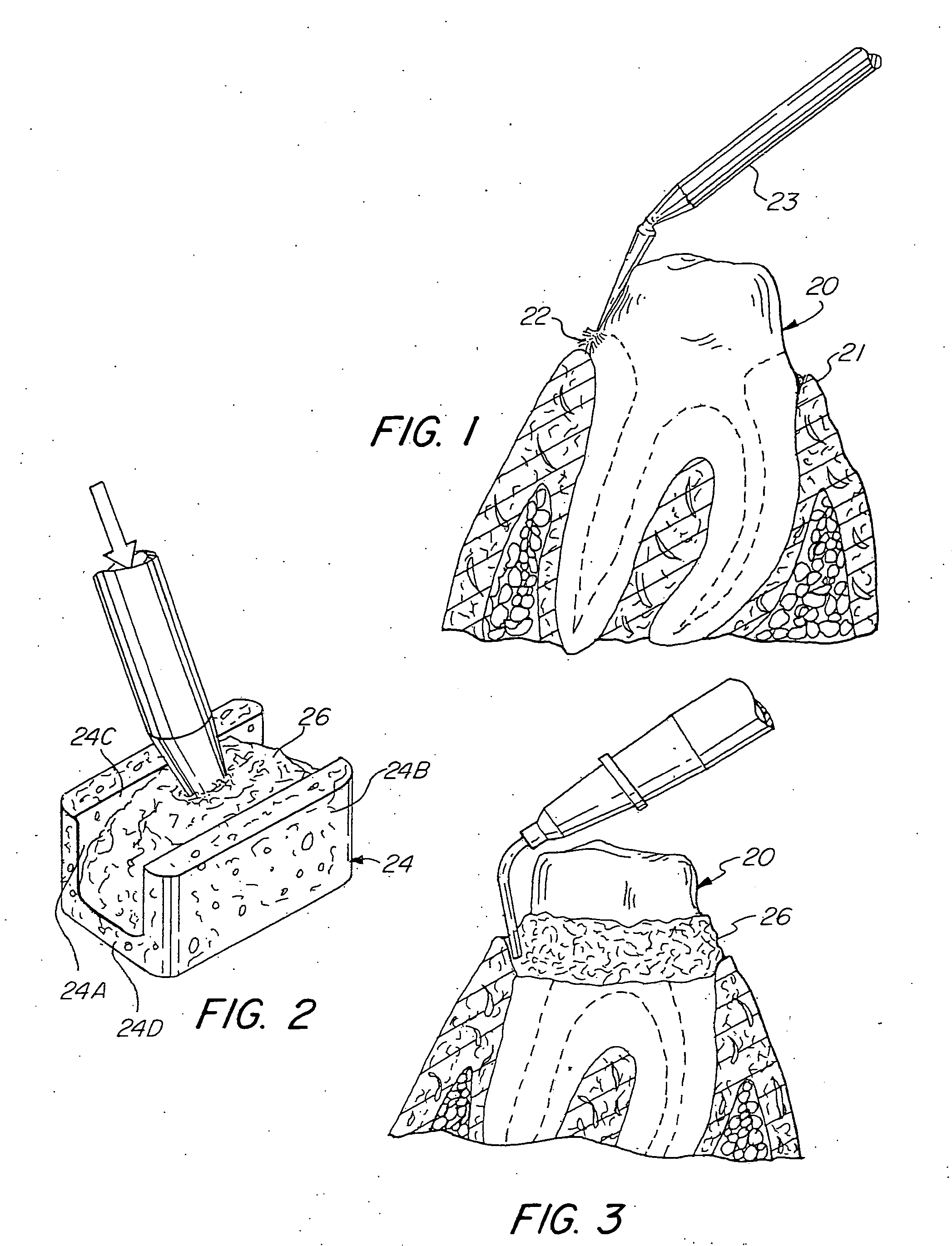

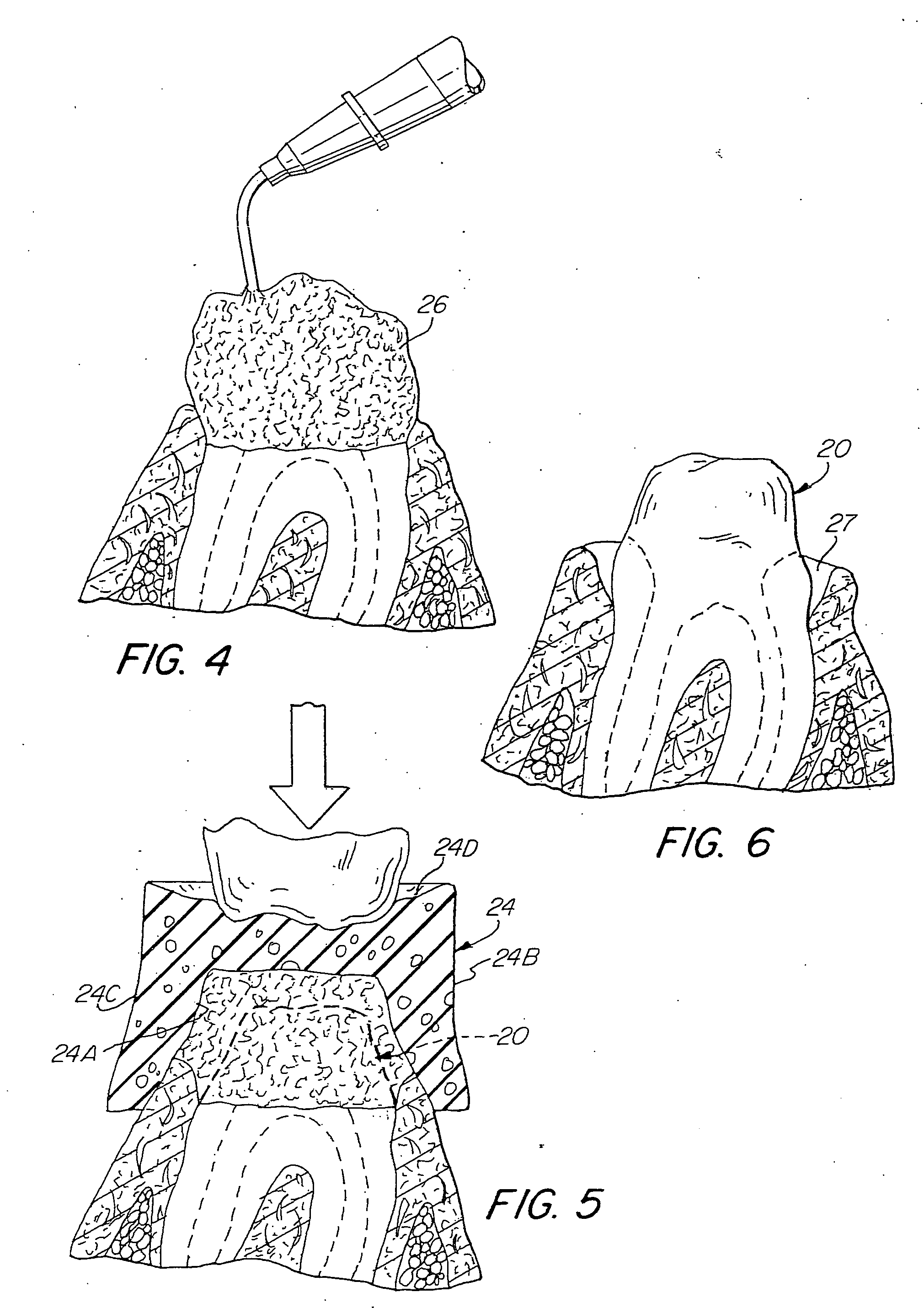

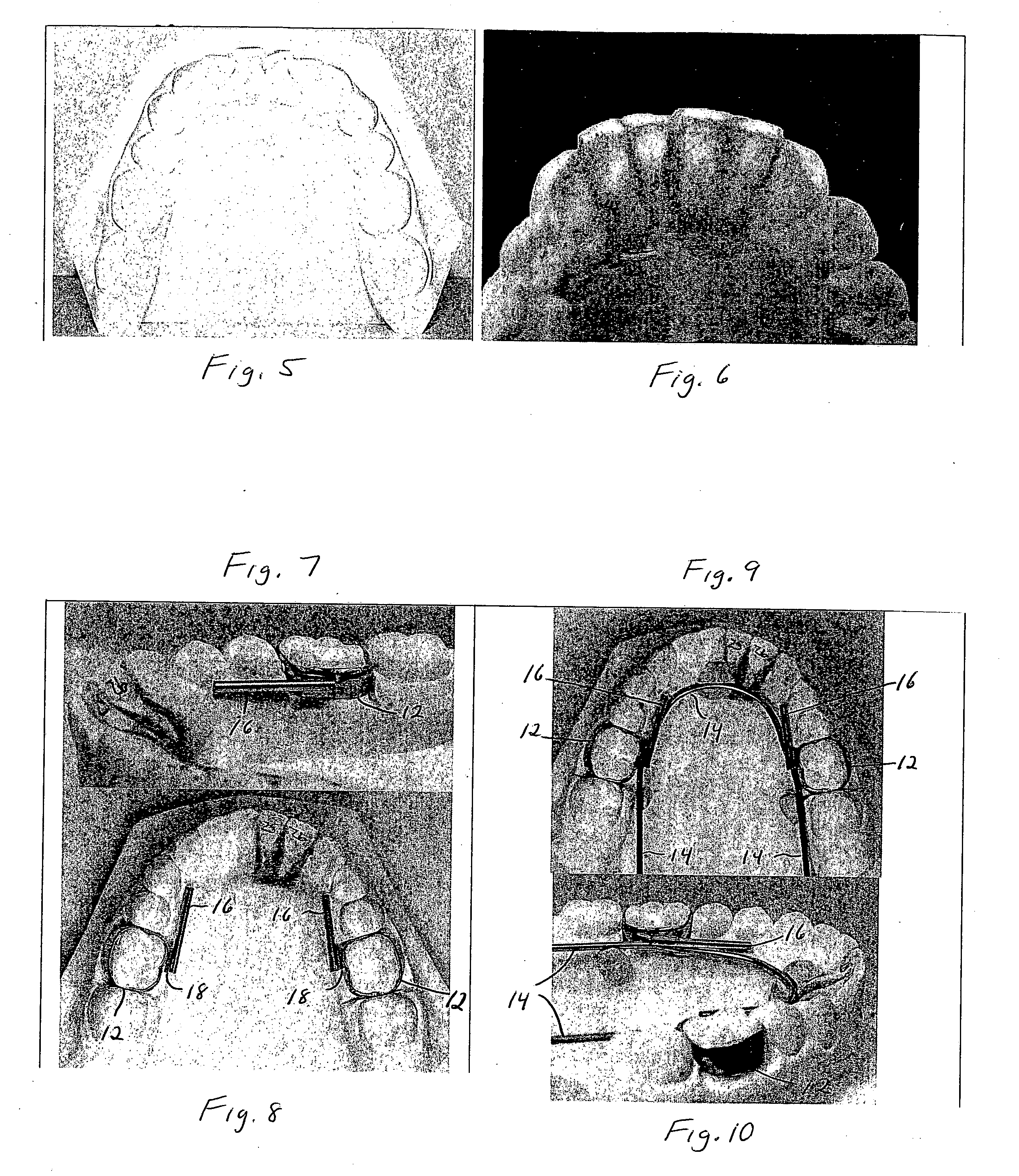

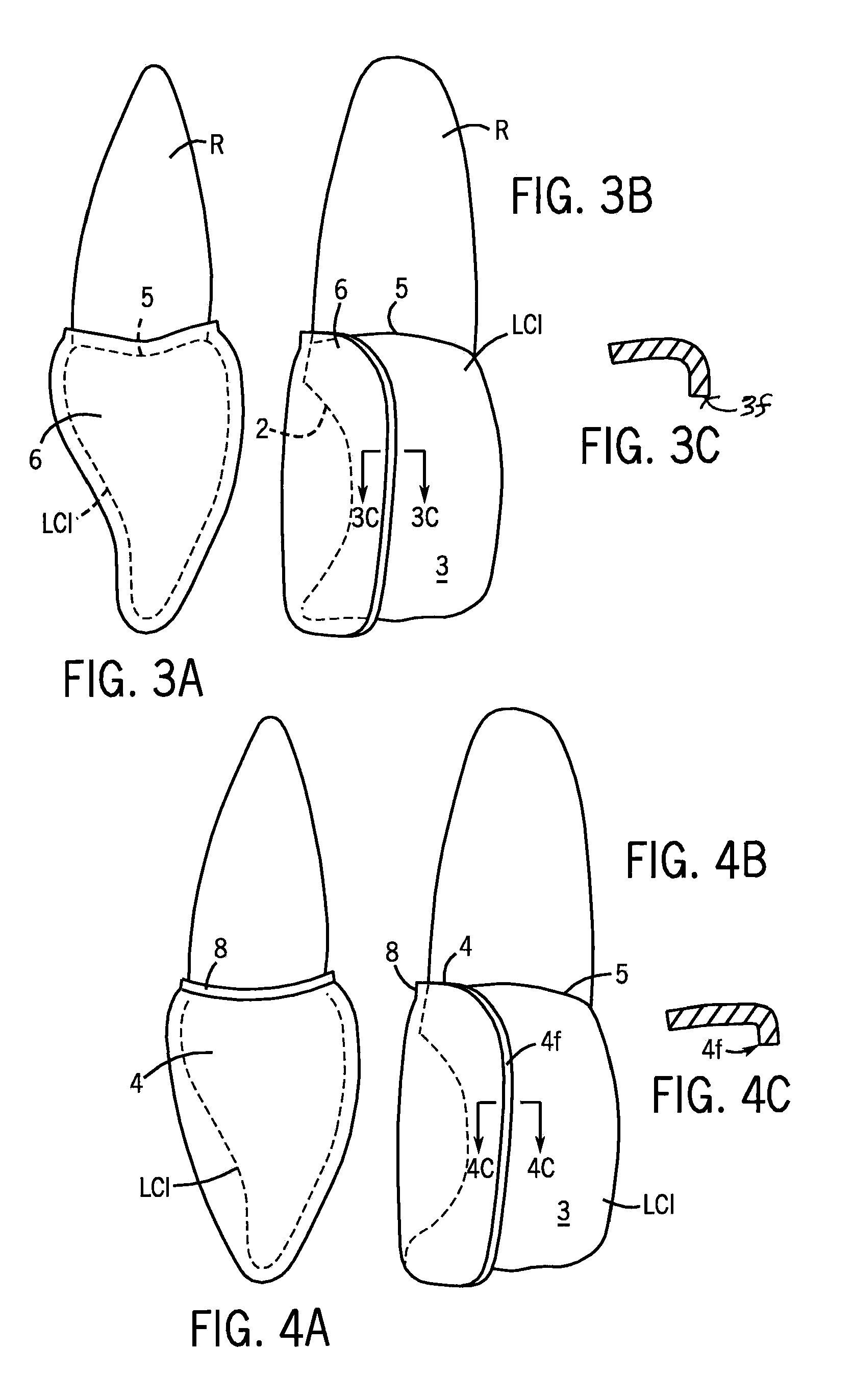

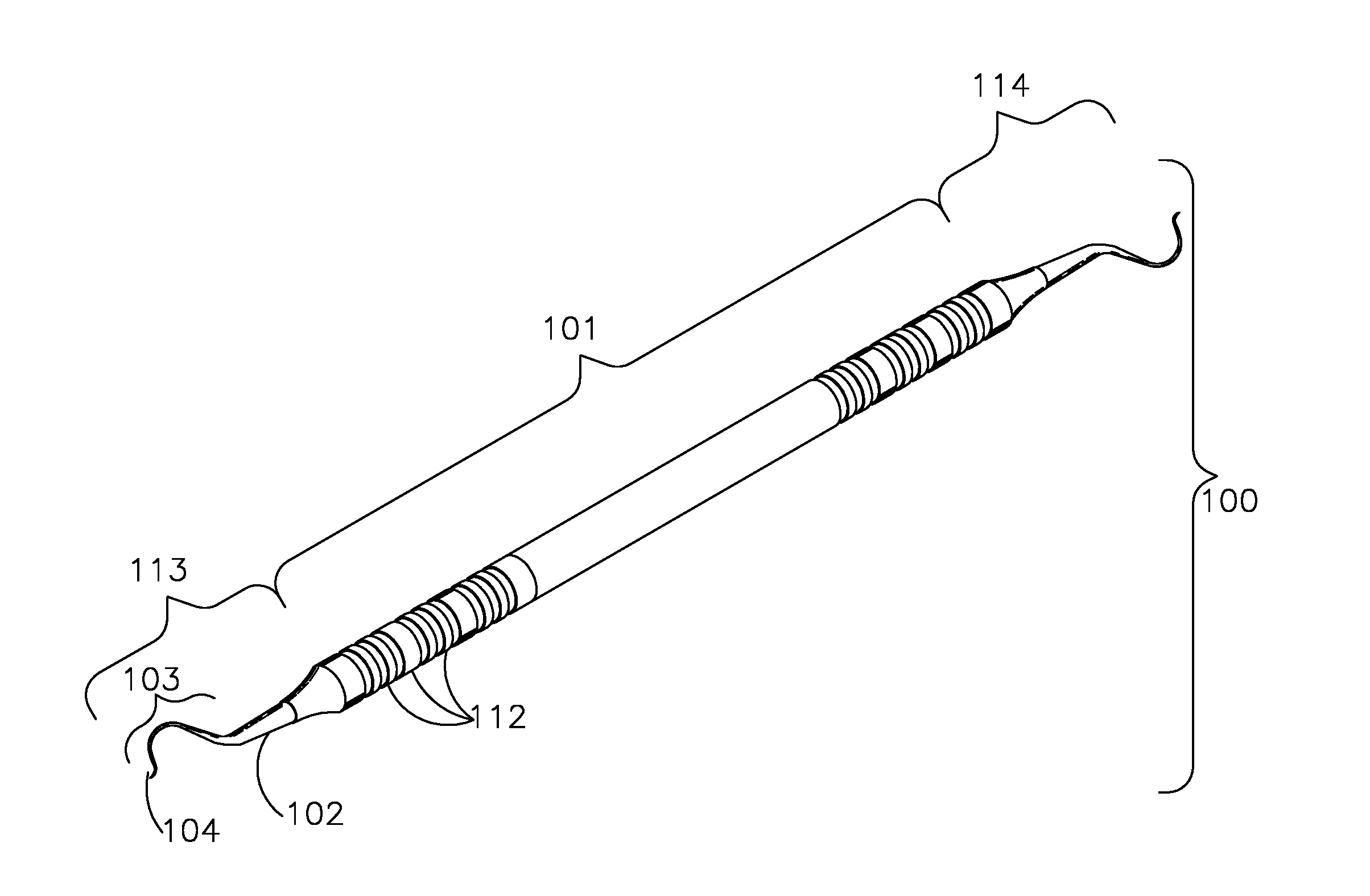

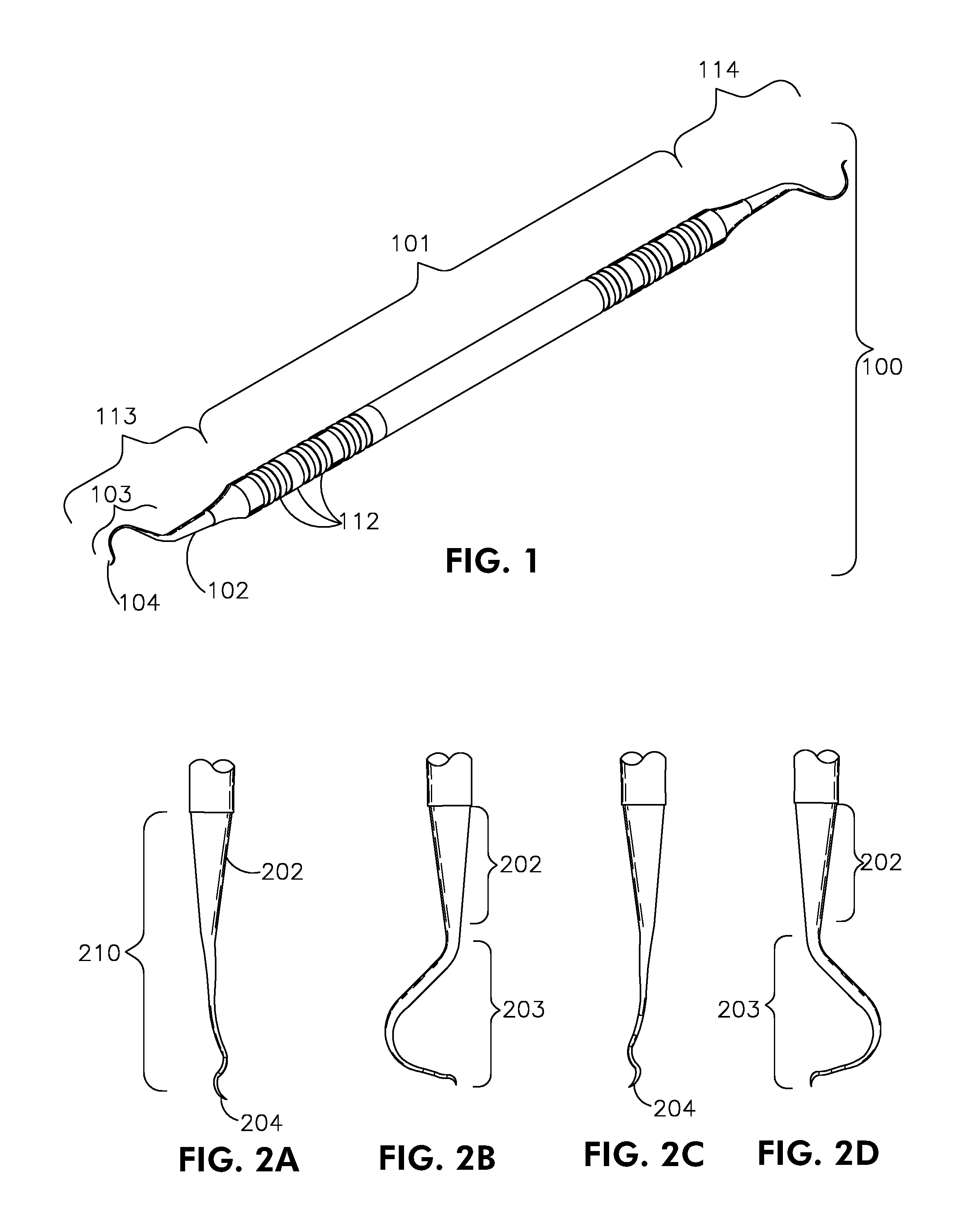

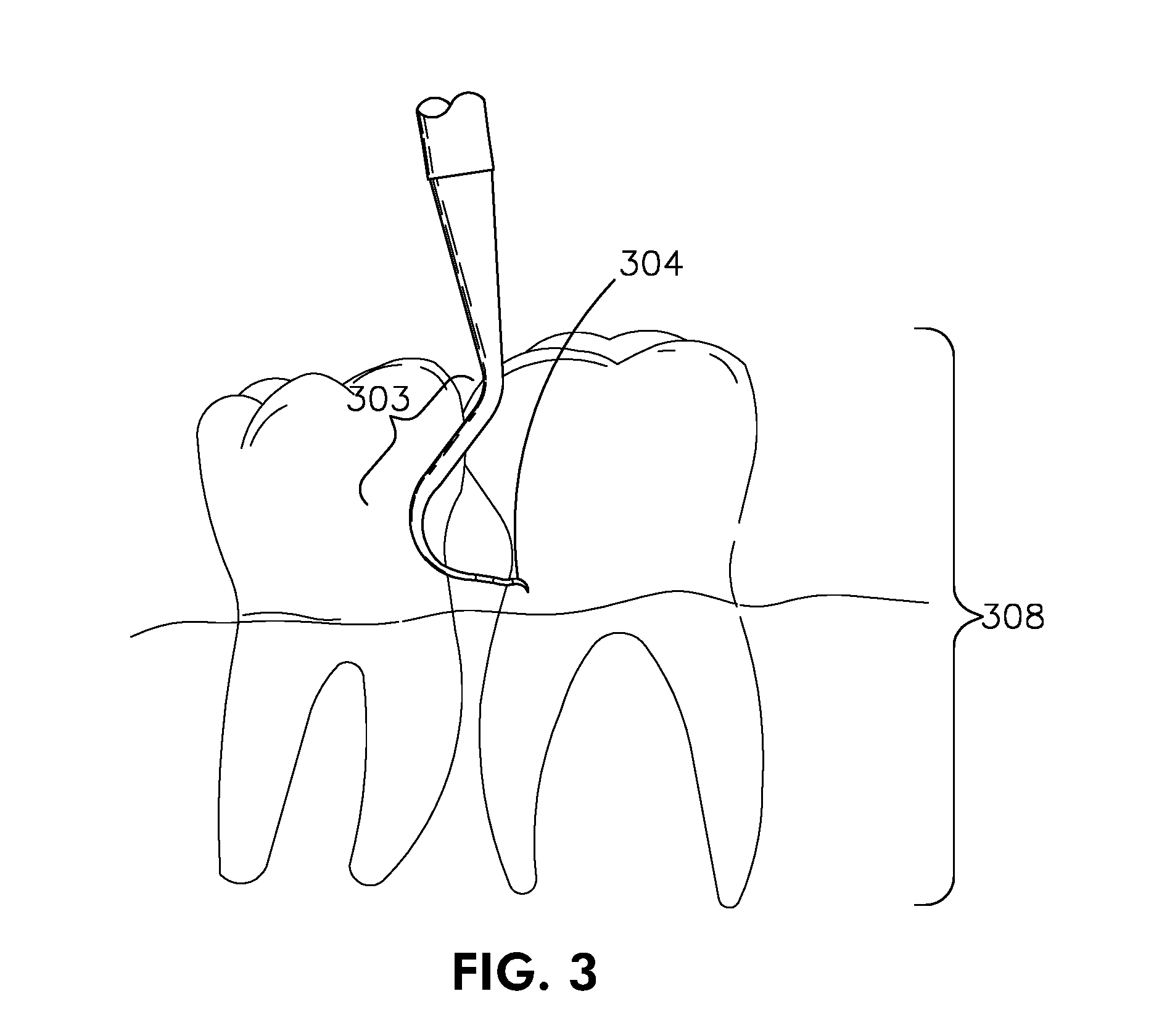

Dental Matrix Devices Specific To Anterior Teeth, and Injection Molded Filling Techniques and Devices

ActiveUS20090191505A1Easy to handleEasy to placeAmalgam presses/mixersDental aidsMold fillingResin-Based Composite

The present invention relates to methods for the restoration of a decayed portion of an anterior tooth or re-restoration of a previously filled anterior tooth, and to dental matrices and composite resin dispensers that may be used in the methods for the restoration of a decayed portion of an anterior tooth

Owner:CLARK DAVID J

Invisible appliance

PendingCN110063801AShort treatment cycleComfortable to wearOthrodonticsClass iii malocclusionGingival margin

The invention provides an invisible appliance which comprises a single-jaw appliance and / or a double-jaw appliance. The single-jaw appliance comprises a maxillary tooth socket and a functional auxiliary part, and the double-jaw appliance comprises a double-jaw tooth socket and a functional auxiliary part. The double-jaw tooth socket comprises an upper jaw tooth socket, a lower jaw tooth socket anda connecting occlusal plate, the functional auxiliary part is selected from at least one of a palatal side plate, a lingual guide wing, an anterior tooth occlusion opening assembly and an extraoral traction assembly, and the anterior tooth occlusion opening assembly comprises a gingival margin bulge and a stress application pad; the extraoral traction assembly comprises an outer side tube and anextra-oral traction bow, and all parts are made of transparent or semi-transparent materials, so that the appliance is invisible. The appliance has a wide clinical application range, is suitable for malocclusion deformity of bone surface type II malocclusion and mild type III and can provide an efficient correction force system in the three-dimensional direction and especially greatly improve thecorrection efficiency in the vertical direction.

Owner:SICHUAN UNIV

Method and device for the retraction and hemostasis of tissue during crown and bridge procedures

InactiveUS20050260543A1Positive in operationEasy to operateImpression capsTeeth cappingGingival spaceSilica gel

Owner:CENTRIX

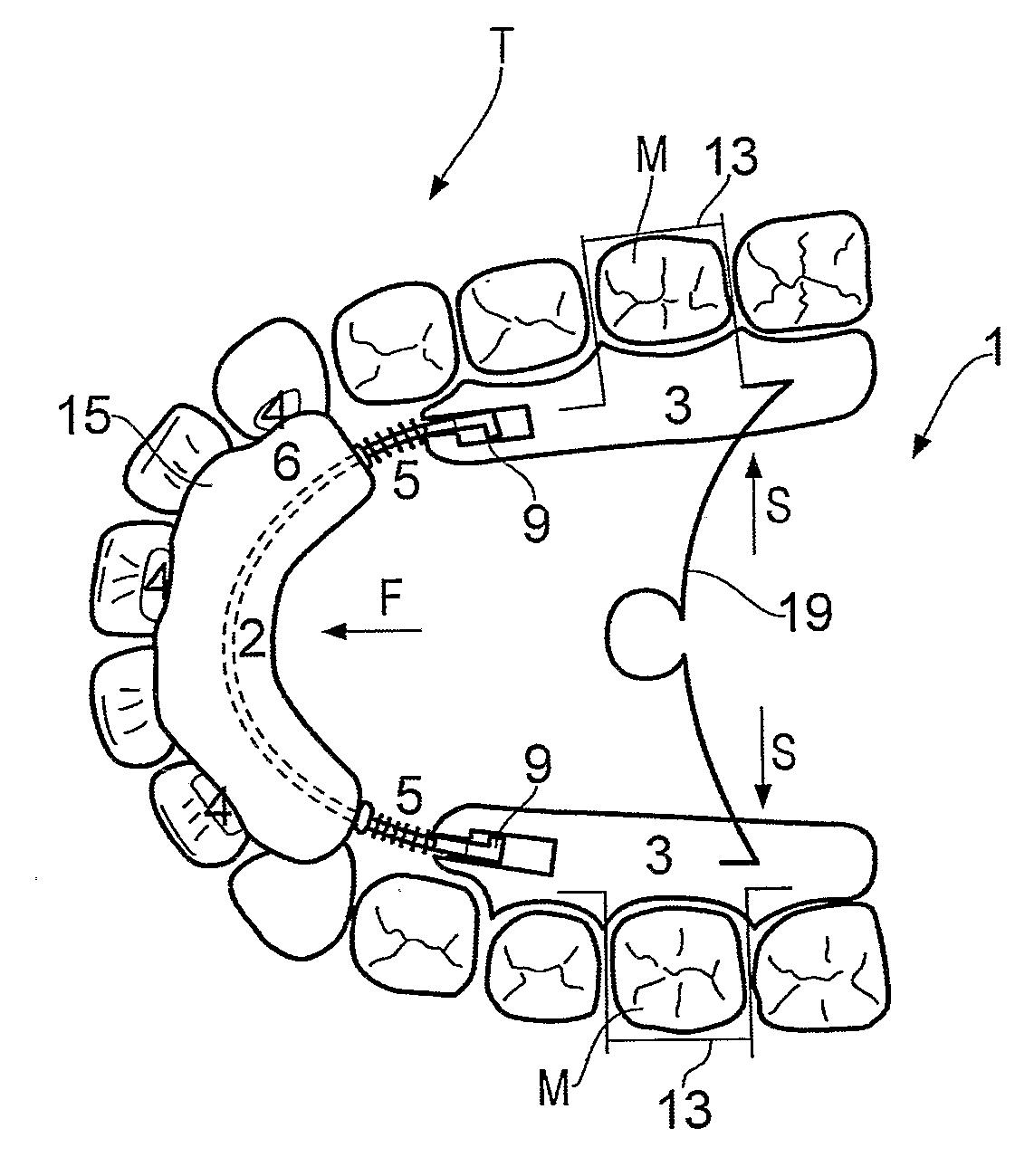

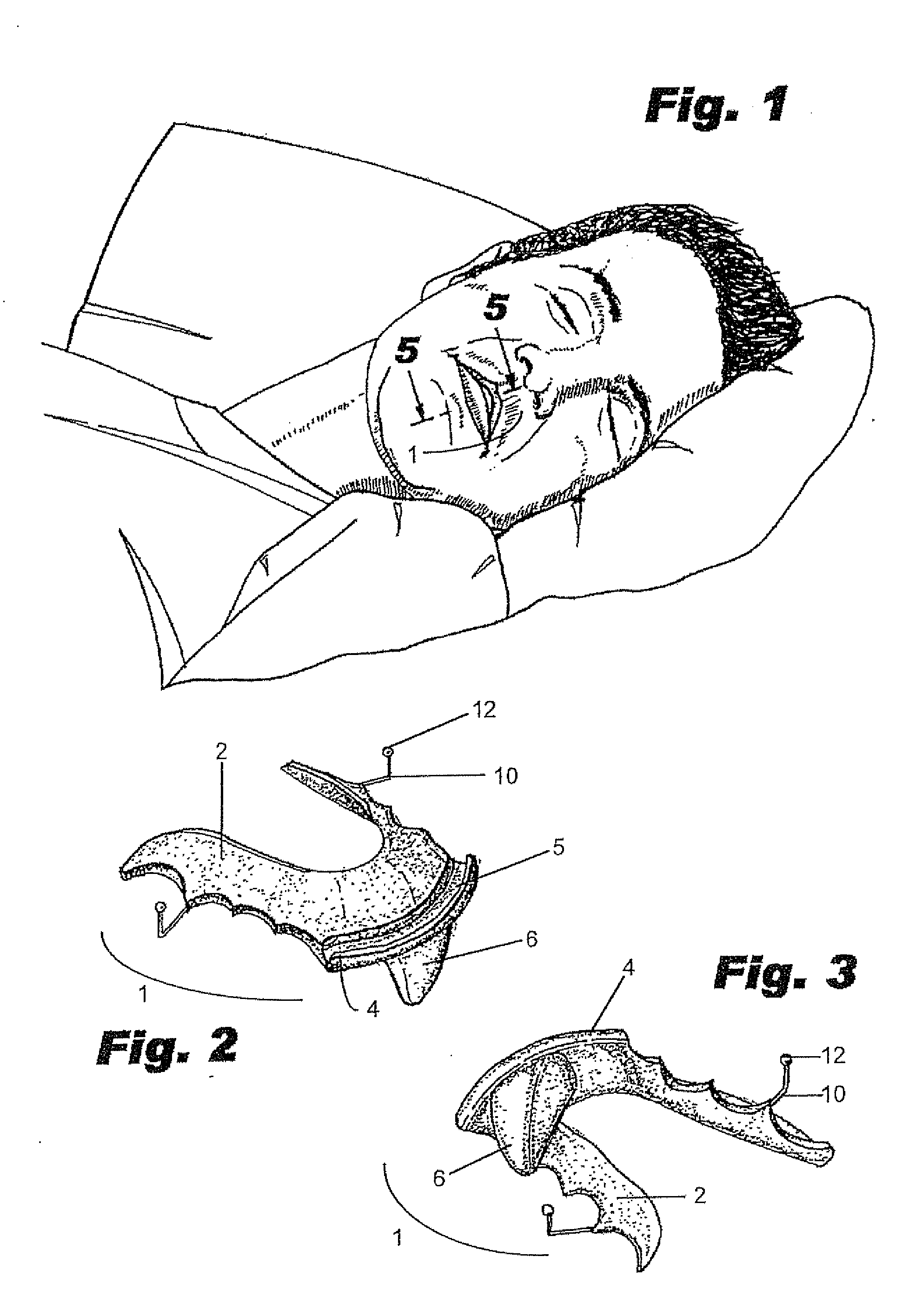

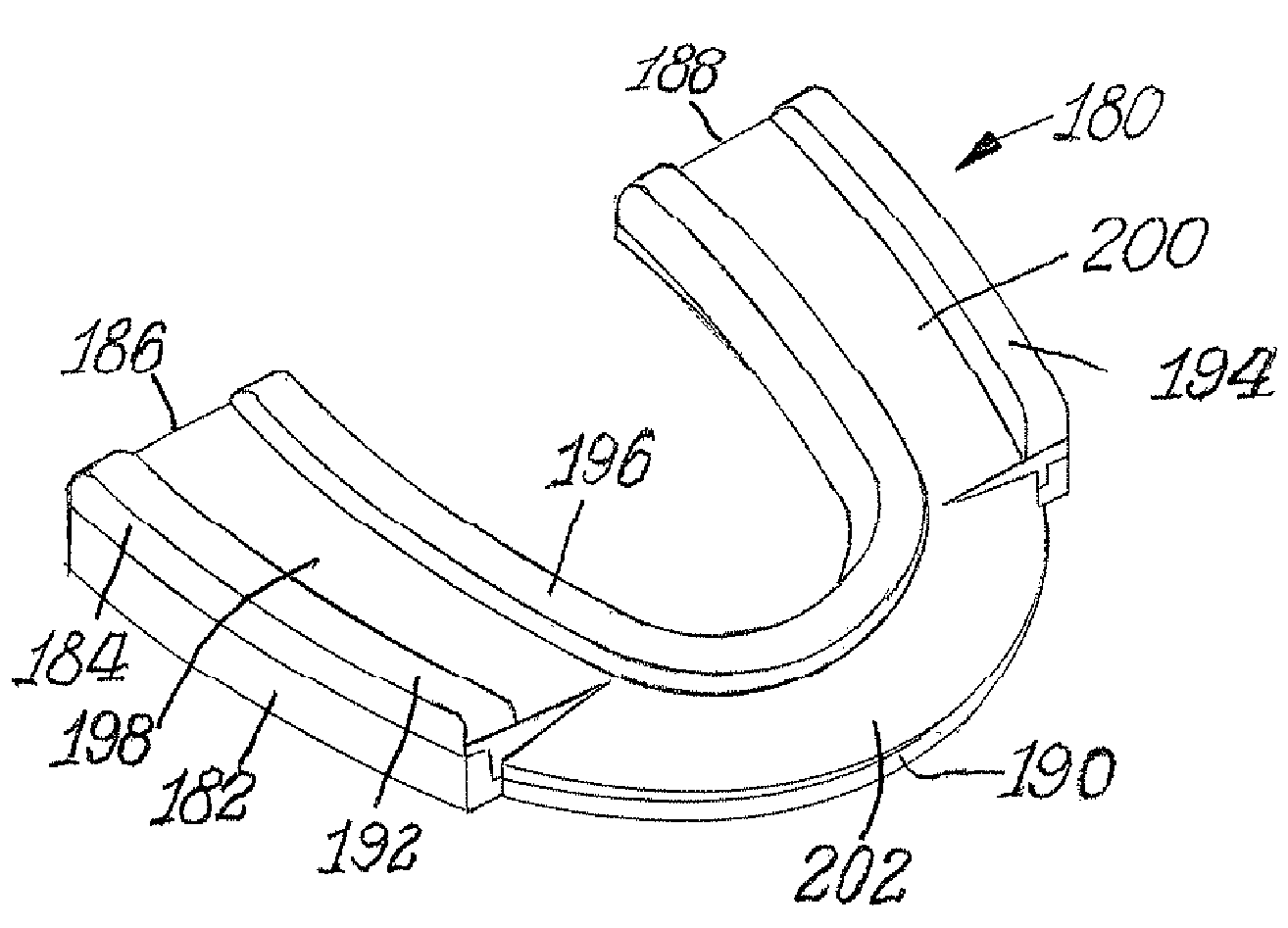

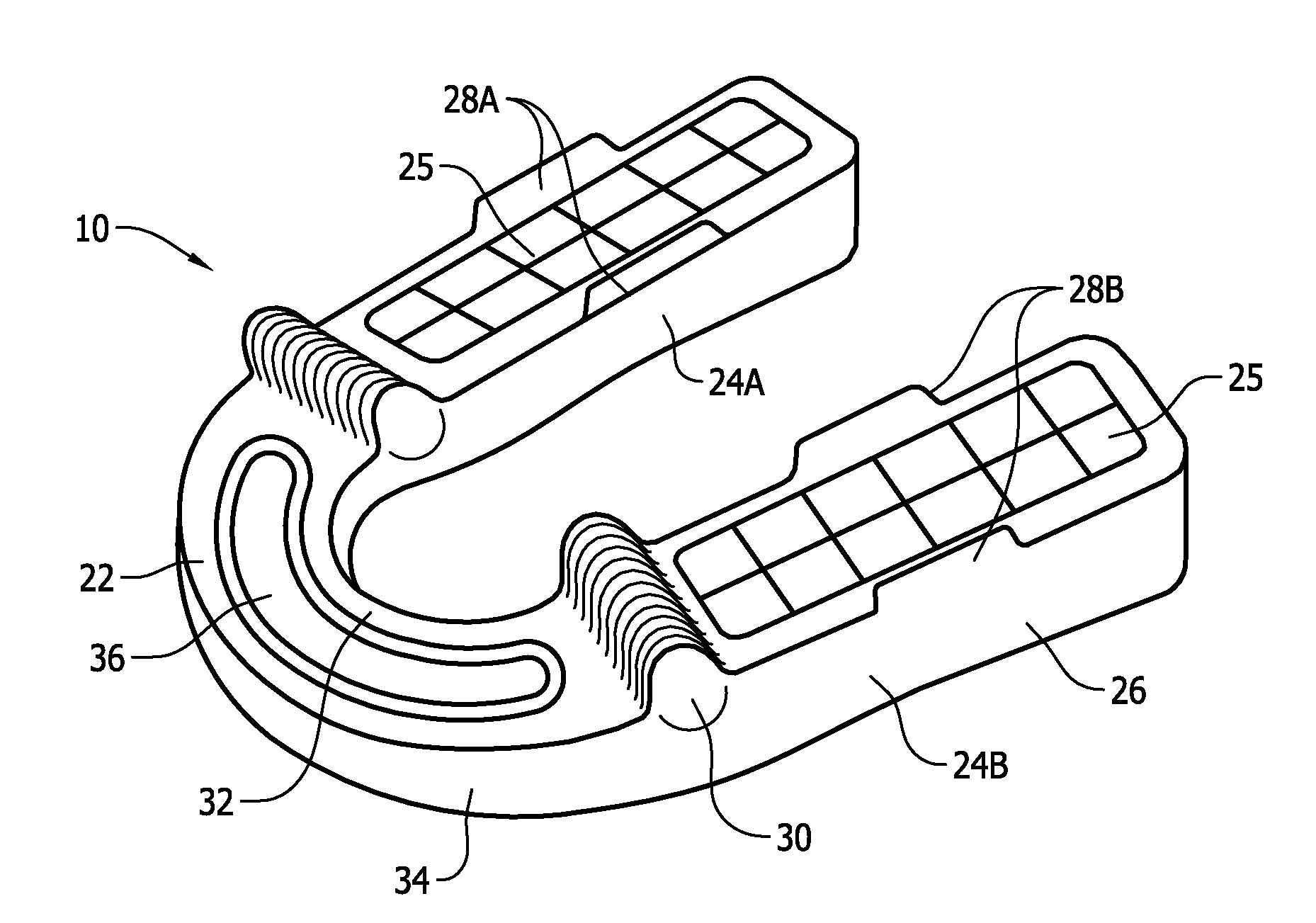

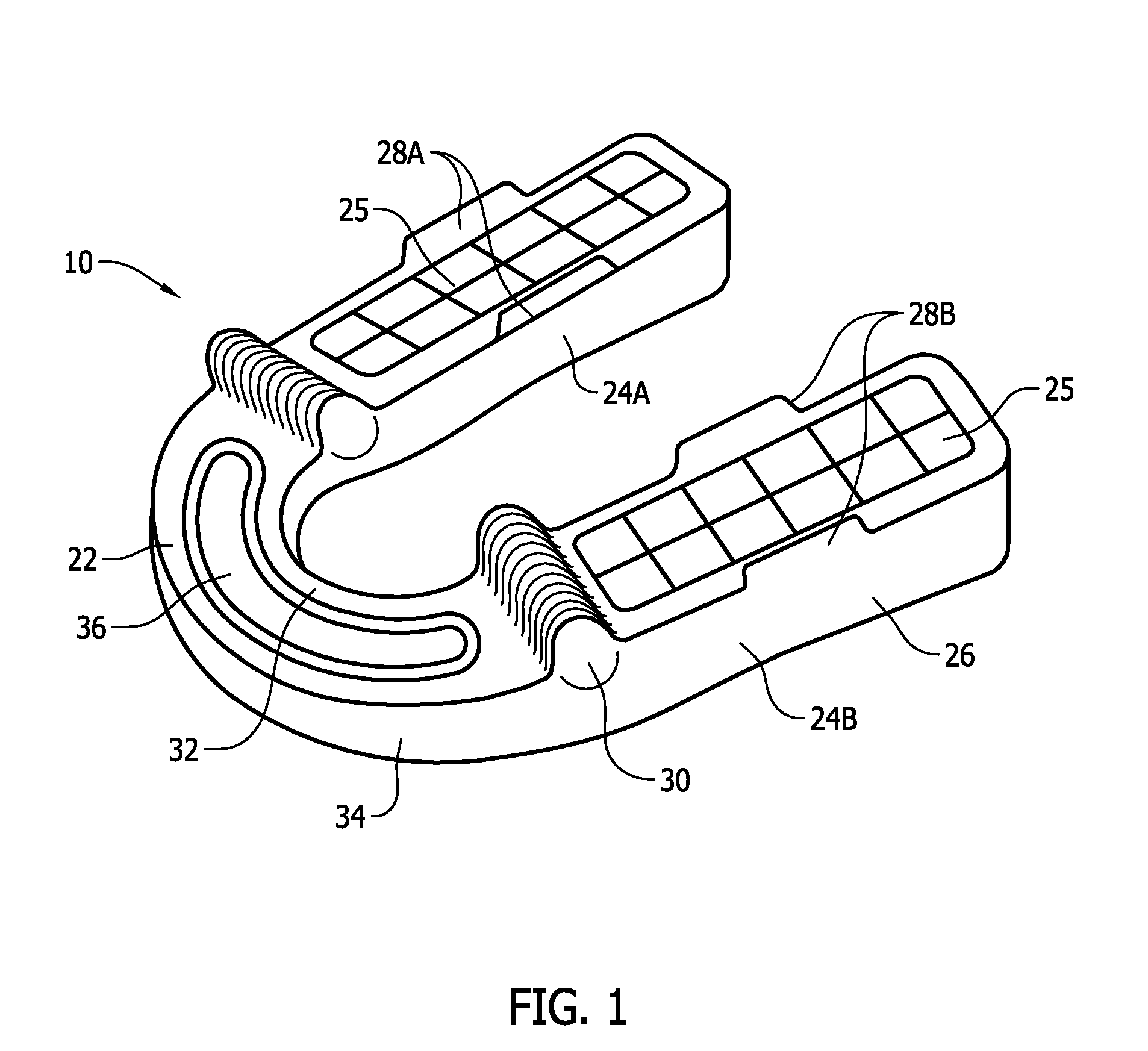

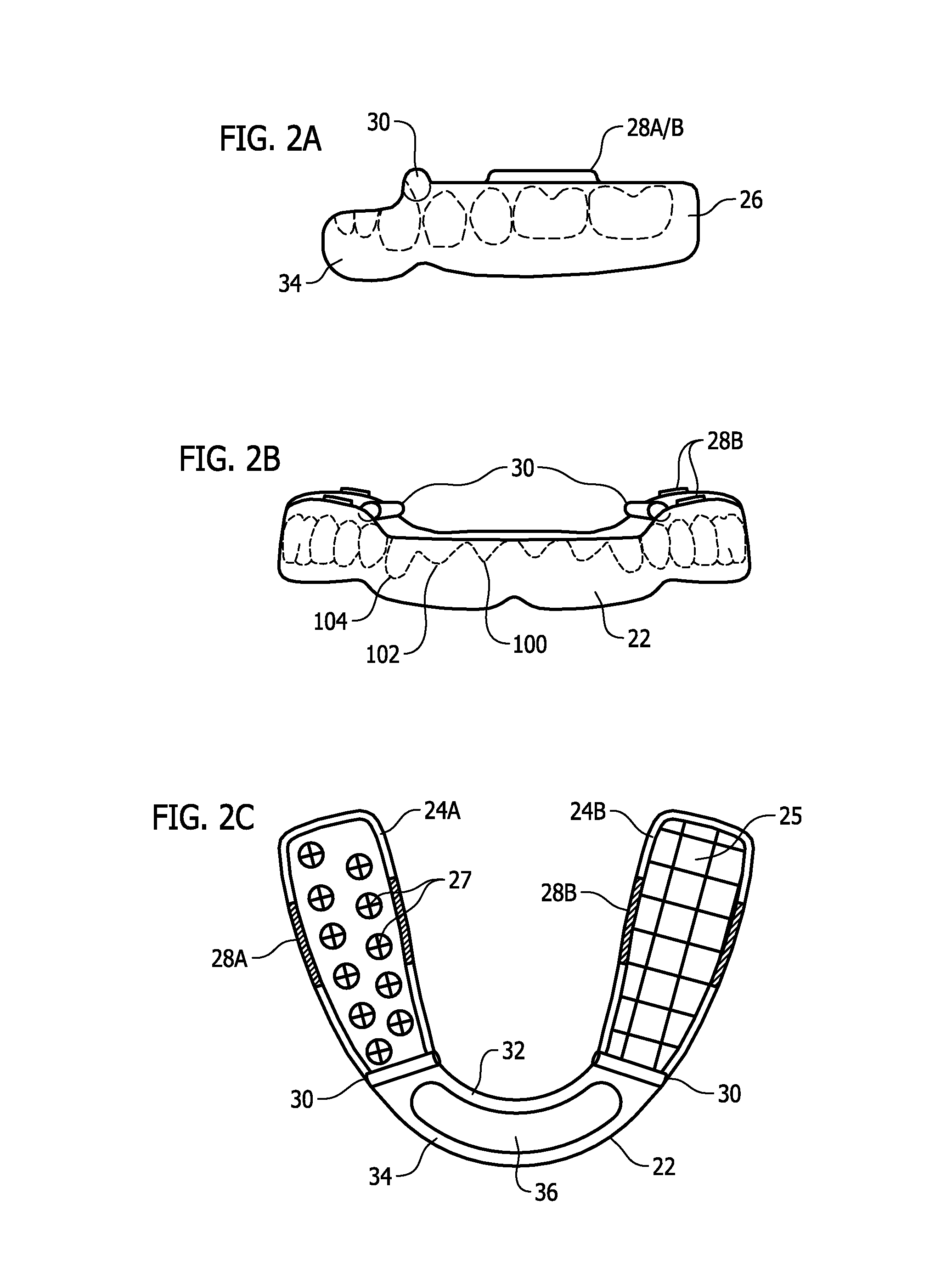

Repositioning Appliance

InactiveUS20140093834A1Minimized tensionPrevent intrusionOthrodonticsSnoring preventionAnterior teethPosterior teeth

A mandible repositioning appliance is provided comprising an anterior member adapted to receive anterior teeth; first and second posterior members, each adapted to receive posterior teeth, wherein each posterior member comprises an occlusal pad support; and a positioning guide formed between the anterior member and each of the first and second posterior members, wherein said guide functions to position the user's mandible into an anatomically correct position achieved when each positioning guide is in position resting between the third and fourth upper and lower anterior teeth when the appliance is in place in the user's mouth.

Owner:ANDARY JOSEPH YOUSSIF

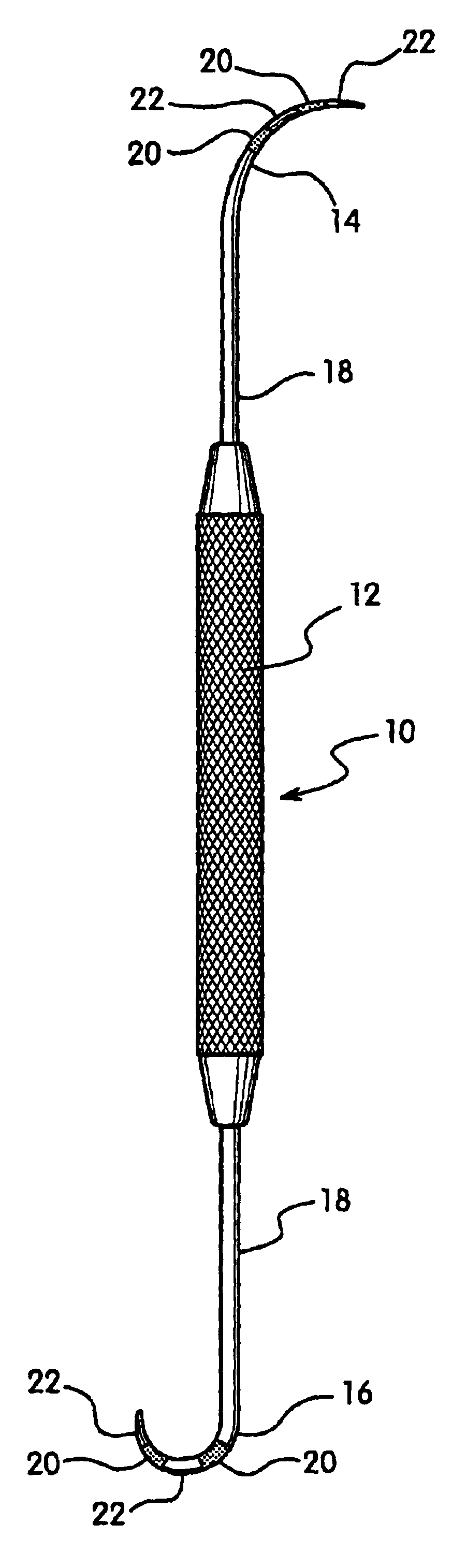

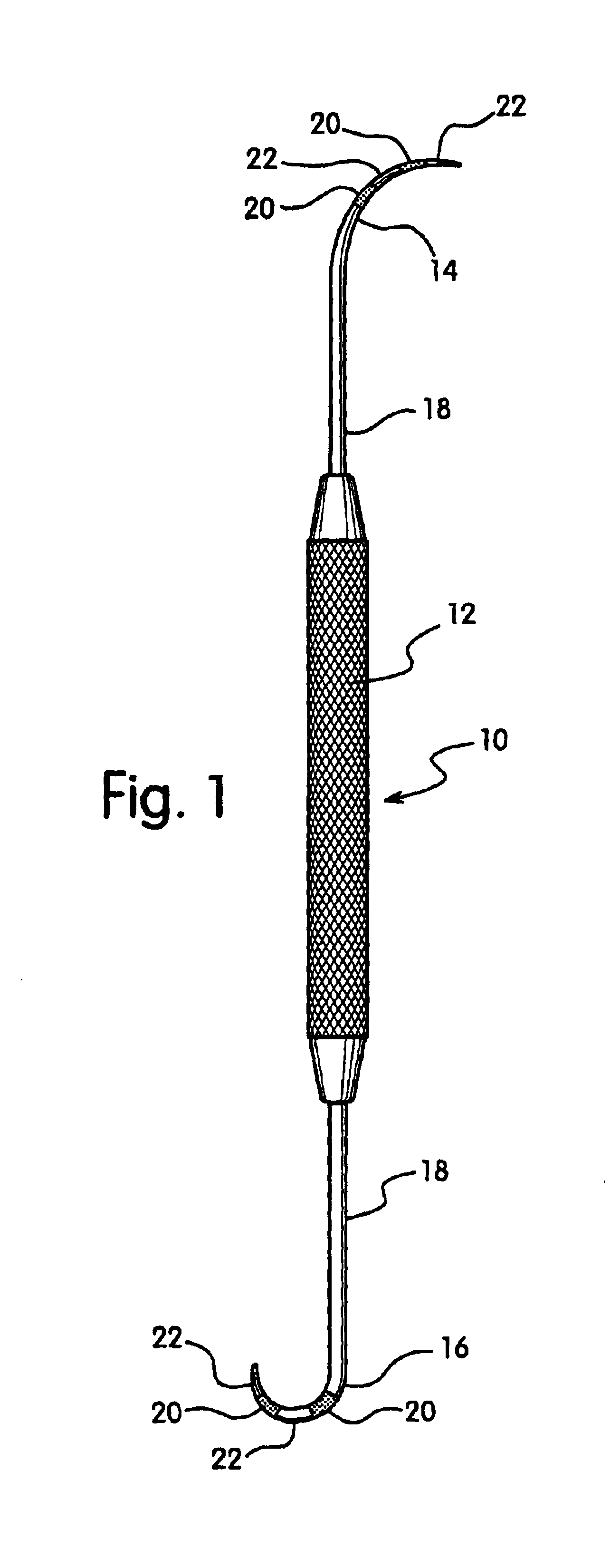

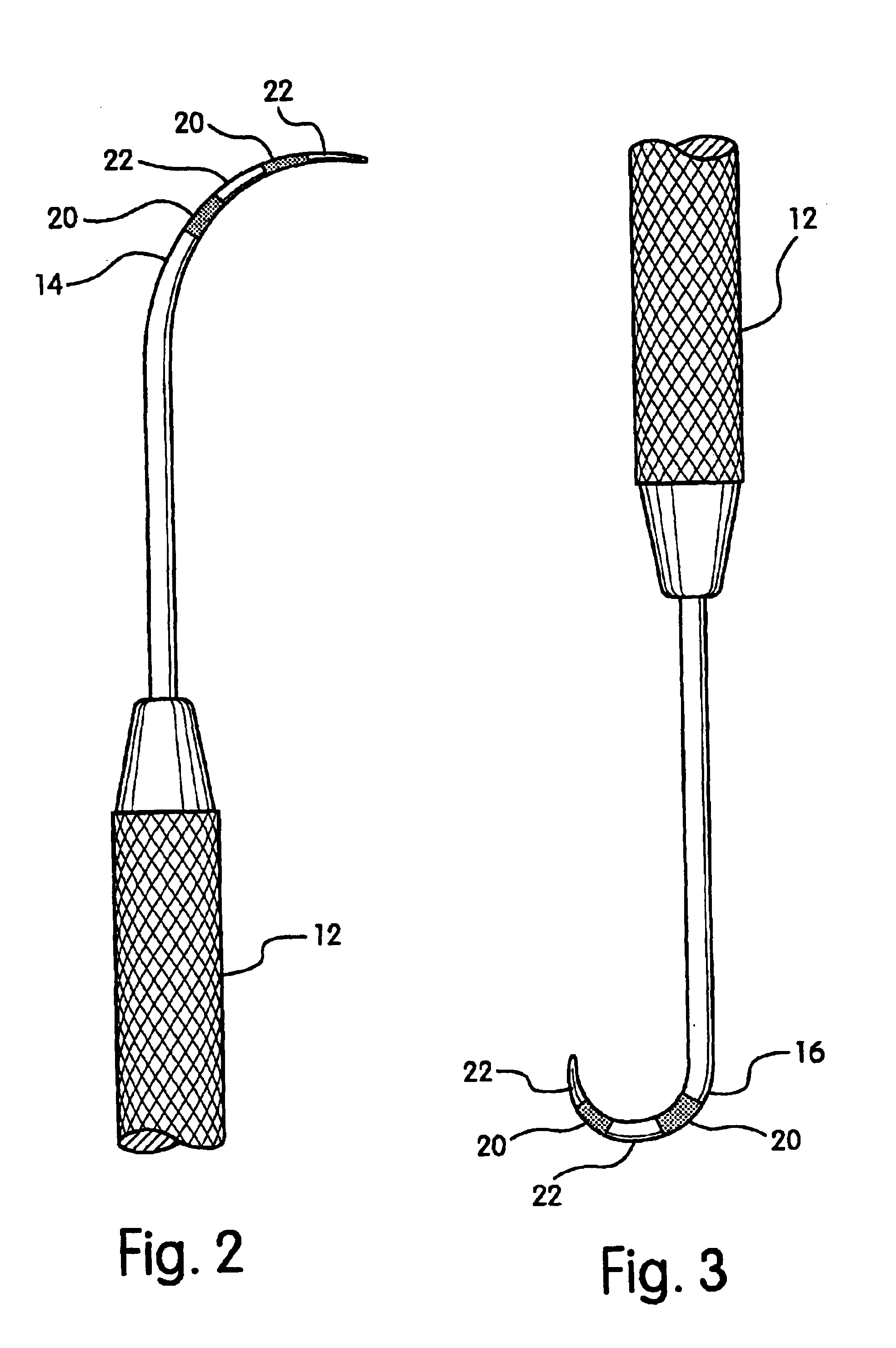

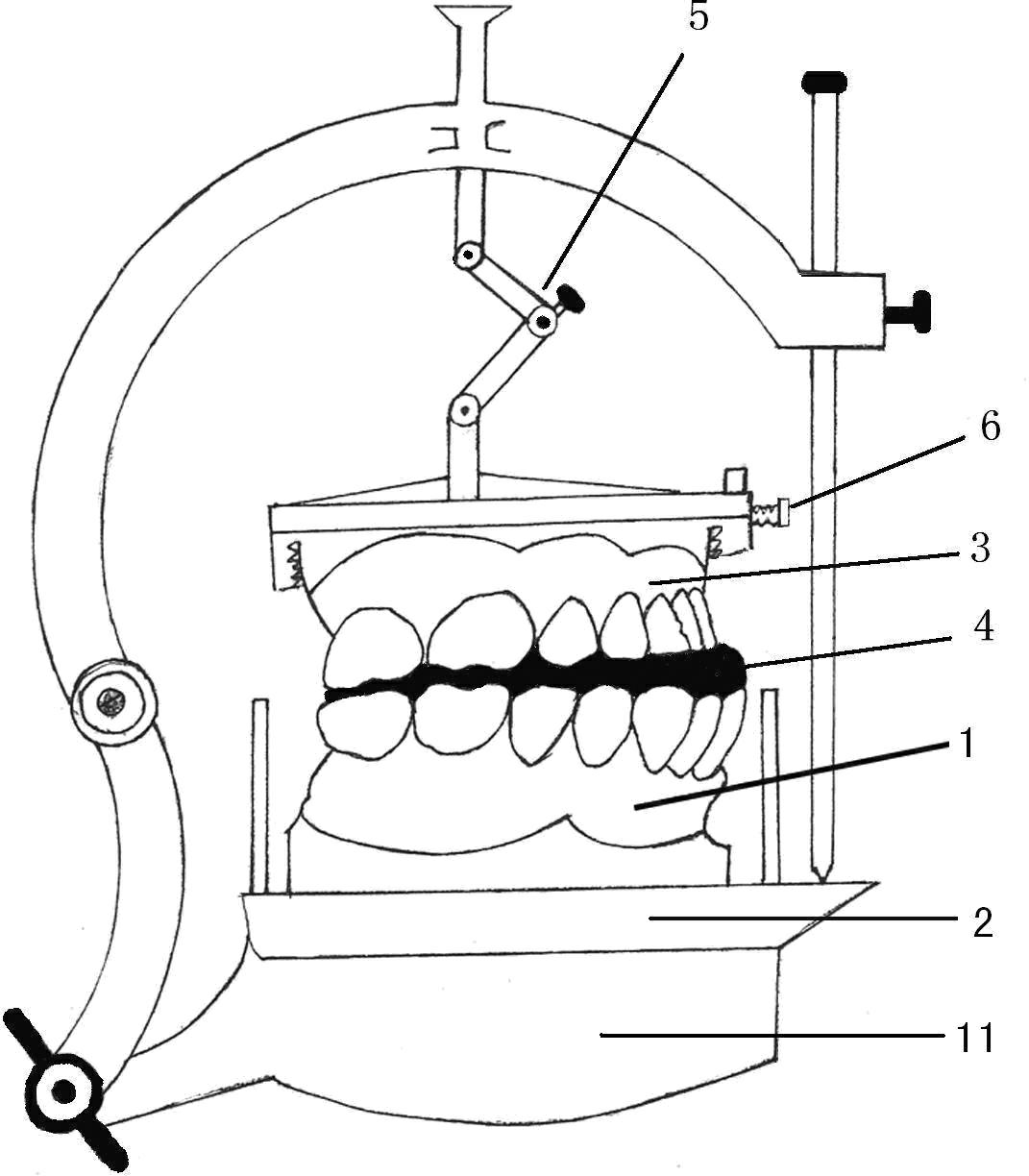

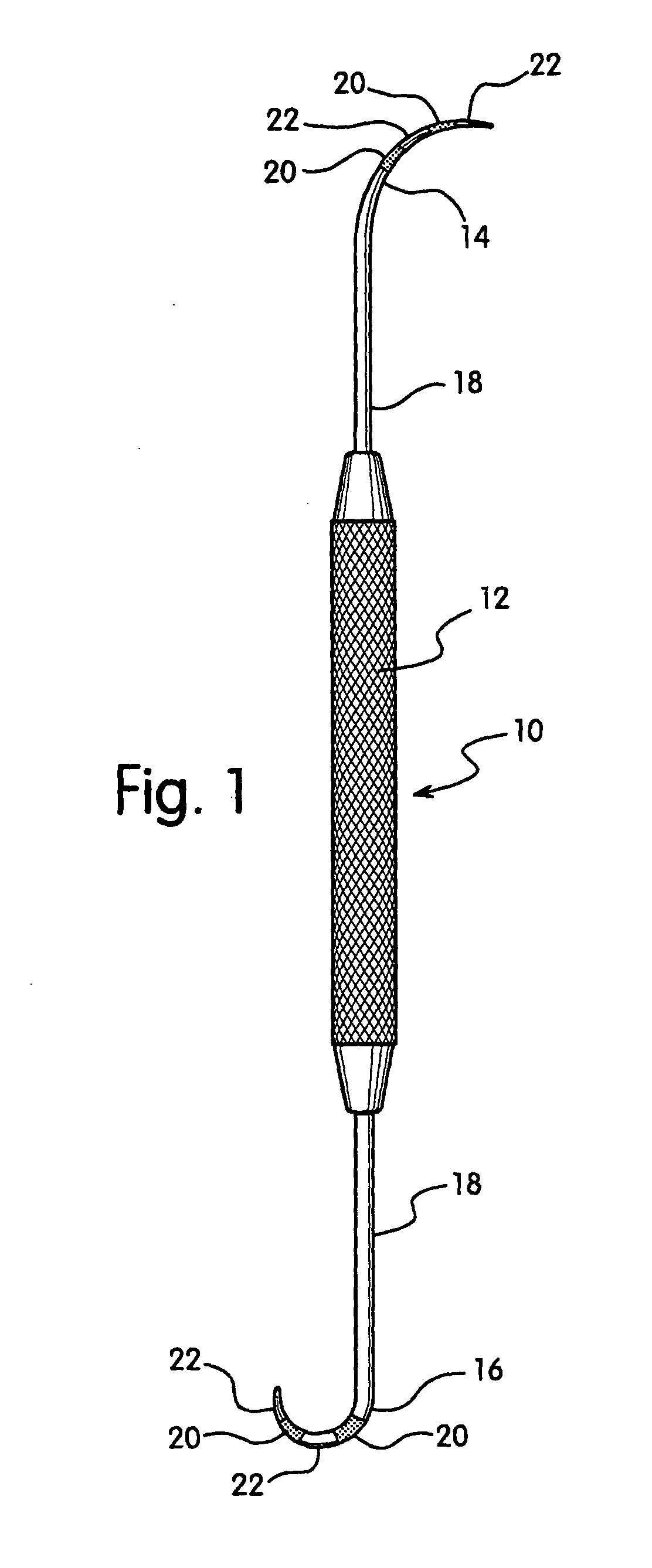

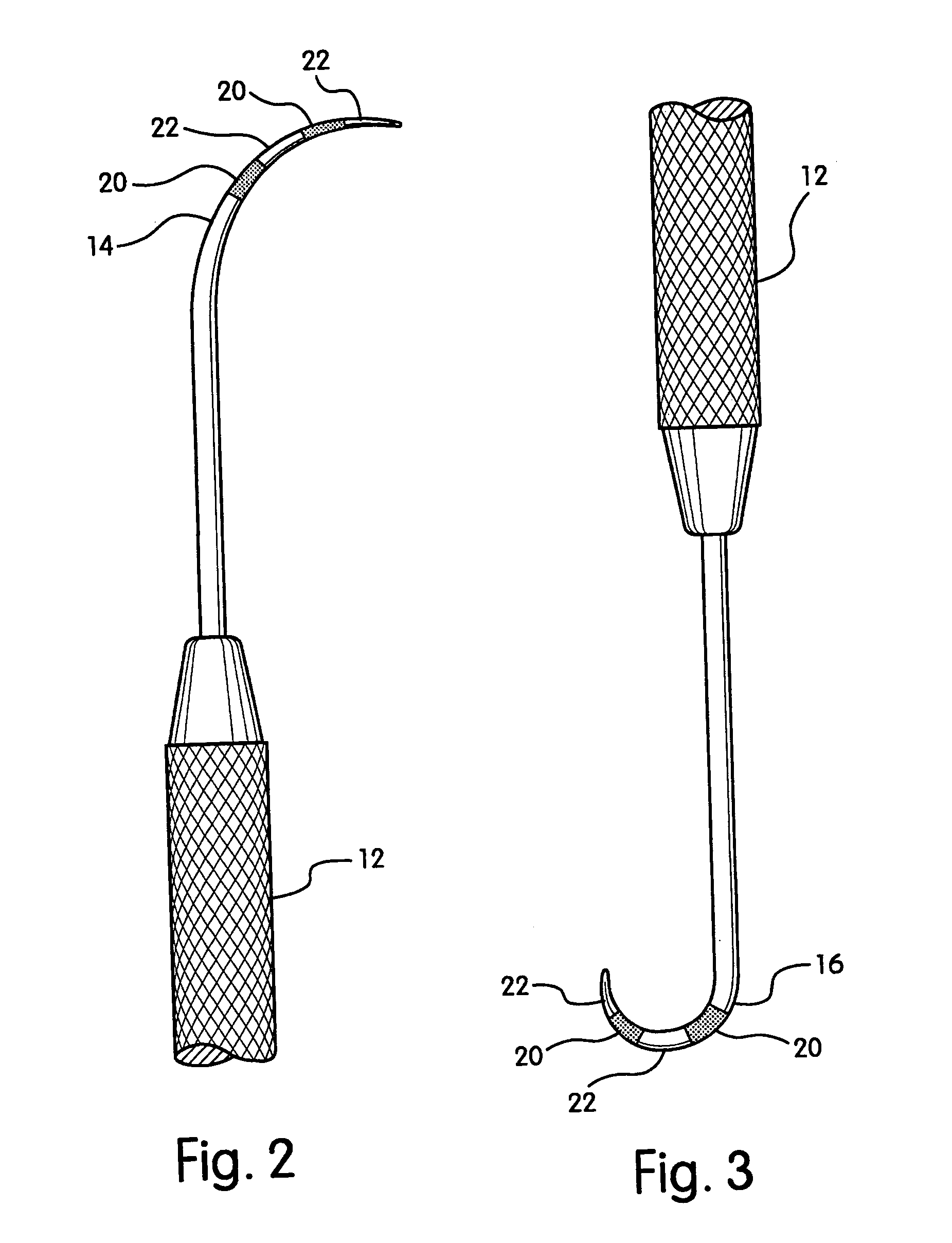

Dental instrument

InactiveUS6893260B2Effective in measuring deposit and imperfection on teethEasy to measureDental toolsDental instrumentsAnterior teeth

This invention is directed to a dental instrument and the use of this dental instrument to measure deposits and other imperfections on a tooth surface. The dental instrument has an elongated portion and on at least one end a general curvature portion. The general curvature portion will have the general curvature of a posterior tooth or an anterior tooth. Preferably it also will be marked with measured segments. By placing the general curvature portion against a tooth a deposit or imperfection on a tooth can be measured. In a preferred embodiment the dental instrument will have a general curvature portion in each end; the general curvature on one end being for posterior teeth and the general curvature on the other end being for anterior teeth. When measuring plaque and related deposits a dye solution can be used to make the deposit more visible.

Owner:COLGATE PALMOLIVE CO

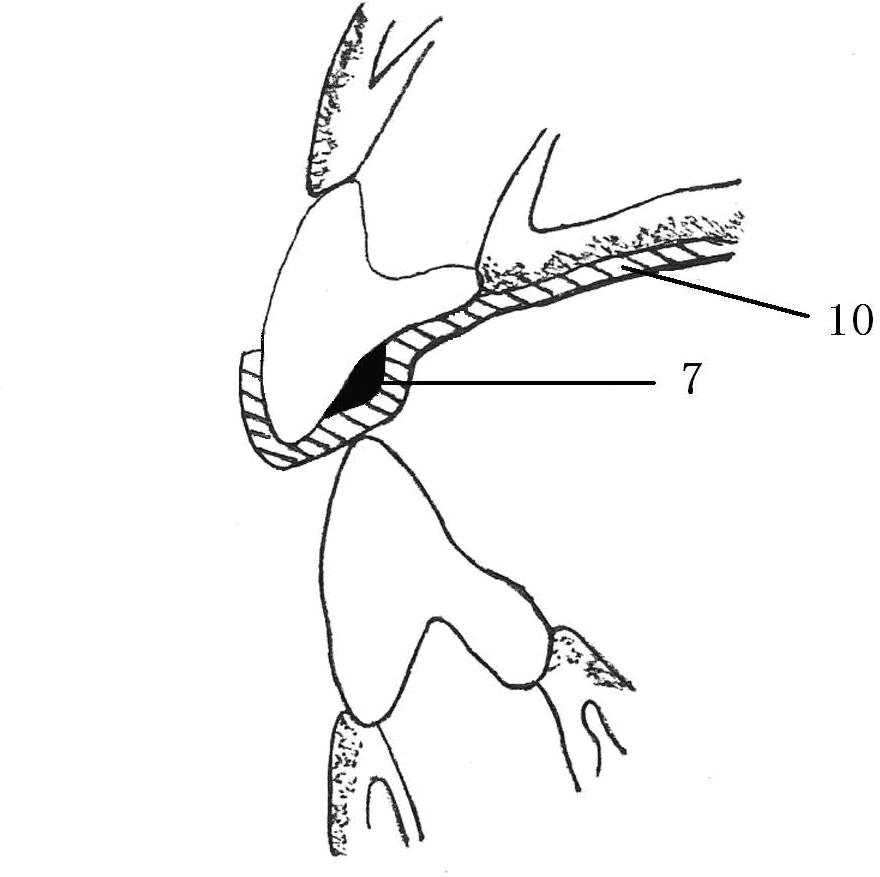

Method for synchronous realization of one-step lamination and forming of occlusal surface of stable occlusal plate

InactiveCN102670340AEasy to operateNo front teeth extrusionDentistryNon-surgical orthopedic devicesBite platesCentric relation

The invention relates to a manufacturing method for a stable occlusal plate in dental medical treatment and particularly relates to a method for synchronous realization of one-step lamination and the forming of an occlusal surface of a stable occlusal plate. The method comprises the following steps: firstly, taking a die; secondly, transferring a centric relation; thirdly, racking; fourthly, filling an undercut; fifthly, filling a clearance; sixthly, pressing a film; seventhly, cutting and polishing; and eighthly, finishing. According to the method disclosed by the invention, the forming of the occulusal surface is finished while one-step lamination is realized, and thus the simplicity in operation is realized; the occlusal surface is made of homogeneous resin film material and is smooth and durable; a patient feels more comfortable when wearing the stable occlusal plate for the first time, compared with a stable occusal plate manufactured by using a conventional method, and has no front-tooth extrusion and pain feeling. Through 82 cases of clinical application for three years, the stable occulusal plate is favorable in effect.

Owner:周小陆

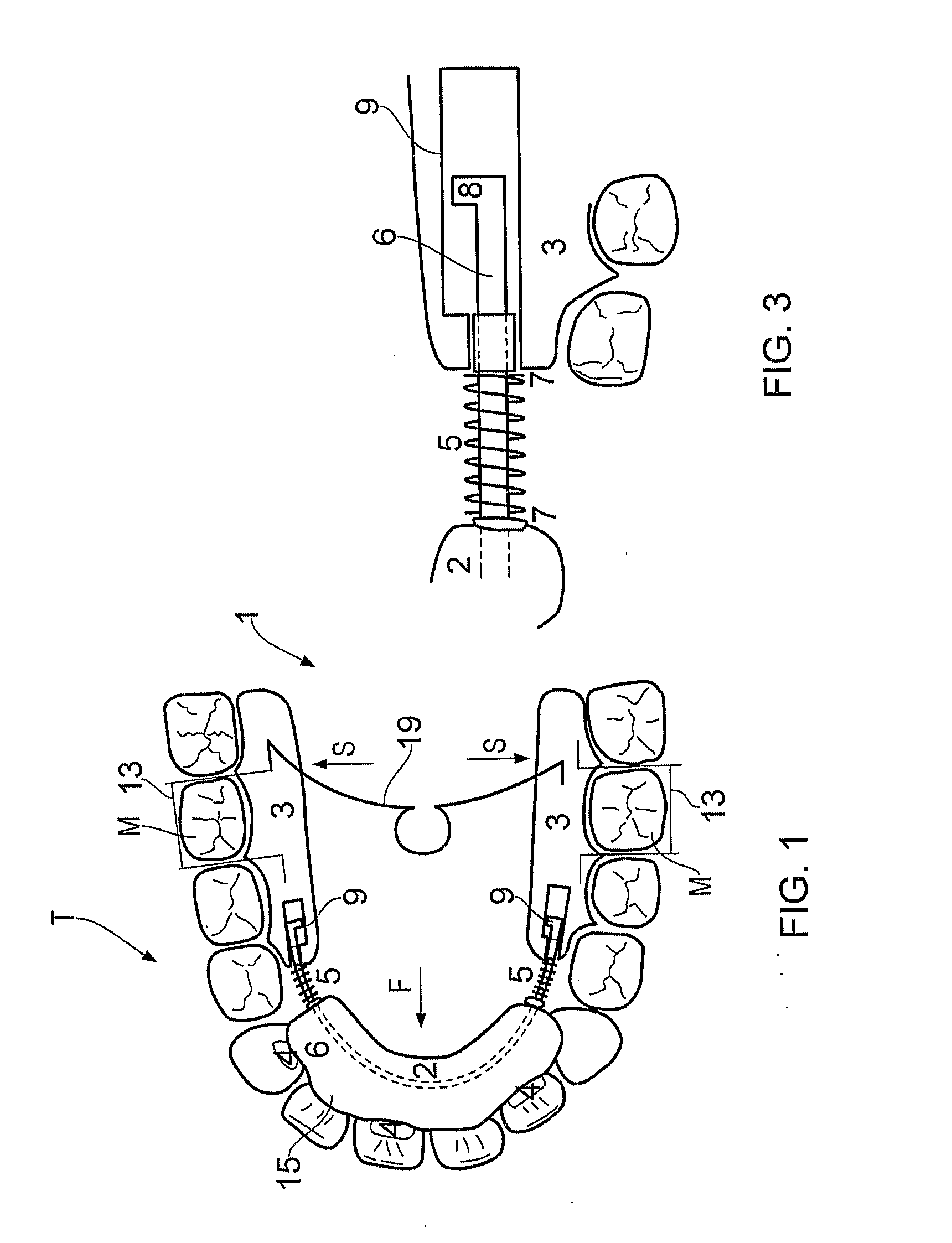

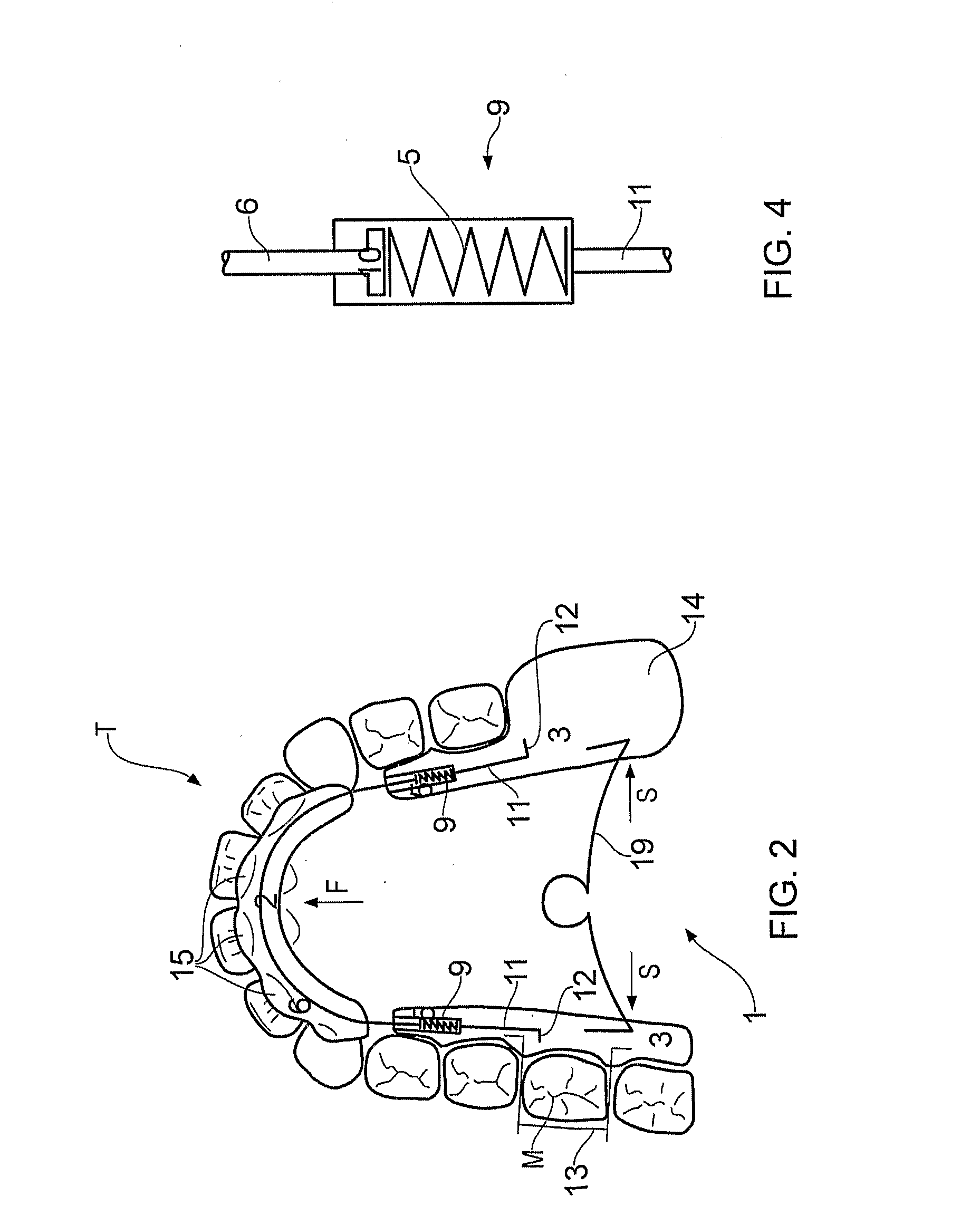

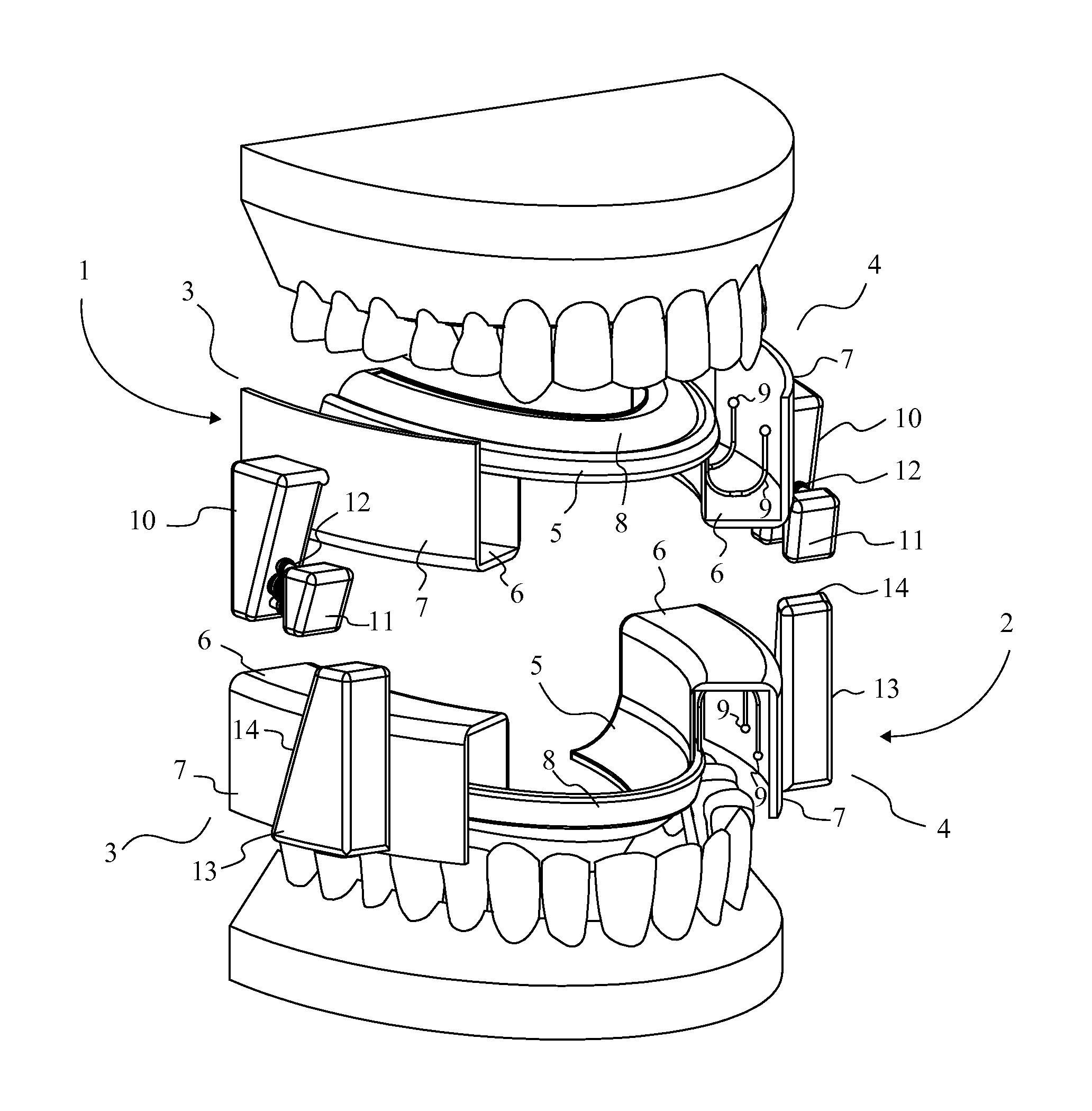

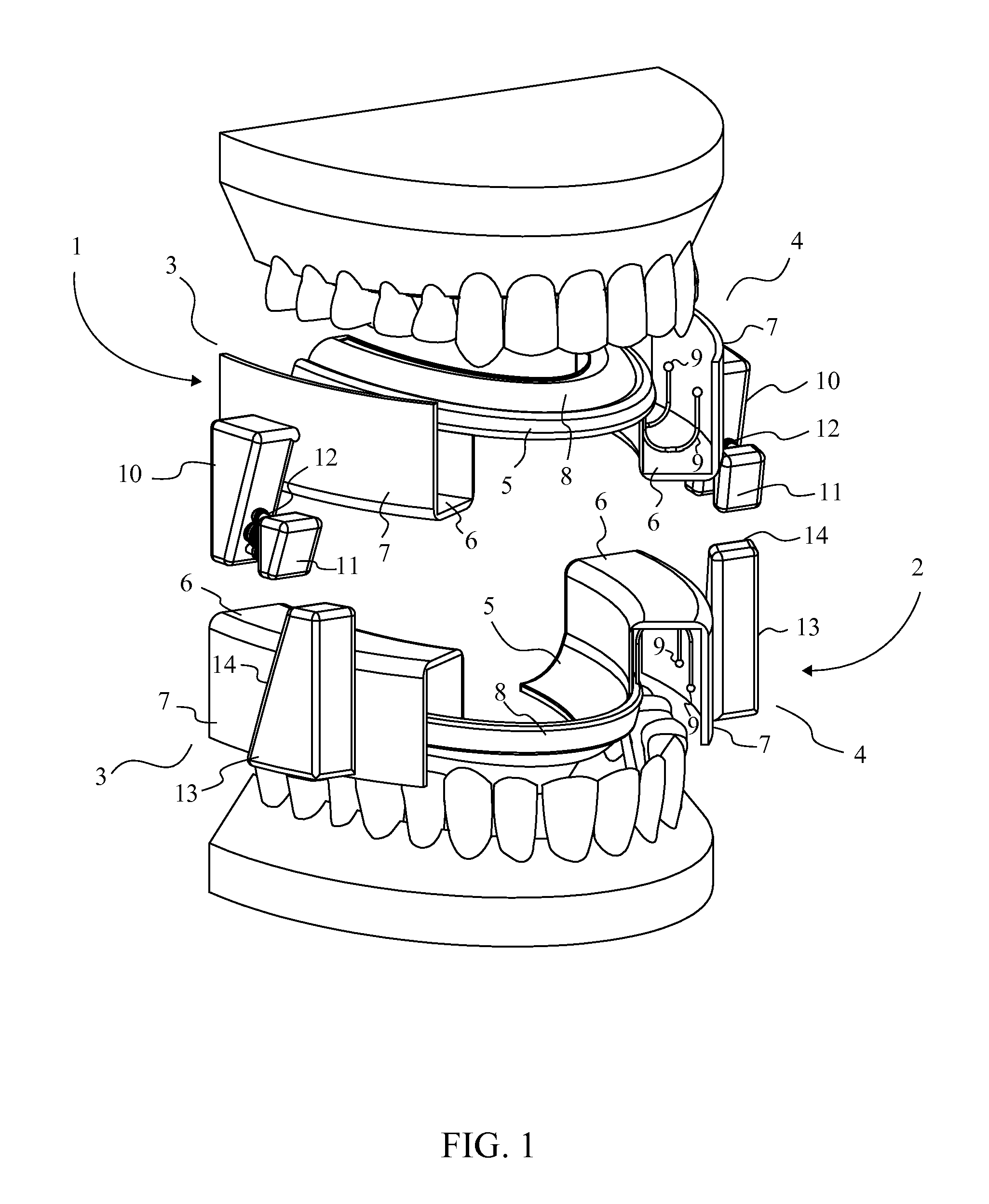

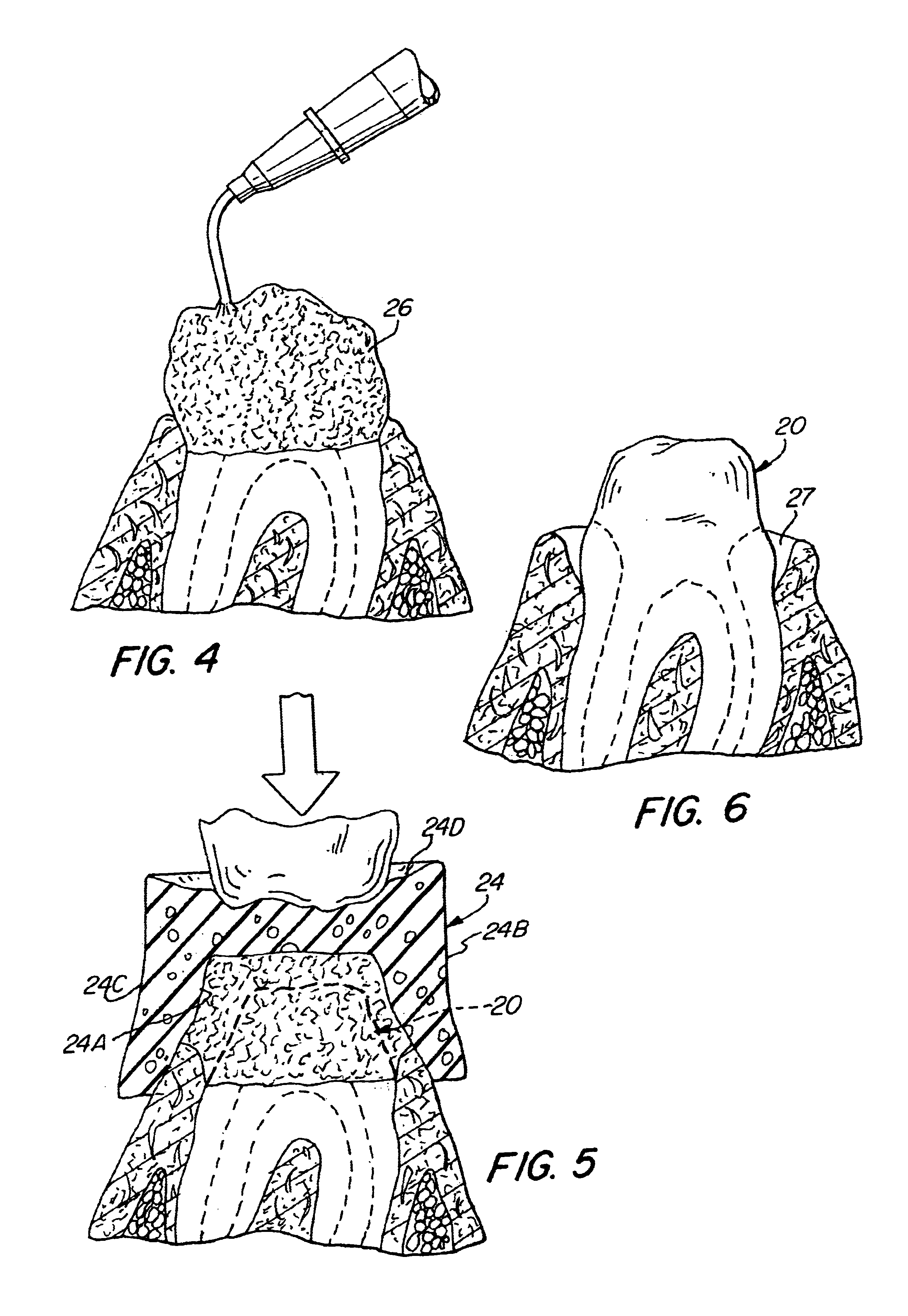

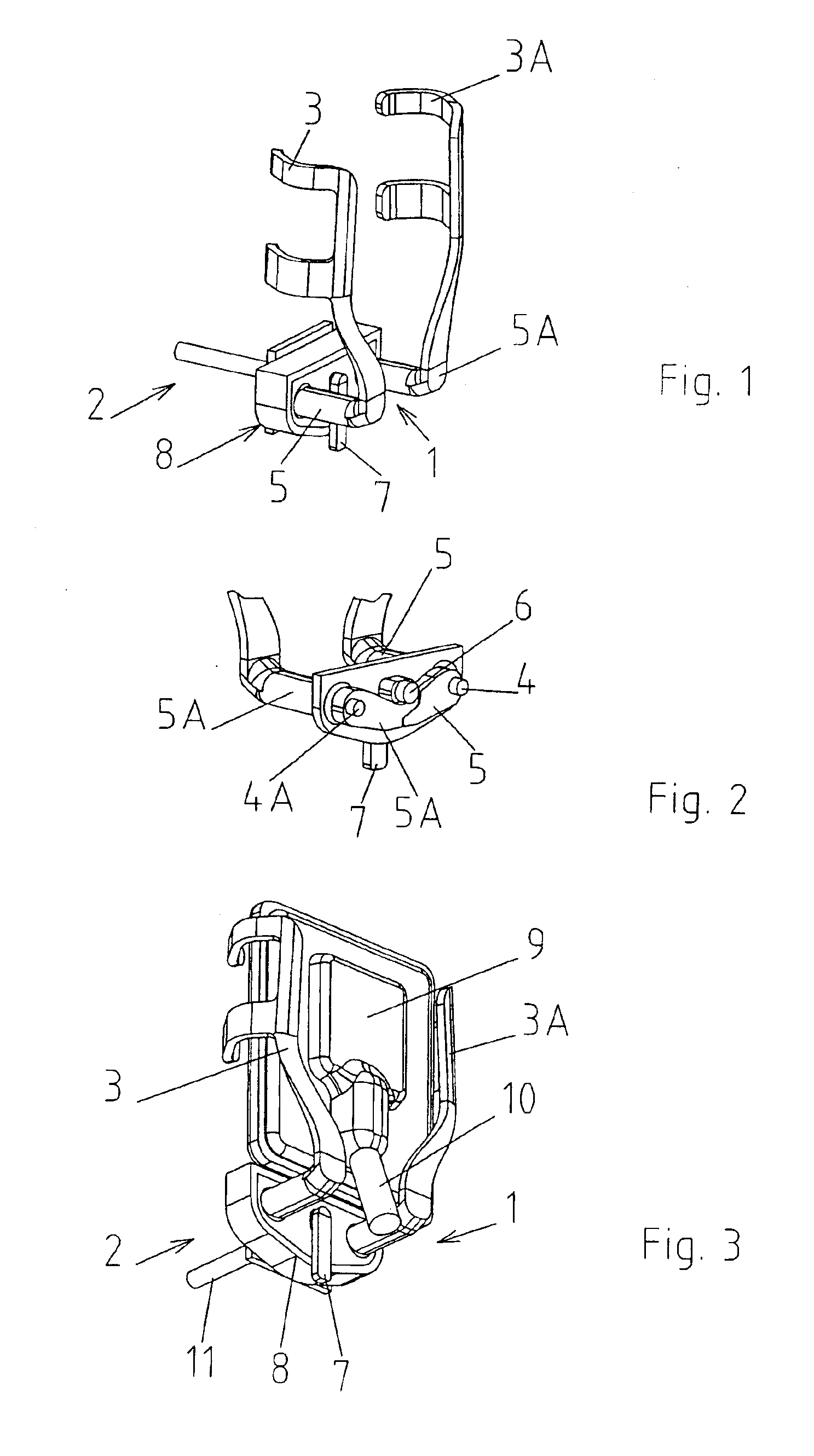

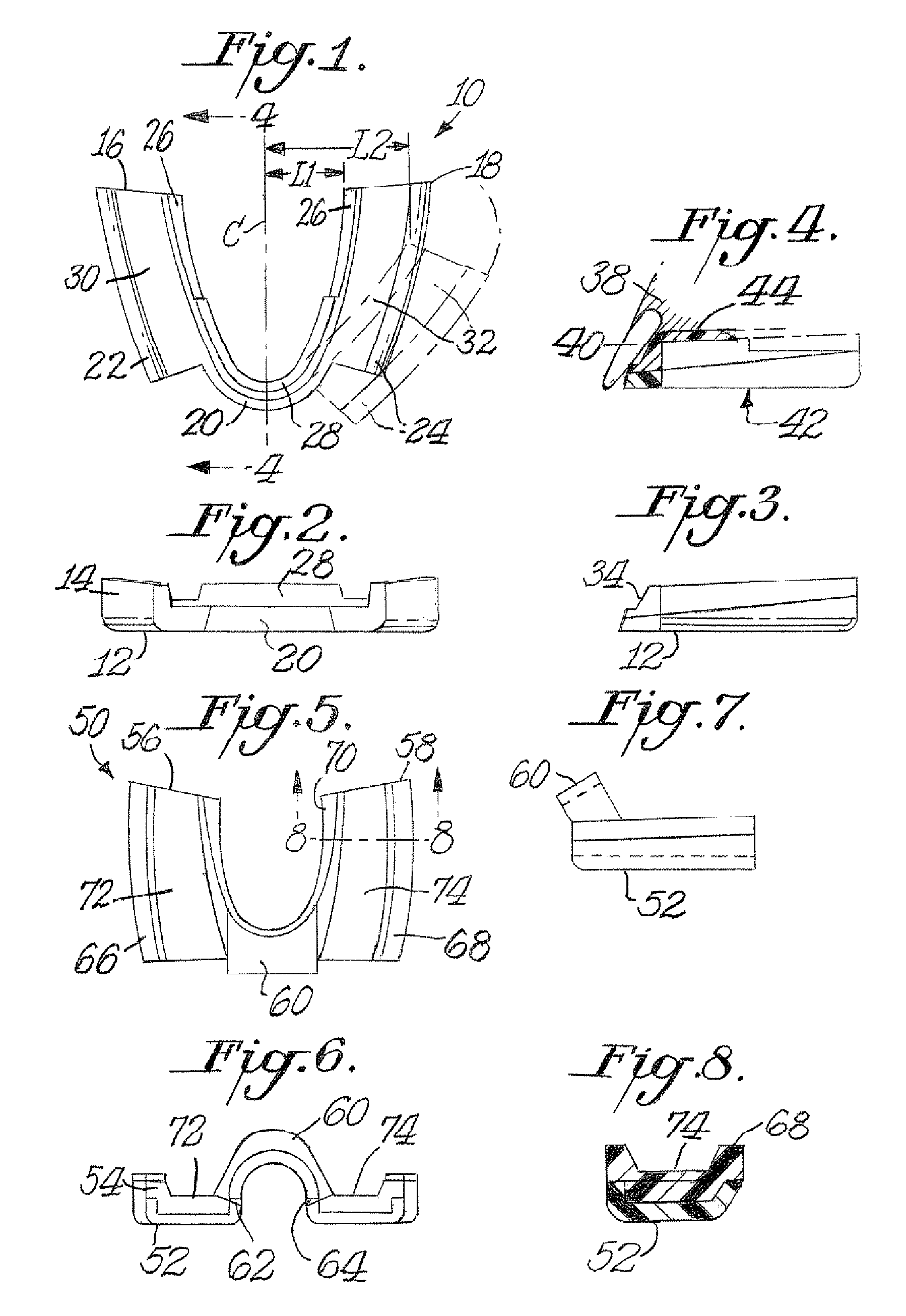

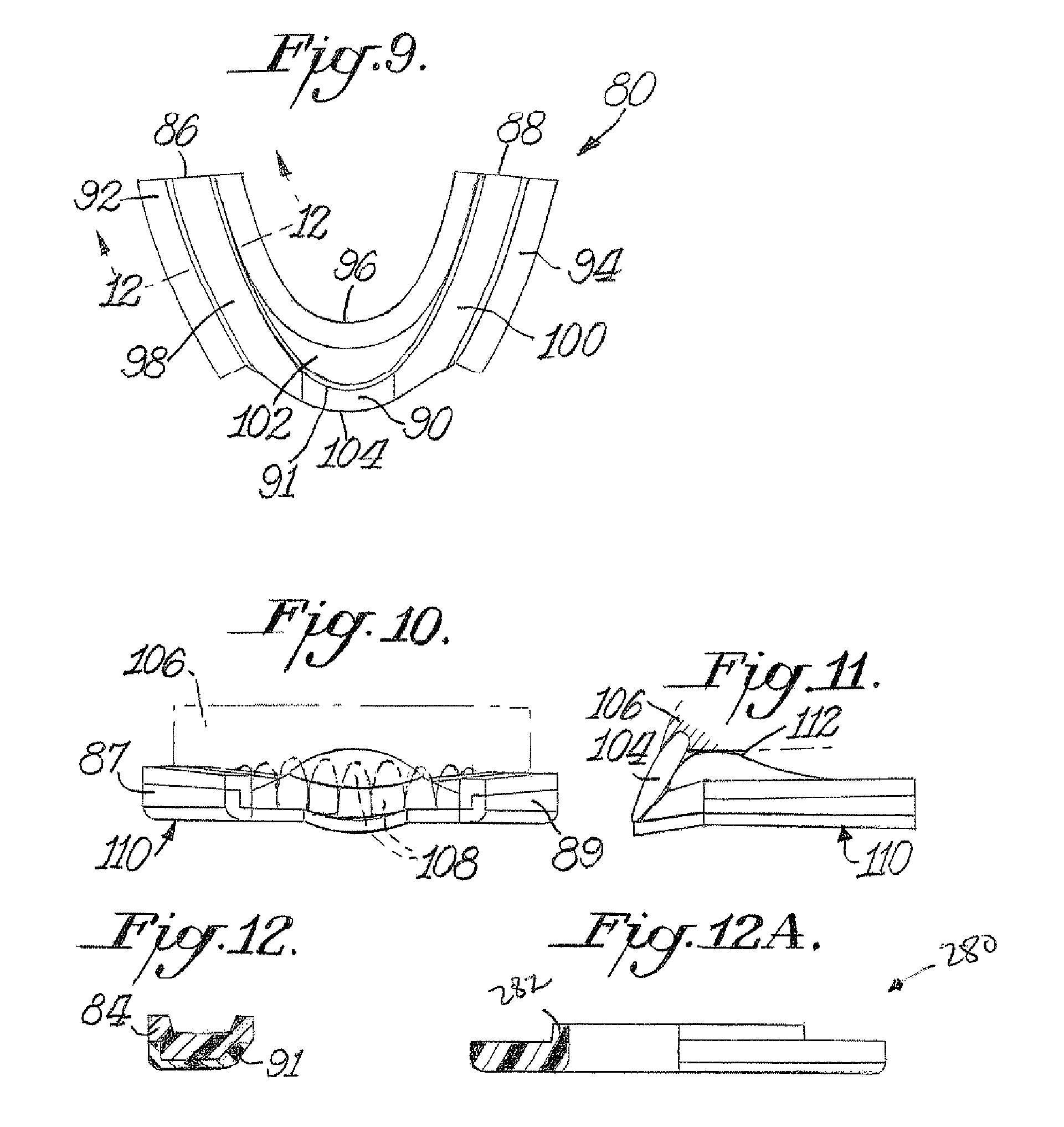

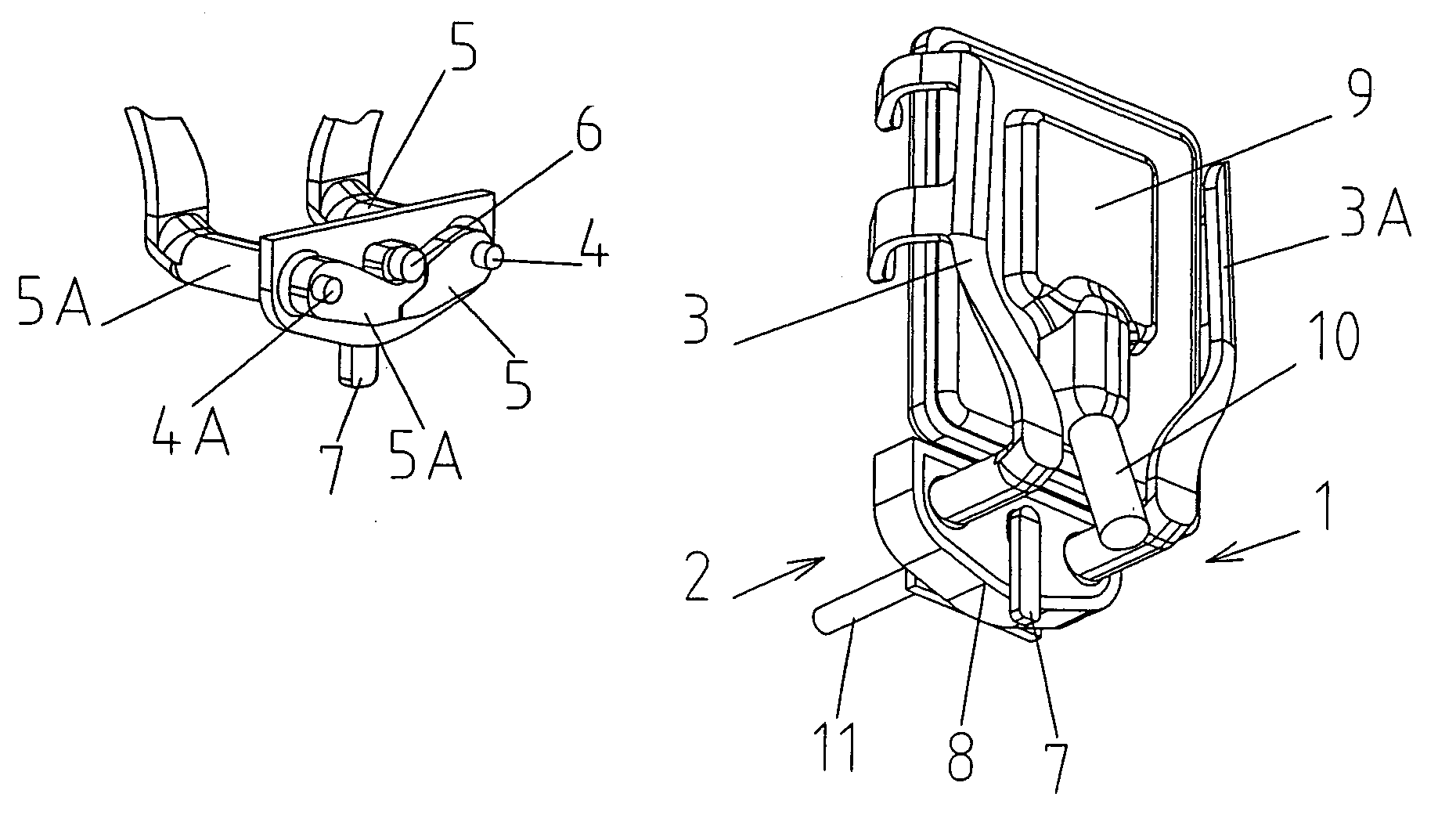

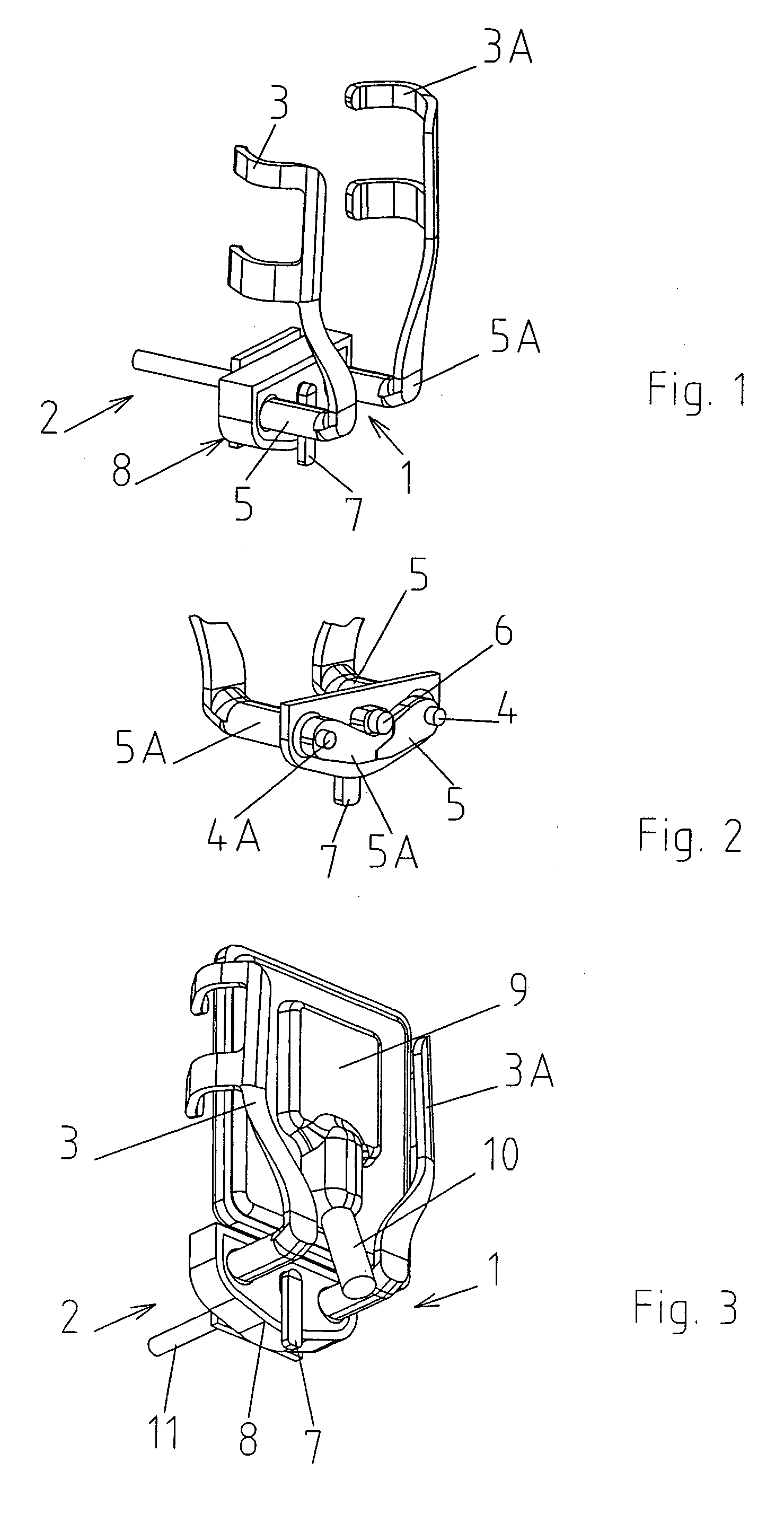

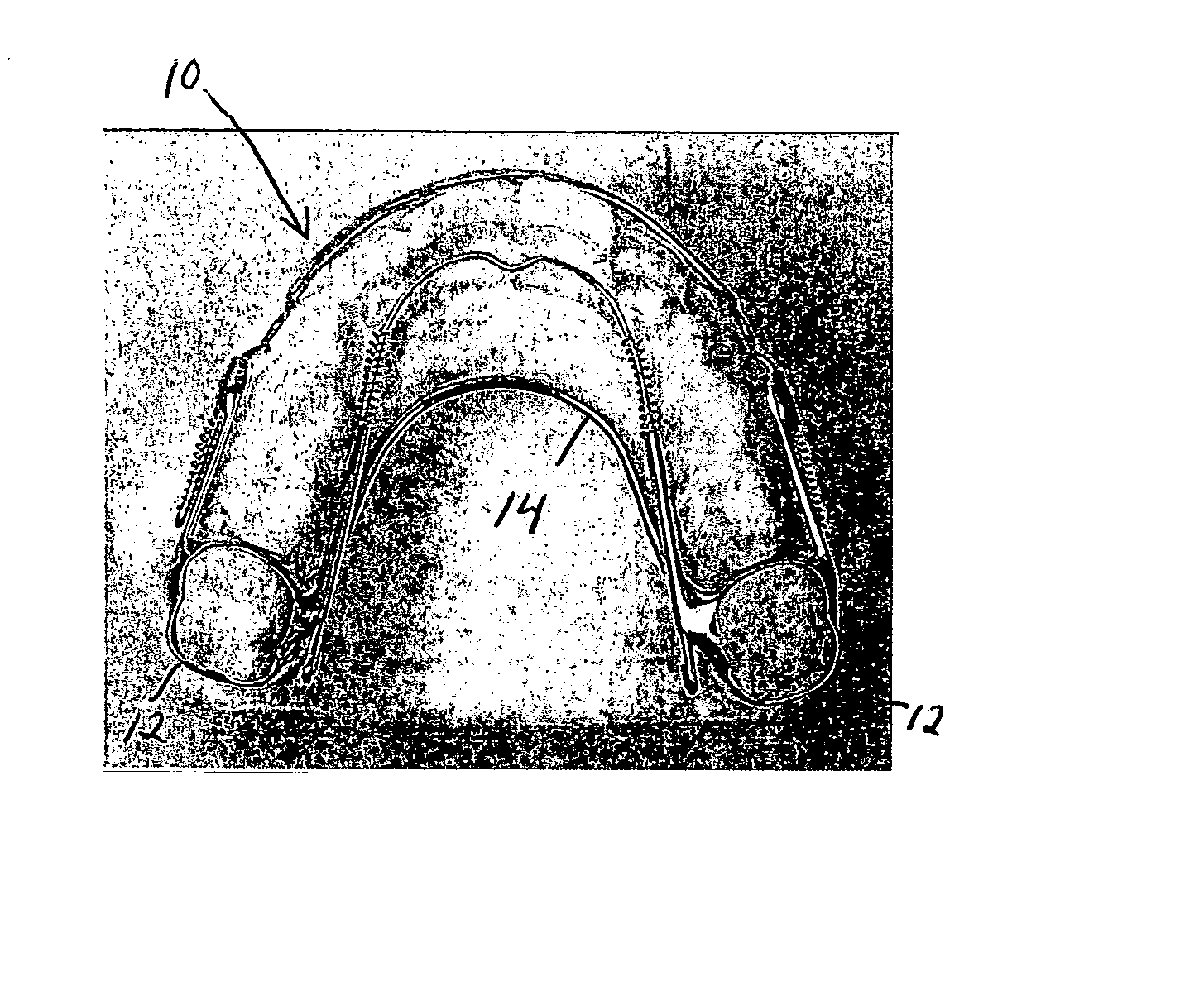

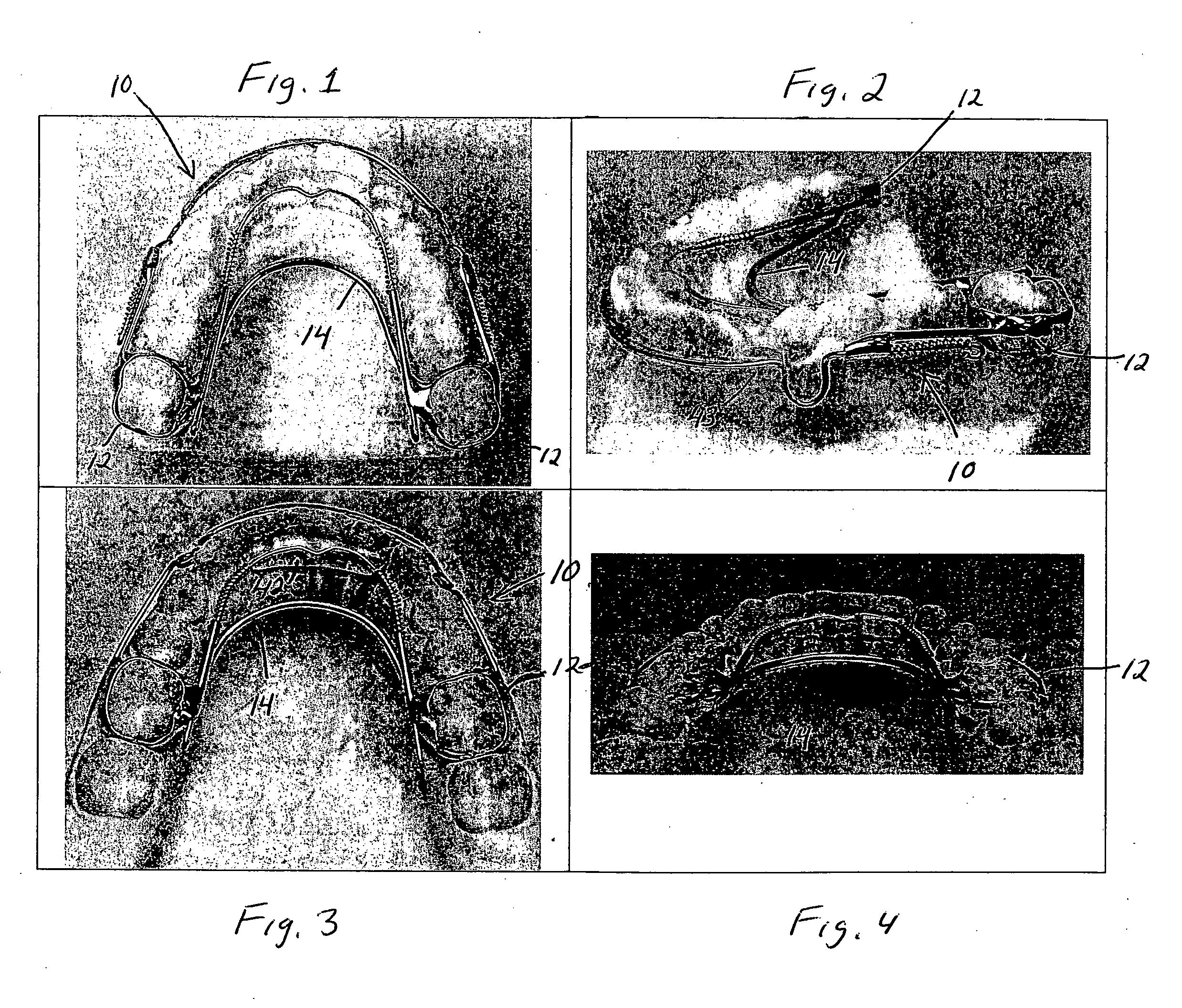

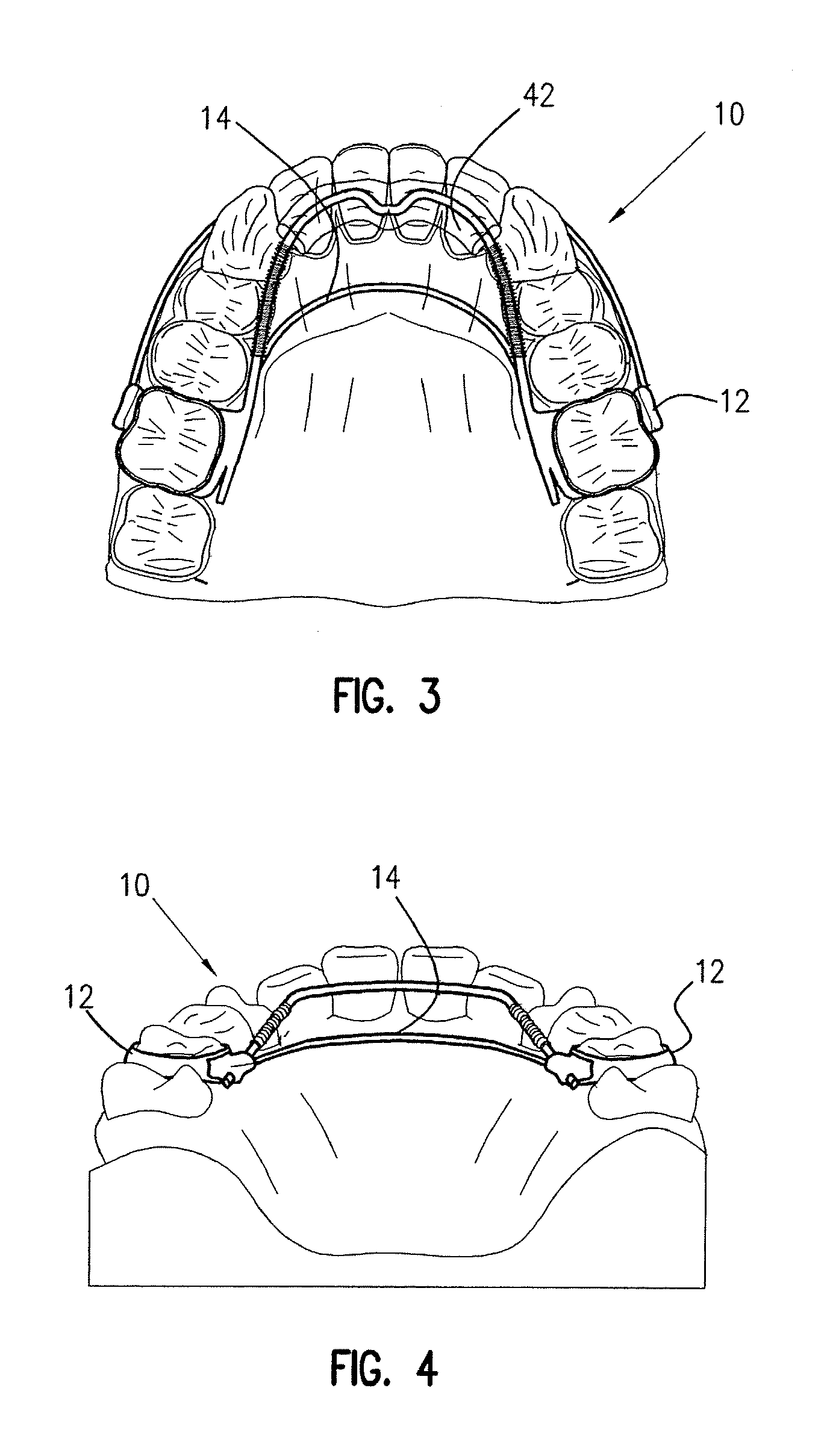

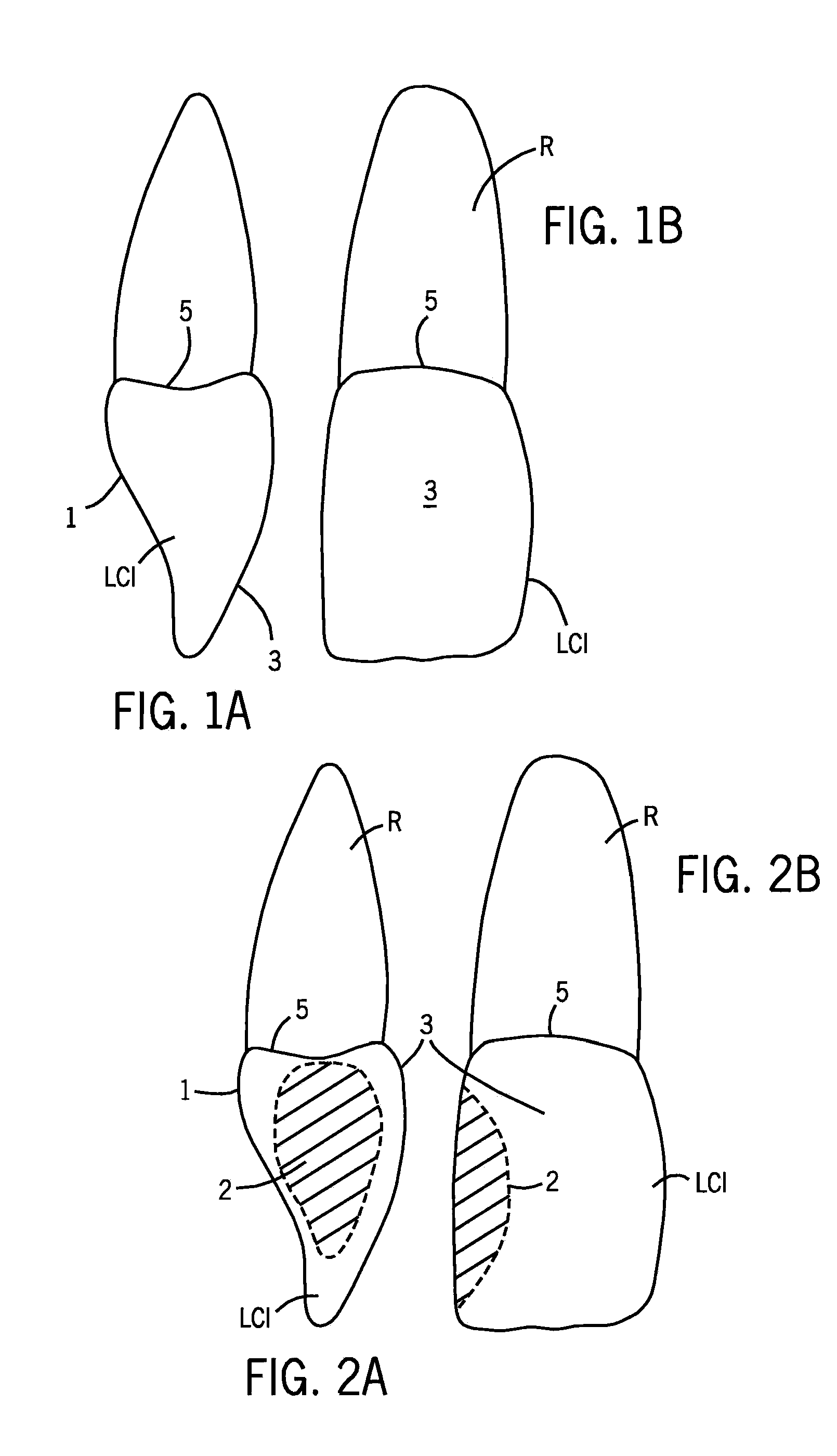

Orthodontic appliance and method

An orthodontic appliance including labial and lingual bodies having teeth-contacting surfaces for acting against targeted anterior teeth of a patient and associated labial and lingual components incorporating spring-loaded biasing means for causing the labial and lingual bodies to act in generally opposed directions and in unison against the surfaces of the targeted anterior teeth. Bands for attaching the appliance to molars and a lingual support component also are provided. The foregoing is applied to a fixed spring aligner, a habit appliance and a bonded crossbite appliance, as well as appliances having new and improved labial and lingual components. The habit appliance includes a labial component to pull anterior teeth into an ideal position, and the aligner and crossbite appliances include labial and lingual components for applying corrective forces to the respective labial and lingual surfaces of the anterior teeth.

Owner:INMAN DONAL P

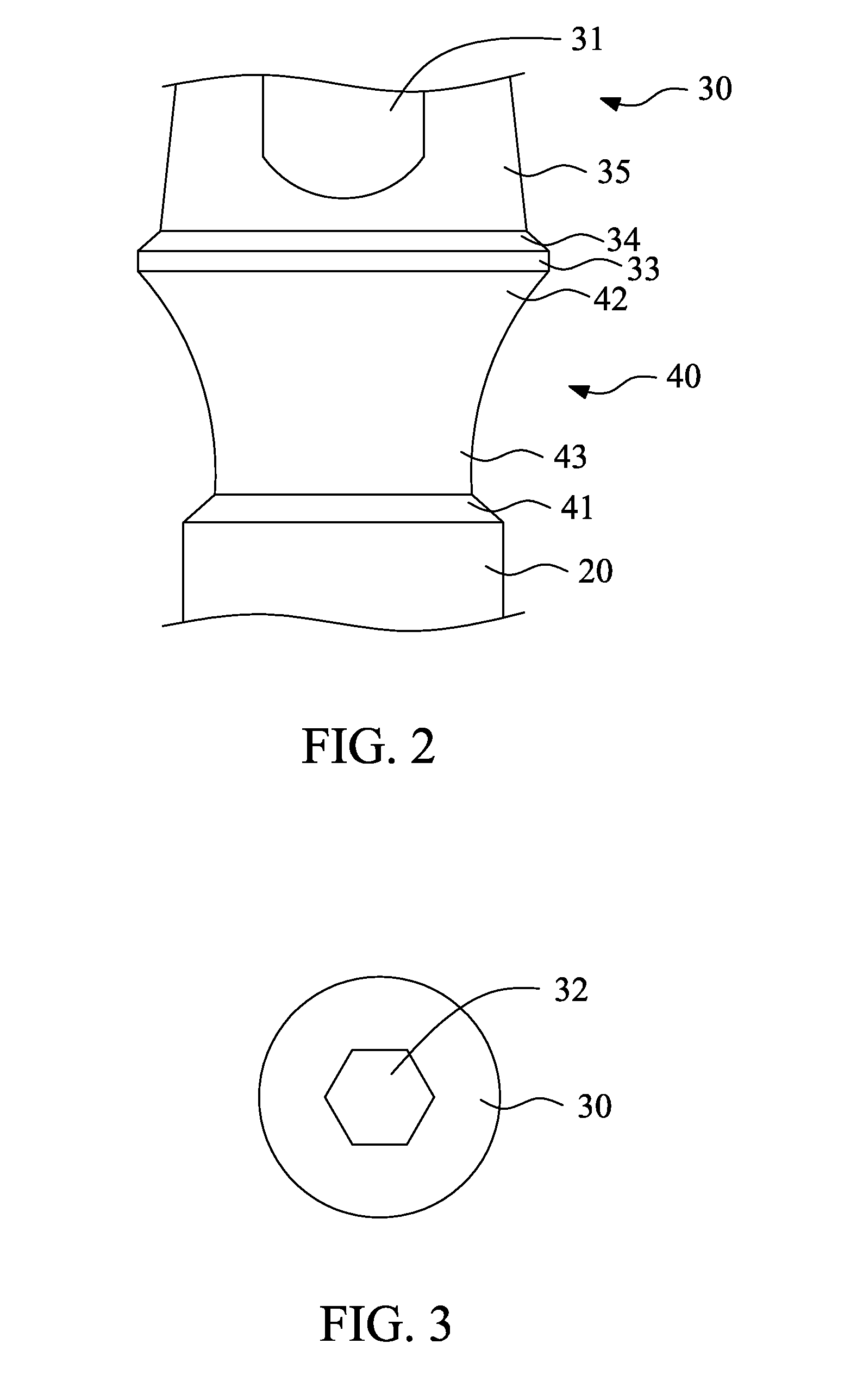

Free angled driver and free angled hole abutment

InactiveCN101365395AEasy to tightenEasy to loosenDental implantsWrenchesDental implantAnterior teeth

In case of straight driver, the entrance of screw inserting hole of implant prosthesis is on the same line with implant fixture's axis. Due to this position of the hole, final prosthesis has many difficulties. Thus. the free angled driver(301) is invented. For maxillay anterior teeth, we can move the screw hole to ligual surface of prosthesis(511). We can make esthetic and convenient prosthesis with capability of easy screwing and unscrewing. Also. I invented the free angled hole abutment(300) for the free angled implant driver,so we can move occlusal hole to the ideal position. It is an epoch-making change to solve many problems in the contemporary dental implant prosthetics.

Owner:李钟琥

Orthodontic appliance and method

An orthodontic appliance including labial and lingual bodies having teeth-contacting surfaces for acting against targeted anterior teeth of a patient and associated labial and lingual components incorporating spring-loaded biasing means for causing the labial and lingual bodies to act in generally opposed directions and in unison against the surfaces of the targeted anterior teeth. Bands for attaching the appliance to molars and a lingual support component also are provided. The foregoing is applied to a fixed spring aligner, a habit appliance and a bonded crossbite appliance, as well as appliances having new and improved labial and lingual components. The habit appliance includes a labial component to pull anterior teeth into an ideal position, and the aligner and crossbite appliances include labial and lingual components for applying corrective forces to the respective labial and lingual surfaces of the anterior teeth.

Owner:INMAN DONAL P

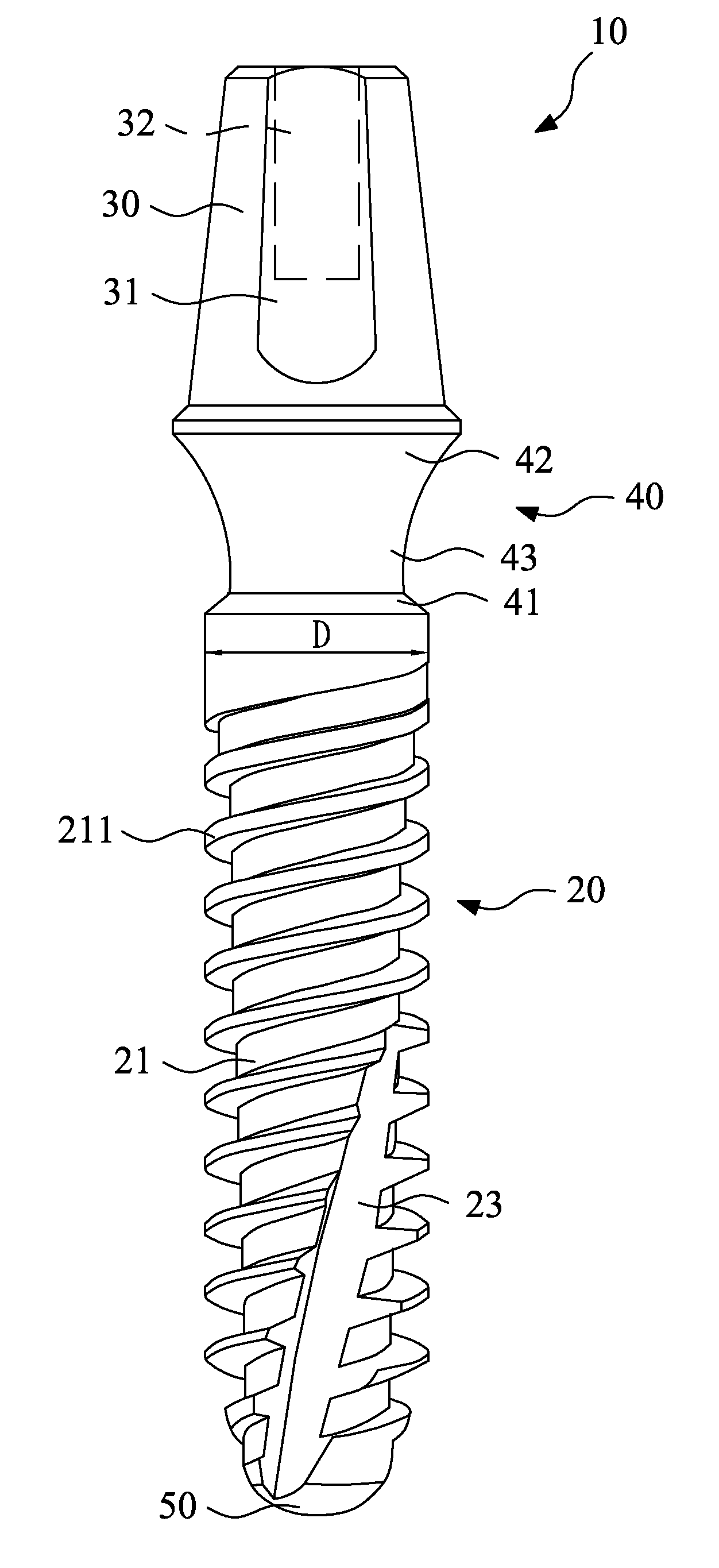

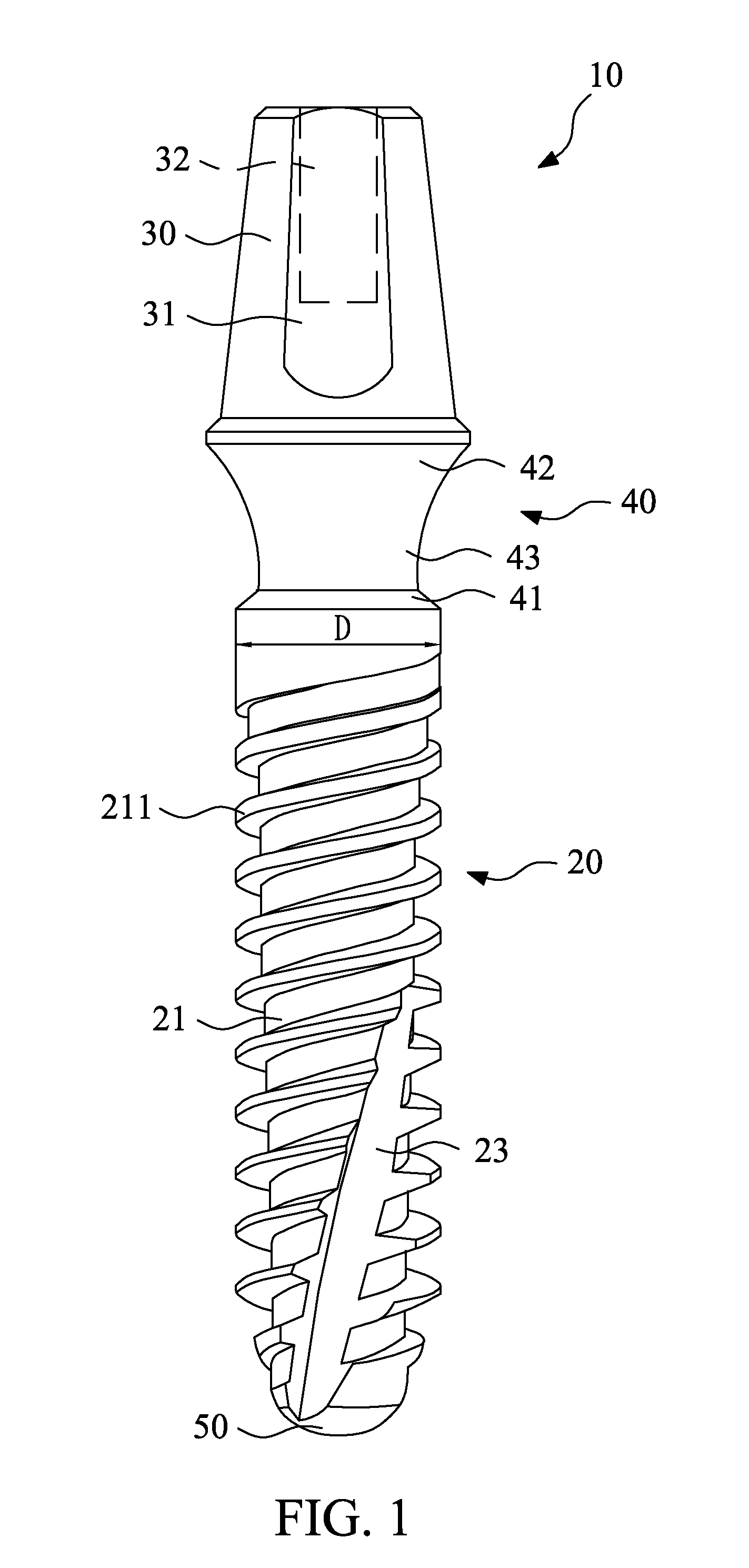

Dental implant

The invention provides a dental implant including a body portion, an abutment portion and a connection portion. The body portion has a body outer diameter. The connection portion is connected between the body portion and the abutment portion. The body portion, the connection portion and the abutment portion are integrally formed. The connection portion has a first area connected to the body portion. An outer diameter of the first area is less than the body outer diameter of the body portion adjacent to the first area. The connection portion has an indented structure to adhere the alveolar bone and grow the soft tissue, so that a biologic width is formed between the soft tissue and the hard tissue to prevent bacteria in the mouth from invading the alveolar bone tissue, thereby solving the problem of osteanabrosis in conventional dentistry, and satisfying the clinical aesthetic requirement of the anterior teeth.

Owner:METAL INDS RES & DEV CENT

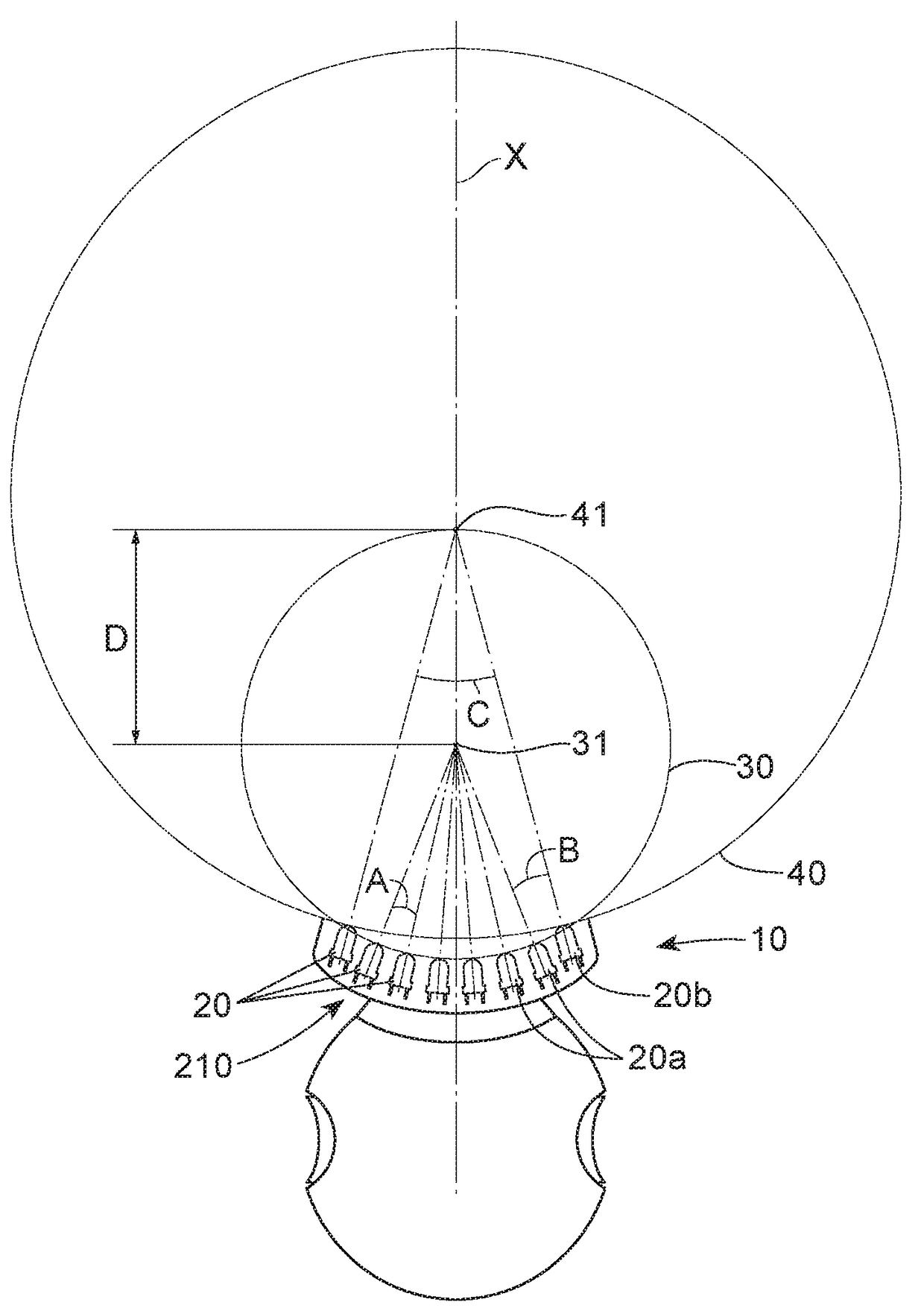

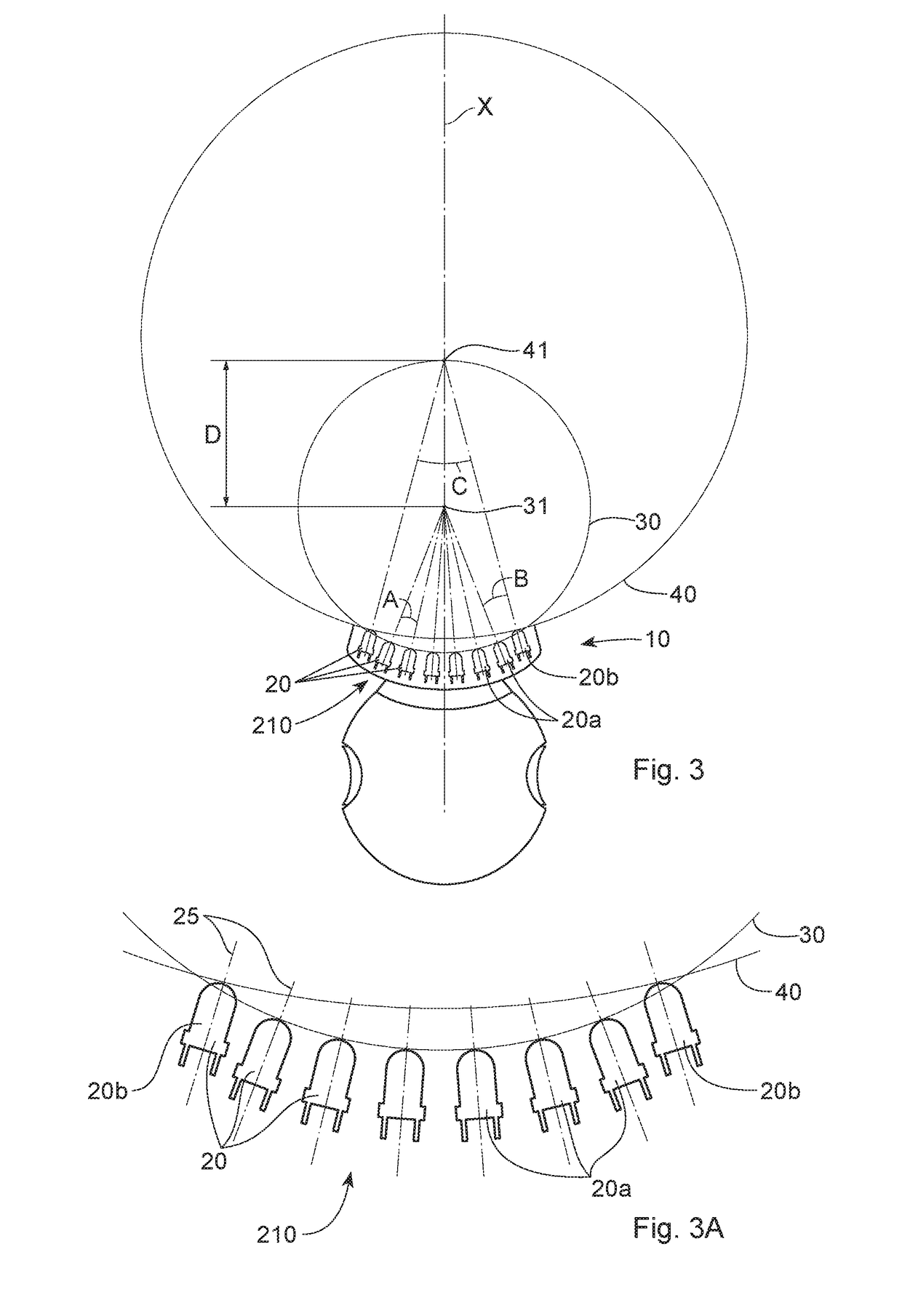

Tooth-whitening process

ActiveUS10099064B2Stable positionIncreased versatilityDentistryLight therapyLed arrayAnterior surface

A tooth-whitening process includes providing an array of LEDs disposed in a first plane and forming an inner arc having an inner focal point and an outer arc having an outer focal different from the inner focal point; applying a whitening composition to at least the anterior surfaces of at least six mandibular or maxillary anterior teeth and maintaining the whitening composition on the at least six teeth for a first time period; after the first time period, directing a light radiation comprising blue visible light or near-visible UV light of at least a threshold intensity from the least a first array of LEDs for a second time period to the anterior surfaces of the at least six teeth, the first time period having a duration greater than 50% of a total duration of the first time period and the second time period; and removing the whitening composition from the at least six teeth.

Owner:THE PROCTER & GAMBLE COMPANY

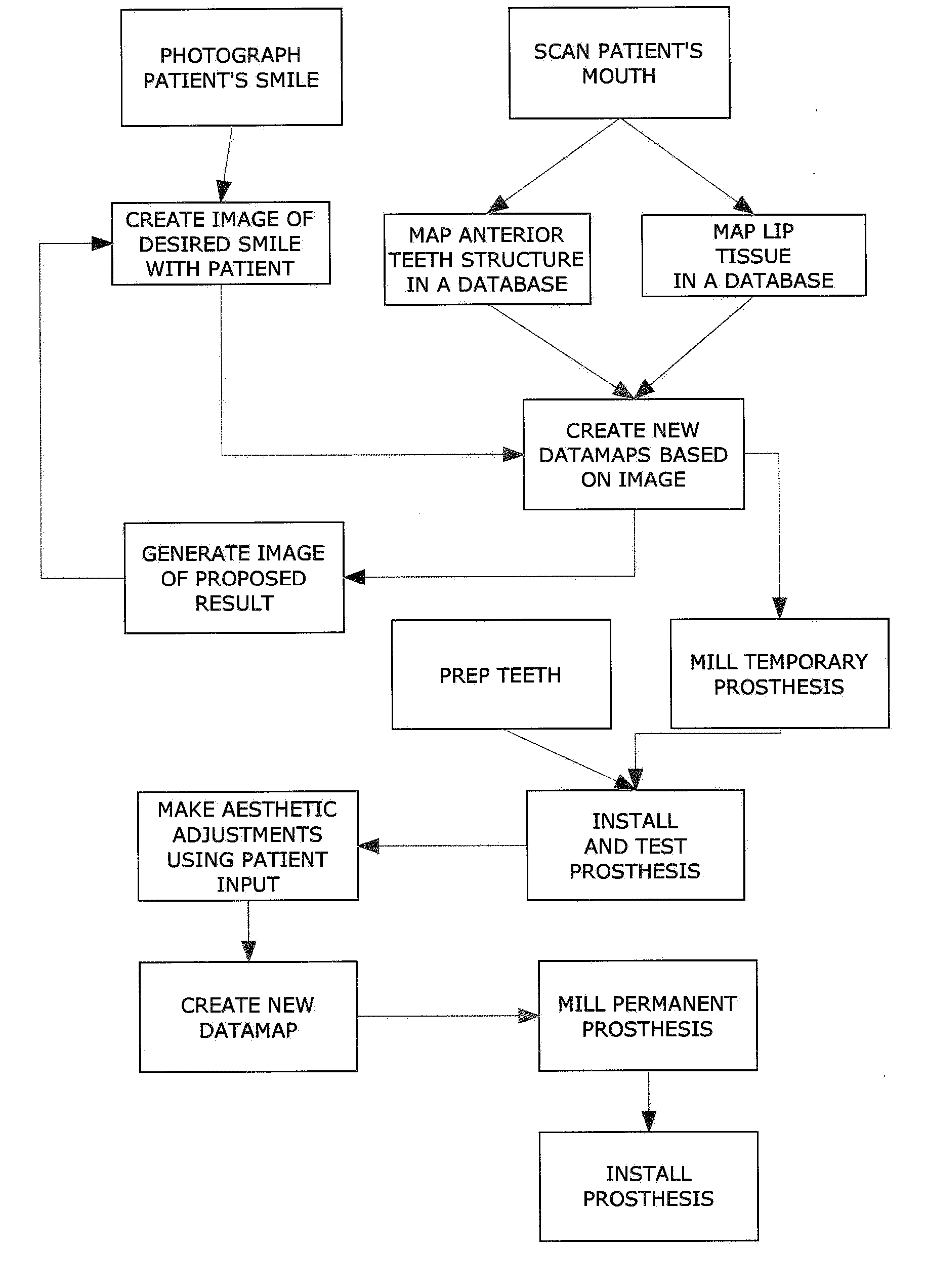

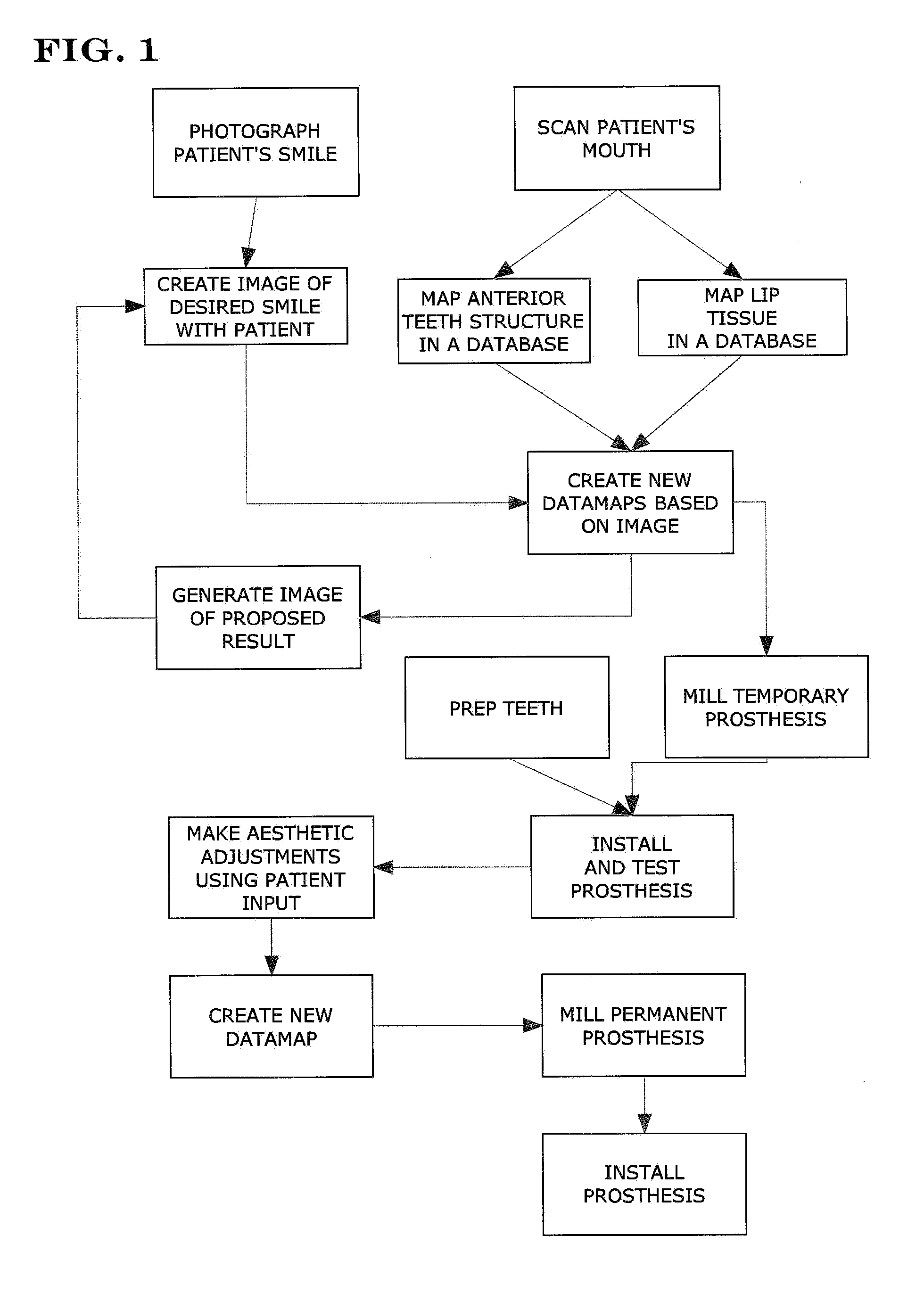

Dental method of smile design

A patient's smile is improved by photoimaging the patient's smile and scanning the patient's anterior teeth and associated soft lip structure to obtain sets of data mapping the patient's anterior teeth and associated soft tissue structure. The photo image is used to create a desired smile image which is then used to amend the data map of anterior teeth to a substantially identical resultant image which is then used to mill temporary and permanent prosthesis

Owner:MELETIOU JR DEMETRIOS S

Dental Composite Dispenser For Injection Molded Filling Techniques

InactiveUS20090191506A1Easy to handleEasy to placeImpression capsAmalgam presses/mixersMold fillingDental composite

The present invention relates to methods for the restoration of a decayed portion of an anterior tooth or re-restoration of a previously filled anterior tooth, and to dental matrices and composite resin dispensers that may be used in the methods for the restoration of a decayed portion of an anterior tooth.

Owner:CLARK DAVID J

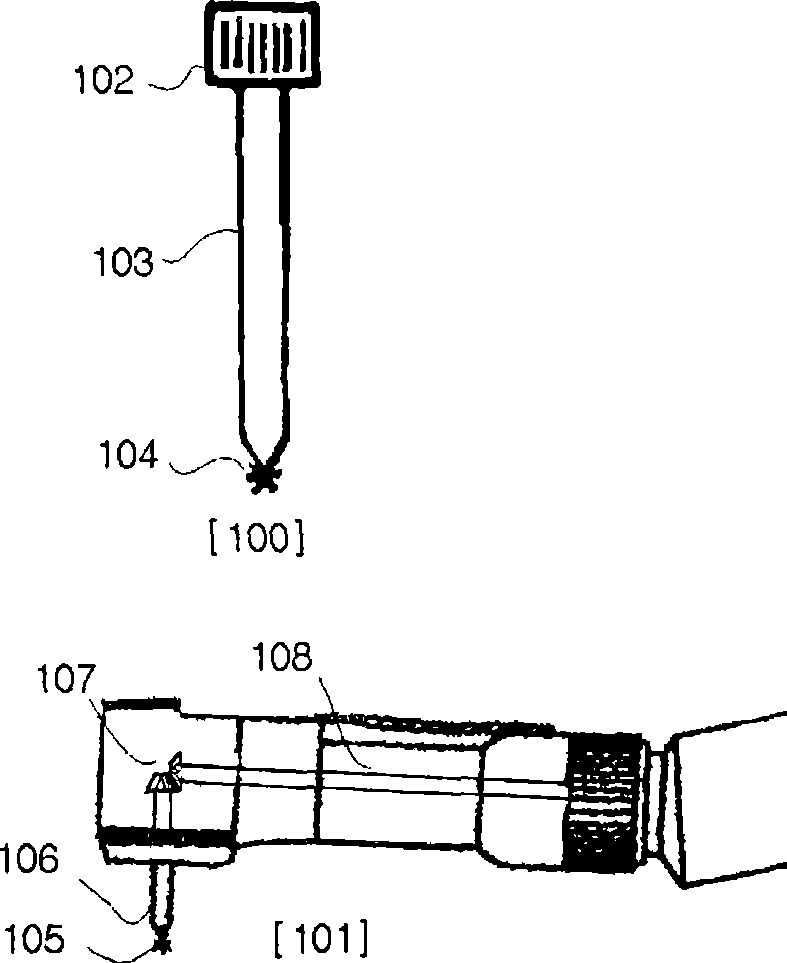

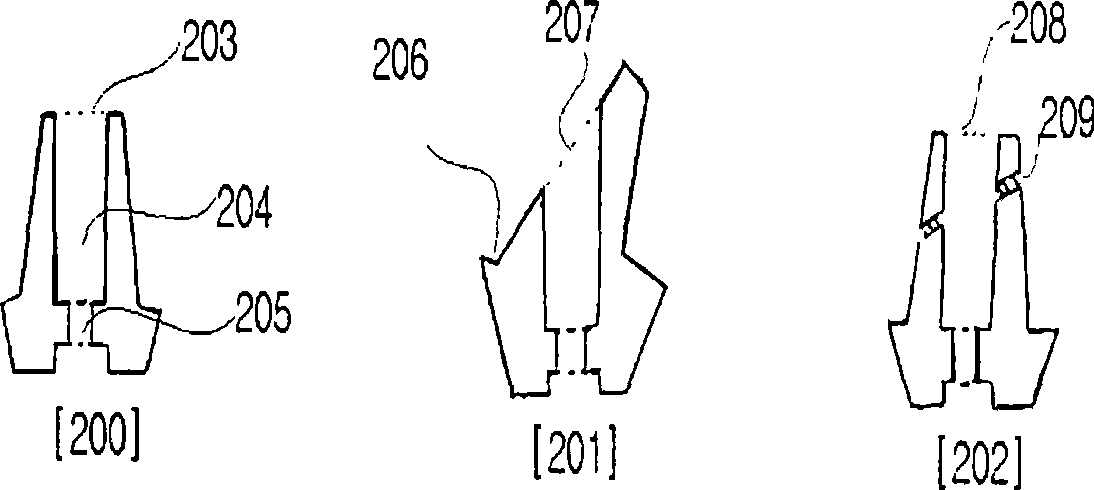

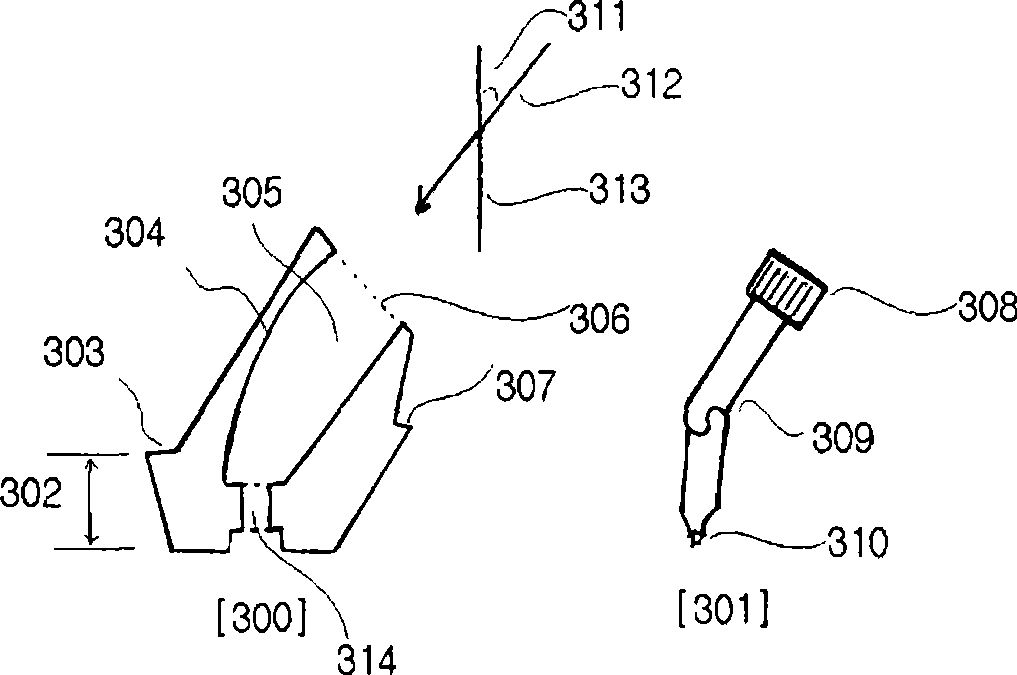

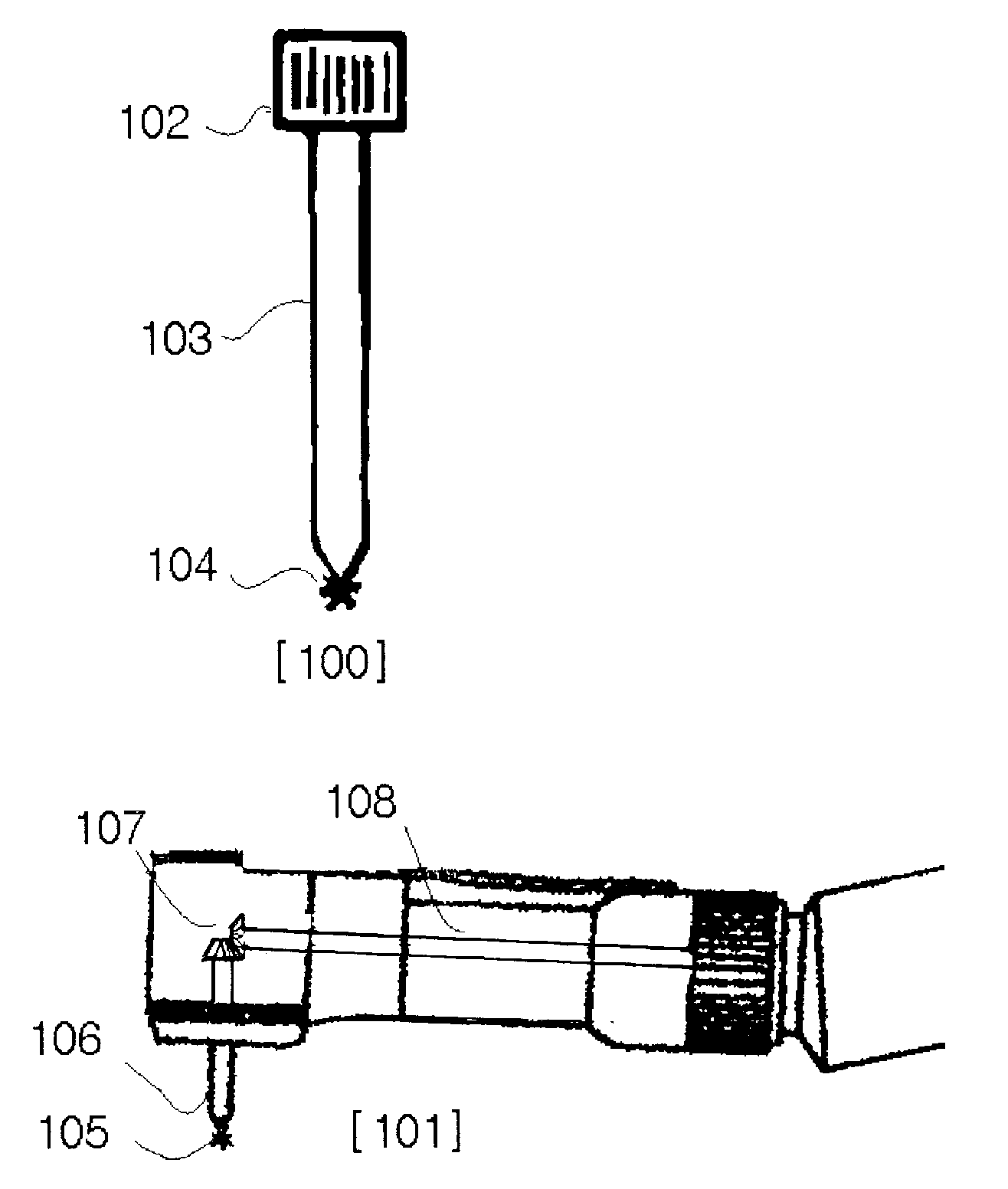

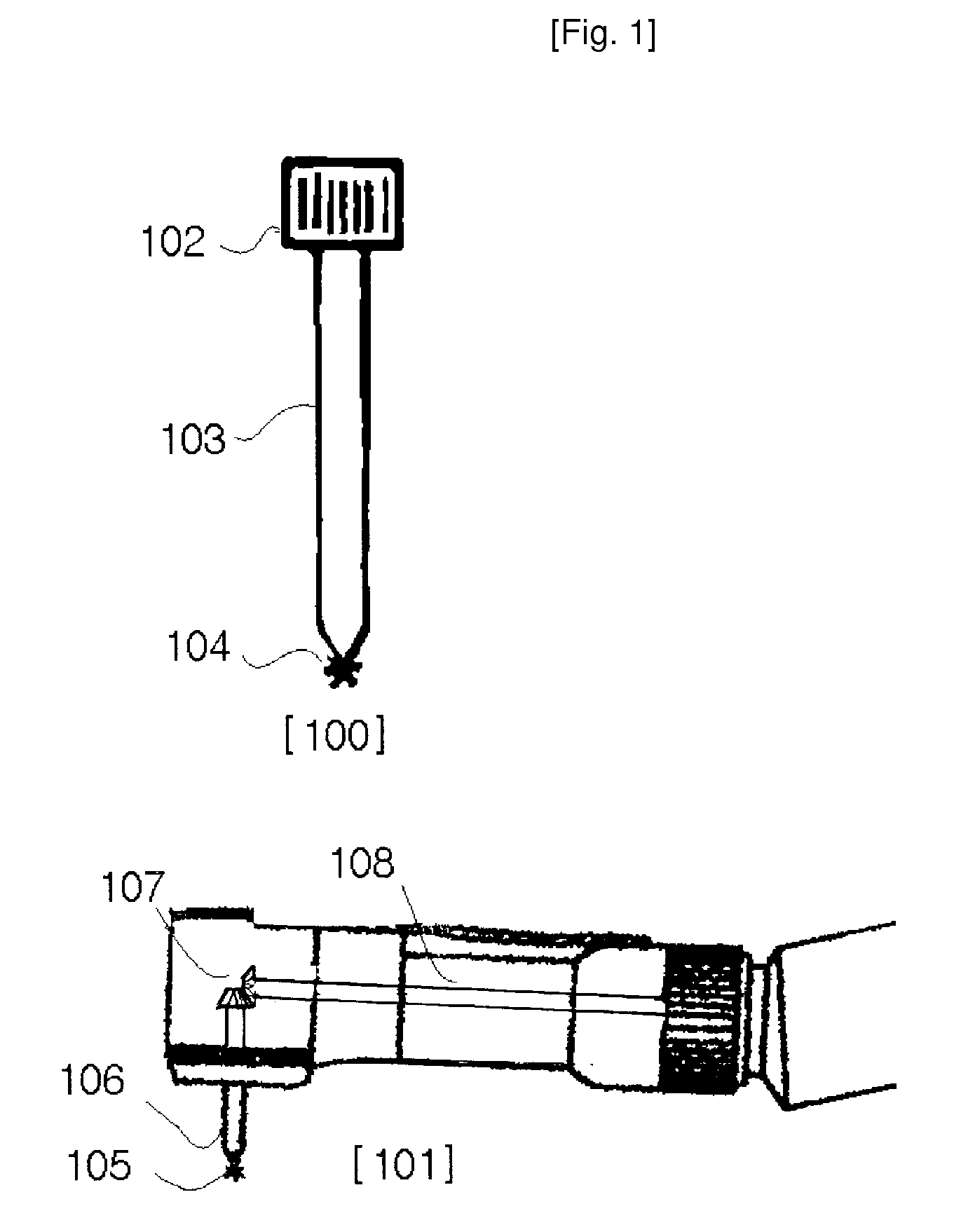

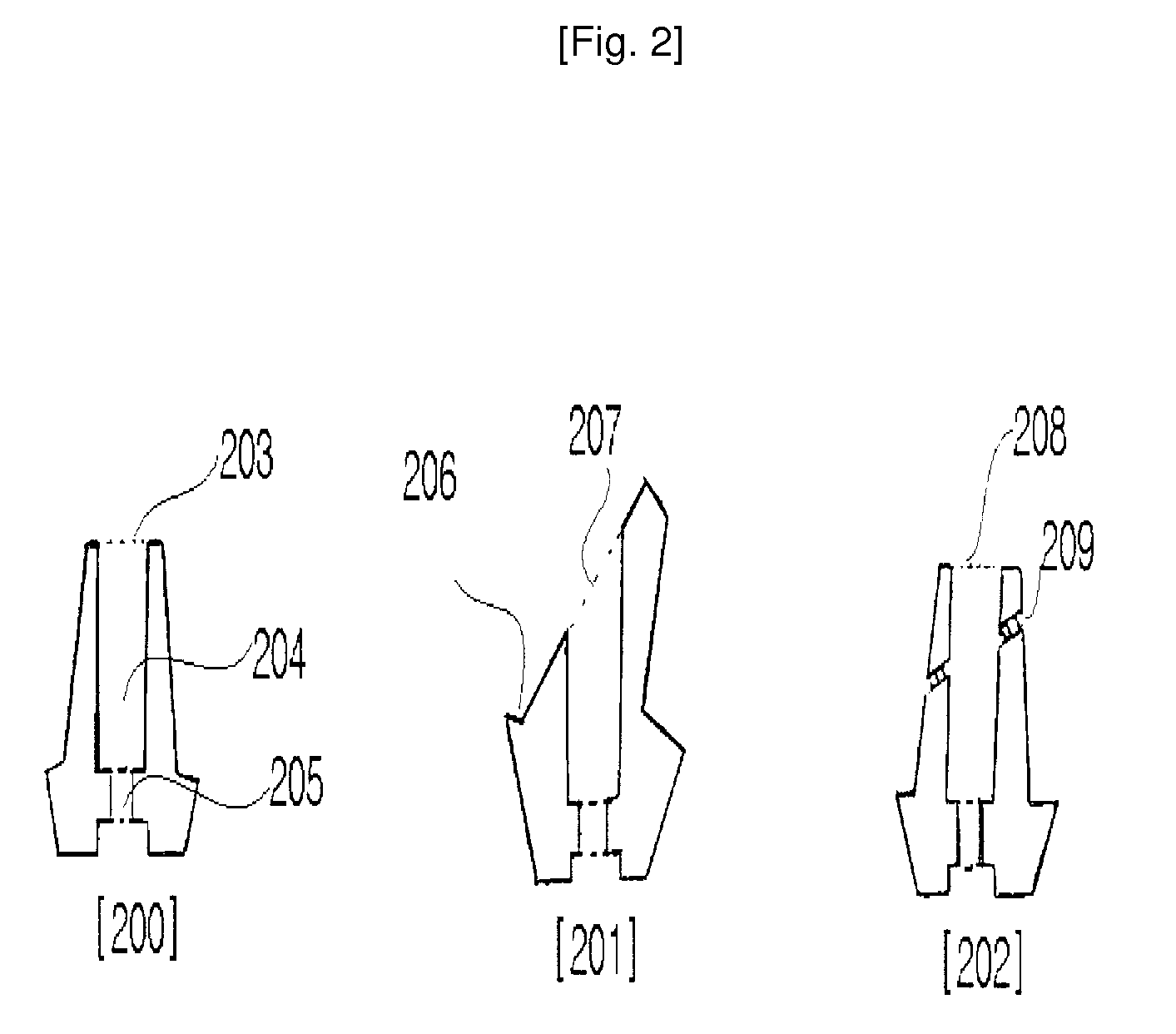

Free Angled Implant Driver and Free Angled Hole Implant Abutment

In case of straight driver (100), The entrance of screw inserting hole of Implant prosthesis is on the same line with implant fixture's axis. Due to this position of the hole, final prosthesis has many difficulties. Thus. I invented the free angled driver (301). For maxillay anterior teeth, we can move the screw hole to lingual surface of prosthesis (511). we can make esthetic and convenient prosthesis with capability of easy screwing and unscrewing. Also. I invented the free angled hole abutment (300) for the free angled implant driver (301), so we can move occlusal hole to the ideal position. It is an epoch-making change to solve many problems in the contemporary dental implant prosthetics.

Owner:LEE JONG HO

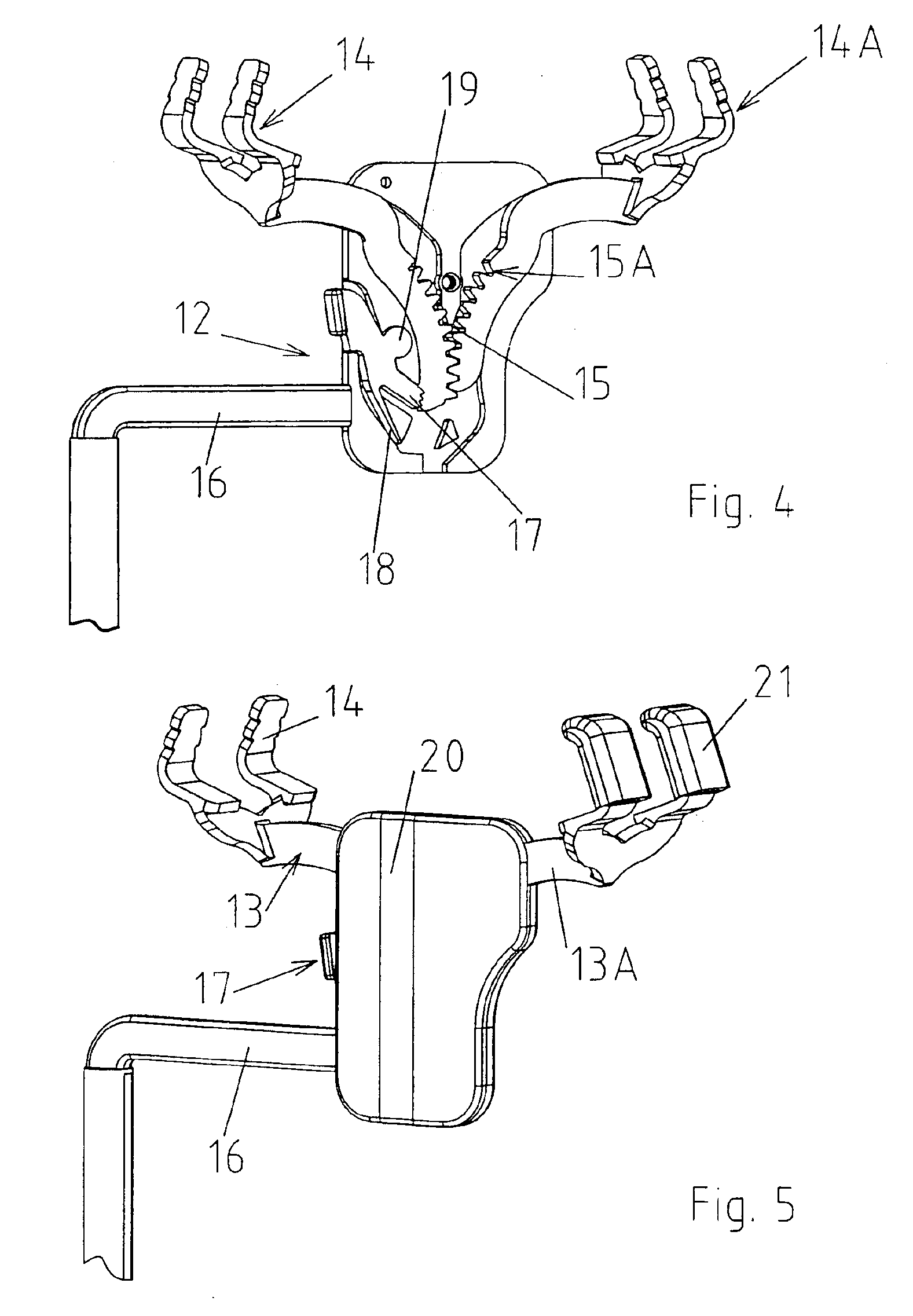

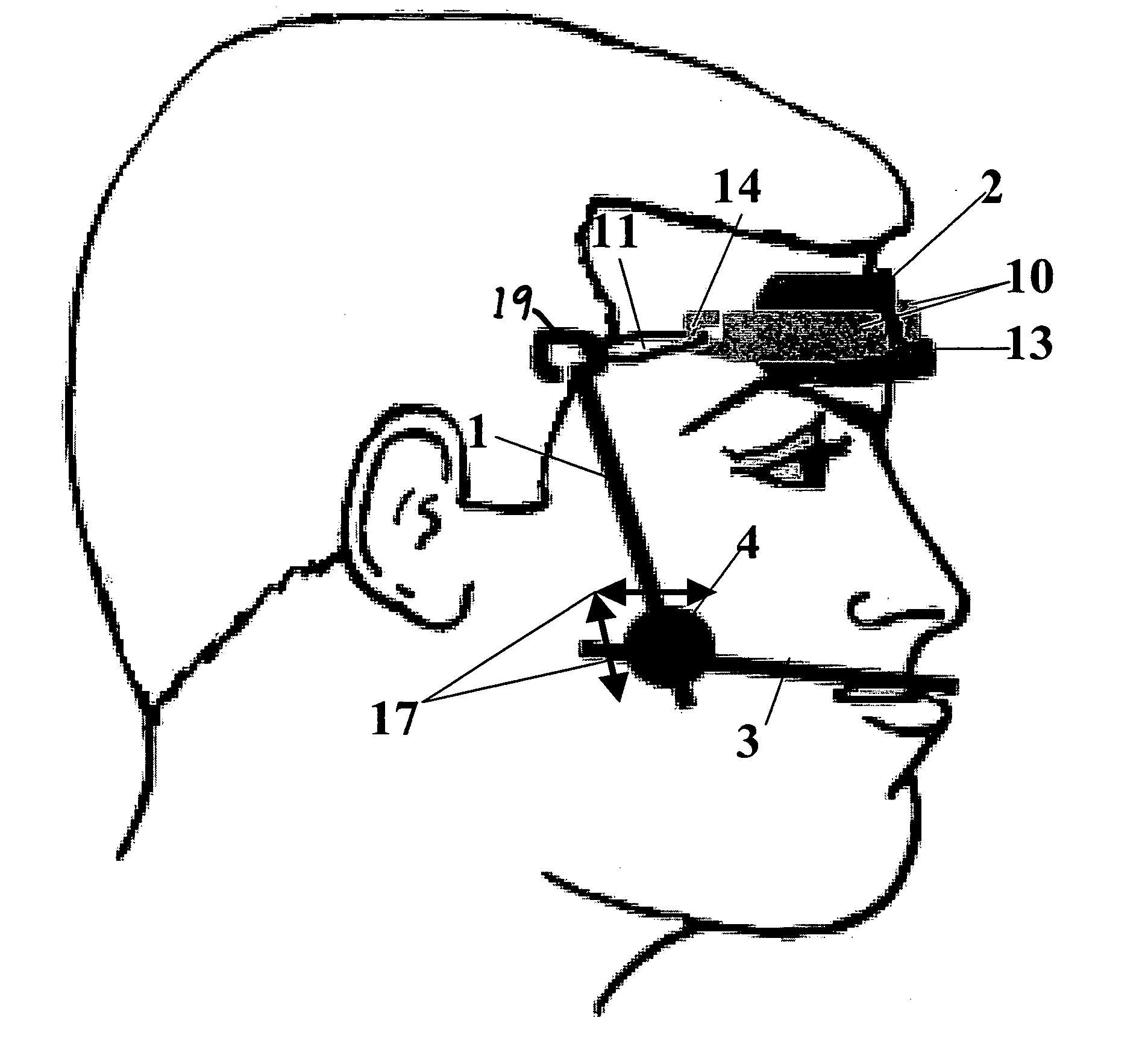

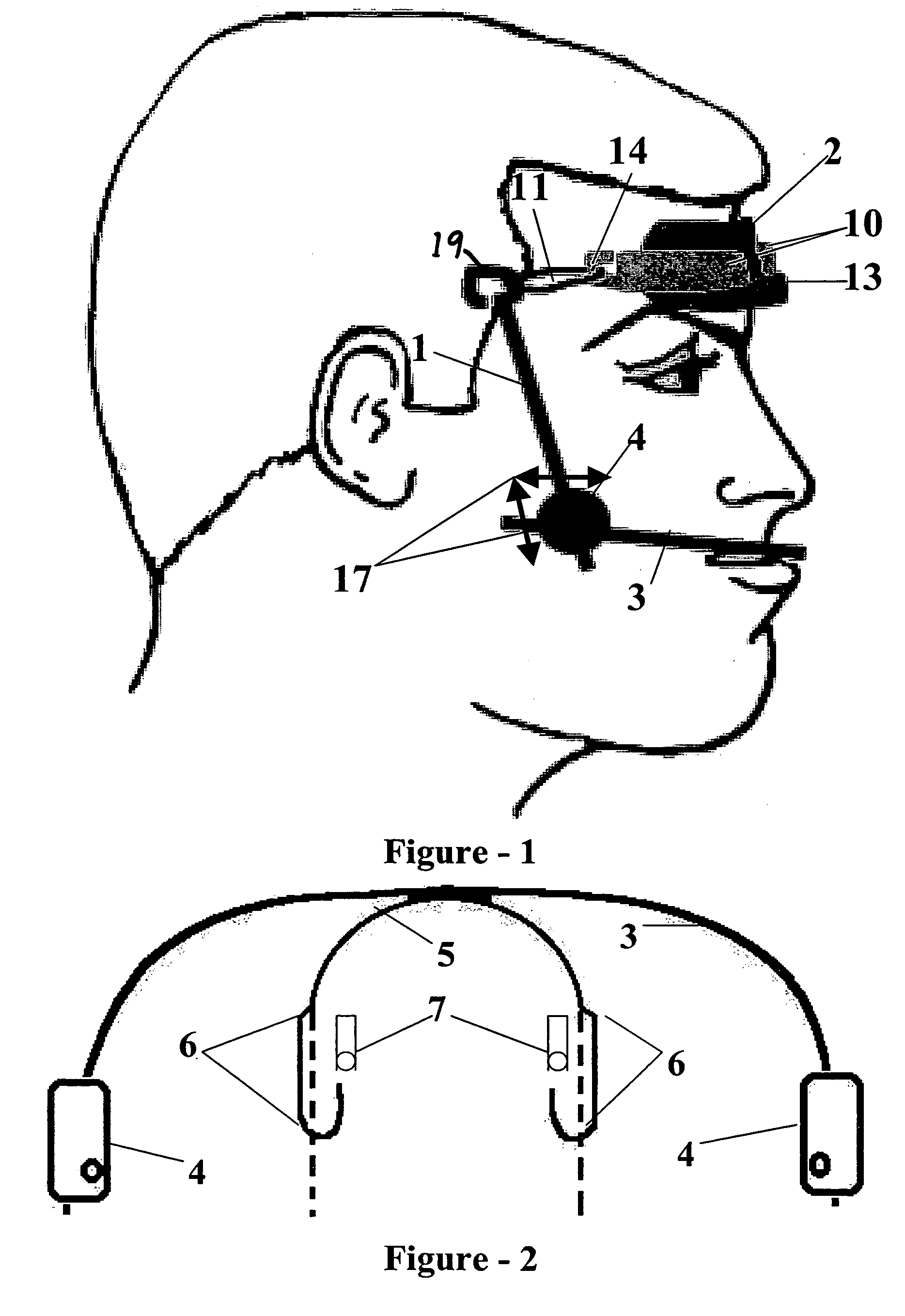

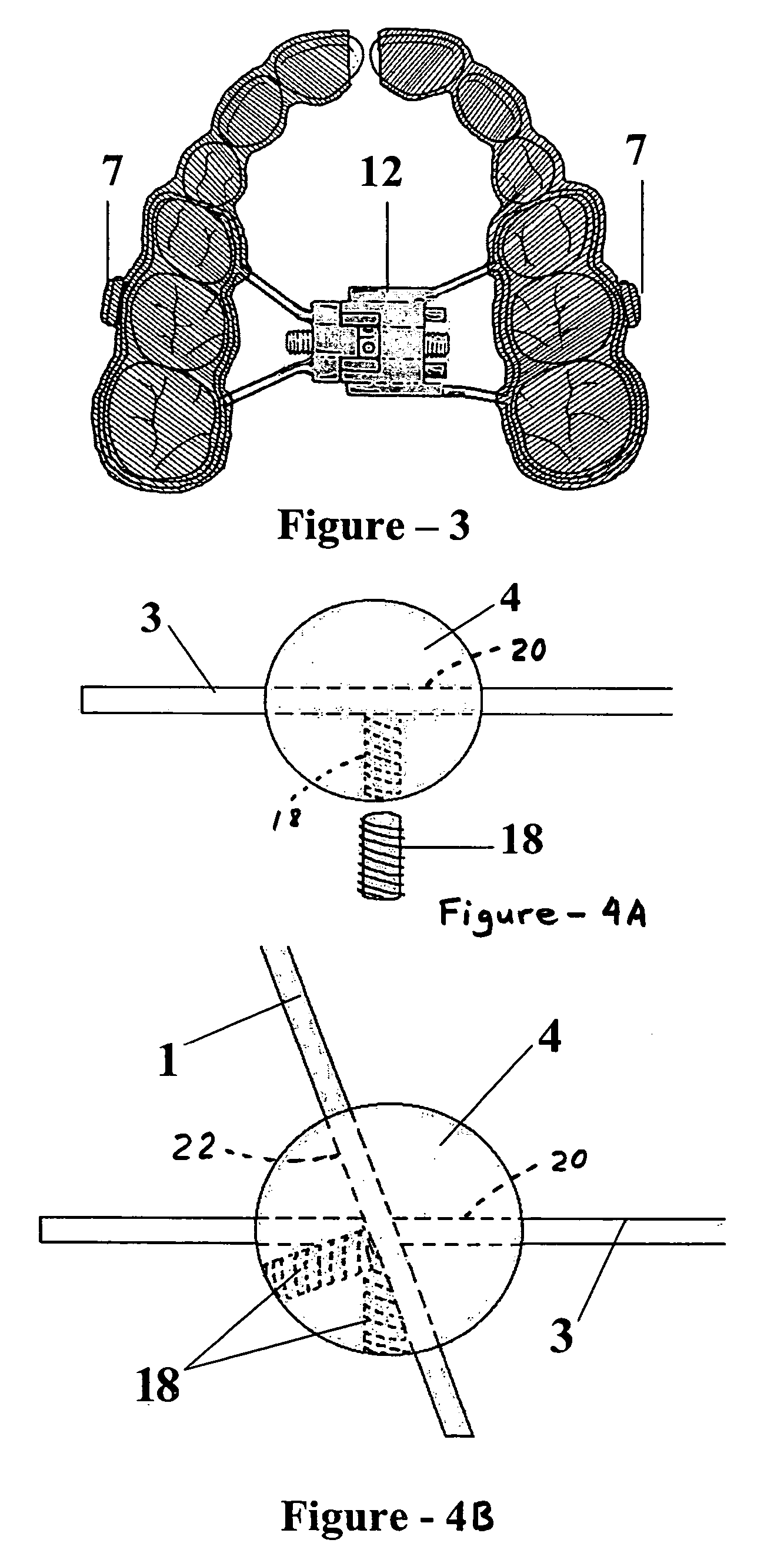

Protraction headgear

A facebow which overcomes the adverse effects and limitations of current designs by rotating the maxilla in a downward and forward direction, which assists in correcting anterior open bites. This is accomplished by a design that produces forces above the center of resistance of the maxilla and parallel to the Frankfurt horizontal plane. The extra-oral headgear design is characterized by providing two independent adjustments (forehead width and horizontal / vertical dimensions) that allow the appliance to be customized to each patient. In particular, the two independent adjustments are provided by a fully adjustable forehead pad and bilateral adjustable blocks on opposite sides of the facebow extra-oral frame to provide horizontal and vertical adjustments.

Owner:GREAT LAKES ORTHODONTICS

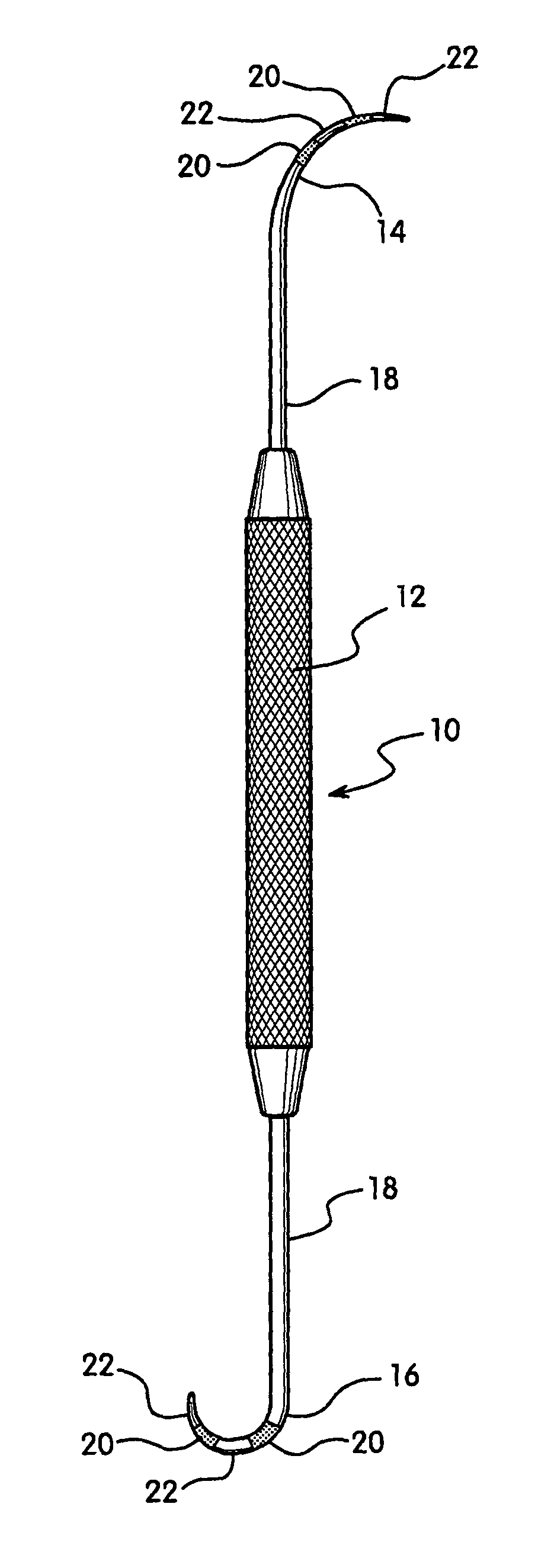

Dental instrument

This invention is directed to a dental instrument and the use of this dental instrument to measure deposits and other imperfections on a tooth surface. The dental instrument has an elongated portion and on at least one end a general curvature portion. The general curvature portion will have the general curvature of a posterior tooth or an anterior tooth. Preferably it also will be marked with measured segments. By placing the general curvature portion against a tooth a deposit or imperfection on a tooth can be measured. In a preferred embodiment the dental instrument will have a general curvature portion in each end; the general curvature on one end being for posterior teeth and the general curvature on the other end being for anterior teeth. When measuring plaque and related deposits a dye solution can be used to make the deposit more visible.

Owner:COLGATE PALMOLIVE CO

Area-specific dental instrument

An area-specific dental instrument is provided, which comprises an arcuate S-shaped shank and an arcuate blade further comprising a sharpened convex surface. This instrument can be capable of cleaning plaque and calculus from the lingual surfaces of anterior teeth and concave surfaces between teeth at the cemento-enamel junction.

Owner:BEACH TAMARA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com