Dental Composite Dispenser For Injection Molded Filling Techniques

a technology of injection molding and dental composites, which is applied in the field of dental composite dispensers for injection molding filling techniques, to achieve the effects of improving the shrinkage of flowable composites, reducing the viscosity of paste composites, and improving the handling and placemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

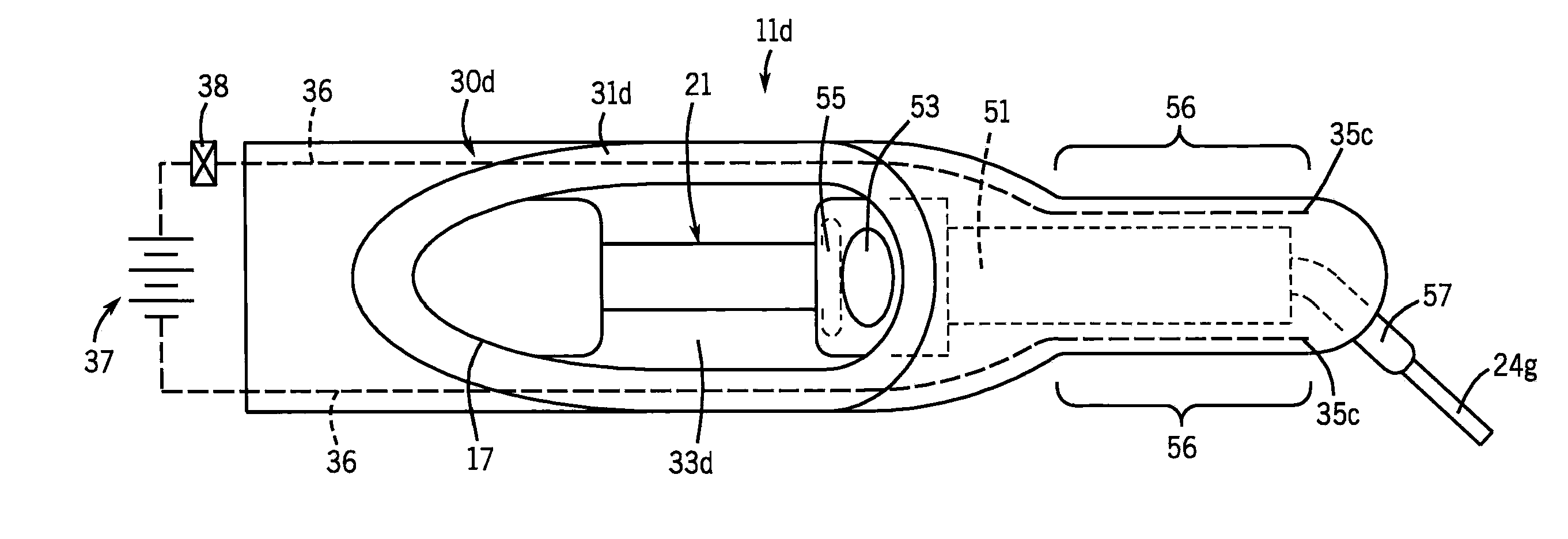

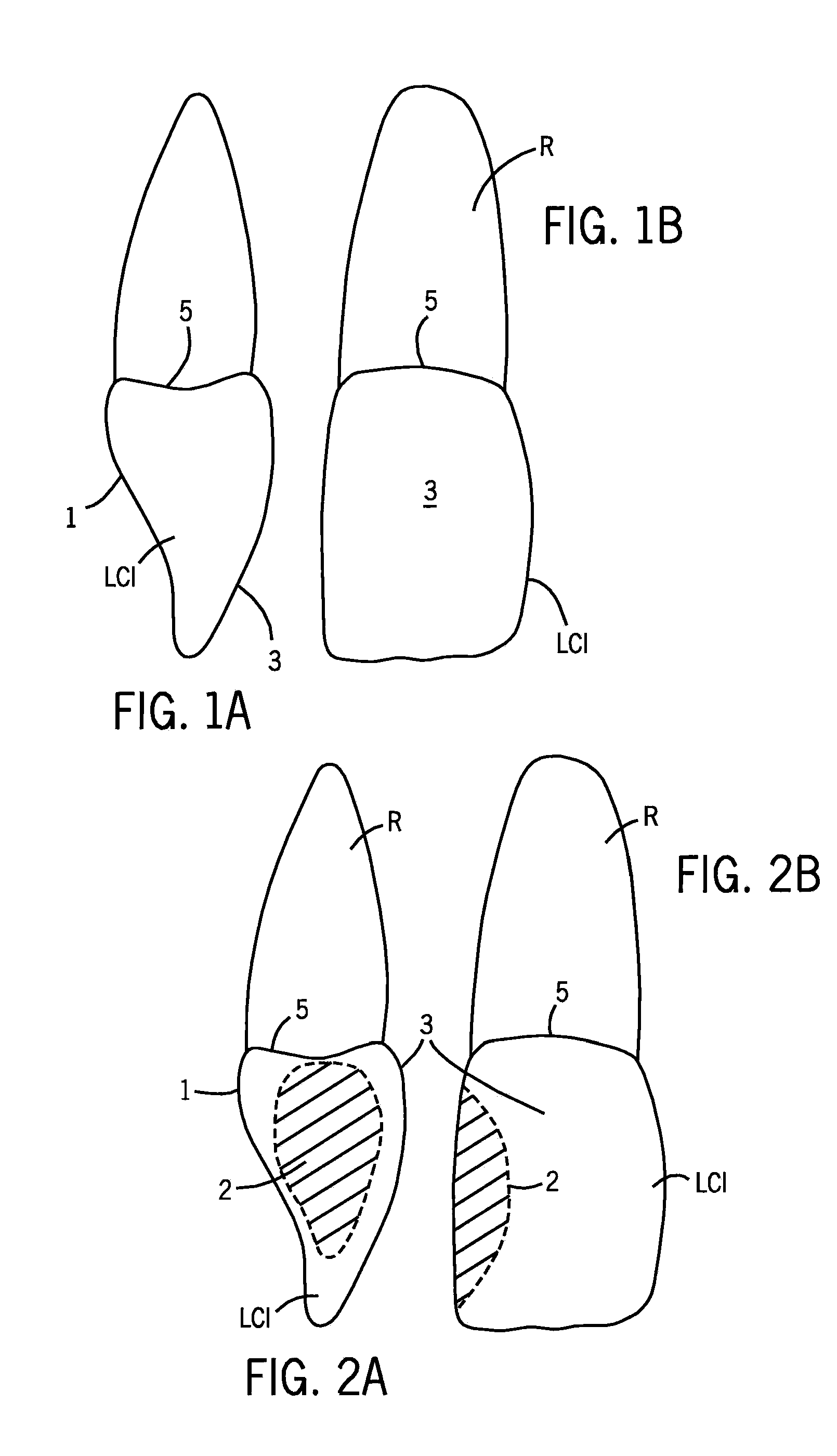

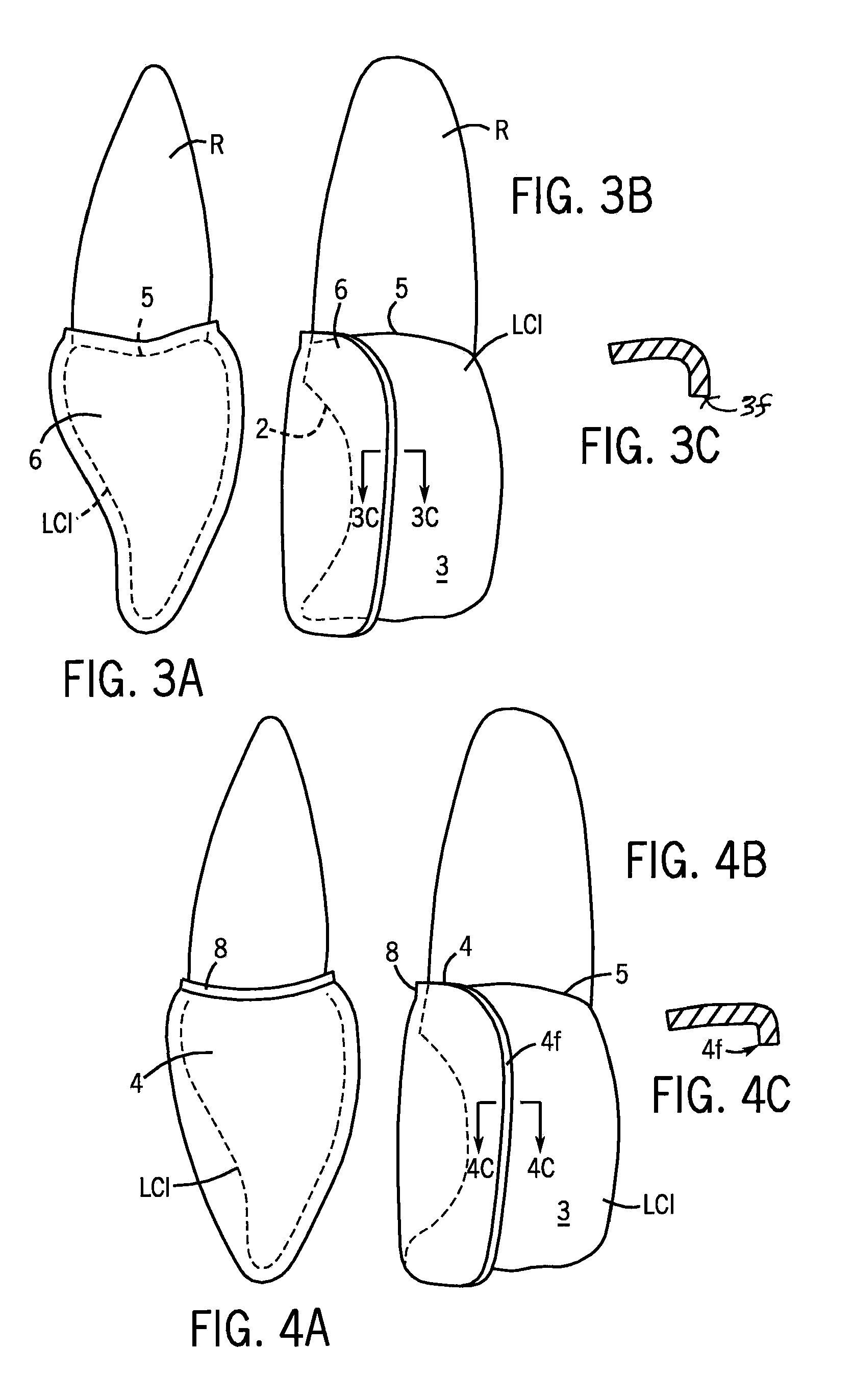

[0065]The invention provides improved methods, dental matrices, composite dispensers, and kits for the restoration of a decayed portion of an anterior tooth.

[0066]In an example method according to the invention for the restoration of a tooth, the dentist locates a tooth having a cavity. A hollow cavity preparation is prepared in a tooth. The tools and techniques for forming the hollow cavity preparation are well known in the art and therefore will not be explained further.

[0067]In order to properly deposit the restorative material on the side of the tooth without undesired leaking of the restorative material beyond the side of the tooth, the dentist places a dental matrix around at least a portion of the tooth. In the invention, a sectional anatomic translucent dental matrix is placed on the tooth. When the matrix is placed around at least a portion of the tooth, the matrix acts as a form for the desired shape of the restored tooth.

[0068]The cavity preparation in the tooth is then e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com