Method for synchronous realization of one-step lamination and forming of occlusal surface of stable occlusal plate

A technology of occlusal plates and occlusal surfaces, which is applied in the fields of medical science, non-surgical orthopedic surgery, and dentistry. It can solve the problems of self-curing resin being not durable, cumbersome production process, and discomfort of front teeth, etc., and achieves good results and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

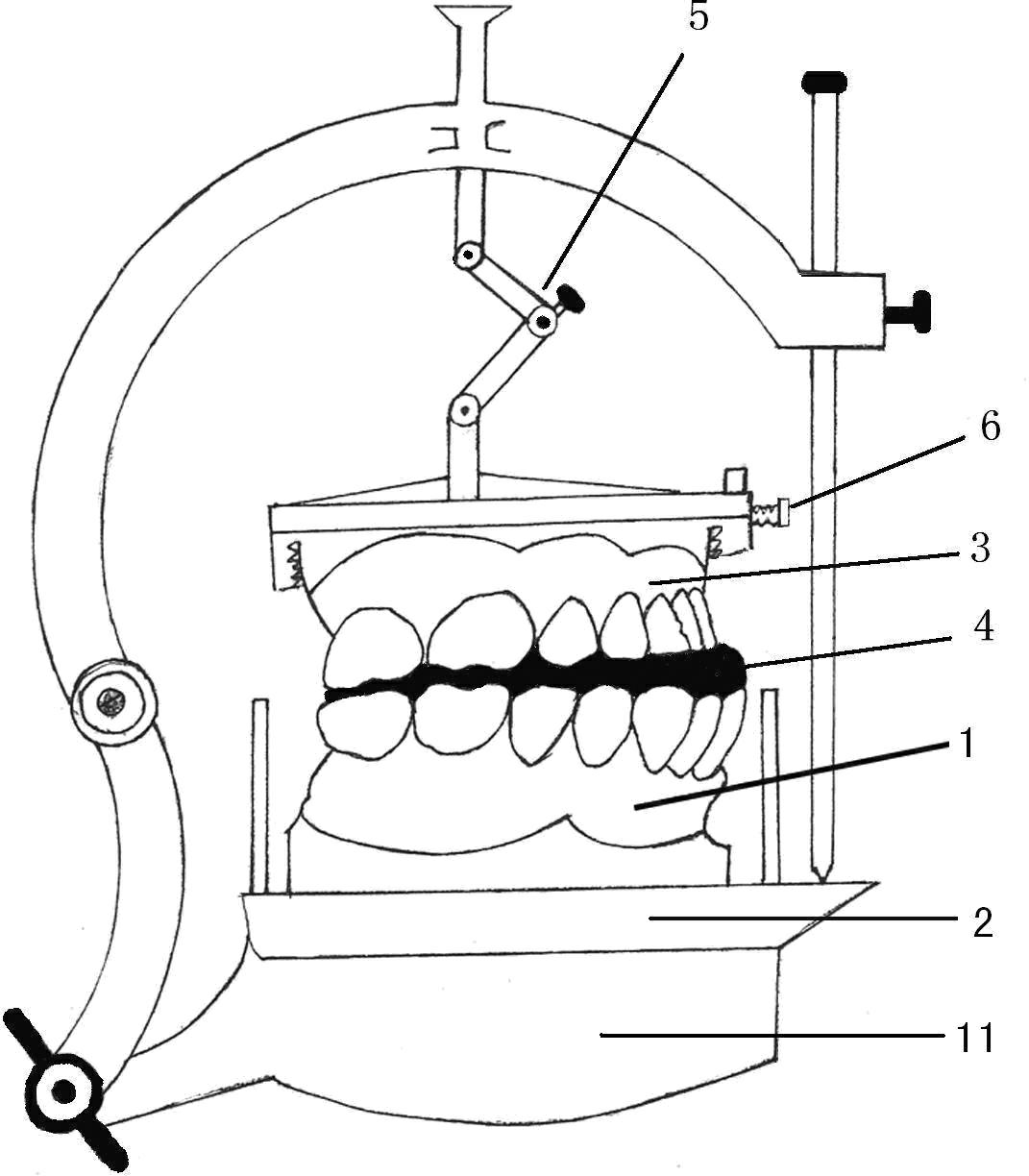

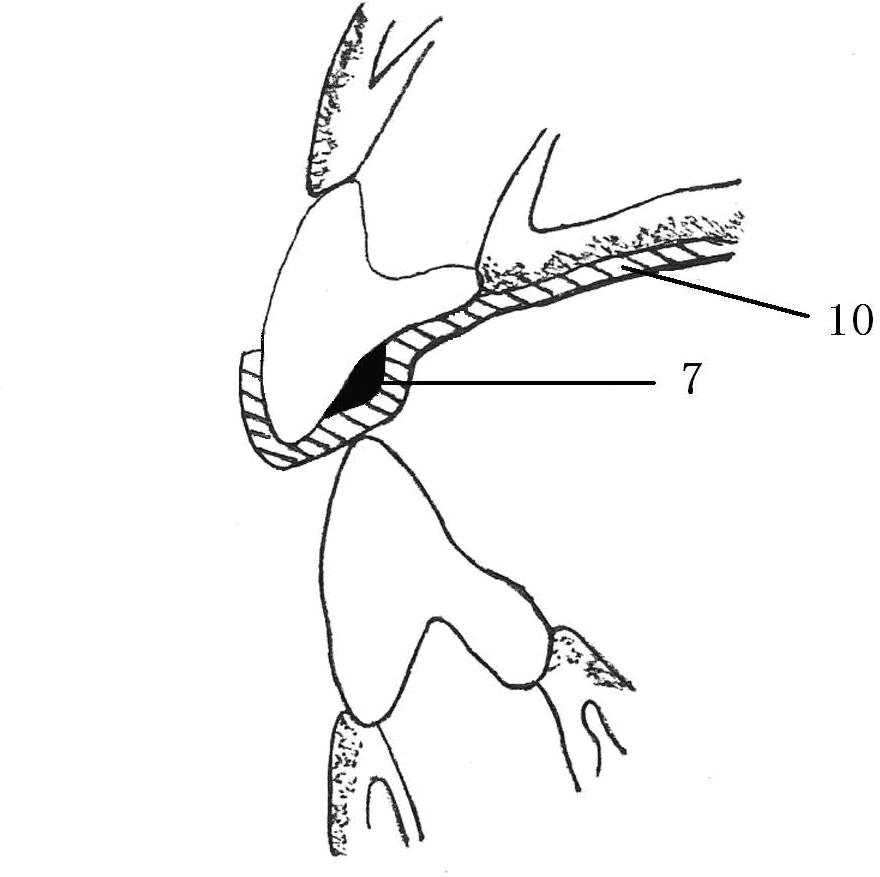

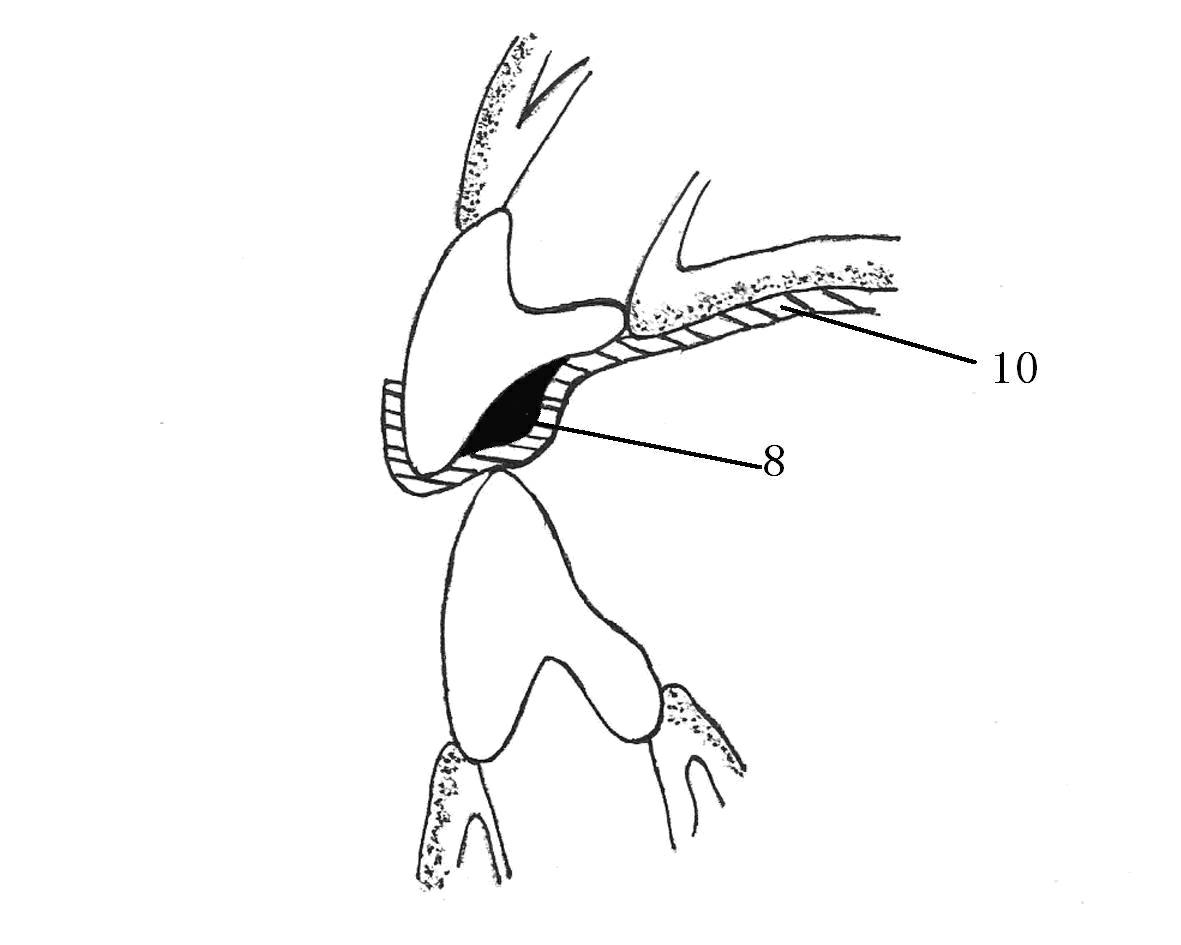

[0037] Refer to attached Figure 1~4 According to the present invention, the method for forming the occlusal surface of a stable occlusal plate by one-time pressing film comprises the following steps:

[0038] 1) Take the printing film

[0039] Inject the melted injection agar into the occlusal surface of the patient's posterior teeth and the lingual fossa of the upper anterior teeth, and immediately use the alginate printing film material to routinely take the printing film, and fill the superhard plaster model. It is required to take every tooth. Especially for the final molars, the agar can eliminate the air bubbles on the occlusal surface of the imprinted film, and obtain the maxillary tooth model 1 and the mandibular tooth model 3 with accurate occlusal.

[0040] 2) Transfer the median relationship

[0041] Use base wax or silicone rubber for occlusal recording to transfer the median relationship between the upper and lower jaws of the patient to form a median relations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com