Free angled driver and free angled hole abutment

A technology of drivers and implants, applied in the fields of dental implants, dental drilling, medical science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

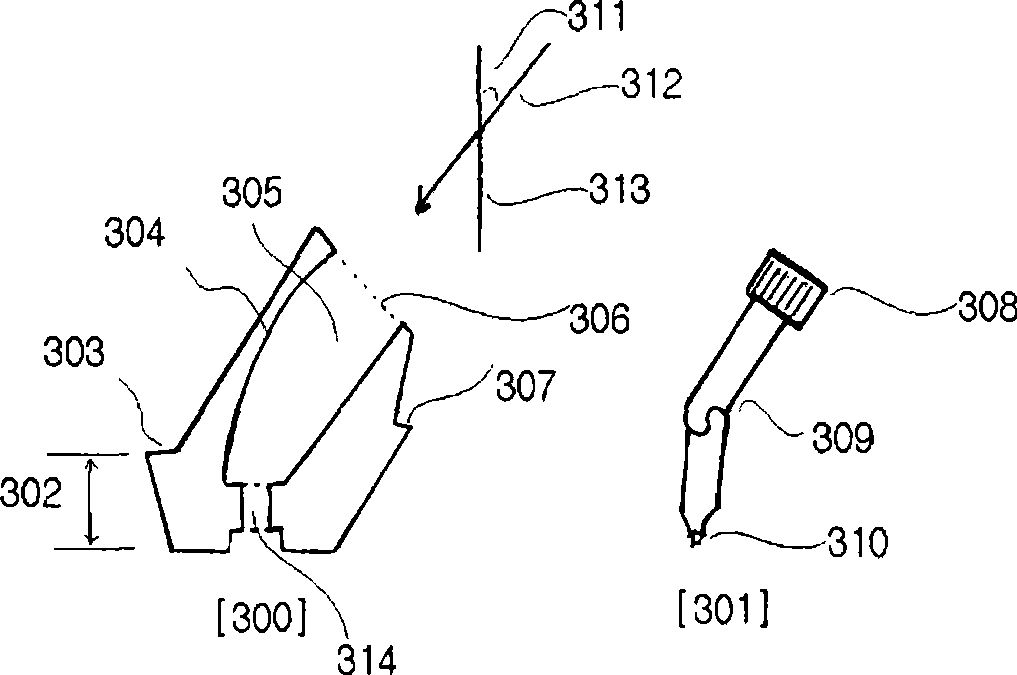

[0133] [128] The free-angle implant driver 301 for the implant is executed by the driver handle 308 of the power shaft 312 or the head type connection 1002, the torque transmission part 309 that transmits the rotational force from the driver handle along the driver rod 313, The working shaft 310 is made up of drive components.

[0134] [129] The torque transmitting member is a combination of rings, gears, wires or tubes.

[0135] [130] image 3 is a diagram of a free-angle driver with an annular angle portion 309. If the handle is turned, the ring transmits torque along the working end of the driver.

[0136] [131] Figure 5 is a view of a prosthesis 501 where the torque transfer parts of the two rings are made easy to tighten and loosen by a tube 509 guiding the retention screw holes.

[0137] [132] The free angle drive length from the working end 310 to the torque transfer member 309 should be short enough that these members should be located within the abutment.

[013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com