Method for extracting filament gutta-percha from eucommia leaf and skin

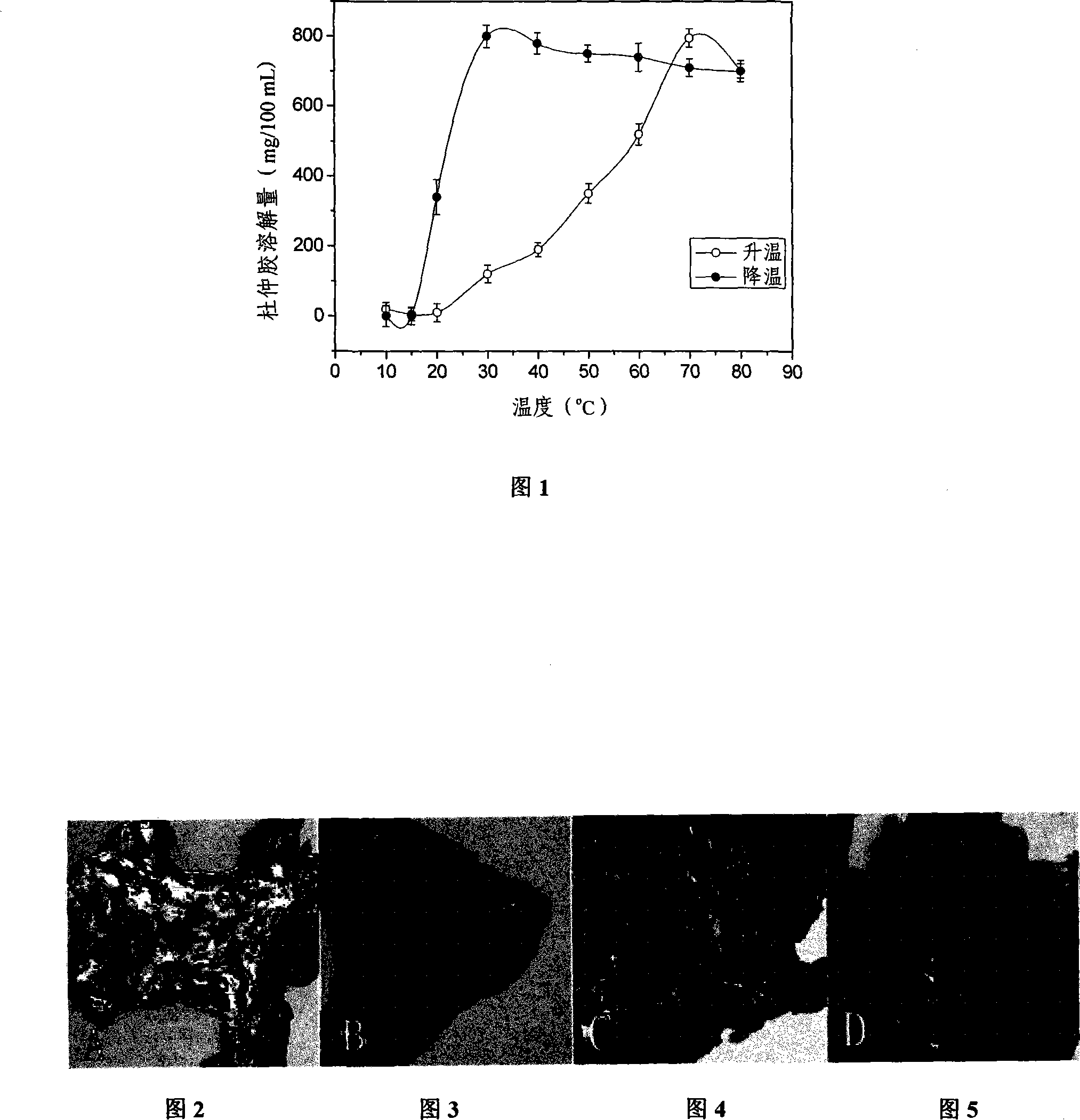

A technology of Eucommia leaf and Eucommia gum, which is applied in the field of extracting Eucommia ulmoides, can solve the problems of destroying the structure of Eucommia collagen, reducing the stretchability, toughness, elasticity and crystallization of Eucommia gum, and achieving the effect of high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following examples are used to further illustrate the present invention:

[0013] Step 1: Remove the cuticle

[0014] Slightly crush the Eucommia leaves or bark of Eucommia, and process them into about 1-3cm 2 Place the piece in a 250ml conical beaker, add 200ml of NaOH solution with a mass fraction of 1%, shake it on a shaker at 30°C to 70°C and 120r / min for 6h; filter, and wash the obtained filter residue with 2000ml of distilled water to pH The value is 7.0, and then dried in an oven at 50°C to constant weight;

[0015] Step 2: Enzymatic hydrolysis of cell wall fibers

[0016] Add 50mL of cellulase solution purchased from Zhangjiagang Jinyuan Biochemical Co., Ltd. with a pH of 4 to the leaves of the filter residue obtained in the previous step, and 100ml of the corresponding buffer solution with pH=4, shake well; place at 50°C In a water-bath shaker, shake for 2 hours at a rotational speed of 120r / min; similarly filter, dry the leaf filter residue in an oven a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com