Natural and fatigue-resistant gutta-percha vulcanized rubber and preparation method thereof

A vulcanized rubber and fatigue-resistant technology, which is applied in the field of natural fatigue-resistant Eucommia vulcanized rubber and its preparation, can solve the problems of fatigue damage of rubber products, achieve the effects of reducing heat generation and wear volume, increasing fatigue life, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

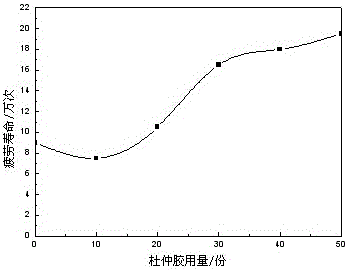

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with examples.

[0011] The present invention prepares fatigue-resistant eucommia gum and its combined rubber vulcanizate according to a specific process, and the described eucommia gum and its combined rubber vulcanized rubber include the following components in parts by weight:

[0012] Eucommia gum / combined rubber: 100-10 / 0-90 parts; active agent: 4-8 parts;

[0013] Antiaging agent: 1-4 parts; Vulcanizing agent: 1-6 parts;

[0014] Reinforcing filler: 30-80 parts; vulcanization accelerator: 1-4 parts;

[0015] Softener: 0-10 parts

[0016] The eucommia gum involved in the present invention is a kind of good insulating material with the characteristics of hard quality at room temperature, low melting point, easy processing, etc., and it has good acid resistance, alkali resistance and seawater corrosion resistance. Adding eucommia gum to natural rubber or synthetic rubber can reduce the heat gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com