A method for extracting eucommia gum from eucommia leaves

A technology for eucommia gum and eucommia leaves, which is applied in the field of extracting eucommia gum from eucommia leaves by biological methods, can solve the problems of production efficiency, low production cost, low added output value, unutilized active ingredients, long production cycle, etc., and achieves reduction of infrastructure costs. , Reduce the amount of material handling, and promote the effect of rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

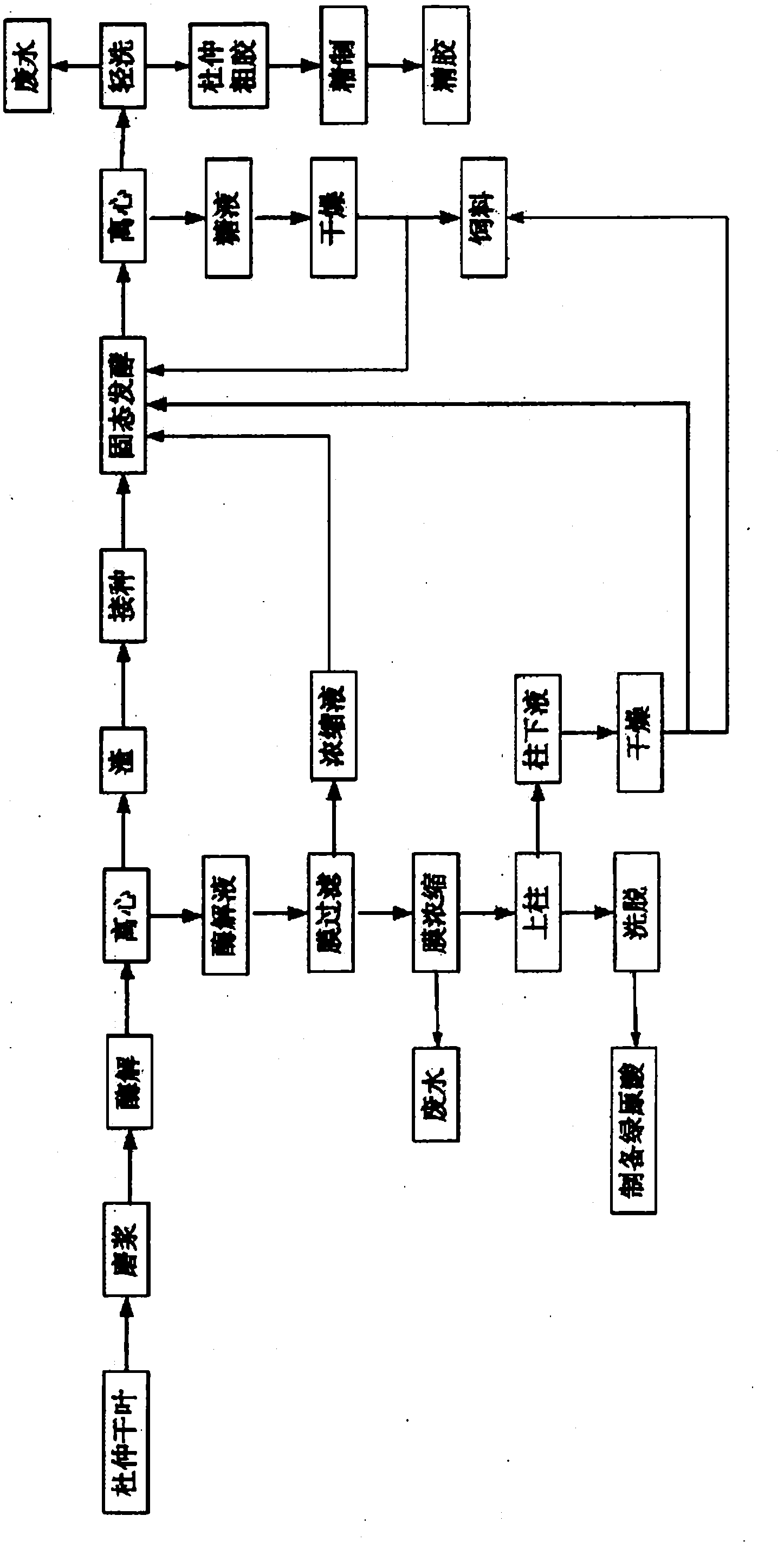

Image

Examples

Embodiment 1

[0021] The first step: preprocessing. Take 20kg of dried leaves of Eucommia ulmoides, add 40kg of water, grind with a steel mill, then add 120kg of water and 0.1kg of protease, hydrolyze for 2 hours at a pH of 6 and a temperature of 55°C, and centrifuge.

[0022] The second step: nitrogen source preparation. The supernatant is filtered through a N100 microfiltration membrane to remove macromolecular proteins and suspended solids; the permeate is concentrated through a nanofiltration membrane, and the concentration ratio is 6 times; the concentrated solution is adsorbed by perforated adsorption resin for chlorogenic acid. Dried the under-column liquid and microfiltration concentrate to obtain protein and polypeptide and mixed them for use.

[0023] The third step: the extraction of Eucommia gum. Inoculate Eucommia ulmoides-16 in the slag obtained by centrifugation for solid-state fermentation, the inoculum size is 0.3kg, add the nitrogen source and glucose prepared in the pre...

Embodiment 2

[0025] The first step: preprocessing. Take 20kg of dried leaves of Eucommia ulmoides, add 40kg of water, grind with a steel mill, then add 120kg of water and 0.1kg of protease, hydrolyze for 2 hours at a pH of 6 and a temperature of 55°C, and centrifuge.

[0026] The second step: nitrogen source preparation. The supernatant is filtered through a N100 microfiltration membrane to remove macromolecular proteins and suspended solids; the permeate is concentrated through a nanofiltration membrane, and the concentration ratio is 6 times; the concentrated solution is adsorbed by perforated adsorption resin for chlorogenic acid. The under-column liquid and the microfiltration concentrate were dried to obtain a protein and polypeptide mixture for use.

[0027] The third step: the extraction of Eucommia gum. Inoculate Eucommia ulmoides-16 in the slag obtained by centrifugation for solid-state fermentation, the inoculum size is 0.3kg, add the prepared protein, polypeptide mixture and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com