Method for extraction and separation of chlorogenic acid, pinoresinol diglucoside, aucubin and gutta-percha from eucommia ulmodies oliv raw material

A technology of pinoresinol diglucoside and aucubin, applied in chemical instruments and methods, separation/purification of carboxylic acid esters, sugar derivatives, etc., can solve the problems of cumbersome operation, high cost, waste of active ingredients, etc. Achieve simple operation, low cost, and meet the effect of industrial large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Extraction: Weigh 50kg of fresh bark of Eucommia ulmoides, cut it into 5-10cm sections with a medicine cutter, then pulverize it into a coarse powder through a hammer mill, put it into a multi-functional extraction tank, add 80% methanol and stir and reflux for extraction twice, Add 200L for the first time, extract for 2 hours, add 150L for the second time, extract for 1 hour, the extract is discharged through the screen at the bottom of the tank, filtered through a pipeline filter, and the extracts are collected twice and combined. After methanol is recovered from the extraction residue, it is used for later use. Concentrate the extract under reduced pressure to 25L, transfer it to an alcohol sink, add 25L of water, heat to 80°C, stir for 30min, cool to 8-10°C, let stand for 12h, and then centrifuge through a three-legged centrifuge bag to obtain centrifuged liquid.

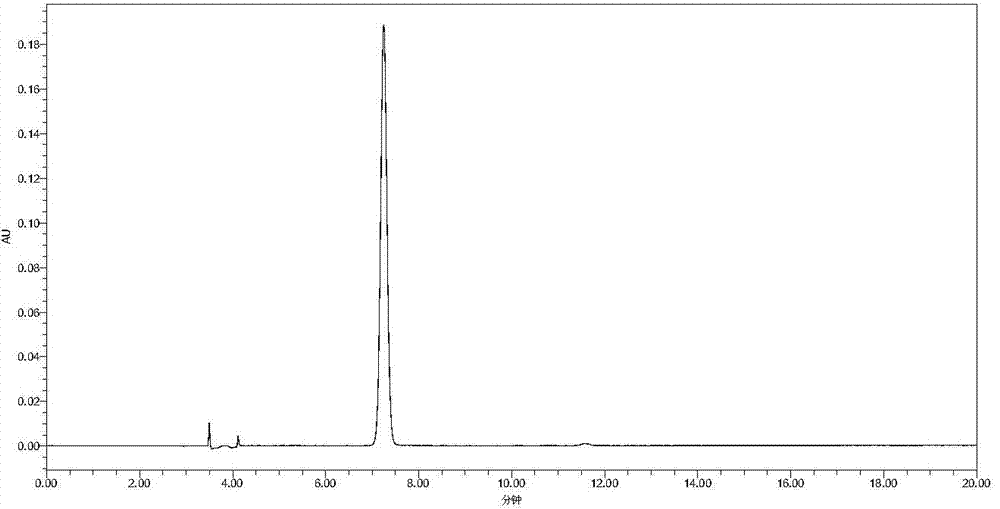

[0033] Enrichment: The centrifugate is completely absorbed by D101 macroporous resin, washed with wat...

Embodiment 2

[0037]Extraction: Weigh 200kg of Eucommia ulmoides bark commercially available, cut into 5-10cm sections with a medicine cutter, then pulverize into coarse powder with a hammer mill, put it into a multi-functional extraction tank, add 70% ethanol to stir and reflux for extraction twice , add 1600L for the first time, extract for 2 hours, add 1200L for the second time, extract for 1 hour, the extract is discharged through the screen at the bottom of the tank, filtered through a pipeline filter, and the two extracts are collected and combined. Extract the residue to recycle ethanol and keep it for later use. Concentrate the extract to 200L under reduced pressure, transfer it to an alcohol precipitation tank, add 200L water, heat to 85°C, stir for 30min, cool to 10-15°C, let stand for 24h, and then centrifuge through a three-legged centrifuge bag to obtain centrifuged liquid.

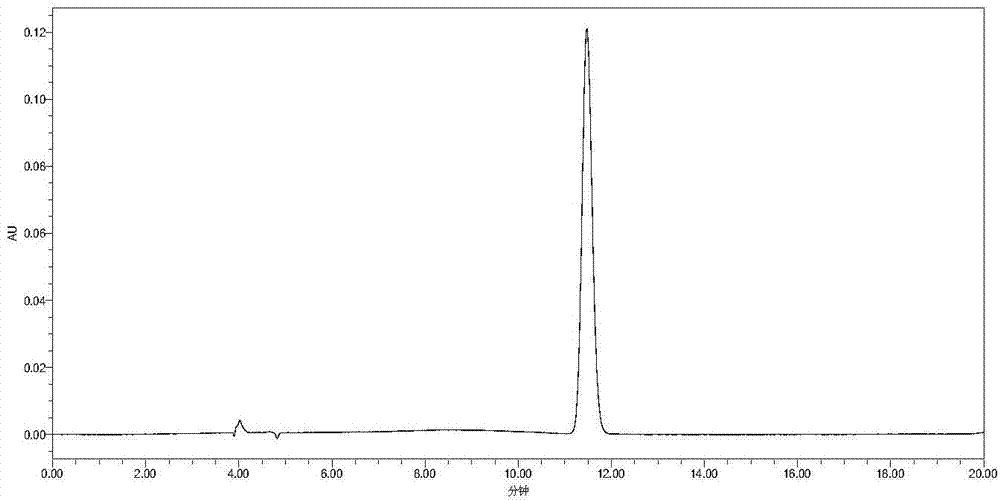

[0038] Enrichment: Adsorb the centrifugate completely through alumina, wash with water until colorless...

Embodiment 3

[0043] Extraction: Weigh 20kg fresh and dried skin of Eucommia ulmoides, slice it, stir fry it in a frying pan for 30 minutes, and then pulverize it into a coarse powder through a hammer mill, put it into a multi-functional extraction tank, add acetone to stir and reflux for extraction twice, the first Add 80L for the first time, extract for 2 hours, add 60L for the second time, extract for 1 hour, the extract is discharged through the screen at the bottom of the tank, filtered through a pipeline filter, and the extracts are collected twice and combined. The acetone is recovered from the extraction residue, which is set aside. Concentrate the extract to 10L under reduced pressure, transfer it to an alcohol sink, add 10L of water, heat to 80°C, stir for 30min, cool to 8-10°C, let stand for 12h, and then centrifuge through a three-legged centrifuge bag to obtain centrifuged liquid.

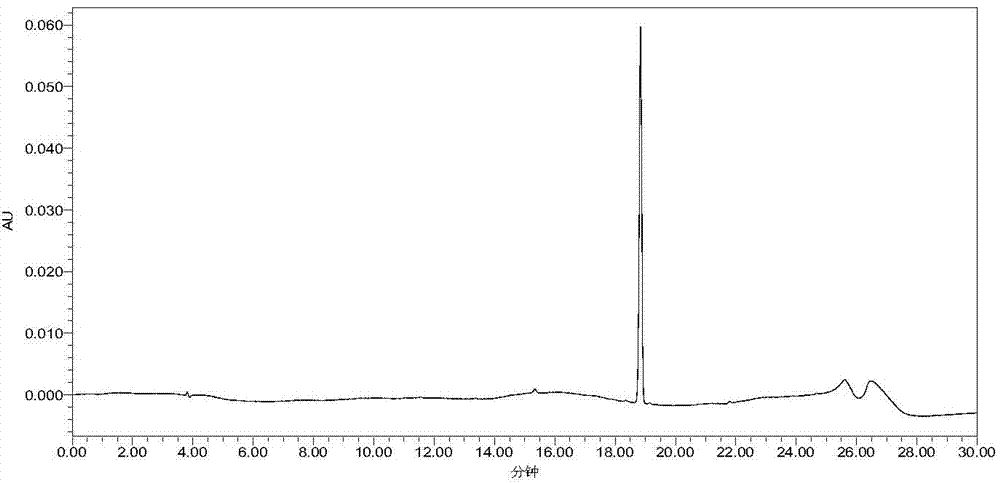

[0044] Enrichment: The centrifugate is completely absorbed by D101 macroporous resin, washed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com