Patents

Literature

161 results about "Luting agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A luting agent is an application of a dental cement. Luting agents connect an underlying tooth structure to a fixed prosthesis, hence giving rise to the term, luting agent, as they lute, or glue, two different structures together. There are two major purposes of luting agents in Dentistry – to secure a cast restoration in fixed prosthodontics (e.g. for use of retaining of an inlay, crowns, or bridges), and to keep orthodontic bands and appliances in situ.

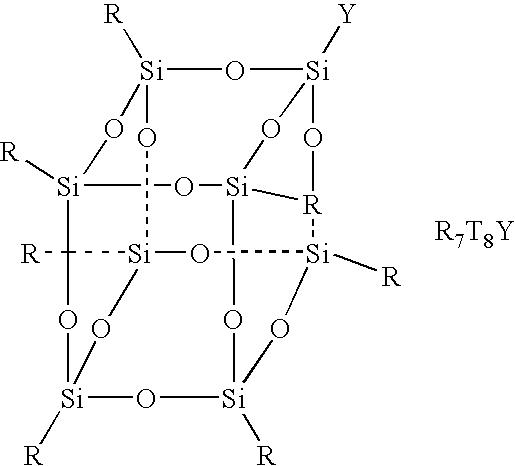

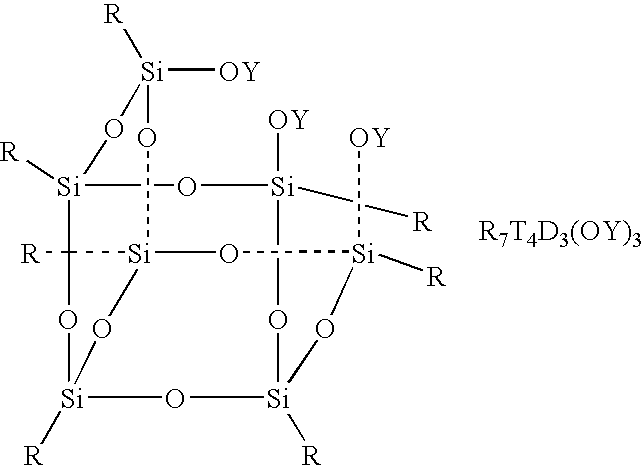

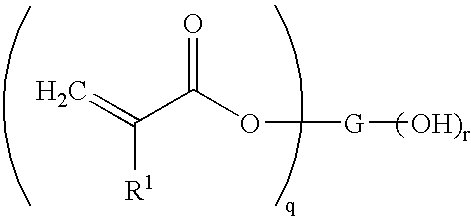

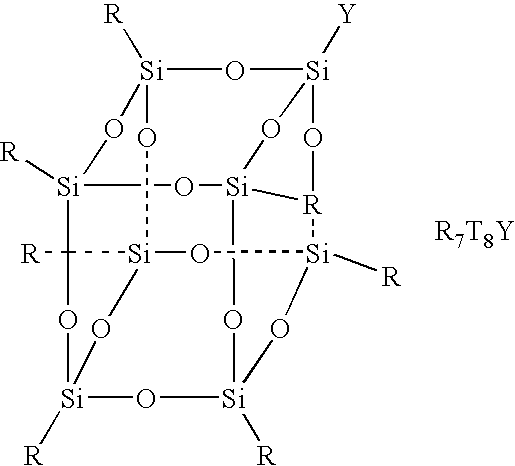

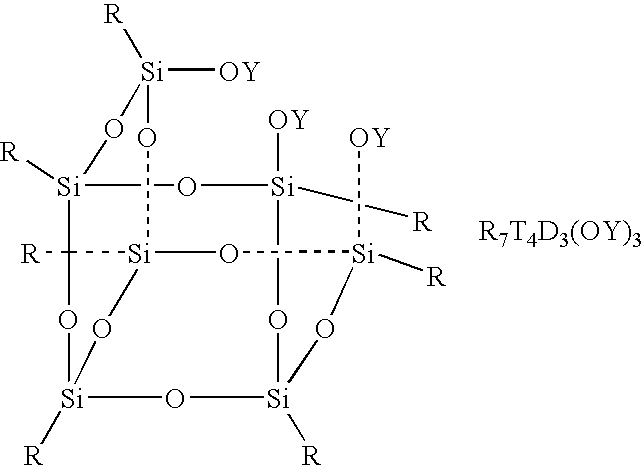

Dental composite materials and method of manufacture thereof

A dental composite material that comprises a polyhedral oligomeric silsesquioxane is disclosed. The dental composite material is useful for a variety of dental materials, treatments, and restorative functions including crown and bridge materials, fillings, adhesives, sealants, luting agents or cements, denture base materials, orthodontic materials and sealants, and other dental restorative materials.

Owner:PENTRON CLINICAL TECH

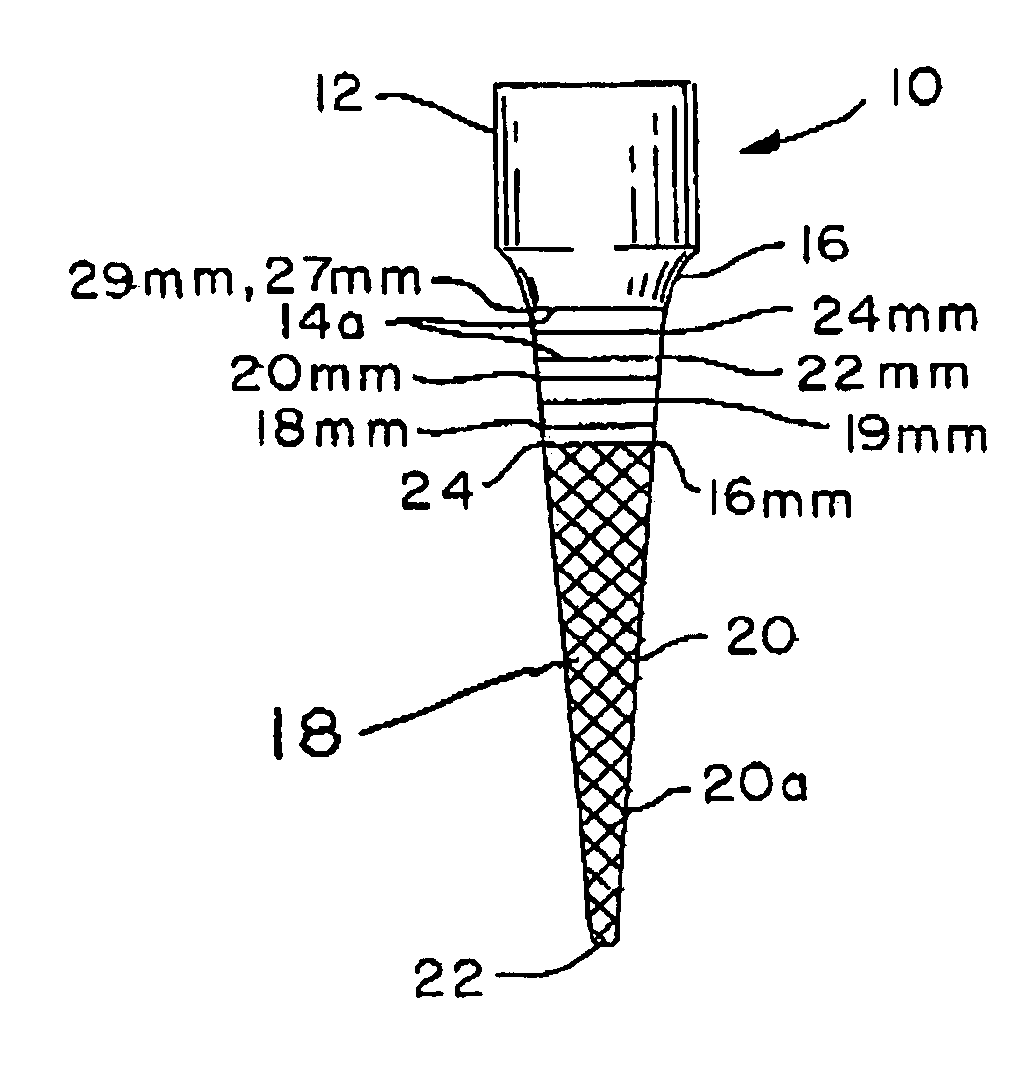

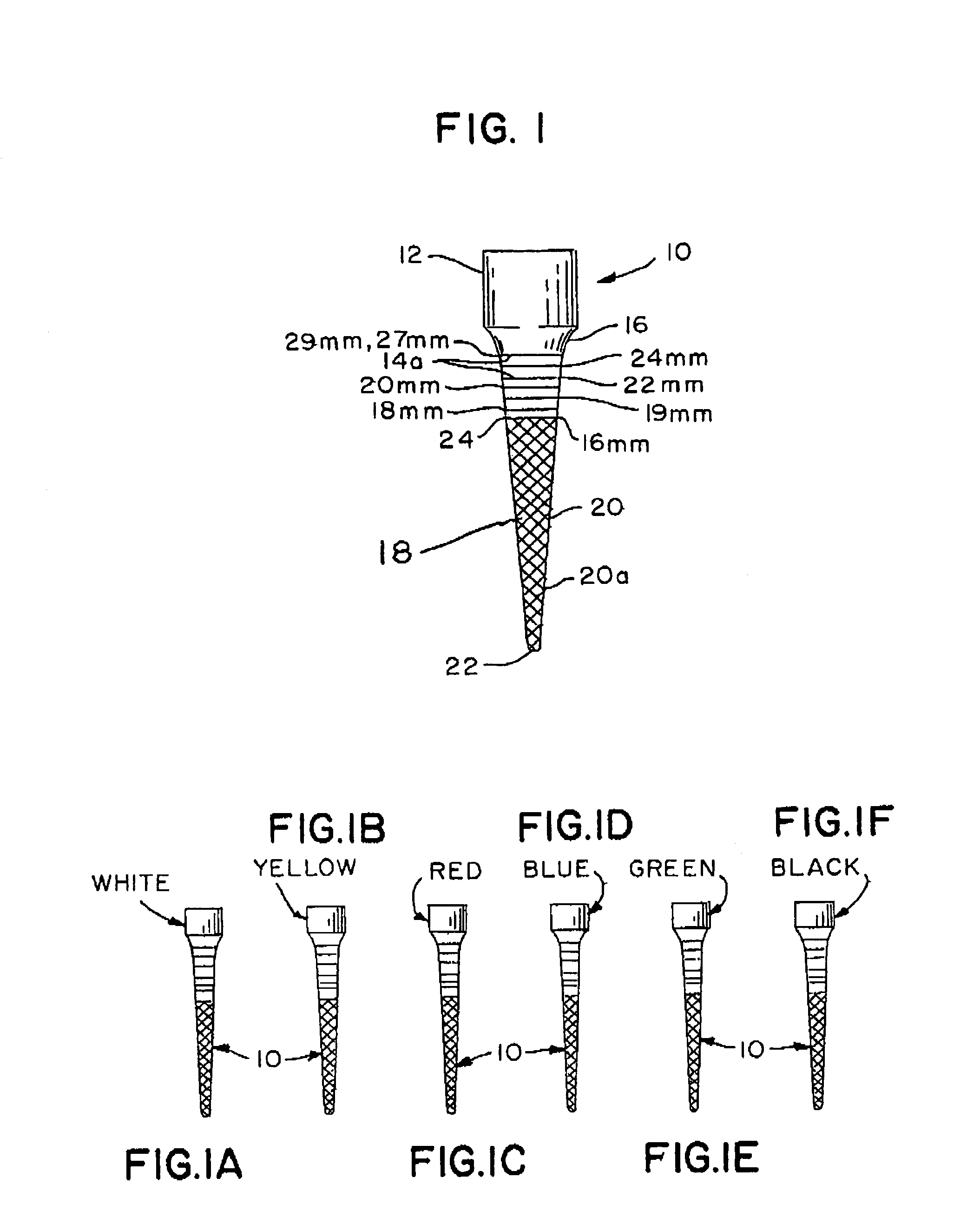

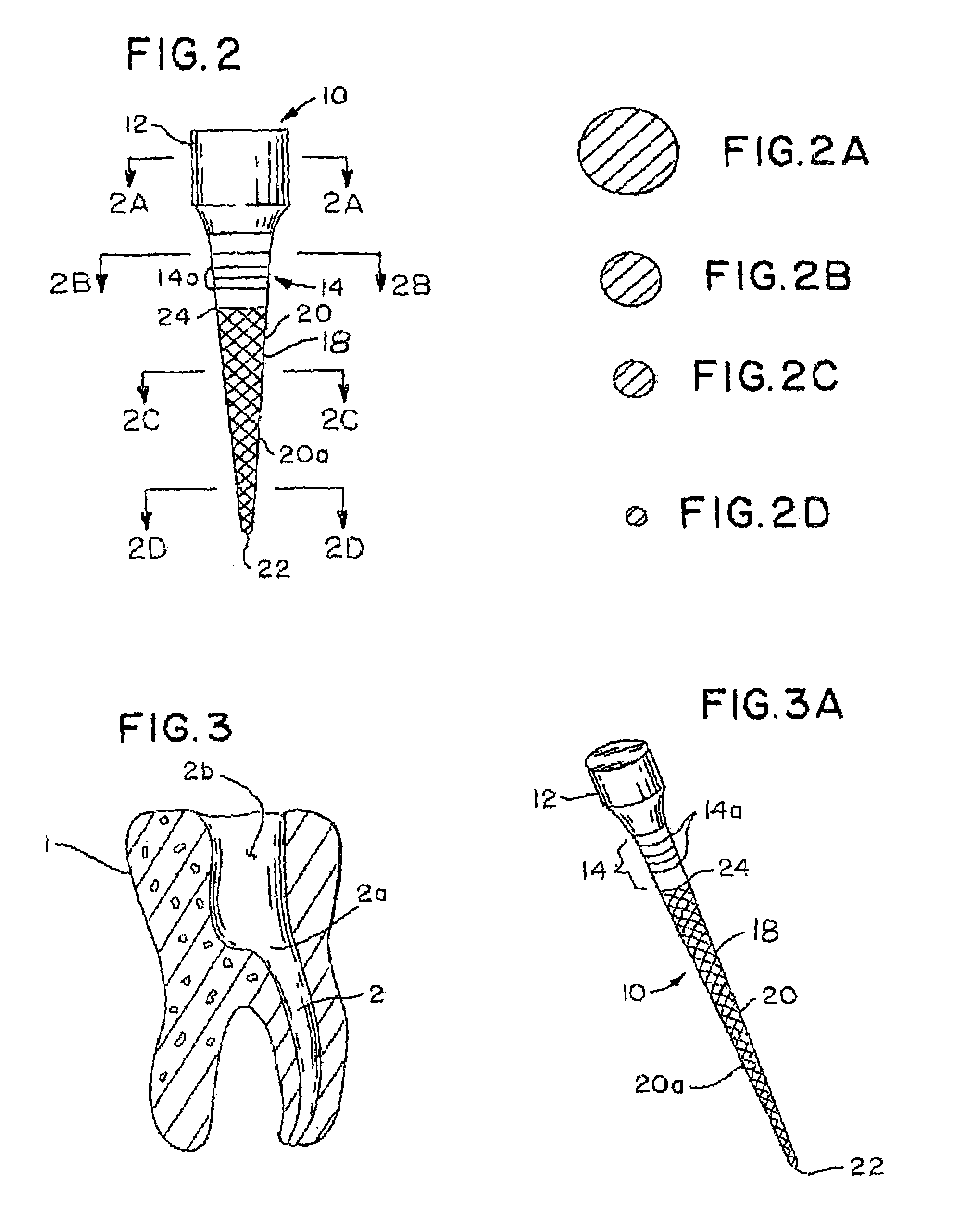

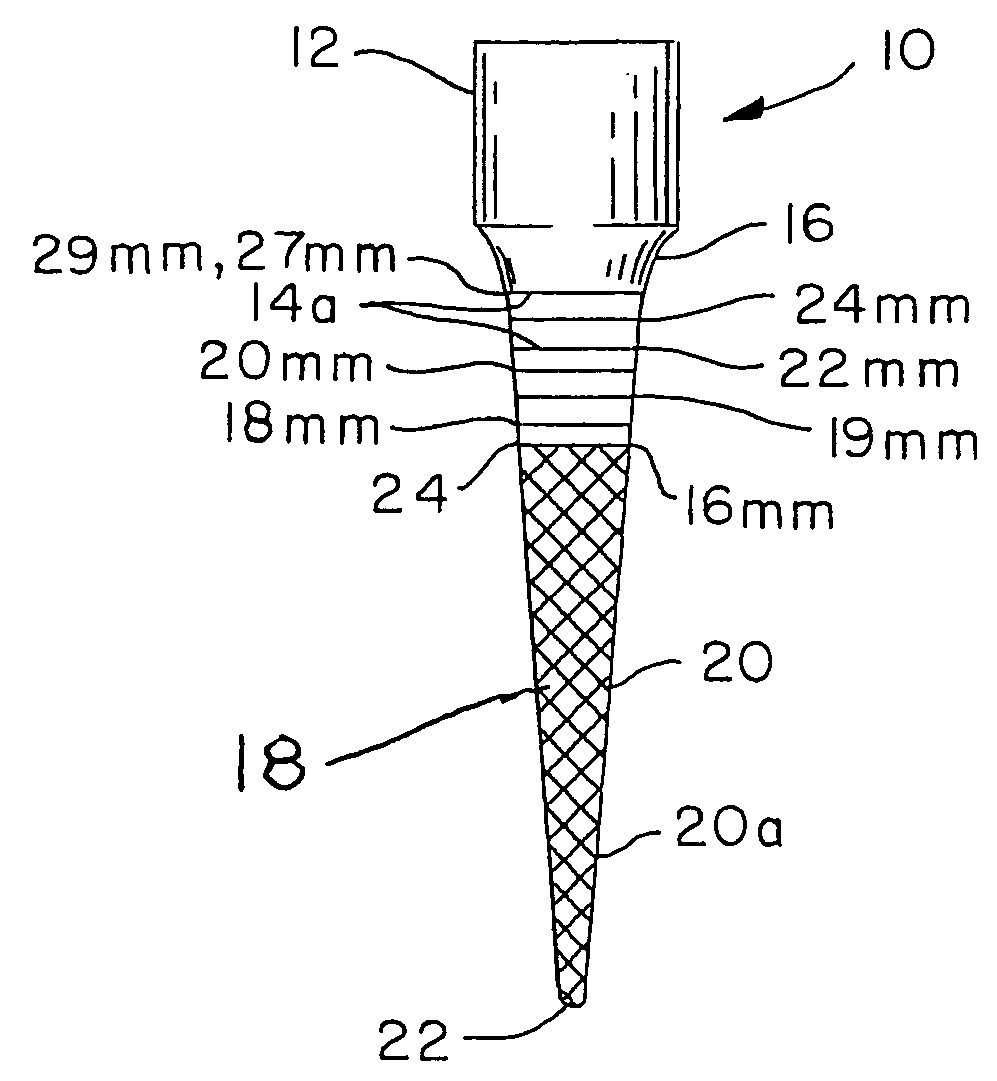

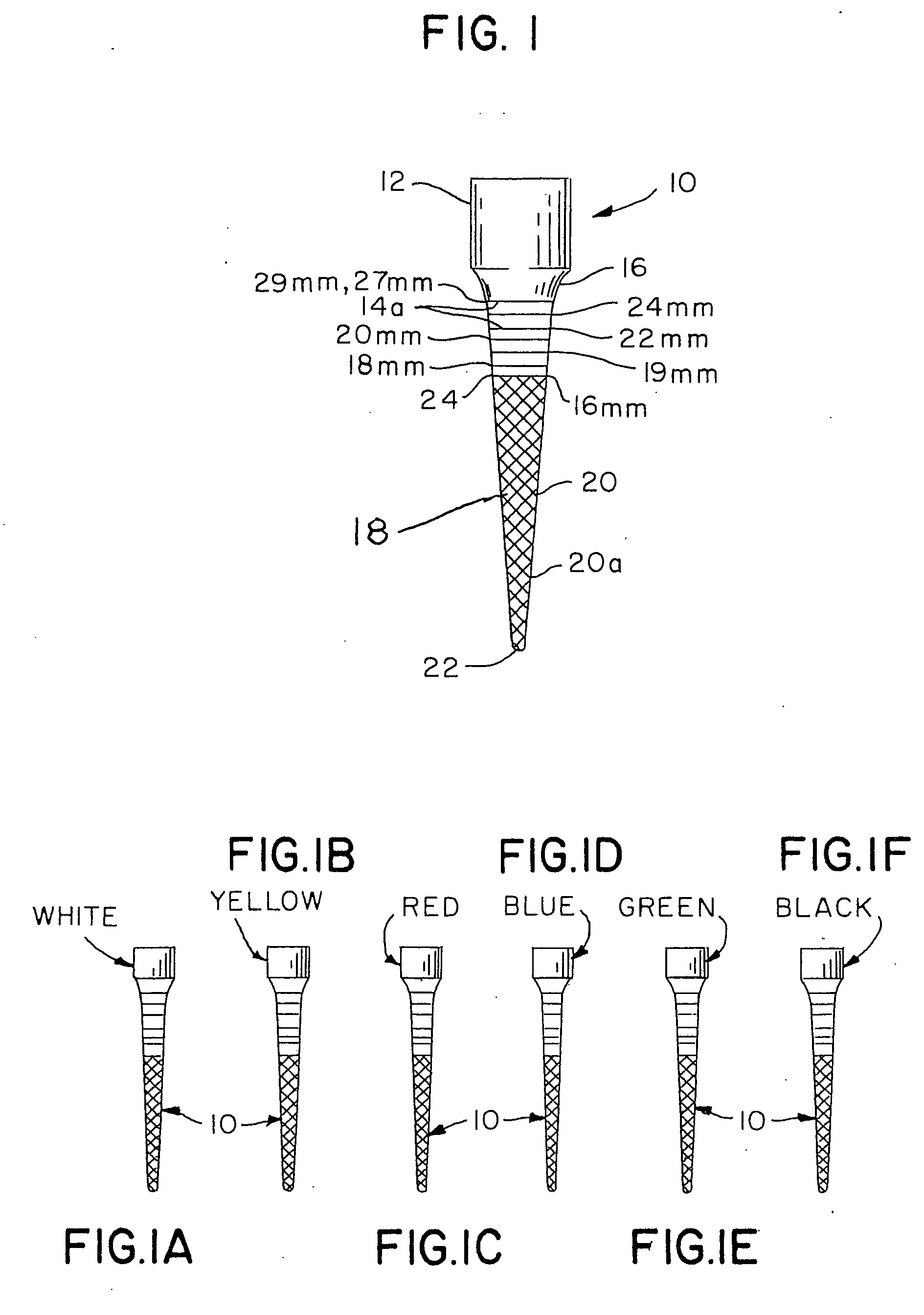

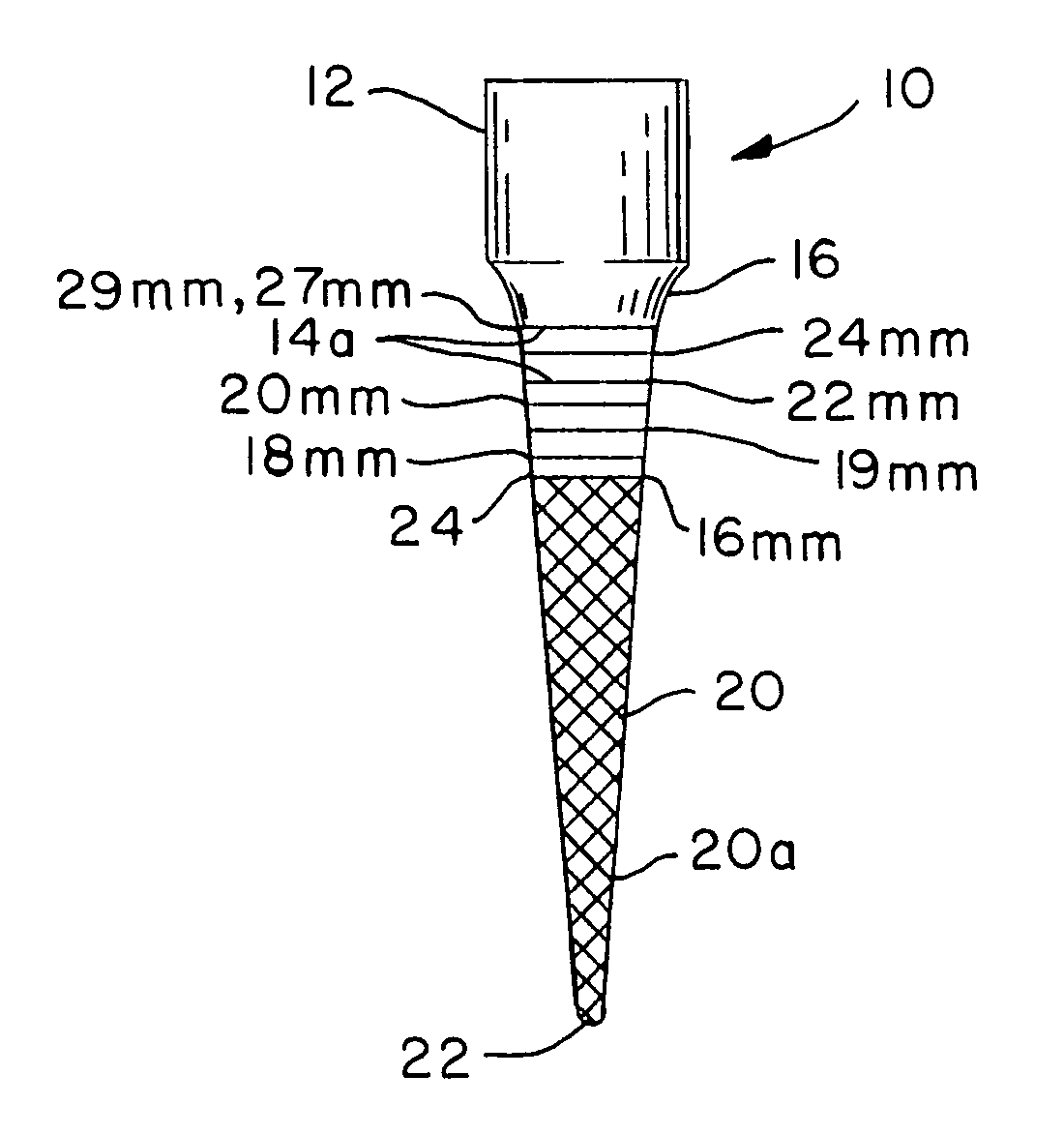

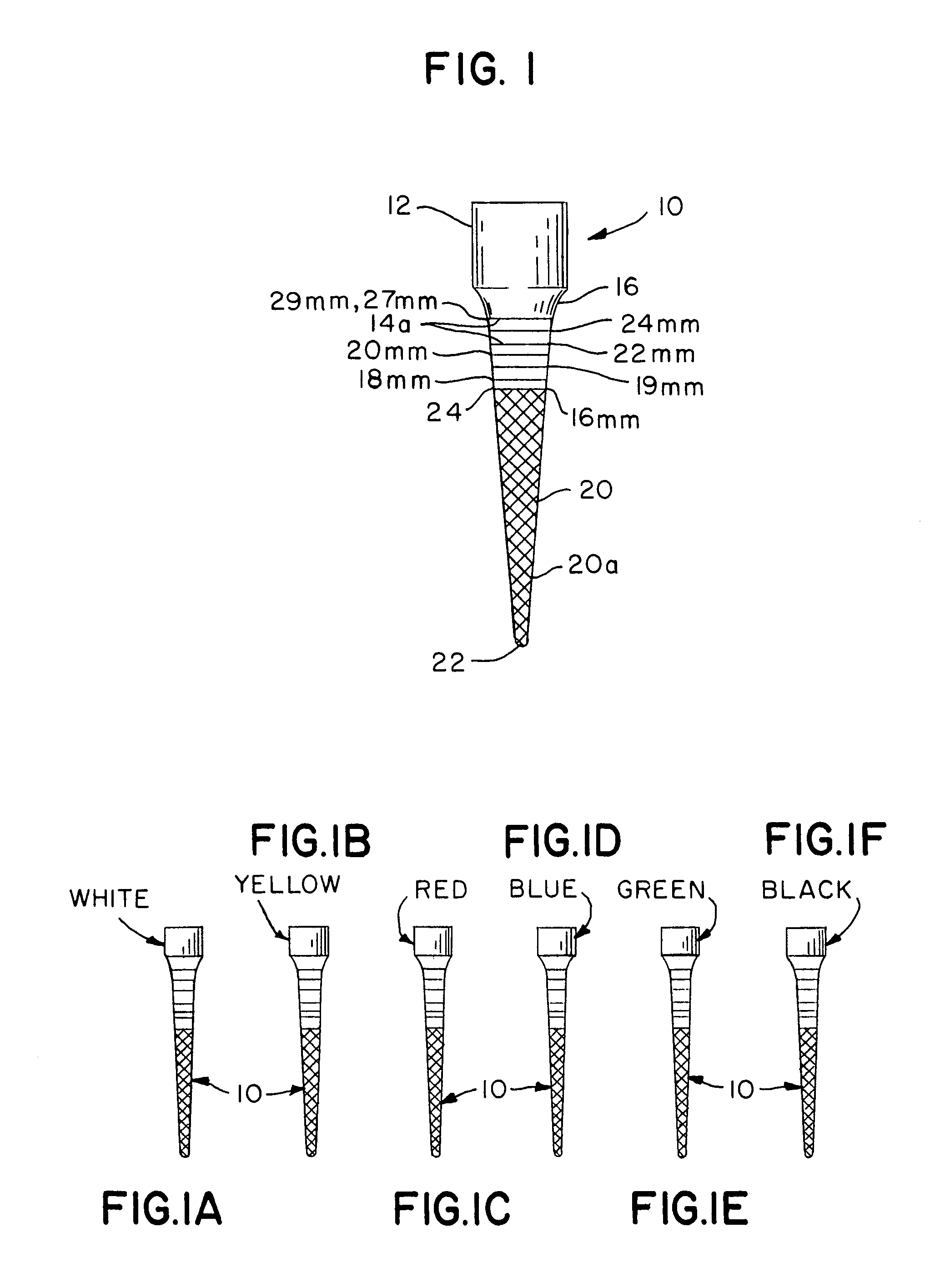

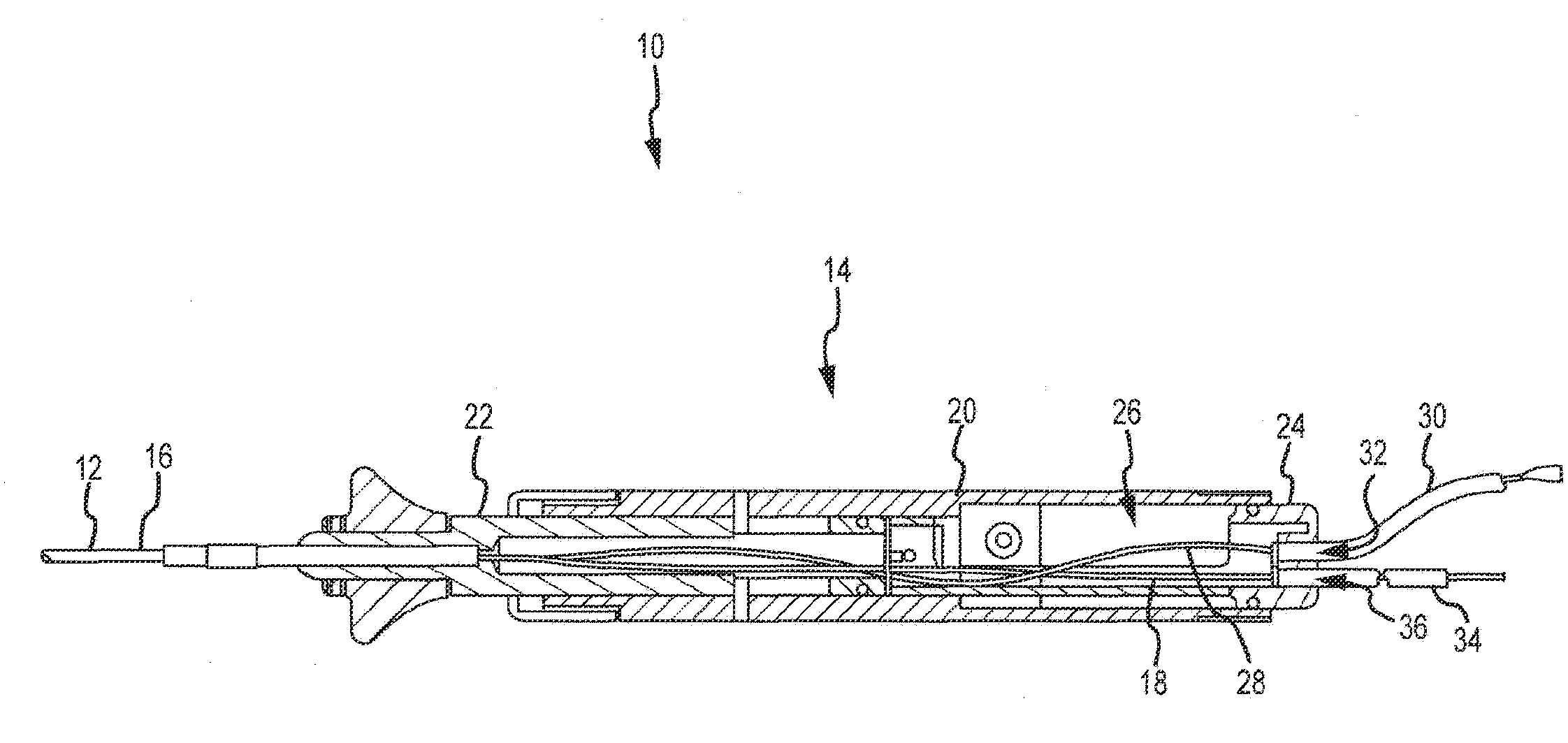

Integral gutta percha core/cone obturation technique

ActiveUS7021936B2Reduce leakageEasy to useImpression capsTeeth fillingGlass ionomersDelivery vehicle

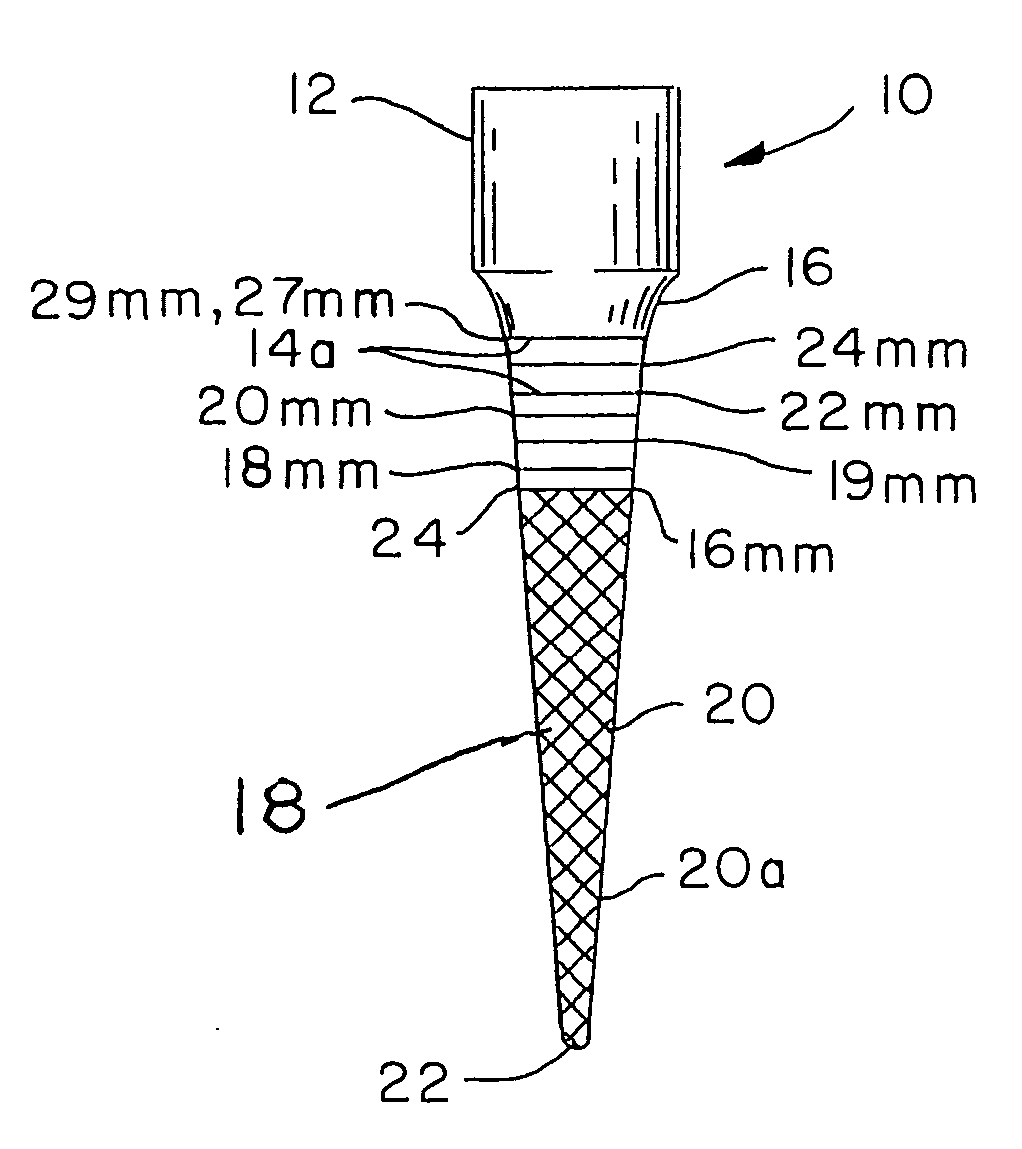

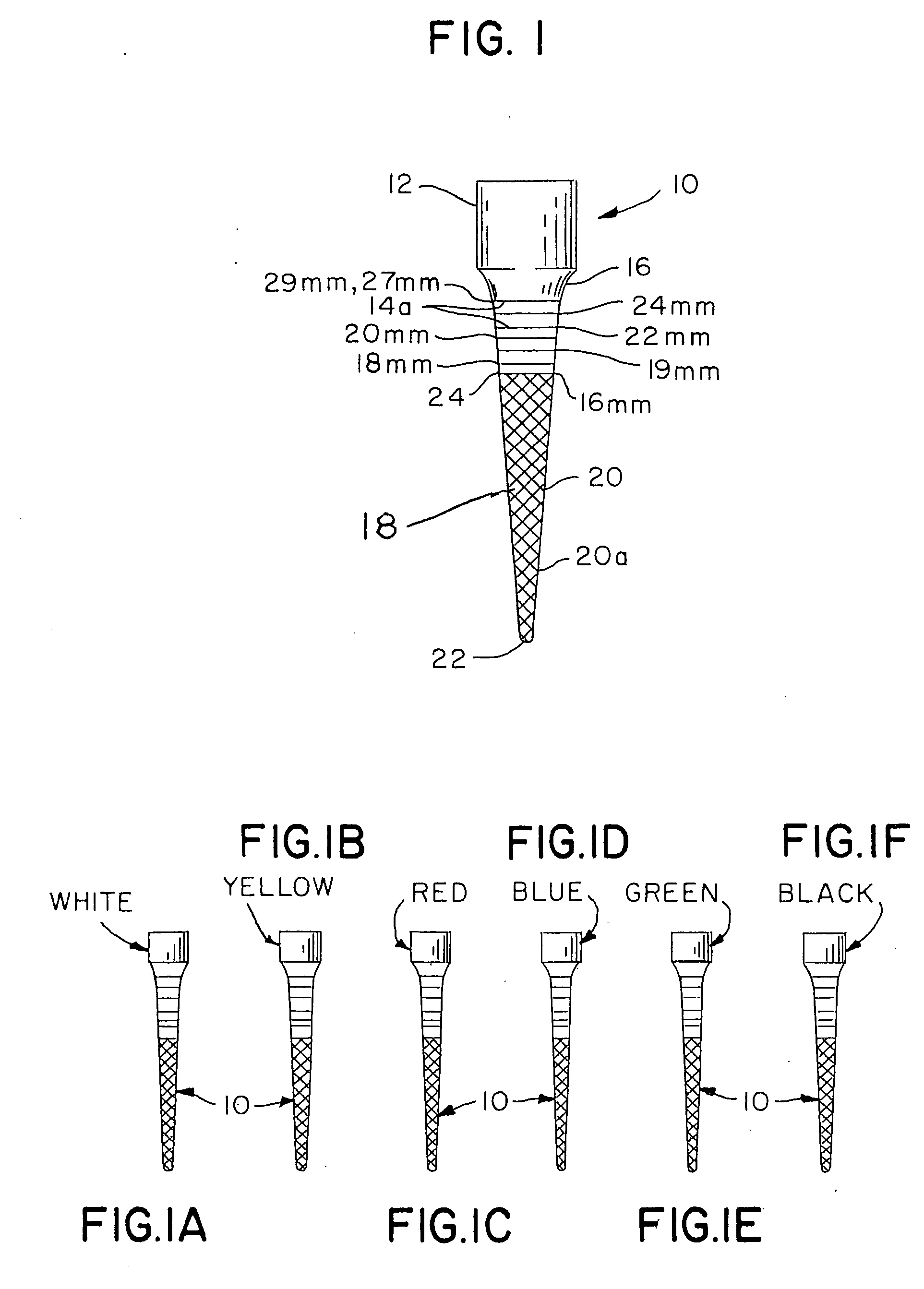

An integral, one-piece silanated particle impregnated gutta percha core / cone technique employs a thin layer of a luting agent, such as glass ionomer cement with a machined gutta percha core / cone, precisely matches the preparation, thereby reducing leakage and achieving a hermetic seal. The hermetic seal is further enhanced by a mono-block bond that occurs between the silanated particles in the gutta percha and the appropriate chemical sealant. Optional cryogenic treatment of the gutta percha material changes its molecular weight, making it stiffer and conducive to forming an integral, one piece core / cone, without the need for a separate carrier core to install the tapered gutta percha core / cone within the root canal. Additionally, the tapered body of the core / cone may be reticulated in a slightly three dimensional texturized framework to increase surface area and therefore increase retention. Optional line demarcation indicia are also placed on the core / cone. Additionally, the head of the core / cone can be gripped by a delivery vehicle clasp.

Owner:ENDODONTIC EDUCATIONAL SEMINARS

Fiber reinforced graphite rubber plate and its preparation method

This invention relates to a fiber reinforced graphite rubber plate utilized at pipeline flange and its preparation. It mainly solves the flaws of present techniques using rubber as luting agent and existing low temperature property. It can not completely substitute asbestos gaskets use condition, so it limits the serviceable range of this material; And it also solves the technique problems, such as: graphite content is low, particle is fairly coarse, working condition is narrow, especially the bearing temperature range is fairly small and so on. This invention composition; and quality percentage are: rubber 10-20%, flexibility graphite 55-75%, strengthened fiber 3-10%, stuffing 5-25%, the rest is sulfurizing accessory ingredient. Its preparation: progress heat treatment for graphite piece, after cooling and compact progress shattering, orderly add flexibility graphite powder, operation agent, sulfurizing accessory ingredient, strengthened fiber, sol rubber to mix; use forming piece equipment, utilize relative rotation of roller tube to carry out forming piece and producing piece; utilize flat plate sulfurizing machine to sulfurize half-finished product, yield the invented product.

Owner:浙江国泰萧星密封材料股份有限公司

Dental composite materials and method of manufacture thereof

A dental composite material that comprises a polyhedral oligomeric silsesquioxane is disclosed. The dental composite material is useful for a variety of dental materials, treatments, and restorative functions including crown and bridge materials, fillings, adhesives, sealants, luting agents or cements, denture base materials, orthodontic materials and sealants, and other dental restorative materials.

Owner:PENTRON CLINICAL TECH

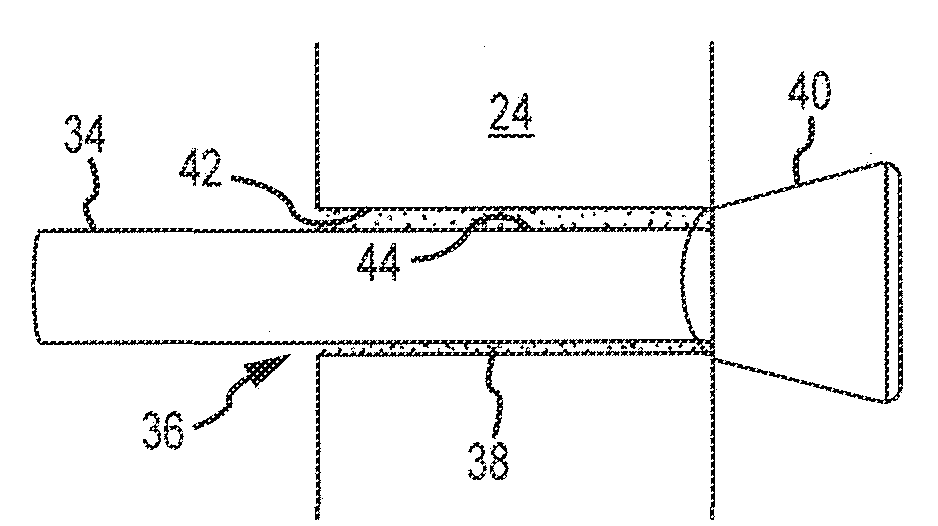

Integral gutta percha core/cone obturation technique

InactiveUS20060154213A1Reduce leakageEasy to useTeeth fillingTeeth cappingGlass ionomersDelivery vehicle

An integral, one-piece gutta percha core / cone technique employs a thin layer of a luting agent, such as glass ionomer cement with a machined gutta percha core / cone, precisely matches the preparation, thereby reducing leakage and achieving a hermetic seal. Optional cryogenic treatment of the gutta percha material changes its molecular weight, making it stiffer and conducive to forming an integral, one piece core / cone, without the need for a separate carrier core to install the tapered gutta percha core / cone within the root canal. Additionally, the tapered body of the core / cone may be reticulated in a slightly three dimensional texturized framework to increase surface area and therefore increase retention. Optional line demarcation indicia are also placed on the core / cone. Additionally, the head of the core / cone can be gripped by a delivery vehicle clasp.

Owner:KOCH KENNETH +1

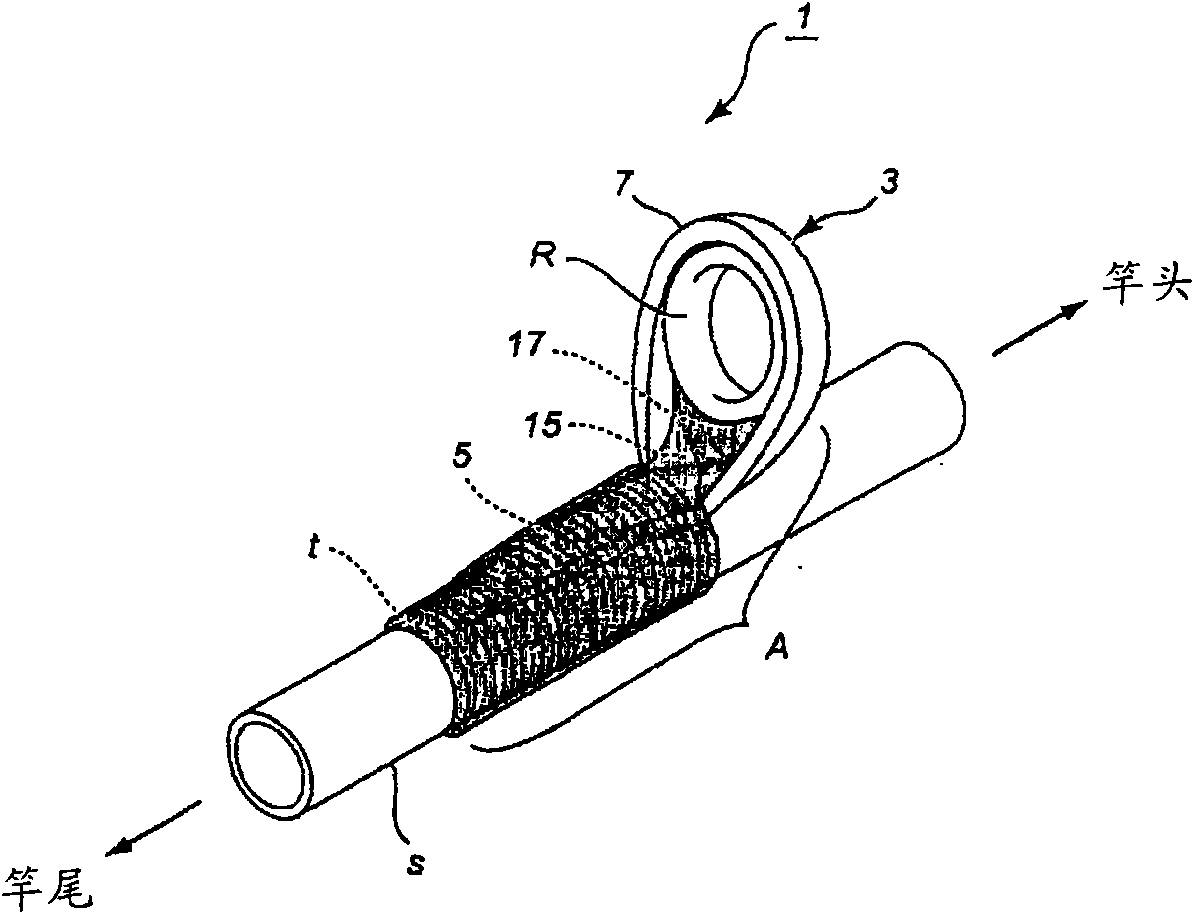

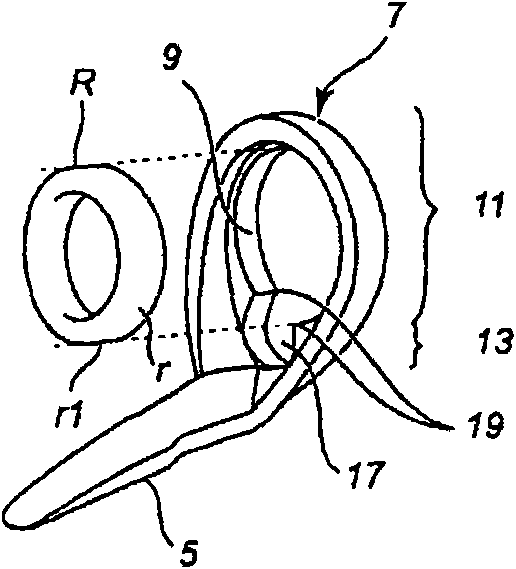

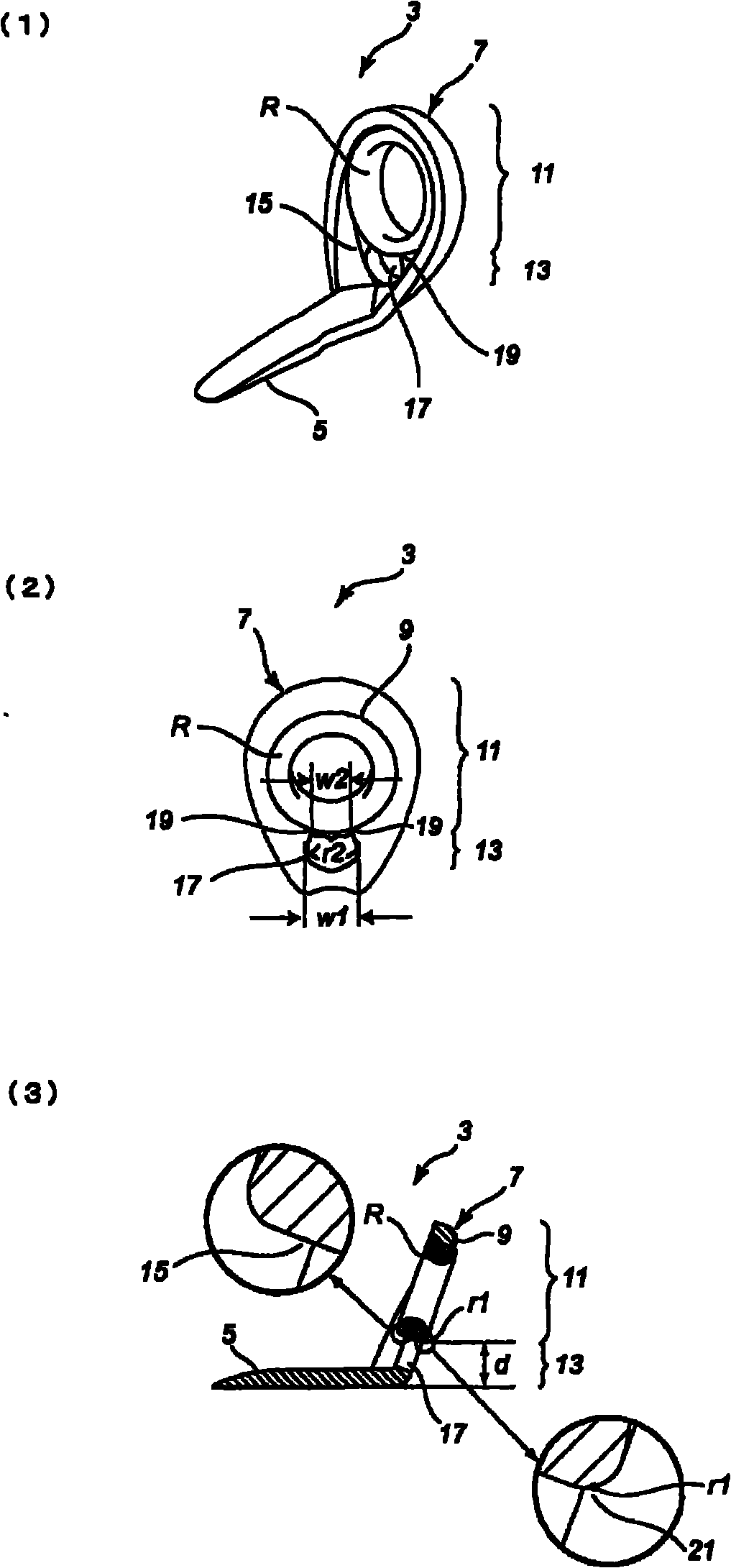

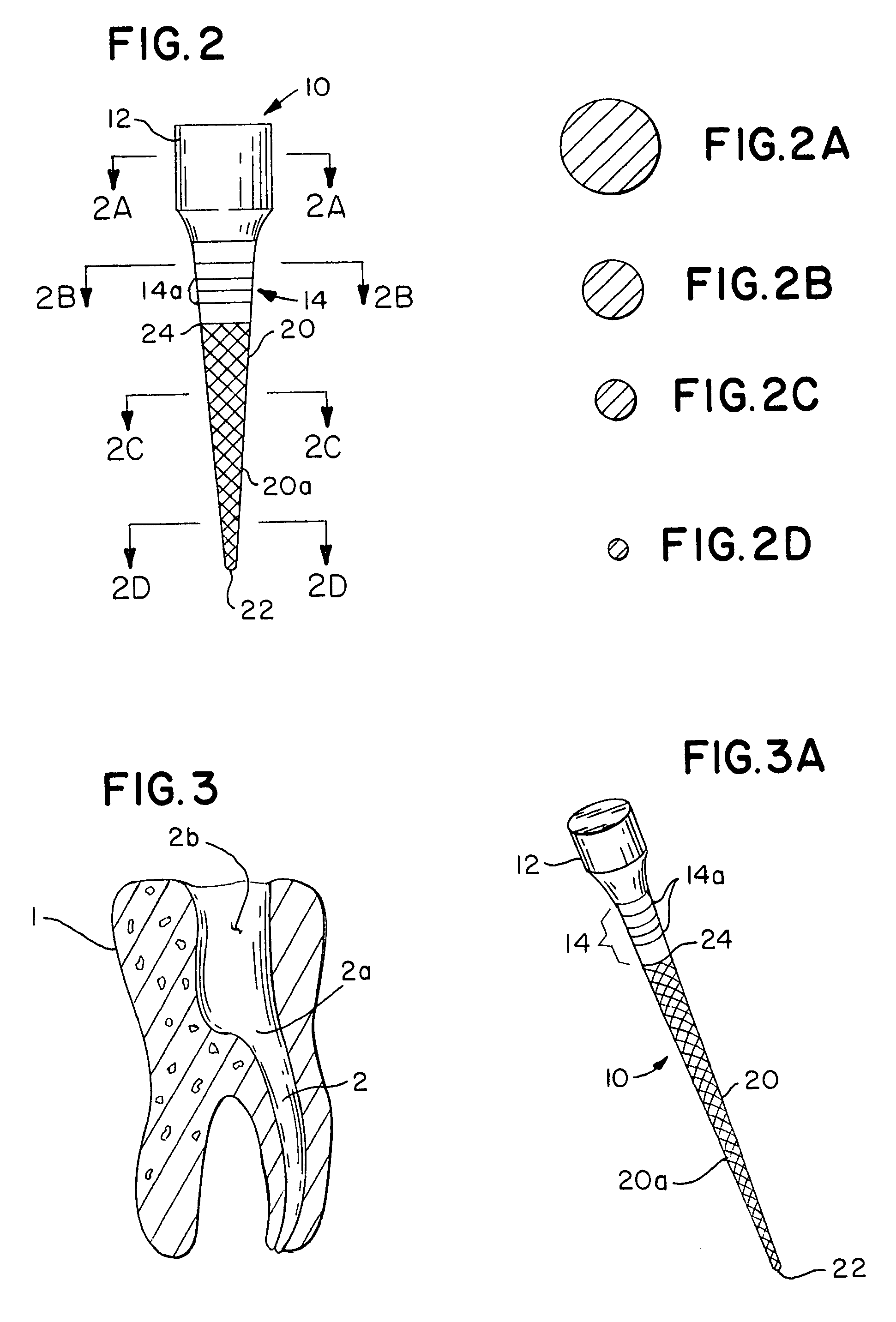

Fishing line guiding device and fishing rod

Provided is a fishing line guiding device that is difficult to move relative to a fishing rod. A ring holding part (7) of the fishing line guiding device (3) is provided with a gap part (17). When the surface of a foot part is coated with adhesive agent (liquid), the adhesive agent passes through the gap part to reach the root edge and flows from the edge to drop to the peripheral surface of a rod (s) to cure, such that the foot part (5) is firmly fixed on the rod body. On the other hand, the gap part has a capillary phenomenon, the adhesive agent (liquid) flowed into a clearance between the gap parts to rise from the clearance, further to rise along a jogged dent (15) arranged on the rod tail side and a jogged dent (21) arranged on the rod head side. Thereby, two sides of the jogged dent are filled with the cured adhesive agent (A), even if a holding frame of the ring holding part has a gap part, a conductor ring (R) also can be firmly fixed on the ring holding part without loss of ring holding strength. It is possible to prevent salt from remaining in the jogged dents and try for light weight.

Owner:FUJI IND

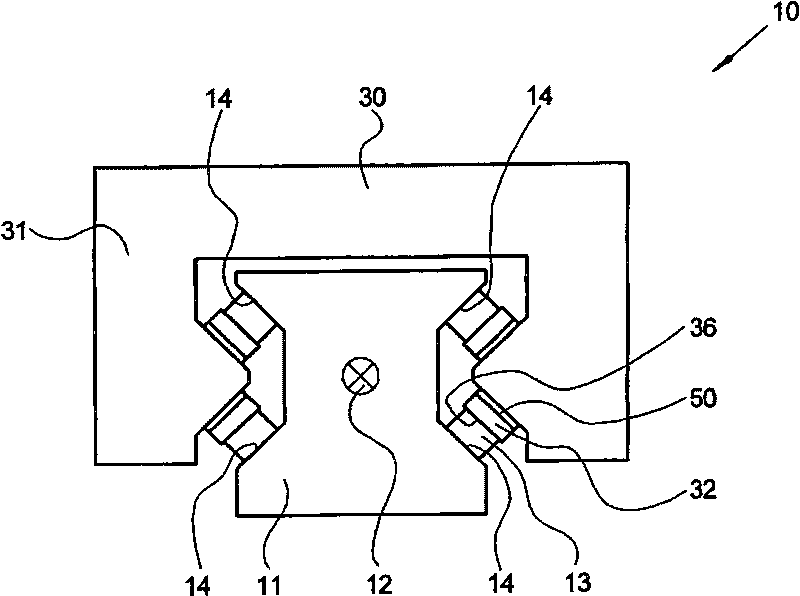

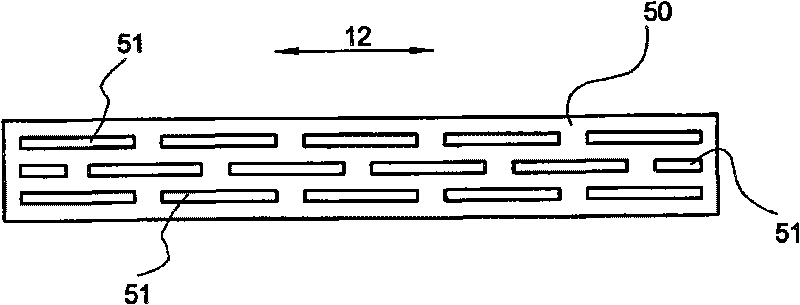

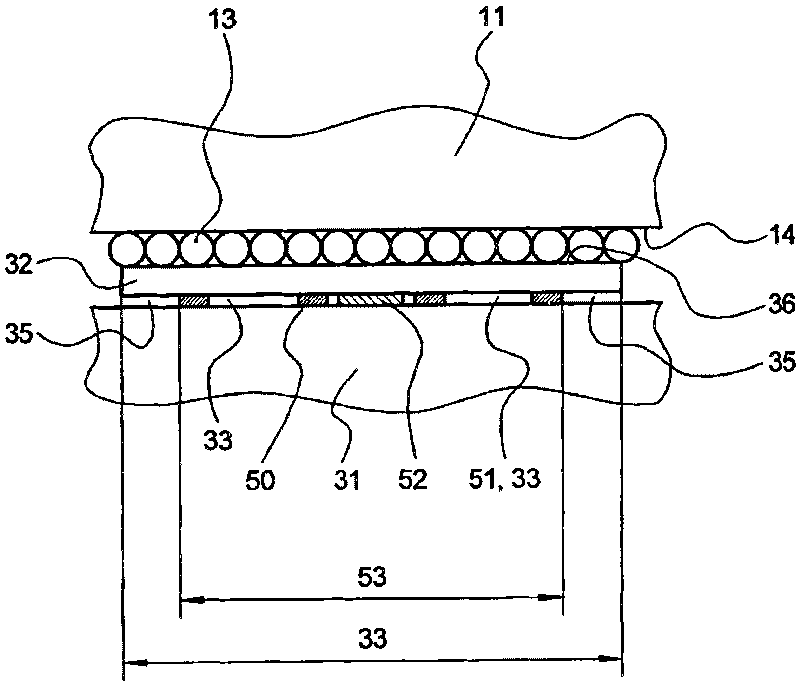

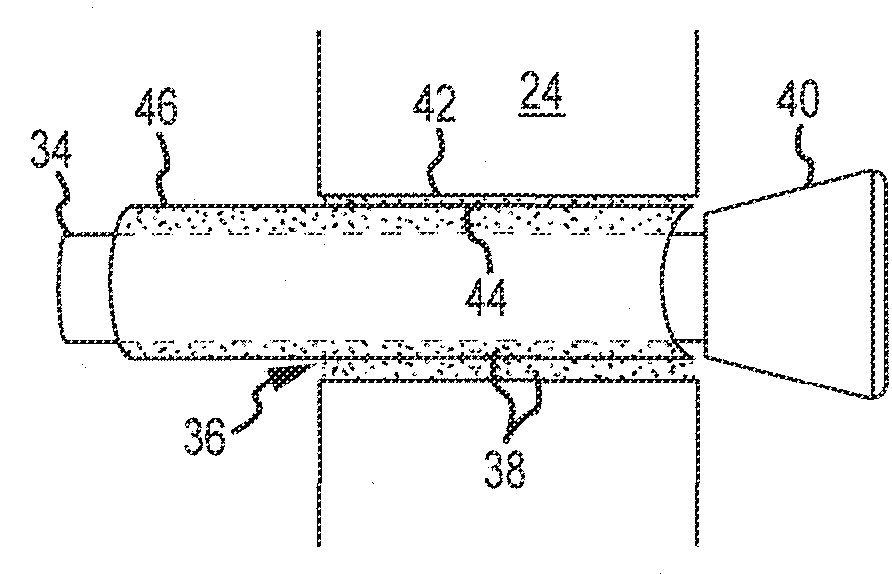

Linear rolling bearing having bonded rolling surface components

InactiveCN101725636AIncrease stiffnessLow costLinear bearingsBearing assemblyRolling-element bearingClassical mechanics

The invention relates to a guiding slide carriage (30) of linear rolling bearing (10). The guiding slide carriage can be supported a guiding rail (11) extended in the longitudinal direction (12) in a longitudinally movable way by a plurality of rolling bodies (13); wherein, the guiding slide carriage (30) comprises at least one rolling surface component (32); the rolling surface component has at least one slide carriage rolling surface (36) used for the rolling body (13); wherein, the rolling surface component (32) is fixed on the main body (31) of the guiding slide carriage (30) by at least one adhesive layer (33). According to the present invention, a thin plate (50) having at least one through hole is disposed between the rolling surface component (32) and the main body (31); and the adhesive layer is disposed in the through hole.

Owner:ROBERT BOSCH GMBH

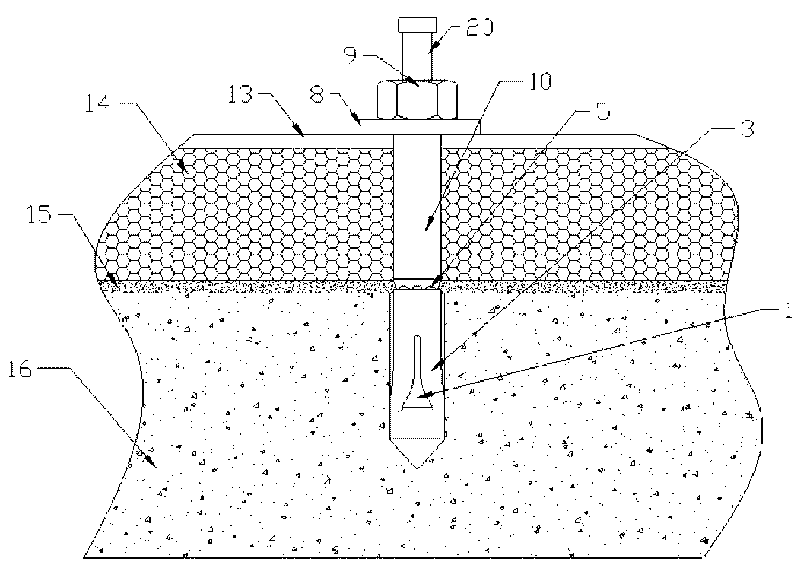

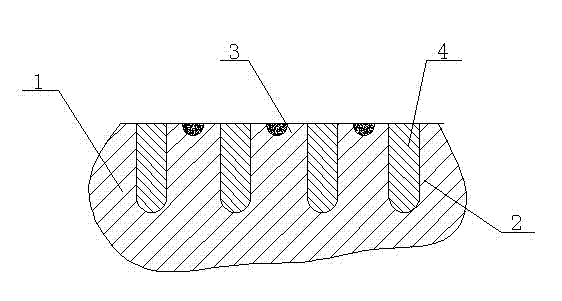

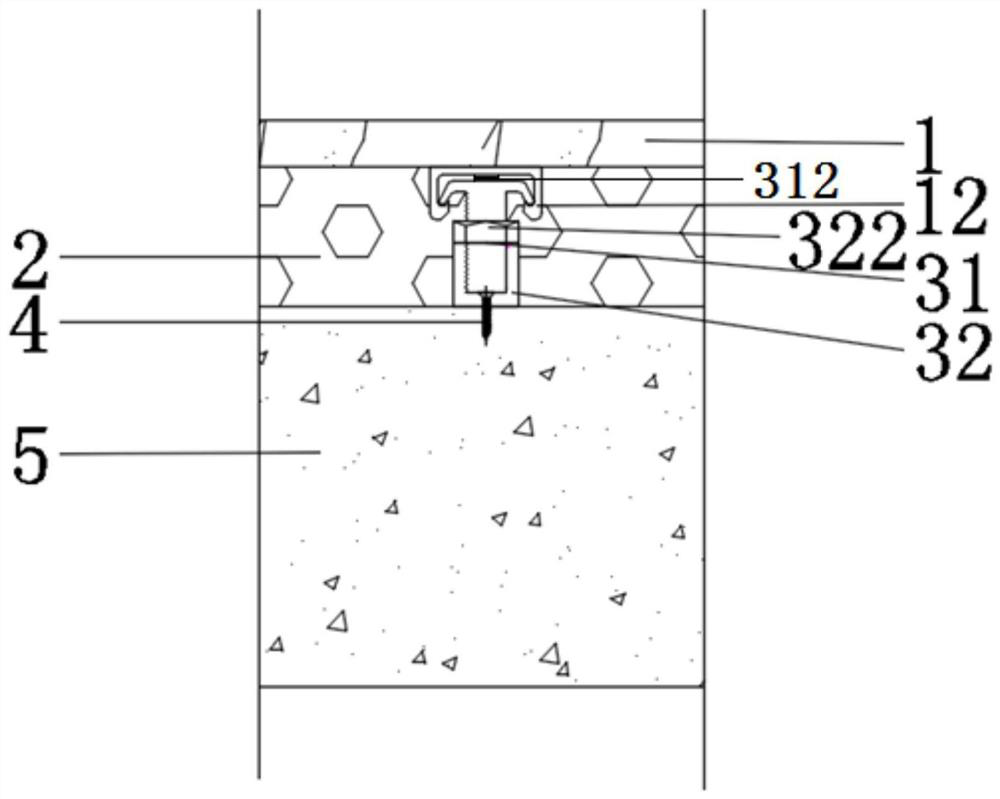

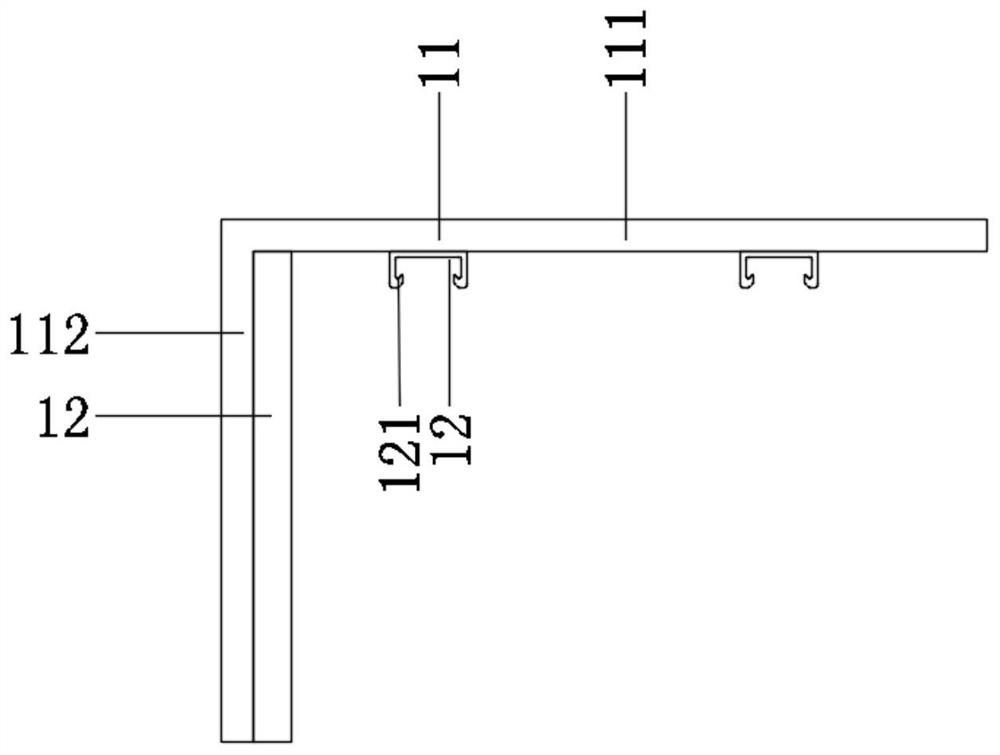

Method for constructing plate adhesion and anchor structure used in the method

The invention discloses a method for constructing plate adhesion and an anchor structure used in the method. The method for constructing plate adhesion and the anchor structure used in the method solve the problems of slow speed and inconvenient operation in existing methods of constructing plate adhesion. The method for construction mainly comprises the following steps: fixing a plate on a fixed object through utilizing an anchor, wherein the anchor is provided with a pre-arranged liquid injection structure, the liquid injection port of the liquid injection structure is located on the external end portion of the anchor structure, and a liquid outlet is located in a gap between the plate and the fixed object. The anchor is provided with an expansion sleeve and a taper head connected through a screw thread, the expansion sleeve and the taper head are utilized to enable the anchor to firmly fix the plate, adhesive is injected into the gap between the plate and the fixed object from the liquid injection port on the liquid injection structure, after the adhesive is solidified, firm adhesion between the plate and the fixed object can be realized, and then the main part in the anchor structure can be screwed out.

Owner:叶君华

Integral gutta percha technique

InactiveUS20060154212A1Reduce leakageEasy to useTeeth fillingTeeth cappingGlass ionomersGutta-percha

An integral, one-piece silanated particle impregnated gutta percha core / cone technique employs a thin layer of a luting agent, such as glass ionomer cement with a machined gutta percha core / cone, precisely matches the preparation, thereby reducing leakage and achieving a hermetic seal. The hermetic seal is further enhanced by a mono-block bond that occurs between the silanated particles in the gutta percha and the appropriate chemical sealant. Optional cryogenic treatment of the gutta percha material changes its molecular weight, making it stiffer and conducive to forming an integral, one piece core / cone, without the need for a separate carrier core to install the tapered gutta percha core / cone within the root canal. Additionally, the tapered body of the core / cone may be reticulated in a slightly three dimensional texturized framework to increase surface area and therefore increase retention. Optional line demarcation indicia are also placed on the core / cone. Additionally, the head of the core / cone can be gripped by a delivery vehicle clasp.

Owner:KOCH KENNETH +2

Integral gutta percha technique

ActiveUS7097455B2Reduce leakageEasy to useImpression capsWheelchairs/patient conveyanceGlass ionomersGutta-percha

An integral, one-piece silanated particle impregnated gutta percha core / cone technique employs a thin layer of a luting agent, such as glass ionomer cement with a machined gutta percha core / cone, precisely matches the preparation, thereby reducing leakage and achieving a hermetic seal. The hermetic seal is further enhanced by a mono-block bond that occurs between the silanated particles in the gutta percha and the appropriate chemical sealant. Optional cryogenic treatment of the gutta percha material changes its molecular weight, making it stiffer and conducive to forming an integral, one piece core / cone, without the need for a separate carrier core to install the tapered gutta percha core / cone within the root canal. Additionally, the tapered body of the core / cone may be reticulated in a slightly three dimensional texturized framework to increase surface area and therefore increase retention. Optional line demarcation indicia are also placed on the core / cone. Additionally, the head of the core / cone can be gripped by a delivery vehicle clasp.

Owner:BATCHING SYST +2

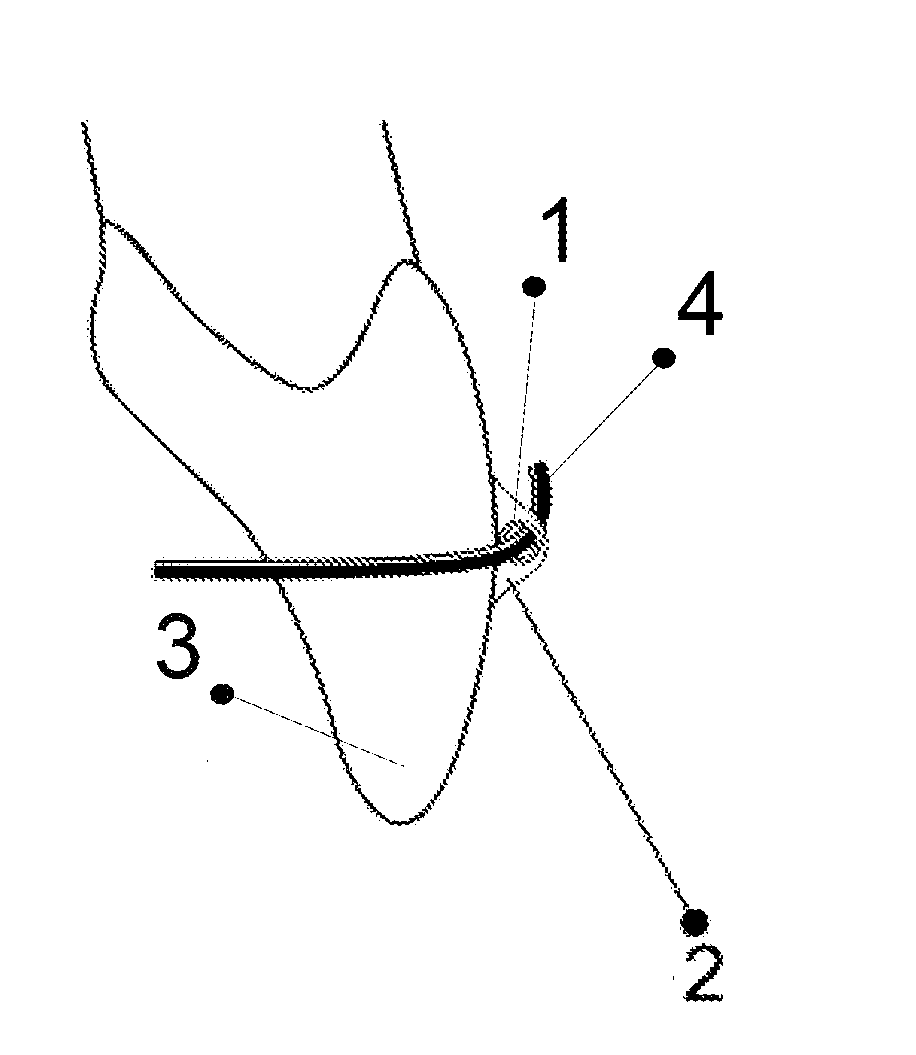

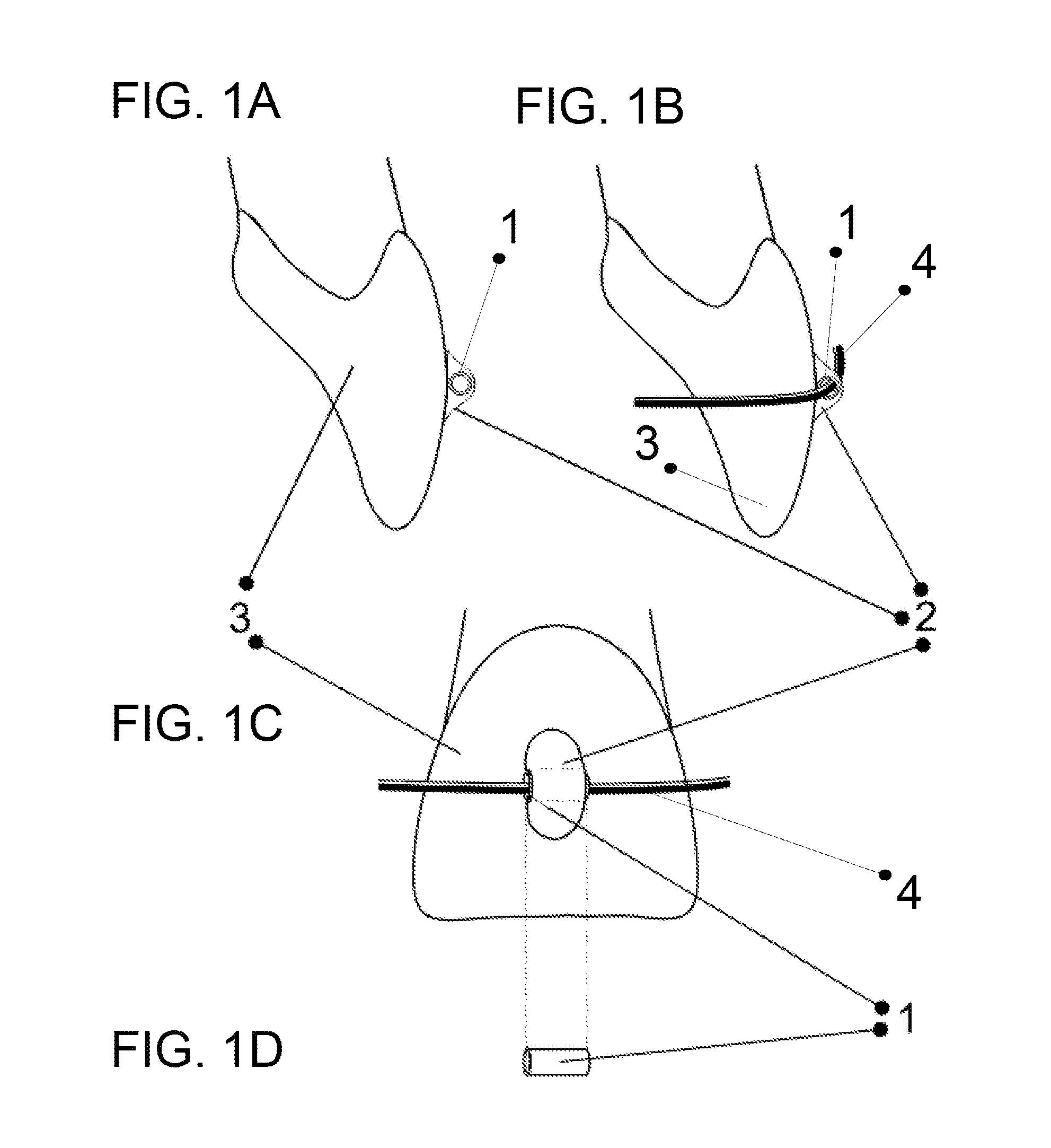

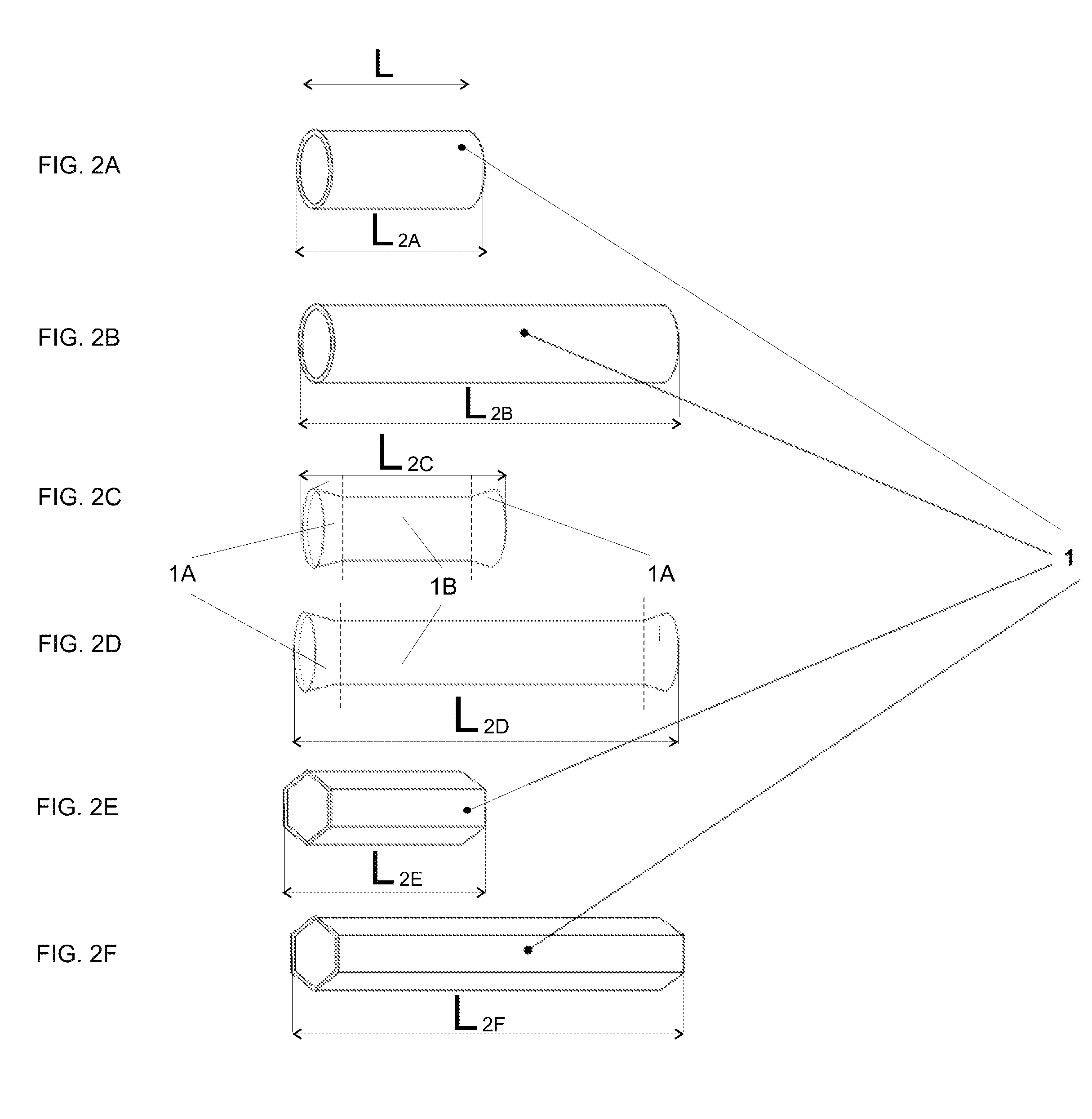

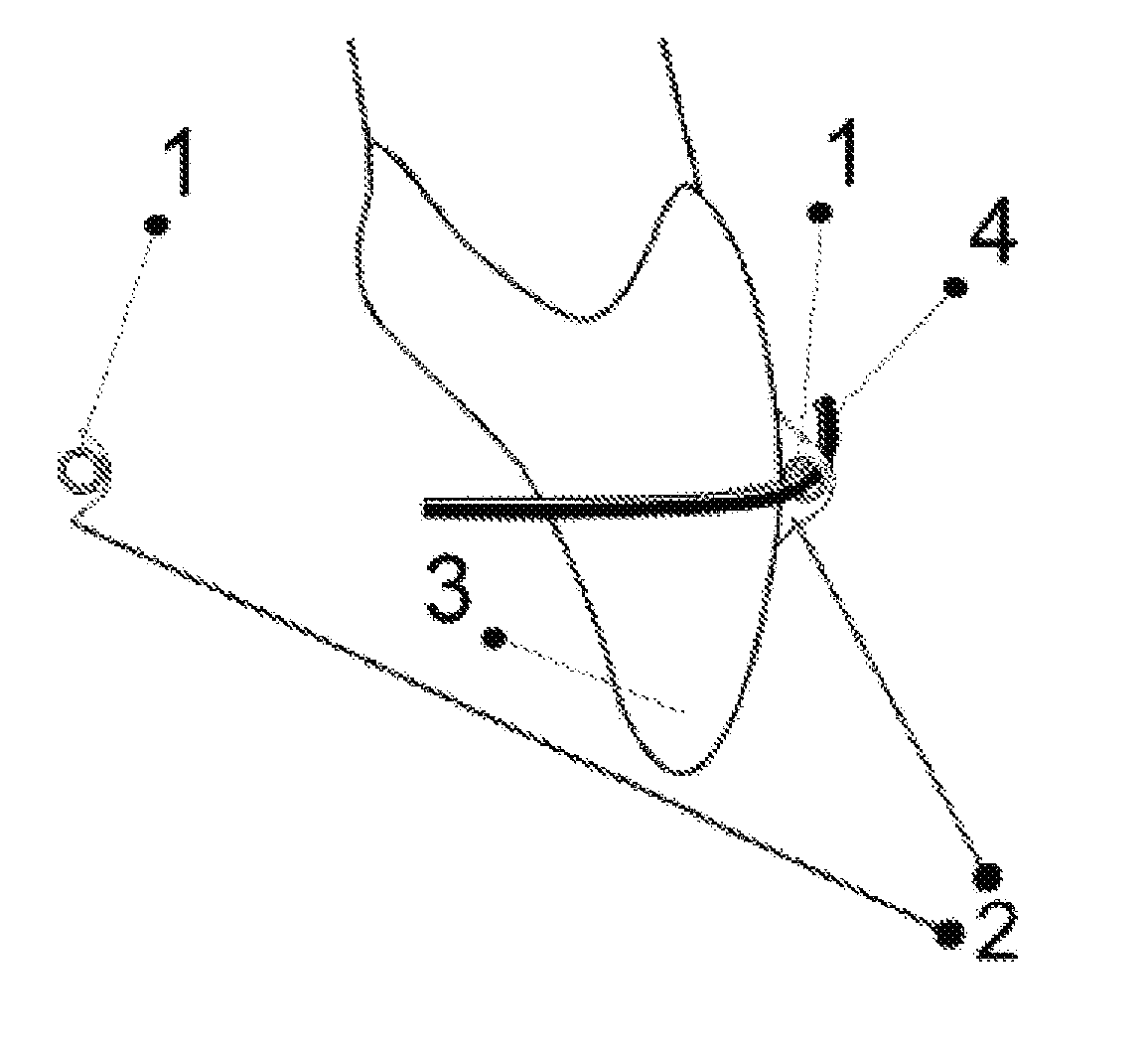

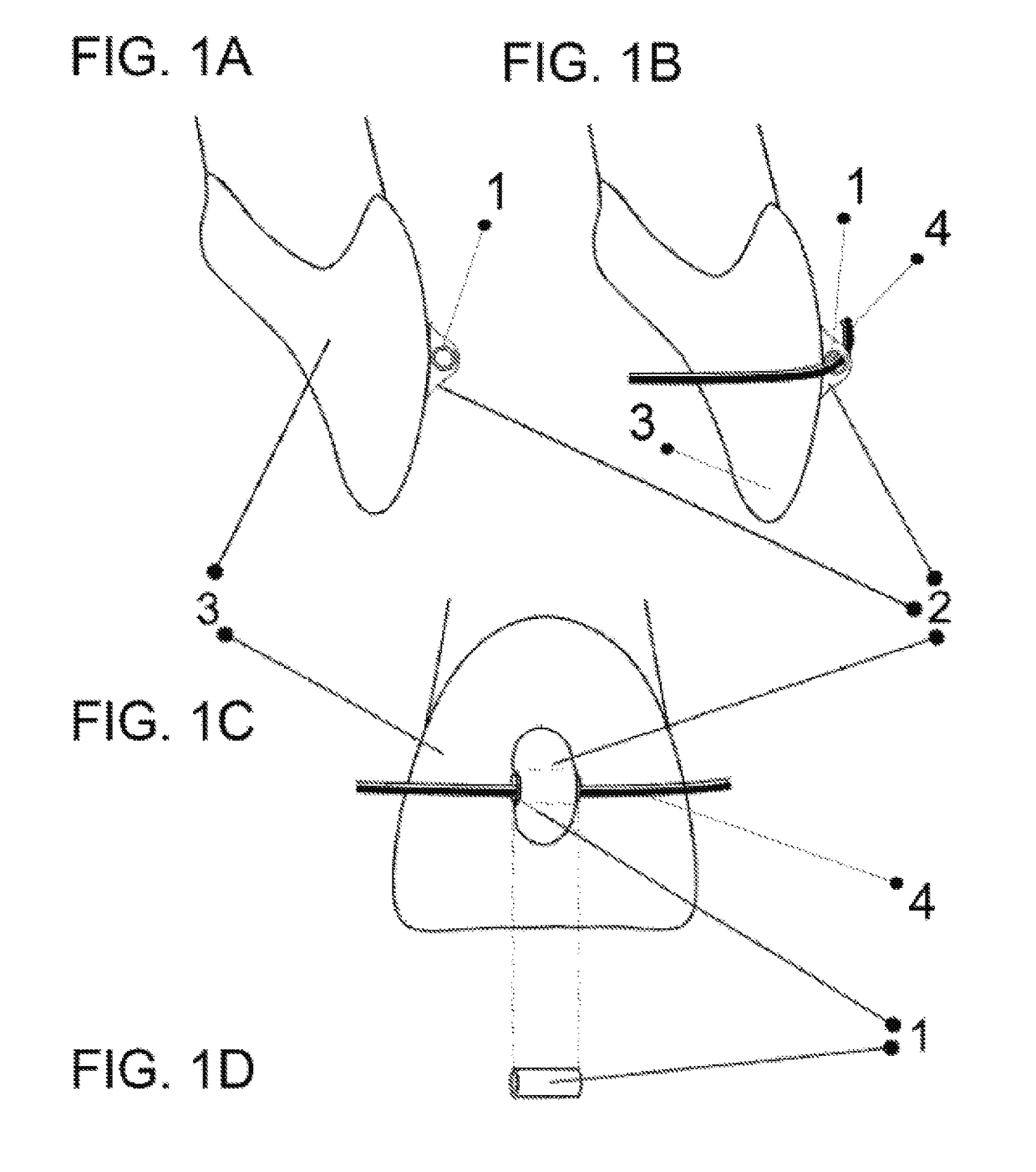

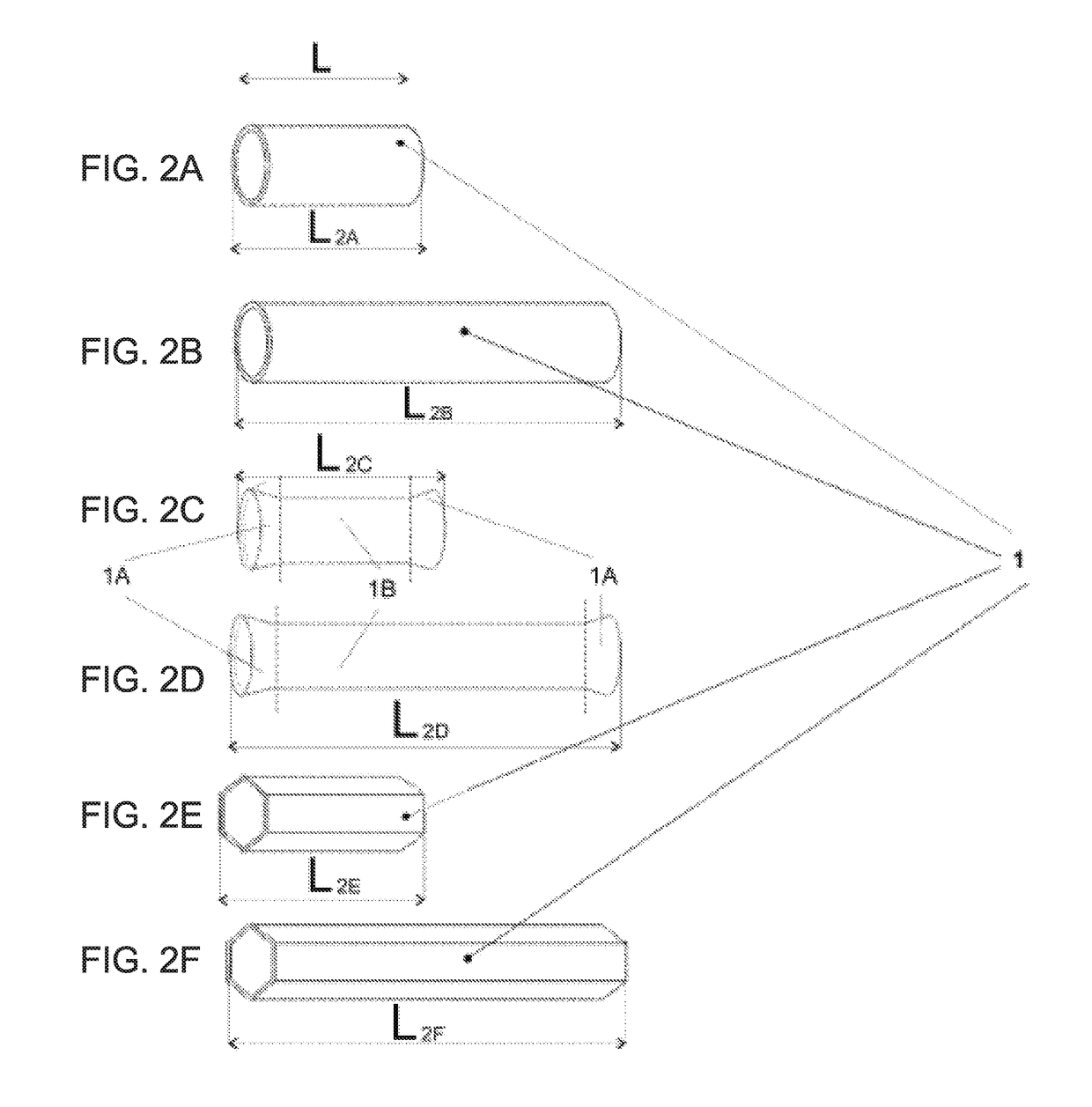

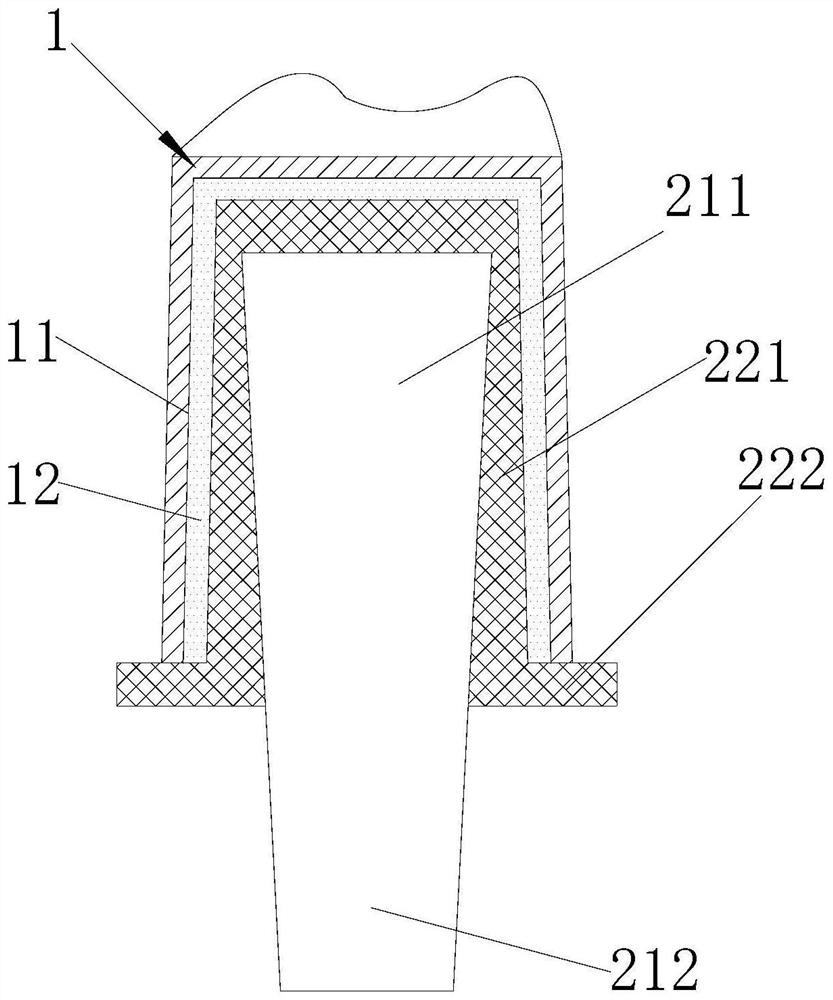

Orthodontics System and Method of Use

The present disclosure relates to an orthodontic system and a method of using the same to perform orthodontics. In one example, an orthodontic system is presented. The orthodontic system includes a tube having at least one sidewall and two opening ends, and a luting agent. The luting agent is disposed on at least a portion of one or more of the at least one sidewall of the tube and a portion of a surface of a tooth onto which the tube is directly attached or adhered. The two opening ends of the tube remain substantially open so that a wire can move along the tube.

Owner:ARIZA JOAQUIN T

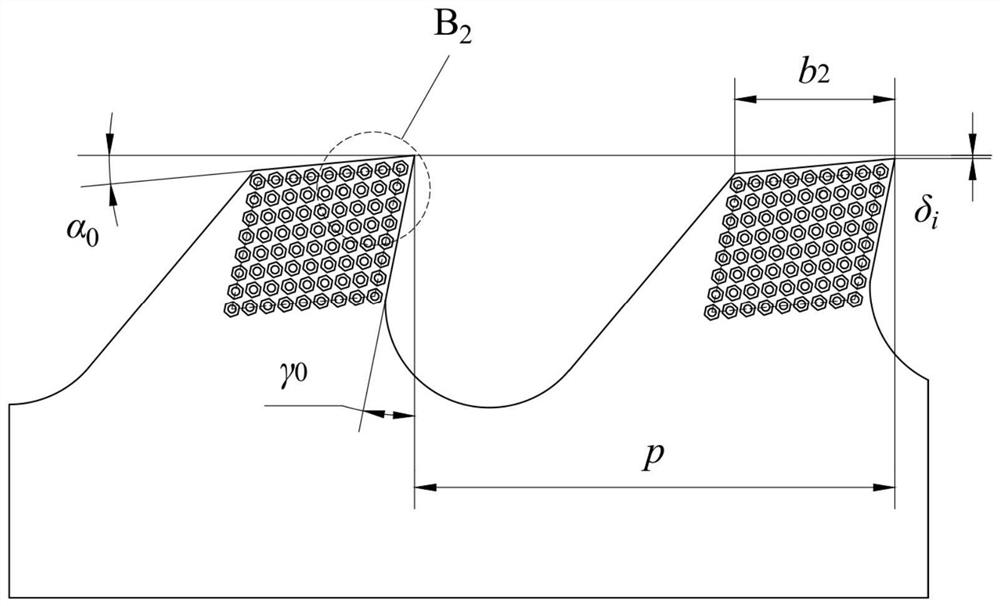

Novel squeeze roller type roller surface structure

The invention discloses a novel squeeze roller type roller surface structure, which comprises a roller sleeve and stud nails, wherein stud holes and grooves are staggered and distributed on the outer surface of the roller sleeve; the stud nails are arranged in the stud holes by adhesive in a clearance fit mode; and the upper end surfaces of the stud nails are flush or lower than the outer surface of the roller sleeve. The squeeze roller type roller surface structure is characterized in that spherical pit or semi-spherical pit structures which are distributed on the whole roller surface and are staggered and arranged. When equipment is in load operation, one layer of self-generating material pad is generated on the surface of the roller sleeve. The material pad is used for bearing abrasion and impact by ultrahard objects, such as iron blocks and the like. The material pad of the structure has a high forming speed so as to improve the abrasion resistance of the roller surface, prolong the service life of the roller surface and improve the hard object impact resistance of the roller surface stud nails.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

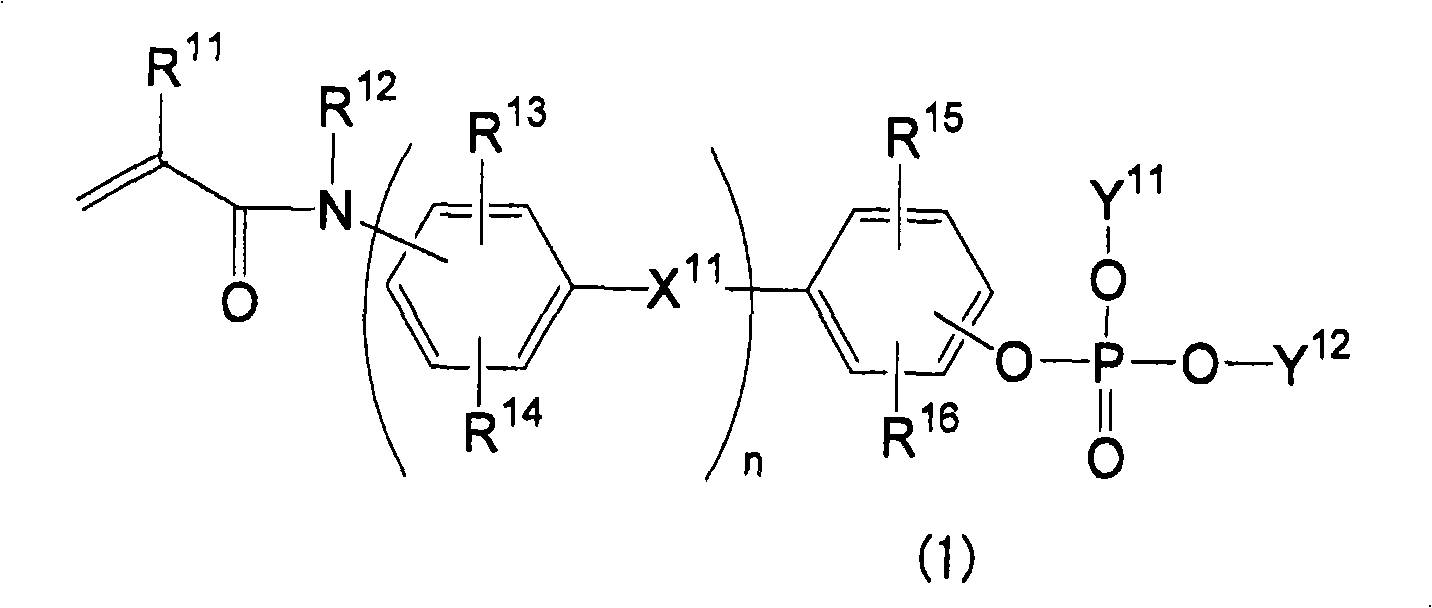

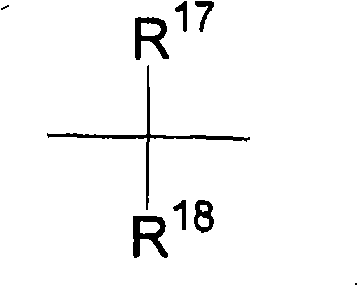

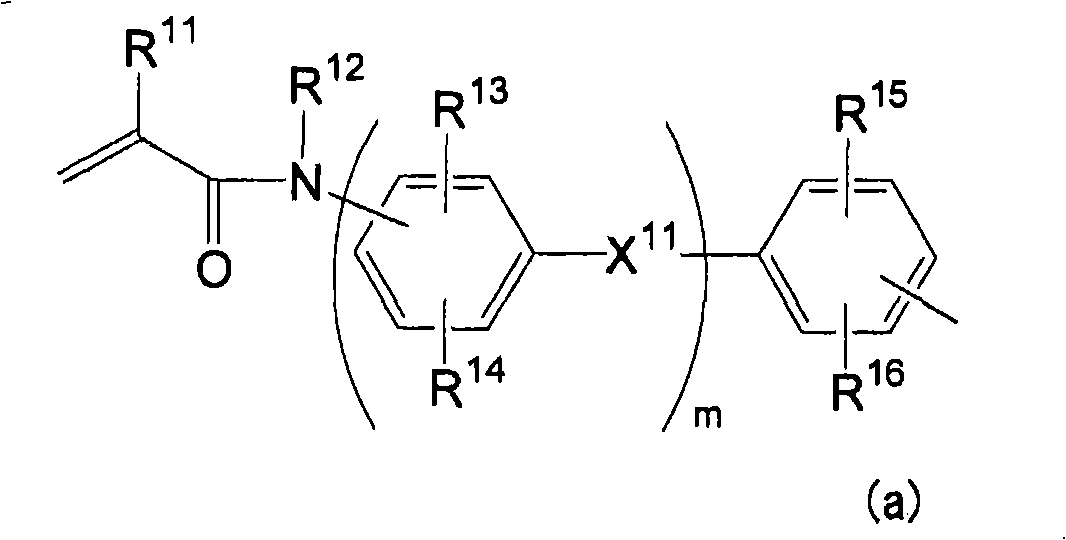

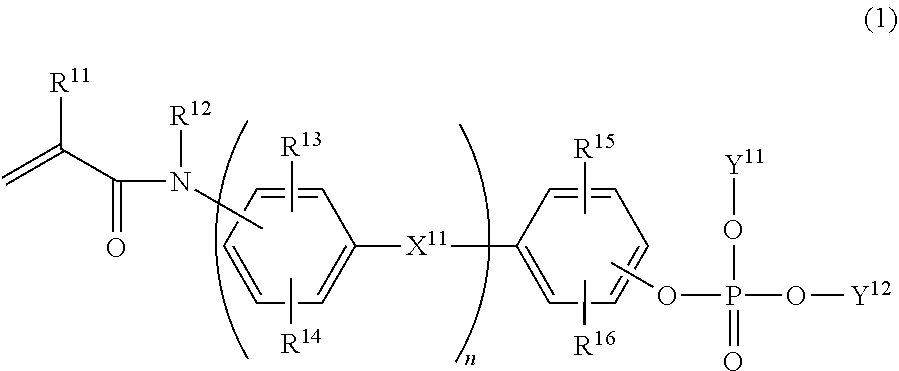

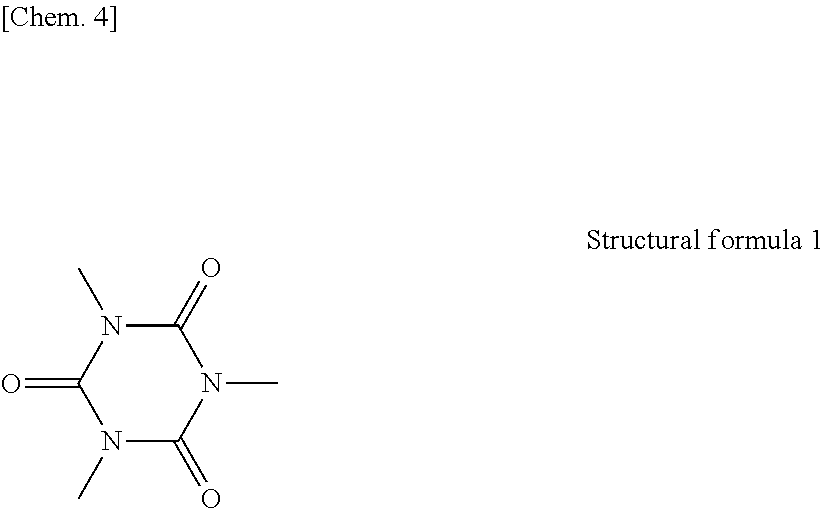

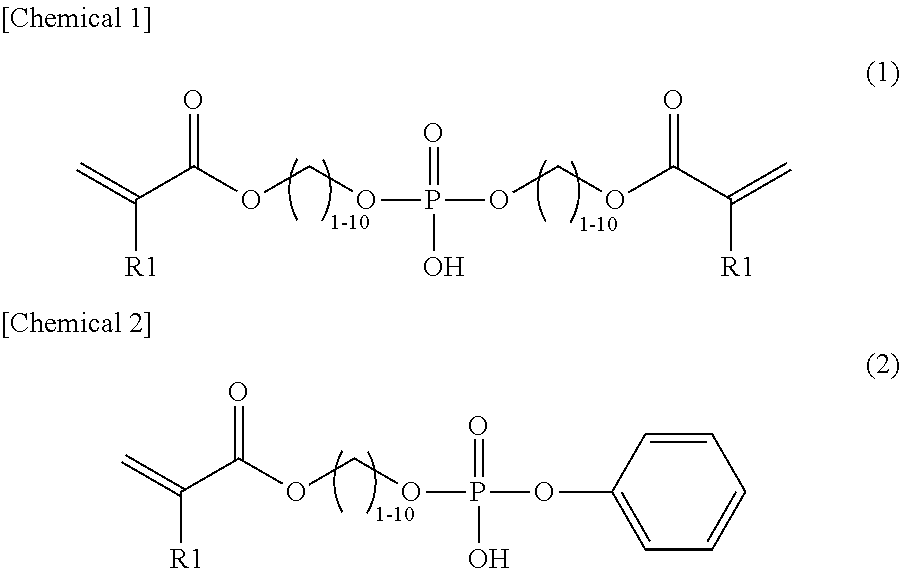

Phosphate ester compound, metal salt thereof, dental material, and demtal composition

ActiveCN101516896APreserve operabilitySimple and fast operationImpression capsMedical preparationsPhosphateChemical compound

The invention provides a phosphate compound having an unsaturated double bond and a metal salt thereof; a dental material containing a phosphate compound having an unsaturated double bond and / or a metal salt thereof; and a dental composition containing a phosphate compound having an unsaturated double bond and / or a metal salt thereof. The phosphate compound of the invention provides a dental material and a dental composition such as a bonding material, adhesive material and a dental luting agent that are highly stable during storage, convenient for handling, and that exhibit higher adhesiveness and bond durability.

Owner:MITSUI CHEM INC

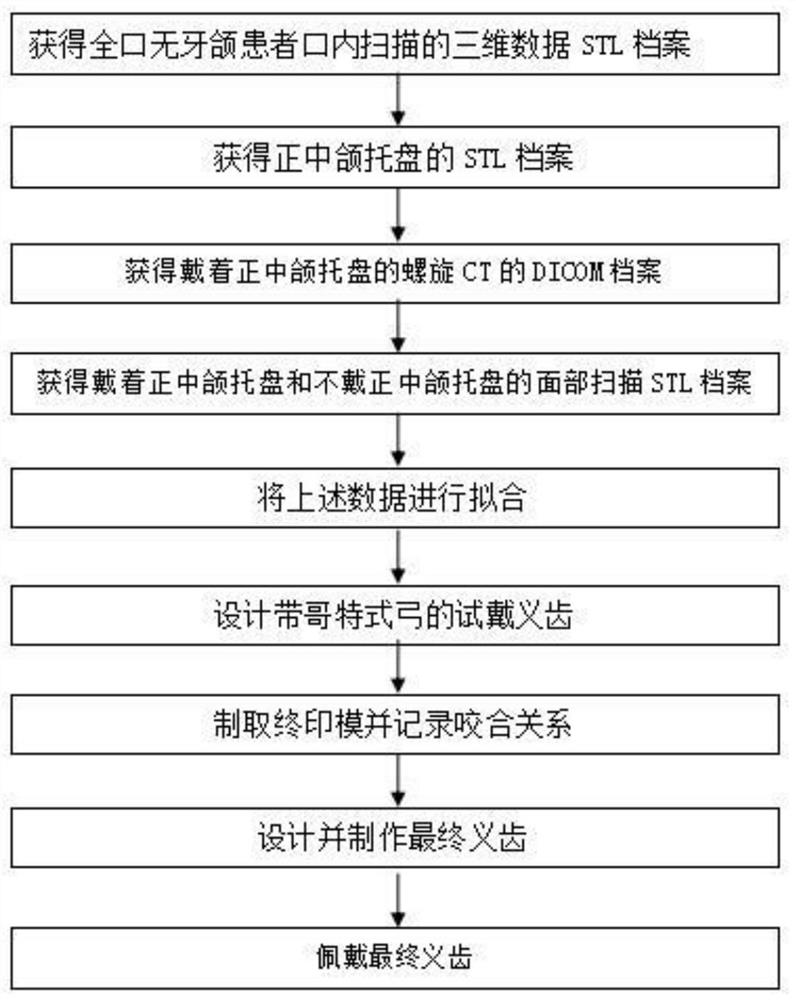

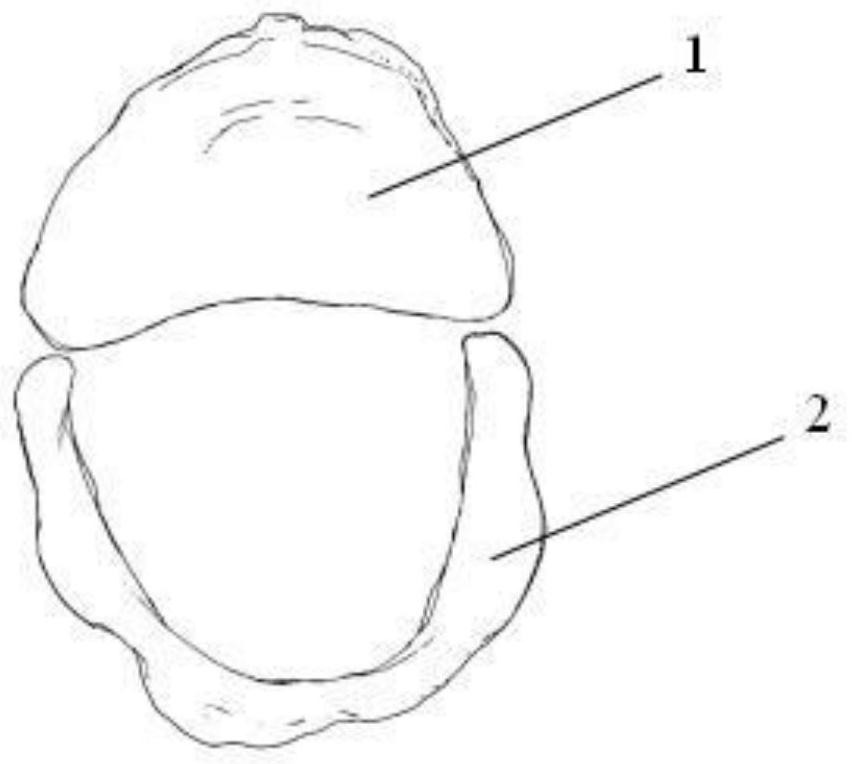

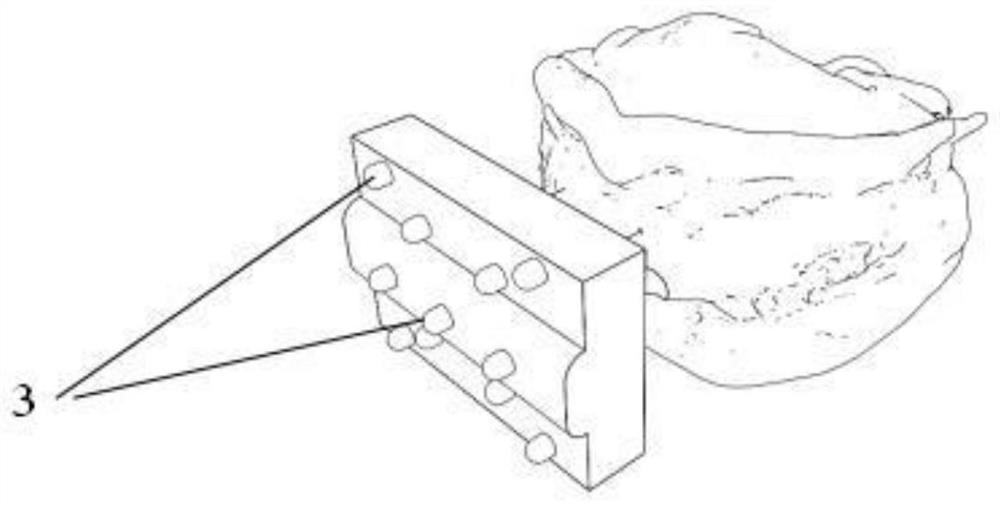

Full-process digital manufacturing method of complete dentures

ActiveCN112535545AImprove try-in effectHigh strengthImpression capsArtificial teethAnatomical structuresEntire mouth

The invention provides a full-process digital manufacturing method of complete dentures. The full-process digital manufacturing method comprises the following steps: acquiring an STL file of three-dimensional data by intraoral scanning of a patient with complete edentulous jaw; putting the median occlusal tray into the mouth, recording the morphology of the mucous membrane surface of the upper jawand the lower jaw and the relative position relation of the upper jaw to the lower jaw, obtaining an STL file of three-dimensional data of the median occlusal tray by scanning; and obtaining a DICOMfile about spiral CT or CBCT of the edentulous jaw patient wearing the median occlusal tray. The full-process digital manufacturing method of the present invention has the advantages as follows: 1, athree-dimensional space about maxillofacial region of the patient is constructed by fitting four digital files, and the occlusal plane in which the patient tries on the dentures and morphology and position of the anterior teeth are set with reference of the anatomical structure of the maxillofacial region of the patient, thereby improving the try-on effect of the dentures; 2, a final impression scanning and copying technology is utilized to accurately manufacture the morphology of a final denture base; and 3, a base plate and a artificial dentition are obtained by adhering the separately cut resin discs with different colors and high strength through adhesive, thereby achieving high cutting precision, high strength of the resin discs and good wear resistance of the artificial teeth.

Owner:成都橙子思创医疗科技有限公司

Phosphate compound, metal salt thereof, dental material and dental composition

InactiveUS20100024683A1Excellent handleabilityGood storage stabilityImpression capsOther chemical processesPhosphateDouble bond

The invention provides a phosphate compound having an unsaturated double bond and a metal salt thereof; a dental material containing a phosphate compound having an unsaturated double bond and / or a metal salt thereof; and a dental composition containing a phosphate compound having an unsaturated double bond and / or a metal salt thereof. The phosphate compound of the invention provides a dental material and a dental composition such as a bonding material, adhesive material and a dental luting agent that are highly stable during storage, convenient for handling, and that exhibit higher adhesiveness and bond durability.

Owner:MITSUI CHEM INC

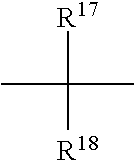

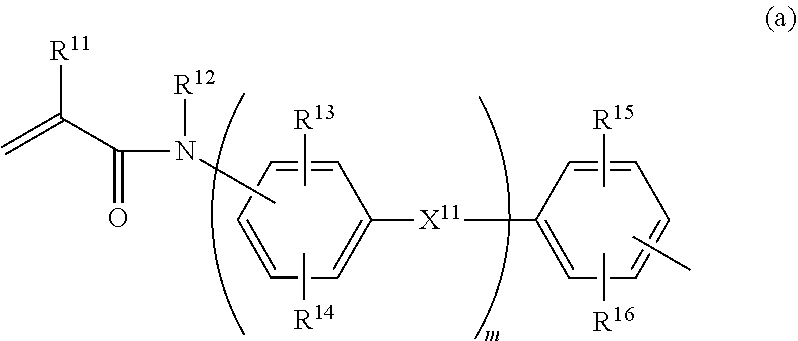

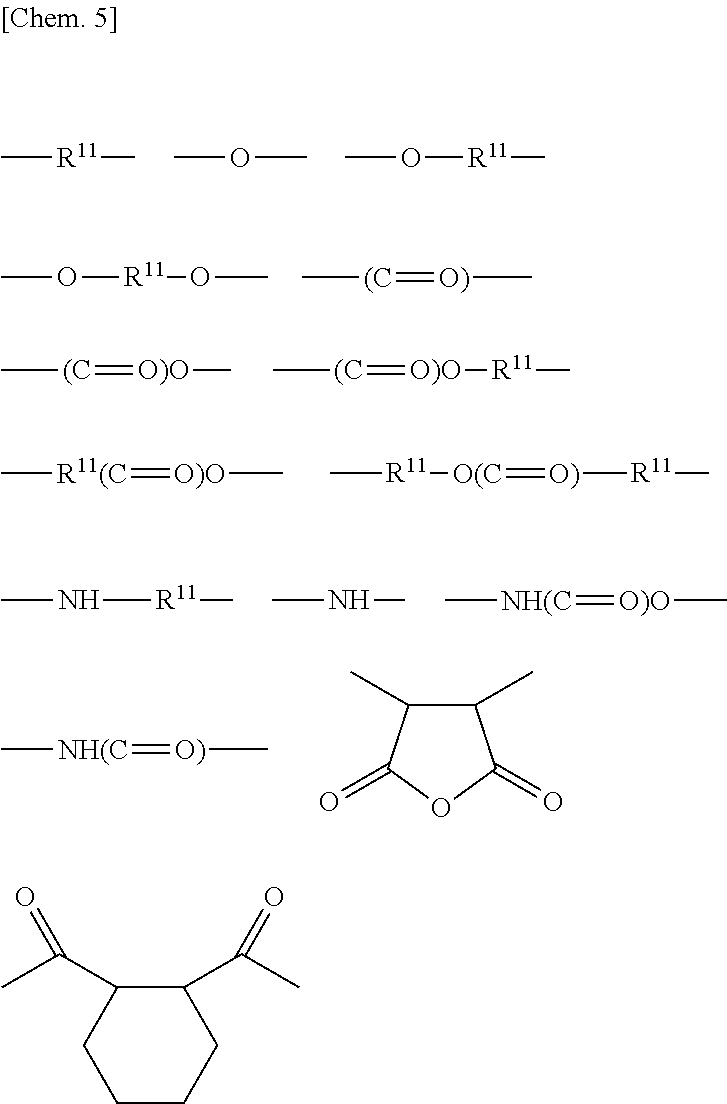

Dental adhesive composition, dental adhesive primer,dental adhesive bonding material, dental adhesivecomposite resin, and dental adhesive resin cement

ActiveUS20150190313A1Excellent adhesive forceExcellent adhesion durabilityImpression capsDentistry preparationsDental Bonding AgentAdhesive resin cement

Provided are a dental adhesive composition, a dental adhesive primer, a dental adhesive bonding material, a dental adhesive composite resin, and a dental adhesive resin cement each having an excellent adhesive force and excellent adhesion durability. Specifically, provided are a dental adhesive composition, including (A) a polymerizable monomer containing an acidic group-containing polymerizable monomer, and (B) a dendritic polymer, and a dental adhesive primer, a dental adhesive bonding material, a dental adhesive composite resin, and a dental adhesive resin cement each using the dental adhesive composition.

Owner:TOKUYAMA DENTAL CORP

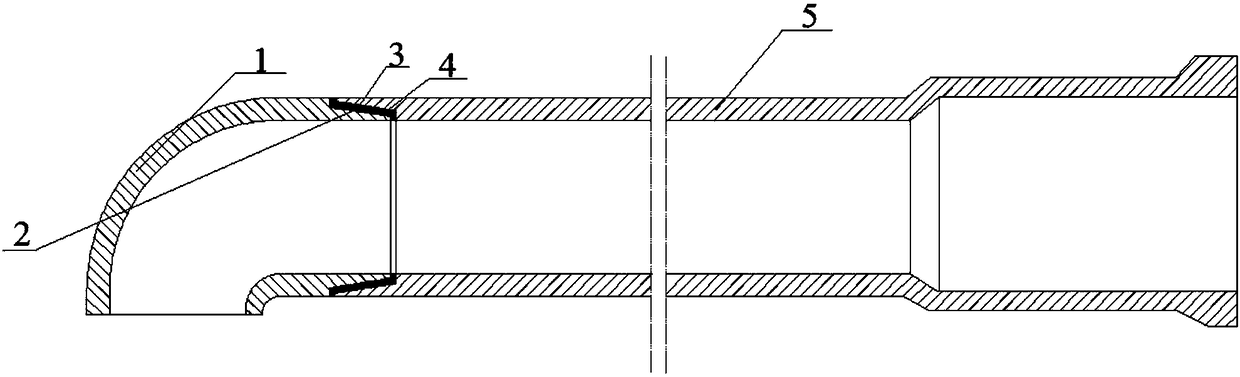

Orthodontic system and method of use

The present disclosure relates to an orthodontic system and a method of using the same to perform orthodontics. In one example, an orthodontic system is presented. The orthodontic system includes a tube having at least one sidewall and two opening ends, and a luting agent. The luting agent is disposed on at least a portion of one or more of the at least one sidewall of the tube and a portion of a surface of a tooth onto which the tube is directly attached or adhered. The two opening ends of the tube remain substantially open so that a wire can move along the tube.

Owner:ARIZA JOAQUIN T

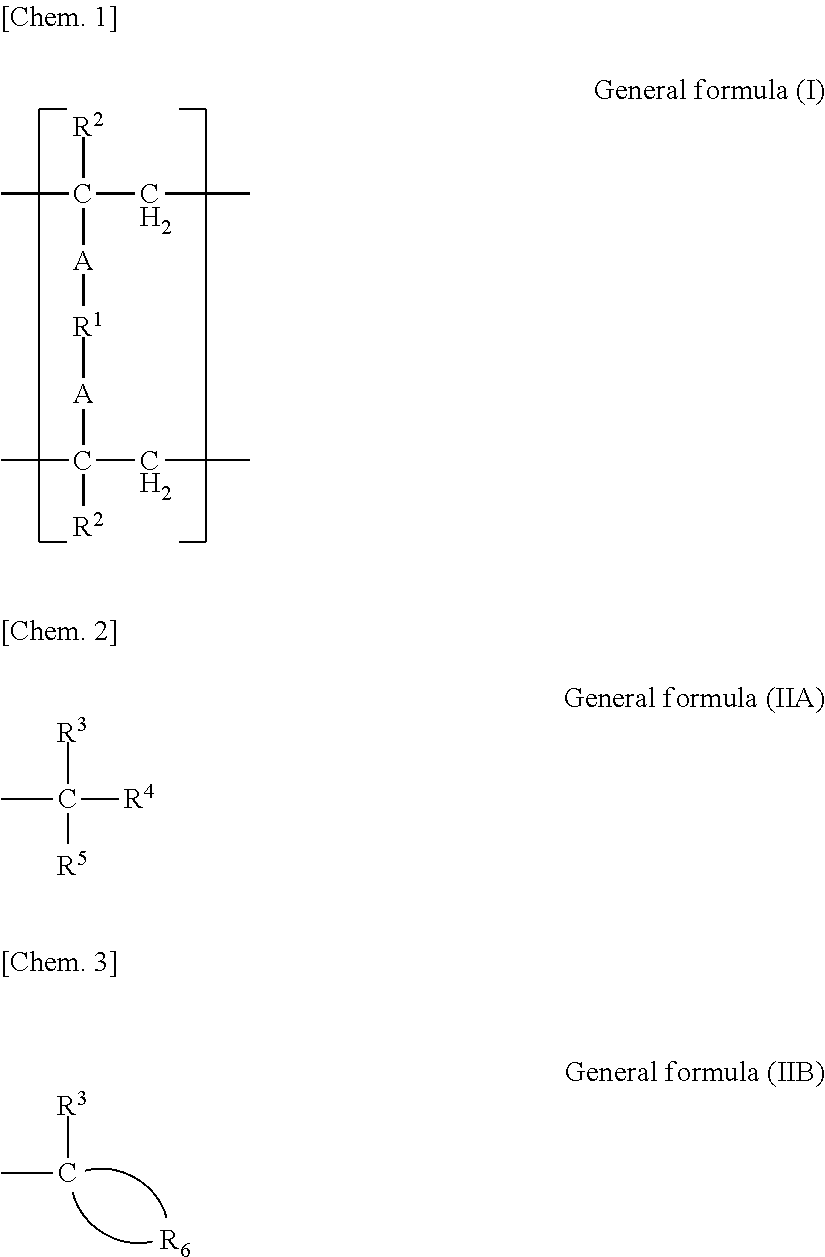

Dental adhesive composition

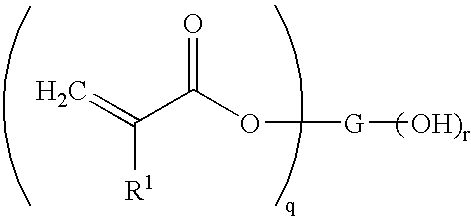

ActiveUS8796354B2High bonding strengthImprove adhesion strengthImpression capsSurgical adhesives2-methylpropeneTitanium ion

[Problems] A dental adhesive composition containing an acid group-containing polymerizable monomer, that can be used as a dental adhesive material or a primer. The dental adhesive composition has excellent durability of adhesion exhibiting further improved adhering strength and durability of adhesion enabling teeth to be more strongly adhered to a composite resin or a prosthetic over extended periods of time.[Means for Solution] The dental adhesive composition contains a polymerizable monomer and ions of an element of the Group IV as basic components, at least 10 mass % of the polymerizable monomer being a polymerizable monomer having a hydrogenphosphate diester group, such as bis(2-methacryloyloxyethyl)hydrogenphosphate or 2-methacryloyloxyethylphenyl hydrogenphosphate, and the content of ions of the element of the Group IV such as titanium ions or zirconium ions in the composition being 0.1 to 1.0 in terms of mole ratio to the hydrogenphosphate diester groups of the polymerizable monomer that has the hydrogenphosphate diester group.

Owner:TOKUYAMA DENTAL CORP

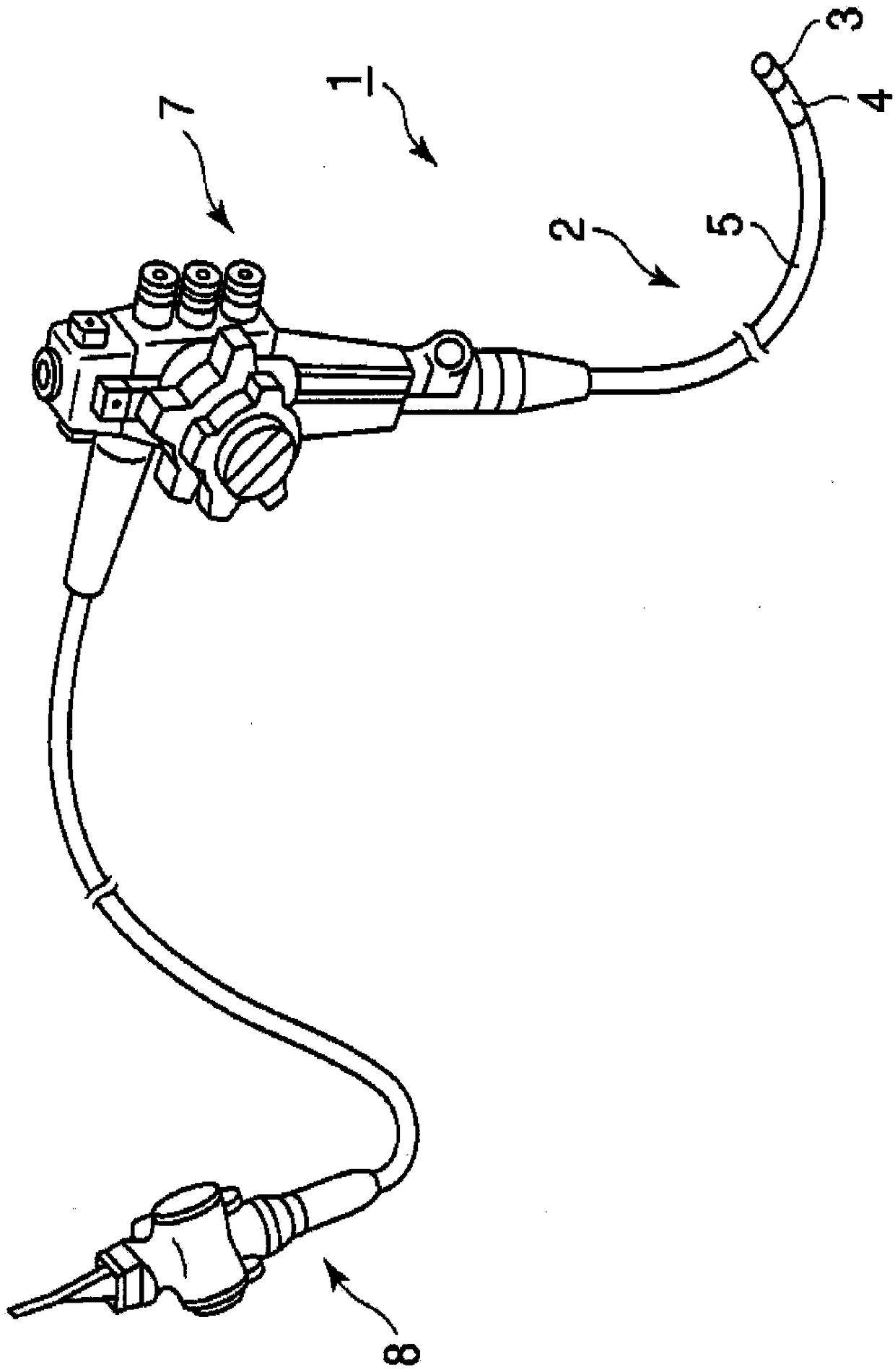

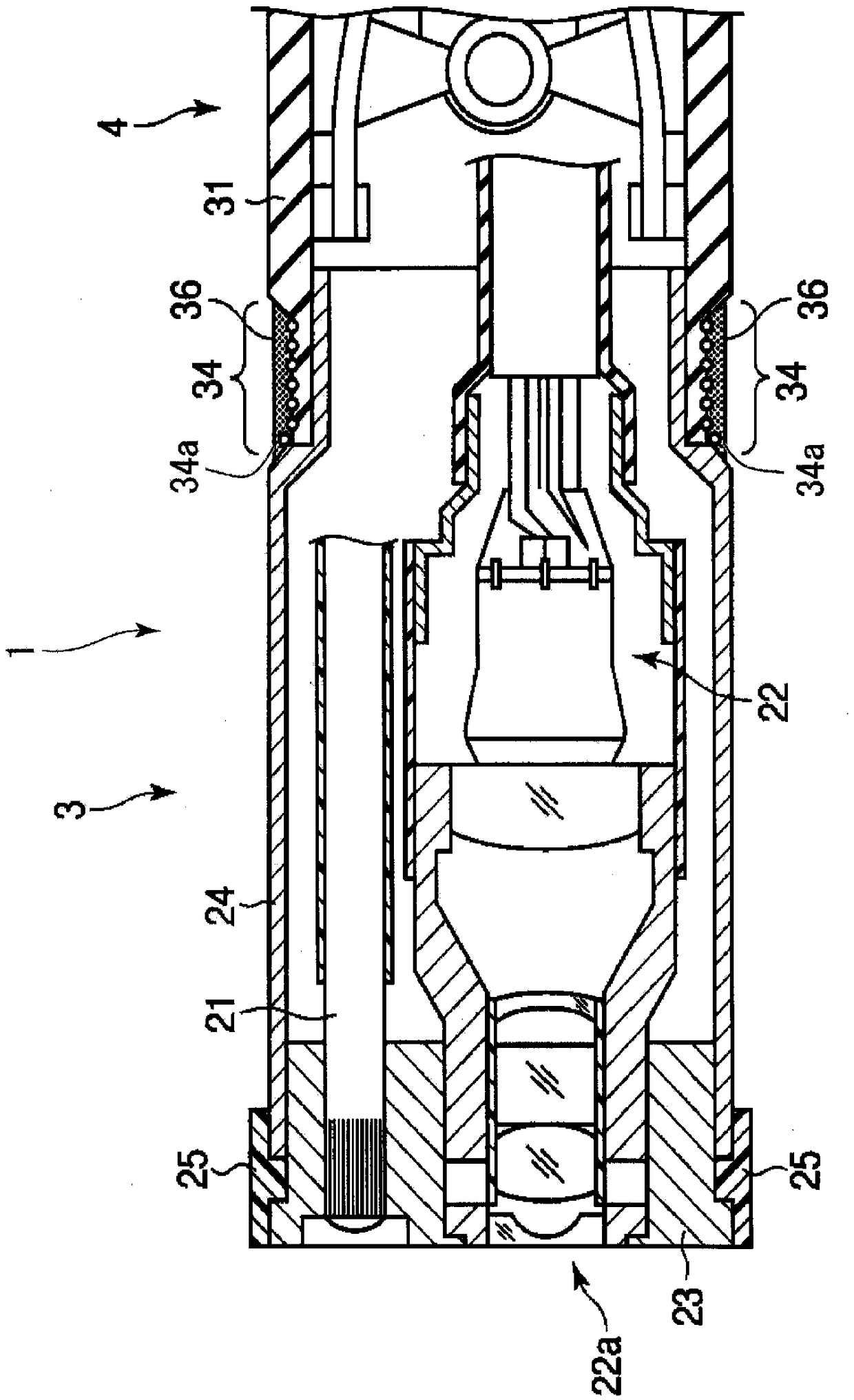

Adhesive composition, ultrasonic transducer, endoscopic device, and ultrasonic endoscopic device

ActiveCN109312205AImprove patienceUltrasonic/sonic/infrasonic diagnosticsNon-macromolecular adhesive additivesEpoxyMedicine

This adhesive composition contains an epoxy resin as a main component, and includes an inorganic zwitterion exchanger.

Owner:OLYMPUS CORP

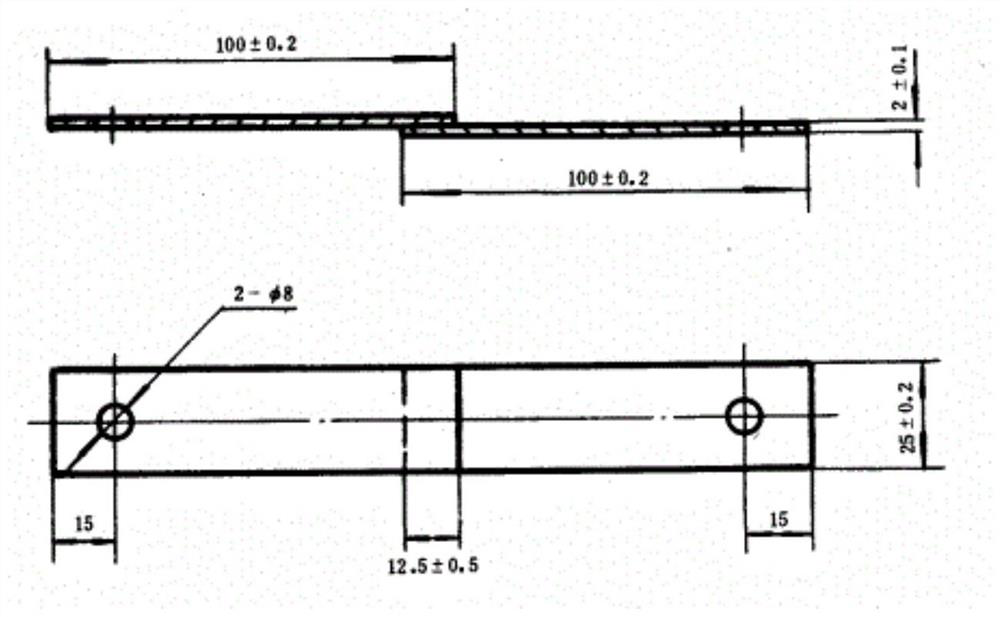

Clamp and method for testing tensile shear creep of adhesive by cross method

PendingCN112098192APrevent rotationReduce mistakesMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesAdhesive cementStructural engineering

The invention discloses a clamp and a method for testing tensile shear creep of an adhesive by a cross method, and belongs to the field of adhesive shear creep testing. A U-shaped first clamping platewith two J-shaped hook grooves in one end and a rectangular second clamping plate with a J-shaped hook groove in one end are used for forming a clamp, and a crossed sample is effectively fixed in theclamp. According to the invention, a crossed sample can be fixed, a shear creep test is carried out by using a tensile load, and rotation of the test piece caused by traction of the bonding layer iseliminated, so that the shear creep performance of the adhesive is more accurately tested, the clamp can be suitable for test pieces with different bonding layer thicknesses, clamps with different specifications do not need to be prepared, the test cost is reduced, and the test efficiency is improved, and the test efficiency is improved.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD +1

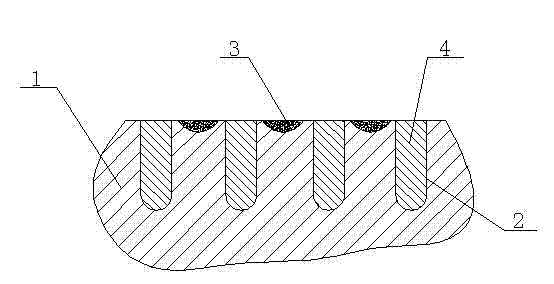

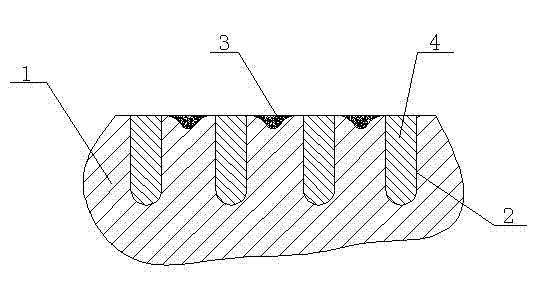

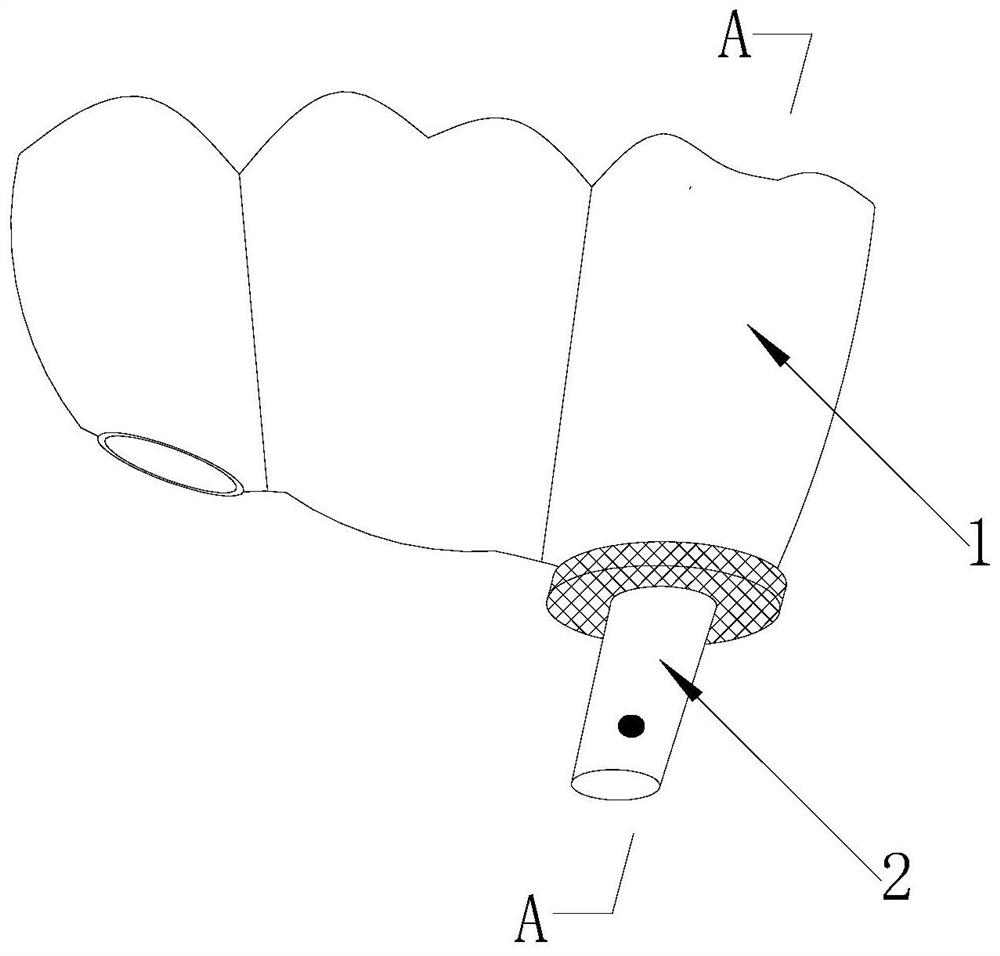

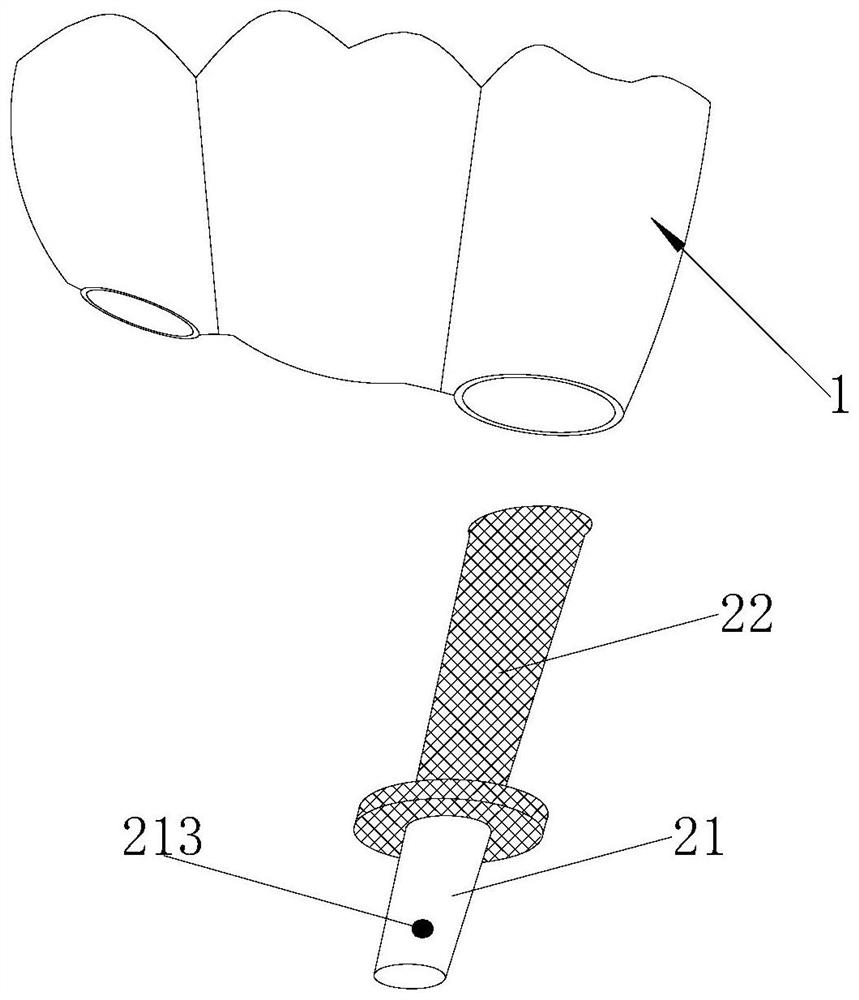

Implant upper part repair pre-bonded abutment replica and preparation method thereof

The invention discloses an implant upper part repair pre-bonded abutment replica and a preparation method thereof. The implant upper part repair pre-bonded abutment replica comprises an implant upperpart repair body and a pre-bonded abutment replica inserted into the implant upper part repair body; the pre-bonded abutment replica comprises a steel nail and a resin abutment replica formed at one end of the steel nail; the end, fixedly provided with the resin abutment replica, of the steel nail is a fixed end, the end, away from the resin abutment replica, of the steel nail is a clamping end, and a mark is arranged at the clamping end; and the resin abutment replica comprises an embedding part and a sealing part. An abutment in the mouth of a patient can be simulated outside the mouth of the patient through the pre-bonded abutment replica, so that redundant adhesive can be effectively cleaned outside the mouth of the patient, cleaning operation of the adhesive is changed from intraoraloperation to extraoral operation, the tooth wearing time of a doctor is shortened, the mouth opening time and pain of the patient are reduced, a series of complications such as inflammation and feverof the oral cavity of the patient due to the fact that the adhesive is not completely cleaned can be avoided, and the health of the patient is protected.

Owner:美尚(广州)医疗科技有限公司

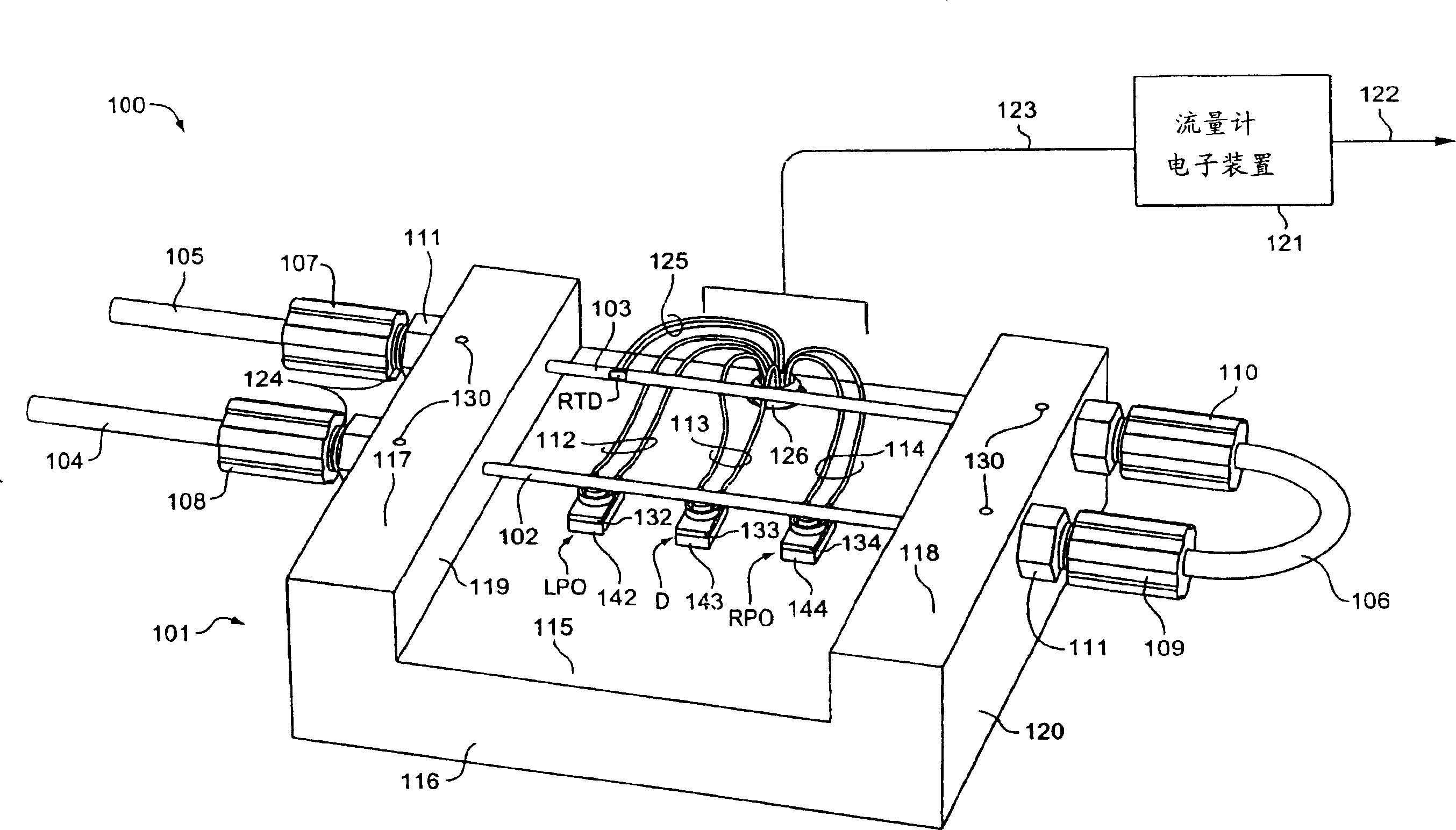

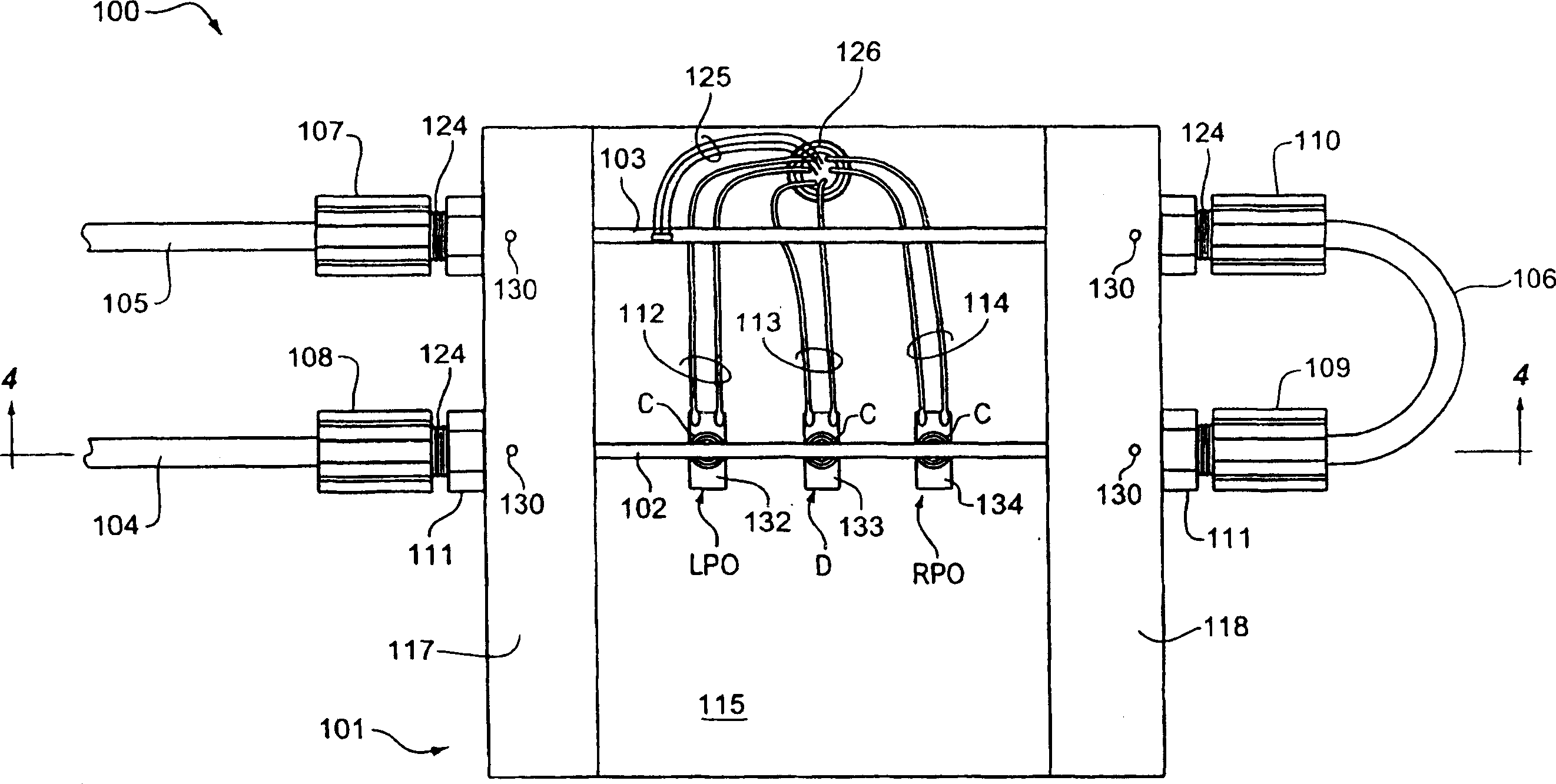

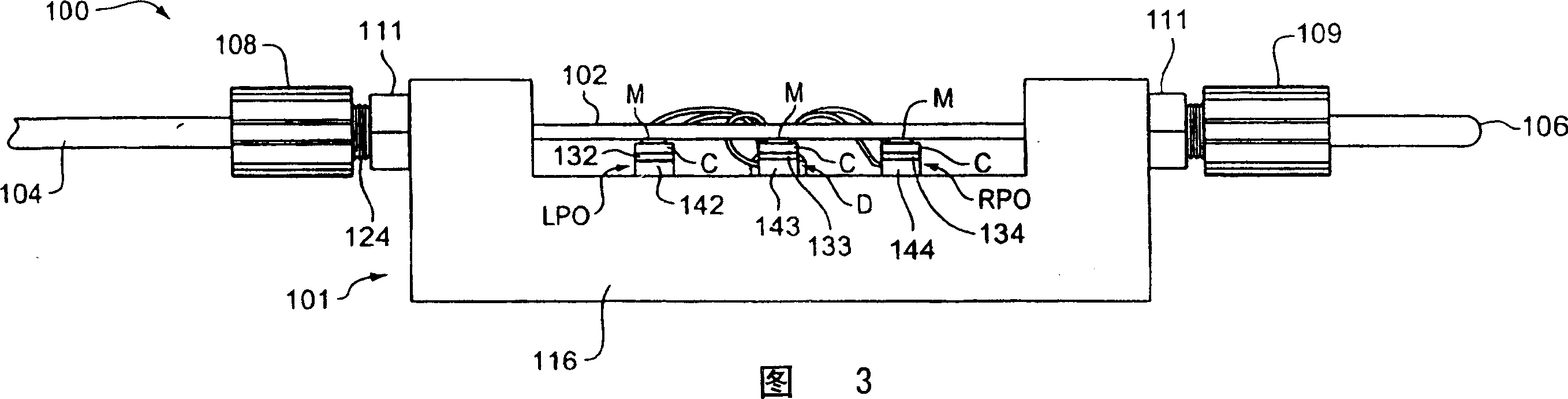

Manufacturing flow meters having a flow tube made of a fluoropolymer substance

A flow meter (500) is disclosed that is comprised of a base (552), a driver (D), pick-offs (LPO, RPO), and a flow tube (501) made from a fluoropolymer substance. The base of the flow meter is comprised of a first leg (517) and a second leg (518). The first leg includes a tube opening (502) and an adhesive opening (504) and the second leg includes a tube opening (512) and an adhesive opening (514). The flow tube passes through the tube openings of the first leg and the second leg. The tube opening of the first leg has a diameter slightly larger than the flow tube to create a gap (506) between the tube opening and the flow tube. The adhesive opening of the first leg provides access to the gap so that adhesive may be applied to the flow tube and an inner surface (508) of the tube opening to affix the flow tube to the base. The adhesive opening in the second leg performs the same function.

Owner:EMERSON ELECTRIC CO

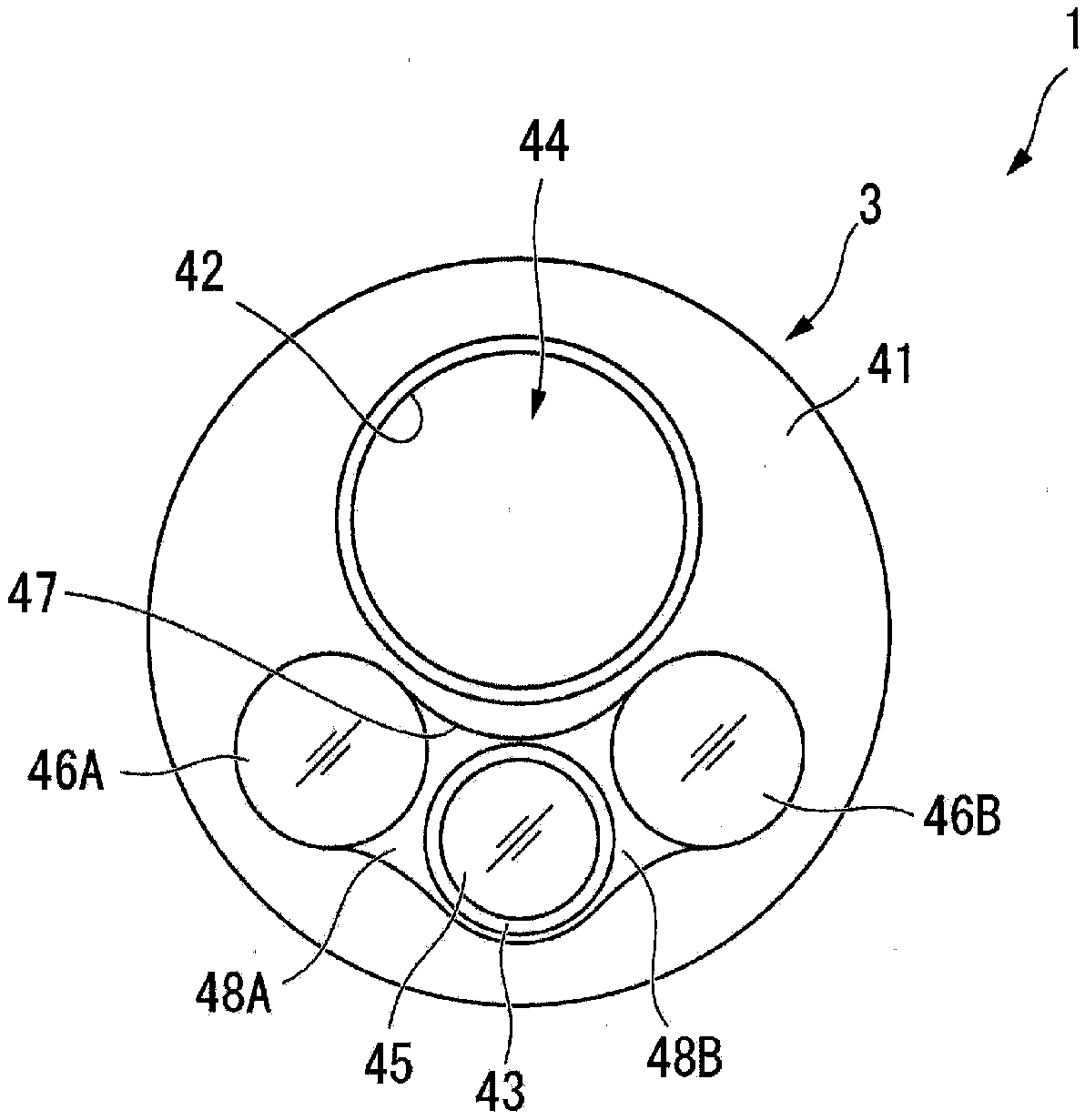

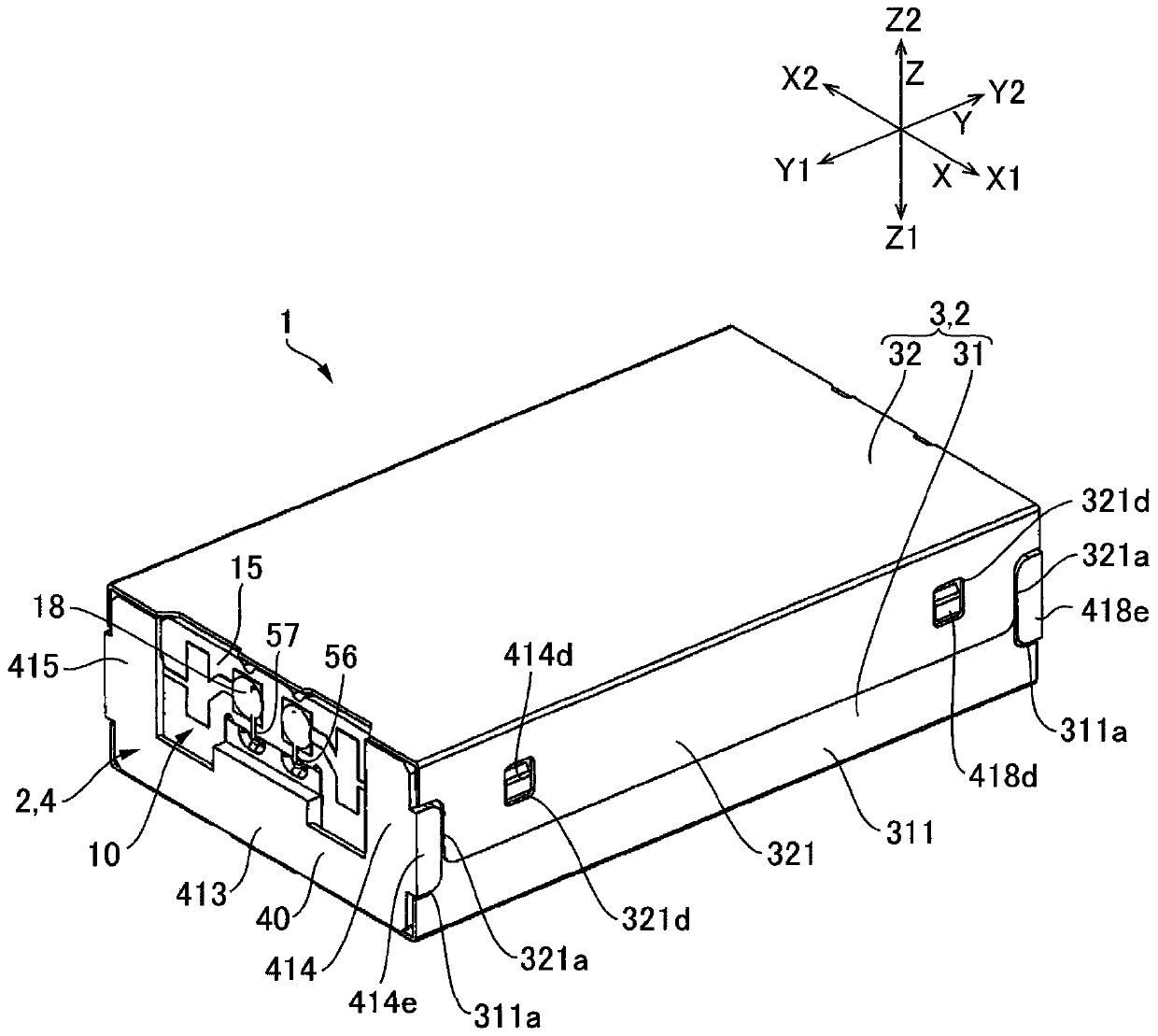

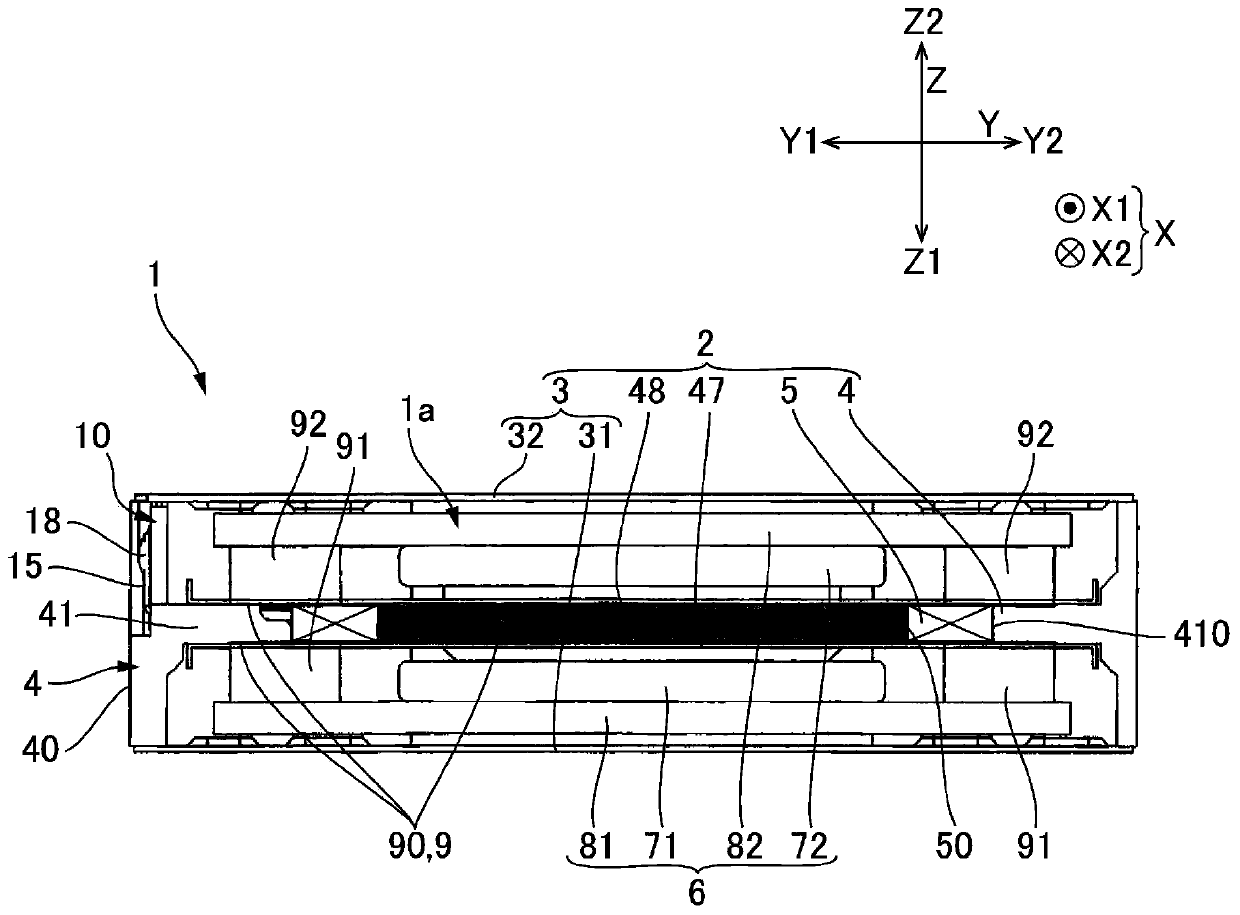

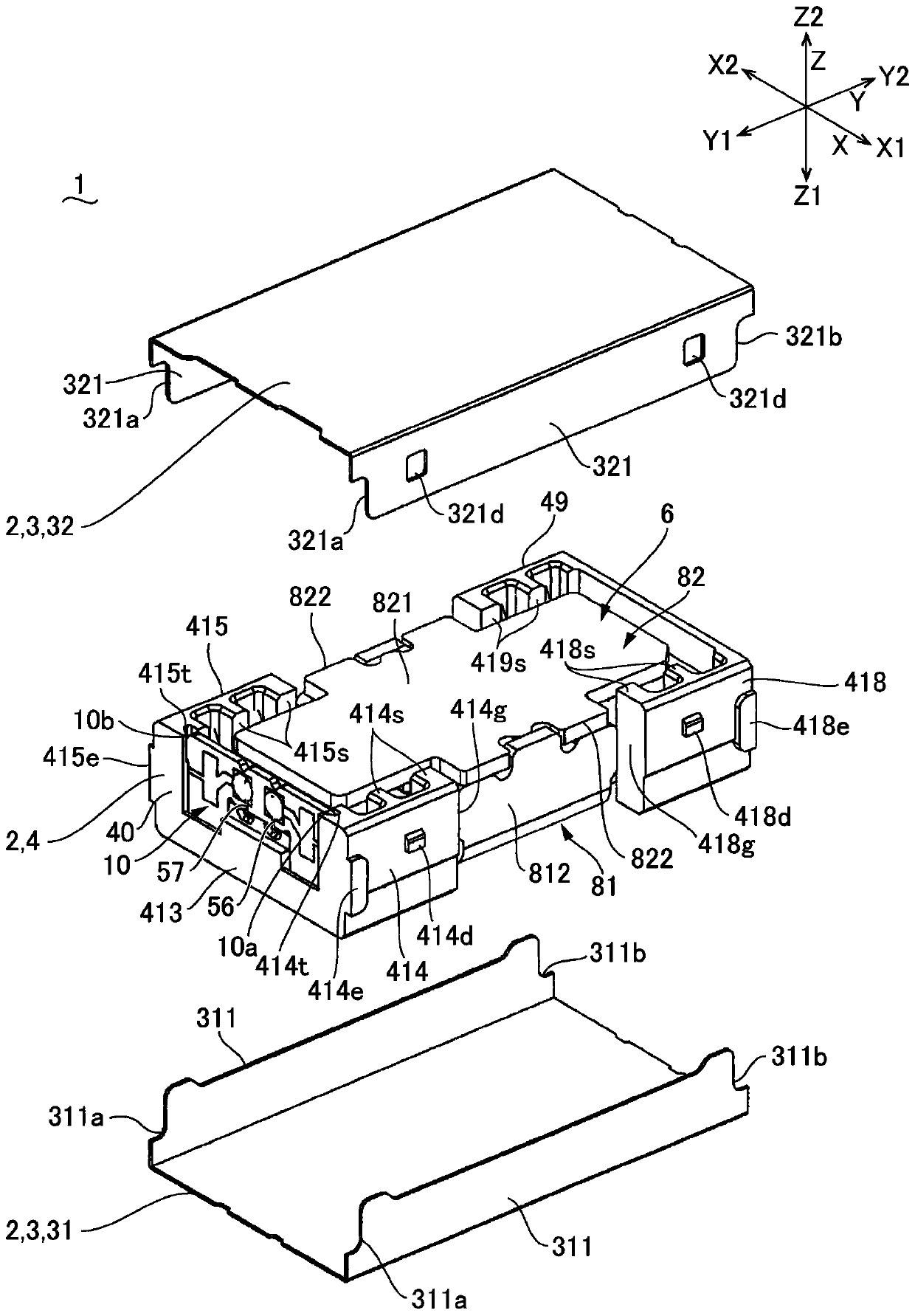

Actuator

The invention provides an actuator capable of properly adhering a coil arranged in a coil arrangement hole of a coil holder to the coil holder. In the actuator, a coil (5) is arranged inside a coil arrangement hole (410) that passes through the coil holder (4) in a first direction Z, and a first plate (47) is arranged so as to overlap the coil arrangement hole (410) and a plate section (41) from one side Z1 in the first direction Z. Therefore, after the adhesive is filled into a hollow core part (50) of the coil (5), a second plate (48) is overlapped. The adhesive flows between the coil (5) and the coil holder (4), between the coil (5) and the first plate (47), between the first plate (47) and the coil holder (4), between the coil (5) and the second plate (48), and between the second plate(48) and the coil holder (4). Therefore, when the adhesive is cured, the coil (5), the first plate (47), the second plate (48), and the coil holder (4) are appropriately fixed by the adhesive.

Owner:SANKYO SEIKI MFG CO LTD

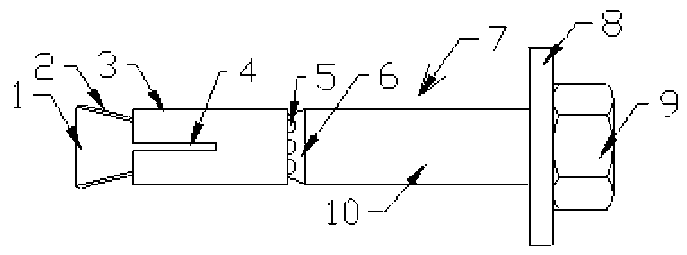

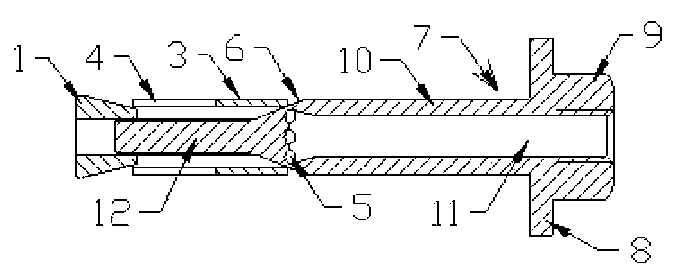

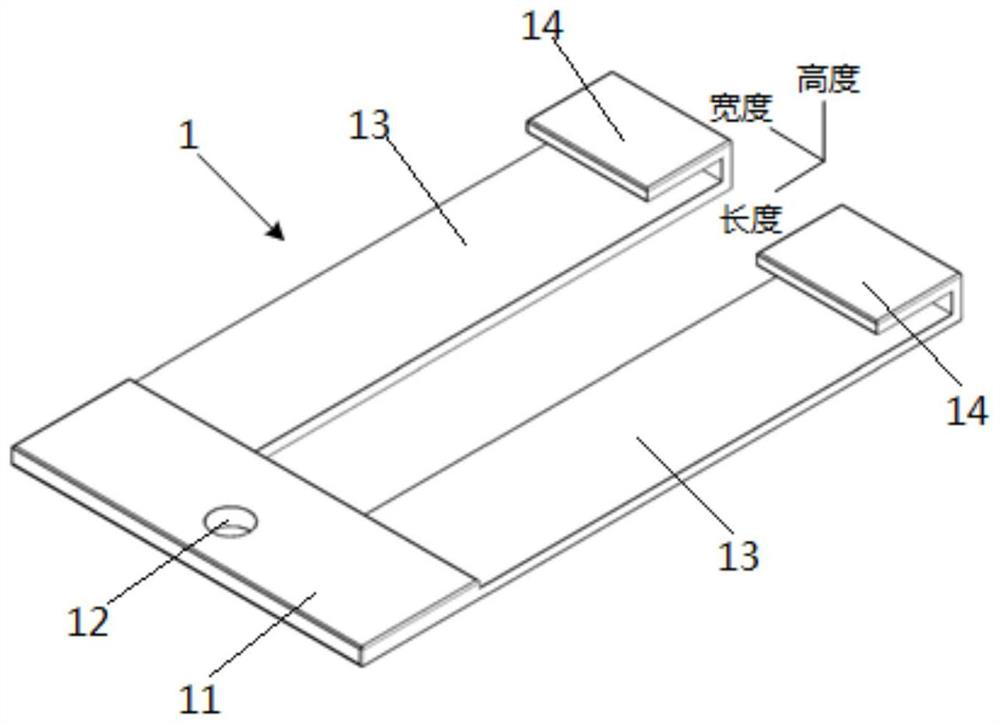

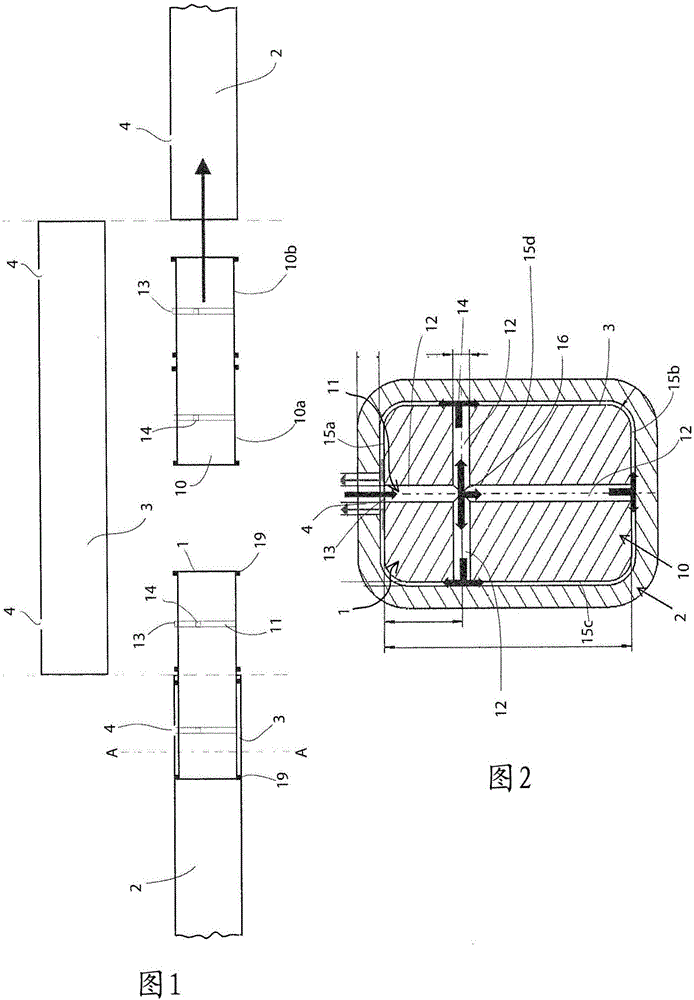

Adhesive-distributing device and method for adhesively bonding hollow profiles using an adhesive-distributing device

The present invention relates to an adhesive-distributing device (1) for use in repairing or reconditioning a hollow profile (2), consisting of an adapter body (10), in which is arranged at least one channel system (11) made up of at least two channels (12) connected to one another, wherein at least one channel (12) is connected to an injection opening (13) for injecting adhesive into the channel system (11), and wherein it is also the case that each channel (12) is designed with at least one exit opening (14).

Owner:BAYERISCHE MOTOREN WERKE AG

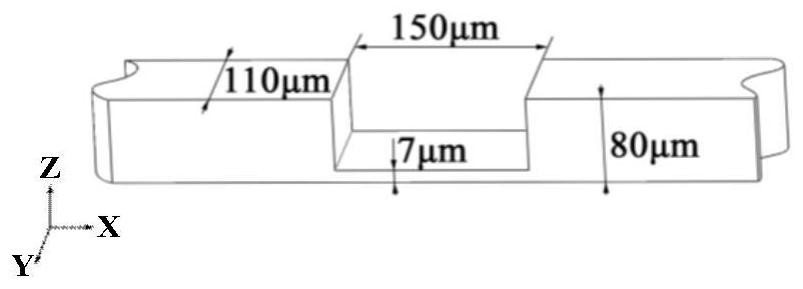

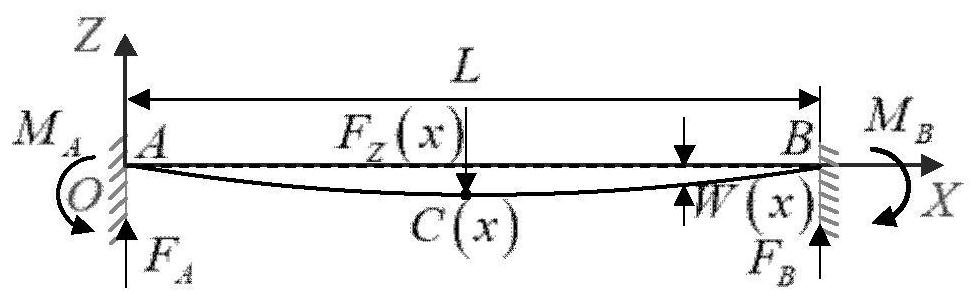

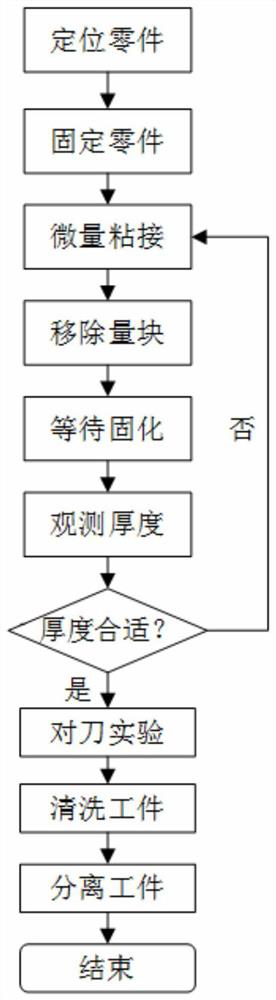

Auxiliary machining method for aviation thin-wall micro-structure part

InactiveCN112404532ASolve processing problemsImprove processing qualityWork clamping meansMilling equipment detailsAviationAdhesive

The invention discloses an auxiliary machining method for an aviation thin-wall microstructure part. The auxiliary machining method comprises the following steps: 1) positioning the aviation thin-wallmicrostructure part; 2) respectively applying pressure to two ends of the aviation thin-wall microstructure part by using two micro-diameter needle heads; 3) in the process that the two micro-diameter needle heads are used for applying pressure, the other micro-diameter needle head is used for dipping a trace amount of adhesive, and the trace amount of adhesive is made to make contact with a thin-neck inner base line of the aviation thin-wall microstructure part; 4) removing a vertical high-precision gauge block; 5) keeping the two micro-diameter needle heads to apply pressure to the two endsof the aviation thin-wall micro-structure part all the time until the trace amount of adhesive flows and is cured; and 6) observing the thickness of the trace amount of adhesive by adopting a magnifying lens to ensure that the thickness of the trace amount of adhesive is greater than the thickness of the microstructure, and the like. The machining process for the aviation thin-wall microstructurepart has the obvious auxiliary improvement effect, the operation process is clear, the method is simple and practical, and application and popularization of aviation instrument microstructure part machining are facilitated.

Owner:CHONGQING UNIV +1

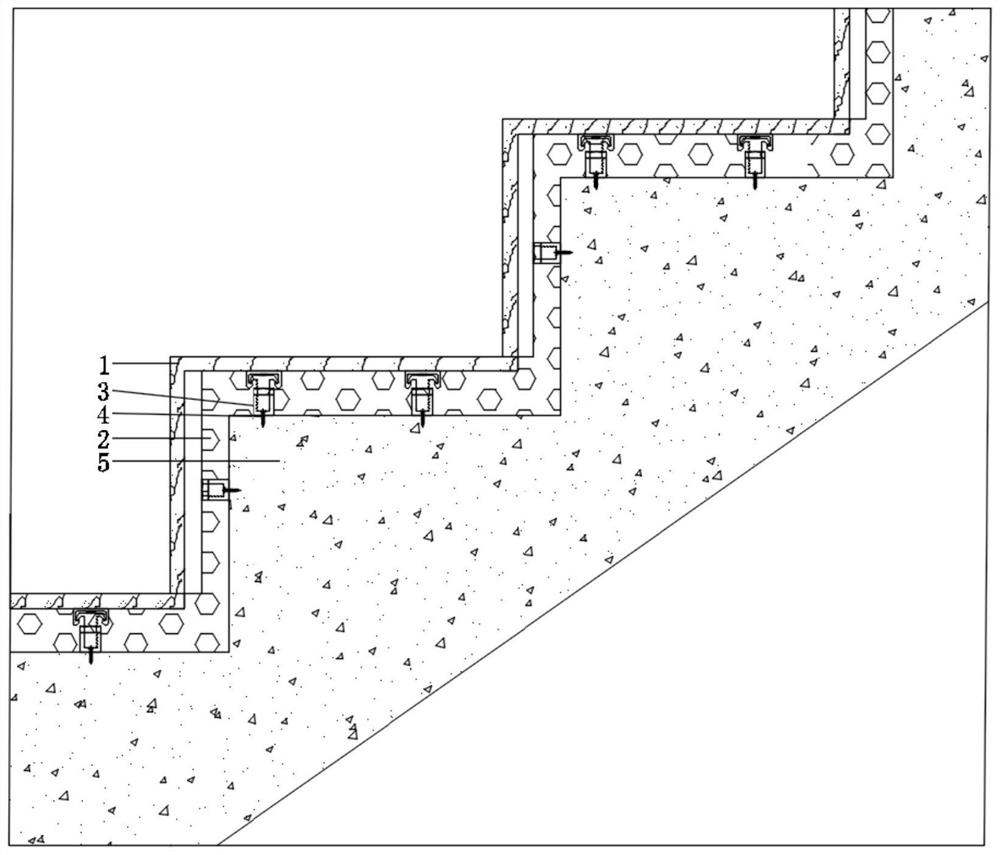

Fabricated stair step and construction method thereof

PendingCN112177258AStandardize your designRealize factory productionTreadsBuilding material handlingDesign standardAdhesive

The invention provides a fabricated stair step. U-shaped groove reinforcing ribs are fixed to an L-shaped step surface layer, U-shaped grooves in the kicking face U-shaped groove reinforcing ribs andU-shaped grooves in the tread U-shaped groove reinforcing ribs are installed on T-shaped adjusting pieces, the T-shaped adjusting pieces are installed on fixing devices, and the fixing devices are fixed to a tread and a kicking face of an original stair face through first fixing pieces. The invention relates to a construction method of the fabricated stair step. Fabricated dry operation construction is adopted, the kicking face and the tread of the stair step serve as an integral unit component, traditional wet operation construction is replaced, the construction steps are simplified, the construction period is shortened, the engineering quality is improved through factory standardized production, the loss of cement mortar adhesives and other materials is reduced, pollution sources in theconstruction link are reduced, green and environment-friendly construction is achieved, design standardization, production factorization and construction fabrication of the stair step are achieved, and the construction quality and the construction efficiency are improved.

Owner:SHENZHEN RUIHE CONSTR DECORATION

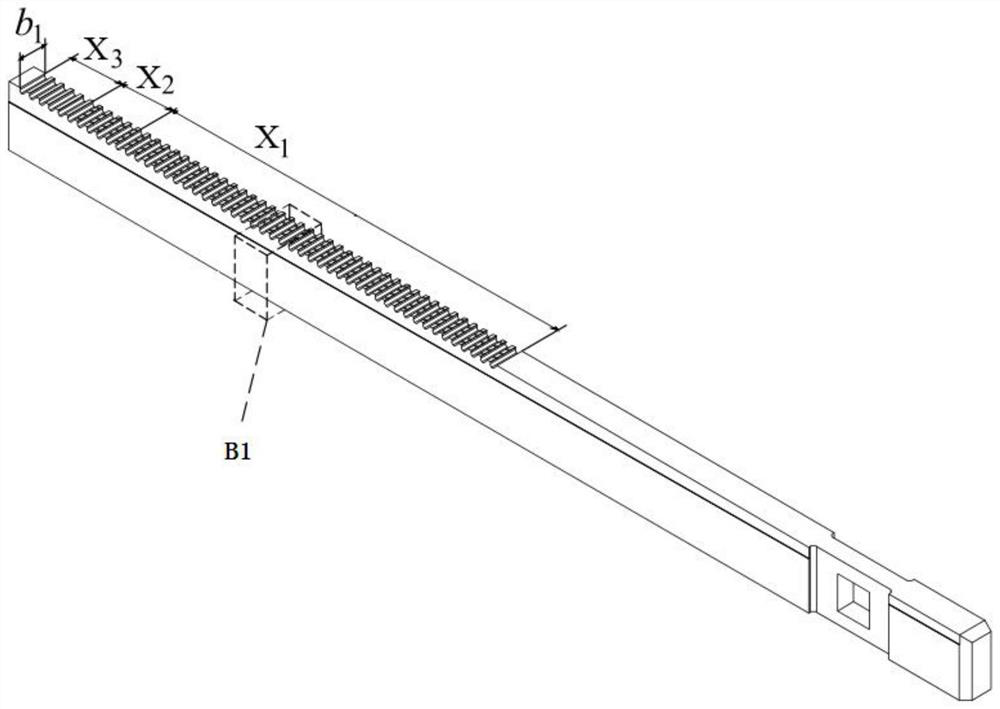

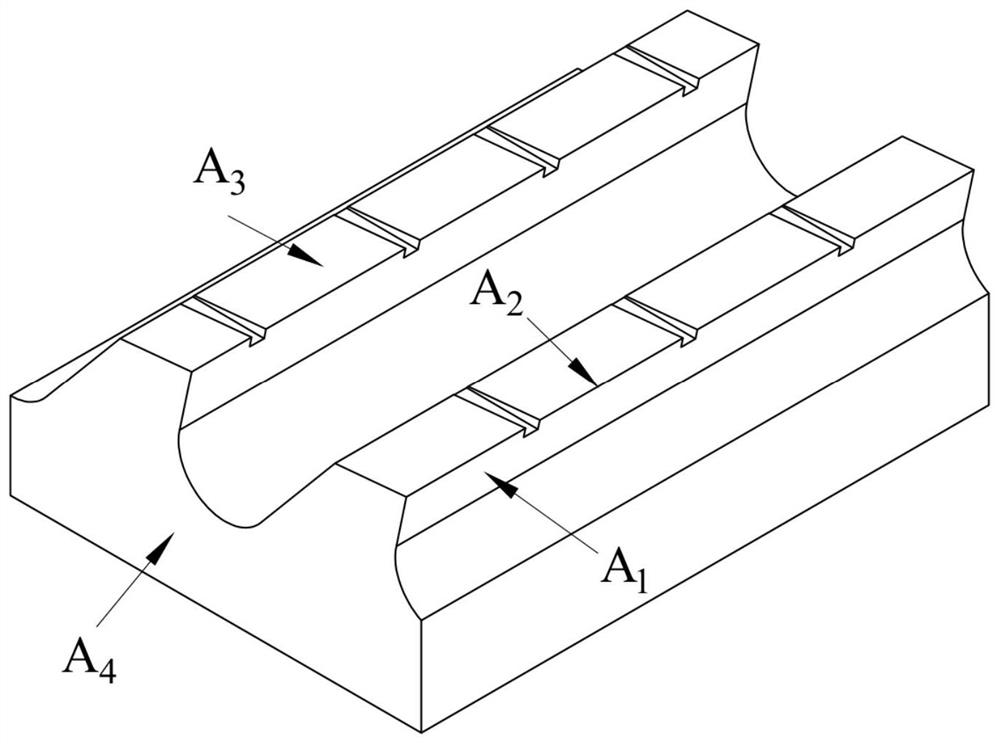

Broach with honeycomb-like microstructures and preparation method of broach

The invention discloses a broach with honeycomb-like microstructures and a preparation method of the broach, and solves the problems that when existing broaching teeth cut materials difficult to process, the top ends of the teeth are relatively low in heat dissipation speed and serious in friction wear. According to the broach with the honeycomb-like microstructure and the preparation method of the broach, the two broach teeth side faces of each broach tooth in the coarse pull area and the semi-fine pull area are both provided with the honeycomb-like microstructures arranged in a parallelogramwith M rows timing N columns; the honeycomb-like microstructures are provided with composite pits, cylindrical protrusions and silica gel fillers; the cylindrical protrusions are integrally formed with the side surfaces of the broach teeth; each composite pit is composed of a regular hexagonal pit and a regular quadrangular pit which coincide with the central axis; each silica gel filler is injected between the corresponding composite pit and the corresponding cylindrical protrusion; and the bottom of each silica gel filler is bonded with the bottom of the corresponding composite pit througha silica gel hot vulcanization adhesive. The broach with the honeycomb-like microstructure and the preparation method of the broach optimize the heat dissipation and vibration suppression performanceof the broach, and achieves the purposes of protecting the broach, reducing the abrasion of the broach, prolonging the service life of the broach and improving the use efficiency of the broach.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Combined special-shaped cast pipe and production method thereof

InactiveCN108515143ADecorativeEasy constructionFoundry mouldsFoundry coresCentrifugationSurface roughness

The invention relates to a combined special-shaped cast pipe and a production method thereof, and belongs to a special-shaped centrifugation cast iron pipe and a production method thereof. The technical problems of low precision, low efficiency, high comprehensive price and poor outer surface roughness degree of the existing special-shaped pipe can be mainly solved. The combined special-shaped cast pipe is characterized in that the combined special-shaped cast pipe consists of a bonding part, a bonding agent and a straight pipe, wherein the bonding part is cast and shaped by a sand casting method; the straight pipe is cast and made through centrifugation; the bonding surface of the straight pipe and the bonding matching surface of the bonding part are bonded by bonding agents so that the straight pipe and the bonding parts are connected into a whole. The production method comprises the following steps of a, performing machine processing on the bonding matched surface of the bonding part; b, performing machine processing on the bonding surface of the straight pipe; c, preparing the bonding agents; d, bonding the bonding part and the straight pipe; e, drying the cast pipe.

Owner:绛县恒通铸造有限公司

System and method for coupling a tube with a medical device handle

InactiveCN104321104AFacilitate acceptanceElectrocardiographyGuide wiresMechanical engineeringMedical device

An elongate medical device handle may comprise a body defining an interior, an exterior, and a connector port extending between the interior and the exterior and defining an axis. The connector port comprises a portion having a polygonal cross-section taken transverse to the axis. In an embodiment, the polygonal cross-section may comprise a star shape. In an embodiment, a connector, such as a fluid connector, may be secured in the connector port using an adhesive.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

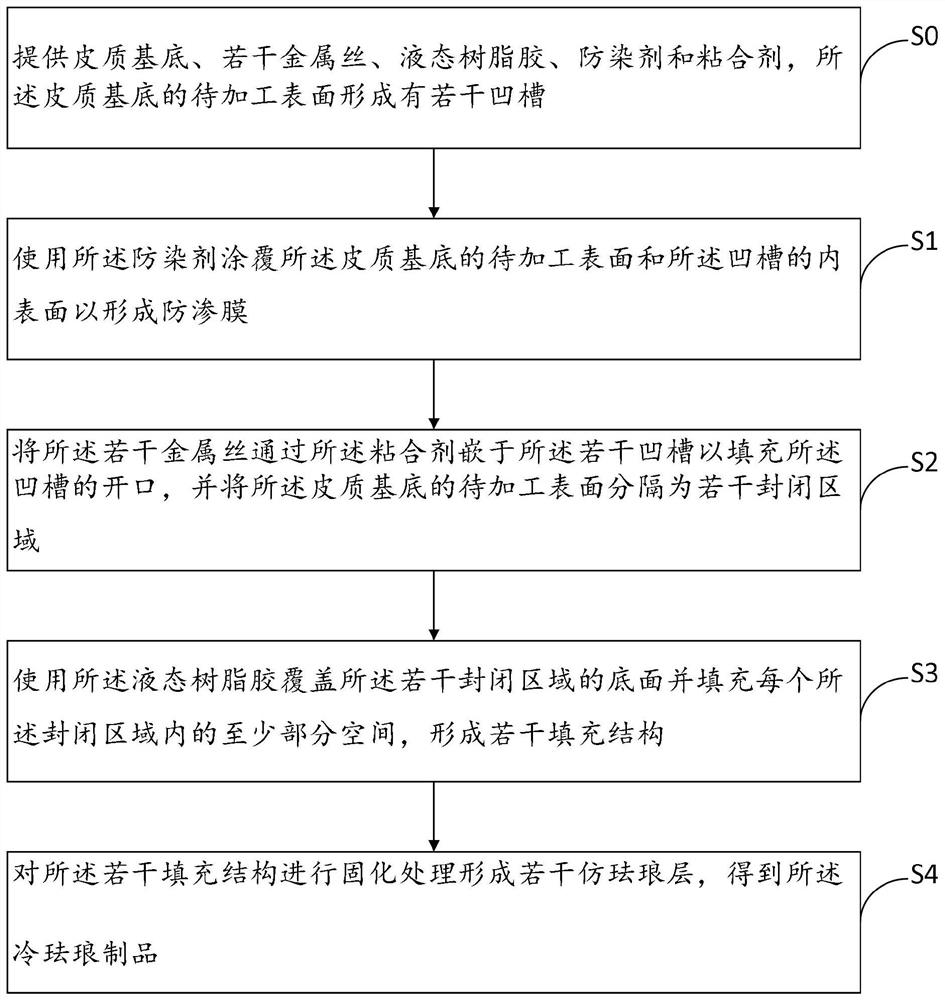

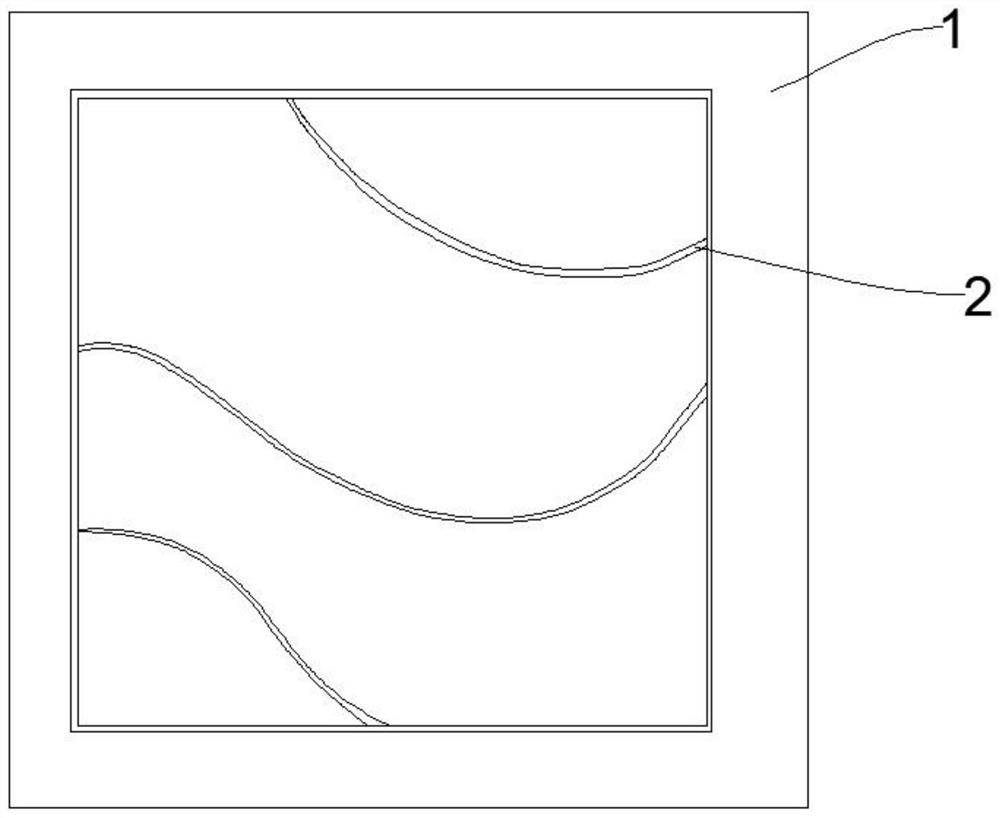

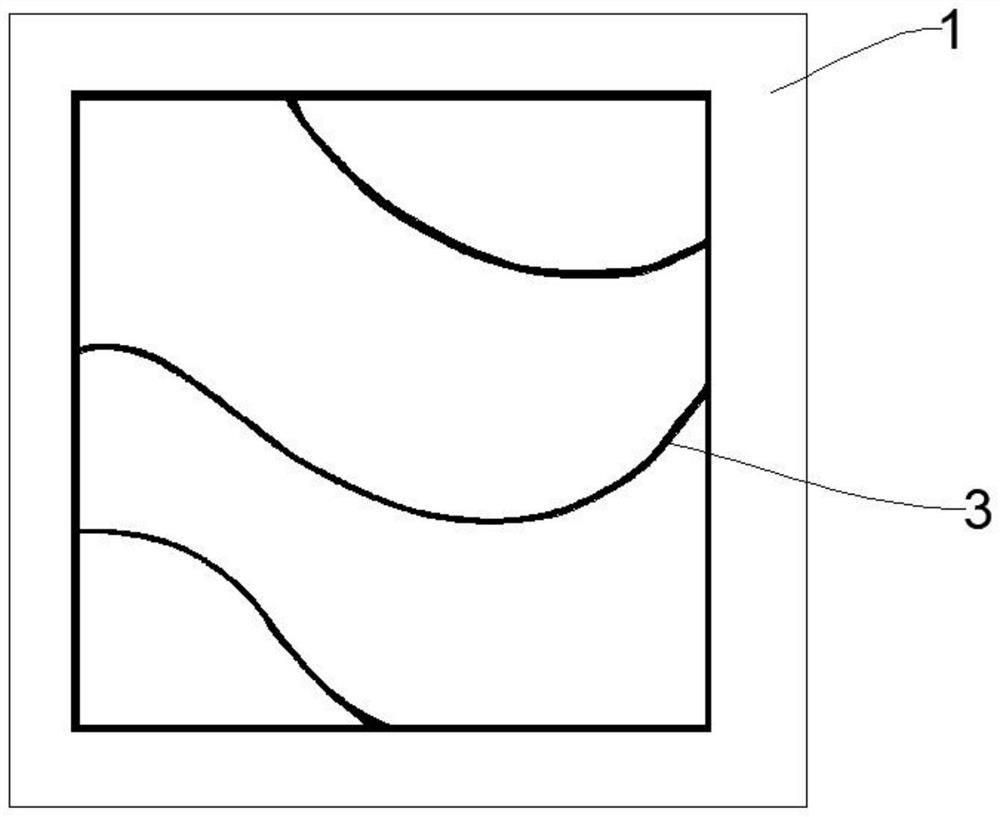

Preparation method of cold enamel product

InactiveCN113752740AGuaranteed bonding strengthDecorative surface effectsSpecial ornamental structuresPolymer scienceAdhesive

The invention provides a preparation method of a cold enamel product. The preparation method comprises the following steps of treating a leather substrate with a plurality of grooves by using an anti-seepage fixing film, embedding a plurality of metal wires into the grooves by using a binder, dividing the leather substrate into a plurality of closed areas, and filling the closed areas with liquid resin adhesive to form a plurality of enamel-imitating layers. The anti-seepage fixing film covers and is fixed on the to-be-processed surface of the leather substrate and the surfaces of the grooves, so that the situation that the bonding strength between the metal wires and the leather substrate is reduced due to permeation of the subsequently used adhesive is avoided; and the metal wires are used for forming the closed areas in a surrounding mode, the fixing effect on the enamel-imitating layers is further enhanced, and therefore the enamel-imitating effect is achieved on the surface of the leather substrate, the application range of the enamel-imitating technology is expanded, and meanwhile the bonding strength between the leather substrate and the enamel-imitating layers is guaranteed.

Owner:SHANGHAI ART & DESIGN ACADAMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com