Patents

Literature

49 results about "Entire mouth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Teethbrush

Owner:GARNER ROBERT +4

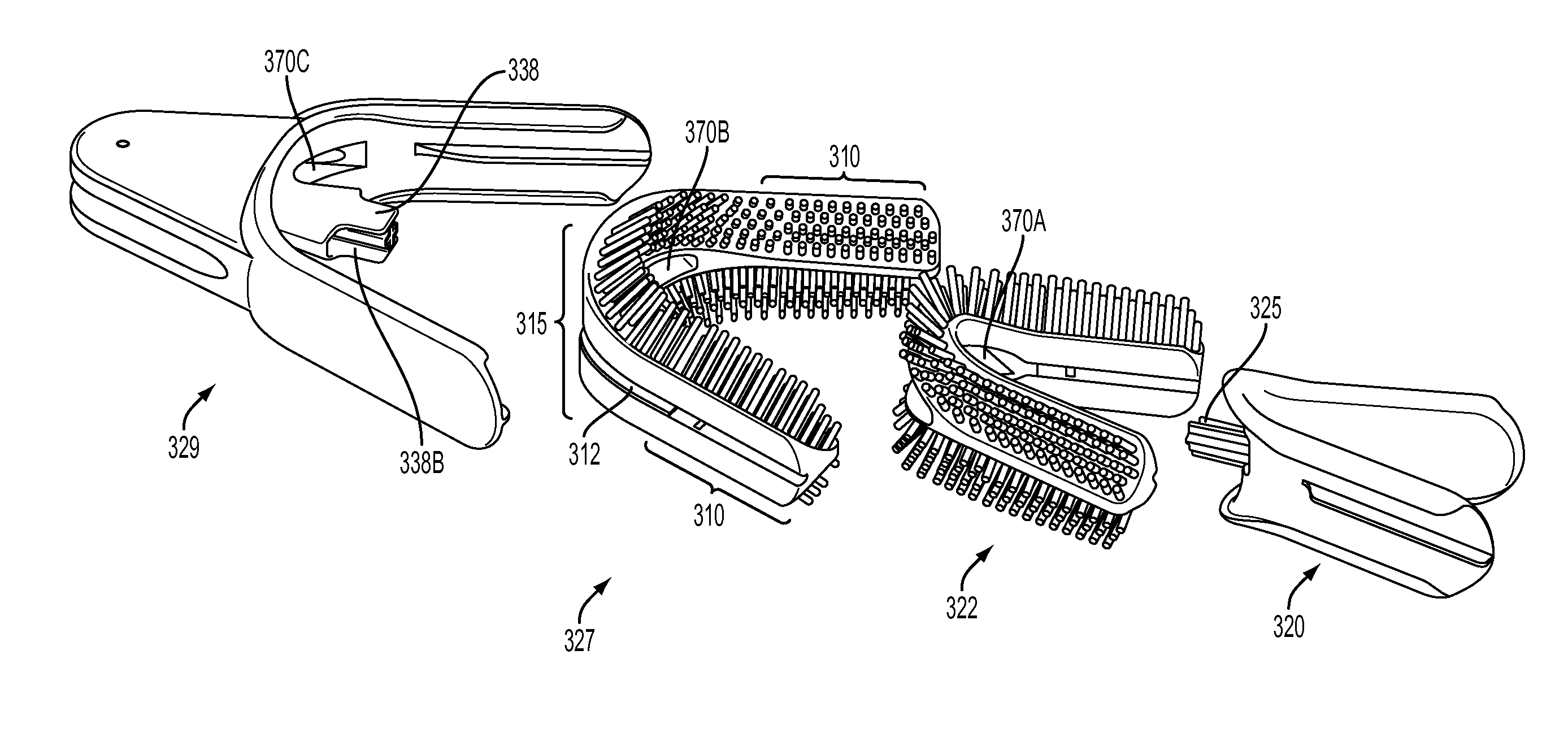

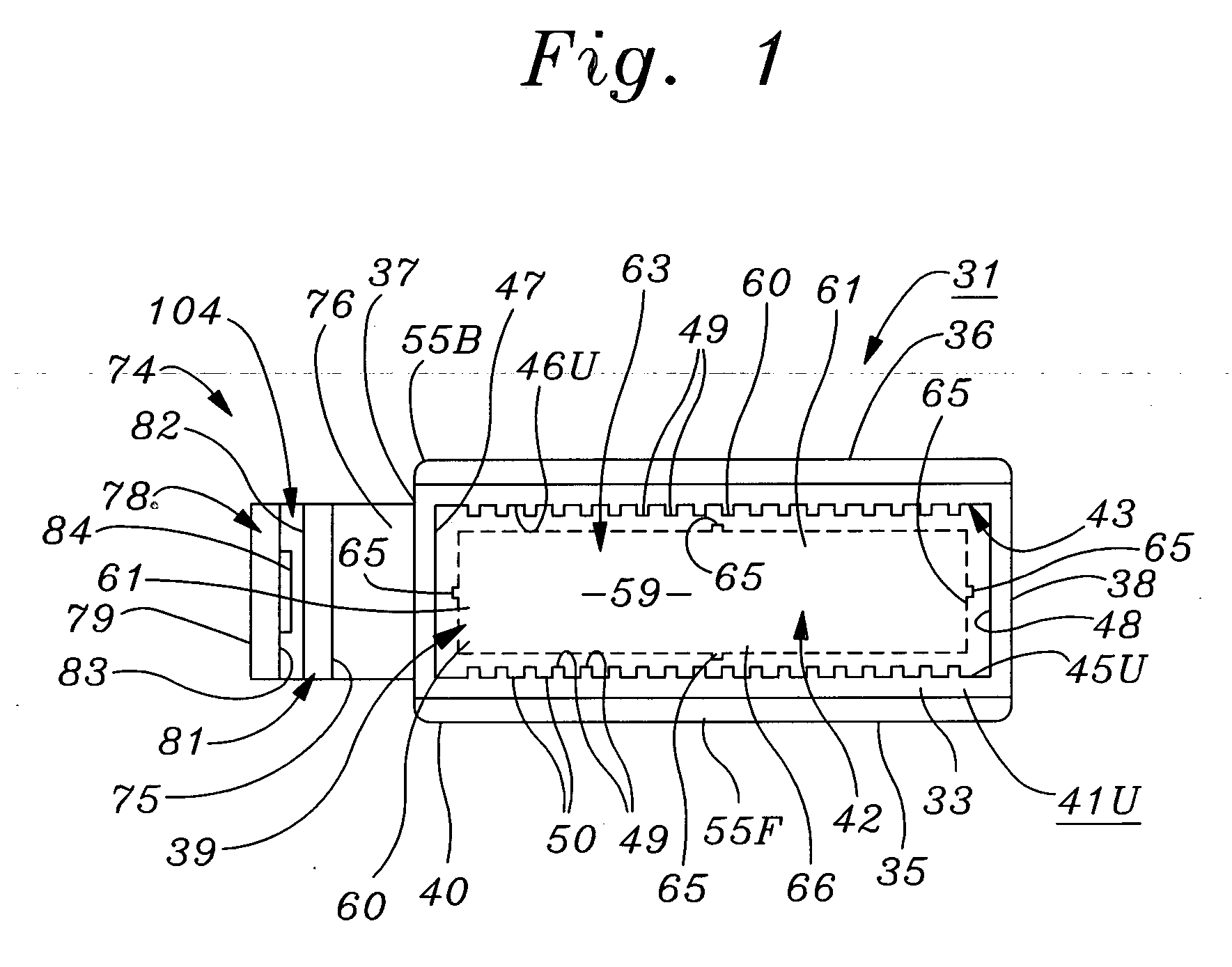

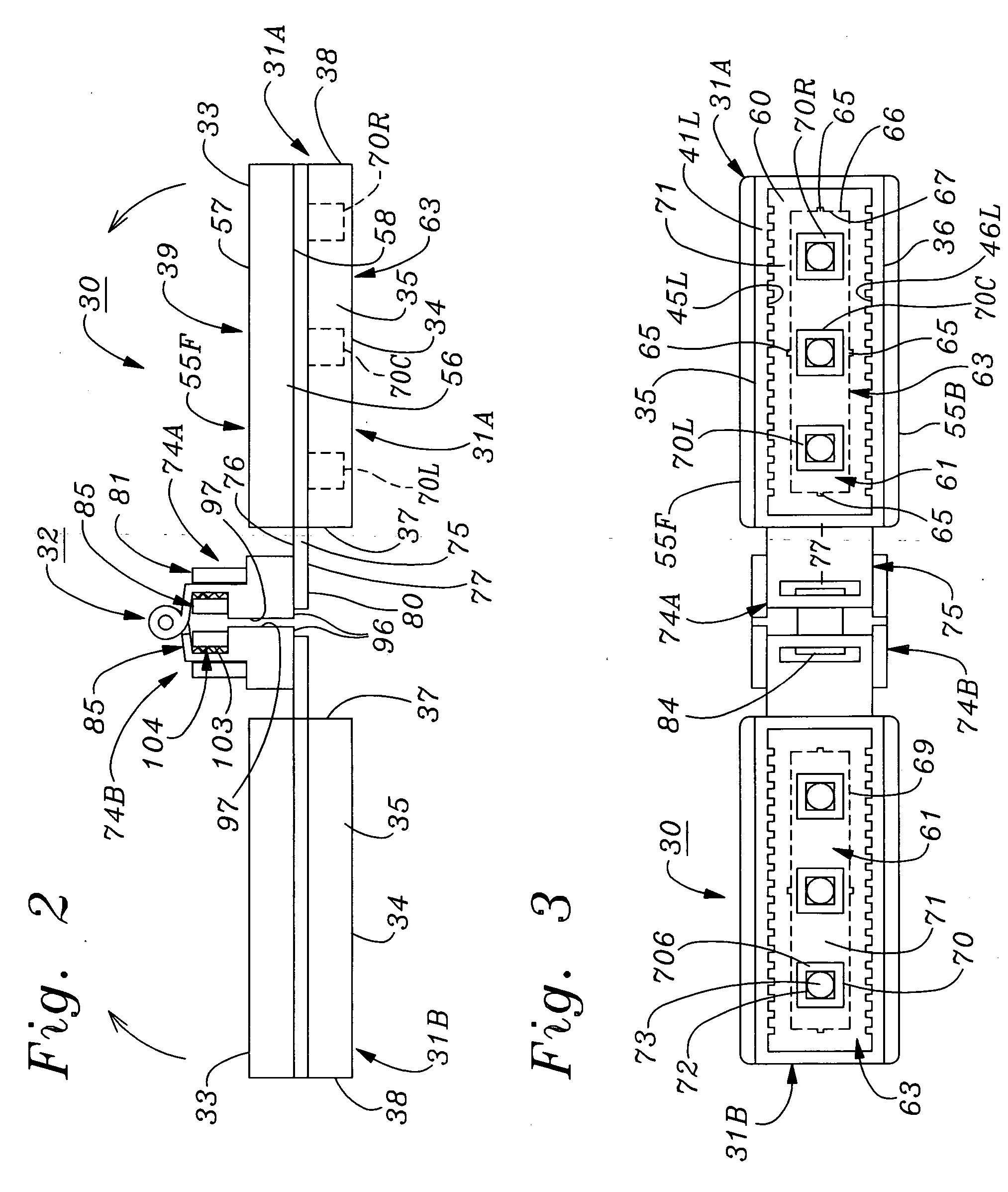

Dental prostheses modeling system with symmetric double-well trays slidably mountable to articulator

A dental prostheses modeling system includes a molding tray for molding the base of a quadrant or full-arch dental model cast which has a longitudinally disposed partition panel disposed generally between upper and lower surfaces of the tray that forms therewithin an upper well for receiving liquid die stone to mold the base of a dental impression model, and a lower well shaped symmetrically to the upper well for providing clearance for optional manipulating pins installable in the bases of selected die segments modeling individual dental prostheses severed from the hardened die stone base of the model. The partition panel includes peripheral flanges for supporting the base of the dental model, and an openable central portion for enabling a hardened dental model to be ejected from the tray, and for providing access for manipulating pins depending downwardly from die segments. A pair of slide receptacles for slidably receiving a modeling tray is removably attachable to upper and lower arms of a laboratory articulator, from which a pair of molding trays holding a pair of dental models can be slidably removed and attached to a disposable hinge mechanism to comprise a articulateable full-mouth model for a dentist and patient.

Owner:HONSTEIN JERRY P

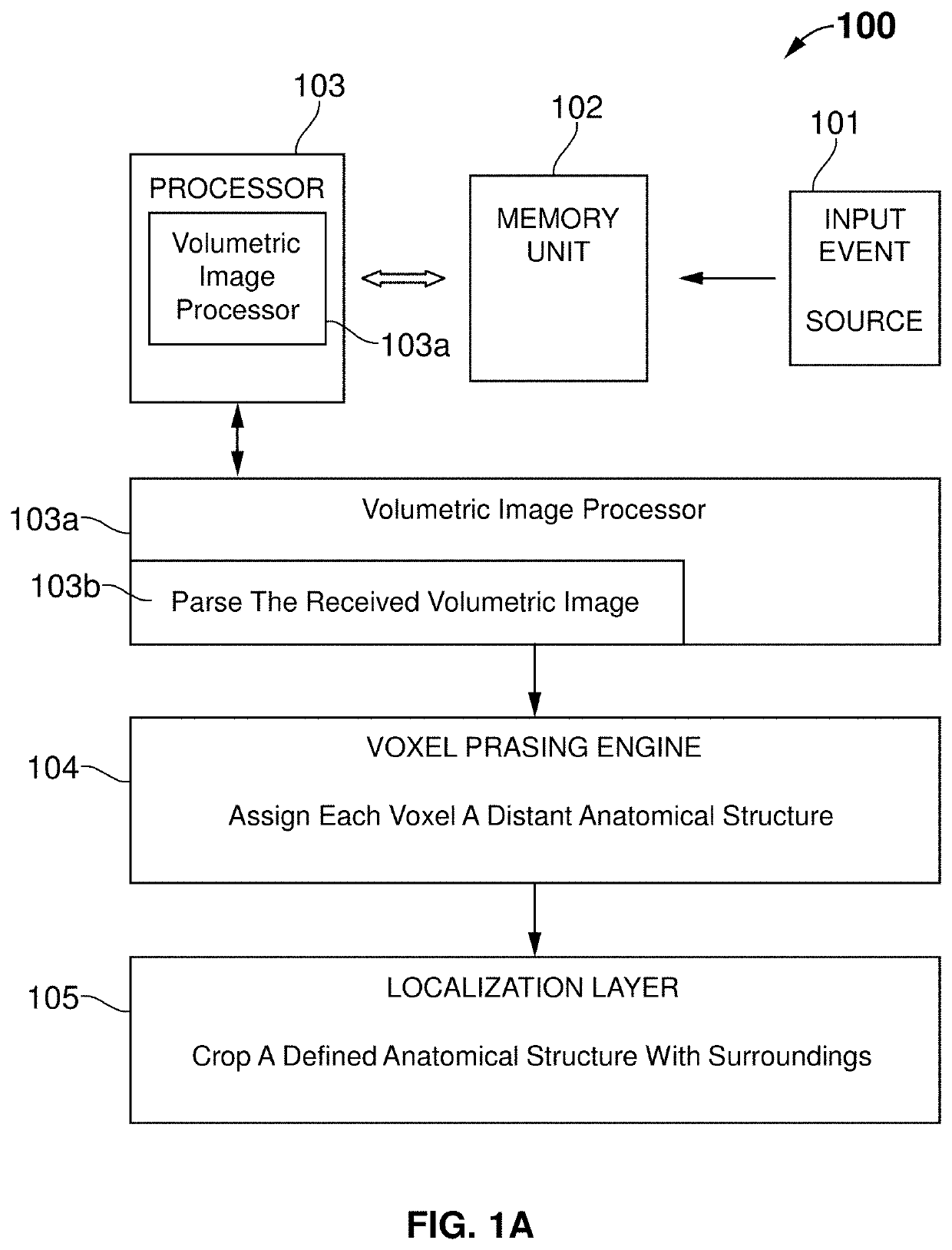

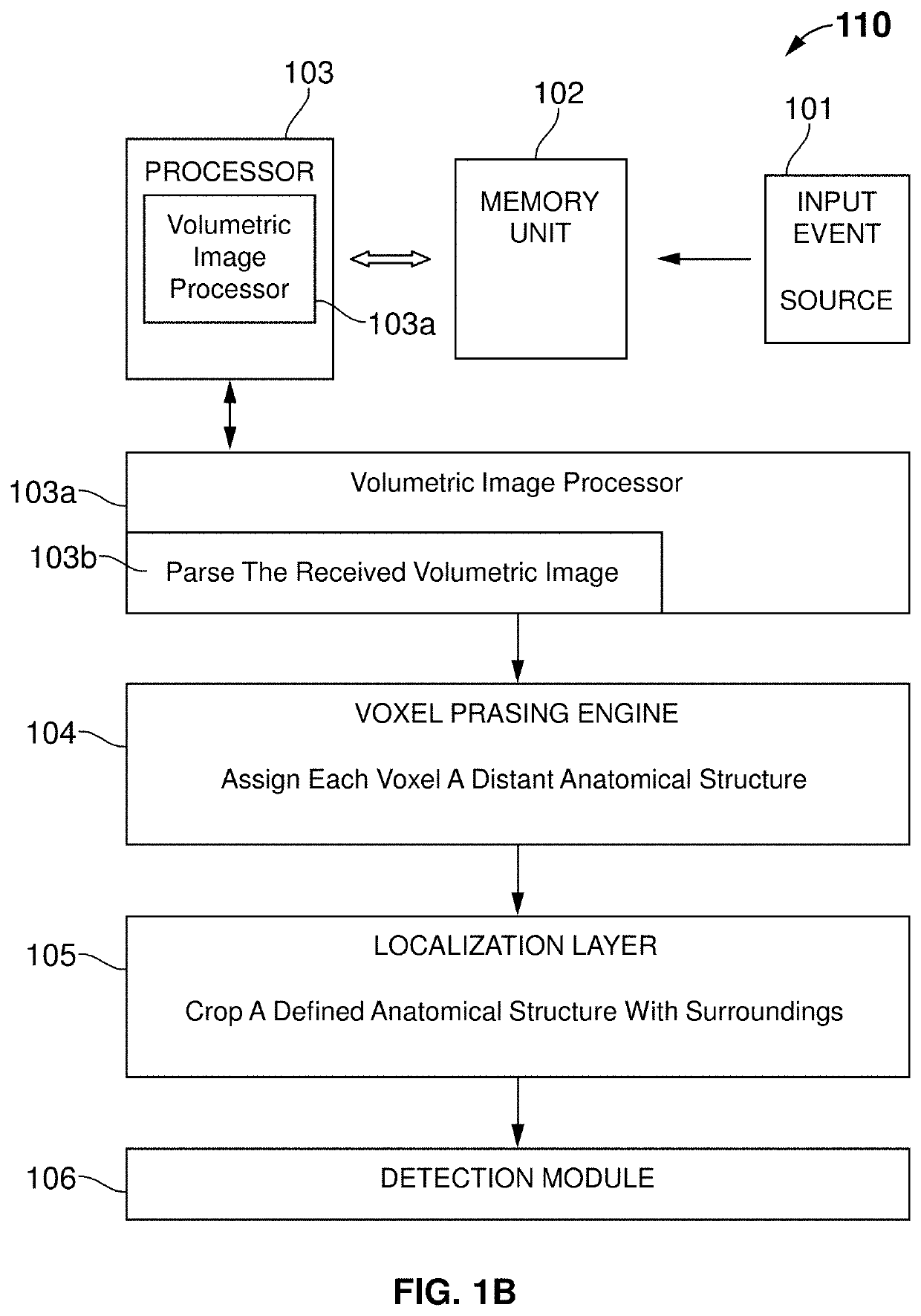

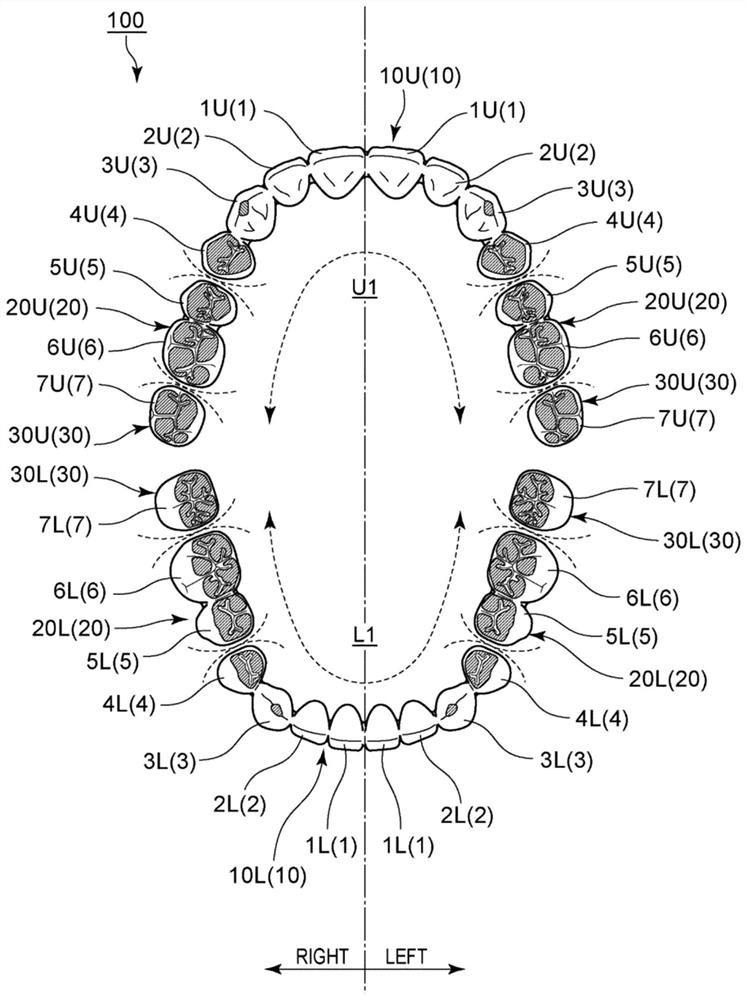

Automated Tooth Localization, Enumeration, and Diagnostic System and Method

ActiveUS20200305808A1Promote resultsMedical automated diagnosisDiagnostic recording/measuringEntire mouthComputer vision

A system and method for automated localization, enumeration, and diagnoses of a tooth / condition. The system detects a condition for at least one defined localized and enumerated tooth structure within a cropped image from a full mouth series based on any one of a pixel-level prediction, wherein said condition is detected by at least one of detecting or segmenting a condition on at least one of the enumerated tooth structures within the cropped image by a 2-D R-CNN.

Owner:DIAGNOCAT INC

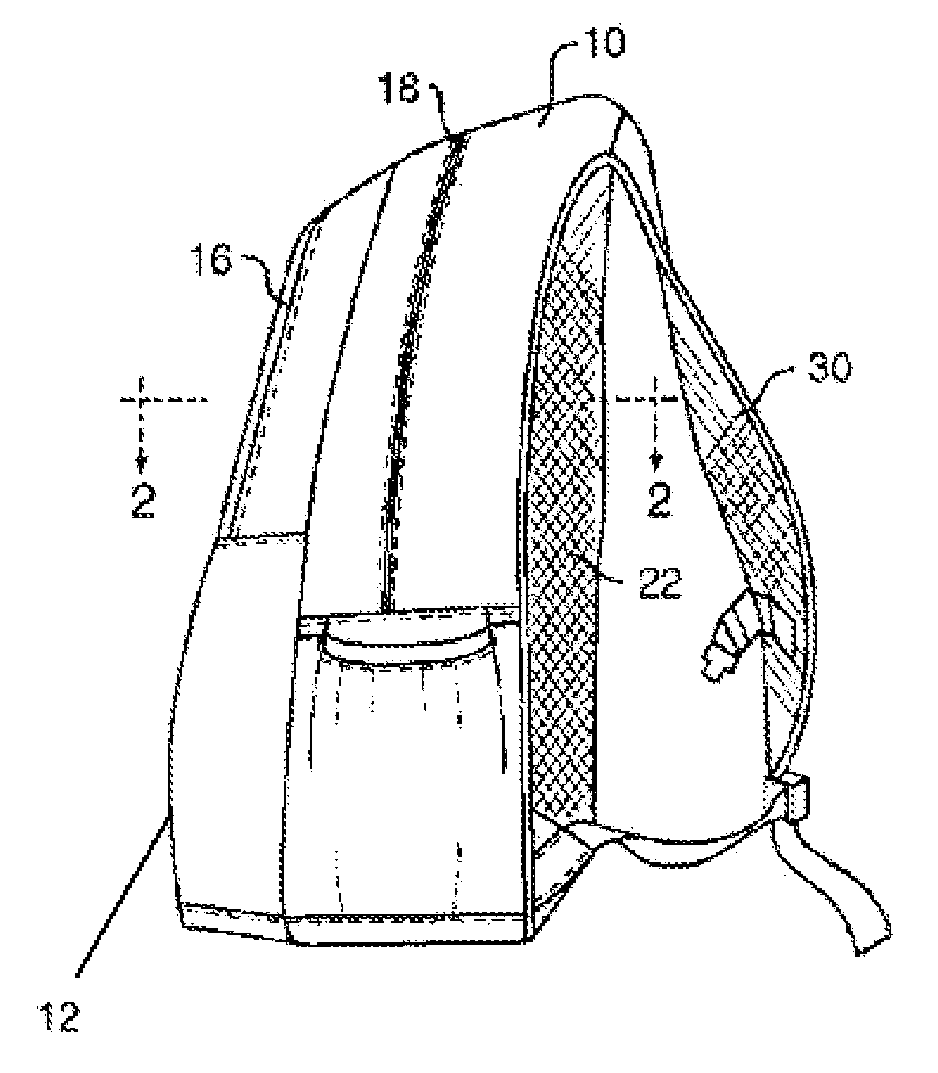

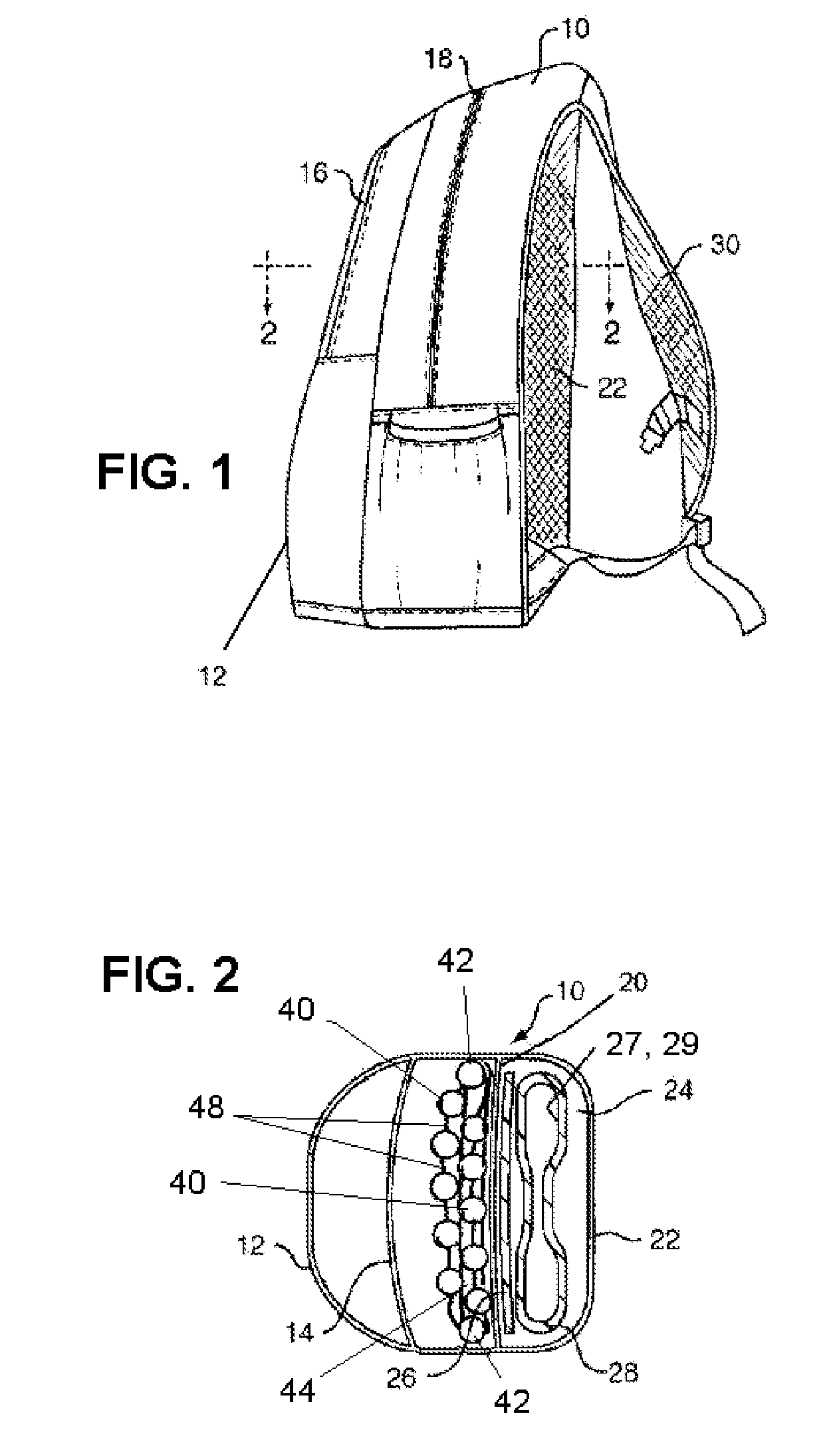

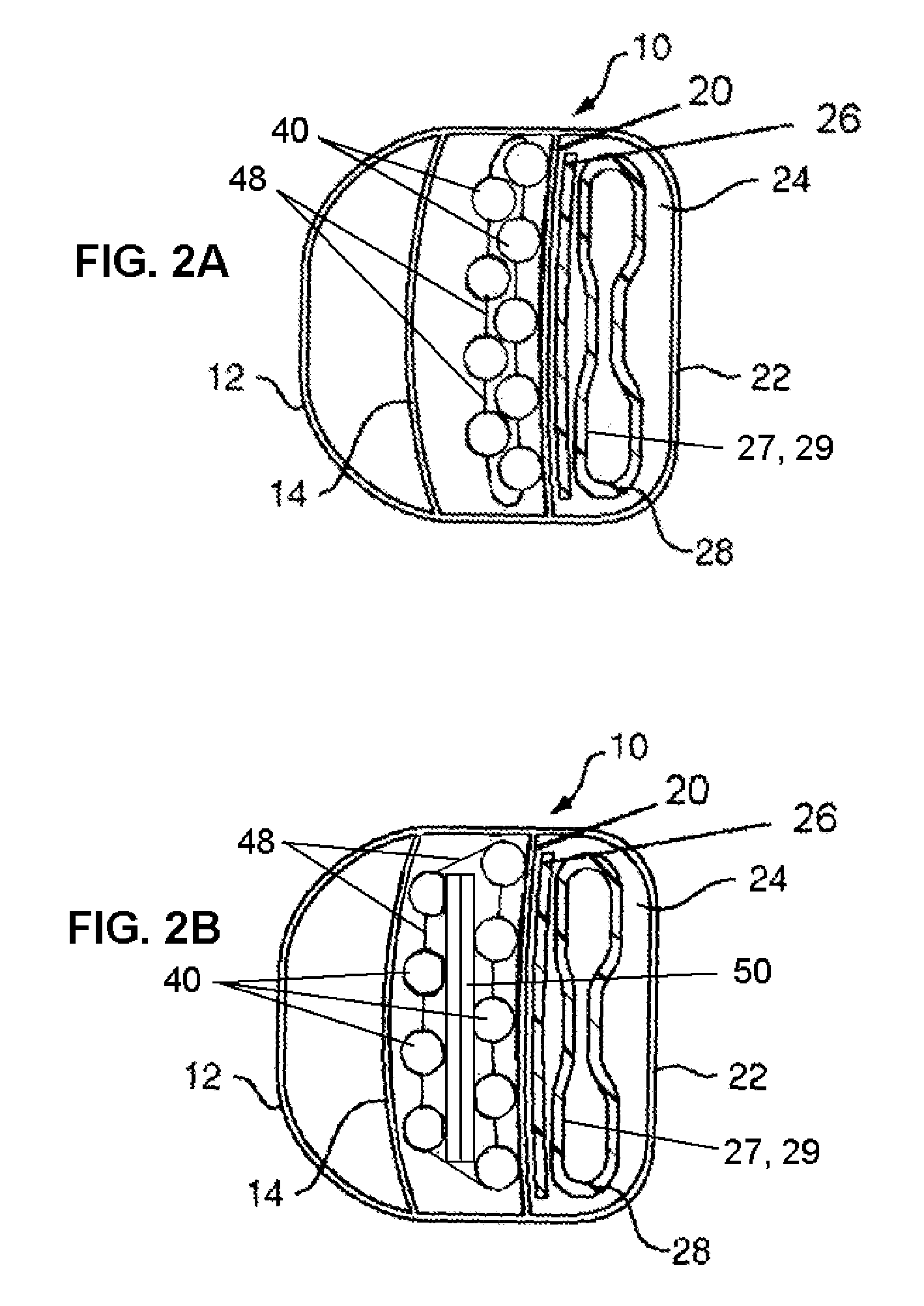

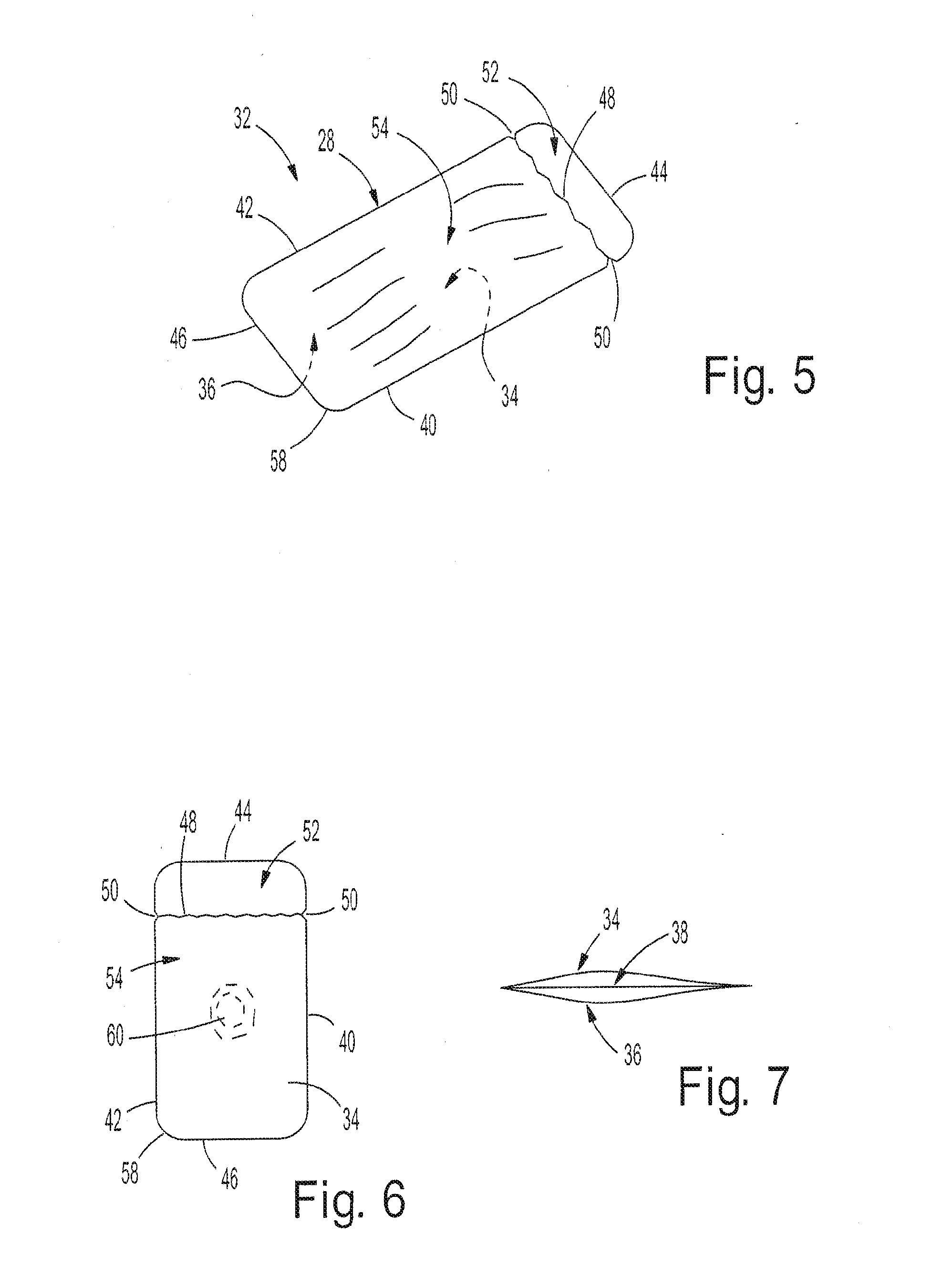

Air-cushion backpack and laptop sleeve

InactiveUS20110120893A1Facilitate inflationFacilitate inflating and deflatingTravelling sacksLuggageEntire mouthEngineering

A backpack has a front pocket containing a plate and a pair of shoulder straps for holding the plate against the back of a user. A pressurizable, flexible and elastic bladder covers the plate and has inside surfaces with an embossed pattern for preventing sticking together of facing walls of the bladder to facilitating an initial inflation of the bladder. A pair of tubular extensions extend from the bladder and into the shoulder straps, one of the tubular extensions being for inflating and deflating the bladder. A mouth-inflatable check valve connected to extension is location so as to be accessible to the user for inflating the bladder and a valve cover is detachably connected over the entire mouth engageable perimeter of the check valve for keeping it clear. Semi-rigid liners in the shoulder straps near the bladder form channels for facilitating inflating and deflating of the bladder. A pair of cushion panels in, or separate from the backpack, include pluralities of offset parallel, partially filled air tubes spaced by webs for minimizing volume when there is nothing between the cushion panels.

Owner:E MISHAN & SONS

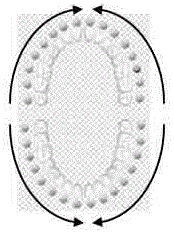

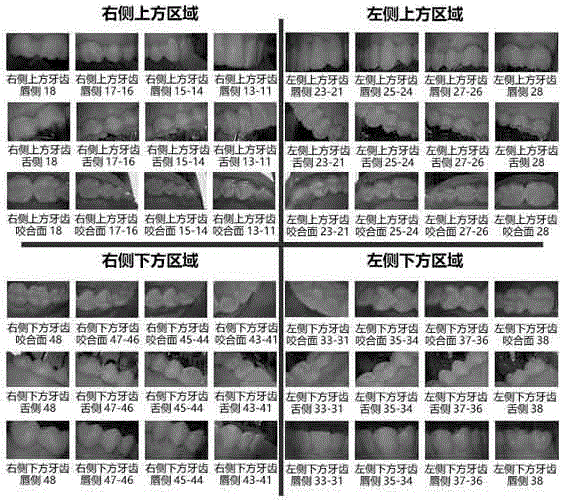

Oral cavity micro viewer application system and full-oral-cavity shooting method

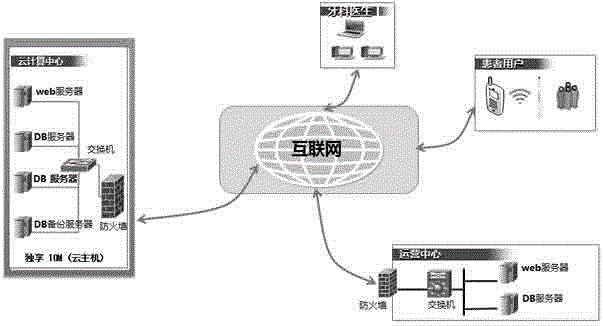

InactiveCN106202889AReduce difficultyImprove effectivenessTelemedicineMedical image data managementWeb siteWeb service

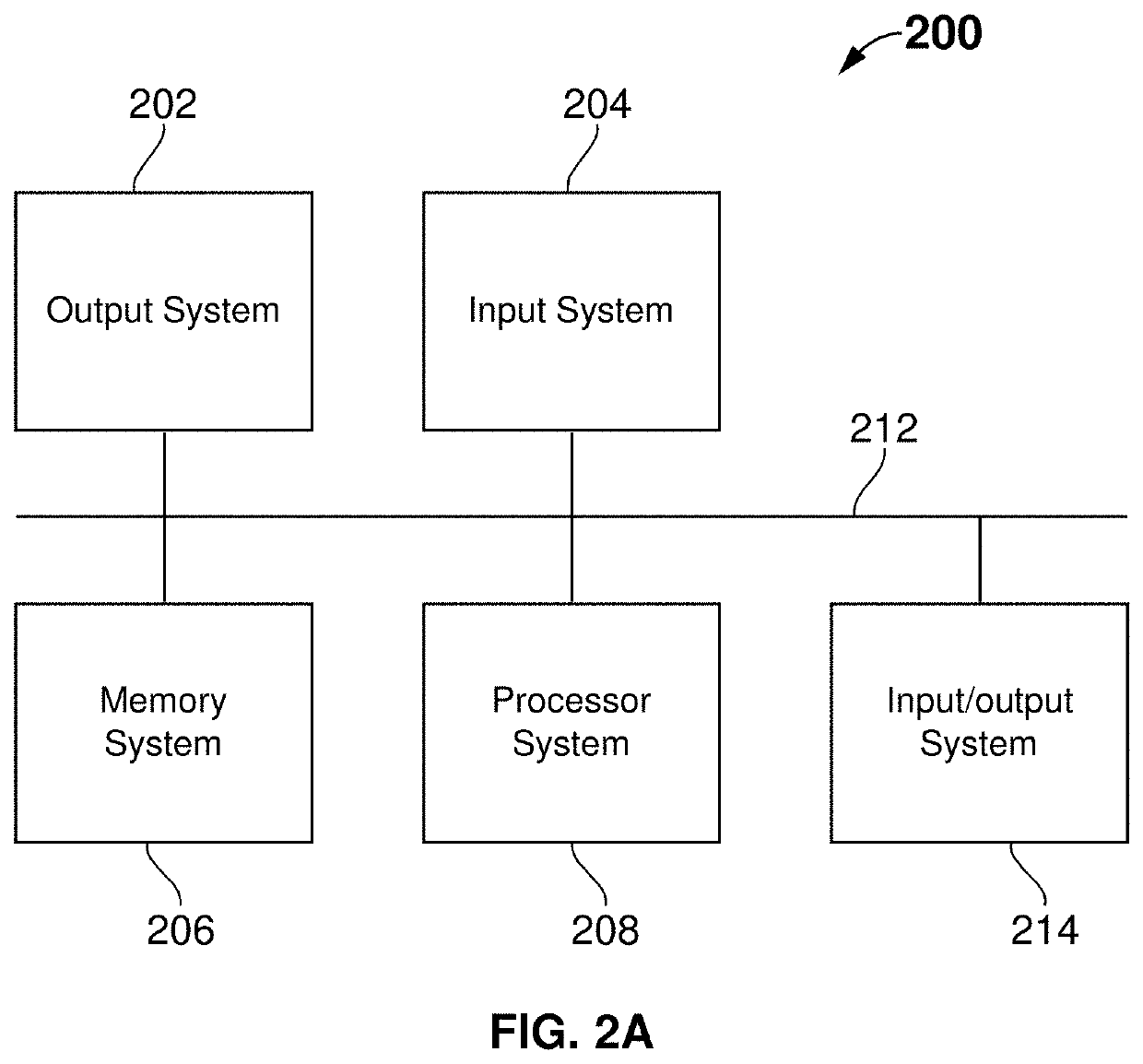

The invention discloses an oral cavity micro viewer application system. The system is composed of four subsystems including a cloud storage and management platform, a doctor side network, a patient side oral cavity micro viewer APP and an operation center which communicate through the Internet. The cloud storage and management platform is composed of a firewall, a switch, a web server, a DB backup server and two DB servers; the operation center is composed of a firewall, a switch, a web server and a DB server, and the web server communicates with the Internet through the switch and the firewall. The system sets up an effective communication channel between a patient and a dentist, the difficulty of self-examination of the patient is greatly reduced through special equipment and reasonable shooting and display methods, the effectiveness and accuracy of examination results are promoted, and help is provided for the patient to form the habit of examining the oral cavity by himself at regular time.

Owner:上海艾牙健康科技有限公司

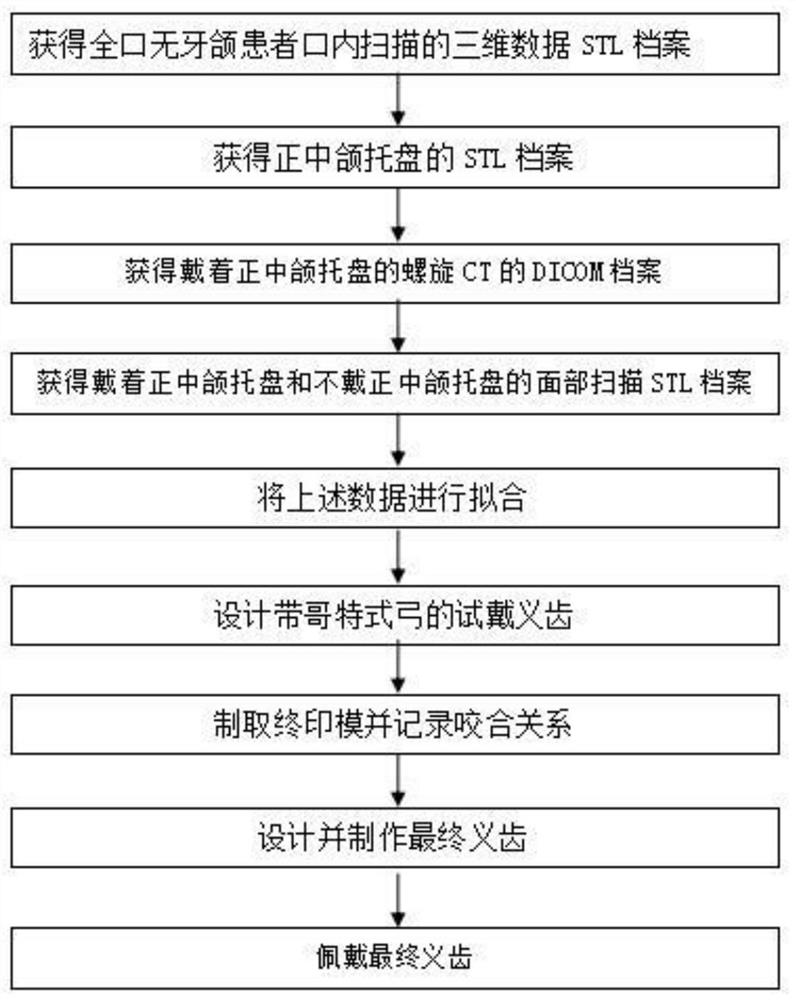

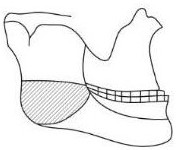

Full-process digital manufacturing method of complete dentures

ActiveCN112535545AImprove try-in effectHigh strengthImpression capsArtificial teethAnatomical structuresEntire mouth

The invention provides a full-process digital manufacturing method of complete dentures. The full-process digital manufacturing method comprises the following steps: acquiring an STL file of three-dimensional data by intraoral scanning of a patient with complete edentulous jaw; putting the median occlusal tray into the mouth, recording the morphology of the mucous membrane surface of the upper jawand the lower jaw and the relative position relation of the upper jaw to the lower jaw, obtaining an STL file of three-dimensional data of the median occlusal tray by scanning; and obtaining a DICOMfile about spiral CT or CBCT of the edentulous jaw patient wearing the median occlusal tray. The full-process digital manufacturing method of the present invention has the advantages as follows: 1, athree-dimensional space about maxillofacial region of the patient is constructed by fitting four digital files, and the occlusal plane in which the patient tries on the dentures and morphology and position of the anterior teeth are set with reference of the anatomical structure of the maxillofacial region of the patient, thereby improving the try-on effect of the dentures; 2, a final impression scanning and copying technology is utilized to accurately manufacture the morphology of a final denture base; and 3, a base plate and a artificial dentition are obtained by adhering the separately cut resin discs with different colors and high strength through adhesive, thereby achieving high cutting precision, high strength of the resin discs and good wear resistance of the artificial teeth.

Owner:成都橙子思创医疗科技有限公司

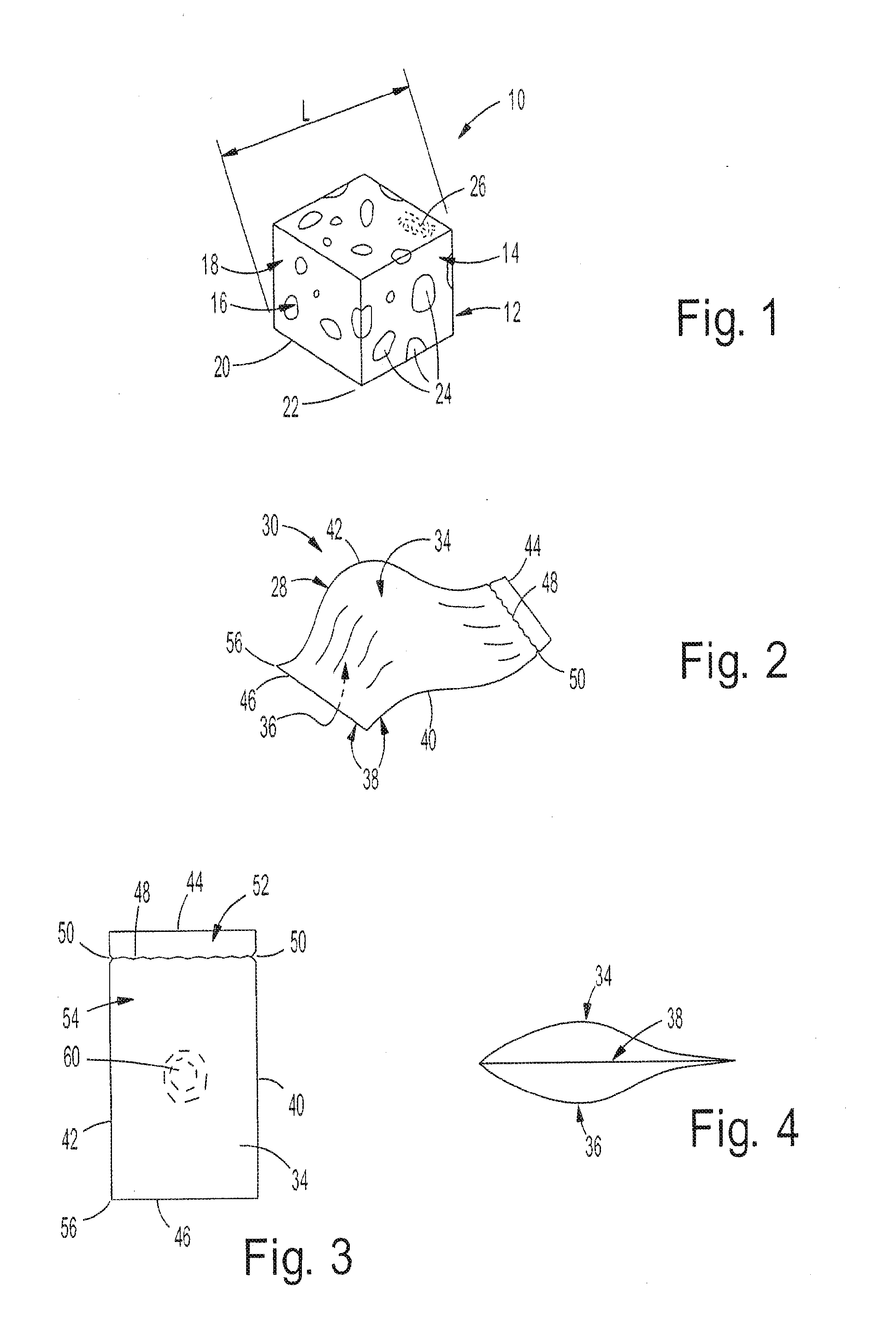

Mouth cleaner

A single use flexible disposable oral device, which is operated either by the tongue or by a chewing action, for cleaning the entire mouth cavity. The oral device contains a dentifrice and is made of a spongy material. It is formed as a cube having faces and is provided with voids at its external envelope. The edges and vertexes of the external envelope may be harder than the faces and an internal core of the cube. The oral device is contained within a package that may be flat and may contain flushing liquid.

Owner:UNGER DANY +1

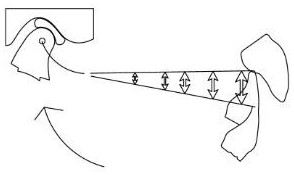

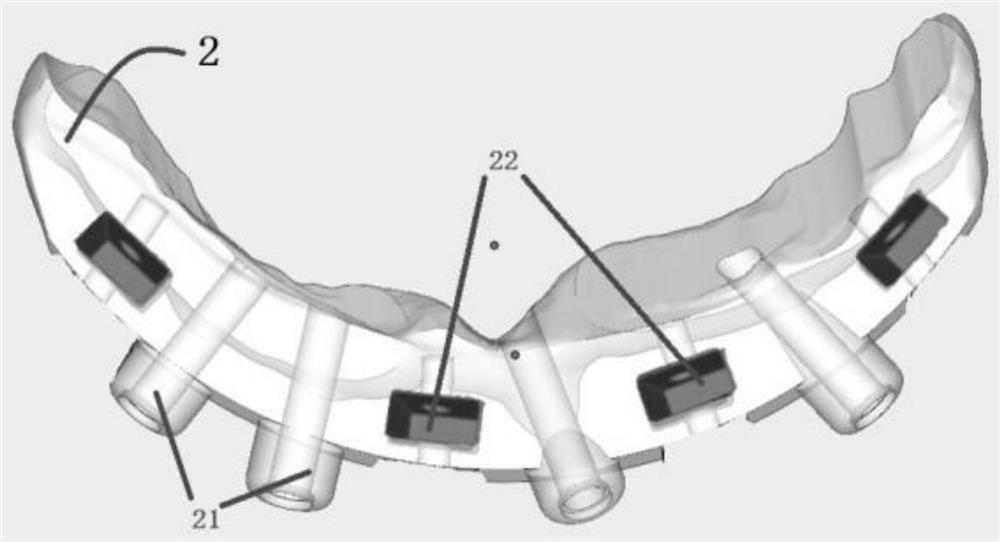

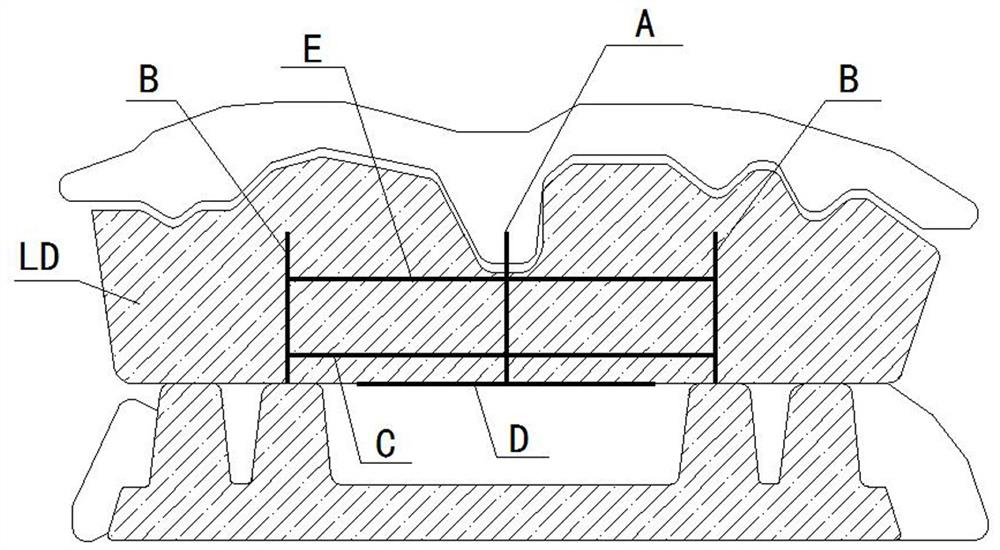

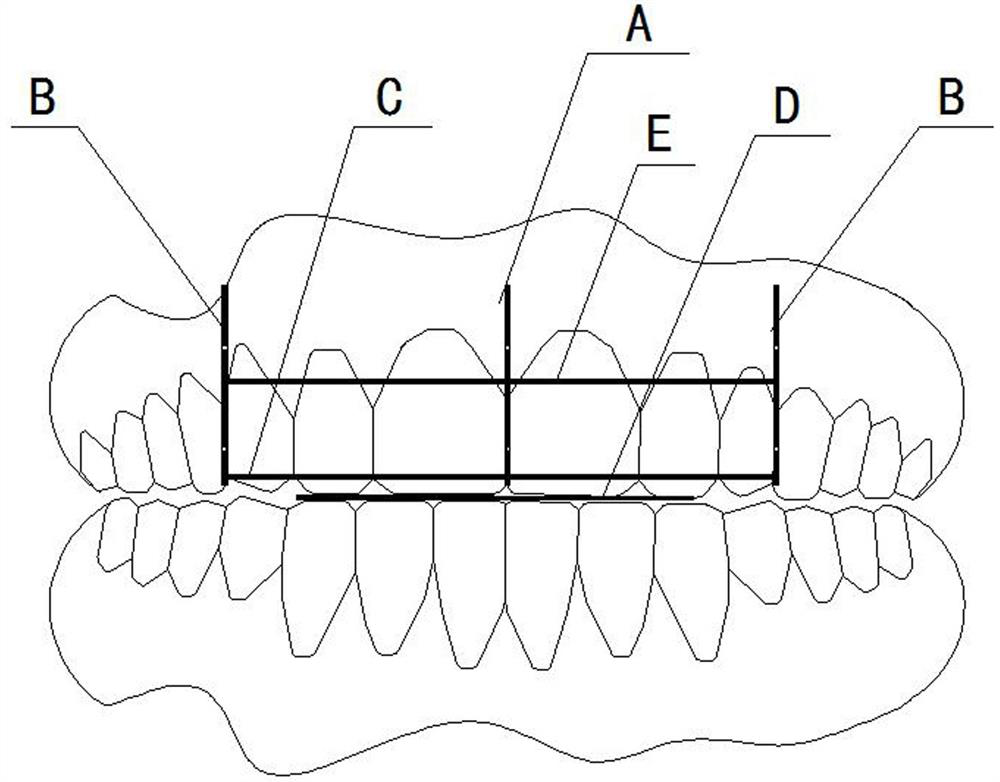

Invisible correction method for treating class 2 and class 3 malocclusion by using occlusion repositioning device

The invention discloses an invisible correction method for treating class 2 and class 3 malocclusion by using an occlusion repositioning device, which comprises the following steps: respectively fixing the occlusion repositioning device on the mandibular or maxillary posterior tooth area on both sides, taking a maxillary and mandibular full-mouth model, filling a plaster model, scanning, transmitting an obtained STL file to invisible correction design software, performing multi-step invisible correction design, finally forming an STL design file, outputting the STL design file to a 3D printer to print a female mold, and pressing a transparent high polymer material on the female mold to form the bracket-free invisible corrector. The design process of the invention comprises the following steps: firstly, fixing an occlusion repositioning device to a back tooth area, connecting the back tooth area as a whole, not designing movement, only correcting an anterior tooth area, correcting the back tooth area, and finally finely adjusting the positions of upper and lower jaw teeth, thereby finishing orthodontic treatment of class 2 and class 3 malocclusion.

Owner:万善军

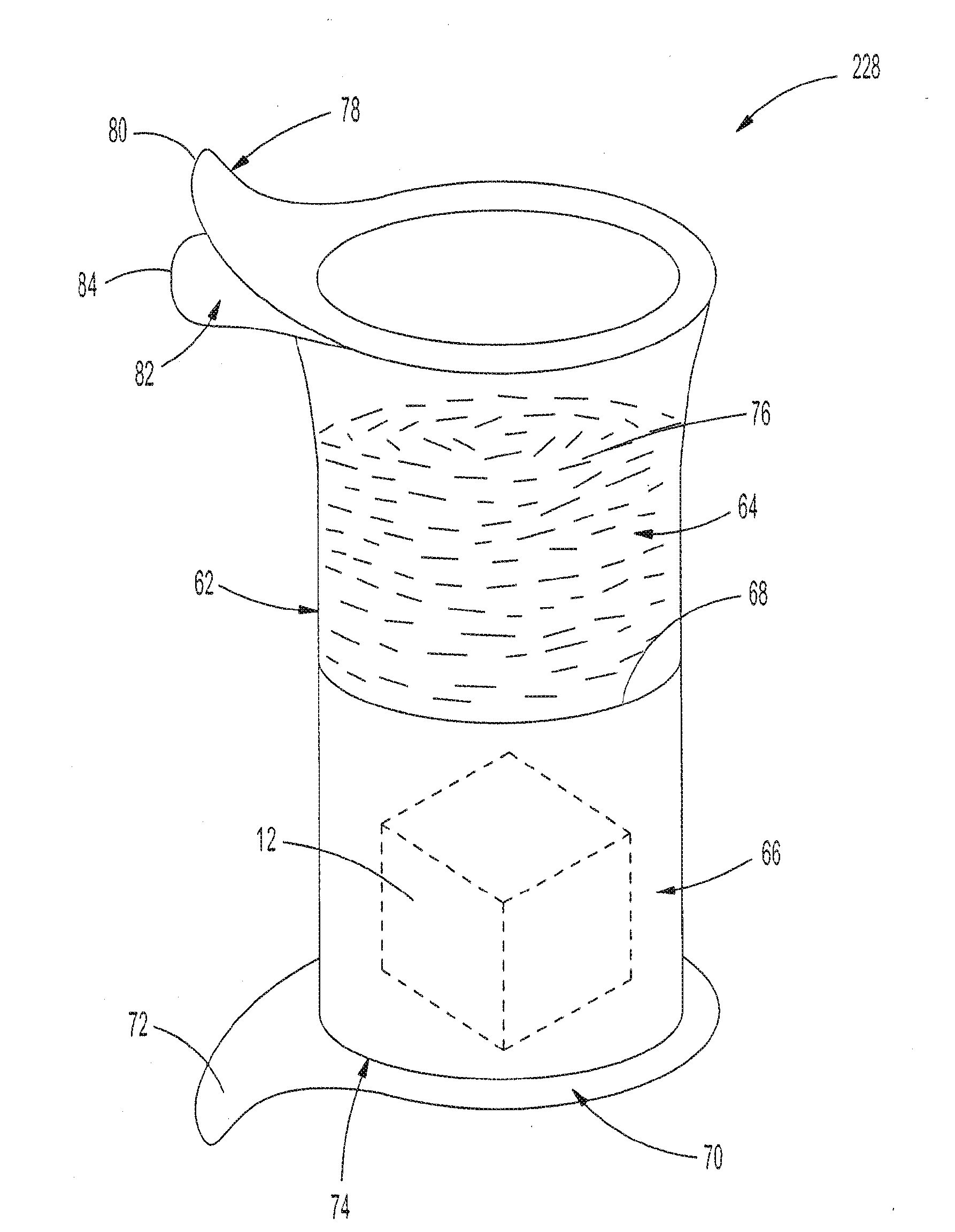

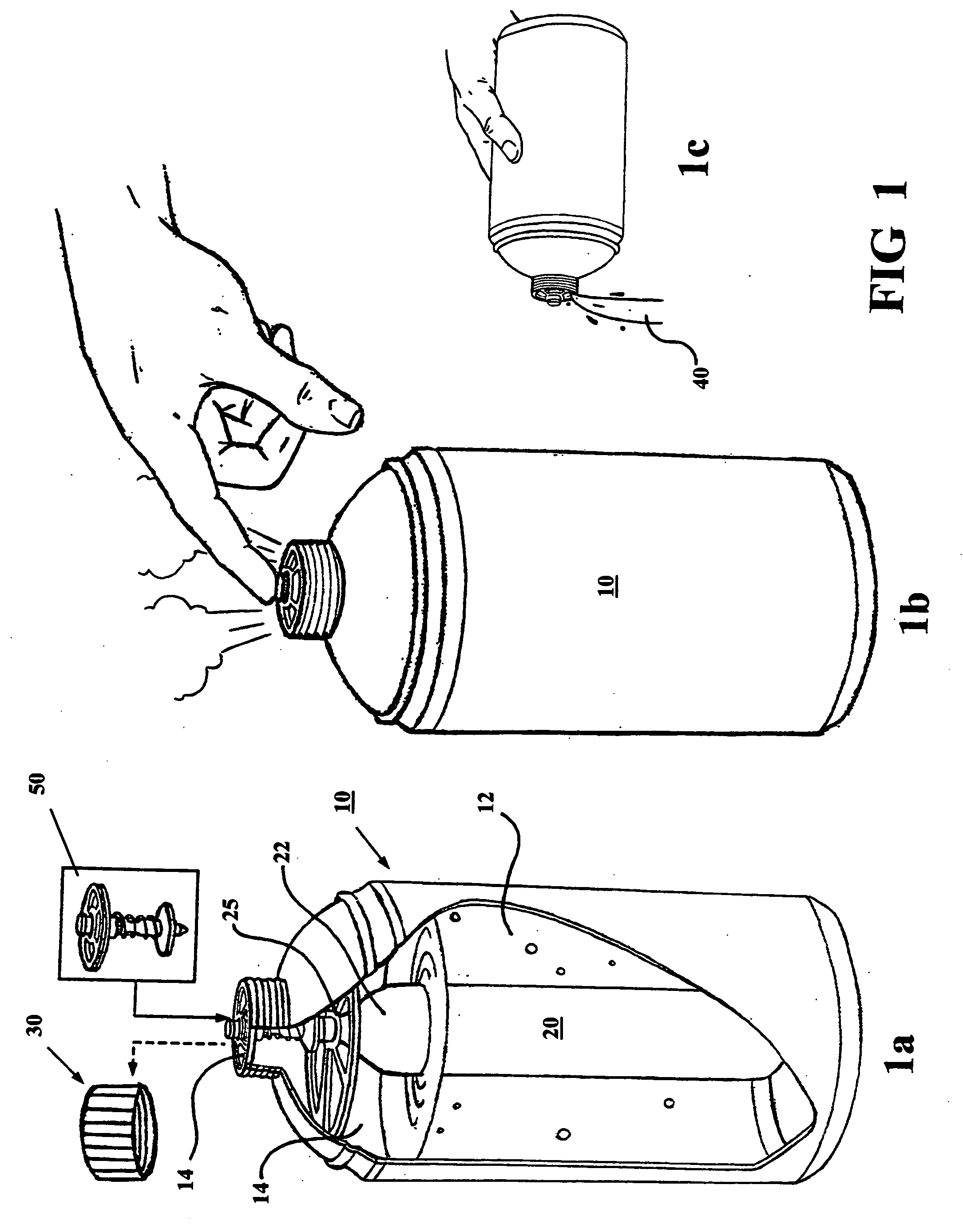

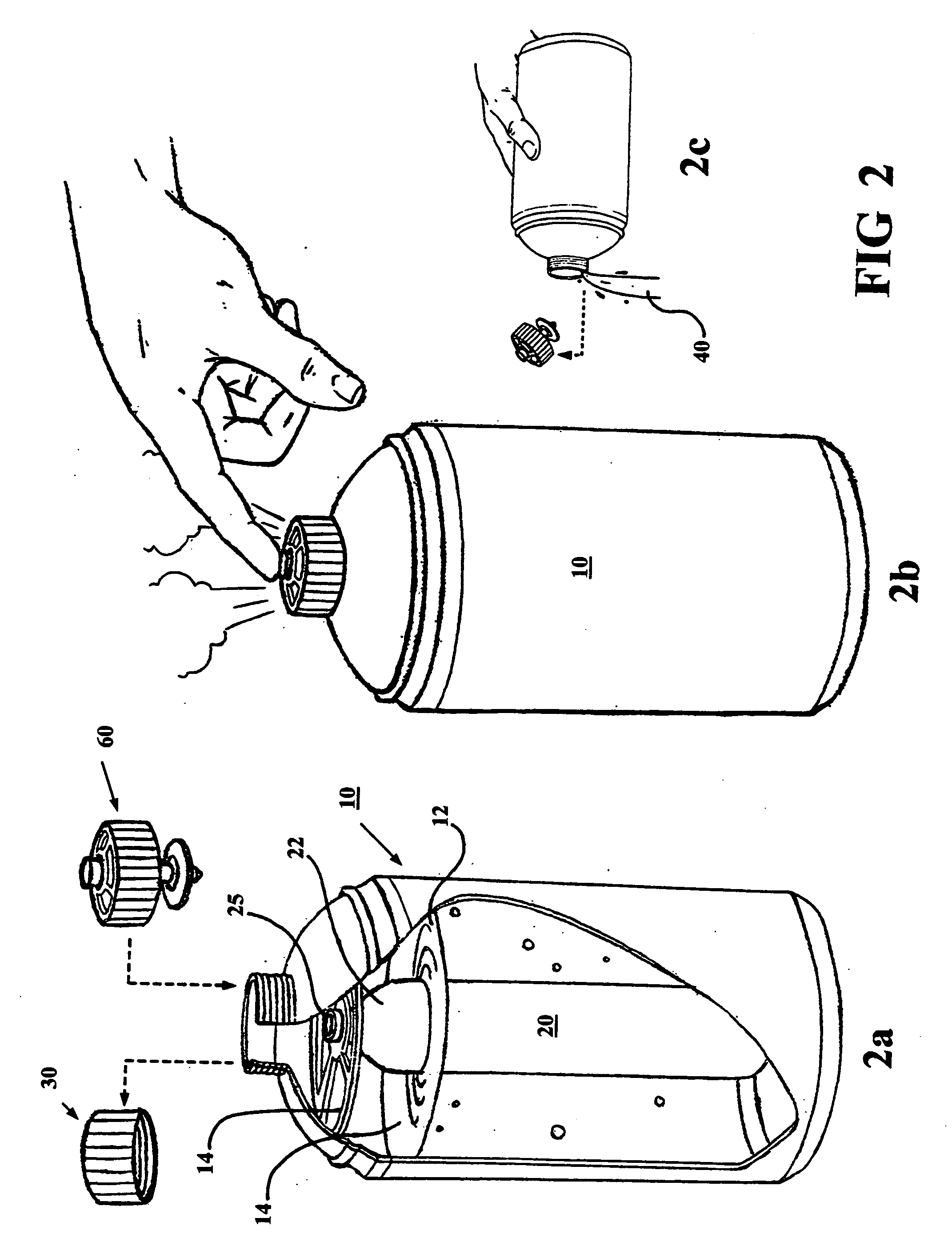

Self-chilling beverage container and method

InactiveUS20070175233A1Lighting and heating apparatusCooling fluid circulationEntire mouthEngineering

An iceless method of providing a chilled beverage to a customer by supplying a container that not only contains the beverage but also contains a compartment filled with a compressed gas for selectively cooling the liquid in the container before consuming it. The apparatus is characterized by the fact that the end of the gas compartment adjacent the mouth of the beverage compartment occupies less than the entire mouth of the beverage compartment so that when the closure member is removed, a liquid contained in the beverage compartment may be conveniently poured out, whether or not the frangible cover of the gas compartment has first been punctured for releasing the gas.

Owner:ST JAMES DAVID M

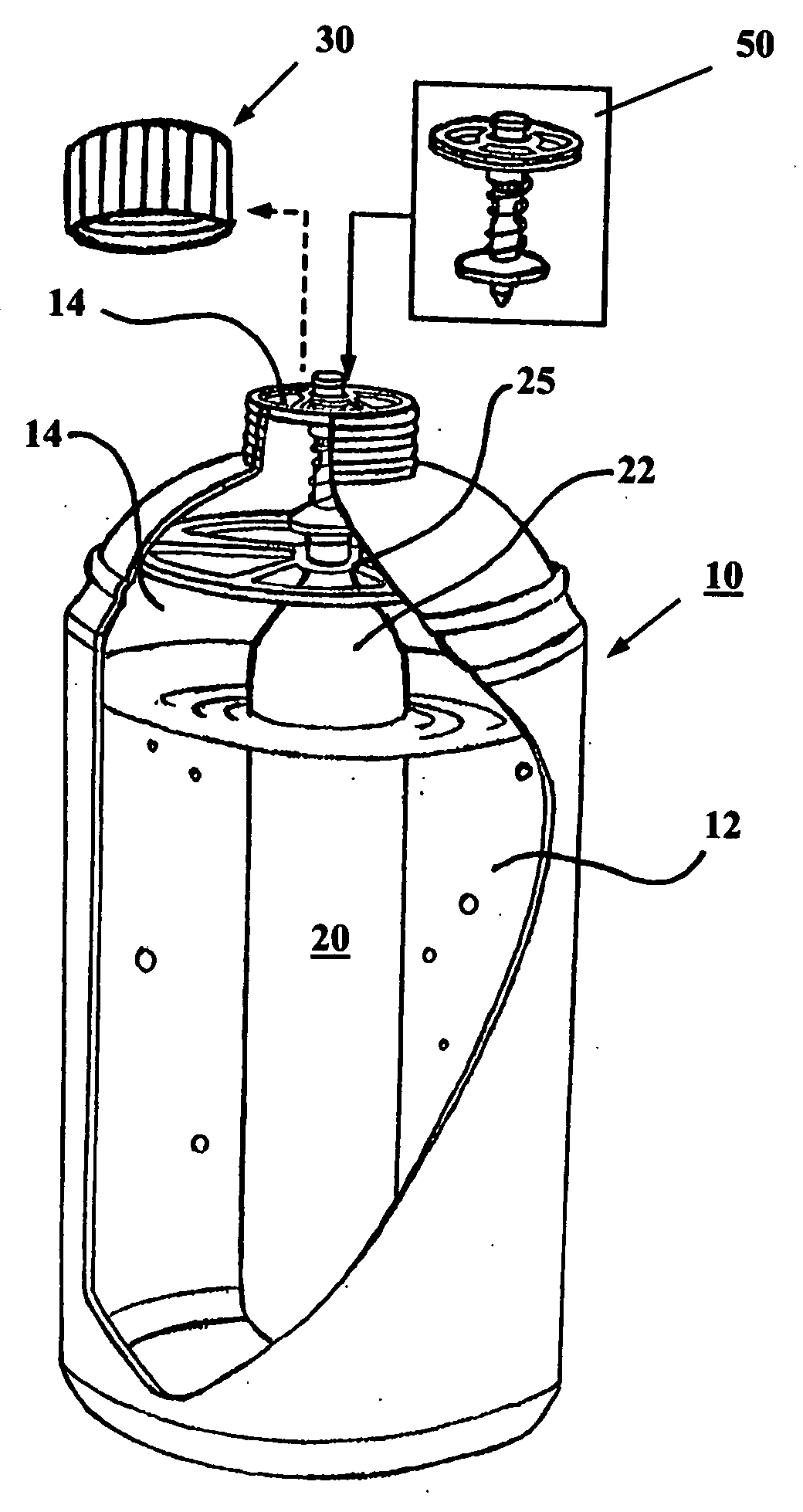

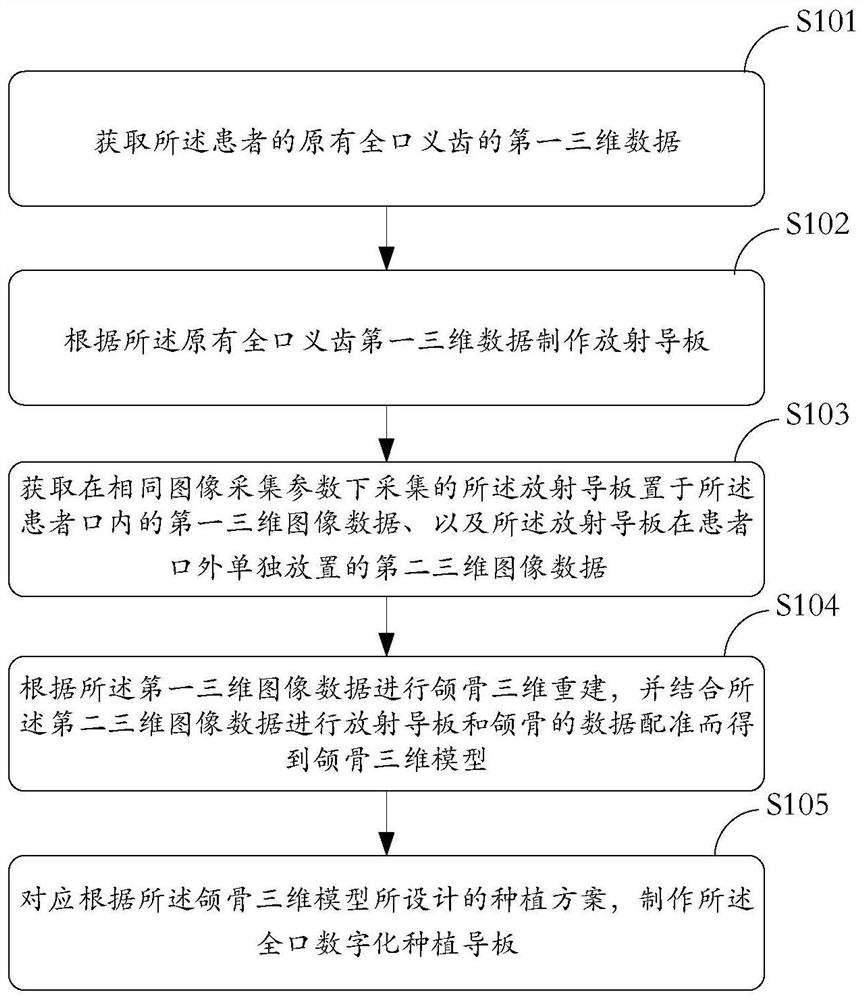

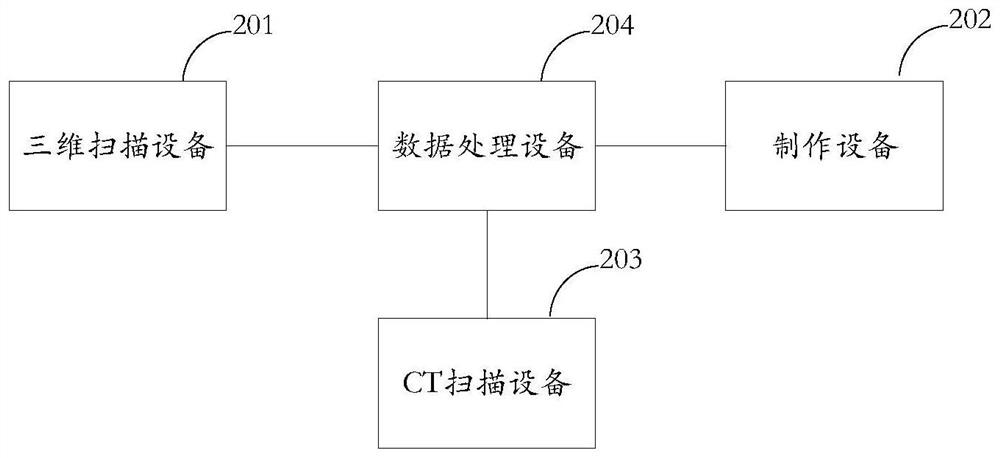

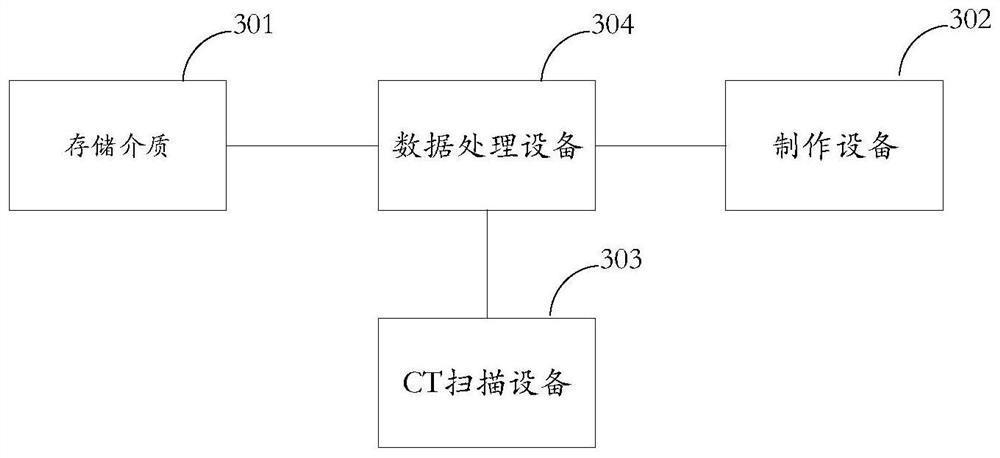

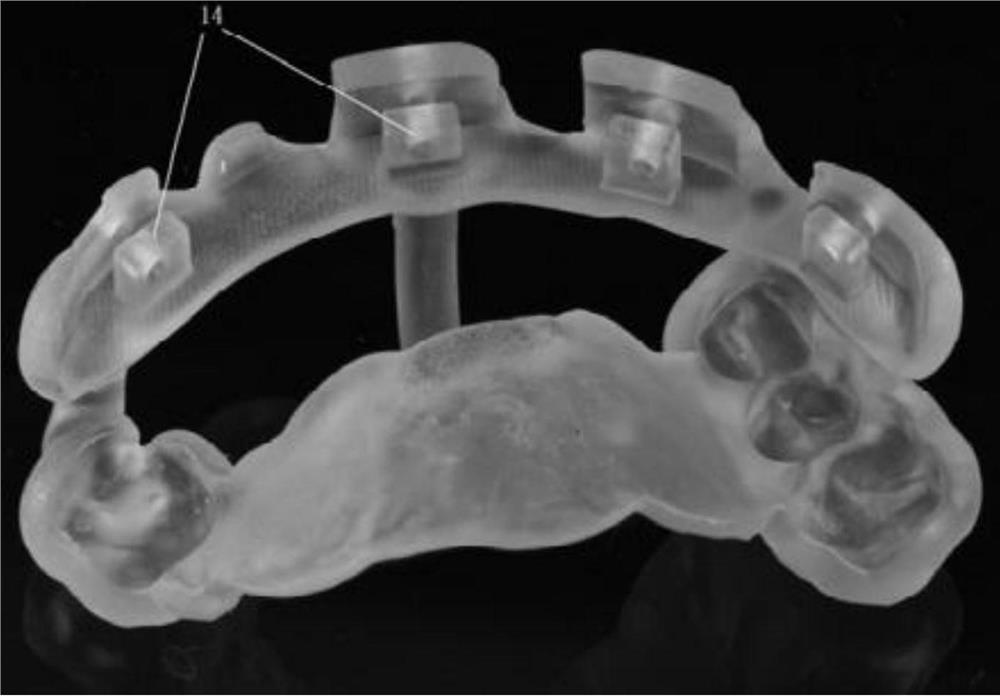

Manufacturing method and manufacturing system of wholly oral digital planting guide plate

InactiveCN111772840AHigh precisionImprove efficiencyDental implantsRadiation diagnostics for dentistryJaw boneEntire mouth

The application provides a manufacturing method and manufacturing system of a wholly oral digital planting guide plate, which is applied to manufacturing of the wholly oral digital planting guide plate for patients having part of dentition deletion of an original complete denture complete denture. The manufacturing method comprises the steps of collecting first three-dimensional data of the original complete denture of a patient; manufacturing a radiation guide plate according to the first three-dimensional data of the original complete denture; collecting first three-dimensional image data ofthe radiation guide plate placed in the mouth of the patient and second three-dimensional image data of the radiation guide plate separately placed outside the mouth of the patient through same imagecollecting parameters; performing jawbone three-dimensional reconstruction according to the first three-dimensional image data, and through combination with the second three-dimensional image data, performing registration on the radiation guide plate and jawbone data to obtain a jawbone three dimensional model; and manufacturing the wholly oral digital planting guide plate corresponding to a planting scheme designed according to the jawbone three dimensional model. Compared with the prior art, the manufacturing method disclosed by the invention has the advantages that clinical operations arereduced, manufacturing precision and manufacturing efficiency of the wholly oral digital planting guide plate are improved, and the production cycle is shortened.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

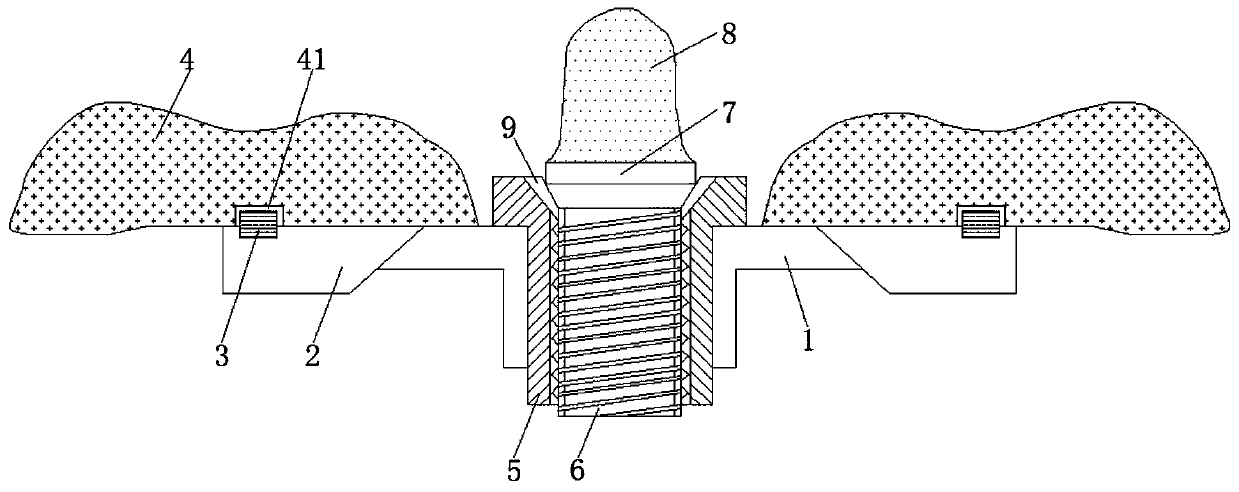

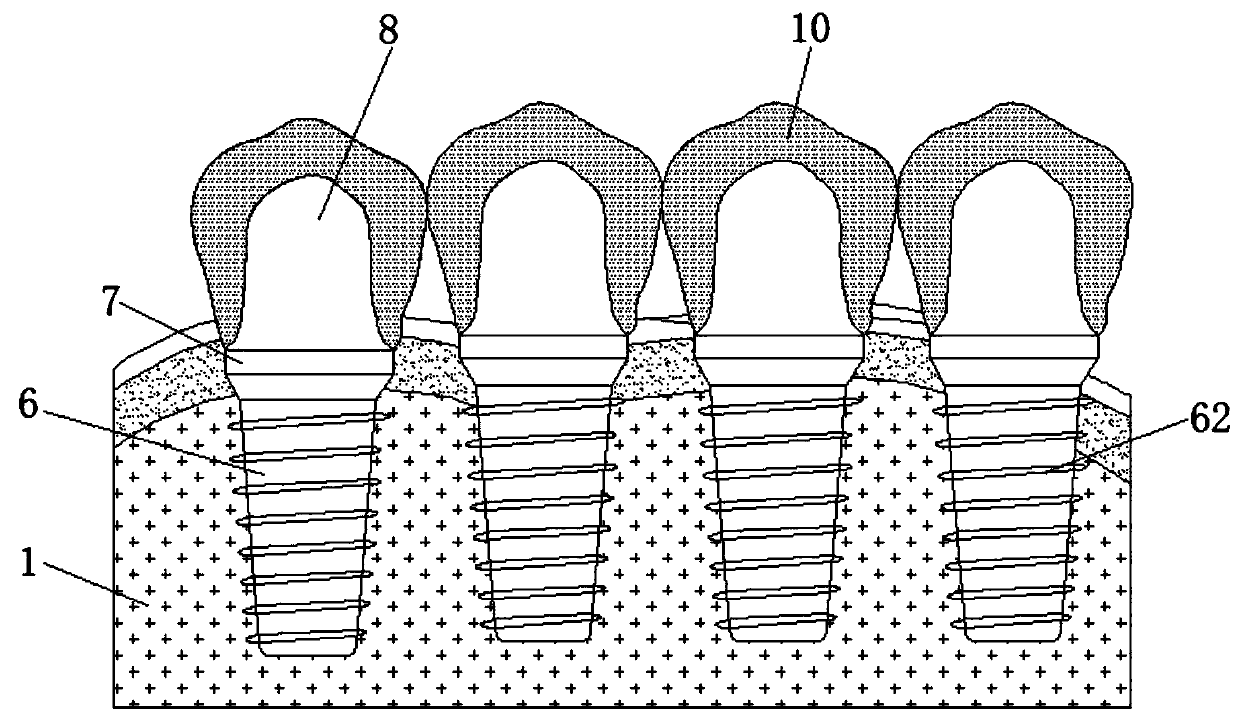

A full mouth edentulous implant restoration system

The invention discloses a full-mouth edentulous implant repair system and method and relates to the technical field of edentulous implants. The full-mouth edentulous implant repair system comprises asupporting table, a guide pipe and a screw, wherein a fixing block is fixedly connected to the outer side of the supporting table, the top of the fixing block is fixedly connected with a supporting surface through a fixing bolt, the guide pipe is fixedly connected to the inner side of the supporting table, the screw is in threaded connection with the interior of the guide pipe, a threaded groove is formed in the surface of the screw, a base table is arranged at the top of the screw, and the top of the screw is fixedly connected with the base table through a connecting nail. According to the full-mouth edentulous implant repair system and method, the system is designed and digitally processed, the operation risk of doctors and the working strength of technicians during post-operation restoration are effectively reduced, the implant efficiency is improved by adopting a whole tooth structure, the stability of implanted teeth is better guaranteed, the problem of breakage of patients in theuse process is avoided, the structure is simple, and the improvement of the working efficiency is facilitated.

Owner:珠海新茂义齿科技有限公司

Processing method of fresh yeast extract paste chicken essence cube

InactiveCN107495272AStrong fragranceImprove decomposition rateLipidic food ingredientsUltra high pressure food processesFlavorChicken Flavor

The invention relates to a processing method of fresh yeast extract paste chicken essence cubes. The processing method is characterized in that yeast extract paste is produced with baker's yeast, beer yeast and torula yeast as raw materials and is used for enhancing flavor and taste and balancing mouth feel; chicken paste is used for enhancing initial flavor; chicken oil brings a natural chicken fragrance to the chicken essence cubes. Through steps of pectin slurry coating, granulation and cube pressing, the raw materials are not liable to deteriorate, and problems that chicken essence is easy to absorb moisture and cake and is liable to deteriorate are solved. The chicken essence cubes have mellow and thick chicken flavor, has outstanding delicate taste and is improved in entire mouth feel.

Owner:安徽悠咔食品有限公司

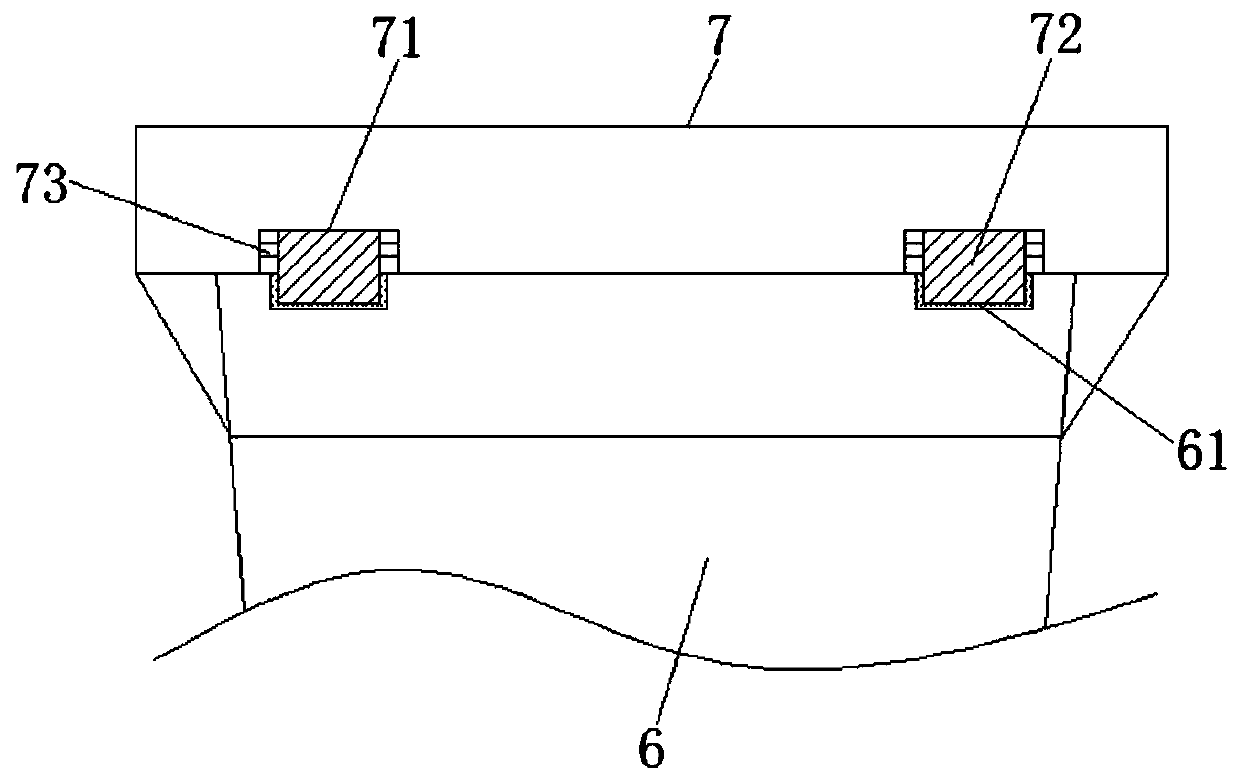

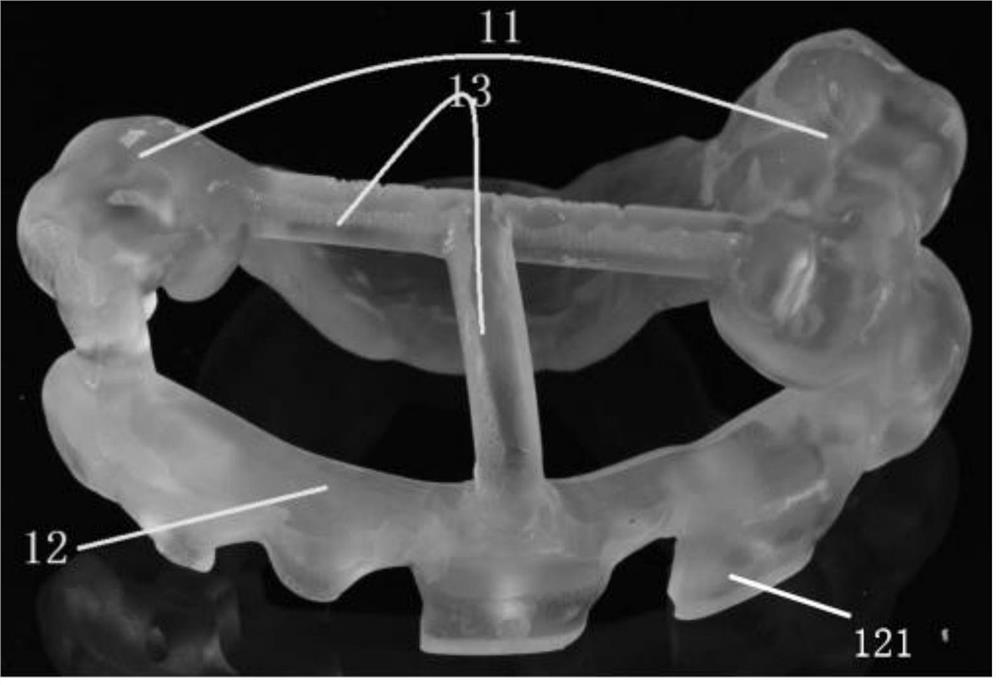

Whole-course digital combined guide plate suitable for full-mouth implant surgery

The invention provides a whole-course digital combined guide plate suitable for a full-mouth implant surgery. The whole-course digital combined guide plate comprises a digital positioning guide plate, a digital osteotomy guide plate, a digital end guide plate and positioning nails, and further comprises a digital temporary tooth which is retained after being connected with the digital osteotomy guide plate. The positioning guide plate and the osteotomy guide plate are connected in a combined bolt way mode, the positioning nails do not need to be taken out in the whole process, and guide plate positioning does not need to be conducted again in the subsequent process after initial positioning is completed throughout the process, so that accuracy of digital guidance on implant surgery is guaranteed; and meanwhile, immediate wearing of temporary teeth can be achieved, and surgery time is saved to a great extent.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Can cover

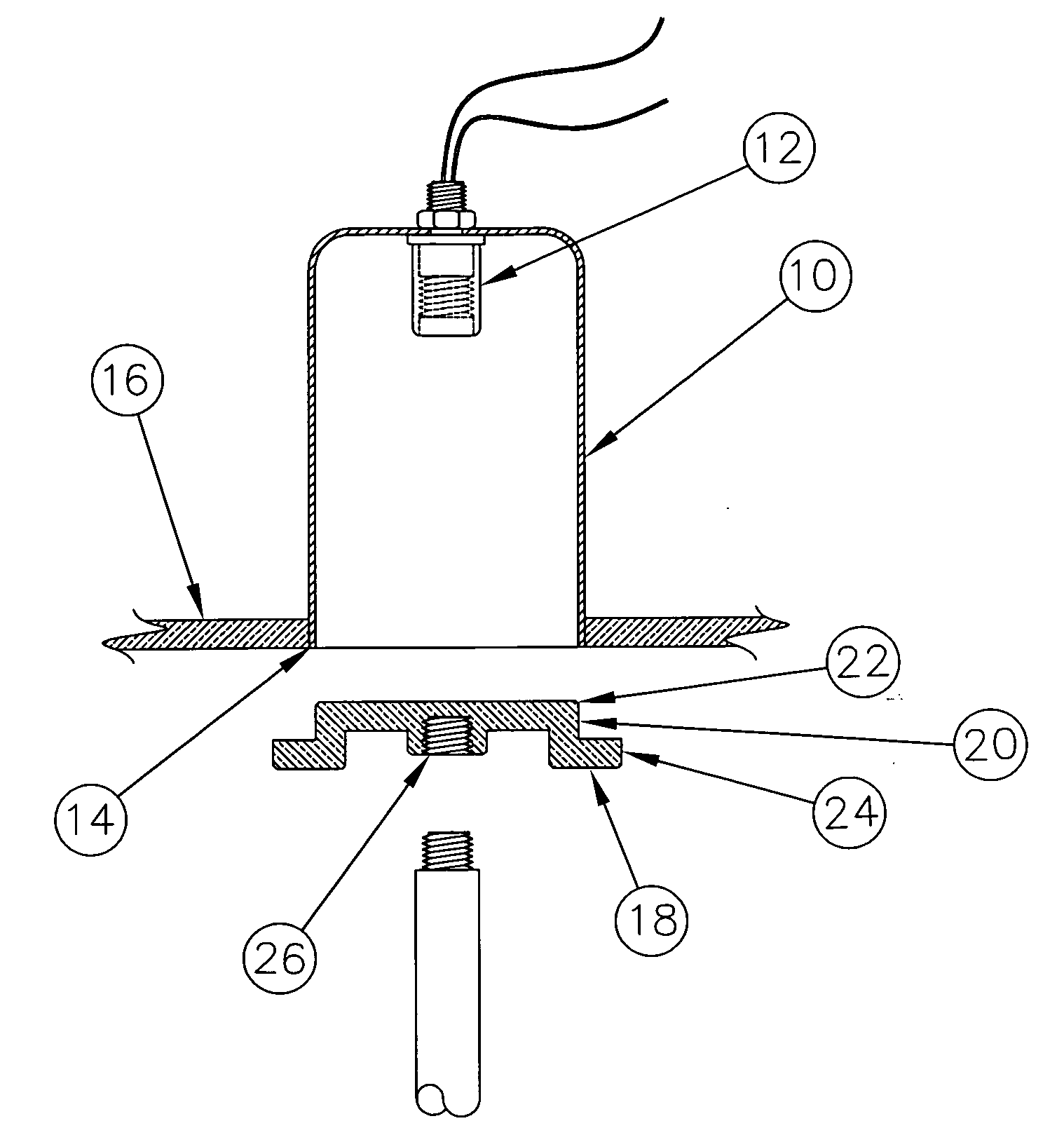

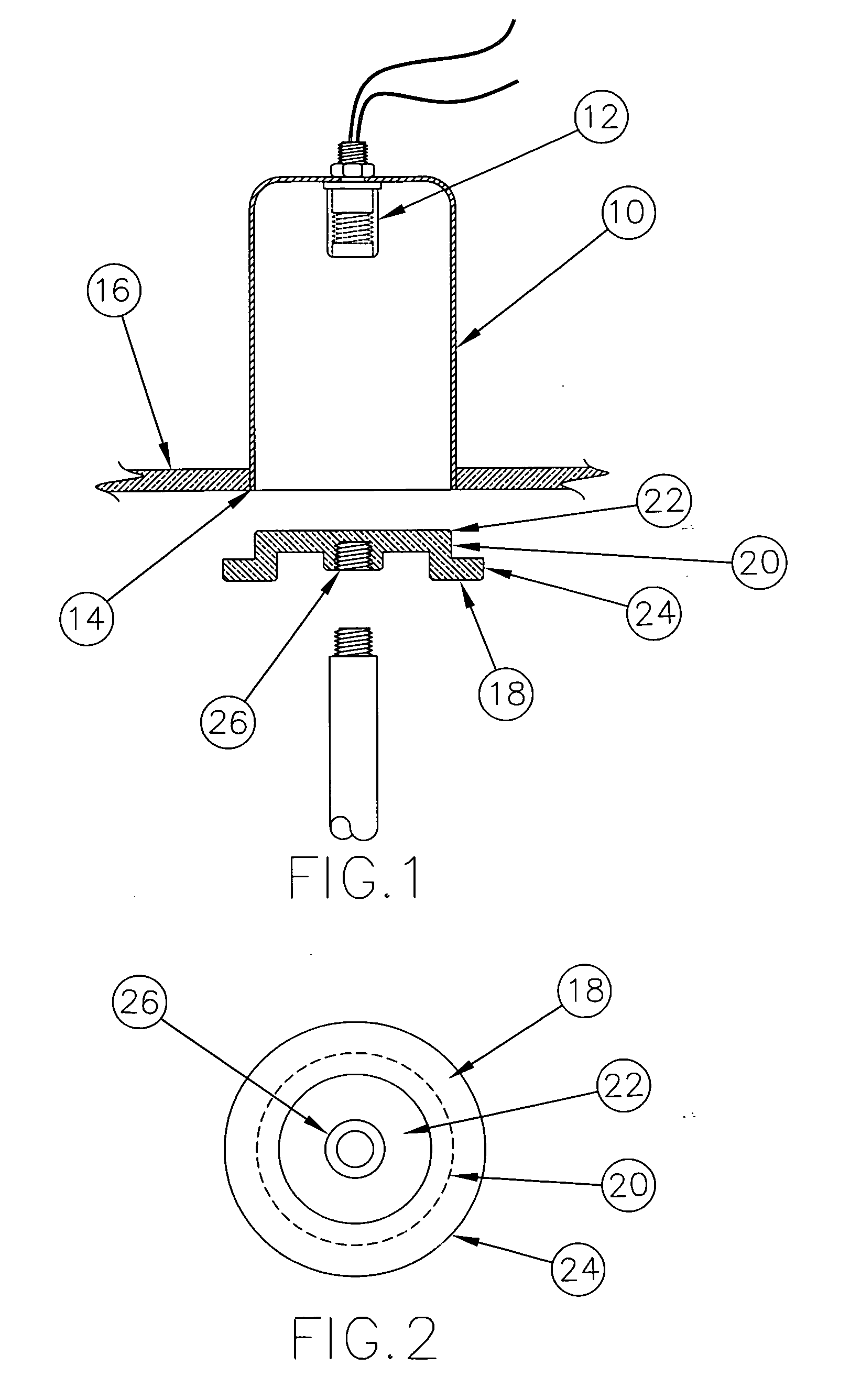

InactiveUS20100214772A1Quickly and easily and removedAvoid applicationFixed installationEntire mouthEngineering

A can cover for a recessed can light which extends over the entire mouth of the can and which has a friction fit within the can and which is provided with an internally threaded stud may be provided on the interior of the can cover to allow installers to engage the stud with a pole like apparatus to facilitate removal of the can cover.

Owner:MAGDOVITZ GRANT

Manufacturing method of comfortable full-mouth adsorption false tooth meeting aesthetic function

InactiveCN112716633ASimple and practical featuresEasy to implement and practical featuresArtificial teethEntire mouthEngineering

The invention relates to a manufacturing method of a comfortable full-mouth adsorption false tooth meeting an aesthetic function, and belongs to the field of false tooth manufacturing, wherein the method comprises the steps: drawing a central line, a mouth angle line and a lip base line on a temporary base plate loaded with a wax rim after occlusion mouth testing, and taking a bisector of jaw spacing after mouth testing; marking out an incision edge connecting line of the anterior incisor below the lip base line, and marking out a smile line above the lip base line; connecting the incisor edge line of the anterior incisor with the bisector of the jaw spacing after mouth testing to form a tooth arrangement plane curve on the same plane, wherein the mouth angle line is a positioning line between a three-tooth distal center and a four-tooth proximal center, the curve length from the mouth angle line to the central line is the basis for determining the width specification of the whole set of false tooth, the smile line is a base line for determining the tooth neck of the anterior incisor, and the distance from the smile line to the incisor edge connecting line of the anterior incisor is the basis for determining the height specification of the whole set of false tooth. Therefore, specification parameters of the whole set of false teeth and tooth arrangement positions of the false teeth can be determined, and the method is simple and easy to implement and has aesthetic characteristics on the premise of meeting false tooth functions.

Owner:洛阳曦美义齿有限公司

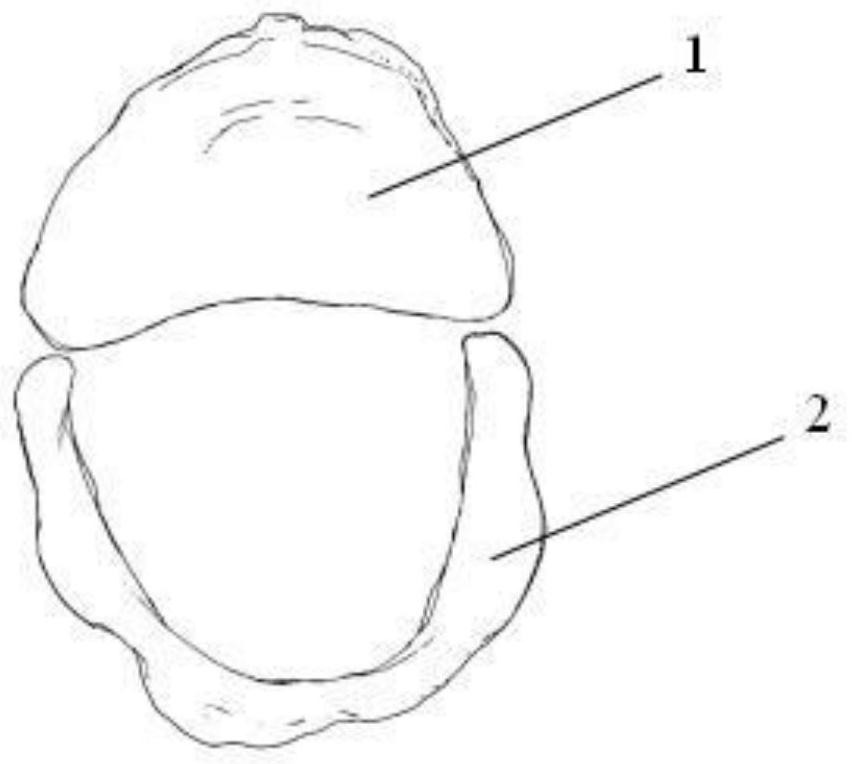

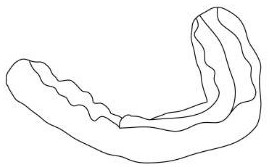

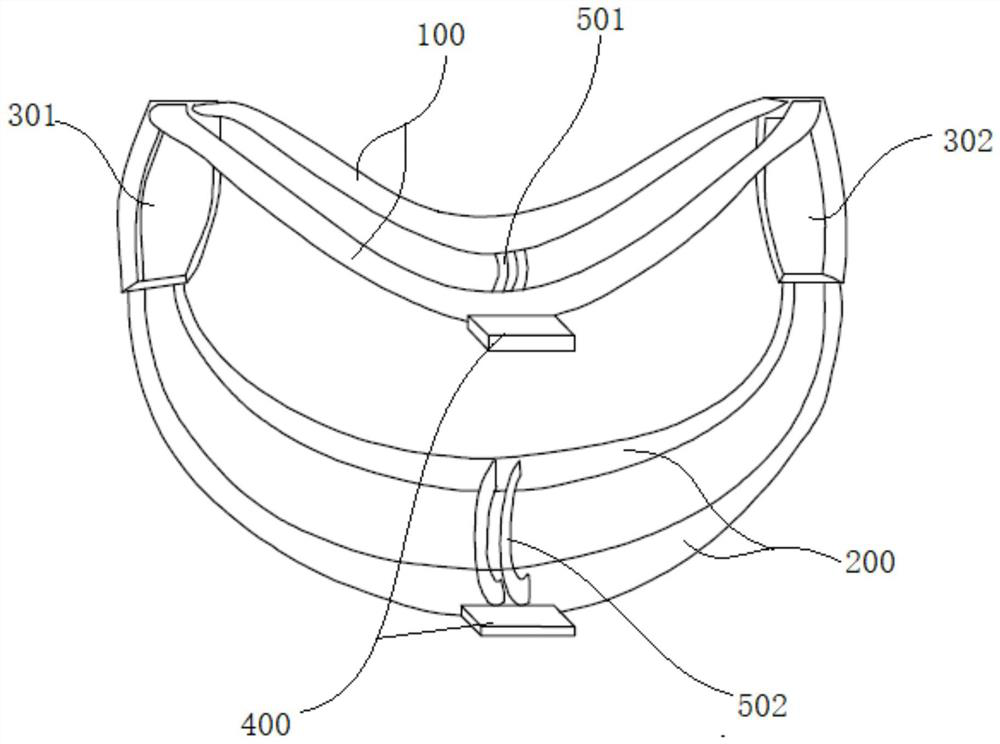

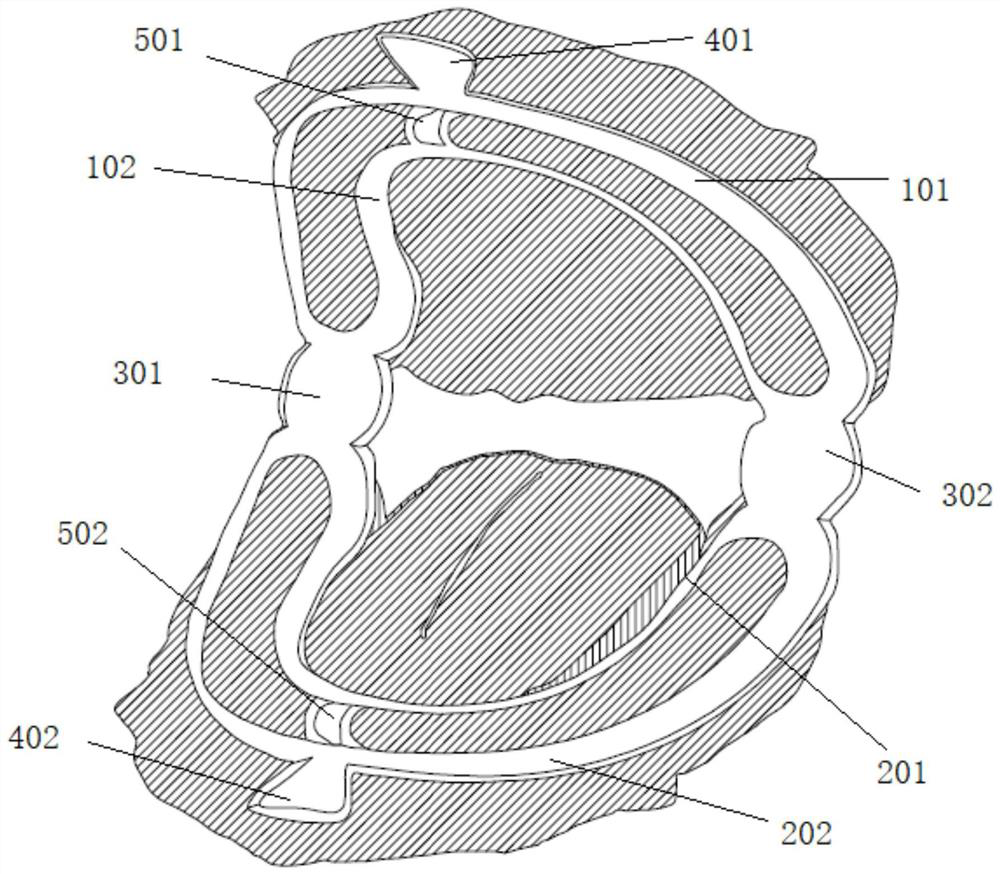

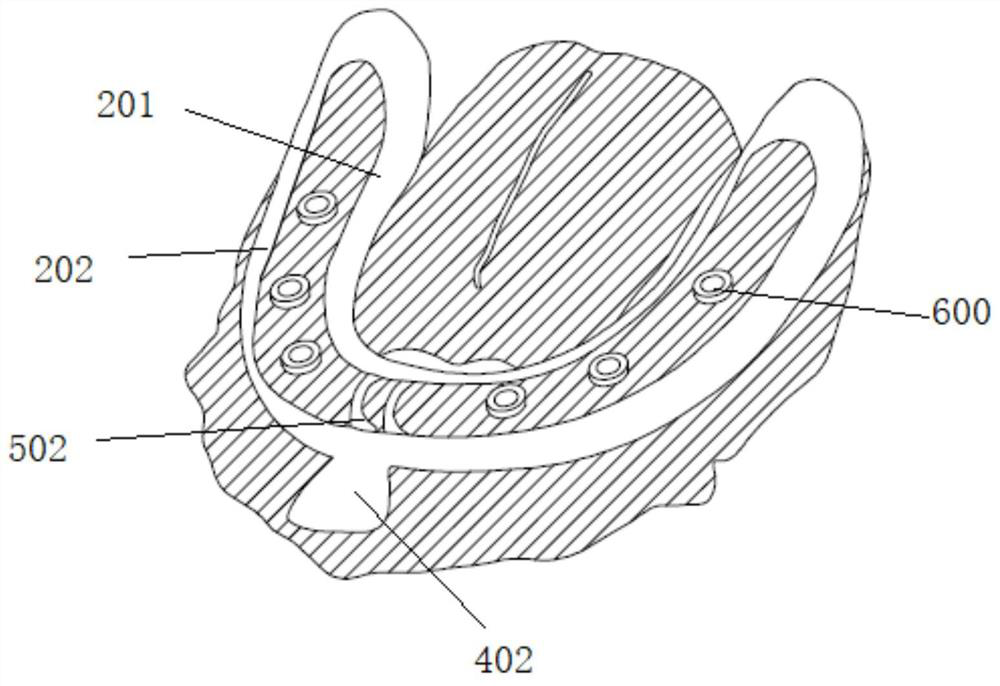

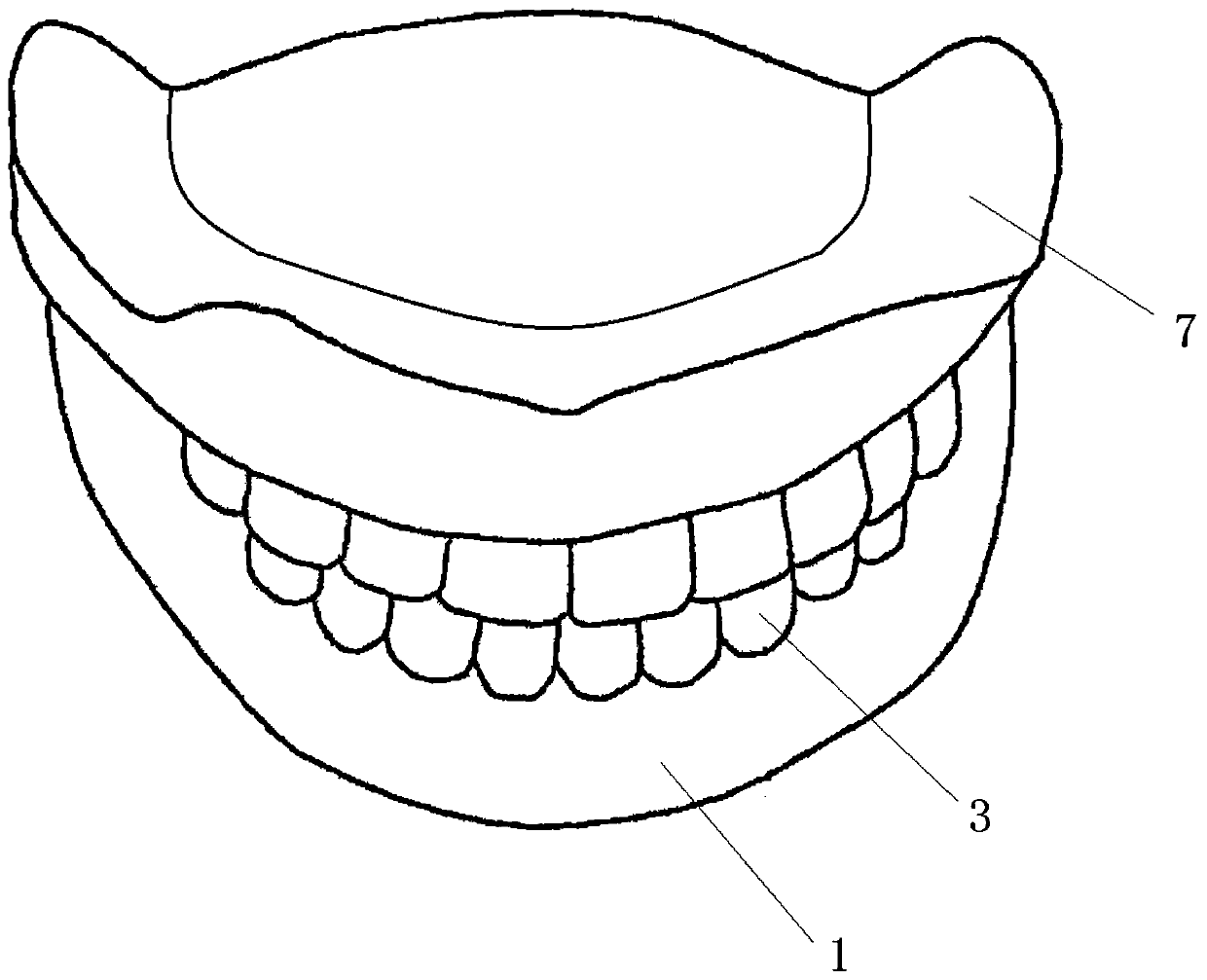

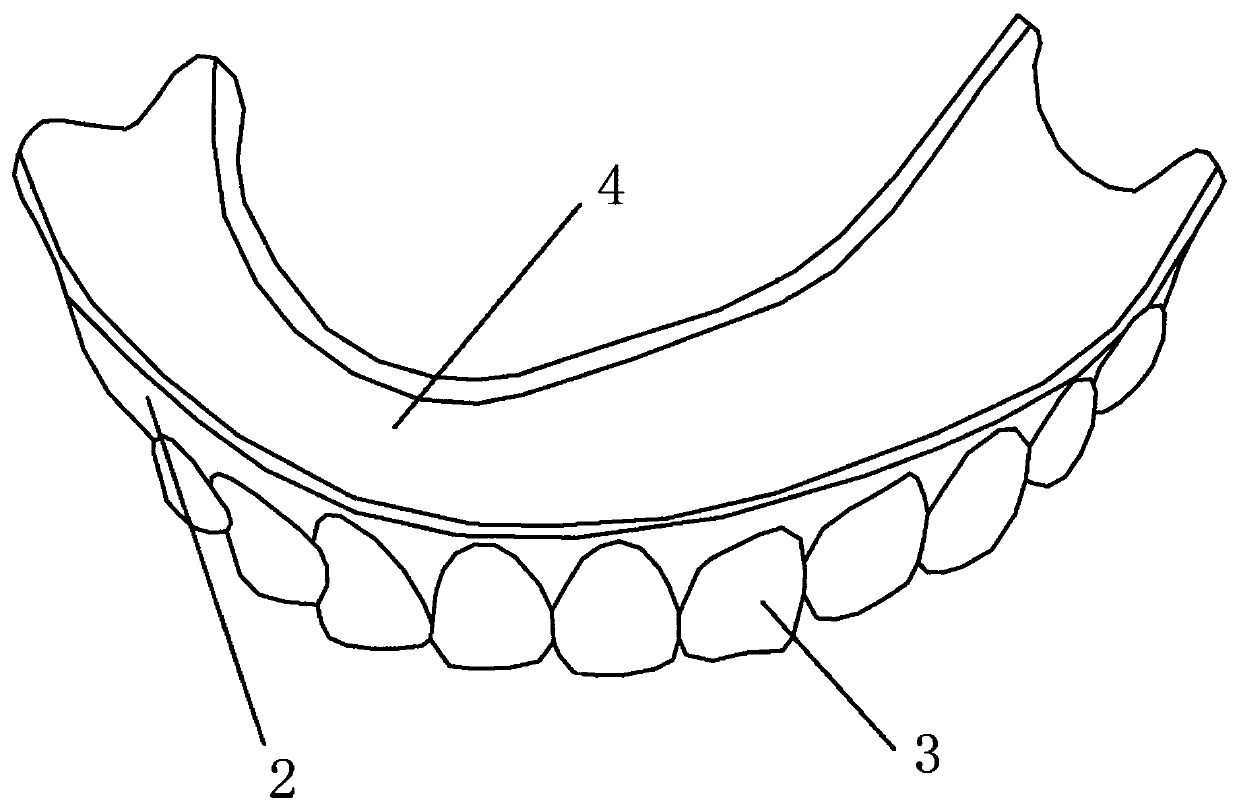

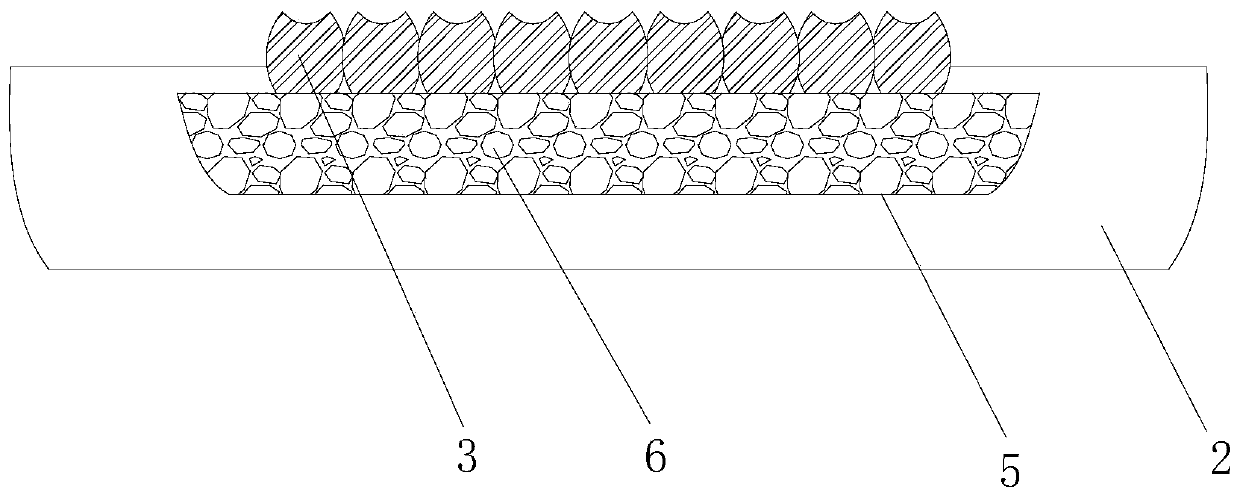

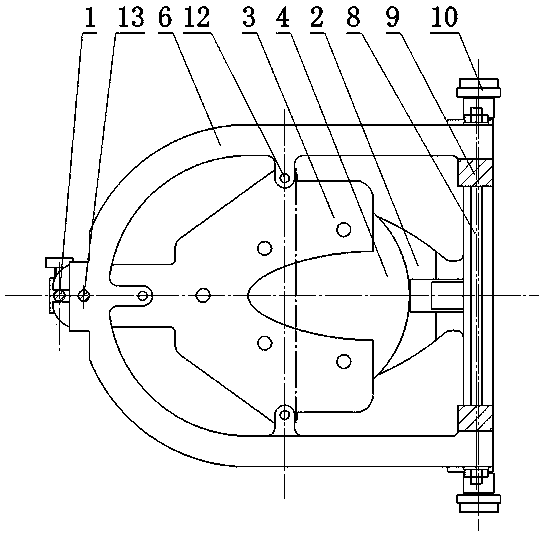

Mouth gag for full-mouth planting

PendingCN113425442ADoes not block the surgical field of viewImprove the convenience of surgeryDental implantsSurgeryEntire mouthMandibular ramus

The invention discloses a mouth gag for full-mouth planting. The mouth gag comprises an upper jaw supporting groove, a lower jaw supporting groove, a first connecting part and a second connecting part, the first end of the upper jaw supporting groove is connected with the first end of the lower jaw supporting groove through a first connecting part; the second end of the upper jaw supporting groove is connected with the second end of the lower jaw supporting groove through a second connecting part; during use, the upper jaw supporting groove is arranged on an upper jaw alveolar ridge in a sleeving mode and abuts against the upper jaw alveolar ridge, and the alveolar ridge top of the upper jaw alveolar ridge is exposed; the lower jaw supporting groove is arranged on the lower jaw alveolar ridge in a sleeving mode and abuts against the lower jaw alveolar ridge, and the alveolar ridge top of the lower jaw alveolar ridge is exposed. The mouth gag is attached to the soft tissue in the corresponding oral cavity, avoids an operation area and opens the soft tissue in the direction away from the operation area, the operation view cannot be shielded, and operation convenience is greatly improved.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

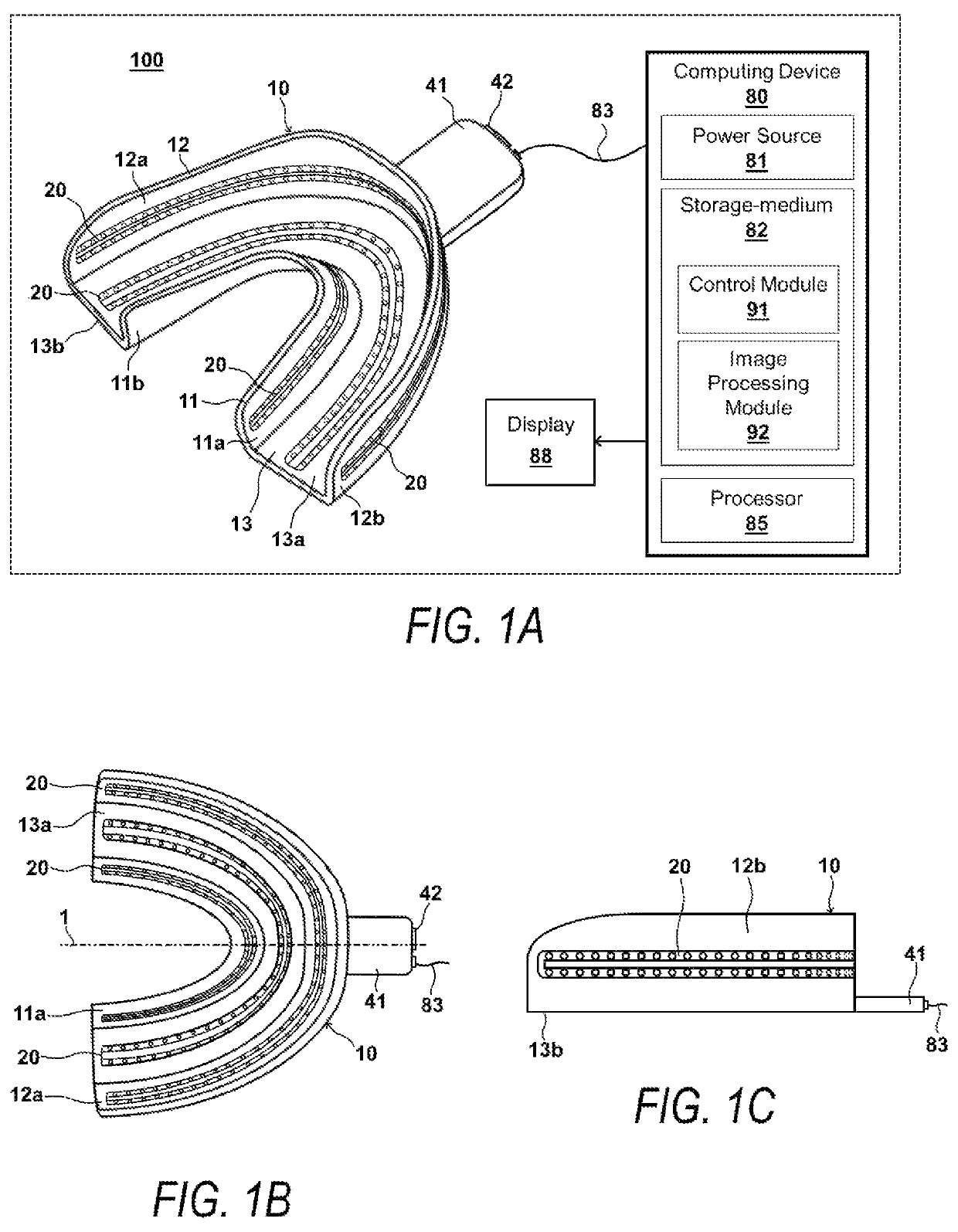

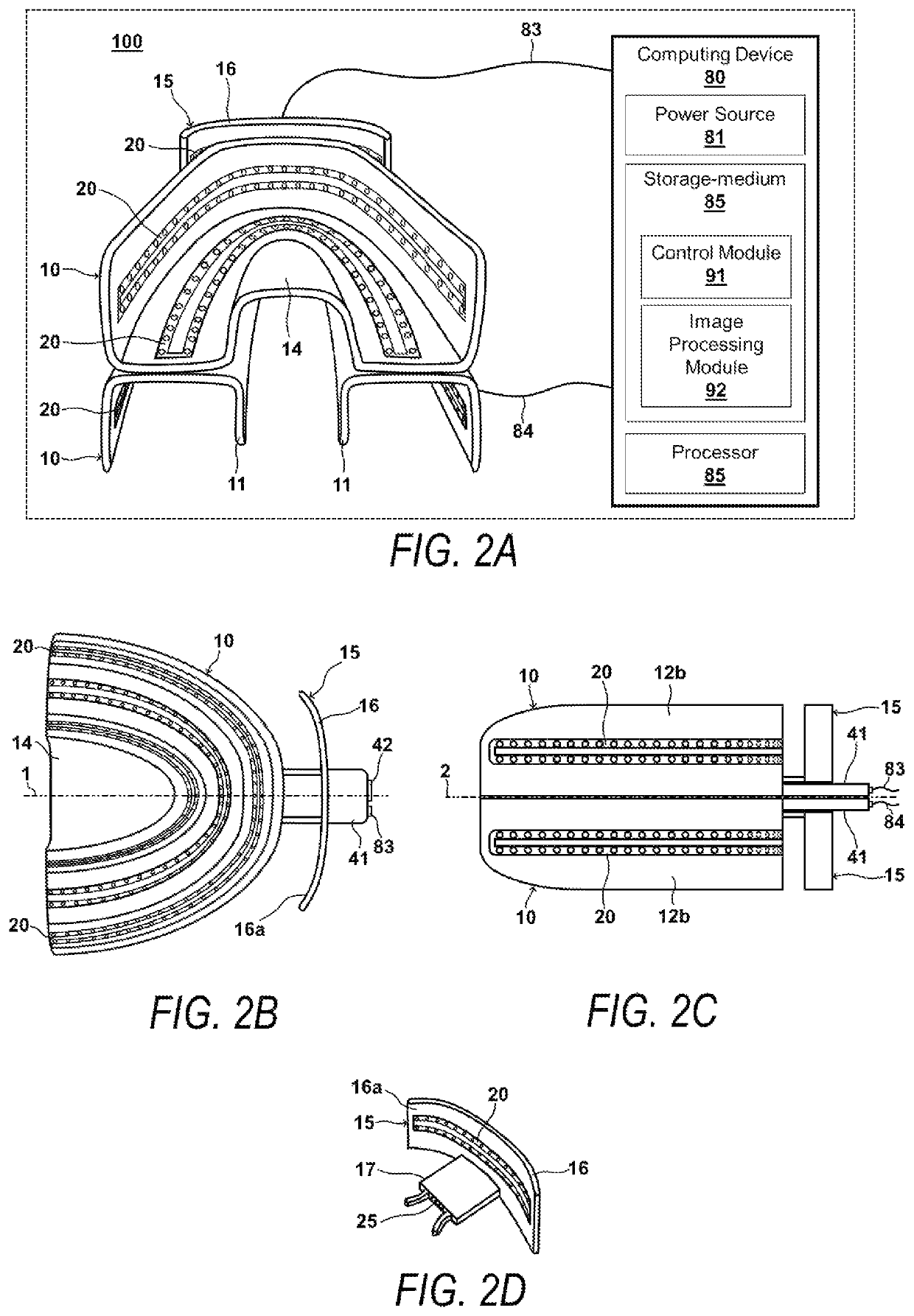

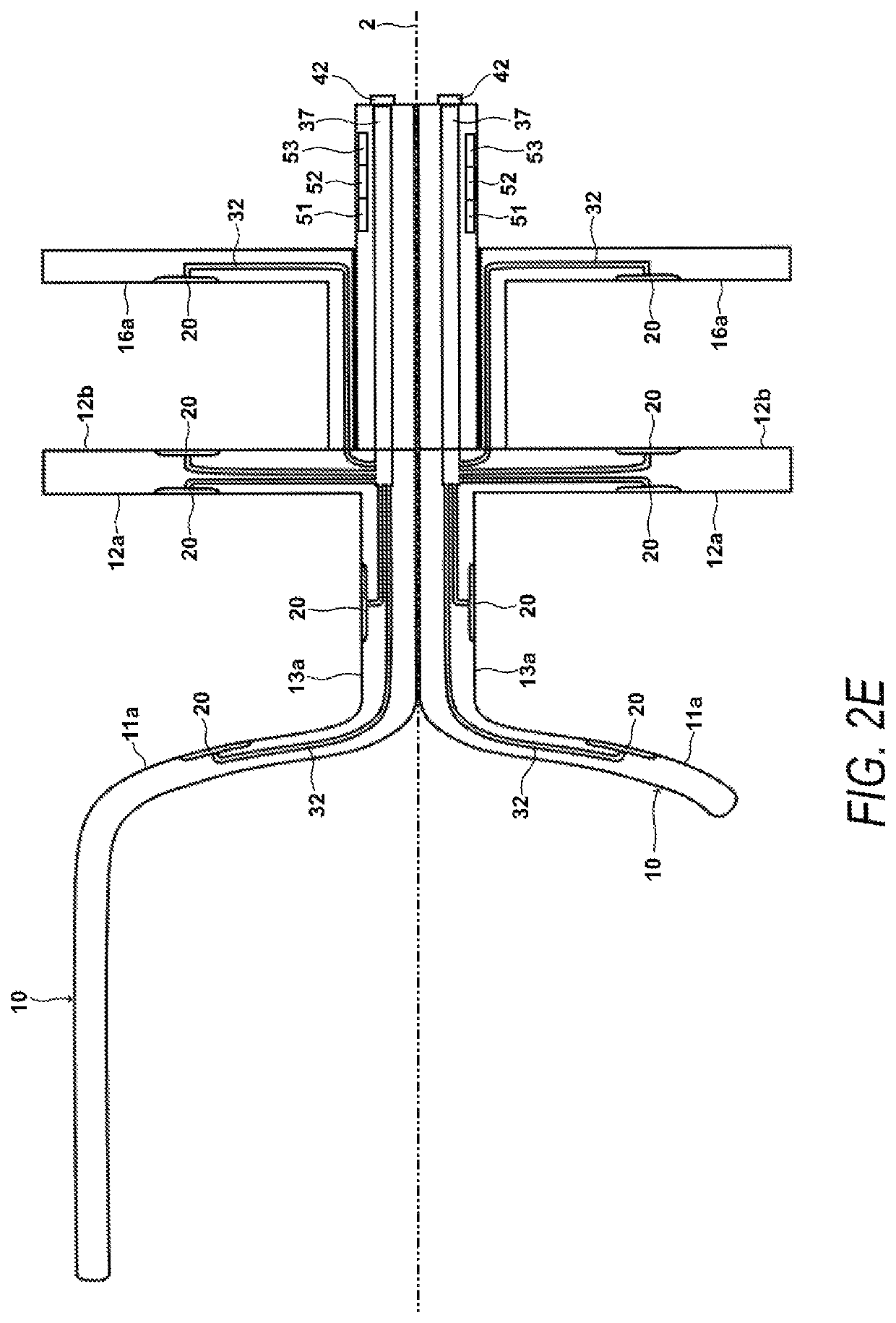

Three-dimensional oral imaging system and method

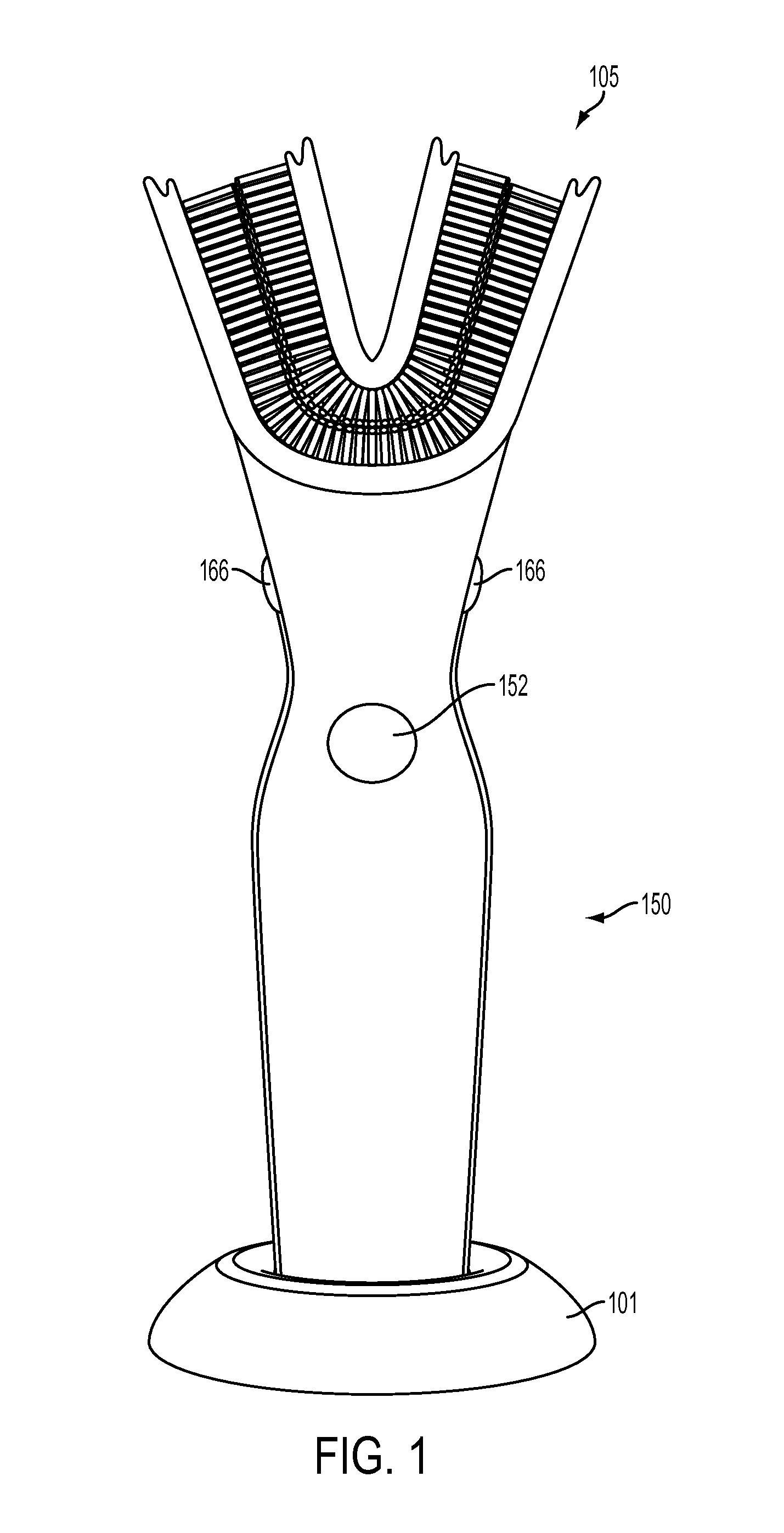

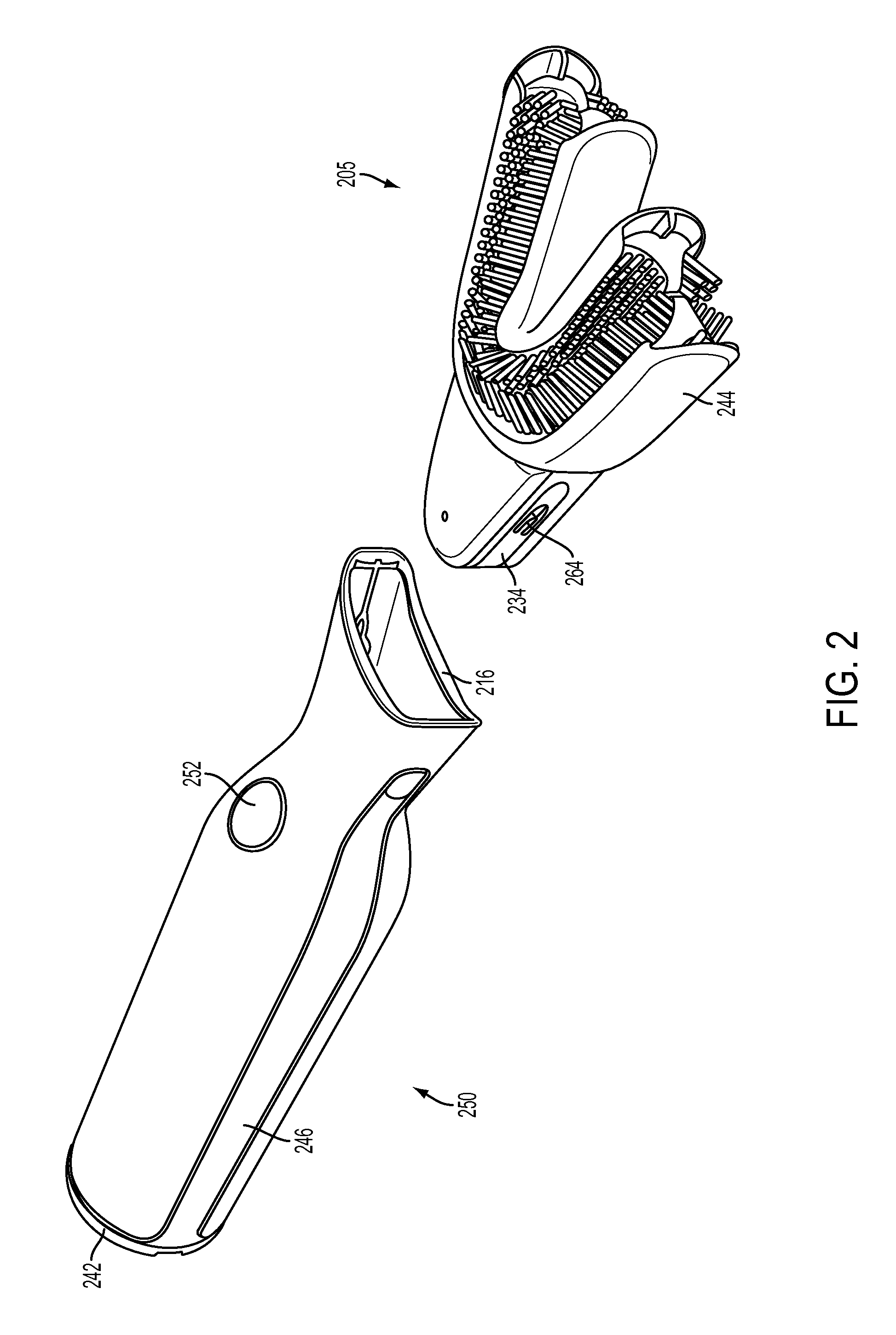

ActiveUS11382727B1Reduce the amount requiredReduce reflectivityImpression capsSomatoscopeEntire mouthEntire oral cavity

An oral imaging system and method for acquiring dental impression scans is provided by having one or more imaging strips with illumination elements and imaging sensors that are positioned along the contour of the various surfaces of a dental tray and acquire images of the lips, teeth, and gum regions of a mouth. Fluid channels interconnecting a vacuum source or pressurized air source to openings near the imaging sensors on the dental tray are provided to reduce condensation on the imaging sensors. An extraoral extension may also be provided to acquire images of the exterior region of the lips. Furthermore, two dental trays of the present invention may be stacked together so that the entire mouth may be scanned at one time. A ramp is provided on the lower dental tray in the stacked configuration for acquiring relative jaw positions.

Owner:DENTM LLC

Full denture and preparation method thereof

PendingCN111150509AImprove retention effectNot easy to looseFastening prosthesisArtificial teethFull denturesEntire mouth

The invention discloses a full denture and a preparation method thereof. The full denture comprises a lower denture assembly which comprises a lower base support, wherein lower dentures are embedded at the top part of the lower base support; a lower fitting groove matched with an alveolar ridge is arranged at the bottom part of the lower base support; and a weighting part is arranged in the lowerbase support. The full denture provided by the invention has the following advantages: the lower fitting groove matched with the alveolar ridge is arranged at the bottom part of the lower base support, and the base support can be tightly attached to the mucosa of the alveolar ridge, so the full denture has good position fixing performance; meanwhile, the weighting part is arranged in the lower base support to increase the weight of the lower base support and reinforce the adhesive force and the sealing performance of the base support, so the position fixing performance of the full denture is greatly improved; and the lower base support of the full denture is tightly and firmly combined with the alveolar ridge, so the full denture is not easy to loosen, fall off and float upwards, is comfortable for a user to wear, and has wide application prospect.

Owner:常映明

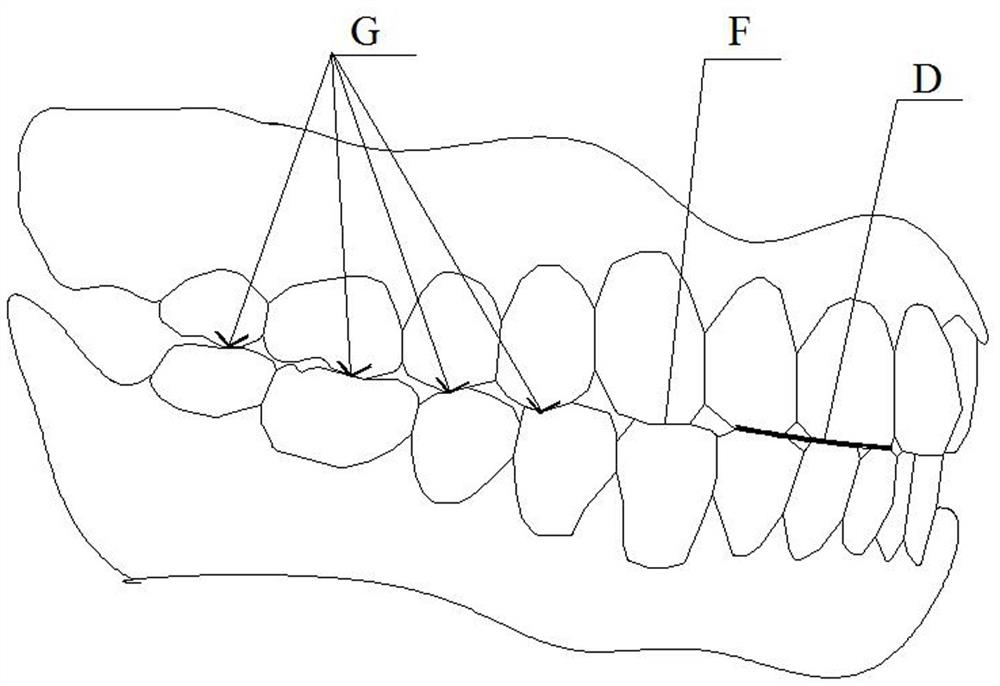

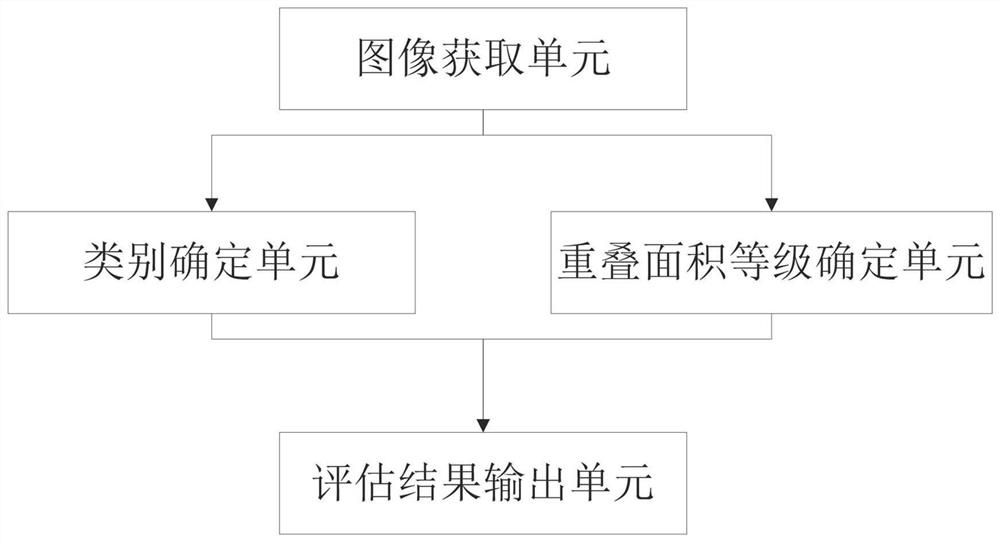

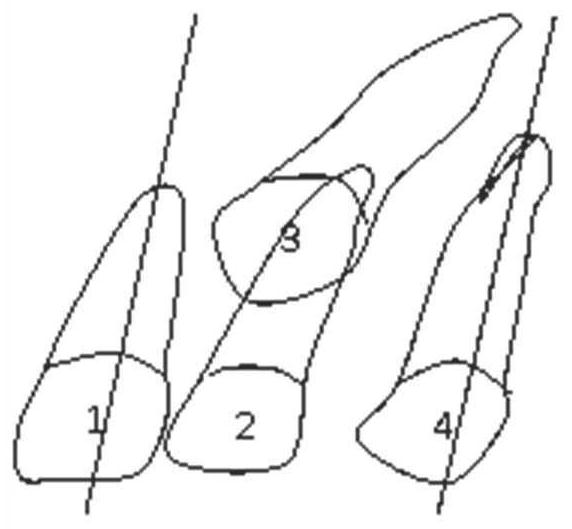

Maxillary impacted canine tooth correction difficulty assessment system

InactiveCN113197686AAvoid burdenConvenient for clinical operationOthrodonticsTomosynthesisEntire mouthOral problems

The invention relates to a maxillary impacted canine tooth correction difficulty assessment system, relates to the technical field of orthodontics, and aims to solve the problem that correction difficulty assessment is not objective enough when maxillary impacted canine teeth are corrected. The maxillary impacted canine tooth correction difficulty assessment system comprises an image acquisition unit, a category determination unit, an overlapping area grade determination unit and an assessment result output unit. The correction evaluation difficulty of the maxillary impacted canine tooth is obtained by carrying out classification and area calculation on the obtained full-mouth curved surface fault slices of the maxillary impacted canine tooth. The system is used for assisting doctors in tooth correction difficulty assessment.

Owner:何武成

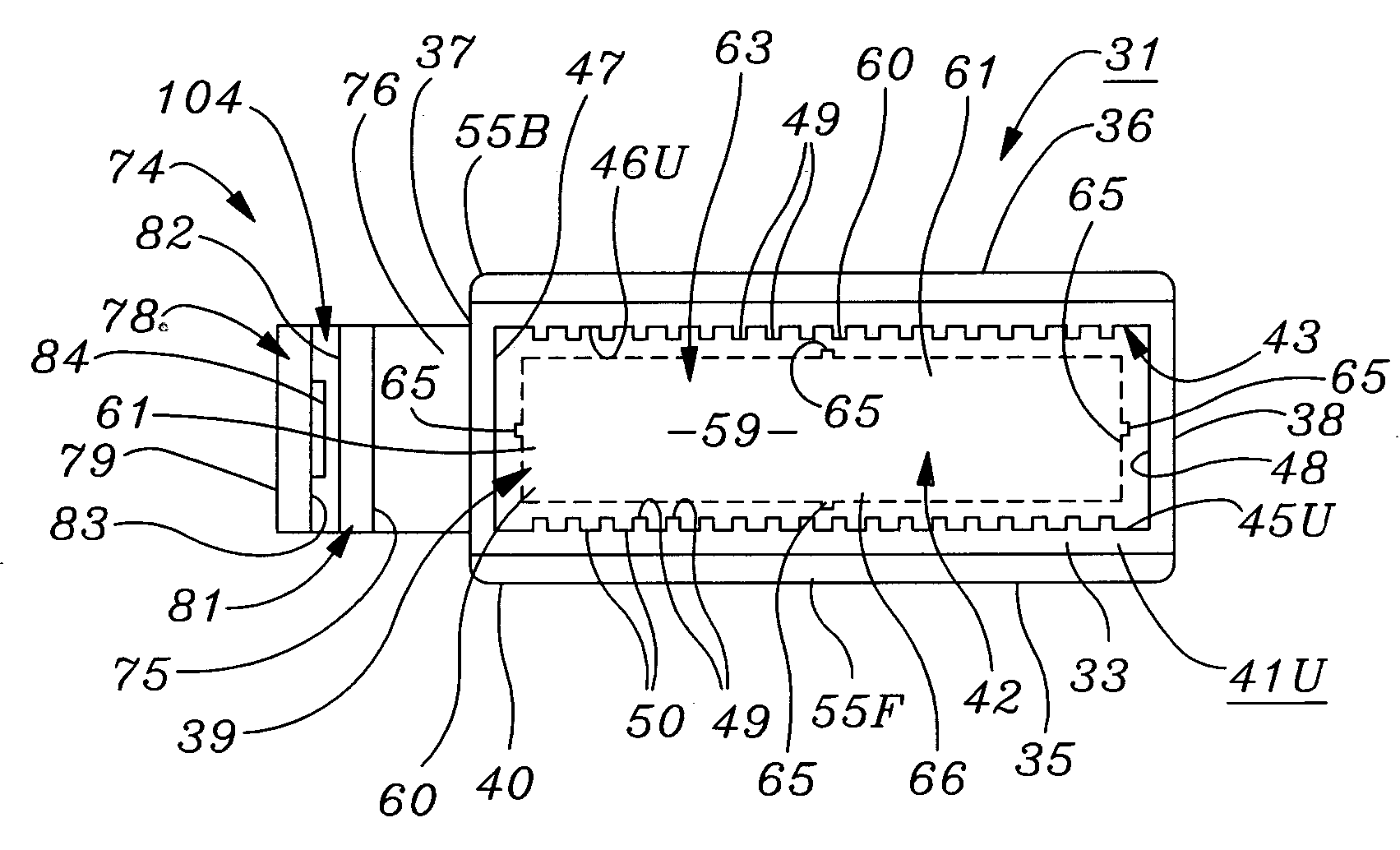

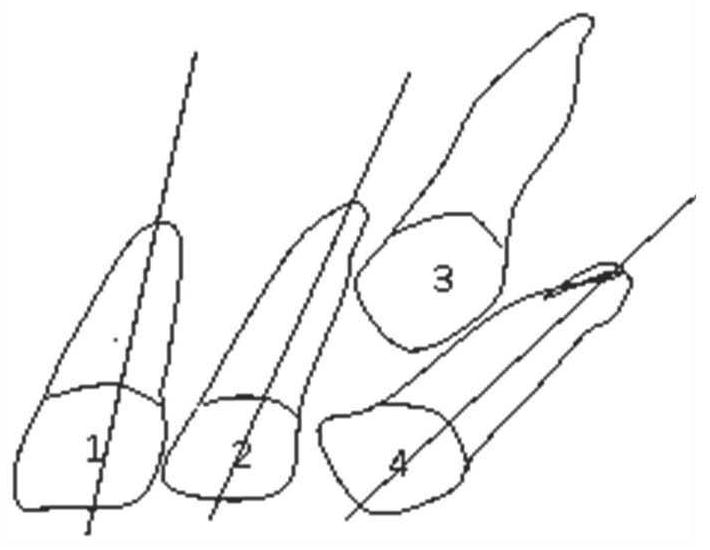

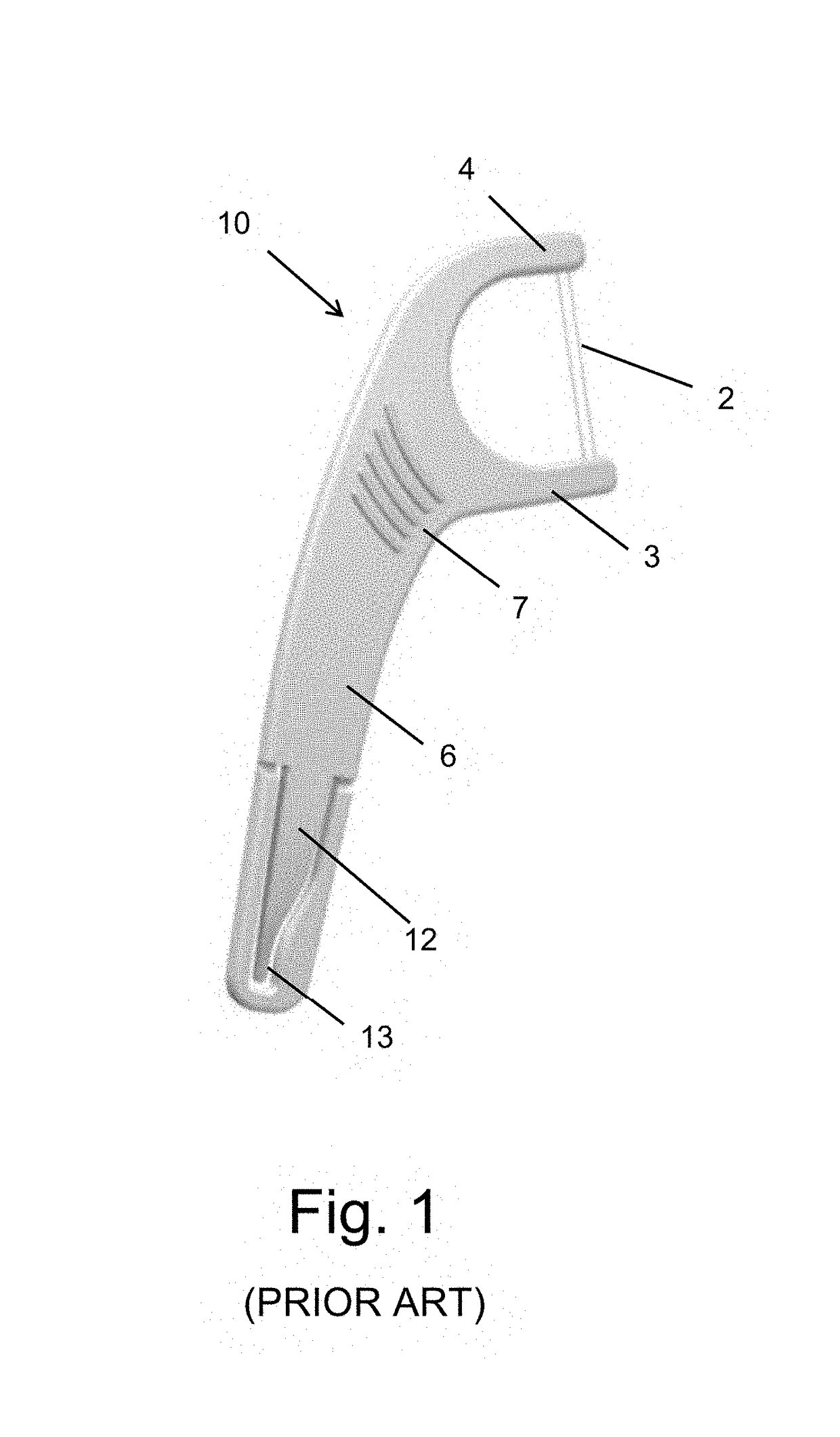

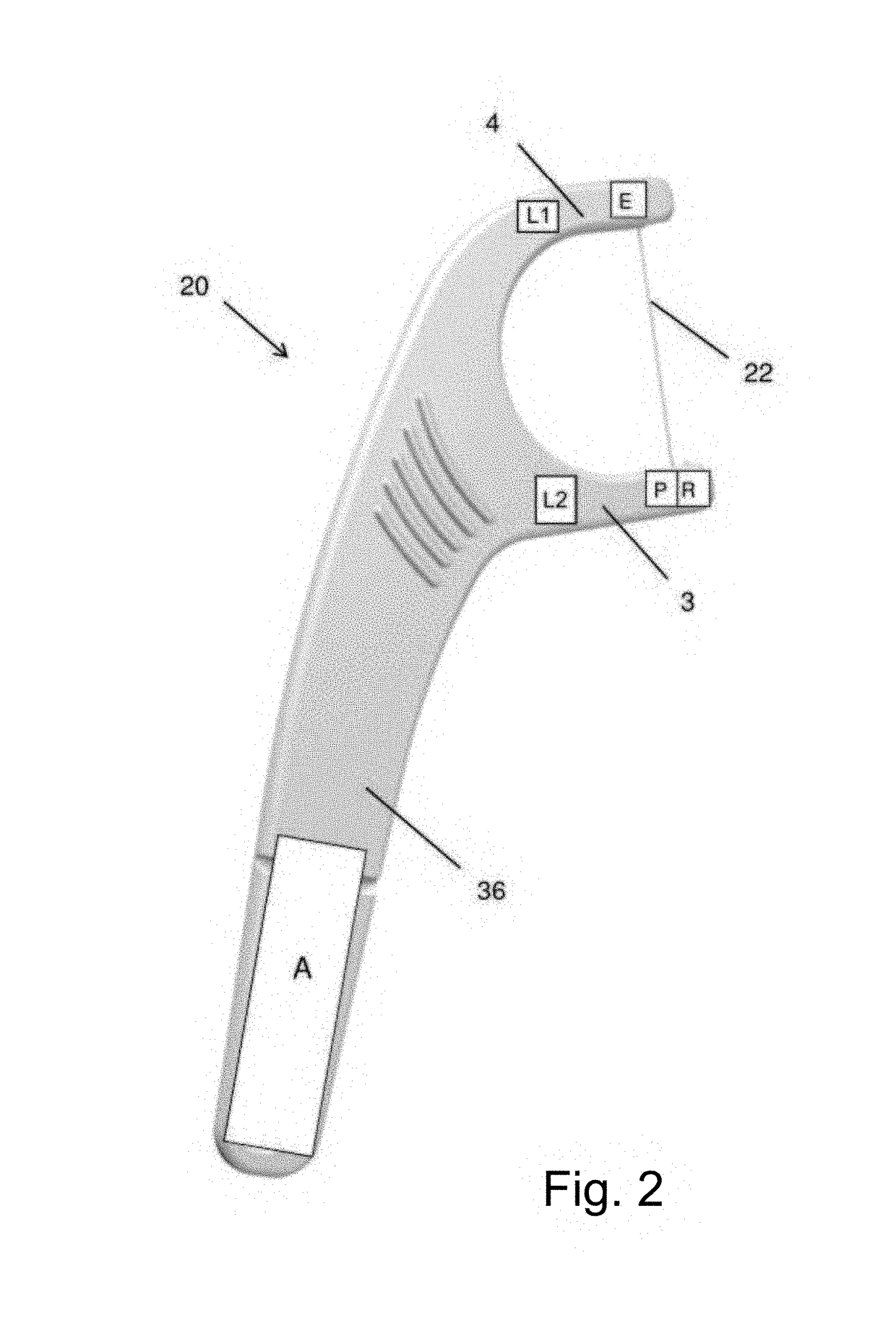

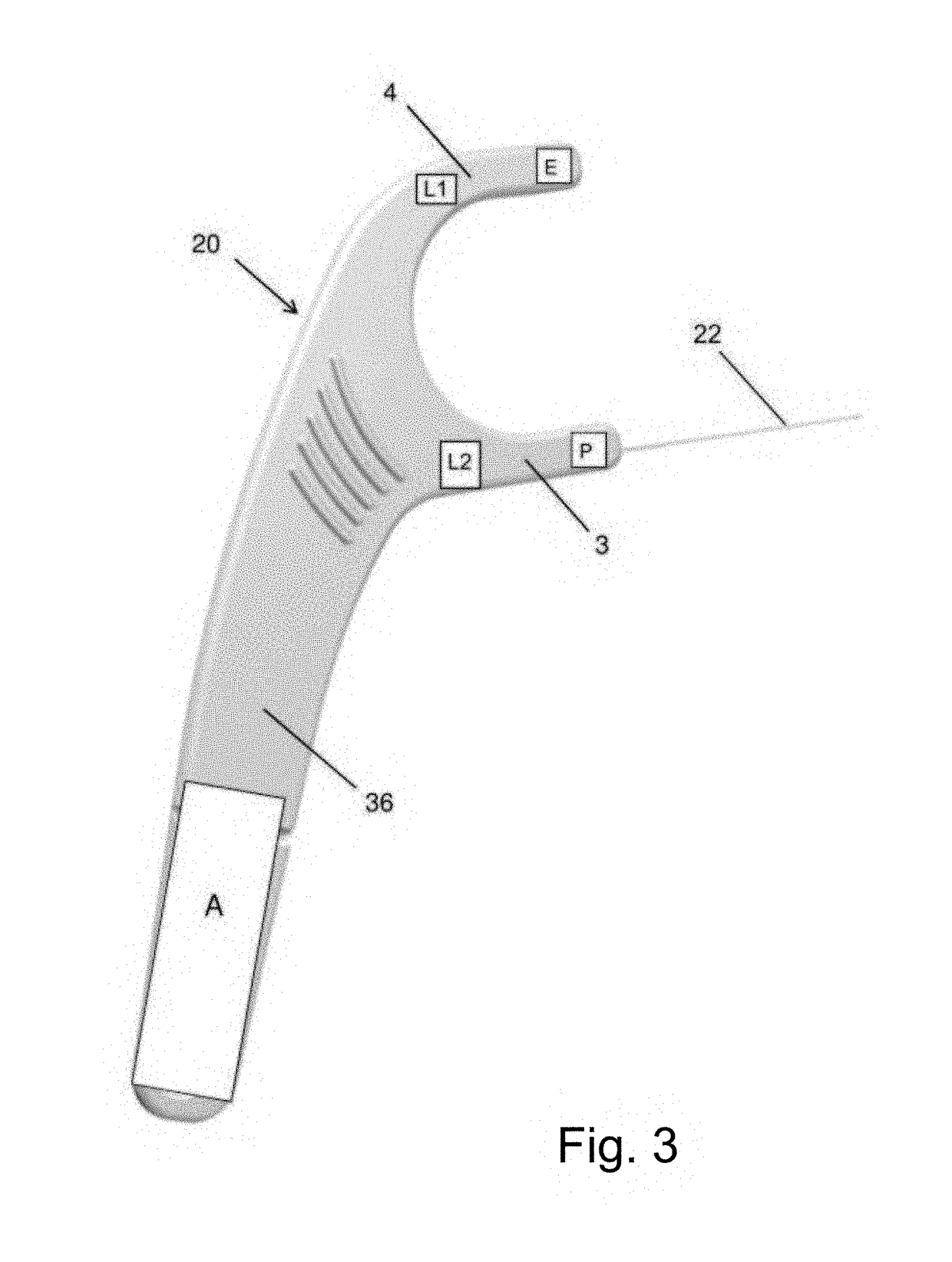

Adjustable interdental cleaning element and a device and method therefor

A dental hygiene device which comprises first and second spaced fixed elements, a third element interconnected with both said first and second elements to define an opening between said first and second elements within which a dental structure to be flossed is receivable, an elongated cleaning element usable in a flossing operation with first and second longitudinal ends, a first member by which said cleaning element is held and selectively directable from said first element to said second element, and a second member associated with said second element by which said cleaning element is detachably secured. The dental hygiene device is preferably operated by one hand only. In addition, the user can clean the entire mouth using one dental hygiene device.

Owner:HOROWITZ AMIR

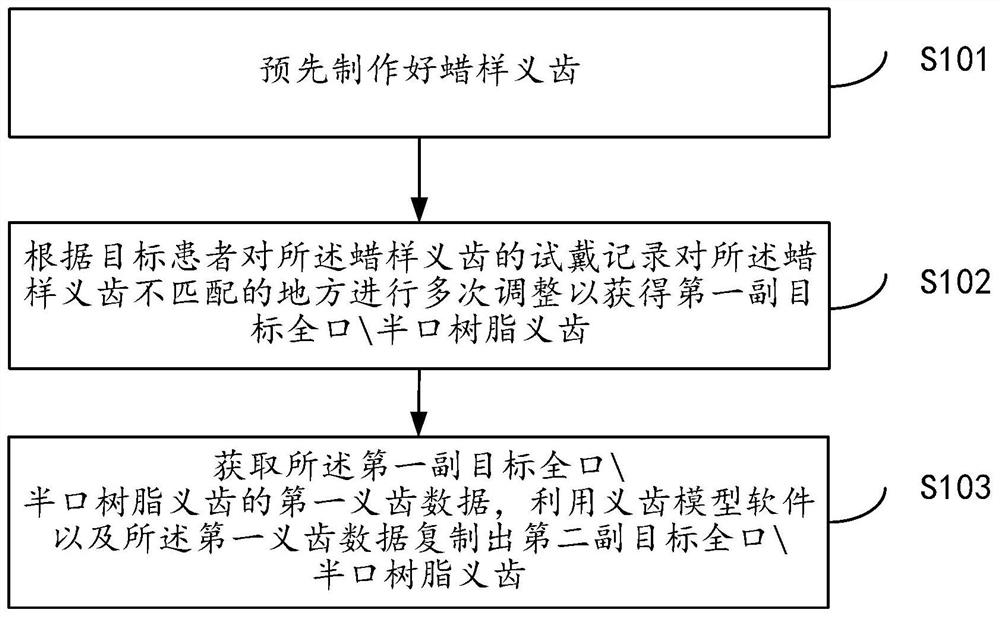

Method for quickly and accurately copying false teeth

ActiveCN112022397AFast exact copyExtended use timeArtificial teeth3D printingEntire mouthBiomedical engineering

The invention discloses a method for quickly and accurately copying false teeth. The method comprises the following steps of making wax-like false teeth in advance; according to a try-in record of thewax-like false teeth by a target patient, adjusting the unmatched parts of the wax-like false teeth for multiple times to obtain a first set of target full-mouth\half-mouth resin false teeth; and acquiring first false tooth data of the first set of target full-mouth\half-mouth resin false teeth, and copying a second set of target full-mouth\half-mouth resin false teeth by utilizing false tooth model software and the first false tooth data. By means of existing 3D printing and CAD\CAM cutting technologies, in a traditional full-mouth tooth making process, the false teeth, finally and completely adapting to the oral cavity, of the patient are copied, the patient finally obtains the two sets of false teeth, the false teeth are replaced every other day for use, and therefore the use time of the false teeth is prolonged.

Owner:北京联袂义齿技术有限公司

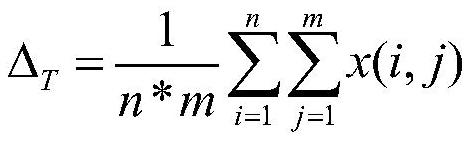

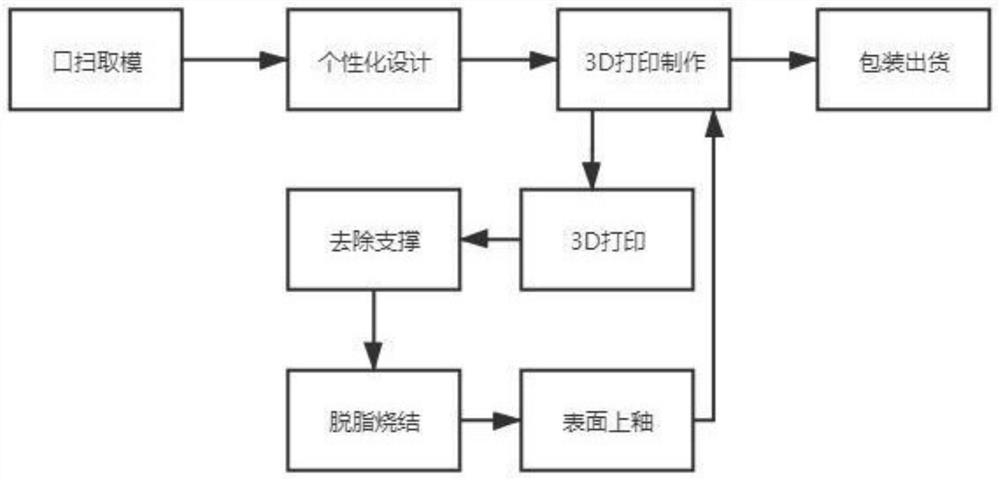

All-ceramic whitening tooth socket and preparation method thereof

PendingCN113317902ADoes not affect organizational structureReduce cumbersome operationsDentistryComputer Aided DesignEntire mouth

The invention relates to an all-ceramic whitening tooth socket and a preparation method thereof. The preparation method comprises the following steps: scanning the oral cavity of a patient through a scanner to obtain a digital model of the whole dentition of the patient; inputting the digital model into computer-aided design software, determining a tooth position to be manufactured based on the tooth socket requirement of the patient, determining an outer crown mode, adding a connecting body, selecting a digital impression and a jaw tooth in the computer-aided design software based on the tooth position to be manufactured, and further obtaining an order corresponding to the tooth position; respectively determining the direction of an insertion path and drawing an edge line contour based on the dentition condition and the undercut filling condition of a patient, selecting digital tooth forms in a tooth form database, then connecting each independent digital tooth form in a digital model into a whole, and obtaining tooth socket data; and performing secondary processing on the tooth socket data to obtain tooth socket model data, and performing printing based on the tooth socket model data to generate the all-ceramic whitening tooth socket; Healthy teeth do not need to be polished, the teeth are not affected, and existing tedious tooth whitening steps are simplified.

Owner:杭州泰利斯医疗科技有限公司

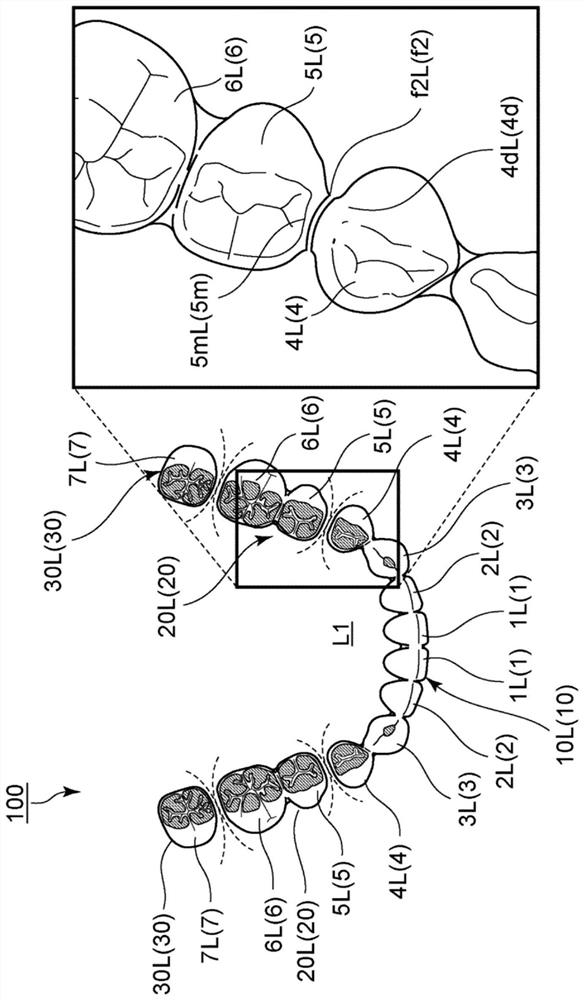

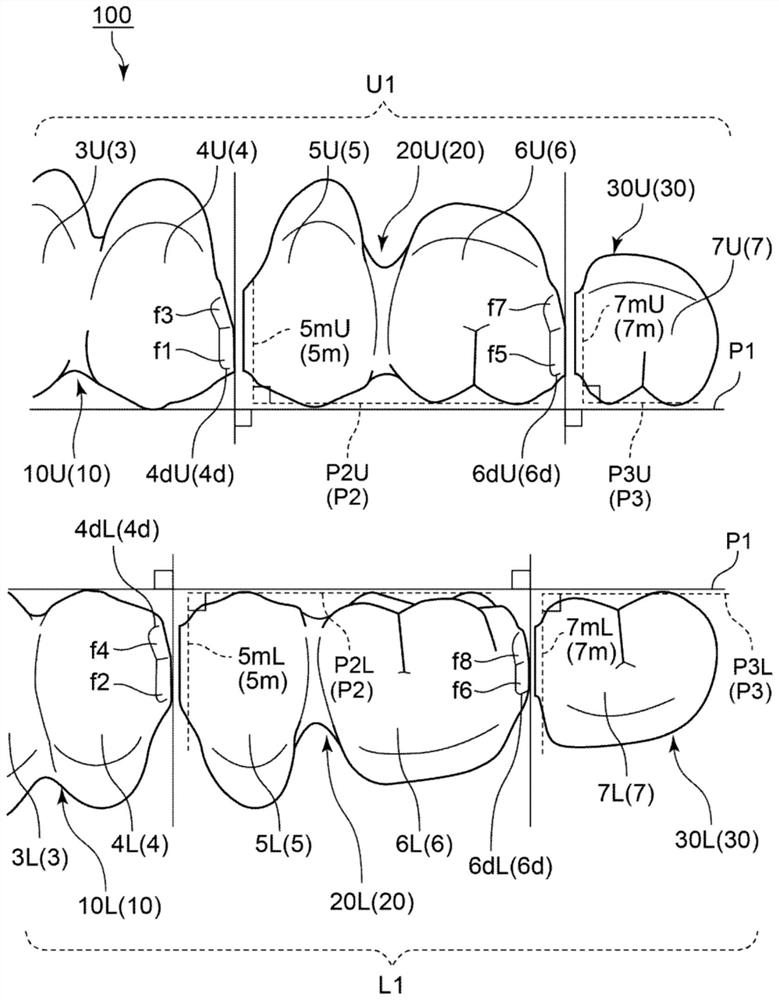

PARTIALLY CONNECTED COMPLETIVE ARTIFICIAL TOOTH HAVING ADJUSTMENT OF dental arch and occlusion bend

PendingCN113925637AShort and efficient productionExcellent occlusal relationshipFastening prosthesisArtificial teethEntire mouthGonial angle

Owner:SHOFU INC

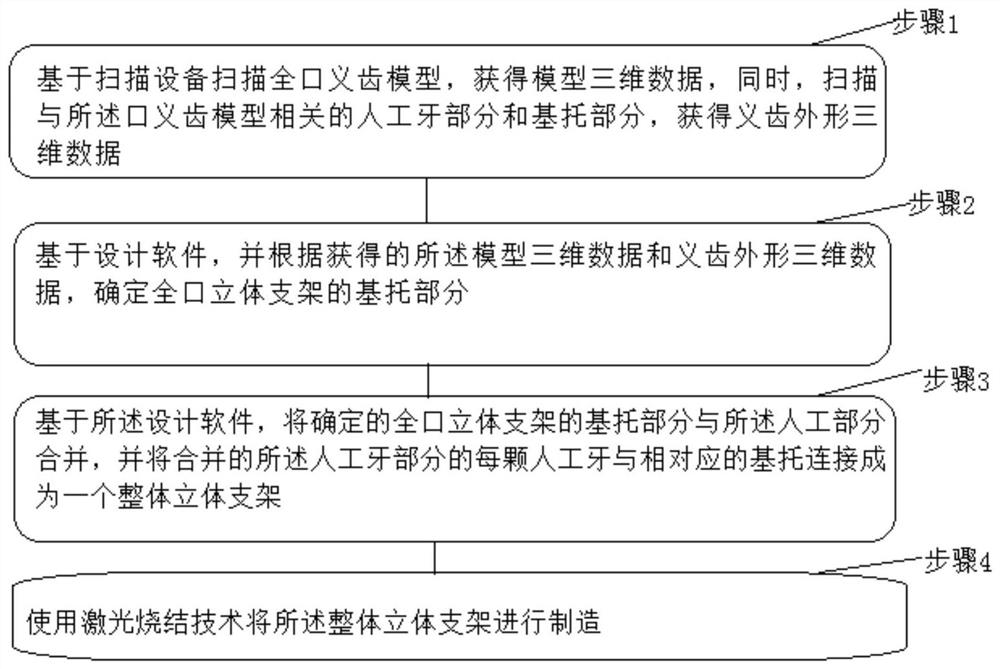

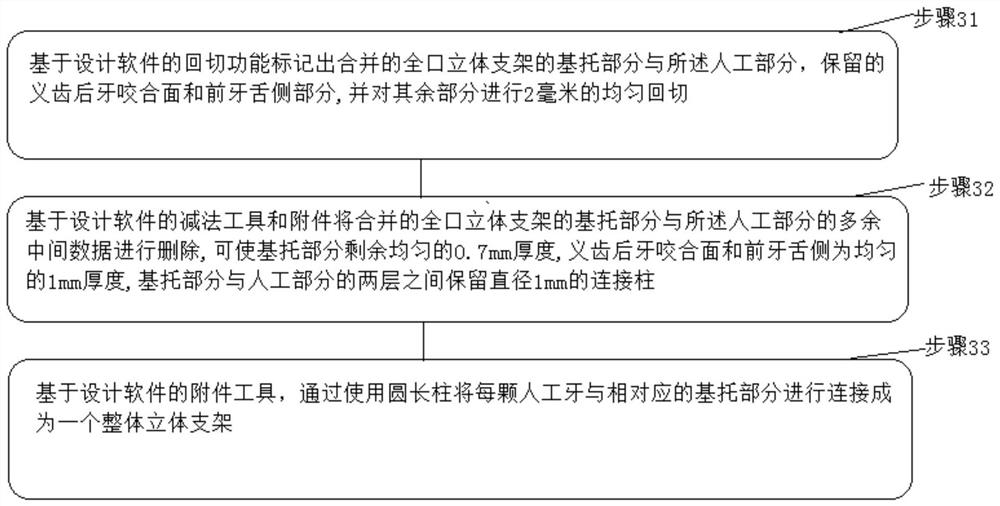

A digital manufacturing method of three-dimensional brackets for complete dentures

ActiveCN111529105BAdditive manufacturing apparatusCharacter and pattern recognitionEntire mouthDesign software

The invention provides a digital manufacturing method of a three-dimensional bracket for a complete denture, which scans a complete denture model based on a scanning device to obtain three-dimensional data of the model, and at the same time, scans the artificial tooth part and the base part related to the denture model to obtain the shape of the denture Three-dimensional data; based on the design software, and according to the obtained three-dimensional data of the model and the three-dimensional data of the shape of the denture, the base part of the full-mouth three-dimensional bracket is determined; based on the design software, the determined base part of the full-mouth three-dimensional bracket is merged with the artificial part, And each artificial tooth of the combined artificial tooth part is connected with the corresponding base to form a whole three-dimensional bracket; the whole three-dimensional bracket is manufactured by using laser sintering technology. It replaces the traditional method of manufacturing denture brackets with manual wax pattern and casting technology, which has high technical precision and high speed, simplifies the manufacturing process of three-dimensional brackets, reduces manufacturing difficulty, and improves the precision and metal quality of denture brackets.

Owner:北京联袂义齿技术有限公司

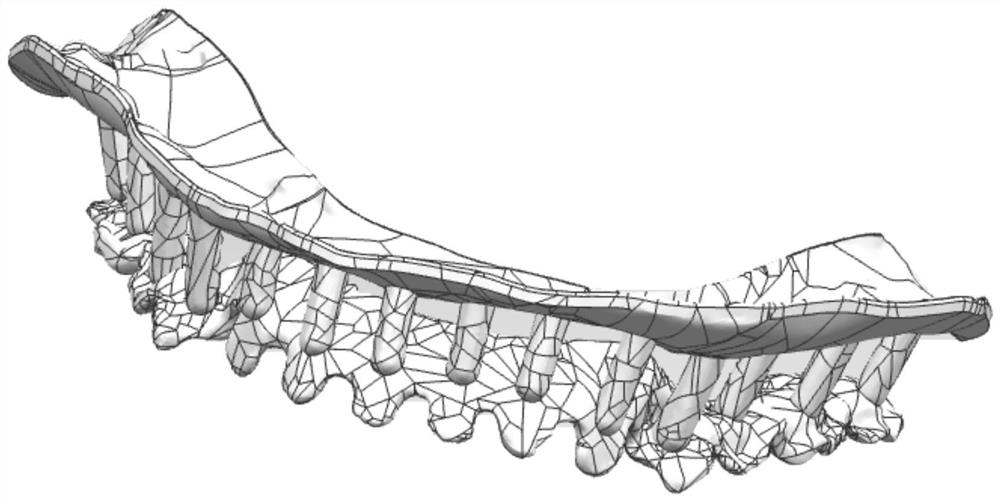

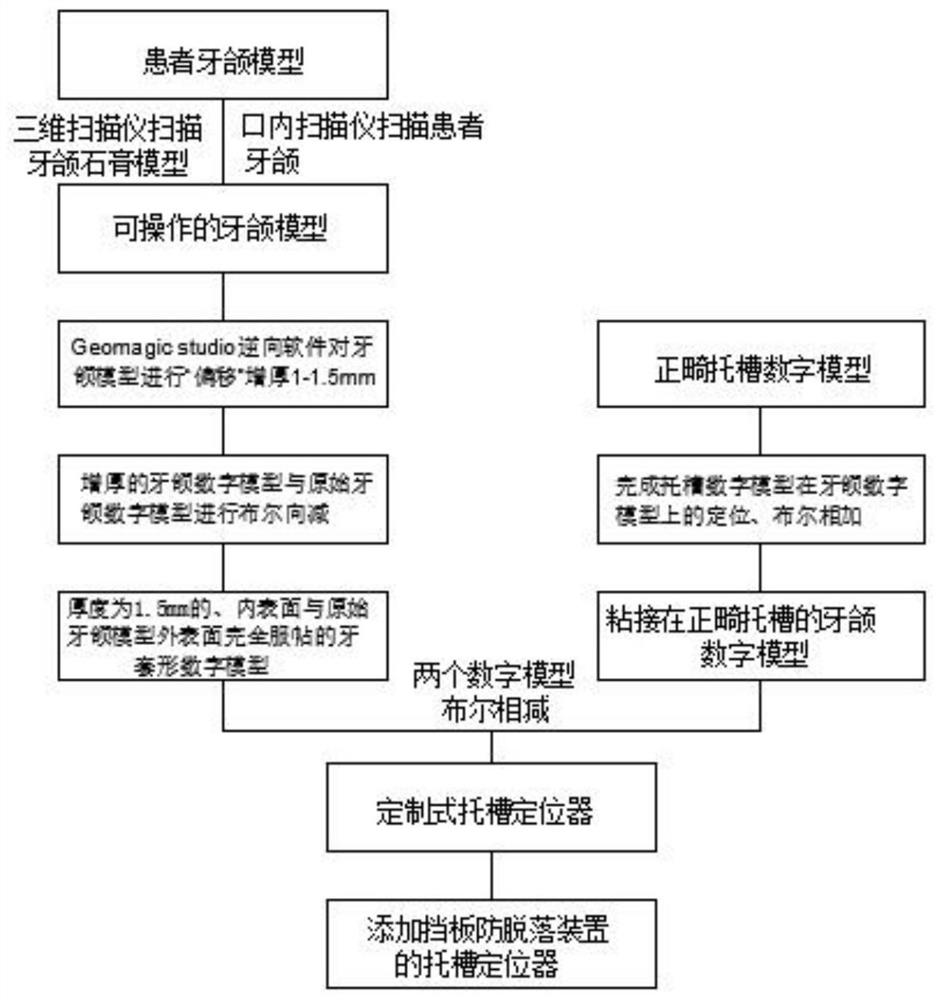

A custom-made bracket locator and its manufacturing method

ActiveCN108378940BReasonable designReduce the difficulty of clinical operationBracketsEntire mouthMechanical engineering

The invention discloses a custom-made bracket positioner and a manufacturing method thereof, including obtaining a patient's dental model, thickening the dental model, constructing a brace-shaped digital model, bonding the dental digital model to the orthodontic bracket, obtaining The custom-made bracket positioner and the added baffle anti-falling device have the beneficial effects of the invention: the placement and positioning of the brackets can be completed at one time, saving the doctor's chairside operation time; Locating this step that destroys the bonding strength ensures the effect of bracket bonding. The customized device makes the patient more comfortable during the bonding process of the bracket. The customized mechanism can meet the positioning of the full-mouth bracket or partial bracket. For bracket positioning of individual teeth, the bracket positioner with baffle plate can prevent the bracket from falling off before the bracket adhesive is completely dry, without the need for clinical retention by doctors, which improves efficiency.

Owner:保定翰阳科技有限公司

High-activity royal jelly freeze-dried powder and preparation method thereof

InactiveCN109549147AIncrease activityImprove utilizationFood shapingFood ingredient as mouthfeel improving agentMANNITOL/SORBITOLFreeze-drying

The invention discloses high-activity royal jelly freeze-dried powder and a preparation method thereof. The freeze-dried powder comprises the following components in parts by weight of 150-250 parts of fresh royal jelly, 1-3 parts of cream, 3-6 parts of lactobacillus plantarum, 2-9 parts of bacillus coagulans, 1-3 parts of an emulsifying agent, 2-4 parts of a co-emulsifier, 4-15 parts of xylitol,3-5 parts of mannitol and 1-4 parts of a lemon essence extract. The prepared freeze-dried powder is high in activity degree, contains components capable of promoting peristalsis of intestines and stomach, and can be effectively absorbed by human bodies, so that the freeze-dried powder can promote utilization degree of the components; and besides, the emulsifying components are added in the beginning of preparation, the molecular volume can be reduced, so that the freeze-dried powder can be well absorbed by human bodies, and the entire mouth feel is outstanding.

Owner:NANJING LAOSHAN PHARMA +1

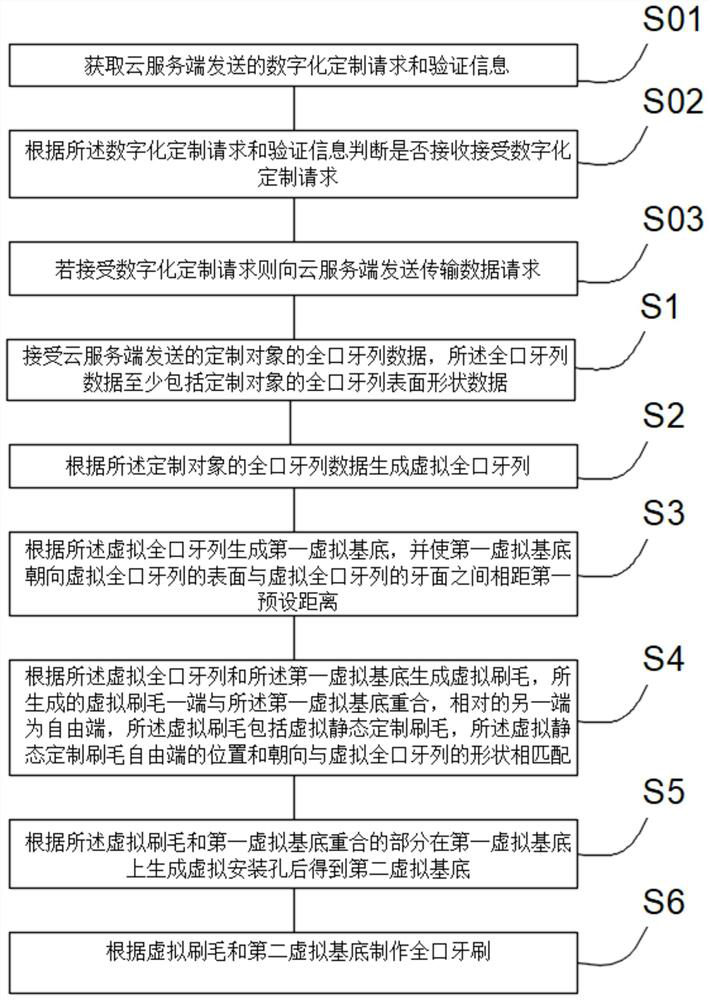

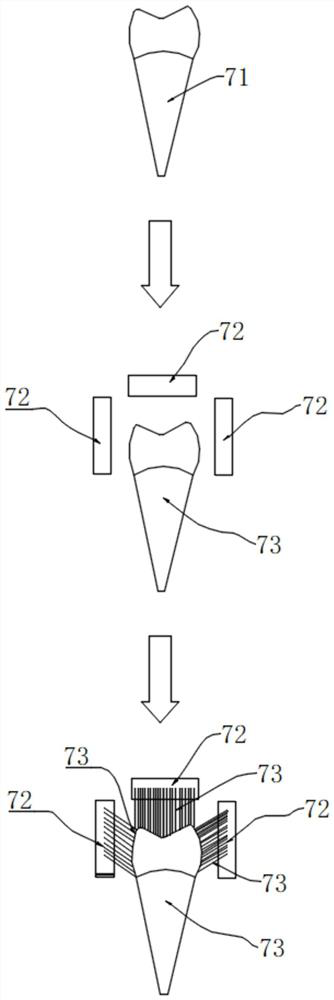

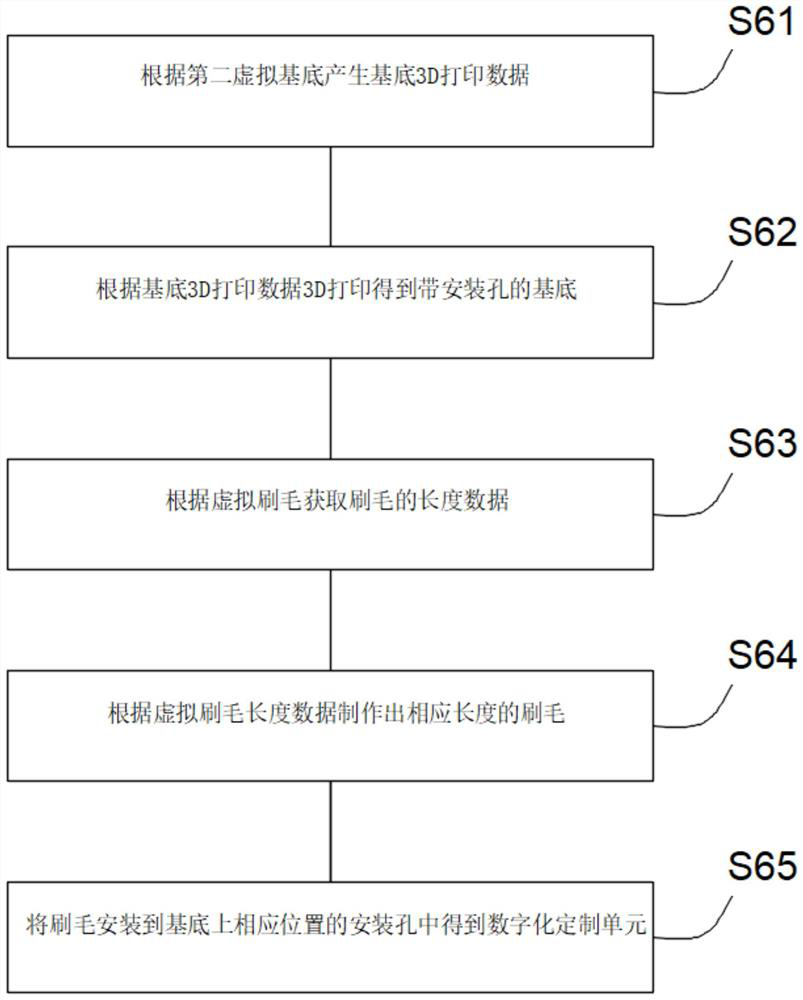

Full-mouth toothbrush digital cloud customization method and full-mouth toothbrush based on digital customization

PendingCN114159183ARealize distributed remote customizationClean enoughGeometric CADAdditive manufacturing apparatusComputer hardwareProgramming language

The invention belongs to the technical field of digital customization, and particularly relates to a full-mouth toothbrush digital cloud customization method and a full-mouth toothbrush based on digital customization. The full-mouth toothbrush digital cloud customization method comprises the following steps: acquiring a digital customization request and verification information sent by a cloud server; receiving full-mouth dentition data of the customized object sent by the cloud server, wherein the full-mouth dentition data at least comprises full-mouth dentition surface shape data of the customized object; generating a virtual full-mouth dentition according to the full-mouth dentition data of the customized object; generating a first virtual substrate according to the virtual full-mouth dentition; virtual bristles are generated; obtaining a second virtual substrate according to the overlapped part of the virtual bristles and the first virtual substrate; and manufacturing the full-mouth toothbrush. The invention discloses a full-mouth toothbrush based on digital cloud customization. The full-mouth toothbrush comprises a cleaning body, a driving device and a digital customization unit, the oral cavity cleaning effect can be remarkably improved, the cleaning time is shortened, and the complexity of user operation is reduced.

Owner:成都高新宸西科技有限公司

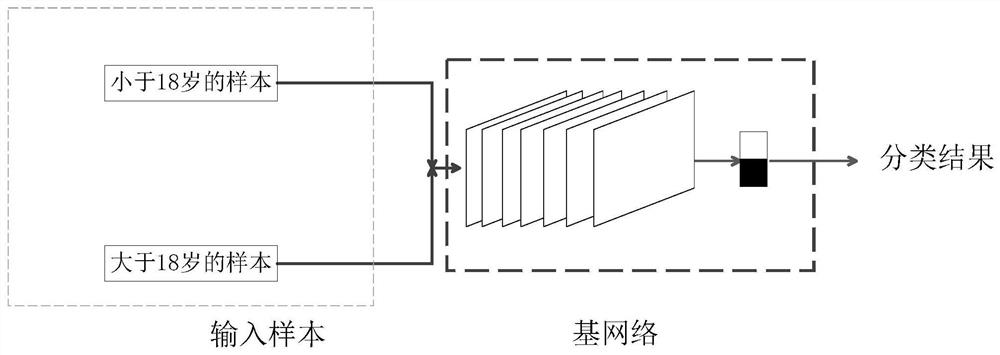

System and method for establishing age evaluation model based on deep learning technology

PendingCN112086198ARealize automated evaluationAvoid missingMedical simulationHealth-index calculationData setAlgorithm

The invention discloses a system and method for establishing an age evaluation model based on a deep learning technology. The method comprises the steps of photographing a full-mouth curved-surface fault film of Chinese Han population in the northwest, dividing a curved-surface fault film data set into a training set, a verification set and a test set according to the proportion of 8:1:1, inputting the training set into an EfficitNet-B5 network, carrying out the training of a classifier, and finally, establishing an automatic classification model of 18 years old or not through the performanceof the classifier on the test set. A traditional deep learning model is simplified, a label directly related to an output value is added to an image, a neural network model related to the input imageand the output value is established through a computer algorithm, and then automatic evaluation of the image is achieved; and the whole curved surface fault film is selected as the input image of theneural network instead of being limited to teeth in a certain area, the most comprehensive tooth information is provided for a computer to explore the correlation between the tooth structure and the age, and missing of other structural new information with prompt significance is avoided.

Owner:西安交通大学口腔医院 +1

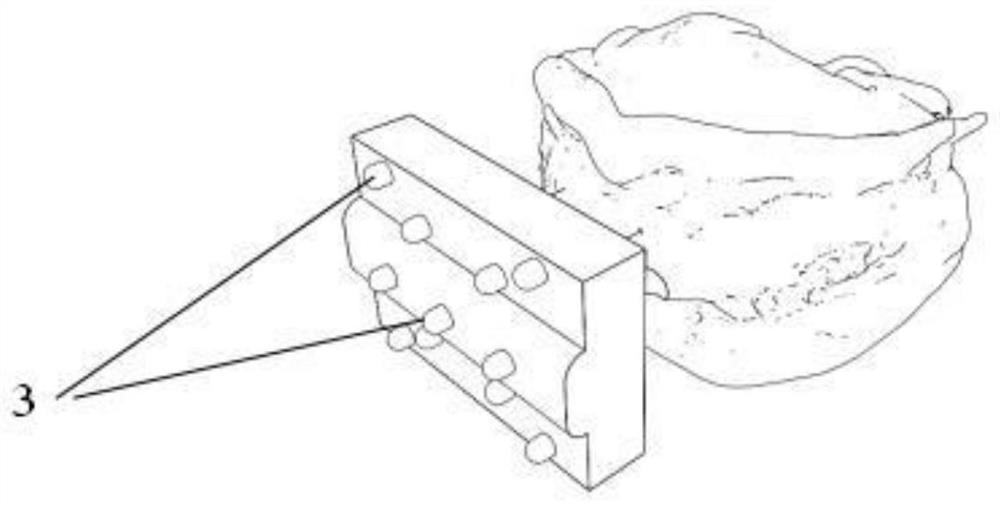

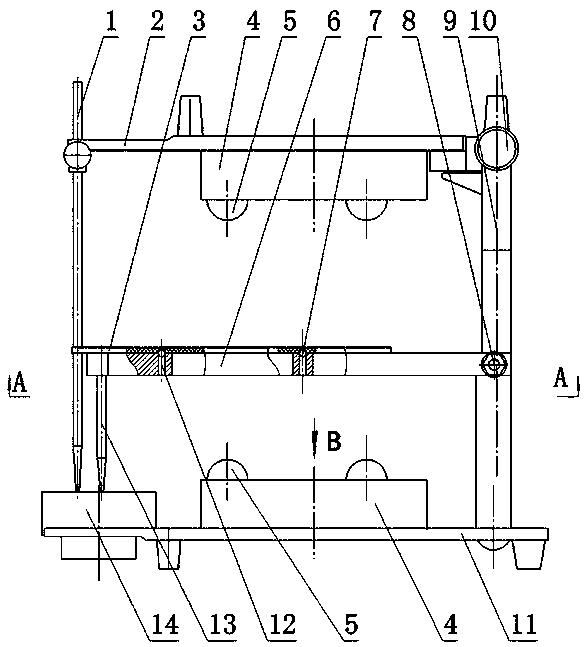

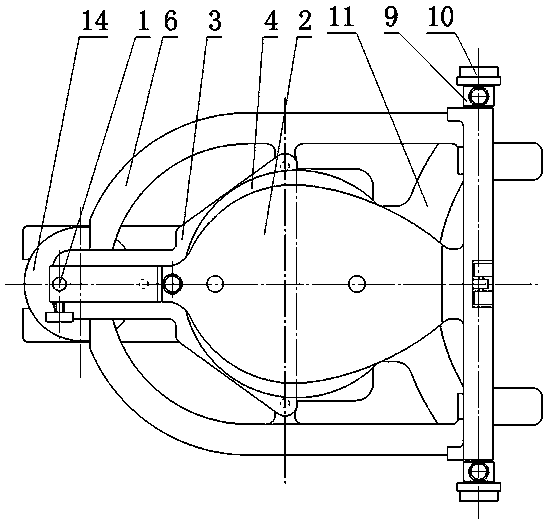

A method for quickly making digital implant guide plate and its special positioning jaw frame

The invention discloses a method for fast making a digital implantation guide plate and a special positioning jaw frame for implementing the method. The method for fast making the digital implantationguide plate comprises the following steps of wearing a barium-containing complete denture or a barium-containing partial denture and a positioning tray in the mouth of a patient, and acquiring three-dimensional oral image data of soft and hard tissue in the mouth of the patient through an oral CBCT or three-dimensional CT appliance; engaging a plaster cast with the positioning tray on the positioning jaw frame, enabling the plaster cast to be matched with a clamping apparatus of a five-axis cutting appliance, taking down the plaster cast, and making an implantation guide plate blank on the plaster cast through a compression molding or plastic coating method; importing the three-dimensional oral image data into an implantation guide plate designing device, carrying out coordinate positioning and coordinate matching, and designing an implantation position, direction and depth; importing three-dimensional position data of an implant designed by the implantation guide plate designing device into a control system of the five-axis cutting appliance, and making an implantation positioning guide hole according to the implantation position designed by the implantation guide plate designingdevice, so as to obtain the implantation guide plate.

Owner:张辉

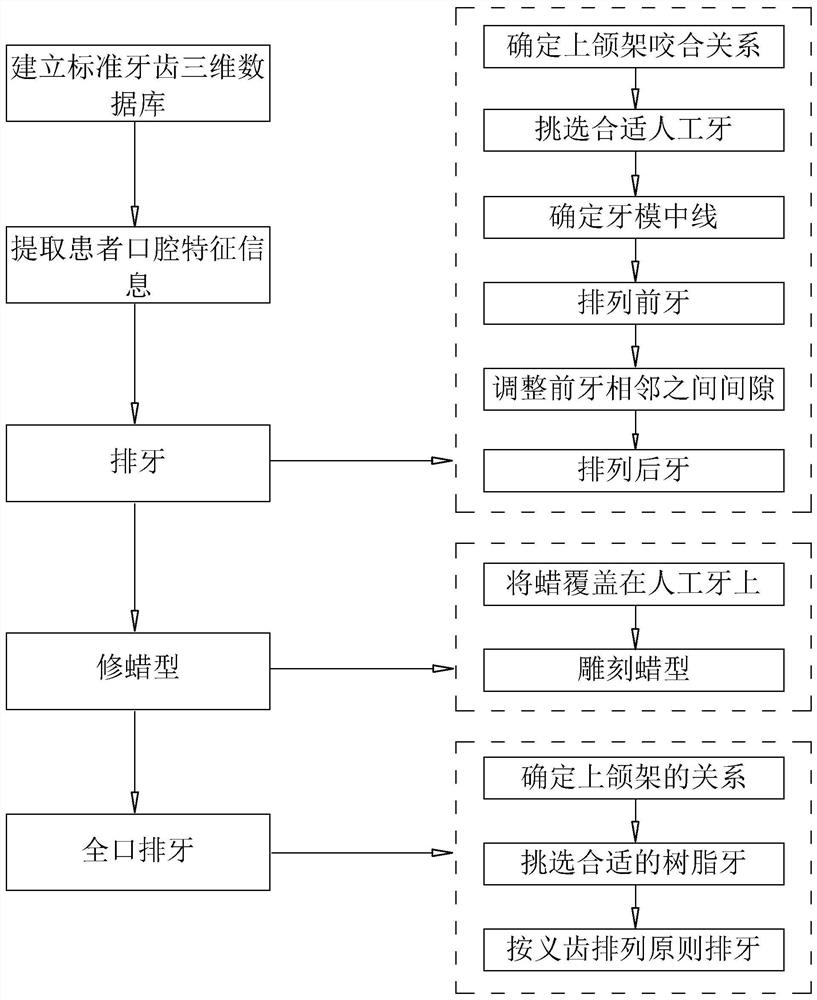

Tooth arrangement process for movable stent manufacturing

The application relates to the field of dentures, in particular to a tooth arrangement process for movable stent manufacturing. The tooth arrangement process comprises the following steps: S1, establishing a tooth feature 3D database of standard teeth; S2, extracting oral cavity feature information of a patient; S3, arranging teeth: a, determining an occlusion relationship of an upper jaw frame; b, selecting proper artificial teeth; c, determining the center line of a dental cast ; d, arranging anterior teeth; e, adjusting adjacent the gap of every two adjacent teeth in the same row of the anterior teeth of the upper jaw and the lower jaw, and automatically generating a posterior tooth arrangement line according to the arranged anterior teeth; and f, arranging posterior teeth; S4, repairing a wax pattern: a, making wax covers a region, between the artificial teeth and mucous membrane transition , on the cast; and b, carving the wax pattern; and S5, arranging complete teeth: a, determining the relationship of the upper jaw frame; b, selecting proper resin teeth; and c, arranging the teeth on the principle of complete denture arrangement. The tooth arrangement process has the effect of improving the tooth arrangement attractiveness and individuation degree of the complete dentures.

Owner:北京圣爱吉友和义齿制作有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com