Patents

Literature

31 results about "Full dentures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full dentures are an entire set of artificial teeth which are used to replace a person's natural teeth. Reasons for needing dentures vary greatly and can include tooth decay or an injury that resulted in a loss of teeth.

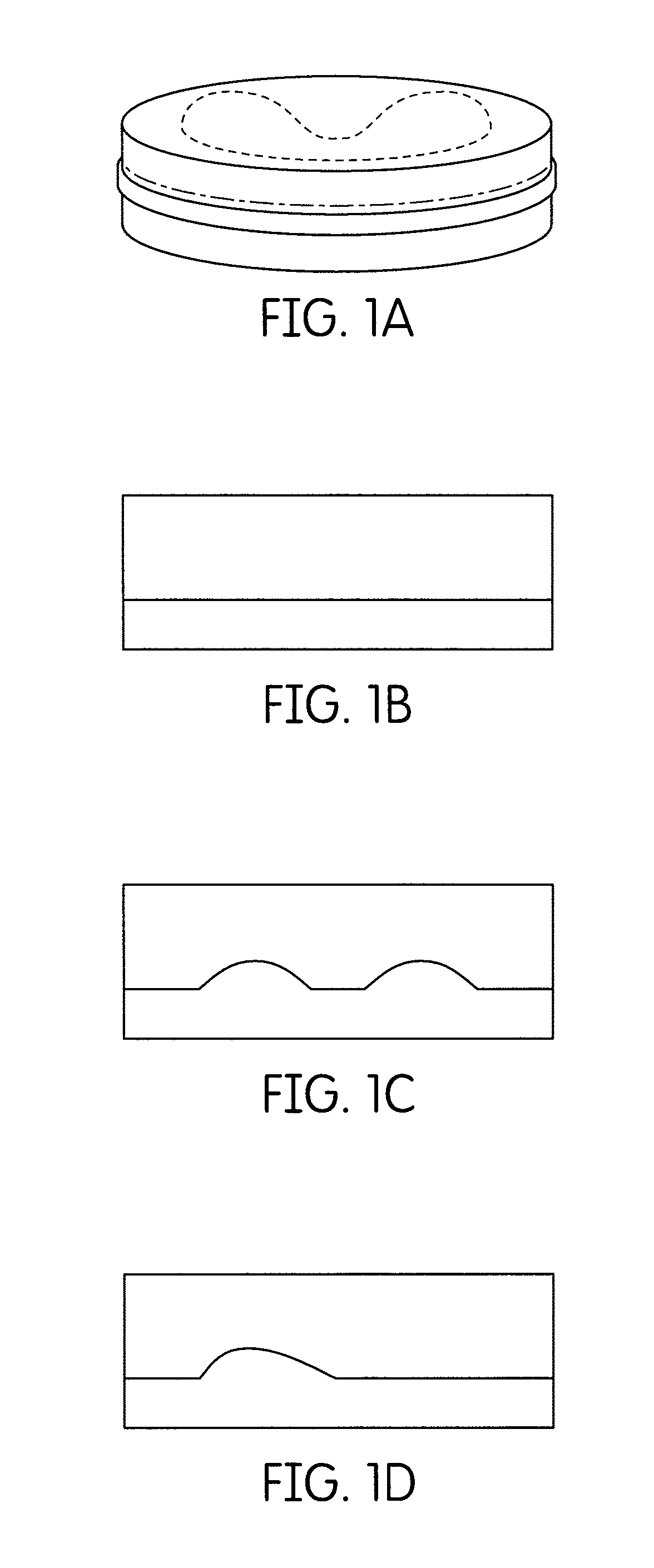

Three-dimensional fabricating material systems and methods for producing layered dental products

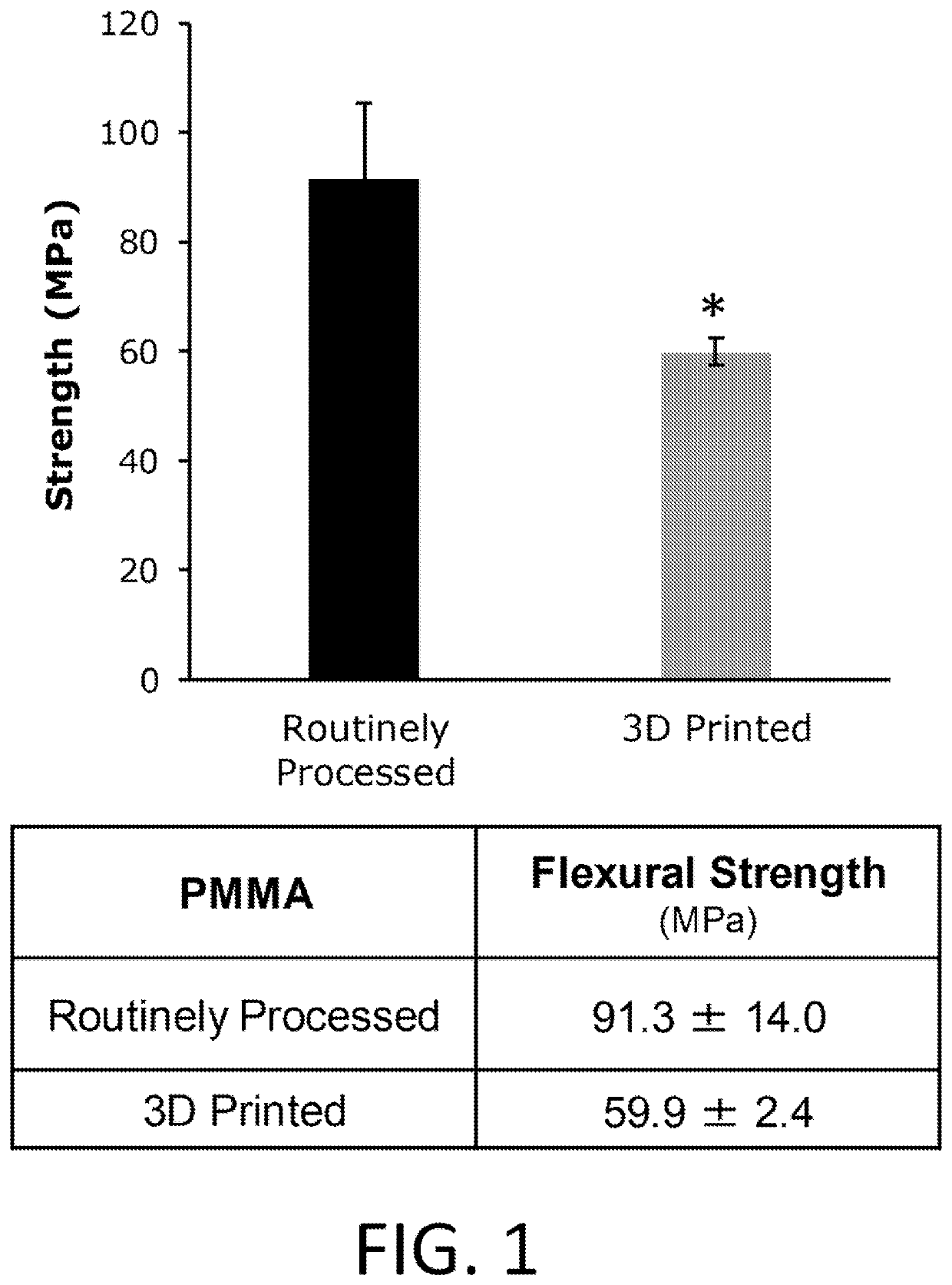

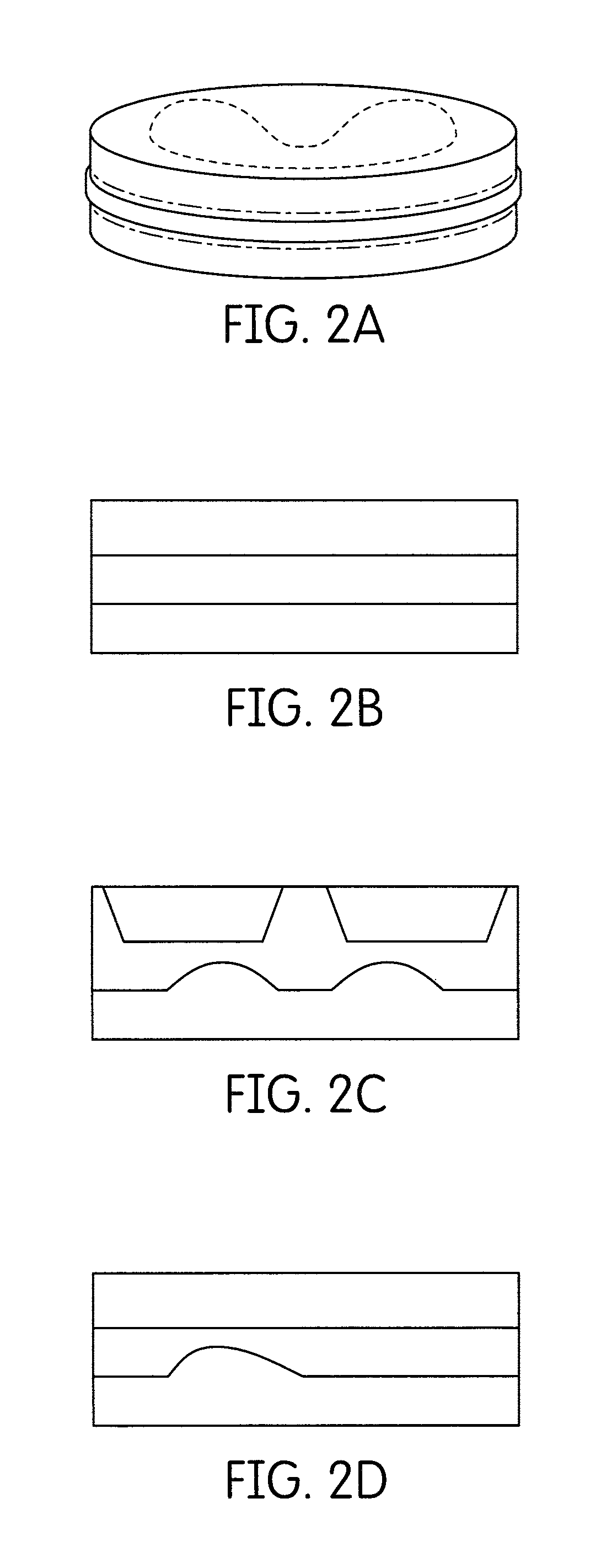

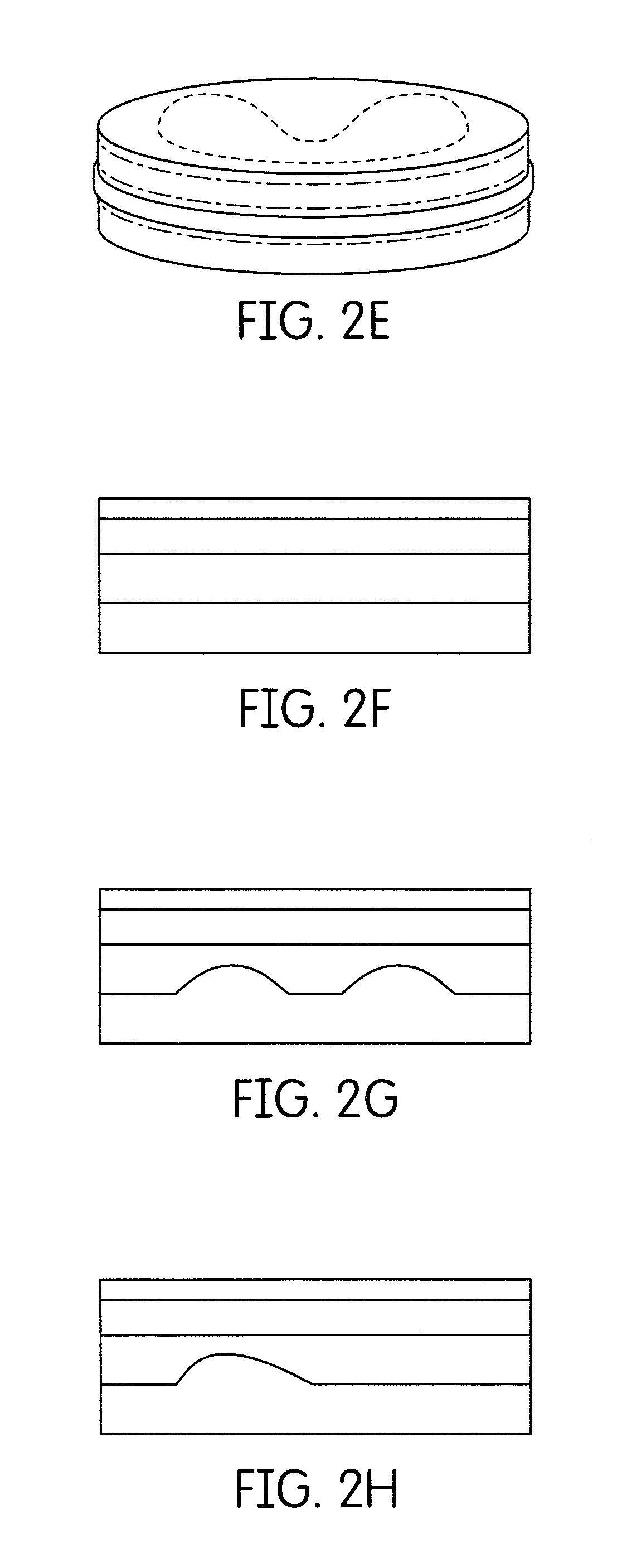

ActiveUS20170360534A1Highly shapeHigh wear resistanceAdditive manufacturing apparatusImpression capsFull denturesDental Product

This invention designs and builds multiple layers (two layers or more) of various dental devices, specifically denture base or denture, where printed multiple layered denture base with teeth cavities to receive artificial denture tooth materials to form final dental devices, such as partial and full dentures. It can also print denture teeth. This invention also designs and prints multiple layers (two layers or more) of denture base with artificial denture teeth to form final dental devices, such as partial and full dentures. A method for manufacturing a layered denture is provided. The invention provides a multiple layered denture base materials for printing a denture base. The invention also provides a multiple layered denture tooth materials for printing artificial denture teeth. Highly shape adjustable or shape memory polymer layer(s) may be used in these multiple layered denture base forms. Different layer of material has different mechanical and physical properties to meet different need, which provide added benefits to the patients, dental professional and dental laboratory.

Owner:DENTSPLY SIRONA INC

Hydrogel sheets and shapes for oral care

InactiveUS20070122362A1Enhanced inhibitory effectReduce releaseCosmetic preparationsToilet preparationsCross-linkBeam energy

A hydrogel for use in oral care. The hydrogel is ion beam cross-linked, the hydrogel is adapted to be disposed in the oral cavity and may be adapted to provide a denture fixative or may be loaded with a whitening agent for use in whitening one or more teeth and disposed on or adjacent one or more teeth and the whitening agent is slow-released to whiten the one or more teeth. Other loading materials may include materials for treatment of alveolitis or malodor, inter alia. The present invention is a new hydrophilic oral and dental cohesive hydrogel sheet designed to securely grip and cushion prosthetic devices in the human mouth with the further ability to slow release antimicrobial or other orally desirable agents. Additionally, the invention also provides a method of making an orally cohesive device that: 1) is easily adapted and applied to a removable dental prosthesis; 2) bonds well to alveolar ridge / palatal mucosa and denture acrylic materials; and 3) releases cleanly, with no tacky or thixotropic residue when the prosthesis is removed. The cohesive hydrogel gel device is a hydrogel-forming polymer mixed with water, optionally surrounding an internal scrim, and uses an electron-beam energy source to cause cross-linking. The method does not need any chemical additive to affect the cross-linking. Furthermore the beam energy can be adjusted to optimize the cohesive properties of either side of the device, as well as to compensate for addition of orally active agents, if any are chosen. The hydrogel sheets are pre-cut to fit most sizes of maxillary and mandibular full denture prostheses, but can be easily trimmed with a scissors by the end user for the ideal custom fit of any full or partial denture, in either arch.

Owner:GINIGER MARTIN S +1

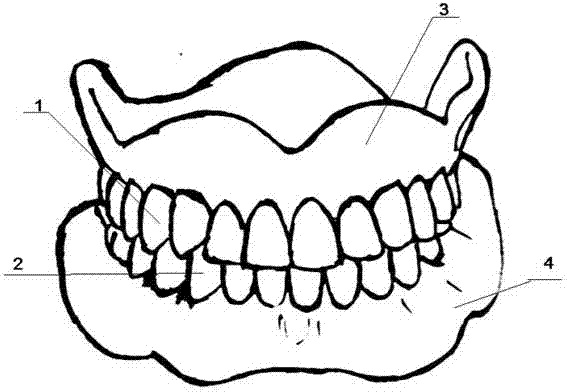

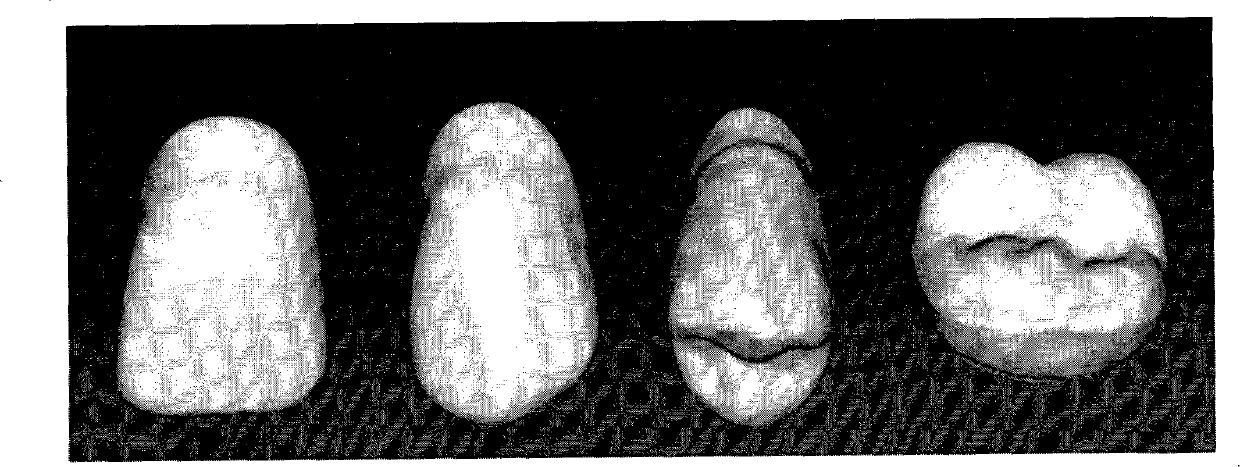

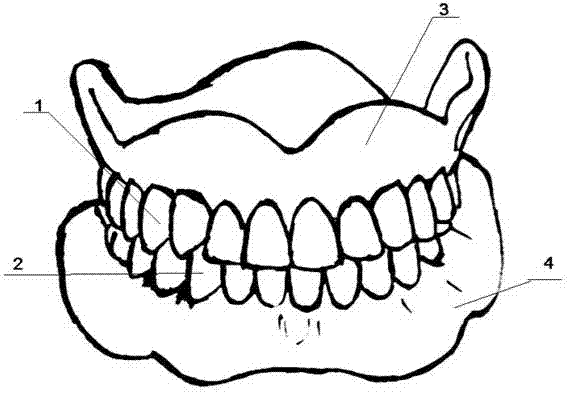

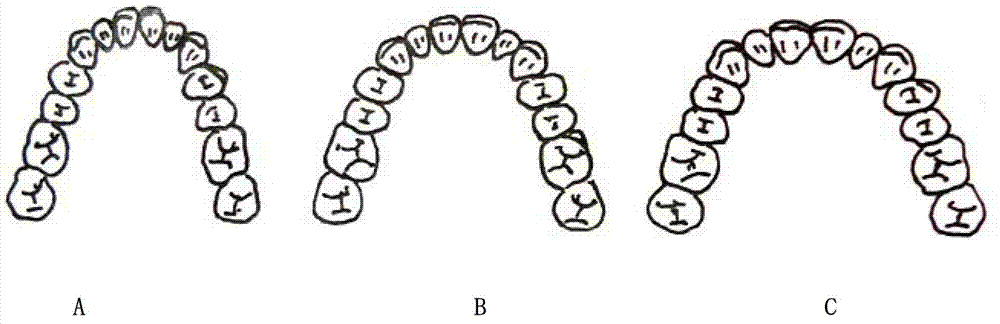

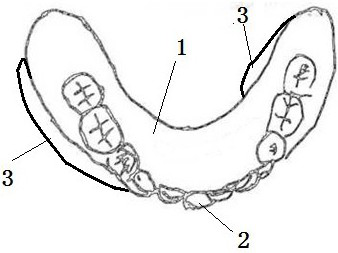

Complete dentition full denture finished product resin tooth and preparation method thereof

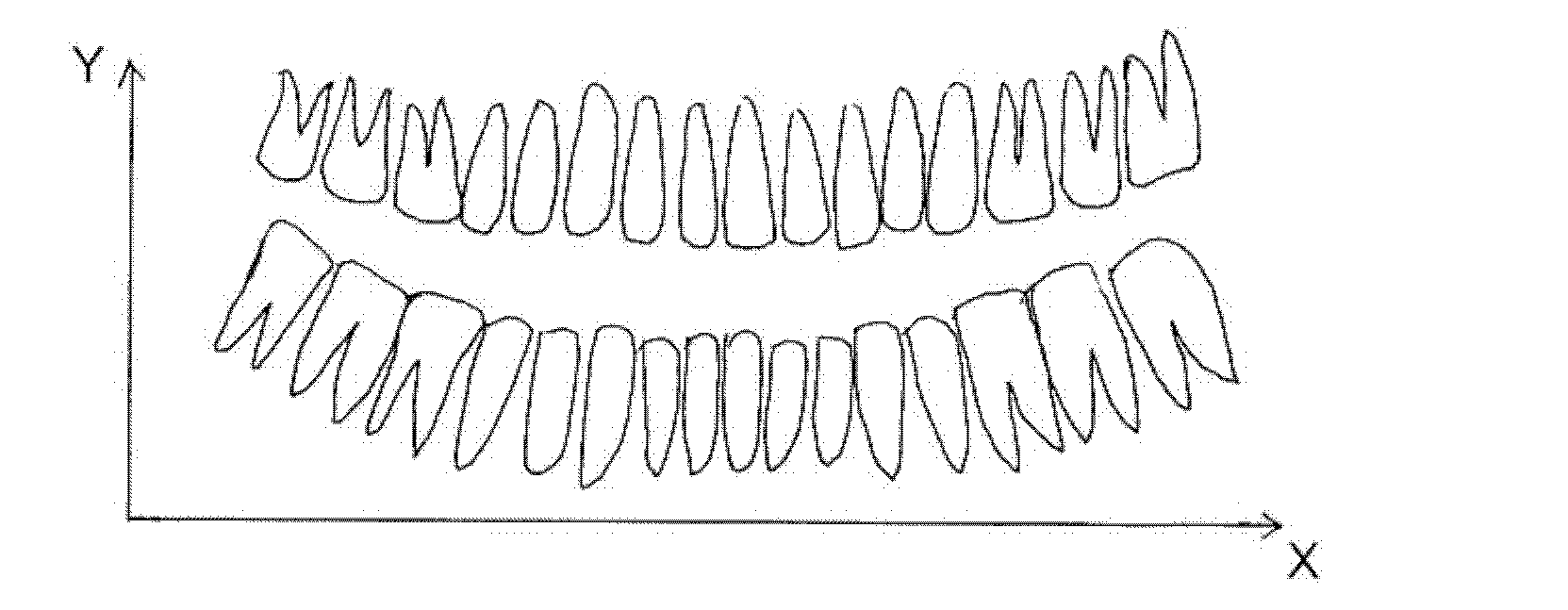

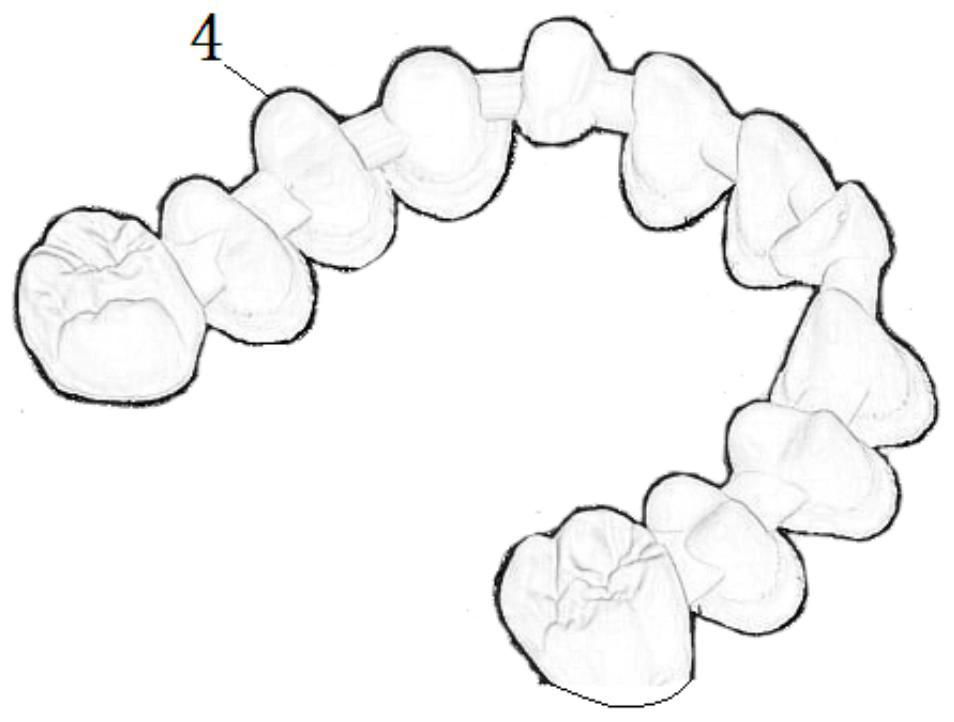

ActiveCN102805670AFast centric biteMinimize the difference in tooth row levelImpression capsArtificial teethOcclusal AdjustmentLower dentition

The invention relates to a complete dentition full denture finished product resin tooth, which comprises an upper denture, a lower denture, an upper dentition and a lower dentition, wherein the upper dentition is fixedly connected with the upper denture; the lower dentition is fixedly connected with the lower denture; and the upper dentition and the lower dentition are engaged with each other and are integral dentitions respectively. According to the complete dentition full denture finished product resin tooth, during arrangement of teeth and wearing, the upper dentition and the lower dentition are quickly and centrally engaged, so that the arrangement efficiency of the teeth is increased, the difference in tooth arrangement level of technicians is reduced, and the aims of guaranteeing wide close contact, reducing the clinical occlusal adjustment time and shortening the treatment time of patients are fulfilled. Each tooth is arranged according to an inclination angle in the tooth arrangement standard and positional relation of each dental cusp and an occlusal plane; the upper dentition and the lower dentition are matched teeth and are centrally engaged without error basically; the chair-side occlusal adjustment time of the full denture is reduced; the treatment time is shortened; and the comfort and the satisfaction of patients are improved.

Owner:SHANDONG UNIV

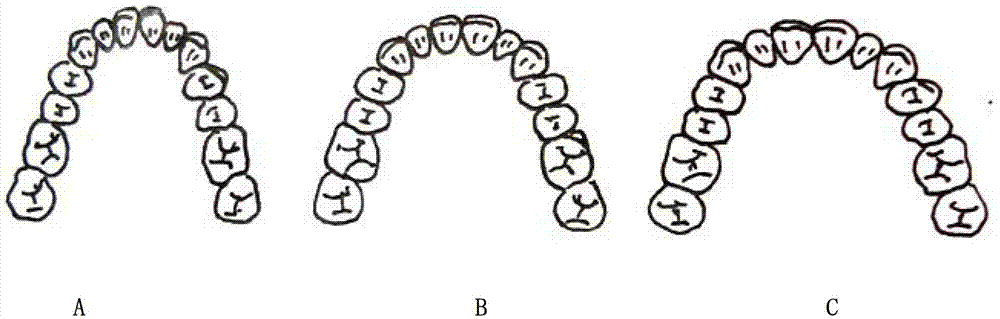

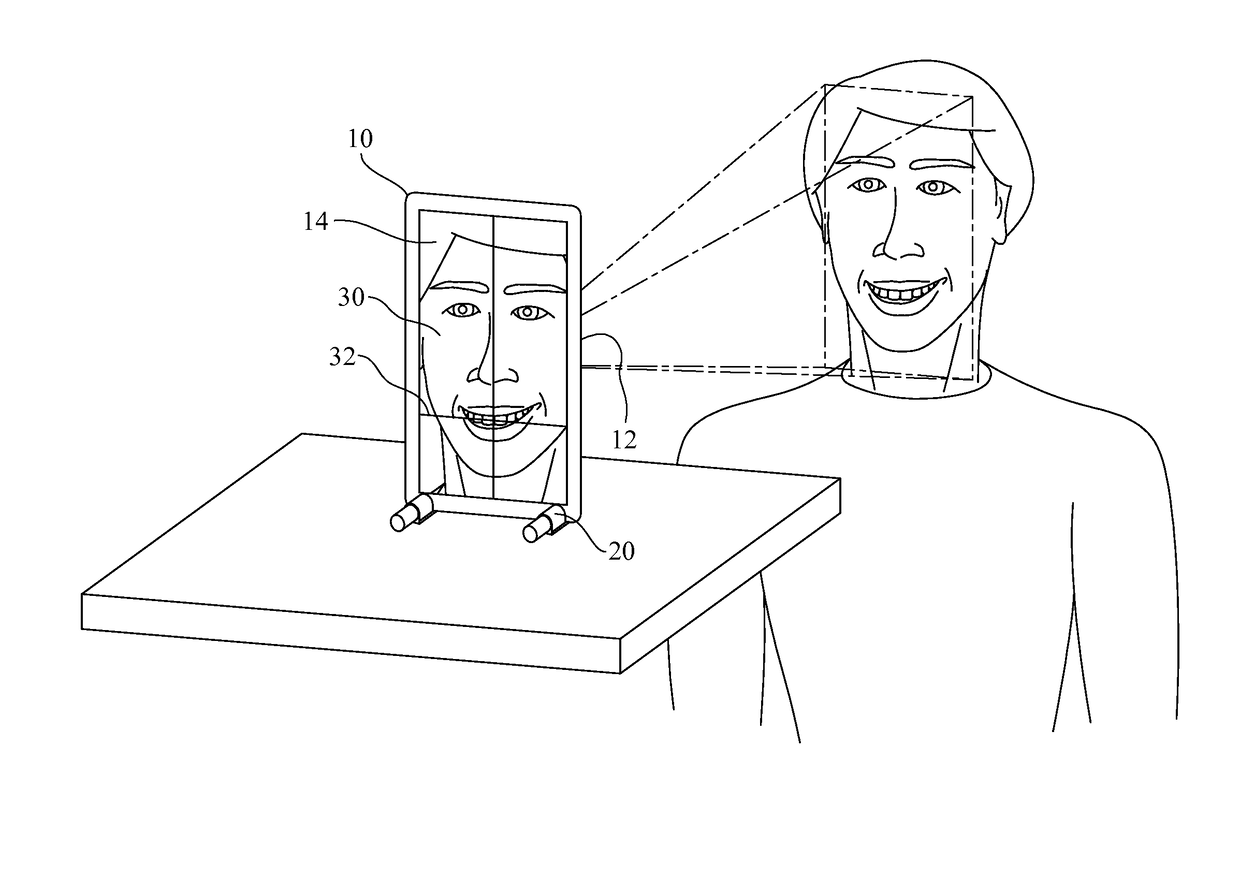

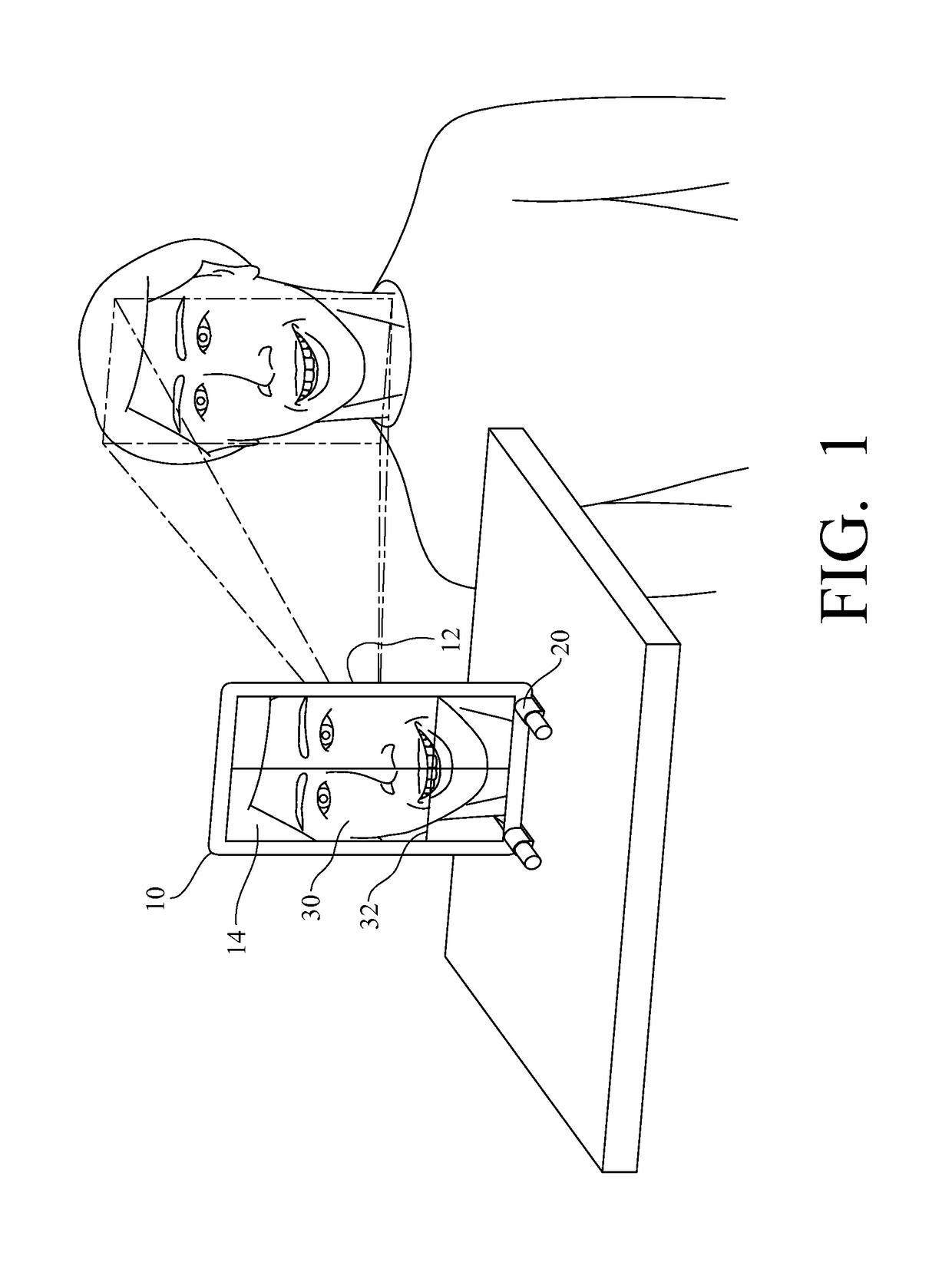

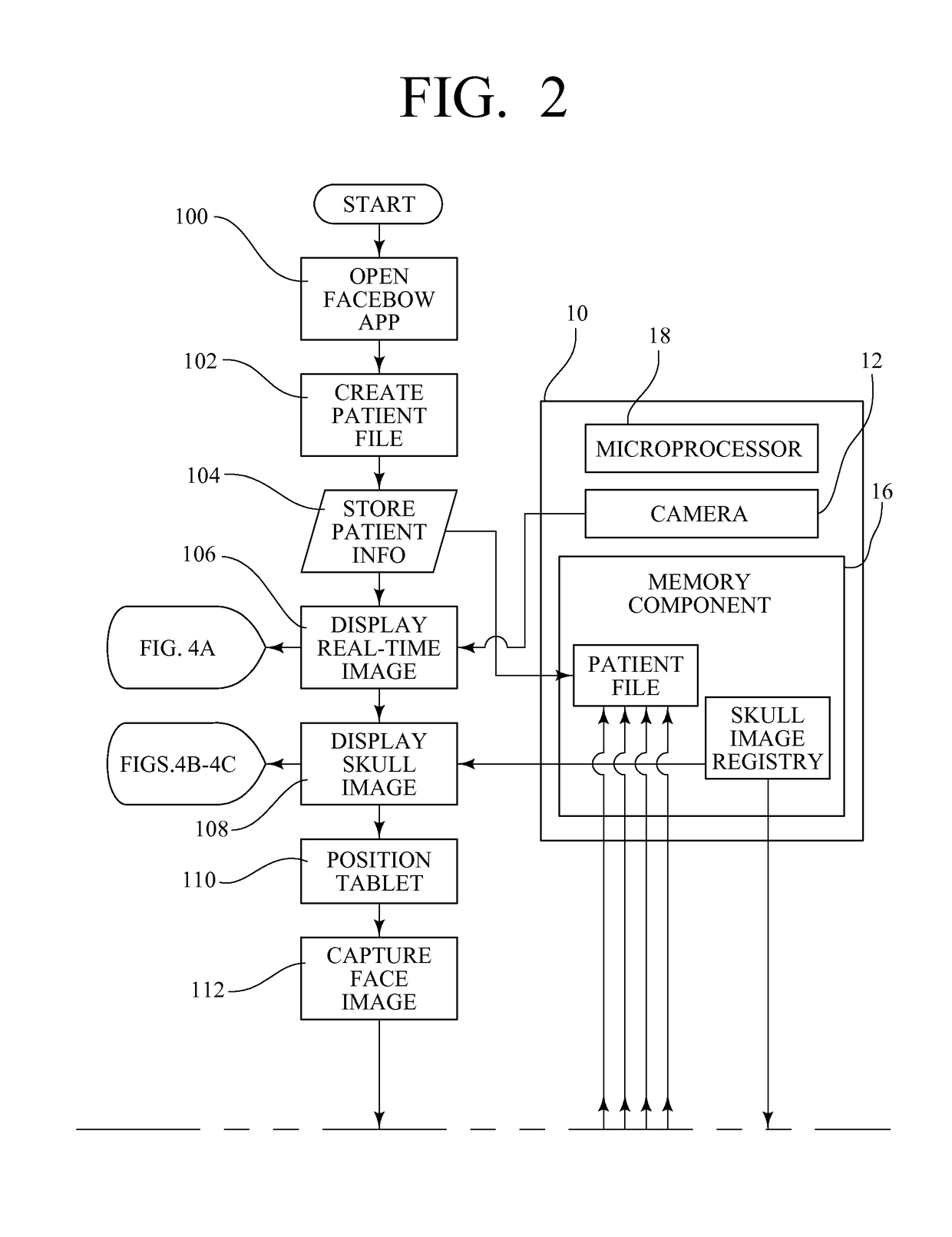

Method and system for recording characteristics of the occlusal arch of a patient using a portable computing device

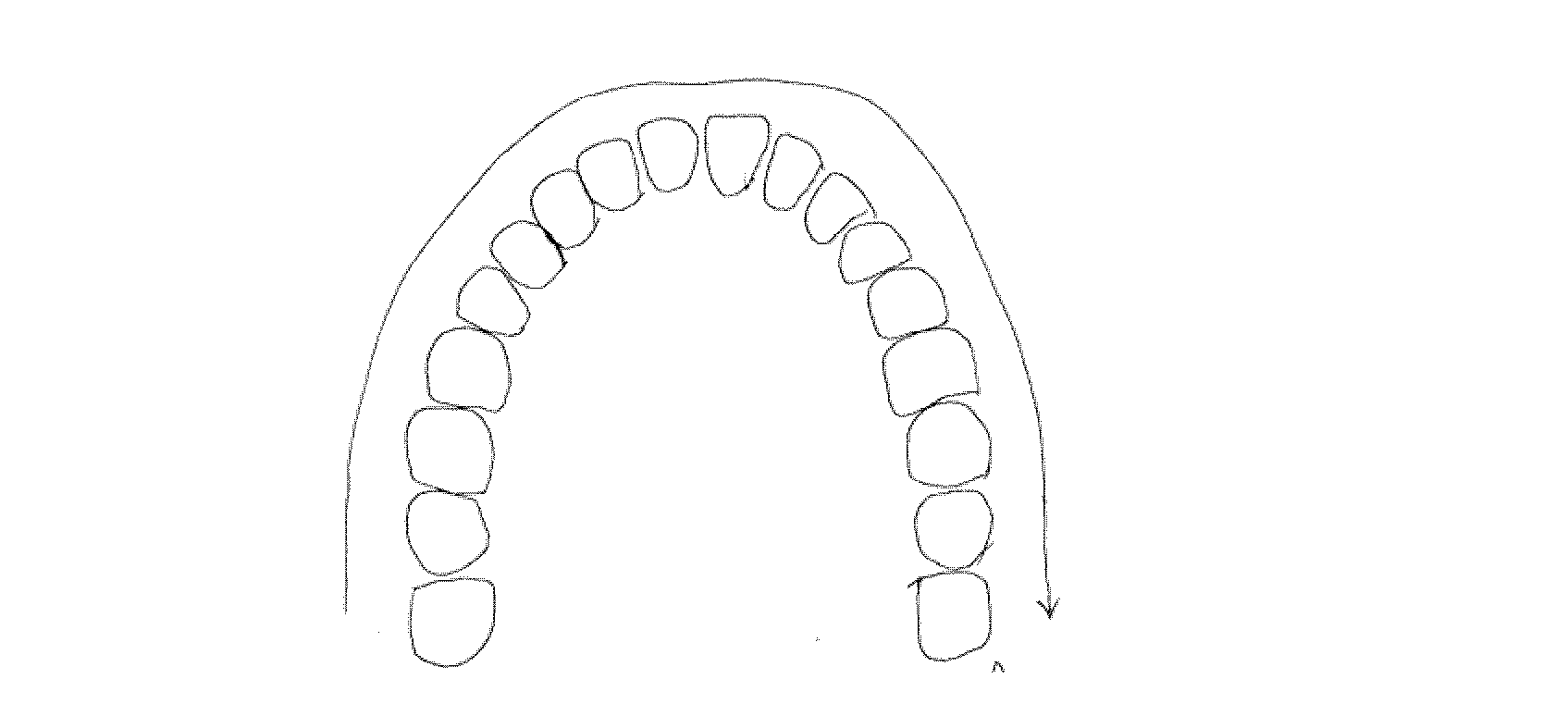

An exemplary virtual facebow system comprises a software program which is run on a tablet or other portable computing device with a microprocessor, an internal memory component, an image capture device, and a display screen. The virtual facebow system is used to record characteristics of the occlusal arch of a patient including, but not limited to, the midline of the patient's face, the steepness and cant of the occlusal arch, as well as a record of which maxillary (upper) teeth make contact with which mandibular (lower) teeth. The recorded characteristics are then used to replicate the alignment of the patient's occlusal arch with the maxillary cast in a lab stand, and the maxillary cast can then be moved to an articulator for the production of customized dental prosthetics for the patient including, but not limited to, restorations and partial or full dentures.

Owner:WHIP MIX CORP

Data processing method of panoramagram generated by dental CBCT (cone beam computed tomography)

The invention discloses a data processing method of a panoramagram generated by a dental CBCT (cone beam computed tomography), comprising the steps of obtaining three-dimensional image data of full denture from oral digital tomography equipment; initializing a dental arch curve as a starting point of contraction or expansion; taking the contracted or extended curve as a dental arch curve used when expanding the panoramagram; obtaining a coordinate of each point on the curve, computing the normal direction of each point on the curve and setting the distance of the curve contracting inwards or expanding outwards; moving each point on the curve in the outer normal direction or inner normal direction of the point with a distance d; computing the distance of one point on a new curve to all points on the original curve; according to a distance threshold, performing screening; generating a final curve by all non-abandoned points on the new curve; and splicing multiple columns of data obtained by the final curve together in sequence to generate a corresponding panoramagram.

Owner:LARGEV INSTR CORP LTD

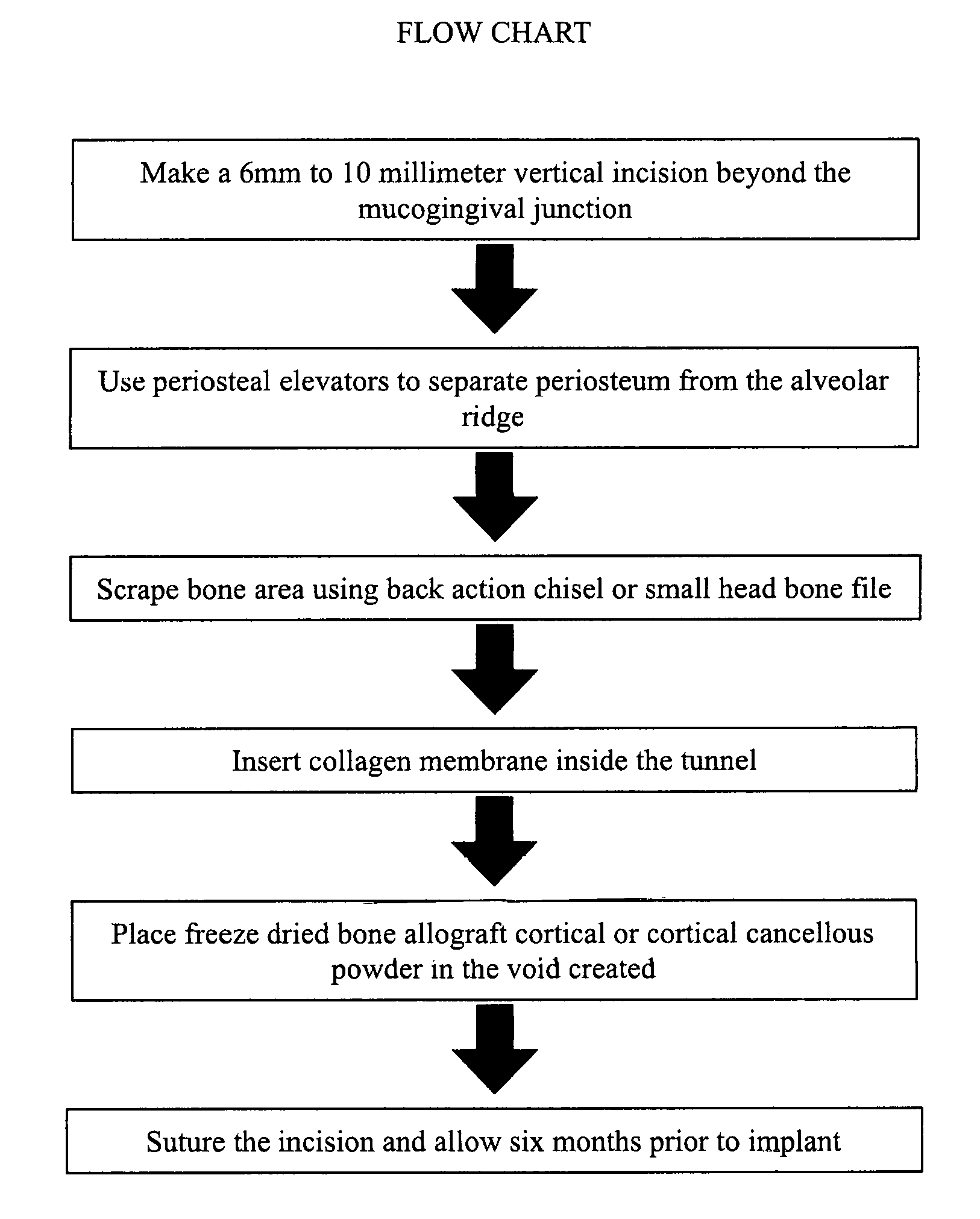

Periodontal Subperiosteal Tunnel Bone Graft Technique

Tunnel bone grafting according to the proposed method can be used when an individual has a facial bone defect due to periodontal disease, cleft palate or trauma. The proposed method can be utilized for implant placement, it reduces wrinkles and supports facial muscle in order to make the individual look younger. The method can also be used to create a thicker alveolar ridge in order to stabilize full dentures or partial dentures. Its advantages over conventional guided bone regeneration techniques is that the proposed method is minimally invasive and lessens trauma to patients, prevents soft tissue opening, and reduces surgery time. Specifically, it minimizes the incision size and thus reduces trauma to the patient. Further, this reduces the risk of complications, including excessive bleeding, due to the minimization of the incision size. There is also considerable reduction in post surgery swelling using the proposed method as opposed to conventional techniques.

Owner:JEONG SUNG JOO

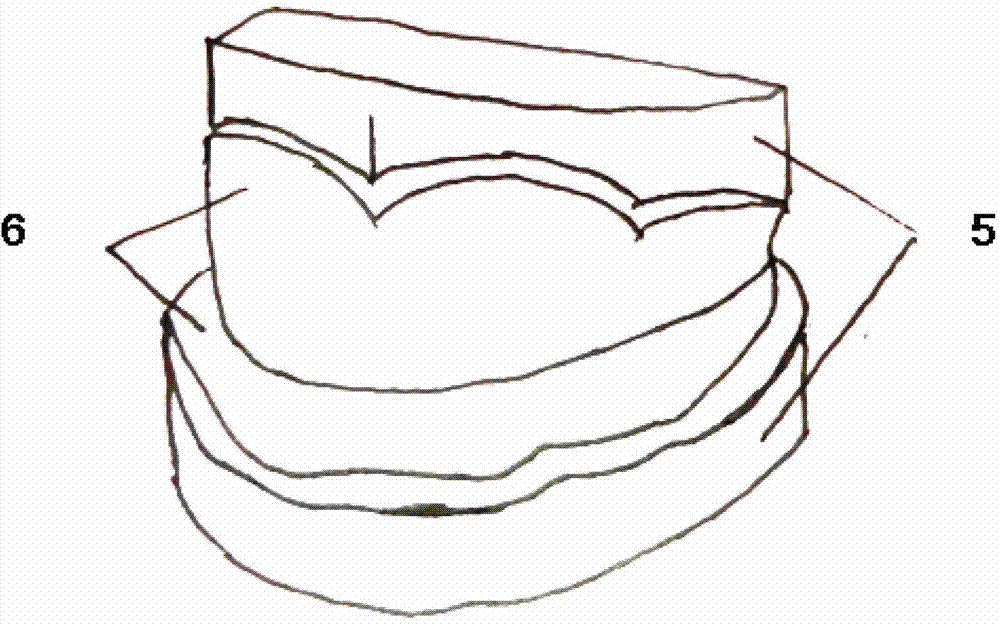

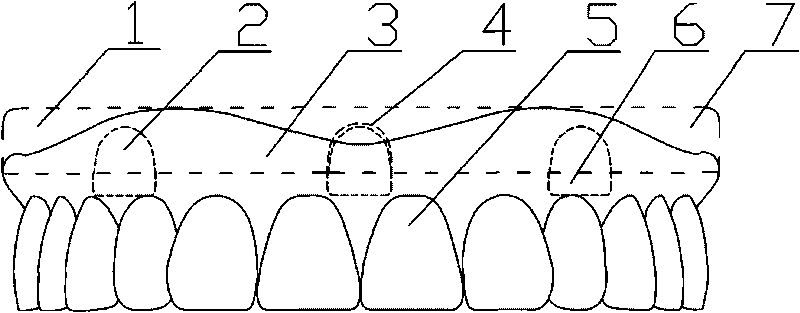

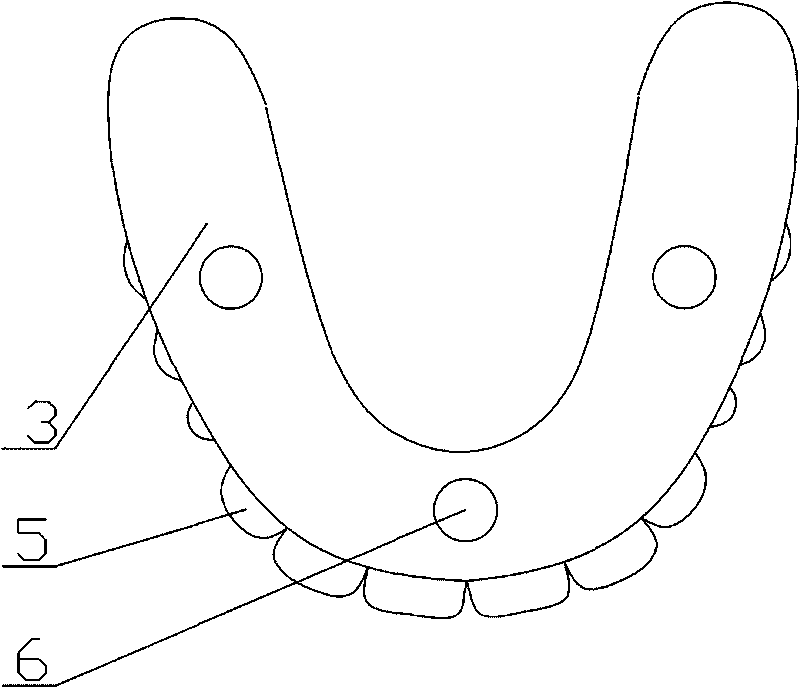

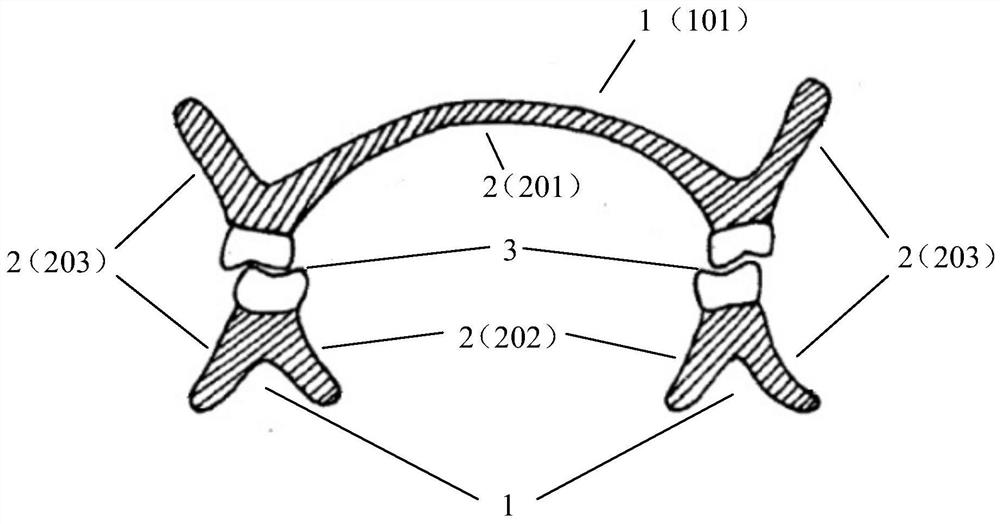

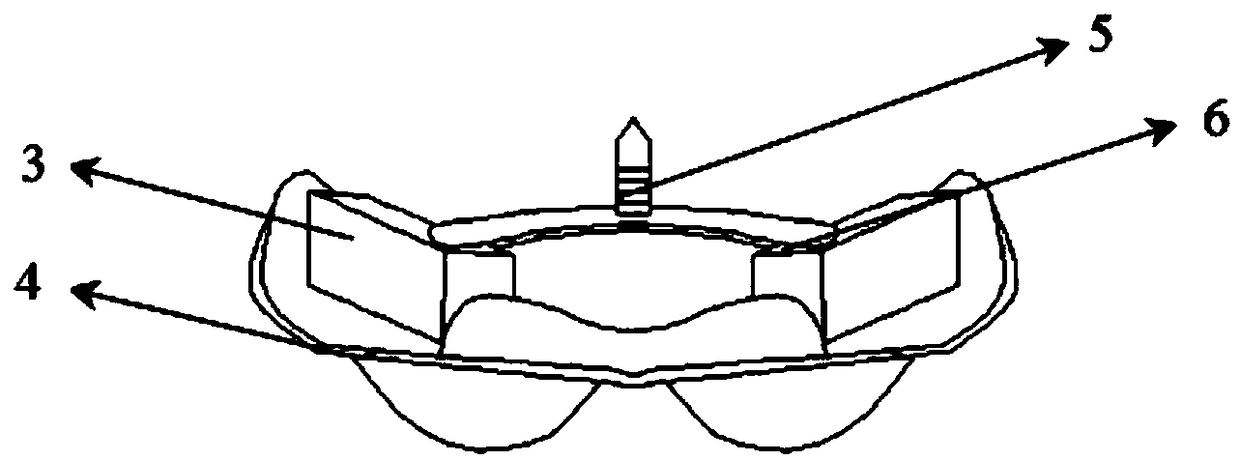

Full denture base manufacturing method

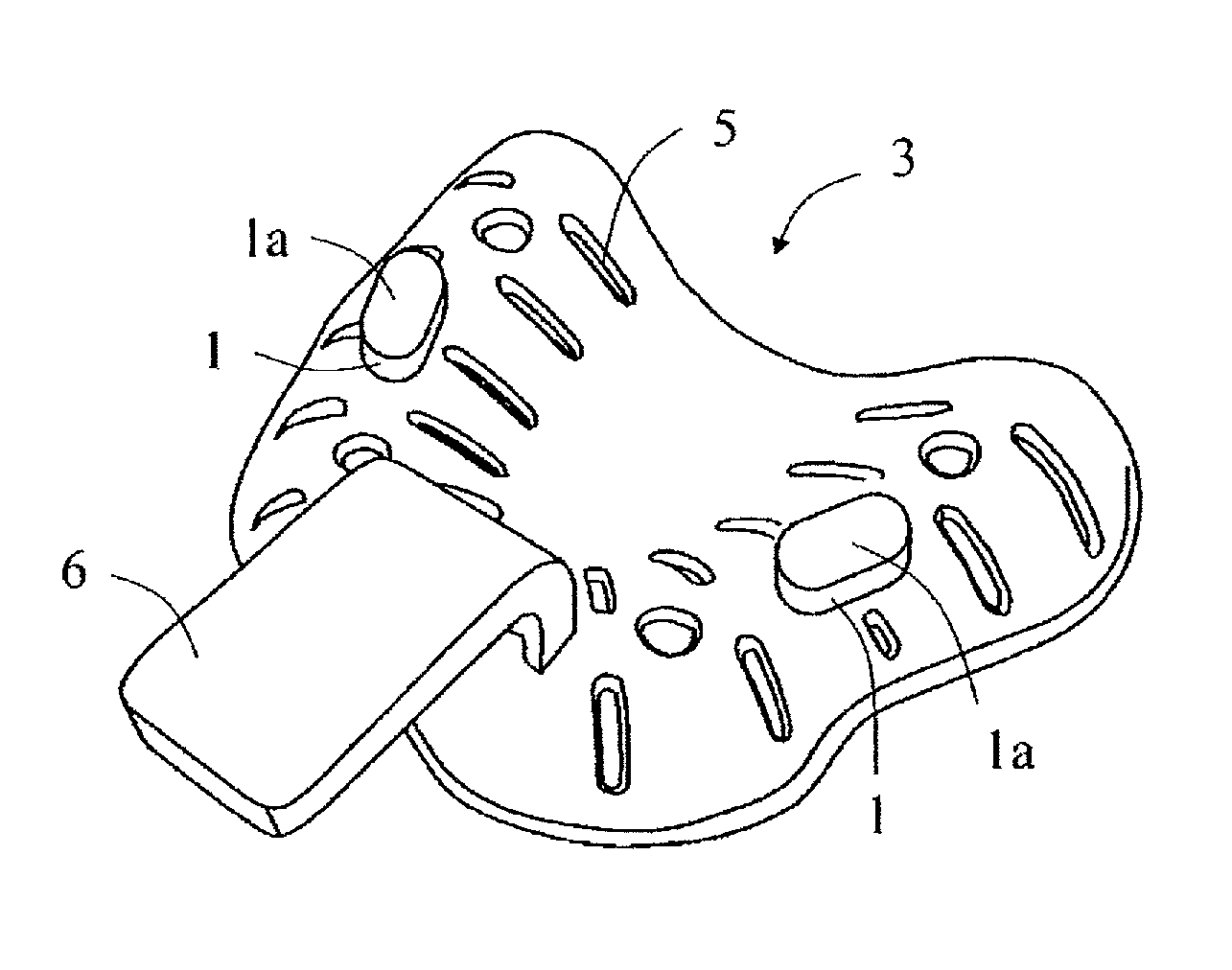

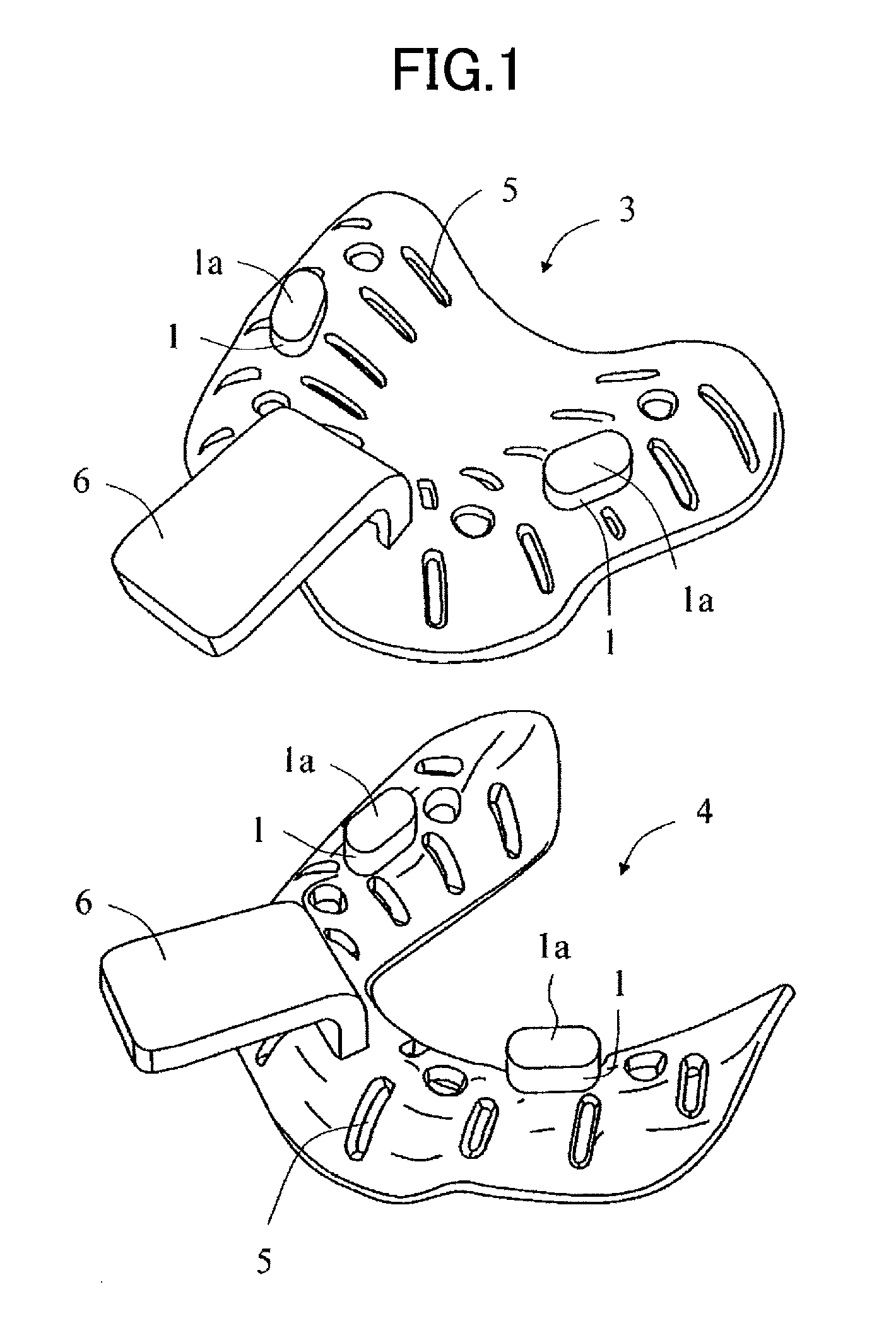

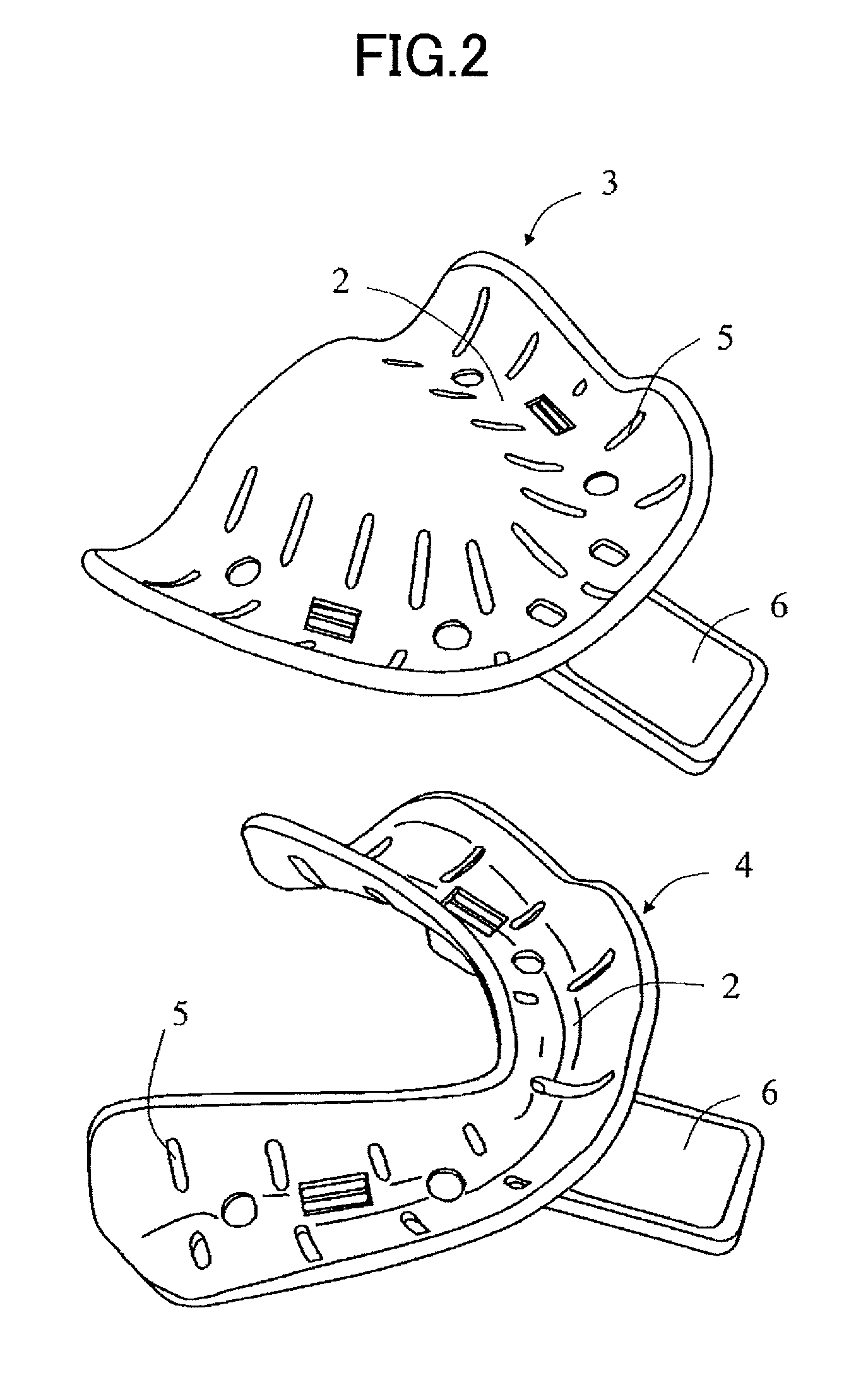

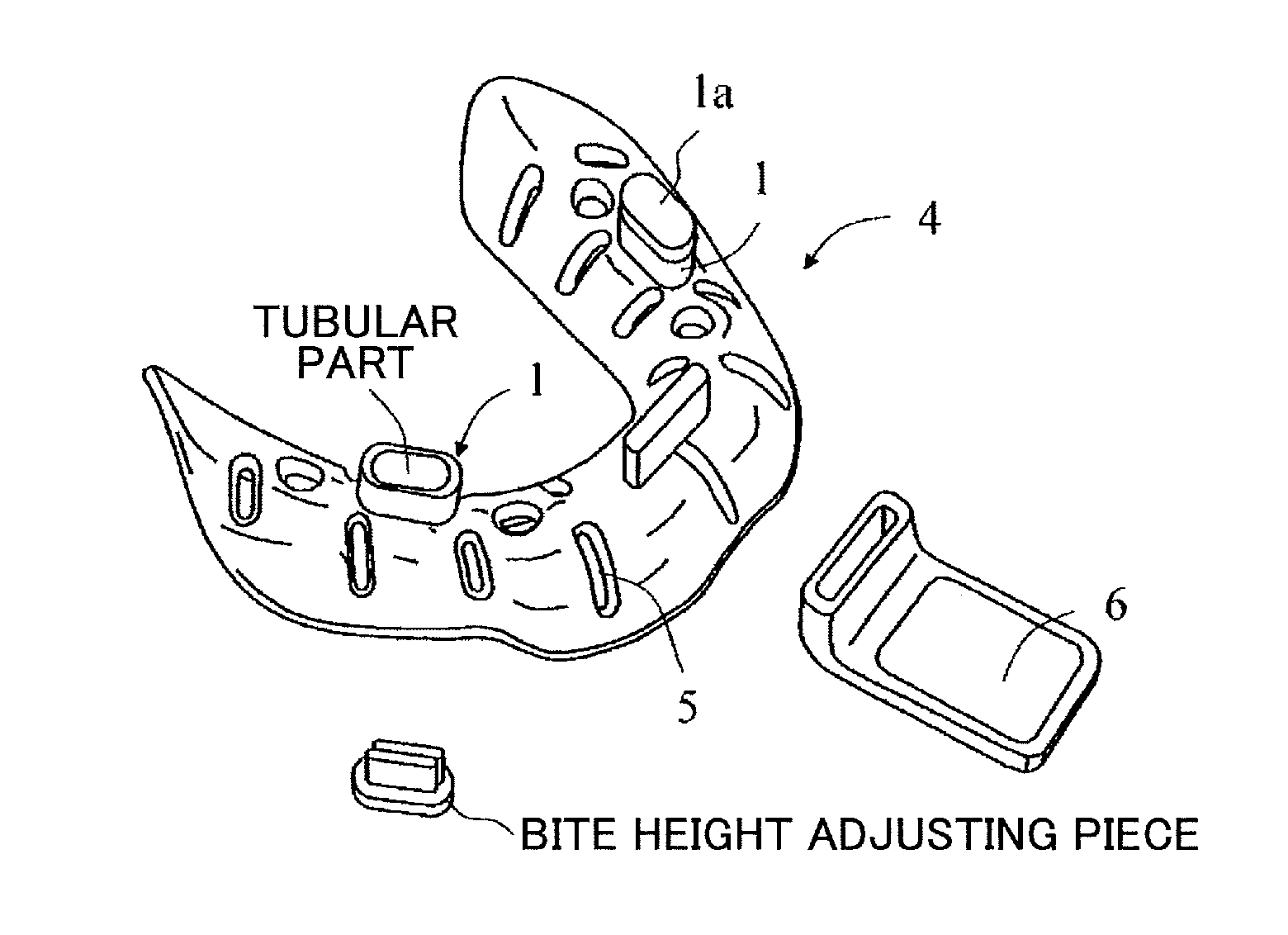

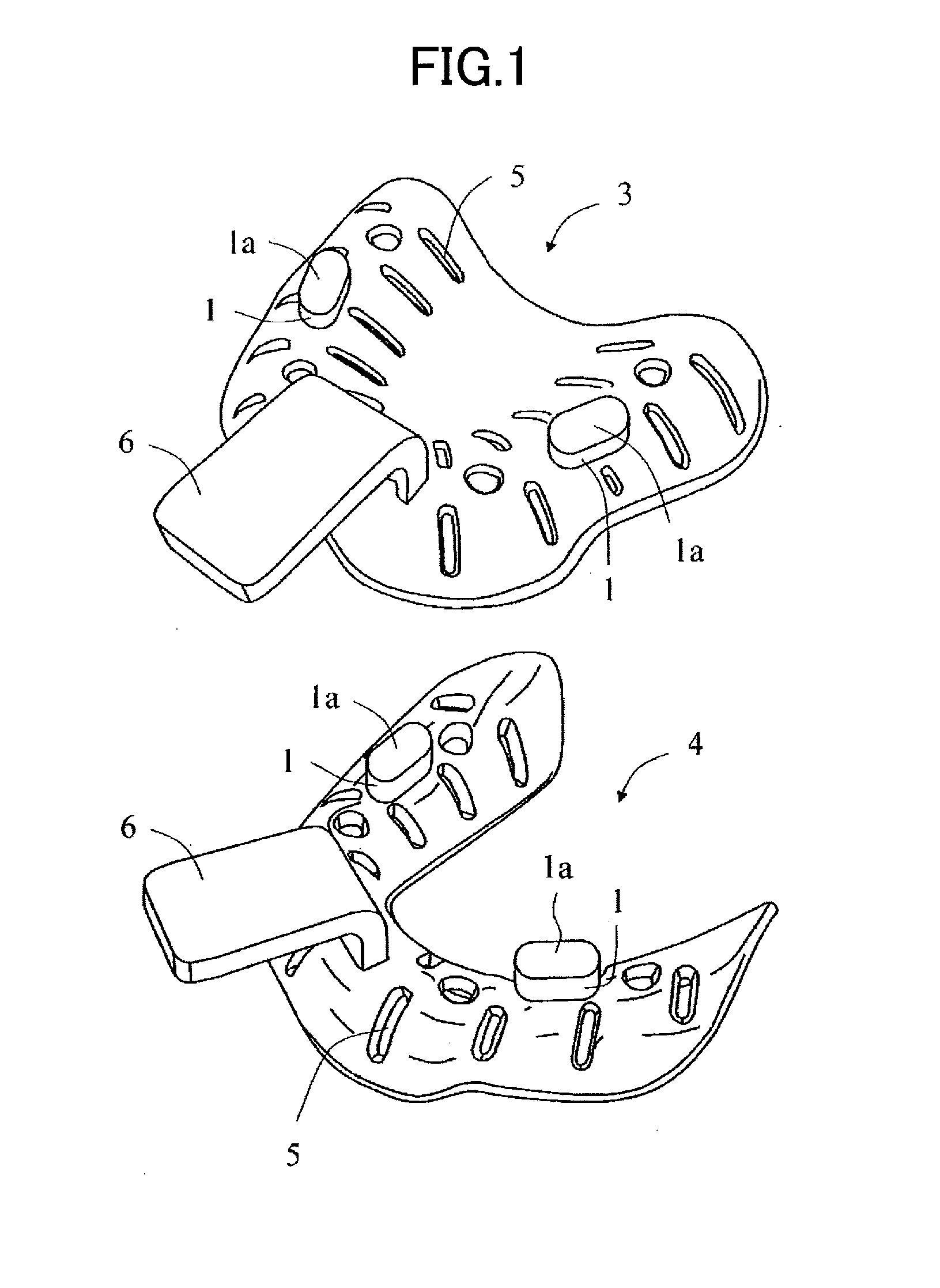

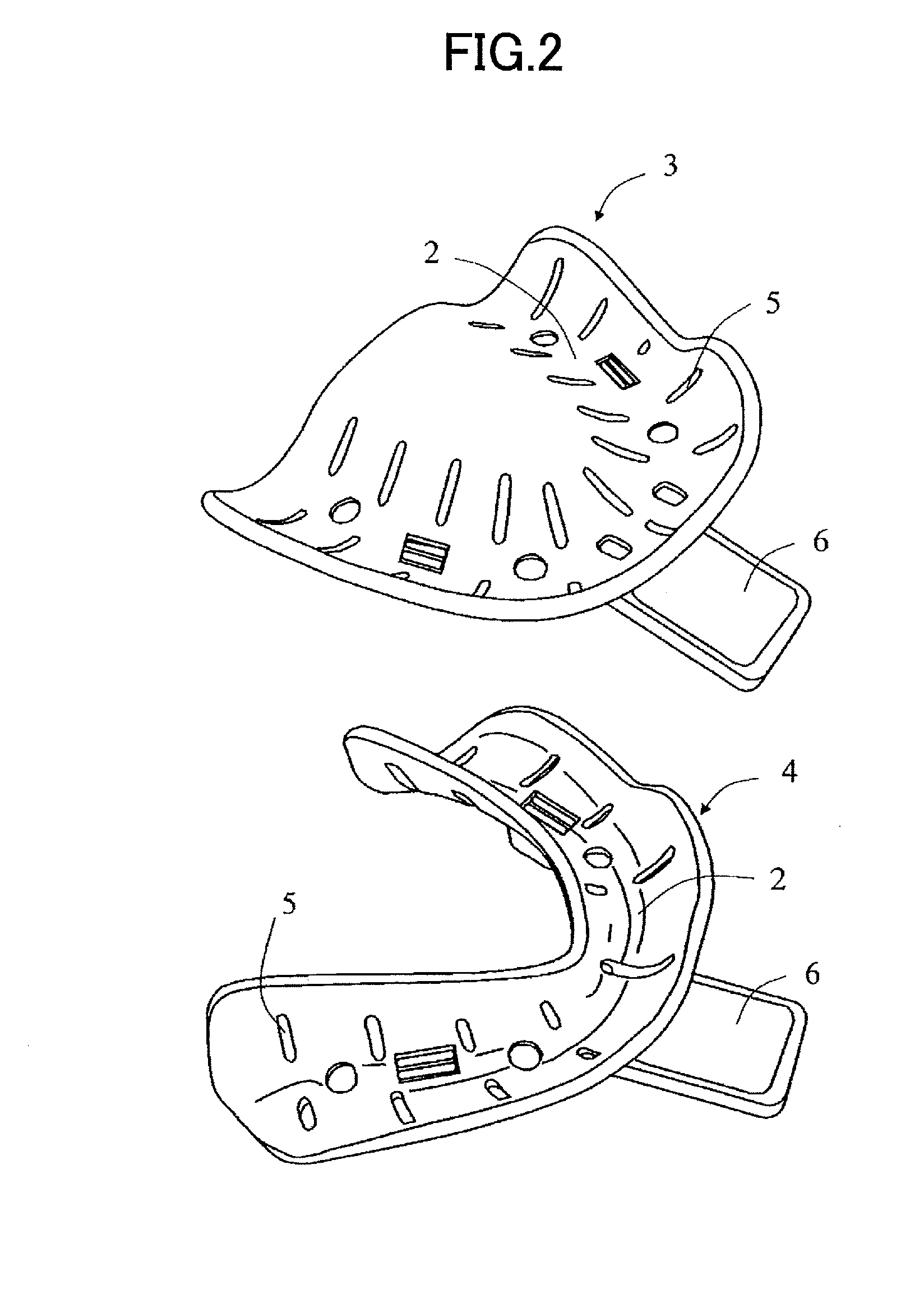

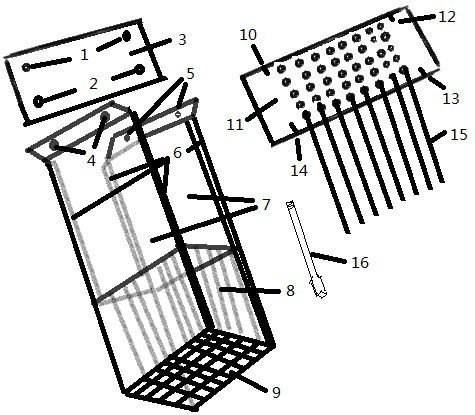

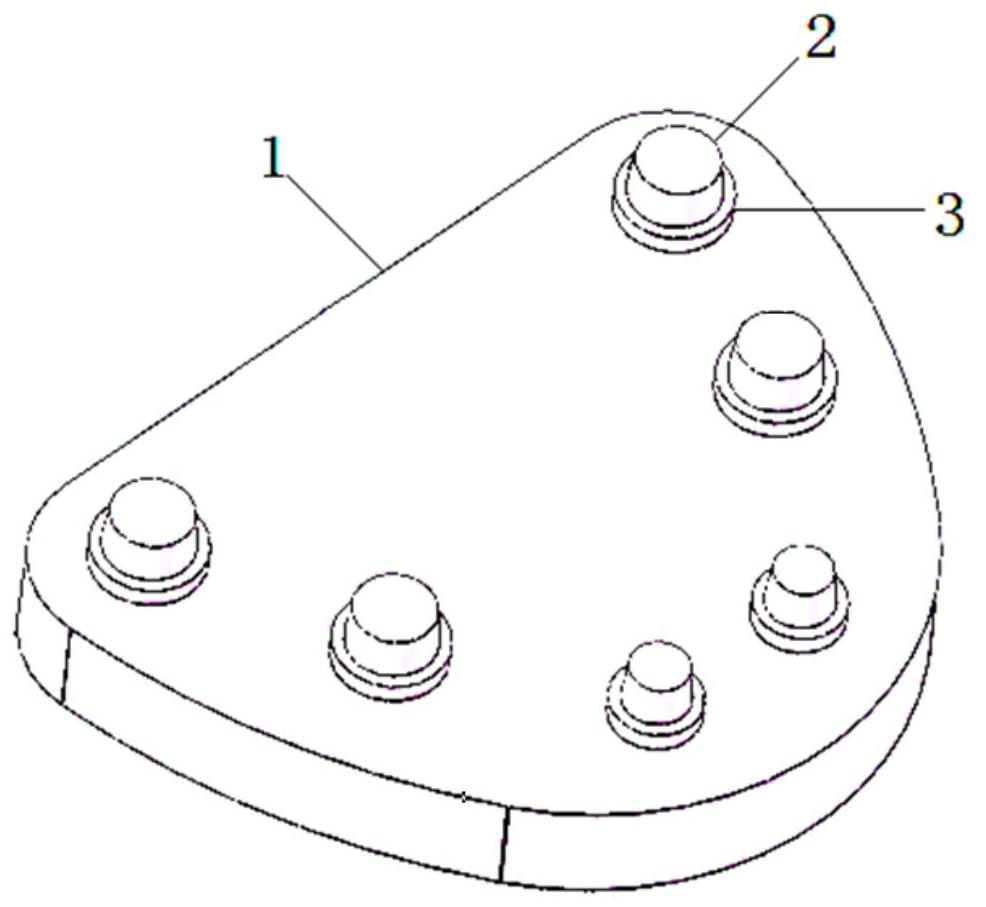

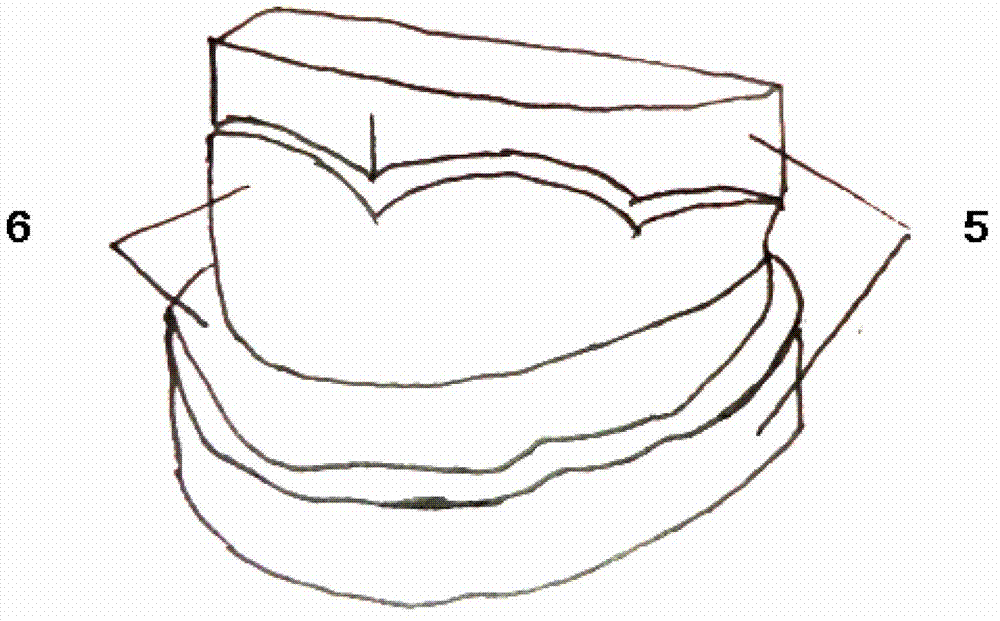

ActiveUS9498310B2Easy to copyEasy transferImpression capsMachines/enginesDental ArticulatorsImpression trays

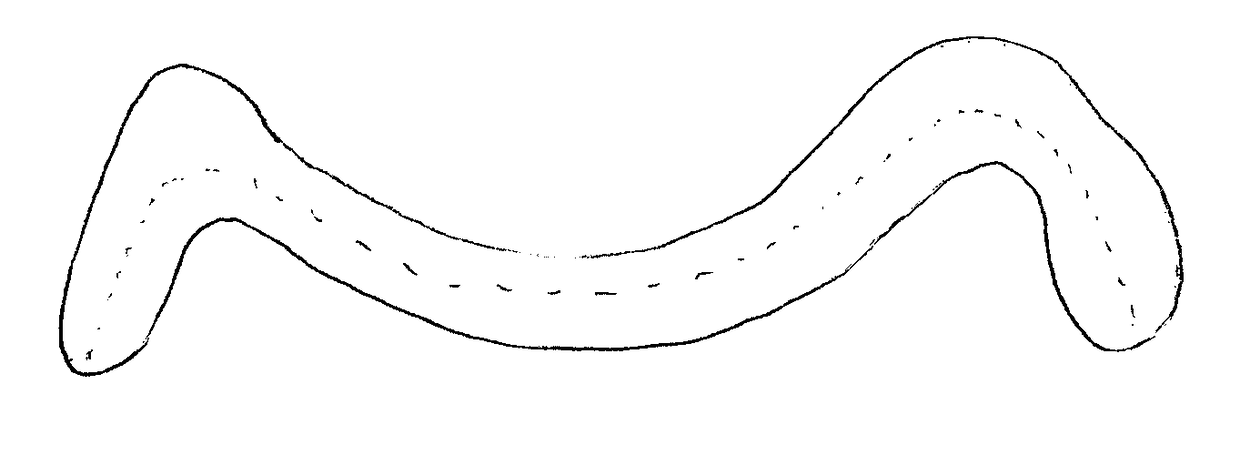

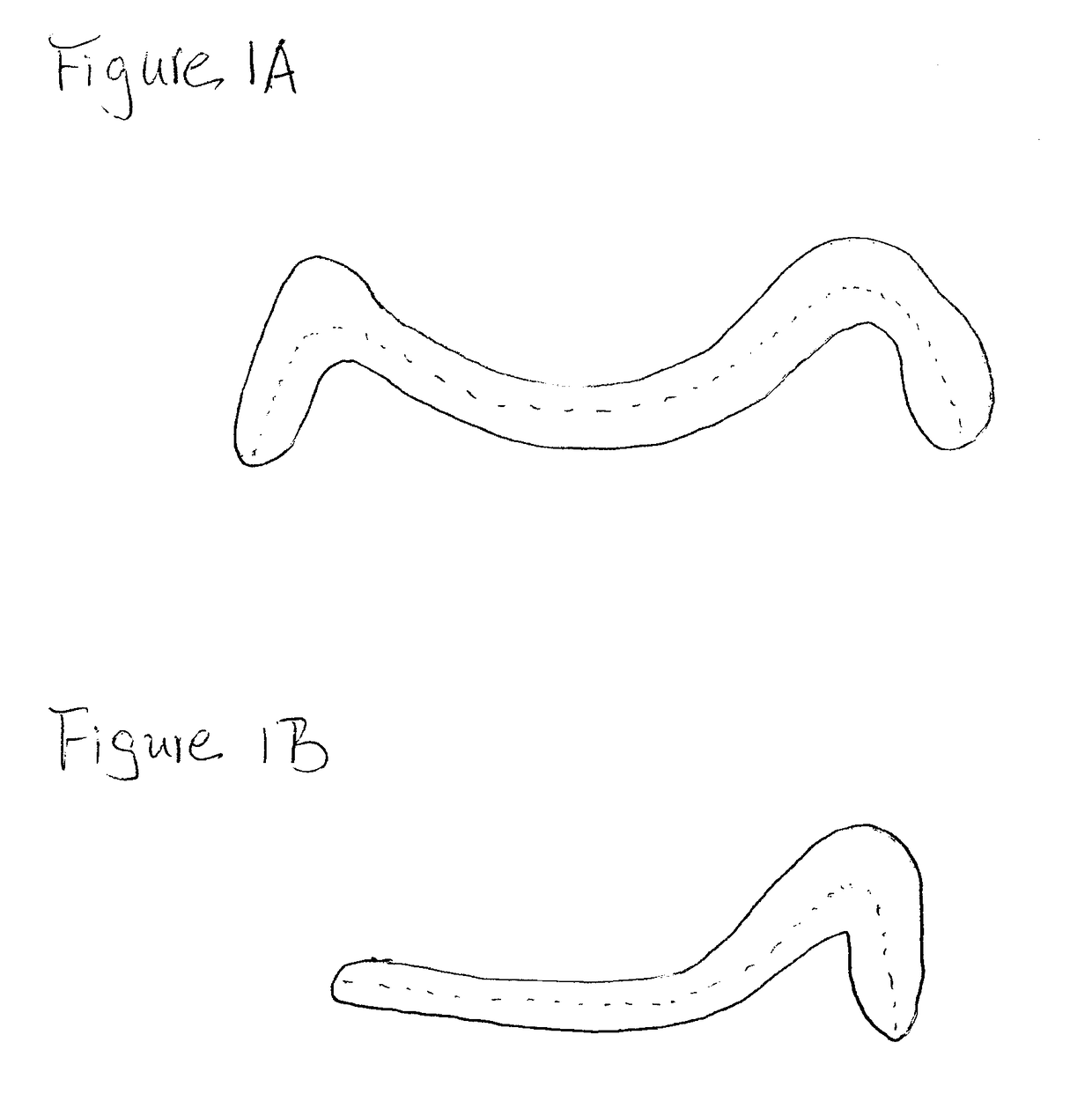

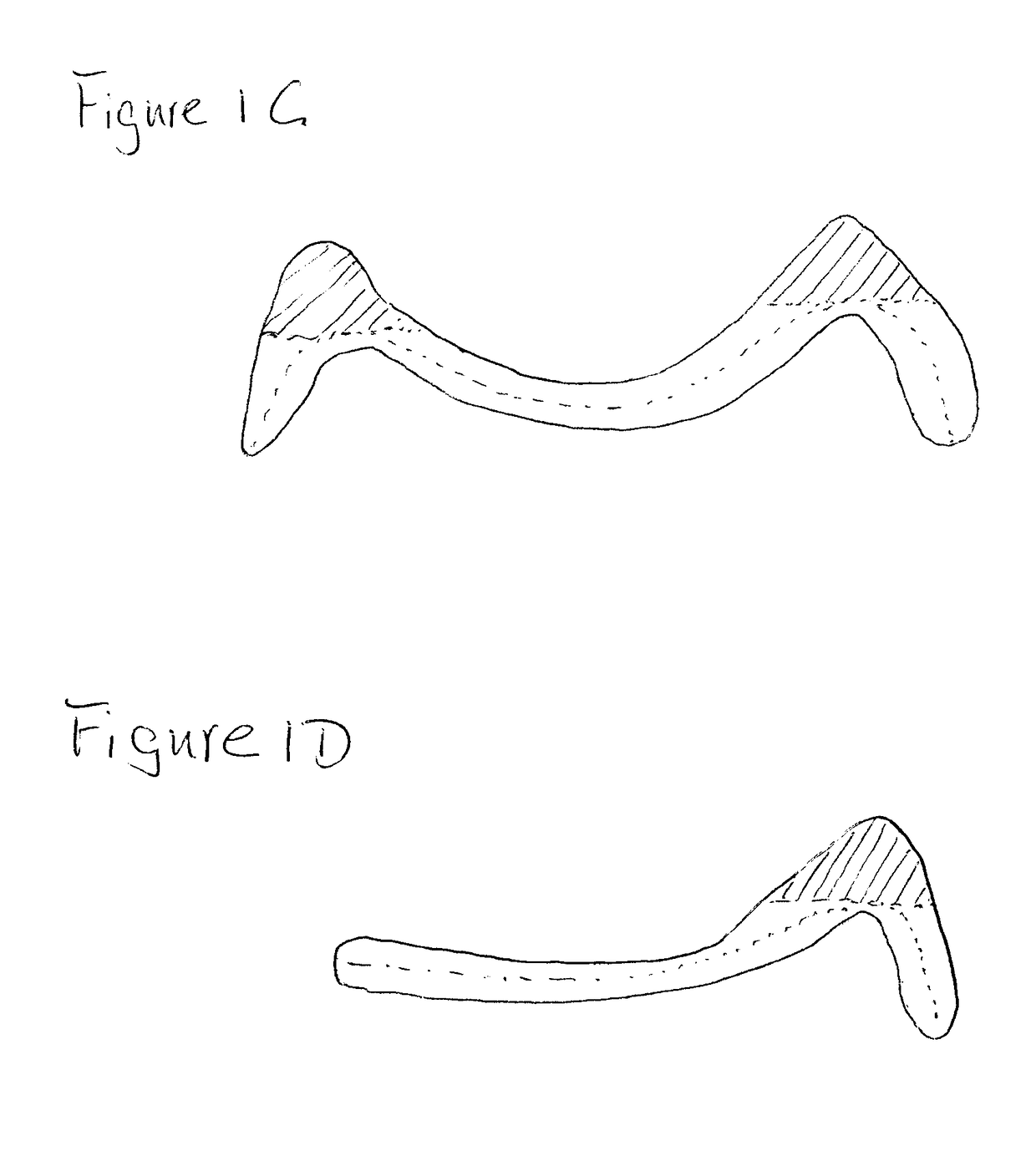

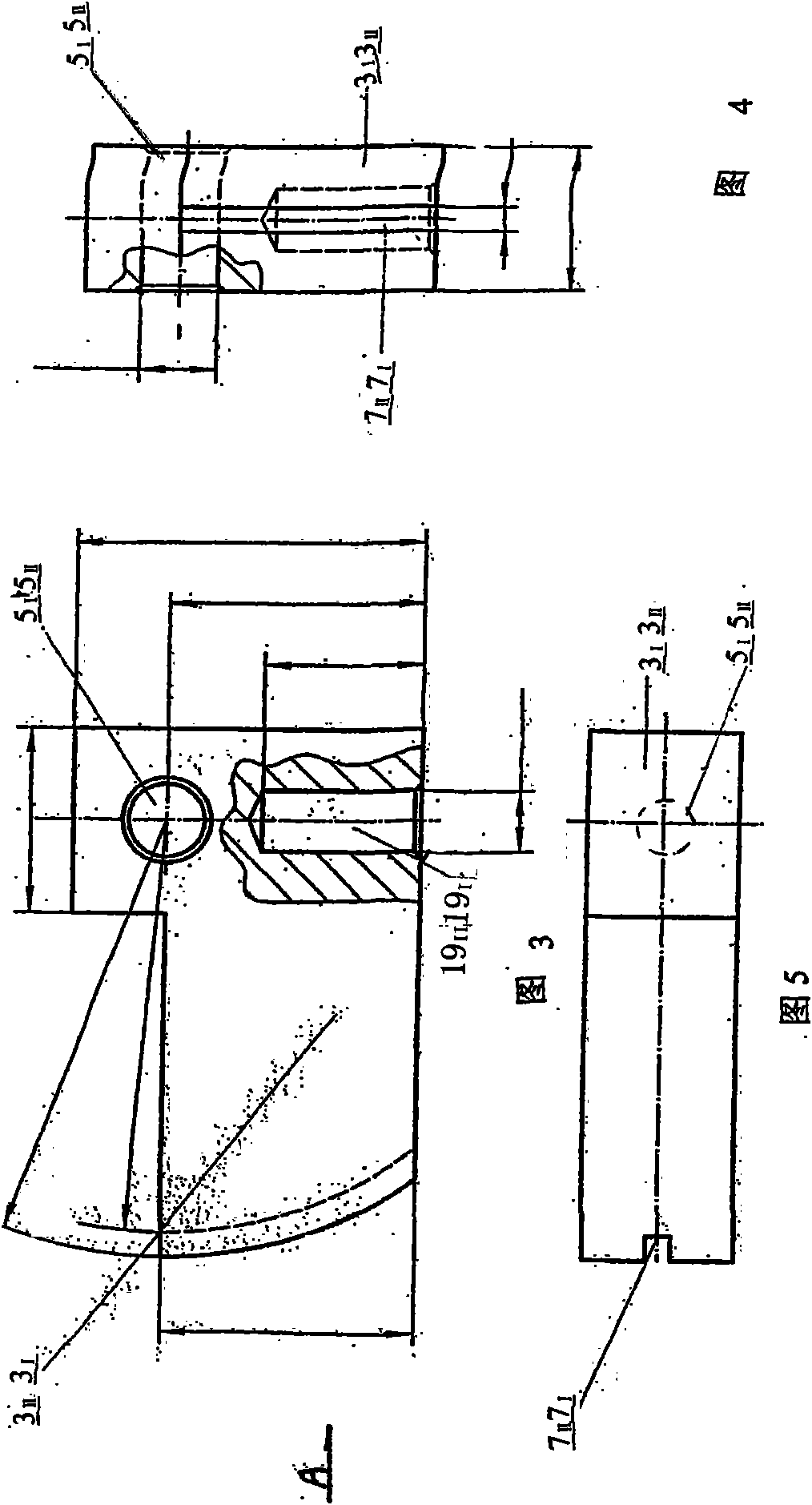

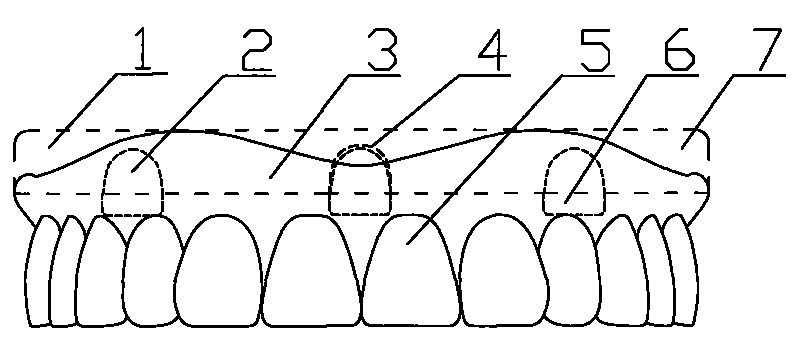

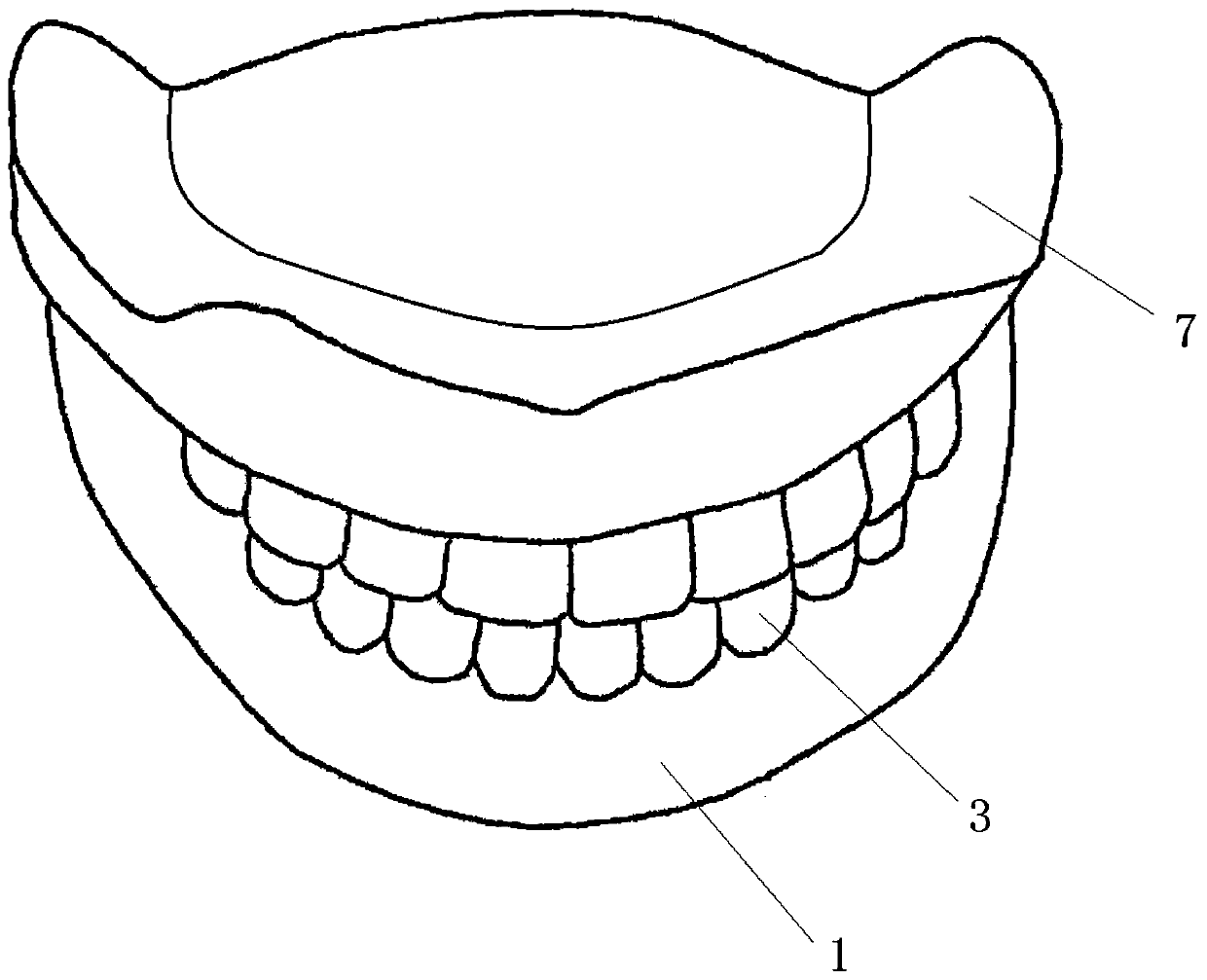

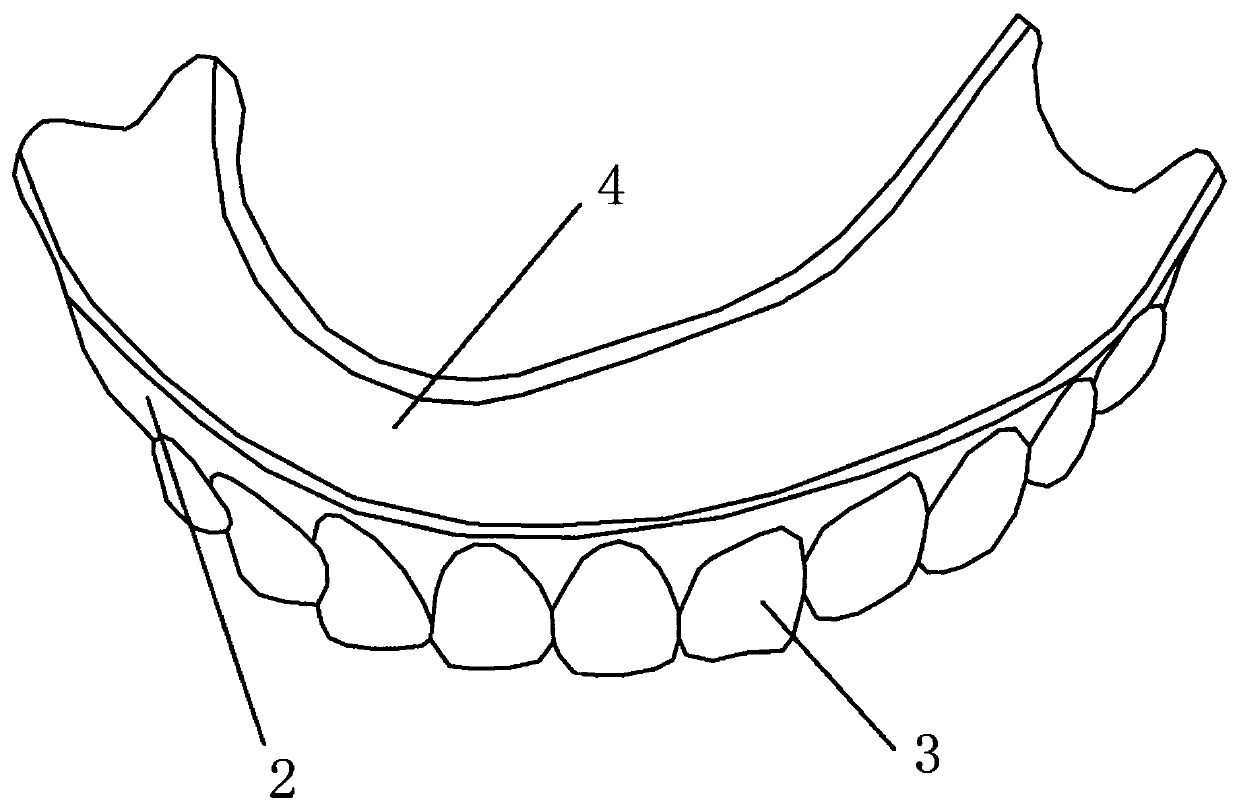

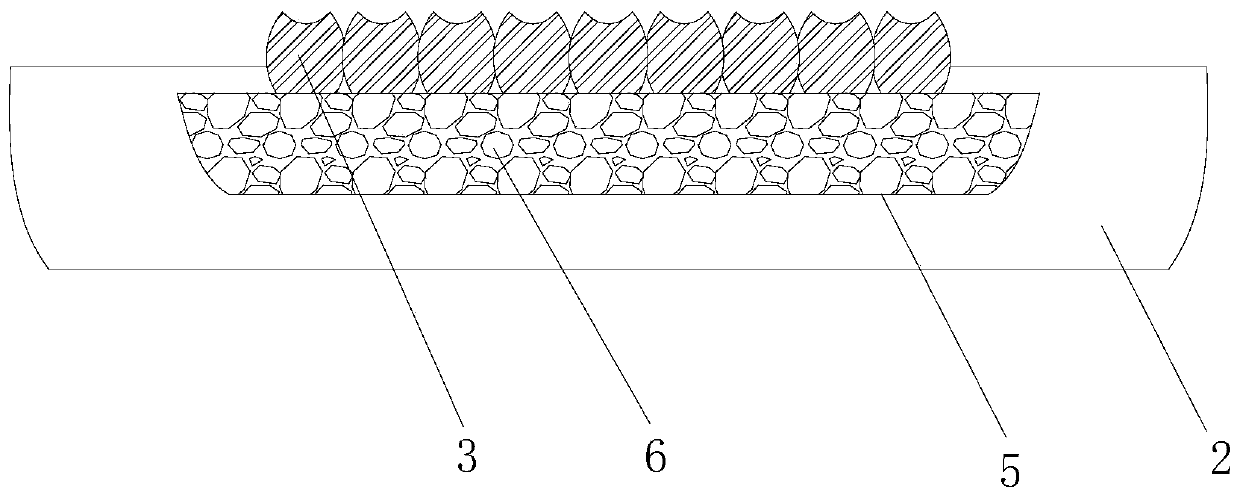

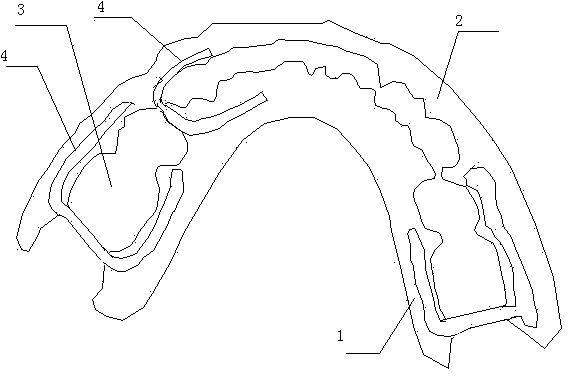

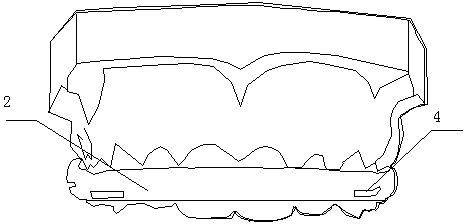

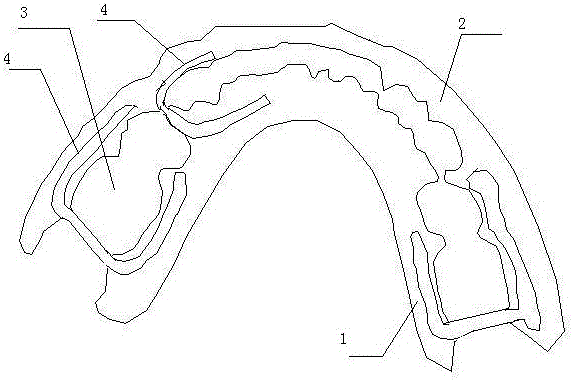

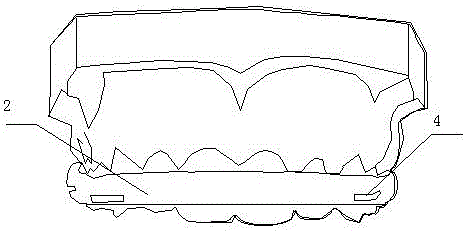

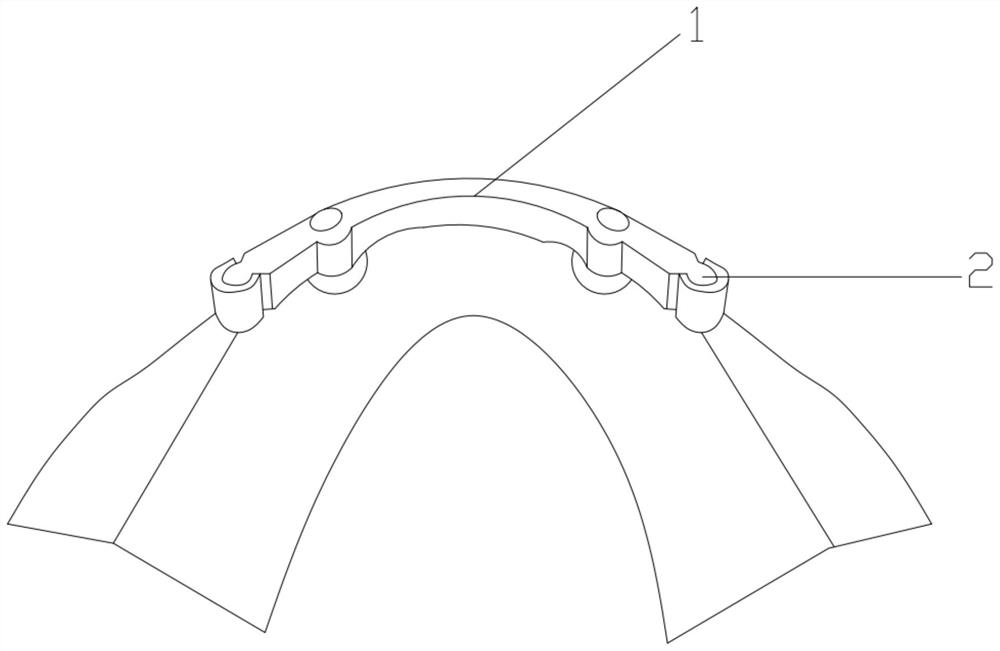

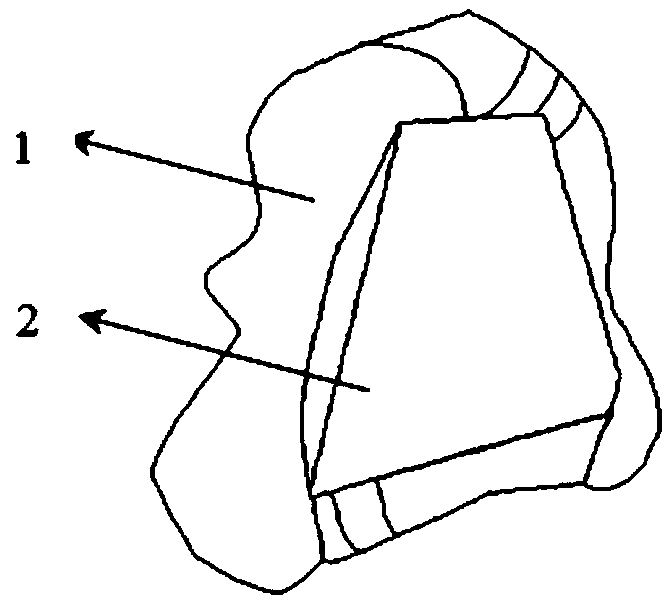

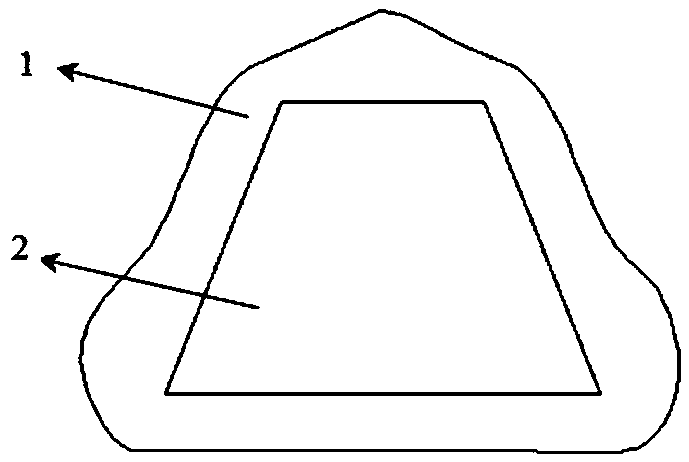

A full denture base manufacturing method is provided that can easily manufacture a full denture base, using a set of maxillary impression tray and a mandibular impression tray for taking an impression from a patient including an edentulous patient.An impression material is applied on each of a maxillary impression tray 3 and a mandibular impression tray 4 configuring a set of impression trays, and respectively having a U-shaped groove, the U-shaped groove having a front surface side on which the impression material is to be applied and being provided with projecting parts 1 on a back surface side thereof, and the applied impression material is pressed against an alveolar ridge within an oral cavity and set, to determine bite position and height in a state in which at least a part of flat top surfaces of the projecting parts 1 contact each other, the second impression material is applied between back surfaces of the impression trays 3, 4 and set in a state in which at least a part of the flat top surfaces contact each other, each of the impression trays 3, 4 and the impression material are removed from within the oral cavity in one piece of the maxillary and mandibular impression trays, or separately in two pieces of the maxillary and mandibular impression trays, and a model material is thereafter injected to each impression material on the removed maxillary and mandibular impression trays and set, in order to manufacture an edentulous jaw model, and the edentulous jaw model is set on an articulator in a state in which the bite position and height that are determined in advance are reflected, in order to manufacture a full denture base.

Owner:GC CORP

Full denture base manufacturing method

ActiveUS20150190216A1Easy to copyEasy transferImpression capsDental articulatorsDental ArticulatorsFull dentures

A full denture base manufacturing method is provided that can easily manufacture a full denture base, using a set of maxillary impression tray and a mandibular impression tray for taking an impression from a patient including an edentulous patient.An impression material is applied on each of a maxillary impression tray 3 and a mandibular impression tray 4 configuring a set of impression trays, and respectively having a U-shaped groove, the U-shaped groove having a front surface side on which the impression material is to be applied and being provided with projecting parts 1 on a back surface side thereof, and the applied impression material is pressed against an alveolar ridge within an oral cavity and set, to determine bite position and height in a state in which at least a part of flat top surfaces of the projecting parts 1 contact each other, the second impression material is applied between back surfaces of the impression trays 3, 4 and set in a state in which at least a part of the flat top surfaces contact each other, each of the impression trays 3, 4 and the impression material are removed from within the oral cavity in one piece of the maxillary and mandibular impression trays, or separately in two pieces of the maxillary and mandibular impression trays, and a model material is thereafter injected to each impression material on the removed maxillary and mandibular impression trays and set, in order to manufacture an edentulous jaw model, and the edentulous jaw model is set on an articulator in a state in which the bite position and height that are determined in advance are reflected, in order to manufacture a full denture base.

Owner:GC CORP

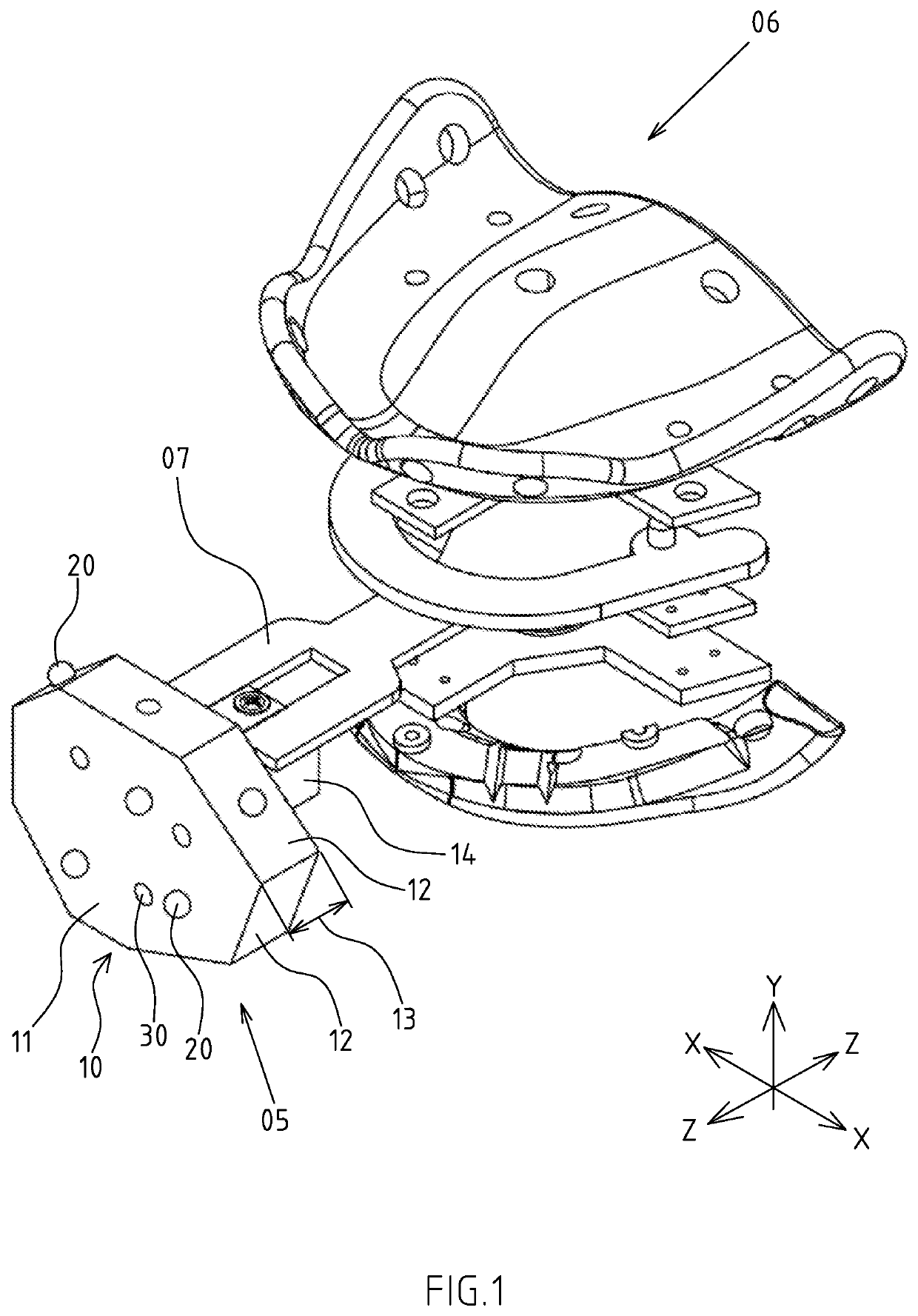

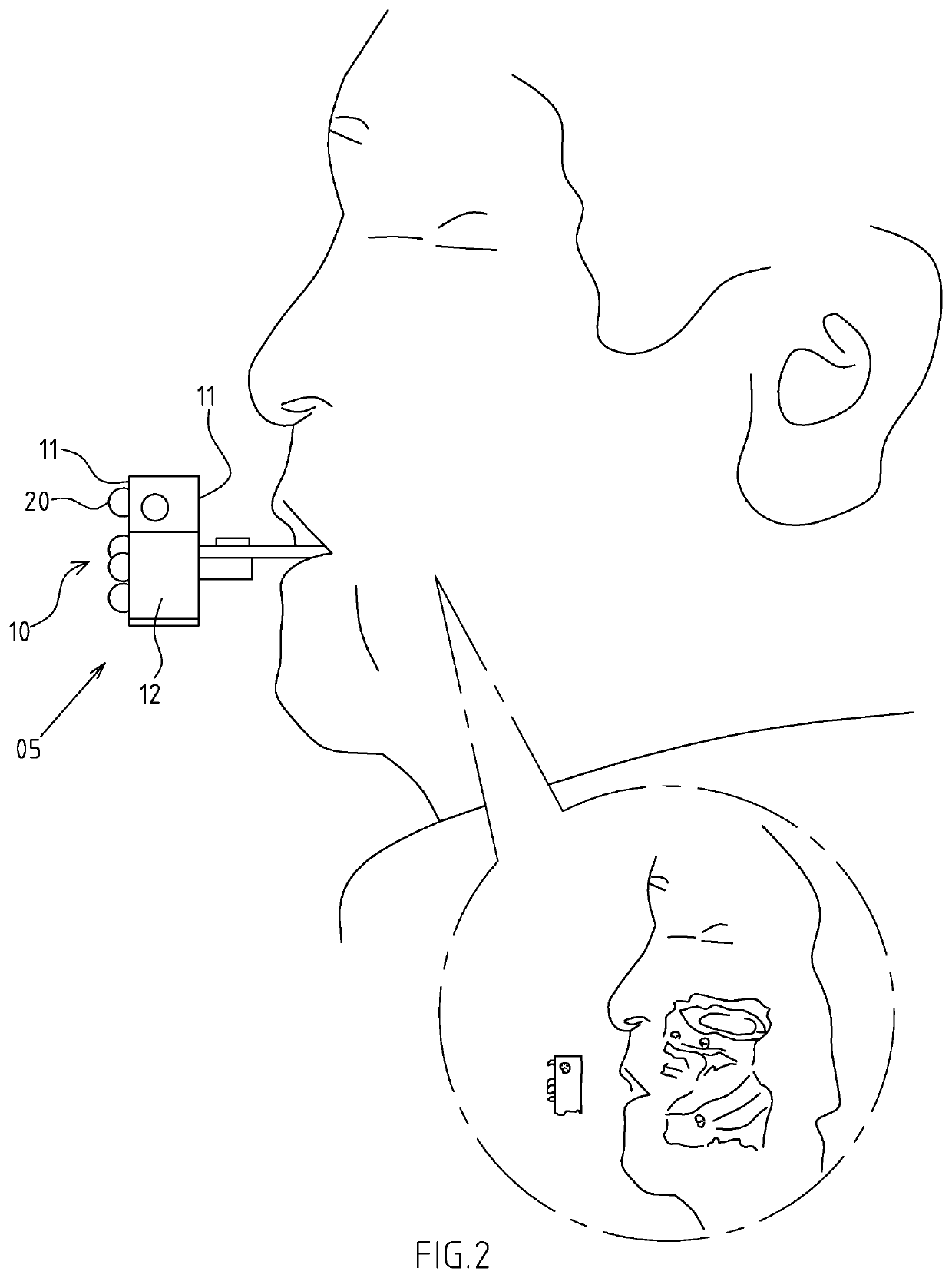

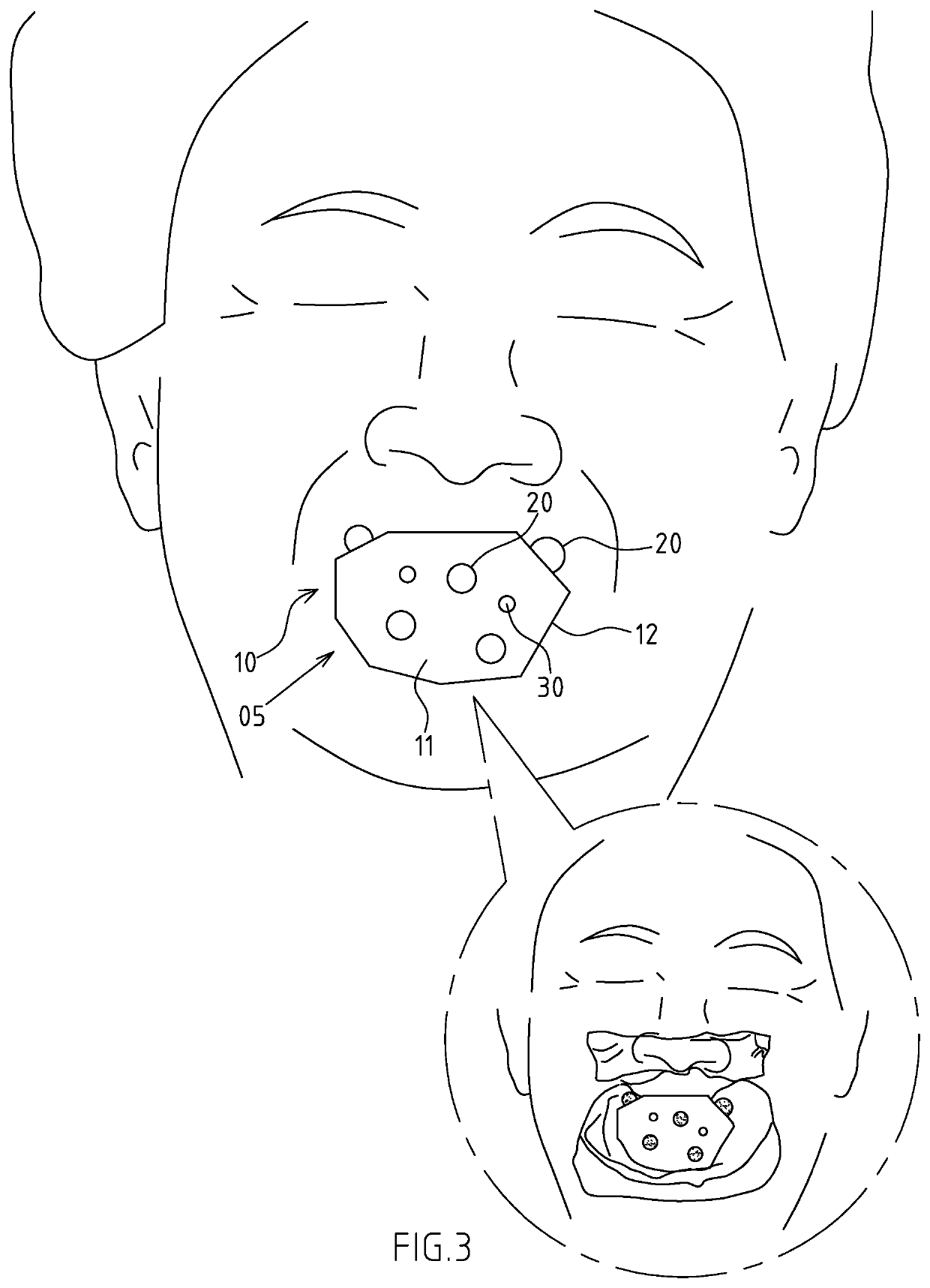

Face scanning and positioning structure used for full denture

InactiveUS20190374317A1Image degradationImprove comprehensive applicabilityImpression capsSurgeryFace scanningFull dentures

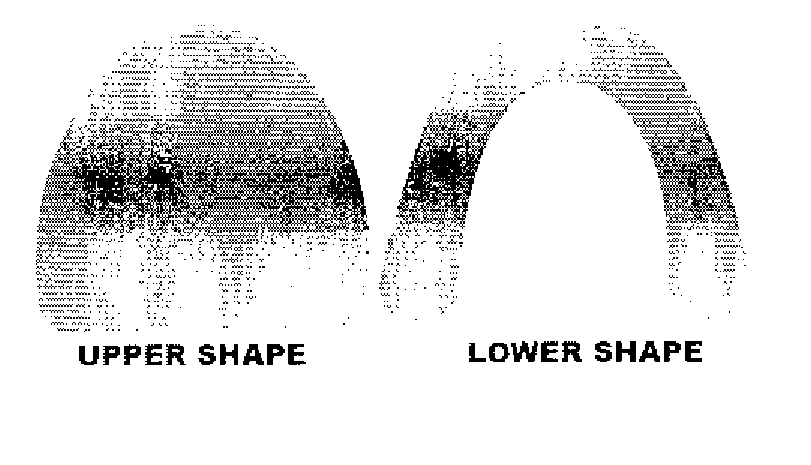

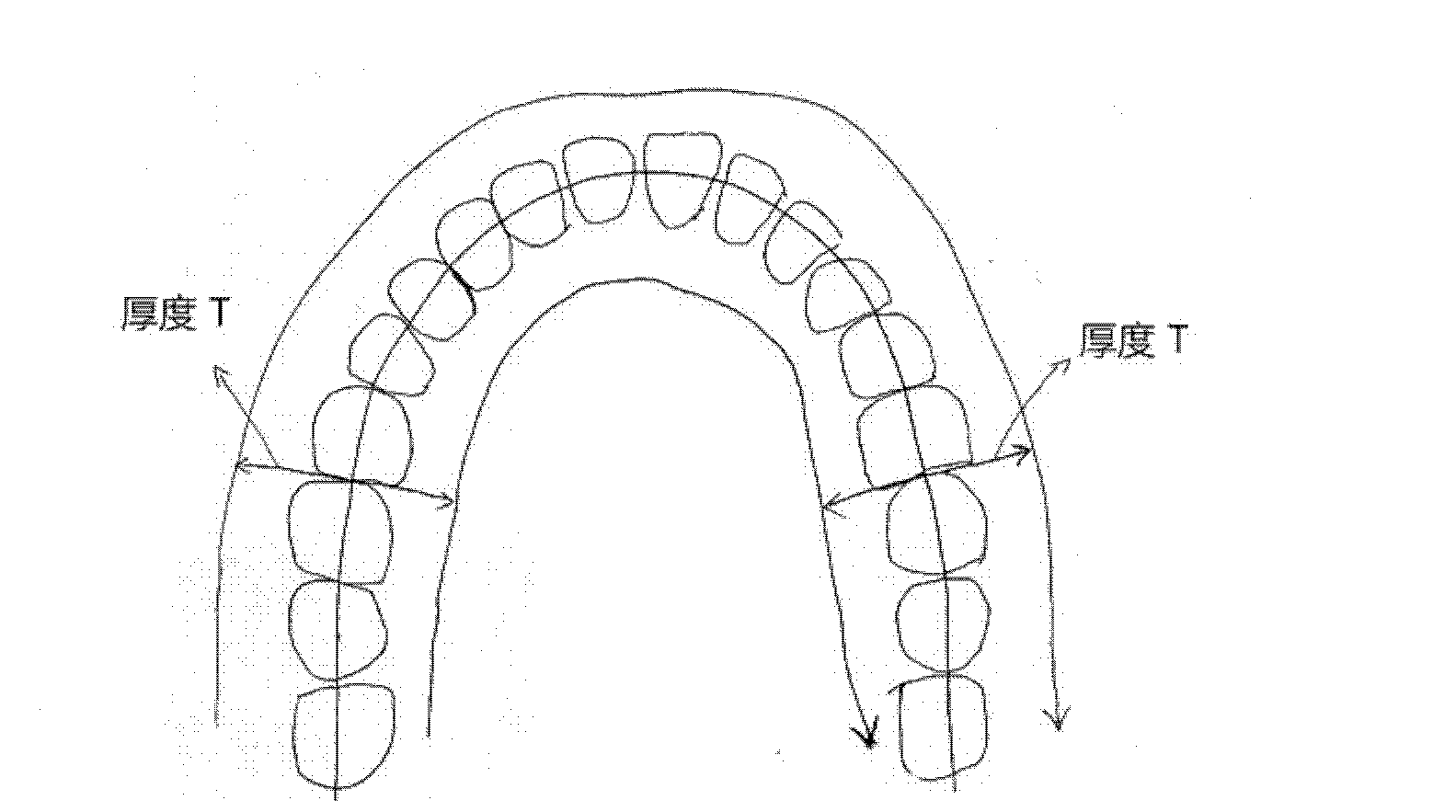

A face scanning and positioning structure used for a full denture includes an irregularly shaped body, development projections, and concave portions. The irregularly shaped body defines an asymmetrical face portion along an X-axis, an asymmetrical side portion along a Y-axis, and a thickness along a Z-axis. The development projections are arranged on the asymmetrical face portion and the asymmetrical side portion at predetermined positions. The development projections protrude outwardly. The concave portions are arranged on the asymmetrical face portion and the asymmetrical side portion at predetermined positions. The concave portions each have a concave shape. Through the development projections and the concave portions, the irregularly shaped body is in the form of an asymmetrical structure along the X-axis, the Y-axis, and the Z-axis. Through the irregular protrusions and concave portions, the face scanning and positioning structure can effectively reduce the image overlay error of a specific axis.

Owner:CHIOU WEN HSIN +1

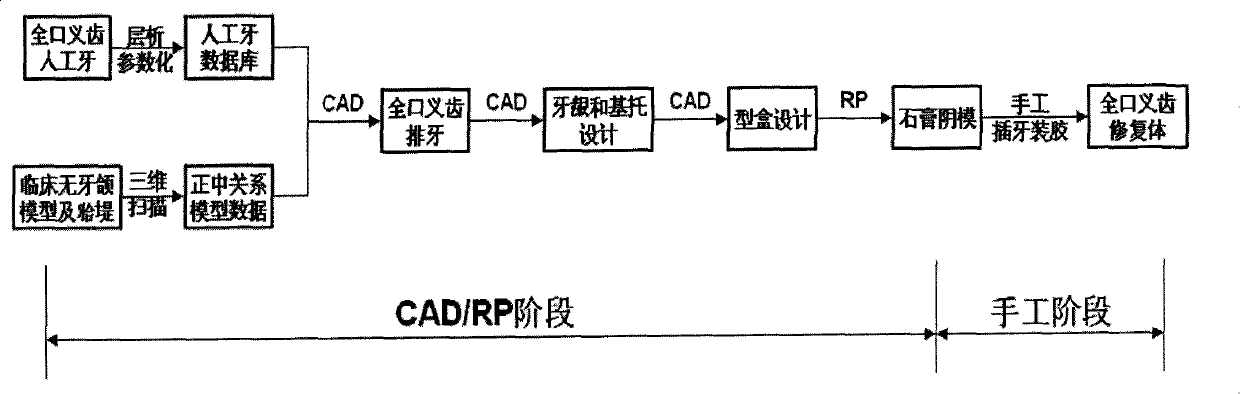

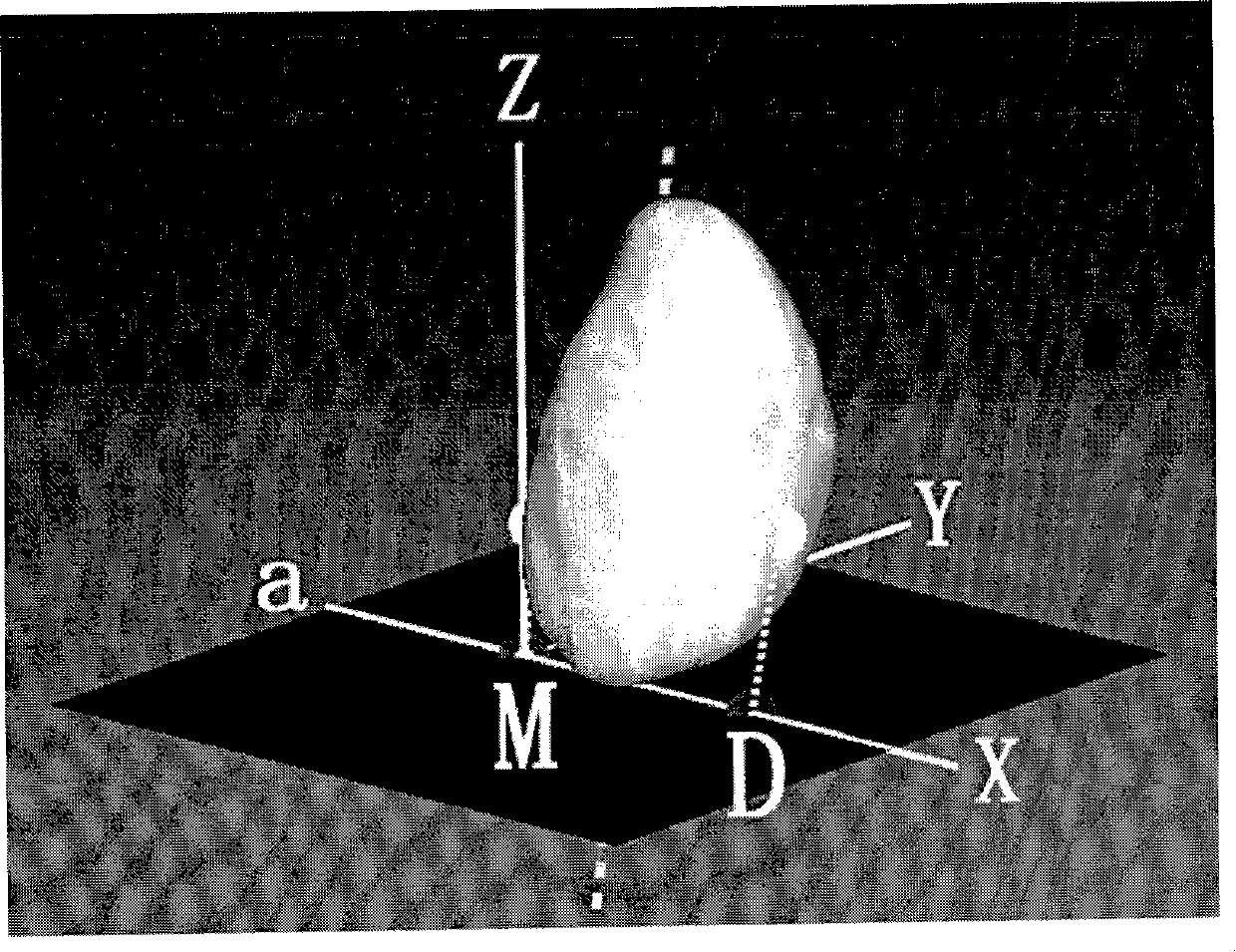

A design and manufacture method of complete denture based on cad/rp technology

InactiveCN101548911BSimplify complicated proceduresImprove accuracyDiagnostic recording/measuringSensorsSoftware designManual insertion

The invention discloses a method for manufacturing a neutral zone complete denture based on CAD / RP (Computer Aided Design / Rapid Prototyping, computer-aided design and rapid prototyping) technology. The method comprises the following steps: establishing a three-dimensional graphic database of complete dentures and artificial teeth based on parametric positioning; collecting data on the upper and lower edentulous jaws and the jaw embankment in the neutral zone based on the three-dimensional laser scanning technology with spatial position relationships; Based on reverse engineering software, design the complete denture artificial dentition that conforms to the theory of neutral zone and complete denture balanced tooth arrangement; based on reverse engineering software, design the gingiva and base that conform to the theory of neutral zone of complete denture and aesthetic principles; based on CAD / RP technology full denture box design and processing, manual tooth insertion and glue to complete the complete denture restoration. The invention pioneered the idea of "two-step method". The manual teeth arrangement and wax pattern production with the highest technical content and the most complicated operation in traditional production are completed by computer and rapid prototyping technology. The second step of the "step method" can complete the entire production of complete dentures, which greatly simplifies the complicated procedures of traditional handcrafts, improves the efficiency and accuracy of restorations, and realizes the design and production process of complete dentures from manual to manual. Digital transformation.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

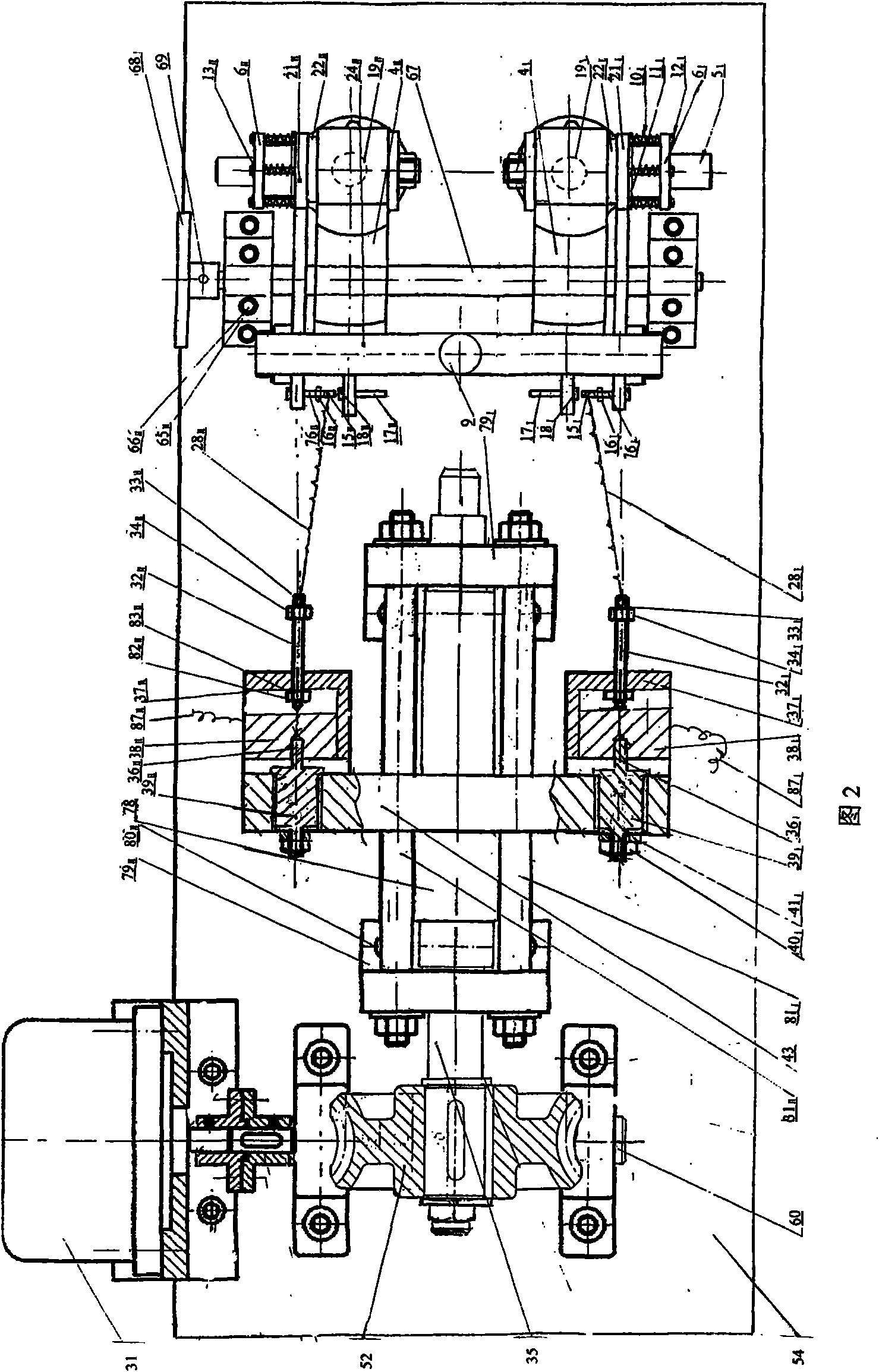

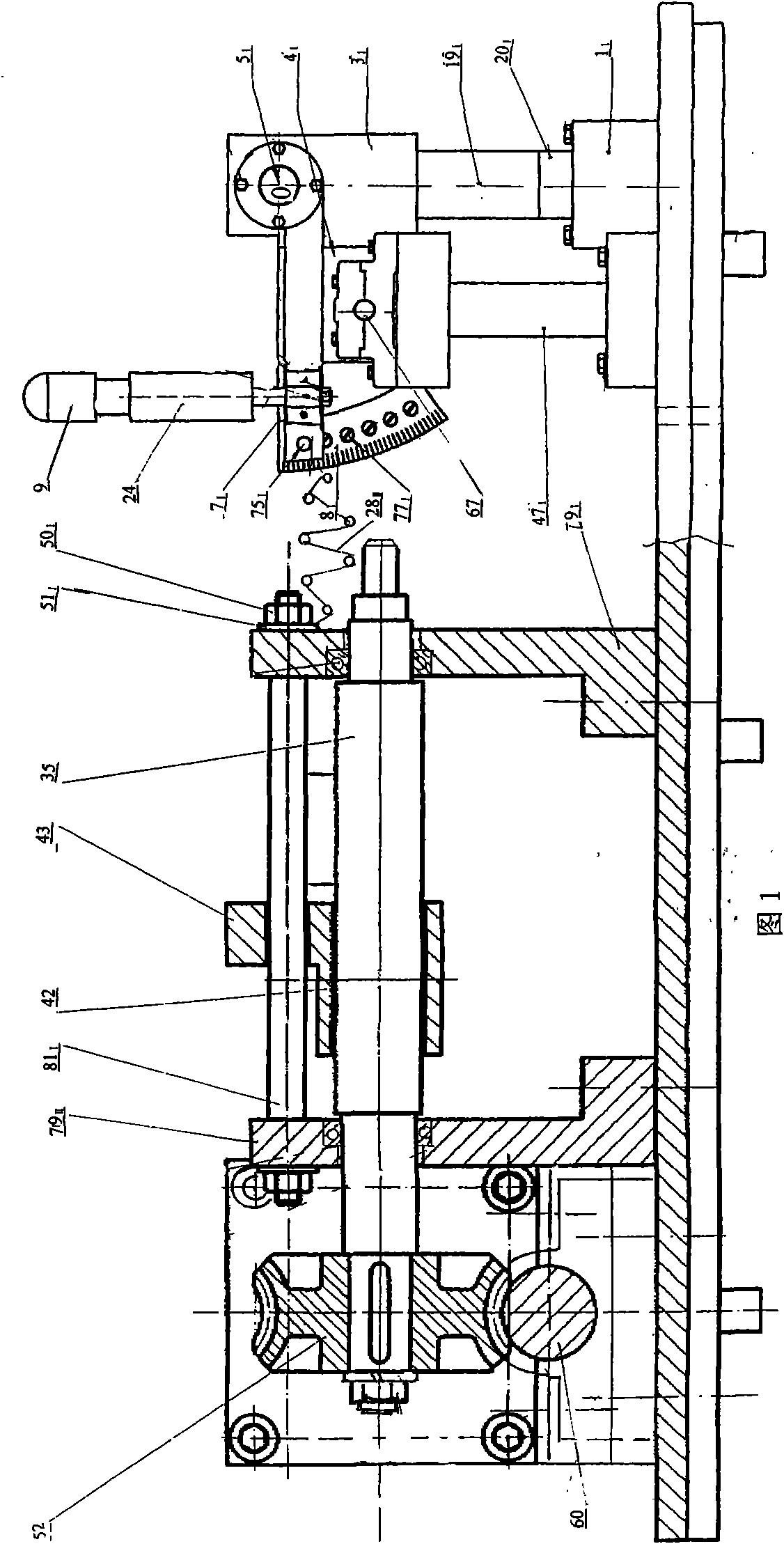

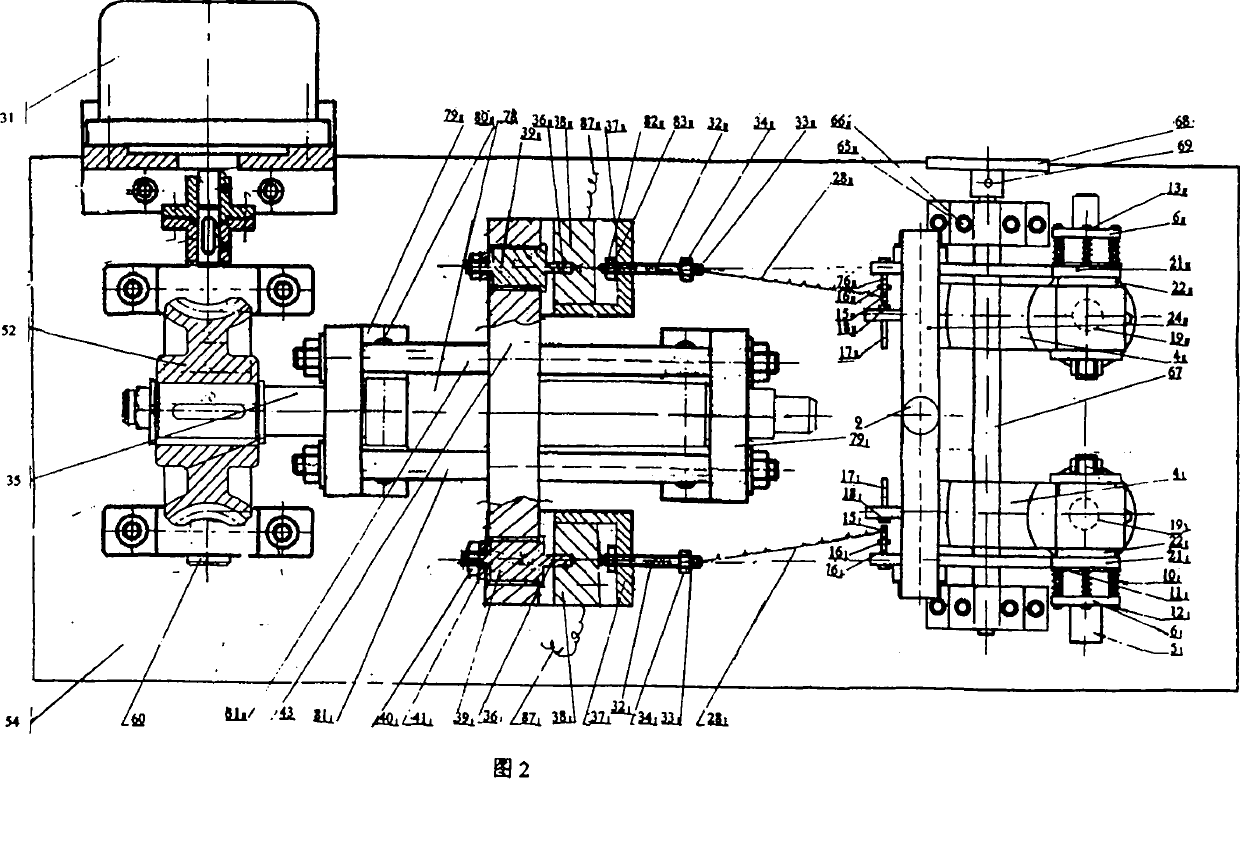

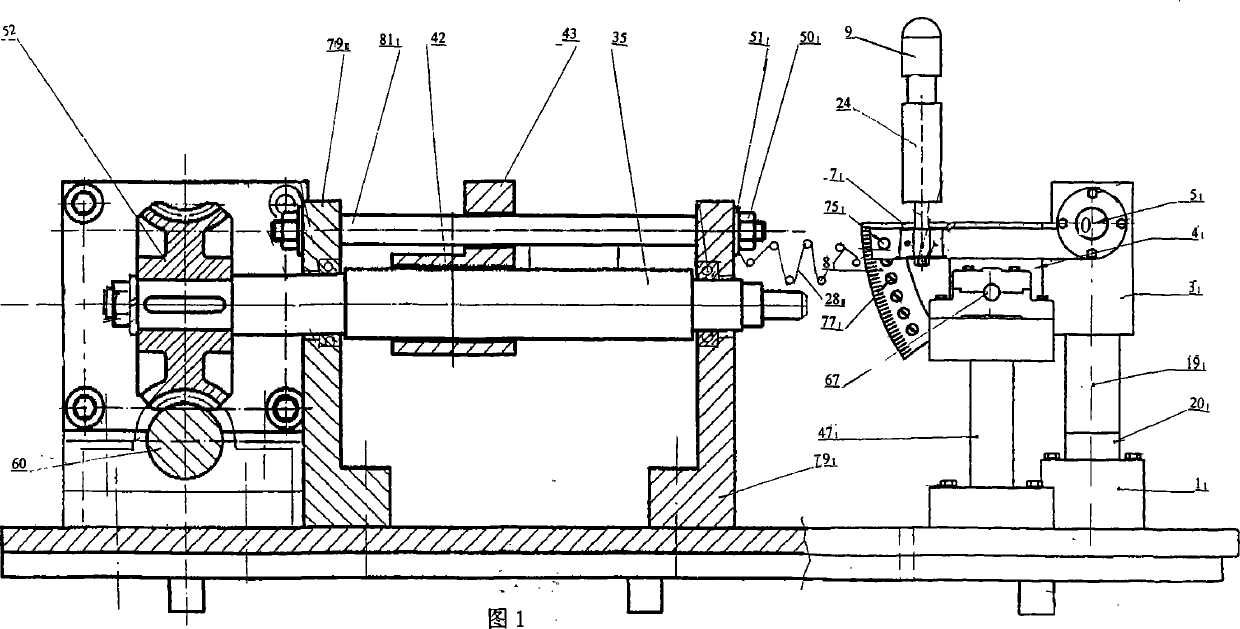

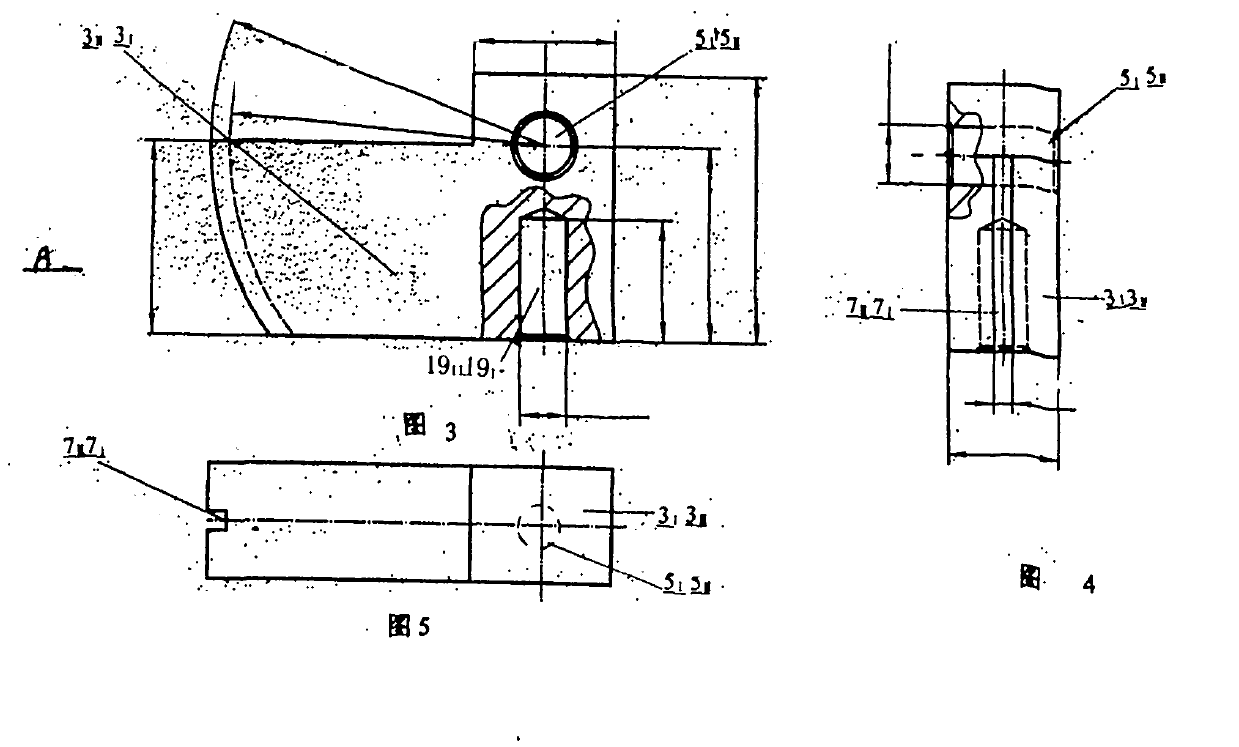

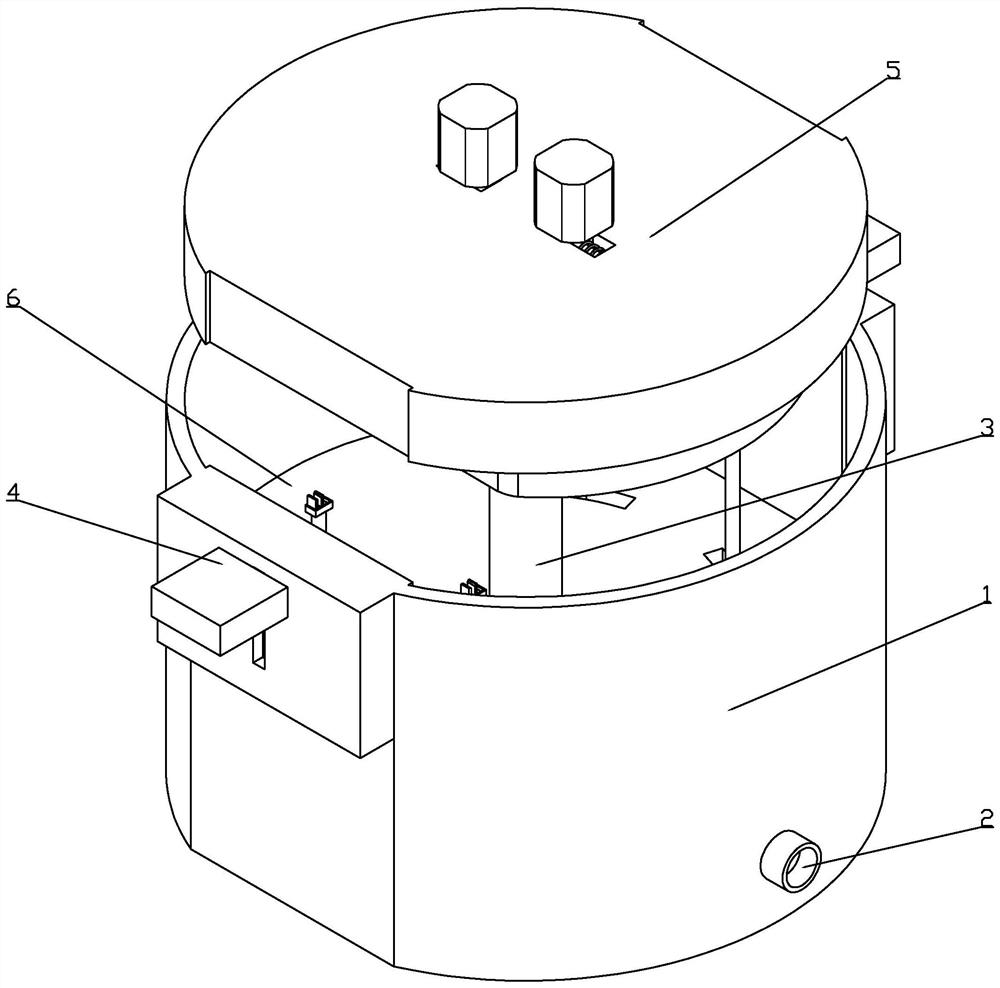

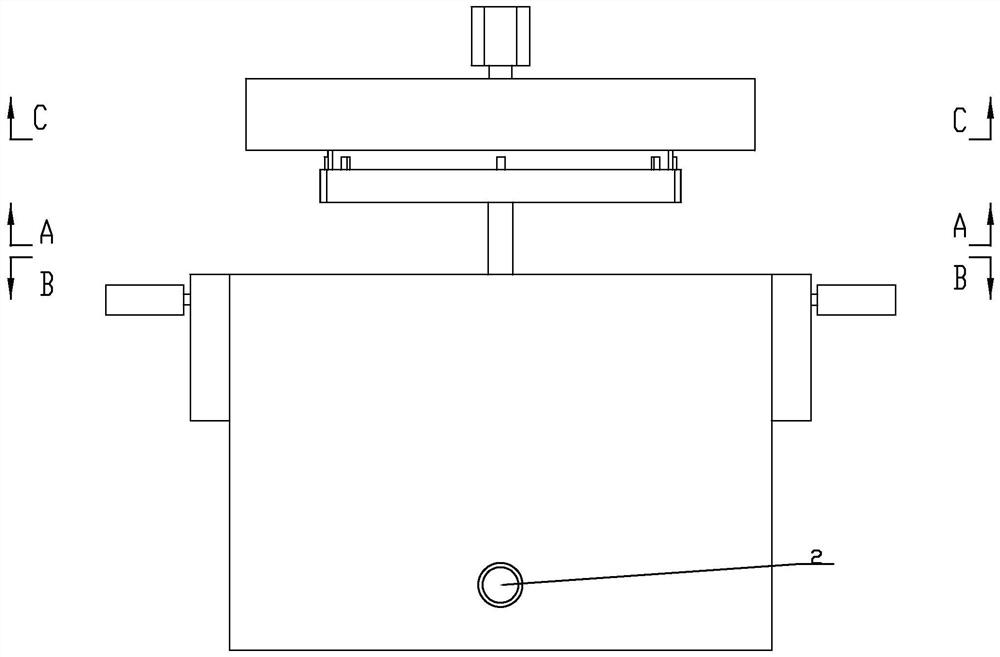

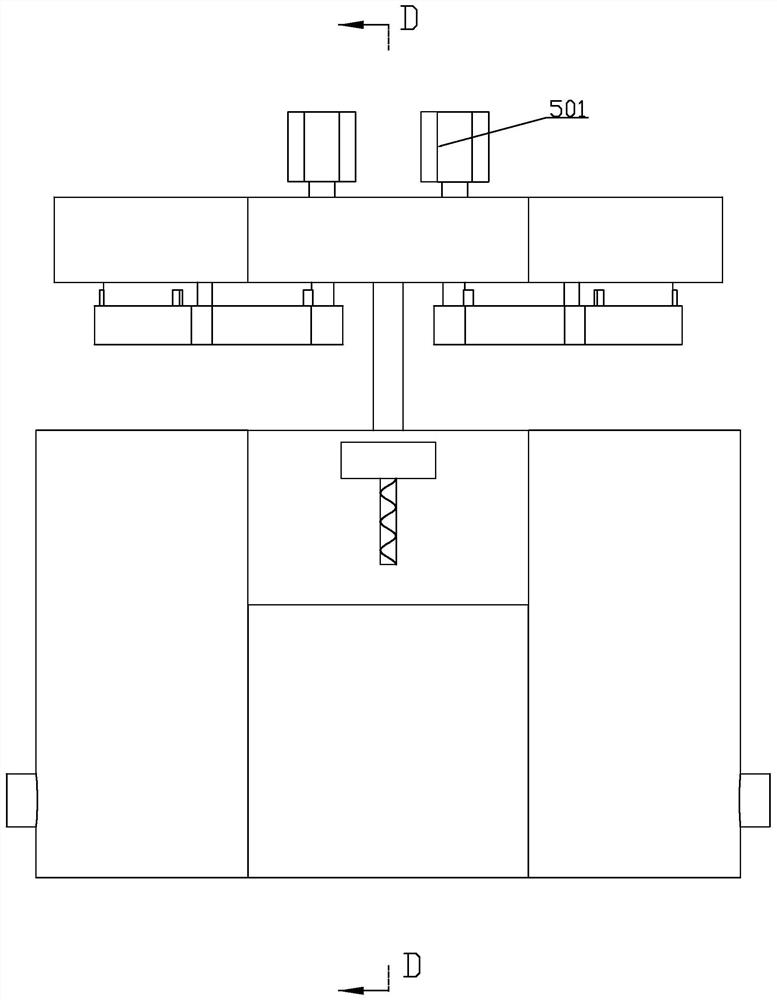

Buccal multi-bending spring space three-dimensional dynamometer

The invention relates to a buccal multi-bending spring space three-dimensional dynamometer, which is applied to simulating a maxilla, a mandible and a temporomandibular joint, and predicting the push and pull force values generated on crossover points of the maxilla and the mandible when a correction patient wears multi-bending springs 28I and 28II to perform mouth opening and closing motions. The dynamometer has accurate measurement and can instruct the clinical allopathic wearing according to the following steps: (1) putting two terminal filaments of the 28I and the 28II into a 15I, a 15II and upper jaws 33I and 33II fastening the terminal filaments, and moving a bracket 43 leftwards and rightwards so as to measure the pulling-pressing stress values and the displacements of the 28I and the 28II to a full denture; (2) elongating the 28I and the 28II, fastening the same into holes of the 15I, the 15II, the 33I and the 33II, moving a 32I and a 32II to adjust the stress values to approach to 0, driving a 35, the 32I and the 32II to move rightwards, and measuring the maximum pressing stress value of the full denture of the upper jaw and the lower jaw when the 28I and the 28II are pressed to a mouth-closing state; and (3) measuring the stress values and the displacements of the 28I and the 28II along the scales of 5 degrees, 10 degrees and 15 degrees of a 8I and a 8II by the 15I and the 15II; and if a 21I and a 21II move around a center leftwards and rightwards (the 15I and the 15II are 3 millimeters away from the central displacement), repeating the steps (1) and (2) to measure acting forces and displacement values.

Owner:侯录 +1

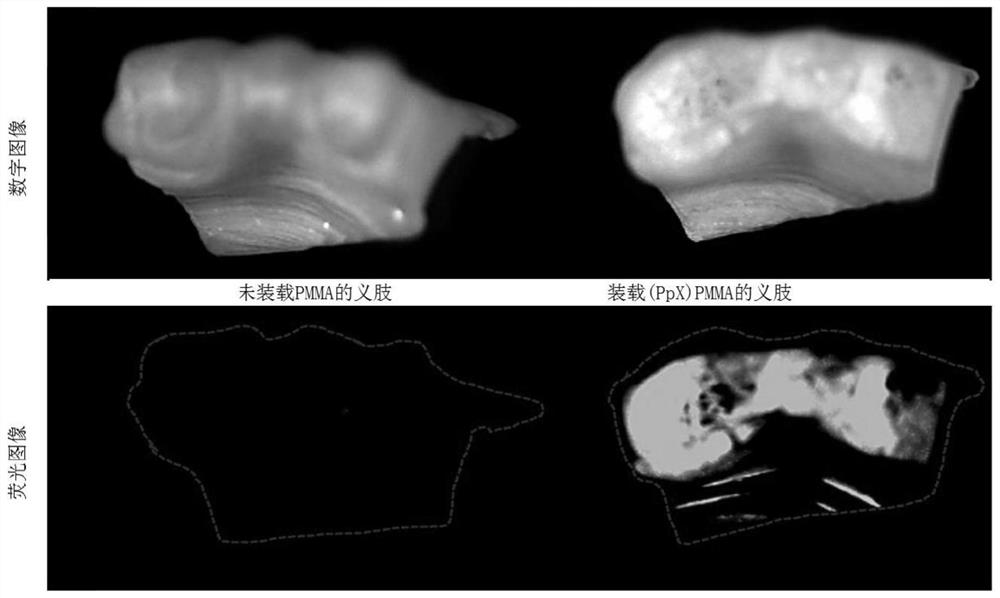

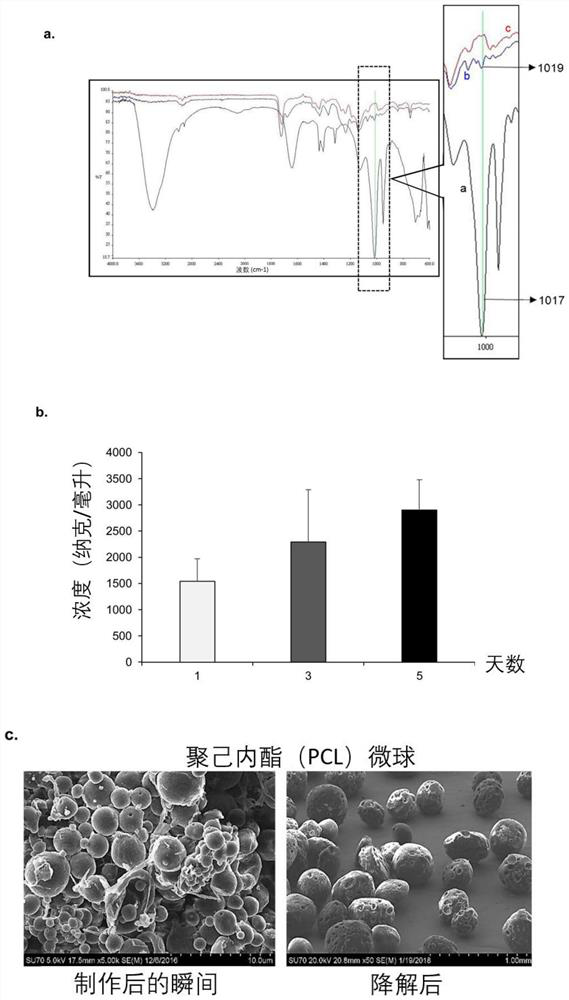

Functionalized prosthetic interfaces for the prevention and treatment of dental conditions

PendingUS20220160488A1Sustained releaseRemissionOrganic active ingredientsAdditive manufacturing apparatusOral mucous membraneMucosal disease

Provided are compositions and devices containing microspheres encapsulating one or more drug(s). The compositions and devices may be used to treat or prevent infection associated or caused by oral mucosal diseases, oral infections, oral conditions, dental conditions, or surgical recovery. The devices include, but are not limited to, splints, mouth guards, full dentures, partial dentures, or fillings. The devices may be manufactured from filaments that have a composition of the present disclosure. Also provided are methods of making and using the devices and compositions.

Owner:OPTIMED TECH

Upper jaw complete denture

InactiveCN101732100AOvercoming discomfortOvercome defects that affect taste effectsDental prostheticsFull denturesAbutment

The invention relates to a denture, in particular to an upper jaw complete denture. The upper jaw complete denture comprises a denture dental holder which is provided with denture teeth. The denture also comprises an upper abutment which is fixed on the root of tooth or the gum of a user; the denture dental holder is provided with a lower abutment corresponding to the upper abutment; the upper abutment and the lower abutment are both made of material capable of magnetic attraction, and at least one of the upper abutment and the lower abutment has magnetic property. Because adopting artful structure, the invention removes the fitting part, i.e. a sucking disc in the prior art and fixes the denture in the mouth of the user by the magnetic attraction of the lower abutment on the denture dental holder and the upper abutment fixed on the gum of the user, so that the invention overcomes the defects that the fitting part in the prior art causes wearers to feel uncomfortable and taste effect is affected.

Owner:章双华

Full denture and preparation method thereof

PendingCN111150509AImprove retention effectNot easy to looseFastening prosthesisArtificial teethFull denturesEntire mouth

The invention discloses a full denture and a preparation method thereof. The full denture comprises a lower denture assembly which comprises a lower base support, wherein lower dentures are embedded at the top part of the lower base support; a lower fitting groove matched with an alveolar ridge is arranged at the bottom part of the lower base support; and a weighting part is arranged in the lowerbase support. The full denture provided by the invention has the following advantages: the lower fitting groove matched with the alveolar ridge is arranged at the bottom part of the lower base support, and the base support can be tightly attached to the mucosa of the alveolar ridge, so the full denture has good position fixing performance; meanwhile, the weighting part is arranged in the lower base support to increase the weight of the lower base support and reinforce the adhesive force and the sealing performance of the base support, so the position fixing performance of the full denture is greatly improved; and the lower base support of the full denture is tightly and firmly combined with the alveolar ridge, so the full denture is not easy to loosen, fall off and float upwards, is comfortable for a user to wear, and has wide application prospect.

Owner:常映明

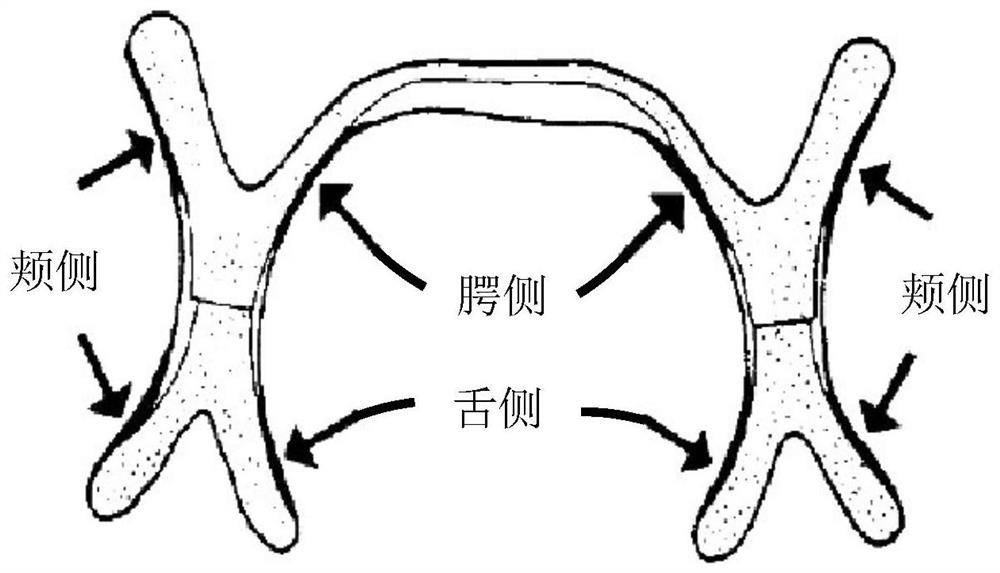

Full denture plastic splint type transparent tooth holder

The invention discloses a full denture plastic splint type transparent tooth holder. The full denture plastic splint type transparent tooth holder comprises two parts, i.e., an inner rack body and an outer rack body, wherein the inner rack is fixedly connected with the outer rack body through stainless steel wires; the inner rack body and the outer rack body are held close to the buccal and lingual surfaces of teeth and the lingual dental socket mucous membrane; a cavity between the inner rack body and the outer rack body is made according to the size of the teeth; the tooth occlusal surface is fully exposed. The full denture plastic splint type transparent tooth holder is held close to the teeth; the holder is tailored; the inner rack body and the outer rack body are closely attached to each tooth on both buccal and lingual sides without gap in order to provide guarantee for achieving the treatment purpose; the holder is stable to wear, tight, non-leveraging, and comfortable and attractive for a patient to wear, and the temporal-mandibular joint can be effectively protected; the holder is small in size and does not affect the pronunciation or the normal oral function; the inner rack body and the outer rack body of a functional part of the holder are made of plastic and have certain hardness and slight elasticity, the occlusal surface contains no plastic, no wear is caused by the occlusion, and four steel wires for connecting the inner rack body and the outer rack body have certain elasticity, so the holder is firm and difficult to damage.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

A full dentition plastic splint type transparent tooth fixer

The invention discloses a full denture plastic splint type transparent tooth holder. The full denture plastic splint type transparent tooth holder comprises two parts, i.e., an inner rack body and an outer rack body, wherein the inner rack is fixedly connected with the outer rack body through stainless steel wires; the inner rack body and the outer rack body are held close to the buccal and lingual surfaces of teeth and the lingual dental socket mucous membrane; a cavity between the inner rack body and the outer rack body is made according to the size of the teeth; the tooth occlusal surface is fully exposed. The full denture plastic splint type transparent tooth holder is held close to the teeth; the holder is tailored; the inner rack body and the outer rack body are closely attached to each tooth on both buccal and lingual sides without gap in order to provide guarantee for achieving the treatment purpose; the holder is stable to wear, tight, non-leveraging, and comfortable and attractive for a patient to wear, and the temporal-mandibular joint can be effectively protected; the holder is small in size and does not affect the pronunciation or the normal oral function; the inner rack body and the outer rack body of a functional part of the holder are made of plastic and have certain hardness and slight elasticity, the occlusal surface contains no plastic, no wear is caused by the occlusion, and four steel wires for connecting the inner rack body and the outer rack body have certain elasticity, so the holder is firm and difficult to damage.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

Food chopper

The invention relates to a food chopper, which is provided by thinking, making and improving when a user wears a full denture and chews food, the user cannot exert force to chew the food, otherwise, the user can hurt gums, the user wants to be good if the food is small, some food chopping tools are seen on the net, such as multi-connected scissors are strenuous, and other food chopping tools are inconvenient to carry. According to the invention, greater force can be applied to food through hand pressing by means of body weight, and the device has the characteristics of labor saving, convenience in carrying and high efficiency, and is mainly applied to infants without teeth, old people without teeth and full dentures, and toothache patients who cannot bite with force; large or hard food placed in the bowl is pressed and chopped by the food chopper, so that the food chopper is convenient to chew and swallow, such as meat pies, steamed buns, dumplings, noodles and the like, and also can be applied to chopping common food and vegetables, such as garlic, green Chinese onion and the like; the information is written to people in need, and contributions are hoped to bring convenience to the life of people.

Owner:魏成越

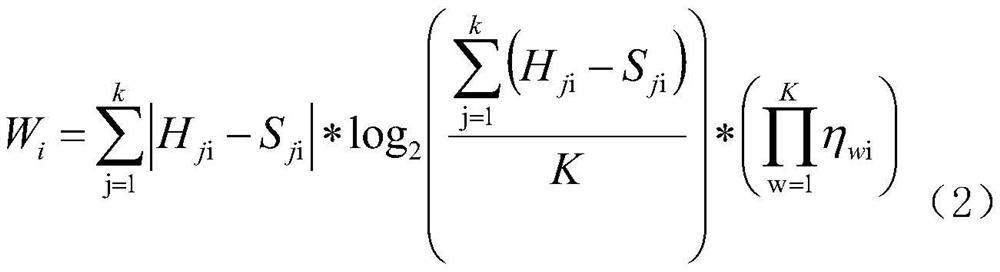

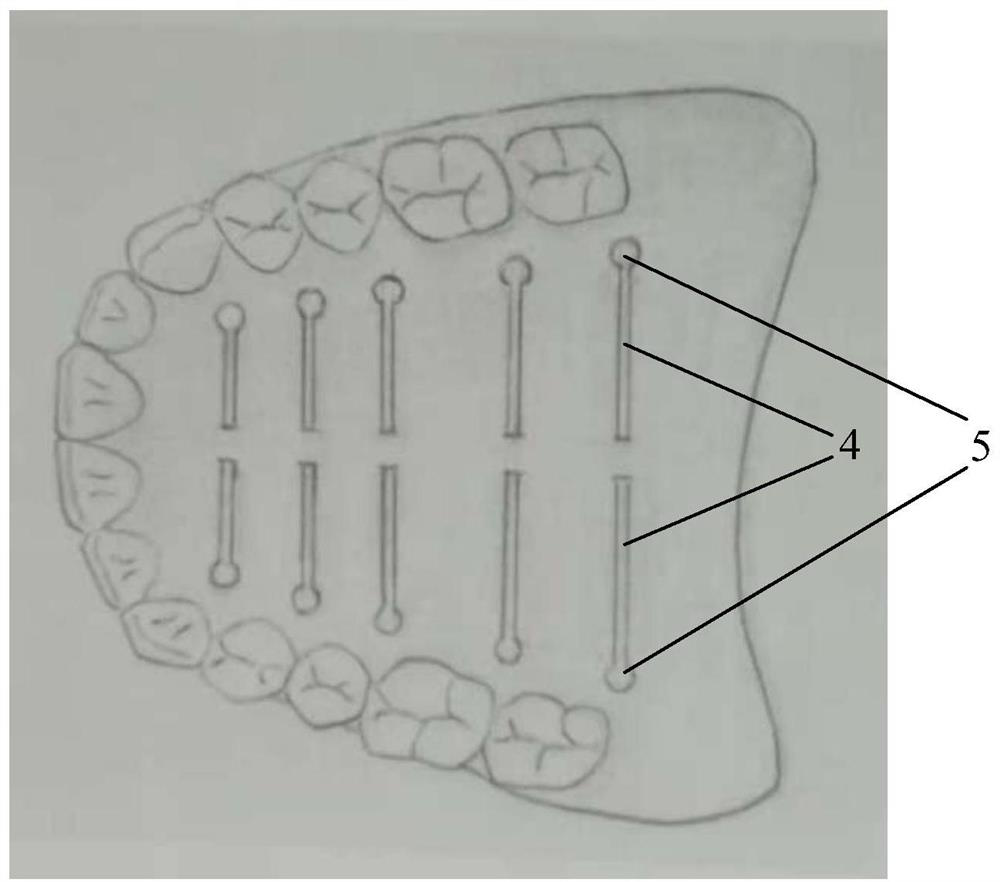

A standard detection method for 3D printing accuracy of dental medical products

ActiveCN110095063BQuick quantification of actual print accuracyEasily identify sources of errorUsing optical meansComputer printingMedical product

The invention relates to a standard detection method for 3D printing accuracy of oral medical products, which comprises the following steps: designing and processing a standard preparation model of a full dentition fixed denture; designing a full dentition fixed denture data D0, the outer surface data is D1, and the inner surface data D2; use the 3D printer to be evaluated to process the entity, place it on the standard preparation model of the full dentition fixed denture, and scan to obtain the three-dimensional data of the outer surface D3; make an impression of the inner surface of the full dentition fixed denture, and scan it to obtain D4 ; Use the common area registration algorithm to register D1, D2, D3, and D4 to D0 respectively; use the 3D deviation analysis command to calculate the single tooth, multiple teeth, and single-jaw full dentition between D1 and D3, and between D2 and D4 The average distance and root mean square error value of . The invention can quickly quantify the actual printing accuracy of the 3D printer when printing different oral medical products, different dental arch spans, and different manufacturing stages, so as to facilitate the determination of error sources and the improvement of the printing process.

Owner:NANJING PROFETA INTELLIGENT TECH CO LTD

Buccal multi-bending spring space three-dimensional dynamometer

The invention relates to a buccal multi-bending spring space three-dimensional dynamometer (in figure 2), which is applied to simulating a maxilla, a mandible and a temporom and ibular joint, and predicting the push and pull force values generated on crossover points of the maxilla and the mandible when a correction patient wears multi-bending springs 28I and 28II to perform mouth opening and closing motions. The dynamometer has accurate measurement and can instruct the clinical allopathic wearing according to the following steps: (1) putting two terminal filaments of the 28I and the 28II into a 15I, a 15II and upper jaws 33I and 33II fastening the terminal filaments, and moving a bracket 43 leftwards and rightwards so as to measure the pulling-pressing stress values and the displacements of the 28I and the 28II to a full denture; (2) elongating the 28I and the 28II, fastening the same into holes of the 15I, the 15II, the 33I and the 33II, moving a 32I and a 32II to adjust the stress values to approach to 0, driving a 35, the 32I and the 32II to move rightwards, and measuring the maximum pressing stress value of the full denture of the upper jaw and the lower jaw when the 28I and the 28II are pressed to a mouth-closing state; and (3) measuring the stress values and the displacements of the 28I and the 28II along the scales of 5 degrees, 10 degrees and 15 degrees of a 8I and a 8II by the 15I and the 15II; and if a 21I and a 21II move around a center leftwards and rightwards (the 15I and the 15II are 3 millimeters away from the central displacement), repeating the steps (1) and (2) to measure acting forces and displacement values.

Owner:侯录 +1

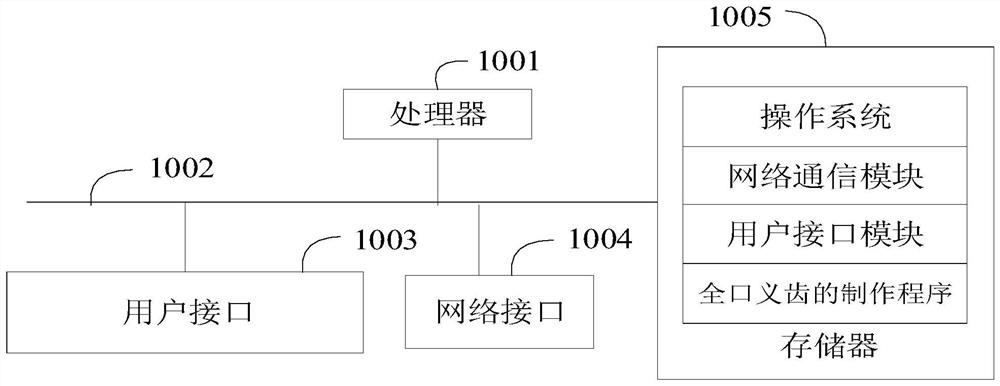

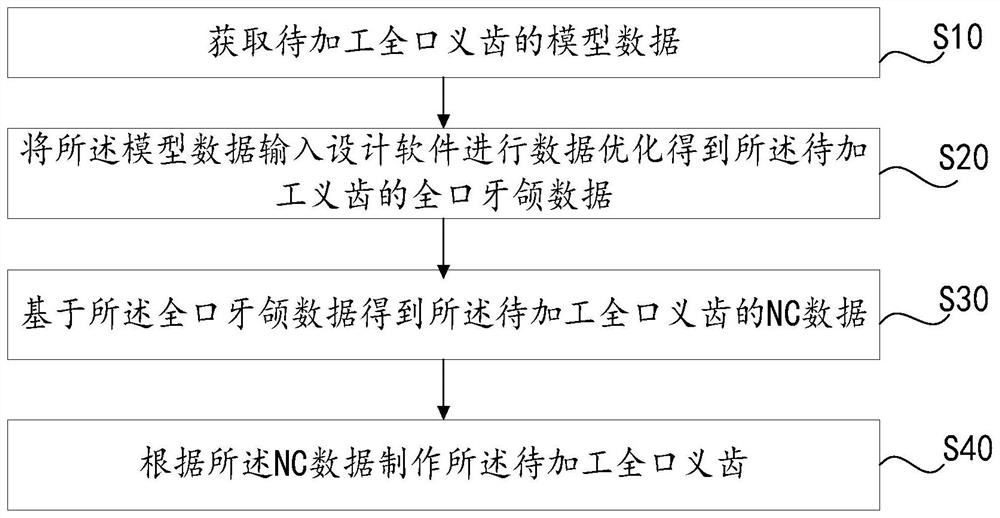

Complete denture manufacturing method, system and equipment and storage medium

PendingCN114145870AGuaranteed efficiencyGuaranteed machining accuracyArtificial teethProgramming languageFull dentures

The invention discloses a complete denture manufacturing method, system and device and a storage medium, and the method comprises the steps: obtaining model data of a complete denture to be processed; inputting the model data into design software for data optimization to obtain complete tooth jaw data of the complete denture to be processed; obtaining NC data of the to-be-added complete artificial tooth based on the complete tooth jaw data; and manufacturing the complete denture to be processed according to the NC data. The full-mouth model data is optimized through design software to obtain full-mouth tooth jaw data of the human oral cavity, corresponding NC data is generated, and a corresponding full denture is manufactured on cutting equipment based on the NC data. While ensuring that the complete denture model is suitable for the oral environment of a user, the denture processing efficiency and processing precision are also ensured.

Owner:SHENZHEN UP3D TECH CO LTD

Complete dentition full denture finished product resin tooth and preparation method thereof

ActiveCN102805670BFast centric biteMinimize the difference in tooth row levelImpression capsArtificial teethOcclusal AdjustmentLower dentition

Owner:SHANDONG UNIV

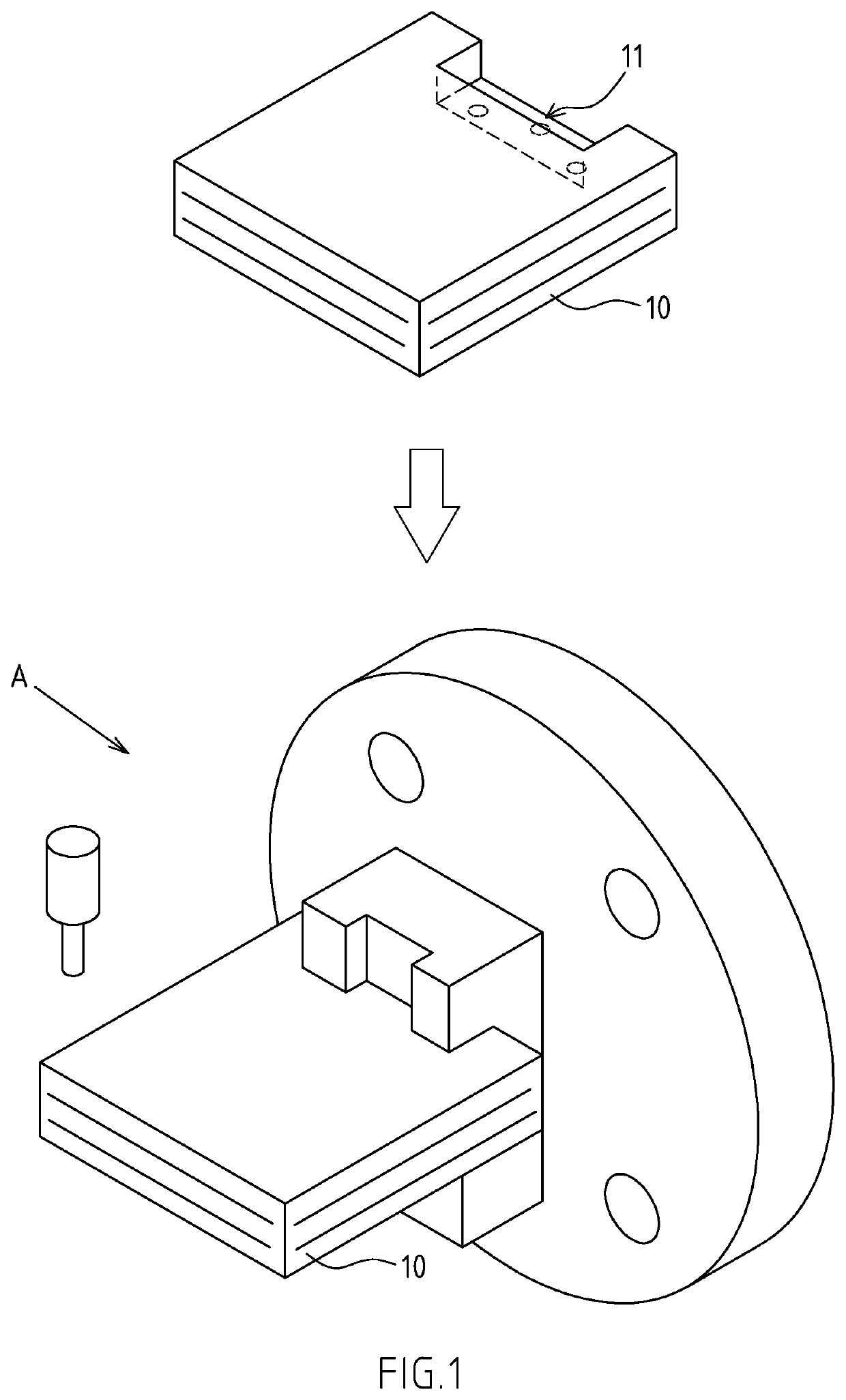

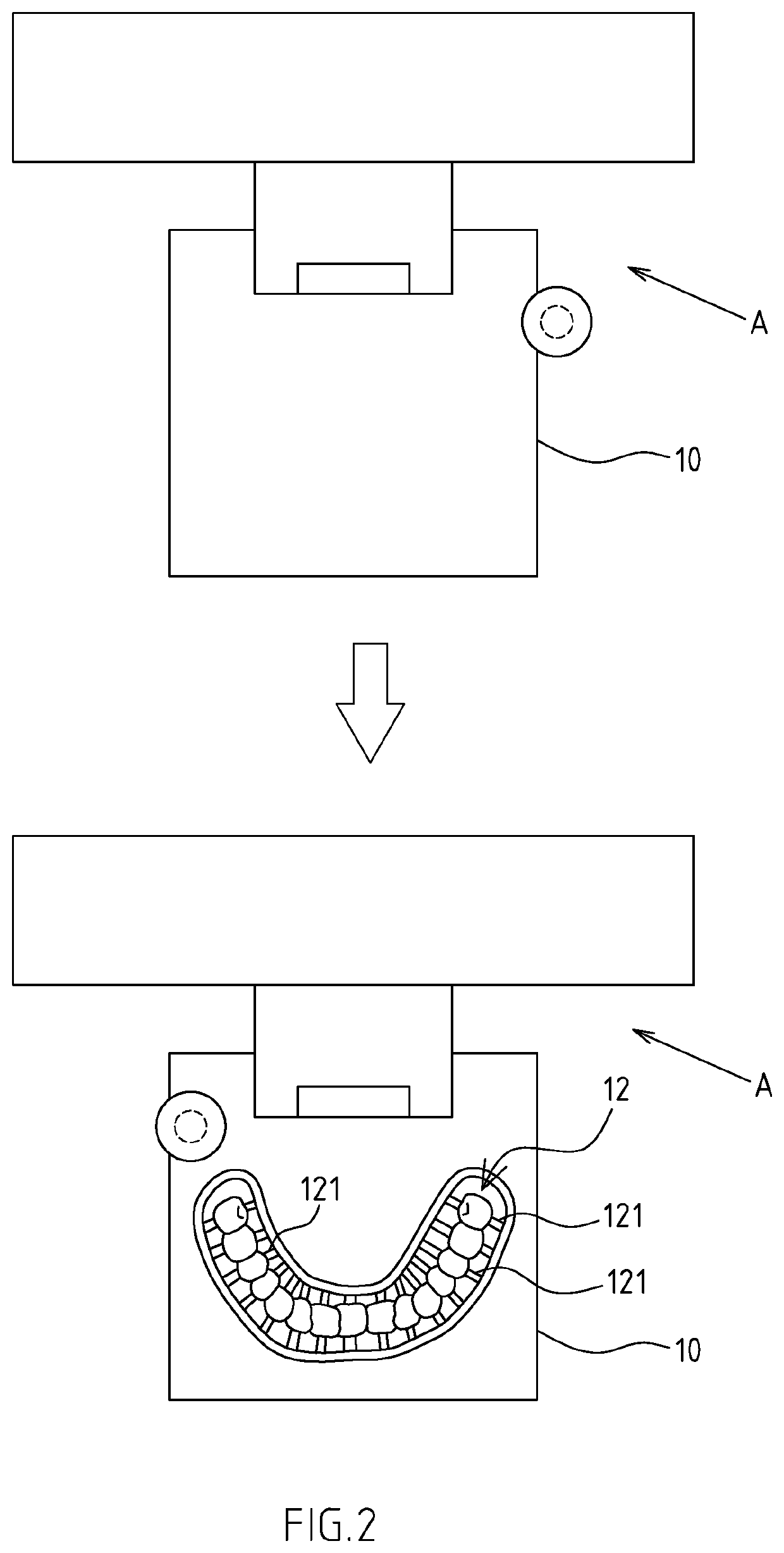

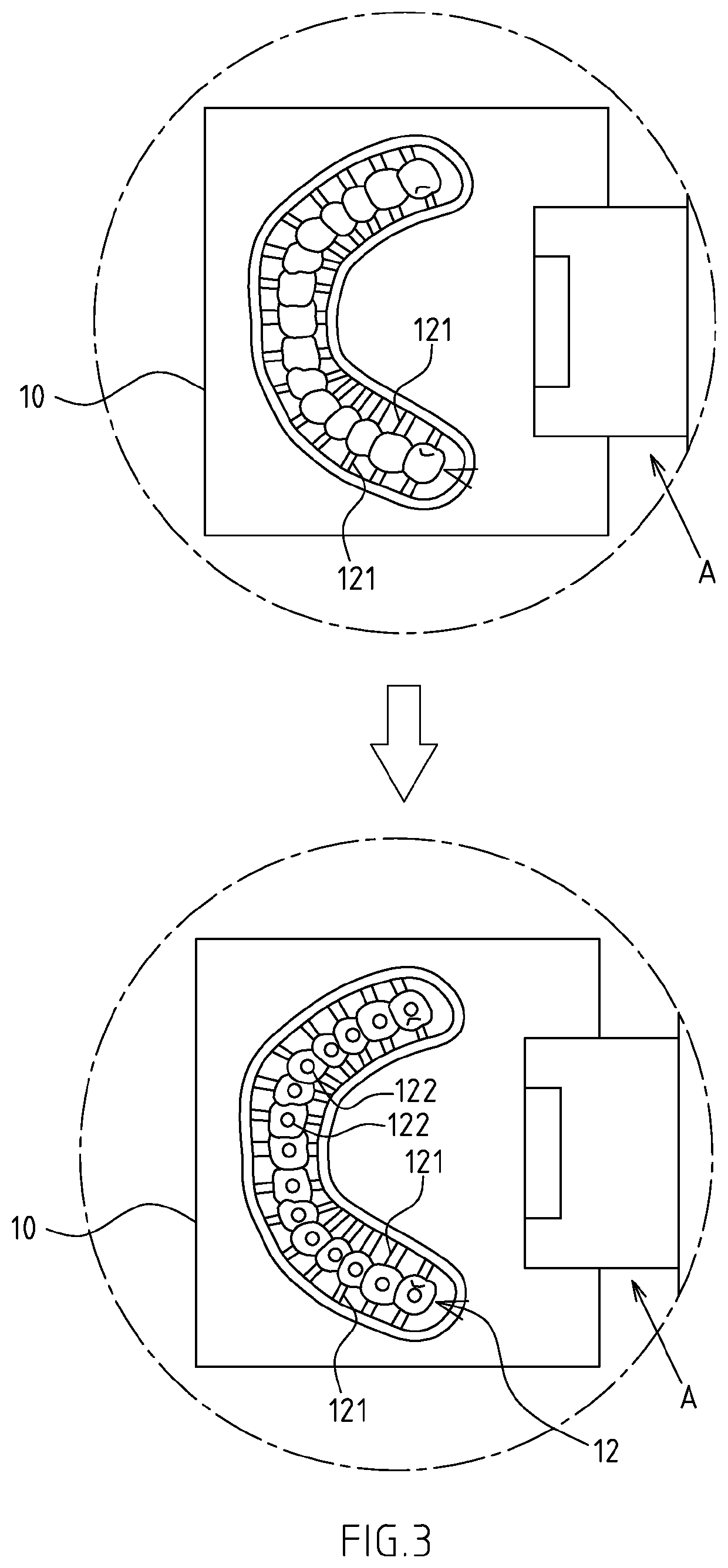

Full denture processing and shaping method and material block thereof

InactiveUS20190374319A1Improve convenienceImprove precisionArtificial teethDomestic articlesFull denturesPlastic materials

A full denture processing and shaping method and a material block thereof are disclosed. The full denture processing and shaping method comprises the follow steps of: providing a hard colored material block to be positioned to a processing device, a portion of the hard colored material block being shaped into a tooth-shaped structure; mounting the hard colored material block in an injection mold; injecting a soft plastic material with a different color into the injection mold, the soft plastic material being polymerized to form a gingival colored material block to constitute a multicolor structure; demoulding the injection mold to take out the material blocks for processing, the gingival colored material block being shaped into a denture base.

Owner:CHIOU WEN HSIN +1

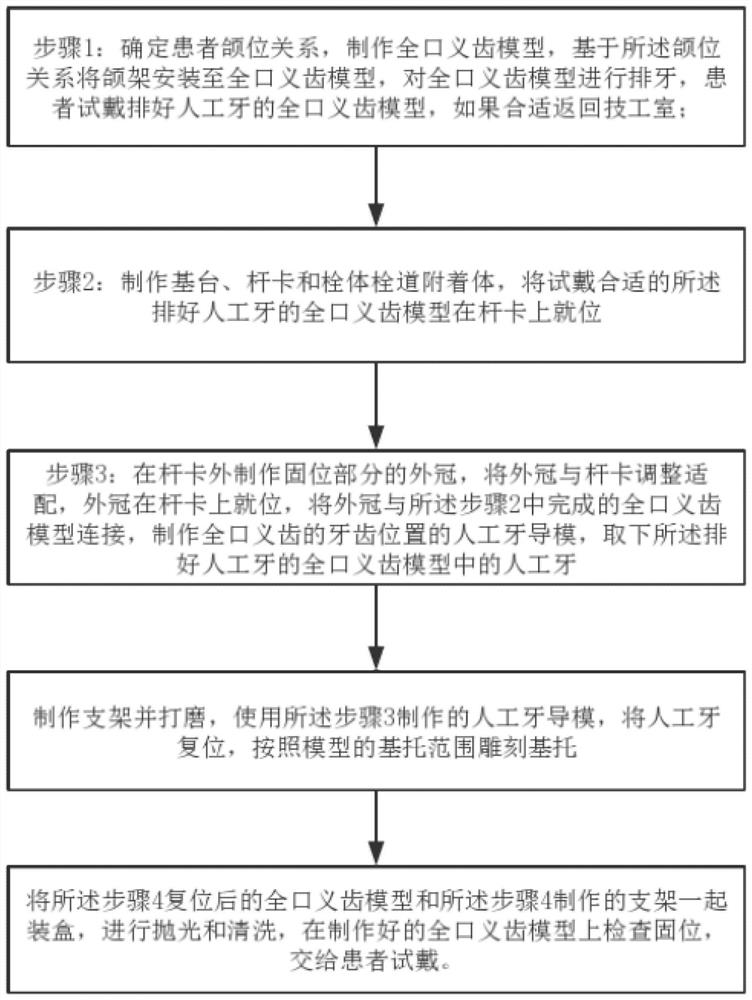

A kind of usage of dental plug body plugway attachment body

ActiveCN112451138BSolve the lack of retentionGeometric CADDesign optimisation/simulationFull denturesTooth position

The invention provides a method of dental plugway attachment, comprising the following steps: determining the patient's jaw position relationship, transferring the obtained jaw position relationship to the jaw frame, arranging the teeth, and making the final model; making the abutment, For the bar and plug attachments, place a suitable full denture model on the bar; make the outer crown of the retaining part outside the bar, adjust the outer crown to the bar, and place the outer crown on the bar. The crown is connected to the complete denture model; the artificial tooth guide mold of the tooth position of the complete denture is made, and the artificial tooth is removed; the bracket is made and polished, and the artificial tooth guide mold is used to reset the artificial tooth according to the base range of the model Carve the base; box the fabricated complete denture model with the bracket, polish and clean it, check the retention on the fabricated complete denture model, and hand it over to the patient for a try-on. The addition of plug body plug attachments at the end of the bar solves the problem of the decrease in the retention force of the denture after 3-5 years of restoration of the existing implant bar-type complete denture.

Owner:北京联袂义齿技术有限公司

Dental complete denture denture care device and method of use thereof

ActiveCN112869903BTroubleshoot Cleaned DevicesFull cleaning of device issuesTooth cleaningFull denturesNursing care

Owner:杨平

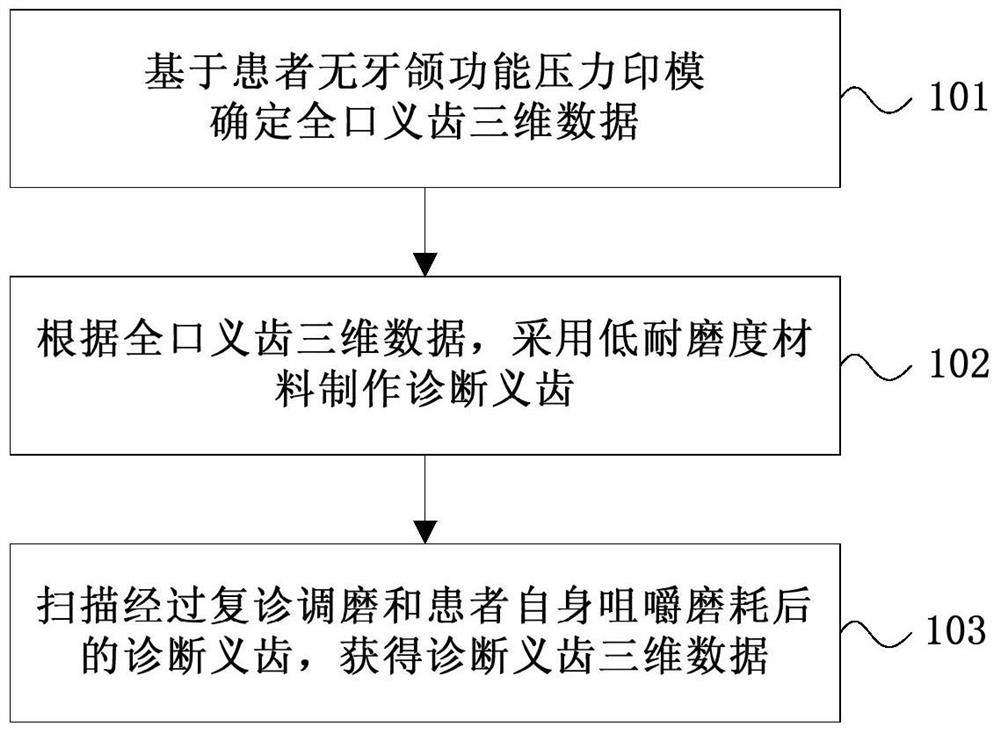

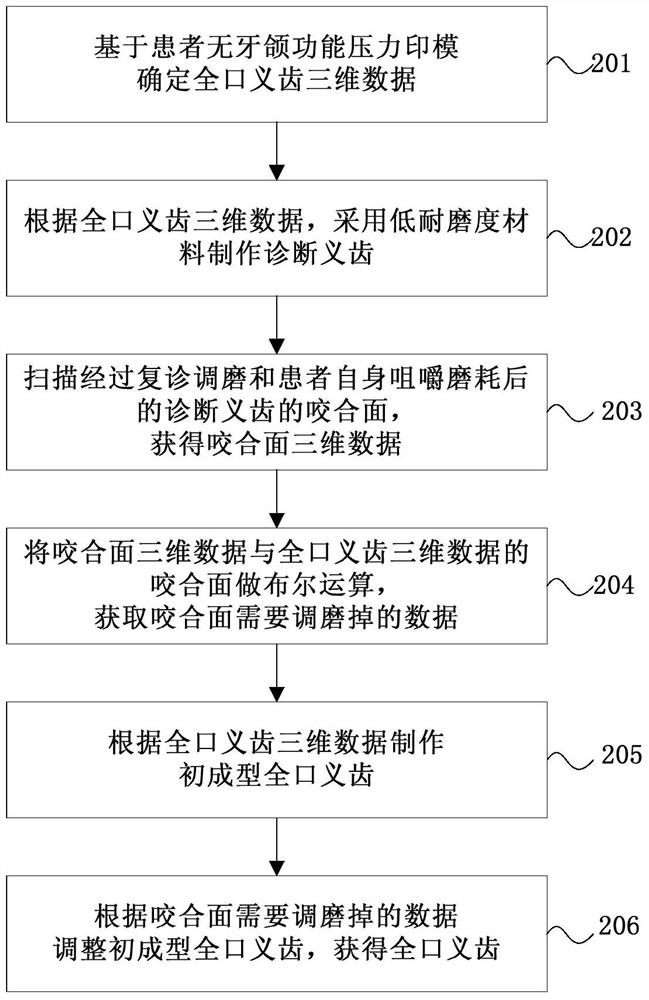

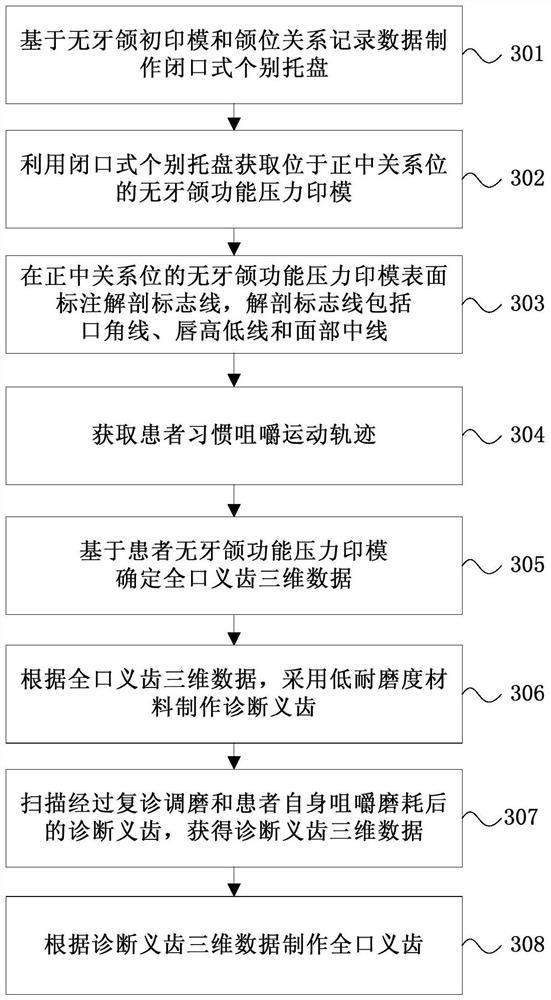

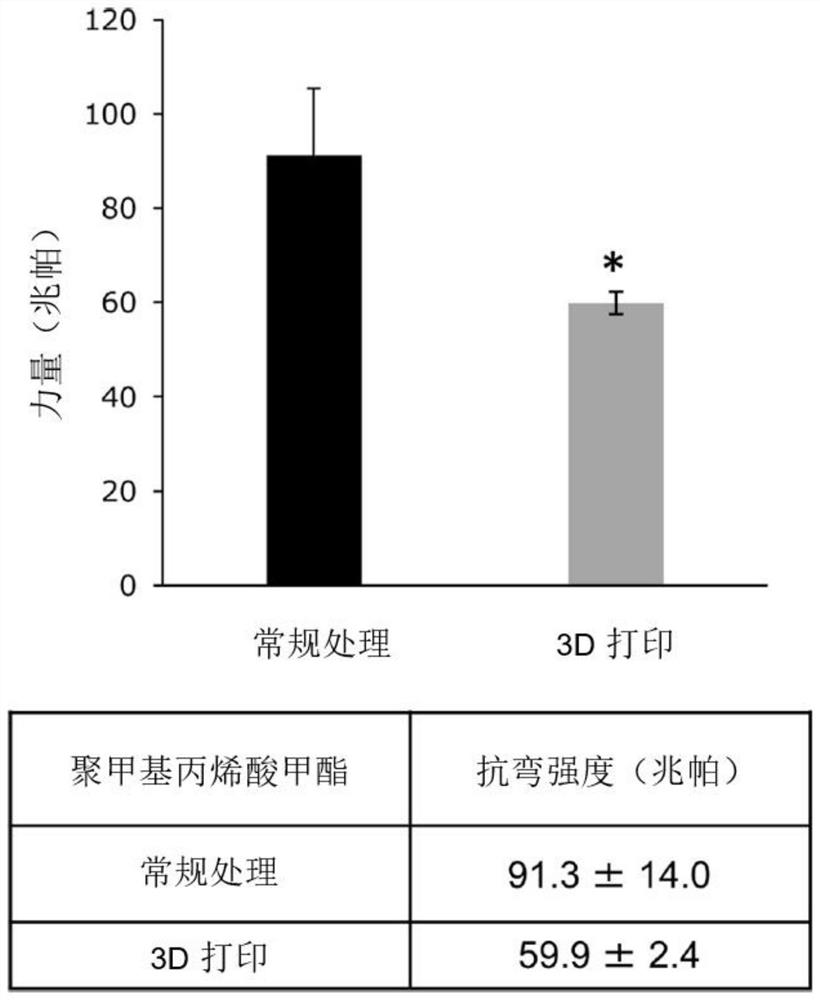

Method and equipment for making functional and adaptable digital complete denture

ActiveCN108024847BImprove production efficiencyImprove accuracyArtificial teethFull denturesDentistry

A method for making a full denture, the method comprising: determining 3D data of a full denture on the basis of a functional pressure impression of an edentulous patient (101); using, on the basis of the 3D data, a low abrasion-resistant material to make a diagnostic denture (102); scanning the diagnostic denture after adjustment and preparation followed by occlusal wearing by the patient, and obtaining diagnostic denture 3D data to make a full denture according thereto (103). A functionally adaptive and digital apparatus for making a full denture is also provided. The full denture made using the method and apparatus of the present invention can better meet the needs of a patient, improve the precision of denture production, and enhance user comfort.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

A kind of semi-finished complete denture based on prefabricated dentition structure and the rapid manufacturing method of complete denture

ActiveCN112618074BOmit first impressionReduce workloadImpression capsArtificial teethImpression traysFull dentures

The invention provides a semi-finished complete denture based on a prefabricated dentition structure and a rapid production method of the complete denture, aiming at reducing the workload of dentists and technicians and reducing the waiting time of patients under the premise of accurately fitting the patient. The semi-finished complete denture includes a prefabricated temporary base of thermosetting resin material and a prefabricated dentition fixedly combined with it; the prefabricated temporary base is provided with a plurality of strip-shaped holes, and the width of the hole on one side of the polished surface is Slightly larger than the width of the orifice on one side of the tissue surface; the strip-shaped holes in the palatal area of the preformed temporary base of the upper jaw are symmetrically distributed on the left and right, and both ends of the length direction are closed; One end on the top reaches the edge of the preformed temporary base, forming an opening on the edge of the preformed temporary base, and the other end is closed; the distance between the lip-palatal (tongue) and buccal-palatal (tongue) of the preformed temporary base tissue surface is slightly It is greater than the distance between the corresponding parts of the clinical complete denture tissue surface to replace the role of the impression tray and reserve a space for the impression material.

Owner:吴瑛

Functionalized prosthetic interfaces for prevention and treatment of dental conditions

Provided are compositions and devices containing microspheres encapsulating one or more drug(s). The compositions and devices may be used to treat or prevent infection associated or caused by oral mucosal diseases, oral infections, oral conditions, dental conditions, or surgical recovery. The devices include, but are not limited to, splints, mouth guards, full dentures, partial dentures, or fillings. The devices may be manufactured from filaments that have a composition of the present disclosure. Also provided are methods of making and using the devices and compositions.

Owner:澳谛医药科技有限公司

Full-mouth denture base suitable for serious undercut deformity of jawbone and manufacturing method thereof

PendingCN112318794ASolve the problem of severe undercuts that require surgery to mount teethSave money on surgeryDental prostheticsSurgical operationJaw bone

The invention discloses a full-mouth denture base suitable for serious undercut deformity of a jawbone and a manufacturing method thereof. The full-mouth denture base comprises a base main body and asoft resin base which is formed by fusing and adhering the base main body into an undercut area of the jawbone. The manufacturing method mainly comprises the following steps: preparing the soft resin,drawing the undercut area on a gypsum model, expanding towards the direction of the base to the undercut area, drawing a connecting area, manufacturing a wax pattern, arranging teeth, filling glue and the like. According to the full-mouth denture base, the soft resin enters the jawbone area with serious undercut deformity and is fused with the common denture materials, so that the problem that teeth can be embedded only after a surgical operation is performed on the jawbone with serious undercut in the past is solved, the jawbone correction surgical operation of a patient is avoided, the operation cost and the operation pain are saved, the teeth can be embedded more conveniently, and important promotional value is achieved.

Owner:南昌迎日口腔诊所

Multiple layered denture block and/or disk

ActiveUS10433939B2Improve wear resistanceArtificial teethDomestic articlesFull denturesDental laboratory

This invention designs and builds multiple layers (two layers or more) of millable dental blocks or disks for milling of various dental devices, specifically denture base blocks or disks of denture base material, where milled teeth cavities to receive artificial denture tooth materials to form final dental devices, such as partial and full dentures. This invention also designs and builds multiple layers (two layers or more) of millable denture base or denture blocks or disks comprised of denture base or / and denture tooth materials to form final dental devices, such as partial and full dentures. A method for manufacturing a layered denture is provided. The invention provides a multiple layered denture base block (or disk) for milling a denture base. The invention also provides a multiple layered denture block (or disk) for milling a denture. Highly shape adjustable or shape memory polymer layer(s) may be used in these multiple layered forms. Different layer of material has different mechanical and physical properties to meet different need, which provide added benefits to the patients, dental professional and dental laboratory.

Owner:DENTSPLY SIRONA INC

Method for determining upper and lower jaw positions using individual trays of 3D printed complete dentures

ActiveCN106901854BMade preciselyEfficient matching of anatomyDental articulatorsEducational modelsFull denturesEngineering

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com