Patents

Literature

36 results about "Dental cusp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2007-11-25 | Dental anatomy | 0 |. A cusp is a hard eminence on a tooth that emerges from the surface of which the tooth bites. Canine teeth each possess a single cusp, while premolars have two each. Molars normally possess either four or five cusps.

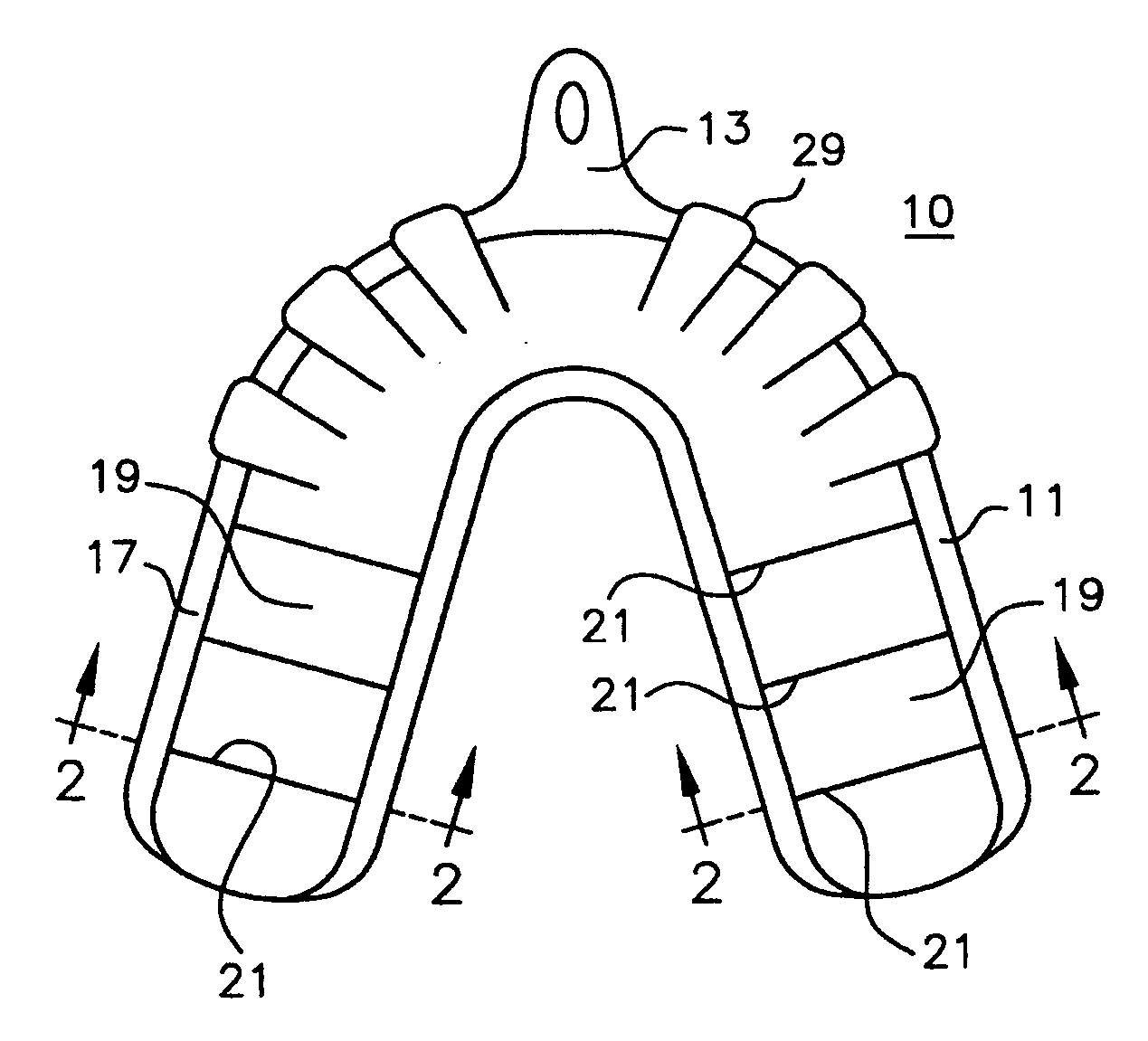

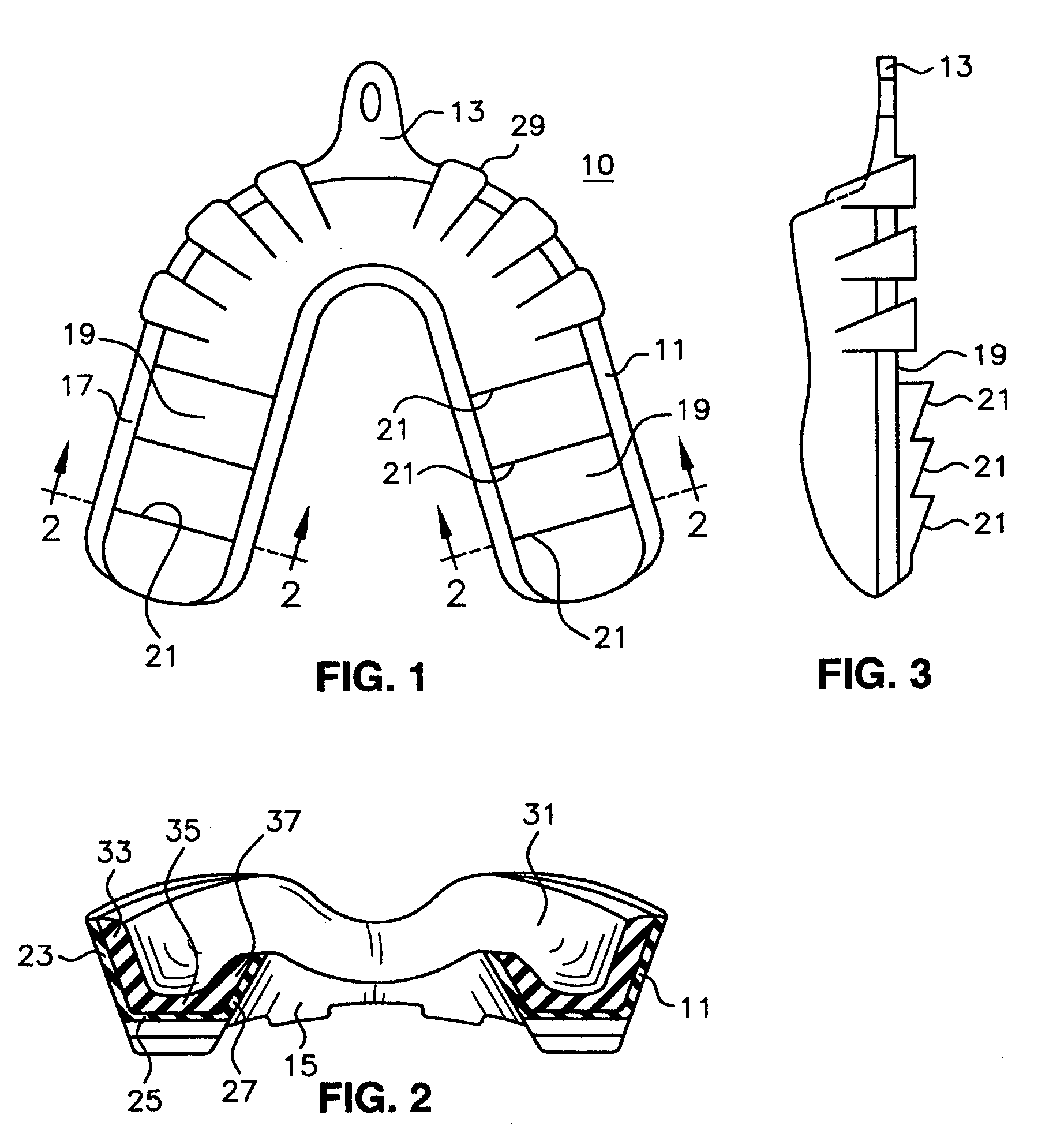

Dual tray athletic mouthguard

A mouthguard for use by athletes, including a dual tray assembly molded together. The first tray is molded from a hard plastic such as an ethylene vinyl acetate copolymer, and has a portion that engage the cusps of the lower jaw molars to prevent the tray from moving backward on impact. A second tray is molded on to the first tray using a soft plastic or gel like material, such as a high percentage vinyl acetate copolymers of ethylene vinyl acetate, that softens at slightly elevated temperatures that a user can easily tolerate. The first time the mouthguard is used, it is heated in warm water, then the user puts it in his or her mouth and bites down to cause the second tray to conform to the upper teeth. When in use, the ridges on the first tray engage the teeth of the lower jaw to prevent movement of the lower jaw on impact.

Owner:SAFE GARD

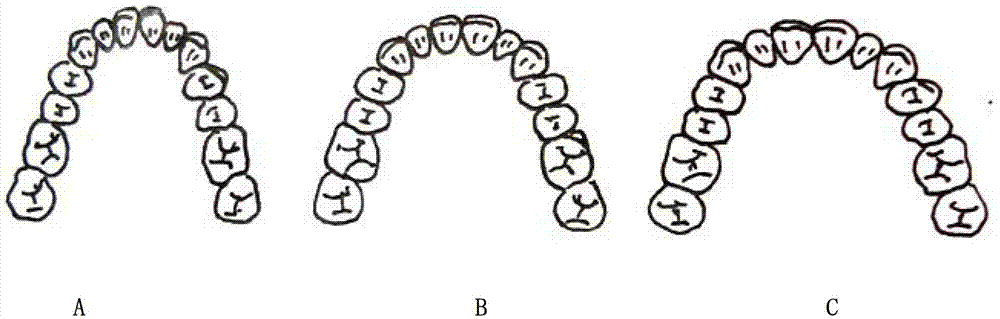

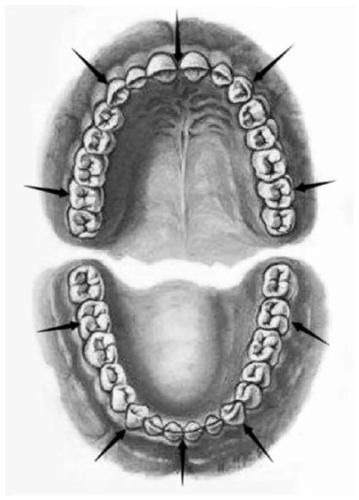

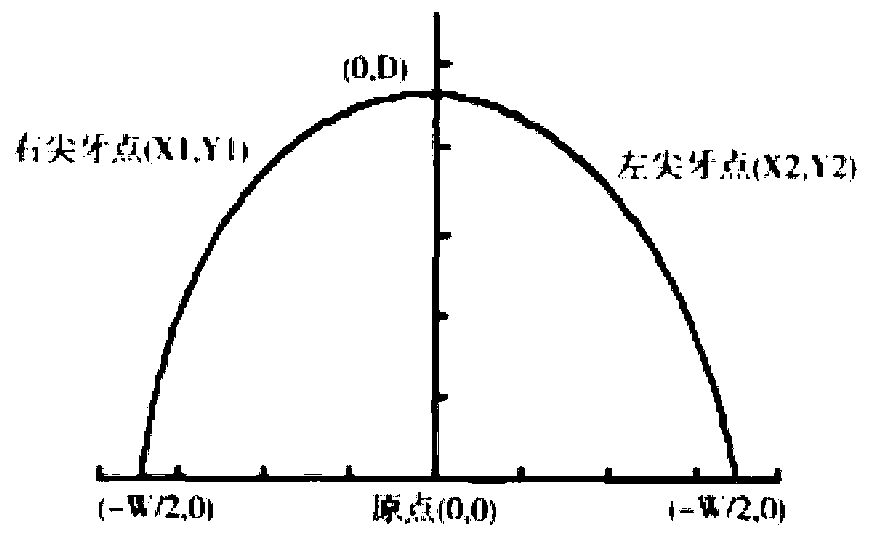

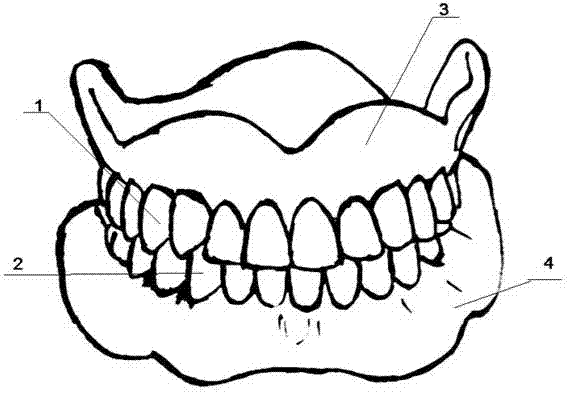

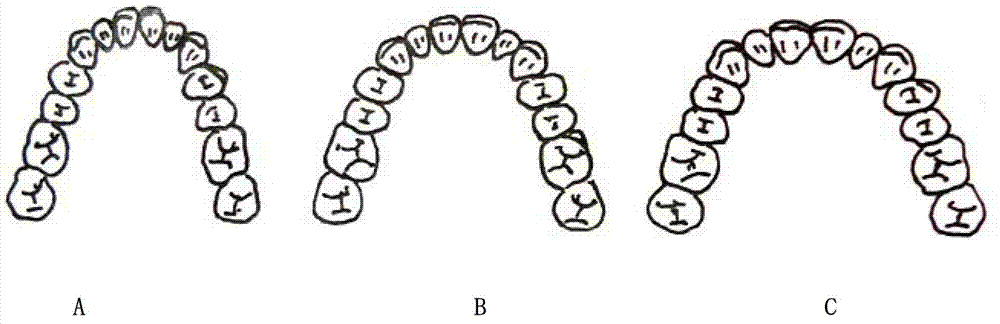

Complete dentition full denture finished product resin tooth and preparation method thereof

ActiveCN102805670AFast centric biteMinimize the difference in tooth row levelImpression capsArtificial teethOcclusal AdjustmentLower dentition

The invention relates to a complete dentition full denture finished product resin tooth, which comprises an upper denture, a lower denture, an upper dentition and a lower dentition, wherein the upper dentition is fixedly connected with the upper denture; the lower dentition is fixedly connected with the lower denture; and the upper dentition and the lower dentition are engaged with each other and are integral dentitions respectively. According to the complete dentition full denture finished product resin tooth, during arrangement of teeth and wearing, the upper dentition and the lower dentition are quickly and centrally engaged, so that the arrangement efficiency of the teeth is increased, the difference in tooth arrangement level of technicians is reduced, and the aims of guaranteeing wide close contact, reducing the clinical occlusal adjustment time and shortening the treatment time of patients are fulfilled. Each tooth is arranged according to an inclination angle in the tooth arrangement standard and positional relation of each dental cusp and an occlusal plane; the upper dentition and the lower dentition are matched teeth and are centrally engaged without error basically; the chair-side occlusal adjustment time of the full denture is reduced; the treatment time is shortened; and the comfort and the satisfaction of patients are improved.

Owner:SHANDONG UNIV

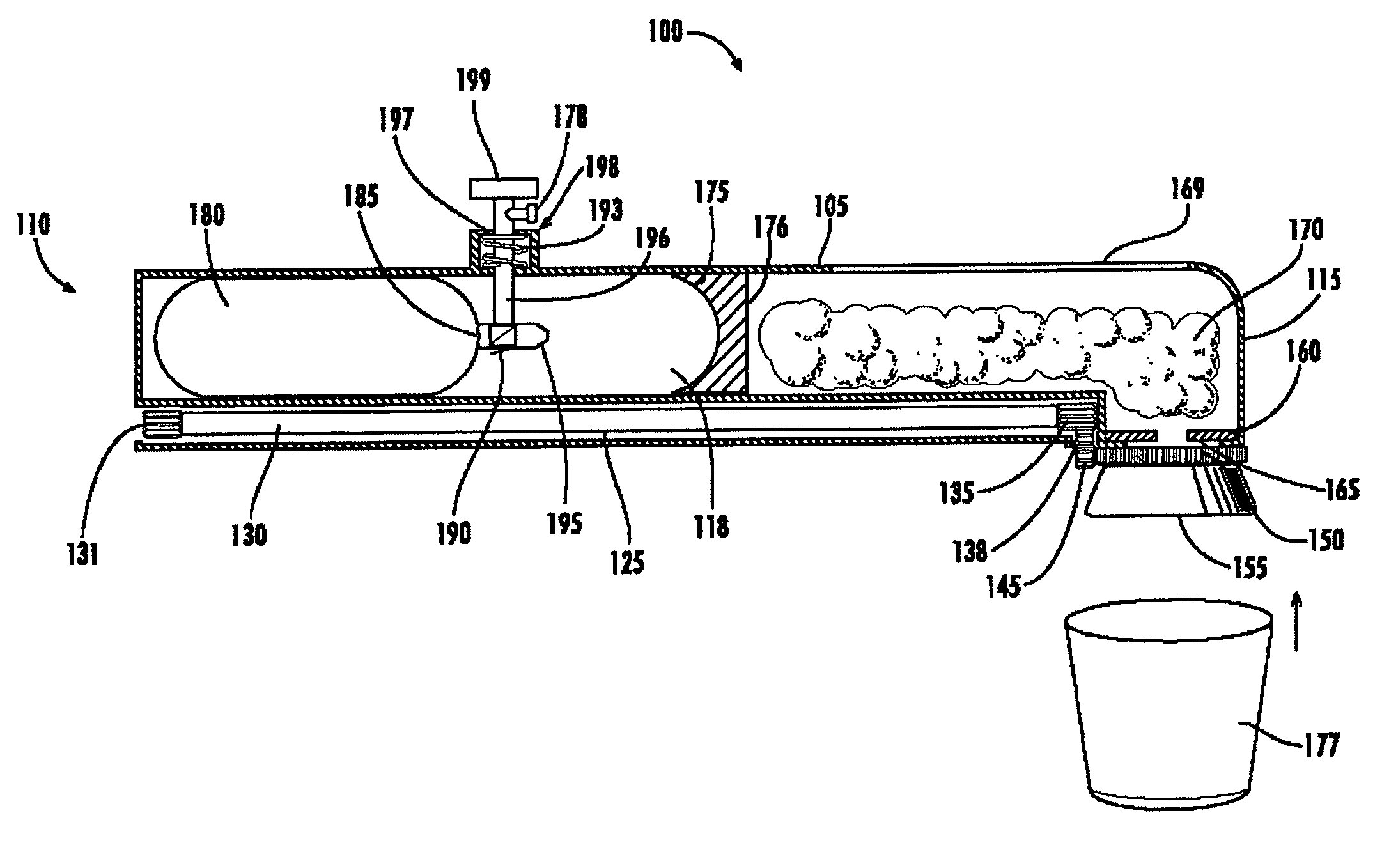

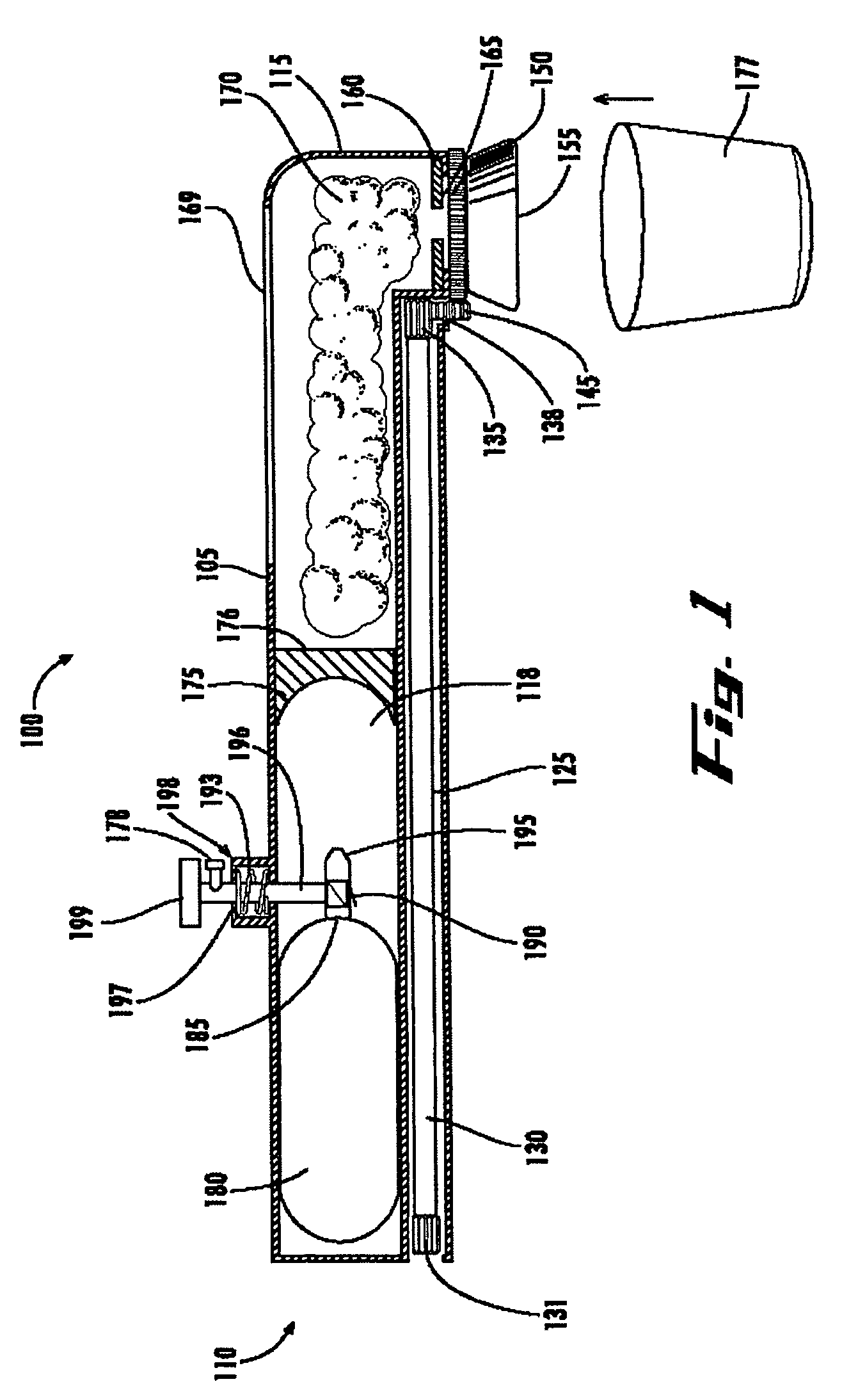

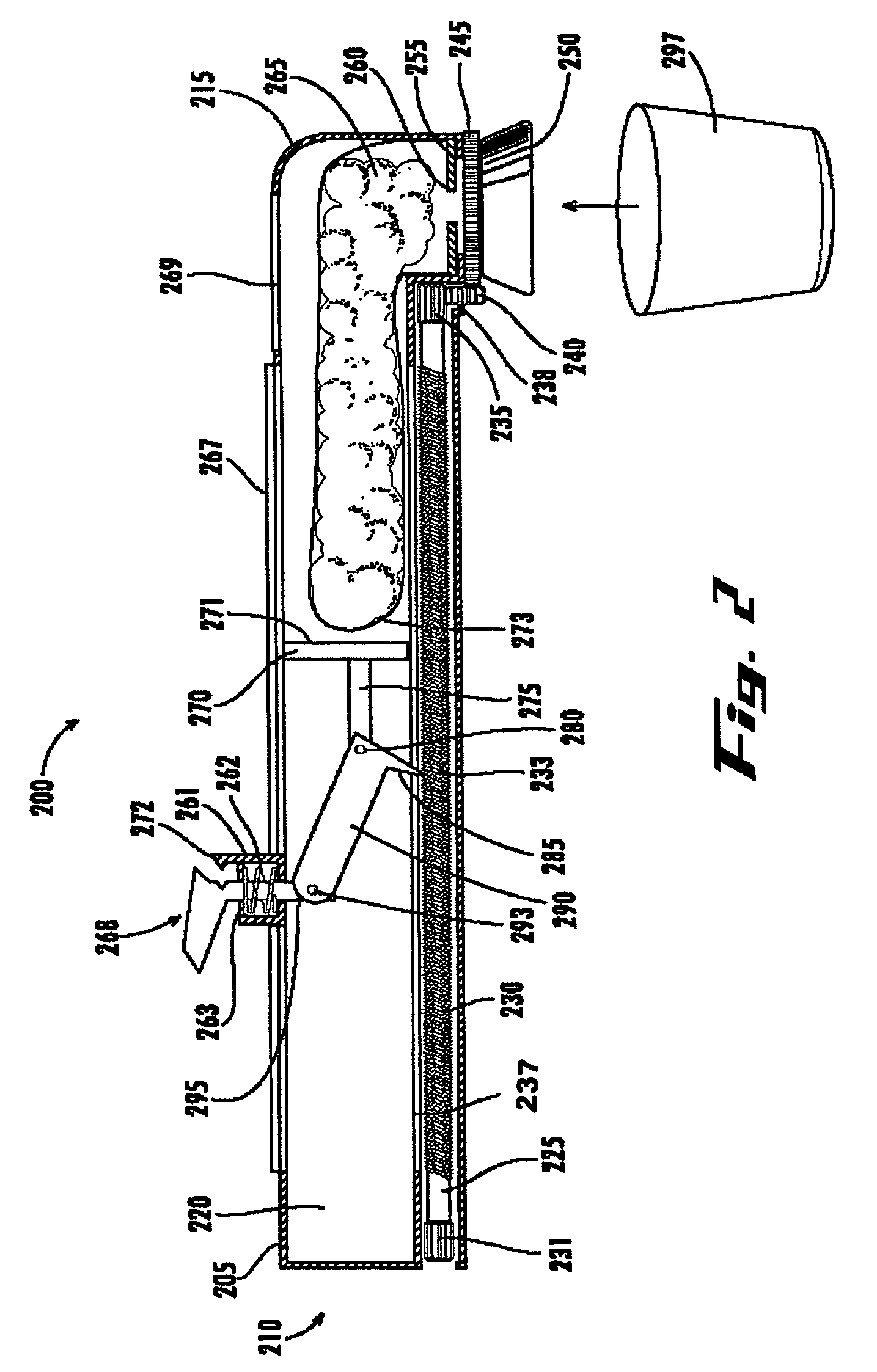

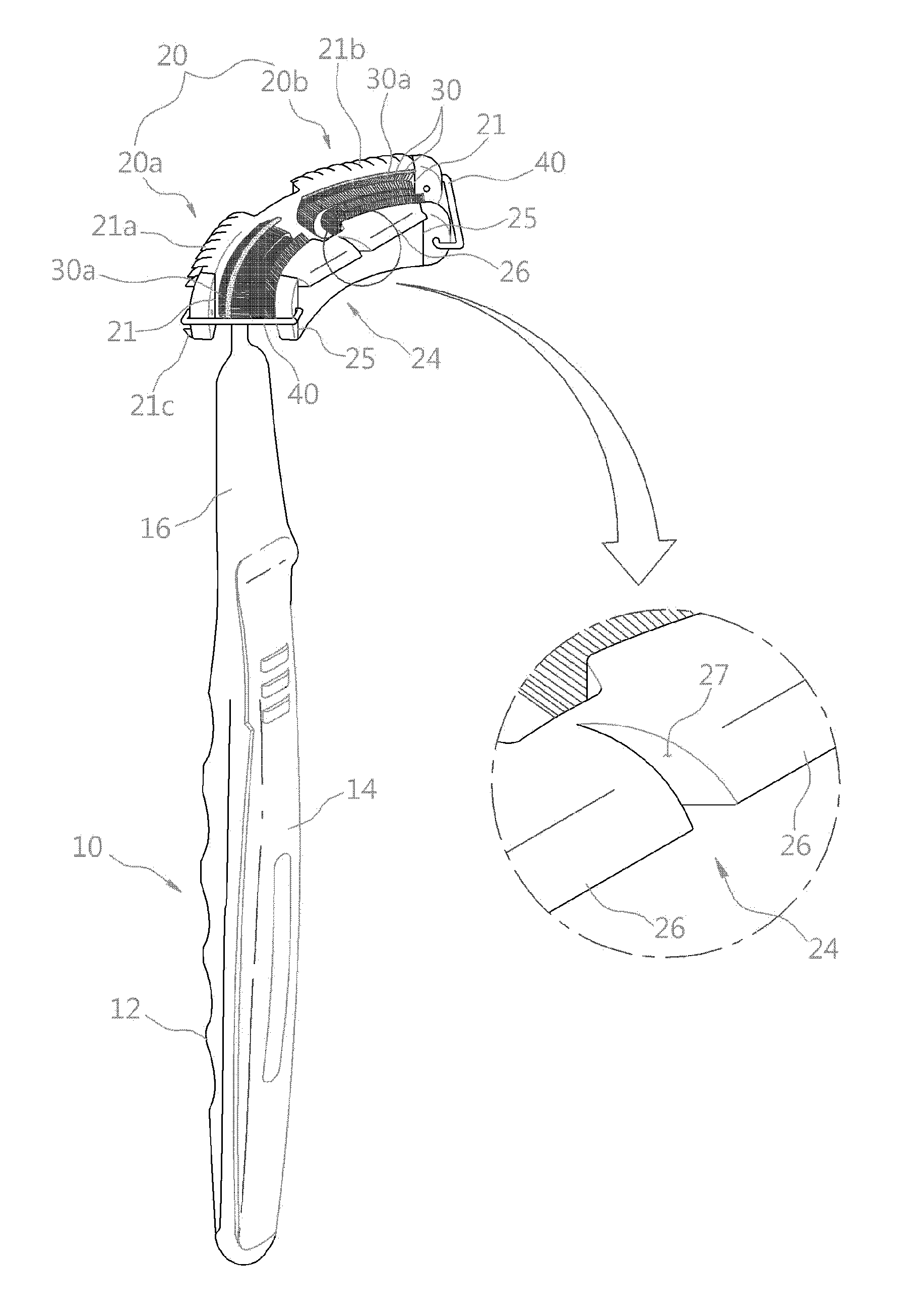

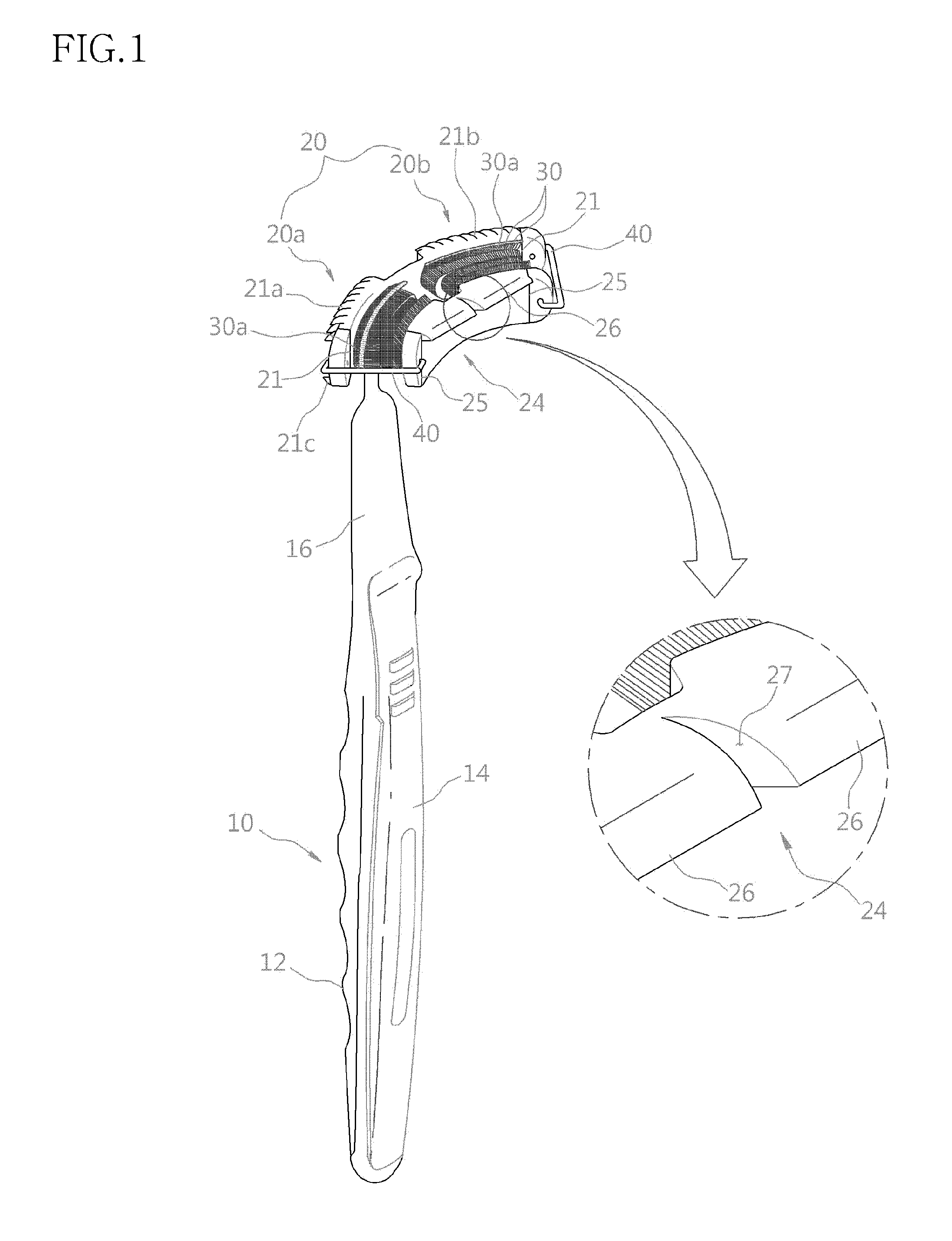

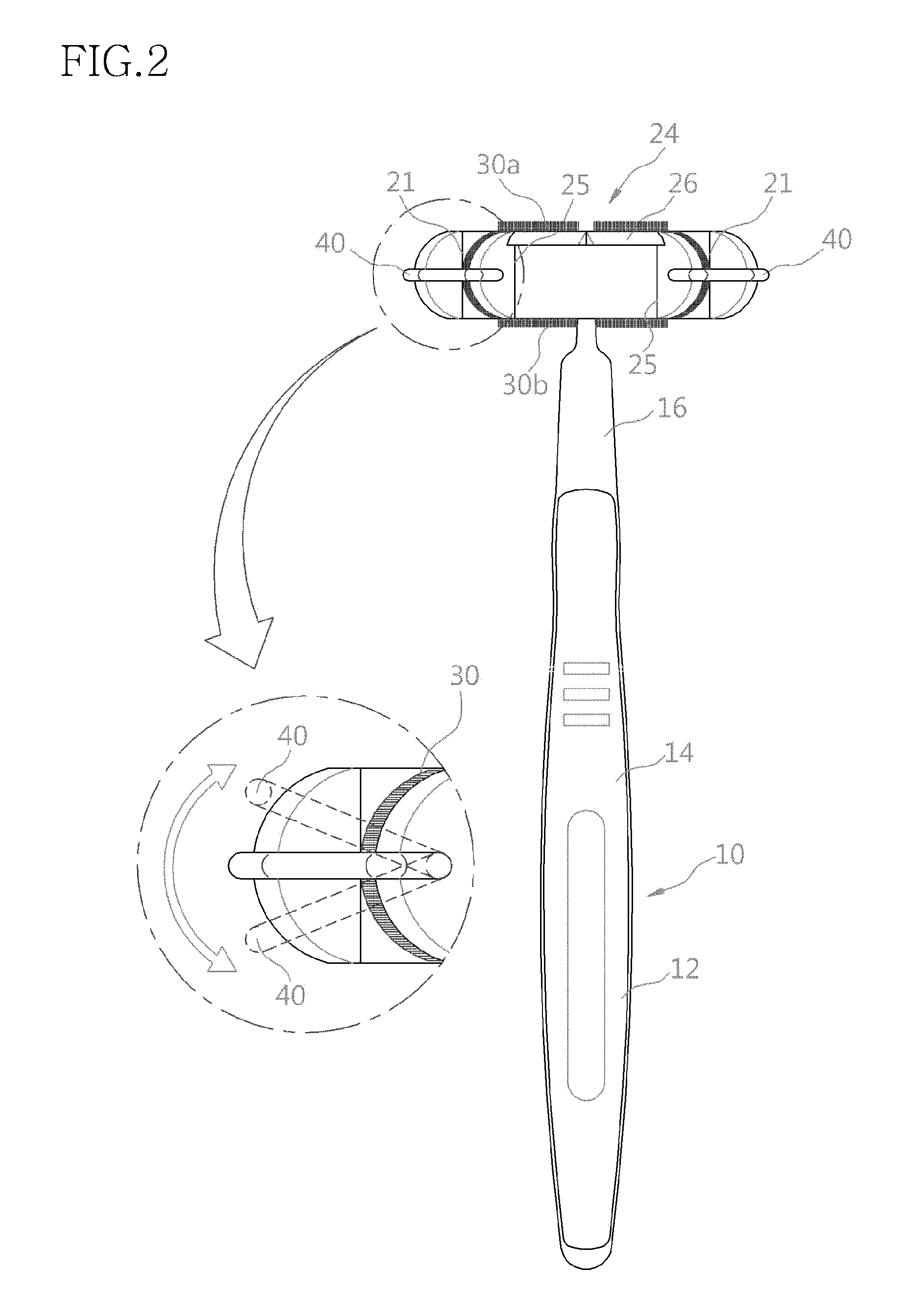

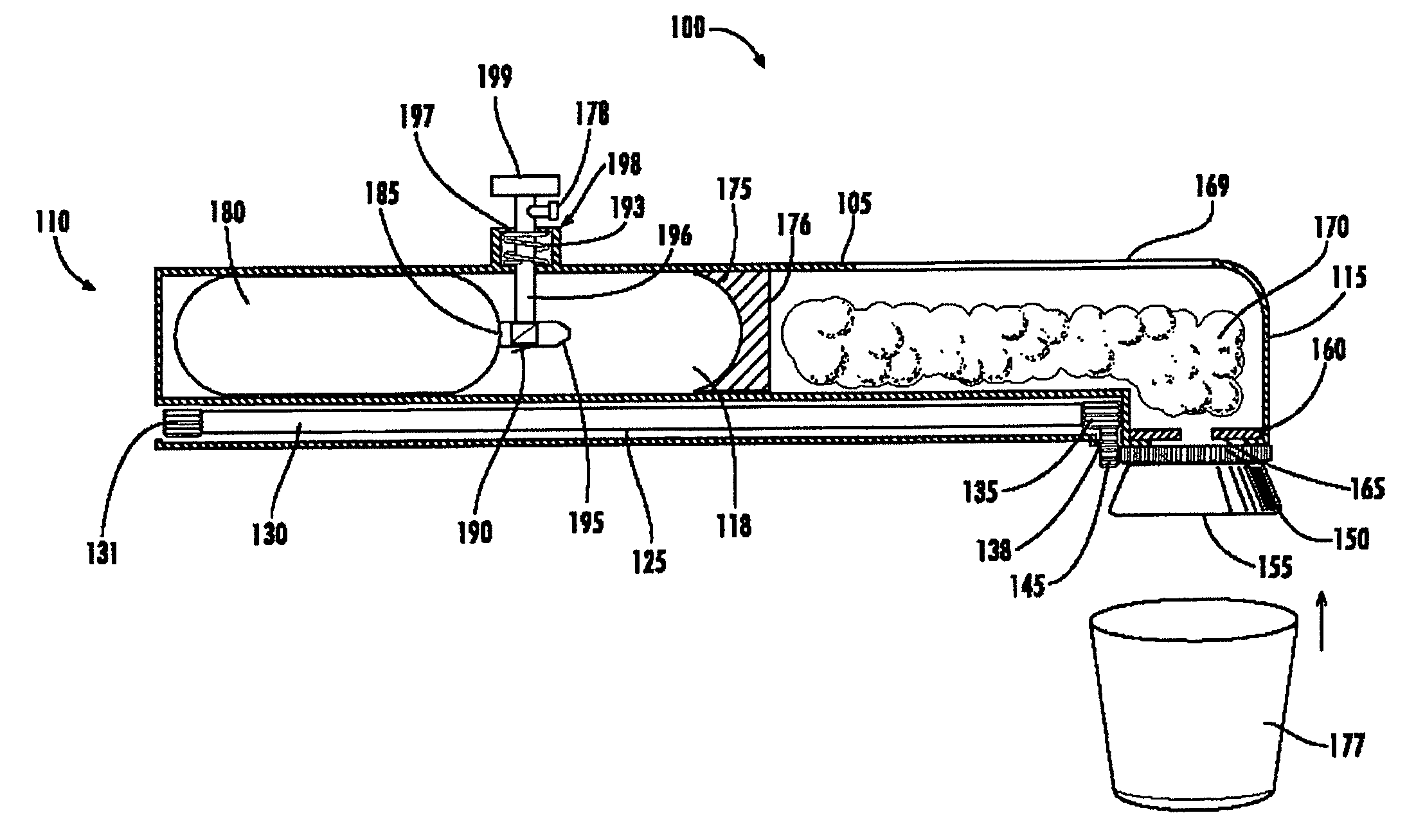

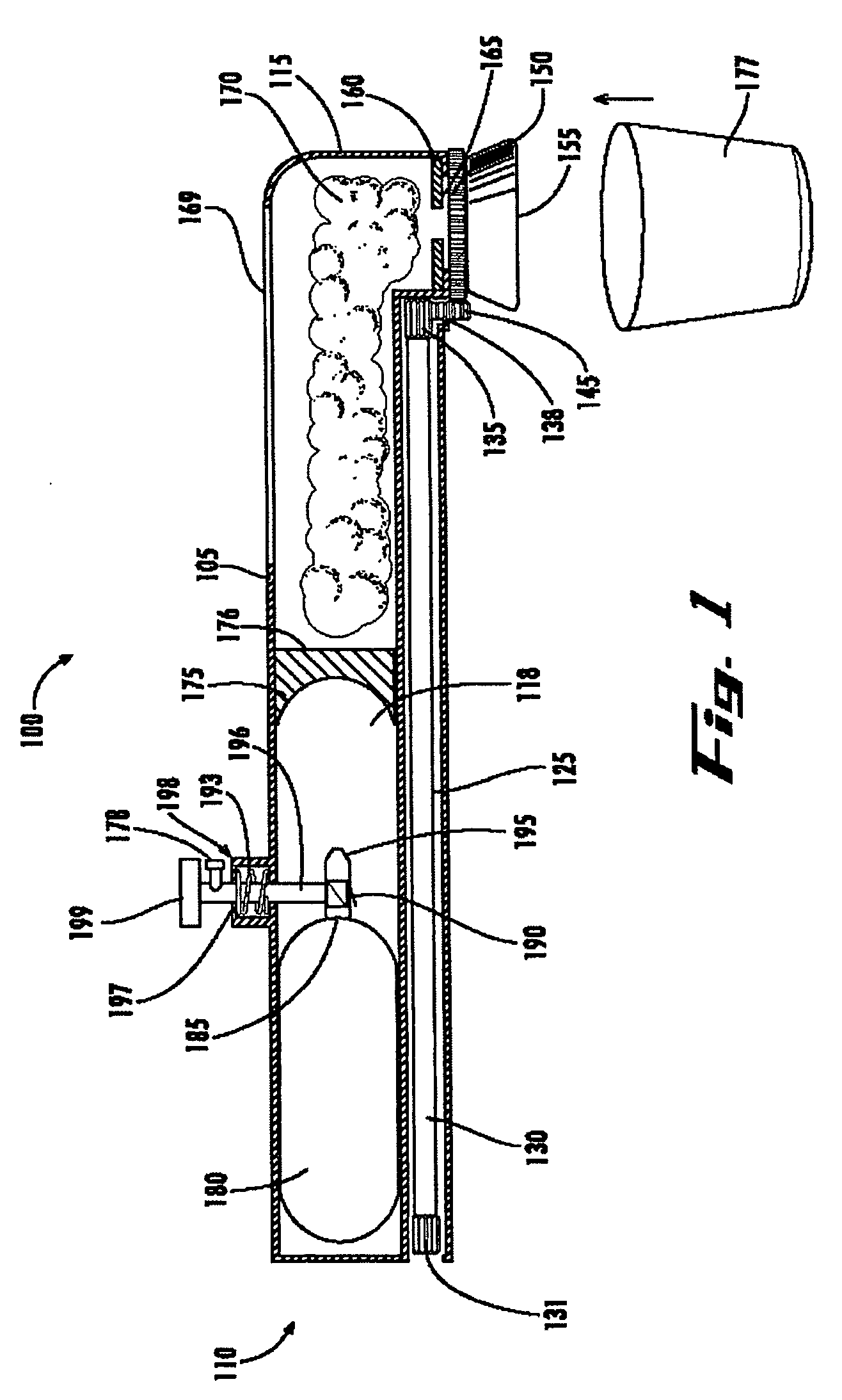

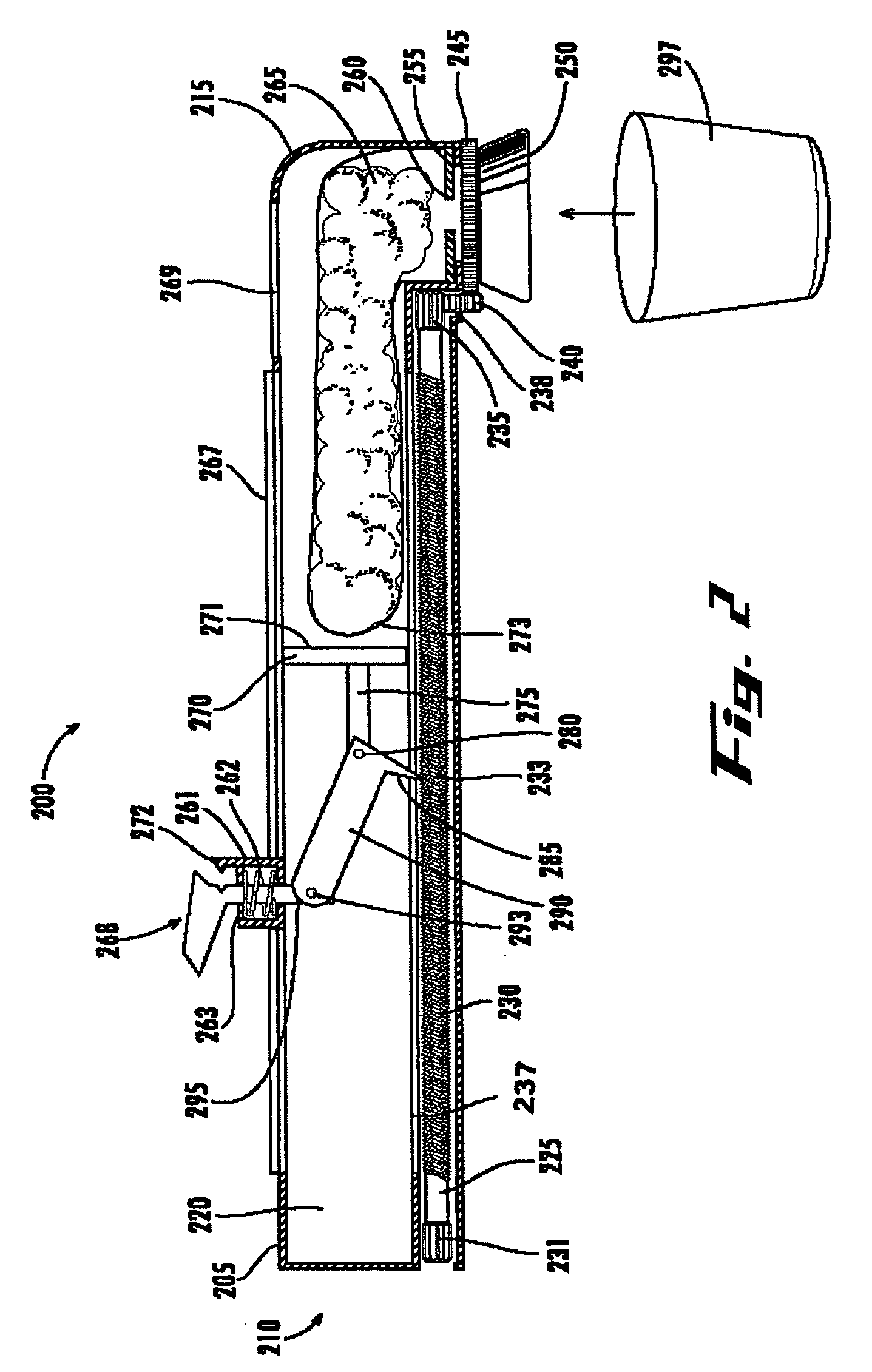

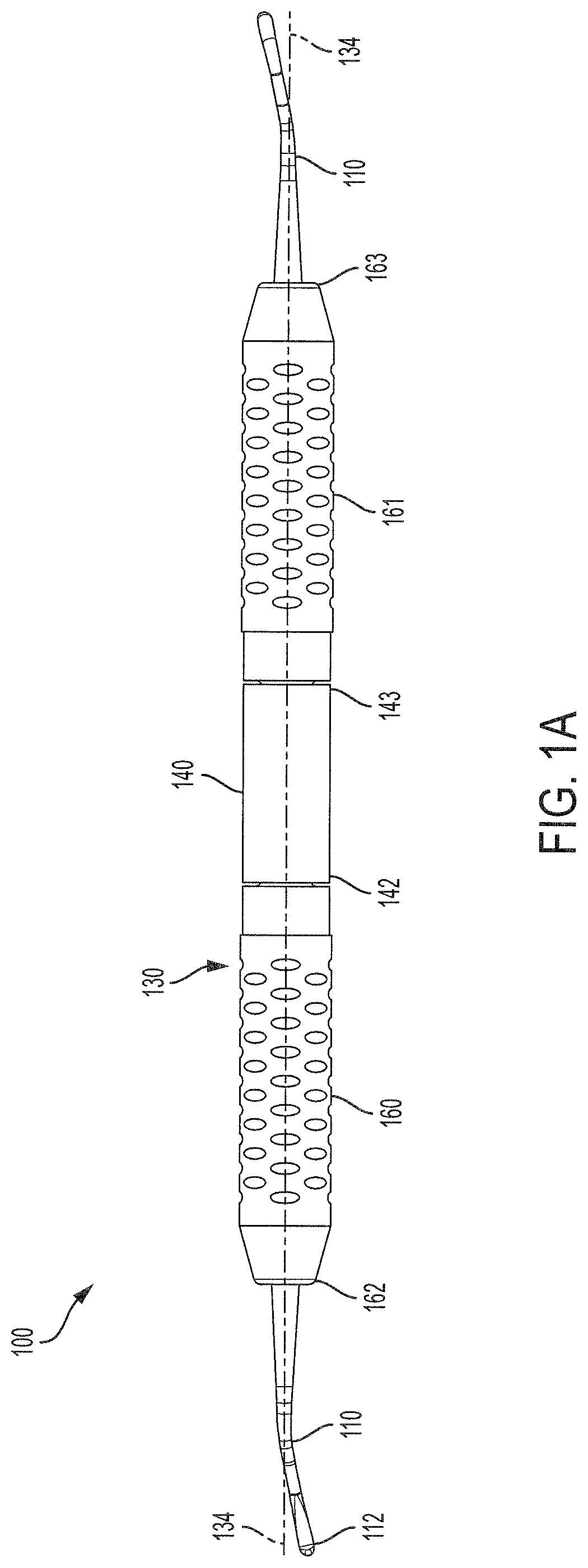

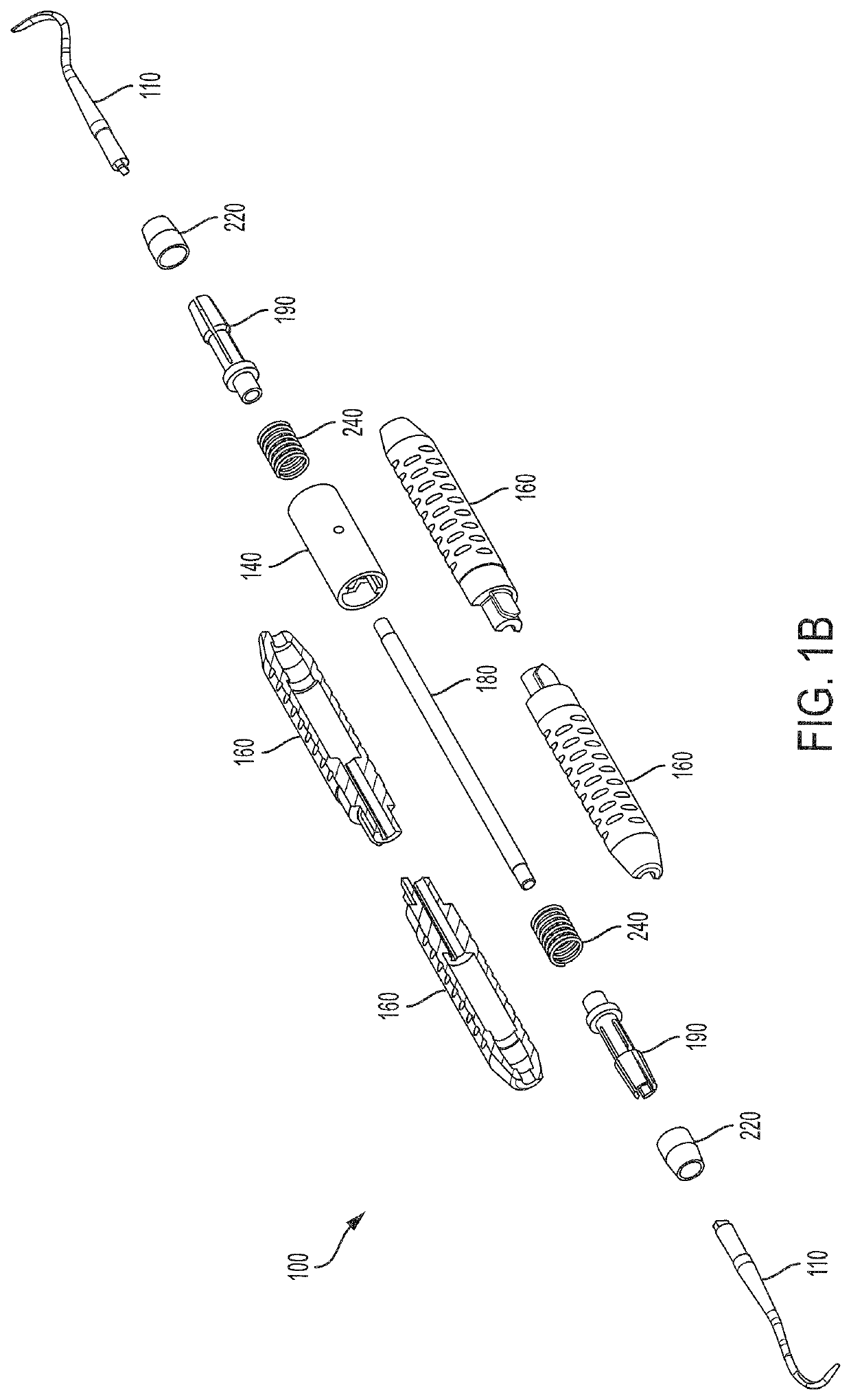

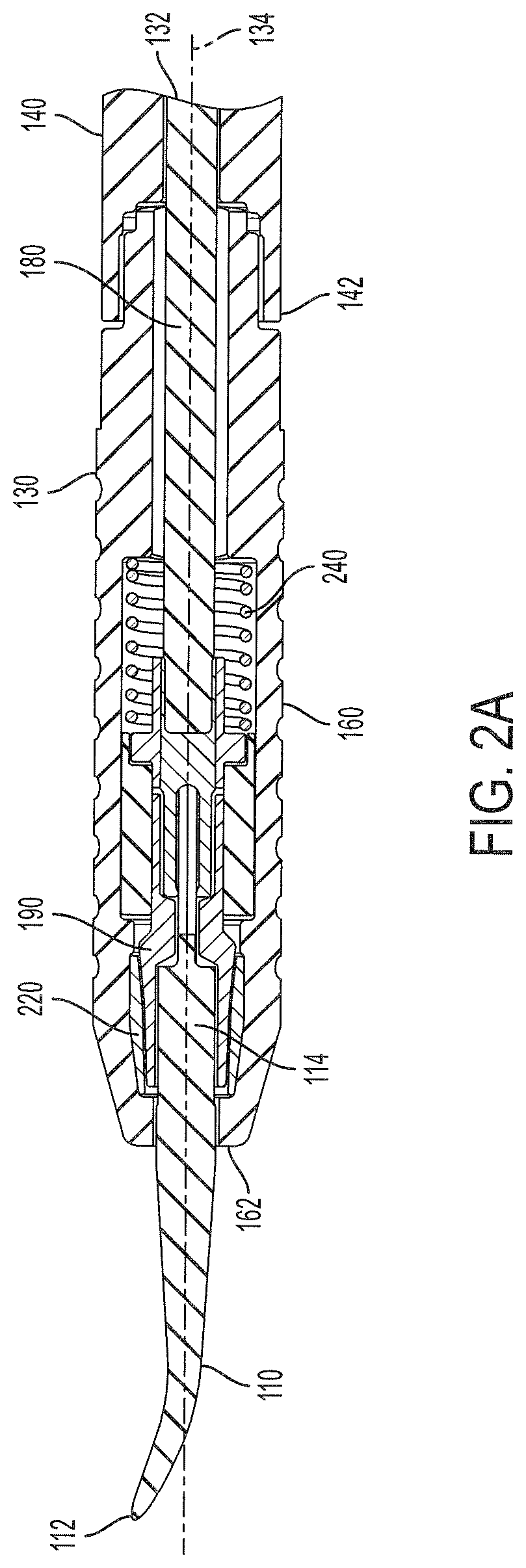

Self-contained dental prophylaxis angle with offset rotational axis

ActiveUS7070412B2Simpler and reliable passageEasy to controlDental toolsTooth rinsingRotational axisEngineering

The present invention discloses a self-contained dental prophylaxis angle with an offset rotational axis and methods for its use in cleaning, polishing, bleaching, bonding, etching, abrading, desensitizing, or otherwise treating teeth. Therapeutic content, such as dentifrice, is contained within the inventive prophylaxis angle, and is dispensed subject to operator control during use of the prophylaxis angle. An offset drive system is provided to power rotation of the dental tip in a system that can be physically separated from the storage and dispensing system for therapeutic content. A self-contained dental prophylaxis angle with an offset rotational axis according to the present invention may be used with a variety of shaped dental tips of varying degrees of rigidity, according the needs of a given clinical application.

Owner:MEDIPURPOSE PTE

Toothbrush using up-and-down movement pattern

Disclosed is a toothbrush using an up-and-down movement pattern, in which two brushes are attached in series to each of inner surfaces of parallel first and second heads having an obtusely bent shape to perform up-and-down brushing. The toothbrush enables simultaneous brushing of inner and outer portions and a cusp portion of a tooth and a cheek pouch and removal of a tongue coating. The toothbrush includes the first and second heads, brushes longitudinally attached to the first and second heads, holes perforated in opposite end positions of the first and second heads, a C-shaped loop pivotally rotatably fitted into the holes of the first and second heads, an elongated U-shaped guide fixed to both ends of the first head, a transfer member connected to the elongated U-shaped guide so as to reciprocate in a longitudinal direction of the first head, and a gripper extending downward from the transfer member.

Owner:HONG HYOUNG PYO

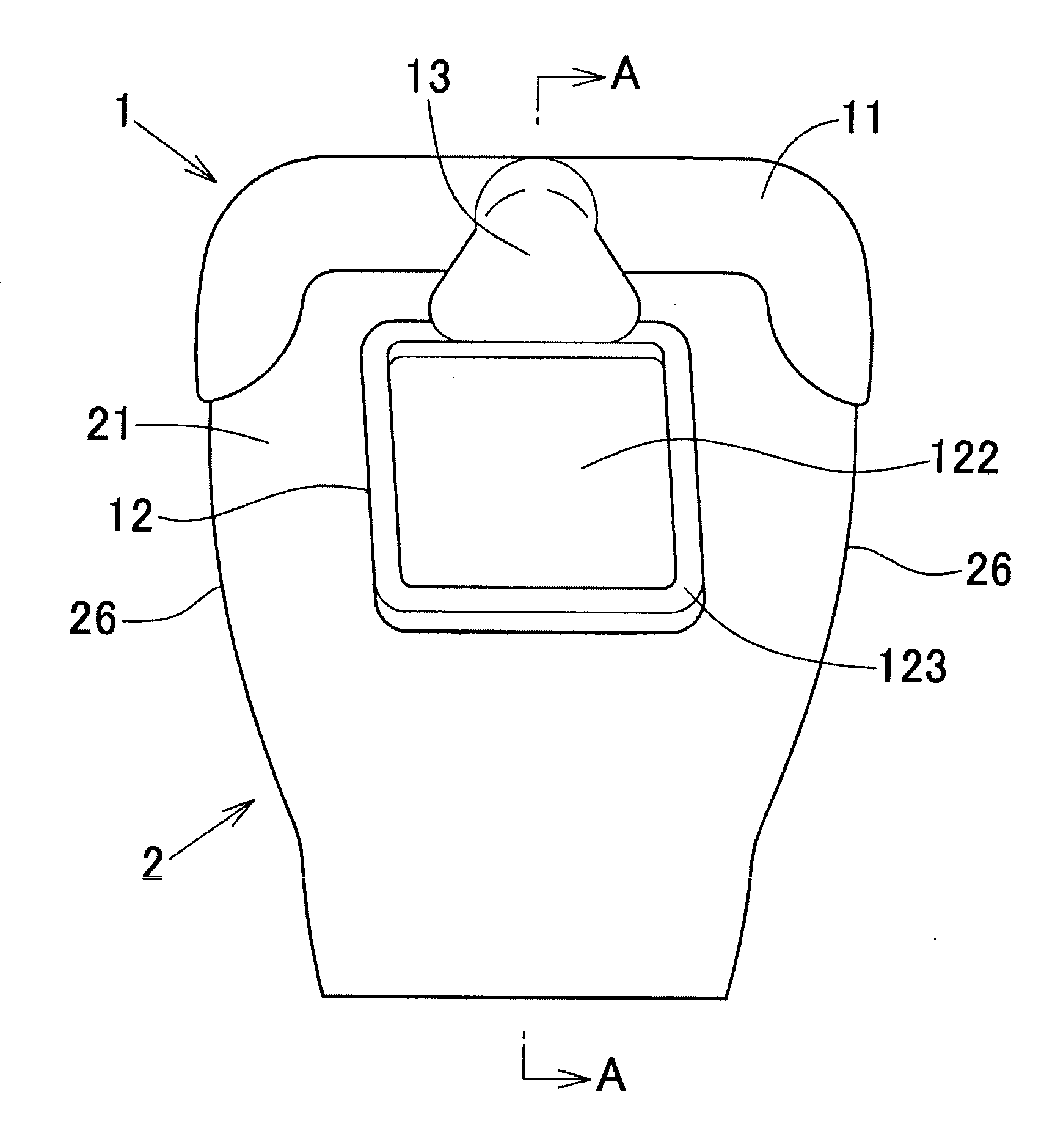

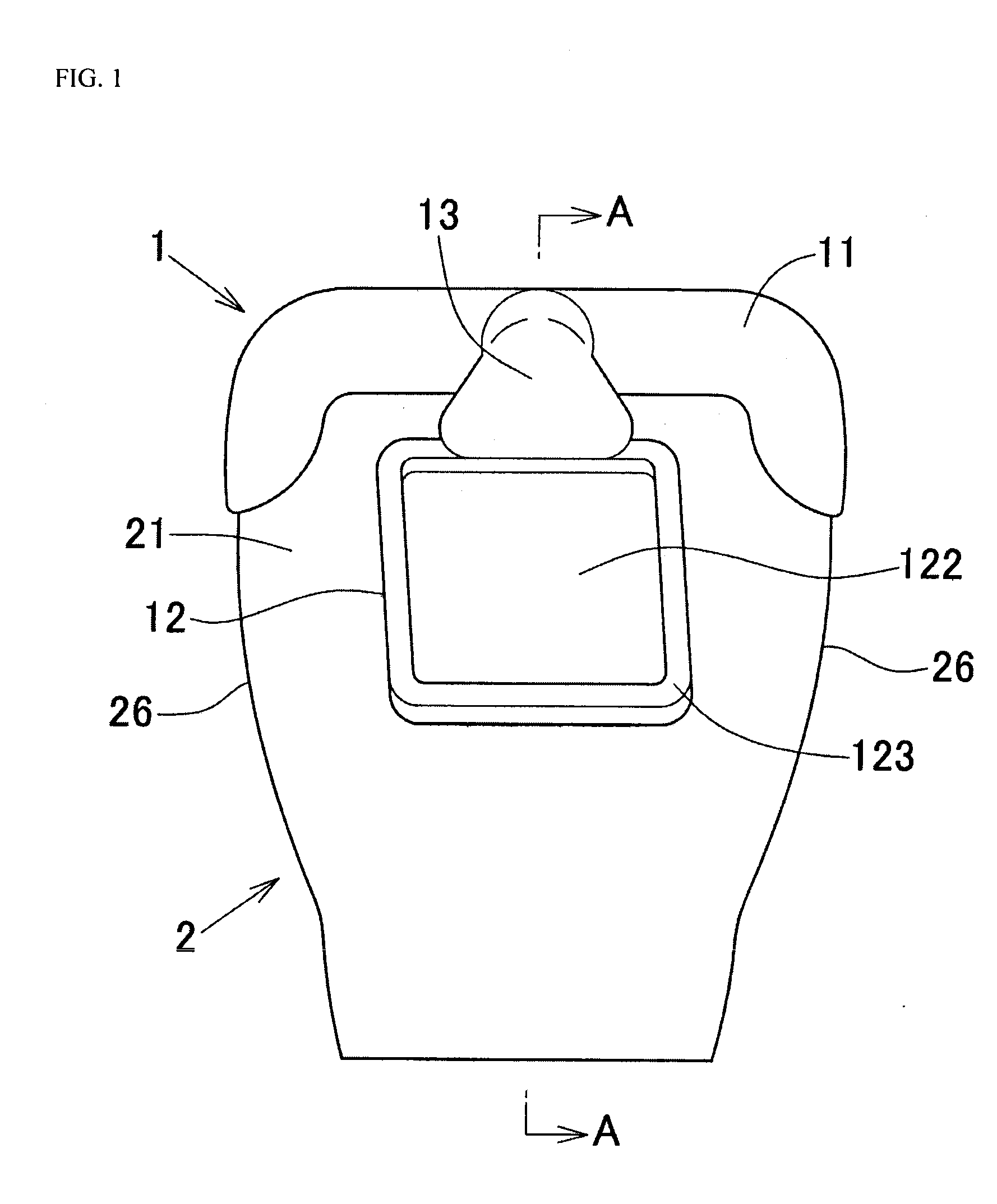

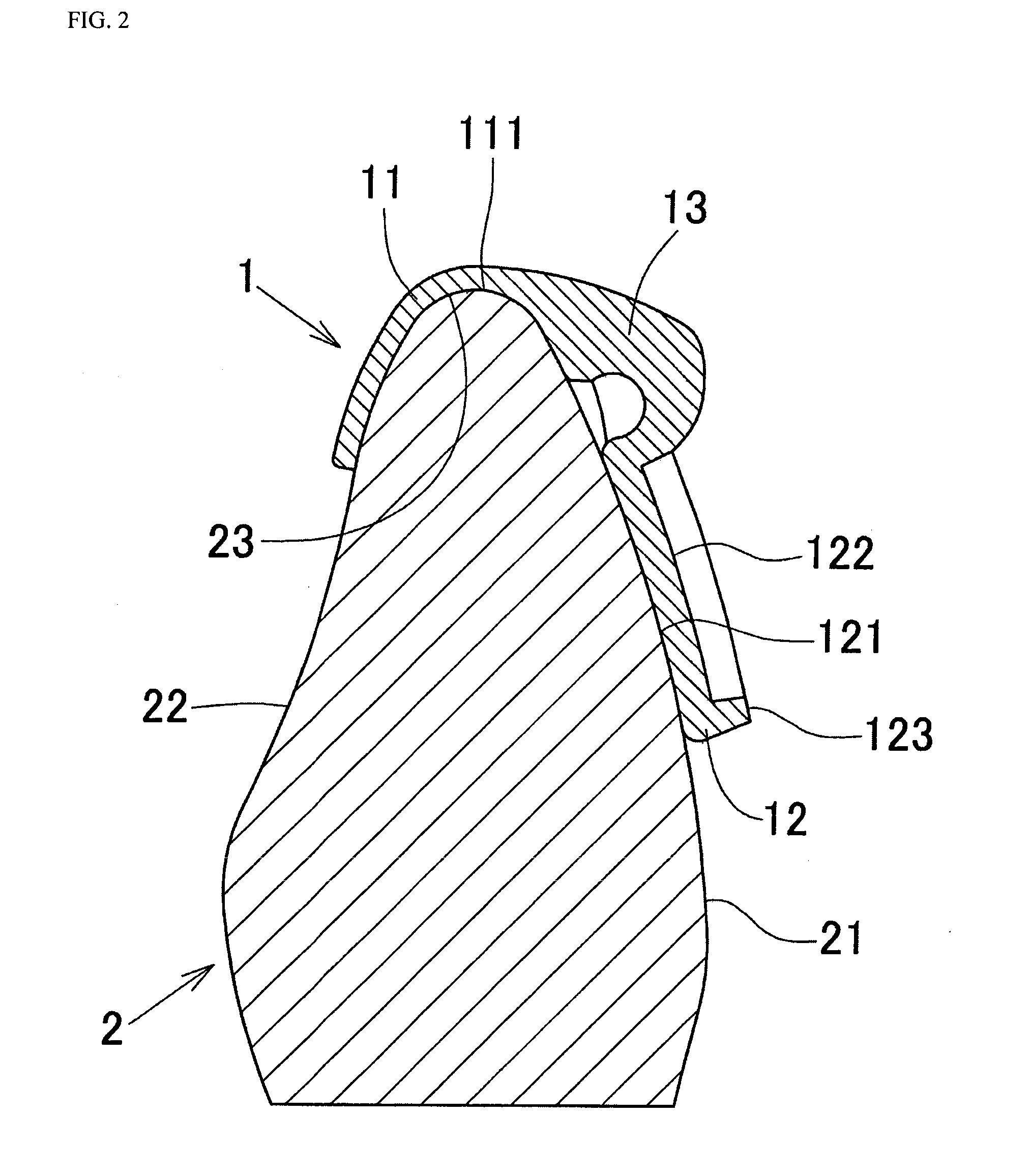

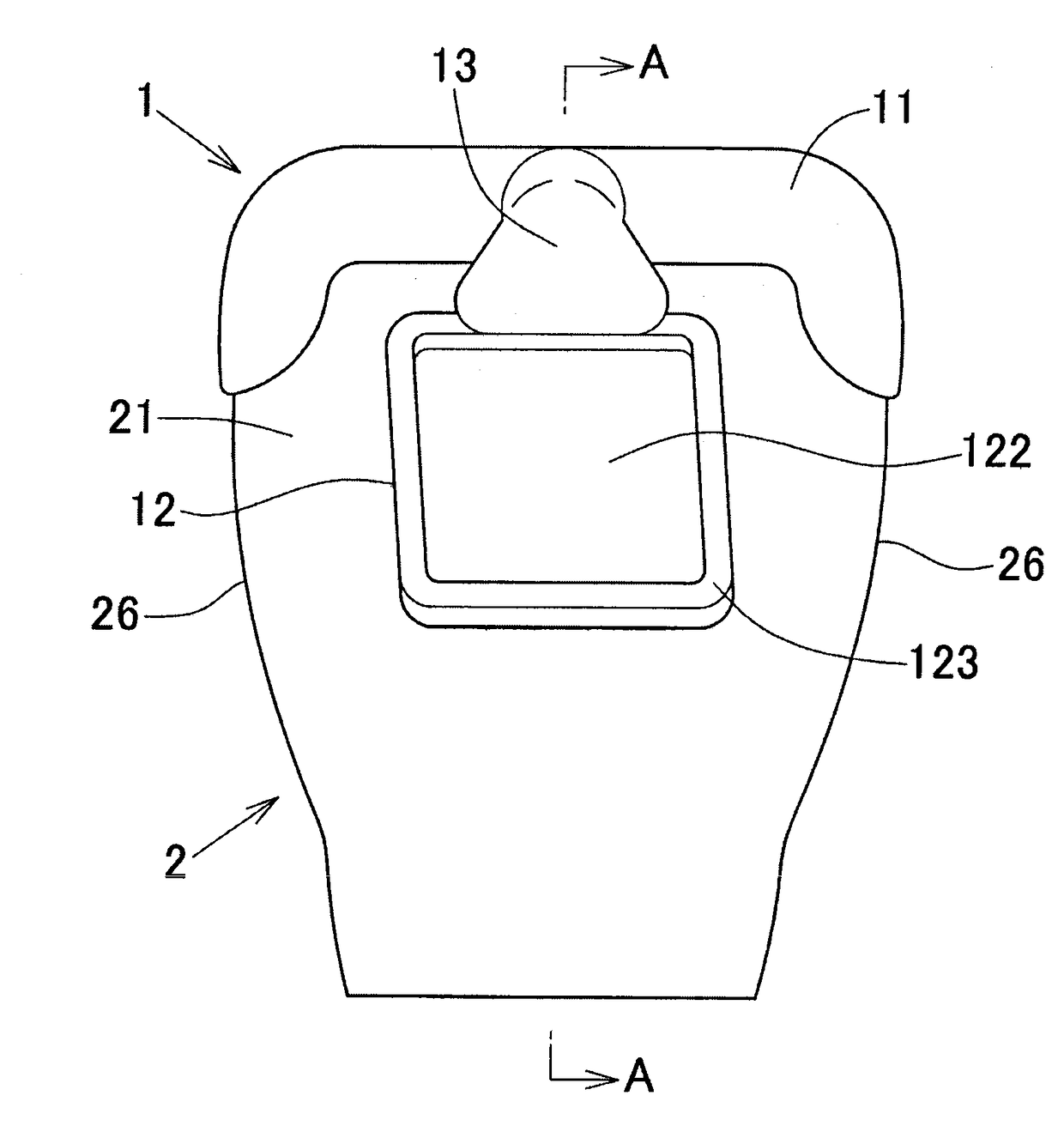

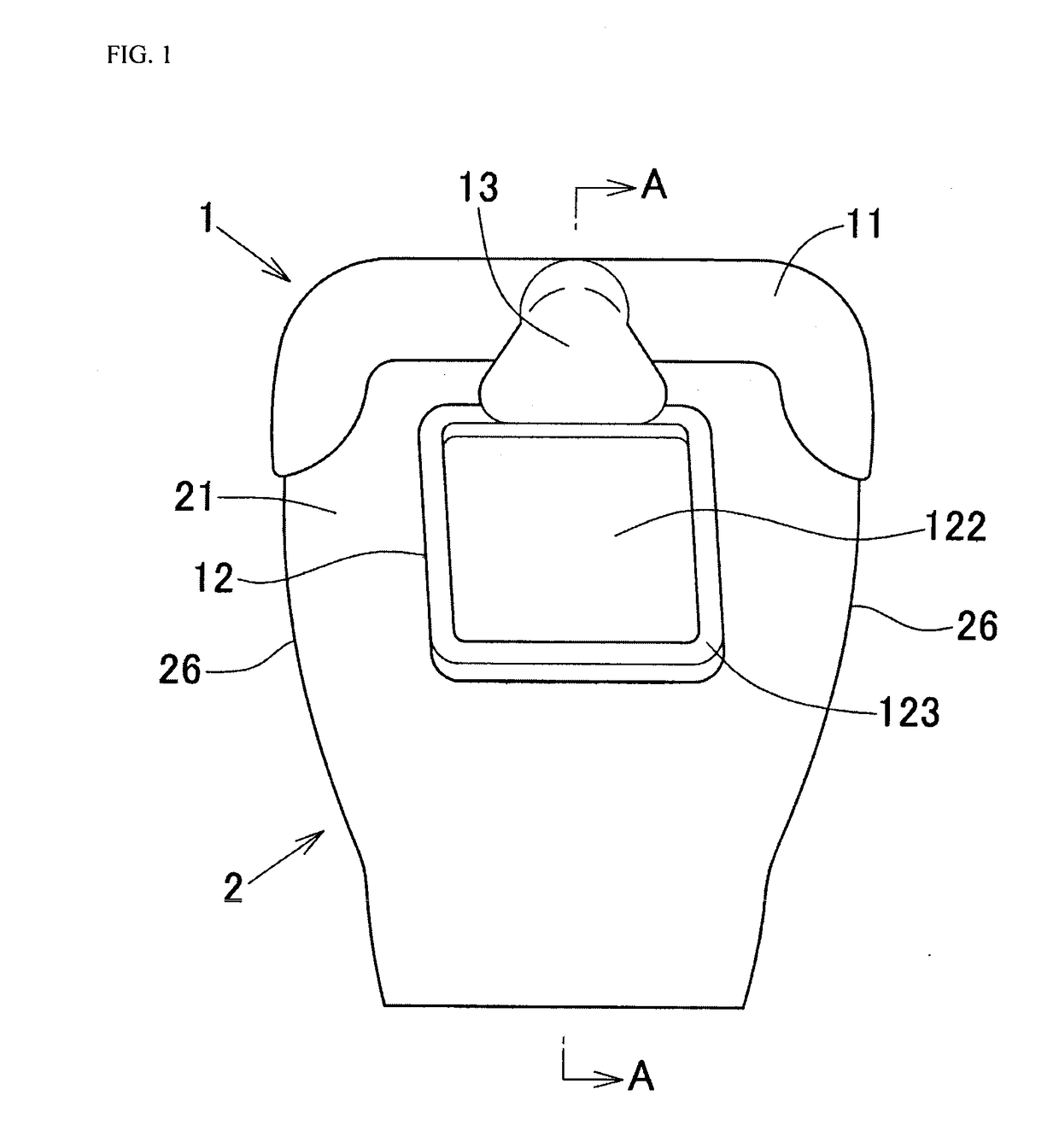

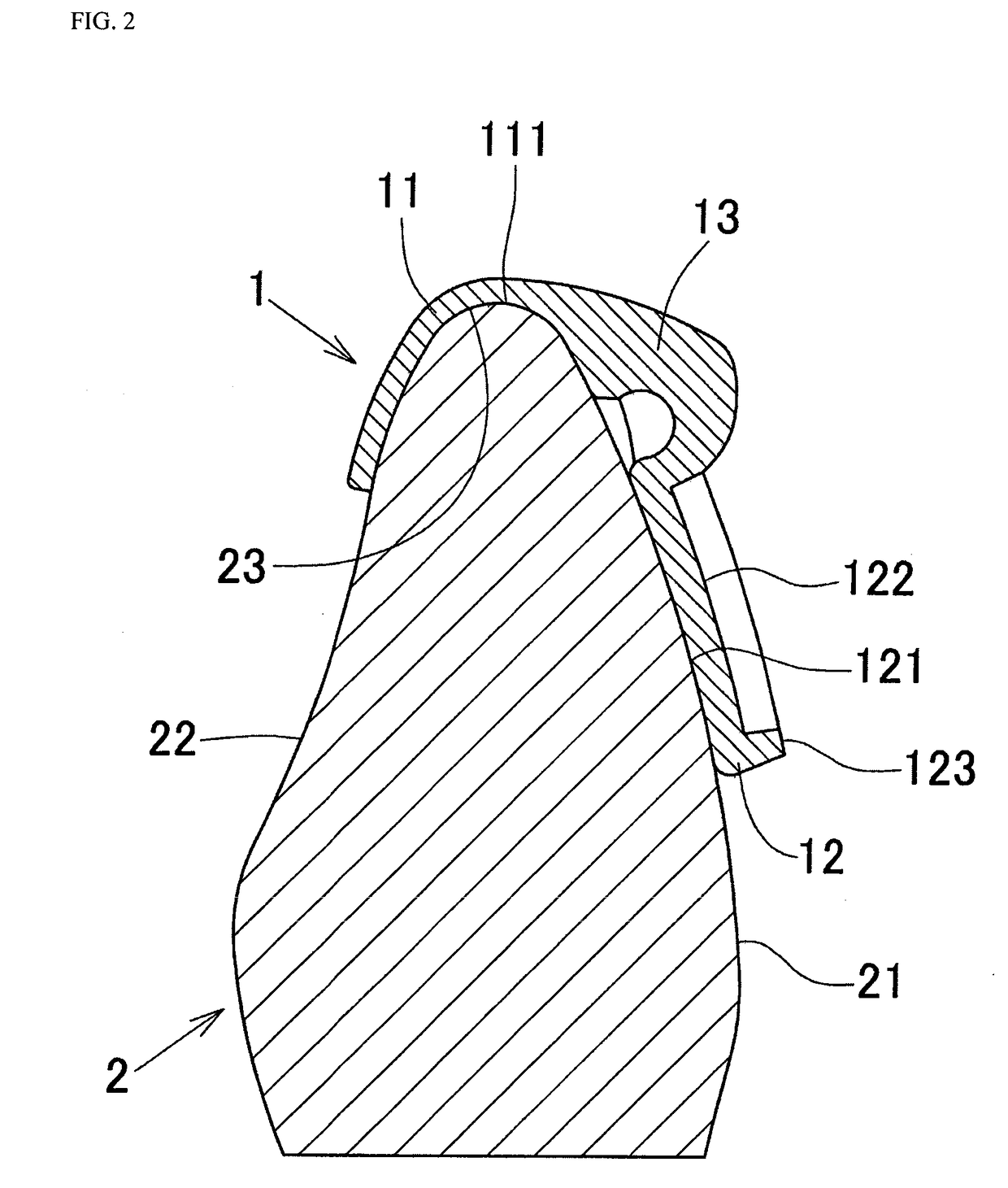

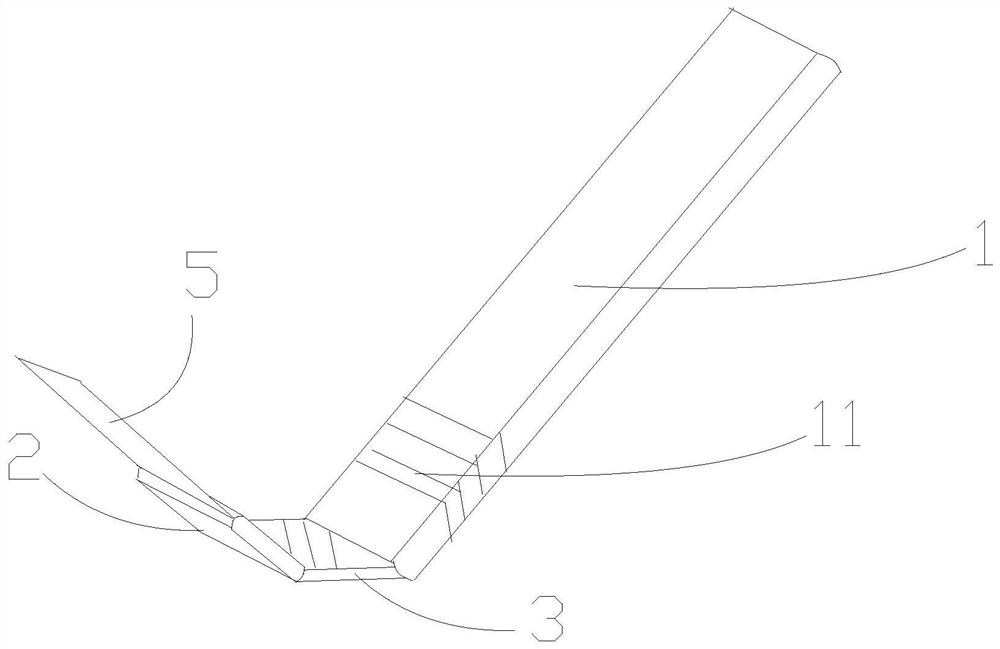

Orthodontic device-setting tool

An orthodontic device-setting tool is provided with: a fitting section having a fitting surface, which covers and fits together with at least one of the incisal margin, the dental cusp, or the occlusal surface of a tooth; a foundation section, which has a back surface that adheres closely to the labial / buccal surface or the lingual surface of the tooth and has, on the surface opposite the back surface, a front face on which the orthodontic device is mounted; and a connecting section that connects the fitting section and the foundation section. The tool has a frame section, which protrudes from the front face of the foundation section and can fit together with the orthodontic device. Use of the orthodontic device-setting tool makes it possible to mount orthodontic devices such as corrective brackets without holding the patient for long periods of time and to mount the orthodontic devices accurately at the desired three-dimensional mounting positions for the orthodontic devices regardless of the skill level of the dentist practitioner. Moreover, the tool can even be used with mass-produced general purpose orthodontic devices, which are not orthodontic devices that have been specially customized as to design, cut, etc. for individual patients.

Owner:OKAZAKI KAZUYUKI

Self-contained dental prophylaxis angle with offset rotational axis

ActiveUS20060024642A1Simpler and reliable passageEasy to controlDental toolsTooth rinsingRotational axisEngineering

The present invention discloses a self-contained dental prophylaxis angle with an offset rotational axis and methods for its use in cleaning, polishing, bleaching, bonding, etching, abrading, desensitizing, or otherwise treating teeth. Therapeutic content, such as dentifrice, is contained within the inventive prophylaxis angle, and is dispensed subject to operator control during use of the prophylaxis angle. An offset drive system is provided to power rotation of the dental tip in a system that can be physically separated from the storage and dispensing system for therapeutic content. A self-contained dental prophylaxis angle with an offset rotational axis according to the present invention may be used with a variety of shaped dental tips of varying degrees of rigidity, according the needs of a given clinical application.

Owner:MEDIPURPOSE PTE

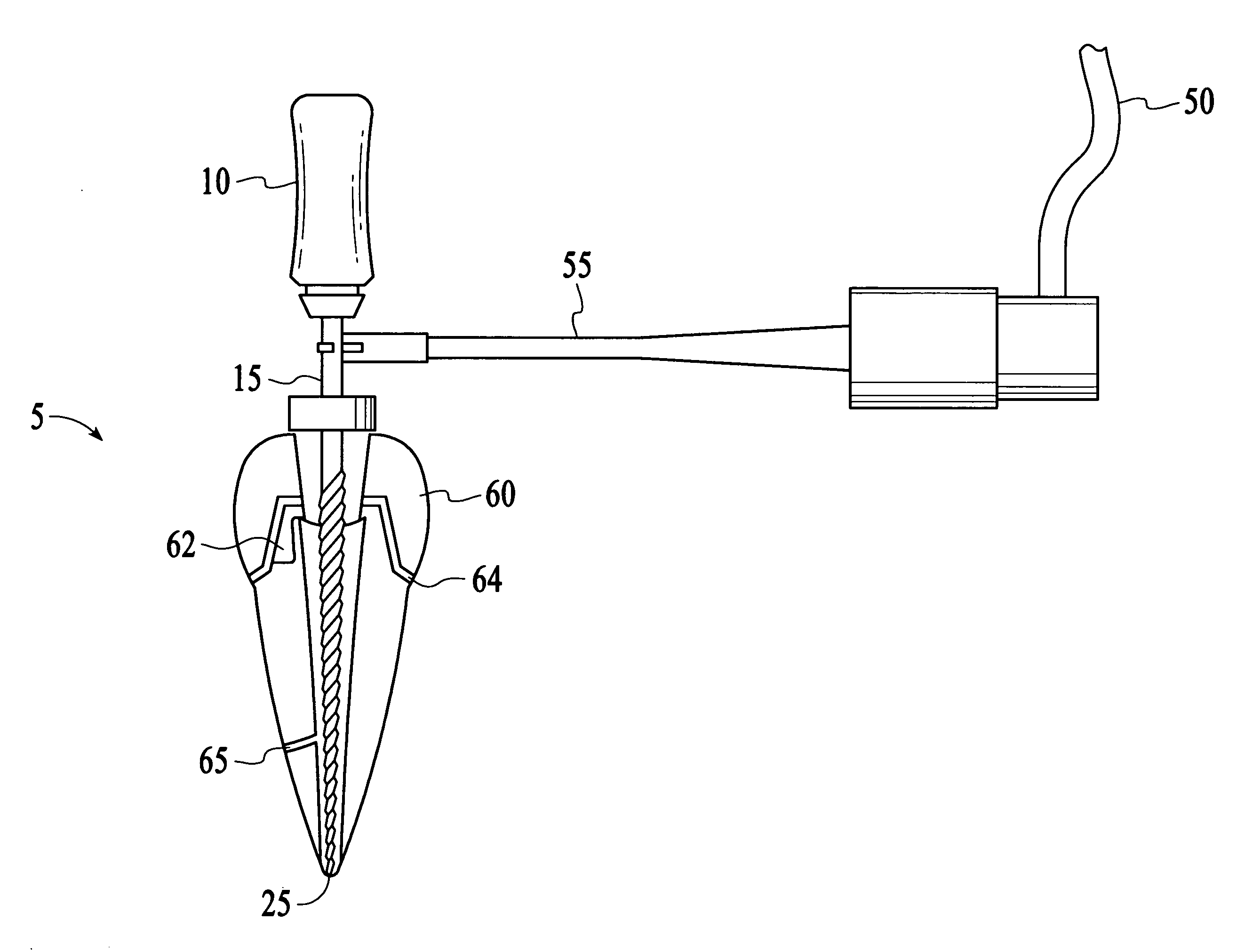

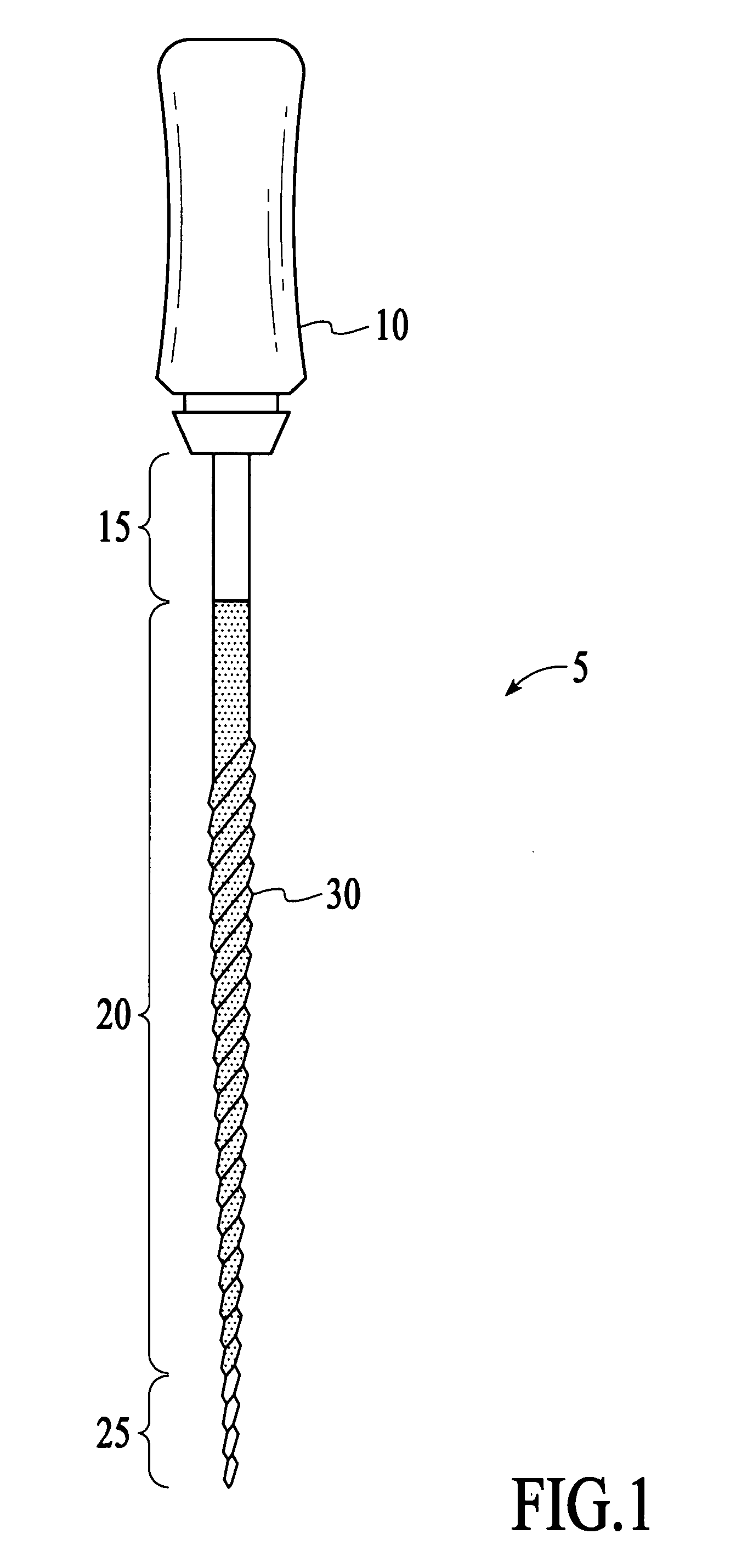

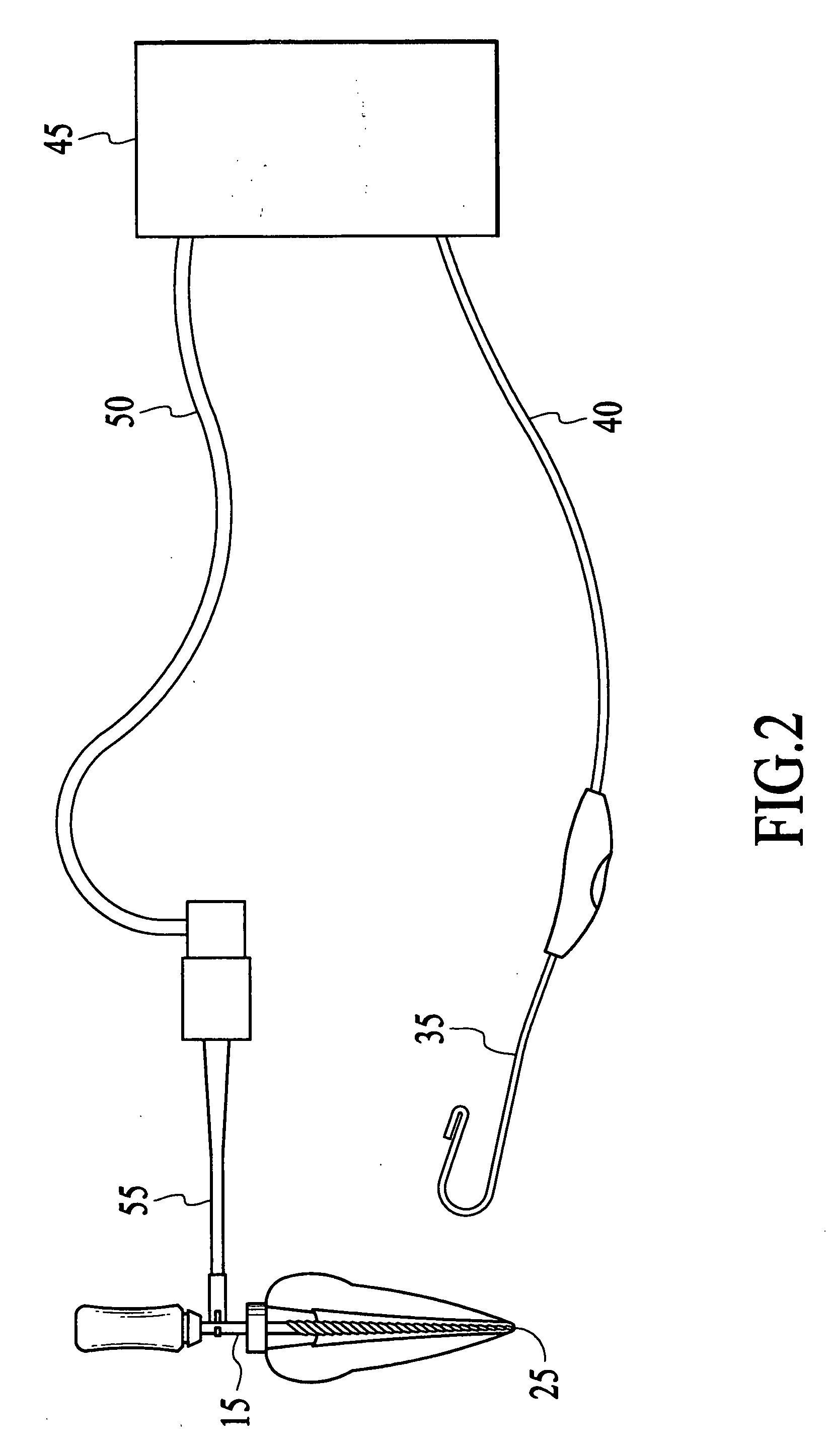

Endodontic instrument with non-conductive coating and method for locating the apex of a tooth

InactiveUS20070218420A1Minimizes problemReduce timeTeeth fillingDental toolsConductive coatingElectrically conductive

An electrically conductive endodontic instrument coated with a non-conductive layer on a portion of the instrument wherein a proximal and distal portion of the instrument remain uncoated and capable of conducting current therethrough using a traditional apex locator or other alerting means. The non-conductive coatings avoid electrical interference from prior restorative work and anatomical variants. The coatings may be smooth to minimize resistance in the endodontic working space or relatively abrasive to facilitate filing where desired. A method for locating the apex of a tooth utilizing an endodontic instrument coated with an electrically non-conductive layer wherein a proximal and distal portion of the instrument remain uncoated and wherein the instrument is advanced in a root canal space toward the apex of a tooth. When the distal portion of the file makes contact with the apex, and a conductive portion of the file is placed in electrical contact with an apex locator, or other alerting means, said contact actuates an alert thereby establishing canal depth while the coated portion of the instrument avoids electrical artifact from prior restorative work and variant anatomy.

Owner:SYRIBEYS PHILIP JOHN

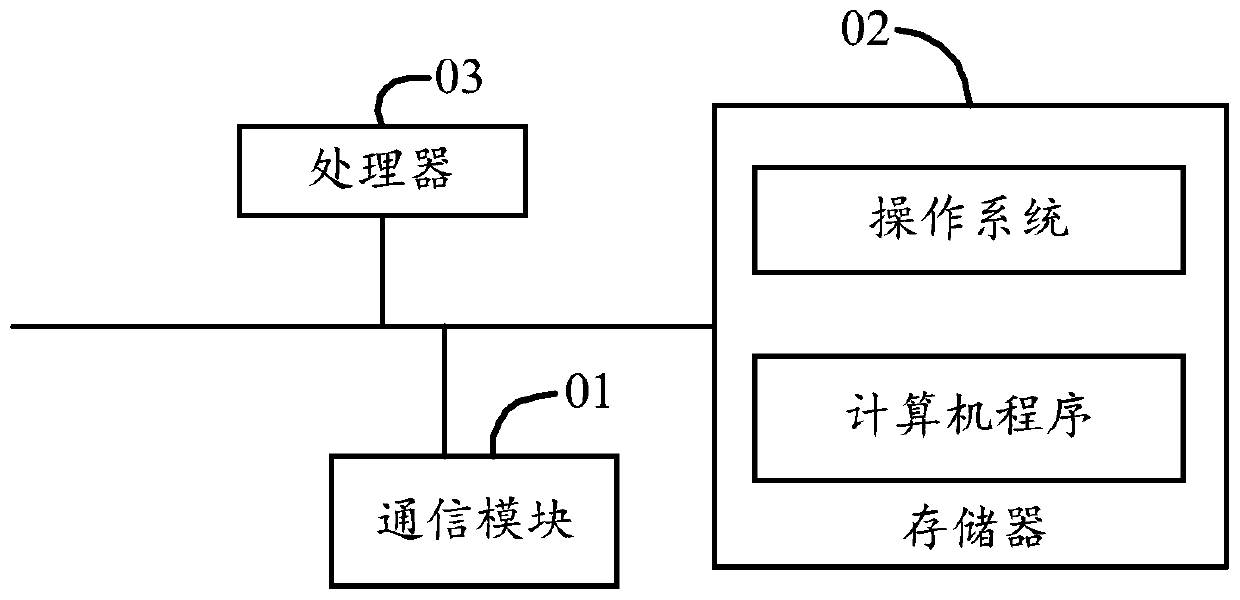

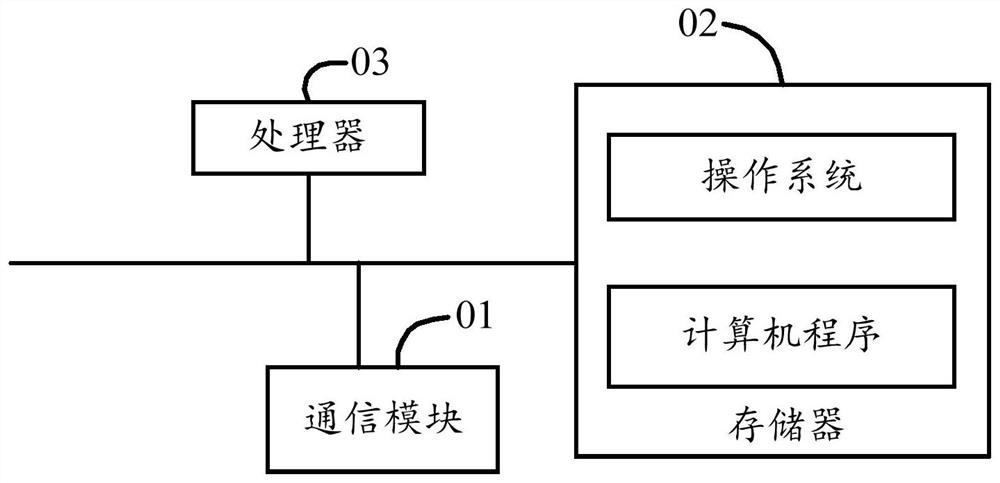

Apex locator

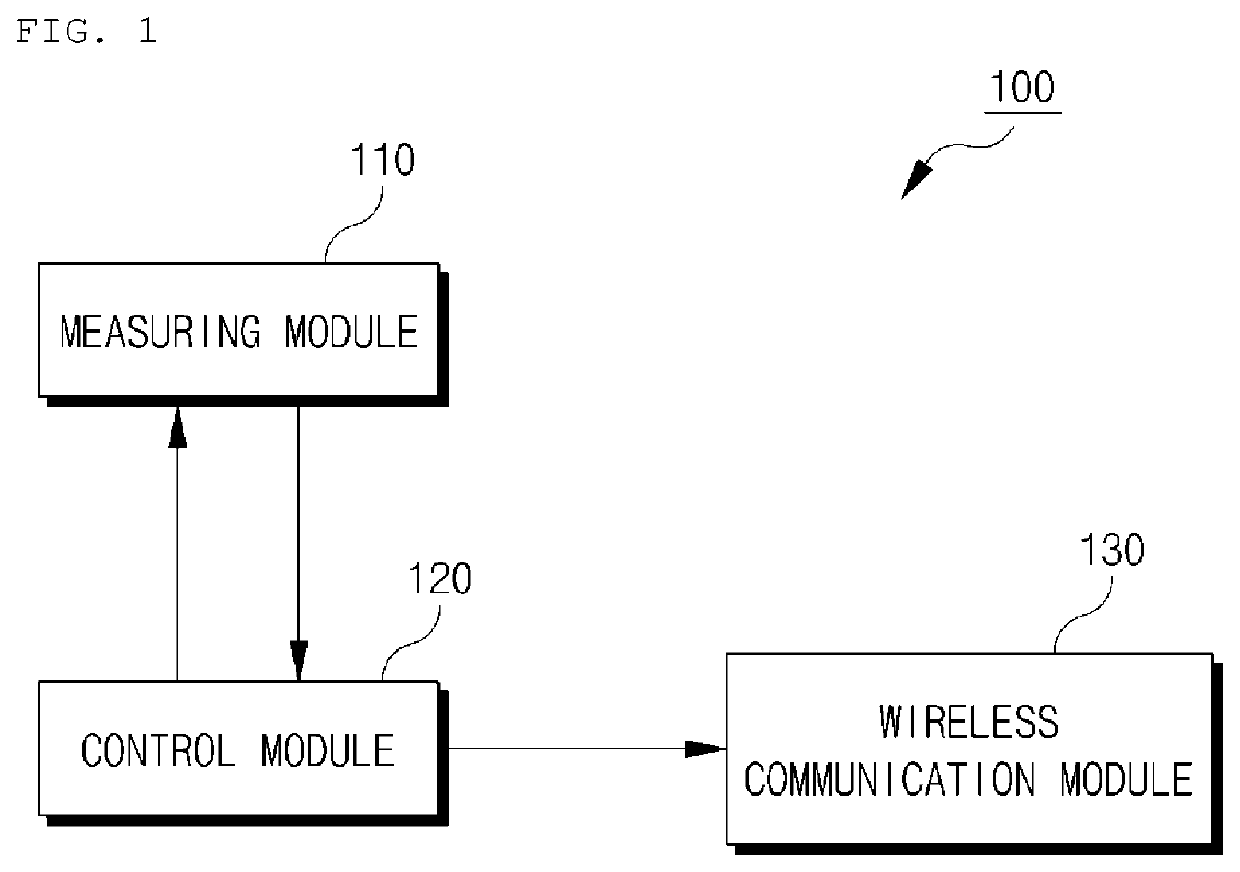

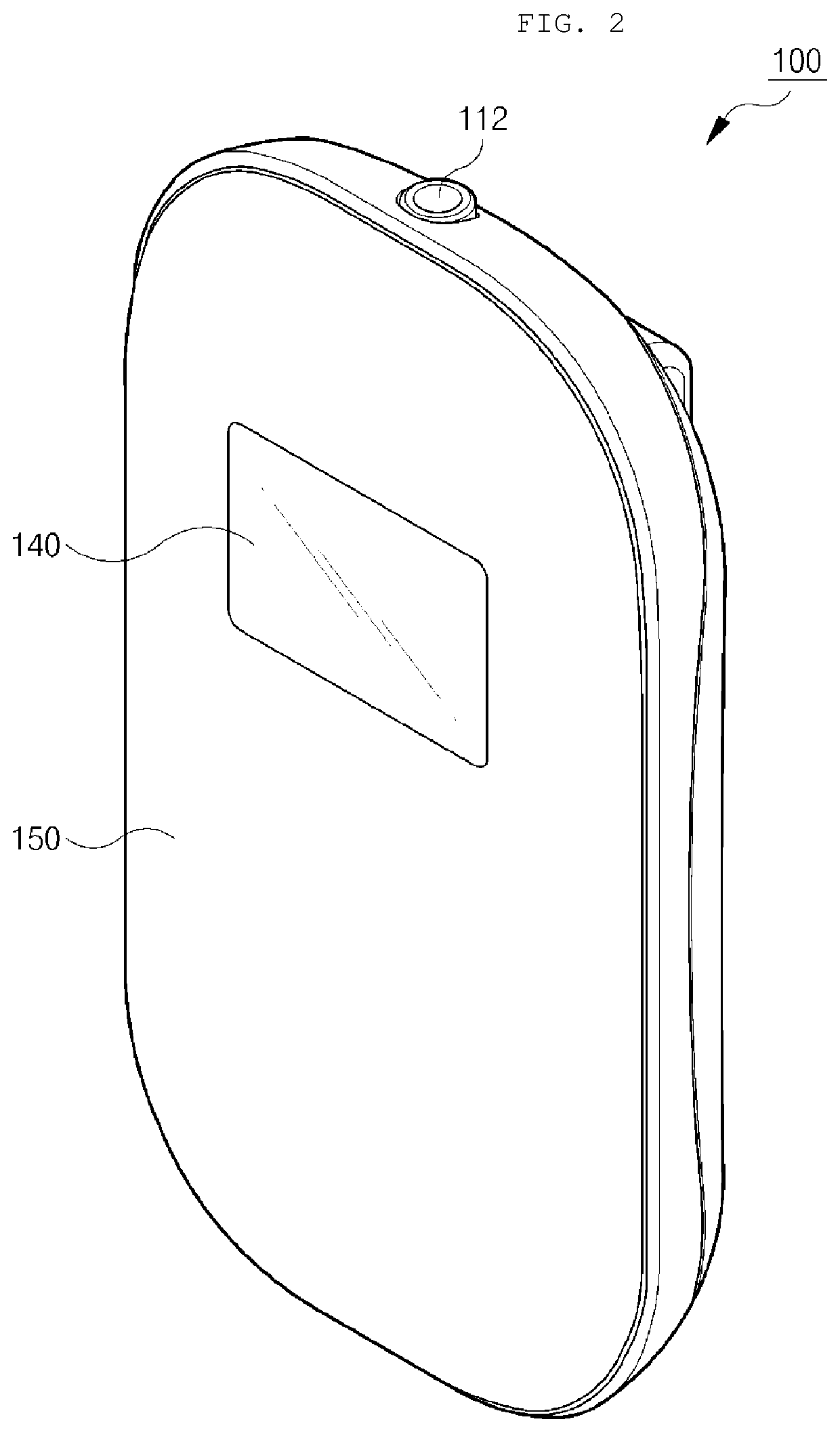

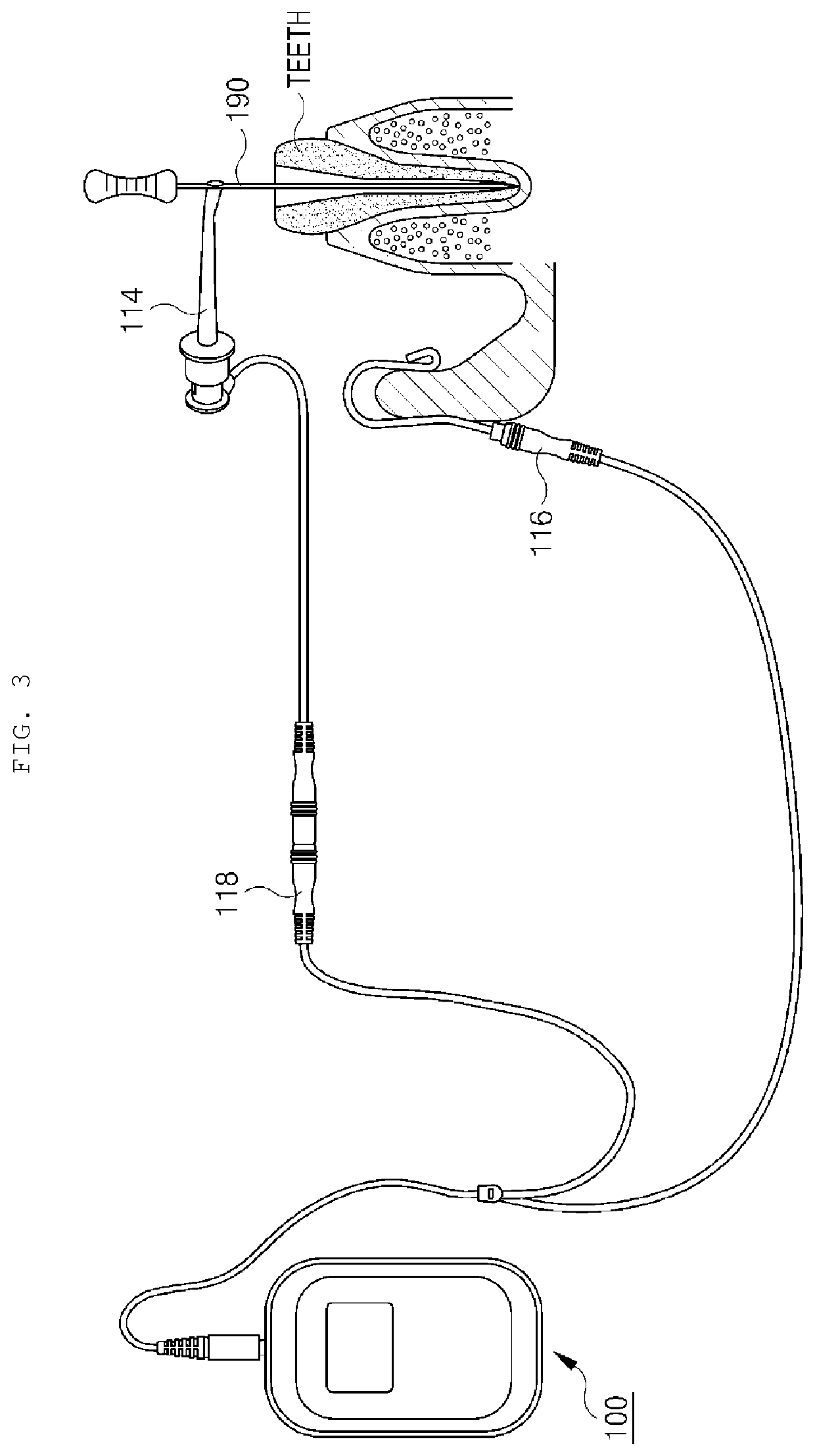

The present invention provides a root canal length measuring device including: a measuring module configured to include a file hook electrically connected to an endodontic file, and a lip hook to be connected to a lip or a gum; a control module configured to measure the value of impedance which varies as the file moves from the surface of a tooth toward the apex of the root of the tooth, and provide an image signal or a sound signal representing information on the position of the apex of the root and information on the length of the apex of the root; and a communication module configured to receive the image signal or the sound signal from the control module, and wirelessly transmit the received signal to a smart device in real time.

Owner:GOODDOCTORS

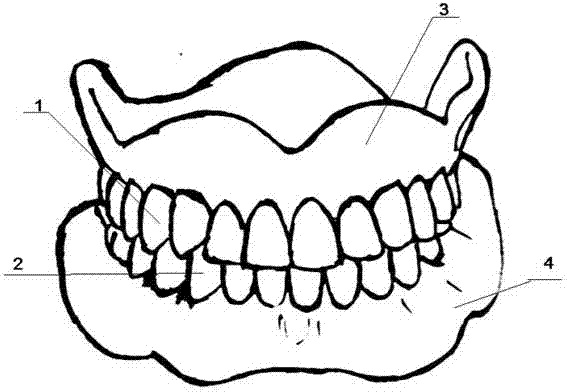

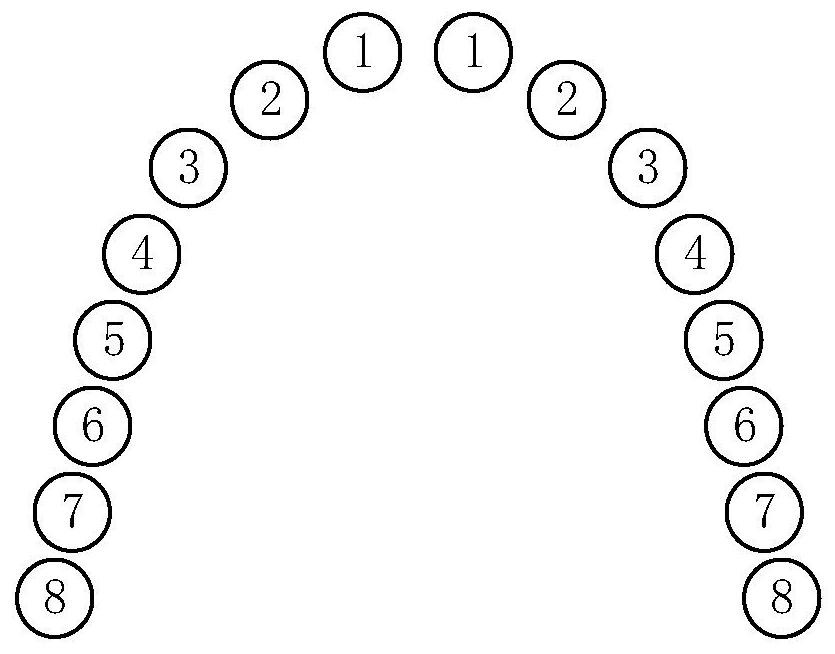

Artificial teeth

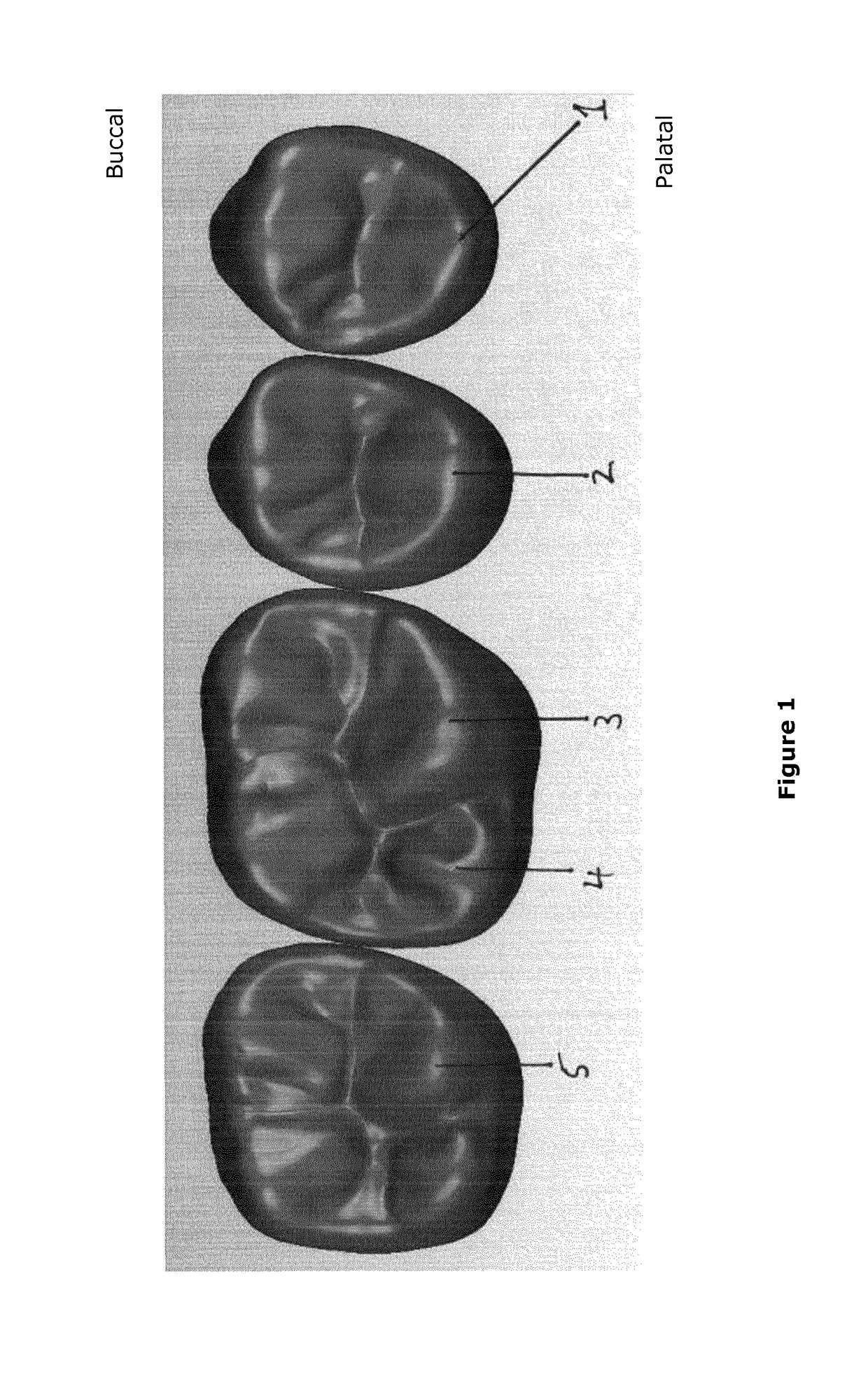

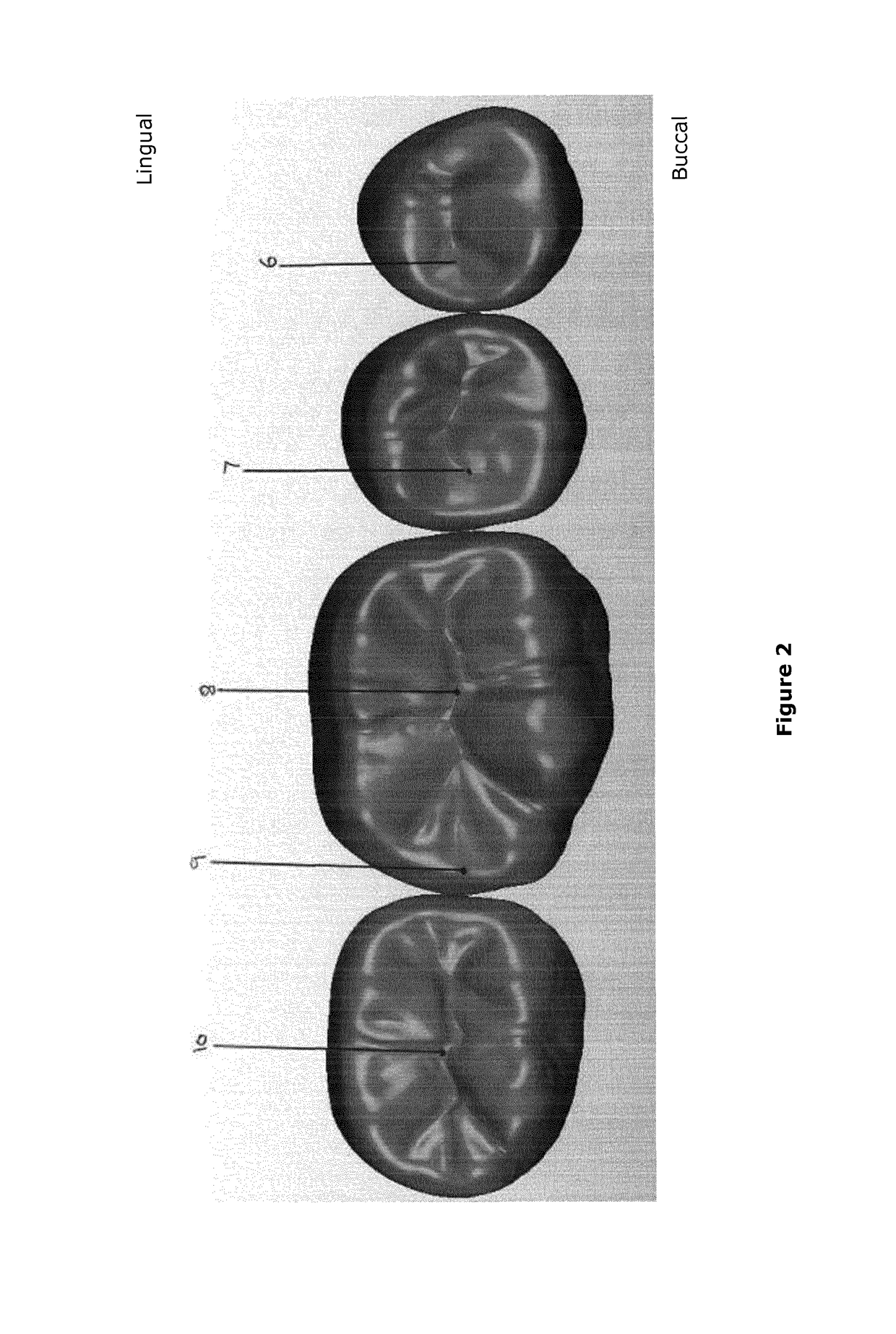

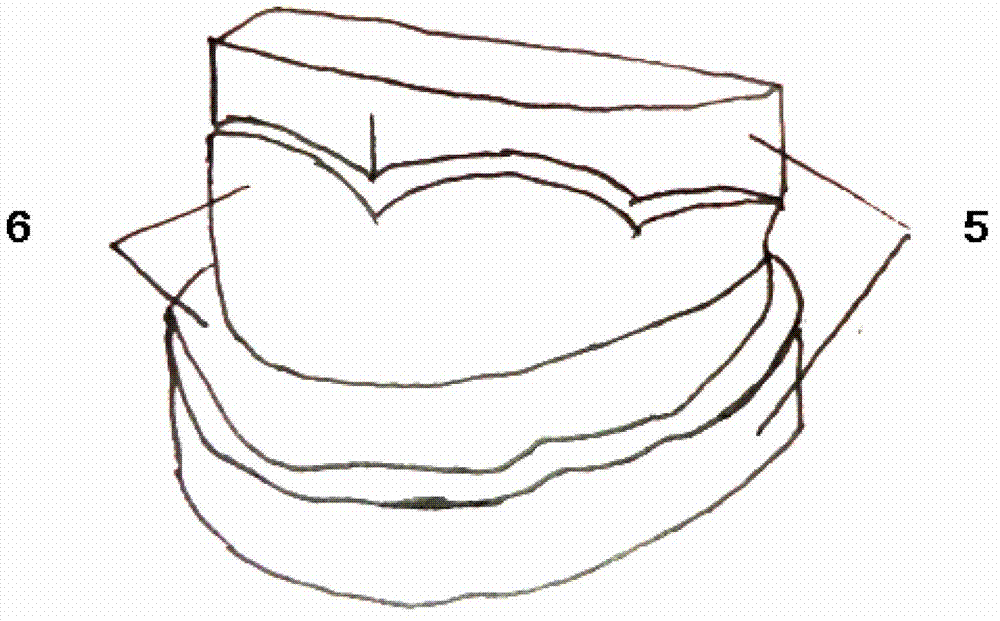

A set of artificial teeth for a denture comprises a maxillary unit and a mandibular unit. When set up in lingualised occlusion, at least one of following occurs: the palatal cusp of the upper 4 (1) fits into the distal fossa of the lower 4 (6), the palatal cusp of the upper 5 (2) fits into the distal fossa of the lower 5 (7), the mesial palatal cusp of the upper 6 (3) fits into the central fossa of the lower 6 (8), the distal palatal cusp of the upper 6 (4) fits onto the marginal ridge of the lower 6 (9) and the mesial palatal cusp of the upper 7 (5) fits into the central fossa of the lower 7 (10). The buccal cusps of the lower teeth are out of contact with the upper teeth, such that the cusp / fossa dimensions and relationships of the teeth concerned enable the occlusal scheme for the teeth to be changed from lingualised to balanced occlusion simply by softening the wax or resin under the upper posterior teeth and rotating the upper buccal cusps downwards around the said palatal cusps on the upper teeth with such palatal cusps still substantially remaining within the centric stops of the lowers.

Owner:DAVIS SCHOTTLANDER & DAVIS

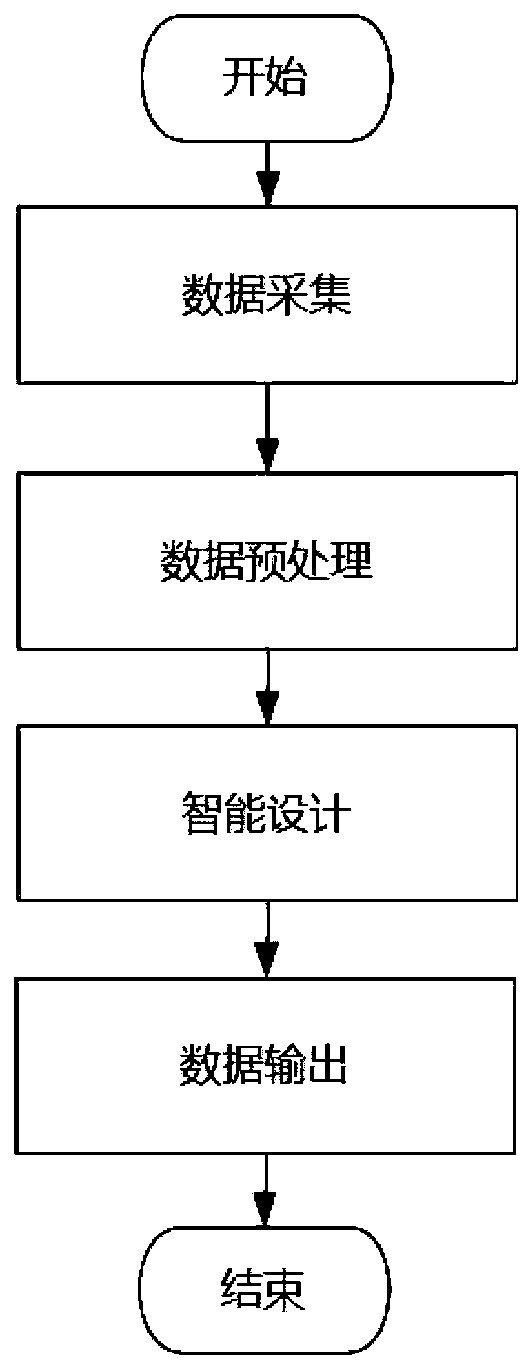

Intelligent design method of digital model for oral digital impression instrument

ActiveCN111568592AQuick callImprove efficiencyMedical simulationDental implantsData acquisitionBiomedical engineering

The invention belongs to the technical field of medical computer-aided designs and particularly discloses an intelligent design method of a digital model for an oral digital impression instrument. Themethod comprises the steps of data acquisition, data preprocessing, intelligent design, alternative dental crown matching, dental pattern adjustment and the like. A to-be-produced tooth is rapidly and accurately produced through extracting a distance between adjacent teeth of the to-be-produced tooth, buccal and lingual dental arch crown curves, a gum diameter height and cusp pit and fissure ridge shape features of opposite jaws, performing intelligent matching and adjusting alternative dental crown models, so that the processing speed of a false tooth is increased and an intermediate link ofprocessing is reduced.

Owner:CHENGDU BESMILE MEDICAL TECH CORP LTD

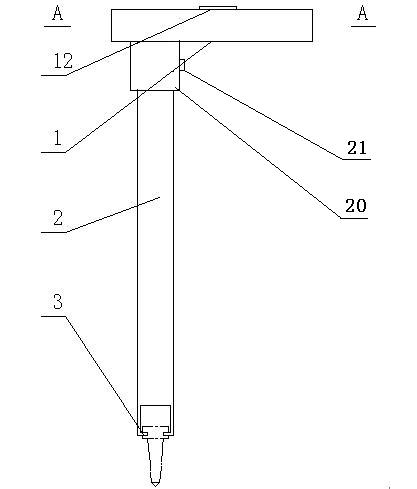

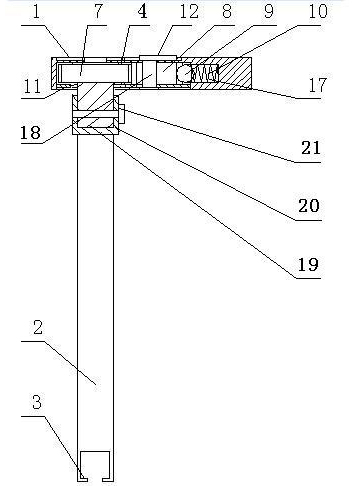

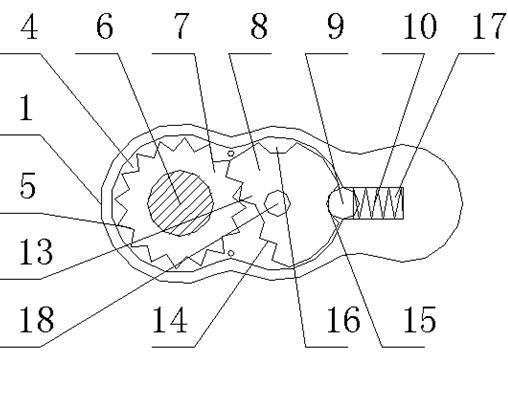

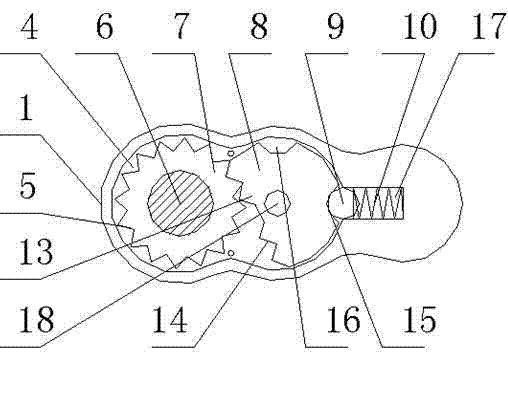

Special bolt driver for bone screw

The invention relates to the technical field of medical appliances, in particular to a special bolt driver for a bone screw. The special bolt driver comprises a handle and a bolt driver body, and is characterized in that the front end of the bolt driver body is provided with two teeth; the back end of the bolt driver body is provided with a locating block; the teeth are made of stainless steel materials, dental cusps of the teeth are opposite; a direction-turning device groove is arranged in the handle; and a direction-turning device is arranged in the direction-turning device groove and formed by a rotating shaft, a gear wheel, a cone, a locating ball, a spring, the locating plate, a locating sleeve and a wrench pin. Because the structure is adopted, the special bolt driver for the bone screw can be detachably stored, is beneficial to carrying and disinfection, and has the advantages of novel structure, fastness, reduction of patient pains, convenience for installation and disassembling and the like.

Owner:鞠传宝

Orthodontic device-setting tool

An orthodontic device-setting tool is provided with: a fitting section having a fitting surface, which covers and fits together with at least one of the incisal margin, the dental cusp, or the occlusal surface of a tooth; a foundation section, which has a back surface that adheres closely to the labial / buccal surface or the lingual surface of the tooth and has, on the surface opposite the back surface, a front face on which the orthodontic device is mounted; and a connecting section that connects the fitting section and the foundation section. The tool has a frame section, which protrudes from the front face of the foundation section and can fit together with the orthodontic device. Use of the orthodontic device-setting tool makes it possible to mount orthodontic devices such as corrective brackets without holding the patient for long periods of time and to mount the orthodontic devices accurately at the desired three-dimensional mounting positions for the orthodontic devices regardless of the skill level of the dentist practitioner. Moreover, the tool can even be used with mass-produced general purpose orthodontic devices, which are not orthodontic devices that have been specially customized as to design, cut, etc. for individual patients.

Owner:OKAZAKI KAZUYUKI

Digitizing design method of individual function bionic crown shape

The invention relates to a digitizing design method of an individual function bionic crown shape. The digitizing design method comprises the steps that upper and lower jaw tooth columns in normal occlusion are scanned in batches as a standard template database; tooth position preparation bodies to be repaired, adjacent teeth and opposite jaw teeth are scanned to be recorded as data D1; the adjacent teeth and the opposite jaw teeth in the D1 are used as common areas to be correspondingly matched with data in the standard template database, and matched data D2 are selected; crown data in the D2which have the same tooth position with teeth to be repaired are fused with the tooth position preparation bodies to be repaired, and initial data of the repairing bodies are generated; intercuspal occlusion is conducted, and no intersection between the opposite jaw teeth is adjusted; a functional occlusal surface on a tooth crown of an opposite side same area of the two mesiocclusion and distocclusion adjacent teeth and a tooth arch is extracted, and a movement trail of the tooth position to be repaired is generated; and an enveloping surface of the movement of the opposite jaw tooth cusps istaken as a functional occlusal surface form of the teeth to be repaired. According to the digitizing design method, the process of designing of tooth bionic axial surfaces, the functional occlusal surfaces and physiological wearing surfaces by a senior dental expert can be imitated, and rapid bionic designing is achieved.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

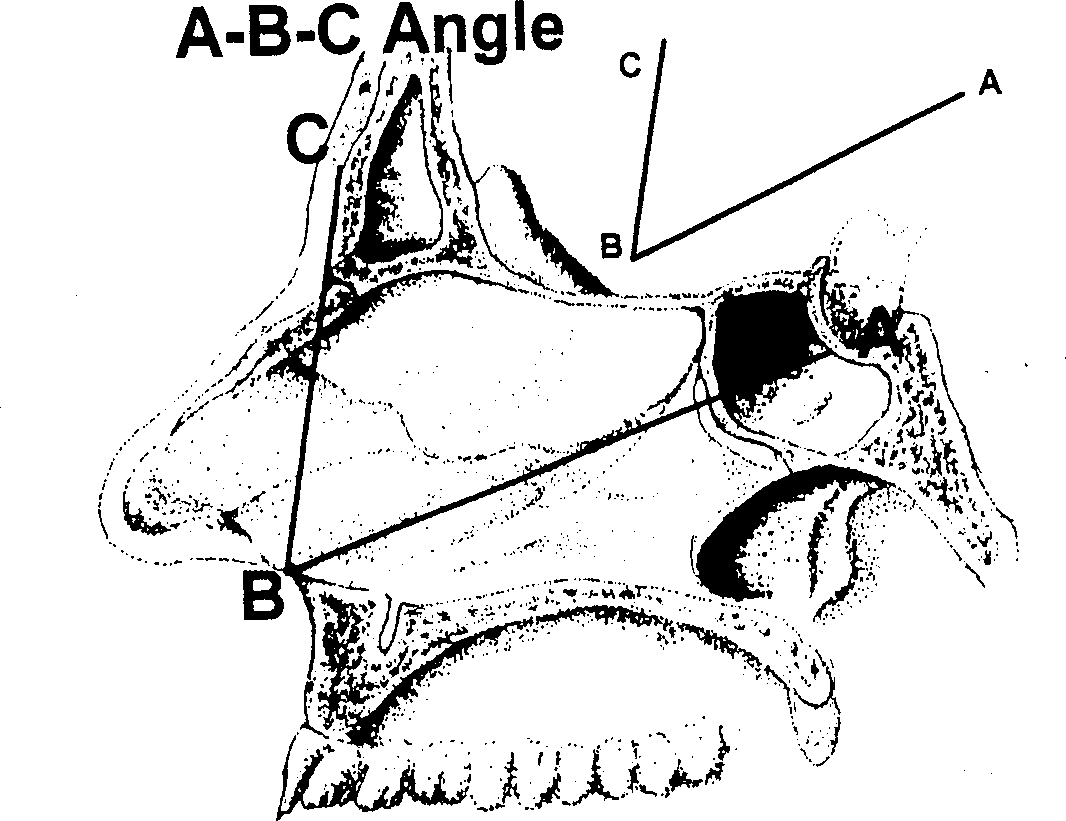

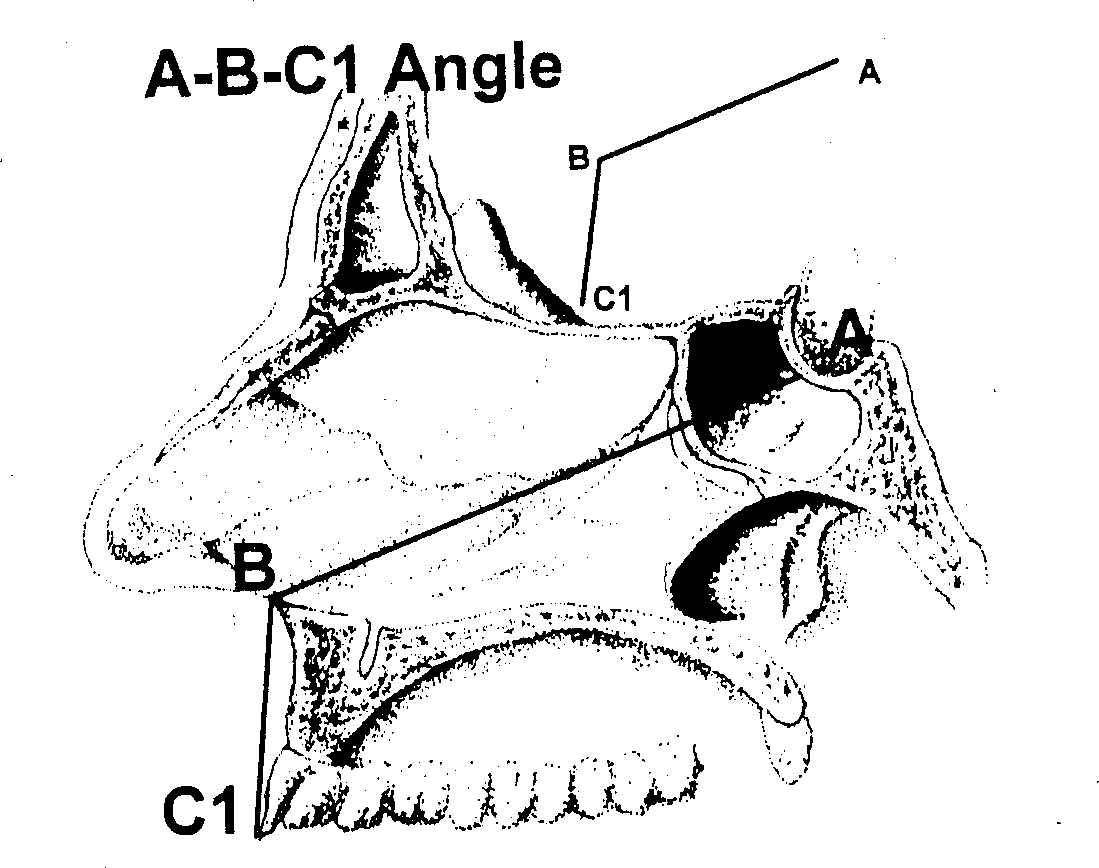

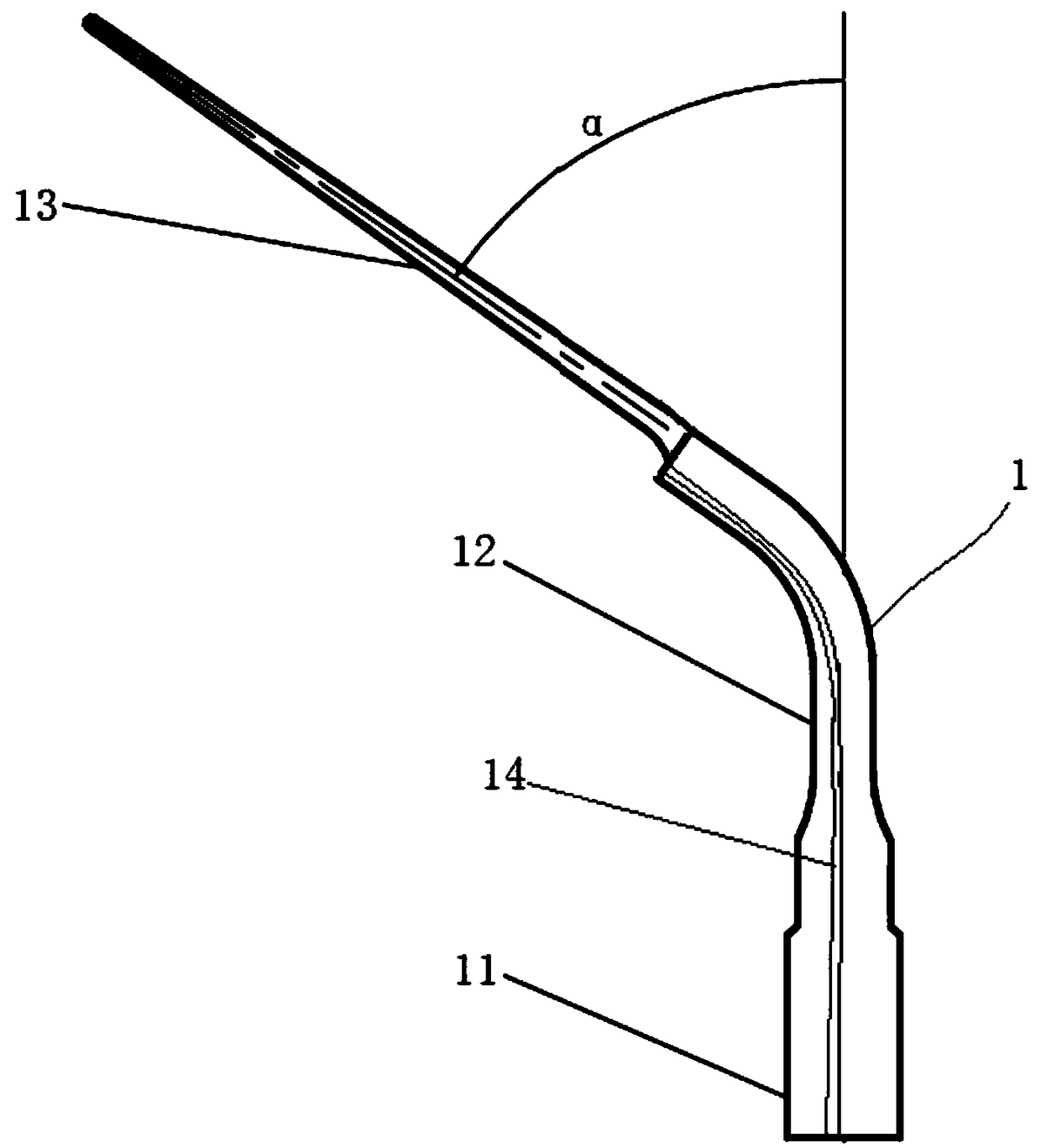

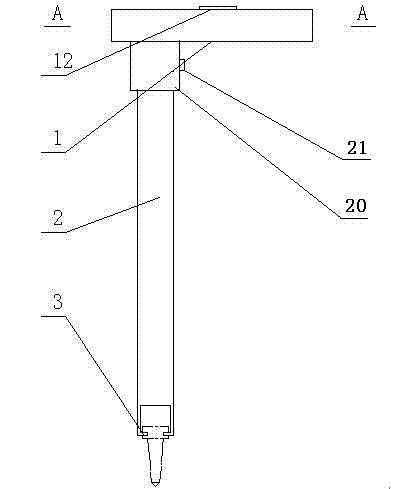

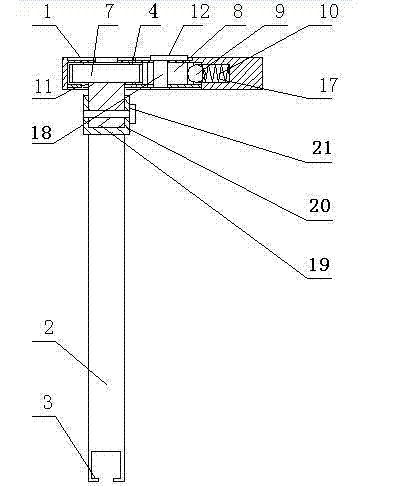

Operation positioning method from sphernoidal sinus to saddle ragion and simple positioning instrument

InactiveCN1337211AAvoid radiation damageShorten operation timeDiagnosticsInstruments for stereotaxic surgeryNasal cavityNose

The present invention discloses an included angle measurement method using anterior nasal spina as centre to implement positining method for making transsphenoidal surgery of sella turcica region andits simple position finder. Said method includes midpoint of superciliary arch, nasal spina-saddle and nasal spina included angle positioing method and premaxillary dental cusp, nasal spina-saddle and nasal spina included angle positioing method. Said invented simple position finder is formed from cross bar with fixing screw, U-shaped frame, spherical coordinatometer, connecting bar, indication screw of midpoint of superciliary arch, measurement probe, indication screw of anterior nasal spina and international stanard adult system nasal retractor. Said invention can make accurate positioing, can prevent radiation damage, shorten operation time and raise rate of success of operation.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

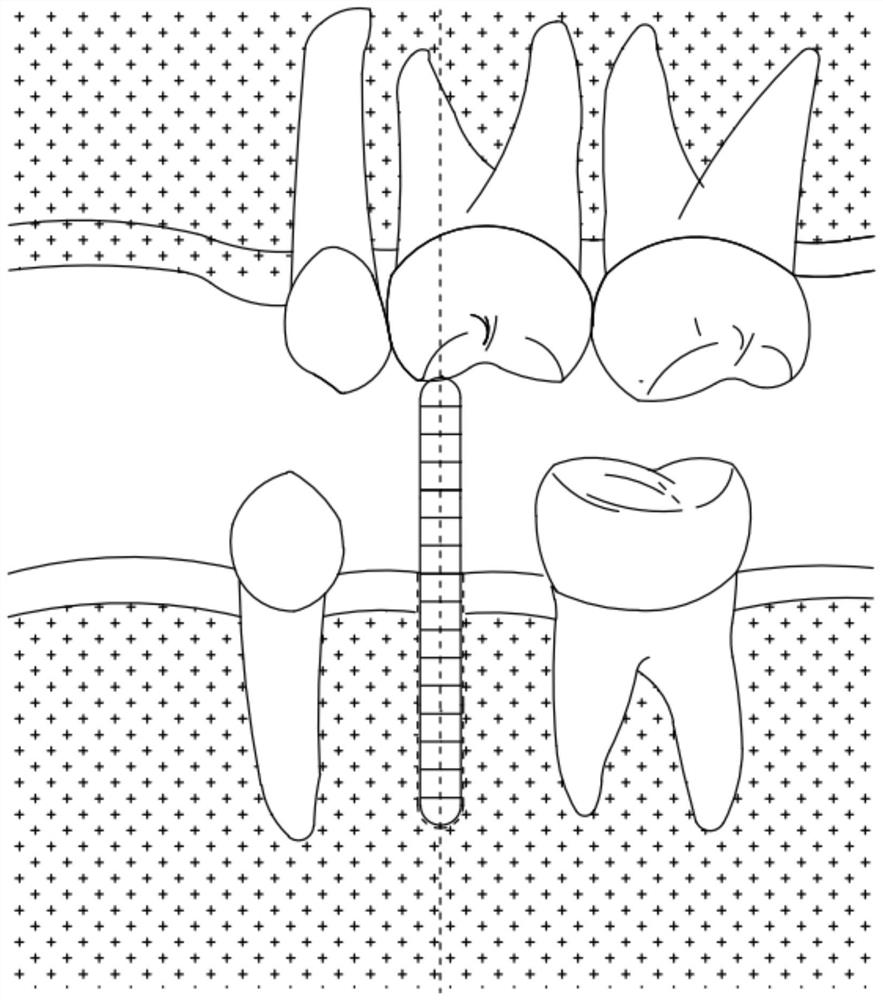

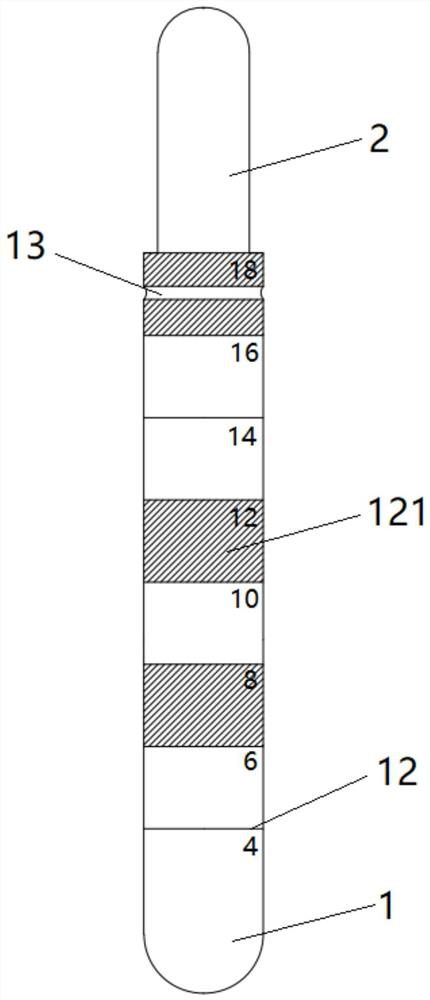

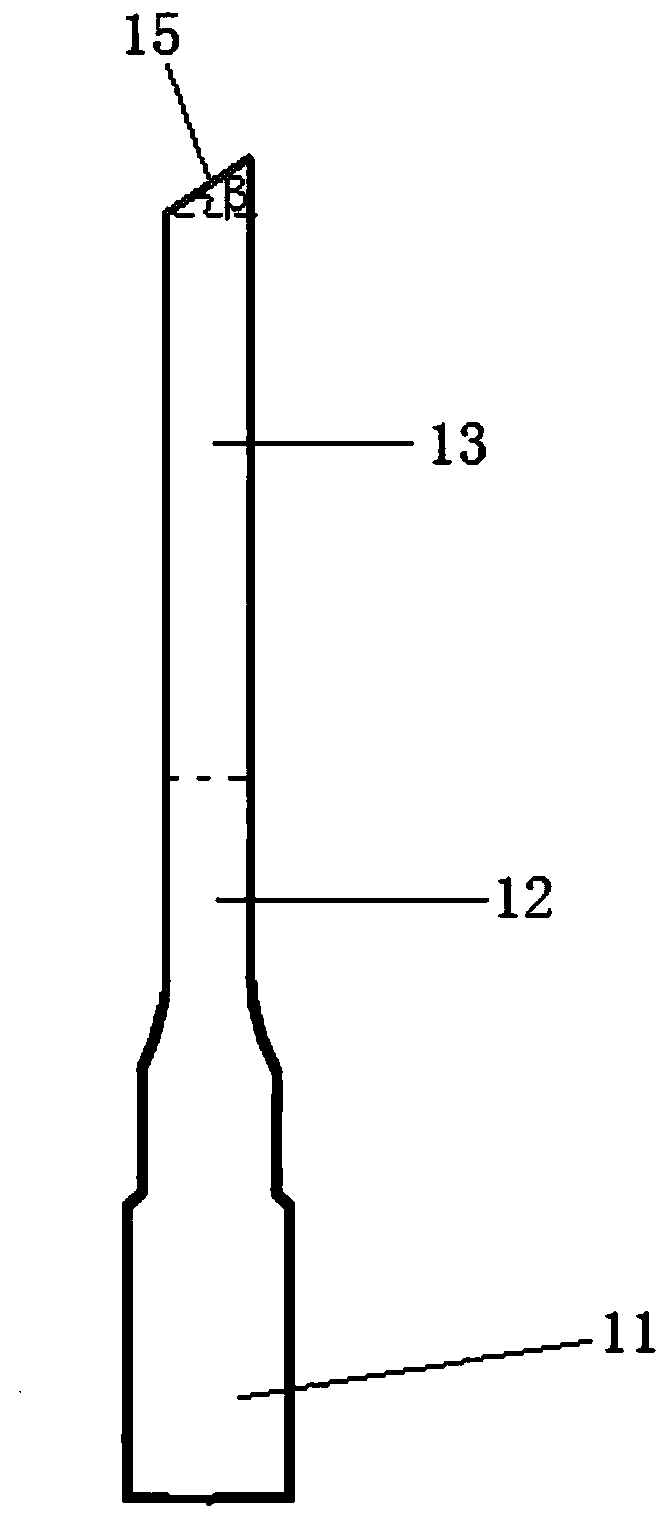

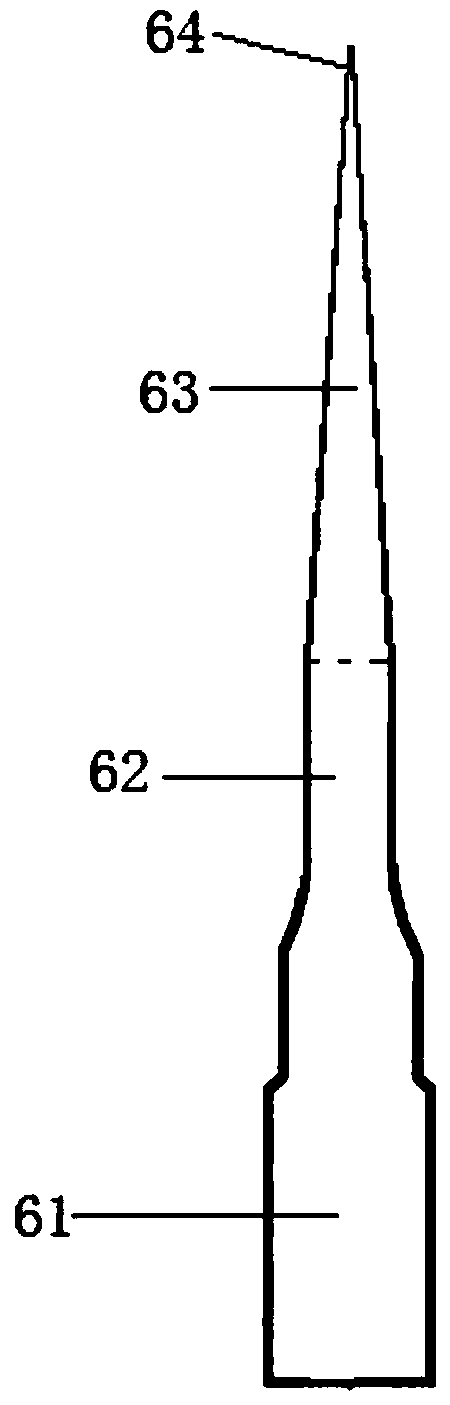

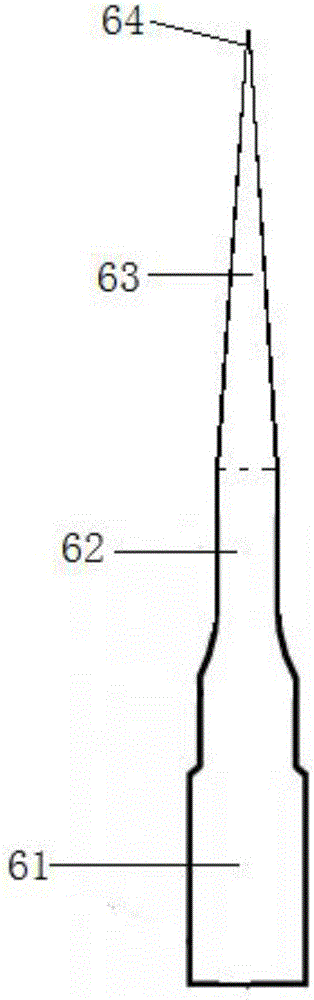

Implant cavity measuring rod and method with restoration guidance under tooth tip dislocation as reference

PendingCN112807120AAccurate measurementAccurate adjustment effectDentistryBiomechanicsBiomedical engineering

The invention discloses an implant cavity measuring rod and method with restoration guidance under tooth tip dislocation as reference. The measuring rod comprises an in-bone rod and an occlusion rod, wherein the interior of the in-bone rod is hollow to form a hollow cavity, the occlusion rod is telescopically embedded in the hollow cavity and is in friction fit with the hollow cavity, the occlusion rod and the in-bone rod are coaxially arranged, the in-bone rod is used for being embedded in a cavity and protruding out of a bone surface, the occlusion rod is higher than the occlusion surface of an adjacent tooth and is used for abutting against and making contact with an involution tooth, and the outer wall of the in-bone rod is provided with a scale. The method adopts multiple measuring rods with progressively increased diameters, in the process of gradually expanding the cavity, the cavity is measured once after each time of hole expansion is completed, and the position, depth and axial direction of the cavity and the contact relation between a subsequently implanted implant and the occlusion surface of the involution tooth are obtained with the ideal occlusion state of the tooth tip dislocation of a patient as reference. The long-term aesthetics, biomechanics and occlusion function stability of the patient after the implant is implanted are effectively guaranteed.

Owner:南方医科大学口腔医院

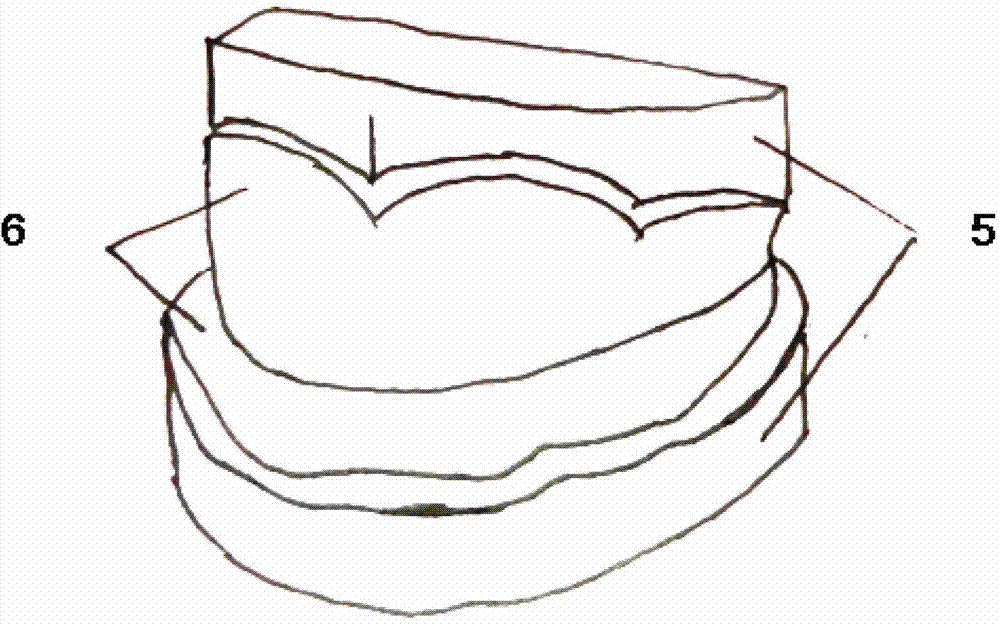

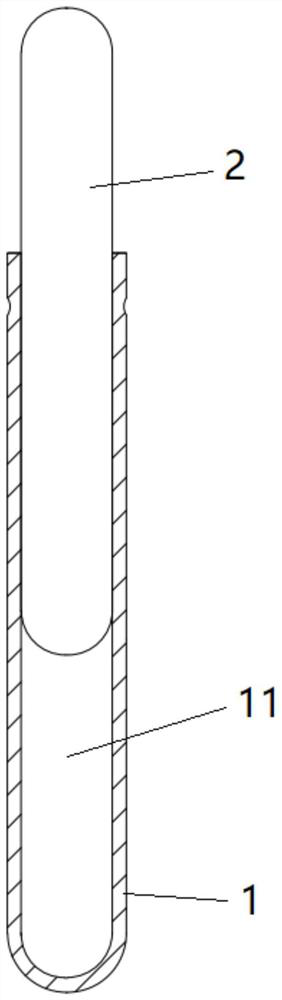

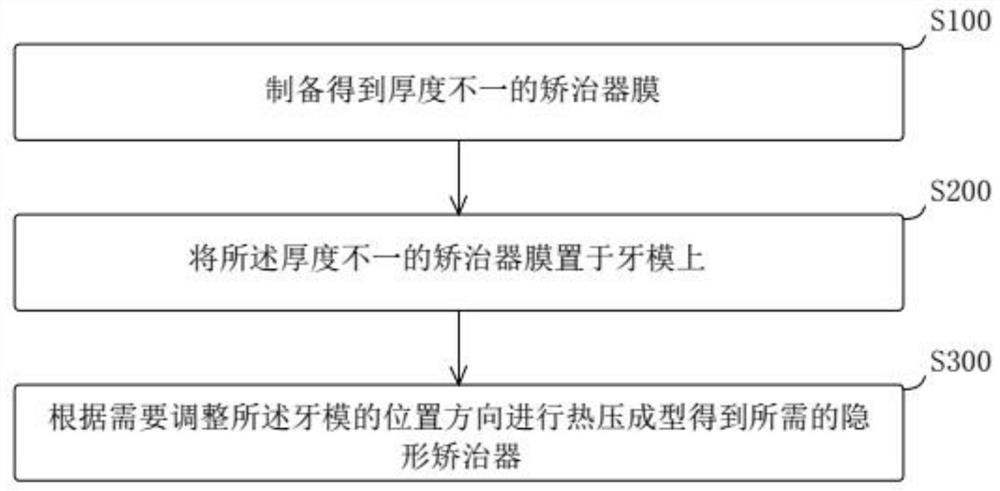

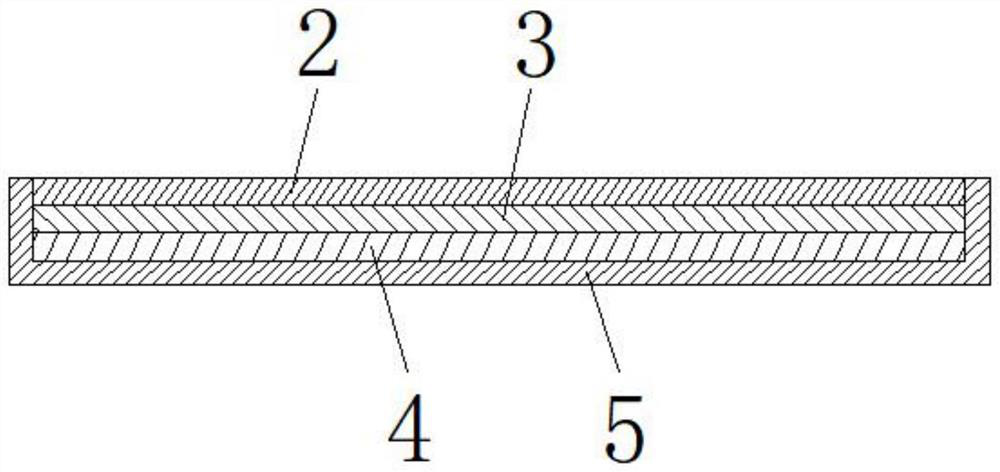

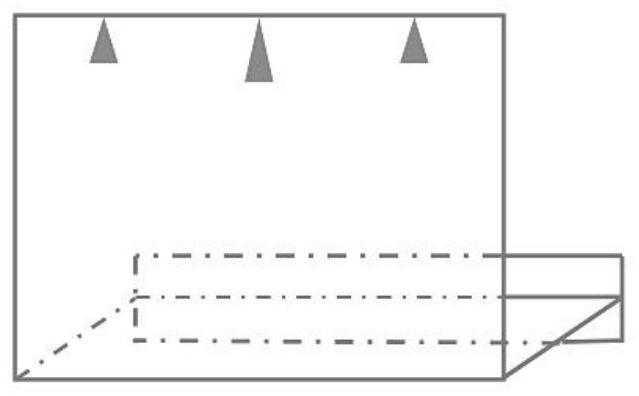

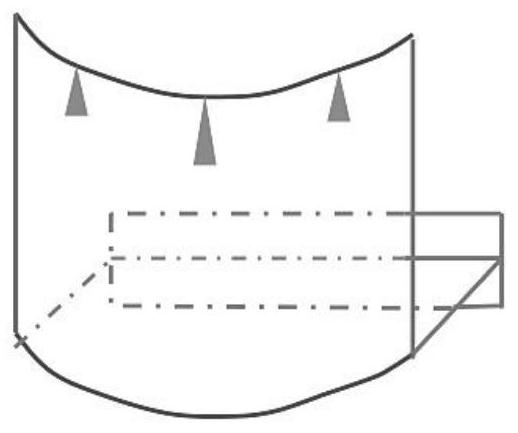

Invisible appliance with controllable thicknesses in all directions and preparation method thereof

The invention discloses an invisible appliance with controllable thicknesses in all directions and a preparation method thereof. The method comprises the following steps of preparing appliance films with different thicknesses; placing the appliance films with different thicknesses on a dental cast; and adjusting the position and the direction of the dental cast as required, and carrying out hot press molding to obtain the required invisible appliance. By means of the method, it can be set that the tooth tip part of the invisible appliance is relatively thick, the position needing relatively large correction force is relatively thick, and the part which does not need correction is relatively thin, so that the thicknesses of the invisible appliance in all directions can be adjusted accordingto an actual correction scheme, control over correction force in all directions is achieved, and therefore the correction curative effect is improved, the correction period is shortened, and moreover, the correction experience of the patient is improved, and personalized correction is truly realized.

Owner:SHENZHEN TOOLINK TECH CO LTD

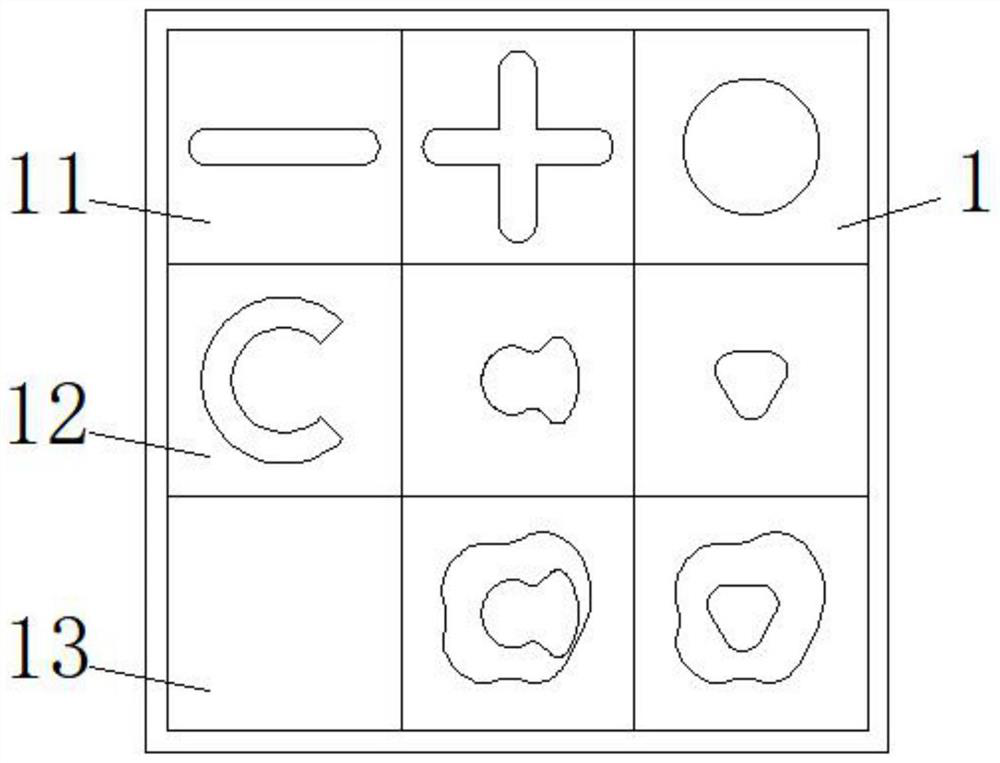

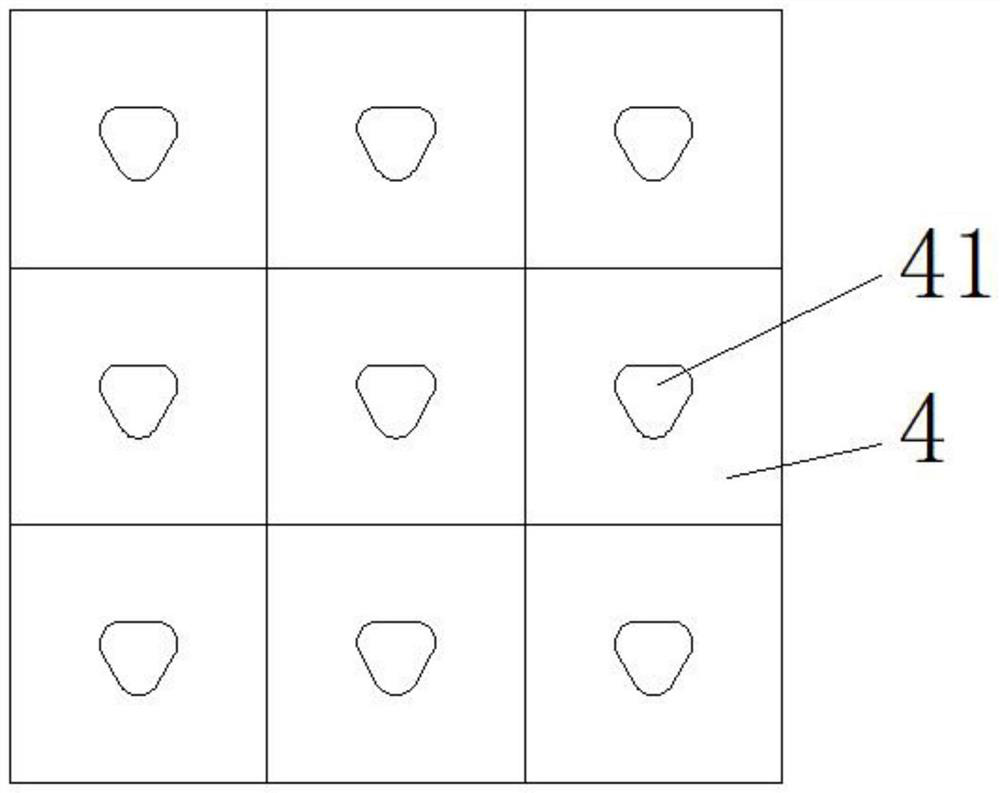

Advanced modular model for training dental operation hand feeling

The invention provides an advanced modular model for training dental operation hand feeling, which comprises a model main body, a simulated enamel layer, a dentin layer, a dental pulp cavity layer and a transparent back plate layer from top to bottom in sequence, and is characterized in that the model main body is provided with a Sudoku structure; a linear training structure, a cross-shaped training structure, a circular training structure, a C-shaped training structure, a dovetail-shaped training structure and a circular triangular training structure are arranged on the Sudoku structure, and a blank area and two protruding surface simulation tooth tip form areas are further arranged on the Sudoku structure. The hand fine motion ability of students can be trained step by step, the three-dimensional feeling from the horizontal direction to the vertical direction and from the plane to the inclined plane with the tooth tips can be achieved, the fine feeling of the students applying the high-speed drill point to move in the model in the transverse direction, the longitudinal direction and the arc line under the stable fulcrum can be trained, and the fine feeling of gradually abrading and cutting different tissues of the tooth body and falling in the marrow penetrating process can be trained; therefore, the hand stability and flexibility of the student can be trained.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY +1

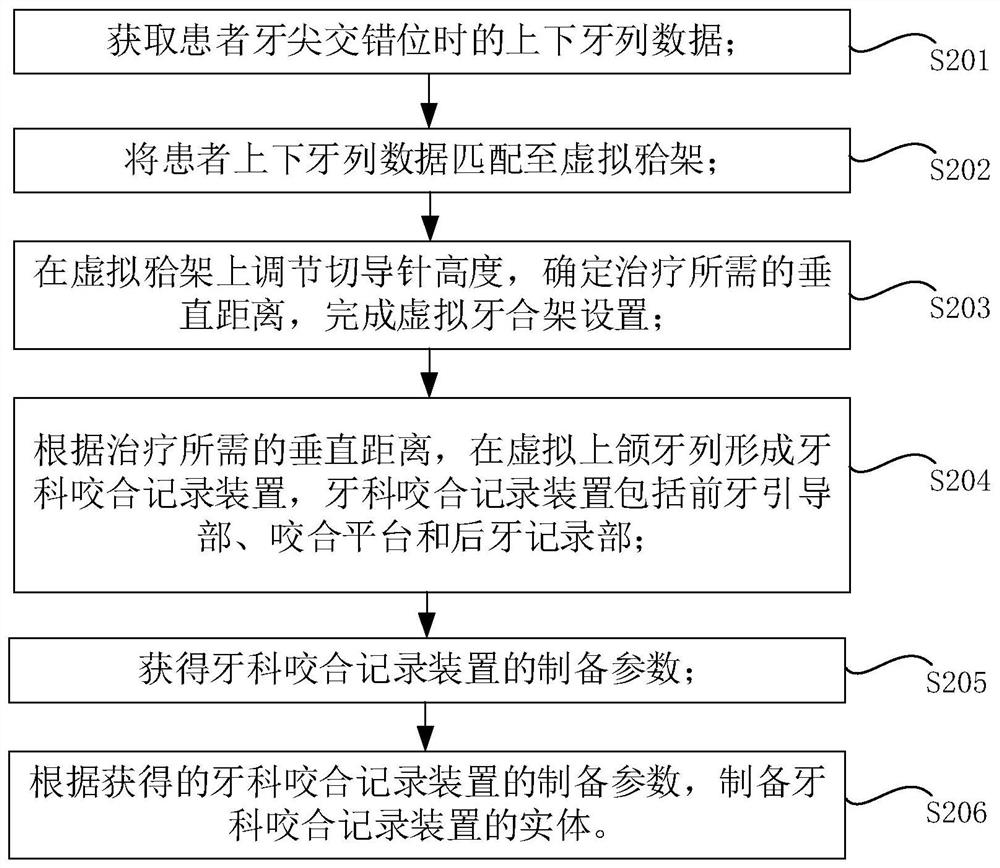

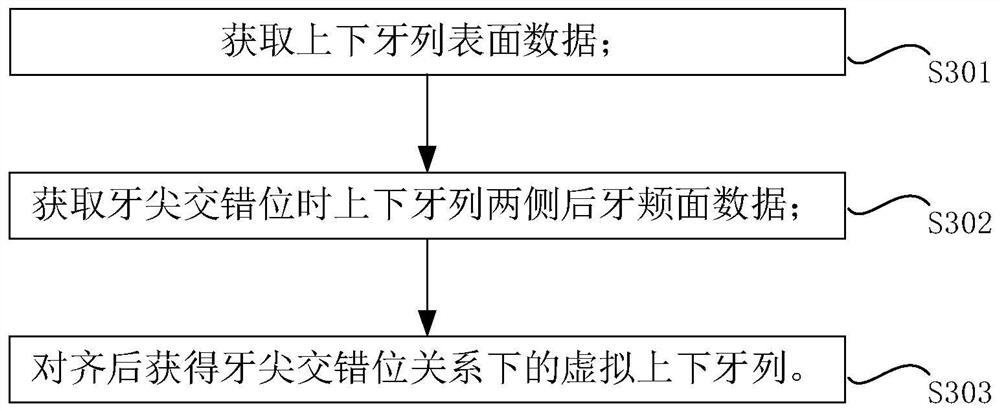

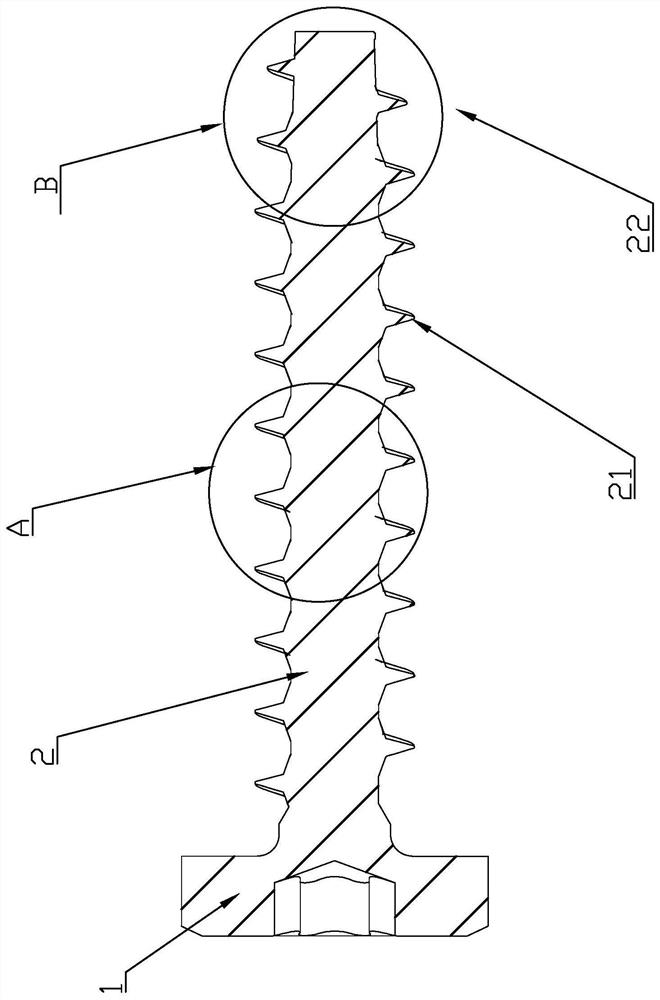

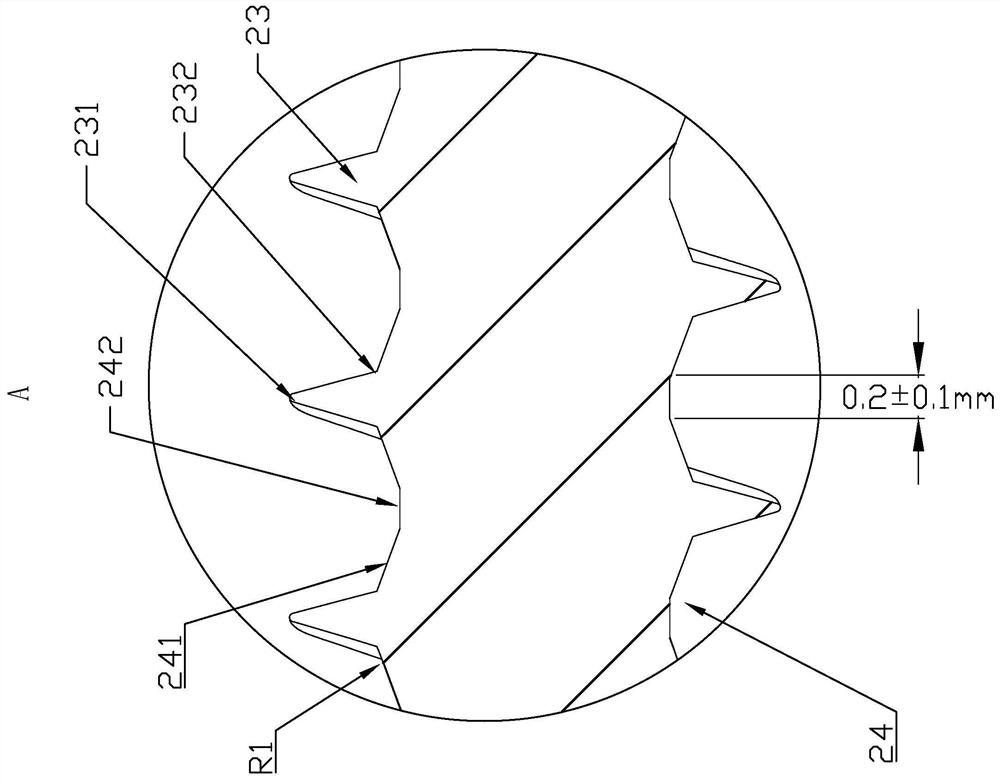

Manufacturing method of dental occlusion recording device and dental occlusion recording device

The invention relates to the technical field of oral cavity auxiliary medical instruments, and provides a manufacturing method of a dental occlusion recording device, the dental occlusion recording device and a using method of the dental occlusion recording device. The manufacturing method of the dental occlusion recording device comprises the following steps: acquiring upper and lower dentition data when tooth tips of a patient are staggered; matching the upper and lower dentition data of the patient to a virtual frame; adjusting the height of a cutting guide needle on the virtual frame, and determining the vertical distance needed by treatment; forming the dental occlusion recording device on the virtual maxillary dentition according to the vertical distance required by treatment; obtaining preparation parameters of the dental occlusion recording device; and preparing an entity of the dental occlusion recording device according to the obtained preparation parameters of the dental occlusion recording device. The manufacturing method is completed by using a digital technology, and the manufacturing method is simpler, more efficient and higher in precision. By means of the method, the real jaw position relation needed by treatment can be directly obtained, errors caused by a process for indirectly determining the jaw position relation by operating a hinge shaft on the frame are avoided, and the accuracy of determining the jaw position relation can be improved.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

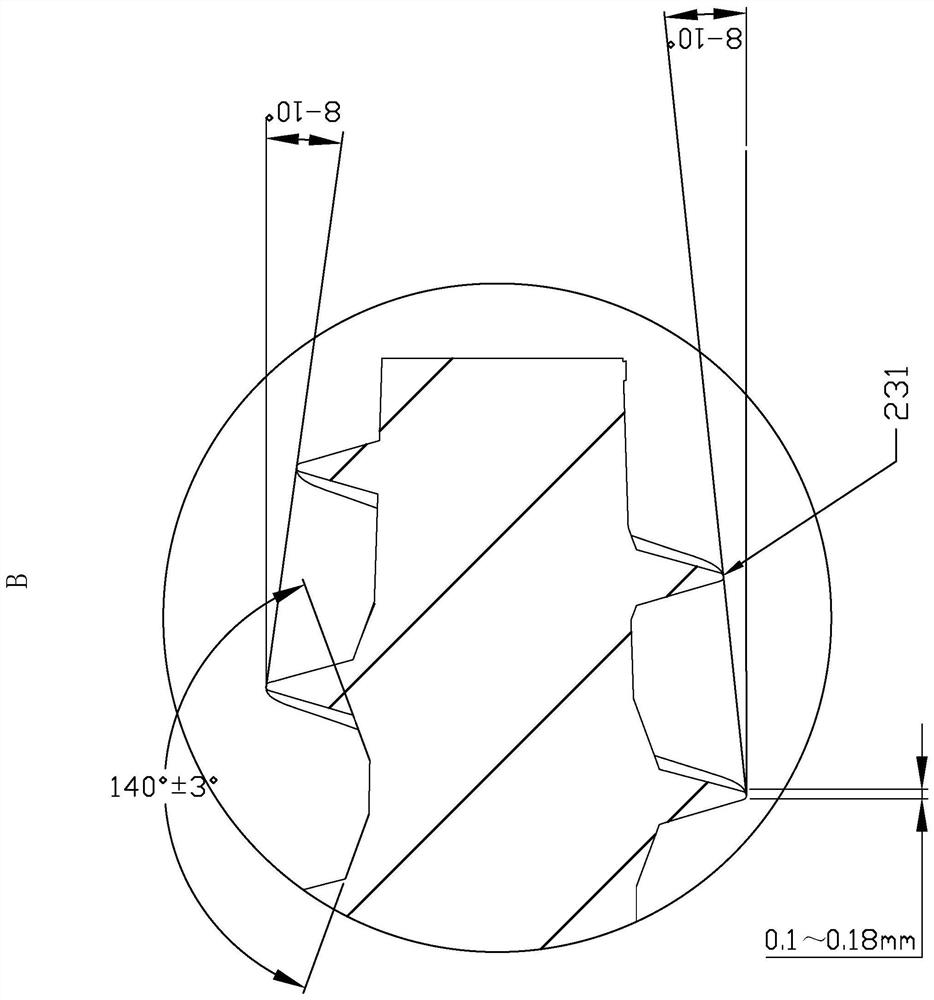

Self-tapping screw quickly installed on plastic part and machining device thereof

The invention relates to a self-tapping screw quickly installed on a plastic part. The self-tapping screw comprises a head part and a screw rod part, wherein the screw rod part comprises a parallel thread part and a guide thread part; the parallel thread part forms thread teeth with the consistent tooth height from the head part to the guide thread part; the guide thread part forms thread teeth with the tooth height gradually decreased from the parallel thread part to the tail end of the screw rod part; each thread tooth comprises a tooth tip and a tooth bottom; the thread pitch of the threadteeth is 2.69mm; the length of the guide thread part is 2-2.5 thread pitches; and the included angle between the tangent line of the tooth tip of the guide thread part and the tangent line of the tooth tip of the parallel thread part is 8-10 degrees. By the adoption of the technical scheme, the thread parts are used for connecting a steel part and the plastic part after being subjected to quenching and tempering heat treatment, the plastic part does not need to be provided with a machined thread by itself through the self-extrusion screw, only one unthreaded hole is needed, an embedded nut isomitted, the connecting and locking strength can meet the requirement for high strength, the self-tapping screw is perfectly matched with plastic in the locking process, and the situation that the plastic is damaged by heat energy generated by locking is reduced.

Owner:浙江明泰控股发展股份有限公司

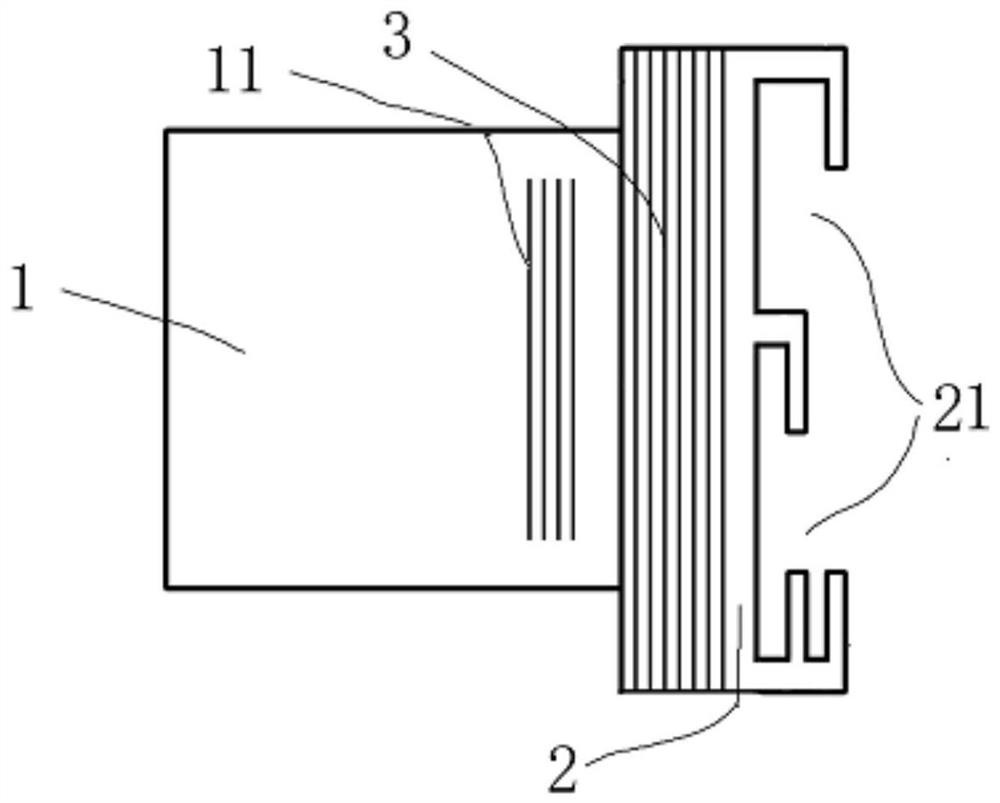

Bracket positioning guide plate and using method thereof

The invention discloses a bracket positioning guide plate, which comprises several independent guide plates, the independent guide plate comprises a lip side positioning plate, a horizontal stabilizing plate and a tongue side retaining plate; the invention further provides a using method of the bracket positioning guide plate, firstly, a long axis of a tooth body is drawn on a tooth model; a firstbonding layer is laid on the lingual side of a tooth occlusal surface; then an independent guide plate in a proper shape is selected to be placed at the first bonding layer, the horizontal stabilizing plate abuts against the tooth cutting edge or the tooth tip, the lip side positioning plate abuts against the tooth lip face, the center line of the lip side positioning plate coincides with the long axis of the tooth, and finally a second bonding layer is laid on the surfaces of the horizontal stabilizing plate, the tongue side fixing plate and the first bonding layer. The independent guide plate can be used for positioning the mounting position of the bracket on a certain tooth, the independent guide plate of the lip side positioning plate with a proper shape is selected for positioning the bracket of each tooth, the operation is similar to movable type printing, the procedure of individually customizing a plastic plate is omitted, and the bracket positioning difficulty and the positioning cost are reduced.

Owner:JILIN UNIV

tooth cleaning kit

Owner:NANNING WEIYE ELECTROMECHANICAL TECH CO LTD

A digital design method for the shape of a bionic dental crown with individual functions

The invention relates to a digital design method for the shape of a bionic dental crown with individual functions. The steps are: batch scan normal occlusal upper and lower jaw dentition as a standard template database; is the data D1; use the adjacent teeth and opposing teeth in D1 as the common area to match with the data in the standard template database, and select the matching data D2; use the crown data in D2 at the same position as the tooth to be repaired and the data to be repaired Dental preparations were fused to generate initial restoration data; the cusps were staggered and adjusted so that there was no intersection with the opposing teeth; the functional occlusal surfaces of the two adjacent teeth in the mesiodistal and the crowns on the opposite side of the dental arch were extracted , to generate the motion trajectory of the teeth to be repaired; use the envelope surface of the movement of the opposing cusp as the functional occlusal surface shape of the teeth to be repaired. The invention can imitate the process of senior dental experts designing the bionic axial surface, the functional occlusal surface and the physiological wear surface of the tooth, so as to realize the rapid bionic design.

Owner:NANJING PROFETA INTELLIGENT TECH CO LTD

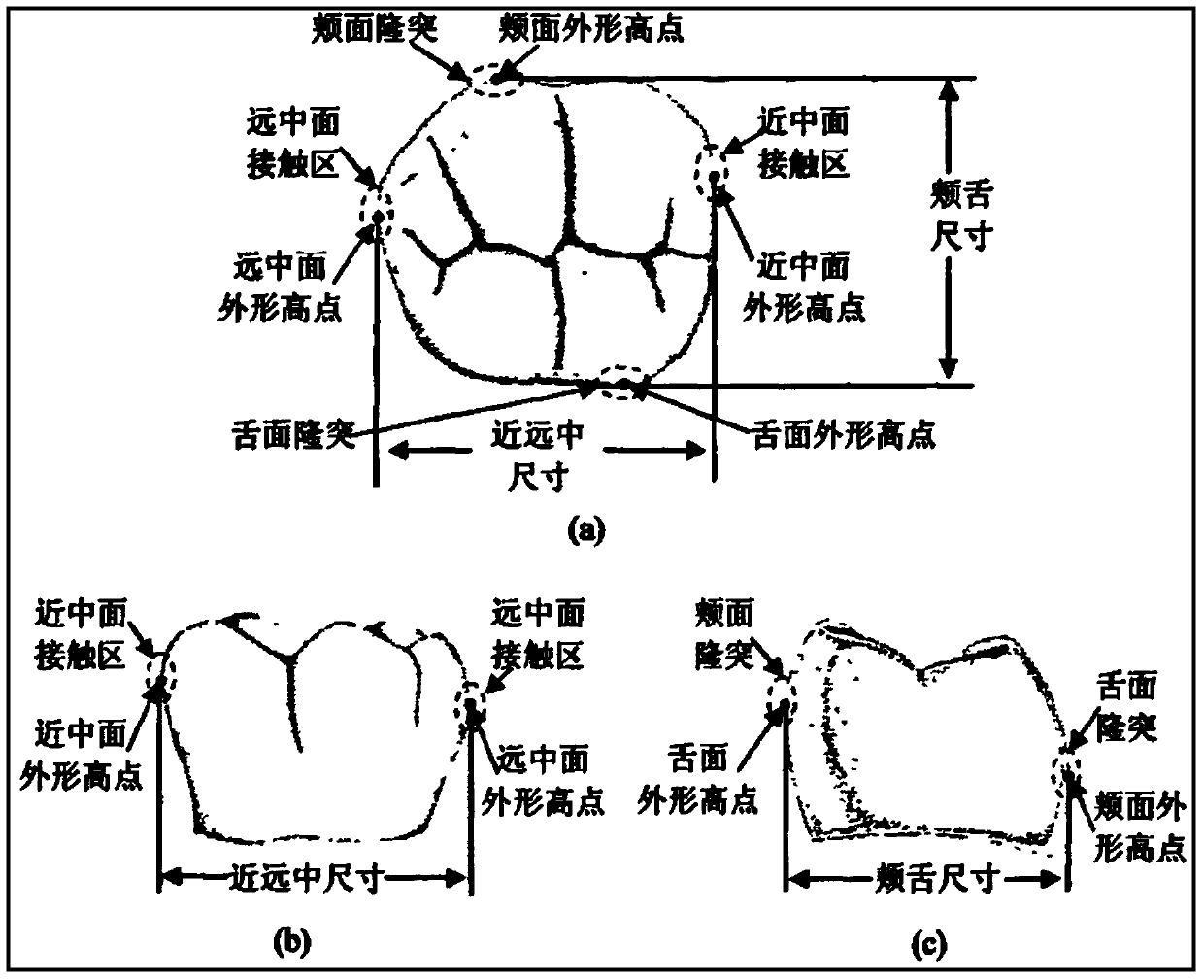

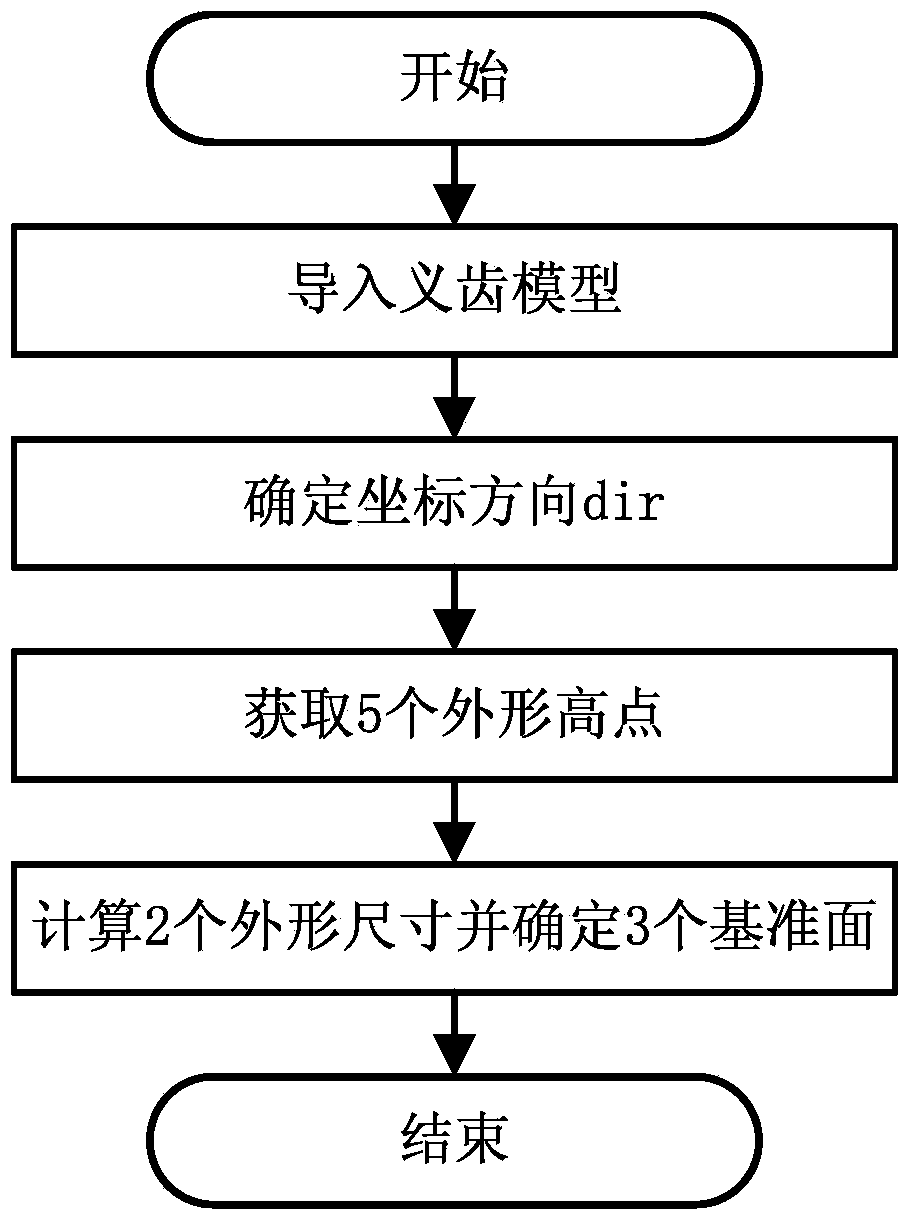

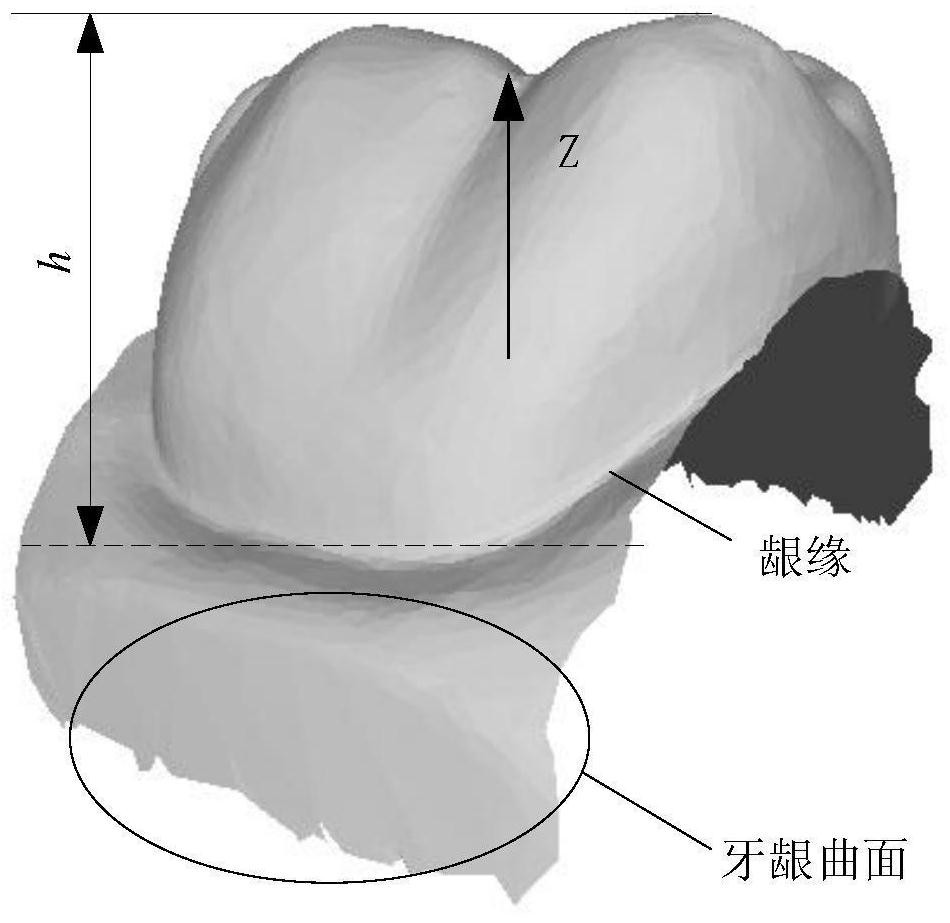

A Measuring Method of Form and Position Parameters of Digital Denture

The invention discloses a position and configuration parameter measuring method of a digital denture. The method comprises the following steps: introducing a denture model; adjusting a coordinate system of the denture model, so that a coordinate direction dir of the denture model, wherein the coordinate direction dir satisfies the following relations that an z axle is parallel to the direction ofa long axis, an x axle is parallel to a far-middle-near direction, a y axle is parallel to a buccolingual or labiolingual direction, and the directions of the x axle, the y axle and the z axle conforms to a right-hand rule; in accordance with the coordinate direction dir, recognizing five appearance high points of a denture within an h height range in a mode of calculating coordinate extreme values, wherein the h is a preset height threshold and the h is used for predicting a distance from a dental cusp to a gingival margin; and in accordance with the five appearance high points of the denture, calculating two appearance dimensions and three datum planes. According to the method provided by the invent, by adding the height threshold h, the method not only has the property of being strong in operability but also guarantees the reliability of a recognition result; the method, which calculates the two appearance dimensions and the three datum planes in accordance with the five appearancehigh points of the denture, is more convenient. The method provided by the invention can be widely applied to the denture repair field.

Owner:FOSHAN NUOWEI TECH

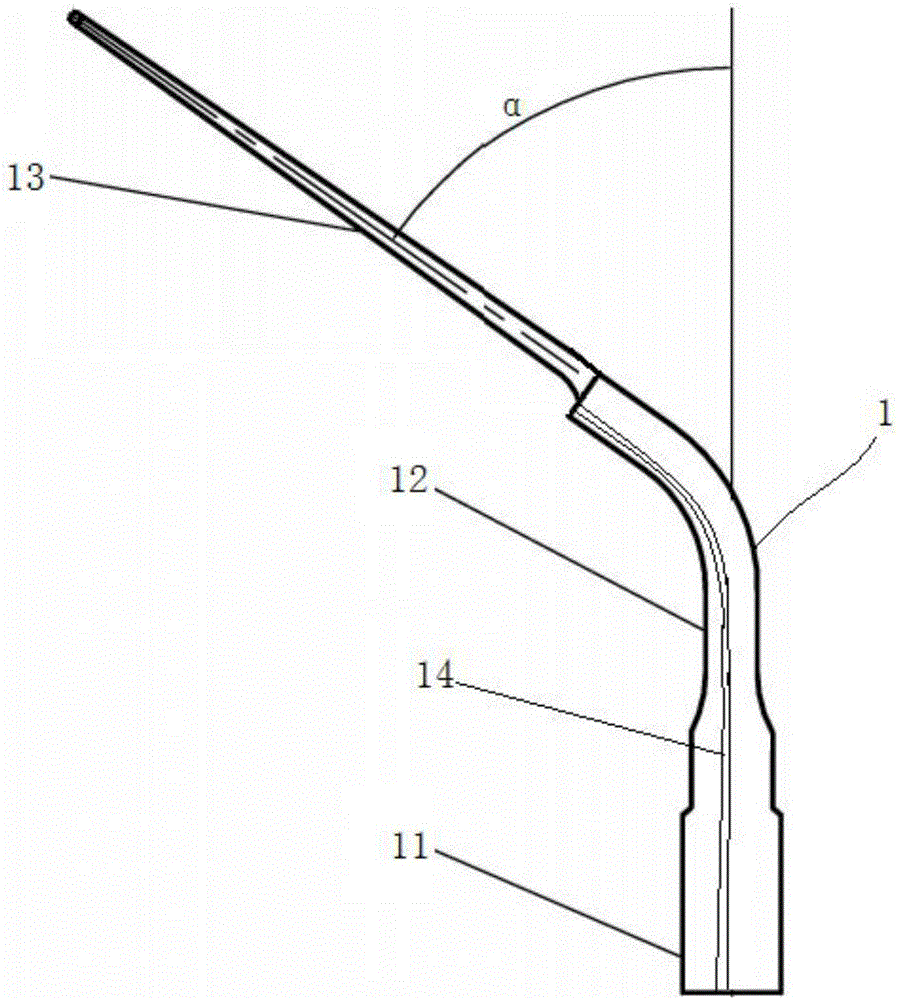

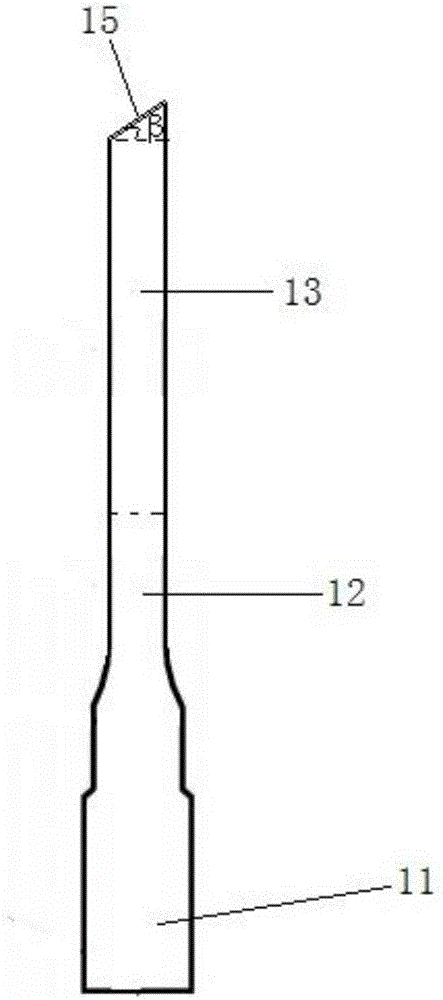

Tooth cleaning kit

The invention relates to a tooth cleaning kit, which consists of a work tip unit, a polishing unit and a fixed frame unit. The work tip unit includes supragingival tooth cleaning work tip, a shallow periodontal tooth cleaning work tip and a deep periodontal tooth cleaning work tip; the end face of the supragingival tooth cleaning work tip head is a beveled end face, and the end faces of the shallow periodontal tooth cleaning work tip and the deep periodontal tooth cleaning work tip are both tips; during use, firstly the supragingival tooth cleaning work tip is utilized to remove supragingival and tooth neck calculuses, dental plaques and dental cusp hard matters; then the shallow periodontal tooth cleaning work tip is employed to eliminate shallow periodontal calculuses and dental plaques rapidly and thoroughly; the deep periodontal tooth cleaning work tip is utilized to remove periodontal deep calculuses; and then a polish brush is employed to conduct preliminary polishing on the cleaned tooth faces, and a prophy cup is adopted for fine polishing. The tooth cleaning kit provided by the invention realizes leveling and polishing of tooth surfaces while rapidly and thoroughly cleaning teeth.

Owner:NANNING WEIYE ELECTROMECHANICAL TECH CO LTD

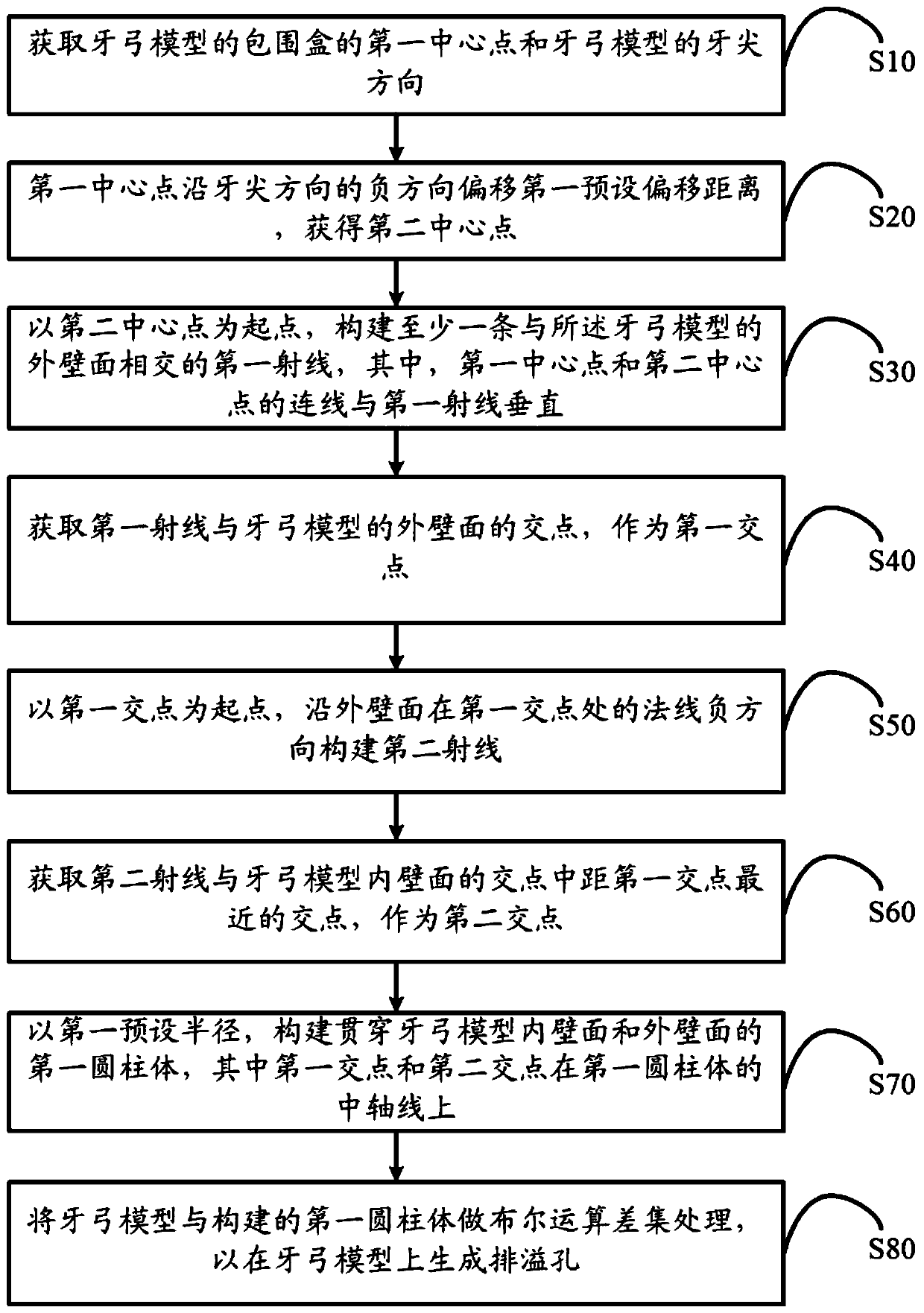

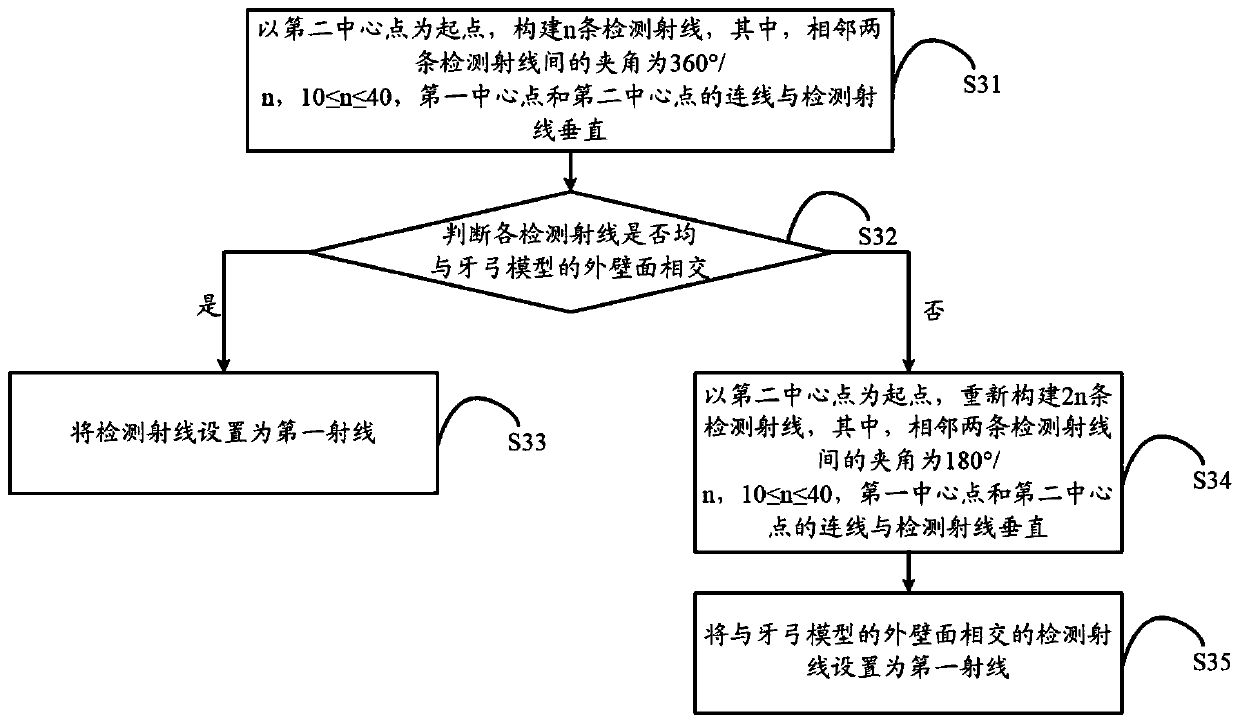

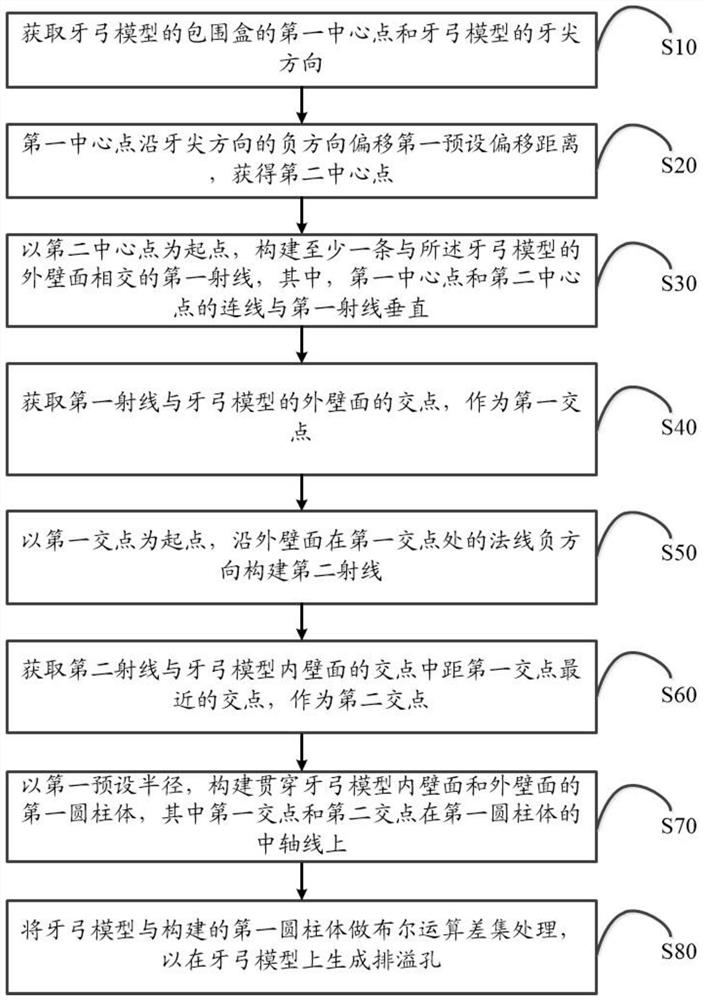

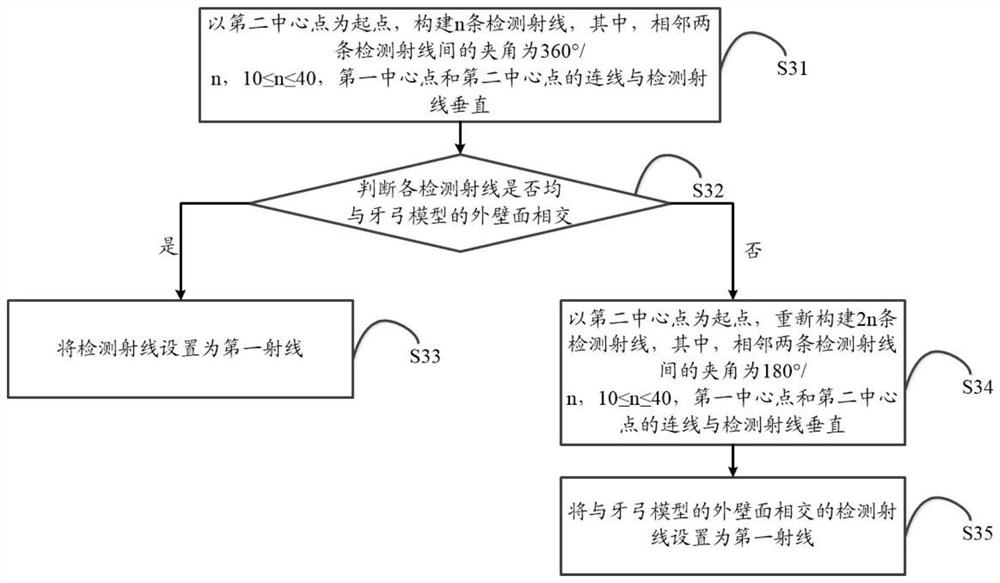

Generation method of overflowing holes, terminal and storage medium

ActiveCN111449781AAvoid the problem of reduced spillage effect3D printingDental prostheticsOral problemsDesign software

The invention discloses a generation method of overflowing holes, a terminal and a storage medium. The method comprises the following steps: acquiring a second central point according to a first central point of a bounding box of a dental arch model, a tooth tip direction and a first preset offset distance; constructing n first rays by taking the second central point as a starting point; taking anintersection point of the first rays and the outer wall surface of the dental arch model as a first intersection point; constructing second rays along a negative direction of a normal of an outer wall surface at the first intersection point by taking the first intersection point as a starting point; acquiring an intersection point, which is nearest to the first intersection point, in the intersection points of the second rays and an inner wall surface of the dental arch model as a second intersection point; constructing a first cylinder penetrating the inner wall surface and outer wall surface of the dental arch model by virtue of a first preset radius; and carrying out Boolean calculation difference set processing on the dental arch model and the first cylinder, so as to generate the overflowing holes. According to the generation method, the problems that the sizes and shapes of overflowing holes generated for a dental arch model in dental three-dimensional design software are fixed,and therefore, partial overflowing holes cannot play a role of overflowing are solved.

Owner:SHENZHEN UP3D TECH CO LTD

Dental instrument with removable dental tip and method of assembly

A dental instrument includes at least one removable or replaceable dental tip. The dental instrument includes a spring actuated collet and collar housed internally within a handle. The handle includes a handle center affixed to a center rod and a grip portion housing the collet and collar and a handle center affixed to a center rod. The center rod is affixed to the collet. The collet includes spring fingers that are biased radially inward by the collar to retain the dental tip. When the grip portion of the handle is rotated about a longitudinal axis of the handle relative to the handle center, camming surfaces associated with the grip portion and the handle center cause translational movement along the longitudinal axis to engage or disengage the collar from the collet.

Owner:AMERICAN EAGLE INSTR

Complete dentition full denture finished product resin tooth and preparation method thereof

ActiveCN102805670BFast centric biteMinimize the difference in tooth row levelImpression capsArtificial teethOcclusal AdjustmentLower dentition

Owner:SHANDONG UNIV

Special bolt driver for bone screw

The invention relates to the technical field of medical appliances, in particular to a special bolt driver for a bone screw. The special bolt driver comprises a handle and a bolt driver body, and is characterized in that the front end of the bolt driver body is provided with two teeth; the back end of the bolt driver body is provided with a locating block; the teeth are made of stainless steel materials, dental cusps of the teeth are opposite; a direction-turning device groove is arranged in the handle; and a direction-turning device is arranged in the direction-turning device groove and formed by a rotating shaft, a gear wheel, a cone, a locating ball, a spring, the locating plate, a locating piece and a wrench pin. Because the structure is adopted, the special bolt driver for the bone screw can be detachably stored, is beneficial to carrying and disinfection, and has the advantages of novel structure, fastness, reduction of patient pains, convenience for installation and disassembling and the like.

Owner:鞠传宝

Bite-type oral periapical film projection positioning frame

PendingCN111772666ASolve the flutter problemEliminate the sense of hospitalRadiation diagnostics for dentistryPhotographyProjection imageOral problems

The invention discloses a bite-type oral periapical film projection positioning frame which comprises a functional end and a hand-held end for fixing an image plate. The functional end and the hand-held end are connected by a bending part, when front teeth are shoot, the bending part is used to be bite by the teeth for positioning. The bite-type oral periapical film projection positioning frame can be used to shoot the projection images of the front teeth as well as the projection images of back teeth. During the shooting process, the image plate is inserted into the inner side of the to-be-shoot teeth of a patient through the hand-held end, the angle of the image plate is adjusted, then the front teeth of the patient bite the positioning frame, and the image plate is fixed through bitingof the front teeth. Hands of the patient can be completely liberated, the hospital infection problem of touching the perioral tissues at the time of holding by the patient is effectively solved, the problem of floating of the image plate caused by the instability of hand-holding is solved, the inaccurate angle and motion artifacts caused by tooth and tooth tip interference and moving are removed,the fixation through the bite is more stable, and the shooting quality is further improved accordingly.

Owner:上海市口腔病防治院

Generation method, terminal and storage medium of overflow hole

ActiveCN111449781BAvoid the problem of reduced spillage effect3D printingDental prostheticsOral problemsMechanical engineering

The invention discloses a generation method, terminal and storage medium of an overflow hole. The method includes: obtaining the first center point, the tooth cusp direction and the first preset offset distance of the bounding box of the dental arch model. Two central points; construct n first rays with the second central point as the starting point; take the intersection of the first ray and the outer wall of the dental arch model as the first intersection; take the first intersection as the starting point, along the outer wall at the first intersection Construct the second ray in the negative direction of the normal line at the position; obtain the intersection point closest to the first intersection point among the intersection points between the second ray and the inner wall of the dental arch model, and use it as the second intersection point; use the first preset radius to construct a penetrating inner wall of the dental arch model and the first cylinder on the outer wall; perform Boolean difference processing on the dental arch model and the first cylinder to generate overflow holes. The invention solves the problem that the size and shape of the overflow holes generated for the dental arch model in the existing dental three-dimensional design software are fixed, so that some overflow holes cannot play the role of overflow drainage.

Owner:SHENZHEN UP3D TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com