A Measuring Method of Form and Position Parameters of Digital Denture

A technology for parameter measurement and denture, applied in the field of dental prosthesis, can solve the problems of poor operability, unreliability, unfavorable denture scaling, positioning and matching, etc., to achieve the effect of strong operability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

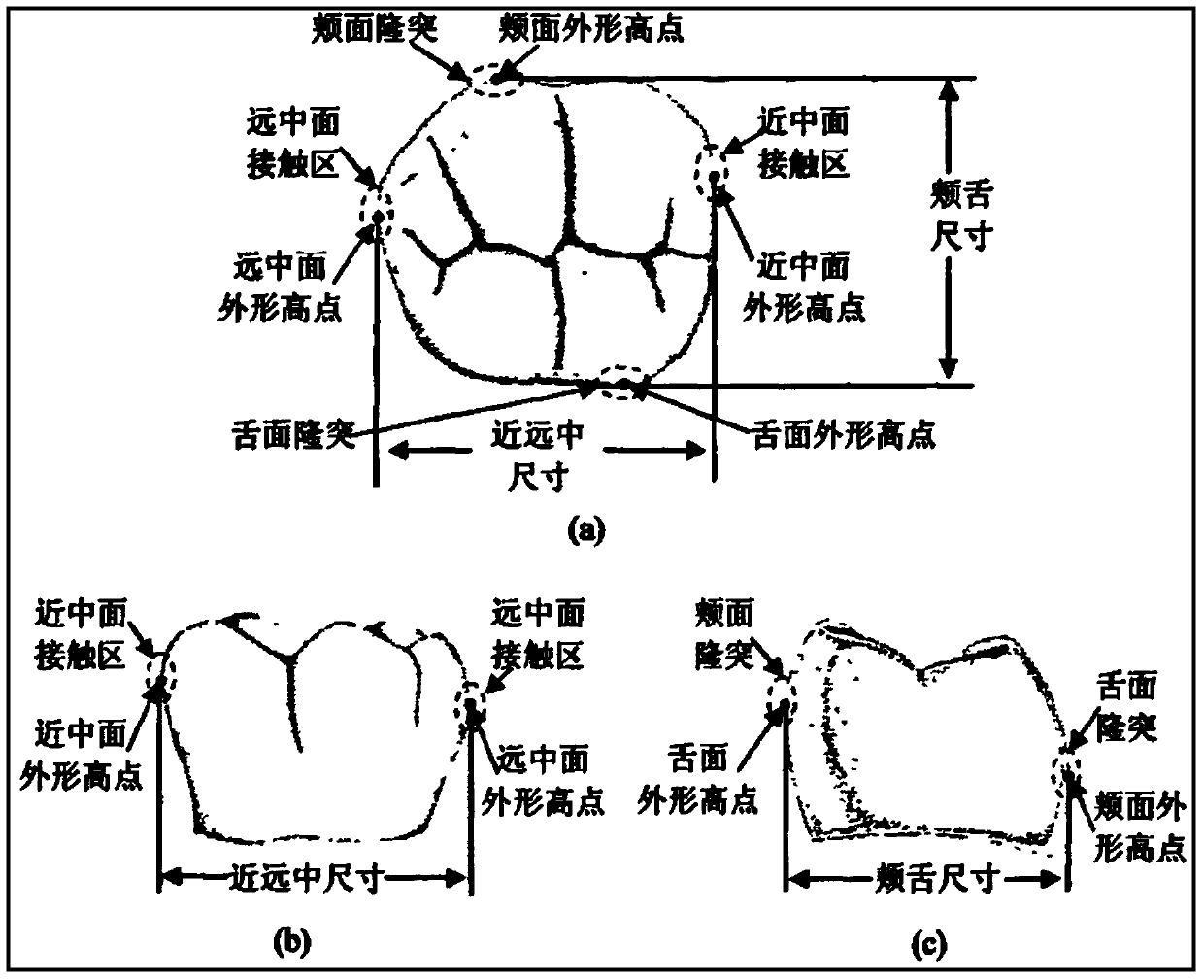

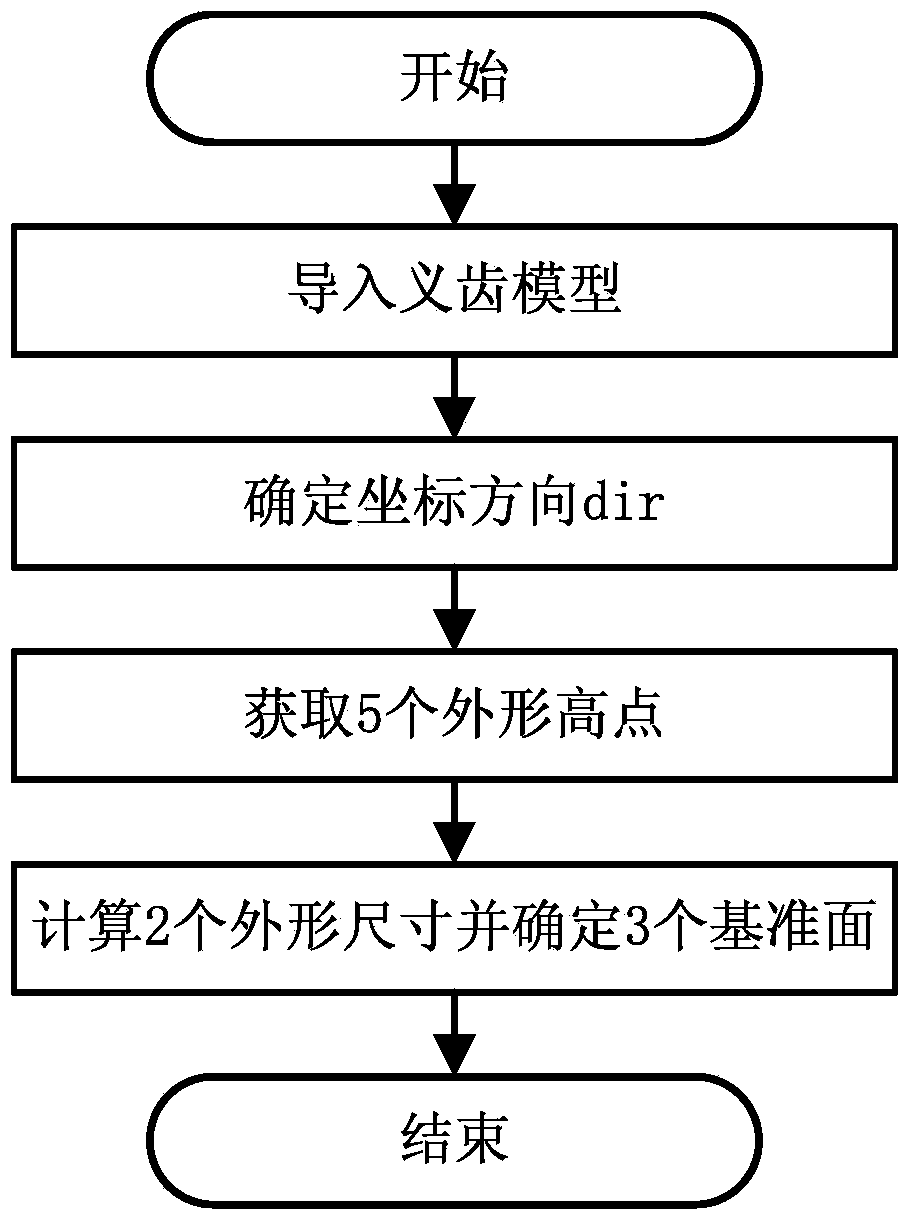

[0077] Aiming at the problems of poor operability, unreliability and inconvenience in the prior art, the present invention proposes a brand-new measuring method for shape and position parameters of digital dentures. Such as figure 2 As shown, the method mainly includes the following steps:

[0078] Step 1: Import the denture model.

[0079] The processing object of the present invention is a triangular mesh model of a single denture, and the types of the denture include: a standard crown, a single tooth cut from the dentition, an abutment model and an inlay preparation.

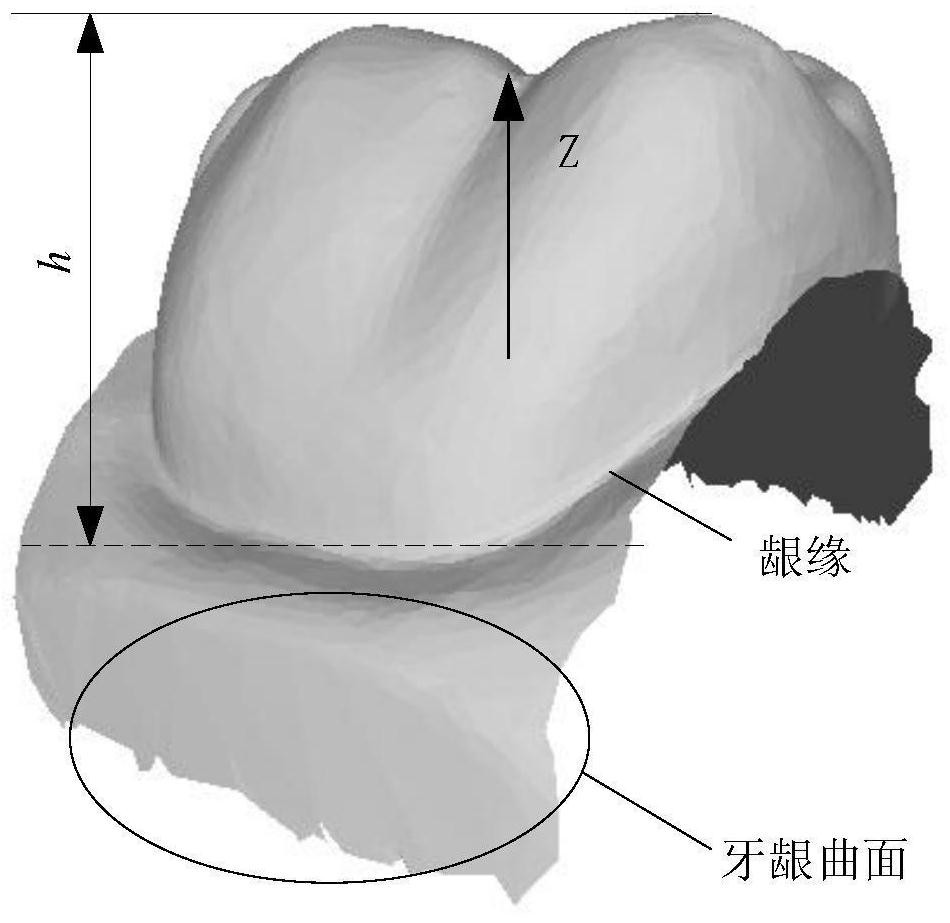

[0080] Step 2: Determine the coordinate direction dir: adjust the coordinate system of the denture model so that the coordinate direction dir satisfies: the z-axis is parallel to the long axis of the teeth, the x-axis is parallel to the mesio-distal direction, and the y-axis is parallel to the buccal-lingual or labial-lingual direction, The x, y, and z directions conform to the right-hand rule. dir is dif...

Embodiment 2

[0100] In the design of an inlay restoration, it is first necessary to match the standard crown to the inlay preparation. In order to further illustrate the effect of a method for measuring shape and position parameters of a digital denture of the present invention, an example of applying the method of the present invention to the matching of standard crowns and inlay preparations is now given, such as Figure 9 shown.

[0101] Such as Figure 9 As shown, this embodiment specifically includes the following steps:

[0102] Step 1: Enter the inlay preparation and the standard crown of the same name.

[0103] refer to Figure 10 , input the inlay preparation Inlay and the standard crown Crown model of the same name. Among them, the standard crown usually has a reasonable coordinate direction dir, while the coordinate system of the inlay preparation needs to be further adjusted.

[0104] Step 2: Adjust the coordinate direction of the inlay preparation.

[0105] Standard crow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com