Mesoporous graphene foam as well as preparation method thereof

A technology of mesoporous graphene and layered graphene is applied in the field of mesoporous graphene foam and its preparation, which can solve the problems of difficult industrial scale-up, high C/O ratio, and high raw material cost, and achieve mass production, high C/O ratio and high cost. O ratio, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

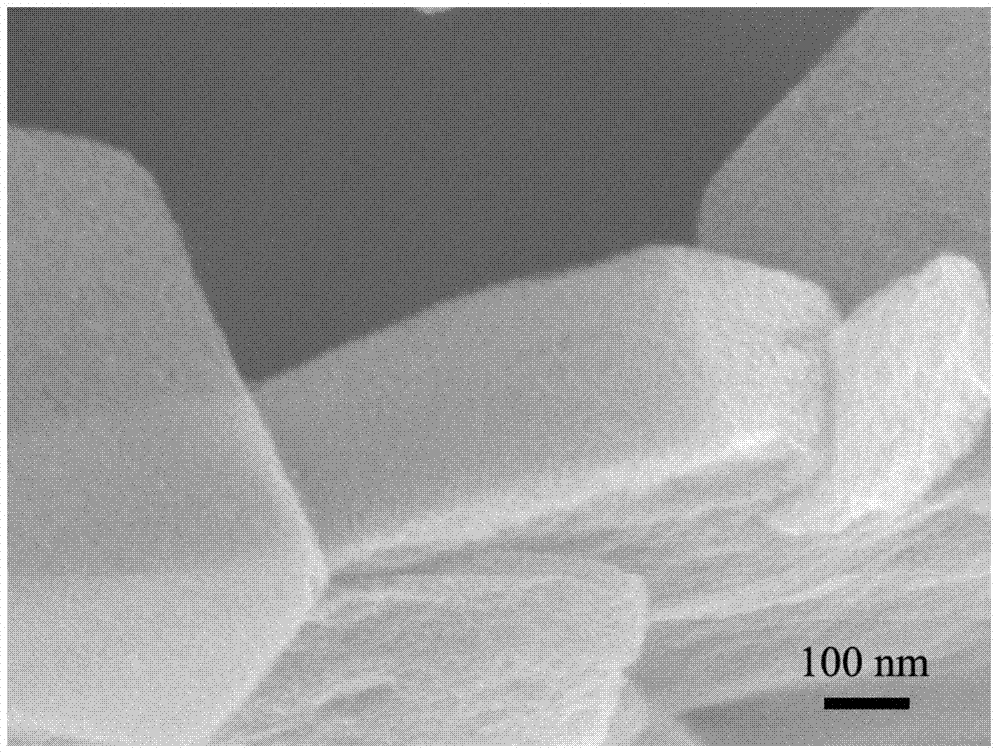

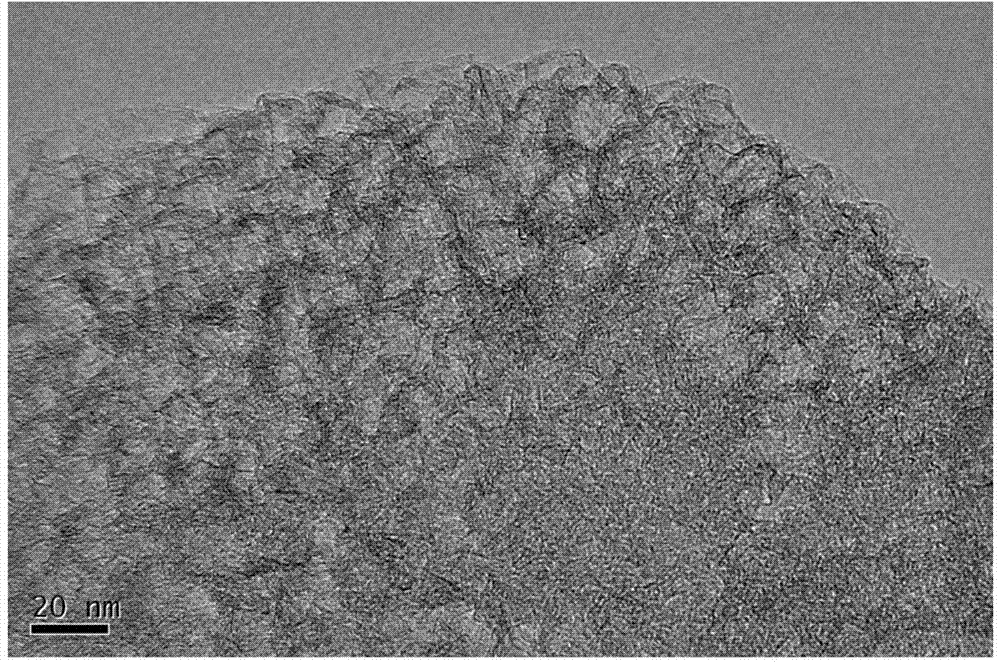

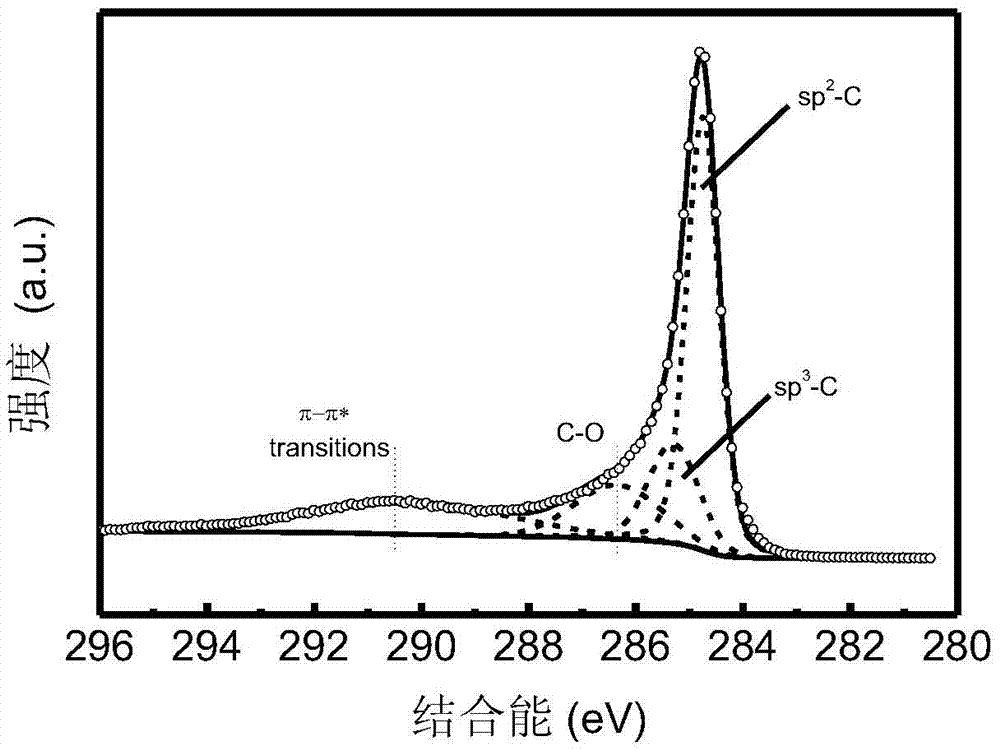

Embodiment 1

[0037] Dissolve 12.32g of polyethylene glycol 2000 in 160ml of deionized water, add 14g of magnesium oxide, and stir at room temperature for 24 hours; transfer the above mixture to a hydrothermal kettle with a volume of 200ml, put it into a homogeneous reactor, and Perform hydrothermal reaction at 200°C for 48 hours, take it out, cool it down to room temperature naturally, filter it with suction, wash it with deionized water, and dry it in an oven at 100°C for 8 hours to obtain the template precursor Mg(OH) 2 ; The resulting template precursor Mg(OH) 2 Put it into a muffle furnace, raise the temperature to 550°C at a heating rate of 1-100°C / min, and burn at a constant temperature of 550°C for 8 hours to obtain a textured magnesium oxide template, such as Figure 5 , Figure 6 and Figure 7 shown. Then, 1.5 g of the obtained textured magnesia template was placed in a quartz fluidized bed, using argon as a carrier gas with a flow rate of 400 sccm; To the reaction temperature...

Embodiment 2

[0039] Dissolve 12.32g of polyethylene glycol 2000 in 160ml of deionized water, add 14g of magnesium oxide, and stir at room temperature for 24 hours; transfer the above mixture to a hydrothermal kettle with a volume of 200ml, put it into a homogeneous reactor, and heat it at 240°C Perform hydrothermal reaction at high temperature for 24 hours, take it out, cool it down to room temperature naturally, filter it with suction, wash it with deionized water, and dry it in an oven at 100°C for 8 hours to obtain the template precursor Mg(OH) 2 Put the obtained sample into a muffle furnace, raise the temperature to 450°C at a heating rate of 1-100°C / min, and burn at a constant temperature of 450°C for 8 hours to obtain a textured magnesium oxide template. Then, place 1.5g textured magnesia template in the quartz fluidized bed, use argon as the carrier gas, and the flow rate is 400 sccm; under this atmosphere, the temperature of the reactor is raised from room temperature to The reacti...

Embodiment 3

[0041] Dissolve 12.32g of polyethylene glycol 20000 in 160ml of deionized water, add 14g of magnesium oxide, and stir at room temperature for 24 hours; transfer the above mixture to a 200ml hydrothermal kettle, put it into a homogeneous reactor, and heat Perform hydrothermal reaction at high temperature for 24 hours, take it out, cool it down to room temperature naturally, filter it with suction, wash it with deionized water, and dry it in an oven at 80°C for 10 hours to obtain the template precursor Mg(OH) 2 Put the obtained sample into a muffle furnace, raise the temperature to 450°C at a heating rate of 1-100°C / min, and burn at a constant temperature of 450°C for 8 hours to obtain a textured magnesium oxide template. Then, 2 g of textured magnesium oxide templates were placed in a fixed bed, using argon as a carrier gas with a flow rate of 600 sccm; ℃, the carbon source methane is introduced, the flow rate is 80sccm, and the space velocity during the reaction is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com