Method and device for preparing low-tar combustible gas through biomass gasification

A technology of biomass coke and biomass, which is applied in the manufacture of combustible gas, granular/powdered fuel gasification, petroleum industry, etc. It can solve the problems of not involving catalytic active substances, low equipment processing efficiency, low carbon layer reactivity, etc. problem, to achieve the effects of compensating for low heat conduction rate, improving heterogeneous reaction activity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment takes the following steps:

[0035] (1) Biomass is gasified after being crushed to obtain gasification gas products (including gasification gas and tar) and biomass coke, and the gas products and biomass coke are quickly separated;

[0036] (2) heating the biomass coke separated in step (1) into a microwave field to form a local hot spot on the surface of the biomass coke to activate the biomass coke;

[0037] (3) passing the gas product separated in the step (1) through the biomass coke layer treated in the step (2), and catalytically cracking the tar therein. And make the gasification gas and biomass coke undergo secondary reaction to generate combustible gas.

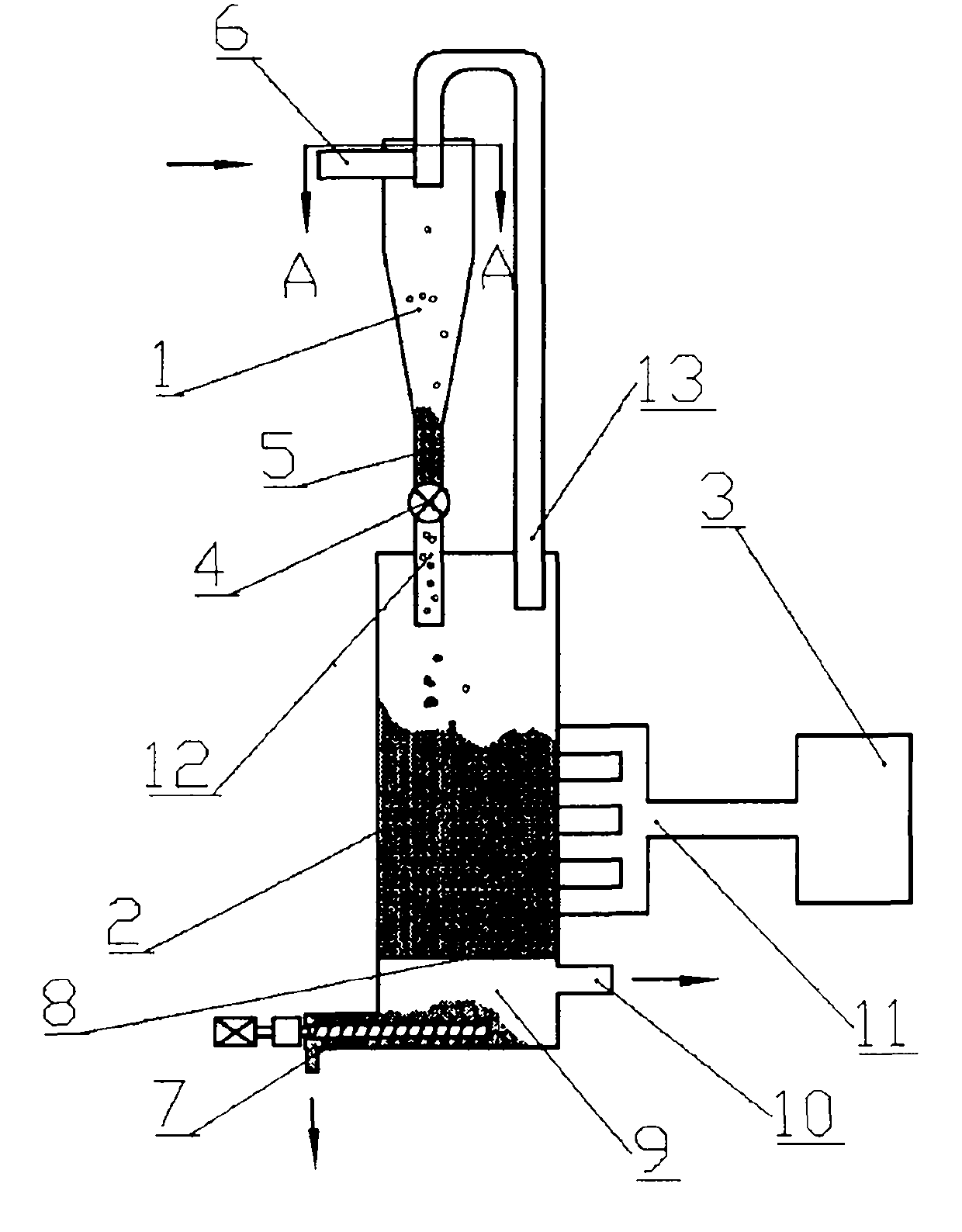

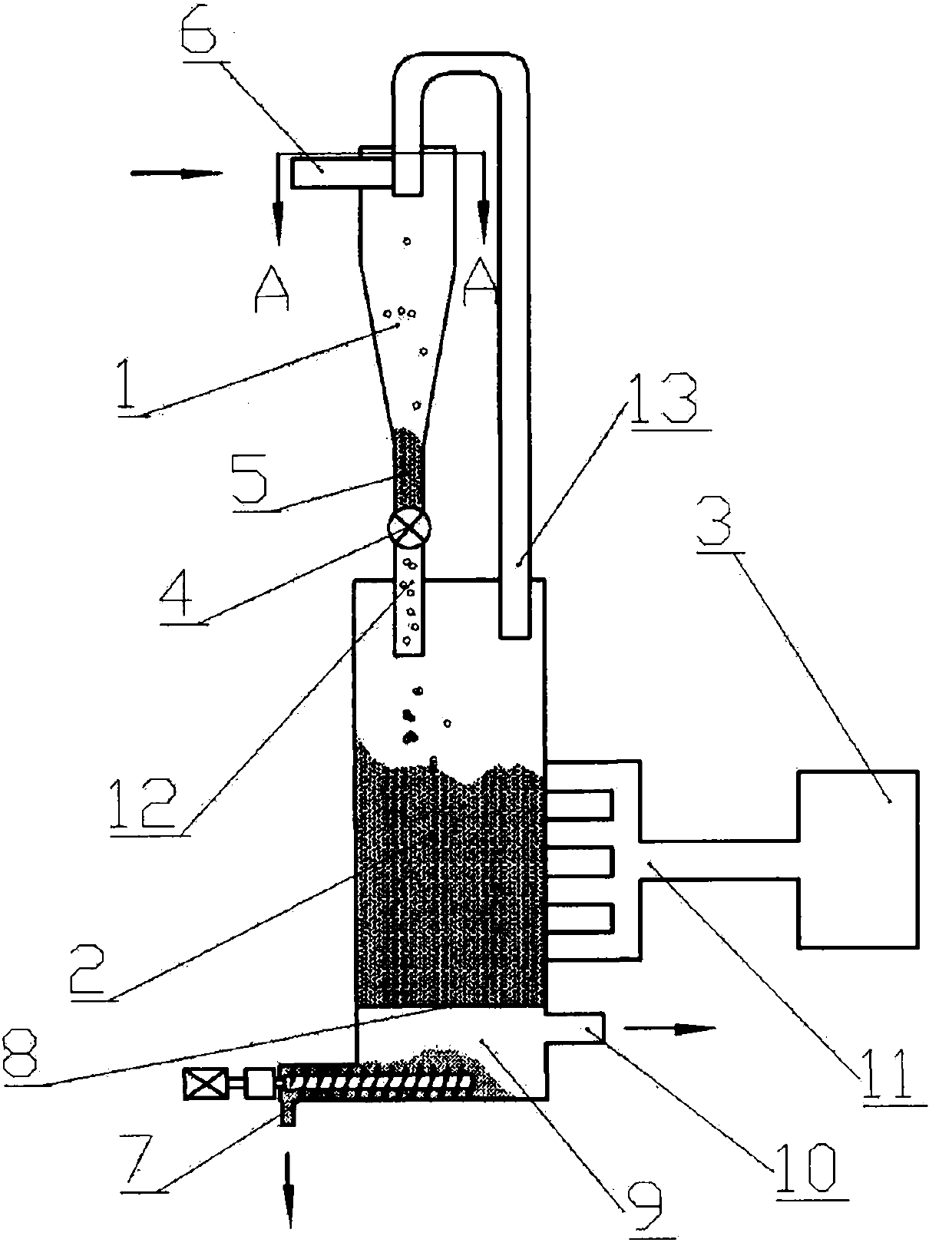

[0038] In the step (1), the biomass fine particles are carried into the cyclone gasifier 1 by the gasification medium, and the air velocity is 18m / s; the gasification temperature of the biomass gasification is 700°C; the oxygen-enriched air is O 2 The volume percentage is 100% air, and the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com