Serial L-shaped non-phase change superconducting heat pipe heat recovery type volatile organic chemicals (VOCs) incinerator

A non-phase-change superconducting, heat recovery technology, applied in the field of serialized L-shaped non-phase-change superconducting heat pipe heat recovery VOCS incinerator, can solve the problem of increasing construction and maintenance costs, pipeline blockage, and increasing the number of incinerators construction cost etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

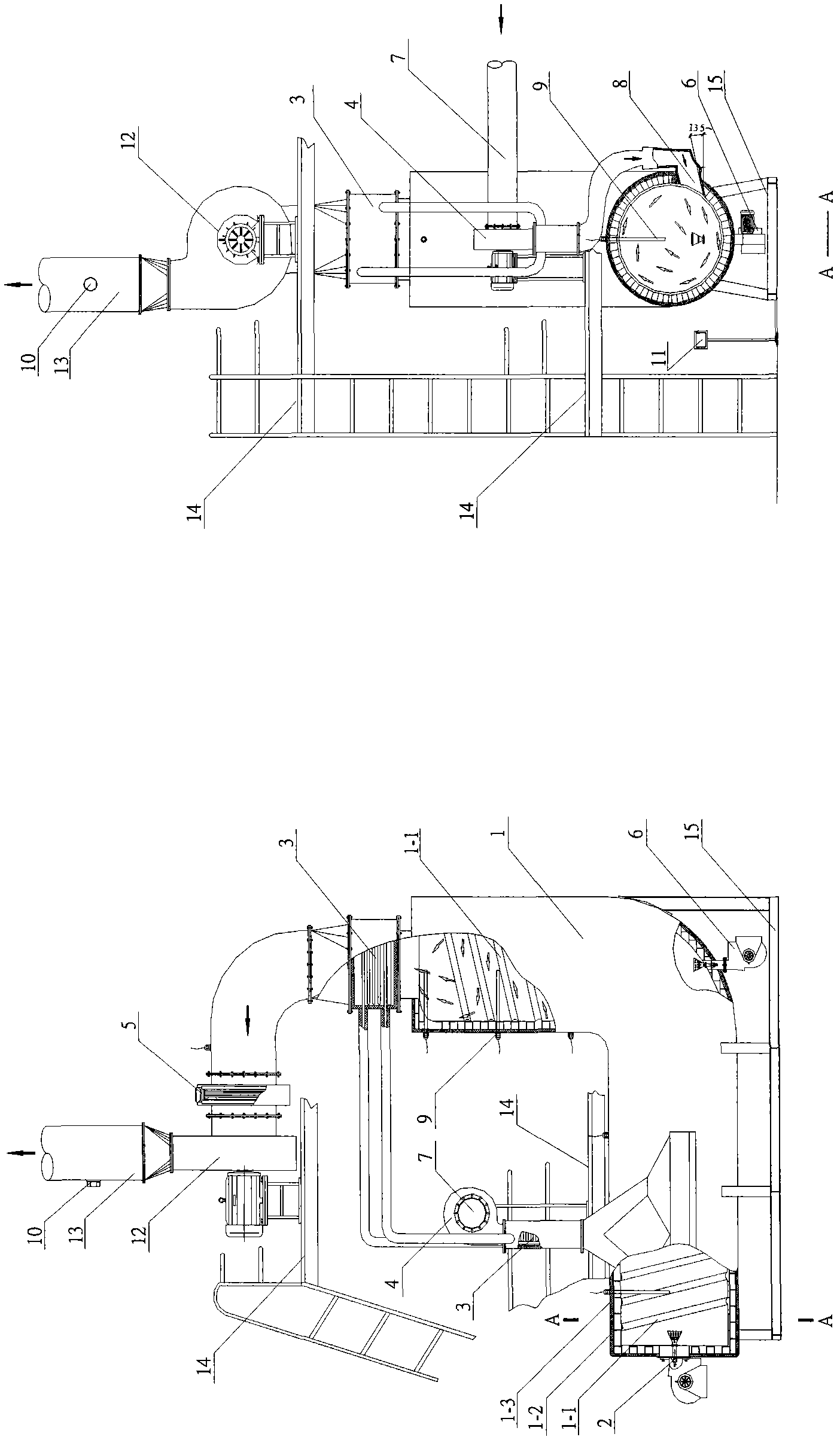

[0037] In order to enable those skilled in the art to better understand the present invention, a detailed description is hereby provided in conjunction with the accompanying drawings.

[0038] Please refer to the drawings shown in the description, the present invention discloses a series of L-type non-phase-change superconducting heat pipe heat recovery VOC S Incinerator, a serialized L-shaped non-phase-change superconducting heat pipe heat recovery VOC suitable for all VOCs treatment S The incinerator consists of: inner spiral VOCs gas incinerator body 1, ceramic Archimedes spiral furnace 1-1, 50MM thick asbestos insulation board 1-2, steel plate shell 1-3, primary burner 2, non-phase Variable superconducting heat pipe heat exchanger 3, processing fan 4, detachable exhaust filter 5, secondary burner 6, waste gas input pipe 7, air inlet 8, temperature detector 9, exhaust detection hole 10, PLC control Box 11, secondary fan 12, chimney 13, working platform 14, body of furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com