Method for promoting excess sludge microorganisms to hydrolyze by using thermophilic geobacillus sp

A technology of Geobacillus and excess sludge, which is applied in sludge treatment, biological sludge treatment and other directions, can solve the problems of high cost and low microbial biohydrolysis rate of excess sludge, and can improve the cracking rate and the hydrolysis rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: a kind of thermophilic geobacillus of the present embodiment promotes the method for microbial hydrolysis of surplus sludge to carry out according to the following steps:

[0017] 1. Inoculate a ring of cryopreserved Geobacillus thermophiles into LB medium, and culture on a rotary shaker at 40-60°C and 100-120r / min for 24-36 hours with ventilation to obtain activated Geobacillus thermophiles;

[0018] 2. Take a ring of activated Geobacillus thermophila and inoculate it in the fermentation medium, and cultivate it at 40-80°C for 12-24 hours to obtain the fermentation broth of Geobacillus thermophila;

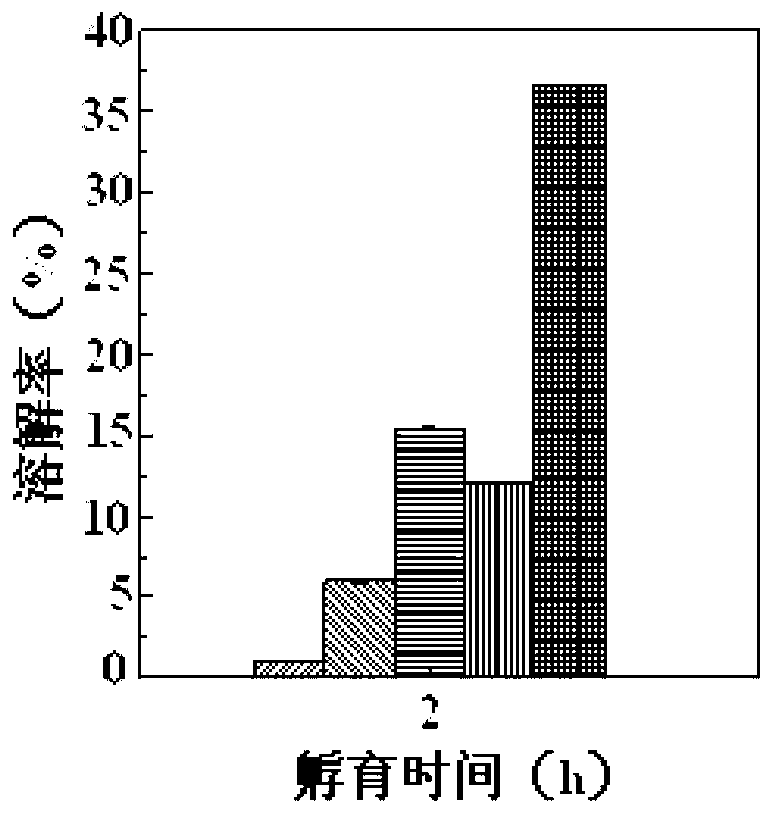

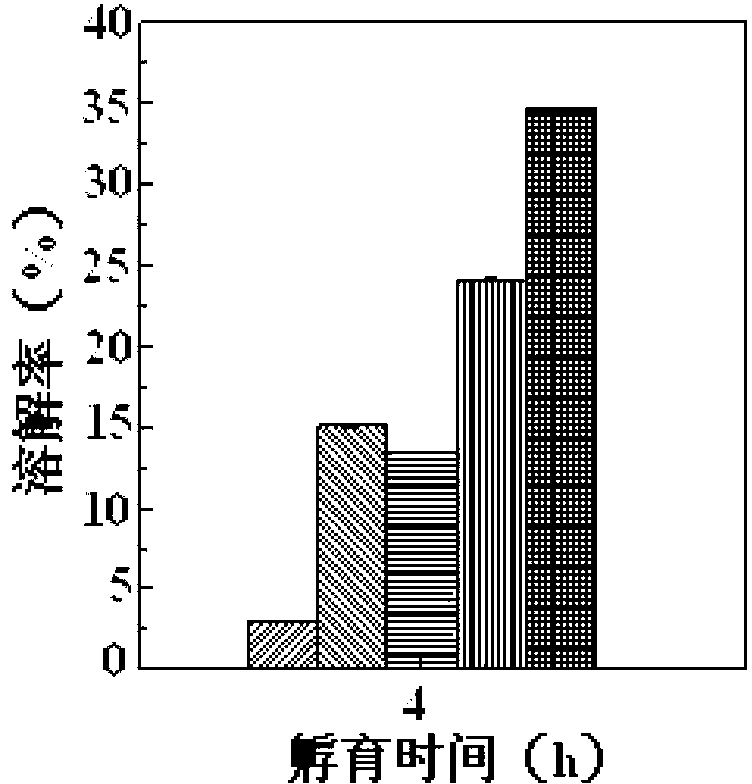

[0019] 3. Take 75-200 mL of the supernatant of the Geobacillus thermophila fermented liquid obtained in step 2, and add it to the remaining sludge to obtain a 300-mL mixed solution, and place the mixed solution in a water bath at 60-80°C for 1-6 hours. Complete the thermophilic Geobacillus to promote the microbial hydrolysis of excess sludge;

[0...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, culture is carried out on a rotary shaker at 60° C. and 120 r / min for 24 hours with aeration. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment 3: This embodiment differs from specific embodiment 1 or 2 in that: in step 2, culture at 60° C. for 24 hours. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com