Small and medium-sized city household garbage sorting treatment system and method

A treatment system and domestic waste technology, applied in the field of domestic waste sorting and treatment systems in small and medium-sized cities, can solve problems such as incomplete fermentation, unsatisfactory compost quality, and failure to realize waste recycling, so as to improve the hydrolysis speed and rate, and improve Fertilizer efficiency and utilization value, to achieve the effect of precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

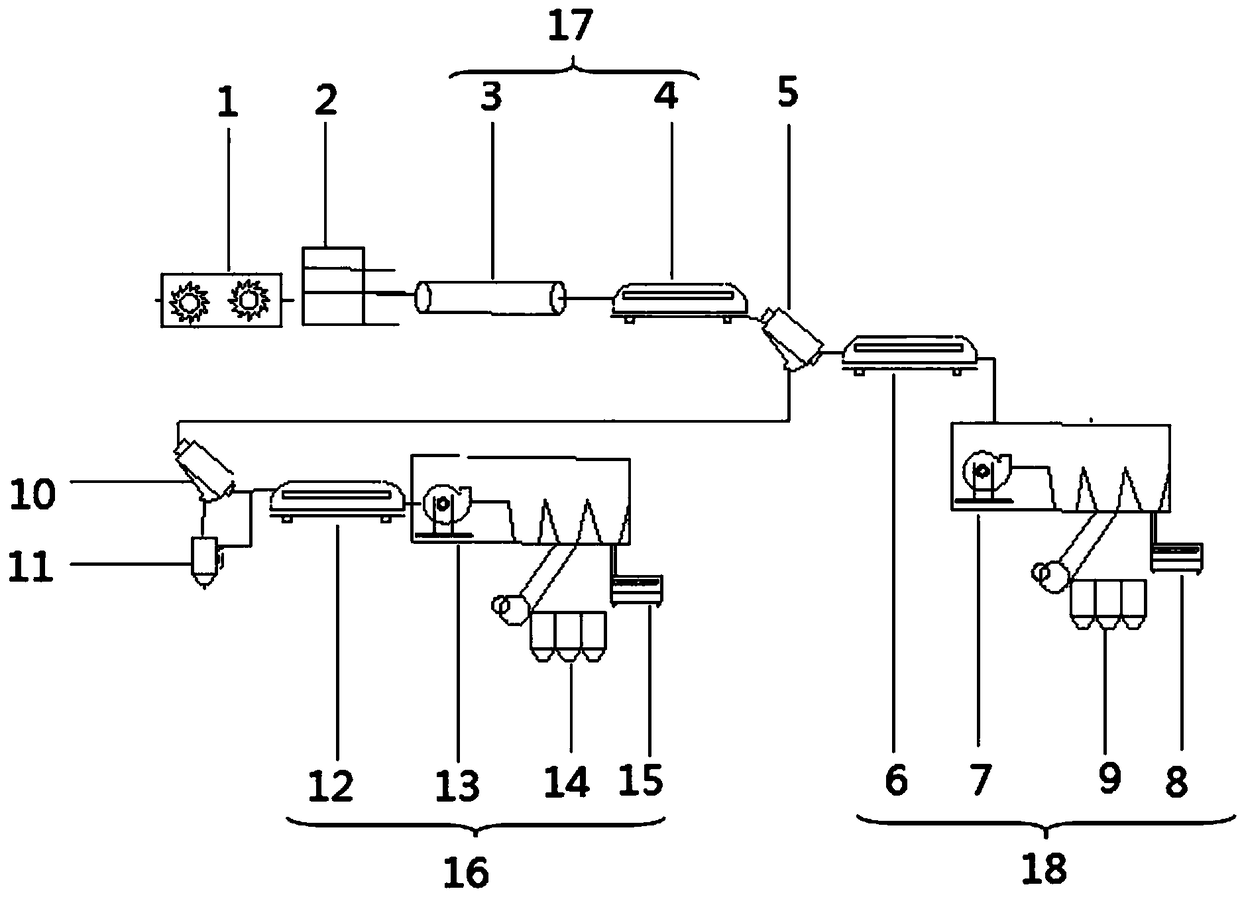

[0067] A domestic waste sorting and processing system for small and medium-sized cities. The sorting and processing system includes a domestic waste sorting system and a domestic waste processing system. The domestic waste processing system is arranged downstream of the domestic waste sorting system. The domestic waste sorting system and the domestic waste processing The systems all include a transportation system, and the transportation system includes a driving grab device, a screw conveying device and a belt conveying device. The domestic waste treatment system includes organic matter treatment system, sewage treatment system and non-organic recyclables treatment system; the sewage treatment system includes deodorization system, sewage treatment system and hazardous substance treatment system; the deodorization system includes settling chamber and sequentially The cyclone dust collector, biological deodorization filter, active coke adsorption tower and negative pressure exha...

Embodiment 2

[0073] The domestic waste sorting system includes: bag breaking and dismantling device 1, pre-sorting device 2, primary sorting device 17, drum screen device, primary sorting device 18, secondary sorting device 16 and vibrating screen device 11; bag breaking device The splitting device 1 includes a cutter device and an electric control box; wherein the electric control box provides power supply for the cutter device. The cutter device adopts the roller hob type, and the blade adopts a four-section two-way opening and closing blade. The blade closes when crushing and opens in both directions when self-cleaning. The pre-sorting device 2 is arranged downstream of the bag-breaking and dismantling device 1. The pre-sorting device 2 includes two-stage vibrating screens. The apertures of the vibrating screens are 15mm and 220mm respectively, and the separated particle sizes are between 15mm and 220mm. of domestic waste. Primary sorting 17 is arranged on the downstream of pre-sorting...

Embodiment 3

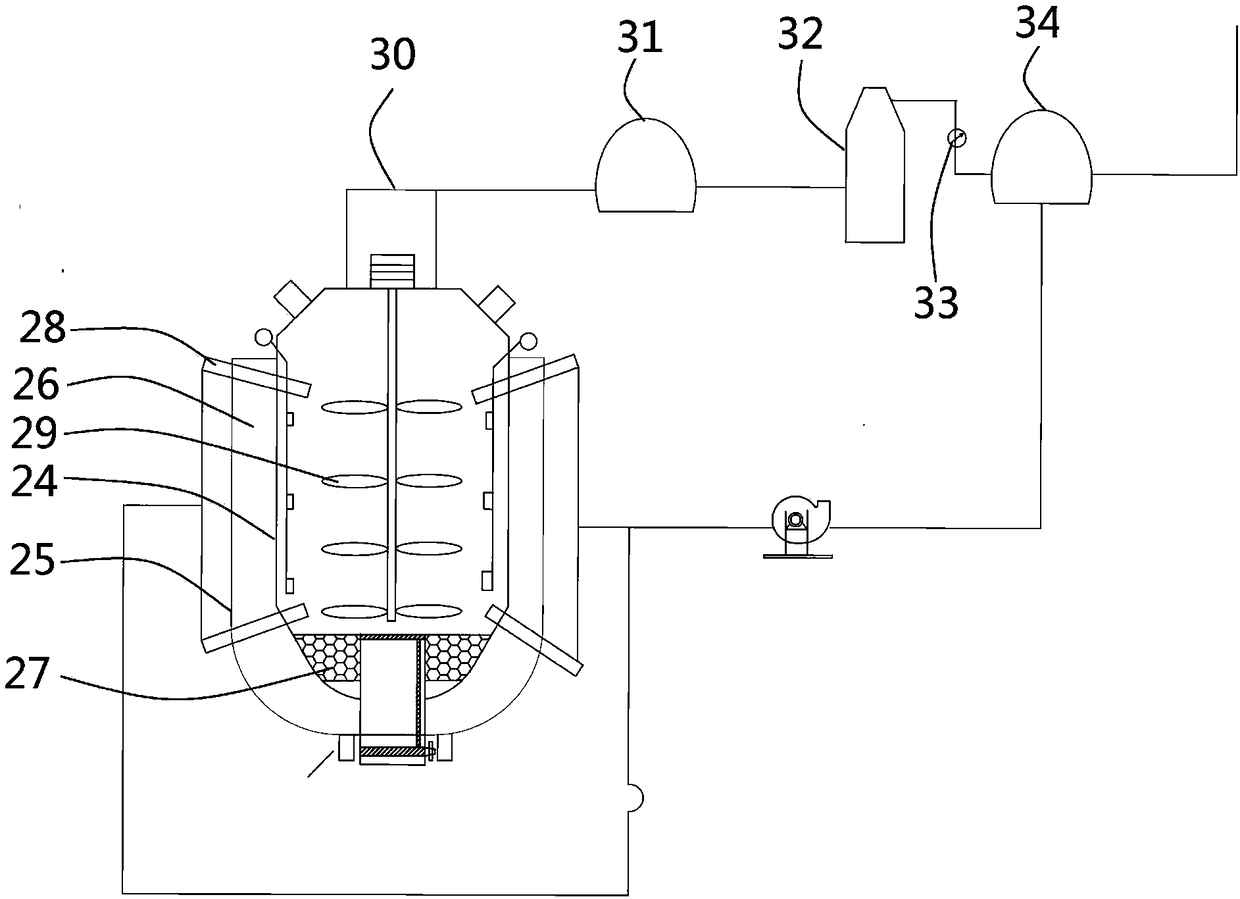

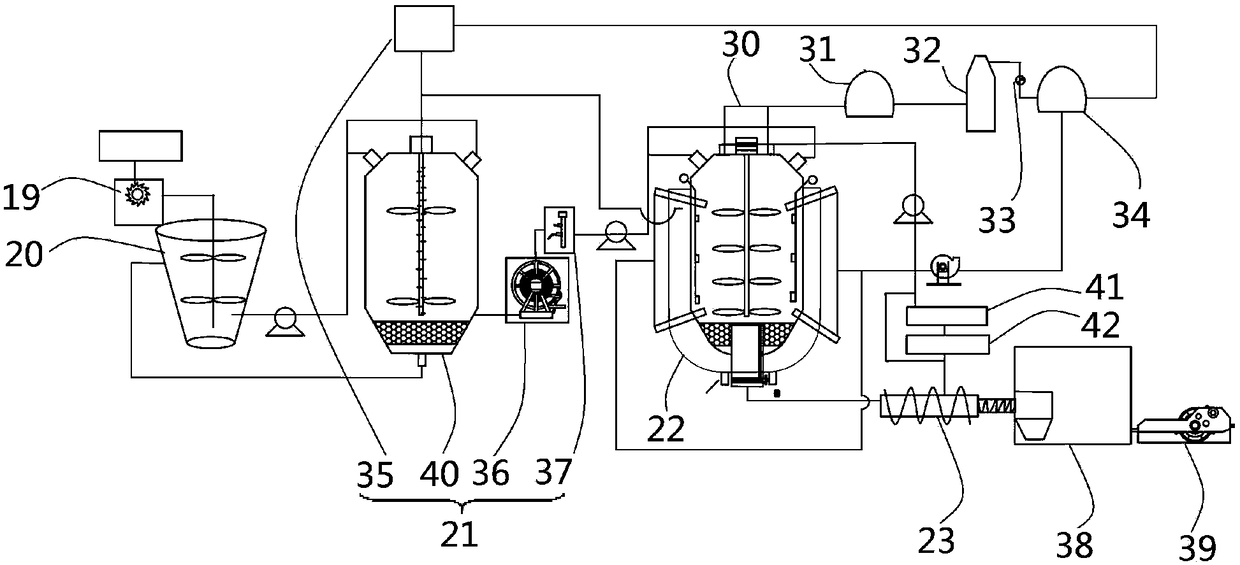

[0079] The thermal hydrolysis-anaerobic fermentation combined system includes a crushing device 19 and a homogenizing device 20 , a thermal hydrolysis device 21 , an anaerobic fermentation device 22 and a solid-liquid separation device 23 arranged downstream of the crushing device 19 in sequence. Wherein, the homogenizing device 20 includes a homogeneous slurry tank, a rotary fine grid, a paddle mixer, a homogeneous regulator and a hydrocyclone desander; a paddle mixer is arranged in the homogeneous slurry tank; the pulverized slurry After homogenization, the light floating impurities in the slurry are intercepted by the rotary fine grid, and the sand is regularly discharged by the hydrocyclone desander. Wherein the thermal hydrolysis device 21 is a high temperature and high pressure thermal hydrolysis device, and the thermal hydrolysis device 21 comprises a high temperature and high pressure thermal hydrolysis tank 40, a steam boiler 35, a flash evaporator 36 and a heat exchan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com