Patents

Literature

89results about How to "Improve fermentation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for strengthening traditional solid fermentation of vinegar by mixed agent and application of mixed agent

ActiveCN106434264AShorten the fermentation cycleImprove fermentation efficiencyBacteriaMicroorganism based processesLaboratory cultureBacillus amyloliquefaciens

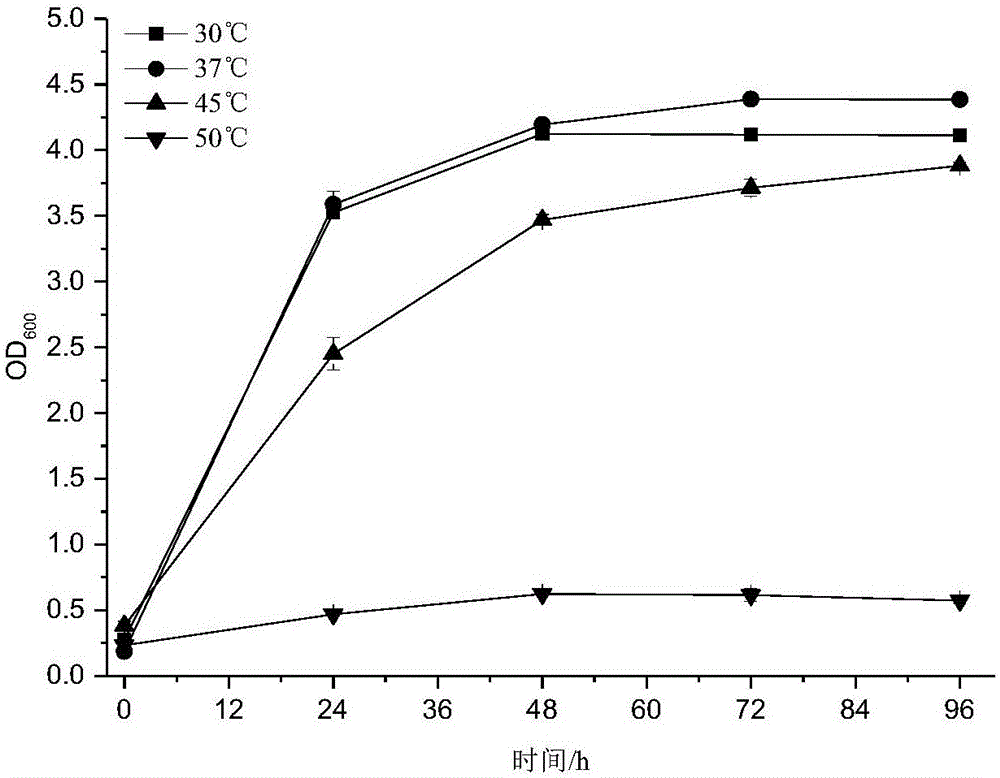

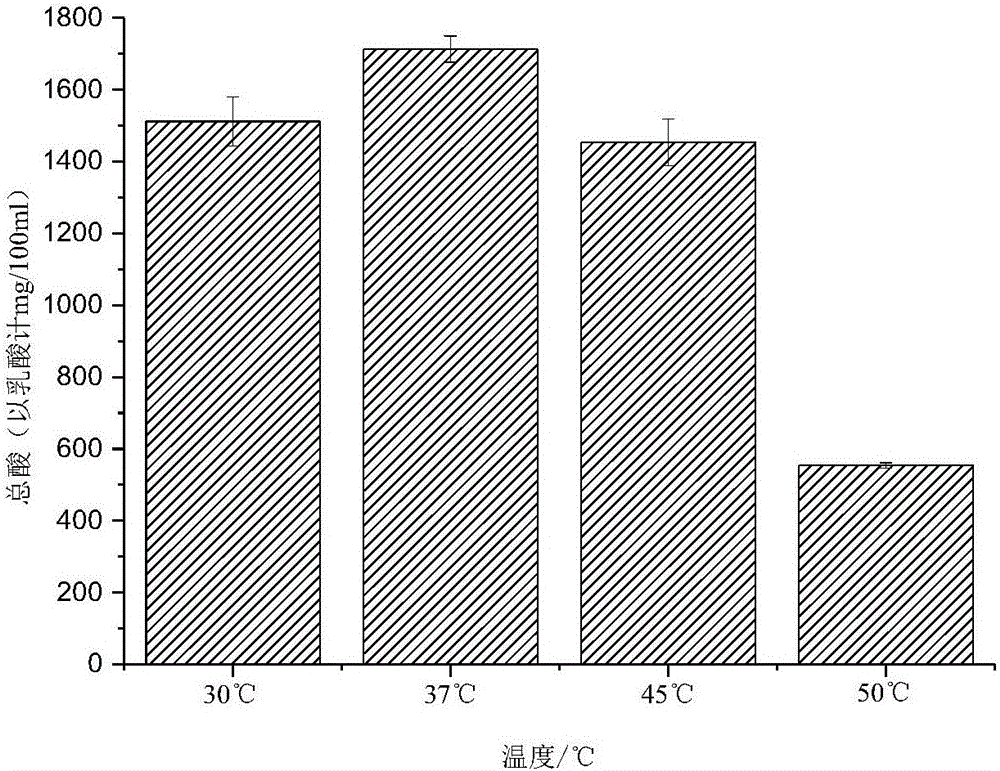

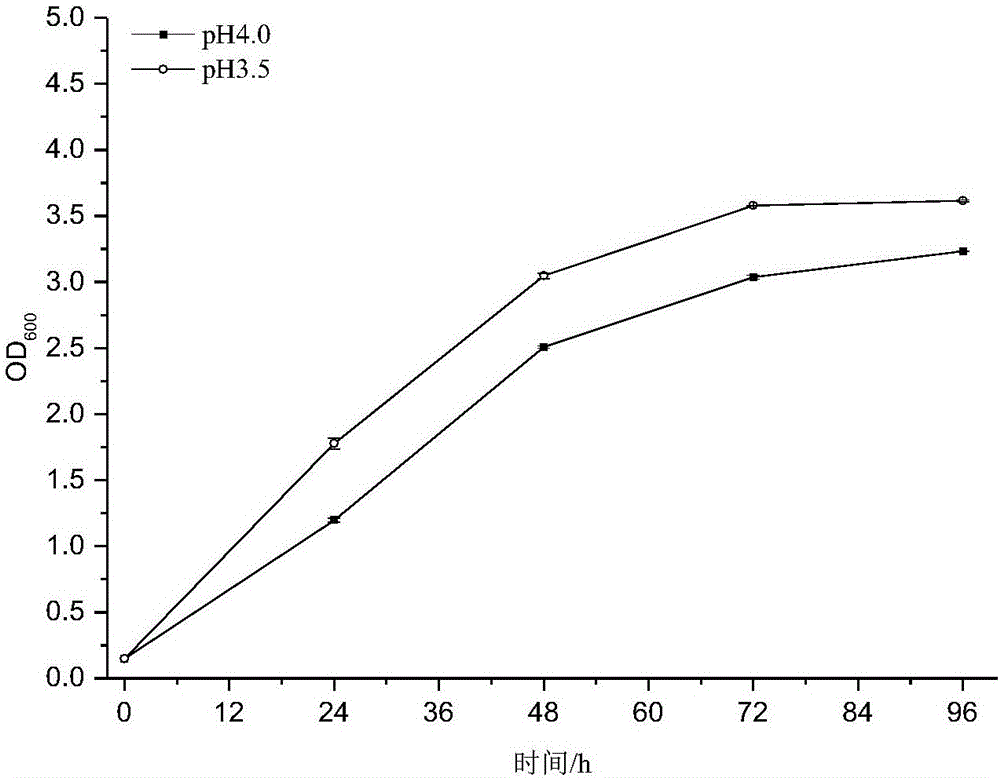

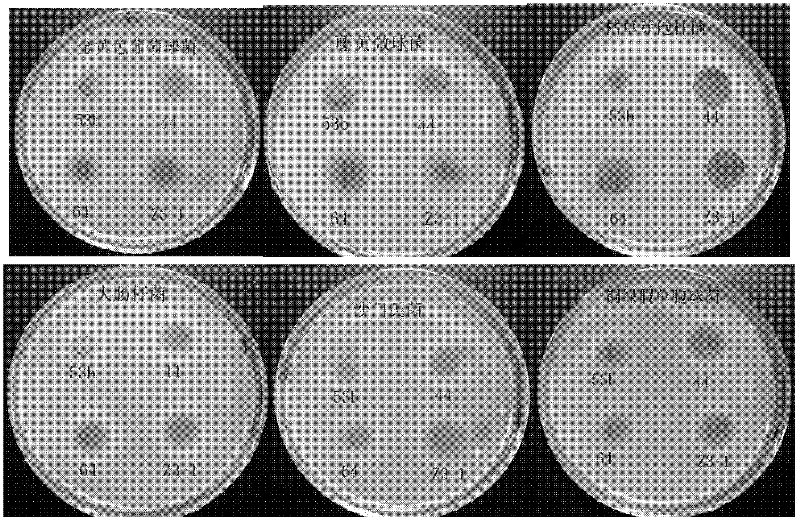

The invention discloses a method for strengthening traditional solid fermentation of vinegar by a mixed agent, and belongs to the technical field of food fermentation. The invention further discloses lactobacillus helveticus and application thereof. The lactobacillus helveticus is separated from traditional Chinese vinegar brewing mass and collected with a collection number being CGMCC No. 12062 in China General Microbiological Culture Collection Center, Institute of Microbiology, Chinese Academy of Sciences NO.1, West Beichen Road, Chaoyang District, Beijing, China. The lactobacillus helveticus is resistant to temperatures and acids and capable of highly yielding exopolysaccharides and gamma-aminobutyric acid. The mixed agent prepared from the lactobacillus helveticus, pediococcus acidilactici, hansenula anomala and bacillus amyloliquefaciens is applied to the traditional vinegar fermentation process, so that fermentation period can be remarkably shortened, raw material use ratio is increased, the content of active ingredients such as the exopolysaccharides and the gamma-aminobutyric acid in products is increased, and the antioxidant function of the vinegar products is improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

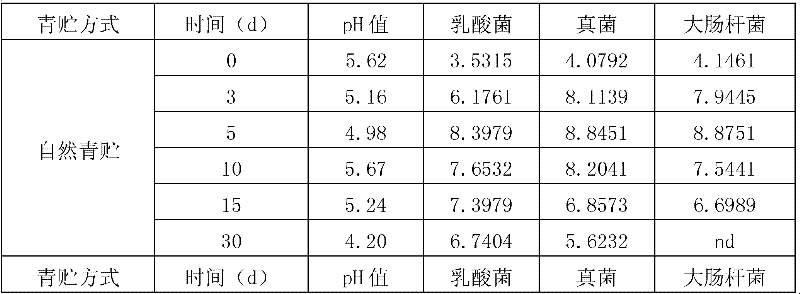

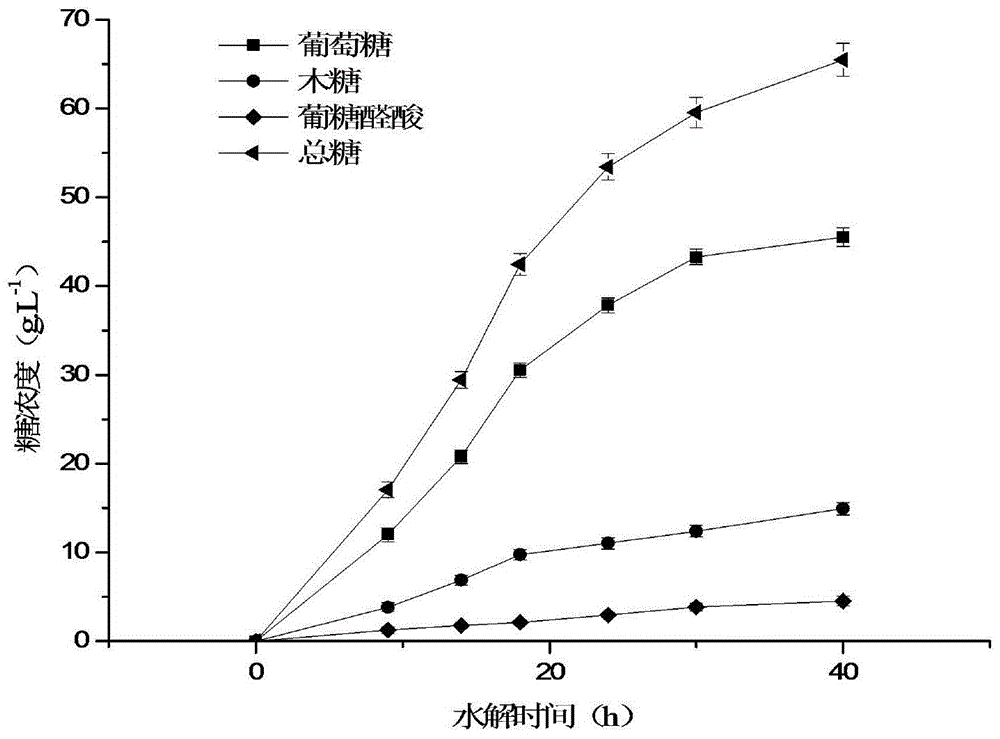

Applications of Lactobacillus plantarum in complete-strain Triticumspp silage

InactiveCN102640885AImprove fermentation efficiencyLow costBacteriaMicroorganism based processesLaboratory cultureOrganic acid

The invention discloses applications of Lactobacillus plantarum in the complete-strain Triticumspp silage, wherein Lactobacillus plantarum is Lactobacillus plantarum Z3-1, and the accession number in China General Microbiological Culture Collection Center is CGMCC (China General Microbiological Culture Collection Center) No.5027. The bacterial strain can improve the nutritional value of stem, leaf and seed silage of Triticumspp in high milk ripe stage; escherichia coli is lower than the detection line after silage for 15 days; and butyrate which is easy to cause stink is not contained. Compared with the natural silage, inoculation Z3-1 silage is fermented for 30 days; pH is lower; the content of lactic acid in organic acid is improved by 196%; the content of acetic acid is improved by 159%; the content of crude protein is improved by 8.32%; and the content of coarse fiber is lowered by 12.6%. By applying the Lactobacillus plantarum Z3-1 CGMCC No.5027 provided by the invention, the inoculation silage complete-strain Triticumspp has the advantages of good effects and low cost and the like, and can be applied to the production of the environment-friendly biological feed.

Owner:ZHENGZHOU UNIV

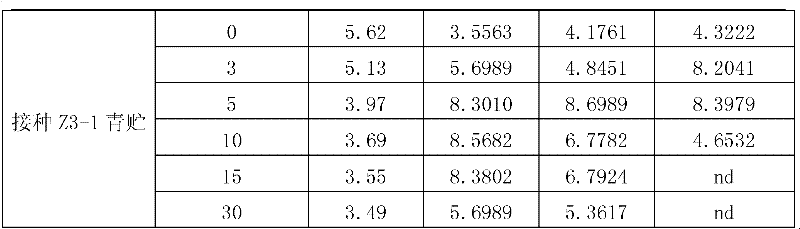

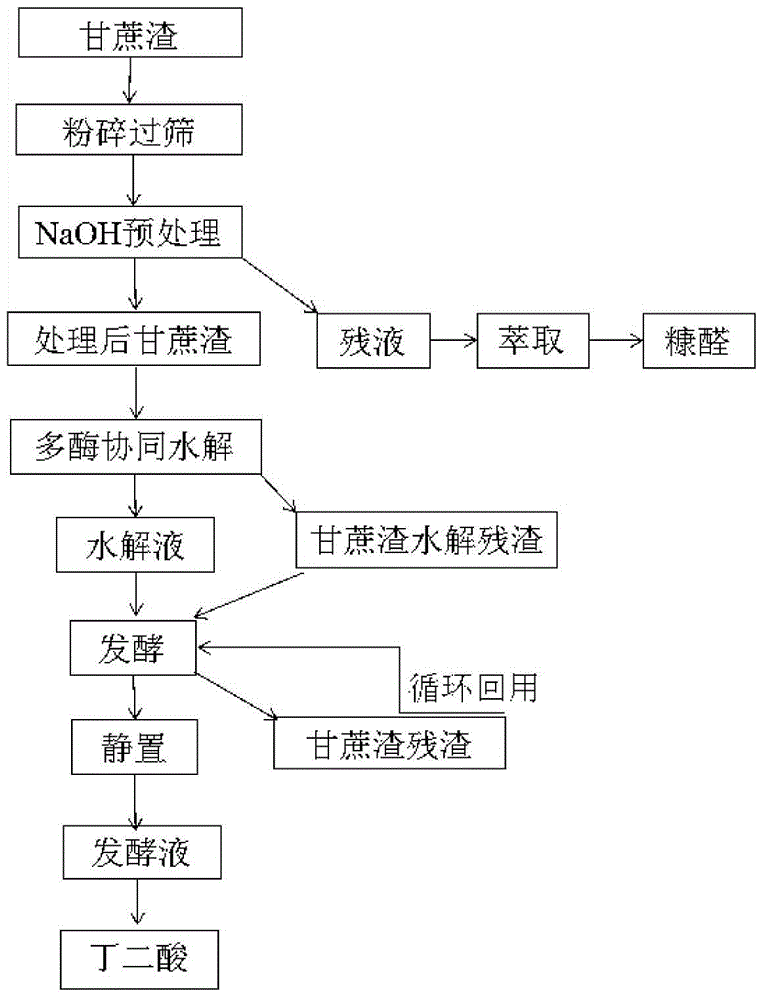

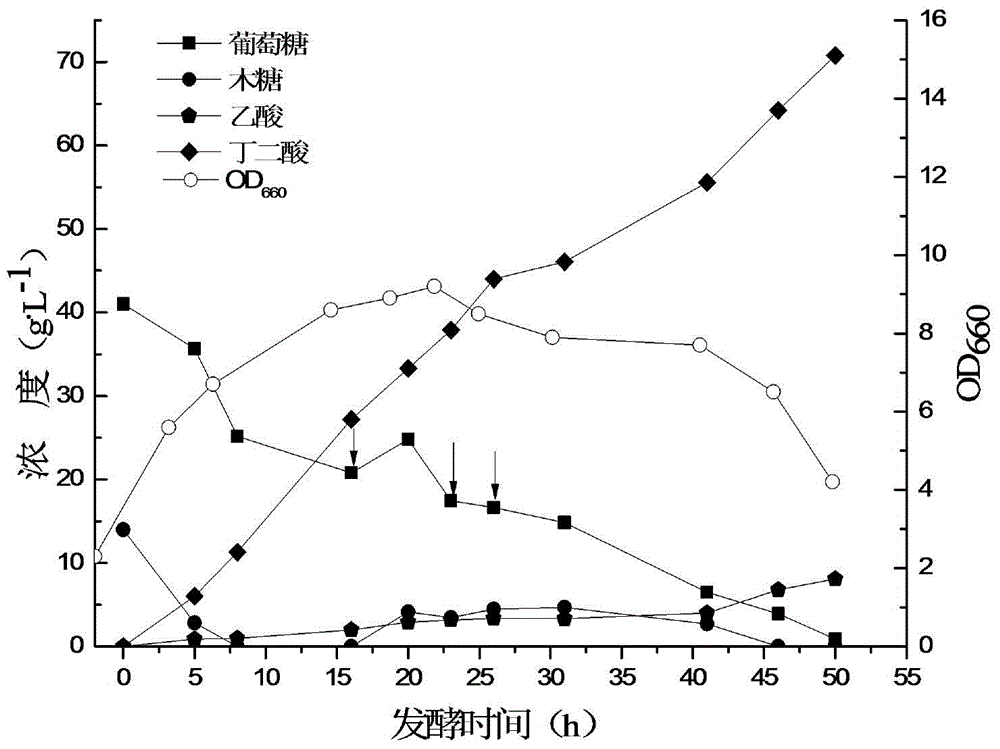

Method for producing succinic acid by taking sugarcane bagasse as raw materials through fermentation

InactiveCN104894174AReduce fermentation costsImprove fermentation efficiencyOrganic chemistryMicroorganism based processesChemistryFermentation broth

The invention discloses a method for producing succinic acid by taking sugarcane bagasse as raw materials through fermentation and belongs to the technical field of bioengineering. The method is characterized by comprising the following steps of taking the sugarcane bagasse which is main byproducts in the sugar pressing industry as raw materials, and performing crushing, pretreatment with dilute alkali as well as common hydrolysis on cellulase, xylanase, beta-glucanase and pectinase to obtain a hydrolyzed sugar solution; fermenting the hydrolyzed sugar solution by using actinobacillus succinogenes to produce the succinic acid; meanwhile, residues left by hydrolyzing the sugarcane bagasse are added into fermented solution, so that the fermentation can be repeatedly operated, seed culture can be omitted and furfural in residual liquid obtained by extraction of organic solvent and pretreatment with the dilute alkali can be utilized. According to the method disclosed by the invention, reasonable utilization of hydrolyzed residues of the sugarcane bagasse is realized, and the conventional fermented seed culture link is reduced, so that the fermentation cost is reduced, and the fermentation efficiency is improved; besides, the requirement on fermentation equipment is low, extra improvement on an existing fermentation tank is not needed, and the method is suitable for industrial production.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Health wine containing longan, clausena lansium, aloe, sapota and pawpaw and technology thereof

InactiveCN102925320AFully fermentedImprove fermentation efficiencyAlcoholic beverage preparationChemistryAloe arborescens

The invention provides a method for preparing a health wine containing longan, clausena lansium, aloe, sapota and / or pawpaw. The method comprises the following steps of: adding yeast with flocculation optimization characteristics and a fermentation aid into the longan juice for fermentation; and then adding clausena lansium, aloe, sapota and / or pawpaw juice to obtain the health wine.

Owner:李恩东

Plant straw fermentation agent and method of using same

InactiveCN107177528AHigh activityImprove fermentation efficiencyFungiBacteriaOXALIC ACID DIHYDRATEEffective microorganism

The invention discloses a plant straw fermentation agent and a method of using the same. The plant straw fermentation agent comprises, by weight, 2-4 parts of Bacillus mucilaginosus, 3-5 parts of Mucor, 6-12 parts of EM (effective microorganism) bacteria, 1-3 parts of Bacillus subtilis, 2-4 parts of oxalic acid, 5-7 parts of amino acids, 2-5 parts of Aspergilli, 2-5 parts of pectin, 5-9 parts of enzyme preparations, 3-5 parts of sterilizing agents and 5-8 parts of active carbon particles. According to the method, plant straws are moderately softened through the oxalic acid, polysaccharides of cell walls of the straws of the straws are hydrolyzed by the aid of the enzyme preparations added into the fermentation agent to obtain monosaccharide mixtures, and fermentation is performed by selecting corresponding fermentation bacteria; fermentation is rapid, and fermentation efficiency is high.

Owner:安徽永志环能科技有限公司

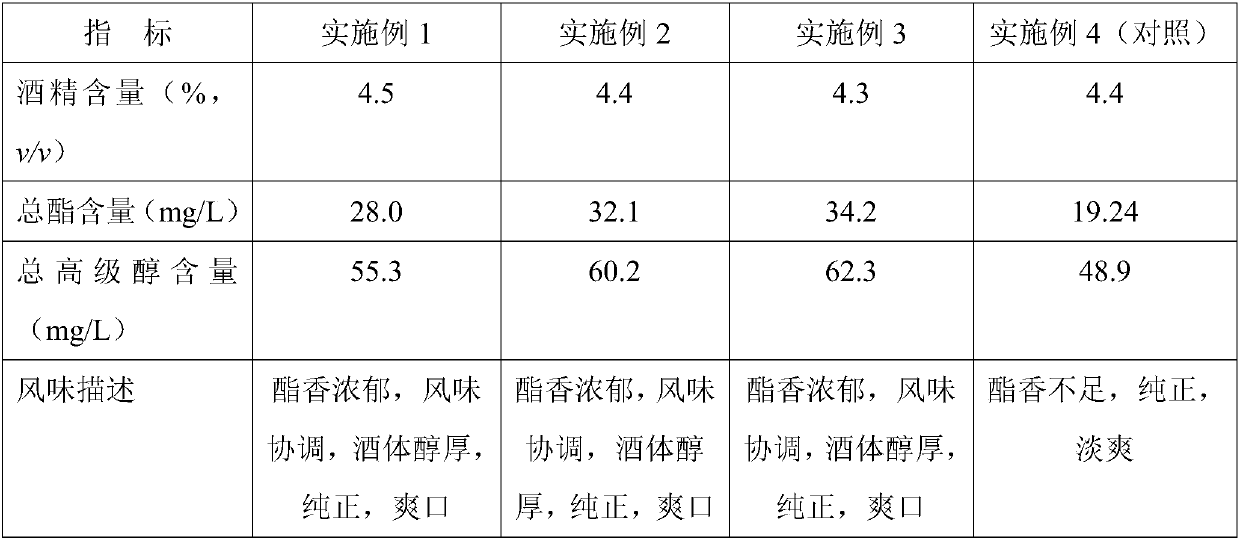

Preparation method of beer through mixed fermentation of zygosaccharomyces cidri and saccharomyces cerevisiae

InactiveCN107904058AIncrease the content of ester aroma substancesImprove fermentation efficiencyMicroorganism based processesBeer brewingChemistryFlavor

The invention discloses a preparation method of beer through mixed fermentation of zygosaccharomyces cidri and saccharomyces cerevisiae. The preparation method relates to the technical field of beer brewing, and comprises the following steps of (a) inoculating the saccharomyces cerevisiae and pichia pastoris on an inclined surface into a 12-degree P wholewheat juice, carrying out spread cultivation step by step, and collecting a yeast paste; (b) smashing malt, saccharifying, filtering, boiling, adding hops and sediments, and preparing into the 12-degree P wholewheat juice; (c) quickly coolingthe wheat juice to 10 DEG C, inoculating saccharomyces cerevisiae paste (3.0 to 6.0g / L) and pichia pastoris paste (0.01 to 1.0g / L), and carrying out main fermentation at 8 to 12 DEG C for 7 days; carrying out post-fermentation at the temperature being 0 to 4 DEG C, and storing for 5 to 7 days; filtering to obtain the beer. According to the preparation method provided by the invention, the pichia pastoris and the saccharomyces cerevisiae capable of increasing a beer fragrance flavor are utilized to be mixed and fermented for brewing the beer, so that the ester flavor substance content in the beer is increased, and the beer obtained through fermentation is excellent in quality, rich in ester flavor, harmonized in special flavor, and mellow in beer body.

Owner:DALIAN POLYTECHNIC UNIVERSITY

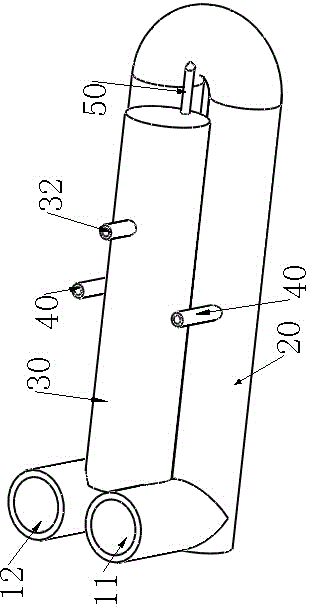

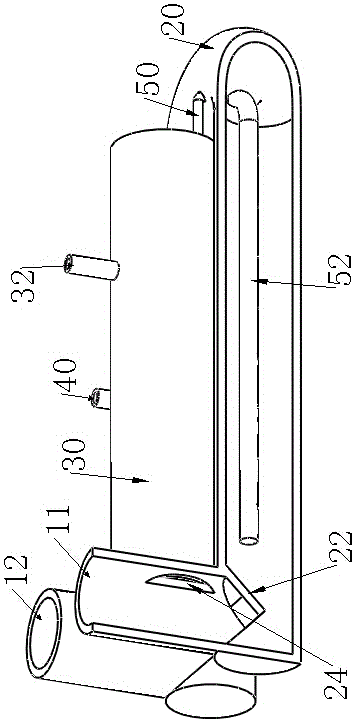

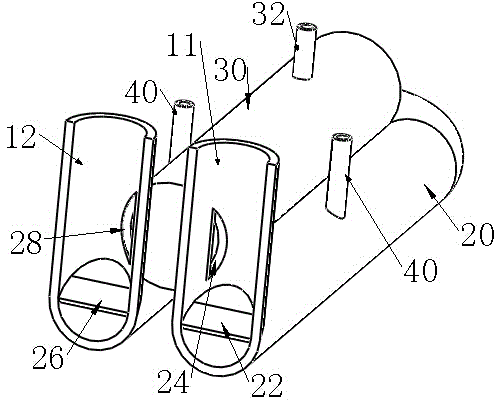

Curved ultra-long fermentation path methane generation device

InactiveCN104531514AGood convection stirring effectImprove fermentation efficiencyGas production bioreactorsWaste based fuelBiogasProcess engineering

The invention discloses a curved ultra-long fermentation path methane generation device. The curved ultra-long fermentation path methane generation device comprises a feeding pipe, a discharging pipe and a U-shaped fermentation pipeline, wherein the U-shaped fermentation pipeline is horizontally arranged, the feeding pipe and the discharging pipe are vertically connected with two end sides of the U-shaped fermentation pipeline, a water pressure room is arranged at the upper part of the U-shaped fermentation pipeline, a drainage hole of the feeding pipe is formed at the joint of the water pressure room and the feeding pipe, the drainage hole of the discharging pipe is formed at the joint of the water pressure room and the discharging pipe, a gas blocking plate of the feeding pipe is arranged at the joint of the U-shaped fermentation pipeline and the feeding pipe, a gas blocking plate of the discharging pipe is arranged at the joint of the U-shaped fermentation pipeline and the discharging pipe, at least one gas blocking plate is further arranged between the gas blocking plate of the discharging pipe and the gas blocking plate of the feeding pipe, a fermentation area is formed between the feeding / discharging pipe and the adjacent gas blocking plate or between the adjacent gas blocking plates, and an independent gas collection pipe is arranged at the top of each fermentation area; the top of each fermentation area is connected with the independent gas collection pipe, and a valve body is arranged on the gas collection pipe; a U-shaped channel type fermentation device is adopted, so that a fermentation route is long; and the water pressure difference and the control of a single-way valve are used to realize full flow of biogas slurry in the system and drive the uniform distribution of strains, thereby effectively preventing encrustation, realizing high gas production rate; therefore the device is suitable for large-scale production.

Owner:梁英

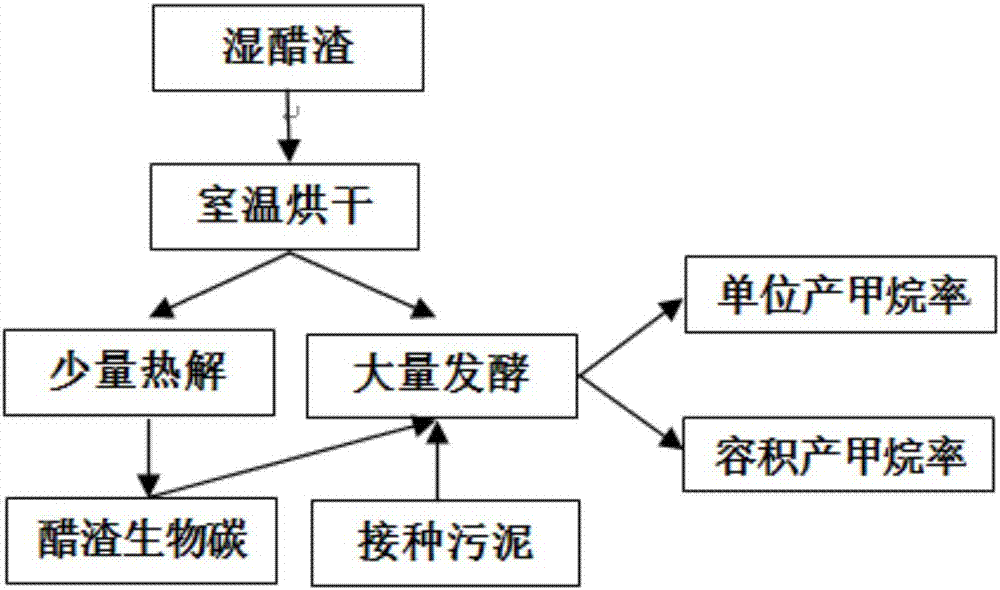

Industrial vinegar residue waste solid anaerobic fermentation methanogenesis method

InactiveCN106929541AReduce water consumptionImprove fermentation efficiencyWaste based fuelFermentationChemistryFixed bed

The invention provides an industrial vinegar residue waste solid anaerobic fermentation methanogenesis method and belongs to the field of vinegar residue reuse. The method comprises the steps of 1, drying vinegar residues at the indoor temperature, putting part of dry vinegar residues into a fixed bed pyrolysis carbonization furnace, pyrolyzing at the temperature of 400-500 DEG C, and preparing vinegar residue charcoal; 2, using the prepared charcoal as an additive and adding the charcoal to the vinegar residues, and carrying out solid anaerobic fermentation and producing methane at the temperature of 37 DEG C or so. Compared with the prior art, according to the industrial vinegar residue waste solid anaerobic fermentation methanogenesis method, row materials themselves are converted to an valid, pollution-free and side-effect-free charcoal additive and is combined with solid anaerobic fermentation, in addition to the vinegar residues, no other components enter, the method has the advantages of less water consumption, free of biogas slurry and large volume gas production of solid fermentation, on this basis, the efficiency of anaerobic fermentation gas production is further improved, and a new thought is provided for effective treatment and resource utilization on industrial and agricultural waste.

Owner:BEIJING UNIV OF CHEM TECH

Production method of peanut acid curd

InactiveCN105558025AFast fermentationImprove fermentation efficiencyMilk preparationStreptococcus thermophilusEmulsion

The invention discloses a production method of peanut acid curd. The production method comprises the following steps: peanut treatment, soaking, milk preparation, mixing, homogenization, sterilization, fermentation agent preparation and inoculation, fermentation and after-ripening. By the adoption of lactobacillus bulgaricus and streptococcus thermophilus, the fermentation speed is high, the fermentation efficiency is high, and the cost is relatively low; the produced peanut acid curd has special fragrance and taste of peanuts and milk, tastes pure, and is uniform emulsion, and free of layering, flocculation and an obvious precipitate layer.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

Method for producing alcohol by utilization of canna edulis ker and plant straws

InactiveCN104911219ANot easy to agglomerateImprove fermentation efficiencyBiofuelsFermentationWater contentChemistry

The invention provides a method for producing alcohol by utilization of canna edulis ker and plant straws and belongs to the alcohol production field. After canna edulis ker and plant straws are cleaned and screened, canna edulis ker and plant straws are crushed respectively. The plant straws are crushed to 40-60 meshes by a pulverizer. The crushed canna edulis ker is subjected to dehydration or water addition, and thus the water content of the processed canna edulis ker is between 13%-17%. The crushed plant straws are mixed with canna edulis ker. Raw materials saccharifying enzyme and white sugar are added and the mixture is fermented for 5-7 days at a temperature of 25 DEG C-45 DEG C. The mixture after fermentation goes into a distillation machine for distillation and goes into a cooling machine for cooling in order. Alcohol obtained after cooling is purified, and the finished product alcohol is obtained finally. The problems are solved that crushed canna edulis ker cannot be fermented fully because of small gaps, thus the alcohol conversion rate is low, the raw material utilization rate is low, and the production cost is raised greatly during the production process in a present method for producing alcohol with canna edulis ker as a raw material.

Owner:陈中志

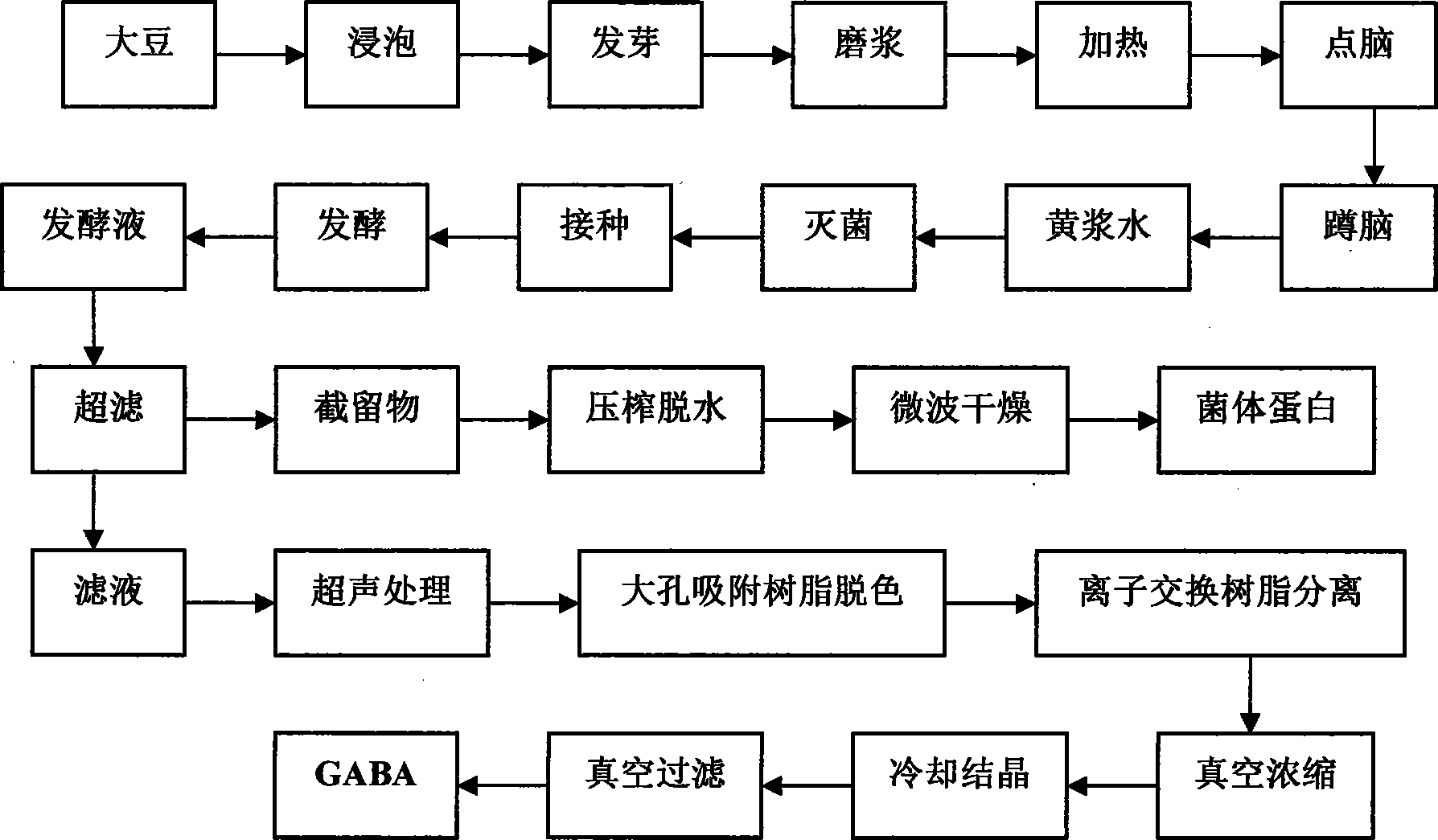

Method for preparing GABA from yellow serofluid through fermention by microorganisms

InactiveCN104031972AImprove fermentation efficiencyShorten fermentation timeFermentationUltrafiltrationChemistry

The invention discloses a method for preparing GABA from yellow serofluid through fermention by microorganisms, and belongs to the technical field of biological fermentation. The method comprises the following steps: (1) carrying out germination treatment on soybeans after soaking, grinding the germinated soybeans to obtain soybean milk, heating, agitating and solidifying the soybean milk, and then separating to obtain yellow serofluid; (2) inoculating and fermenting the yellow serofluid after sterilizing, so as to obtain a fermentation liquor; (3) carrying out ultrafiltration on the fermentation liquor to obtain an intercepted object and filtrate, carrying out micro-wave drying on the intercepted object to obtain mycoprotein after hydraulically pressing and dewatering, carrying out macroporous adsorption resin decolorization and ion exchange resin separation after carrying out ultrasonic treatment on the filtrate, and then carrying out vacuum concentration, cooling and crystallizing, and vacuum filtering to obtain GABA. GABA is prepared by adopting the yellow serofluid through fermentation by compound bacteria, the product is high in yield, the yield is equivalent to that of the product obtained through fermentation by adding sodium glutamate, the product purity can be over 95%, the mycoprotein also can be recovered when GABA is obtained, and industrial continuous production of GABA is facilitated.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

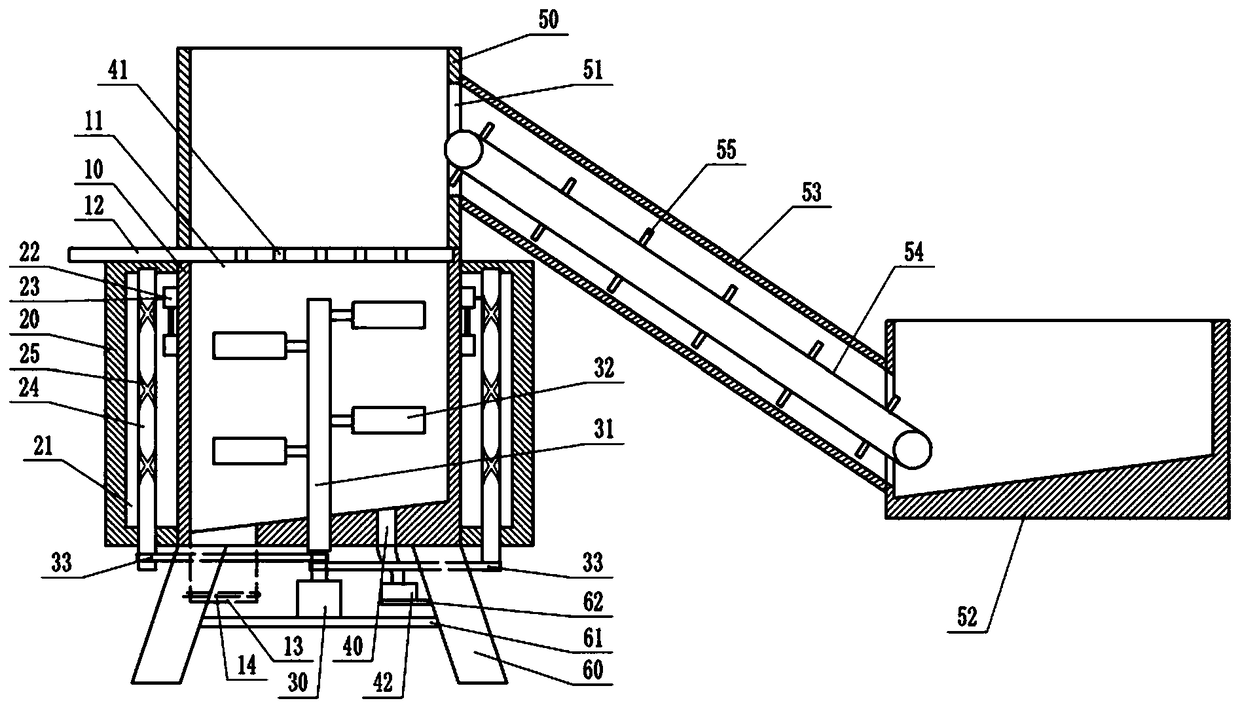

Integrated device for processing sea-buckthorn juice

PendingCN112155215AReduce manufacturing costImprove fermentation efficiencyJuice extractionFood treatmentHippophae rhamnoidesBiology

An integrated device for processing sea-buckthorn juice, including a cleaning machine, a water sieving machine, a seed-pulp separator, a fermentation machine, a filter and a homogenizer, the cleaningmachine is used for cleaning sea-buckthorn fruits, the discharging port of the cleaning machine is arranged above the feeding port of the water sieving machine, and the discharging port of the water sieving machine is connected with a sea-buckthorn fruit feeding port of the seed-pulp separator through a transfer tube; the pulp outlet of the seed-pulp separator is connected with the feeding port ofthe filter, the pomace discharged from the pomace outlet of the filter enters the fermentation machine through a connection tube for fermentation, a juice outlet of the filter is connected with an inlet of the homogenizer, and the fermentation juice outlet of the fermentation machine is connected with an inlet of the homogenizer.

Owner:赵英

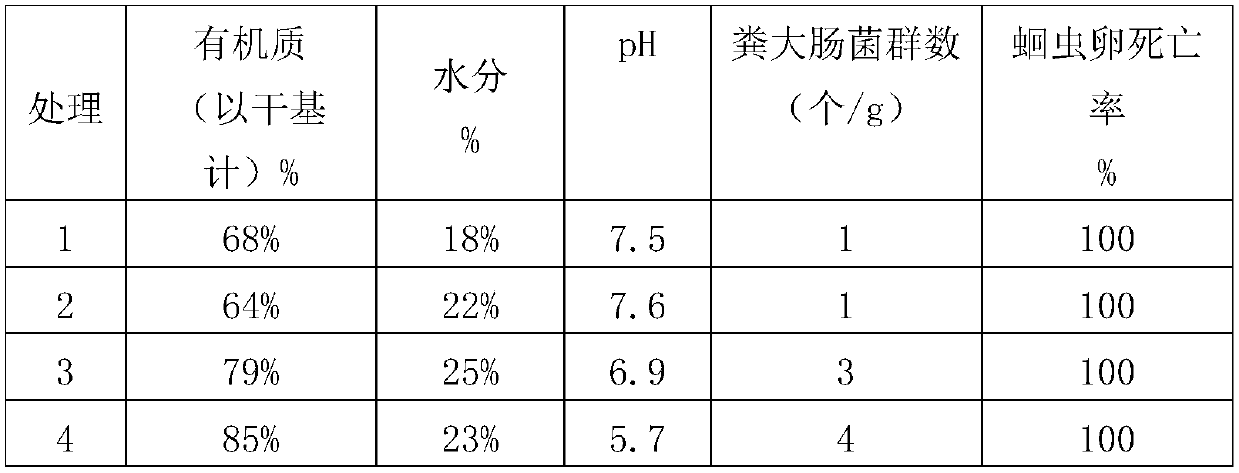

Compost agent for organic fertilizer and preparation method thereof

InactiveCN108676760AFull maturity processImprove fermentation efficiencyBio-organic fraction processingFungiChemistryCompost

The invention discloses a compost agent for an organic fertilizer and a preparation method thereof. The compost agent is prepared from the following components in percentage by weight: 20% to 30% of bacillus mucilaginosus, 20% to 30% of bacillus subtilis, 10% to 20% of bacillus stearothermophilus, 10% to 20% of aspergillus foetidus, and 15% to 25% of bacillus jelly through mixing. The compost agent for the organic fertilizer and the preparation method are suitable for the composting of organic materials using agricultural wastes as the main production raw material, and have the advantages thatthe quick, high-efficient and sufficient composting process can be realized; the fermenting efficiency is effectively improved, the fermenting time is shortened, and the composting degree of the organic fertilizer is guaranteed.

Owner:MICROBIAL FERMENTATION ENG RES CENT CO LTD OF YUNNAN PROVINCE

Chemical industry fermentation device capable of performing uniform stirring

PendingCN110760435AThe mixing structure is cleverly designedImprove fermentation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsChemical industryElectric machinery

The invention discloses a chemical industry fermentation device capable of performing uniform stirring. The chemical industry fermentation device comprises a tank body, wherein a plurality of supporting legs are arranged at the bottom of the tank body; a feeding box is arranged at the top of the side surface of the tank body; a discharging opening is formed in the bottom of the tank body; a driving motor is arranged in the center of the top of the tank body; a stirring structure which is in transmission connection with the driving motor is arranged in the tank body, and comprises a middle shaft rod; the middle shaft rod is fixedly connected with an output shaft of the driving motor; a plurality of rotating rods are arranged in the center of the middle shaft rod in the height direction; therotating rods and the middle shaft rod are mutually and perpendicularly arranged; the rotating rods are arranged along the outer wall of the middle shaft rod in the circumferential direction in an equal spacing manner; a conical surface gear is arranged at the front end of each rotating rod; a plurality of stirring rods which are mutually perpendicular to each rotating rod are arranged on the corresponding rotating rod; and a toothed ring is arranged on the inner wall of the tank body. According to the chemical industry fermentation device disclosed by the invention, the stirring structure isingenious in design; in the stirring process, the effect of stirring raw materials in a multi-direction manner is achieved, so that mixing of the raw materials is sufficient, the fermentation efficiency is improved, and the fermentation effect is guaranteed.

Owner:义乌喵小乐宠物用品有限公司

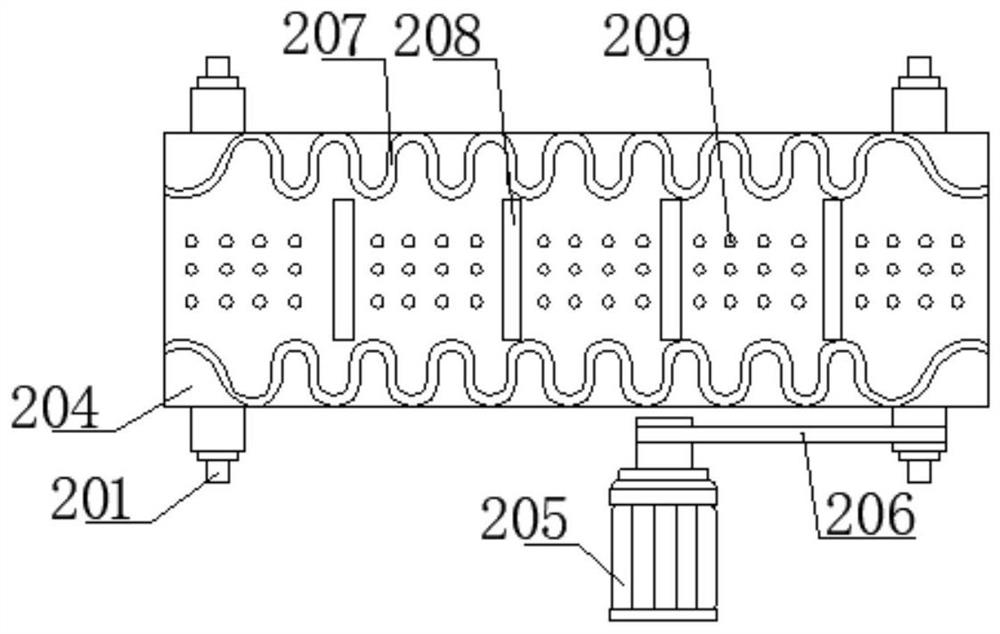

Biogas slurry extraction device

InactiveCN104845868AImprove convectionImprove fermentation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasEngineering

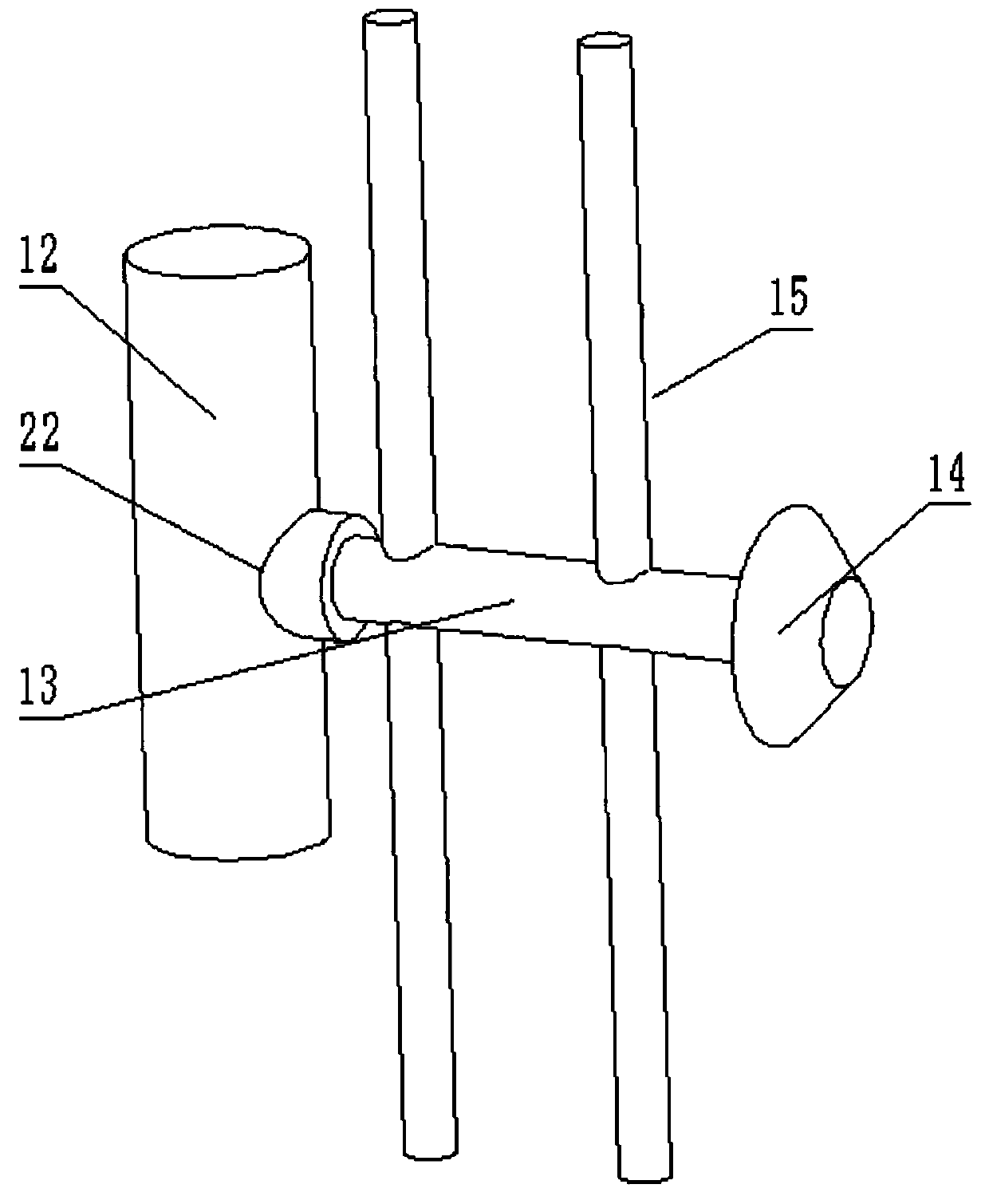

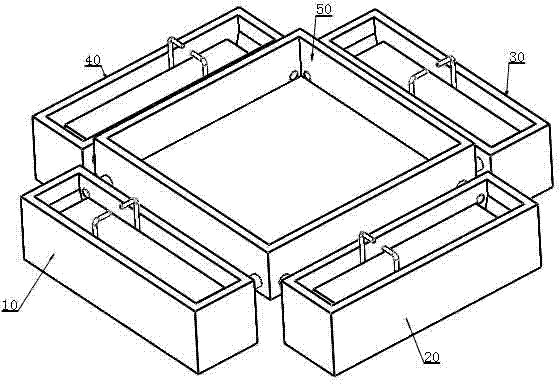

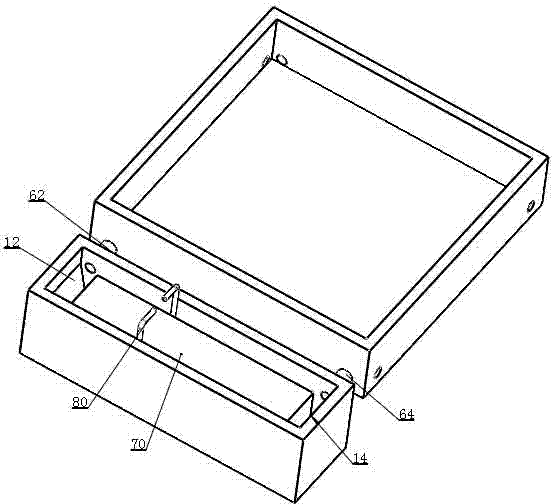

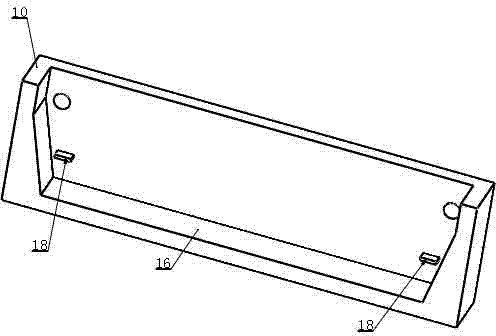

The invention discloses a biogas slurry extraction device which comprises a water pressure chamber, wherein a plurality of fermentation tanks with the same specification are connected with the periphery of the water pressure chamber and are connected with the water pressure chamber through drainage pipes; each drainage pipe comprises a material inlet drainage pipe and a material outlet drainage pipe; material inlets and material outlets are arranged on the left end sides and the right end sides of the fermentation tanks, and fermentation chambers are arranged in the middles of the fermentation tanks and are connected with the material inlets and the material outlets respectively. Gaps exist between the upper side surfaces and the lower side surfaces of gas storage plates and the inner side surfaces of the fermentation tanks; a pneumatic diaphragm pump is arranged in the water pressure chamber, and a gas supply channel of the pneumatic diaphragm pump is communicated with gas guide pipes.

Owner:潘磊

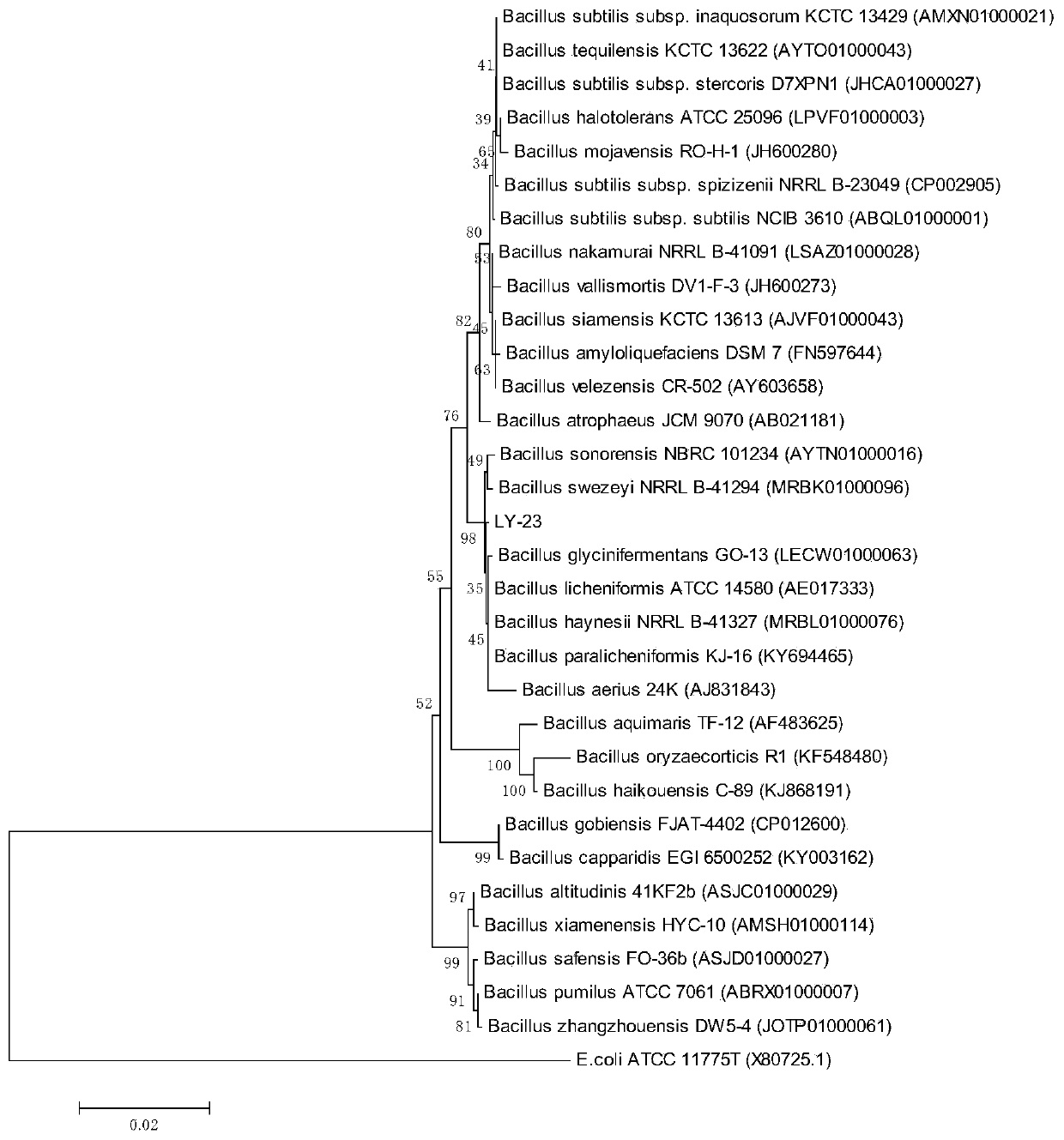

Bacillus haynesii LY-23, bacterial agent, application of bacterial agent and product applying bacillus haynesii LY-23

ActiveCN110218688AStrong enzyme activityImprove fermentation efficiencyBacteriaMicroorganism based processesGlobulinLarge intestine

The invention provides bacillus haynesii LY-23, a bacterial agent, application of the bacterial agent and a product applying the bacillus haynesii LY-23, and relates to the field of microorganisms. The bacillus haynesii LY-23 is separated from the large intestine content of a healthy adult black donkey, multiple carbohydrates can be utilized, the bacillus haynesii LY-23 has good enzymatic activity, wherein proteinase activity, amylase activity and cellulase activity are good, and especially, the bacillus haynesii LY-23 has extremely high cellulase activity; the bacillus haynesii LY-23 furtherincreases the rate of digesting nutrient substances in feed by animals and increases the content of serum immune globulin IgG in the animals. Based on the functions of the bacillus haynesii LY-23, the bacillus haynesii LY-23 can be applied to fermentation, preparation of feed additives, feed, products capable of improving the intestinal tract environment of equus animals and products capable of improving the immunity of the equus animals.

Owner:SHENYANG BOYANG FEED

Alkaline type rapid brewing method of low-salt fish sauce

InactiveCN104642998AShorten the fermentation cycleImprove fermentation efficiencyFood preparationProtein proteinFermented fish

The invention discloses an alkaline type rapid brewing method of low-salt fish sauce. The method comprises the following steps: mixing marine fishes with general drinking water; adding table salt; uniformly mixing; adjusting pH to be 7.0 to 11.0 through an alkaline regulator; maintaining the temperature to ferment; agitating once every two days to promote rapid degrading of protein of the fish bodies; continuously fermenting the product obtained by the constant temperature fermenting for 30 to 60 days; agitating once at every 5 to 10 days to obtain completely fermented fish sauce; filtering to remove residues of the completely fermented fish sauce; after-ripening; removing the upper grease of the fish sauce to obtain the after-ripened and de-greased fish sauce; heating for sterilizing; filtering to remove incompletely-fermented protein and other impurities to obtain clear and transparent low-salt fish sauce which has a good taste. The method is short in fermenting cycle, high in fermenting efficiency, and low in salt in the fish sauce, and the value of low-value marine fishes is increased.

Owner:JIMEI UNIV

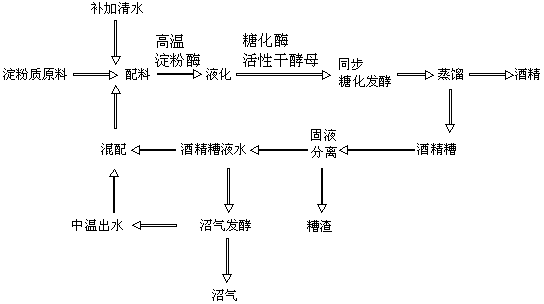

Method for fermenting alcohol by reusing alcohol grain liquid and medium-temperature anaerobic effluent

InactiveCN103382490AImprove fermentation efficiencyLow costBiofuelsWaste based fuelAmmonium hydroxideEnvironmental chemistry

The invention discloses a method for fermenting alcohol by reusing alcohol grain liquid and medium-temperature anaerobic effluent. According to the process method, burdening liquid is added according to the feed liquid weight ratio of 1:1.5-2.4, the burdening liquid is composed of the alcohol grain liquid, the medium-temperature anaerobic effluent and supplemented clean water, the effluent is reused, and ammonium hydroxide or sulfuric acid are not required, so that the effluent treatment cost can be reduced. By controlling the feed water ratio and adjusting the proportion of alcohol grain liquid and the medium-temperature anaerobic effluent to control the pH value, the complex cost-increasing procedures of conducting acid radical removing, ammonia nitrogen removing and additionally adding of acid or alkali to adjust the pH value and the like on the medium-temperature anaerobic effluent in the traditional process are avoided, the production efficiency is greatly improved, the production cost is reduced, sewage discharge in alcohol production is greatly reduced, feed mixing water use cost and sewage treatment cost are saved, more additional products are produced, and considerable market economical benefit is brought.

Owner:HENAN TIANGUAN GRP

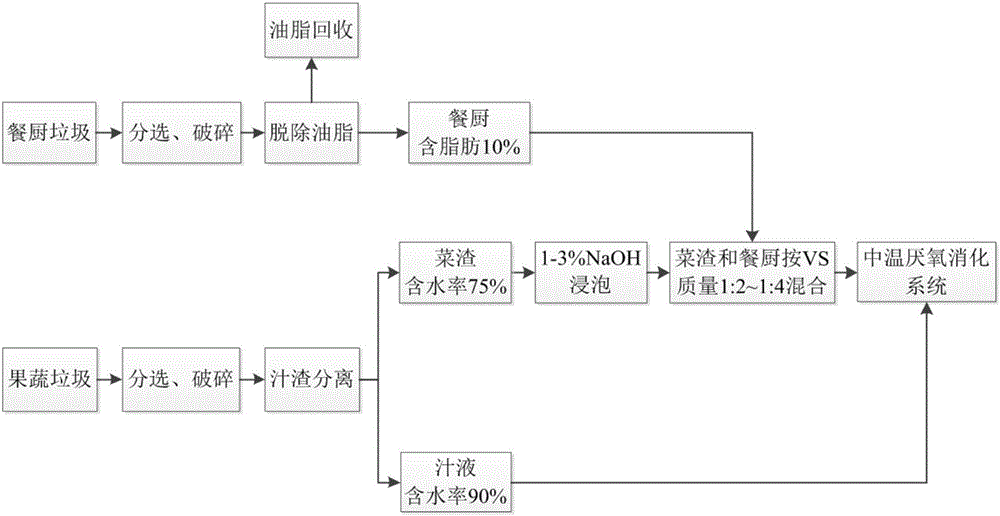

Method for strengthening anaerobic digestion effect by cooperatively fermenting kitchen waste and fruit-vegetable garbage

InactiveCN105886550AImprove fermentation efficiencyConducive to the promotion to large-scale continuous productionWaste based fuelFermentationChemistryAnaerobic digestion

The invention discloses a method for strengthening anaerobic digestion effect by cooperatively fermenting kitchen waste and fruit-vegetable garbage. The method at least comprises the following steps: deoiling the kitchen waste; and separating juice from residue after crushing the fruit-vegetable garbage. According to the method disclosed by the invention, the step of deoiling the kitchen waste and the step of separating juice from residue after crushing the fruit-vegetable garbage are increased, so that the subsequent fermentation efficiency of an anaerobic digestion system is greatly improved, and large-scale continuous production and popularization of an anaerobic digestion technology are facilitated.

Owner:HUATIAN ENG & TECH CORP MCC

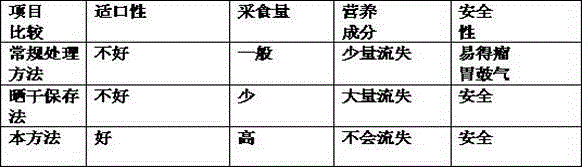

Method for processing broad bean straws into feed

PendingCN105746911AIncrease contact areaImprove fermentation efficiencyFood processingAnimal feeding stuffFeed processingBroad beans

The invention belongs to feed processing methods and particularly relates to a method for processing broad bean straws into feed.The method for processing the broad bean straws into the feed comprises material selection, drying, cutting short, starter culture formula, mixing, anaerobic treatment and biological feed.The defects that the sugar content of the broad bean straws is low and independent ensiling is difficult are overcome, the contact area is increased during fermentation, and the fermentation efficiency is improved; the water content is in the optimal range of the microganism activity, and the microganism activity will be affected by too low or too high water content; finally, the prepared biological feed has the advantages that the feed has special acid fragrance, the palatability is good, sheep likes eating the feed, the nutriments are rich, and the feed is juicy, suitable for storage and free from influences of seasons and harvest seasonality.

Owner:LISHUI AGRI SCI

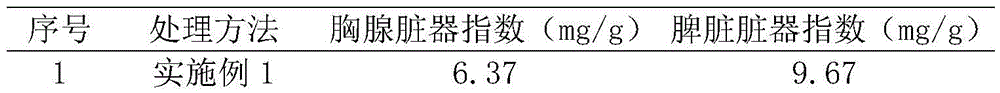

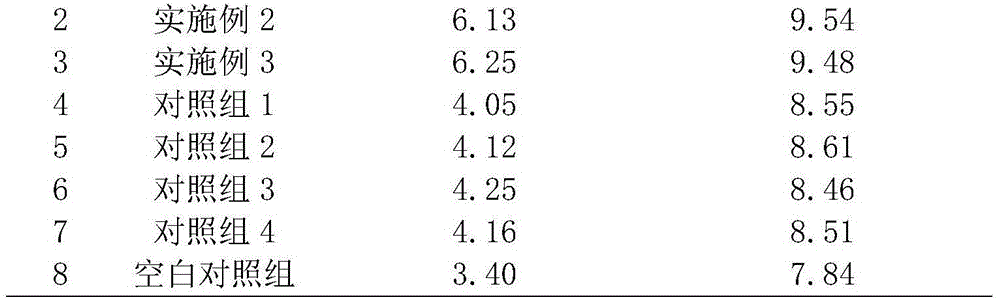

Composite microbial agent for enhancing animal immunity, preparation method and application of composite microbial agent

ActiveCN105647830AImprove fermentation efficiencyImprove immunity and stress abilityFungiBacteriaAnimal breedingImmunity

The invention relates to the field of animal breeding, in particular to a composite microbial agent for enhancing animal immunity, a preparation method and an application of the composite microbial agent. The composite microbial agent comprises following components in terms of the number of cells: 1-10 parts of Brevibacillus laterosporus, 1-10 parts of Candidautilis, 5-15 parts of Bacillus licheniformis and 5-15 parts of Aspergillus oryzae. The invention further provides a preparation of microbial agent fermented powder. According to the microbial agent, combined ratio and mixed fermentation are adopted, strains are mutually influenced, and various nutritional ingredients in a culture medium can be utilized more sufficiently; after the microbial agent is added to animal feed, microflora balance in animal intestine can be adjusted, immunity and stress capability are enhanced, and parasites can be effectively prevented and controlled.

Owner:SHANGHAI HONGYUAN BIOTECH

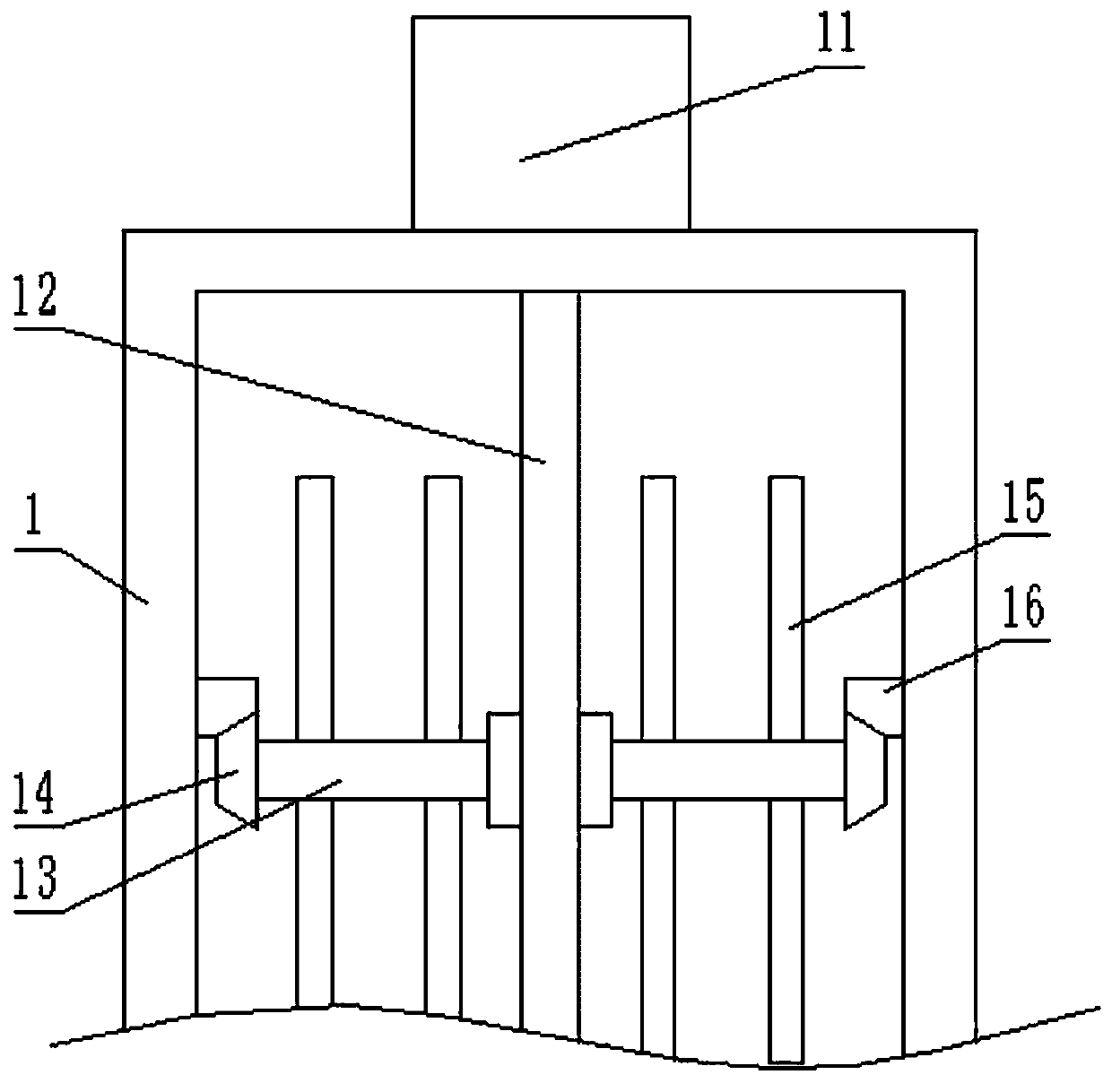

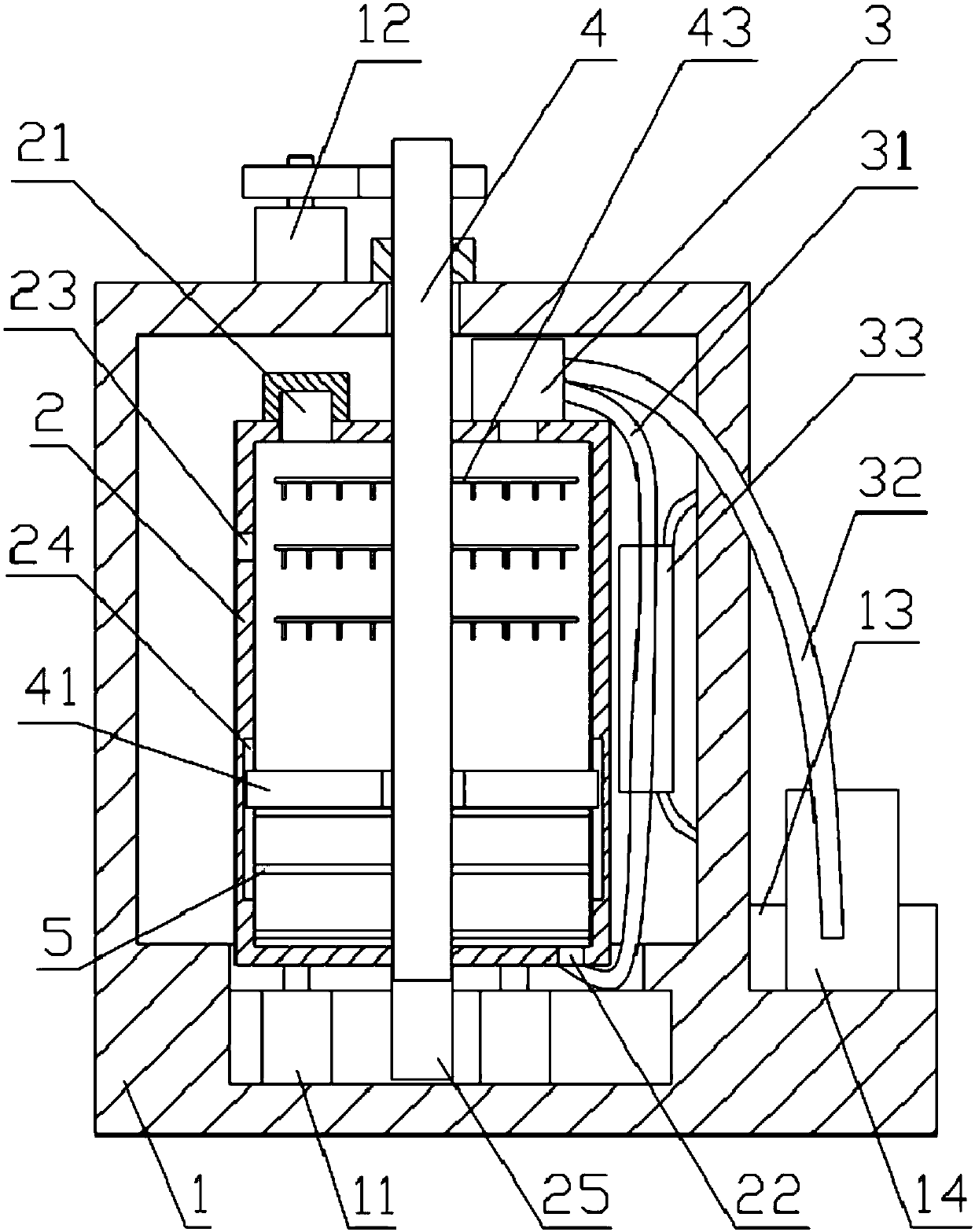

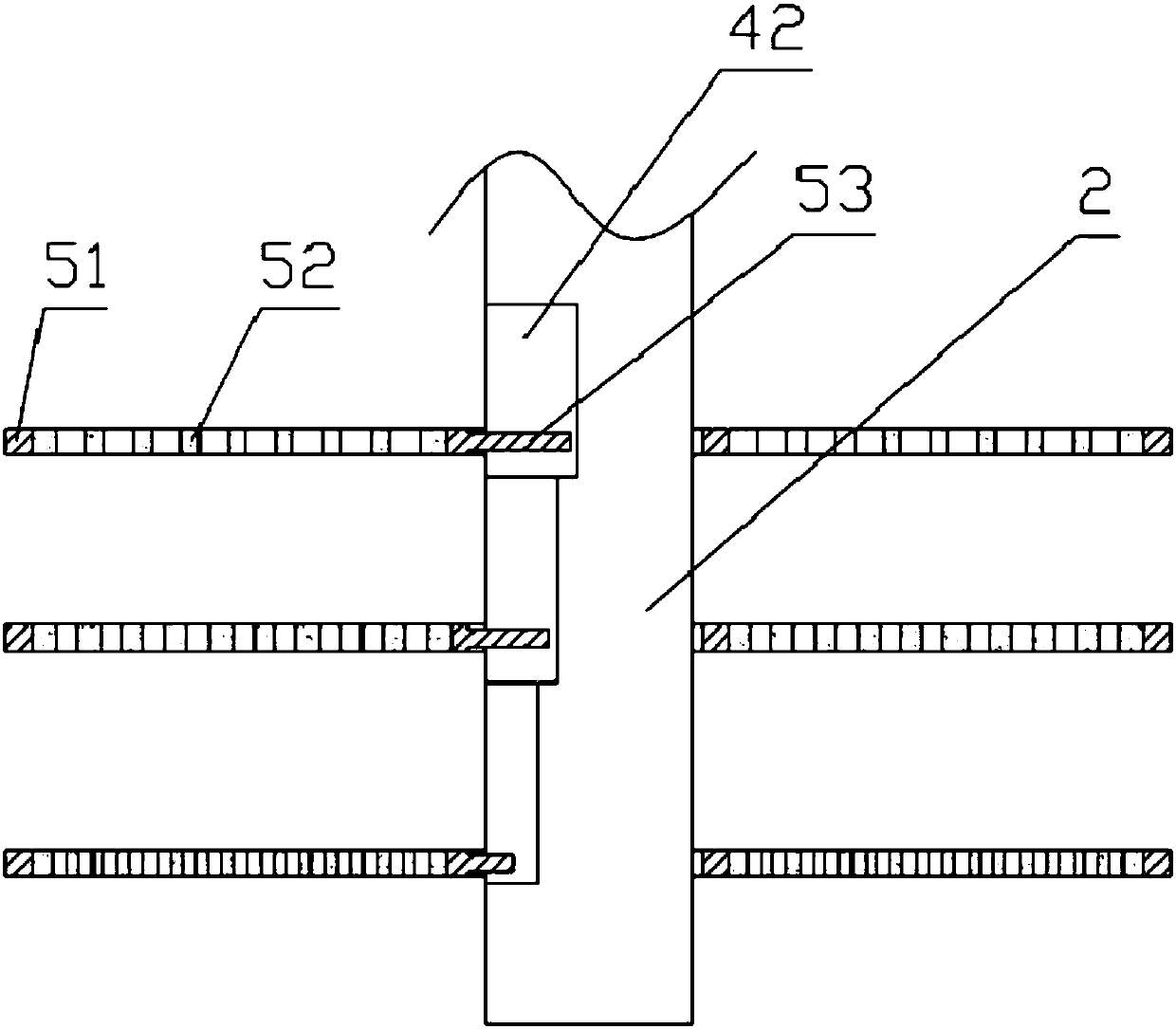

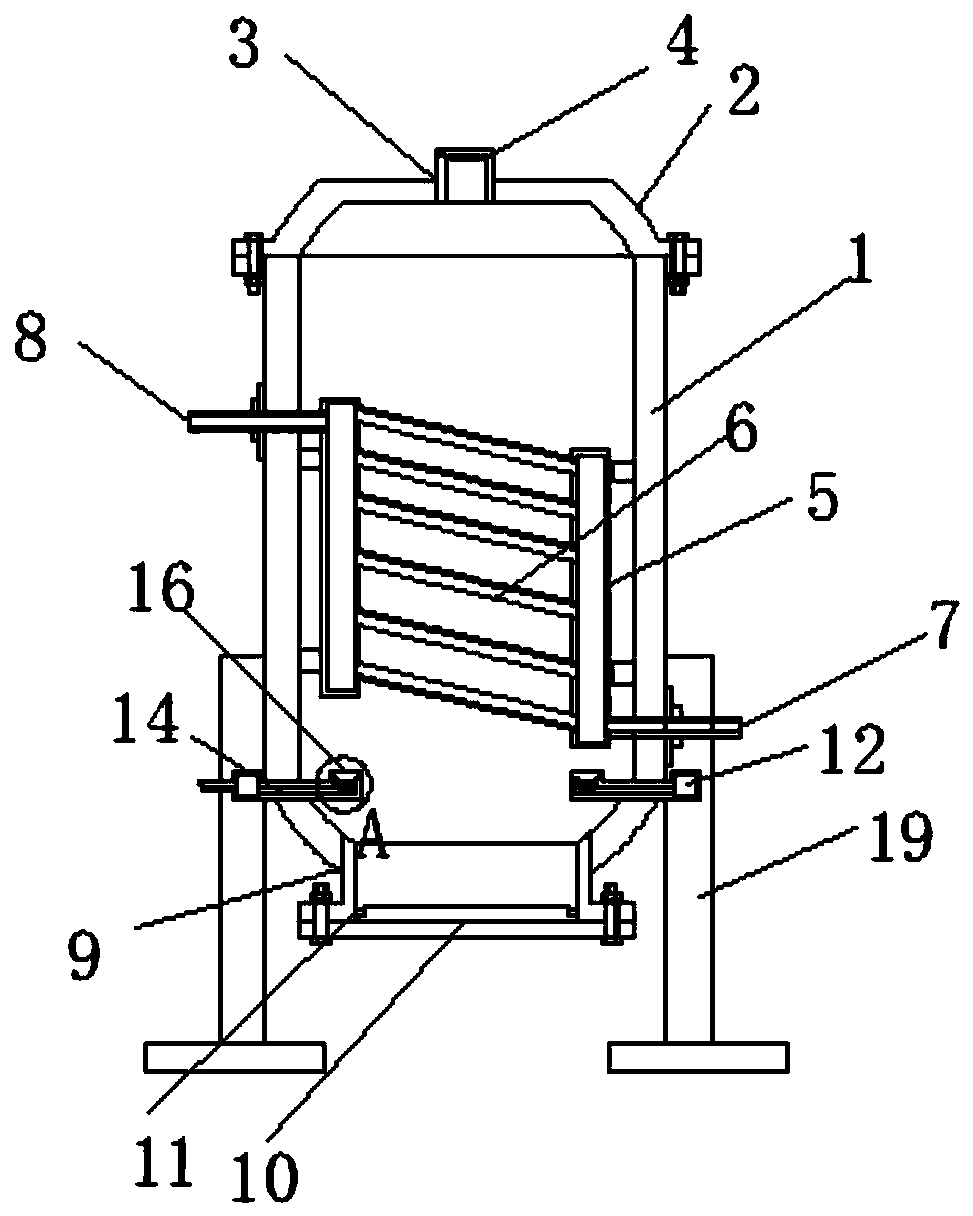

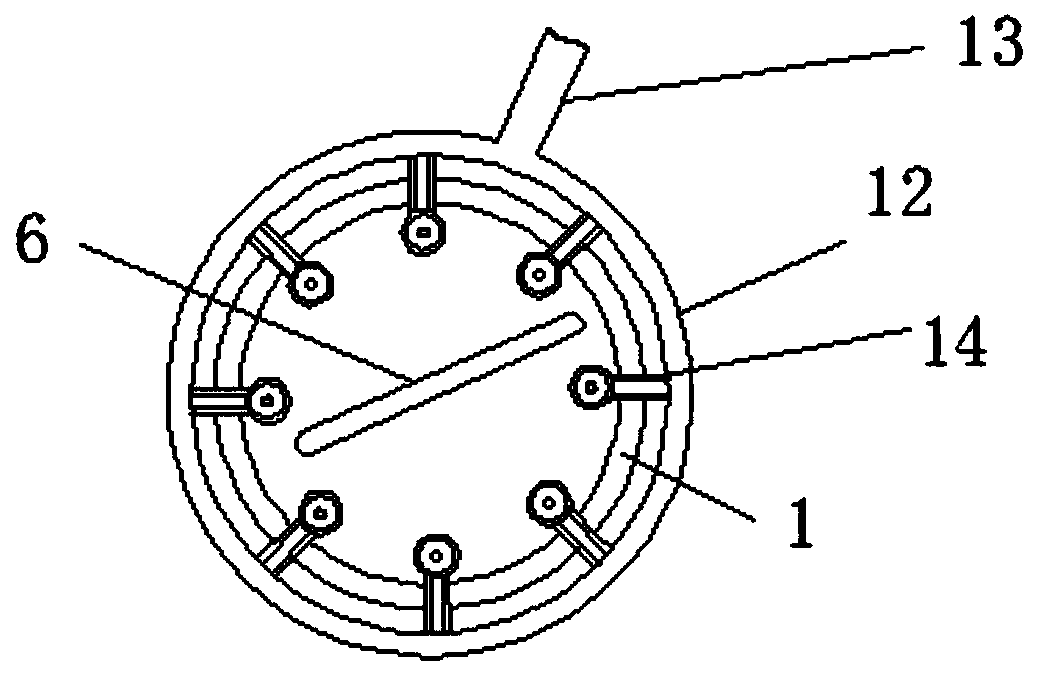

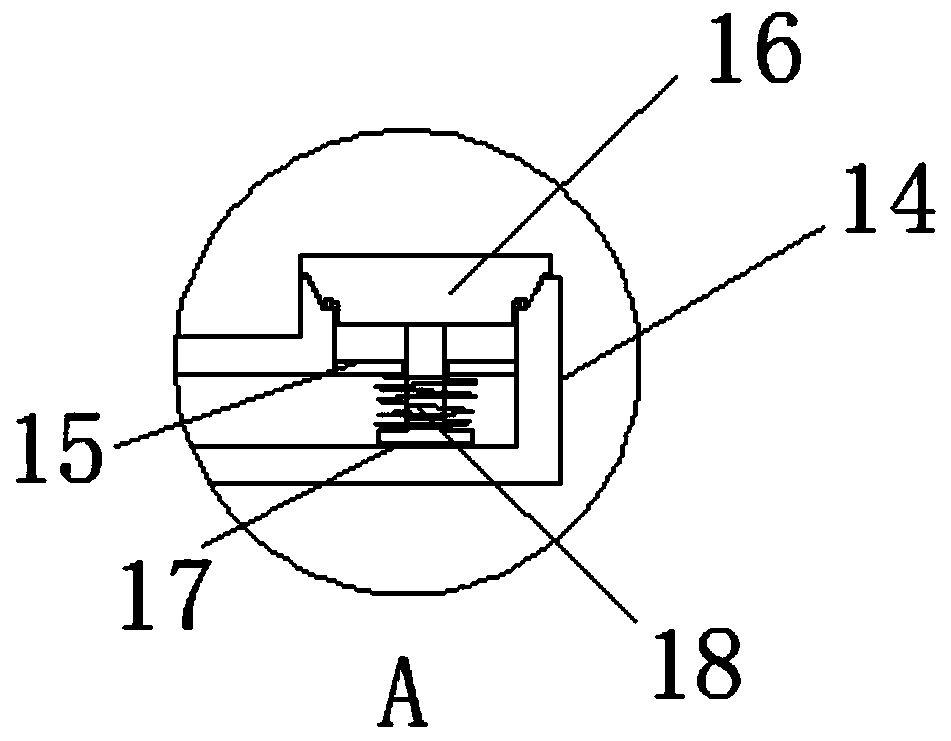

Baijiu fermentation method

InactiveCN107619743AImprove fermentation efficiencyImproves strength and fragranceAlcoholic beverage preparationAgricultural engineeringYeast

The invention relates to the field of Baijiu production and in particular discloses a Baijiu fermentation method. A fermentation device is used for fermenting; the fermentation device comprises a rack, a fermentation barrel, a stirring mechanism and a filtering mechanism, wherein the stirring mechanism comprises a motor, a stirring shaft and a stirring part; a feeding opening is formed in the fermentation barrel; a hydraulic jack is fixed on the rack; the fermentation barrel is fixed on a push rod of the hydraulic jack; a containing cavity is formed in the bottom of the fermentation barrel; the upper end of the stirring shaft penetrates through the top of the fermentation barrel; a liquid outlet is formed in the lower part of the fermentation barrel; a draught fan is fixed on an outer wallof the fermentation barrel; the draught fan is communicated with the upper part of the fermentation barrel and a circulating pipe is fixed at an air outlet end; the circulating pipe can be communicated with the liquid outlet; a cooling pipe sleeves the periphery of the circulating pipe; the filtering mechanism comprises a filtering screen; a sliding groove is formed in the stirring shaft; slidingblocks are fixed at the inner periphery of the filtering screen. The Baijiu fermentation method comprises the following steps: (1) selecting materials; (2) steaming the materials and spreading for cooling; (3) adding distiller's yeast; (4) fermenting; (5) discharging wine. According to the Baijiu fermentation method disclosed by the invention, a condition that the aroma of Baijiu is reduced can be prevented.

Owner:贵州金液郎酒业有限公司

Sealing fermentation device for organic fertilizer

PendingCN109180252AImprove fermentation efficiencySmall temperature differenceOrganic fertiliser preparationThermal insulationOrganic fertilizer

The invention belongs to the technical field of fertilizer fermentation equipment and particularly discloses a sealing fermentation device for an organic fertilizer. The sealing fermentation device comprises a tank body, wherein a feeding hole is formed in the upper end of the tank body, a discharging hole is formed in the lower end of the tank body, a feeding blocking door is arranged at the feeding hole in a sealing manner, a discharging blocking door is arranged at the discharging hole in a sealing manner, a bracket for supporting the tank body is arranged at the lower end of the tank body,the tank body is externally sleeved with a thermal insulation body, and a sealing cavity is formed between the thermal insulation body and the tank body; and a cycle of friction ring is arranged in the sealing cavity outside the tank body in a sliding sleeving manner, a rotating rod which can rotate along the direction vertical to the sliding direction of the friction ring is roitatably arrangedin the sealing cavity, spiral slots which are communicated end to end are formed in the rotating rod, and bulges which stretch into the spiral slots and are in sliding connection with the spiral slotsare arranged on the friction ring. Compared with the prior art, the sealing fermentation device has the advantages that the difference of temperatures at different parts during the fermentation of the organic fertilizer can be reduced, so that the fermentation effect of the organic fertilizer is guaranteed.

Owner:遵义大兴复肥有限责任公司

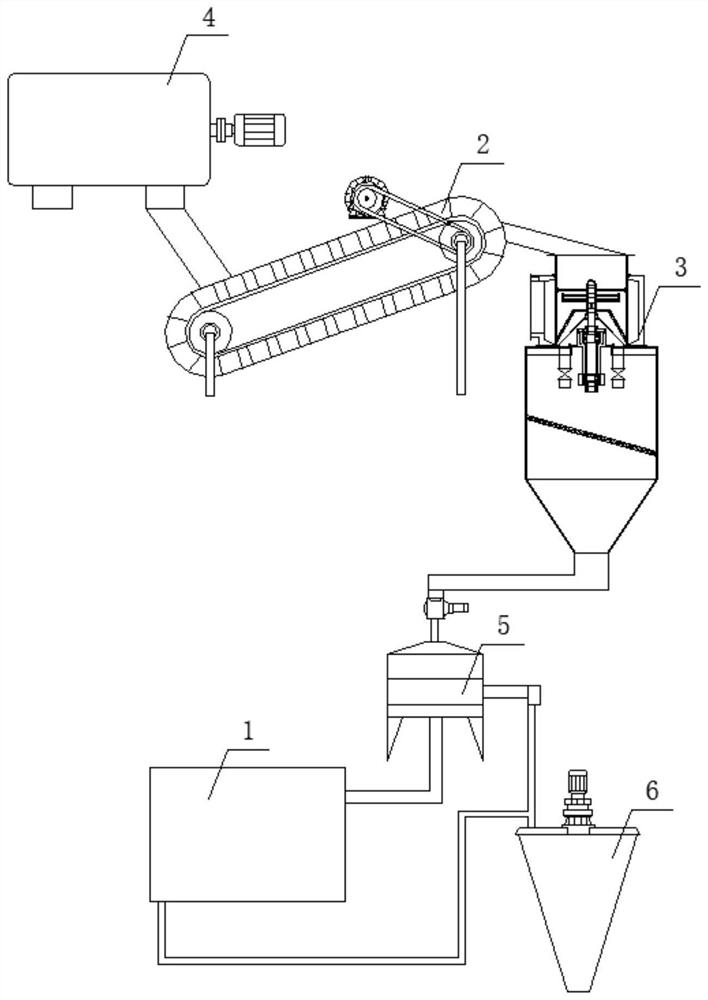

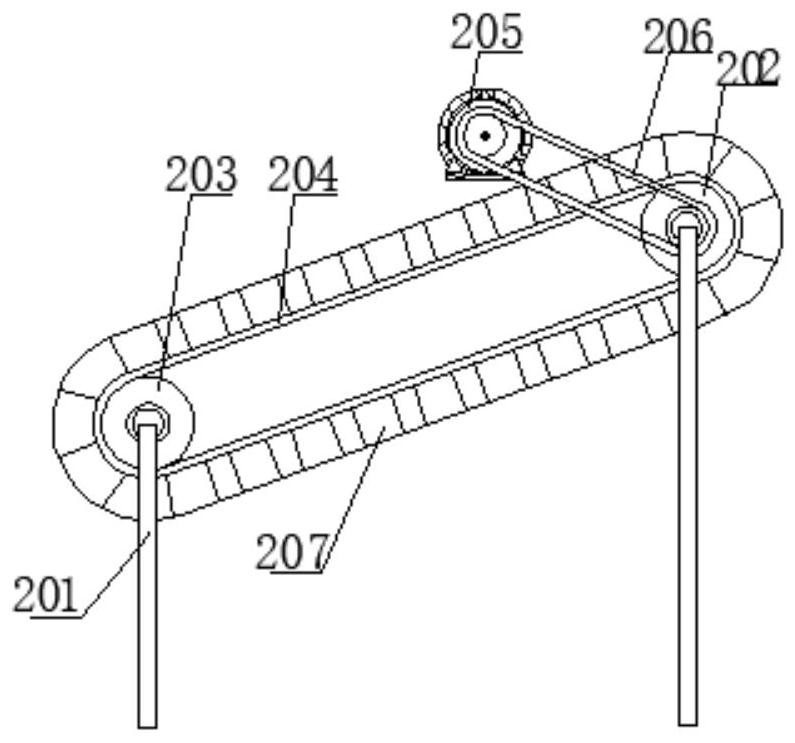

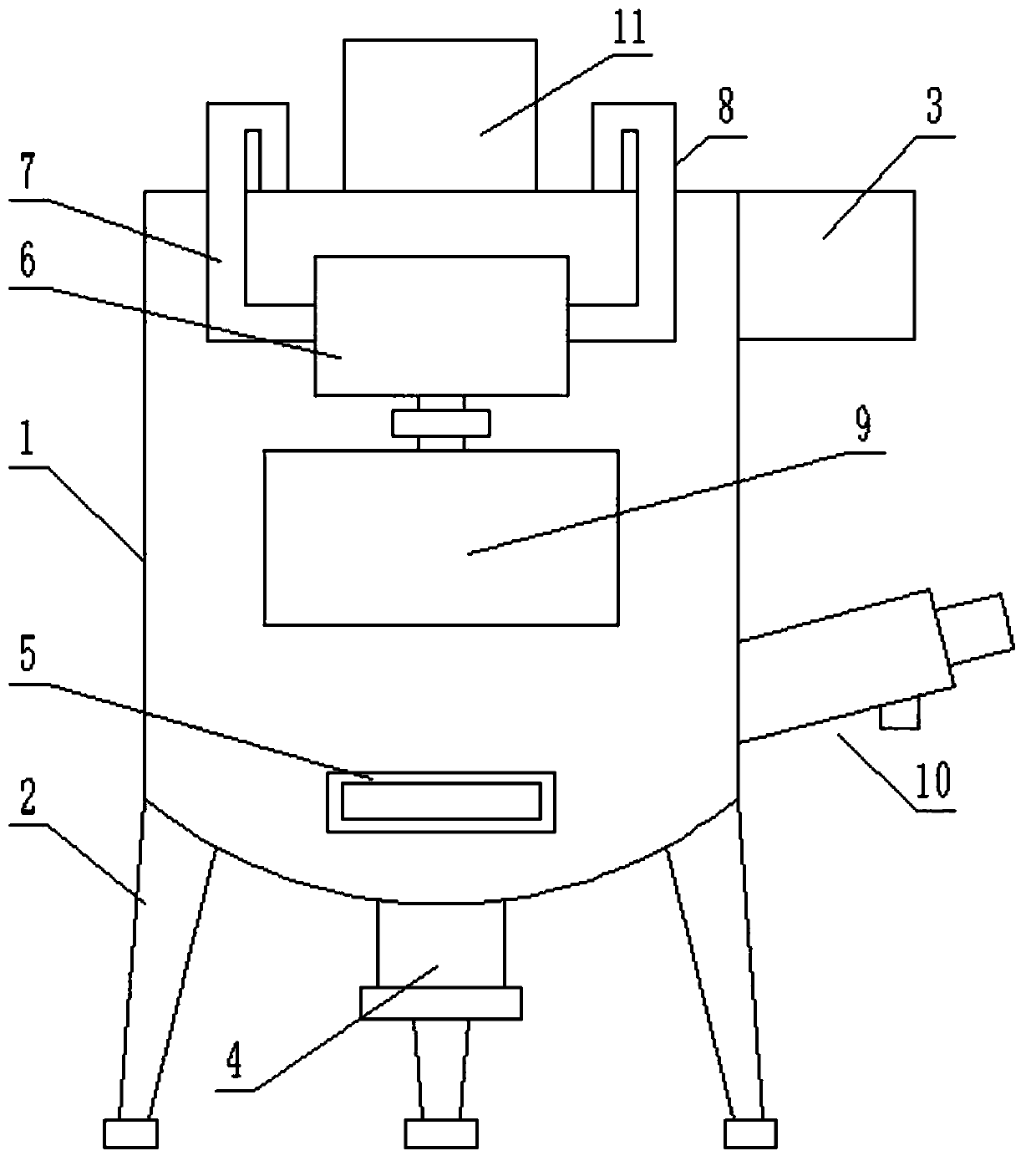

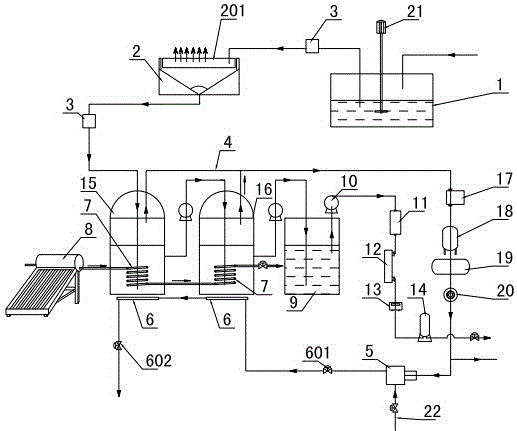

Energy-saving biogas system for pig farms

InactiveCN105062886AIncrease productivityImprove fermentation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasWater transfer

The invention relates to an energy-saving biogas system for pig farms, belonging to the technical field of biogas utilization. A liquid outlet end of a manure-water mixture tank (1) is connected with a filter tank (2) through a pipeline; the pipeline between the manure-water mixture tank (1) and filter tank (2) is provided with a transfer pump (3); a liquid outlet end of the filter tank (2) is connected with a biogas generation mechanism through a manure-water transfer pipeline; a gas outlet end of the biogas generation mechanism is connected with a biogas boiler (5) through a biogas output pipeline (4); a water inlet end of the biogas boiler (5) is connected with a tap water supply pipeline; a water outlet end of the biogas boiler (5) is connected with a floor heating coil pipe (6) through a pipeline; the floor heating coil pipe (6) is positioned below the biogas generation mechanism; a heat exchange casing (7) is arranged in the biogas generation mechanism; and a liquid inlet end of the heat exchange casing (7) is connected with a solar heat exchanger (8) through a pipeline. The energy-saving biogas system for pig farms can keep higher biogas generation efficiency in a cold environment, and can purify and reutilize the manure water.

Owner:陈守亮

Improved polyoxin fermentation culture medium and fermentation process

PendingCN109810925AShorten the fermentation cycleImprove fermentation efficiencyBacteriaMicroorganism based processesCulture mediumsBiotechnology

The invention relates to an improved polyoxin fermentation culture medium and a fermentation process. The polyoxin fermentation culture medium is prepared from the following ingredients: 1% to 2% of maize meal, 1.5% to 3% of soybean cake meal, 1.5% to 3% of cerealose, 0.05% to 0.2% of KH2PO4, 0.05% to 0.2% of NaCl, 0.15% to 0.45% of CaCO3, 0.025% to 0.050% of antifoamer, 0.1% to 2% of (NH4)2SO4andthe balance of aqua sterilisa. According to the improved polyoxin fermentation culture medium and the fermentation process, the fermentation process is optimized, the stability of the fermentation culture medium is improved, and the biological value of the fermentation process is also increased.

Owner:陕西麦可罗生物科技有限公司

Technology of producing monosodium glutamate from potato starch

ActiveCN105124518AImprove fermentation efficiencyShort fermentation timeFood ingredientsFood preparationGlucanMonosodium glutamate

The invention discloses a technology of producing monosodium glutamate from potato starch. The technology comprises the following steps: adding moderate-temperature alpha-diastase, xylanase, 0.2% beta-glucanase and saccharifying enzyme to obtain enzymatic hydrolysate; configuring fermentation medium, sterilizing the fermentation medium and cooling the fermentation medium to 33 DEG C; selecting and inoculating corynebacterium crenatum B9 in the fermentation medium, wherein the inoculum size is 1%, then fermenting at 38 DEG C and cultivating for 29-31 hours; after fermentation, extracting and refining the extract to prepare the monosodium glutamate. The monosodium glutamate prepared according to the technology has a purity of higher than 99.2% and completely satisfies the national requirements of salt-free monosodium glutamate. According to the technology, the corynebacterium crenatum B9 strain can be directly inoculated to ferment; moreover, the technology is high in fermentation efficiency, short in fermentation time and economical in cost. The salt-free monosodium glutamate of the invention is prepared from potato starch and opens up a new direction in the monosodium glutamate production industry.

Owner:广东百味佳味业科技股份有限公司

Organic fertilizer fermentation apparatus

PendingCN110194690AImprove fermentation efficiencyGood fermentation effectFertiliser treatment heating/coolingBio-organic fraction processingCushionPneumatic pressure

The invention relates to an organic fertilizer fermentation apparatus, which comprises a cylinder, a gas outlet pipe, a heat exchange pipe, a gas distribution pipe and a gas cushion block, wherein theupper end of the cylinder is connected to an upper sealing cover, the center position of the upper end of the upper sealing cover is connected to the gas outlet pipe, the upper end of the gas outletpipe is movably connected to a movable cover, and a side plate is arranged inside the cylinder, and is connected to the heat exchange pipe. According to the present invention, the upper end of the cylinder is connected to the gas outlet pipe so as to discharge the internal gas of the cylinder; the upper end of the gas outlet pipe is movably connected to the movable cover, and the movable cover canbe automatically opened under the internal air pressure so as to conveniently and automatically discharge the internal gas; and the interior of the cylinder is provided with the side plate, the sideplate is connected to the heat exchange pipe, and the water flows having different temperatures can be introduced into the heat exchange pipe to perform internal heating or cooling, such that the internal temperature can be controlled to ensure the suitable fermentation temperature of the organic fertilizer so as to improve the fermentation efficiency.

Owner:南通惠农生物有机肥有限公司

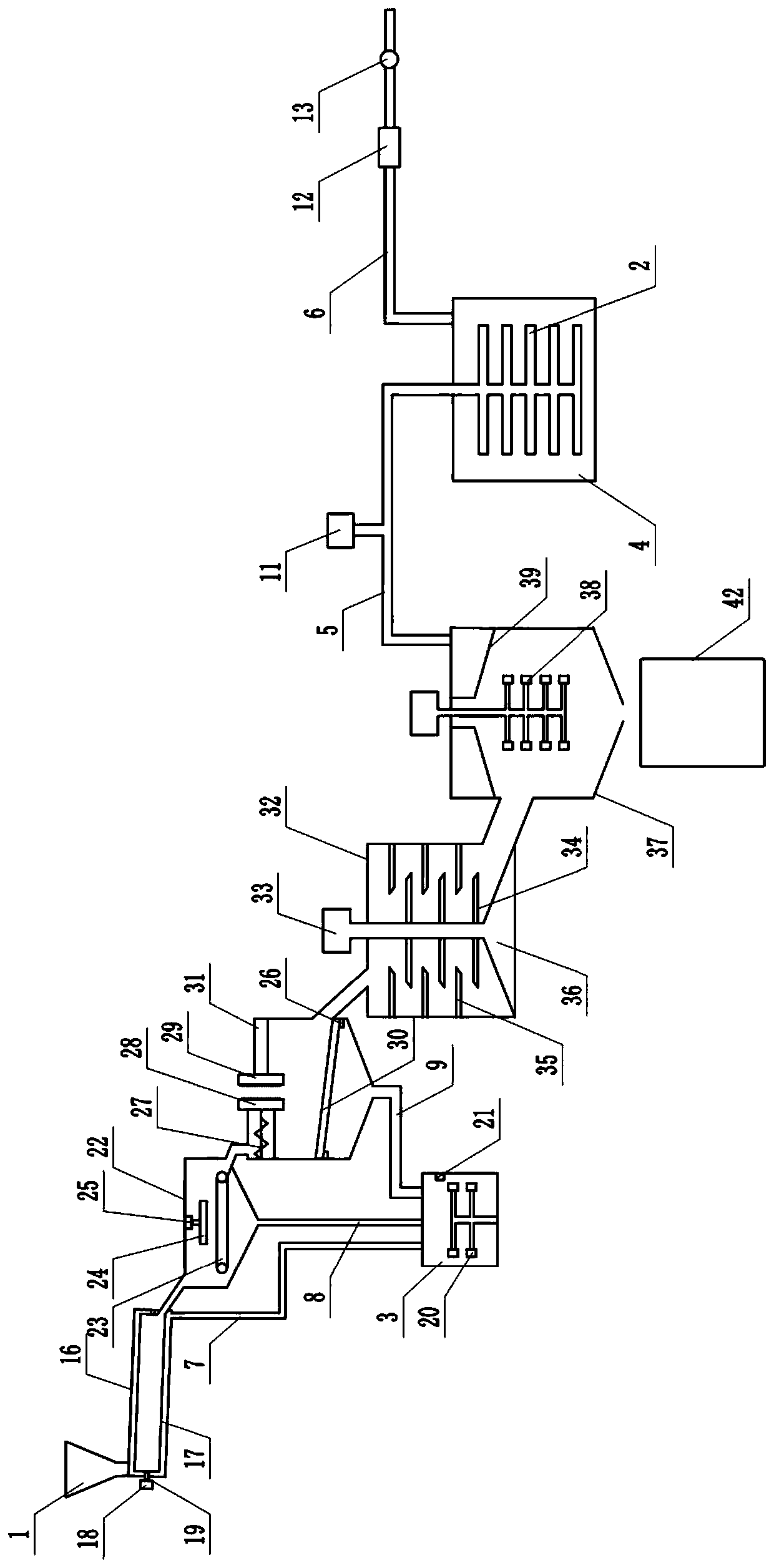

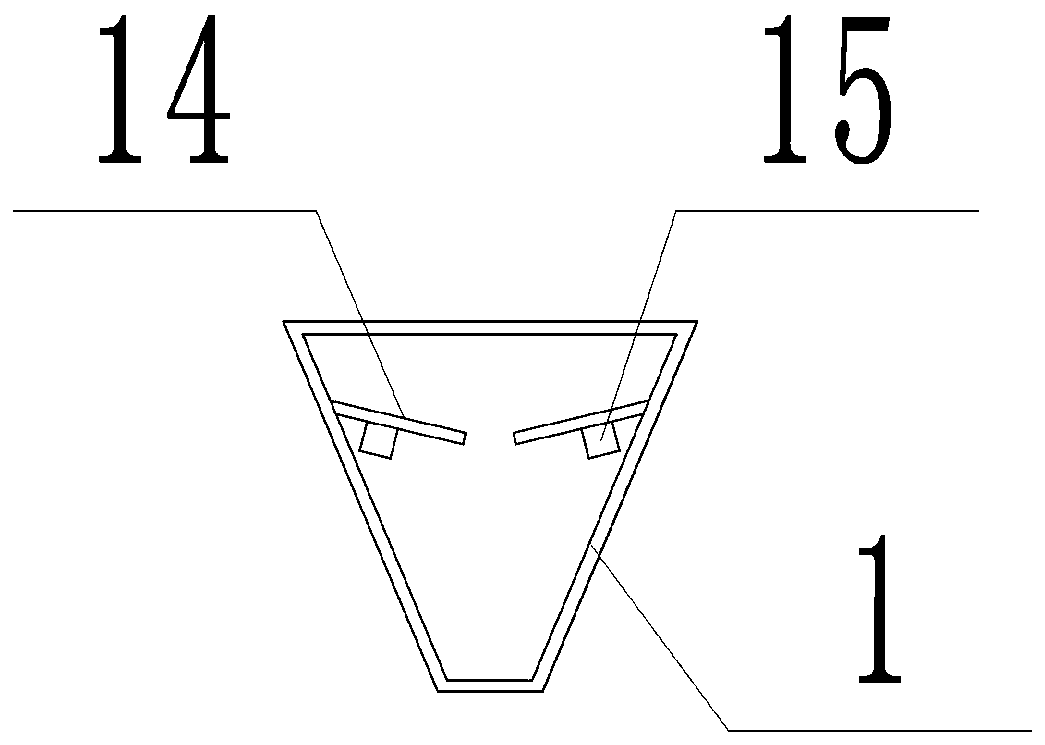

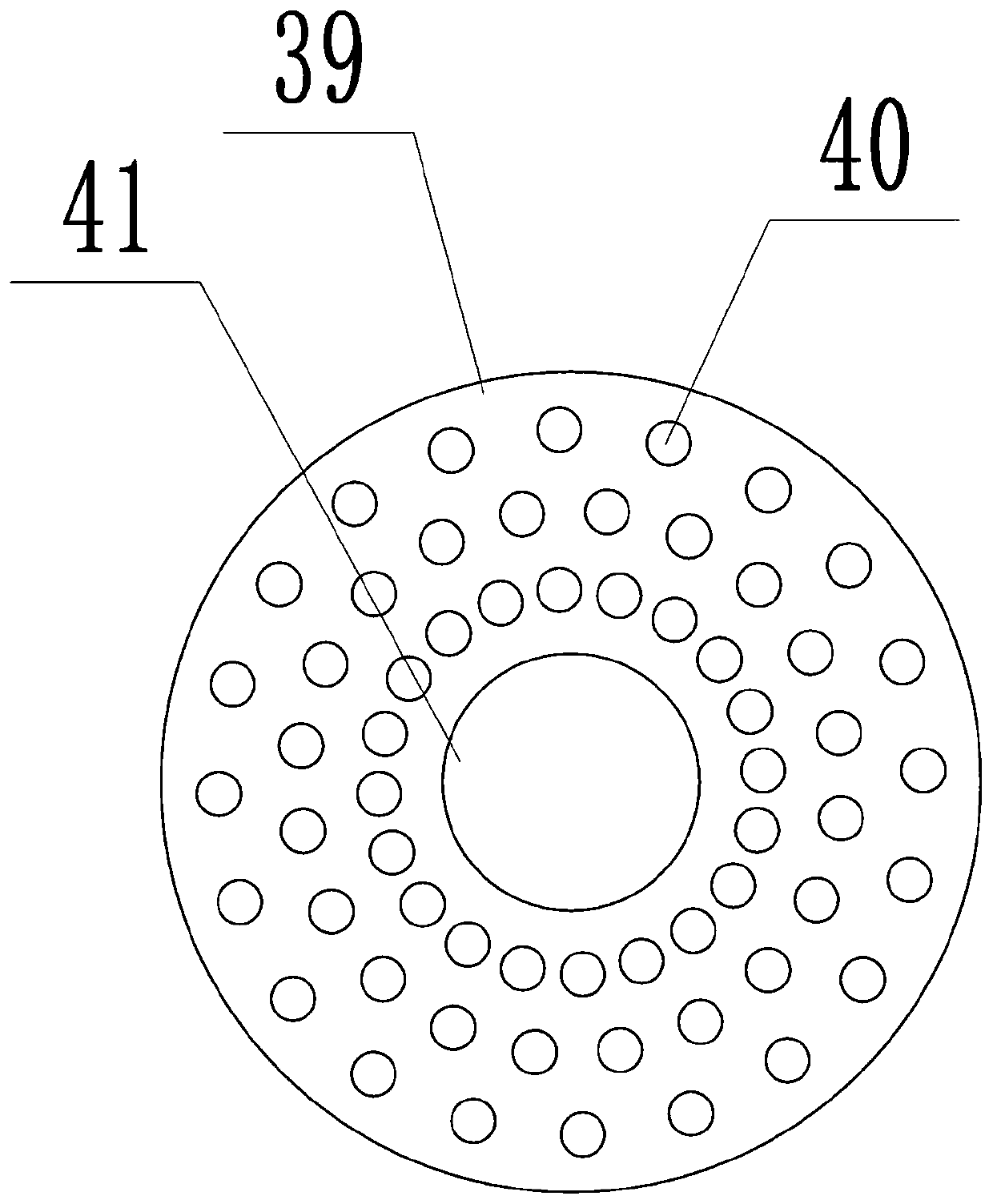

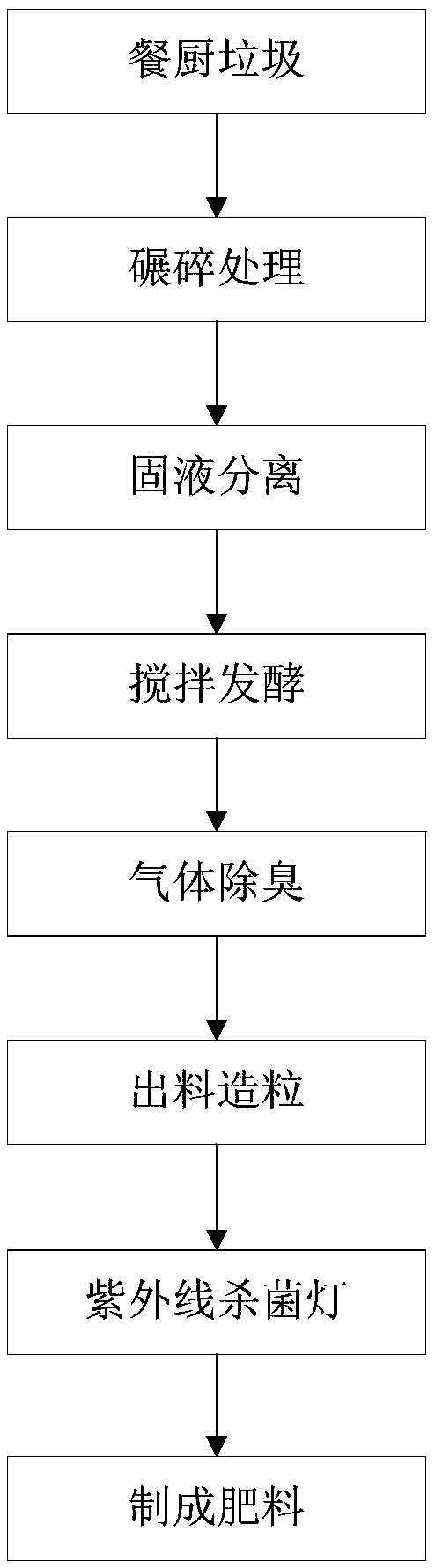

Equipment for preparing fertilizer from kitchen garbage

InactiveCN110550971AFully fermentedImprove fermentation efficiencyClimate change adaptationOrganic fertilisersFertilizerWater tanks

The invention discloses equipment for preparing a fertilizer from kitchen garbage. The equipment for preparing the fertilizer from the kitchen garbage comprises a first solid-liquid separation structure and a second solid-liquid separation structure, the kitchen garbage can be fully subjected to dry-wet separation, by a first crushing structure and a second crushing structure, the garbage can be crushed thoroughly after being subjected to dry-wet separation, it ensures that the kitchen garbage is fully fermented in a fermentation tank, gas generated in a fermentation process is fed into a water tank through an aerator pipe, an ozone generator is arranged in the pipeline, ozone is delivered into the fermented gas, and the fermented gas is filtered through a filter and then discharged afterbeing treated in the water tank. The kitchen garbage can be subjected to dry-wet separation fully and crushed before being fermented, the full fermentation process is ensured, and the fermentation efficiency is improved.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

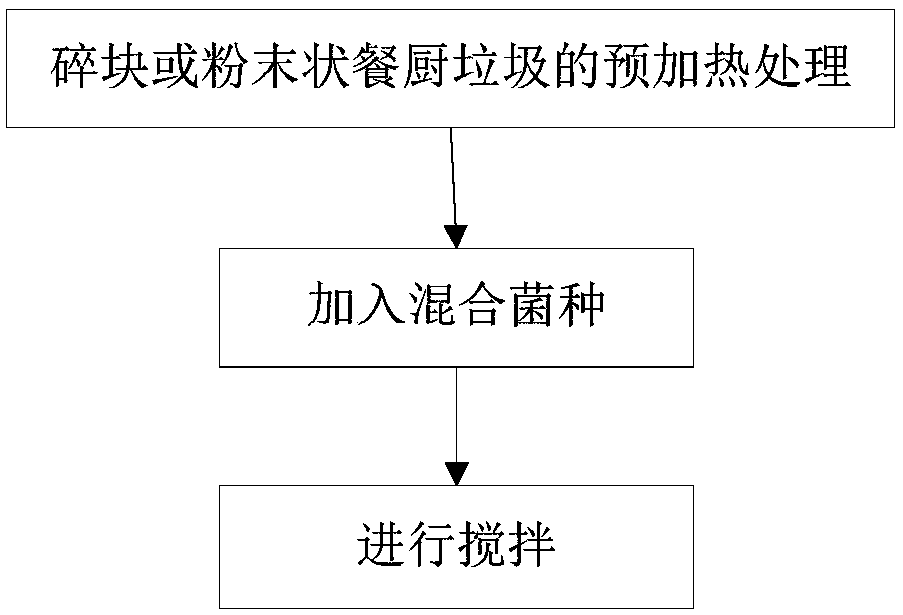

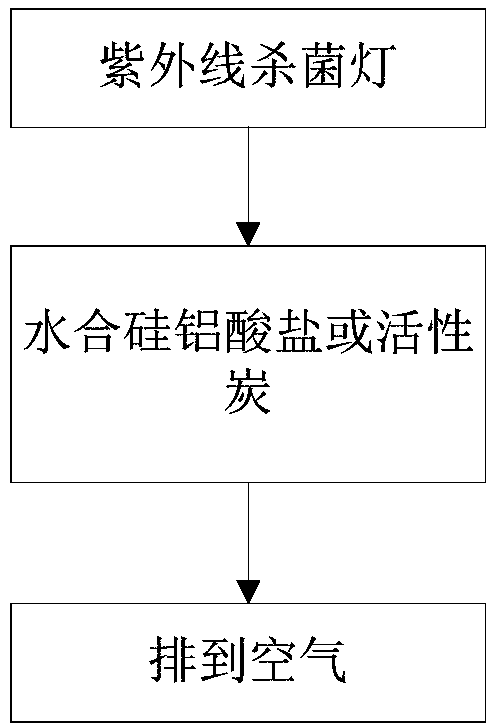

Domestic kitchen waste treatment method

InactiveCN108787704AImprove fermentation efficiencyAvoid odorSolid waste disposalActive carbonActivated carbon

Owner:宁波悦丰新电有限公司

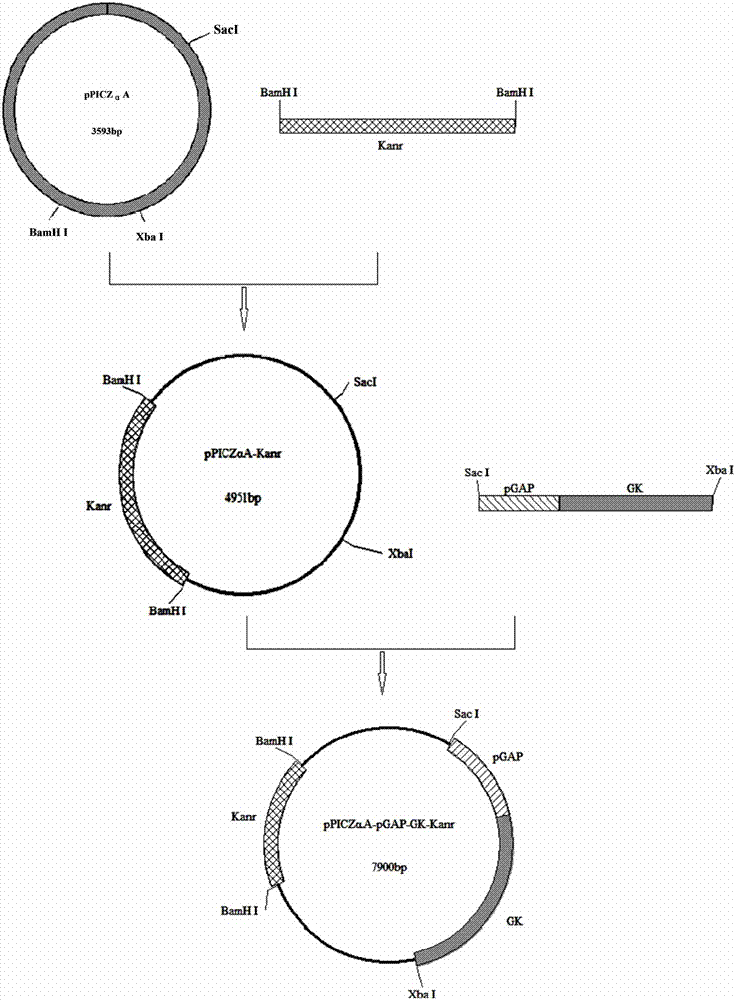

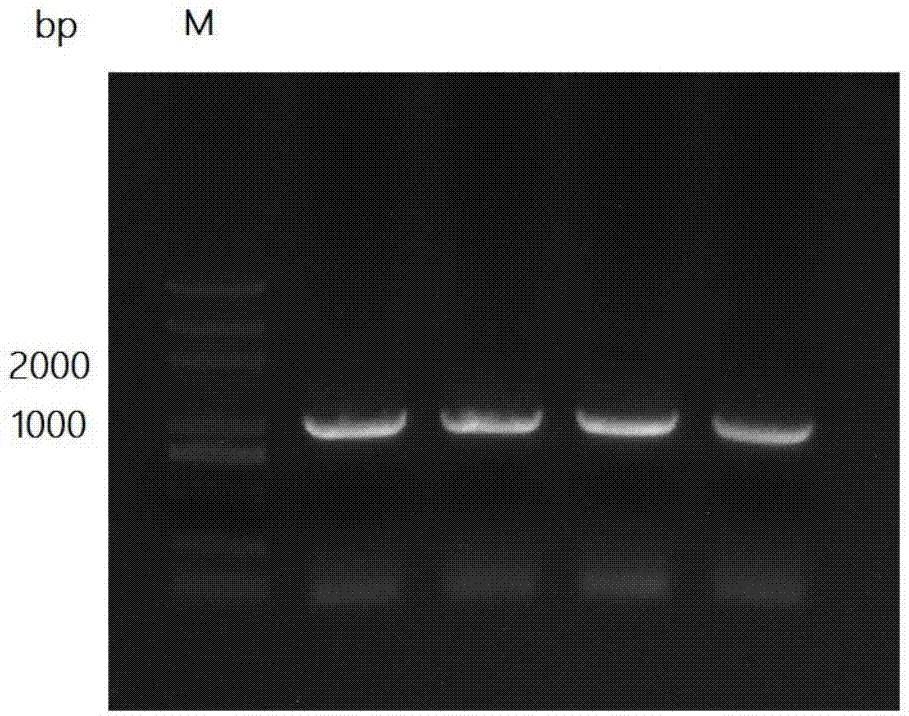

Promoter pYLG and application thereof to construction of Candida tropicalis with high yield of long-chain dicarboxylic acid

ActiveCN107384923AEfficient Glycerin Utilization AbilityImprove fermentation efficiencyFungiTransferasesBiologyDicarboxylic acid

The invention relates to a promoter pYLG and an application thereof to construction of Candida tropicalis with high yield of long-chain dicarboxylic acid. The nucleotide sequence of the promoter pYLG is shown as SEQ ID NO.1. The invention further relates to the application of the promoter pYLG to construction of the Candida tropicalis with high yield of the long-chain dicarboxylic acid. The promoter pYLG capable of controlling expression of Candida tropicalis GK (glycerol kinase) gene in the Candida tropicalis is disclosed for the first time, and the foundation is laid for construction of engineering Candida tropicalis with GK gene regulation capacity.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com