Compost agent for organic fertilizer and preparation method thereof

A technology of organic fertilizer and decomposing agent, applied in the field of organic fertilizer decomposing agent and its preparation, can solve the problems of low efficiency and long processing time, and achieve the effects of reducing fermentation time, ensuring decomposing degree, and improving fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

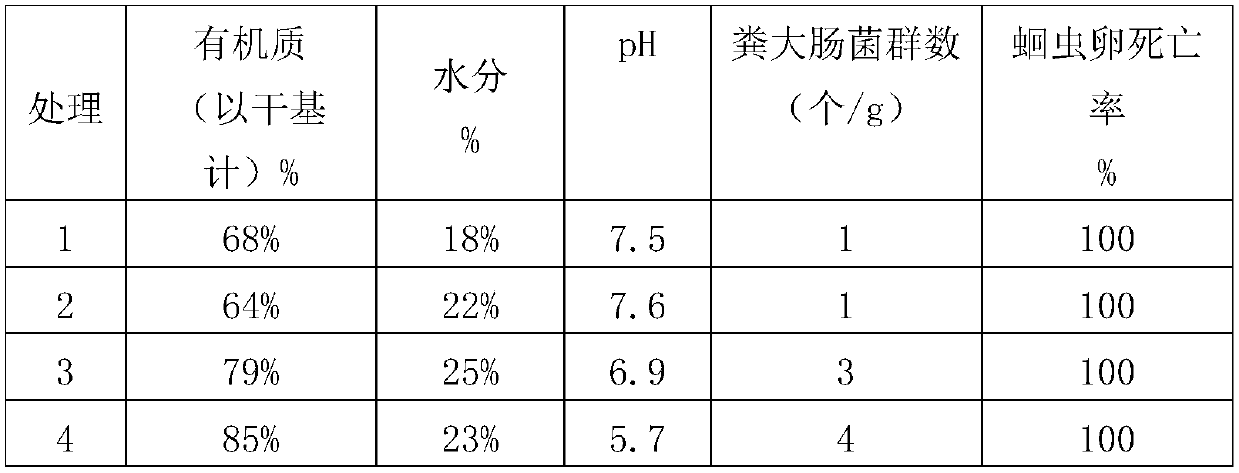

Examples

specific Embodiment 1

[0044] 1) Pretreatment of raw materials: use flue-cured tobacco as raw materials and waste tobacco stems and tobacco dust, the addition amount of each component according to parts by weight is: 50 parts of peat, 50 parts of tobacco stems, and 100 parts of tobacco dust. Tobacco stems and tobacco dust adjust the carbon-to-nitrogen ratio of the raw materials to about 30:1, and then use GaCO 3 Regulate the pH value to 6.5, and the moisture content is adjusted to (weight percent) 50%;

[0045] 2) Mixing: Add an organic fertilizer decomposing agent with a total weight of 3‰ to the above-mentioned pretreated materials, mix the above-mentioned materials evenly, and carry out composting and fermentation in the fermentation workshop;

[0046] 3) Fermentation: During the fermentation process, turn the pile twice a day to meet the oxygen consumption requirements of the bacteria in the fermentation agent. The material produces a fermentation process of heating-high temperature-cooling. Whe...

Embodiment 2

[0049] 1) Pretreatment of raw materials: use flue-cured tobacco as raw materials and waste tobacco stems and tobacco dust, the addition amount of each component according to parts by weight is: 60 parts of peat, 60 parts of tobacco stems, and 80 parts of tobacco dust. The carbon-to-nitrogen ratio of the raw material is adjusted to about 35:1 by the tobacco stem and the tobacco powder, and the pH value is adjusted to 7.5 with GaCO3, and the moisture content is adjusted to (weight percent) 55%;

[0050] 2) Mixing: adding a fermentation agent with a total weight of 5‰ of the material to the above-mentioned pretreated material, mixing the above-mentioned material evenly, and then composting and fermenting in the fermentation workshop;

[0051] 3) Fermentation: During the fermentation process, turn the pile twice a day to meet the oxygen consumption requirements of the bacteria in the fermentation agent. The material produces a fermentation process of heating-high temperature-coolin...

Embodiment 3

[0055] 1) Pretreatment of raw materials: Rapeseed as raw material is used as raw material, and the addition amount of each component according to parts by weight is: 50 parts of peat, 150 parts of rapeseed. The ratio adjustment is about 30:1, and then GaCO3 is used to adjust the pH value to 6.5, and the moisture content is adjusted to (weight percentage) 50%;

[0056] 2) Mixing: Add an organic fertilizer decomposing agent with a total weight of 3‰ to the above-mentioned pretreated materials, mix the above-mentioned materials evenly, and carry out composting and fermentation in the fermentation workshop;

[0057] 3) Fermentation: During the fermentation process, turn the pile twice a day to meet the oxygen consumption requirements of the bacteria in the fermentation agent. The material produces a fermentation process of heating-high temperature-cooling. When a large amount of mycelium is produced in the material, it is non-pungent Odor, when the temperature in the heap drops to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com