Patents

Literature

114results about How to "Guaranteed Maturity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cultivation method for beak-shaped litchis

ActiveCN103651033ASimple stepsIncrease productionCultivating equipmentsHorticulture methodsLychee fruitPolyethylene glycol

The invention provides a cultivation method for beak-shaped litchis. The cultivation method for the beak-shaped litchis comprises the step of harvesting, wherein clusters and 2-3 leaves at the lower section of each cluster are picked; the step of autumn growth promotion, wherein additional nitrogen phosphorus and potassium fertilizer is applied; the step of root irrigation through polyethylene glycol with concentration of 20%; the step of control over winter growth and ringing, wherein ethyl alcohol with concentration of 95% is sprayed to the ringing position, and whitewash with concentration of 2-4% is sprayed to the leaves; the step of flower bud promotion, wherein mixed cytokinin is sprayed one to two times during the germination period; the step of flower thinning and bud thinning, wherein the mixed solution of ethephon and paclobutrazol is sprayed for bud thinning during the squaring period, and the mixed solution of calcium phosphate, glycine and saccharose fatty acid is sprayed for flowing mining during the flower period; the step of stabilizing of fruits, wherein the mixed solution of monopotassium phosphate, 6-benzylaminopurine, naphthylacetic acid, ethylene glycol, cane sugars, borax and ethyl alcohol with concentration of 95% is sprayed during the growth period of the fruits. The cultivation method for the beak-shaped litchis is designed according to the characteristics of the beak-shaped litchis, is simple in step and convenient to operate, saves manpower and material resources, and effectively improves the seedless rate of the fruits, the quality of the fruits of the beak-shaped litchis, and the yield.

Owner:嘉善县魏塘资产管理有限公司

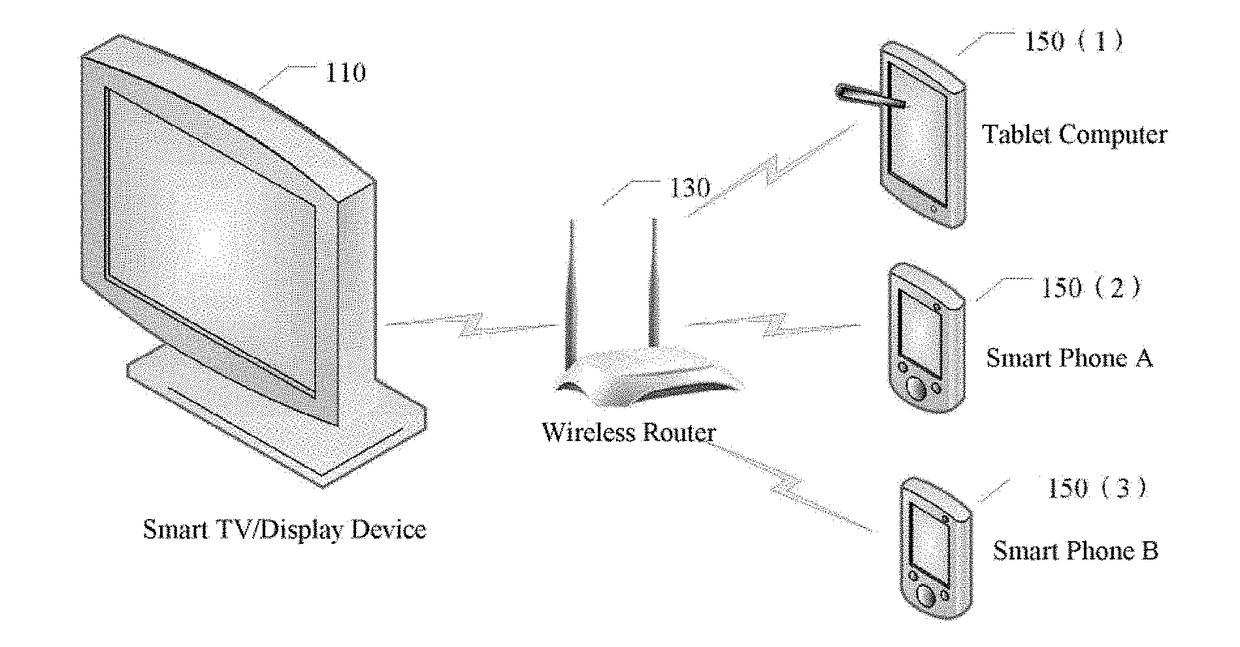

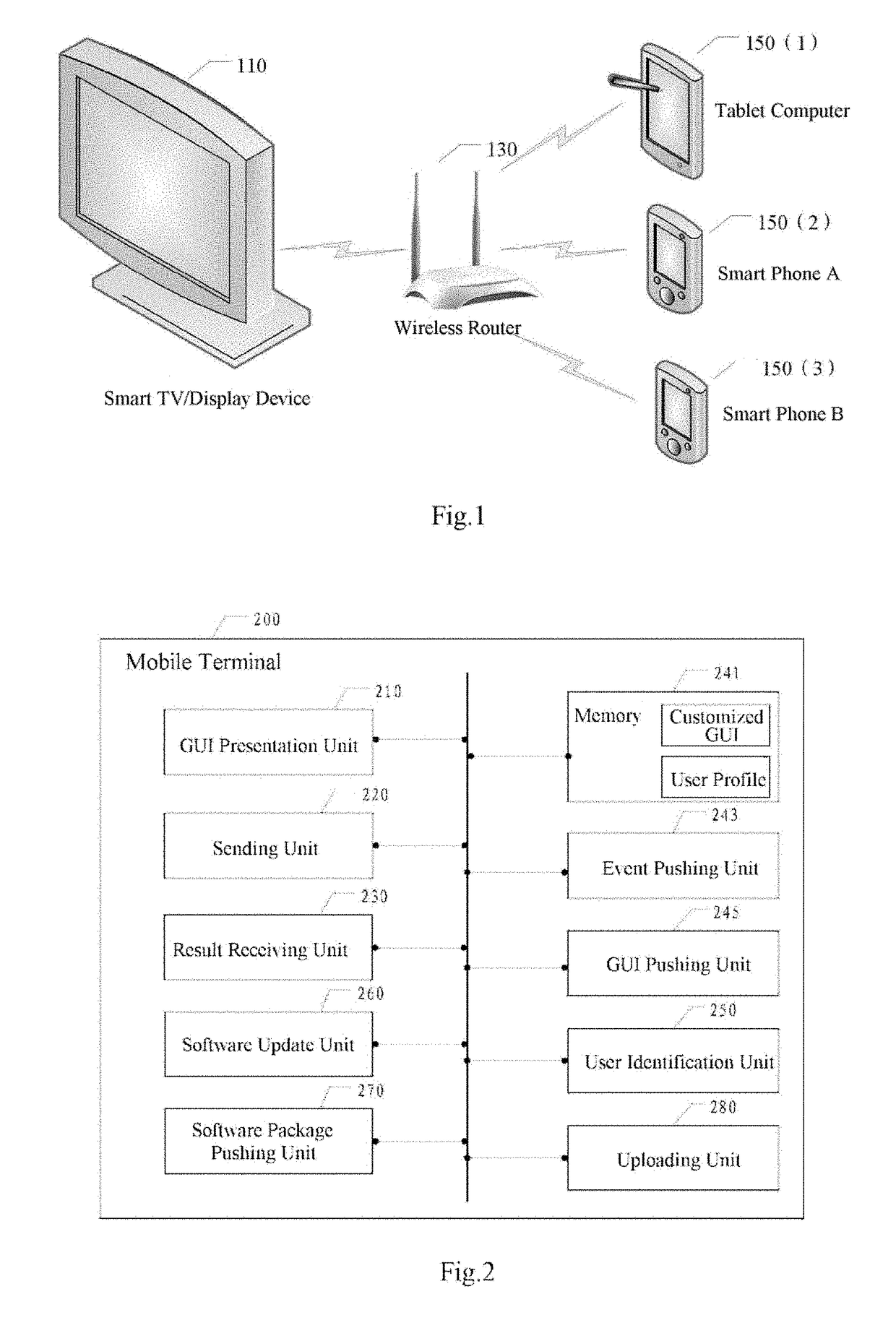

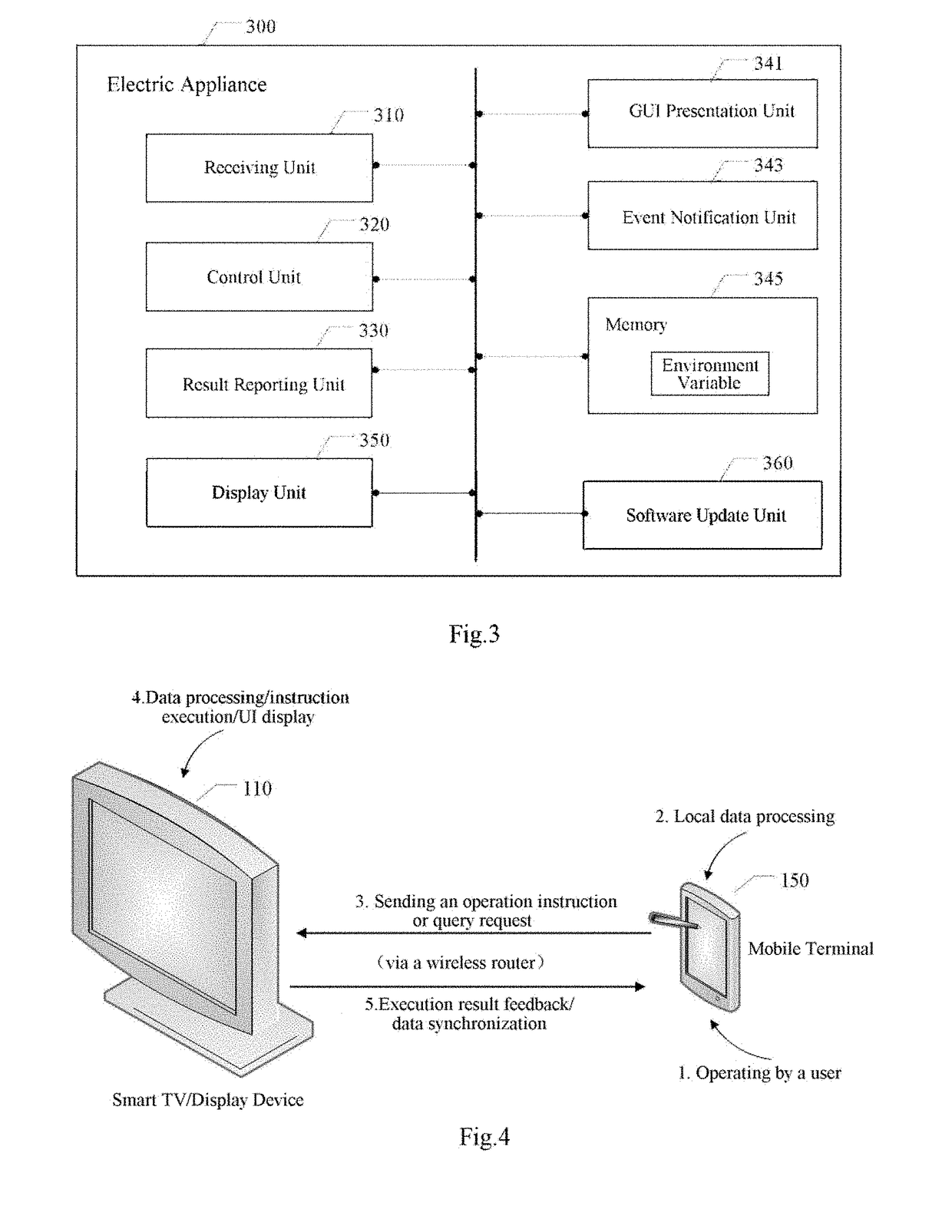

Device, system and method for operating electric appliance by mobile terminal

InactiveUS20180220099A1Easy maintenanceReduce complexityTelevision system detailsColor television detailsTerminal operationControl unit

A system for operating an electric appliance by a mobile terminal is disclosed. The mobile terminal includes a platform-independent GUI presentation unit; a sending unit configured to send, to the electric appliance, an operation instruction and / or query request based on the user interaction input received via a GUI element; and a result receiving unit configured to receive the instruction execution result and / or query result. The electric appliance includes platform-dependent components, including: a receiving unit configured to receive the operation instruction and / or query request; a control unit configured to execute the instruction and / or query; a display unit configured to display contents; and a result report unit configured to report the instruction execution result and / or query result to the mobile terminal. The GUI presentation unit changes at least one GUI element presented, so as to reflect the instruction execution result and / or query result in the GUI.

Owner:BOE TECH GRP CO LTD

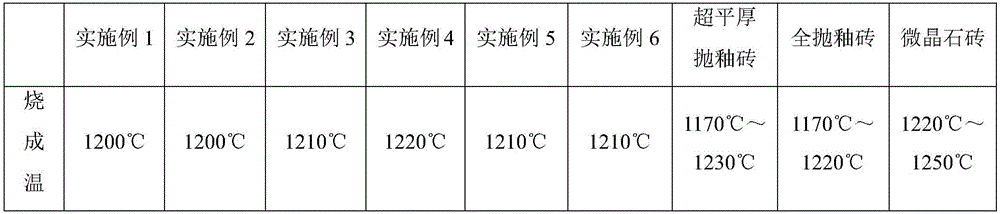

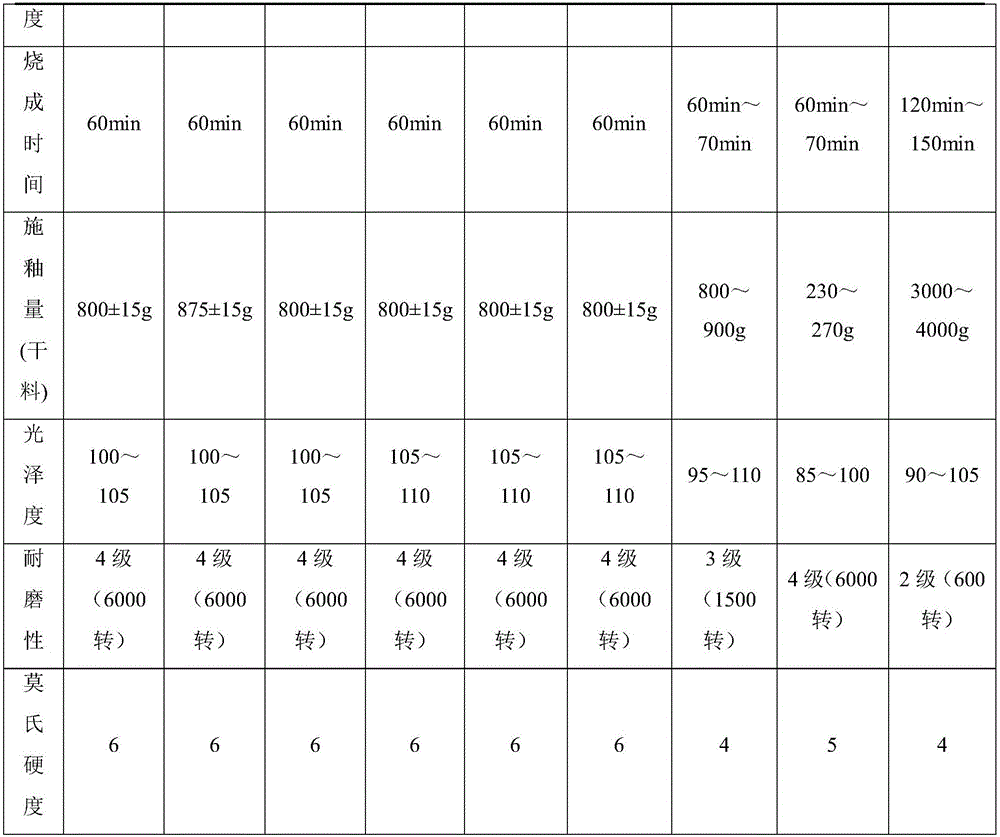

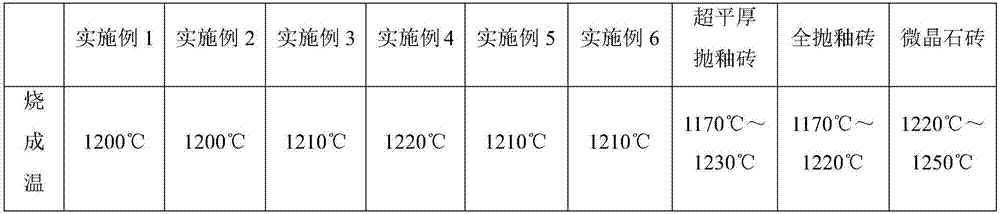

Wear-resistant full-raw material super-flat thick polishing glaze and application thereof

ActiveCN106542735AImproves Mohs hardness and wear resistanceGuaranteed MaturityCeramic glazeEnvironmental resistance

The invention relates to wear-resistant full-raw material super-flat thick polishing glaze and application thereof, and belongs to the technical field of ceramic glaze production and processing. The wear-resistant full-raw material super-flat thick polishing glaze comprises the following components in percentage by mass: 5 to 20 percent of potash feldspar, 25 to 40 percent of soda feldspar, 5 to 10 percent of washed kaolin, 0 to 10 percent of barium carbonate, 0 to 10 percent of strontium carbonate, 5 to 12 percent of zinc oxide, 5 to 10 percent of calcite, 2 to 8 percent of dolomite, 5 to 10 percent of quartz and 8 to 18 percent of white corundum; the specific steps of the application of the wear-resistant full-raw material super-flat thick polishing glaze comprises: applying a layer of engobe on the surface of a green brick, applying wear-resistant full-raw material super-flat thick polishing glaze slurry on the surface of a brick by two times by adopting a linear glaze pouring way or a bell jar glaze pouring way, firing at the temperature of 1160 to 1230 DEG C, then polishing and waxing to obtain a finished brick. According to the full-raw material super-flat thick polishing glaze provided by the invention, on the basis of ensuring the glaze layer thickness, the formula is regulated, and full raw materials adopting meets the requirements of green and environment protection; not only is the phenomenon of water ripple solved, but also the hardness and the wear resistance of the super-flat thick polishing glaze are greatly improved.

Owner:佛山市三水大岛制釉有限公司

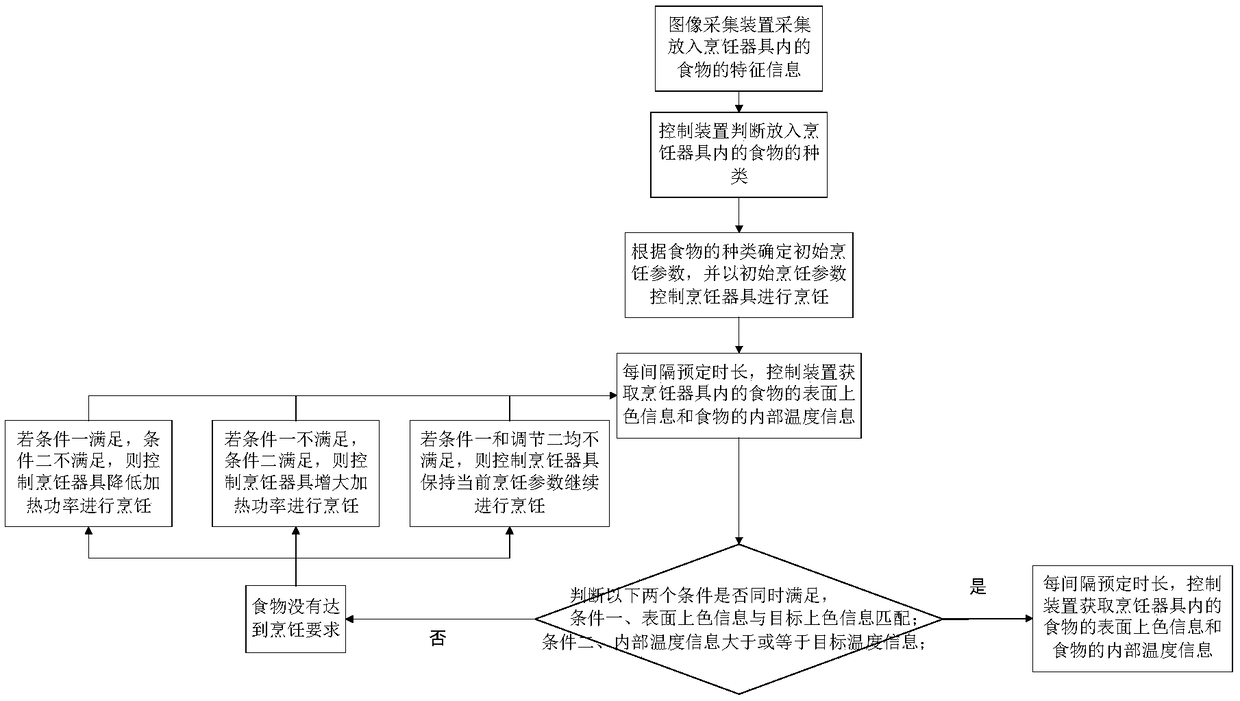

Cooking utensil controlling method and cooking utensil

ActiveCN109445485AGuaranteed MaturityImprove experienceTemperatue controlMicrowave heatingProcess engineeringCooking process

The invention provides a cooking utensil controlling method and a cooking utensil. The cooking utensil includes a control device; and the control device can adjust the cooking parameters of the cooking utensil according to the surface coloring information and internal temperature information of food in the cooking utensil. The controlling method can simultaneously consider the surface coloring information and internal temperature information of the food, so that the ripeness of the food can be judged from multiple aspects, and therefore, adjustment can be performed on the cooking parameters ofthe food, the food can have excellent coloring effects while being guaranteed to be ripe, automatic dynamic adjustment during cooking can be realized, and user experience can be enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

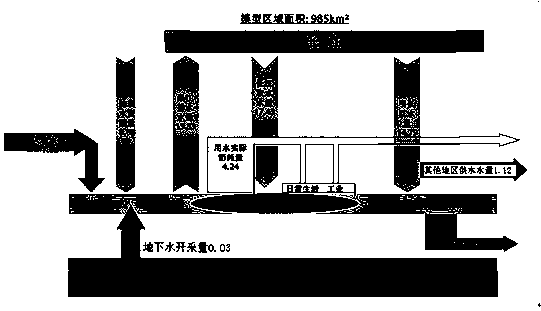

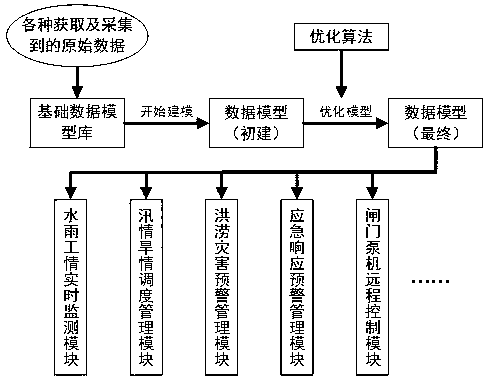

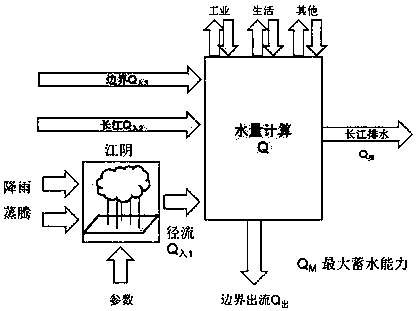

Intelligent scheduling decision-making method for flood and drought control based on extreme climate condition

ActiveCN107657329AGuaranteed to be scientificGuaranteed accuracyClimate change adaptationForecastingDecision schemeOriginal data

The invention discloses an intelligent scheduling decision-making method for flood and drought control based on extreme climate conditions. The intelligent scheduling decision-making method is used inriverside areas and comprises the steps of: step 1) acquiring and collecting various kinds of original data; step 2) preliminarily establishing a virtual reservoir model; step 3) optimizing the virtual reservoir model; step 4) and utilizing a final data model obtained in the step 3) to output various kinds of data to sub-functional modules, thereby achieving the intelligent scheduling decision-making purpose for flood and drought control in the riverside areas under extreme climate conditions. The intelligent scheduling decision-making method can ensure scientificity, precision and reliability of the data, achieves the effects expert early-warning support and decision scheme analysis, can timely respond to the sudden rainstorm process, and immediately starts up a pumping station drainage,not only reduces the water accumulating volume, but also greatly reduce the full-load working process of the pumping station, saves energy and reduces emission, effectively improves the early-warningand handling capacity of flood and drought control in the riverside areas, promotes the improvement of integral level of water resource scheduling management, and has extremely high practicability.

Owner:江苏鸿利智能科技股份有限公司

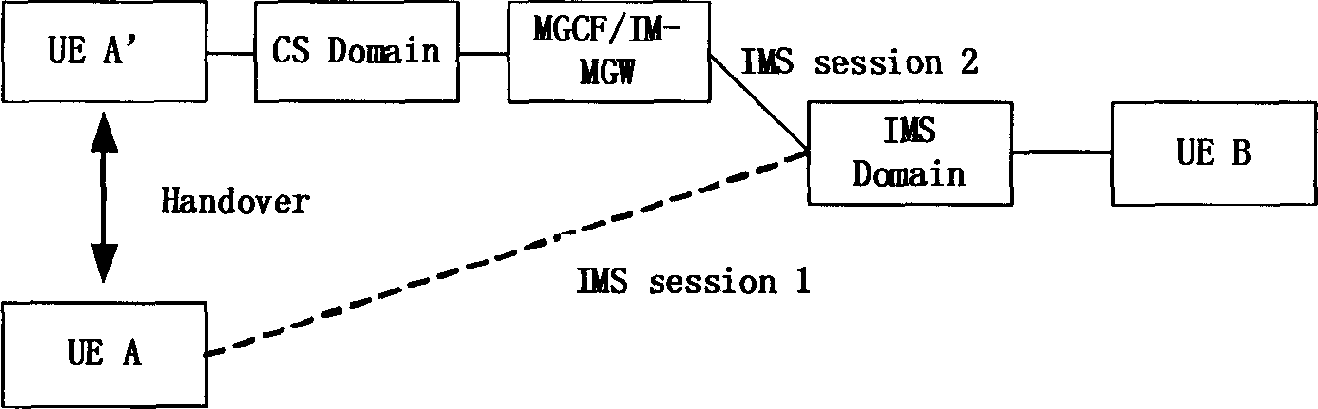

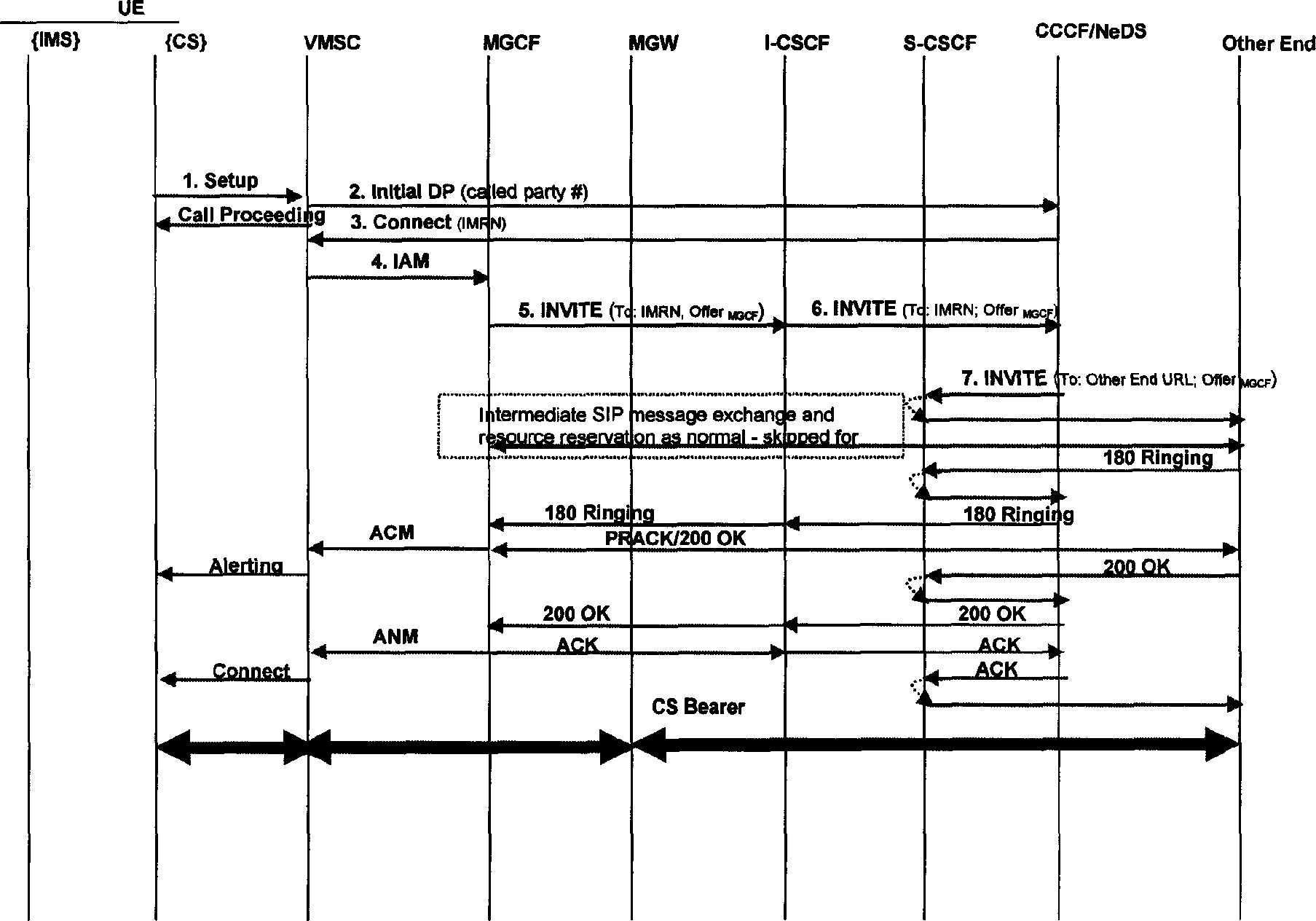

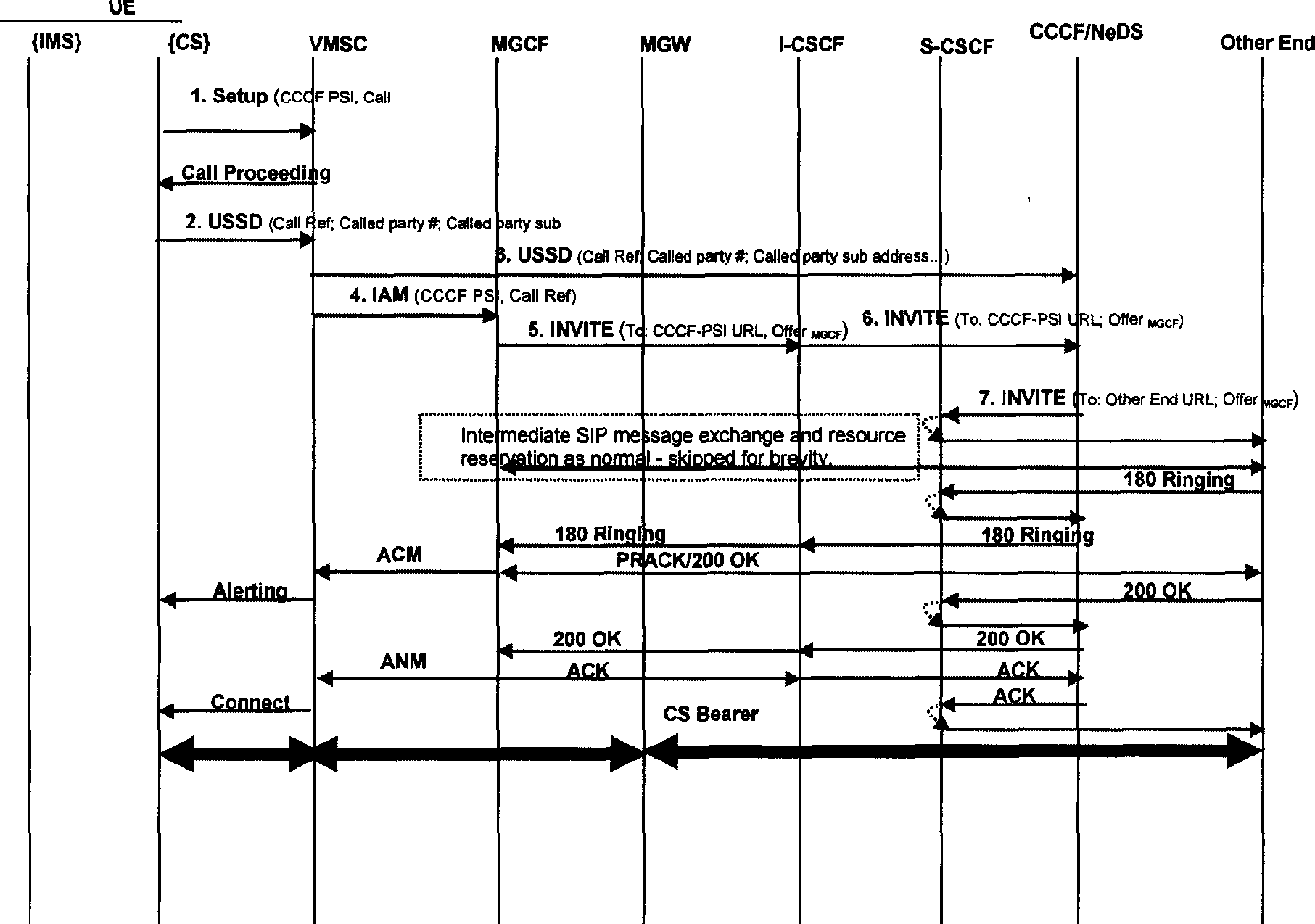

Method and system for building initial call in continuity service of voice service

InactiveCN1802022AGuaranteed MaturityAvoid failureRadio/inductive link selection arrangementsNetwork connectionsElectricityApplication server

Present invention relates to a method and system for establishing calling in continuance voice service. It contains user terminal notifying registration state of application server in circuit domain, application server determining user terminal mode according to user terminal current registered circuit domain network supported route control pattern information, notifying user terminal, when said user terminal originating circuit domain calling, originating calling according to notified originating calling mode. Said invention can maximized utilize dialing side circuit domain CAMEL proceeding initial call establishment and anchoring calling in gsmSCF with CCCF function utilizing USSD Notify / Prefix scheme as CAMEL supply, avoiding calling static anchoring failing due to dialing side circuit CAMEL scarce capacity.

Owner:HUAWEI TECH CO LTD

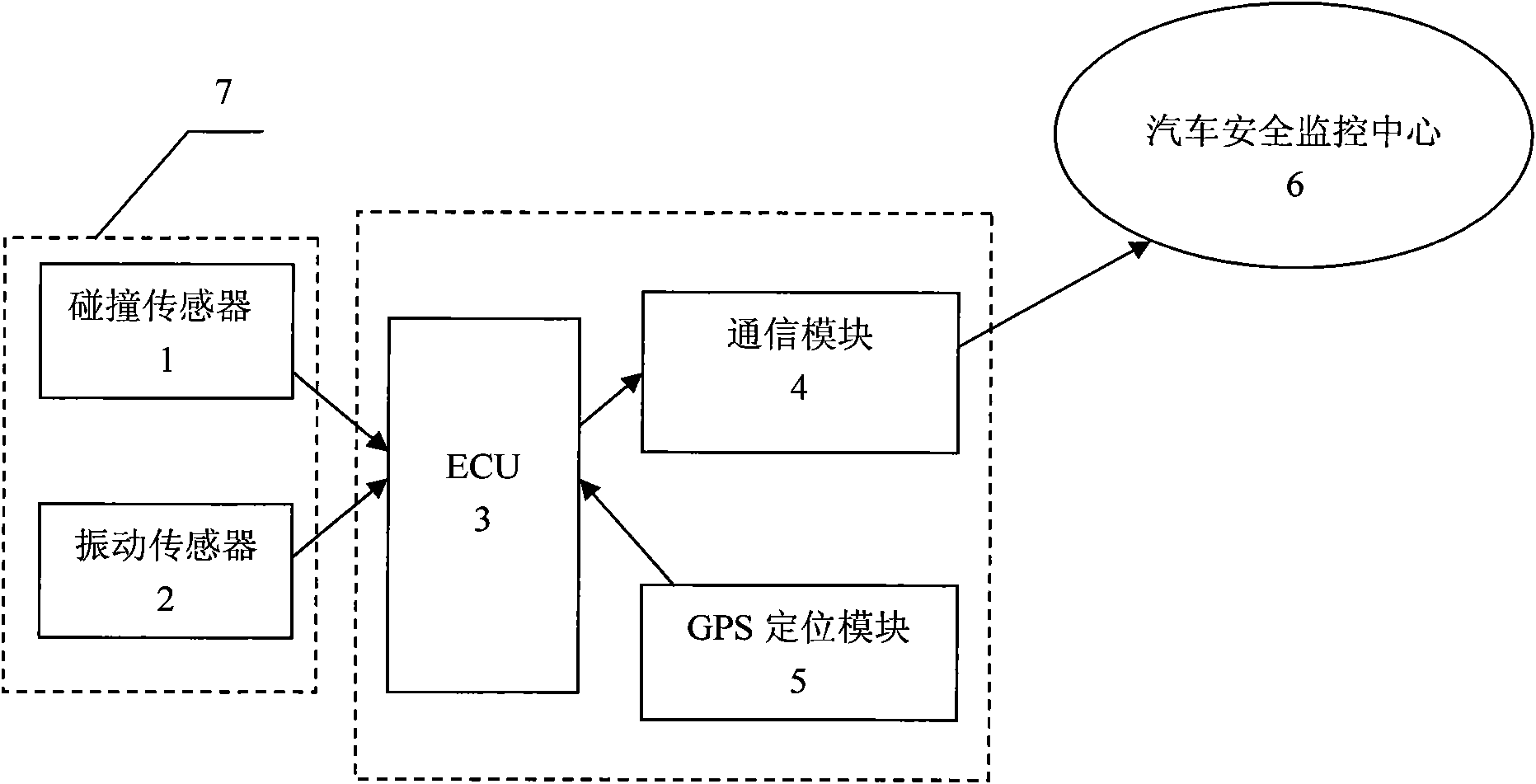

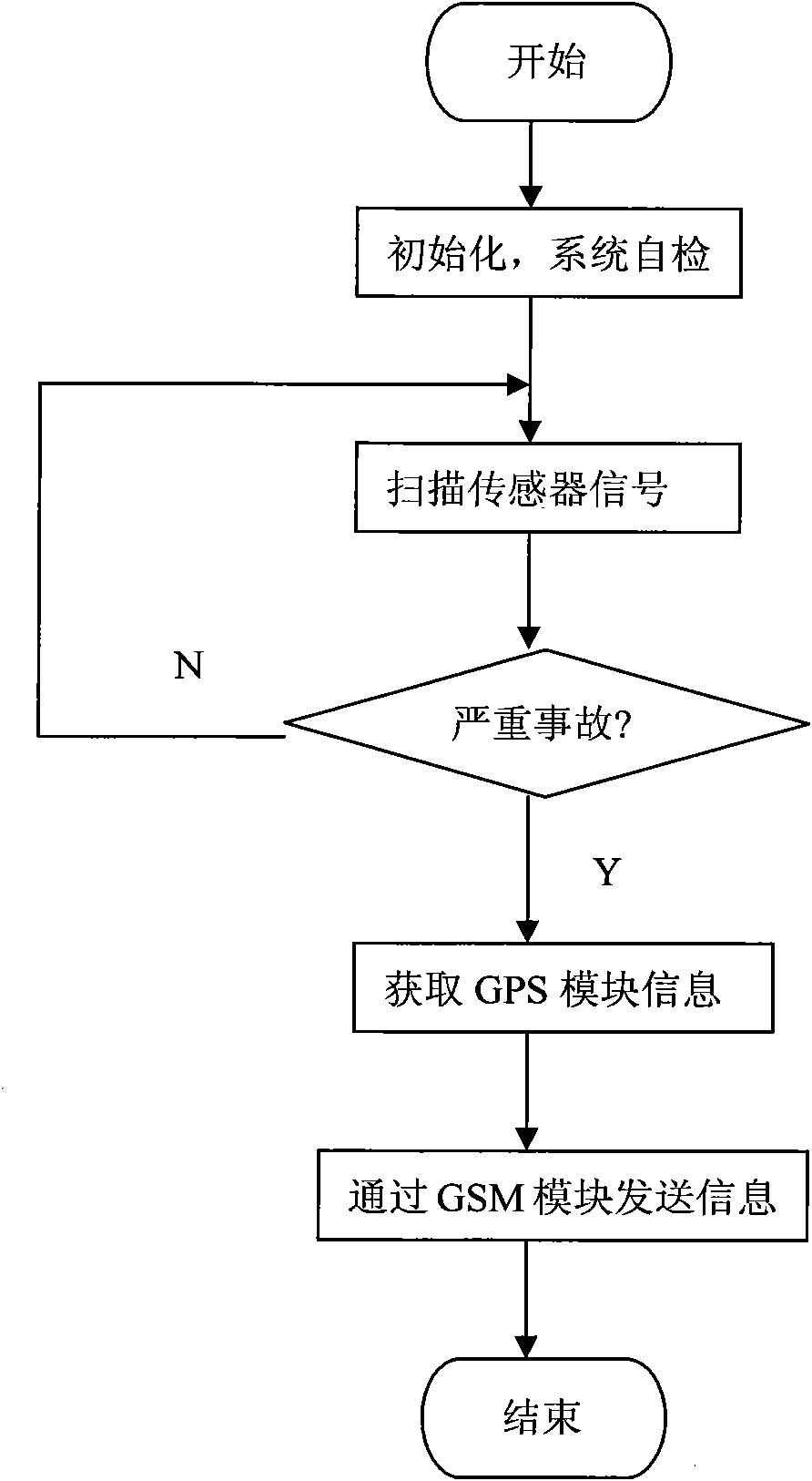

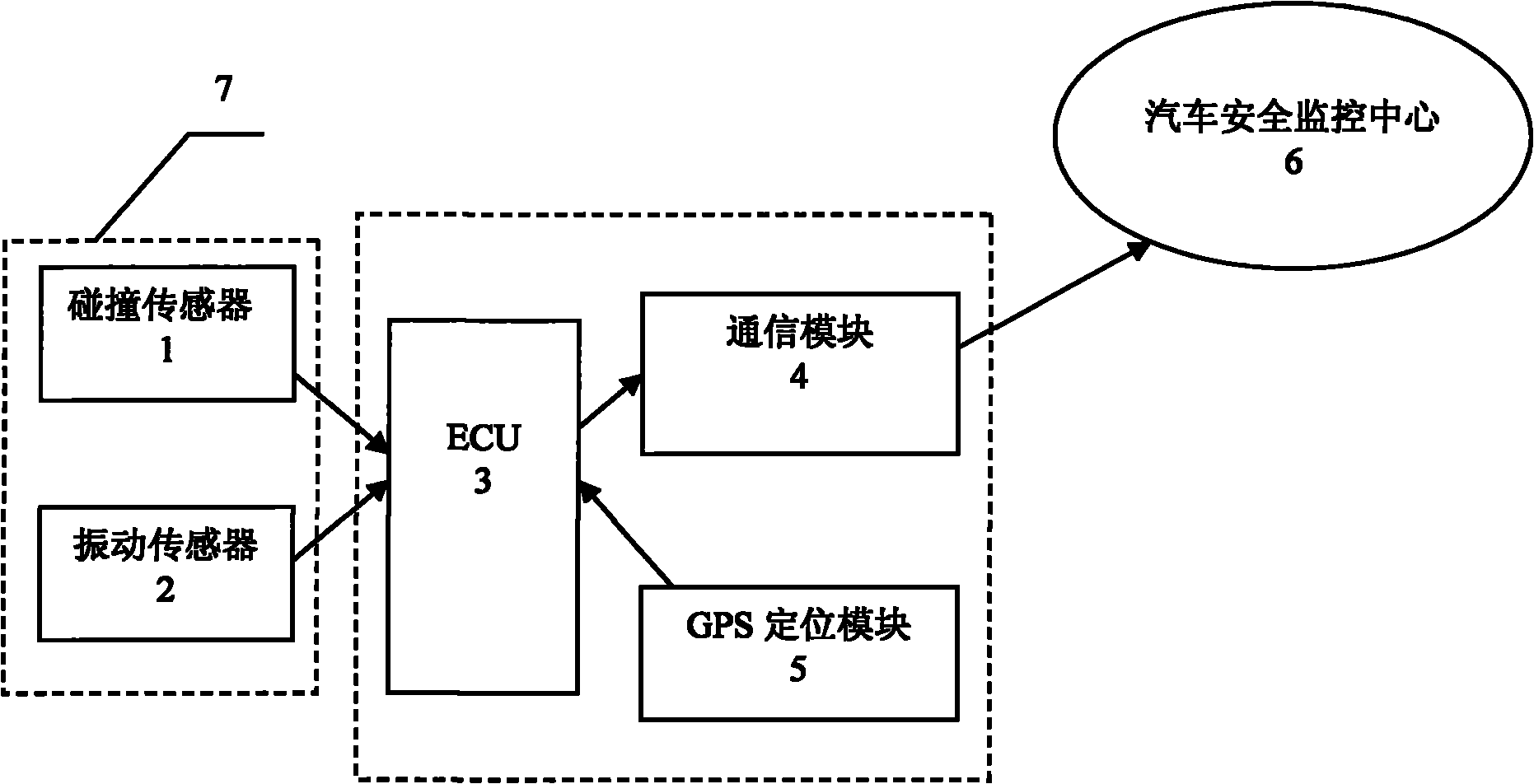

Automatic positioning and emergency processing method of automobile safety accident and device

InactiveCN102314751AGuaranteed reliabilityClear structurePedestrian/occupant safety arrangementAlarmsComputer moduleDynamic positioning

The invention relates to an automatic positioning and emergency processing device of an automobile safety accident, which comprises a detection module, an electronic control unit (ECU), a communication module, a global positioning system (GPS) positioning module and an automobile safety monitoring center, wherein the ECU is respectively connected with the detection module, the communication module and the GPS positioning module, the communication module is connected with the automobile safety monitoring center, and the device also comprises processing methods such as automobile opening, initiation of the device, a self-detecting module detects whether the device works normally and the like. Compared with the prior art, the device has the advantages of clear structure, low cost, high working efficiency, mature and stable system, and the like.

Owner:SHANGHAI UNIV OF ENG SCI

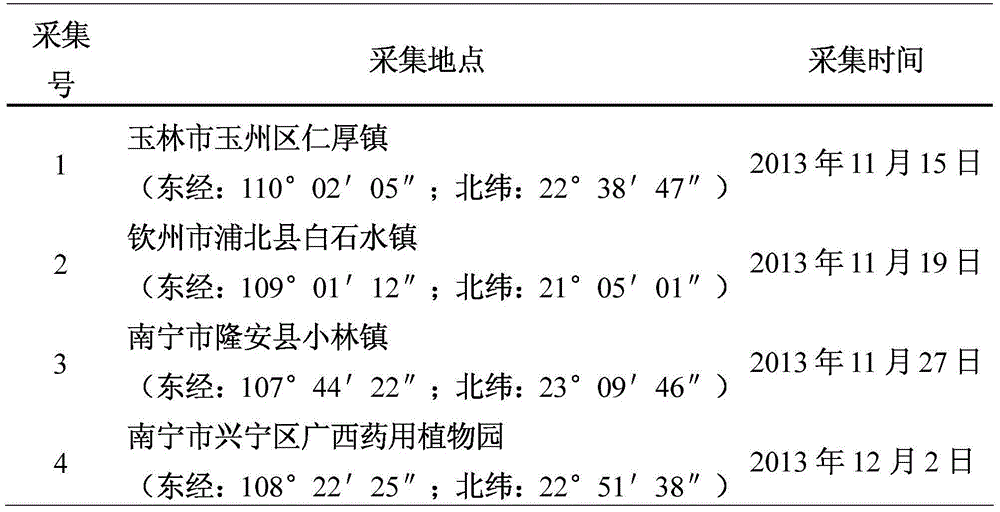

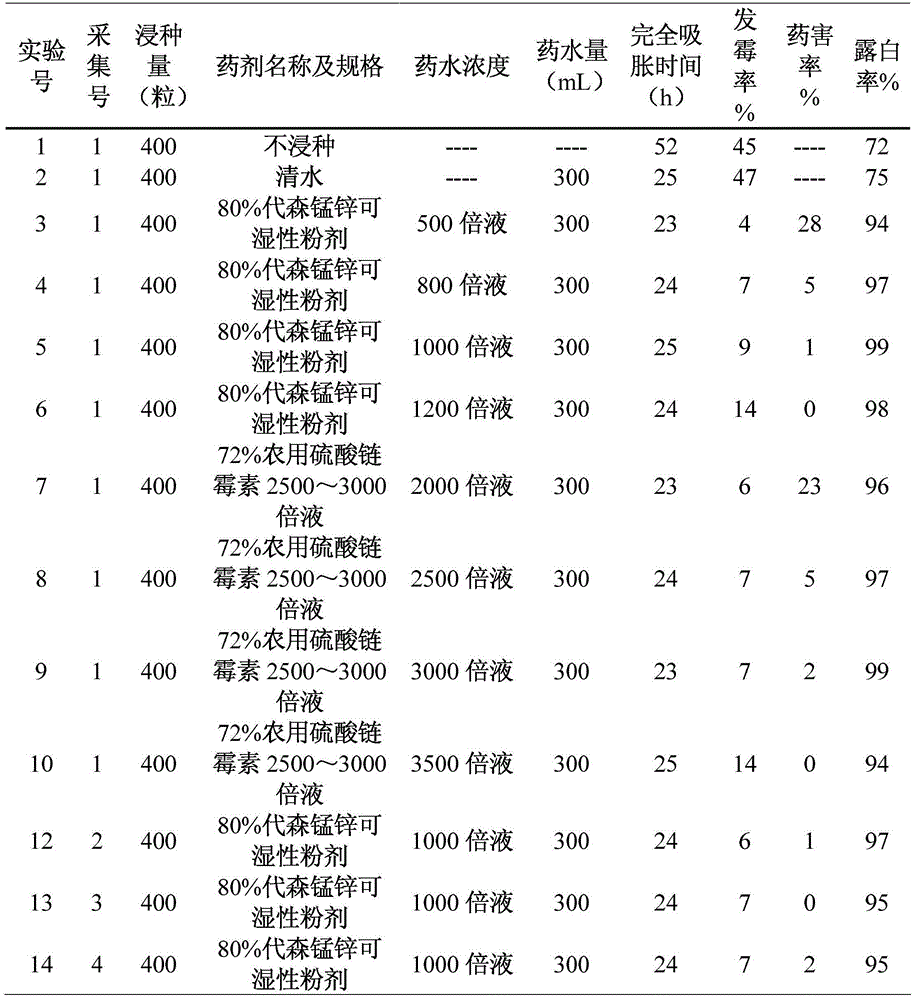

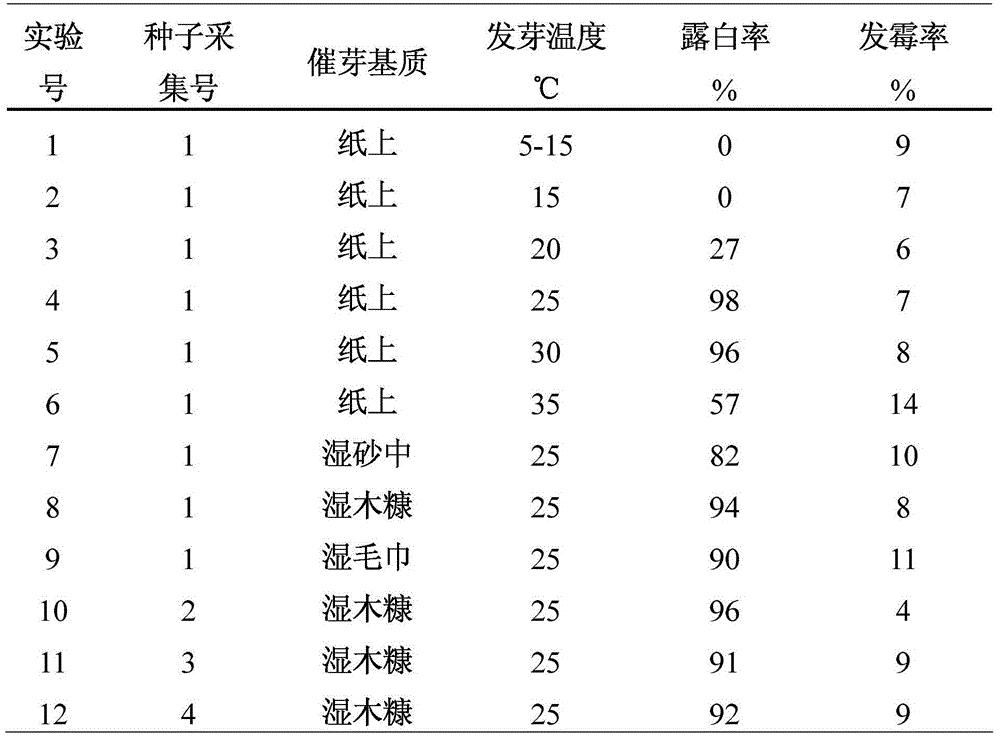

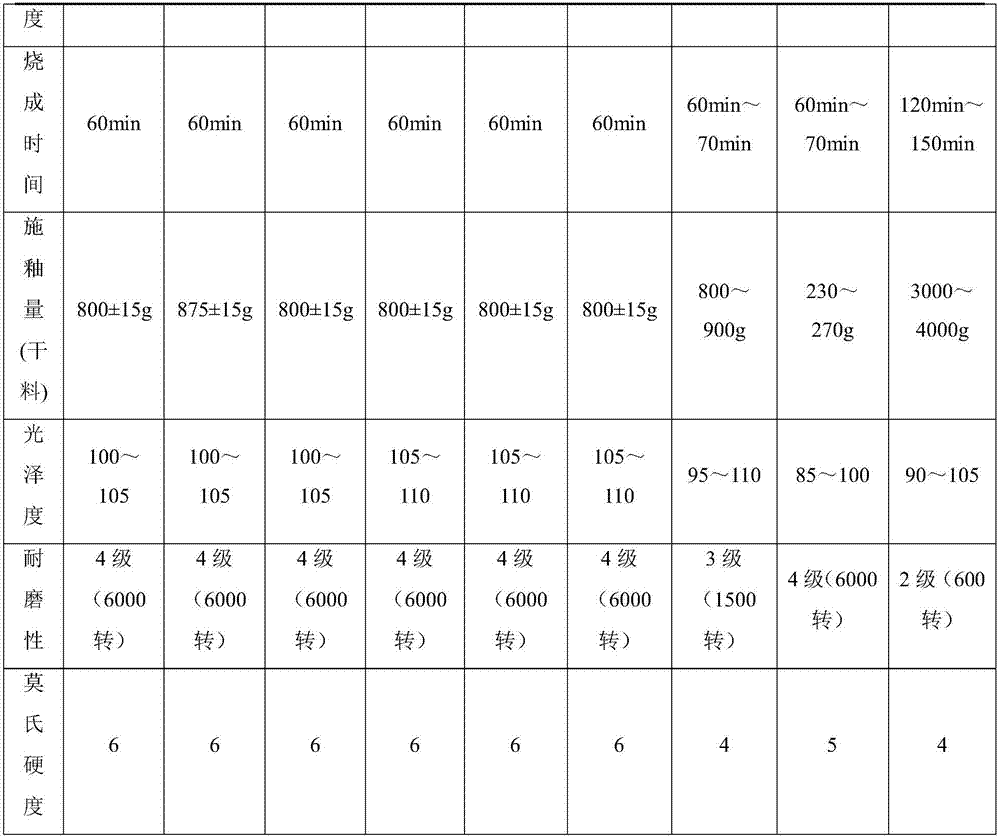

Method for accelerating germination and growing seedlings of millettia specisoa champ seeds in winter

InactiveCN104472063APrevent seed mildewPromote germinationCultivating equipmentsSoilless cultivationWater contentGermination

The invention provides a method for accelerating germination and growing seedlings of millettia specisoa champ seeds in winter. The method comprises the following steps: step 1, mixing the millettia specisoa champ seeds with a sprouting substrate according to a weight ratio of 1: (3-8), placing the mixture into an illumination incubator for 5-15 days, keeping the temperature in the illumination incubator at 25-30 DEG C, maintaining the moisture content of the sprouting substrate at 75-80%, wherein the sprouting substrate comprises 100 parts of China fir sawdust; step 2, burying the millettia specisoa champ seeds obtained in the step 1 into a seedling substrate in a greenhouse, keeping the air humidity in the greenhouse at 85-90 DEG C, and keeping the temperature in the greenhouse to be not higher than 30 DEG C, wherein the seedling substrate comprises garden soil and thoroughly decomposed sawdust according to a weight ratio of (1.5-2.5):1. The method disclosed by the invention increases the germination rate of the millettia specisoa champ seeds in winter from 0 to 90% above, increases the percentage of seedling emergency from 0 to 85% above, and compared with time of the conventional seedling growth in spring, the time is shortened by 2-3 months.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Processing method of curled golden camellia

The invention discloses a processing method of curled golden camellia. The processing method comprises the following technological steps: (1) preparation of materials; (2) pre-freezing and shaping of fresh flowers; (3) vacuum freeze-drying; and (4) dehydration, deactivation and flavoring. According to the method, fine parameter control is implemented during the vacuum freeze-drying process, the rate of finished products is high and the operation is simple. The curled golden camellia produced by the method disclosed by the invention has the advantage of retaining the shape and color of fresh flower type golden camellia; the soaking method is simplified; the caffeine is extremely high in water solubility; the flavor comes out rapidly; the curled golden camellia is full of heavy golden camellia flavor and green grass flavor and is free of bitter taste; total nutrients of the flowers are retained as far as possible, so the curled golden camellia is higher in health care value and the economic efficiency of the golden camellia flowers is remarkably improved.

Owner:广西国茗金花茶科技有限公司

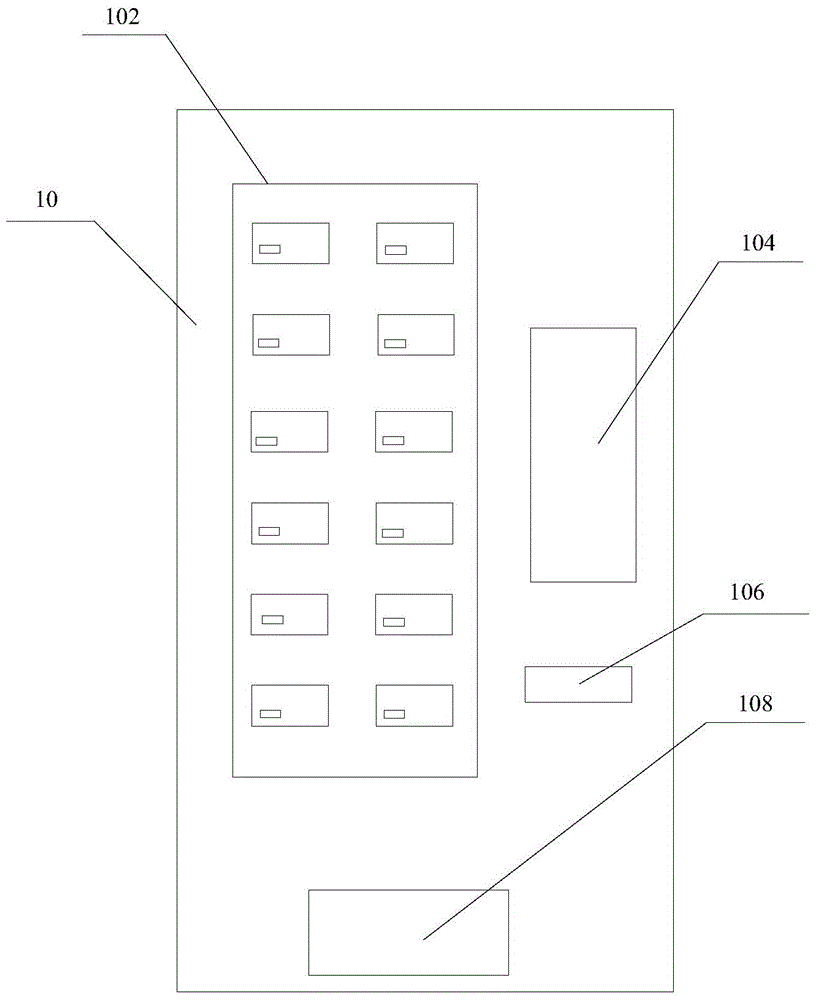

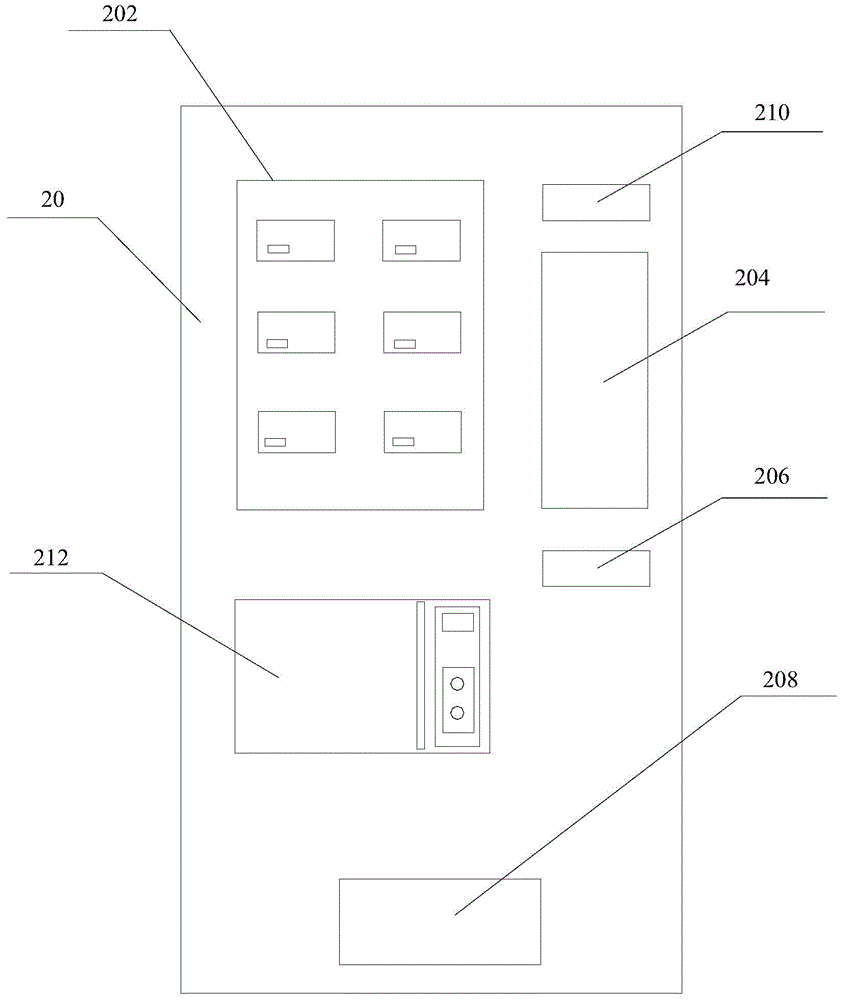

Automatic food heating and vending machine

InactiveCN104637168AQuick and direct accessImprove experienceCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringHeating system

The invention provides an automatic food heating and vending machine comprising an automatic food heating and vending machine body and a food heating system, wherein the food heating system is built in the automatic food heating and vending machine body and is used for automatically heating food. By means of the technical scheme of the invention, no matter a consumer purchases food in any form, the food can be automatically heated, moreover, the operation is simpler and safer, and the heated food can be obtained more quickly and directly, thereby improving the consumer experience and reducing the heat preservation energy consumption at the same time.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

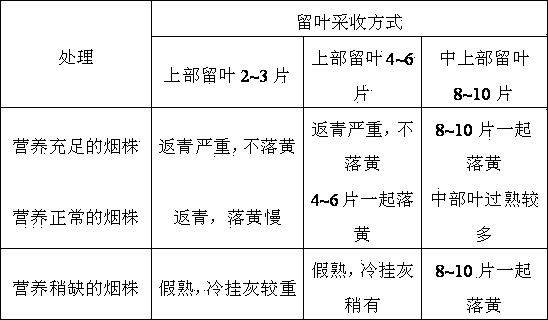

Method for planting tobacco leaves of flue-cured tobacco

ActiveCN104885771AGuaranteed Finish GradeGuaranteed MaturityPlant cultivationCultivating equipmentsGrowth plantSufficient time

Disclosed is a method for planting tobacco leaves of flue-cured tobacco. The method comprises the following steps that after tobacco plants grow to form buds, inflorescences of the buds are shielded through a shading material; after the buds are shielded, a bud removal period is set, and the buds are removed in a picking mode step by step from bottom to top and from exterior to interior; after the buds are shielded, an upper tobacco leaf removal period is set, and tobacco leaves with the length smaller than 15cm are removed in a picking mode step by step; in the last stage of the bud removal period, the shading material is removed, and flowers at the top ends of the tobacco plants are reserved. Different topping means are provided according to features of plant growth, nutrients can guarantee maturity of tobacco leaves in the middle through restraint of maturity of the buds, and it is believed that when a bud opening period is prolonged, the sufficient time is provided for maturity of tobacco leaves on the upper portion; meanwhile, stimulation of growth factors in the process of damage on the apical dominance is reduced to the maximum extent, and generation of nicotine is avoided; the yield is kept, and the finished product grade of the tobacco leaves is guaranteed.

Owner:山东金田生物科技有限公司

Oily sunflower planting method and application thereof in early rice-oily sunflower-rape triple-cropping system

InactiveCN106941919ATake advantage ofSolve the problems of surplus accumulated temperature, low land utilization rate and low outputFertilising methodsAgriculture gas emission reductionBuddingCropping system

The invention relates to an oily sunflower planting method and application thereof in an early rice-oily sunflower-rape triple-cropping system. The oily sunflower planting method comprises the following steps: (1) selecting an improved variety, carrying out plowing, carrying out basal dressing, carrying out furrowing and compartment dividing, and carrying out pitting; (2) carrying out seed manure applying, carrying out sowing, and carrying out irrigation; and (3) carrying out field management and harvesting: carrying out resowing or replanting, and carrying out water drenching; carrying out final thinning, carrying out intertillage weeding, and covering compartment faces of oily sunflowers with rice straws; carrying out topdressing prior to budding of the oily sunflowers; carrying out moisture management after the budding of the oily sunflowers; carrying out disease and insect pest control; carrying out pollination or fertilization; and carrying out harvesting. The oily sunflower planting method disclosed by the invention can be applied to the early rice-oily sunflower-rape triple-cropping system. The oily sunflower planting method disclosed by the invention is high in oily sunflower yield, light in crop disease, insect and weed damage, low in chemical fertilizer consumption and low in cost, can be used for fertilizing soil fertility, improving soil and protecting cultivated land productivity, is water-saving and can be applied to early rice-oily sunflower-rape triple-cropping system planting. According to the application disclosed by the invention, through reasonably matching early rice-oily sunflower-rape varieties, the link-up of oily sunflower-rape crops for rotation is improved, and grain-oil double good harvest, i.e., 500kg of grains per mu and 200kg of oil per mu is achieved.

Owner:湖南省作物研究所

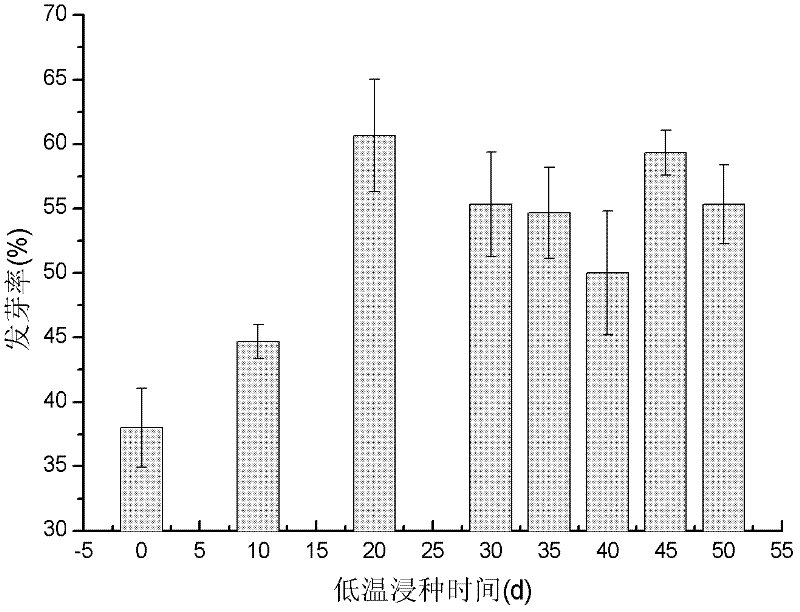

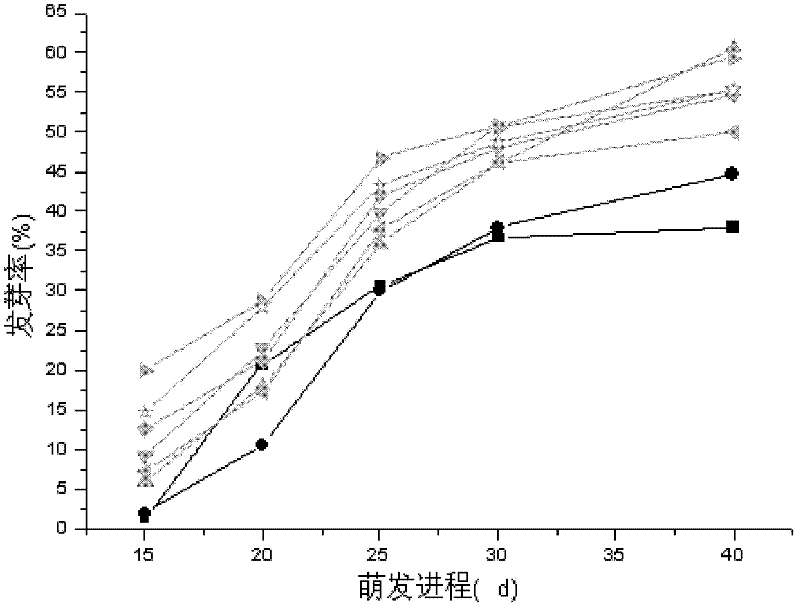

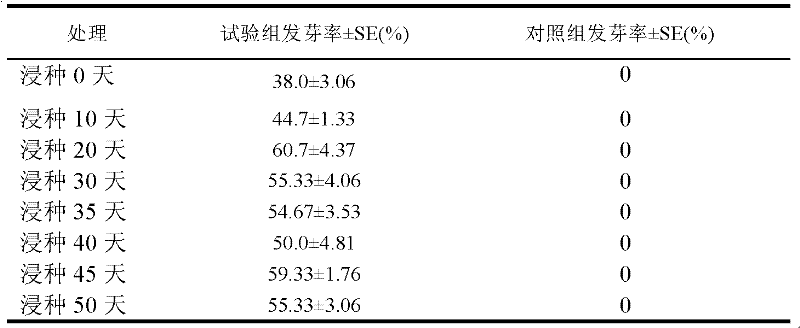

Method for promoting sprouting of Carex limosa seeds

The invention relates to a method for promoting sprouting of Carex limosa seeds, which relates to the technical field of plant seed sprouting, and aims at solving the problem that the sprouting by adopting the present Carex limosa seed sprouting method is low, and comprises the following steps that: A, collecting and selecting seeds; B, processing the seeds; C, germinating. The method has advantages that: A, automatic collection can guarantee the maturity of t he Carex limosa seeds; B, a water selecting method is adopted to select the seeds, so the quality and the activity of the mature seeds of the Carex limosa can be guaranteed; C, due to the adoption of the sterilization, the mature Carex limosa seeds can be prevented from being moldy; and D, by adopting the technology combining the low-temperature seed soaking and variable-temperature culture, the sprouting speed and the germinating rate of the mature Carex limosa seeds can be improved, and the germinating rate can be improved to 50 percent to 61 percent. The method is applied to the field for promoting the sprouting of Carex limosa seeds in marshes.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

High-altitude dry-farmed horsebean cultivation method

InactiveCN102948318AStrong nitrogen fixationIncrease available nitrogenSeed and root treatmentPlant protective coveringsSheet mulchingEconomic benefits

The invention discloses a high-altitude dry-farmed horsebean cultivation method, which relates to an all-film double-ridge furrow drilling technique applied to dry farming areas at the altitude of 2000m to 2500m and belongs to the technical field of horsebean cultivation. The high-altitude dry-farmed horsebean cultivation method which is a horsebean cultivation technique is characterized in that from mid-to-late October to the days before soil freezes up or in the early spring of the next year, an all-film double-ridge furrow drill is adopted to cover the whole ground with films, and after germination is accelerated, horsebean seeds are sowed into the soil under the temperature of 2 DEG C to 8 DEG C; and in the mid-to-late April of the next year, according to the planting depth of 5cm to 6cm and the plant spacing of 18cm to 23cm, seedlings are planted in the middle lower parts of the sunny sides of small and large ridges. The high-altitude dry-farmed horsebean cultivation method has the advantages that the large and small ridges are completely covered by the mulching films, so that moisture supply is guaranteed in the growth period of horsebeans; the ground temperature is increased, the effective accumulated temperature is increased, the growth period of horsebeans is prolonged, the potential of horsebean production can be exerted, and the maturity of horsebeans is guaranteed; and moreover, the economic benefit is remarkable.

Owner:李小玲

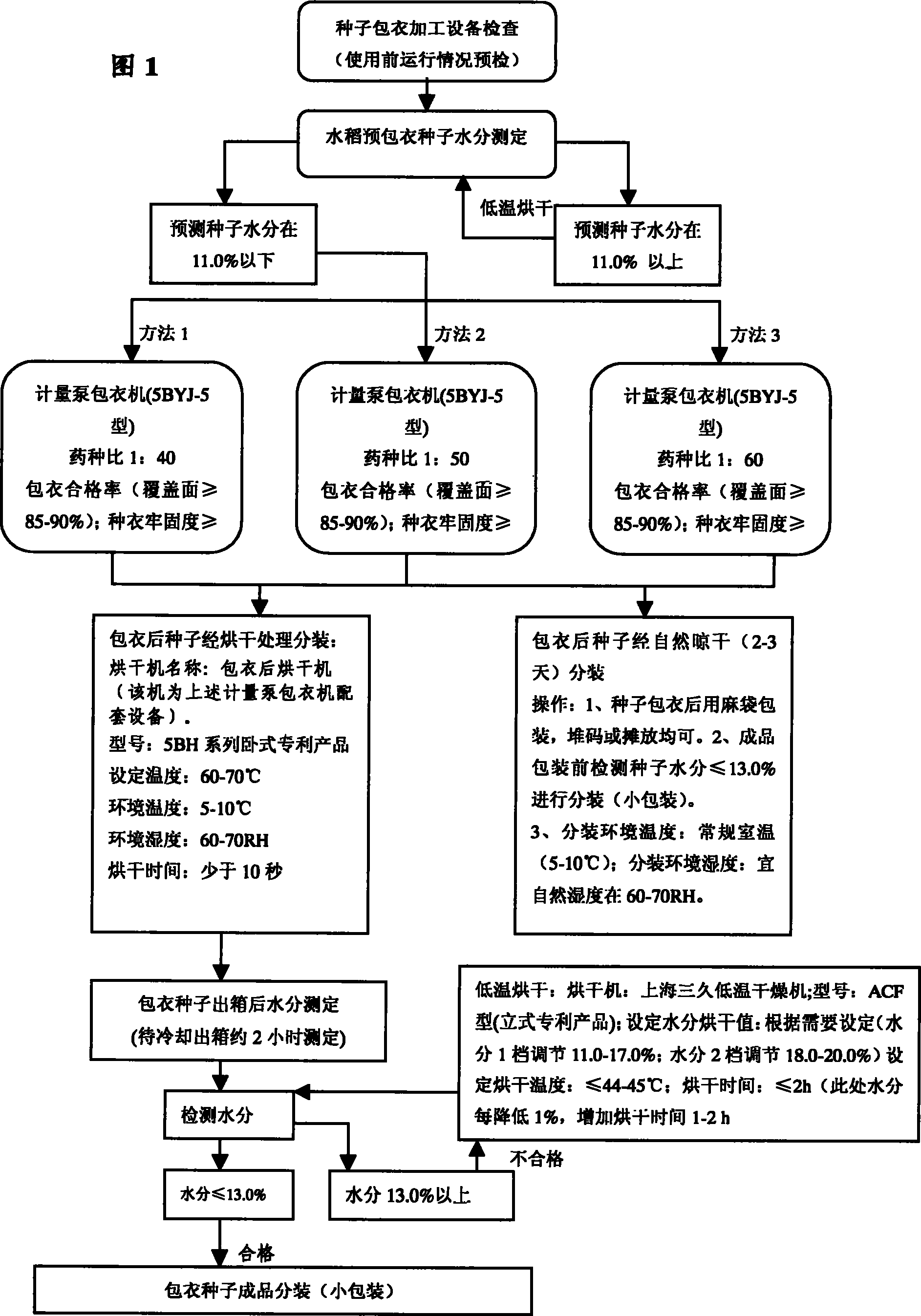

Hybrid rice seed coating agents and method

The present invention is one kind of seed coating agent and its coating process. The hybrid rice seed coating agent consists of the following active components: carbendazim 7-8 weight portions, thiram 7-8 weight portions,paclobutrazol 0.15-1.3 weight portions and prochloraz 0.3-2.66 weight portions. The coating process with the hybrid rice seed coating agent includes the following steps: stoving water content of seed to below 11 %; coating seed in a seed coating machine in the ratio between the seed coating agent and seed of 1 to 40-70; and stoving the coated seed to water content below 13.0 %. Treating rice seed with the seed coating agent can raise the germination rate and rice seedling forming rate obviously, raise rice seedling quality, and result in other positive effects.

Owner:HAINAN SHENNONG DAFENG SEED TECH

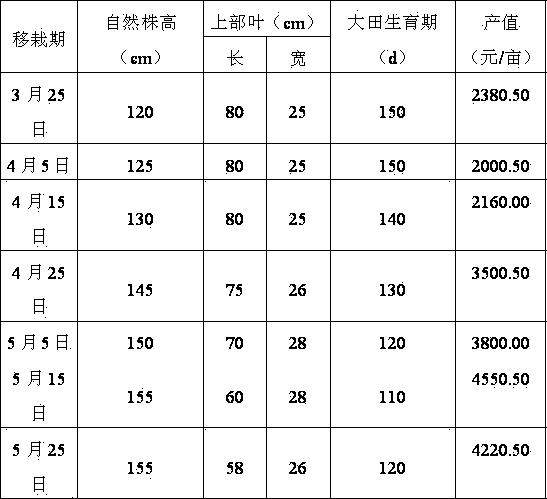

Planting and field management method for Hongda tobacco varieties on mountain land autumn-flowering red earth

ActiveCN104365329AReduce soil bulk densityEliminate bad ingredientsHarvestersFertilising methodsTransplantingTobacco leaf

The invention discloses a planting and field management method for Hongda tobacco varieties on mountain land autumn-flowering red earth. According to the method, seeding is performed within 40-50 days before transplanting, plowing is performed after preceding crops are harvested, then the earth is made idle, or early-maturing crops are planted in the earth, and land preparation is performed within 60-90 days before transplanting; transplanting is performed within 10-15 days before the rainy season, under-film transplanting is adopted, after transplanting, the earth is covered with mulching films, and holing is performed; 2.5 kg-3.5 kg of pure nitrogen is applied per mu, oil cake type organic fertilizer accounts for 45 %-55%, and 40 kg-50 kg of oil cake type organic fertilizer is applied per mu to serve as base fertilizer totally, 20 kg-25 kg of NPK-Zn-B compound fertilizer is applied per mu, and evenly mixed with the organic fertilizer to be applied as base fertilizer, 10 kg-15 kg of potassium sulfate is applied per mu, 75%-85% of the potassium sulfate is applied in holes within 35-45 days after planting, and 15%-25% of the potassium sulfate is applied through spraying within 45-55 days after planting; tobacco plants are topped two times, when center flowers blossom, topping is performed for the first time, big branches are removed, then within 10-15 days, topping is performed for the second time, and tobacco leaves of which the length is smaller than 50 cm, and all tobacco branches are removed; the tobacco leaves are harvested three times, 3-4 leaves are collected after the leaves on the lower portions become yellow and fall off, after 13-15 days, 3-4 leaves are then harvested, and the remaining leaves are harvested at a time after the leaves on the upper middle portions become yellow and fall off in a centralized mode. The method can be sufficiently adapted to the features of the mountain land red earth, promote early maturing and rapid flowering of tobacco seedlings and comprehensively increase the yield of the tobacco leaves and improve the quality of the tobacco leaves.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH

Production process of high-yield full-fat puffed soya bean meal

The invention provides a production process of high-yield full-fat puffed soya bean meal and belongs to the field of feed processing. The production process comprises the following steps: performing magnetic separation on soybeans, and cleaning, tempering, crushing and flaking the obtained soybeans; conveying the soybeans into a puffing machine and puffing to obtain a puffed material; conveying the puffed material into a desolvation layer of a vertical type evaporation-separation machine, and stirring and cooking; and then sequentially drying the puffed material by a drying layer of the vertical type evaporation-separation machine and cooling by a cooling layer of the vertical type evaporation-separation machine. Compared with powder feeding of the puffing machine, the sheet material feeding of the puffing machine has the advantages that the granulation pressure of the puffing machine is lowered, the yield can be improved to 6-8 times that of the powder feeding, the capacity of the machine can be improved by 5 times under the same power condition and the ton energy consumption of products is reduced. The extrusion of the puffing machine and the wet-hot cooking of the vertical type evaporation-separation machine are combined, so that the yield of the full-fat puffed soya bean meal is obviously increased, the curing degree of the soya bean meal is guaranteed, the quality of the product is stable and controllable and the large-scale production of the full-fat puffed soya bean meal is realized.

Owner:MYANDE GRP CO LTD

Chinese toon seed harvesting method

The invention discloses a Chinese toon seed harvesting method. The method is characterized by comprising processes of selecting mother trees, determining harvesting time, harvesting seeds, harvesting fruit, processing seeds and processing fruit; The method comprises following specific steps: selecting Chinese toon mother trees of the appropriate age; harvesting and processing seeds and fruit of the Chinese toon during a fruit mature period; and finally storing the seeds with impurities and shriveled parts removed in a refrigerating chamber with the temperature being 3-5 DEG C. According to the invention, the seeds of the Chinese toon are harvested during an optimum harvesting period, so that the maturity of the seeds can be guaranteed, enough seeds can be collected, and the obtained seeds are high in quality and germination rate. By employing the method, a problem that seeds have a low germination rate when the seeds are stored at room temperature is solved, the germination rate of the seeds in the next year is guaranteed, the seeds can meet large-scale sowing requirements, and favorable conditions are provided for rapid propagation of Chinese toon, thereby bringing good economic and social benefits.

Owner:GUANGXI FORESTRY RES INST

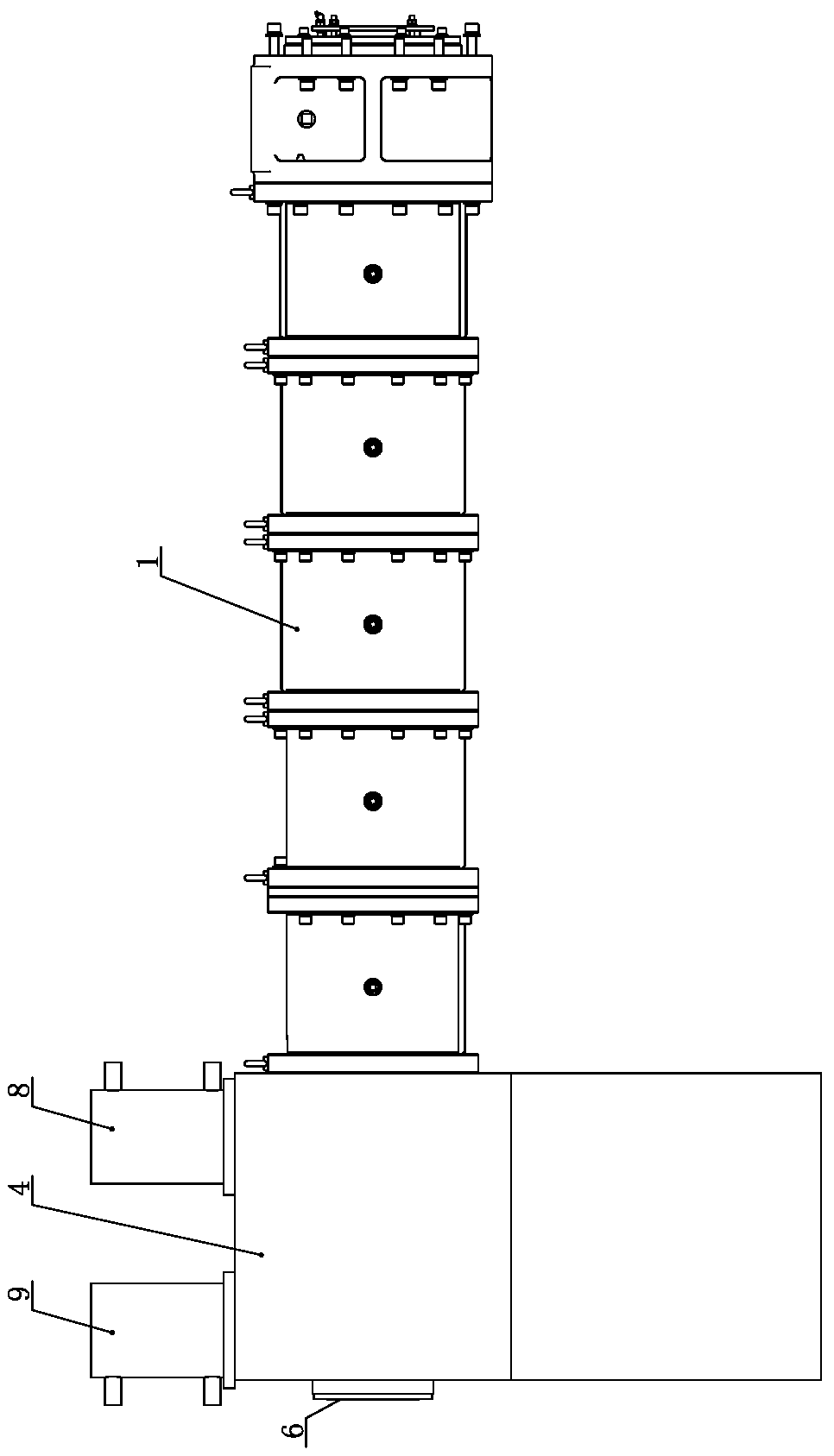

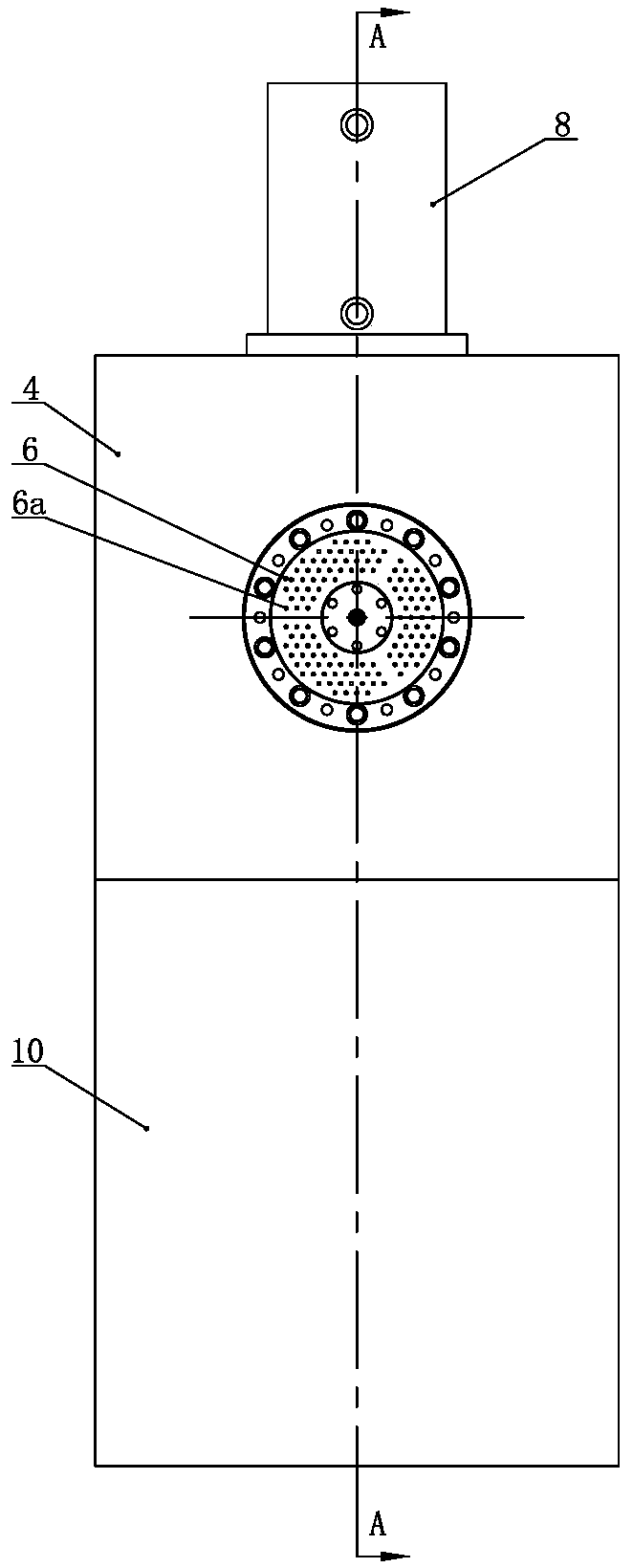

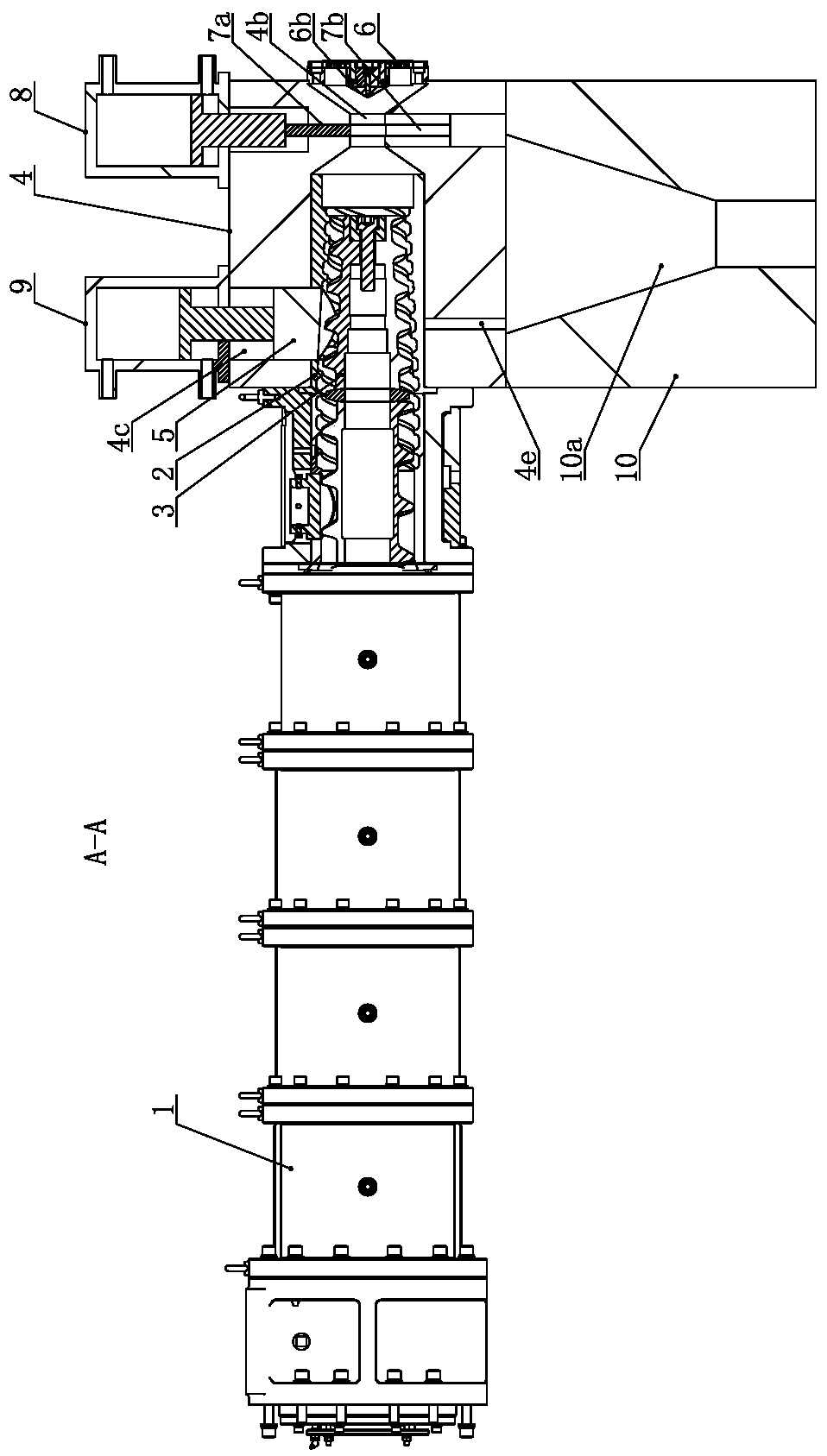

Extruder with adjustable product bulk density

ActiveCN109452681AIncrease the differential pressureGuaranteed MaturityFood shapingWear resistantMechanical engineering

The invention relates to an extruder with adjustable product bulk density. The body of the extruder is arranged with wear-resistant bushing on an inner wall of an extrusion chamber; a screw rotor is arranged in an inner cavity of the wear-resistant bushing; an outlet end of the extruder body is connected with a discharging apparatus; a last-stage extrusion chamber is arranged at an input section of the discharging apparatus; a venturi throat is arranged, close to an output, in an inner cavity of the discharging apparatus; a discharging mould is mounted at the outlet end of the discharging apparatus; a plurality of mould holes are distributed on the discharging mould; an upper pressure-adjusting plate and a lower pressure-adjusting plate are inserted at the venturi throat; an upper adjusting hole with a downward opening is arranged at the lower-end center of the upper pressure-adjusting plate; a lower adjusting hole with an upward opening is arranged at the upper-end center of the lowerpressure-adjusting plate; and an adjustment hole formed by encirclement of the upper adjusting hole and the lower adjusting hole is coaxial with the venturi throat. The top of the wear-resistant bushing is connected with a pressure-relief guide sleeve which extends upwards; a pressure adjusting plug is mounted in an inner cavity of the pressure-relief guide sleeve; and a guide sleeve pressure relief groove is arranged on an inner wall of the pressure-relief guide sleeve. The extruder is capable of very conveniently adjusting pressure of the extrusion chamber, thereby adjusting product bulk density.

Owner:扬州科润德机械有限公司

Method for preparing reinforced sweet persimmon wine

InactiveCN109055096AHigh yieldHigh alcohol contentAlcoholic beverage preparationFermentationDried fruits

The invention provides a method for preparing reinforced sweet persimmon wine. The method comprises the steps: (1) raw material selection and treatment, (2) persimmon peeling, crushing and pulping, (3) squeezing treatment, (4) fermenting, (5) squeezing and fermentation again, (6) distilling, (7) blending, (8) aging and bottling. The method has the advantages that used persimmons are good in quality, astringency removal is carried out at a primary stage, and the obtained reinforced sweet persimmon wine has the styles and characteristics of light golden yellow and clarified transparency, has rich and strong persimmon aroma, honey aroma and dried fruit aroma and complicated and elegant oak aroma and aged aroma, aromas are integrated, and the taste is strong, mellow, delightful, complicated, mellow-full and coordinated and is durable in aftertaste. Persimmon liquor has the styles and characteristics that fresh and clean persimmon aroma is typical and outstanding, the aroma is fine and graceful, the liquor aroma is rich and mellow, the taste is mellow, lasting-sweet, delicate and complete, and the aftertaste is lasting.

Owner:TIANJIN AGRICULTURE COLLEGE

Promoting agent for promoting tobacco mature yellowing and promoting method thereof

InactiveCN104798812AMature jaundice normalGuaranteed MaturityPlant growth regulatorsBiocideBiotechnologyNicotiana tabacum

The invention relates to a promoting agent for promoting tobacco mature yellowing and a promoting method thereof. The promoting agent comprises the following ingredients in percentage by weight: 0.05 to 0.25 percent of glufosinate, 0.5 to 1.5 percent of potassium bicarbonate and the balance water. The promoting method comprises the following steps that in the tobacco mature period of 7 to 10 days before the tobacco harvesting, the promoting agent is sprayed onto leaves of tobacco leaves until the surfaces of the tobacco leaves are wet. In the mature period of the tobacco, the promoting agent capable of accelerating the tobacco mature yellowing is sprayed onto the leaves of tobacco plants, and the activity of nitratases and GS enzymes in the nitrogen element metabolic process is inhibited through the promoting agents, so that the nitrogen element anabolism is decelerated, the catabolism is accelerated, and the degradation of pigment in the tobacco leaves and the macromolecular substances in the tobacco leaves is accelerated, so that the tobacco leaves naturally realize mature yellowing, and meanwhile, the mature degree of the tobacco leaves is also ensured after the sufficient degradation of pigment and macromolecular substances.

Owner:HENAN AGRICULTURAL UNIVERSITY

Preparation process of sweet juice oyster sauce

The invention relates to a preparation process of sweet juice oyster sauce, belonging to the fields of production processes and production equipment of sweet juice oyster sauce. The preparation process is characterized by comprising the following steps: (1) noodle steaming, (2) inoculation, (3) starter propagation, (4) fermentation, (5) filter pressing and (6) refining, sterilization and packaging. By combining the production of north sweet soybean paste with the production of oyster sauce, the fresh and sweet oyster sauce with a sauce flavor is produced, has the freshness and sweetness of the oyster sauce and the sauce flavor of the north sweet soybean paste and is very accordant with speeding favors of north consumers.

Owner:山东玉兔食品股份有限公司

A kind of wear-resisting whole raw material ultra-flat thick polished glaze and its application

The invention relates to wear-resistant full-raw material super-flat thick polishing glaze and application thereof, and belongs to the technical field of ceramic glaze production and processing. The wear-resistant full-raw material super-flat thick polishing glaze comprises the following components in percentage by mass: 5 to 20 percent of potash feldspar, 25 to 40 percent of soda feldspar, 5 to 10 percent of washed kaolin, 0 to 10 percent of barium carbonate, 0 to 10 percent of strontium carbonate, 5 to 12 percent of zinc oxide, 5 to 10 percent of calcite, 2 to 8 percent of dolomite, 5 to 10 percent of quartz and 8 to 18 percent of white corundum; the specific steps of the application of the wear-resistant full-raw material super-flat thick polishing glaze comprises: applying a layer of engobe on the surface of a green brick, applying wear-resistant full-raw material super-flat thick polishing glaze slurry on the surface of a brick by two times by adopting a linear glaze pouring way or a bell jar glaze pouring way, firing at the temperature of 1160 to 1230 DEG C, then polishing and waxing to obtain a finished brick. According to the full-raw material super-flat thick polishing glaze provided by the invention, on the basis of ensuring the glaze layer thickness, the formula is regulated, and full raw materials adopting meets the requirements of green and environment protection; not only is the phenomenon of water ripple solved, but also the hardness and the wear resistance of the super-flat thick polishing glaze are greatly improved.

Owner:佛山市三水大岛制釉有限公司

Seedling raising method of elsholtzia splendens nakai

ActiveCN110463524AHigh yieldAvoid lostBiocidePlant growth regulatorsElsholtzia splendensArtificial environment

The invention belongs to the technical field of garden biology, and particularly relates to a seedling raising method of elsholtzia splendens nakai. According to the method provided by the invention,seeds are harvested by adopting close-to-mature elsholtzia splendens nakai seed spikes; seed loss caused by ejection when the seed spikes mature can be avoided; the problem of difficult collection ofthe elsholtzia splendens nakai seeds is solved; the post-maturation of the elsholtzia splendens nakai seed spikes is promoted by adopting indoor artificial environment treatment, thereby guaranteeingthe maturity of the seeds; at the same time, the germination of the elsholtzia splendens nakai seeds is induced by adopting a self-made pregermination agent, so that the problem of low germination rate of the seeds under natural conditions is solved; by adopting the method provided by the invention, the average seedling rate of the elsholtzia splendens nakai is 99.87%, and the effect is significant; post-maturation treatment of the elsholtzia splendens nakai seed spikes, induction of seed germination, and seedling cultivation do not require special facilities, drugs used are conventional reagents and are cheap and easy to obtain, and the cost is low.

Owner:HUBEI POLYTECHNIC UNIV

Canned lemon and spiced salt tuna and preparation method thereof

InactiveCN104921179AIncrease the sense of saltinessHigh nutritional valueFood preparationLemon juiceVitamin

The present invention discloses a canned lemon and spiced salt tuna and a preparation method thereof. The canned lemon and spiced salt tuna uses frozen tunas as main raw materials and is prepared by thawing, eviscerating, steaming and cooking, spray cooling, slicing processing, canning, adding cooking juice, exhausting and sealing, sterilizing and cooling, and wiping cans. The cooking juice consists of salad oil juice and seasoning cooking juice, and the seasoning cooking juice consists of the following raw materials in weight ratio: white granulated sugar 4-4.2%, refined salt 2-2.2%, lemon juice 0.1-1.1%, potato flour 4.5-5%, corn starch 0.4-0.45%, spiced salt 2-2.1% and the balance being water. The spiced salt is used to increase the salty and fragrant sense of tunas, the sour taste of lemons and the sweet taste of white granulated sugar are matched to enable a moderate sweet and sour taste, the canned lemon and spiced salt tuna is coordinated, refreshing and smooth, and the lemons ease the fishy taste, are rich in various vitamins, and increase the nutritional value of the canned lemon and spiced salt tuna.

Owner:ZHONGGANG FUJIAN AQUATIC FOOD

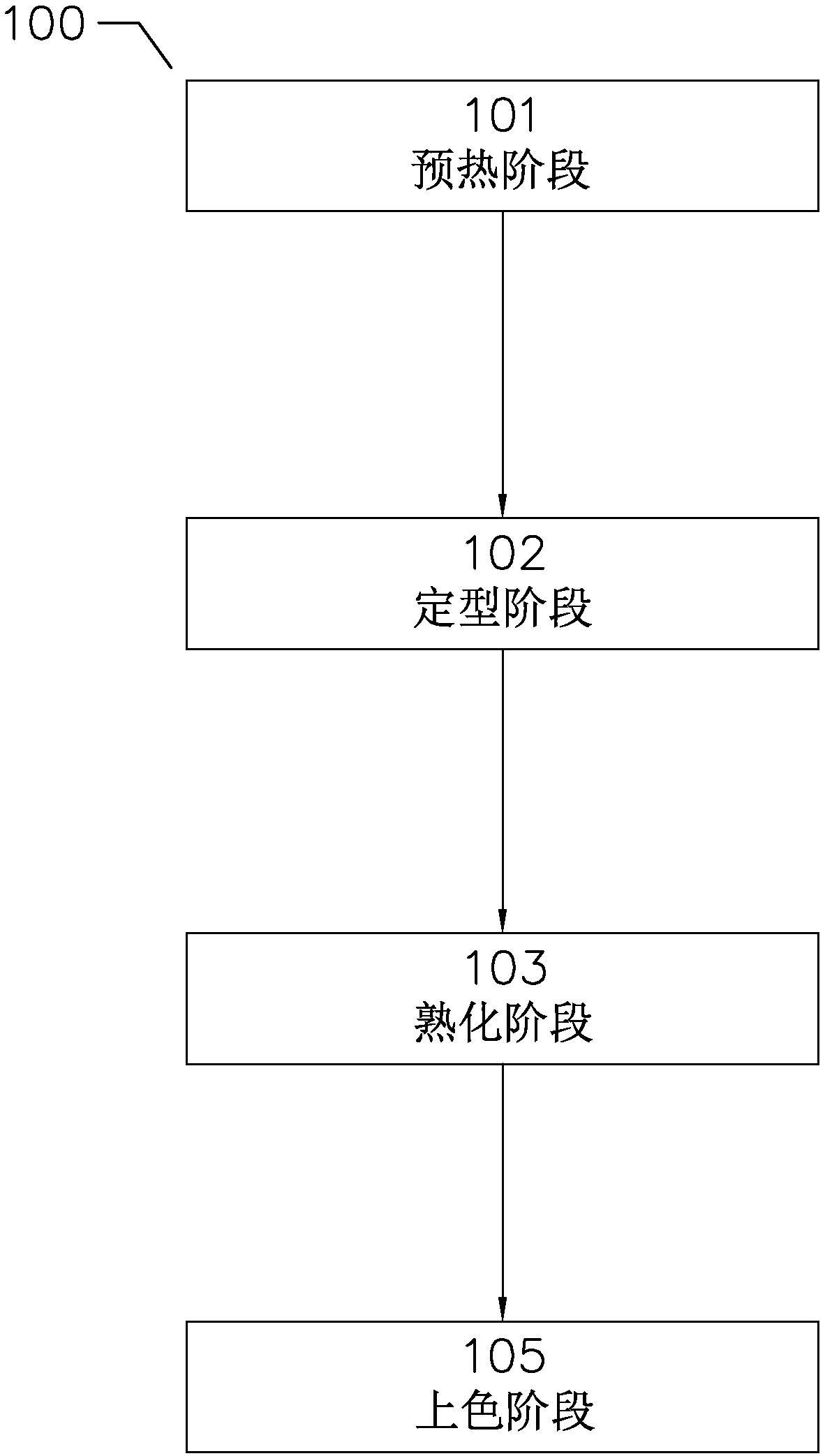

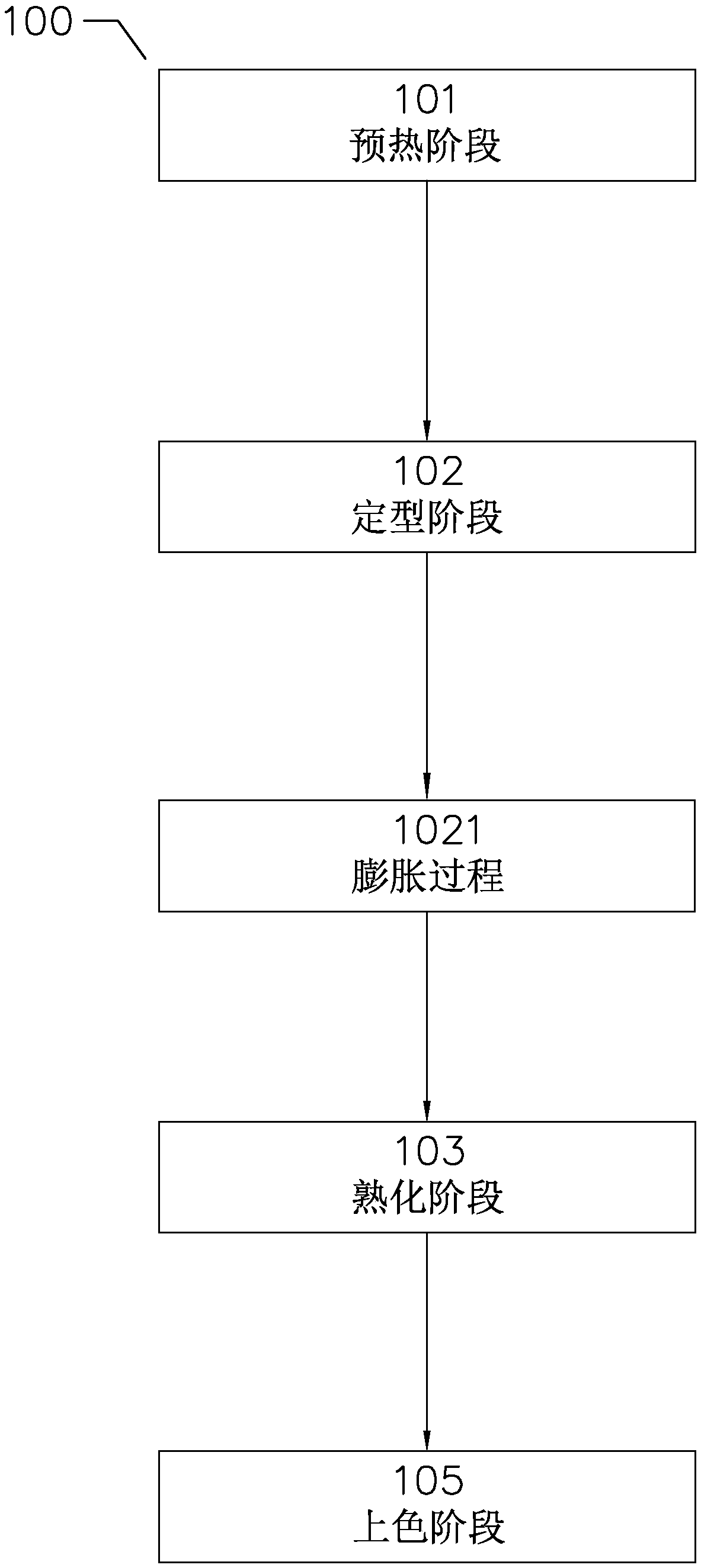

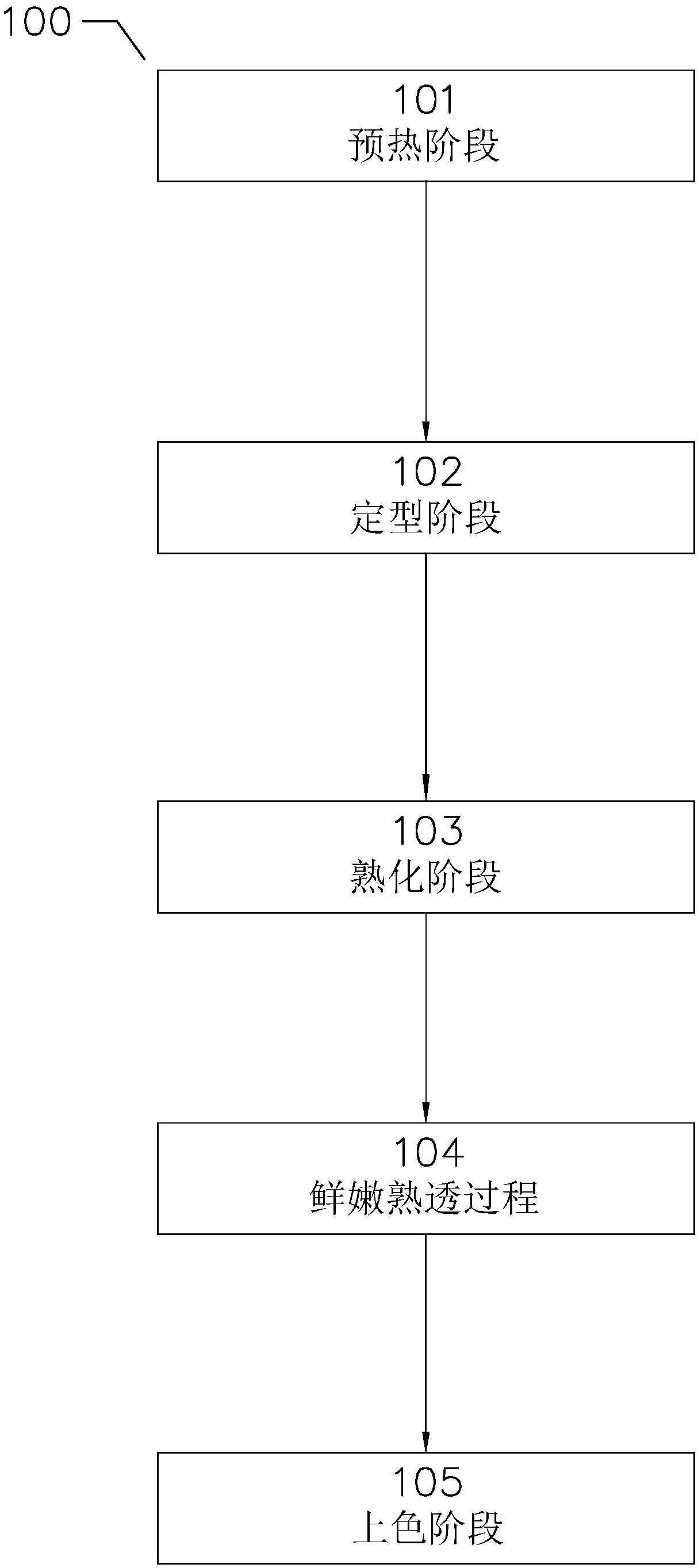

Method for manufacturing pancakes by frying and baking machine

InactiveCN108652465AReduce waiting timeImprove user experienceRoasters/grillsCooking & bakingProcess engineering

The invention provides a method for manufacturing pancakes by a frying and baking machine. The frying and baking machine comprises a heating element and a baking tray. The method comprises the steps that a preheating stage is carried out, specifically, the heating element is controlled to heat the baking tray and oil to a preheating temperature T1; a curing stage is carried out, specifically, theheating element is controlled to heat and warm the baking tray to keep the baking tray at the curing temperature; a coloring stage is carried out, specifically, the heating element is controlled to heat and warm the baking tray to keep the baking tray at the coloring temperature; and a shaping stage before the curing stage and after the preheating stage is carried out, specifically, after a user adds the pancake to the baking pan, the heating element is controlled to keep the baking pan at the shaping temperature T2, and the holding time is t2, wherein 130 DEG C<= T2<= 170 DEG C, 2min <= t2 <=5min, and T1<= T2, so that after the baking tray and oil are preheated, the crust of the pancake is combined with the oil to form a thin and brittle layer to shape the crust of the pancake, the deformation and collapse of the pancake in the subsequent cooking process are prevented, the frying and baking effect of the pancake is improved, and the crispy crust of the pancake is achieved, and the taste of the whole pancake is improved.

Owner:JOYOUNG CO LTD

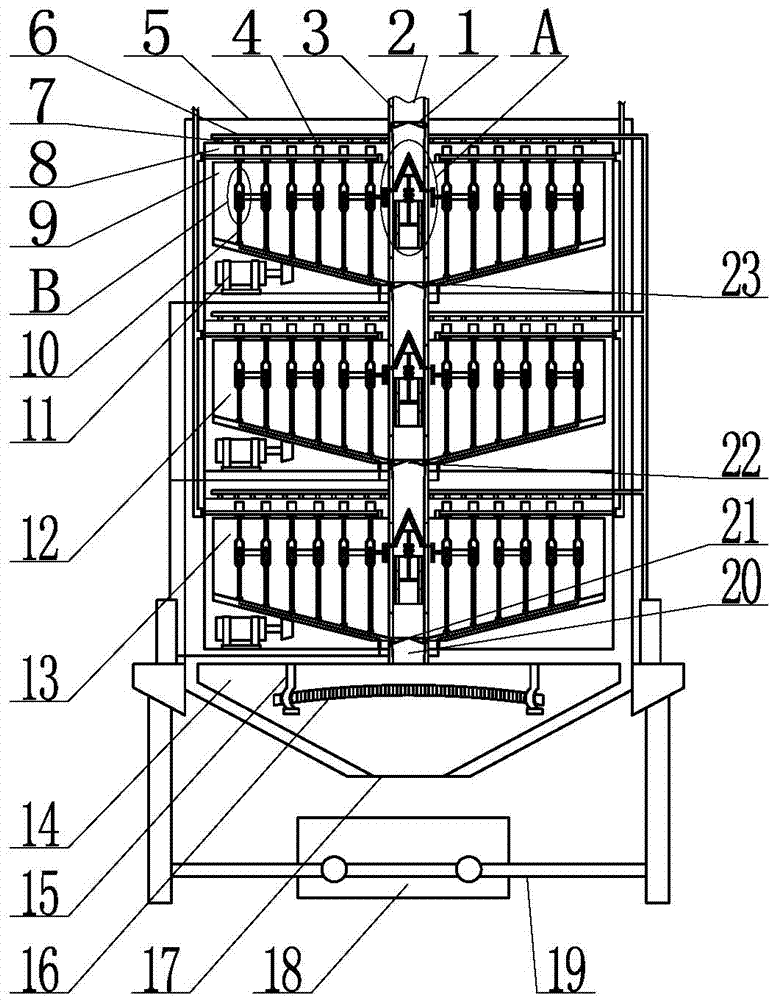

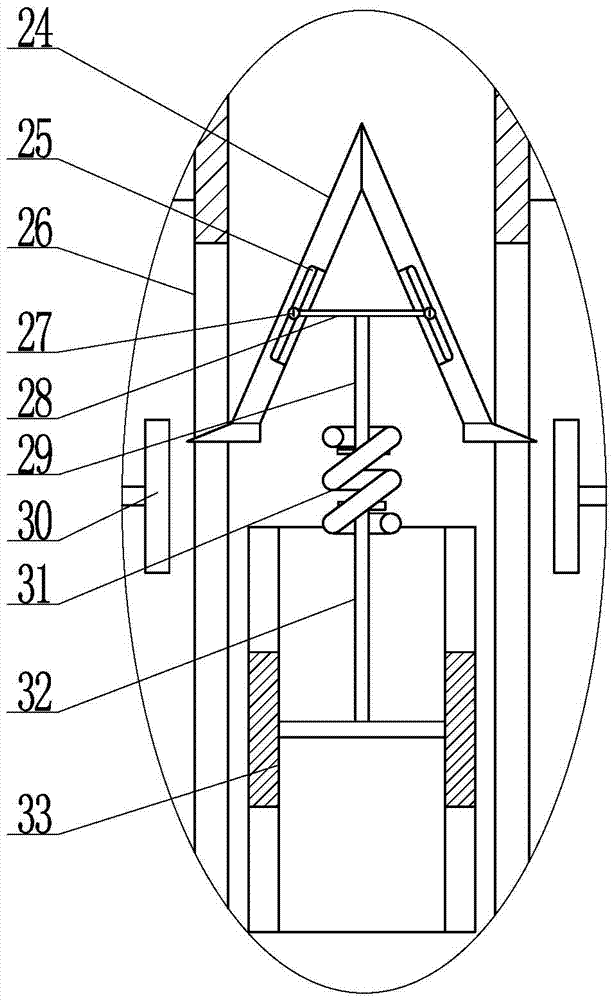

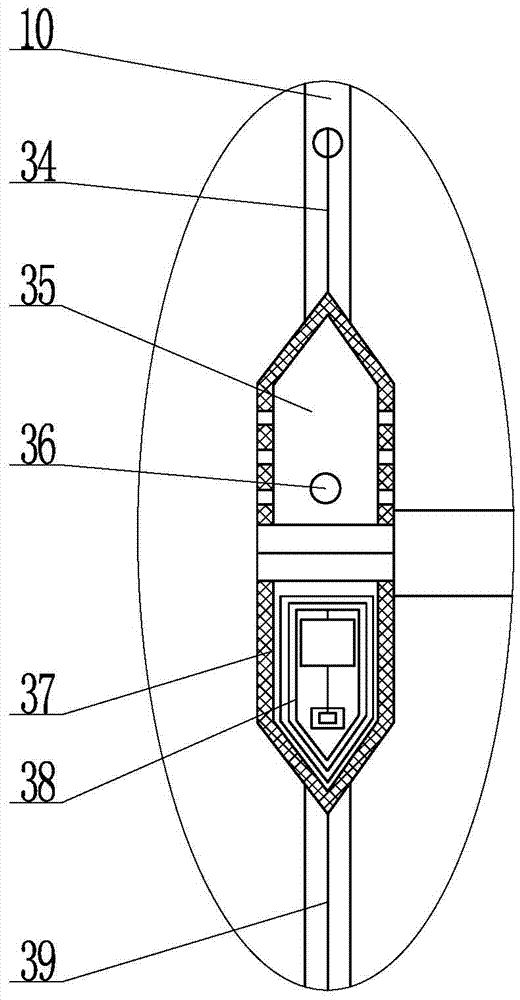

Coke oven coking end monitoring system

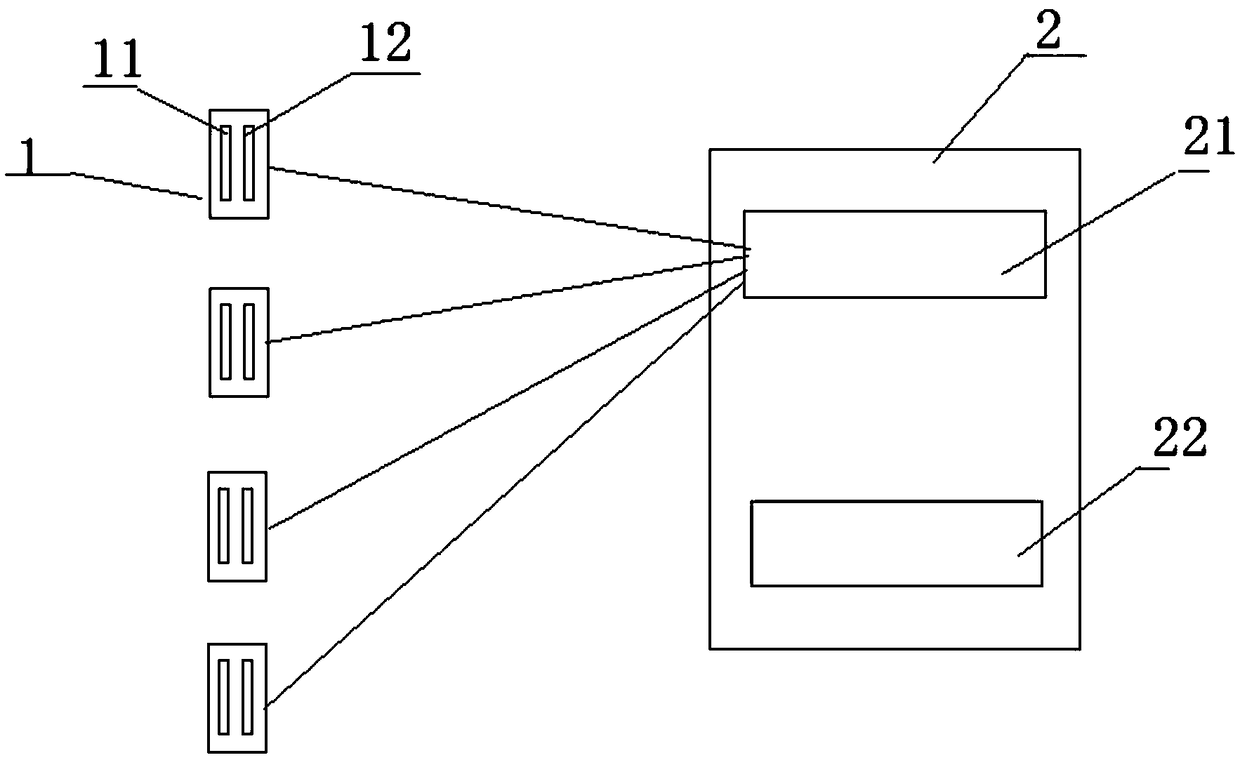

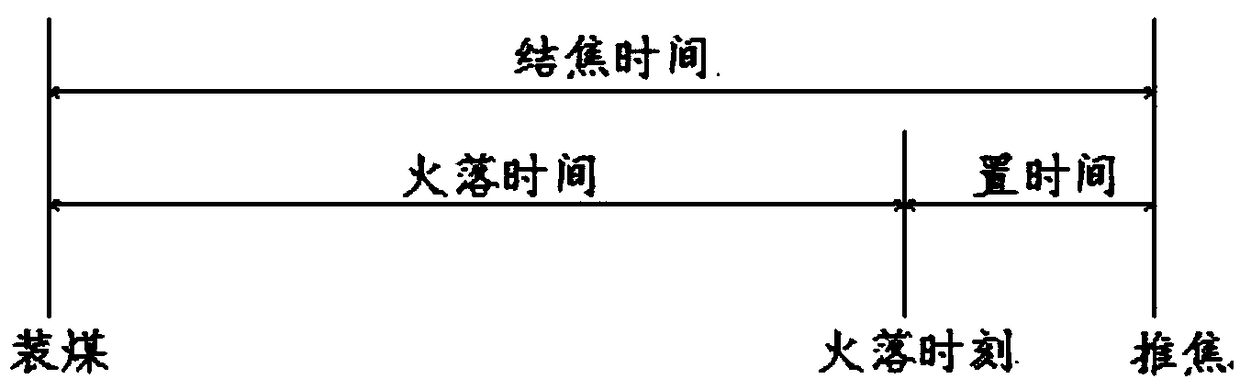

PendingCN109251751AGuaranteed MaturityEasy to manageCombustible gas coke oven heatingMonitoring systemData acquisition

The invention provides a coke oven coking end monitoring system, which comprises a waste gas temperature detecting device (1) and a data collecting and controlling device (2), wherein the waste gas temperature detecting device (1) comprises a group of thermocouples (11) and a group of high-temperature-resistant compensation conduction wires (12), the thermocouples (11) are arranged at the tee position for connecting the riser tube and the bridge tube of a coke oven carbonization chamber, the high-temperature-resistant compensation conduction wires are arranged near the thermocouples (11), andthe data collecting and controlling device (2) comprises a data collecting and processing module (21) and a data storage module (22). According to the present invention, the waste gas temperature is detected, the coking end time is determined by using the waste gas temperature change, and the coking end time, the placing time and the coking time are calculated by using the coking end time, such that the fine-tune and the accurate adjustment of the coke oven heating system can be guided, the visual pollution can be reduced, the energy can be saved, and the coke quality can be ensured.

Owner:NANJING HUYOU METALLURGY MACHINERY MFG

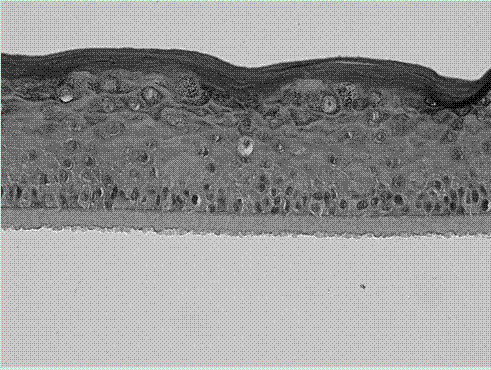

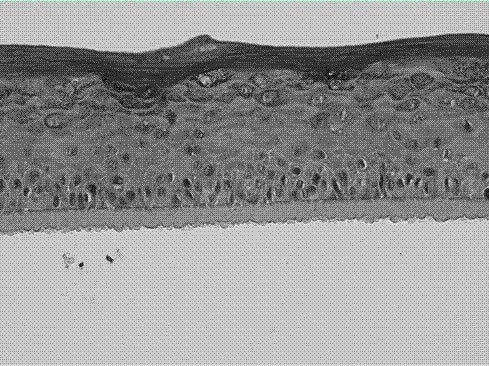

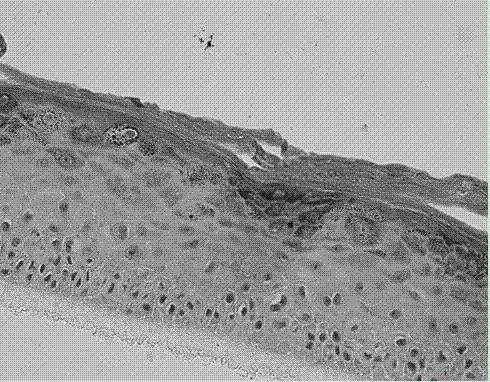

Construction method of 3D epidermis model

ActiveCN107287150APromote growthGuaranteed normal growthCulture processEpidermal cells/skin cellsFiberMitomycin C

The invention belongs to the technical field of tissue engineering and particularly relates to a construction method of a 3D epidermis model. According to the method, a fibroblast treated by using mitomycin C (Mitomycin C, MC) is adopted as a trophoblast and inoculated with a keratinocyte, various factors and proteins secreted by the fibroblast are supplied to the keratinocyte for growth requirements, and meanwhile, low-concentration serum, EGF, insulin and CaCl2 are matched to construct the 3D epidermis model through two phases of submerged culture and gas-liquid surface culture. The constructed 3D epidermis model is highly consistent with a human epidermis structure, the production cost is reduced, and the economical, effective and efficient requirements required by large-scale production of the 3D epidermis model are met.

Owner:GUANGDONG BOXI BIO TECH CO LTD

Method for root promotion and production increasing of continuous cropping sweet potato crops

ActiveCN109006240AImprove absorptionGuaranteed MaturityHorticulture methodsPlant protectionContinuous croppingDisease

The present invention relates to a method for root promotion and production increasing of continuous cropping sweet potato crops. The method comprises the steps of: determining whether melon crops ina fruit swelling period or a mature period generate soil-borne diseases or not; and performing seedling dropping and stem burying processing for the melon crops with soil-borne diseases, and employingbacillus amyloliquefaciens or bacillus licheniformis and a rooting agent to perform root irrigation for newly buried plant stems to promote new root boost of the nodal plate portions so as to achievethe purpose of root promotion of the melon crops with soil-borne diseases. According to the method, about 8-15 days after seedling dropping and stem burying processing, the portion where the stem isnewly buried starts to generate white hair roots with absorption functions, and the plant water and fertilizer absorption function is greatly improved, at this time, plants do not need a sunshade netfor shading even at noon with much sunlight and can absorb enough nutrients for plant growth and swelling of fruits so as to ensure the normal maturing.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

Albizzia seed processing method capable of enabling seedlings to be tidy after seeding

InactiveCN107439086APrevent moistureAvoid nutrient deficienciesBiocideSeed and root treatmentAgronomy

Owner:合肥满地金农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com