Method for manufacturing pancakes by frying and baking machine

A frying machine and noodle technology, which is applied in the direction of roasters/barbecue grids, kitchen utensils, household utensils, etc., can solve the problems of noodle coloring, noodle collapse, and burnt crust, etc., to improve cooking Efficiency, taste enhancement, crispy taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

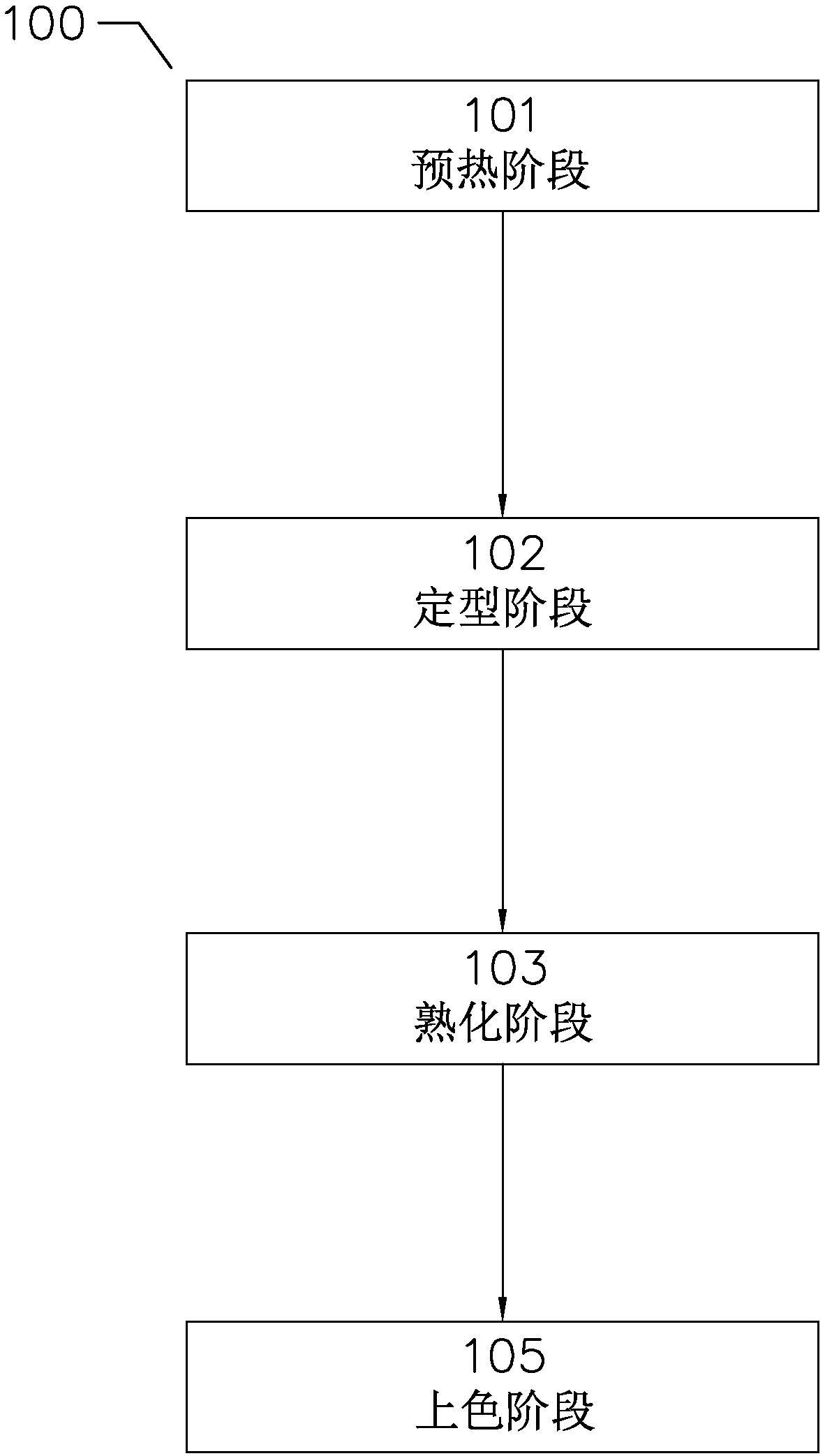

[0039] Such as figure 1 As shown, this embodiment provides a method 100 for making noodle cakes with a frying machine. The frying machine includes a heating element and a baking pan. The frying machine pre-stores the type of ingredients and the corresponding cooking parameters. The cooking parameters include preheating temperature, Setting temperature, curing temperature, coloring temperature and heating time, this embodiment takes the production of unfermented dough cake as an example to illustrate the present invention.

[0040] The method 100 includes:

[0041] Preheating stage 101: controlling the heating element to heat the grill pan and oil to the preheating temperature T 1 ;

[0042] Styling stage 102: After the user adds dough into the pan, control the heating element to keep the pan at the setting temperature T 2 and maintain time t 2 ;

[0043] Curing stage 103: controlling the heating element to heat up the baking pan to keep the baking pan at the curing temper...

Embodiment 2

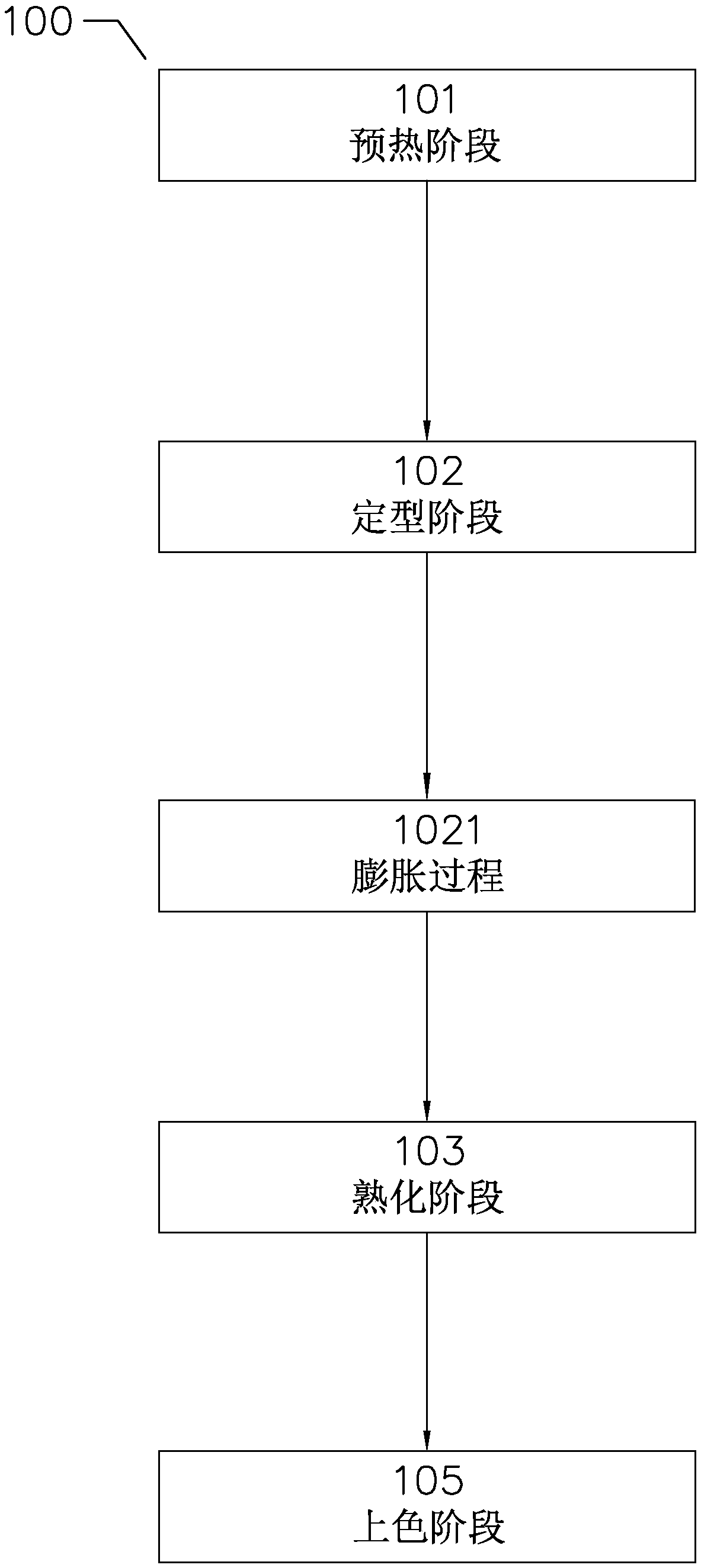

[0061] The difference between this embodiment and Embodiment 1 is that this embodiment illustrates the present invention by taking the production of fermented dough cake as an example, and the setting stage of this embodiment includes an expansion process.

[0062] The method 100 in this embodiment, such as figure 2 As shown, the details are as follows:

[0063] Preheating stage 101: controlling the heating element to heat the grill pan and oil to the preheating temperature T 1 ;

[0064] Styling stage 102: After the user adds dough into the pan, control the heating element to keep the pan at the setting temperature T 2 and maintain time t 2 ;

[0065] Curing stage 103: controlling the heating element to heat up the baking pan to keep the baking pan at the curing temperature;

[0066] Coloring stage 105: controlling the heating element to heat up the baking pan to keep the baking pan at the coloring temperature;

[0067] Wherein, the shaping stage 102 includes an expans...

Embodiment 3

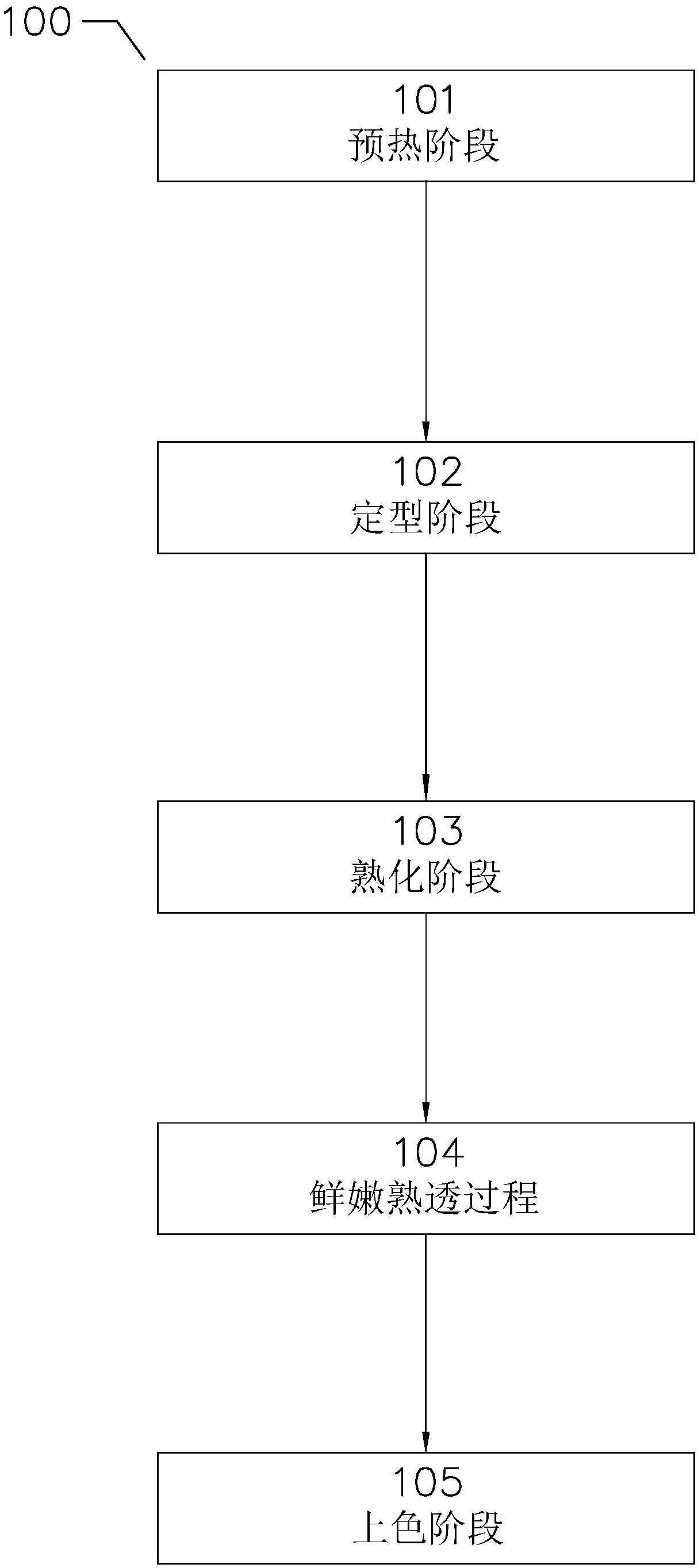

[0075] The difference between this embodiment and Embodiment 1 is that the method also includes a fresh and tender ripening process after the ripening stage and before the coloring stage.

[0076] This embodiment is mainly aimed at the method of making pies. When in use, the user can press the pie function part on the frying machine to start making pies.

[0077] The method 100 in this embodiment, such as image 3 , 4 As shown, the details are as follows:

[0078] Preheating stage 101: controlling the heating element to heat the grill pan and oil to the preheating temperature T 1 ;

[0079] Styling stage 102: After the user adds dough into the pan, control the heating element to keep the pan at the setting temperature T 2 and maintain time t 2 ;

[0080] Curing stage 103: controlling the heating element to heat up the baking pan to keep the baking pan at the curing temperature;

[0081] Fresh, tender and cooked process 104: Control the heating element to heat up the bak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com