Automatic crystal blank polishing and burnishing system and docking mechanism thereof

A docking mechanism and docking frame technology, applied in grinding/polishing equipment, grinding machines, spherical grinding machines, etc., can solve the problems of reducing the efficiency of automatic cycle processing, complicating the connection structure, prolonging the occupation time, etc., and achieving a simple and reasonable structure. Simple action and the effect of reducing the time occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

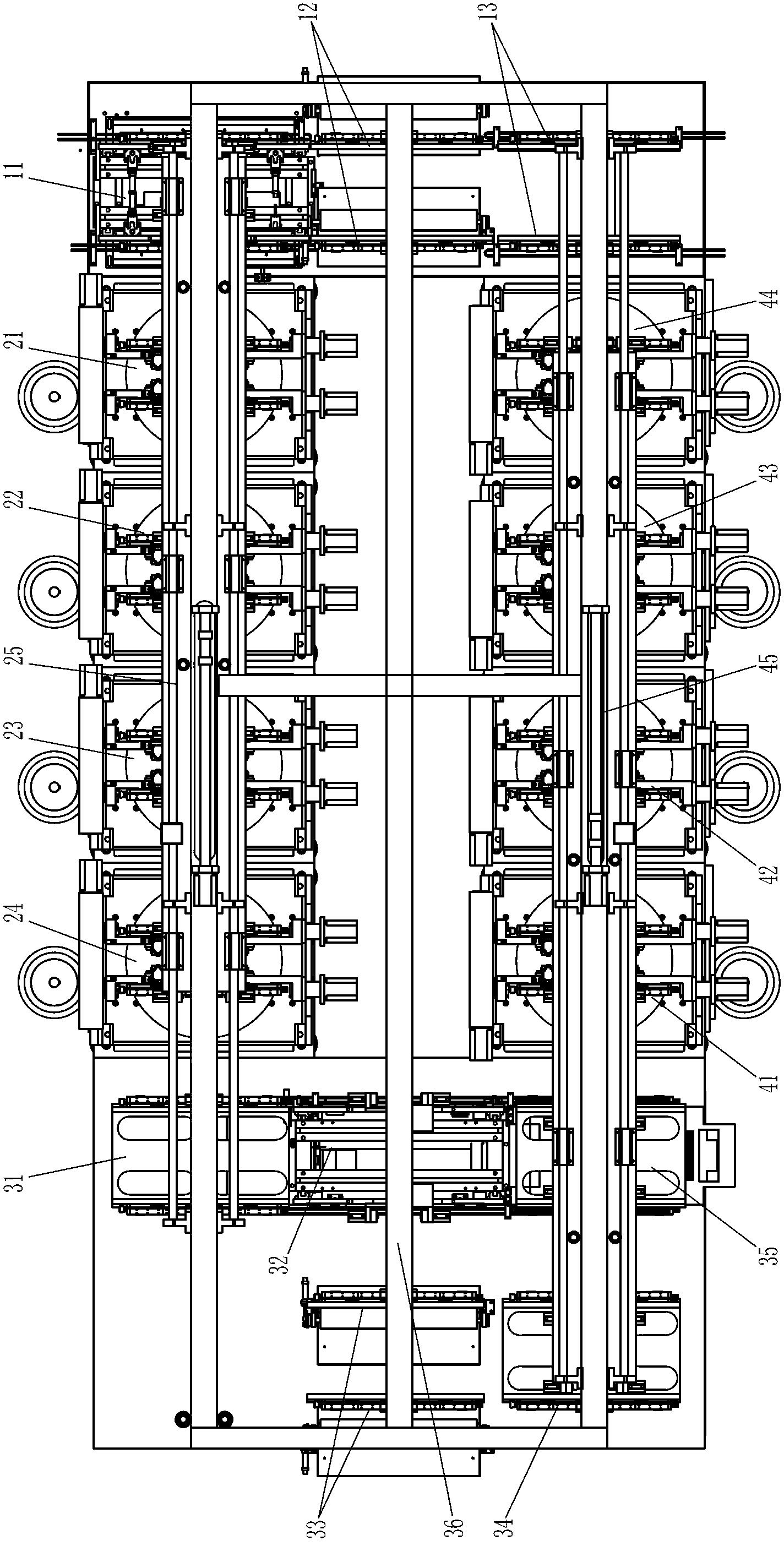

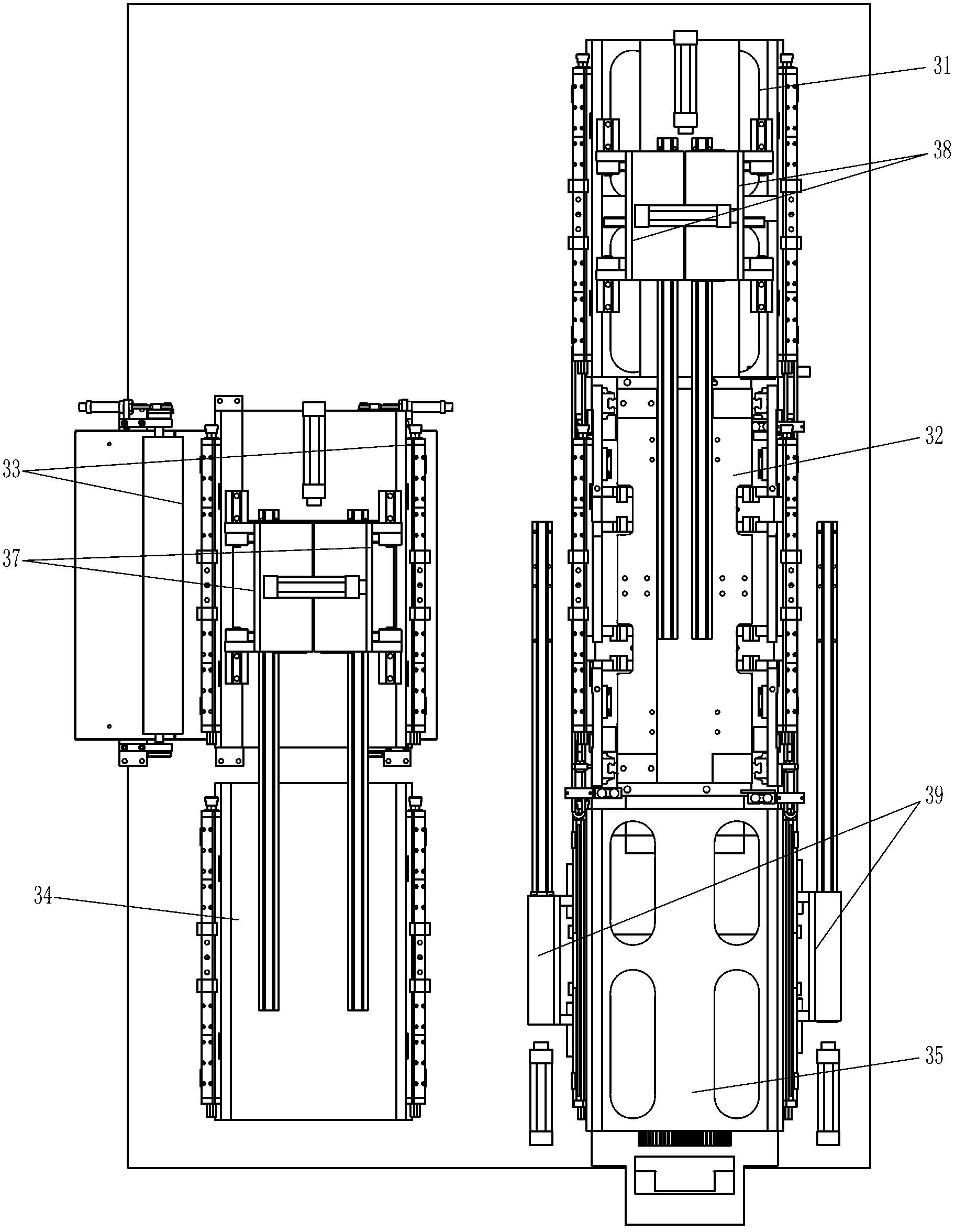

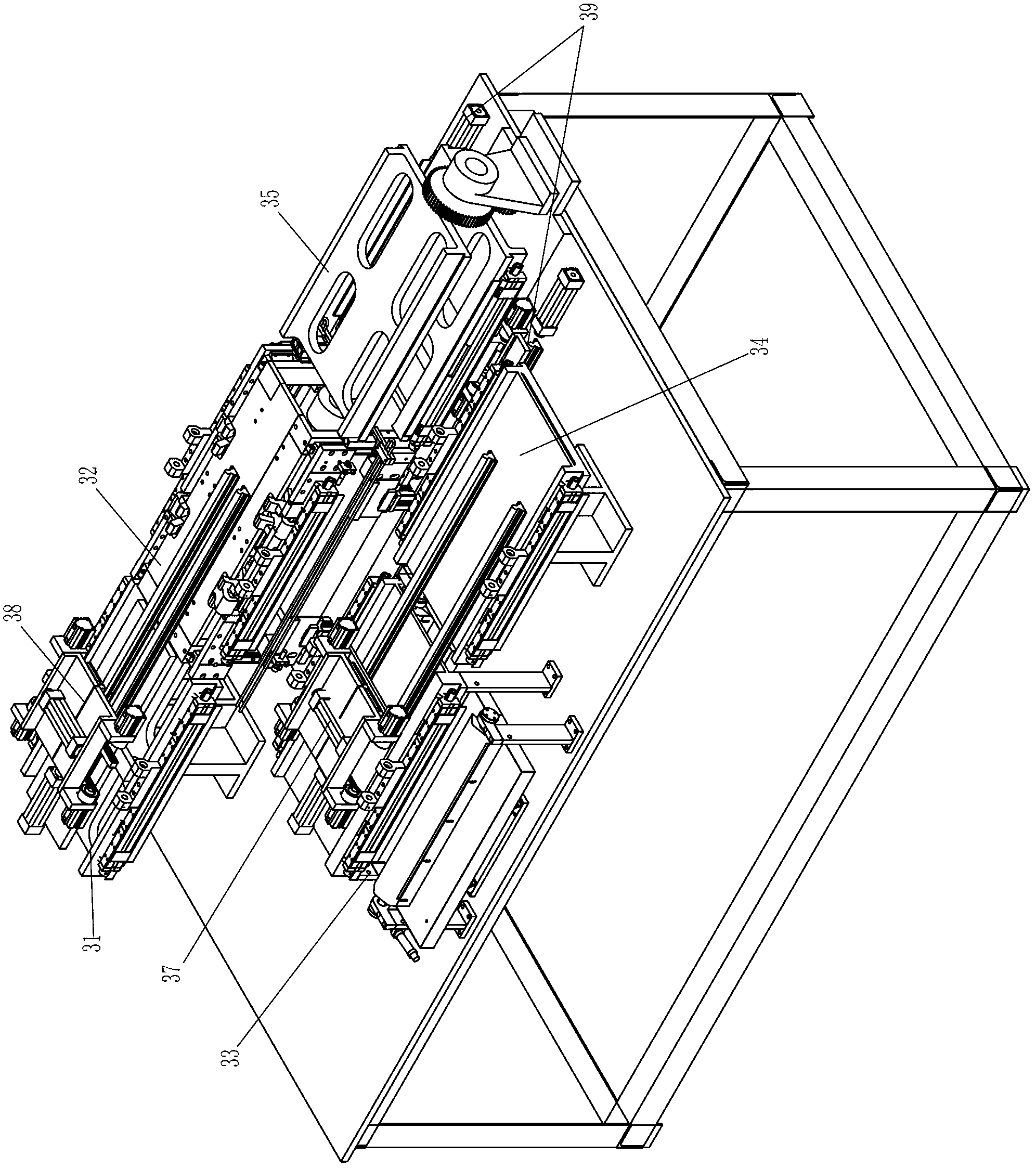

[0036] Such as figure 1 A kind of crystal blank automatic grinding and polishing system shown, comprises: the first left and right transfer mechanism 25, along the first left and right transfer mechanism 25 are arranged in turn to be provided with feeding station 11, two upper hemispheres of crystal blank are ground Upper hemisphere grinding stations 21, 22 for cutting, two upper hemisphere polishing stations 23, 24 and docking stations for polishing the upper hemisphere of the crystal blank, the first left and right transfer mechanism 25 can move left and right and locate And be provided with five manipulators that can pick up and put down the fixture; The second left and right transfer mechanism 45, along the second left and right transfer mechanism 45 are arranged in sequence with the described butt joint station, two lower hemispheres of the crystal blank for grinding The lower hemisphere grinding station 41,42, two lower hemisphere polishing stations 43,44 and blanking st...

Embodiment 2

[0044] An automatic grinding and polishing system for crystal blanks, comprising: a first left and right transfer mechanism, a feeding station arranged in sequence along the first left and right transfer mechanism, and two upper hemisphere mills for grinding the upper hemisphere of crystal blanks Cutting station, two upper hemisphere polishing stations and docking stations for polishing the upper hemisphere of the crystal blank, the first left and right transfer mechanism can move and position left and right and is equipped with six manipulators that can pick up and put down the fixture; The second left and right transfer mechanism is arranged in sequence along the second left and right transfer mechanism with the docking station, two lower hemisphere grinding stations for grinding the lower hemisphere of the crystal blank, and two lower hemisphere grinding stations for the crystal blank. The lower hemisphere polishing station and the blanking station for polishing the lower he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com