Steaming oven PTC thermistor heating element

A thermistor and heating element technology, which is applied in the field of ovens, can solve the problems of complex production of parts, high cost, and non-maintenance of the evaporator, and achieve the effects of fast heating speed, small storage and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

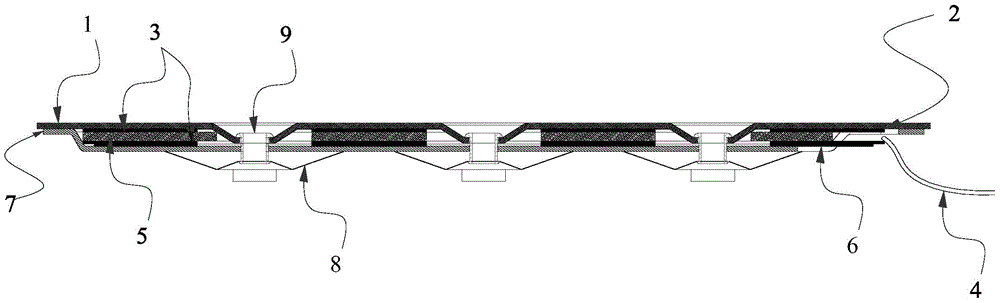

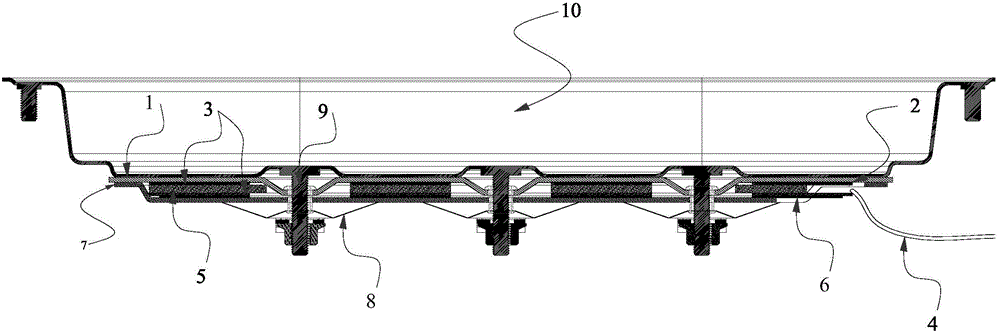

[0029] like figure 1 , figure 2 Shown is that the present invention has a kind of parts of steaming oven PTC thermistor heating element as:

[0030] 1. PTC heat conducting sheet 2. PTC insulating film

[0031] 3. PTC electrode plate 4. Connecting wire

[0032] 5. PTC thermistor 6. Mica sheet

[0033] 7. PTC packaging board 8. PTC packaging tablet

[0034] 9. Riveting nails 10. Evaporation plate

[0035] A PTC thermistor heating element of a steam oven, comprising a PTC thermistor 5 and a riveting nail 9, the PTC thermistor 5 is bonded to a PTC electrode plate 3, and the PTC electrode plate 3 and a connecting wire 4 are connected to each other For riveting, the riveting nails 9 are sequentially put into the PTC package pressing sheet 8, the PTC package plate 7, the mica sheet 6, the PTC thermistor 5, the PTC electrode plate 3, the PTC insulating film 2, and the PTC heat conducting sheet 1 for riveting and fastening. Its PTC thermistor is a PTC type ceramic heater. Its P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com