Patents

Literature

111results about How to "Guaranteed docking accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

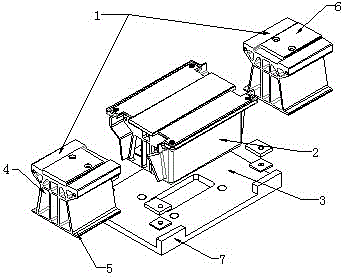

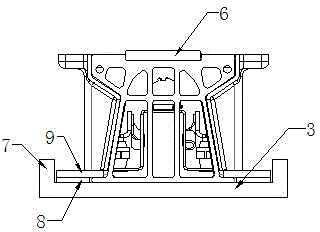

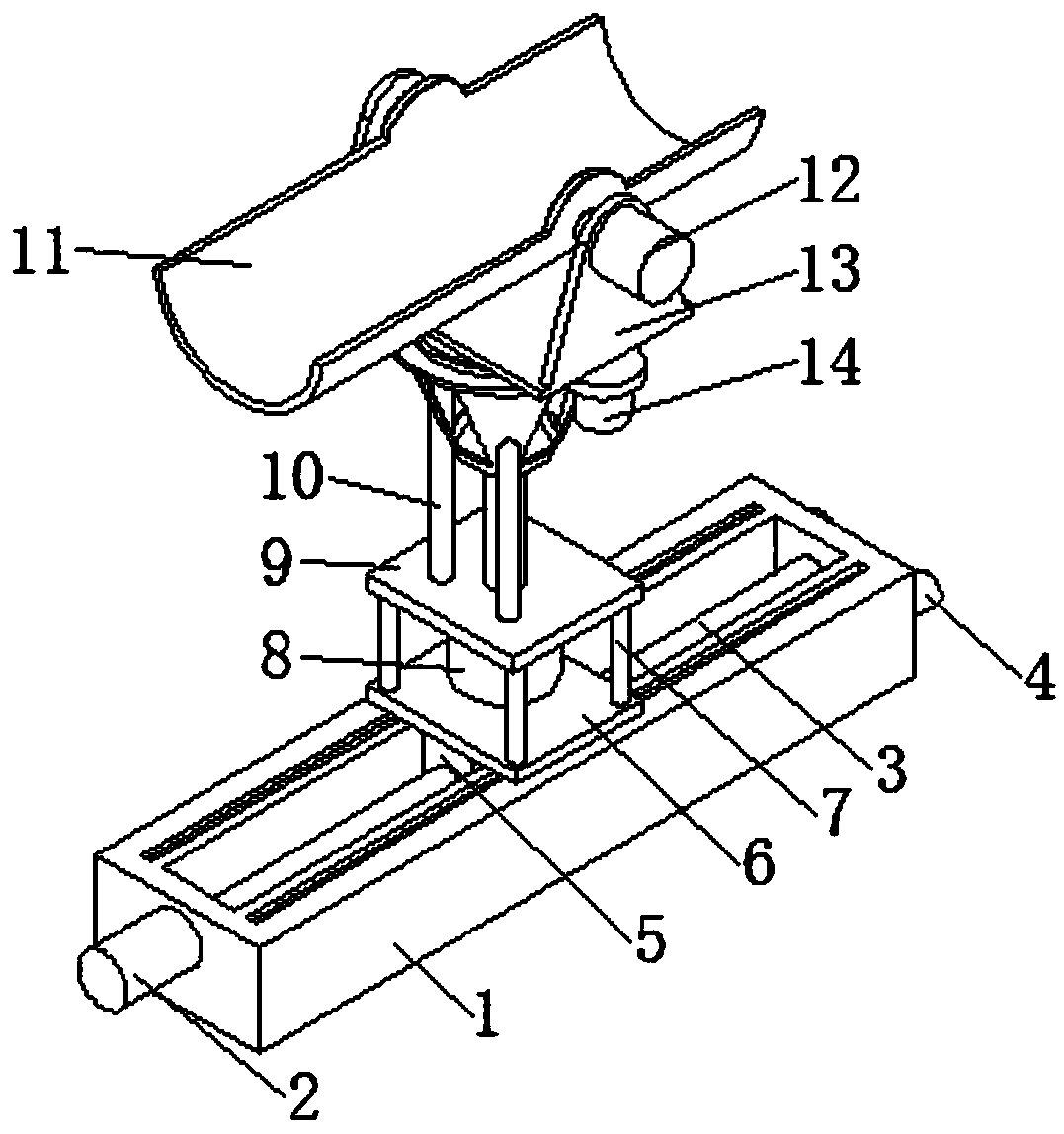

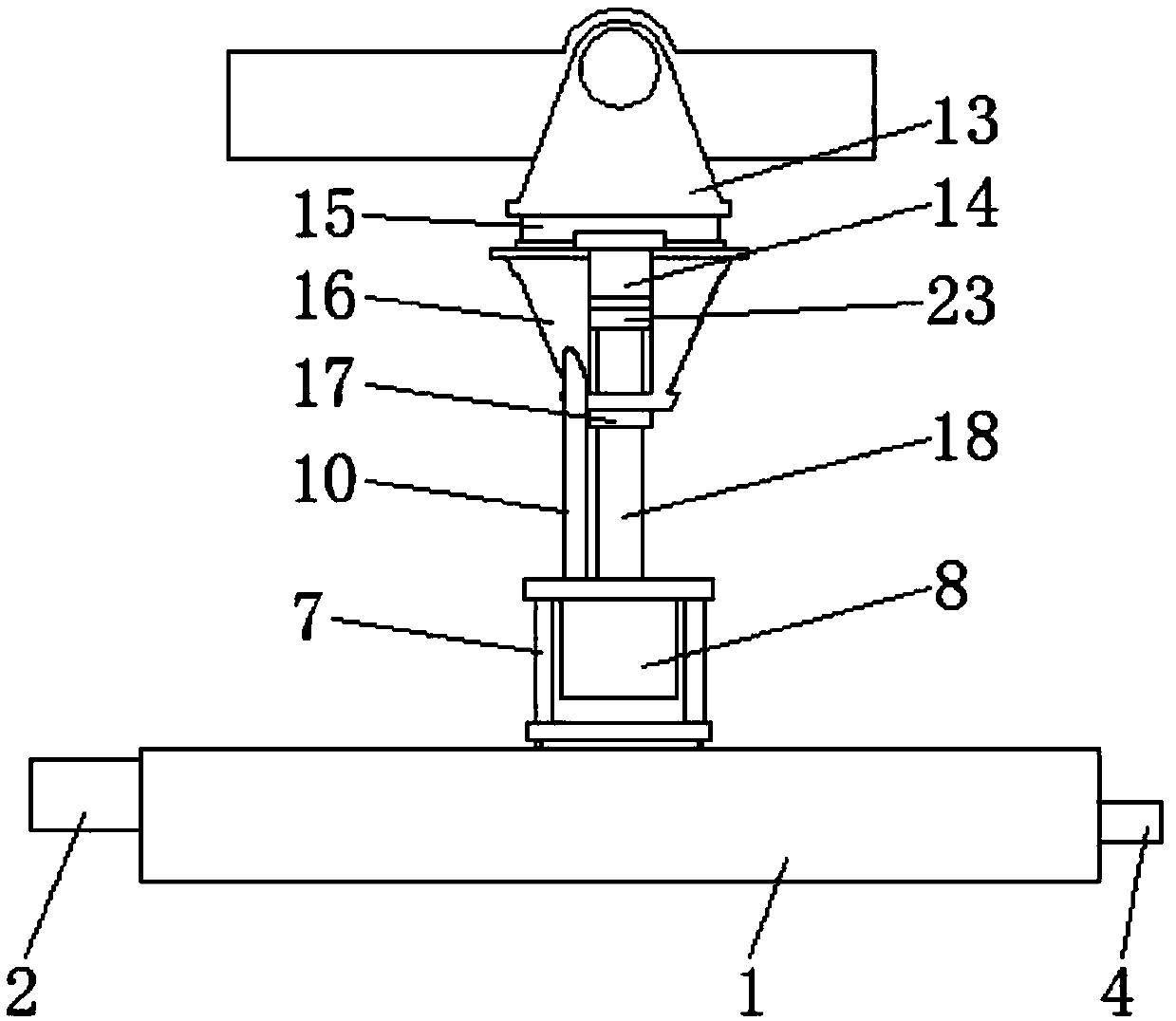

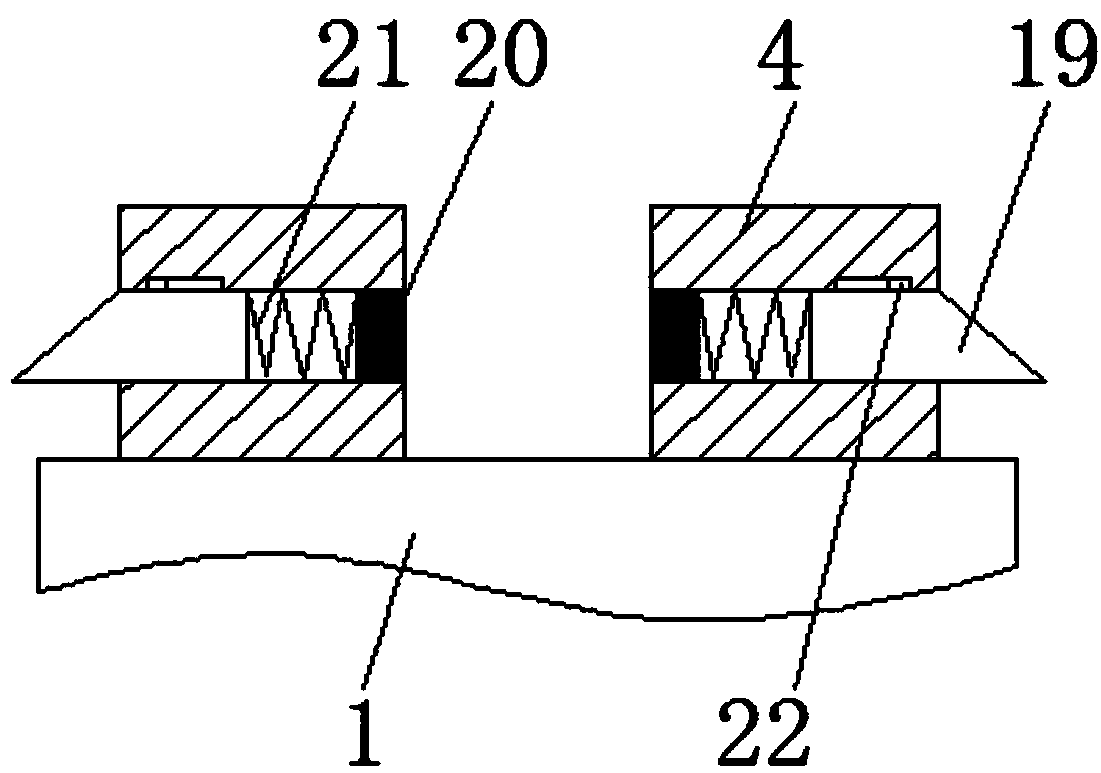

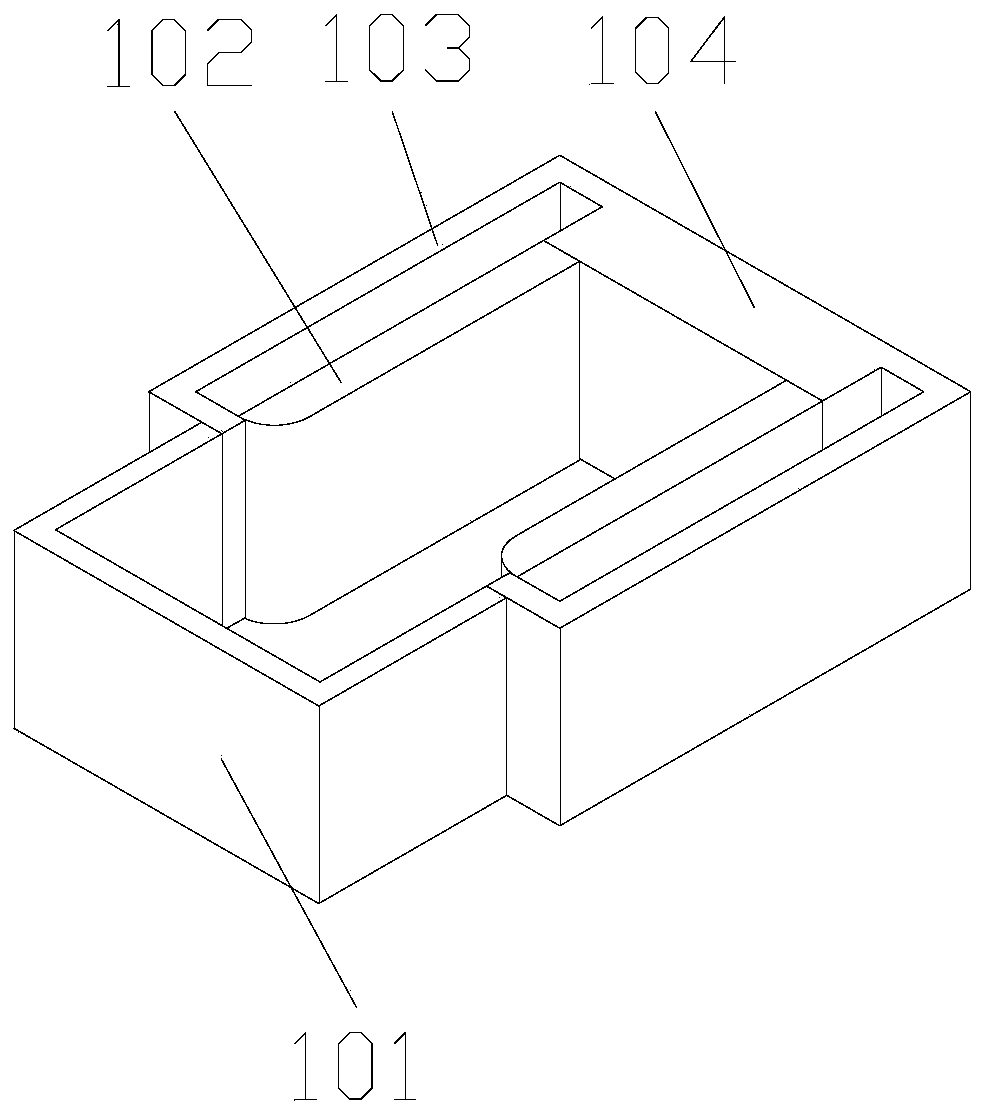

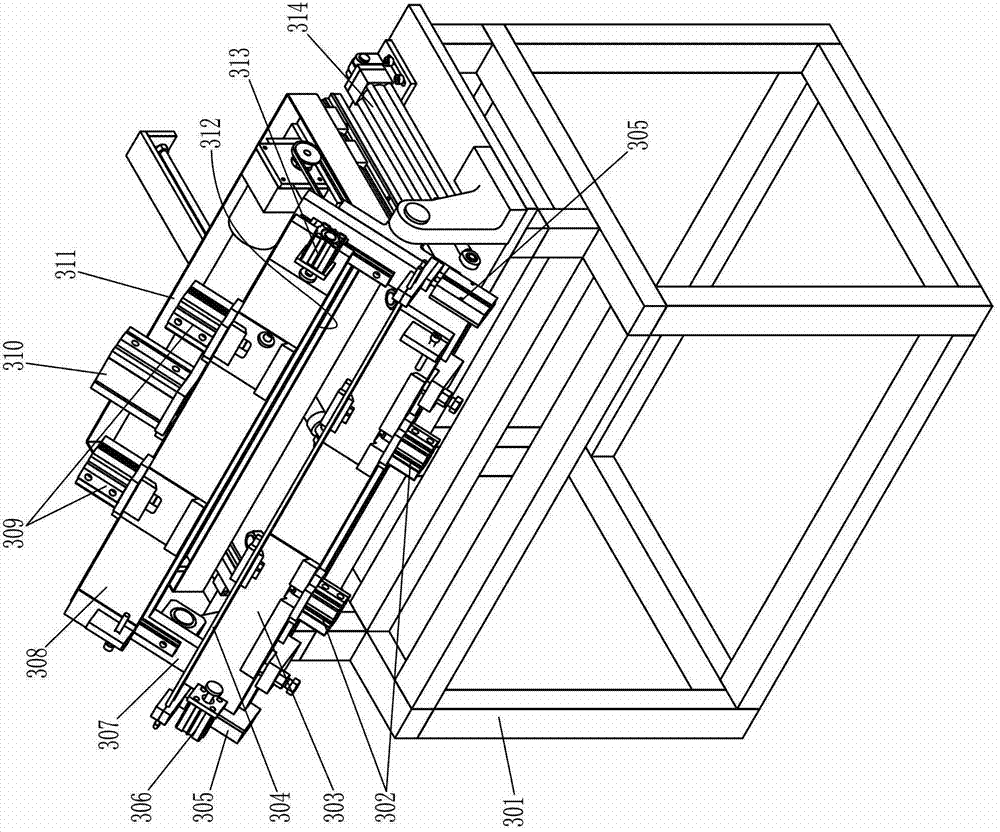

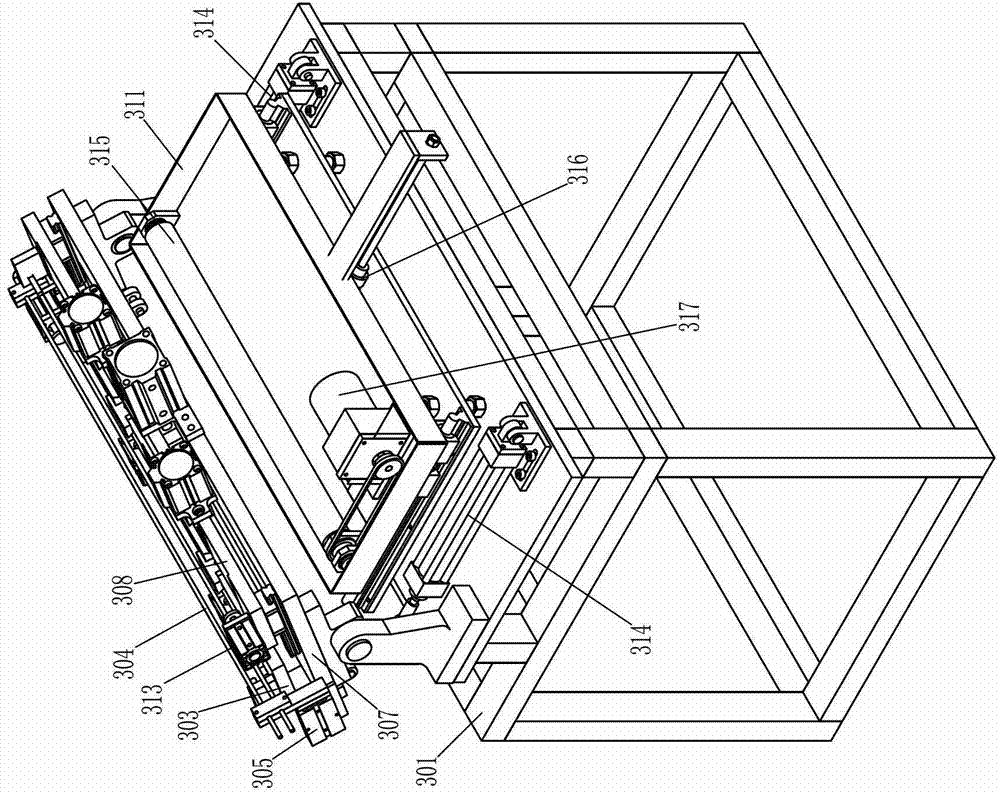

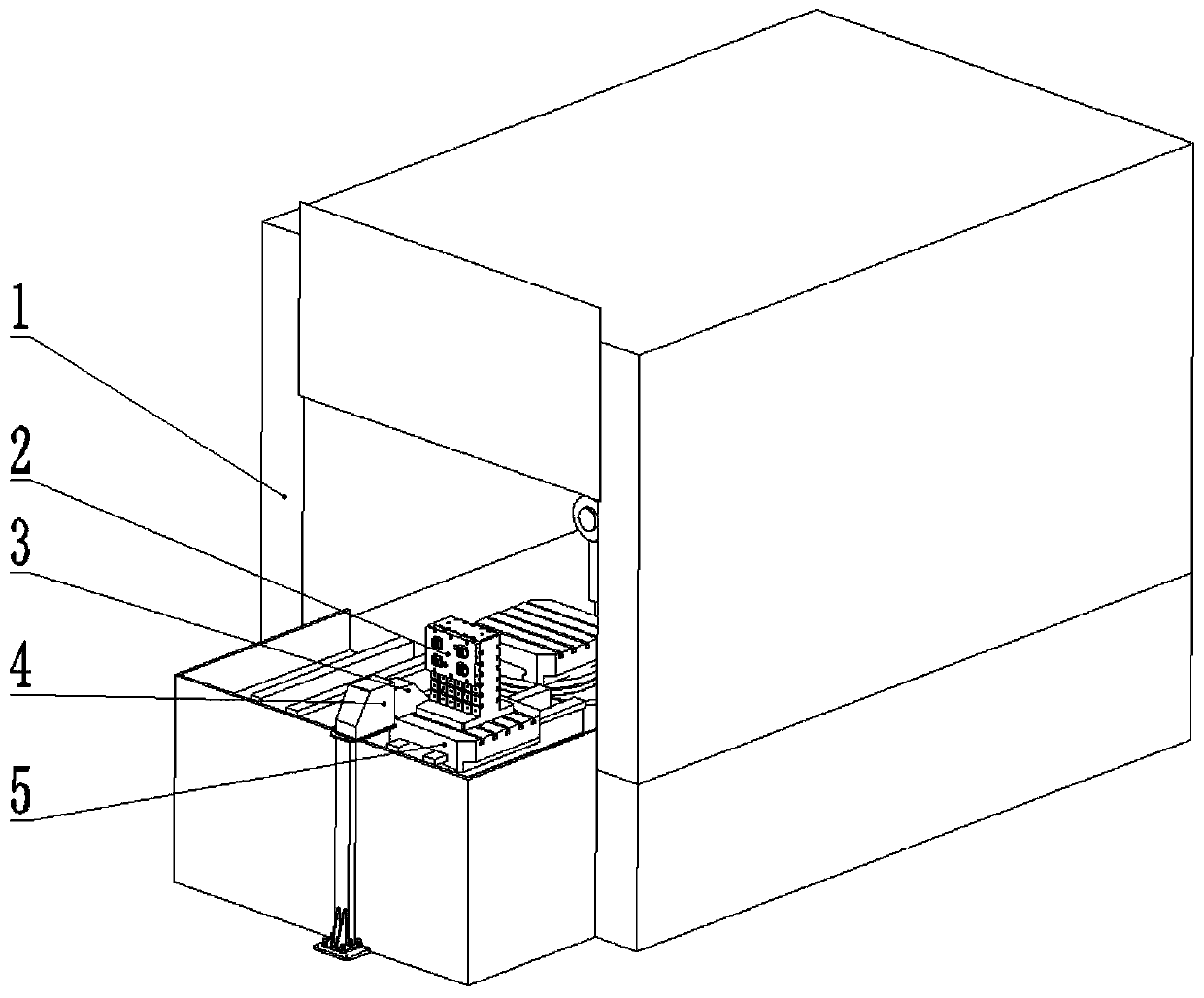

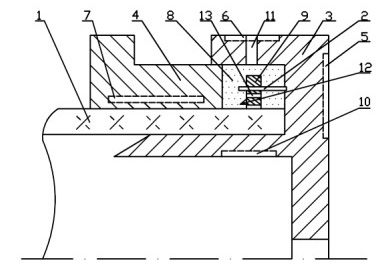

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

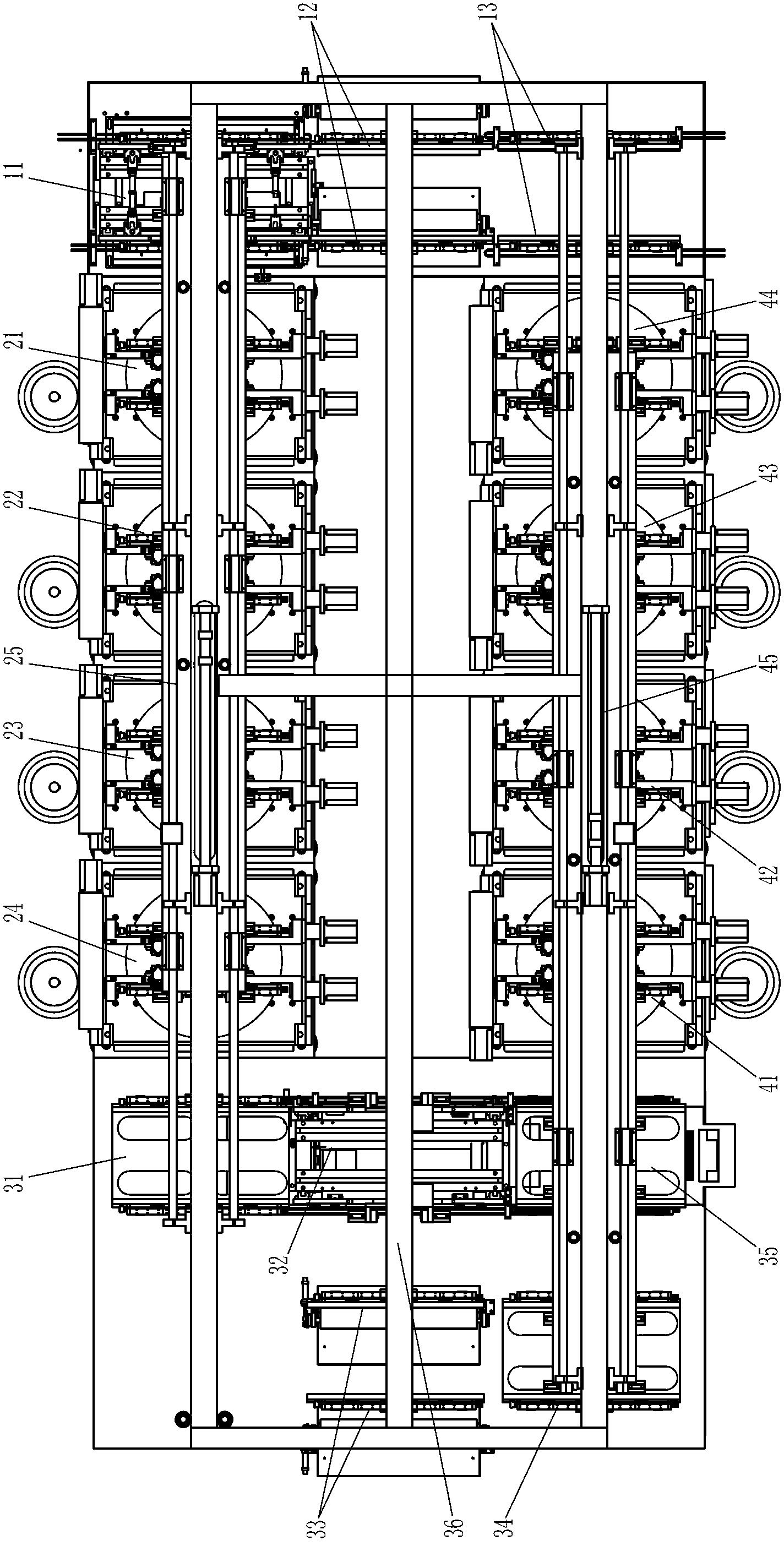

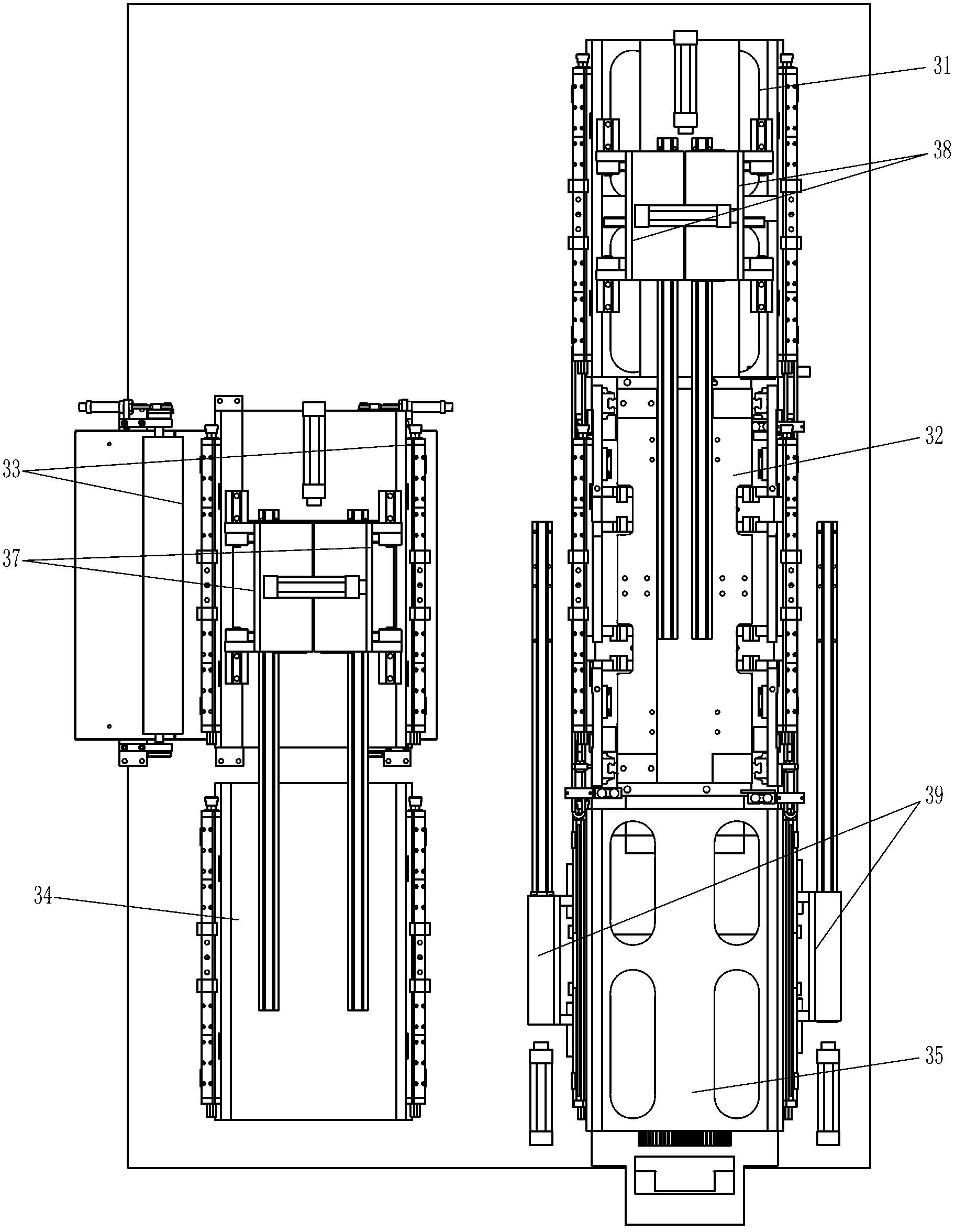

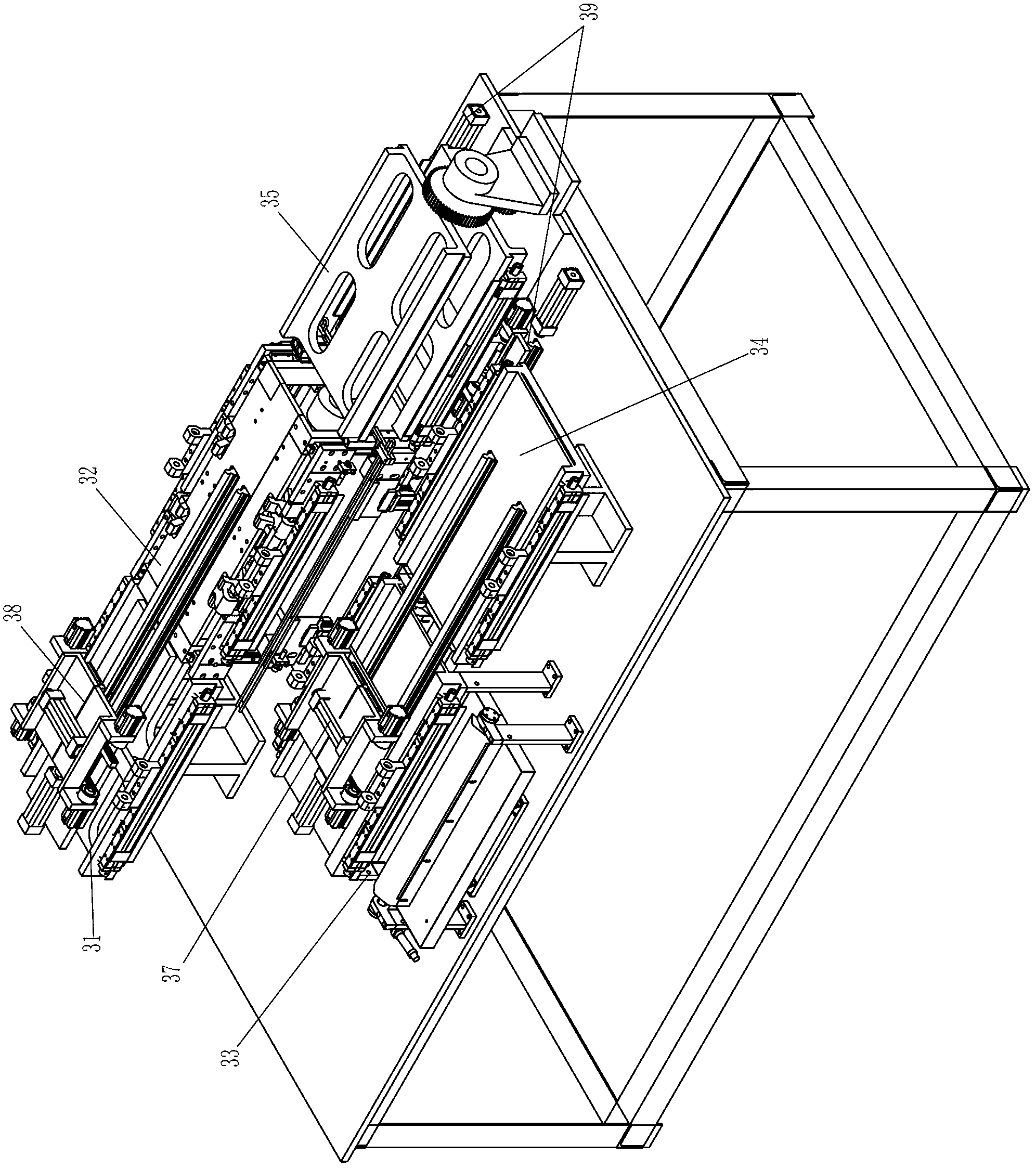

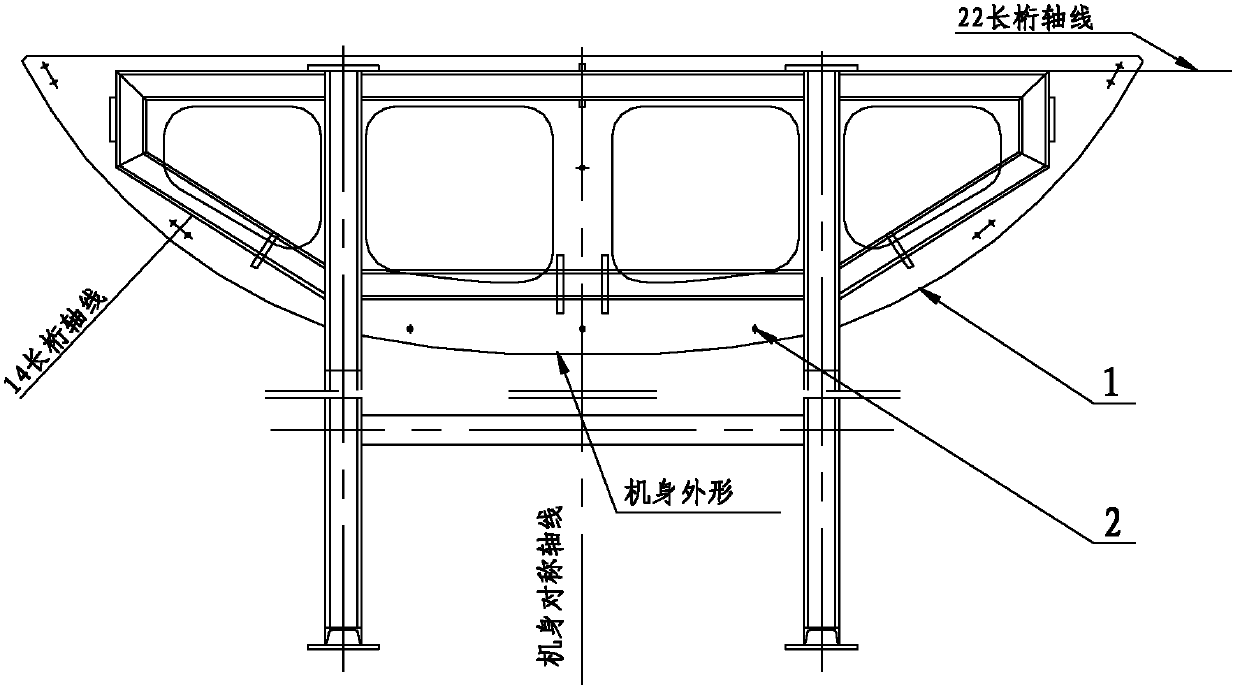

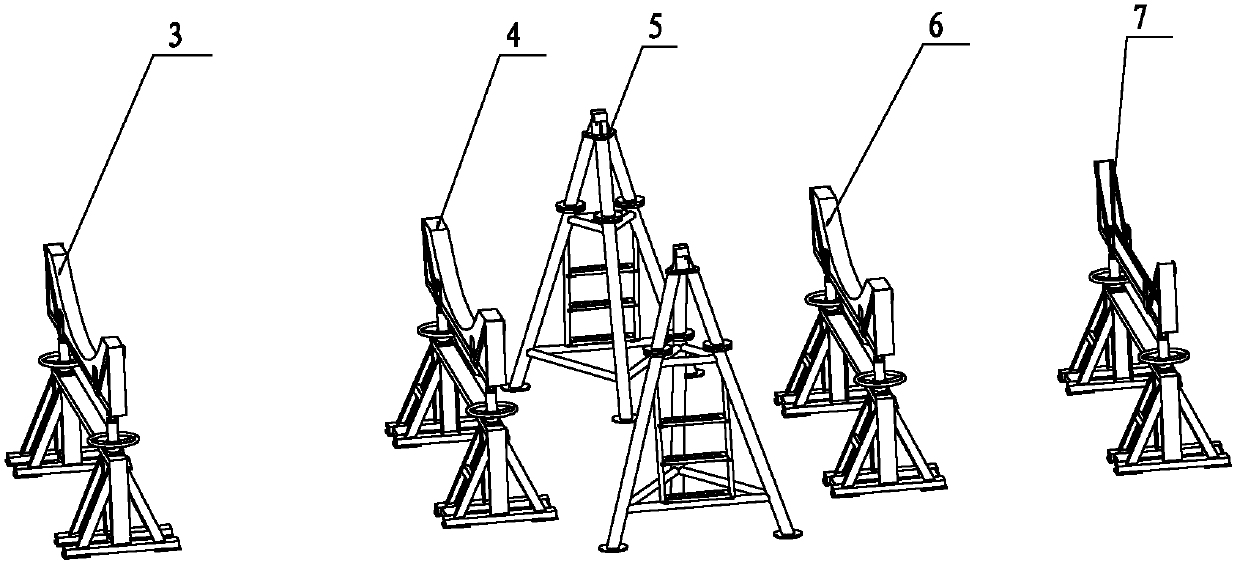

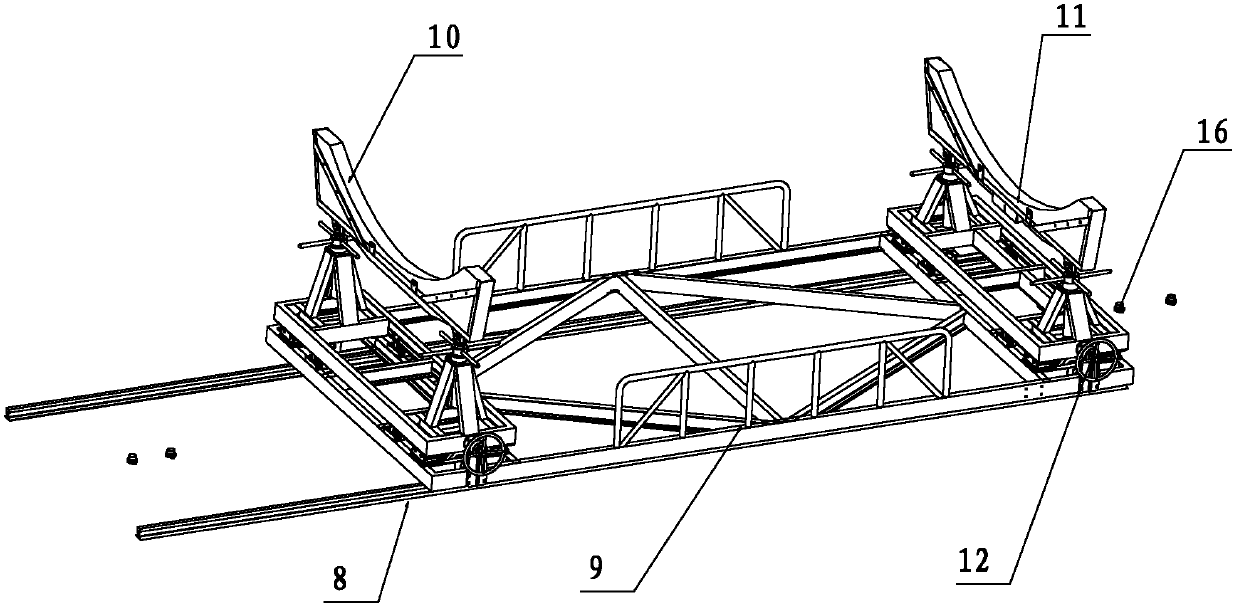

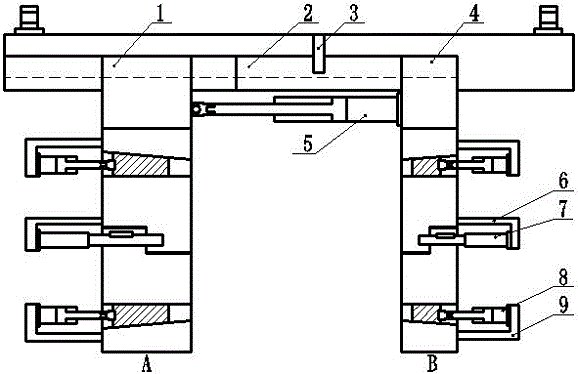

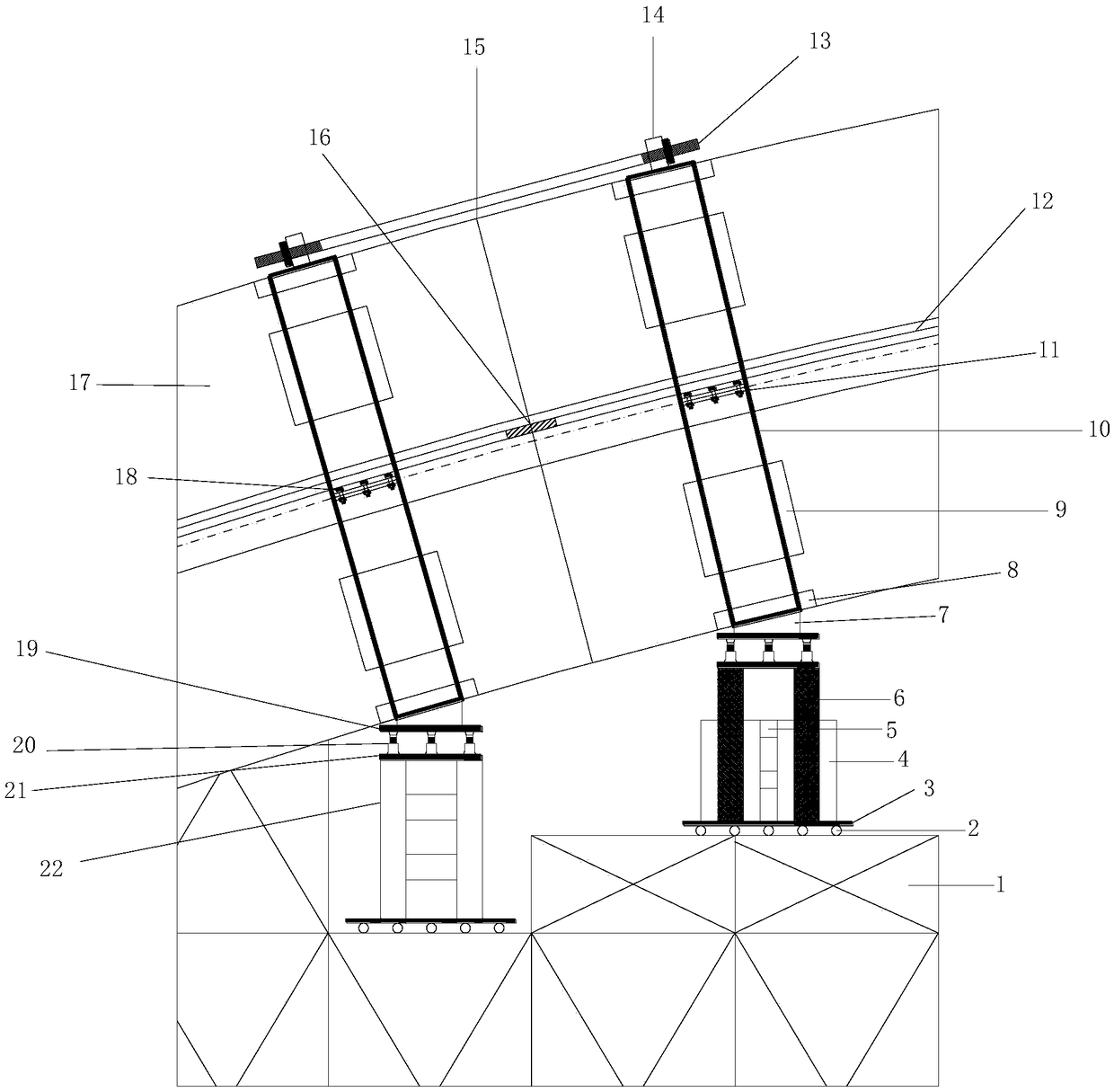

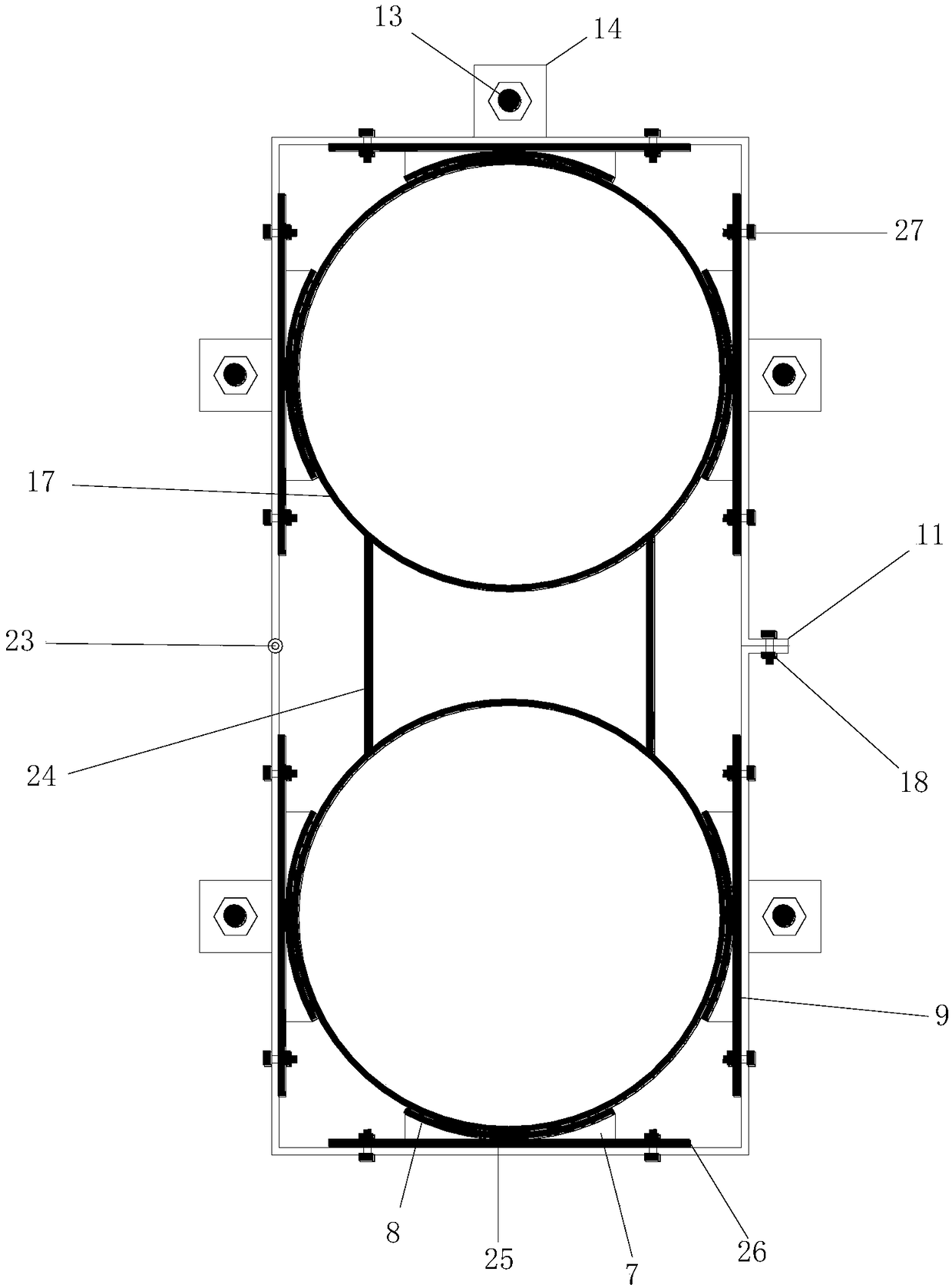

Abutting technological equipment of airplane large components and abutting method thereof

The invention belongs to the technology of airplane abutting, and relates to abutting technological equipment of airplane large components and an abutting method thereof. The abutting technological equipment of the airplane large components disclosed by the invention consists of a fixed part and a movable part, wherein the fixed part comprises a reference flat plate, a main landing gear technological support frame and a plurality of reinforced frame support frames; the movable part comprises a ground rail, a body front section railway car, a locking and positioning device and a centering device, wherein a car body is arranged on the ground rail, the centering device used for preventing the front section from rolling is arranged at the support frame of the car body, and the locking and positioning device is arranged at an abutting surface. When the front section and the middle section of an airplane are abutted via the abutting technological equipment, the position of the middle section is firstly fixed, then the front section is adjusted, and then accurate abutting of the front section and the middle section is realized through railway movement so as to perform subsequent riveting work. According to the abutting technological equipment of the airplane large components and the abutting method thereof, the abutting difficulty and potential safety hazard of the airplane large components are greatly reduced, the manufacturing efficiency and the abutting quality are improved, and the abutting precision of products is effectively ensured.

Owner:SHAANXI AIRCRAFT CORPORATION

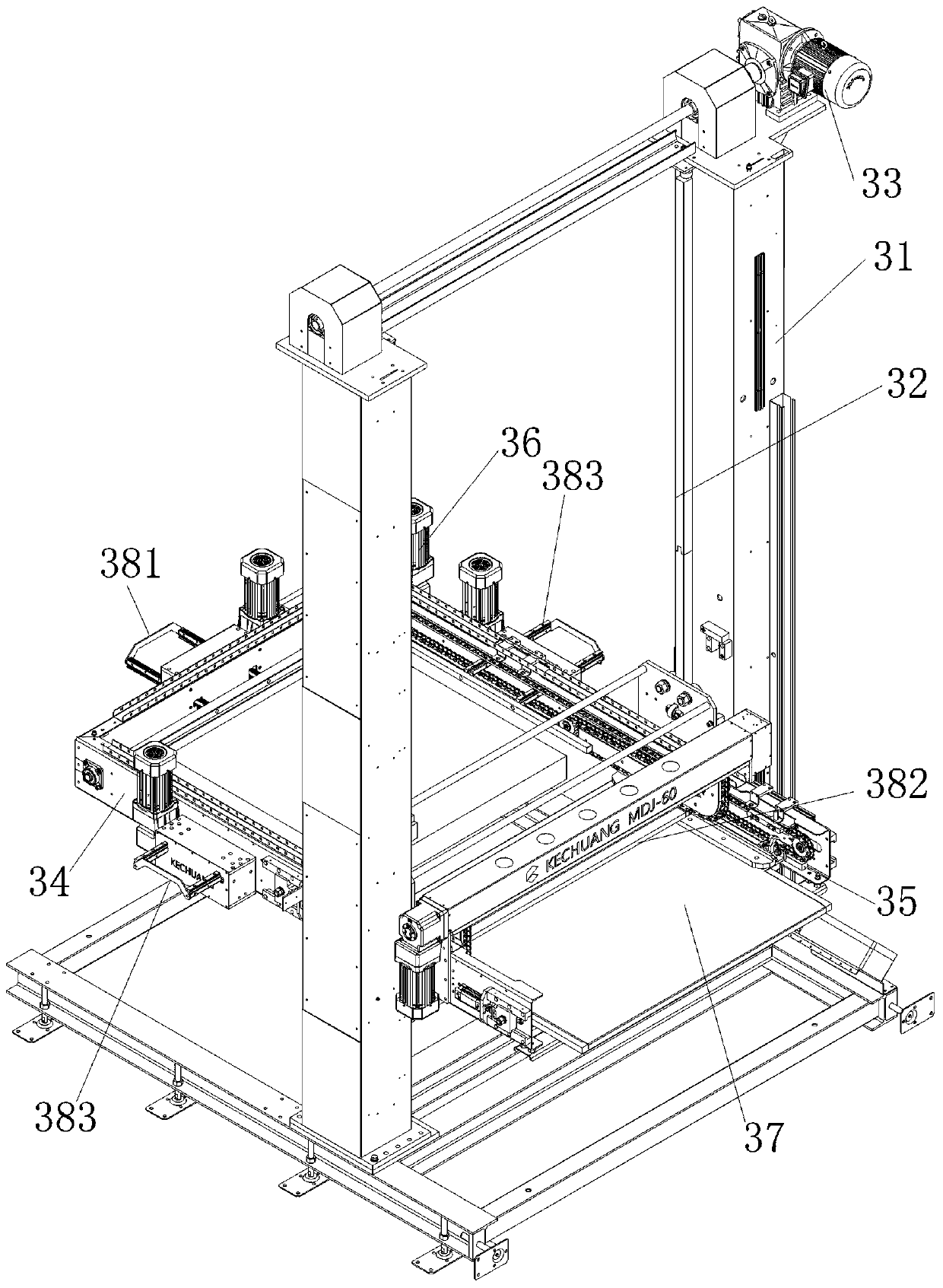

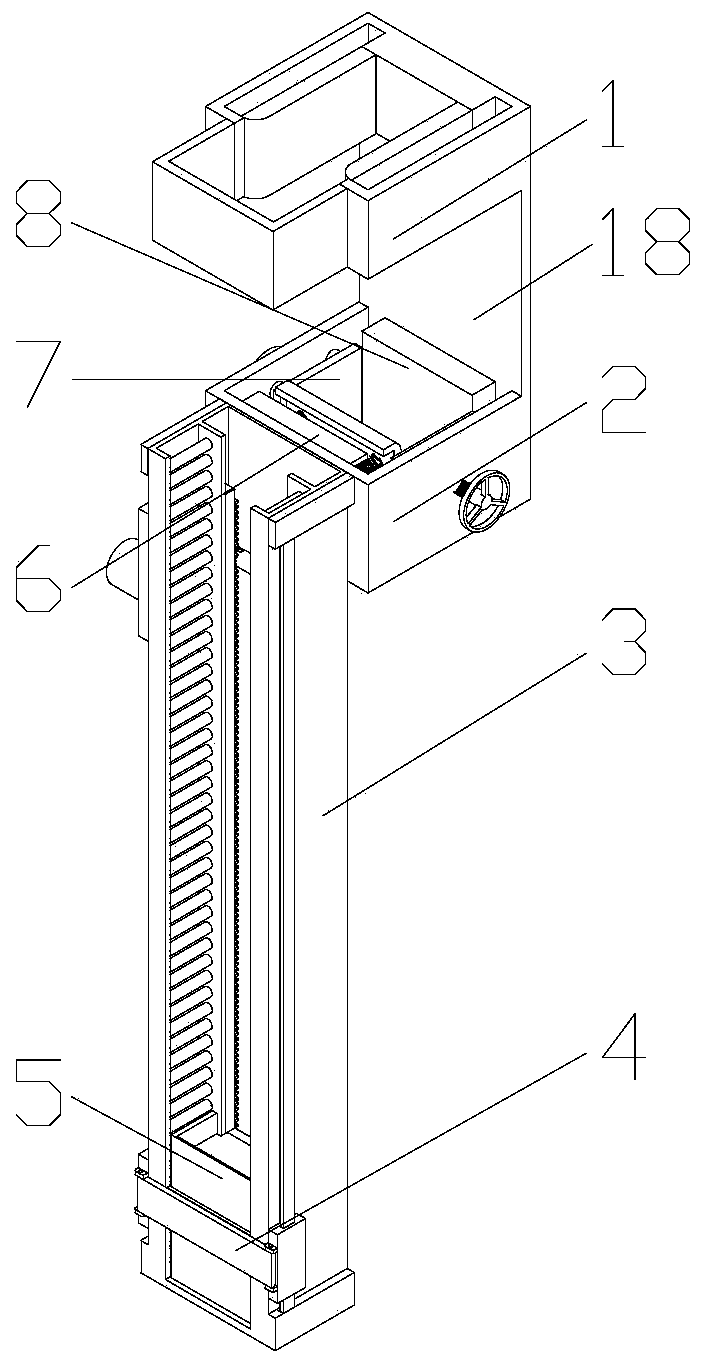

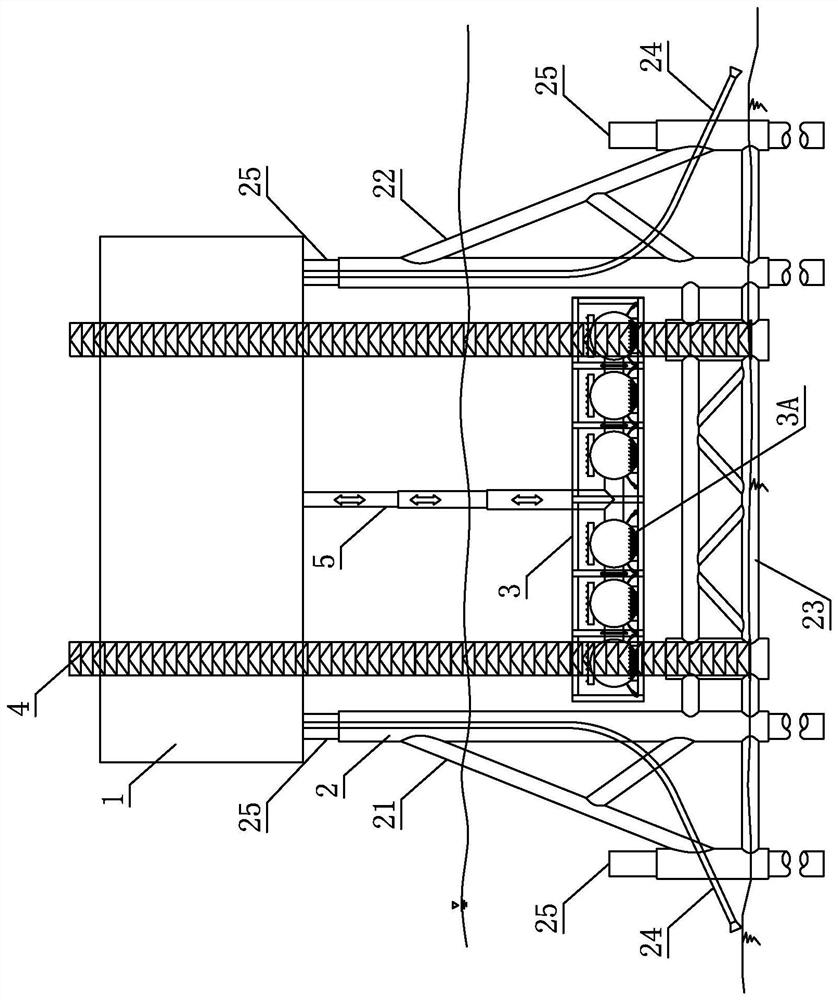

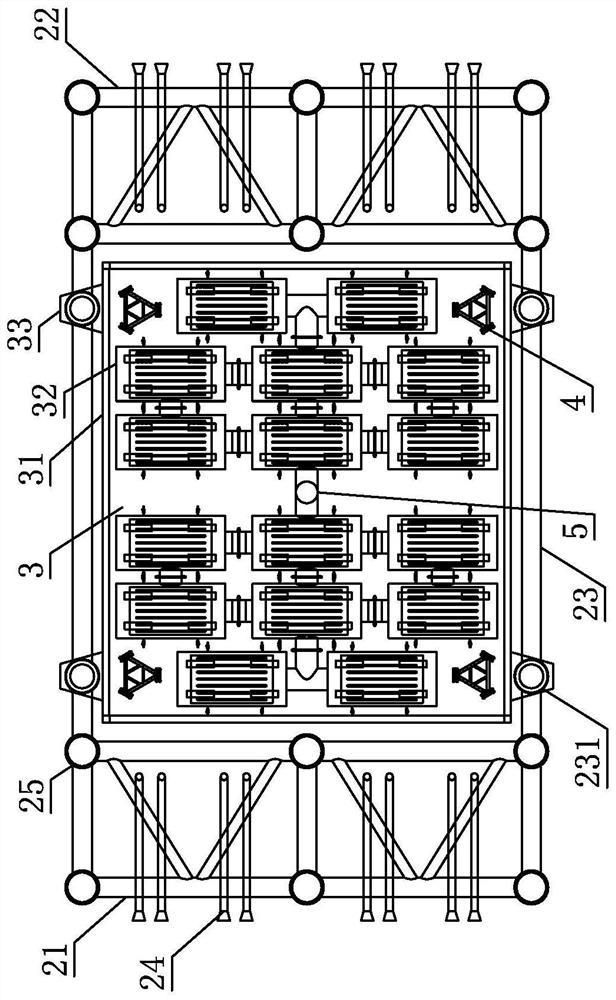

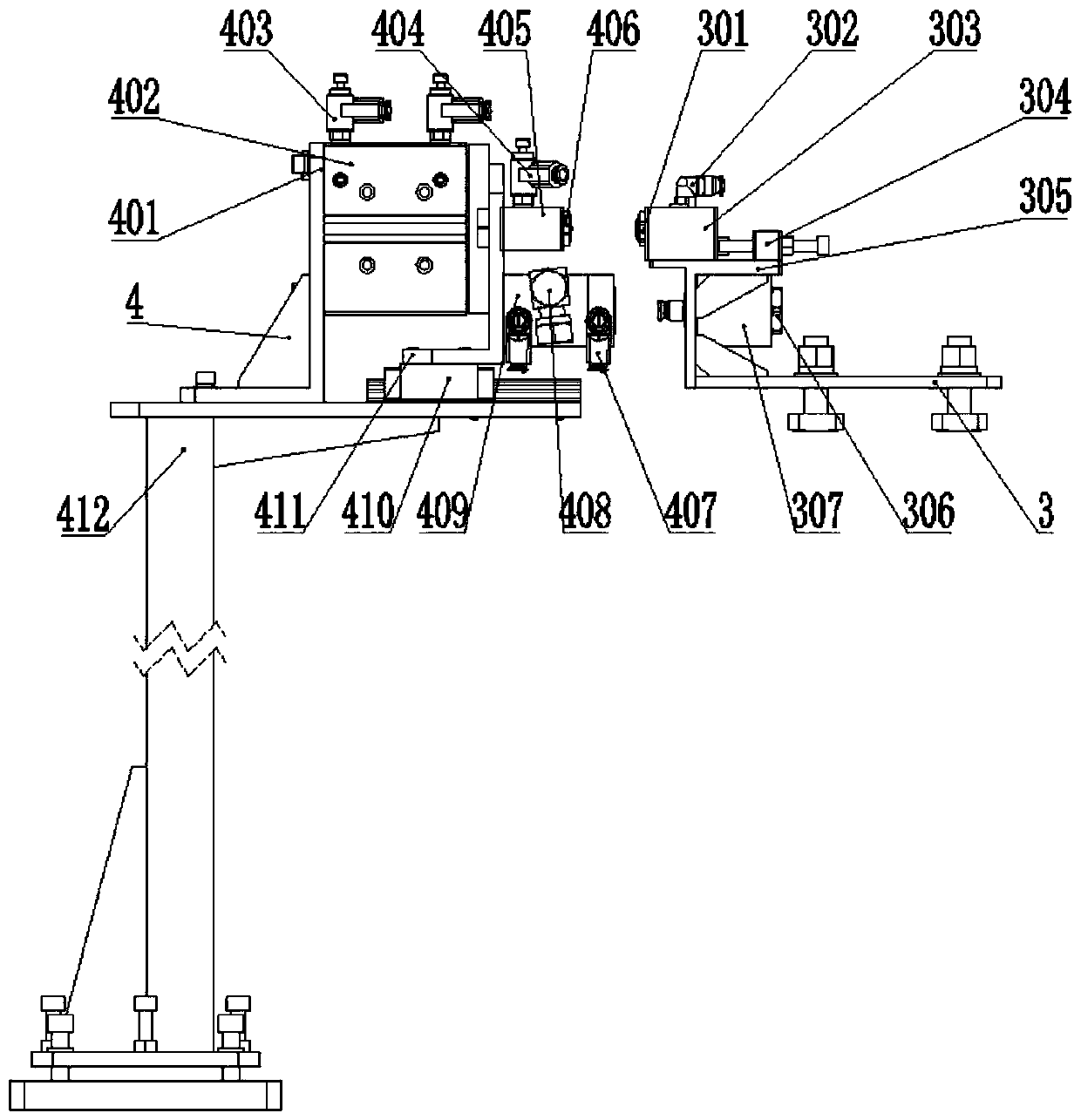

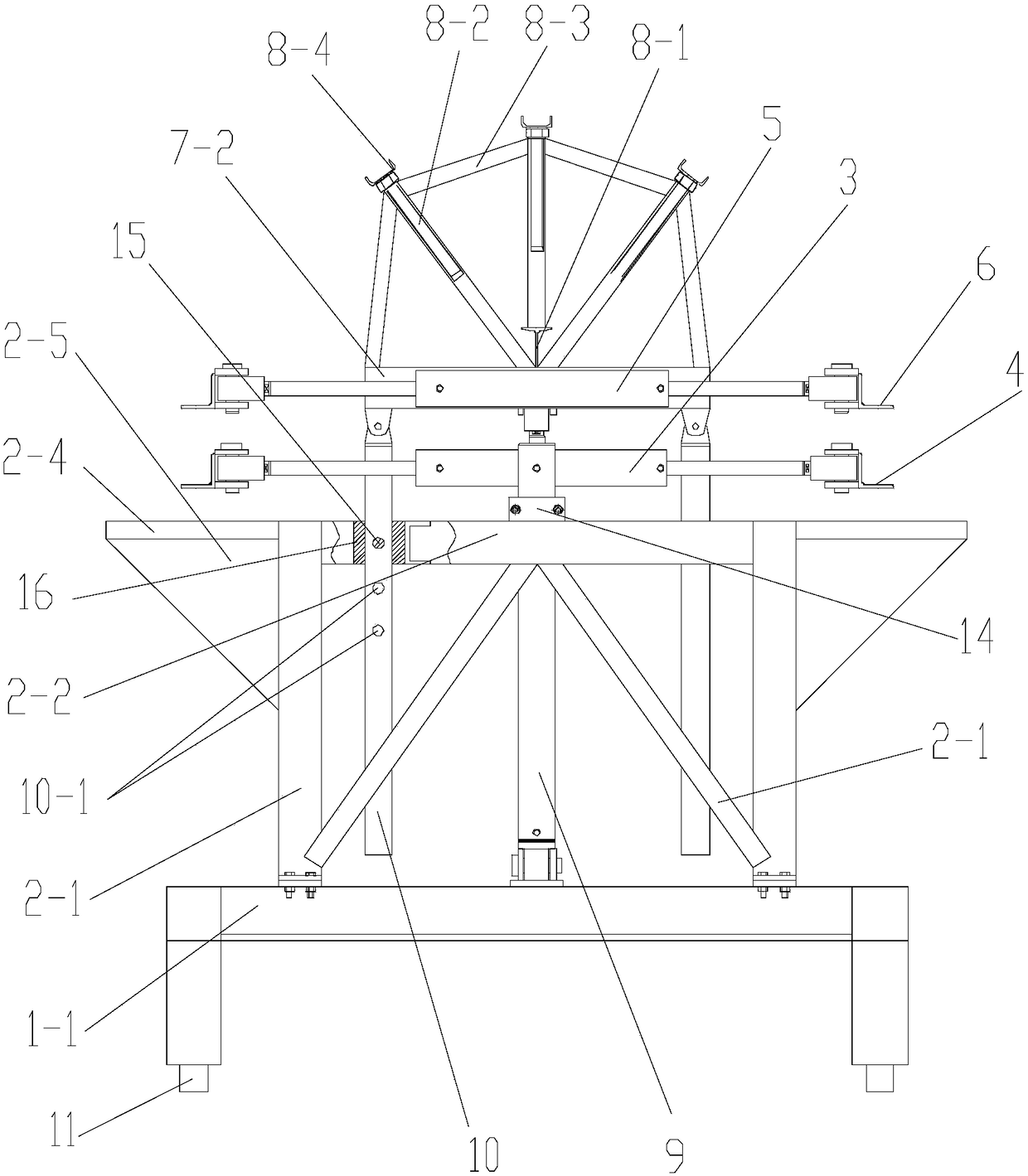

Automatic packaging box stacking machine capable of achieving selective stacking

PendingCN107697646AFacilitated releaseImprove reliabilityStacking articlesDe-stacking articlesPalletizerStructural engineering

The invention discloses an automatic packaging box stacking machine capable of achieving selective stacking, and belongs to the technical field of stacking. The machine comprises an arranging and steering mechanism, a grouping pushing mechanism, a door type stacking mechanism and a matched tray storage supply mechanism which are sequentially arranged on a rack in the packaging box conveying direction. The arranging and steering mechanism comprises a feeding conveying device and a steering device arranged on one side of the feeding conveying device; the machine is characterized in that the steering device comprises a pre-steering baffle and a strengthening check block which are arranged at an interval in the feeding conveying direction, the pre-steering baffle is hinged to a pre-steering air cylinder on the rack through a bending rod and is hinged to the rack to form a swing stretching-out blocking and reset releasing structure, the strengthening check block is connected with a strengthening air cylinder on the rack, and forms a strengthening and resetting releasing structure by means of guidance of a sliding rail and sliding block pair perpendicular to the feeding conveying direction, a packaging box, required to be subject to steering, in the conveying process is subject to rotating and pre-steering operation around the blocked angle by means of blocking of the pre-steering baffle, and pressing strengthening of the blockage angle can be achieved by means of the strengthening check block.

Owner:WEIXIAN KECHUANG LIGHT IND EQUIP

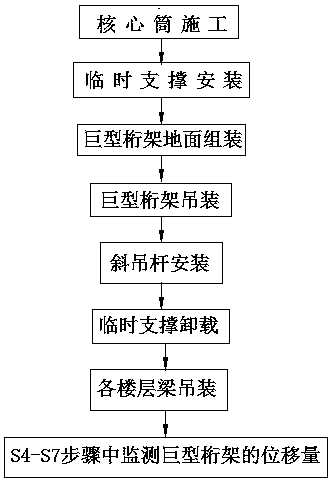

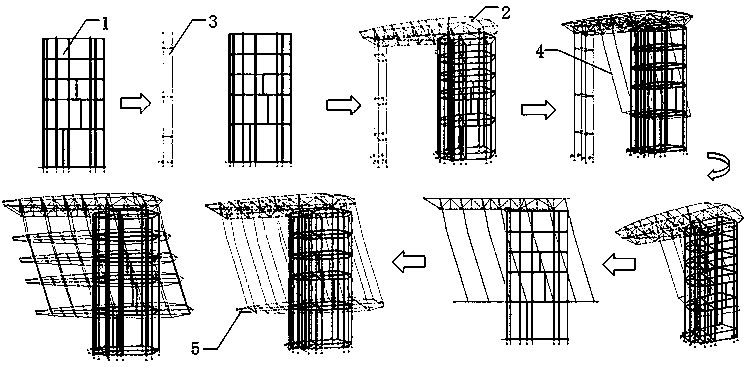

Installation method of special-shaped and curved-surface suspension type steel structure system

ActiveCN111364615AGuarantee welding qualityMeet penetration quality requirementsExtraordinary structuresBuilding material handlingFalseworkArchitectural engineering

The invention belongs to the technical field of steel structure construction, and particularly relates to an installation method of a special-shaped and curved-surface suspension type steel structuresystem. The problems are solved that the construction precision of a traditional installation method is difficult to guarantee, the construction period is long, a large amount of cost needs to be invested in scaffold and inclined suspender layer-by-layer hoisting, and many high-altitude hidden dangers exist. The special-shaped and curved-surface suspension type steel structure system comprises a core cylinder, a giant truss, a temporary support, an inclined suspender and beams of all floors. The installation method comprises the following steps that S1, the core cylinder is constructed; S2, the temporary support is installed; S3, the giant truss is assembled on the ground; S4, the giant truss is hoisted; S5, the inclined suspender is installed; S6, the temporary support is unloaded; S7, the beams of all the floors are hoisted; and S8, the displacement of the giant truss is monitored in the steps of S4-S7. According to the installation method, the construction precision is guaranteed, the installation efficiency is high, the installation construction period is shortened, and the operation safety risk is reduced. The erection and hoisting cost of a scaffold is saved, the high-altitude butting joints are reduced, the near-edge protection cost is reduced, and therefore the construction cost is reduced.

Owner:CHINA SHANXI SIJIAN GRP

Sliding type monorail crane turnout system for mines

The invention discloses a sliding type monorail crane turnout system for mines, belonging to the technical field of mine equipment. The sliding type monorail crane turnout system comprises a frame assembly, a slide track assembly and a hydraulic cylinder, wherein the slide track assembly is connected with the frame assembly through a wheel set; the wheel set can slide inside the frame assembly freely; a hydraulic cylinder flange is fixedly connected with a hydraulic cylinder connecting flange in the frame assembly; and a piston rod is connected with the slide track assembly through a hinge pin. The sliding type monorail crane turnout system is stable in structure and convenient to operate, potential safety hazards of a monorail crane locomotive are avoided, and the abrasion to wheels is reduced; and meanwhile the remote control is realized, and requirements of mines are met.

Owner:徐州苏煤矿山设备制造有限公司

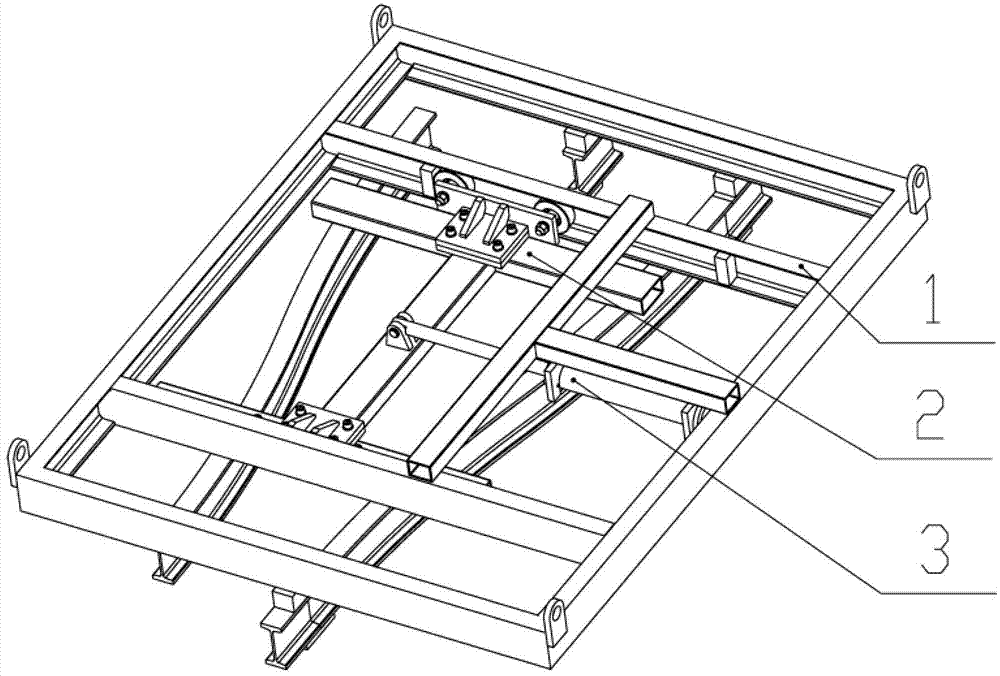

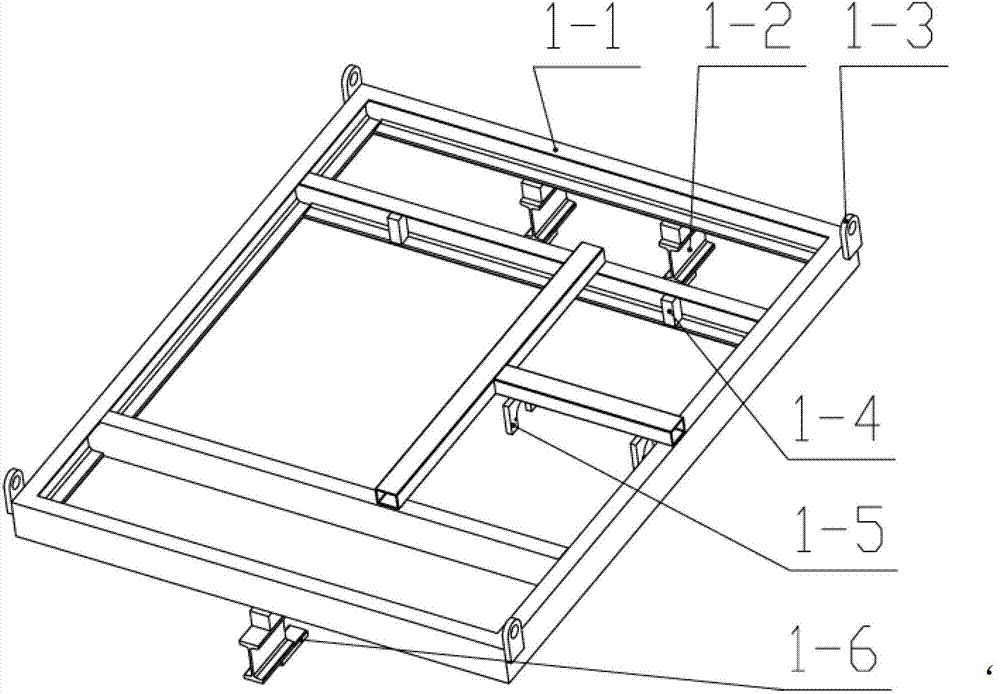

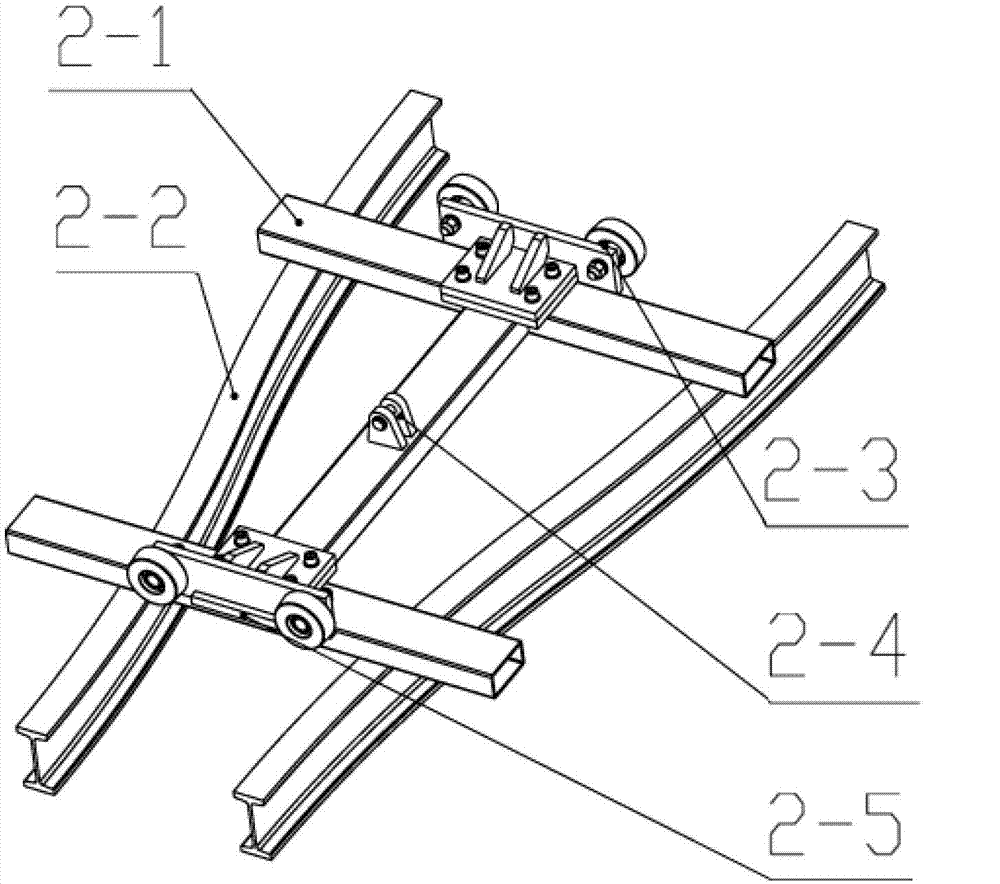

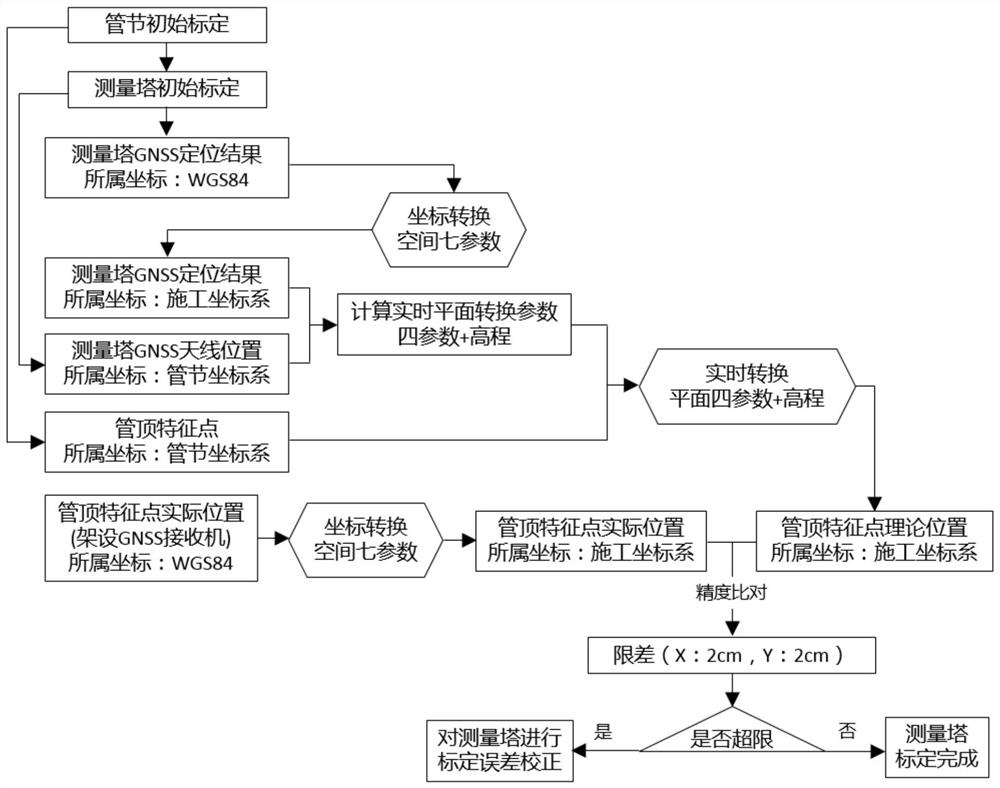

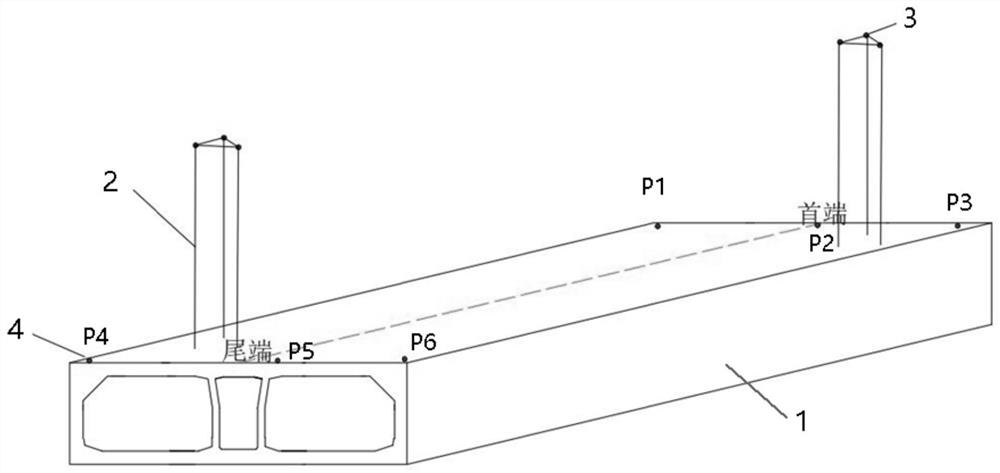

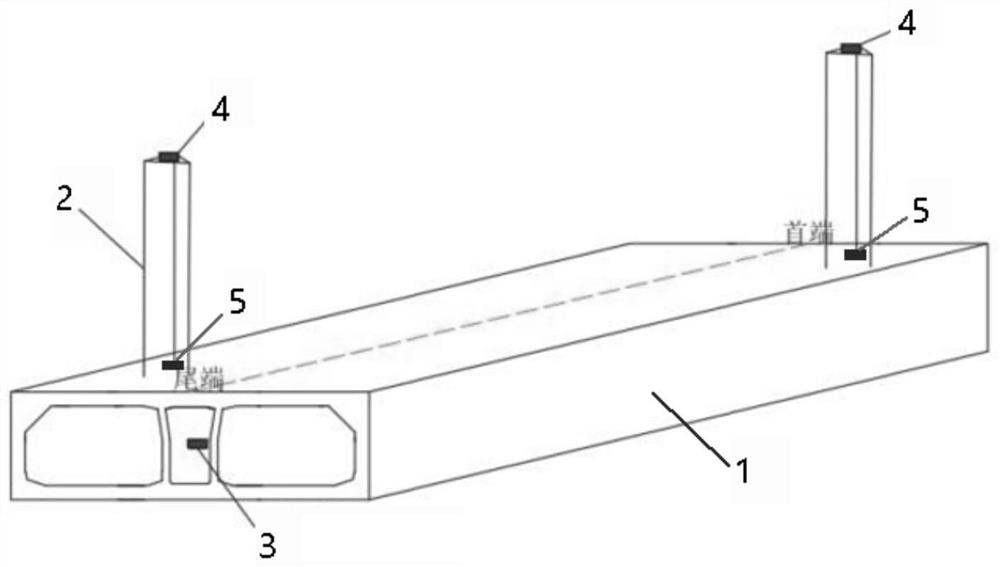

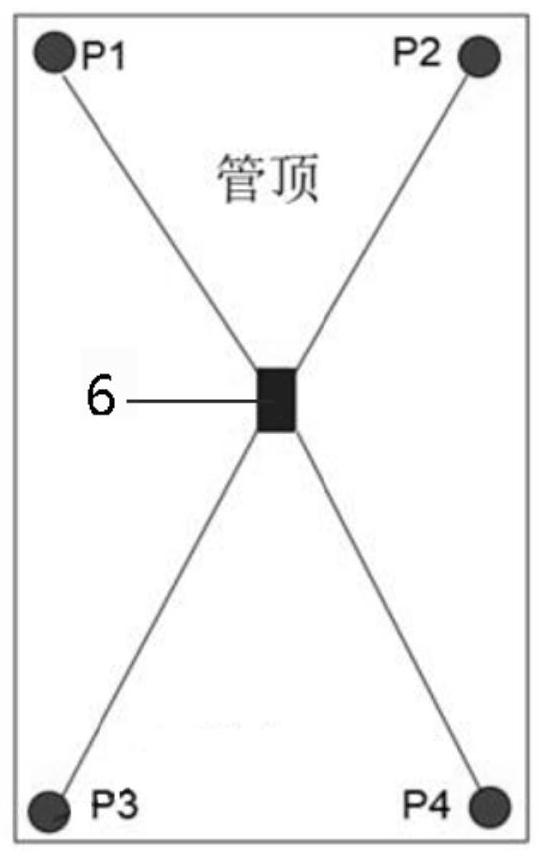

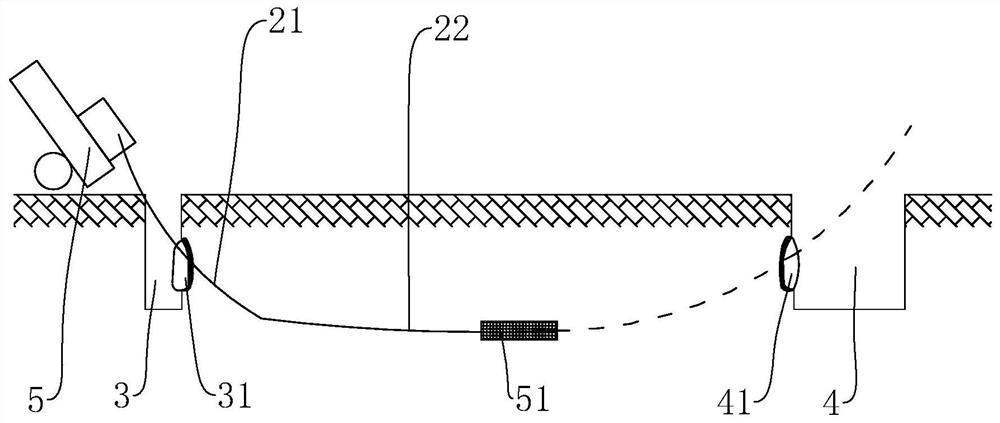

Inverse calibration correction method for positioning precision of immersed tube installation measuring tower

ActiveCN113866802AGuaranteed docking accuracyReduce the risk of docking measurement and controlNuclear energy generationNavigation instrumentsControl systemClassical mechanics

The invention belongs to the technical field of engineering measurement, and particularly relates to an inverse calibration correction method for positioning precision of an immersed tube installation measuring tower. The inverse calibration correction method comprises the steps of measurement and control system calibration, positioning precision correction and the like. The calibration of the measurement and control system further comprises initial calibration of a pipe joint and initial calibration of a measurement tower; the positioning precision correction further comprises construction coordinate system establishment, data processing, precision comparison and correction. According to the method, a GNSS receiver is erected on the pipe top feature points to collect the coordinates in real time and compare the coordinates with the real-time calculation result of the measurement tower measurement and control system, calibration error correction is carried out on the measurement tower before the pipe joint is immersed, the reliability of the calibration precision of the measurement tower is improved, and the installation precision of the immersed pipe is guaranteed.

Owner:CCCC FIRST HARBOR ENG +2

End connection mechanism for embedded power supply system

The invention discloses an end connection mechanism for an embedded power supply system. The end connection mechanism comprises two embedded supports and a bottom plate. Each embedded support comprises a body and a base; a conducting rail is arranged over the body of the embedded support. The embedded supports are fixedly mounted on the bottom plate through their bases. A connection box which can also be fixedly mounted on the bottom plate is disposed between the end embedded supports. The connection box is internally provided with a junction chamber. Two ends of the connection box are in connection fit with the adjacent ends of the embedded supports, respectively. The bottom plate is provided with cable holes admitting passage of cables. The end connection mechanism with the structure is simple in structure and convenient to mount, and the requirement for the level of installation of the embedded supports and the connection box is met; the embedded supports and the bottom plate are fixed by press-fitting of a mounting pressure plate, no structural damage of the embedded supports is required, the production process of the embedded supports is simpler, and the structural strength of the embedded supports can be improved.

Owner:ZHENJIANG DAQO SECHERON TRACTION POWER

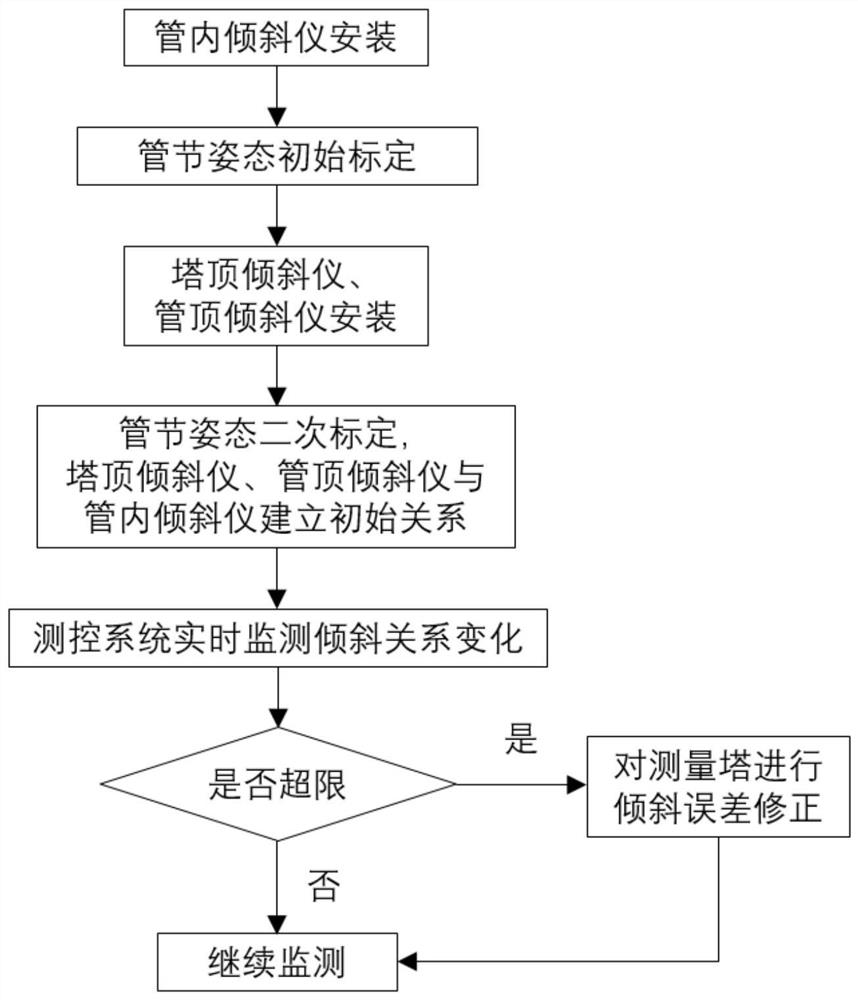

Method for correcting locating inclination error of immersed tube installation measuring tower

ActiveCN113866803APositioning tilt error correctionGuaranteed docking accuracyNuclear energy generationNavigation instrumentsControl engineeringMachine

The invention belongs to the technical field of engineering measurement, and particularly relates to a method for correcting locating an inclination error of an immersed tube installation measuring tower. The method comprises the steps of initial calibration of tube joint postures, installation of clinometer equipment, measurement tower posture calibration, measurement tower positioning inclination error correction and the like. According to the method, clinometers are additionally arranged at the tops of the measuring towers at the head end and the tail end of the pipe joint and the top of the pipe respectively, and the clinometers and the clinometers in the pipe are combined to determine the postures and the mutual relation of the measuring towers and the pipe joint, so that the posture change of the measuring towers is monitored in real time in the sinking process of the pipe joint; real-time automatic prompting and man-machine interaction type real-time correction of the positioning inclination error of the measuring tower are achieved, the positioning precision and reliability of the measuring tower are improved, and the installation precision of the immersed tube is guaranteed.

Owner:CCCC FIRST HARBOR ENG +2

LNG (liquefied natural gas) liquid dome fragment same-mould manufacturing and staged folding method

ActiveCN107284603AGuaranteed flatnessGuaranteed installation accuracyVessel partsEngineeringLiquefied natural gas

The invention discloses an LNG (liquefied natural gas) liquid dome fragment same-mould manufacturing and staged folding method which includes the steps: first, manufacturing a liquid dome fragment (except for an inner stainless steel deck) and a deck panel by the same mould by taking a trunk deck as a base plane to manufacture reverse state fragments (the liquid dome fragment and the adjacent deck panel); second, positive folding: combining the reverse state fragments, then turning the reverse state fragments onto the inner deck and performing positive folding by the same mould by taking the inner deck as a base plane; third, staged erection: lifting away the liquid dome fragment from the deck panel and performing subsequent folding after data are measured in the third step and the deck panel enters dock, transferring the separated liquid dome fragment to a staged site and performing assembly-welding and fitting-out operation with the inner stainless steel deck to form a complete liquid dome fragment. Folding precision of a main portion of the liquid dome fragment and an internal structure of the deck panel is ensured, and deviation of the internal structure in the docking process is decreased.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

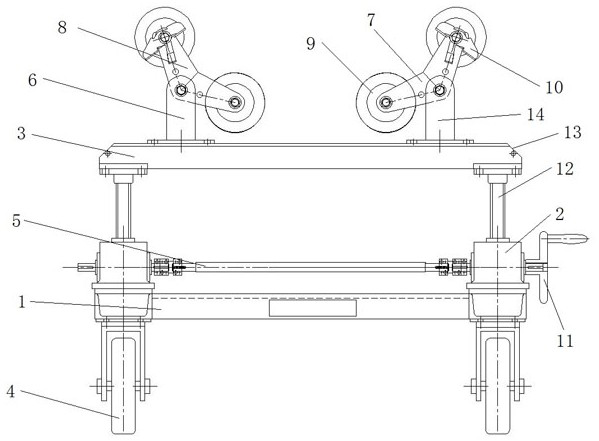

Adjustable support for clinical positions in orthopedics department

ActiveCN108013993AAccurate angleGuaranteed docking accuracyOperating tablesButt jointArchitectural engineering

The invention discloses an adjustable support for clinical positions in the orthopedics department. The support comprises a base. The side end of the base is equipped with installation columns. The installation column and mounting holes in the side surface of an externally-arranged hospital bed are cooperatively installed. The upper surface of the base is equipped with a mounting groove. The mounting groove of the base is internally and rotatably provided with a first lead screw. An input shaft of the first lead screw is connected with an output shaft of a first motor. The first motor is fixedly connected with the base. The outside of the first lead screw is provided with a first lead screw nut in a matching manner. The upper end of the first lead screw nut is fixedly provided with a sliding block. The upper end of the sliding block is equipped with a mounting board through electric telescopic rods. The surface of the mounting board is provided with a through hole. The adjustable support for clinical positions in the orthopedics department can adjust the distance and the height difference between two sections of leg bones while adjusting angles between the leg bones at two ends. Therefore, butt-joint precision is effectively ensured.

Owner:郑春山

Hydraulic docking device used outside large-caliber gathering and transportation pipeline

InactiveCN105598630AShorten laying timeQuick lockWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderHydraulic motor

The invention relates to a hydraulic docking device used outside a large-caliber gathering and transportation pipeline. The hydraulic docking device achieves the purpose of rapidly achieving pipeline docking and repairing on the premise of guaranteeing welding quality. According to the technical scheme, a fixed holding ring, a right rotating holding ring and a left rotating holding ring are each provided with an arc T-shaped groove of certain gradient; the hanging ring end of the right rotating holding ring and the hanging ring end of the left rotating holding ring are connected with two hanging ring ends of the fixed holding ring through rotating hinge pins; hydraulic cylinder ends of horizontal push hydraulic cylinders are connected with horizontal push hydraulic cylinder bases through flanges, and a push rod end acts on the positions of a circular groove of a wedge-shaped locking ring; hydraulic cylinder ends of swing hydraulic motors are connected with swing hydraulic motor bases through flanges, and rotating shaft ends are connected with the rotating hinge pins through couplings. According to the hydraulic docking device, a hoisting form and hydraulic drive are adopted, the hydraulic docking device can adapt to pipe repair under complex working conditions, and meanwhile centring and weld seam gap adjustment between the pipeline to be welded and a new pipeline can be achieved rapidly.

Owner:SOUTHWEST PETROLEUM UNIV

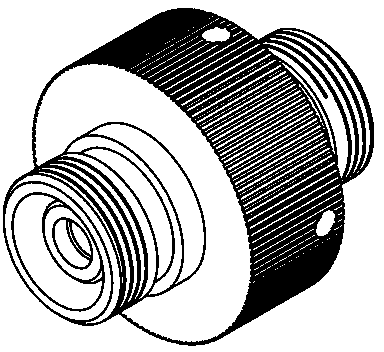

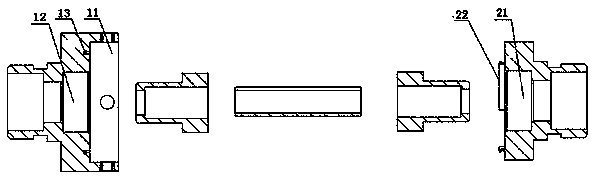

Optical fiber adapter and application thereof

ActiveCN103412376AFacilitate transmissionSimple structureCoupling light guidesManufacturing technologyPolarization-maintaining optical fiber

The invention discloses an optical fiber adapter and the application thereof. The optical fiber adapter comprises a ceramic sleeve which is axially communicated, a first casing pipe, a second casing pipe, an inner shell body and an outer shell body, wherein the first casing pipe and the second casing pipe are mutually connected in a butt joint mode and are respectively arranged outside the ceramic sleeve in a sleeved mode, the first casing pipe is sleeved with the inner shell body, the second casing pipe is sleeved with the outer shell body, and the inner shell body is matched with the outer shell body in a clamping mode. The optical fiber adapter is used for connecting polarization maintaining optical fiber connectors, the precision of butt joint of optical axes of two optical fibers can be guaranteed, the extinction ratio is in the maximum value, and the transmission performance of the optical fibers is optimal. In addition, the requirement for the manufacturing precision of the polarization maintaining optical fiber connectors is low, the manufacturing technology is simple, and manufacturing cost is low. The optical fiber adapter is suitable for the technical field of optical fiber transmission.

Owner:河北四方通信设备有限公司

Steel structure butt jointing device for building construction

ActiveCN111424994AConvenient docking and positioningGuaranteed docking accuracyBuilding material handlingButt jointArchitectural engineering

The invention discloses a steel structure butt jointing device for building construction. The steel structure butt jointing device comprises a limiting mechanism, a fixing mechanism and a supporting plate. One end of the supporting plate is mounted on the limiting mechanism, the other end of the supporting plate is mounted on the fixing mechanism, a fixing groove is formed in one side of the fixing mechanism, and the lifting mechanism is mounted in the fixing groove. A clamping mechanism and a fastening device can clamp steel structures with different sizes, the steel structures with differentsizes can be butted, and the practicability of the device is guaranteed. The lifting mechanism can lift the steel structure needing butt jointing, the steel structure can be conveniently positioned and butted in the air, the labor intensity is reduced, and the butt joint efficiency is guaranteed. The limiting mechanism can limit the steel structure needing butt jointing, the butt jointing precision of the steel structure is guaranteed, and the butt jointing quality of the steel structure is guaranteed.

Owner:BEIJING TIANHENG CONSTR

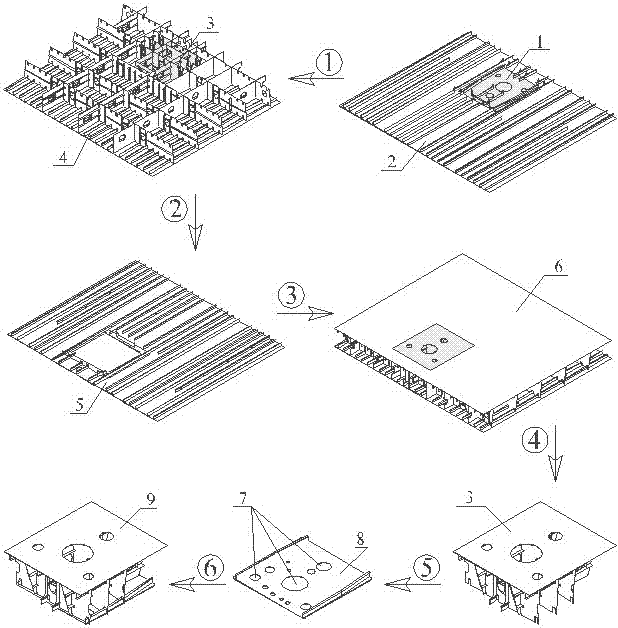

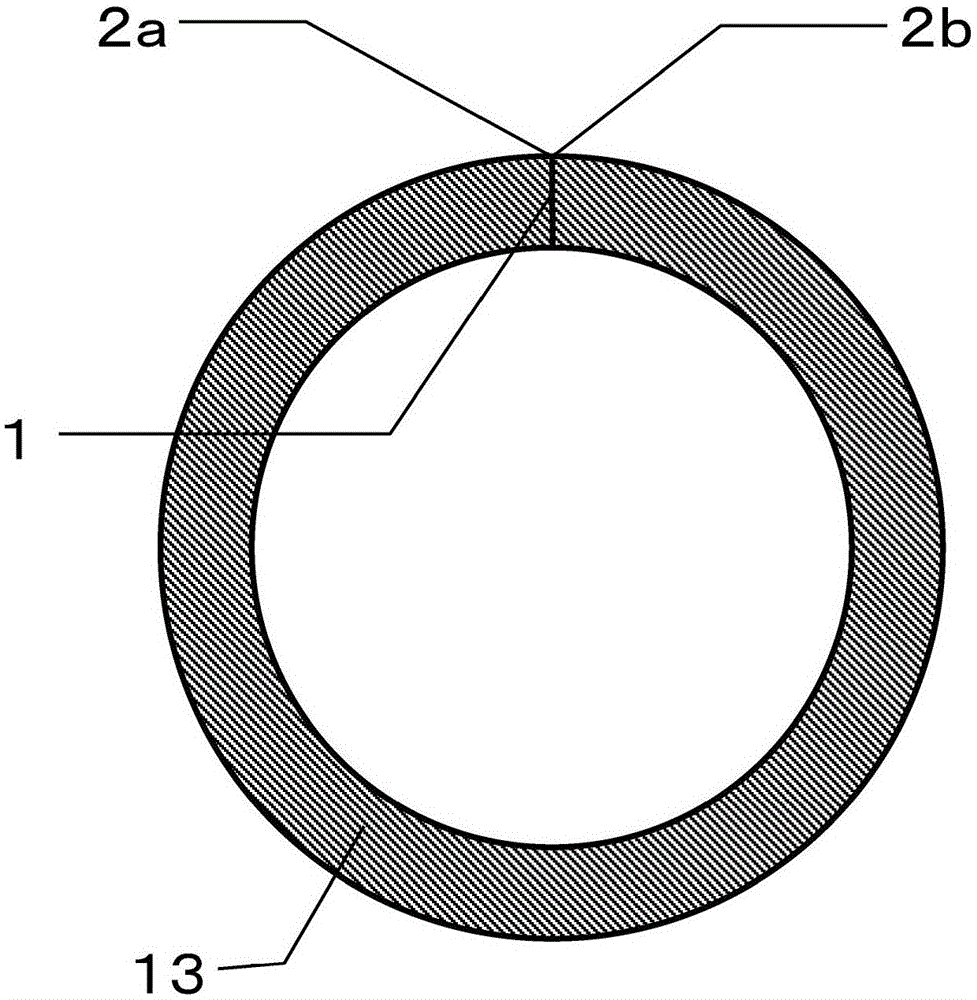

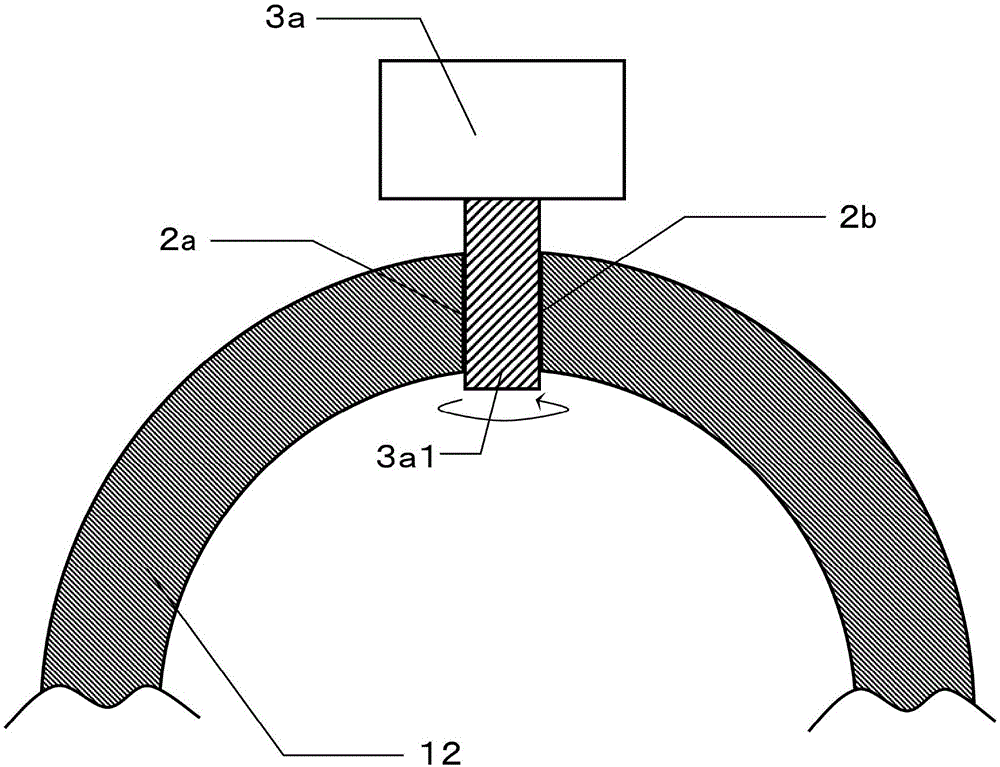

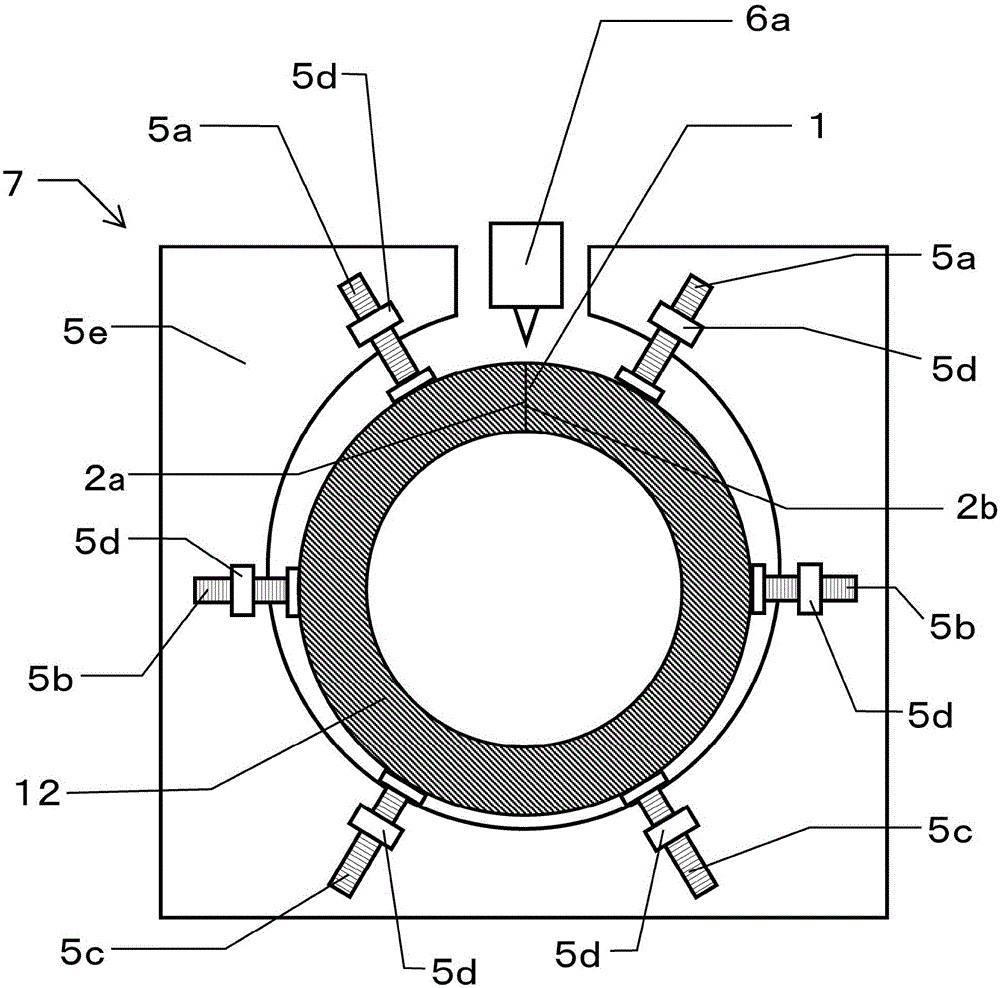

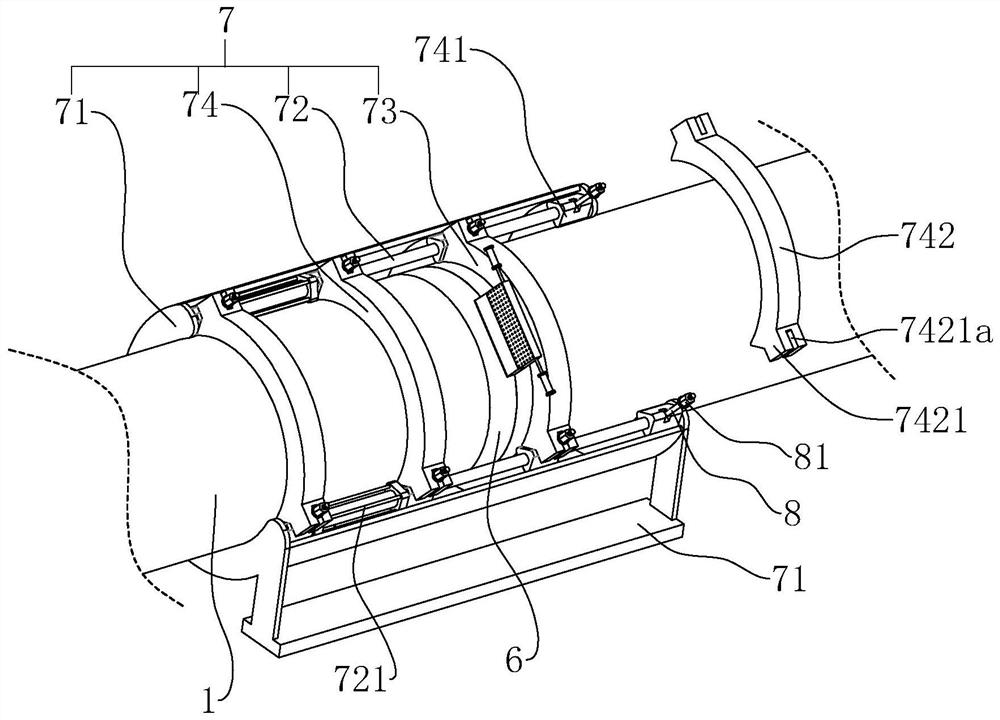

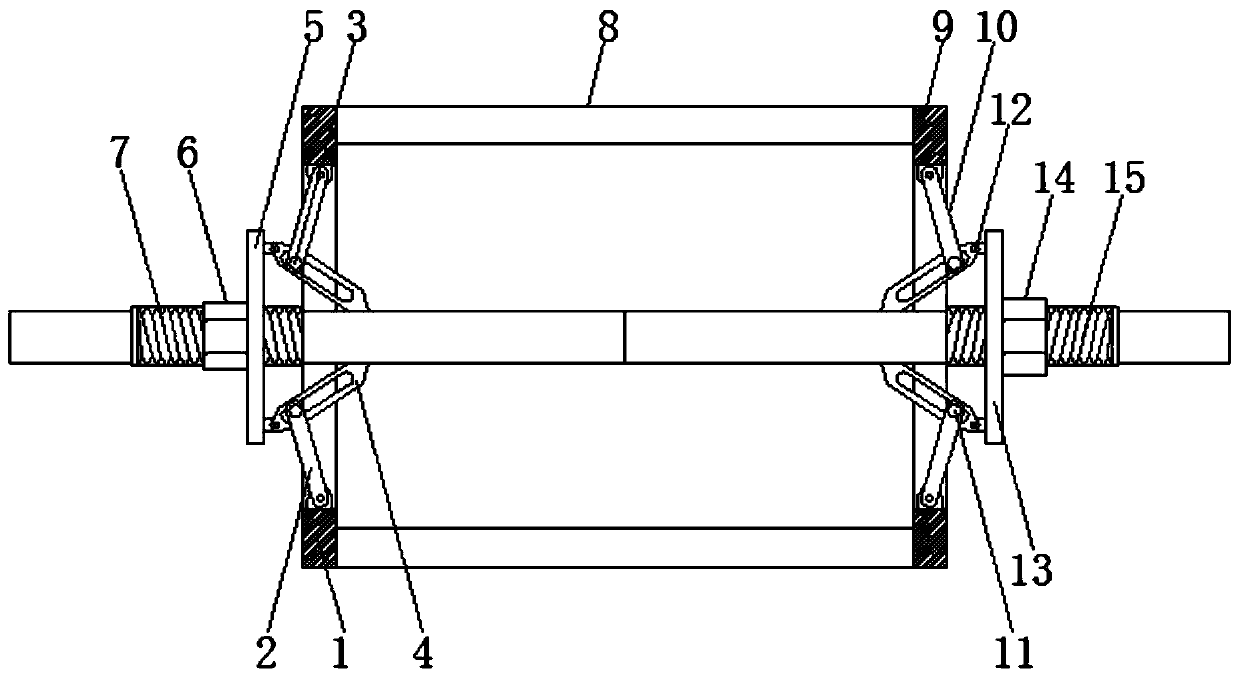

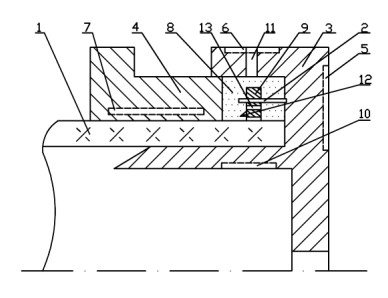

Production method for plate-bending hollow roll, plate-bending hollow roll, and device for steel plate production process

In the present invention, plate-bending processing in which a metal plate is bent into a cylindrical shape is performed. A butting left end surface (2a) and a butting right end surface (2b) of the metal plate (12) are subsequently tack welded by subjecting, to spot welding or the like, a side surface of a butt section (1). Thereafter, an end mill is used to subject the butt section (1) to joint processing, and an interval between the end surfaces is uniformly formed. The outer peripheral surface of the metal plate (12) which has been subjected to joint processing is then pressed by pressing bolts provided to a C-shaped fixation jig (7), to hold a gap in a reduced state. Thereafter, a laser beam welding device (6a) is used to perform laser beam welding on the butt section (1), and, as a result, the butt section (1) is joined, and the metal plate (12) bent into the cylindrical shape is formed into the cylindrical shape. Accordingly, a plate-bending hollow roll can be efficiently produced at low cost, while exhibiting a sufficient facility production capacity, said plate-bending hollow roll enabling the conveyance of steel plate with high surface quality, without having to imprint a roll-surface shape onto the steel plate to be conveyed.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

Trenchless directional drilling construction method for pipeline burying channel

InactiveCN112252973AAvoid destructionLow costArtificial islandsPipe laying and repairArchitectural engineeringPipe

The invention relates to a trenchless directional drilling construction method for a pipeline burying channel. The trenchless directional drilling construction method comprises the following steps that 1, pipe distribution is conducted, specifically, hot melting connection is conducted on the end faces of two PE solid-wall pipes; 2, directional drilling is conducted, specifically, a working pit and a receiving pit are manufactured, and a directional drilling machine is adopted for hole drilling; 3, back chambering construction is conducted, specifically, chambering is conducted in a step-by-step chambering mode to form a pipeline; 4, the pipe is pulled back, specifically, the pipe is pulled by adopting a pipe puller; and 5, inspection wells are manufactured, specifically, foundation pits are excavated in the two sides of an effective pipe section, the prefabricated inspection wells are installed, the prefabricated inspection wells are in waterproof connection with the PE solid-wall pipes, and then the foundation pits and the peripheries of the prefabricated inspection wells are backfilled. Only the working pit and the receiving pit need to be excavated in the ground, drilling, chambering and pipe pulling operations are carried out at the positions of the working pit and the receiving pit, and environmental influences such as multiple construction technology procedures, a largeamount of road surface damage and traffic obstruction caused by pipeline open excavation construction can be avoided.

Owner:广东省构建工程建设有限公司 +1

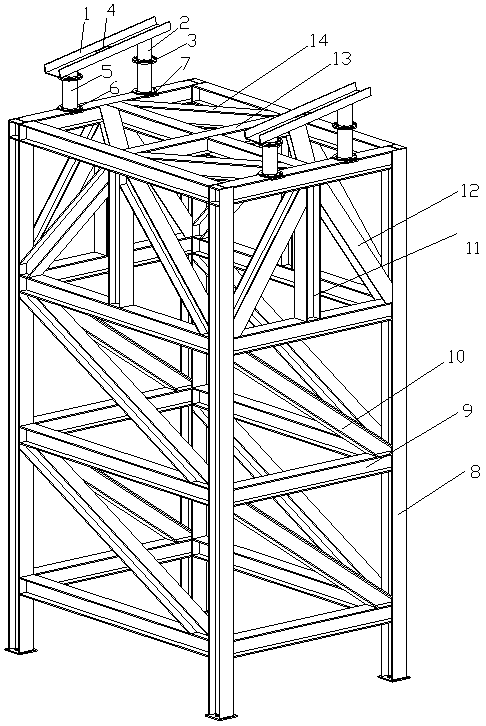

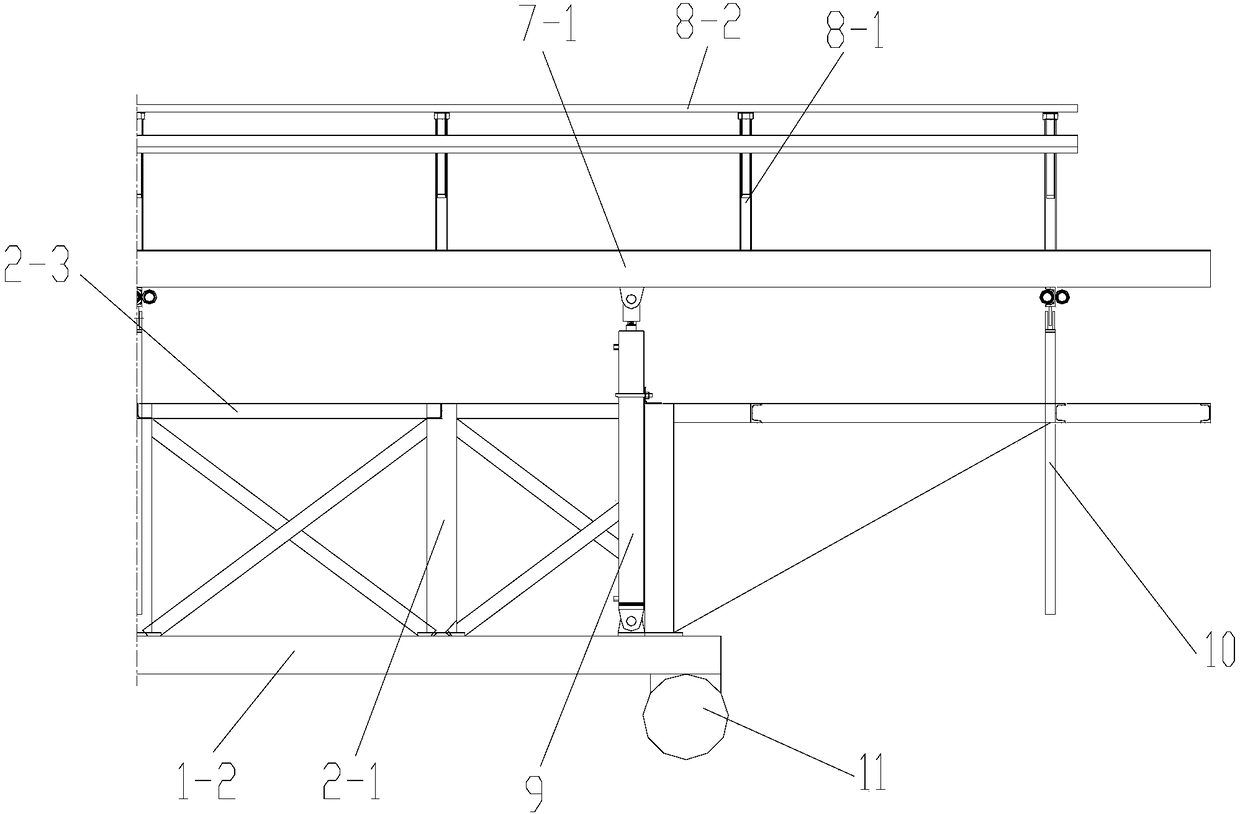

Large-span truss subsection hoisting high-altitude closure measure device and construction method

The invention discloses a large-span truss subsection hoisting high-altitude closing measure device and a construction method. The measure device comprises a plurality of bracket units and a support platform; each bracket unit is composed of a U-shaped groove, two support columns and two flange plates I; the support platform is of a rectangular frame structure and is composed of a plurality of stand columns, a cross beam and support columns; each bracket unit is arranged at the top end of the support platform through two adjusting columns and arranged on a cross beam or a connecting beam in the length direction of the support platform; a plurality of flange plates III corresponding to the bracket units are arranged on the upper surface of the cross beam or the connecting beam in the lengthdirection of the top end of the support platform; flange plates II are arranged at the two ends of each adjusting column; the flange plates II at the top ends of the adjusting columns are correspondingly and fixedly connected with the flange plates I at the bottom ends of the supporting columns; and the flange plates II at the bottom ends of the adjusting columns are correspondingly and fixedly connected with flange plates III arranged on the upper surface of the support platform top beam or connecting beam. The device is high in utilization rate, the butt joint precision of truss main pipesis improved, and the safety of the truss unloading construction process is guaranteed.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

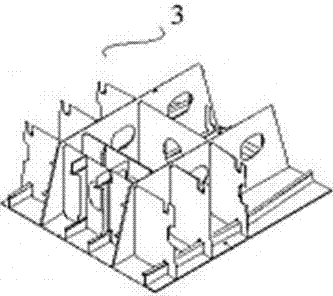

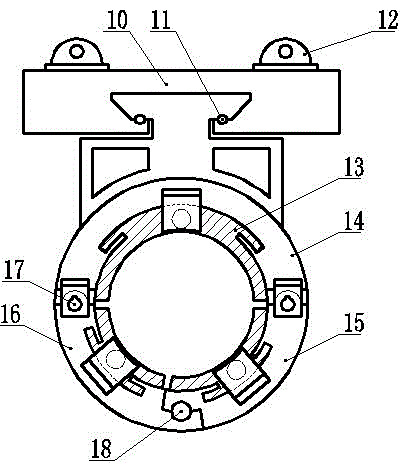

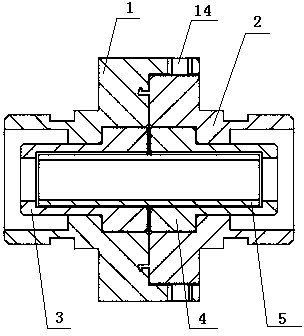

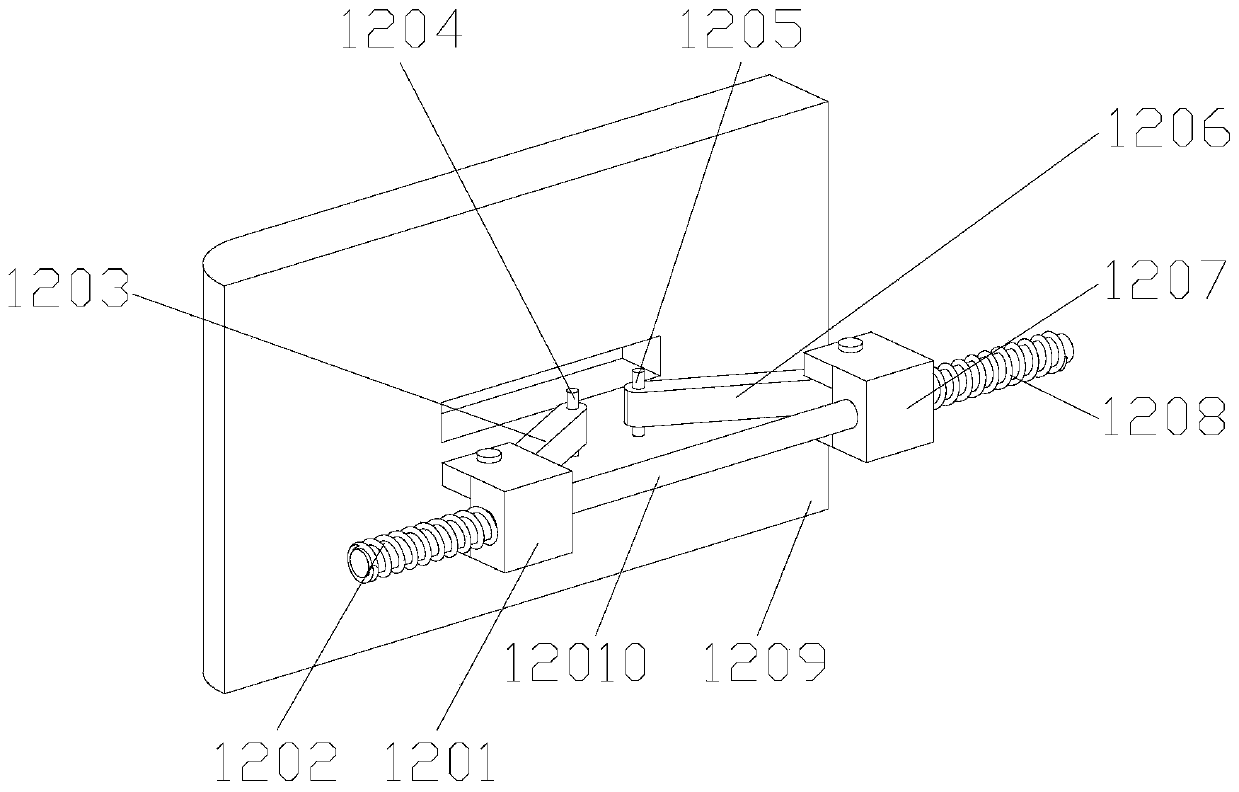

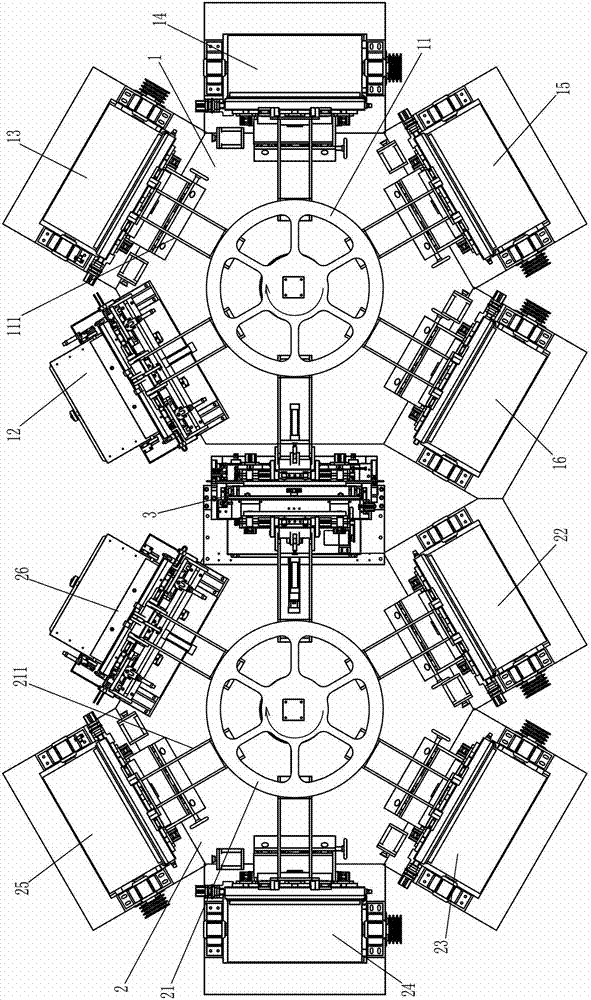

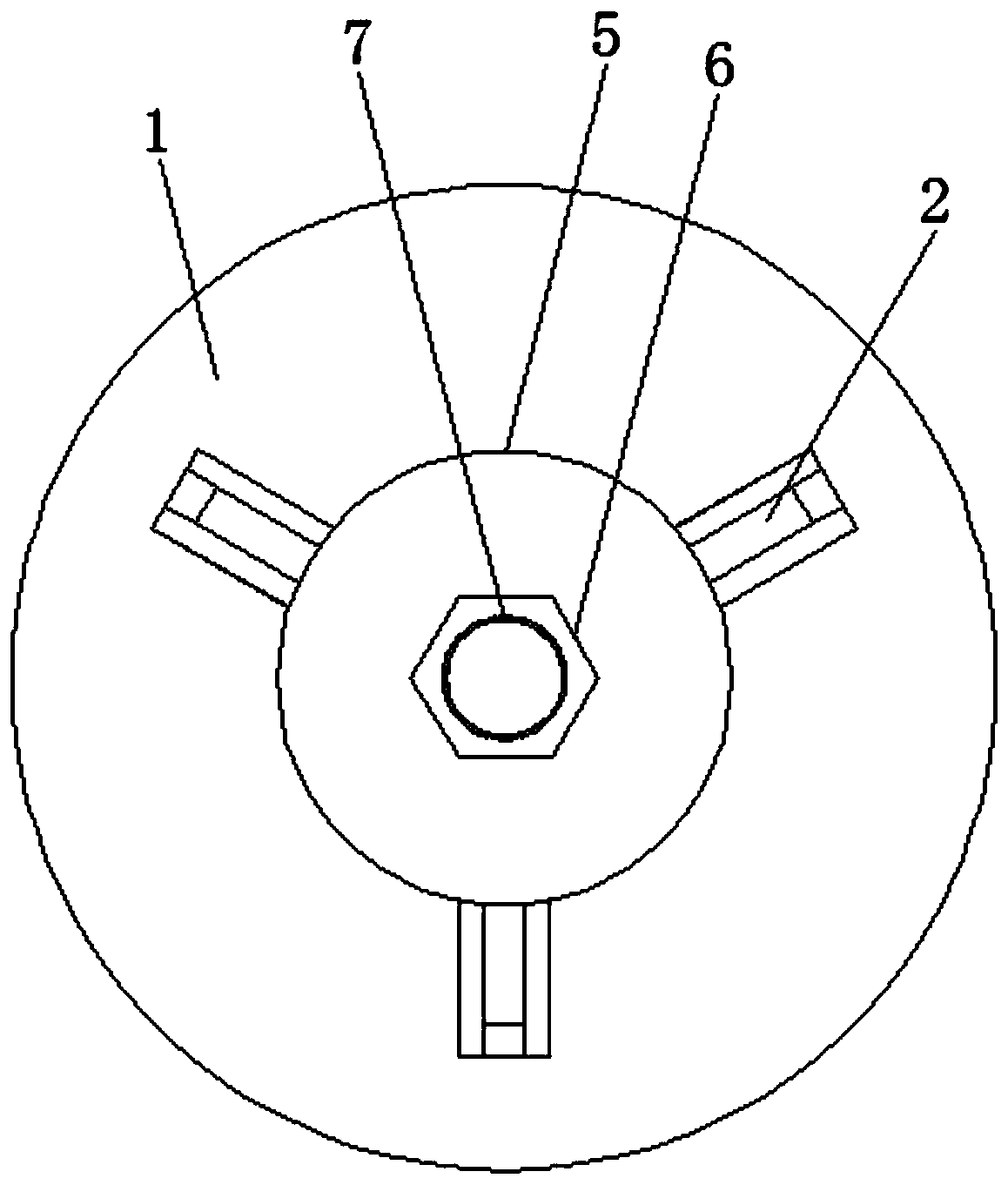

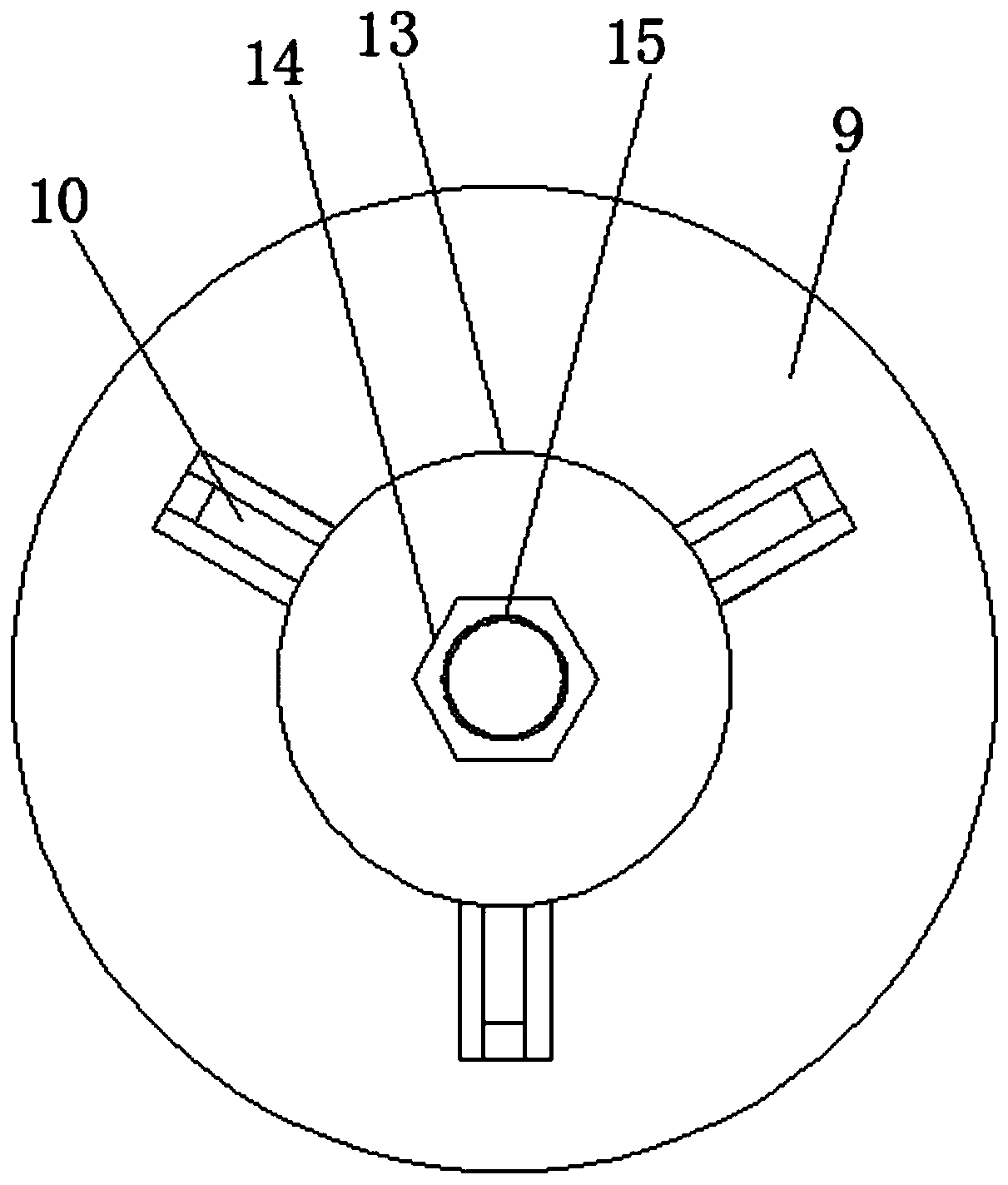

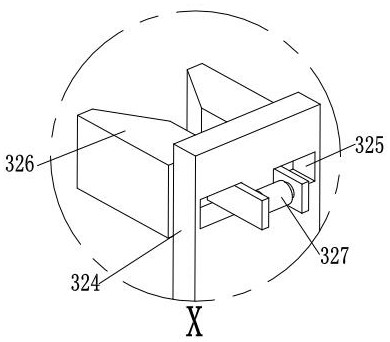

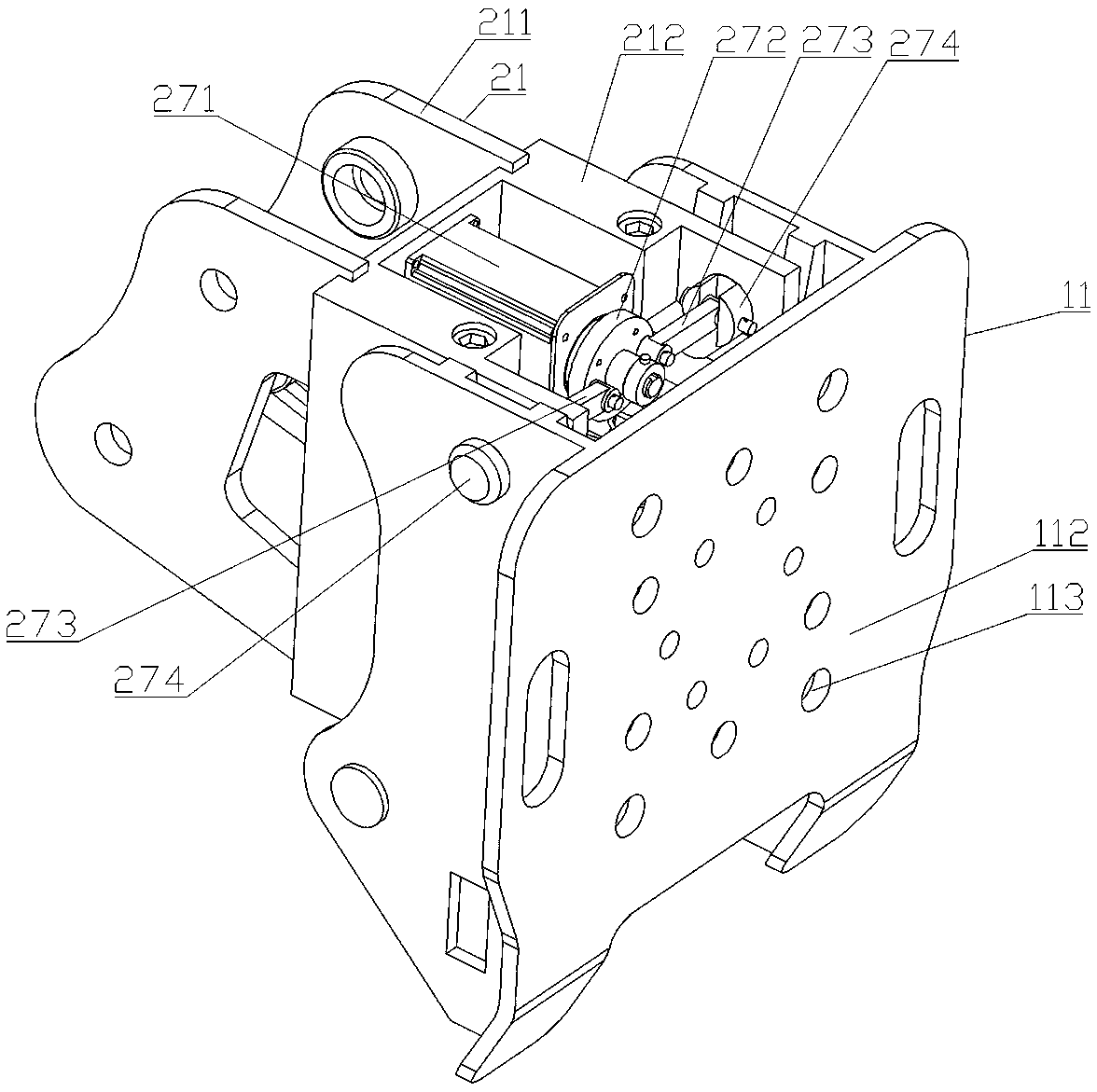

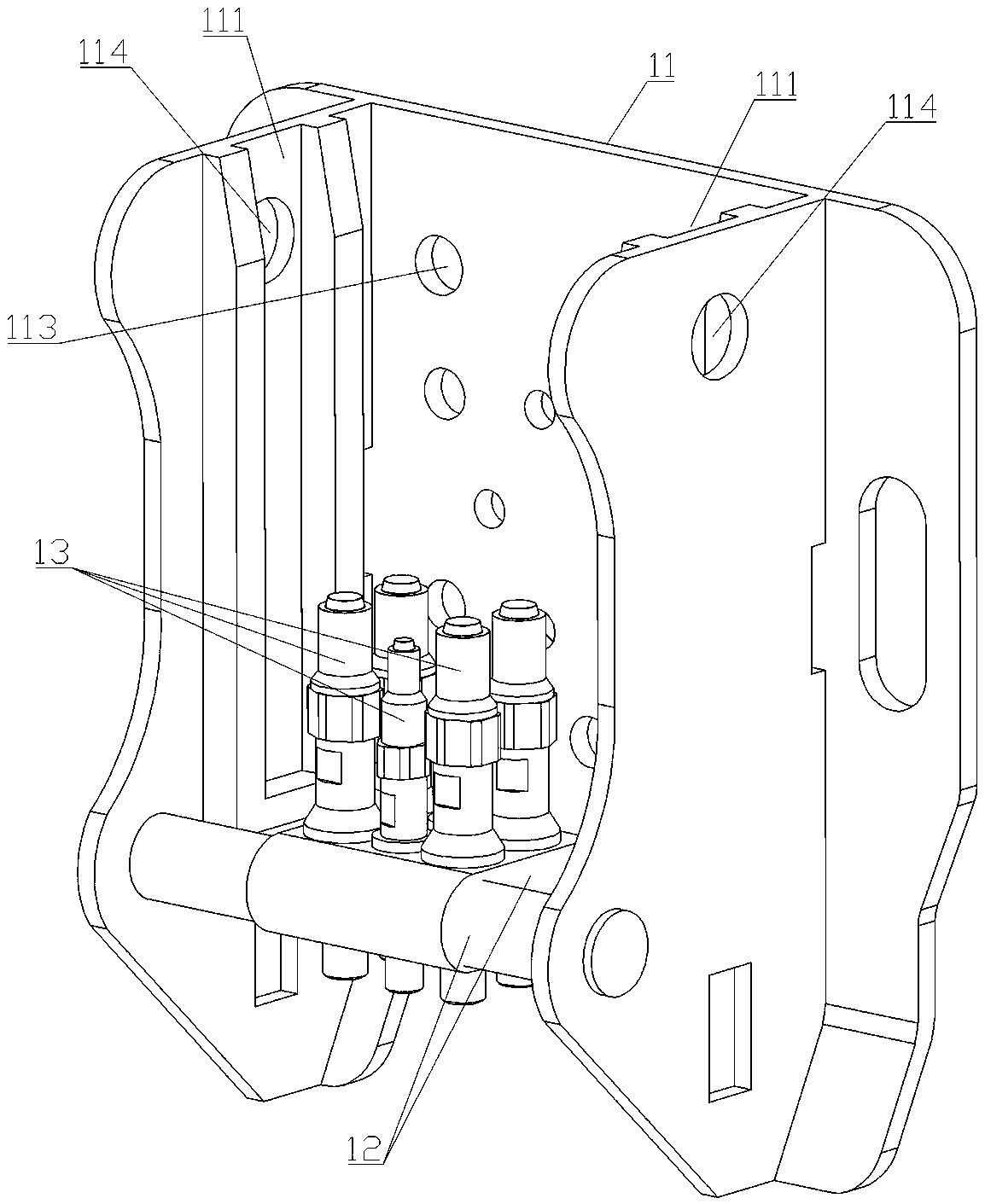

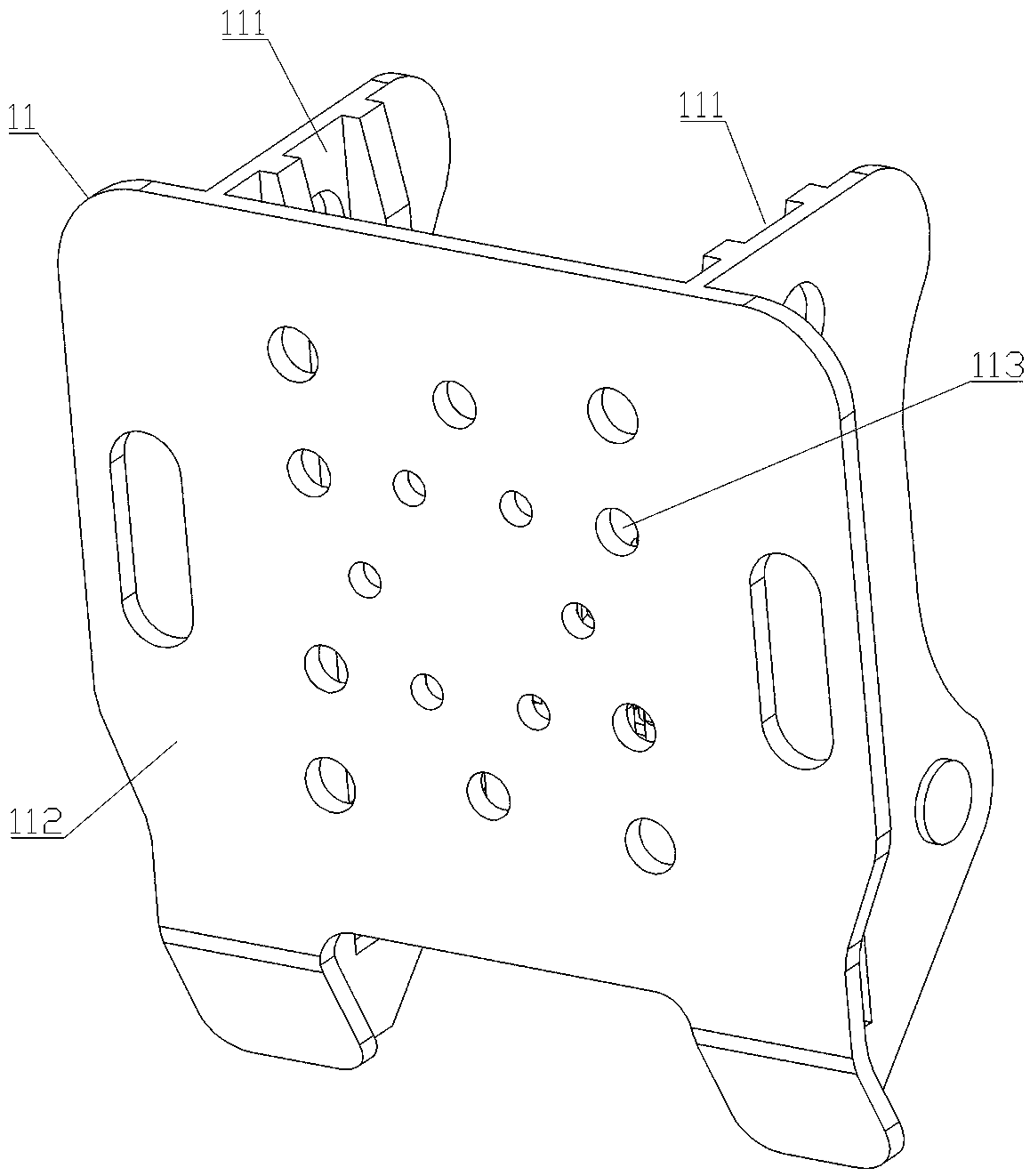

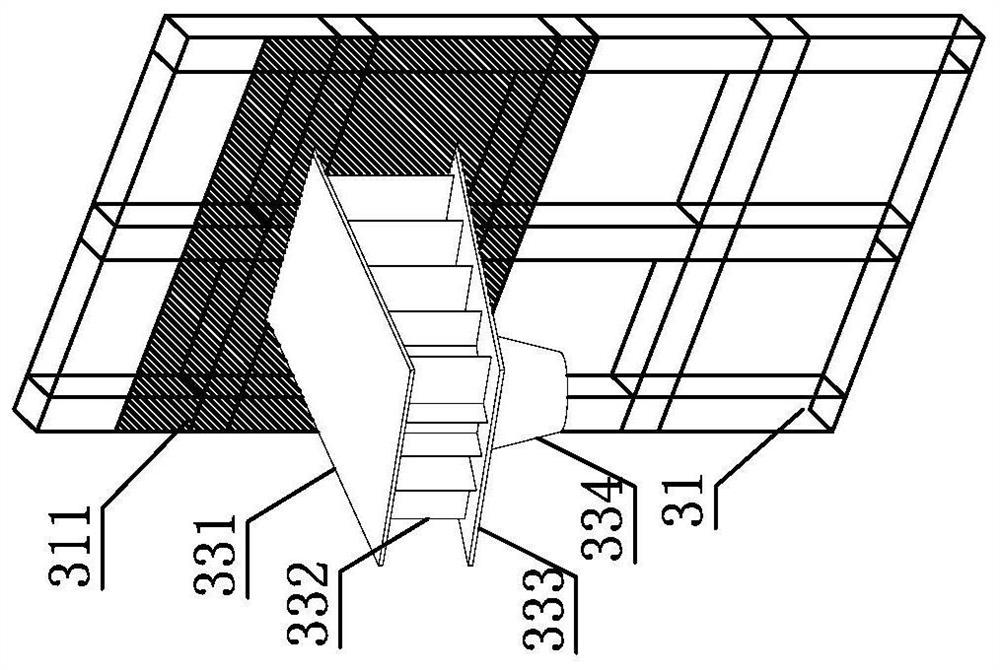

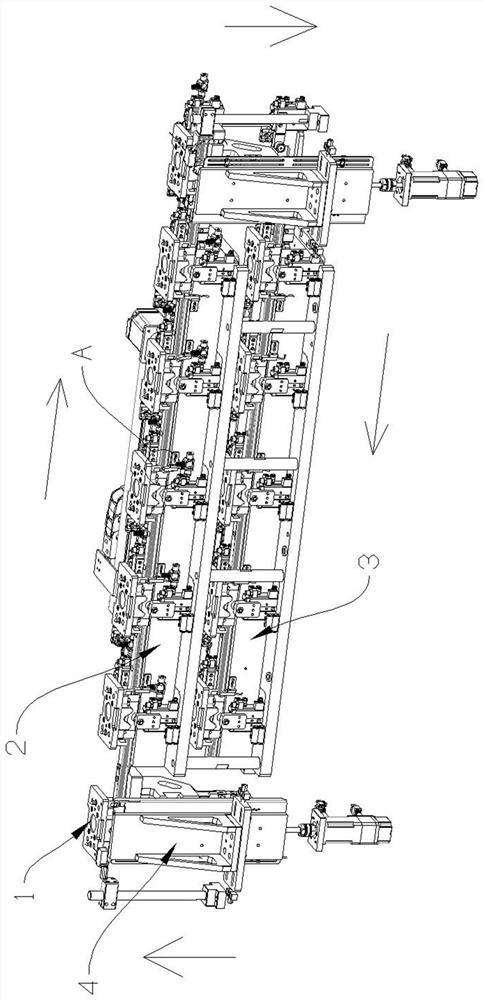

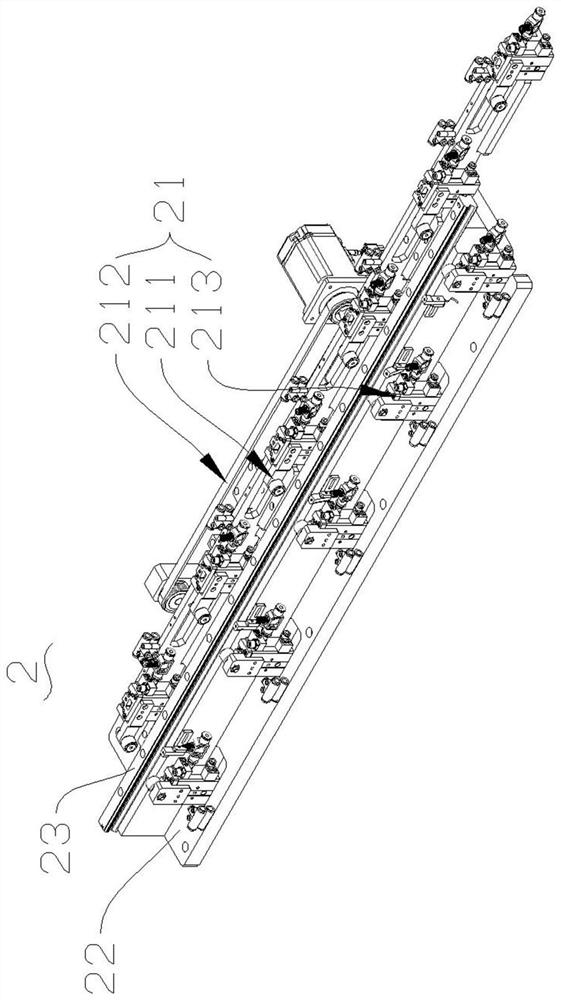

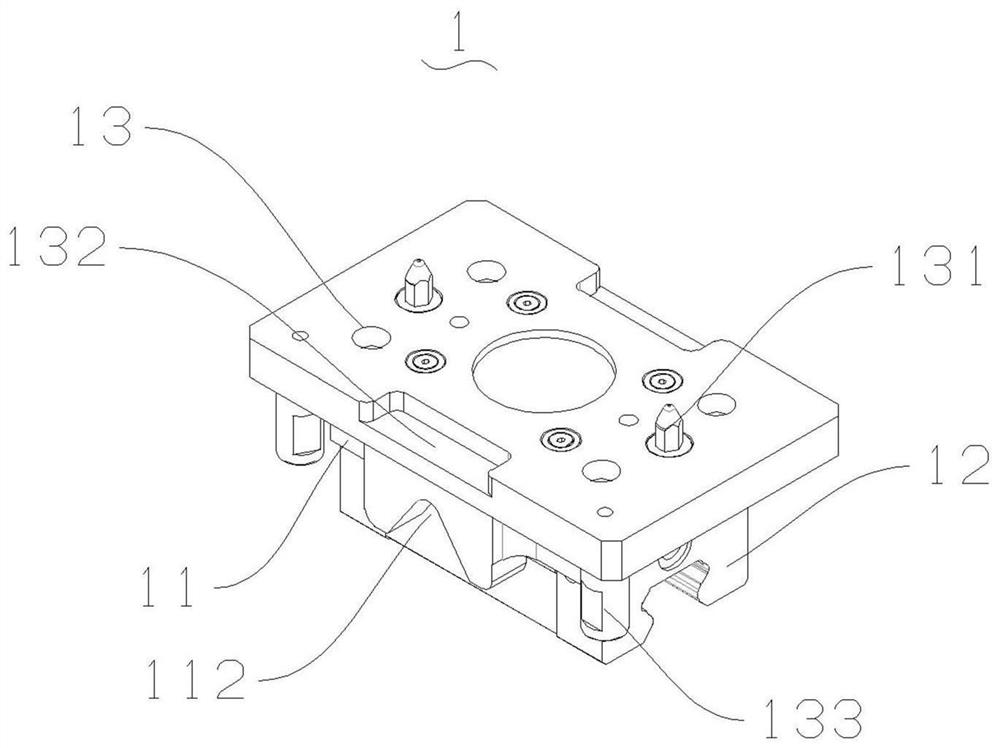

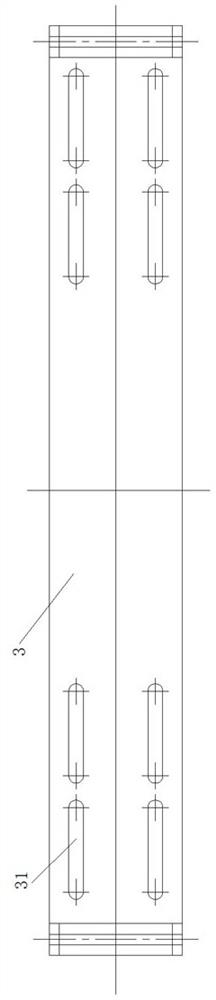

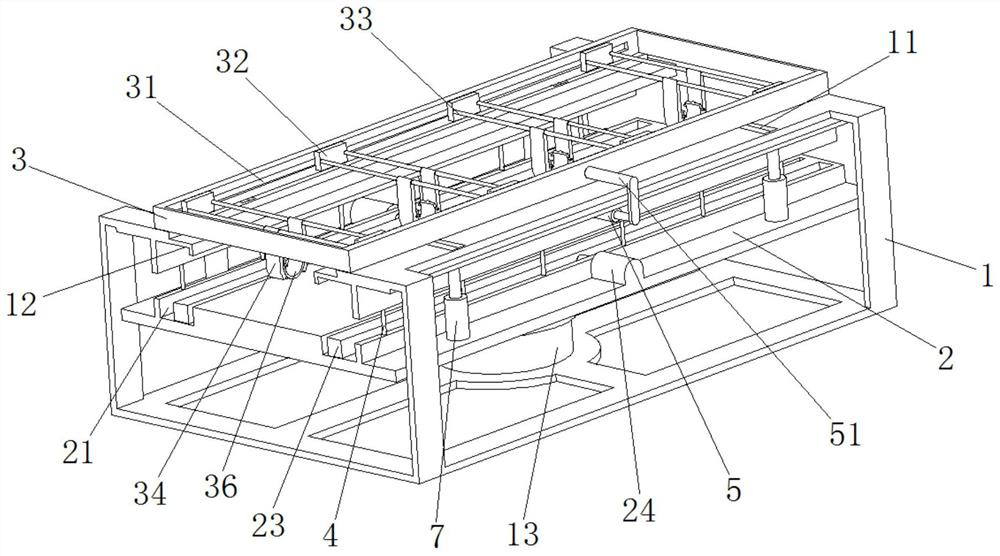

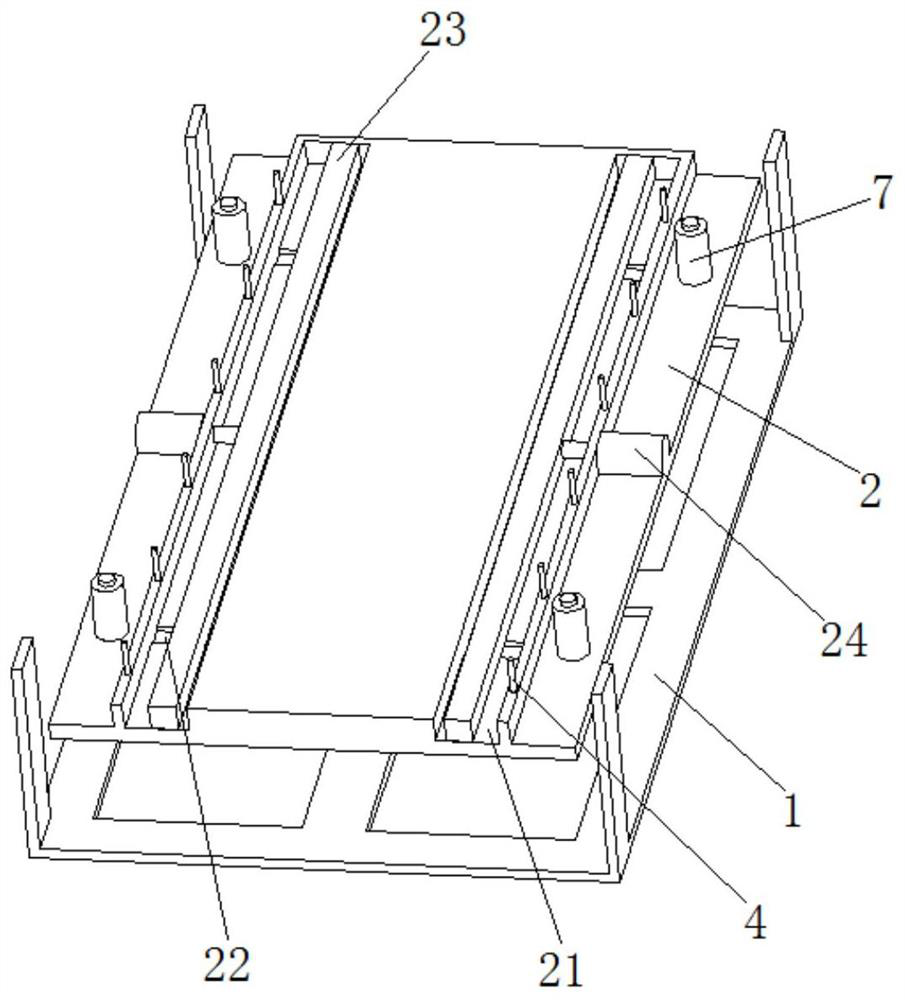

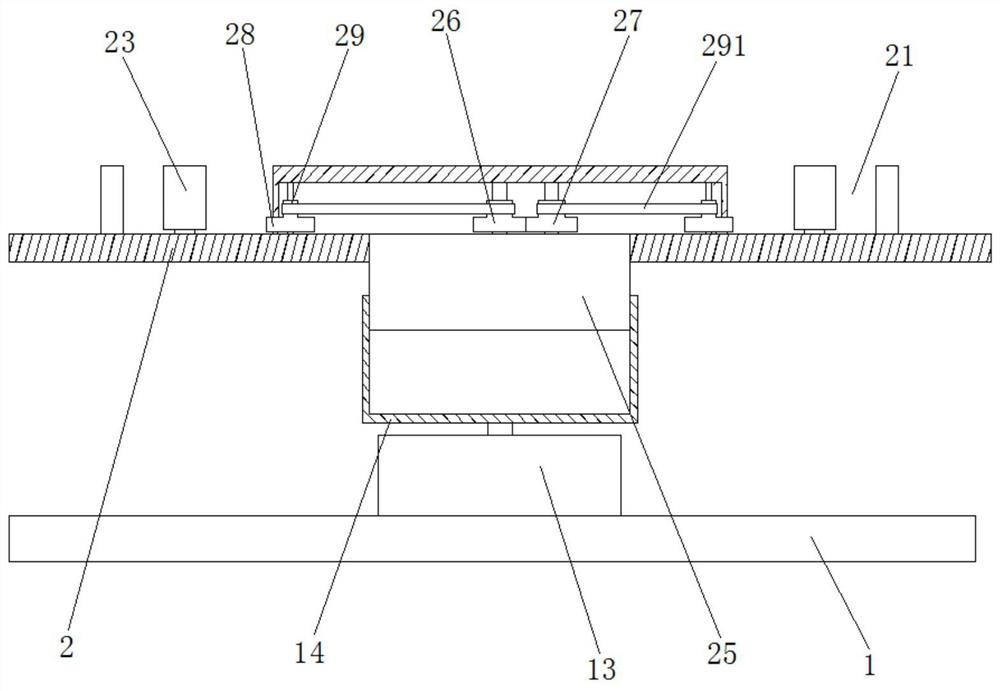

Crystal blank automatic polishing system and docking mechanism thereof

ActiveCN103111926ASimple structure and actionReduced range of rotationSpherical surface grinding machinesGrinding work supportsManipulatorCrystal

The invention discloses a docking mechanism. The docking mechanism comprises a docking rack and an installing plate, wherein the installing plate is provided with a first clamp seat and a second clamp seat. The first clamp seat is fixedly connected with the installing plate, the second clamp seat is connected with the installing plate in a sliding mode and is driven through a sliding driving device, the first clamp seat and the second clamp seat are both provided with a clamp positioning device and a clamp locking device, and a rotary shaft of the installing plate is horizontally arranged and located between the first clamp seat and the second clamp seat. The installing plate is driven to rotate by a rotating driving device which is installed on the docking rack. The installing plate has two rotating stop positions: a vertical state that the second clamp seat is located above the first clamp seat, and a heeling or horizontal state that the first clamp seat and the second clamp seat are both arranged on the installing plate. The invention further discloses a crystal blank automatic polishing system adopting the docking mechanism. By the technical scheme, the docking precision is high, bonding is firm, a mechanical arm structure action is convenient to design, and the docking efficiency and the processing efficiency of the whole automatic polishing system are improved.

Owner:虞雅仙

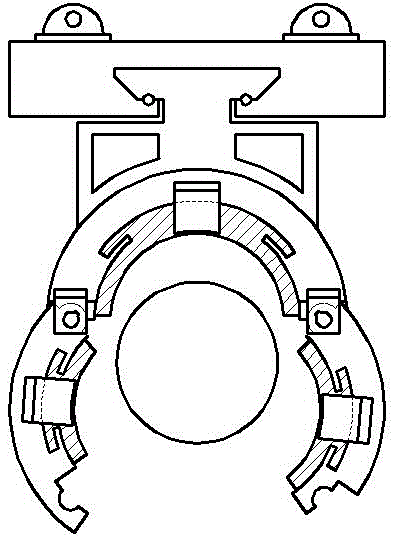

Automatic centering butt joint structure for steel pipe

ActiveCN110497142ASimple structureImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesCircular discButt joint

The invention relates to the technical field of steel detection, and discloses an automatic centering butt joint structure for a steel pipe. The automatic centering butt joint structure comprises a left fixed disc, wherein the interior of the left fixed disc is movably connected with left push rods; the end, away from the left fixed disc, of each left push rod is movably connected with a left connecting block; the exterior of each left connecting block is movably connected with a left clamping block, and the left sides of the left clamping blocks are movably connected with a left push plate; the side, away from the left clamping blocks, of the left push plate is movably connected with a left nut; the interior of the left nut is movably connected with a left feed pipe; and the outer end ofthe left fixed disc is fixedly connected with a frame. According to the automatic centering butt joint structure for the steel pipe, the left push rods are used in cooperation with the left clamping blocks, so that the effect of clamping a left steel pipe is realized, and the position of the left steel pipe is fixed. According to the automatic centering butt joint structure for the steel pipe, theleft push plate is used in cooperation with the left clamping blocks, so that the effect of determining the axis of the left steel pipe is realized, the structure is simple, and the working efficiency can be effectively improved.

Owner:江苏冰溶管业有限公司

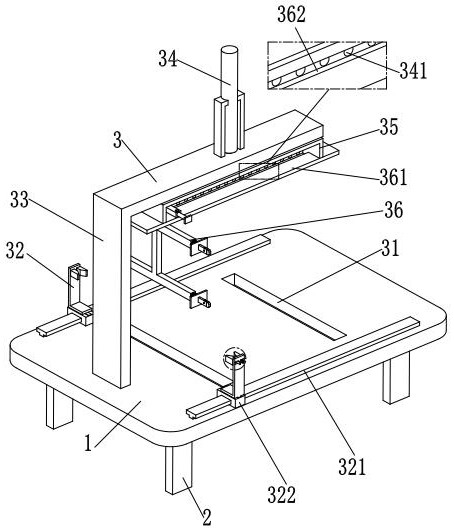

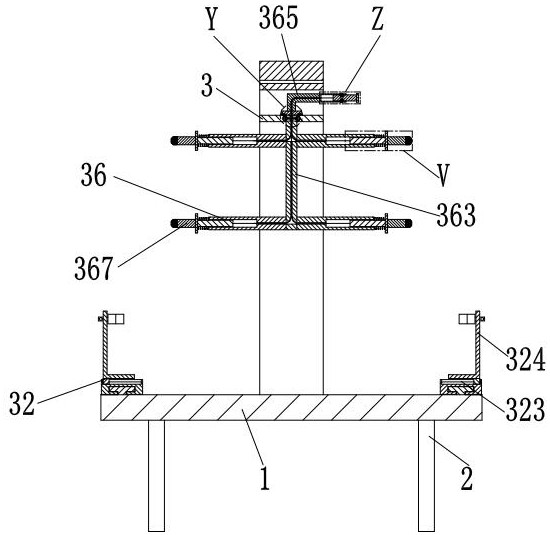

Transformer heat dissipation pipe welding auxiliary clamp

ActiveCN113500344AImprove welding efficiencyGuaranteed cooling effectWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention relates to the technical field of transformer welding, in particular to a transformer heat dissipation pipe welding auxiliary clamp which comprises a mounting bottom plate, supporting plates and an auxiliary welding device, the supporting plates are evenly fixed to the positions, close to the four corners, of the lower end face of the mounting bottom plate, and the auxiliary welding device is arranged at the upper end of the mounting bottom plate. According to the transformer heat dissipation pipe welding auxiliary clamp, the problems that a traditional welding method is tedious, the phenomenon that the positions of butt joint positions are uneven is likely to occur, the heat dissipation effect of heat dissipation pipes is affected, and due to the fact that the number of the heat dissipation pipes is large, the labor amount of the traditional welding method is large, and the welding efficiency of the heat dissipation pipes is low can be solved.

Owner:江苏保庆电器设备有限公司

Rapid connecting and replacing device and method for robot end effector

ActiveCN110919680AQuick disassemblyThe disassembly process is simple and convenientGripping headsPhysical medicine and rehabilitationTeleoperated robot

The invention discloses a rapid connecting and replacing device and method for a robot end effector, and relates to the technical field of automatic connecting and replacing of robot end effectors. The rapid connecting and replacing device for the robot end effector comprises a first assembly body and a second assembly body. The first assembly body comprises a tool disc, a male connector and a male connector base. The second assembly body comprises a connecting base, a guide rod, a female connector, a female connector base, a spring, a limiting block and a locking assembly. When the first assembly body is connected with a connecting part B of the second assembly body through a connecting part A, the male connector is inserted into the female connector, the female connector base is pressedon the limiting block, and the locking assembly can lock or unlock the tool disc. The quick connecting and replacing method for the robot end effector is applied to the quick connecting and replacingdevice for the robot end effector and comprises a butt joint process and a dismounting process. Automatic disassembly and assembly of the robot end effector can be achieved through a remote control robot; the whole disassembly and assembly process is rapid, easy and convenient and good in reliability; and interference between the male connector and the female connector is avoided.

Owner:NANHUA UNIV

Concrete-filled steel tube arch bridge arch rib setting clamp and construction method

InactiveCN108611984AImprove stabilityGuaranteed docking accuracyBridge erection/assemblyArch-type bridgeSteel platesSteel tube

The invention relates to a concrete-filled steel tube arch bridge arch rib setting clamp which comprises a construction support system, a jack, arc-shaped steel carrying plates, arch rib fixing steelplates, steel tube arch rib fixing supports, fastening lug plates, an arc-shaped integral type steel channel, opposite-pull adjustable long screws, arch rib opposite-pull temporary connecting plates,a steel tube arch rib joint, a continuous type stress testing meter, steel tube arch ribs, lug plate fastening bolts, adjustable steel plate top plates, adjustable bolt groups, adjustable steel platebases, a hinge shaft and intermediate batten plates. The construction support system is arranged on the lower portion of a concrete-filled steel tube arch bridge. The upper portion of the constructionsupport system is fixed to reinforcing supporting steel plates through reinforcing steel tube containing steel tubes. The corresponding adjustable steel plate top plate and the corresponding adjustable bolt group are arranged on the upper portion of the reinforcing supporting steel plate on one side to adjust the height, and the jack is arranged on the upper portion of the reinforcing supportingsteel plate on the other side. The clamp has the beneficial effects that the steel tube arch rib fixing supports are arranged, the stability in steel tube arch rib installation construction operationis improved, and butt joint accuracy is effectively guaranteed.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Novel wet-dragging self-installation type offshore transformer substation and seabed big data center integral structure and installation and maintenance method

PendingCN114837478AWide range of applicationsHigh feasibilityArtificial islandsTransformer housesData transmissionElectric energy

The invention relates to a wet-dragging self-installation type offshore substation and seabed big data center integral structure and an installation and maintenance method. The wet-dragging self-installation type offshore substation and seabed big data center integral structure is mainly composed of an offshore substation upper module, an integral jacket, a seabed big data center module and lifting type connecting pile legs for connecting the upper module and the seabed big data center module. According to the invention, a wet-dragging self-installation type integral structure scheme is adopted, the device can be applied to a seabed big data center of an offshore transformer substation structure attached to medium and small upper modules (such as 200MW-500MW offshore booster stations), the application range is wide, the feasibility is high, the additional value of the offshore transformer substation is effectively improved, the electric energy access and data transmission requirements of the seabed big data center are met, and the cost is reduced. And the offshore construction operation flow of each stage of transportation, installation, service operation and maintenance is simplified.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Oil and gas pipeline automatic connecting device for machine tool automatic clamp

ActiveCN111300100AImplement external referencesAvoid destructionWork clamping meansPositioning apparatusEngineeringGas supply

The invention relates to the field of machine tool auxiliary devices, in particular to an oil and gas pipeline automatic connecting device for a machine tool automatic clamp. An internal quick plug assembly comprises an oil pressure quick plug and an internal gas circuit automatic connector, the internal gas circuit automatic connector is arranged on an internal gas distributing block, an externalquick plug assembly comprises an external gas circuit automatic connector and an oil pressure quick socket, the external gas circuit automatic connector is arranged on an external gas distributing block, the oil pressure quick socket and the external gas distributing block are arranged on a movable adapter plate, the oil pressure quick socket is in butt joint with the oil pressure quick plug, theexternal gas circuit automatic connector is in butt joint with the internal gas circuit automatic connector, the oil pressure quick socket is provided with an external oil circuit joint, the externalgas distributing block is provided with an external gas source joint, and the oil pressure quick plug and the internal gas distributing block are provided with internal joints for being connected with a machine tool automatic clamp. According to the device, automatic oil and gas supply of the machine tool automatic clamp is realized, arrangement of a moving pipeline is reduced, and operation intervention of an original system of the machine tool by automatic modification and integration is reduced.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

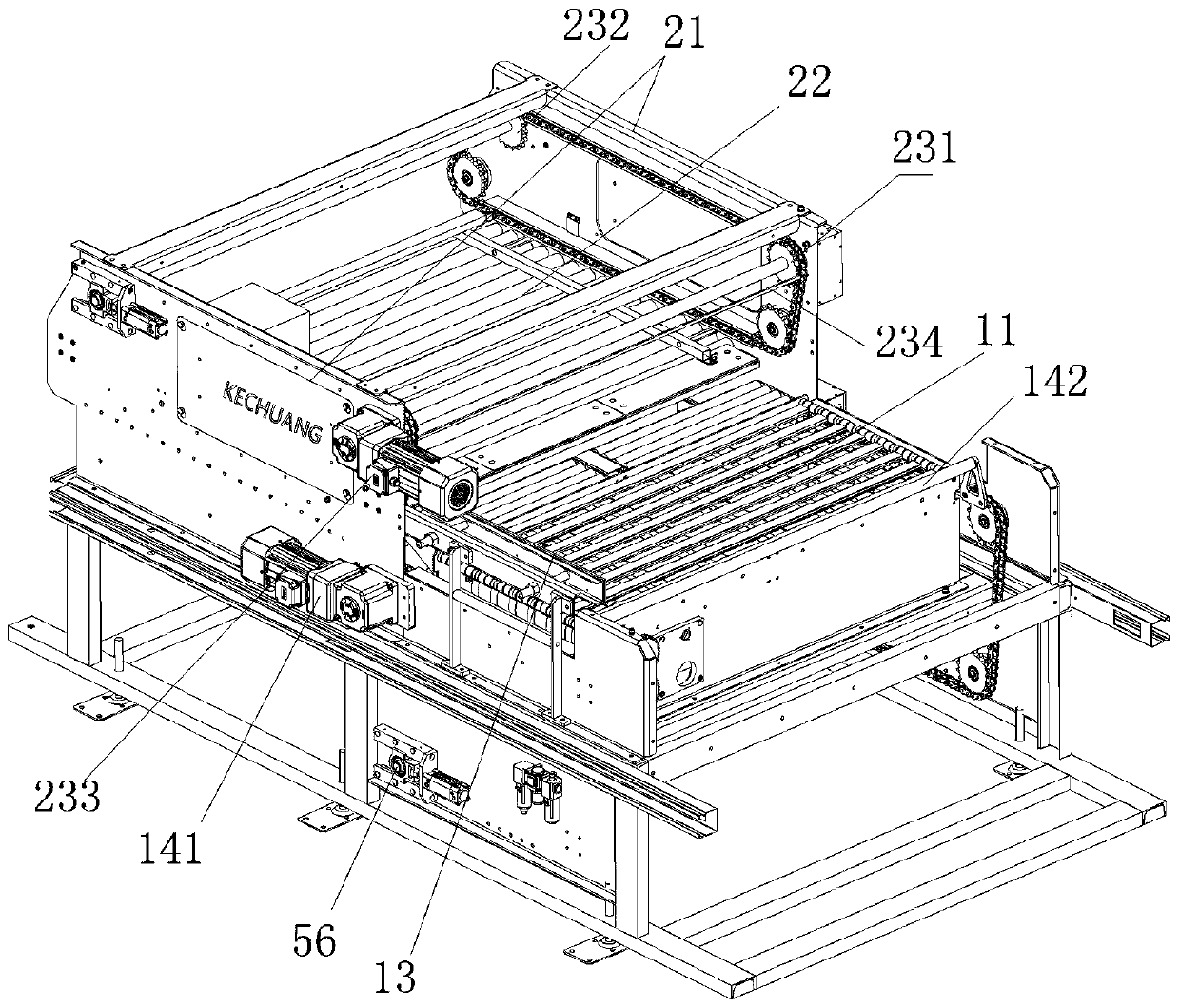

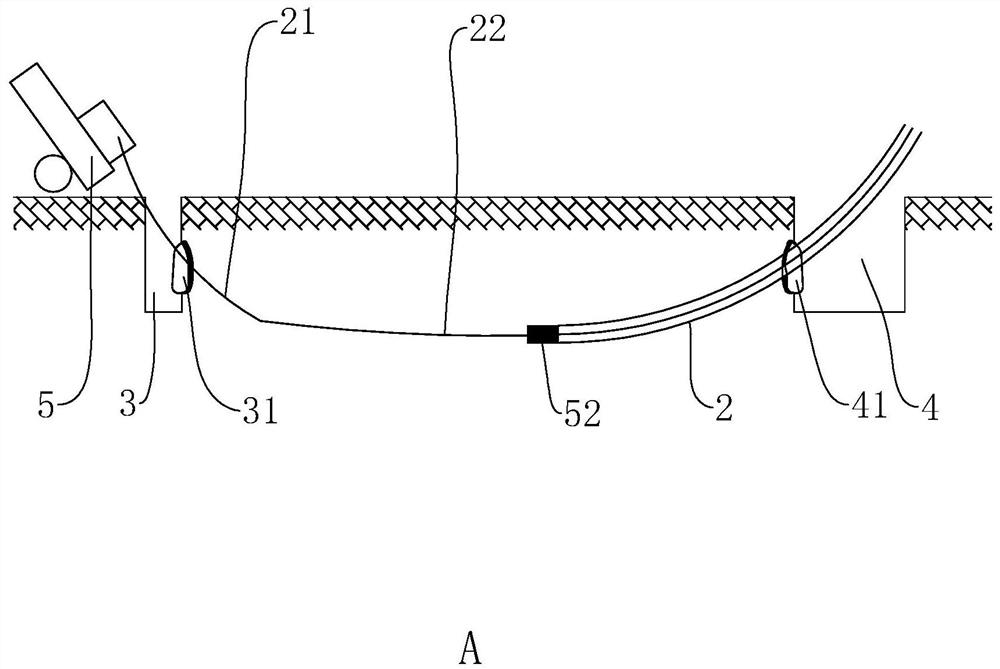

Electronic product assembly return line device

PendingCN111977302AReduce duplicate handlingIncrease profitConveyor partsMechanical conveyorsEngineeringMechanical engineering

The invention discloses an electronic product assembly return line device. The electronic product assembly return line device is used for circularly conveying a plurality of assembly platforms and comprises an upper line body, a lower line body arranged parallel to the upper line body and opposite to the upper line body in operation direction, and lifting mechanisms arranged at the two ends of theupper line body and the lower line body; the multiple assembly platforms are slidably arranged on the upper line body, the lower line body and the lifting mechanisms correspondingly; and the upper line body and the lower line body comprise driving mechanisms driving the assembly platforms to move between the upper line body and the lifting mechanisms or between the lower line body and the liftingmechanisms. According to the electronic product assembly return line device, the assembly platforms in the electronic product assembly process can be automatically returned, and manual repeated carrying is avoided.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

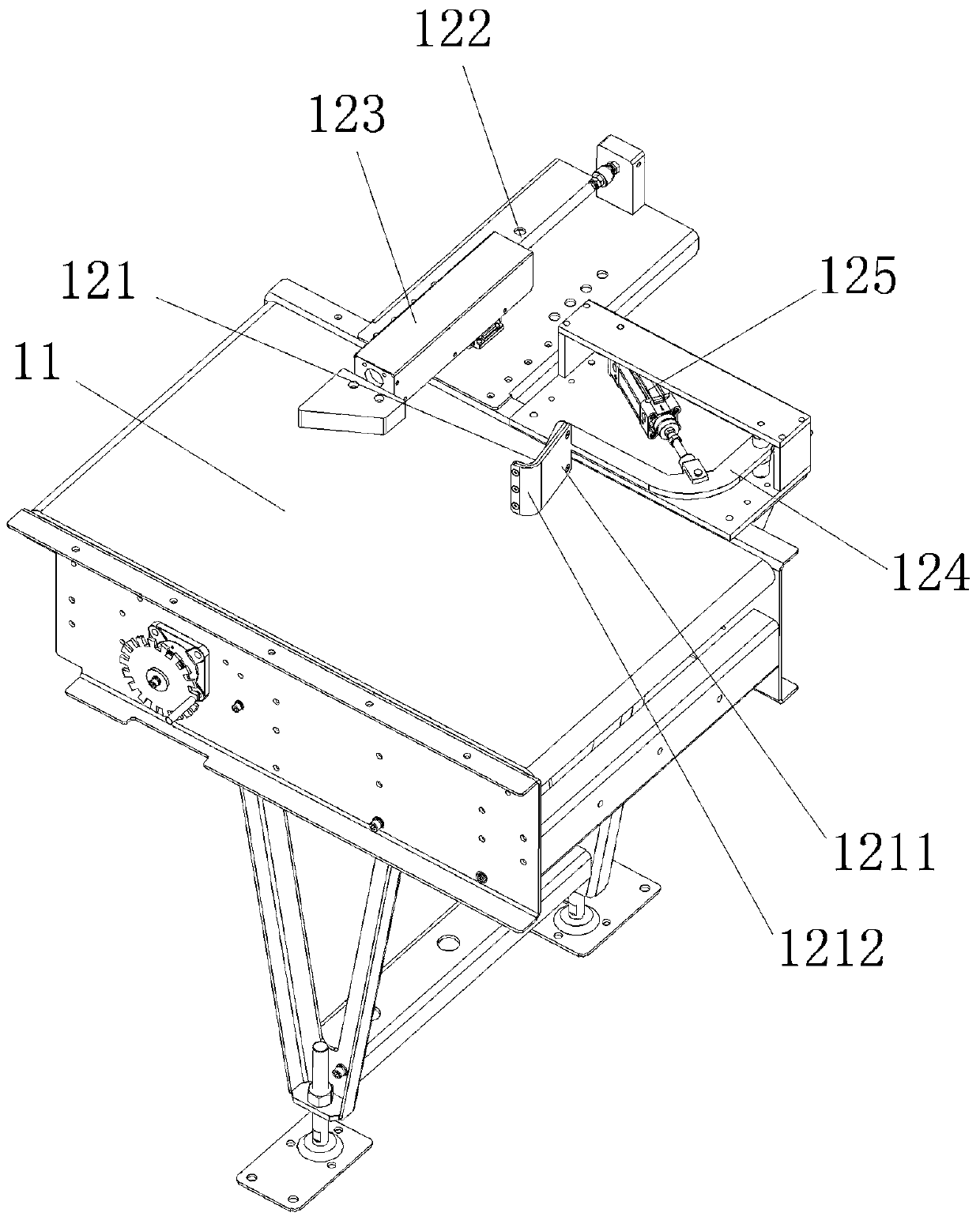

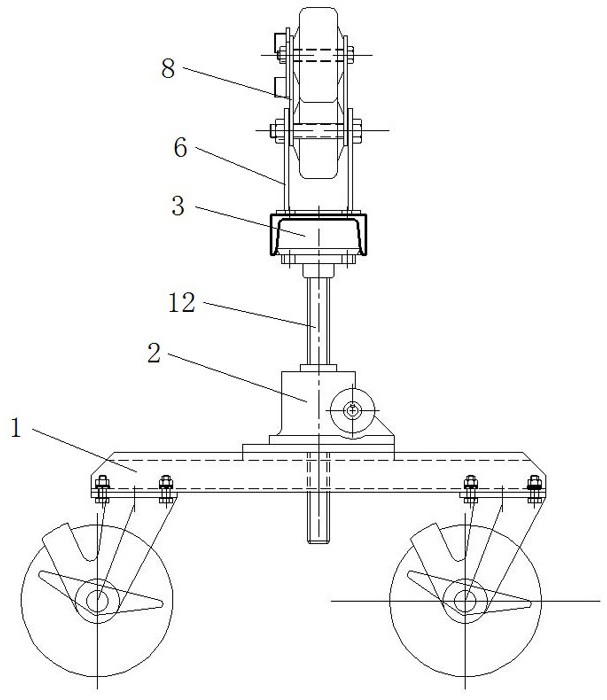

Barrel butt-joint transfer trolley

InactiveCN112875132ARotation does not appearGuaranteed docking accuracyManual conveyance devicesStructural engineeringMechanical engineering

The invention provides a barrel butt-joint transfer trolley. When the barrel butt-joint transfer trolley is in use, a barrel is erected between supporting wheels on a left wheel frame and a right wheel frame, moving wheels are mounted at the bottom of a base, and a transfer trolley body can be pushed to move the barrel to a designated position; due to the fact that the supporting wheels are matched with the barrel in a rolling and supporting mode, at the moment, the supported barrel can rotate relative to the supporting wheels, the angle of the barrel is adjusted, the barrel can be aligned to a butt-joint structure of an adjacent barrel, and then the supporting wheels are locked and fixed through supporting wheel braking structures to keep the barrel at the butt-joint position; and then the barrel at the butt-joint position and the adjacent barrel are connected together in a butt-joint mode to guarantee that the barrels cannot rotate in the butt-joint process, so that the butt-joint accuracy is guaranteed.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

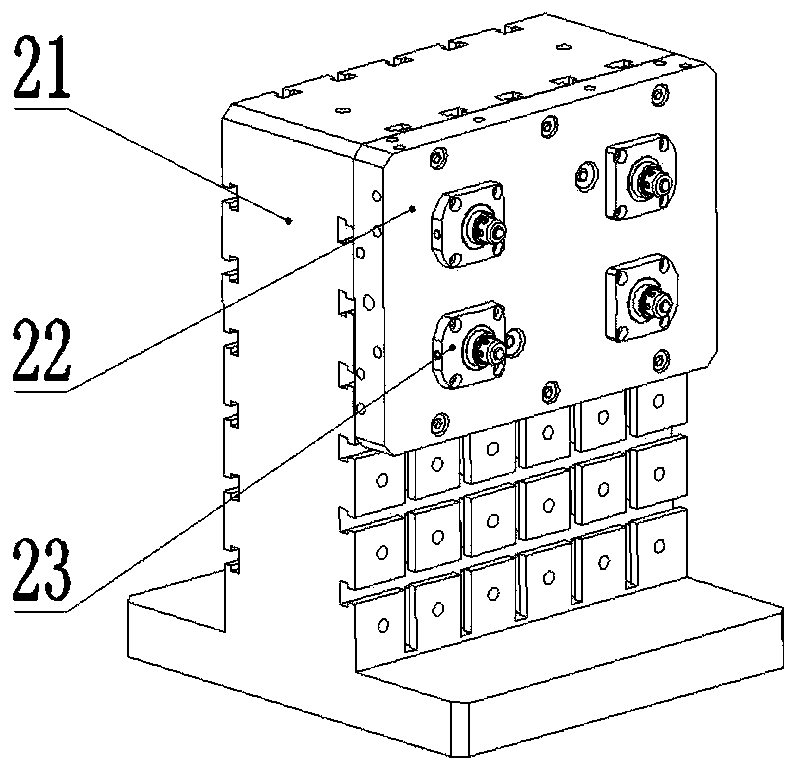

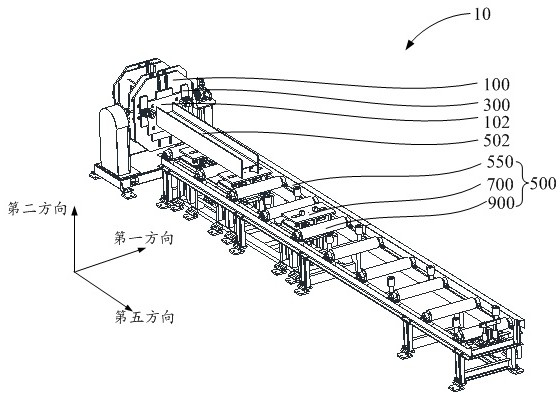

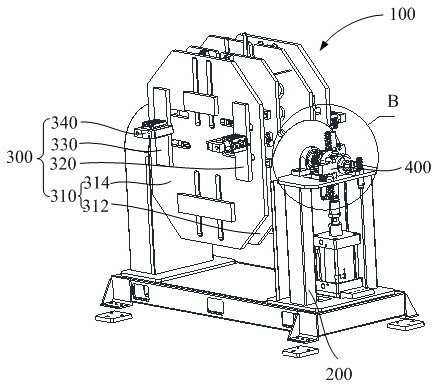

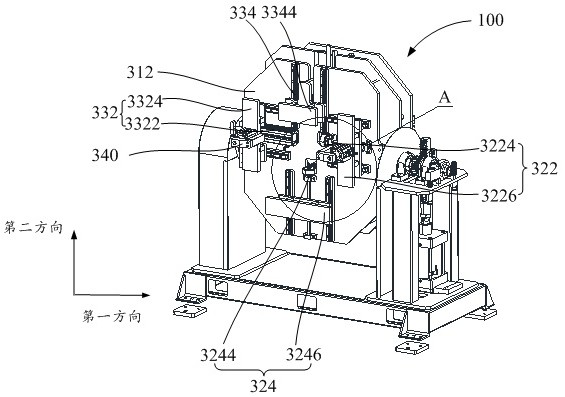

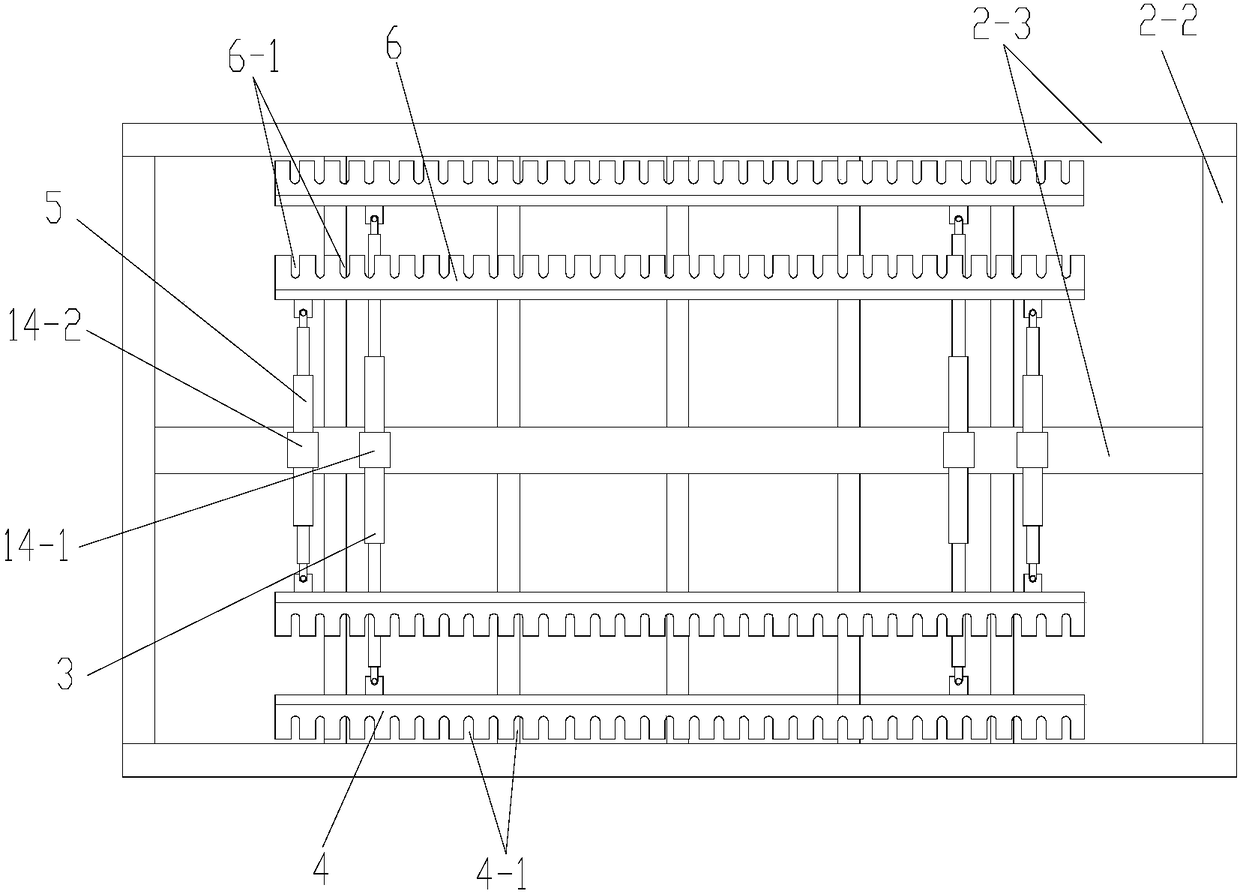

Assembling system

ActiveCN112276561AImprove stabilityGuaranteed docking accuracyAssembly machinesProduction lineButt joint

The invention provides an assembling system, and relates to the technical field of production and assembly. The assembling system comprises a feeding tool, wherein the feeding tool is used for clamping a first workpiece; and a clamping tool, wherein the feeding tool and the clamping tool are oppositely arranged, the clamping tool comprises a positioning mechanism, wherein the positioning mechanismis used for clamping a second workpiece, and a turnover mechanism, wherein the turnover mechanism is connected with the positioning mechanism, and the turnover mechanism is configured to be capable of driving the positioning mechanism to rotate so as to adjust the relative position of the first workpiece and the second workpiece. According to the assembling system, the relative position between the first workpiece and the second workpiece is adjusted, on one hand, the butt joint difficulty of the two workpieces is reduced, and the butt joint efficiency of the workpieces is improved; and on the other hand, the assembling system can be used for butt joint of the workpieces of various different structures, independent special tools do not need to be designed according to the different workpieces, so that the compatibility of the assembling system is improved, and the development cost of a production line is greatly reduced.

Owner:REIS ROBOTICS KUSN

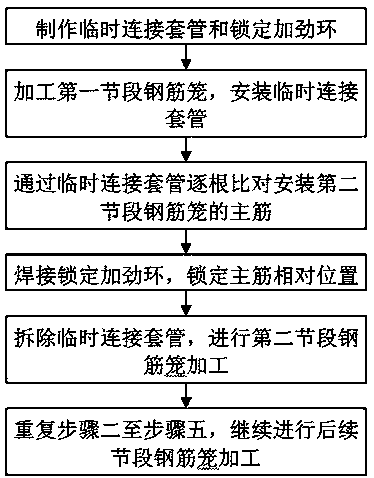

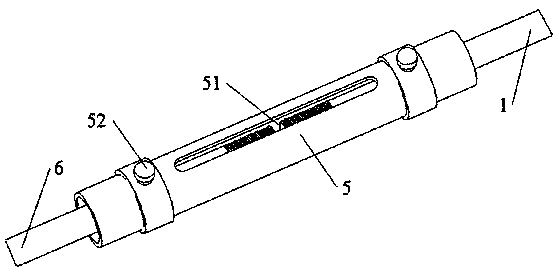

Segmental comparison processing method for reinforcement cage

ActiveCN111036804AImprove docking accuracyEliminate length discrepanciesWire networkBridge engineeringButt joint

The invention discloses a segmental comparison processing method for a reinforcement cage, and belongs to the field of bridge engineering construction. When a seam welder is adopted to machine the reinforcement cage section by section, a main reinforcement temporary connecting sleeve is arranged at the joint of the reinforcement cage, so that the main reinforcement of the to-be-machined section ofthe reinforcement cage is compared and positioned by taking the main reinforcement of the machined section of the reinforcement cage as a reference; after comparison and positioning are completed, alocking stiffening ring is welded near the joint of the reinforcement cage; after the relative positions of the main reinforcements are locked, subsequent processing is carried out; therefore, it is ensured that all the main reinforcements at the reinforcement cage joint are located in the same axis and abut against each other. The butt joint precision of the main reinforcements of reinforcement cage is improved, the problems that in the prior art, the main reinforcements at reinforcement cage joint are often dislocated, different in length, too large in gap and the like are solved, the structure is simple, operation is easy and convenient, the construction efficiency of reinforcement cage lengthening and lowering is improved, the procedure circulation time is shortened, the risk of pile hole collapse is reduced, and the overall construction quality is guaranteed.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

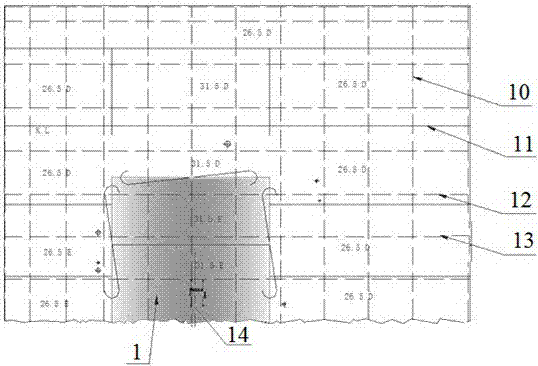

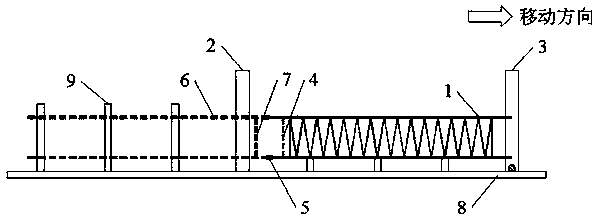

Trolley for open cut culvert and tunnel wall reinforcement mesh frame horizontal moving assembly system and construction method

ActiveCN108423590AGuaranteed docking accuracyImprove assembly efficiencyPortable liftingEngineeringTunnel wall

The invention discloses a trolley for an open cut culvert and tunnel wall reinforcement mesh frame horizontal moving assembly system. The trolley comprises a base frame, a main body frame arranged onthe upper portion of the base frame, a walking mechanism arranged on the lower portion of the base frame, and a jacking device and a horizontal positioning device which are arranged on the main body frame. The invention further discloses a construction method. The method comprises the steps that 1, an arch support reinforcement mesh frame is bound on a construction site, and an arch body reinforcement mesh frame is bound in a reinforcement processing workshop; 2, the arch body reinforcement mesh frame finished binding is horizontally moved to the construction site; 3, the arch body reinforcement mesh frame and the arch support reinforcement mesh frame are assembled; 4, the trolley exits. Accordingly, the function of horizontally moving the arch body reinforcement mesh frame can be achieved, assembly between the arch body reinforcement mesh frame and the arch support reinforcement mesh frame can be achieved, the docking accuracy of arch support reinforcement mesh frame inner layer jointreinforcement and arch body reinforcement mesh frame inner layer joint reinforcement is guaranteed, and the assembly efficiency of the arch body reinforcement mesh frame and the arch support reinforcement mesh frame is improved.

Owner:SHAANXI CONSTR ENG GRP NO 7 BUILDING ENG

Method for manufacturing plastic pipe flange connectors by pressing and sintering

The invention discloses a method for manufacturing plastic pipe flange connectors by pressing and sintering. An upper die component is installed at an end part of a plastic pipe; resin material, which is the same as that of the plastic pipe, is added into a cavity where a die component is formed; then two ends of the die are compressed to form flange preforms; a temperature-controlled heating device is simultaneously started, so as to ensure that the material added is sufficiently molten; compressing and heat preservation are performed for a certain period of time, then a heating power supplyis cut off; and the die is disassembled after being cooled, and then a flange is formed. The special die adopted in the method has a simple structure and is convenient to install and use, and by adopting the heating and compressing forming method, molten powder material completely covers the embedded metal flange and is organically combined with the pipe into a whole body. The connection mode hasthe characteristics that the connection strength is high, the butt accuracy of end surfaces of the flange is guaranteed, and construction is convenient.

Owner:CHANGDE NEMET ENG POLYMERS MATERIALS +1

Automobile exhaust connecting pipe welding, clamping, fixing and displacing tool

ActiveCN111618517AGuaranteed docking accuracyEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention relates to the field of auto spare parts processing, in particular to an automobile exhaust connecting pipe welding, clamping, fixing and displacing tool which comprises a fixed machinetool; a lifting table is inserted in the fixed machine tool; a plurality of spring telescopic rods are symmetrically and fixedly connected onto the lifting table; first sliding chutes are symmetrically formed in the top of the fixed machine tool; a movable frame is arranged on the top of the fixed machine tool; the bottom of the movable frame is inserted in the first sliding chutes; fixed groovesare symmetrically formed in the lifting table; clamping grooves are symmetrically formed above the fixed grooves in the fixed machine tool; second sliding chutes are symmetrically formed in the fixedgrooves; adjusting clamping strips are arranged in the fixed grooves; a first hydraulic cylinder is symmetrically and fixedly connected with the two sides of the lifting table; and the output end of the first hydraulic cylinder penetrates through the fixed grooves to be fixedly connected with one side of the adjusting clamping strips. The automobile exhaust connecting pipe welding, clamping, fixing and displacing tool is simple in structure, can simultaneously clamp and fix a plurality of exhaust connecting pipes precisely, ensures welding precision and is suitable for popularization.

Owner:徐州凯密斯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com