Abutting technological equipment of airplane large components and abutting method thereof

A technology of process equipment and large parts, which is applied in the field of process equipment for the docking of large aircraft parts, can solve problems such as unsatisfactory docking requirements and docking failures, reduce difficulty and safety hazards, improve manufacturing efficiency, and ensure docking accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and specific example the present invention is described in further detail:

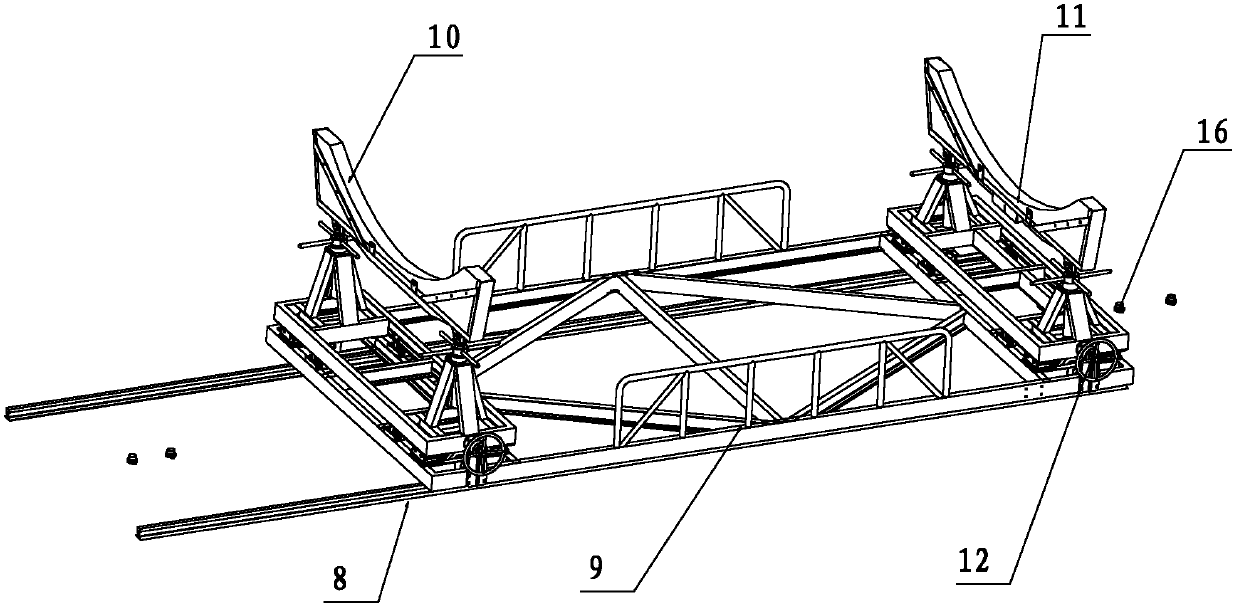

[0041] The technical equipment for the docking of large parts of the aircraft of the present invention uses a certain type of transport aircraft as a platform, and is composed of a fixed part and a movable part.

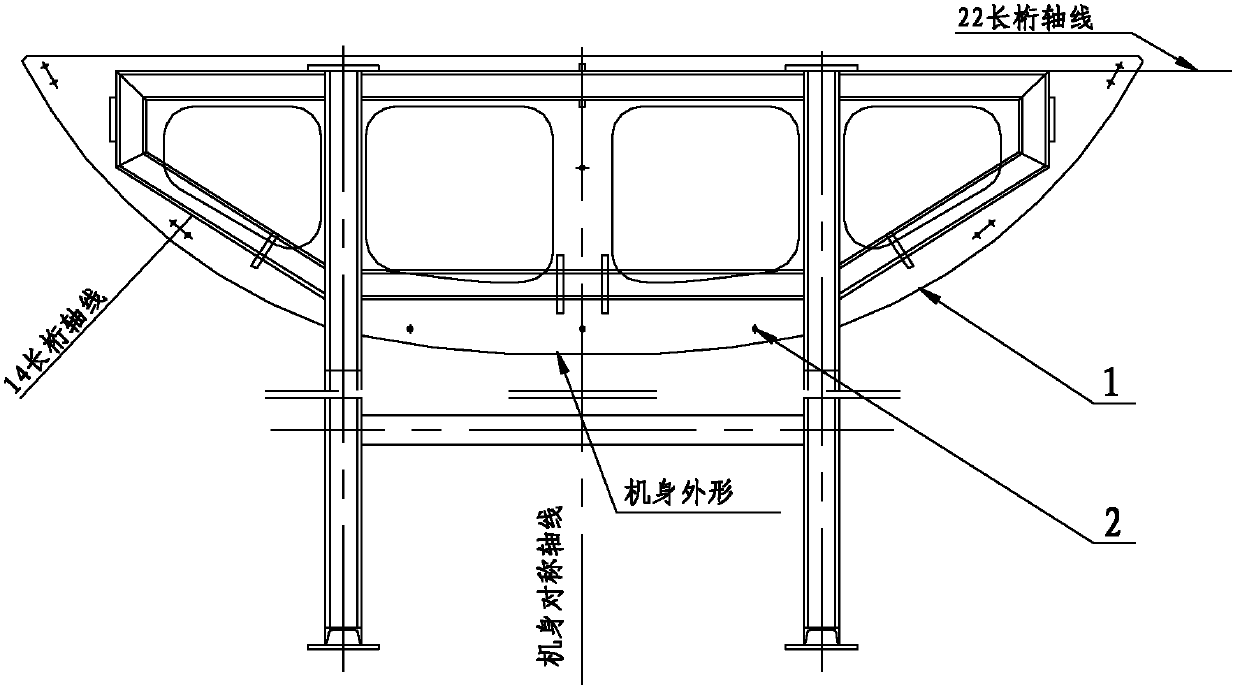

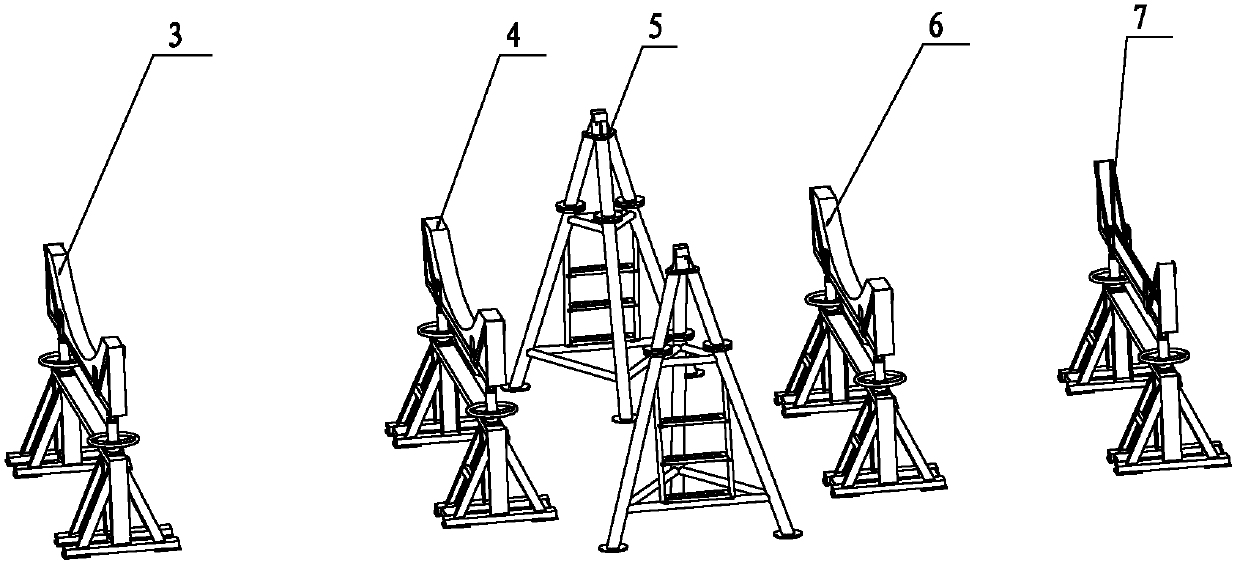

[0042] The fixed part of the process equipment for docking large parts of the aircraft of the present invention includes 41 frame reference flat plates 1, main landing gear process strut support frames 5, 19 frame lifting brackets 3, 25 frame lifting brackets 4, 33 frame lifting brackets 6, 38 frame lifting brackets 7, wherein, 41 frames are docking frames, the main landing gear technology strut support frame is the main landing gear technology strut support place, and 19 frames, 25 frames, 33 frames, and 38 frames are reinforcing frames.

[0043] see figure 1 , which is a structural schematic diagram of the 41 frame reference plate 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com